Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

331 results about "Fluoboric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is mainly produced as a precursor to other fluoroborate salts. It is a strong acid. Fluoroboric acid is corrosive and attacks the skin. It is available commercially as a solution in water and other solvents such as diethyl ether. It is a strong acid with a weakly coordinating, non-oxidizing conjugate base.

Acidizing block remover suitable for complex lithologic reservoir

ActiveCN102775980ASuppressed ionizationRestore permeabilityDrilling compositionSolventFluoboric acid

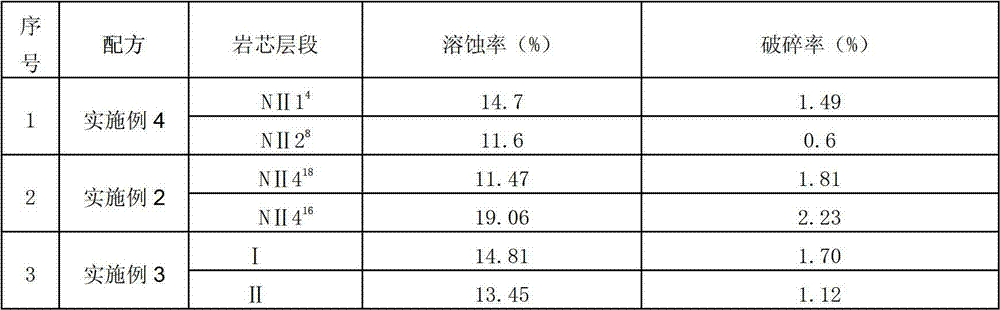

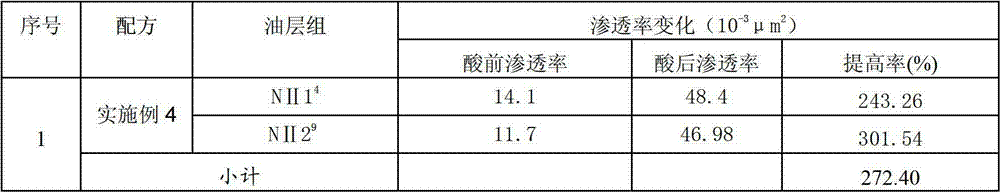

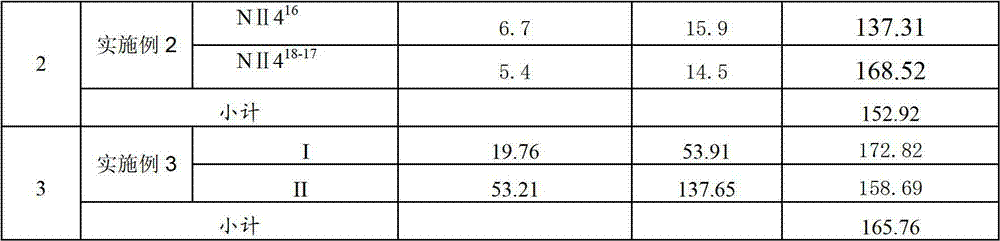

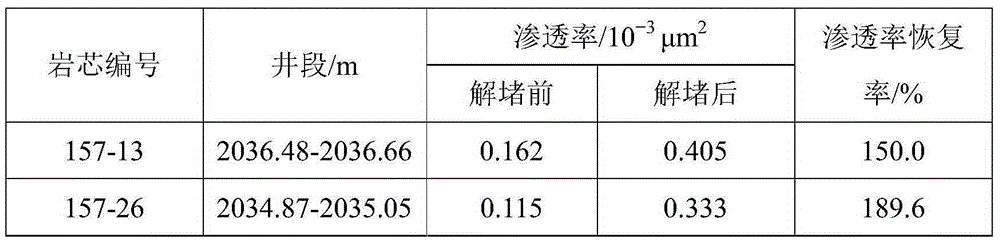

The invention relates to an acidizing block remover suitable for a complex lithologic reservoir. The acidizing block remover suitable for the complex lithologic reservoir comprises the following components by weight: 0-12% of hydrochloric acid, 0-3% of ammonium bifluoride, 0-10% of sulfamic acid, 0-5% of fluoboric acid, 0-3% of boric acid, 0-4% of alcohol, 0-2% of triethanolamine, 3% of glacial acetic acid, 4.0-6.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 0.5-1.0% of penetrating agent, 2.0% of clay stabilizer and 45-88.5% of water. The problems that the lithologic and physical property differences of oil fields are large, the oil fields are in staggered distribution, and the acidizing debugging construction effect of a common water injection well is not ideal are mainly solved. The acidizing block remover suitable for the complex lithologic reservoir can effectively corrode the strata minerals and obstruent, does not destroy a rock skeleton, can prevent secondary precipitation caused by sensitive mineral, improves the water absorbing capacity of the reservoir, and increases the daily increasing water injection rate of an average single-well measure.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

Composition and method for treating a subterranean formation

Aqueous liquid compositions for increasing the permeability of a subterranean formation are disclosed, the compositions being characterized by provision of fluoborate anion (fluoboric acid) and a specified compound or compounds, or mixture thereof, which chelate aluminum ions and aluminum fluoride species. Methods of treating a subterranean formation by injection of the composition(s) into the formation are also described.

Owner:SCHLUMBERGER TECH CORP

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

Rubber seed oil polyalcohol and preparation method thereof

ActiveCN101906016AReduce dependenceIncrease added valuePreparation by alcoholysisEpoxyReaction temperature

The invention relates to rubber seed oil polyalcohol and a preparation method thereof. The method comprises the following steps of: mixing rubber seed oil, hydrogen peroxide and a catalyst serving as raw materials in a weight ratio of 1:0.5-1.5:0.01-0.05, putting the mixture into a reaction kettle, stirring the mixture and raising temperature to 50 to 80 DEG C, keeping reaction temperature for 3 to 8 hours, lowering the temperature to 30 DEG C, separating acid water out, washing the mixture with aqueous solution of sodium carbonate until the pH of the mixture is between 5 and 6, washing the mixture to be neutral with saturated sodium chloride and water, and performing pressure reduction and water removal at the temperature of between 50 and 90 DEG C for 2 to 5 hours to obtain epoxy rubberseed oil; and adding the epoxy rubber seed oil, methanol, isopropanol and fluoboric acid into the reaction kettle in a weight ratio of 1:1-5:1-5:0.002-0.01, raising the temperature to 75 to 100 DEG C, performing a reaction for 0.5 to 3 hours, washing the reaction product with the aqueous solution of the sodium carbonate until the pH of the reaction product is between 5 and 6, washing the reaction product to be neutral with water, and performing vacuum pumping at the temperature of between 50 and 120 DEG C for 2 to 5 hours to obtain the rubber seed oil polyalcohol. In the method, the conventional petroleum chemical is replaced by a non-edible plant oil resource, so that the dependence of polyurethane industry on petroleum chemicals is reduced, and the added value of the rubber seed oil is increased.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Method for manufacturing refined high cleanliness Al-Ti-B alloy

The invention relates to a method for manufacturing a refined high cleanliness Al-Ti-B alloy, comprising the following steps of: (1) melting an aluminum ingot, and adding potassium fluotitanate and potassium fluoborate for alloying; (2) pouring a reaction by-product floating on the surface of aluminum liquid, and neutralizing with alumina powder; (3) raising the temperature of the aluminum liquid, and scattering an alumina powder layer; (4) introducing argon or nitrogen with a pipe so that a residue solution coated in the aluminum liquid floats and is neutralized; (5) measuring the hydrogen content after the solution is treated by utilizing a small bubble rotation and degassing refining technology; (6) scattering a special high temperature anti-oxidation covering agent layer in the hot state of more than 800 DEG C; (7) raising the temperature of the aluminum liquid, introducing the aluminum liquid to a filtering box body filled with an alumina ceramic filter, and carrying out online filtering treatment on the alloy aluminum liquid; and (8) finally, reducing the temperature of the aluminum liquid, discarding scruff scum, and molding by casting to produce Al-Ti-B filaments. The method can effectively separate fluoride salt and other impurities in the Al-Ti-B alloy liquid so that the impurities in an Al-Ti-B alloy refining agent are reduced, and the cleanliness is greatly improved.

Owner:HUNAN JINLIANXING SPECIAL MATERIALS CO LTD

Slow blockage removing agent for oil well and blockage removing method

ActiveCN105255466AUnblock pollutionFree from secondary injuryDrilling compositionClay mineralsFluoboric acid

The invention discloses a slow blockage removing agent for an oil well and a blockage removing method, and belongs to the technical field of oil field exploitation. The slow blockage removing agent is prepared from prepad fluid, main fluid and post-pad fluid, the prepad fluid and the post-pad fluid both take hydrochloric acid as the main component of acid fluid for removing inorganic scale precipitation and dissolving reaction residues, and the main fluid takes glacial acetic acid and fluoboric acid as the main components of acid fluid for stabilizing clay mineral of a reservoir stratum, decreasomg the acid rock reaction speed, enlarging the blockage removing radius and increasing the blockage removing depth. For a fracturing production horizontal well, the treatment fluid is injected into the reservoir stratum in the former stage, the intermediate stage and the later stage, and liquid nitrogen is simultaneously injected, so that residual reaction fluid can be quickly drained after blockage removing construction is performed; pollution blockage near a well bore of the oil well can be effectively removed, the effective permeability near the well bore is increased, the individual-well producing rate is increased, damage caused by excessive acid corrosion to the rock framework of the reservoir stratum can be avoided, and therefore the reservoir stratum can be prevented from being subjected to secondary damage.

Owner:CHINA PETROLEUM & CHEM CORP +1

HAS composite plug removal technology

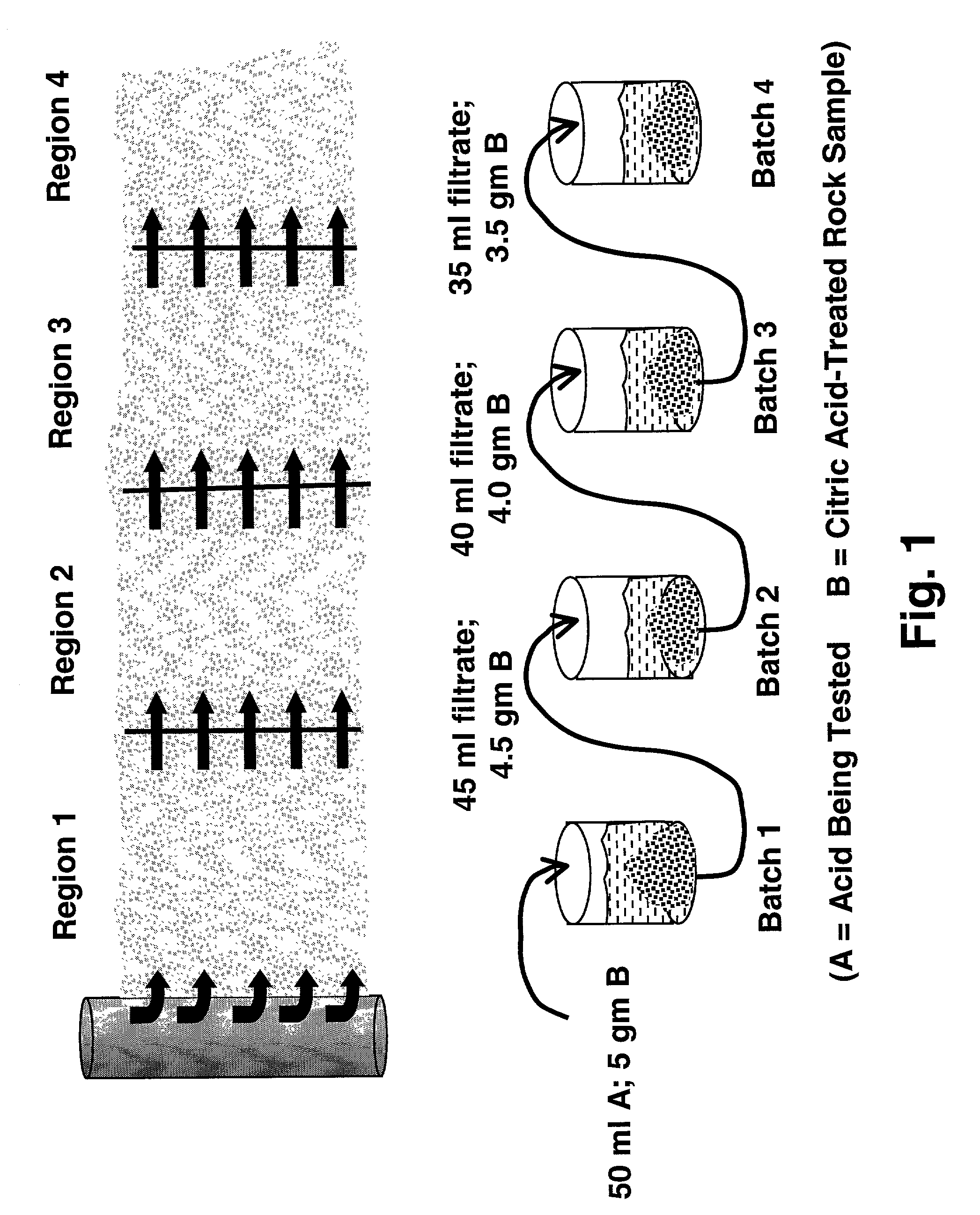

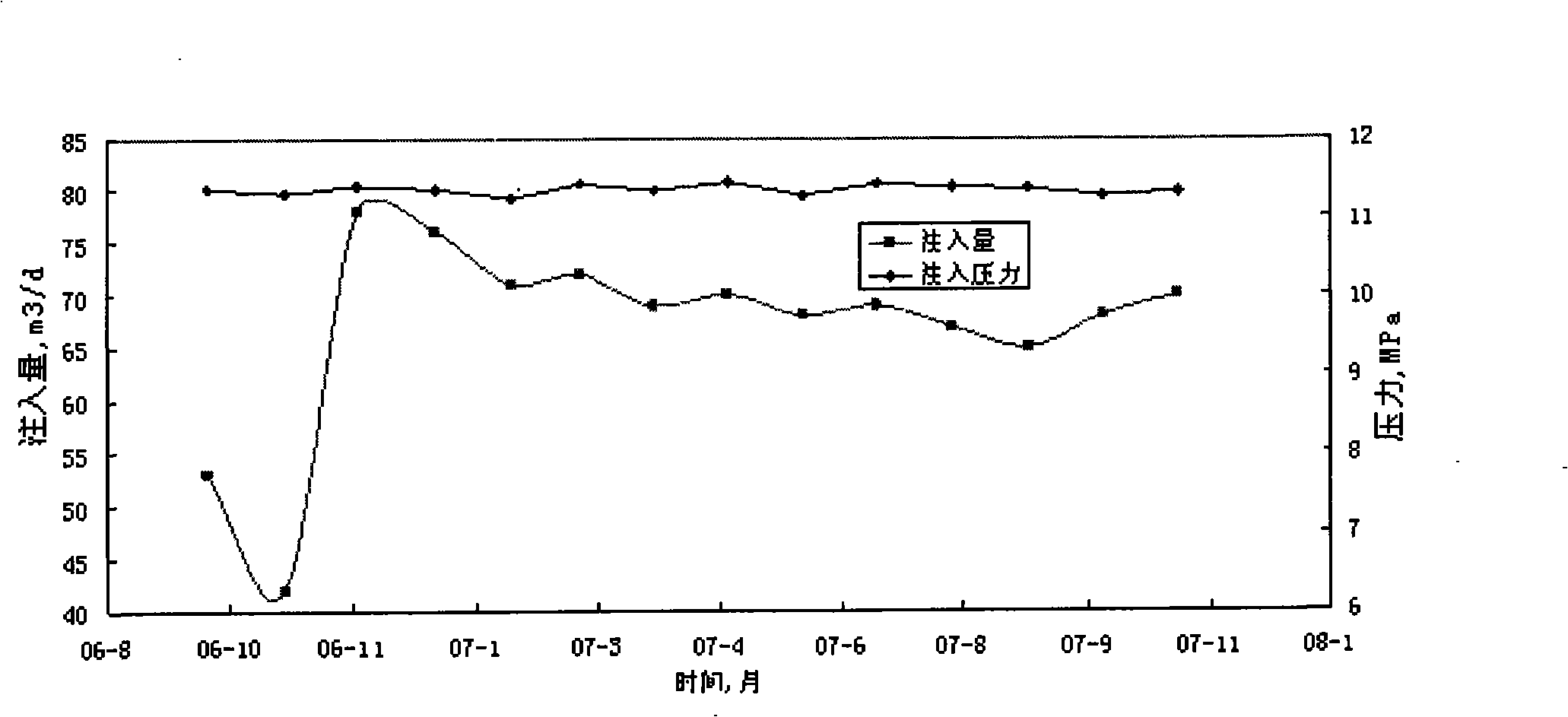

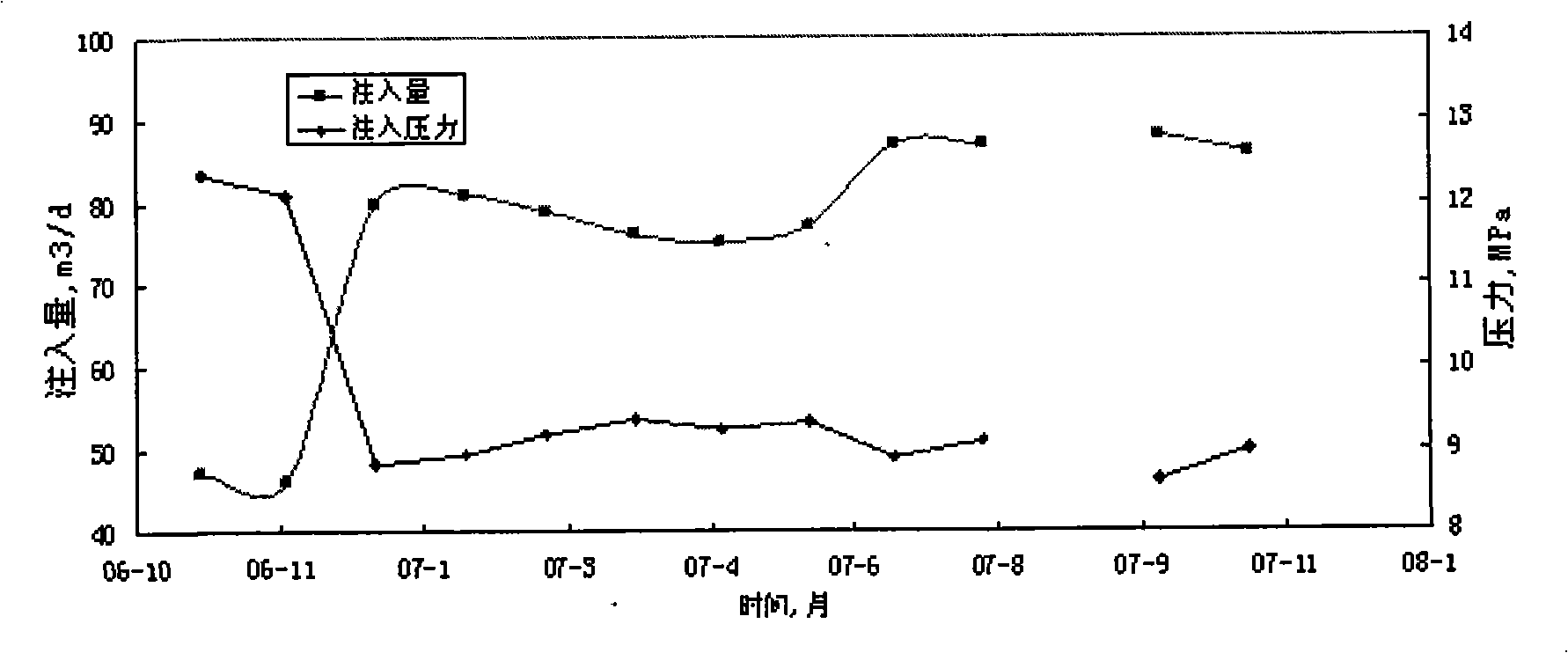

ActiveCN101285378AWater injection pressure is obviousImprove injection abilityFluid removalDrilling compositionHigh concentrationIsobutanol

The invention relates to a HAS composite plug removal process, comprising two parts that: firstly, compound acid is injected into a wellhead of a water injection well by adopting a high pressure pump; secondly, after the interval between 5 to 24 hours, an active agent is injected in by using a high concentration slug or an instillation device, wherein the compound acid is formed by the following composition in percentage by weight: 10 to12 percent of hydrochloric acid, 1 to 2 percent of hydrofluoric acid, 8 to 10 percent of fluoboric acid, 2 percent of glacial acetic acid, 2.0 percent of corrosion inhibitor, 0.1 to 0.2 percent of citric acid, 4.0 to 6.0 percent of isobutanol and 68 to 72 percent of water; the active agent is formed by the following composition in percentage by weight: 0.1 to 0.2 percent of negative nonionic surfactant, 0.3 to 0.5 percent of sodium chloride, the balance being water; the corrosion inhibitor is formed by compositely preparing hexamethylene tetramine and formaldehyde in the proportion of 1 to 1; the negative nonionic surfactant is formed by compositely preparing petroleum benzene sulfonic acid sodium salt and fatty acid alkanolamide in the proportion of 1 to 1. The composite plug removal agent has the effect in the comprehensive plug removal for near bore zones and the deep parts of oil layers, which is long in valid period and obvious in plug removal effect.

Owner:DAQING HUILIAN TECH DEV

Al-Ti-B-rare earth(RE) grain refiner and preparation method thereof

The invention relates to an Al-Ti-B-RE grain refiner and a preparation method thereof. The Al-Ti-B-RE grain refiner is used for Al-Mg-Si alloy, and is characterized by containing the following components in percentage by weight: 6.9 to 7.9 percent of Ti, 1.31 to 1.75 percent of B and 1.5 to 2.0 percent of mixed RE. The mixed RE is cerium-enriched rare earth. The preparation method of the cerium-enriched rare earth comprises: mixing the raw materials according to a weight part ratio, wherein the mixing time is controlled to be 3 to 4 hours; heating an aluminum ingot in a medium frequency induction furnace to an overhigh temperature of 700 to 750 DEG C; filling a mixed pressed block of potassium fluotitanate and potassium fluoborate and cerium-enriched rare earth into a graphite bell jar; clamping the reversed bell jar by using forceps, and pressing the bell jar into the lower middle part of aluminum melt; raising the furnace temperature to 800 to 850 DEG C, and magnetically stirring for 25 to 30 minutes with the induction furnace; after reaction, taking the graphite bell jar out; standing and keeping the temperature for 20 minutes; forcefully stirring the melt once with an artificial graphite rod every 3 minutes, and stirring for more than five times; treating molten alloy; standing and keeping temperature for 15 to 20 minutes; and performing secondary slagging off.

Owner:HUANGGANG HUAER ALUMINUM ALLOY

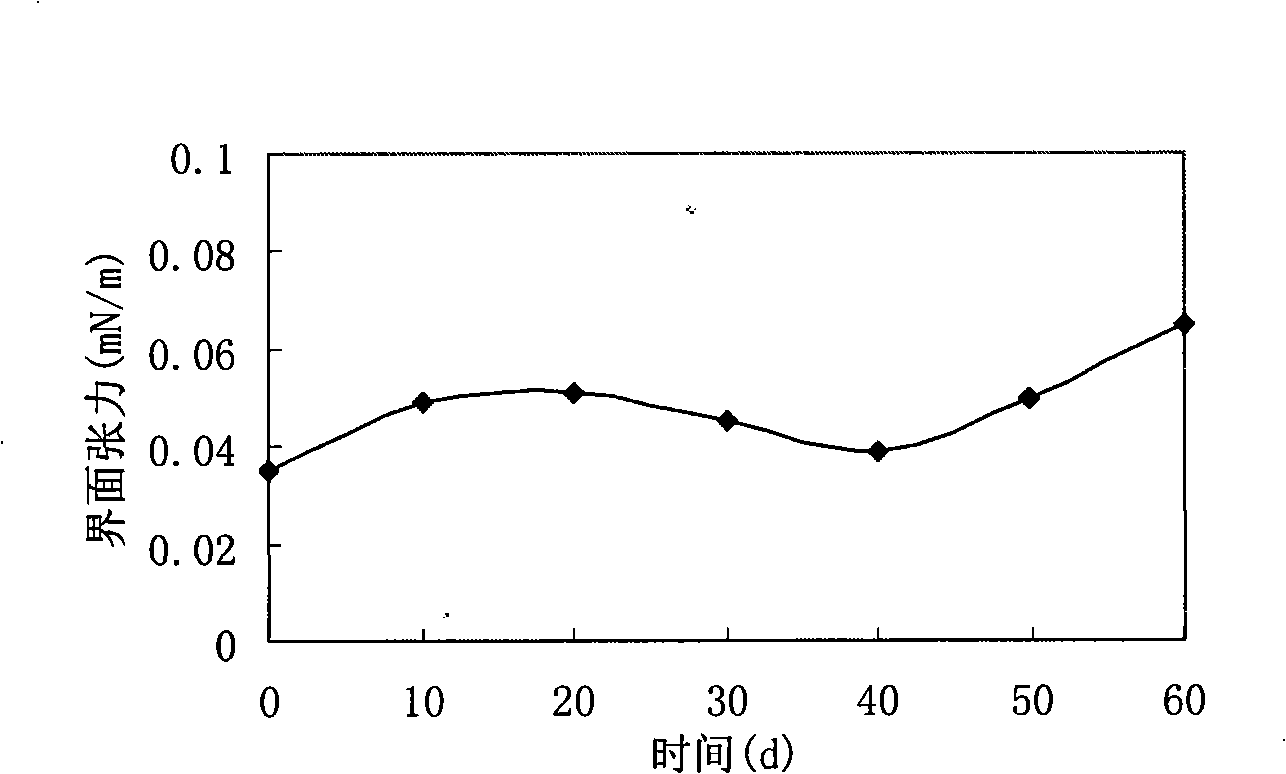

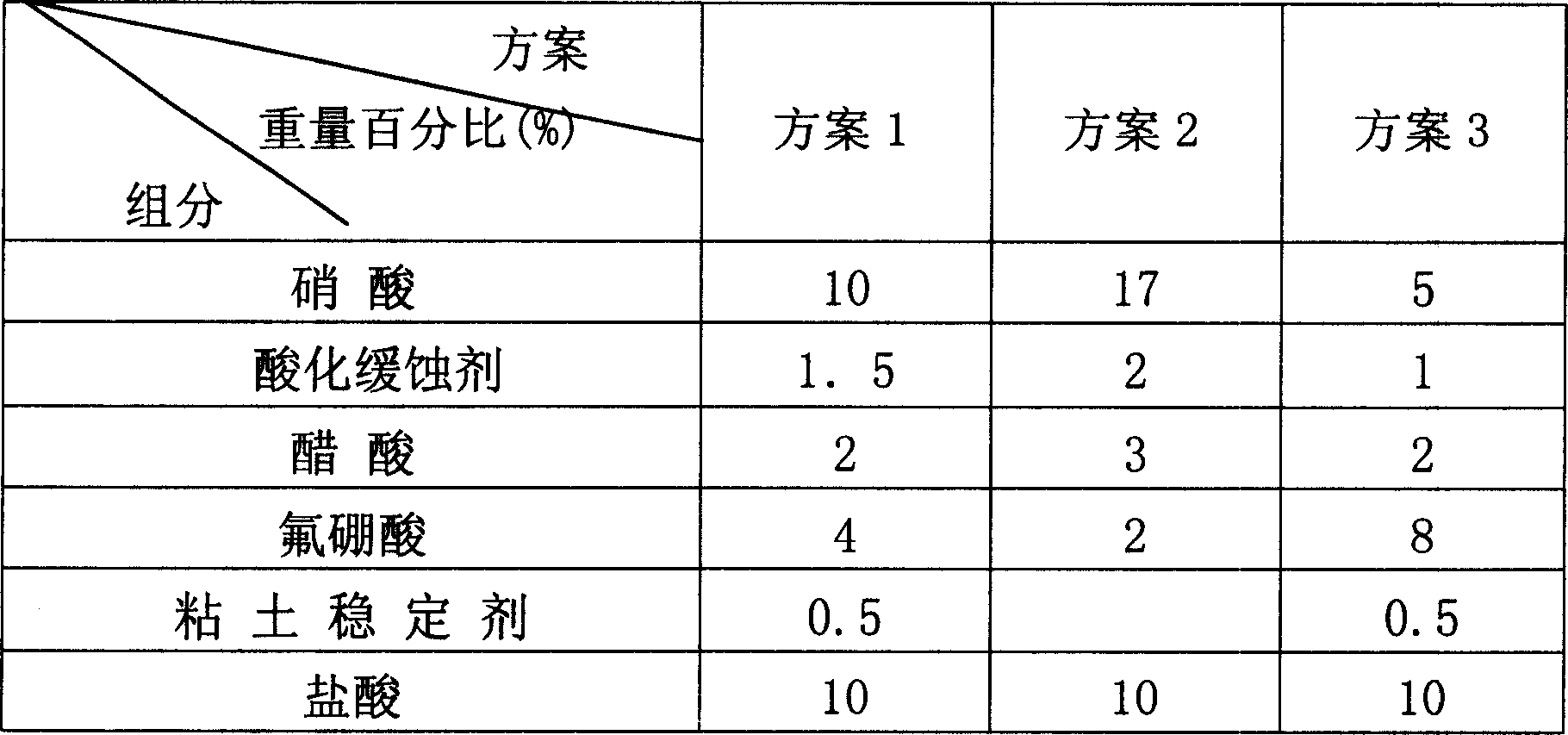

Compound acidifying liquid containing nitric acid and boratofluroic acid and its use method

InactiveCN1528854AUnblockRestore or increase water injection capacityFluid removalHydrogen NitrateAlcohol

The invention is a kind of compound acidification liquid which contains hydrogen nitrate, fluoboric acid and the manufacturing method, it solves the problem that the blocking effect to formation which has large quantity of clay and low temperature. The character lies in: the compound acidification liquid includes hydrogen nitrate, fluoboric acid and acidification inhibitor and whose content is 2%-25%, 1%-15% and 0.5%-5%, the acidification inhibitor is made up of nitrogen compound, potentiating agent, surface activating agent and solvent waterless alcohol; when using the acidification liquid to be inserted into the formation, the usage is 1-6 m3 in each meter, the time in formation can exist for 4-12 hours, the reacted acidification liquid residue can return to the ground.

Owner:LIDA OIL FIELD CHEM REAGENT WORKS SAERTU DISTRICT DAQING CITY

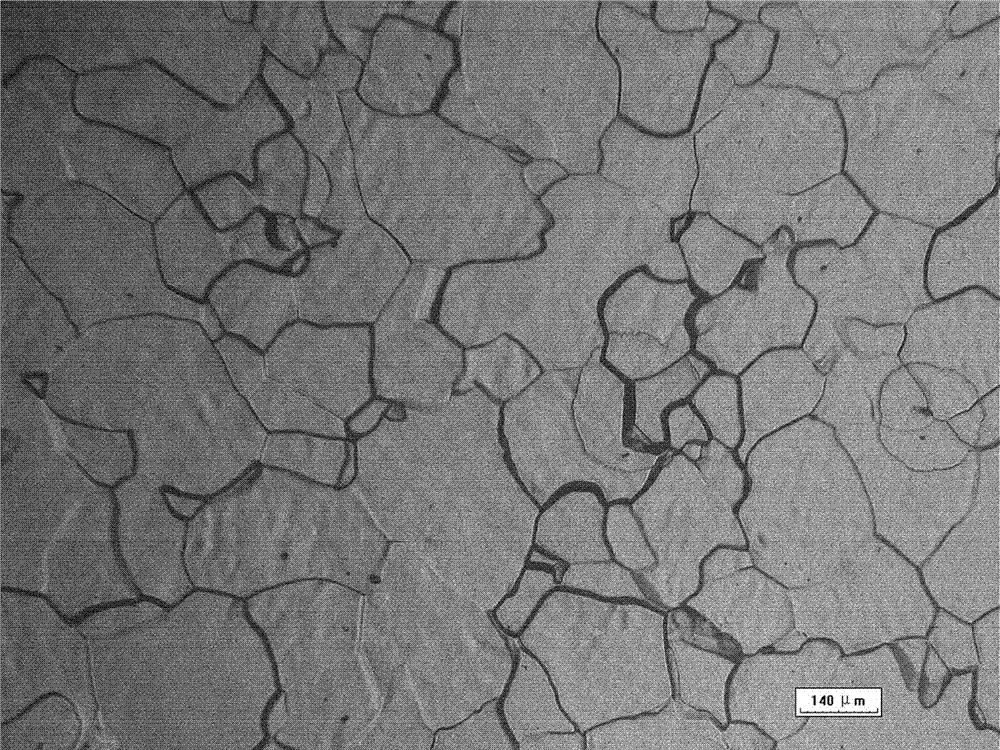

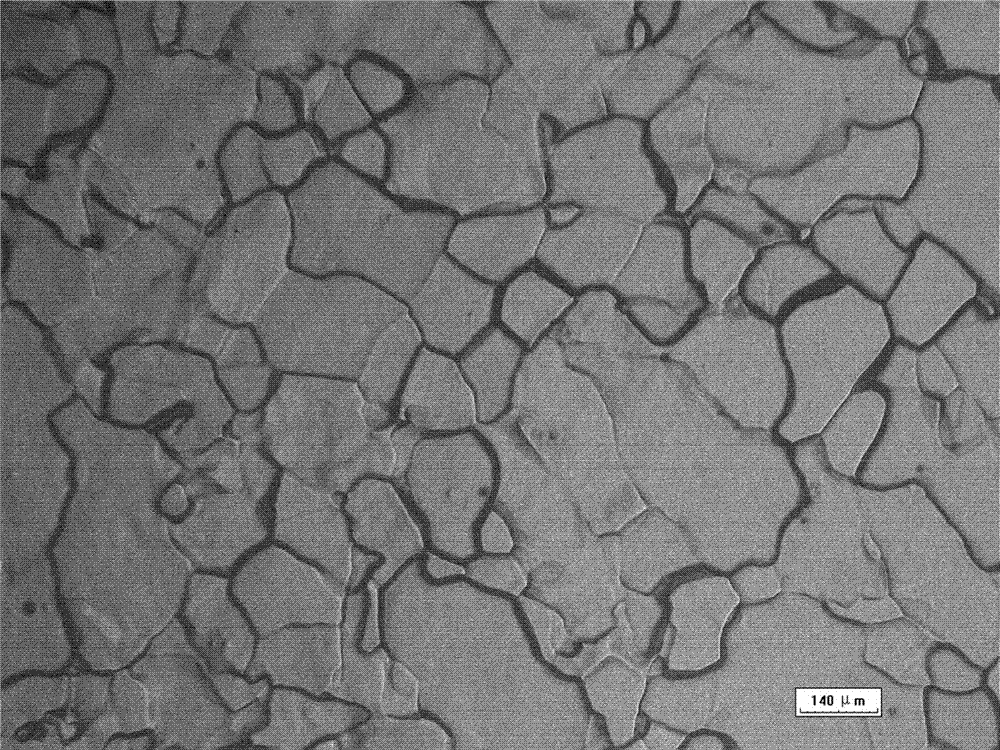

Preparation method for high pure aluminium metallographic sample

InactiveCN103837382AObservation is intuitive and convenientOvercoming the difficulty of being prone to scratchesPreparing sample for investigationElectrolysisDistilled water

The invention discloses a preparation method for a high pure aluminium metallographic sample. The preparation method comprises the following steps of sampling; coarse grinding; fine grinding; electrolysis polishing and film mulching. A formula of a film mulching liquid is composed of hydrofluoric acid, fluoboric acid and distilled water. A volume ratio of hydrofluoric acid (mL) to fluoboric acid (g) to distilled water (mL) is 15:(5-6):400. A prepared high pure aluminium clear metallograph provides convenience for better studying structure and performance of internal tissues of high pure aluminium. The method is simple in operation, low in labor intensity, low in material consumption and high in efficiency.

Owner:LIDA OPTICAL & ELECTRONICS

Compound plug removal technological method for offshore oil field injection well

The invention discloses a compound plug removal technological method for an offshore oil field injection well. The compound plug removal technological method for the offshore oil field injection well is characterized by comprising the following steps of forwards extruding stratum pretreating agent, closing the well for 24 hours, forwards extruding prepad fluid, forwards extruding spacer fluid, forwards extruding oxidative plug removable agent, closing the well for 24 hours, forwards extruding processing agent, forwards extruding postpad fluid, forwards extruding displacing liquid, and finishing construction. The stratum pretreating agent comprises cocoamidopropyl betaine, coconut diethanol amine and sodium lignin sulfonate, the mass ratio among cocoamidopropyl betaine, coconut diethanol amine and sodium lignin sulfonate is 1:1:1, and the use mass concentration is 15%. The prepad fluid is hydrochloric acid, and the mass concentration is 10%. The spacer fluid comprises a compound of tartaric acid, fatty alcohol ether sulfosuccinic acid solution, the mass ratio between tartaric acid and fatty alcohol ether sulfosuccinic acid solution is 2:1, and the mass concentration is 45%. The oxidative plug removal agent comprises a compound of calcium oxide and tert-Butyl hydroperoxide, the mass ratio of calcium oxide and tert-Butyl hydroperoxide is 3:1, and the mass concentration is 35%. The processing agent comprises fluoboric acid, wherein the mass concentration is 13%. The postpad fluid comprises hydrochloric acid, wherein the mass concentration is 10%. The displacing liquid is water injected and allocated on site.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Fluorinated graphene reinforced lubricating oil and preparation method thereof

ActiveCN108130178AImprove performanceImprove wear resistanceLubricant compositionPlasticizerPyrophosphate

The invention provides a fluorinated graphene reinforced lubricating oil and a preparation method thereof, and relates to the technical field of lubricating oil. The fluorinated graphene reinforced lubricating oil comprises the main materials of 200-300 parts of base oil, 2-5 parts of modified fluorinated graphene, 10-15 parts of oleic acid, 10-15 parts of amine solvent, 20-25 parts of anti-wear phosphating solution, 10-15 parts of trimethylolpropane, 2-3 parts of ammonium borofluoride, 2-3 parts of sodium pyrophosphate, 0.5-1 part of a plasticizer, and 0.5-1 part of an emulsifying agent. Thefluorinated graphene is dispersed in the lubricating oil, the bearing capacity and the wear-resisting property of the lubricating oil are both effectively improved, and the fluorinated graphene reinforced lubricating oil has an excellent application prospect.

Owner:XIAMEN 6C TECH CO LTD

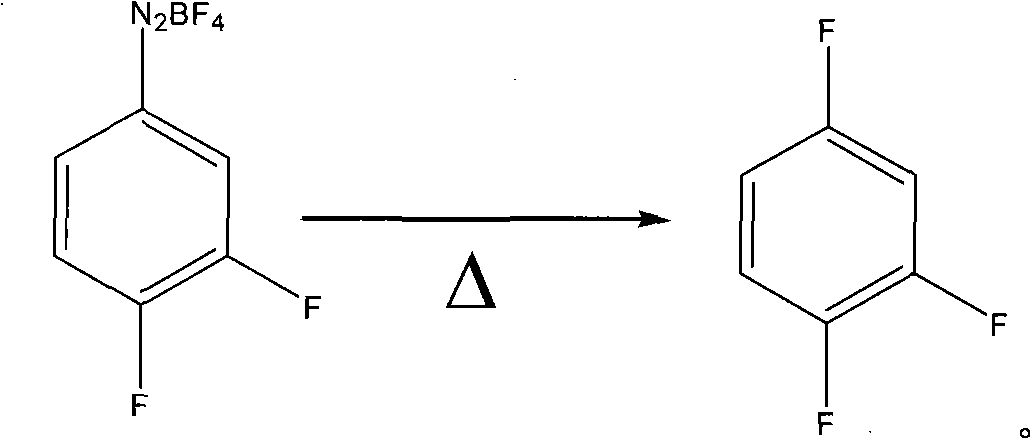

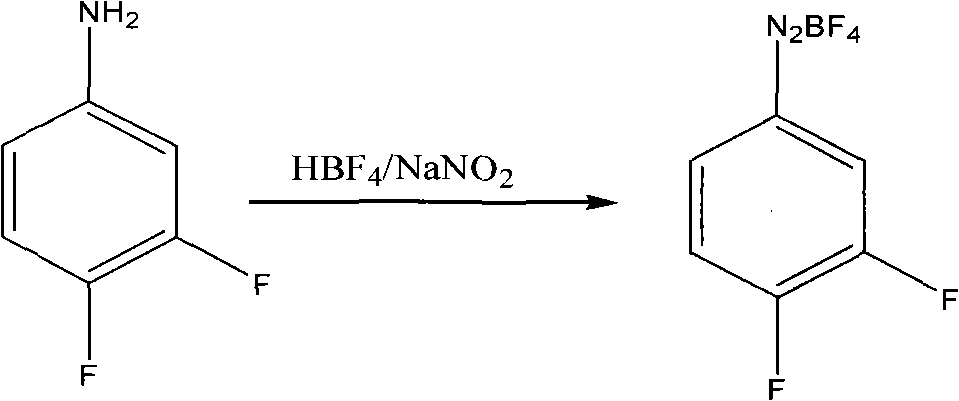

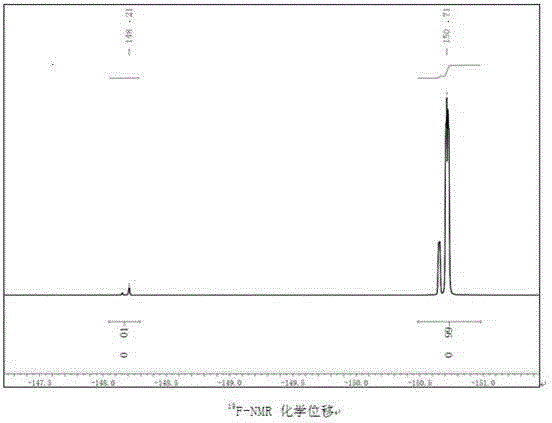

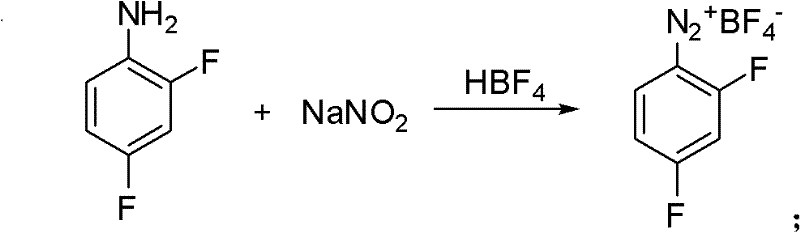

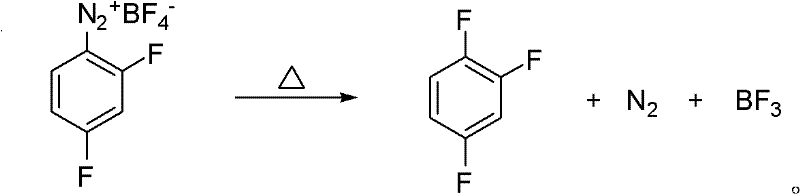

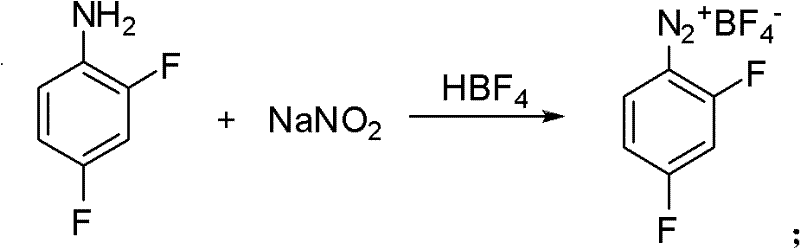

Preparation method of 1,2,4-trifluoro-benzene

ActiveCN101817724ALow costReduce manufacturing costHalogenated hydrocarbon preparationBenzeneSolvent free

The invention relates to a preparation method of 1,2,4-trifluoro-benzene, belonging to the technical field of preparation methods of chemical drug intermediates. The preparation method comprises the following steps of: (1) generating salifying reaction on 3,4-difluoroaniline and fluoboric acid, and then generating diazotization reaction with sodium nitrite to obtain fluoboric acid diazonium salt;and (2) under the solvent-free condition, carrying out high-temperature cracking reaction on the fluoboric acid diazonium salt at the temperature of 80-300 DEG C to obtain 1,2,4-trifluoro-benzene. The preparation method has the advantages of cost saving of raw materials, relatively simple process flow, mild reaction condition, low operation difficulty, operability and convenient aftertreatment; and the prepared products have the purity increased to 98 percent or more now from 80 percent or less originally, are stable in quality, and are suitable for large-scale industrial production.

Owner:ZHEJIANG TIANYU PHARMA

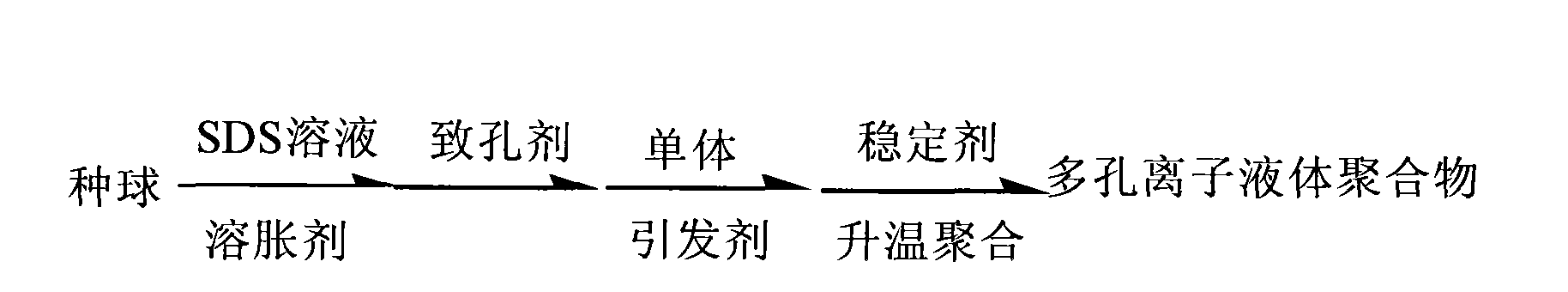

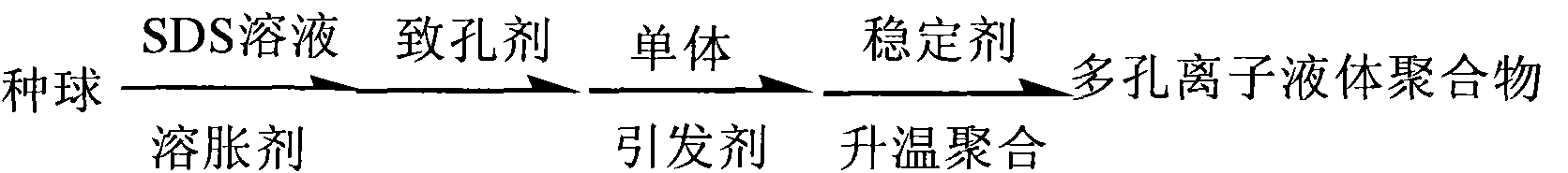

Synthesizing method of porous ion liquid polymer

InactiveCN101786988ANo pollutionIncrease concentrationOrganic chemistryTetrafluoroborateHigh absorption

The invention relates to a synthesizing method of a porous ion liquid polymer, belonging to the field of synthesizing methods for separating and revering CO2 polymers. The synthesizing method of the porous ion liquid polymer comprises the following steps of: A, performing reaction of 1-methylimidazole and chloropropene to generate chlorinated 1-allyl-3-methylimidazole ion liquid; B, performing reaction of the chlorinated 1-allyl-3-methylimidazole ion liquid and fluoboric acid to generate 1-allyl-3-methylimidazole tetrafluoroborate ion liquid; C, performing reaction of the 1-allyl-3-methylimidazole tetrafluoroborate ion liquid with acrylonitrile to generate an ion liquid polymer; D, preparing the porous ion liquid polymer, i.e. adding sodium dodecyl benzene sulfonate, dibutyl phthalate and deionized water to carry out activation by taking the ion liquid polymer as a seedball, then respectively adding normal heptane, normal octane and toluene or cyclohexane to carry out swelling, then adding a monomer and benzoperoxide to carry out secondary swelling, and adding polyvinyl alcohol to carry out polymerization so as to obtain the porous ion liquid polymer. The invention has moderate reaction condition and short CO2 absorption time and high absorption amount in industrial application.

Owner:CHINA UNIV OF MINING & TECH

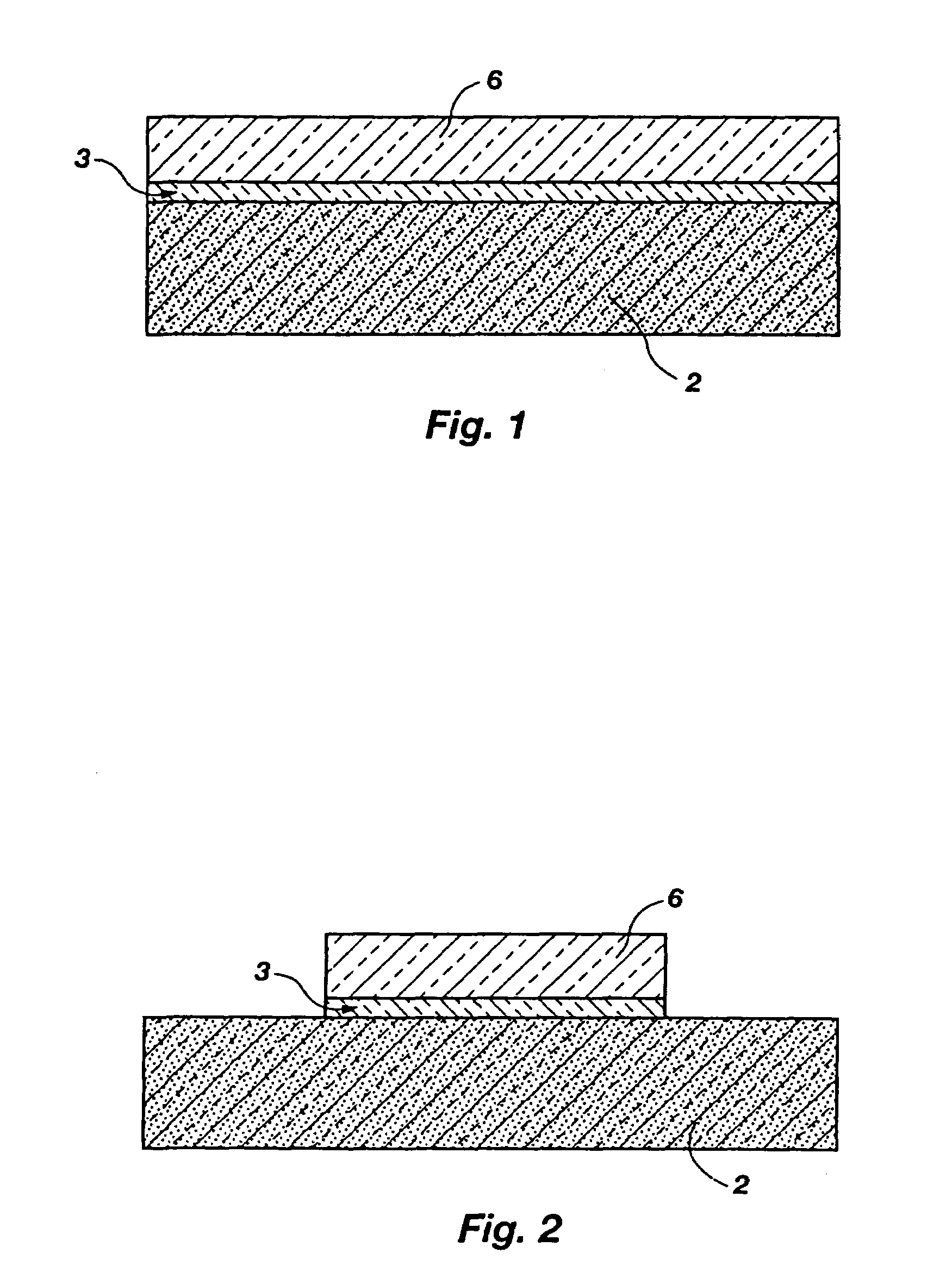

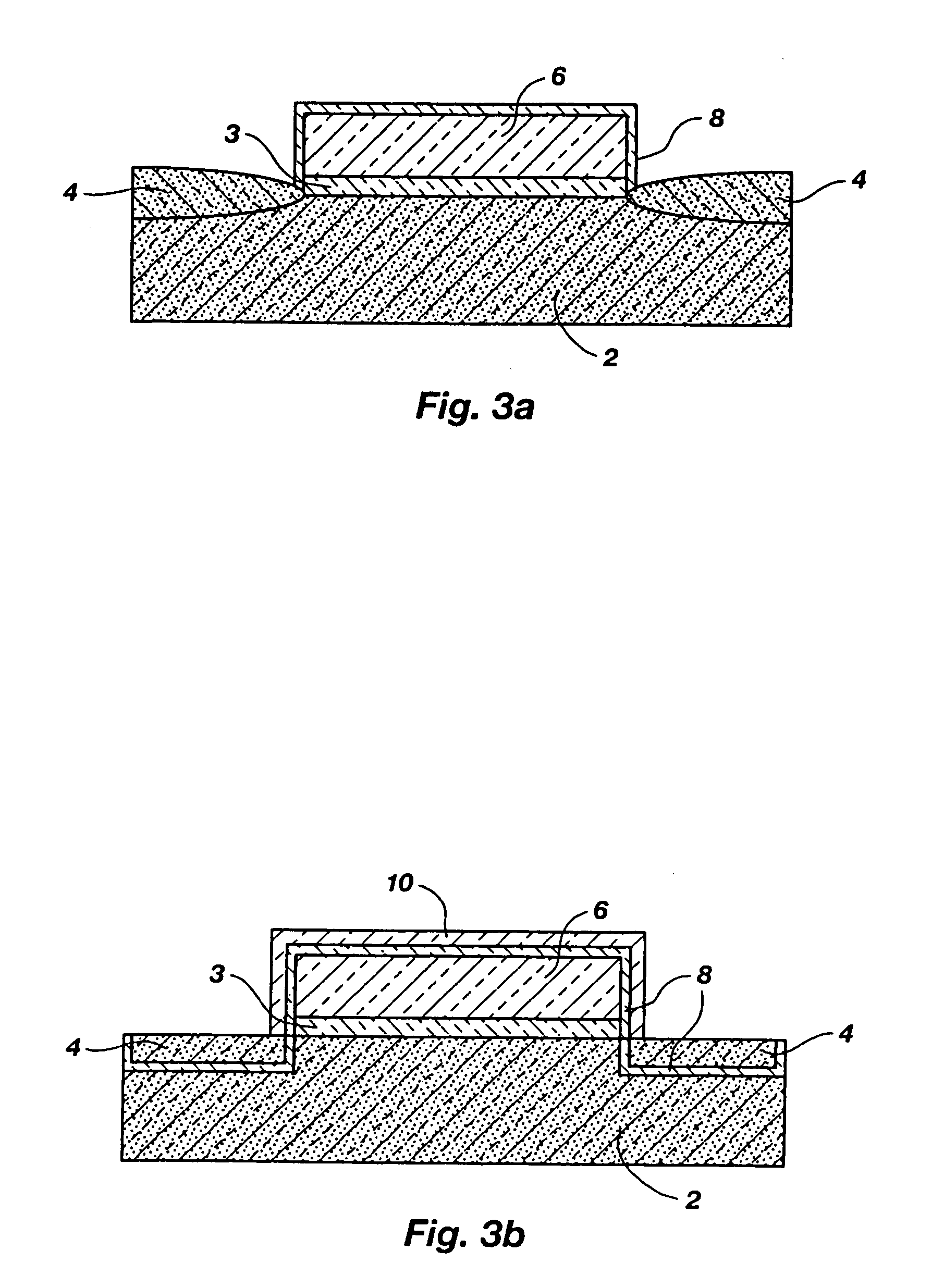

Etchants and etchant systems with plural etch selectivities

InactiveUS7591959B2Minimizes and removeImprove etch selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingPhosphoric acidSilicon oxide

Owner:MICRON TECH INC

Method for preparing potassium borofluoride through fluorine-containing wastewater

ActiveCN103332700ARich sourcesReduce pollutionBoron halogen compoundsHydrogen fluorideAfter treatment

The invention relates to a method for preparing potassium borofluoride through fluorine-containing wastewater. The method is characterized by comprising the following steps: (1) utilizing water to regulate the hydrogen fluoride content of the fluorine-containing wastewater until the mass content of hydrogen fluoride is 12%-17%; (2) completely mixing the wastewater after treatment in the step (1) with potassium chloride saturated solution according to a mass ratio of (3-5):1 so as to fluorate; (3) mixing borax with the wastewater after treatment in the step (1) according to a mass ratio of 1: (3-5), and stirring so as to completely dissolve the borax; mixing solution in the step 2 with solution in the step 3 according to a mass ratio of (0.8-1.2):1, stirring to react, and continuously separating potassium fluoborate out in a reaction process so as to prepare potassium fluoborate suspension; and (5) solid-liquid separating, washing and drying the potassium fluoborate suspension in the step (4) so as to obtain a potassium fluoborate product. The potassium fluoborate product prepared by the method can satisfy the requirements of potassium fluoborate use factories.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

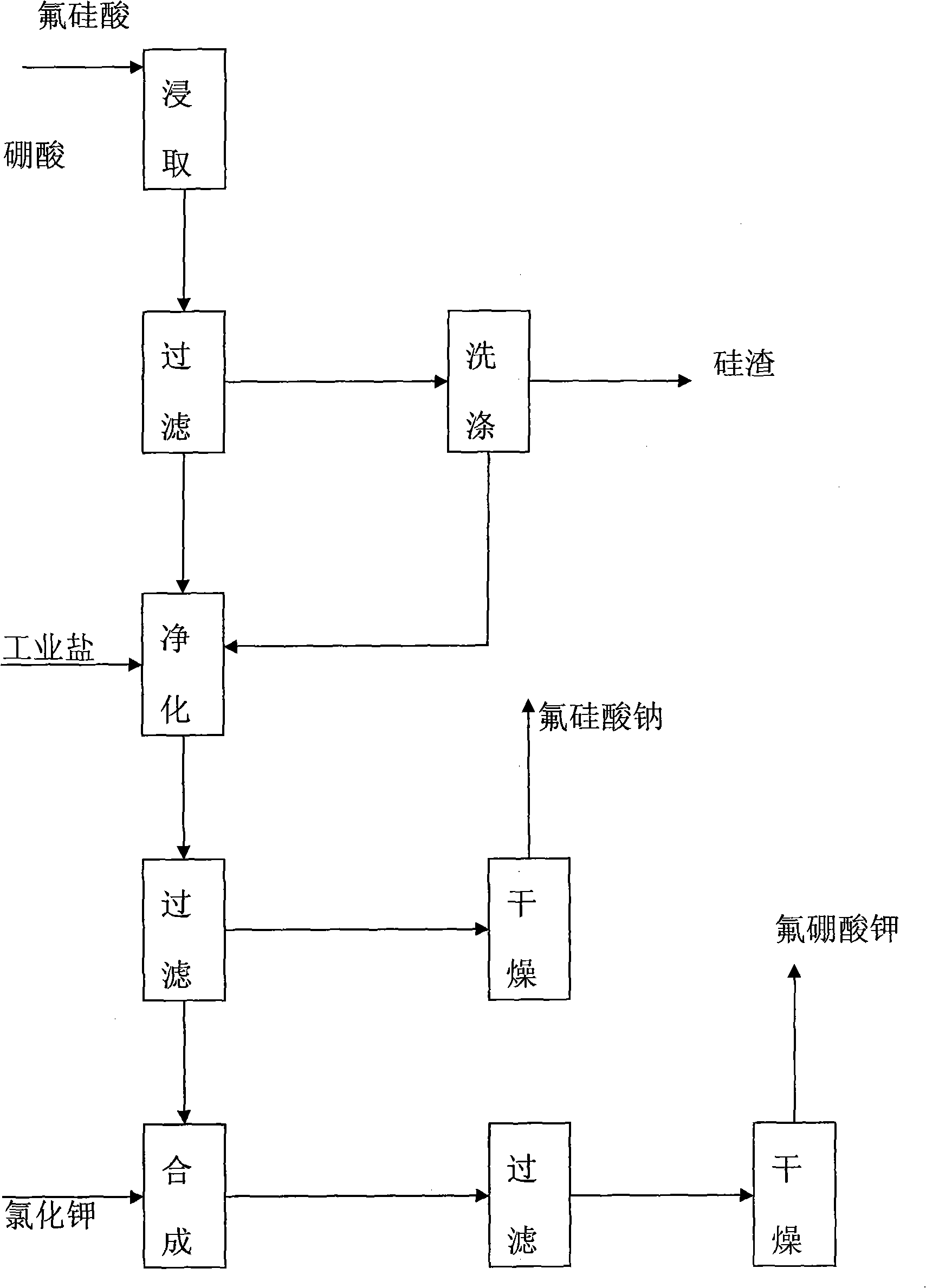

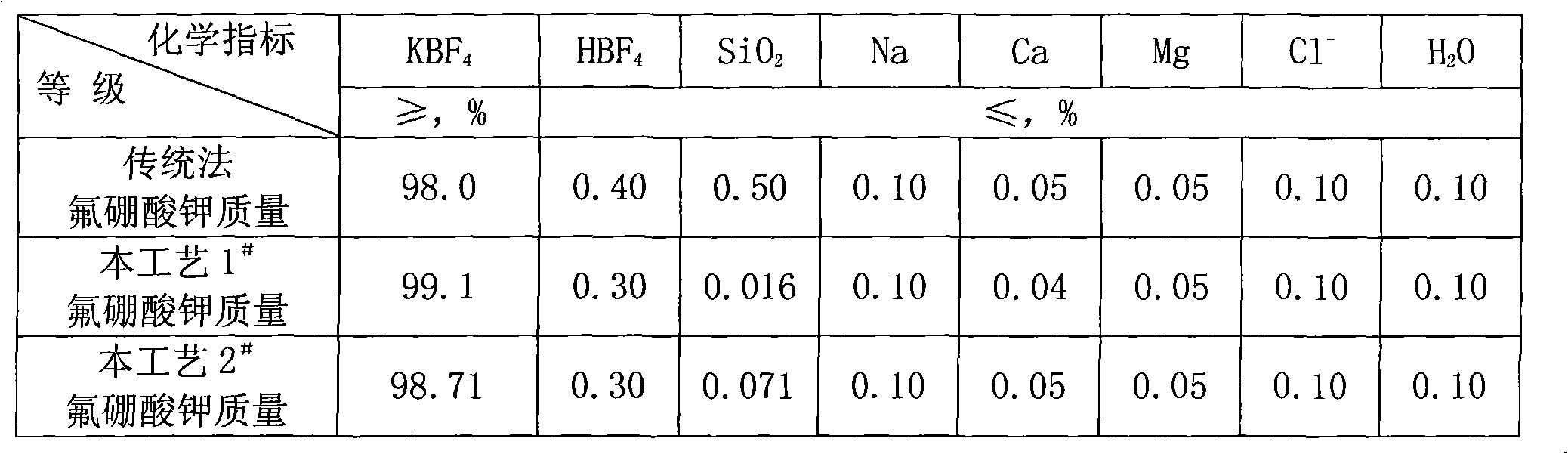

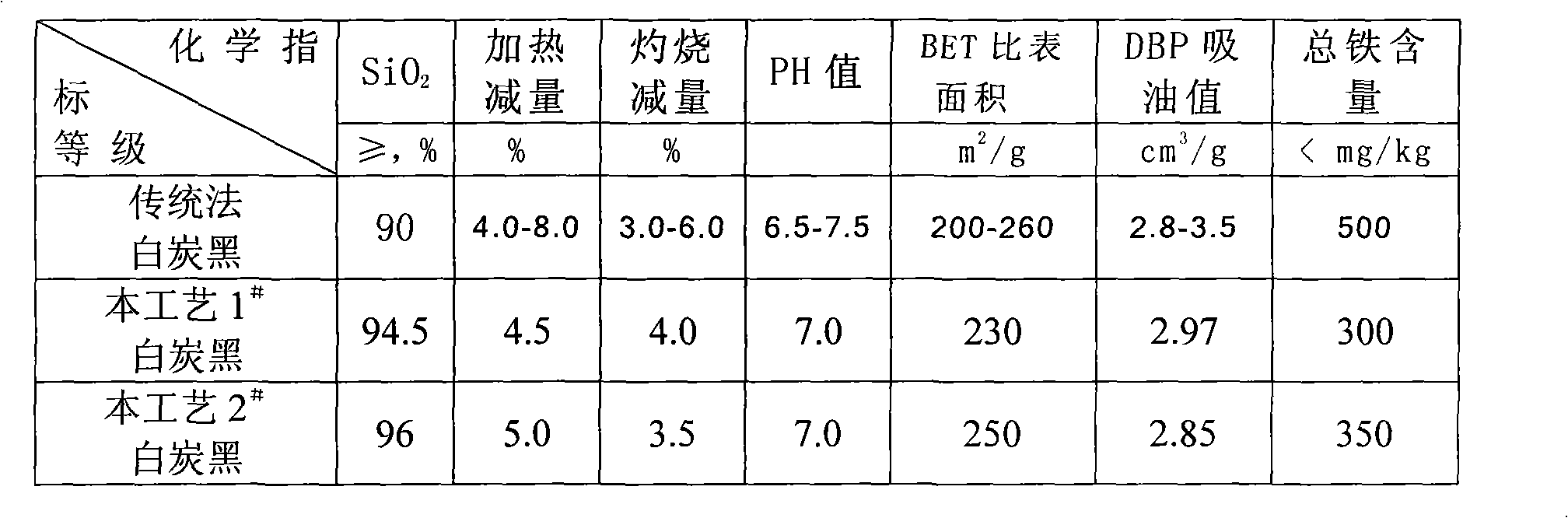

Process for preparing potassium borofluoride and co-production of white carbon black and sodium fluosilicate

InactiveCN101289195ARaw materials are easy to getLow costSilicaSilicon halogen compoundsPotassium borohydrideFiltration

The invention relates to a method for preparing potassium fluoborate with the co-product of white carbon black and sodium fluosilicate, which takes hydrofluosilicic acid, boric acid, industrial salt and potassium chloride as main raw materials and particularly comprises the steps as follows: (1) the hydrofluosilicic acid is firstly added into a leaching tank which is then preheated to 60 DEG C to 100 DEG C and then opened for carrying out stirring, theoretical quantity of boric acid is added into the hydrofluosilicic acid, then the leaching tank is obturated and reaction is carried out continuously for 2.0 hours to 6.0 hours, and leaching is carried out at the constant temperature of 60 DEG C to 100 DEC G; (2) qualified fluoboric acid solution after being leached is filtered, the white carbon black is dried after progressive concentration and washing by levels of water to produce the white carbon black; (3) the filtrate obtained and a first lotion are added with the industrial salt for purifying and disiliconization, then theoretical quantity of industrial salt is added for carrying out reaction for 10 minutes to 30 minutes to prepare sodium fluosilicate slurry; (4) the sodium fluosilicate slurry prepared is filtered, washed and dried to obtain sodium fluosilicate products, and the filtrate obtained is used for synthetizing the potassium fluoborate; (5) theoretical quantity of potassium chloride is added into the filtrate obtained in step (4) for carrying out reaction for 10 minutes to 30 minutes; (6) after the reaction in step (5) completes, filtration is carried out, an ointment is washed by primary water and dried to obtain the potassium fluoborate.

Owner:DO FLUORIDE CHEM CO LTD

Method for preparing 1,2-diol compound by using catalytic hydration of epoxide

ActiveCN101704711ANo pollution problemEasy to recycleEther separation/purificationBulk chemical productionHydration reactionDiol

A method for preparing 1,2-diol compound by using catalytic hydration of epoxide comprises the following steps: adding water and fluoboric acid in a reactor, setting the temperature at 10-99 DEG C, and then adding epoxide in the reactor, wherein the total reaction time is 0.2-5h, and mole ratio of the epoxide, the water and the fluoboric acid is 1:1.5-35:0.00001-0.001. In the invention, the selectivity is high and the separation of the product is simple.

Owner:昌德新材科技股份有限公司

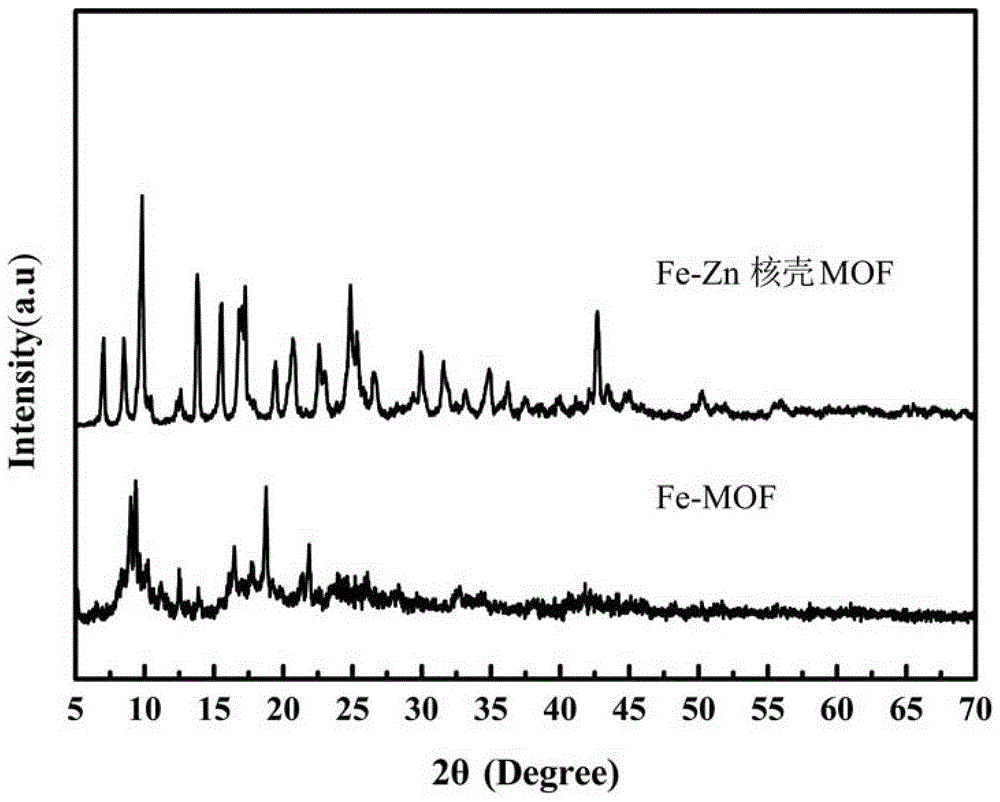

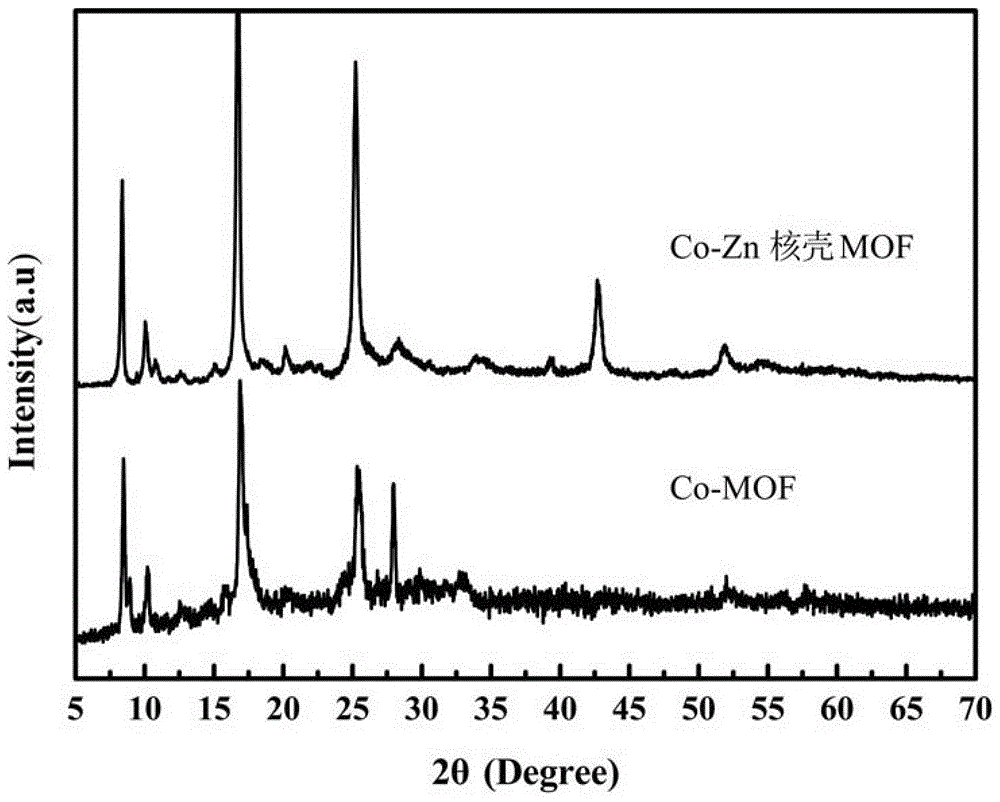

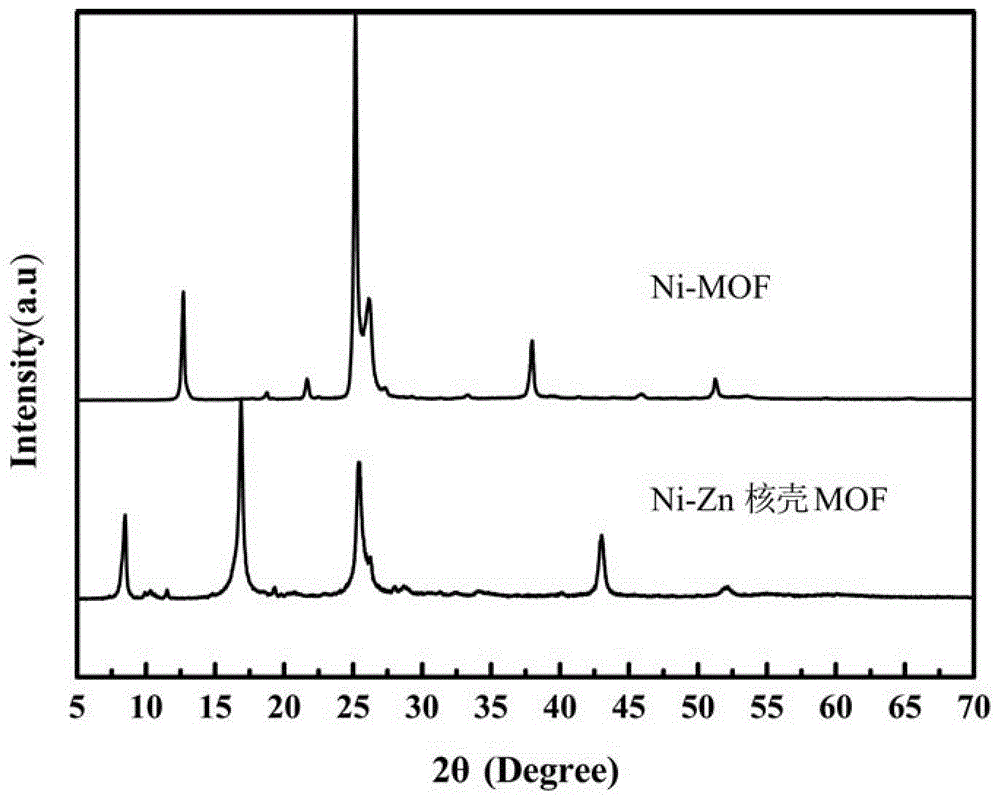

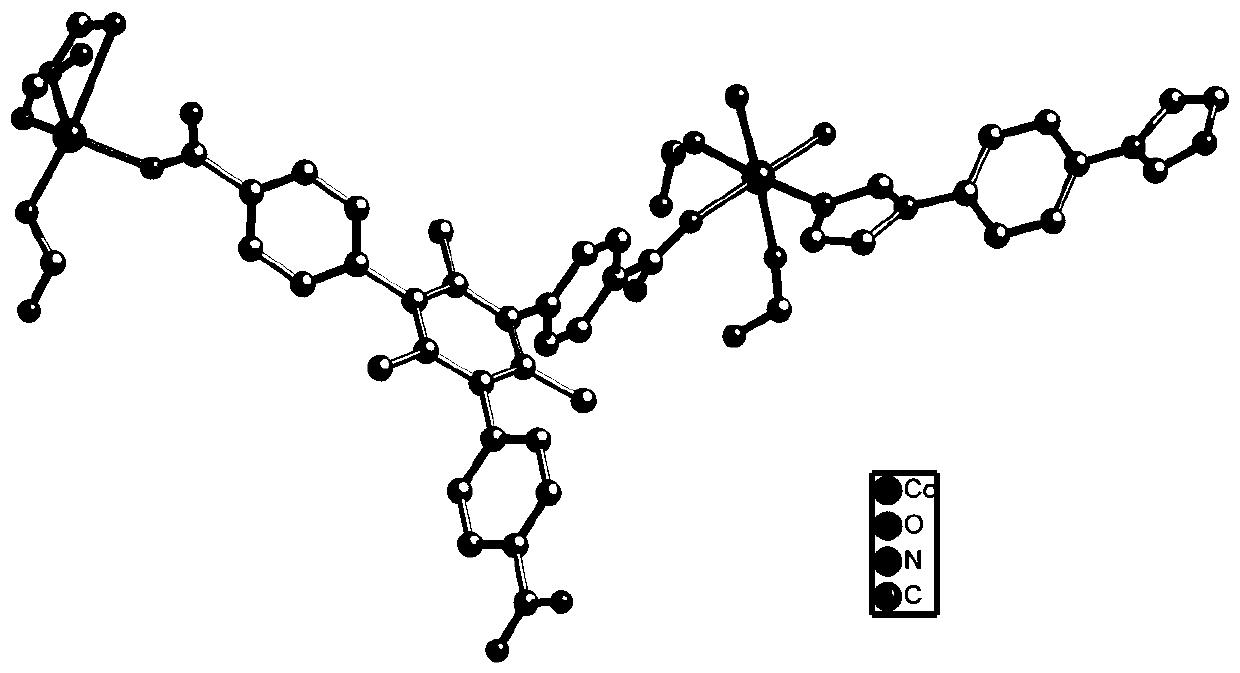

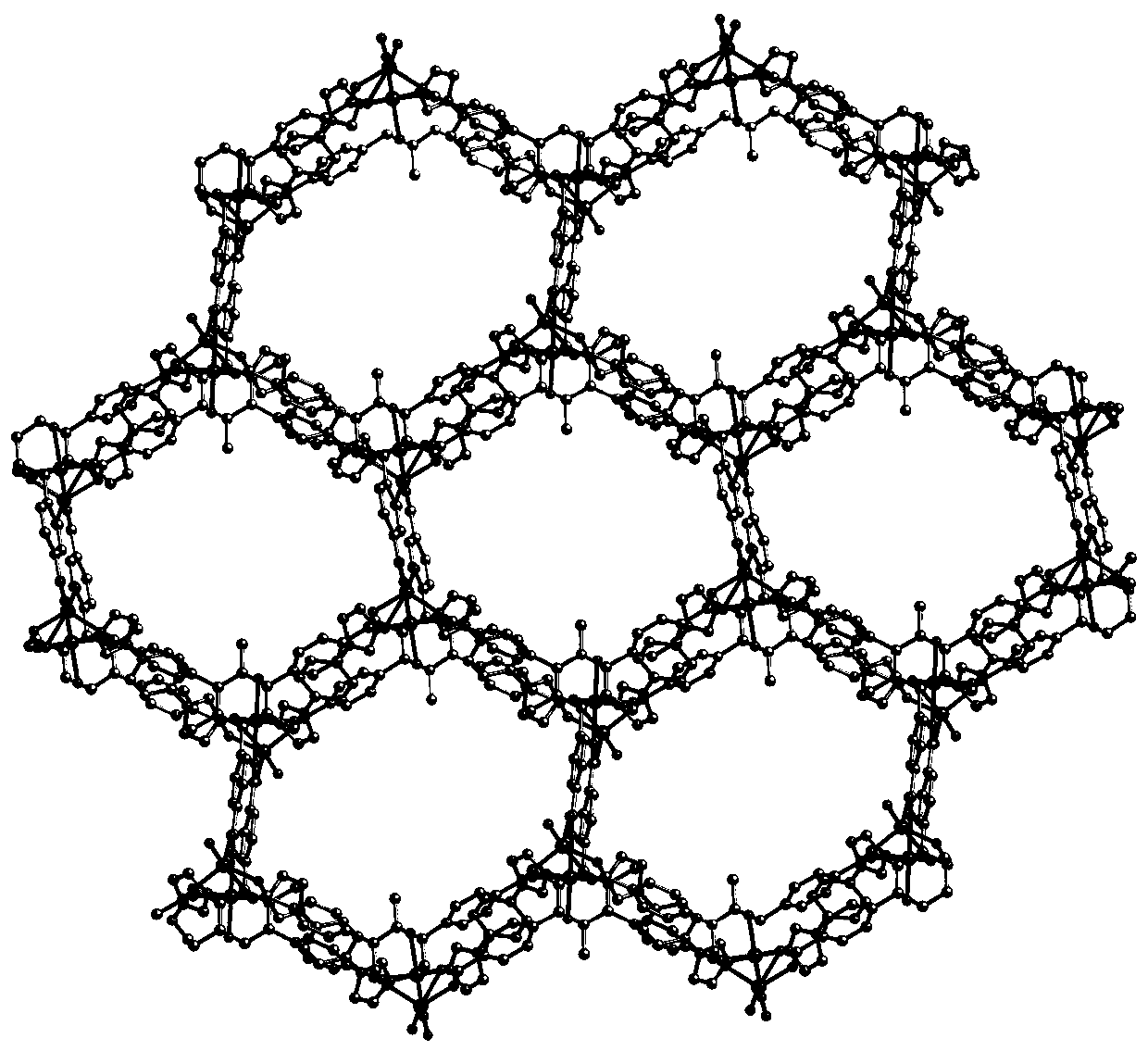

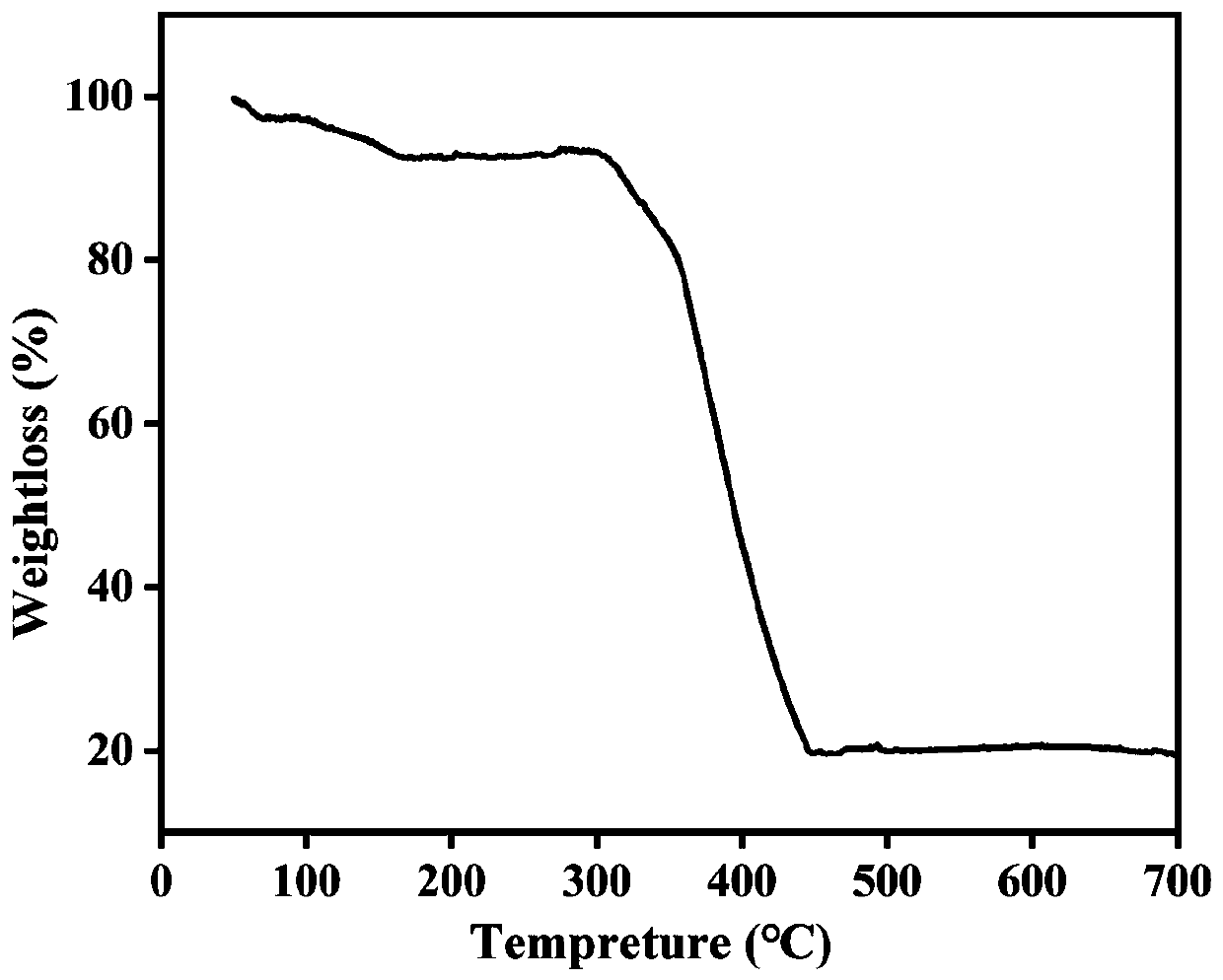

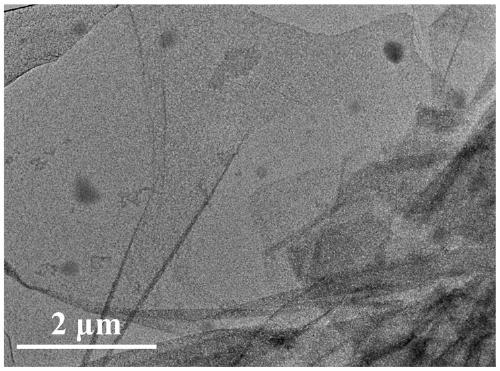

Method for preparing magnetic carbon material from core-shell metal organic framework

InactiveCN106693935ALarge specific surface areaImprove performanceOther chemical processesDispersed particle separationMagnetic carbonCarbonization

The invention discloses a method for preparing a magnetic carbon material from a core-shell metal organic framework. The method comprises the following steps: ultrasonically dissolving an organic ligand and metal salt in a solvent in sequence, dropwise adding 2 to 10 drops of fluoboric acid, transferring the mixture into a polytetrafluoroethylene lining reaction kettle, carrying out reaction in a drying oven, and carrying out filtering and drying to obtain a metal-organic framework material; ultrasonically dissolving an organic ligand and metal salt which are used for synthesizing a 'shell' material in the solvent in sequence, dropwise adding 2 to 10 drops of fluoboric acid, adding the metal-organic framework material serving as a core, then transferring the mixture into the polytetrafluoroethylene lining reaction kettle, carrying out reaction in the drying oven, and carrying out filtering and drying to obtain a core-shell metal organic framework material; carrying out high temperature carbonization heating on the core-shell metal organic framework material to obtain the magnetic carbon material. The carbon material obtained through the method is regular in porous structure, uniform in aperture distribution and magnetic, and has good application value for the aspects such as gas adsorption storage and industrial waste separation; furthermore, the method is simple and feasible in preparation process and high in safety.

Owner:FUJIAN UNIV OF TECH

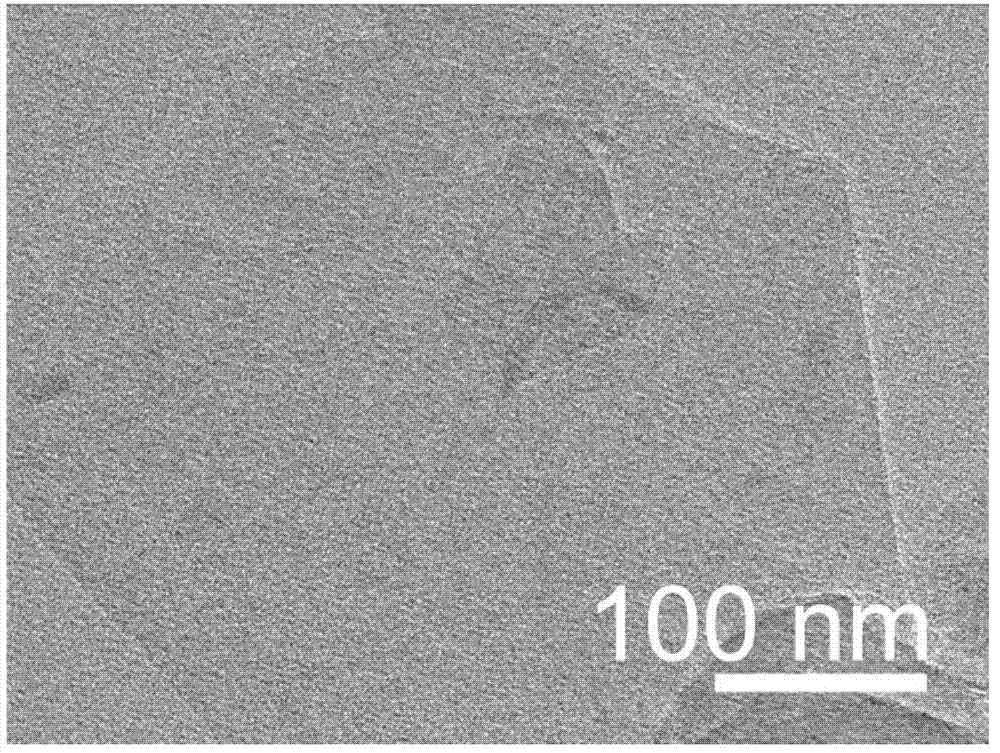

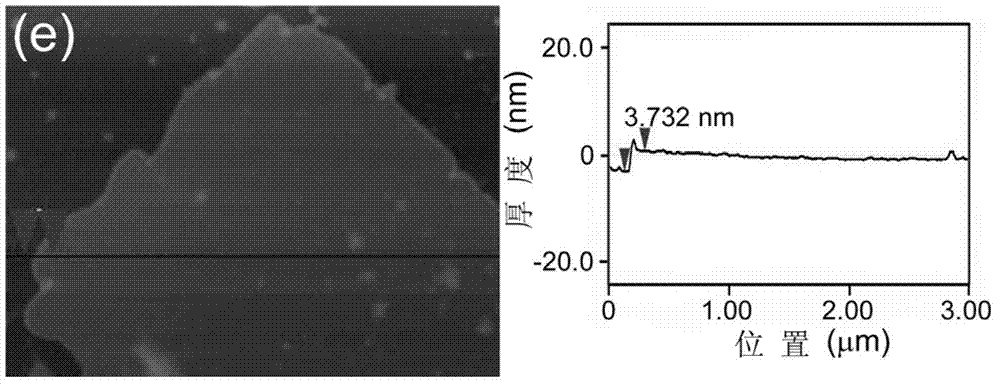

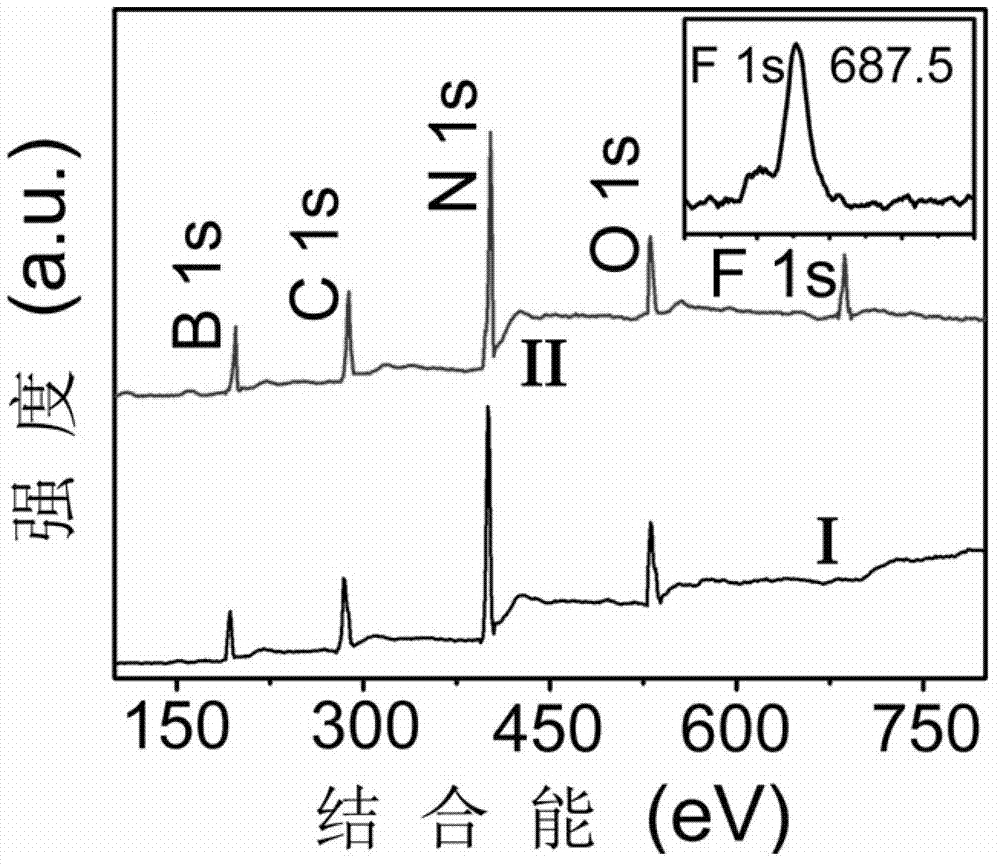

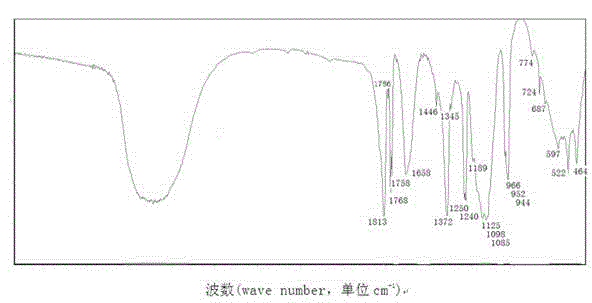

Method for peeling off hexagonal lamellar boron nitride and doping fluorine in hexagonal lamellar boron nitride

InactiveCN102887490AEasy to prepareLow equipment requirementsMaterial nanotechnologyNitrogen compoundsOrganic solventRoom temperature

The invention relates to a method for peeling off hexagonal lamellar boron nitride and doping fluorine in the hexagonal lamellar boron nitride. The method for peeling off hexagonal lamellar boron nitride comprises the steps of: (1) adding a polar organic solvent into boron nitride powder, magnetically stirring for 20 to 30h at 45 to 55 DEG. C to obtain a mixed solution, performing ultrasound after the mixed solution is cooled to the room temperature, then standing for 1 to 3 days, centrifuging supernatant, washing the centrifuged milky white precipitate by acetone, and finally drying to obtain the product; and (2) adding fluoboric acid into the product obtained in the step (1), magnetically stirring for 5 to 10h at 45 to 55 DEG. C, naturally cooling to the room temperature, then centrifuging the obtained product, washing with deionzied water, and finally drying. The preparation method disclosed by the invention is simple, environment-friendly, low in equipment requirements, abundant in raw materials, and convenient for mass production; and the electrical conductivity of the fluorine doped boron nitride obtained by the invention is enhanced.

Owner:DONGHUA UNIV

Series one-pot synthesis method of lithium oxalyldifluroborate

ActiveCN104387411AQuick responseReduce energy consumptionGroup 3/13 element organic compoundsOXALIC ACID DIHYDRATEDistillation

The invention discloses a series one-pot synthesis method of lithium oxalyldifluroborate. The method is characterized by comprising the following steps: sequentially adding a solvent, a lithium salt, boron fluoride or complex thereof, oxalic acid, reaction assistants and other raw materials into a reaction kettle, and reacting at 0-100 DEG C for 2-10 hours; after the reaction finishes, discharging the solvent and byproduct out of the reaction kettle by distillation, and recovering by condensation; and recrystallizing the product, and drying to directly obtain the product with the purity of greater than 99%. The method has the advantages of high production efficiency, safe and simple operation process and no need of complicated purification by recrystallization, and is a lithium oxalyldifluroborate preparation technique suitable for industrial production.

Owner:周阳

Preparation method of 1,2,4-trifluorobenzene

InactiveCN102643160AReduce manufacturing costReduce the discharge of three wastesHalogenated hydrocarbon preparationOrganic solventBoron trifluoride

The invention provides a preparation method of 1,2,4-trifluorobenzene, which comprises the following steps: 1) preparation of fluoboric acid diazonium salt: carrying out diazo-reaction on 2,4-difluoroaniline and sodium nitrate in fluoboric acid to obtain a fluoboric acid diazonium salt intermediate; and 2) preparation of 1,2,4-trifluorobenzene: heating to 100-300 DEG C to decompose the fluoboric acid diazonium salt intermediate while emitting nitrogen gas and boron trifluoride gas. The preparation technique provided by the invention is simple to operate, and has the advantages of low cost, high yield, high product quality and the like; and meanwhile, the quality of the byproduct boron trifluoride organic solvent solution is high, the production cost is greatly lowered, the emission of three wastes is reduced, and thus, the invention is suitable for industrial application.

Owner:Jiangsu Shimeikang Pharmaceutical Co Ltd

Cobalt-based metal organic framework material and application

ActiveCN111303445AEfficient photocatalytic CO

<sub>2</sub>

restore performanceEasy to prepareOrganic-compounds/hydrides/coordination-complexes catalystsHydration reactionPtru catalyst

The invention relates to a cobalt-based metal organic framework material with photocatalytic CO2 reduction performance and a preparation method. A solvothermal method is adopted for synthesis. Cobaltperchlorate hexahydrate, 1, 3, 5-trimethyl-2, 4, 6-tricarboxyl phenyl benzene, 1, 4-di (1-imidazolyl) benzene, N, N-dimethylformamide, fluoboric acid and water are synthesized in a polytetrafluoroethylene reaction kettle to obtain blue blocky crystals, and the blue crystals are washed and dried to obtain the photocatalytic material. The preparation method of the material is relatively simple. Theobtained catalyst has relatively good photocatalytic CO2 reduction capability, the selectivity of the reduction product CO can reach 77%, and the average yield of CO is 1124.8 [mu] mol g<-1> h<-1>. The material can be used as a cheap and efficient photocatalyst to replace precious metal, and the material shows a good application prospect in the field of photocatalysis.

Owner:CHINA THREE GORGES UNIV

Technology for treatment of fluorine-boron-containing wastewater during Ceftezole acid preparation

InactiveCN102963999AReduce fluorine contentIncrease valueMultistage water/sewage treatmentNature of treatment waterAlkali freePotassium

The invention discloses a technology for treatment of fluorine-boron-containing wastewater during Ceftezole acid preparation. According to the technology, boric acid and fluoboric acid are remove from wastewater respectively by a two-stage neutralization reaction, so that the fluorine content of the industrial wastewater is decreased to 5mg / l, the boron content is reduced to 5mg / l, and the pH of the wastewater is 6-7, thus meeting the national wastewater discharge standards. The technology has the advantages of simple operation, small investment, and large by-product value. Calcium borate can be used for alkali-free glass fiber production, and potassium fluoborate can be used as a catalyst for polypropylene synthesis.

Owner:江苏德峰药业有限公司

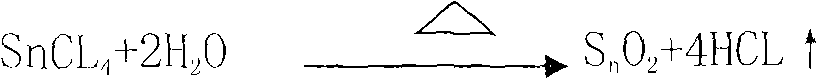

Composition for preparing semiconductor electrothermal film, electrothermal film and preparation method

InactiveCN105722257AReduce leakage currentStable electrothermal conversion performanceHeating element materialsAntimony trichlorideFluoboric acid

The invention relates to a composition for preparing a semiconductor electrothermal film. The composition is prepared from the following components in parts by weight: 15-20 parts of stannic chloride, 6-10 parts of nickel tetrachloride, 10-30 parts of graphite, 3-6 parts of antimony trichloride, 0.2-0.4 part of titanium tetrachloride, 0.2-0.6 part of antimonous oxide, 0.1-0.8 part of fullerene, 0.1-1.5 parts of boric acid, 0.1-1.5 part of fluoboric acid, 0.3-0.5 part of sodium chloride, 3-6 parts of water, 2-4 parts of methylbenzene and 30-50 parts of ethanol. The adhesive force of the semiconductor electrothermal film prepared according to the method on a substrate is 180-200N; the leakage current is smaller than 0.10mA; the electrothermal conversion efficiency is greater than or equal to 99%; the square resistance is 20-500ohm / square; and the lifetime is over 5,000 hours.

Owner:顾伟

Method for manufacturing high-temperature resistant transparent electric heating film

ActiveCN102065589AWide temperature rangeSolution to short lifeHeating element materialsBarium titanateSolvent

The invention relates to a method for manufacturing a high-temperature resistant transparent electric heating film. The method comprises the following steps of: preparing a surface modification solution; purifying a substrate; carrying out surface modification; manufacturing an electrode; and carrying out an electrifying and aging procedure. The method is characterized in that the surface medication solution comprises the following components: 300-500g of stannic chloride as a main material, 3-5g of ruthenium trichloride, 4-7g of bismuth hydroxide as a high-temperature resistance stabilizer, 4-7g of barium titanate as a high-voltage resistance stabilizer, 2-4g of fluoboric acid as a doping agent, a proper quantity of hydrofluoric acid as a doping cosolvent, a proper quantity of hydrochloric acid as a cosolvent and 300-500g of absolute alcohol as a solvent. The method has the advantages of high temperature resistance, antioxidation, dry burning in air, wide using temperature range, long service life, slow attenuation and wide application. The method is suitable for manufacturing a high-temperature resistant transparent electric heating film.

Owner:宁波高新区健坤电热技术有限公司

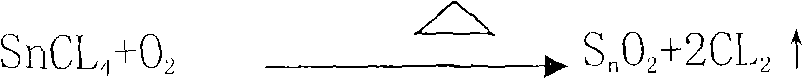

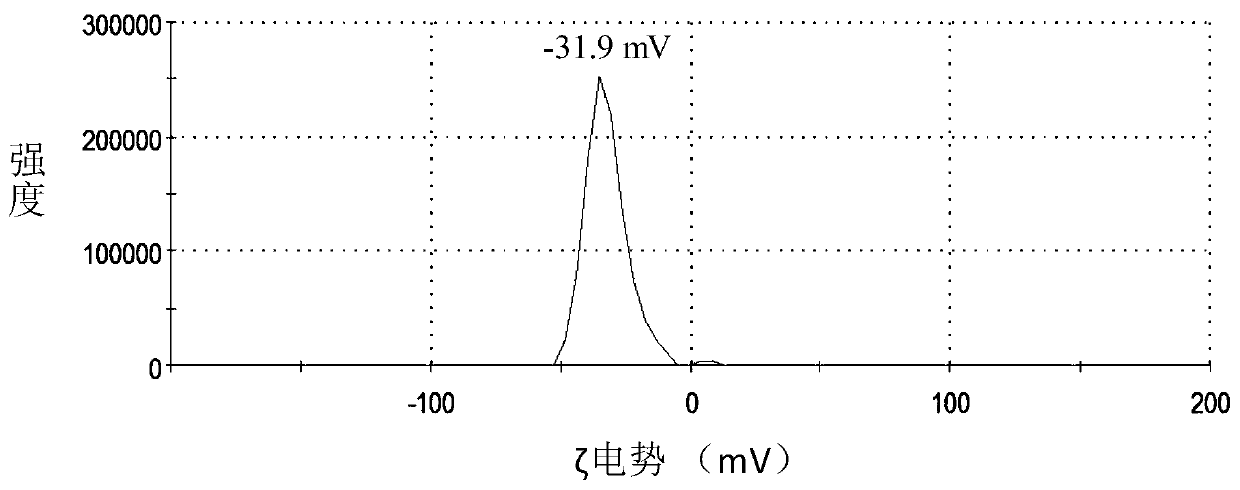

Efficient and general two-dimensional nanometer sheet-zero-dimensional nanocrystalline co-assembly method

InactiveCN109879328AComponents are widely applicableEasy reunionCarbon compoundsFerroso-ferric oxidesChalcoidesOleylamine

The invention relates to an efficient and general two-dimensional nanometer sheet-zero-dimensional nanocrystalline co-assembly method. Long-chain organic ligand (such as oleic acid / oleylamine) coatednanometer particles are synthesized by a solution method; the materials are dispersed in a nonpolar solvent (such as n-hexane and toluene); then, fluoboric acid compounds (such as fluoboric acid, diazonium tetrafluoroborate and nitrosonium tetrafluoroborate) are used for exchanging the nanometer particles into polar solvents (such as N,N- dimethylformamide); at the moment, the zeta potential of the nanometer particles is positive; then, the potential of most nanometer sheets (such as oxidized graphene, transition metal disulfide compounds, layered metal oxides, C3N4, hexagonal boron nitride and transition metal carbide) is negative; through mixing, the nanometer sheets and the nanometer particles are induced to subjected to static assembly for obtaining two-dimensional-zero-dimensional nanometer crystals. The method has the advantages that the idea is novel; the application is wide; simplicity and low cost are realized; the functions and the application can be widely adjusted along with the ingredient change.

Owner:FUDAN UNIV

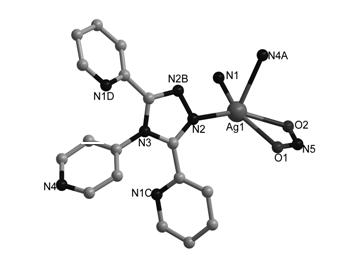

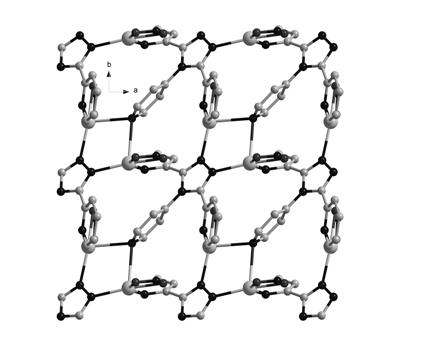

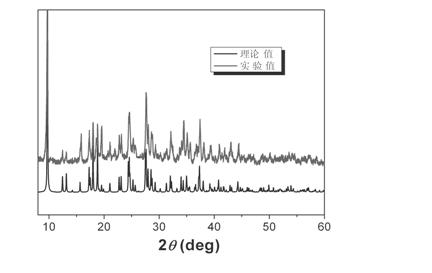

Metallic silver coordination polymer with three-dimensional network structure, and preparation method and application thereof

InactiveCN102516271AEasy to manufactureShort reaction timeSilver organic compoundsAnion exchangersBenzoic acidNitrite ion

The invention relates to 3,4-di(2-pyridyl)-5-(4-pyridyl)-1,2,4-triazole-silver (I) coordination polymer, and preparation and application thereof. The coordination polymer is synthesized by the following steps of: mixing an acetonitrile solution of AgNO2 and a chloroform solution of ligand L at normal temperature and normal pressure, keeping stirring for half an hour, and standing and volatizing for about one week under the shading condition to obtain a colorless blocky monocrystal product. The coordination polymer is easy to prepare, reaction time is short, the aftertreatment step is simple, and the coordination polymer is high in yield. Through the experiment, nitrite ions in the material can be selectively subjected to anion exchange reaction with fluoboric acid ions, hexafluorosilicic acid ions, nitrate radical ions and perchloric acid ions, and cannot be subjected to similar anion exchange reaction with benzoic acid ions, and acetate ions. The coordination polymer overcomes the limit of the conventional anion exchange material, an exchange process is simple and easy to realize, and the coordination polymer is expected to be actually applied in the field of ion exchange materials.

Owner:TIANJIN NORMAL UNIVERSITY

Limiting the loss of tin through oxidation in tin or tin alloy electroplating bath solutions

InactiveUS6923899B2Reduce oxidationAnti-corrosive paintsLiquid/solution decomposition chemical coatingBenzeneOrganic sulfonic acid

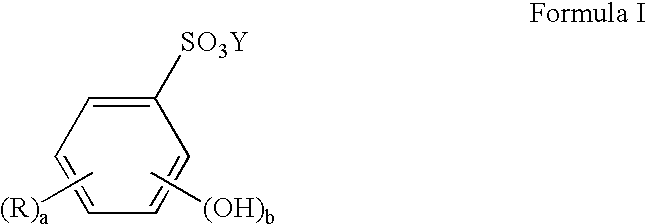

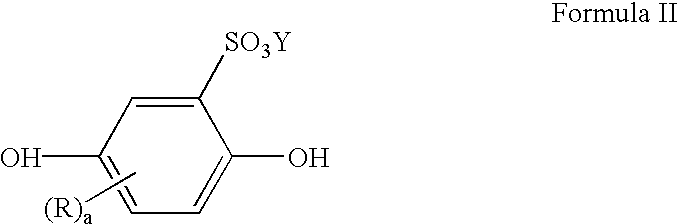

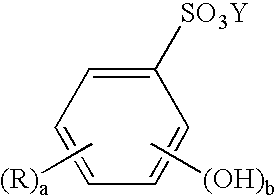

Provided for is a solution for use in the electroplating of tin and tin alloys comprising a basis solution comprising an acid, optionally a salt thereof, the acid selected from the group consisting of fluoboric acid, an organic sulfonic acid, a mineral acid, or a combination thereof; divalent tin ions; and an antioxidant comprising a hydroxy benzene sulfonic acid or salt thereof, in an amount effective to prevent the oxidation of divalent tin ions. Also provided for is a method for electroplating comprising electroplating a substrate using an electroplating solution comprising a hydroxy benzene sulfonic acid or salt thereof in an amount effective to decrease the oxidation of tin ions.

Owner:SHIPLEY CO LLC

Aluminum and aluminum alloy film removing agent and application thereof

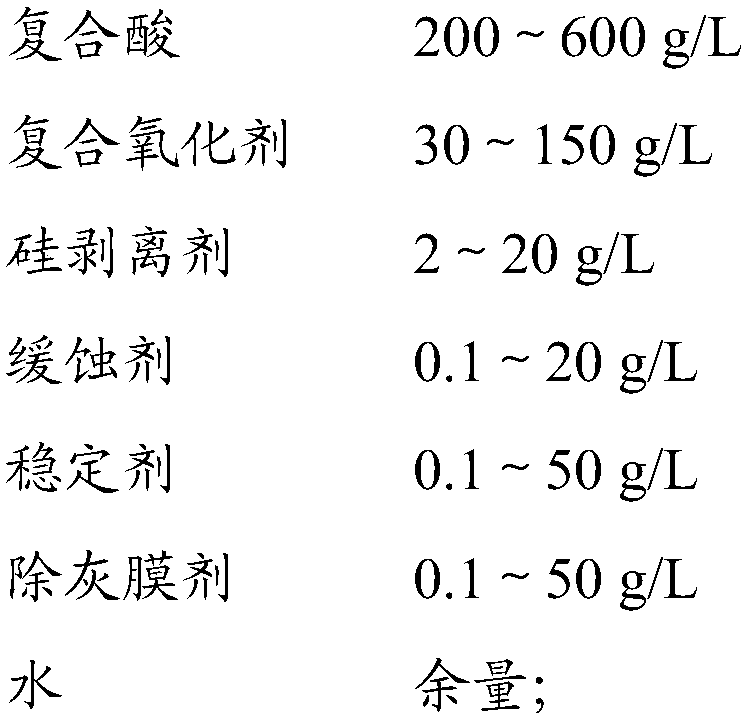

The invention relates to an aluminum and aluminum alloy film removing agent. The aluminum and aluminum alloy film removing agent comprises the following components: 200-600g / L of composite acid, 30-150g / L of a composite oxidant, 2-20g / L of a silicon remover, 0.1-20g / L of corrosion inhibitor, 0.1-50g / L of a stabilizer, 0.1-50g / L of an ash removal film agent and water, wherein the composite acid isselected from at least two of sulfuric acid, aminosulfonic acid, fluoboric acid and chloric acid; and the composite oxidant is selected from at least two of hydrogen peroxide, persulfate, perborate and percarbonate. On the premise of guaranteeing the film removal effect of the aluminum and the aluminum alloy, the aluminum and aluminum alloy film removing agent reduces treatment difficulty of industrial waste gas and industrial wastewater after aluminum and aluminum alloy electroplating.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com