Rare earth-containing aluminium alloy and preparation method thereof

A technology of aluminum alloy and aluminum alloy melt, which is applied in the field of rare earth-containing aluminum alloy and its preparation, can solve the problems of poor corrosion resistance, tensile strength, low elongation, etc., and achieve improved casting performance, grain refinement, The effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

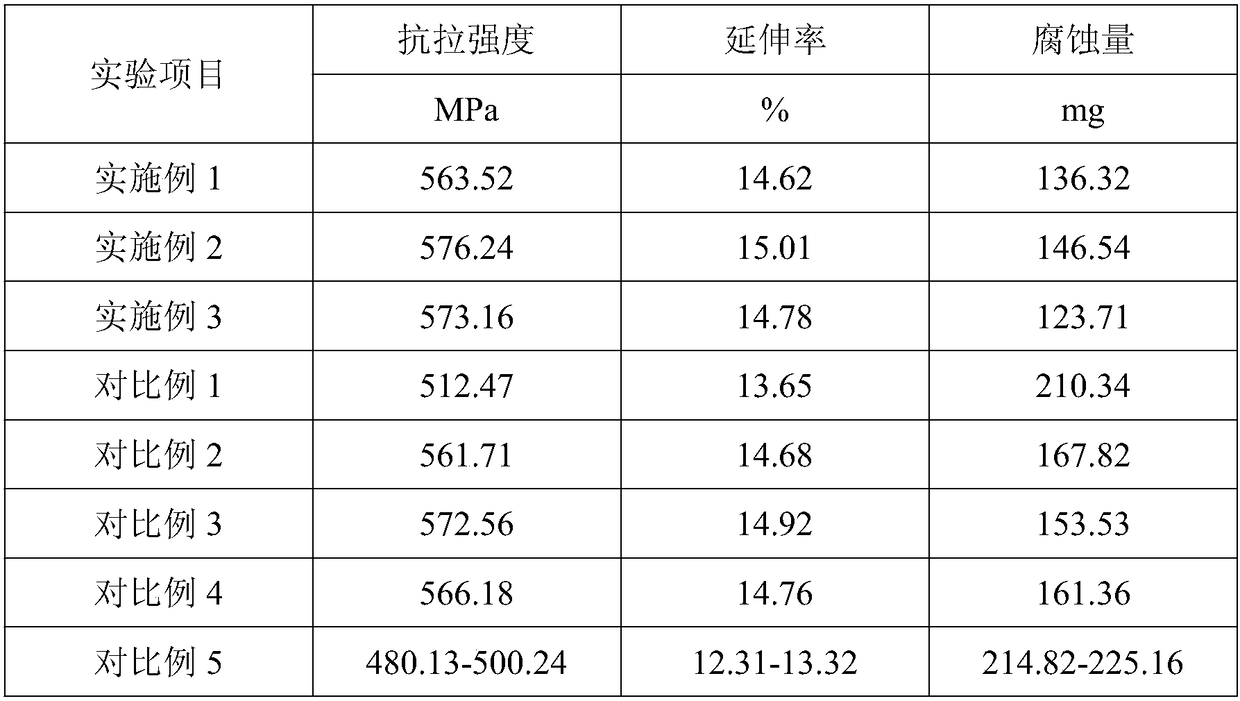

Examples

preparation example Construction

[0030] The preparation method of the aluminum alloy containing rare earth comprises the following steps:

[0031] S1: Add aluminum ingots to the electromagnetic induction furnace, increase the temperature to 850-900°C to melt them, add silicon, manganese, copper, and lanthanum powders wrapped in aluminum foil to melt, and stir the alloy melt. After stirring for 12-14min, perform degassing treatment, stand still, and then perform ultrasonic treatment to obtain an aluminum-silicon-manganese-copper-lanthanum alloy intermediate. The temperature of the ultrasonic treatment is 780-800°C, and the ultrasonic power is 22-25KW. The processing time is 26-32min; adopt the same method to prepare the aluminum-titanium-carbon-cerium alloy intermediate; the aluminum-silicon-manganese-copper-lanthanum alloy intermediate and the aluminum-titanium-carbon-cerium alloy intermediate by weight Making a grain refiner, the size of the grain refiner is below 15 μm;

[0032] S2: Throwing titanium, zinc...

Embodiment 1

[0039] An aluminum alloy containing rare earth, including the following raw materials in mass percentage: 1.3% titanium, 0.03% zinc, 0.6% iron, 0.12% silicon, 0.2% manganese, 1.2% copper, 0.5% carbon, 0.06% chromium, and 1.31% boron , 0.12% magnesium, 0.4% molybdenum, 1.2% tungsten, 0.67% vanadium, 4.5% rare earth elements, 1% refining agent, 1.2% sodium pentafluorophenolate, 4.7% grain refiner, and the rest is aluminum;

[0040] The rare earth elements are in parts by weight, including the following raw materials: 1.3 parts of lanthanum, 1.1 parts of cerium, 0.7 parts of praseodymium, 0.2 parts of neodymium, 0.1 parts of samarium, 0.4 parts of dysprosium, 0.5 parts of holmium, 0.1 parts of ytterbium, and 0.2 parts of yttrium;

[0041] The refining agent includes the following raw materials in parts by weight: 15 parts of sodium chloride, 13 parts of sodium fluoride, 6 parts of graphite, and 5 parts of calcium fluoride;

[0042] The grain refiner includes the following raw mat...

Embodiment 2

[0051] An aluminum alloy containing rare earth, including the following raw materials in mass percentage: 0.9% titanium, 0.1% zinc, 0.5% iron, 0.08% silicon, 0.15% manganese, 1.6% copper, 0.2% carbon, 0.05% chromium, and 0.11% boron , 0.06% magnesium, 0.2% molybdenum, 1.7% tungsten, 0.43% vanadium, 3.5% rare earth elements, 1.6% refining agent, 2.6% sodium pentafluorophenolate, 4.2% grain refiner, and the rest is aluminum;

[0052] The rare earth elements are in parts by weight, including the following raw materials: 1.6 parts of lanthanum, 1.3 parts of cerium, 0.8 parts of praseodymium, 0.6 parts of neodymium, 0.2 parts of samarium, 0.6 parts of dysprosium, 1 part of holmium, 0.4 parts of ytterbium, and 0.5 parts of yttrium;

[0053] The refining agent includes the following raw materials in parts by weight: 25 parts of sodium chloride, 16 parts of sodium fluoride, 8 parts of graphite, and 7 parts of calcium fluoride;

[0054] The grain refiner includes the following raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com