Full-ferrite enamel steel for heat exchanger and production method thereof

A technology of heat exchangers and ferrite, which is applied in the field of all-ferrite enamel steel for heat exchangers and production, can solve the problems of heat exchangers, poor resistance to high temperature deformation, and unsatisfactory adhesion, etc., and achieve improved High-temperature deformation resistance, improved enamel adhesion, good anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

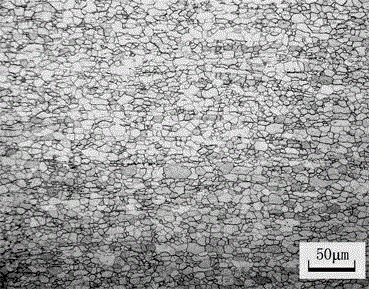

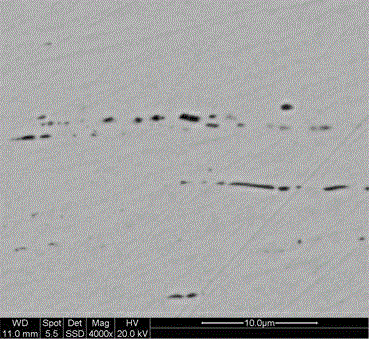

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below:

[0048] Table 1 is the value list of each embodiment of the present invention and comparative examples;

[0049] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0050] Table 3 is a list of various embodiments of the present invention and comparative performance detection situations;

[0051] Table 4 is a list of enamelling detection results of various embodiments of the present invention.

[0052] Each embodiment of the present invention is produced according to the following steps:

[0053] 1) Pretreatment of molten iron, converter smelting, refining and continuous casting;

[0054] 2) Heating the slab and controlling the heating temperature of the slab at 1200~1280°C;

[0055] 3) Carry out continuous hot rolling, and control the final rolling temperature at 880~940°C;

[0056] 4) Carry out coiling and pickling, and control the coiling temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com