Reversible dynamic macroporous elastomer polymer material and its preparation method and application

An elastomeric polymer, dynamic technology, applied in the field of reversible dynamic macroporous elastomeric polymer materials and its preparation, can solve the problems of few explorations in applications, macroporous polymers cannot effectively reversibly switch pore structures, and lack of green and environmentally friendly preparations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

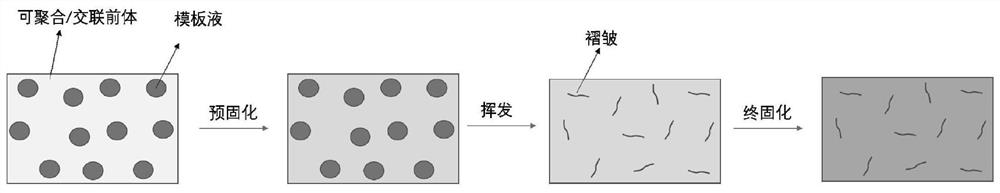

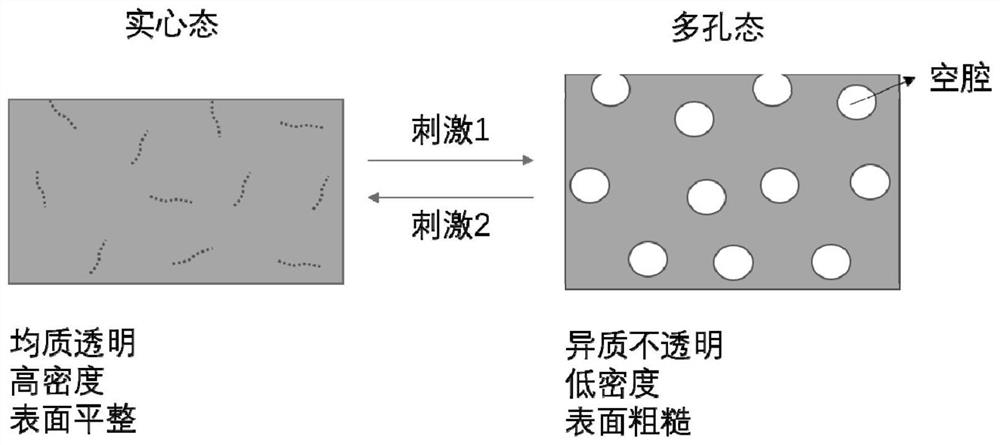

Method used

Image

Examples

Embodiment 1

[0097] The preparation method of obtaining the reversible dynamic macroporous polymer by the small molecule polymerization of this embodiment includes:

[0098] Mix 20g of 4-hydroxybutyl acrylate, 0.2g of 1,6-hexanediol diacrylate, 0.1g of azobisisobutyronitrile and 0.2g of poly(4-hydroxybutyl acrylate) , to obtain a viscous polymeric precursor solution. Then it was mixed with 3.1 g of polyvinyl alcohol water containing 1 wt%, and vigorously stirred to obtain an emulsion. The obtained emulsion was cured for 1 day under room temperature, natural light and exposure conditions, and a dynamically reversible macroporous polymer in a solid state was obtained after curing.

[0099] The reversible dynamic macroporous elastomeric polymer material obtained in this embodiment is a transparent material.

Embodiment 2

[0101] The preparation method of obtaining the reversible dynamic macroporous polymer by the small molecule polymerization of this embodiment includes:

[0102] Mix 20g of 4-hydroxybutyl acrylate, 0.2g of 1,6-hexanediol diacrylate, 0.1g of azobisisobutyronitrile and 0.2g of poly(4-hydroxybutyl acrylate) , to obtain a viscous polymeric precursor solution. Then it was mixed with 3.1 g of pure water and vigorously stirred to obtain an emulsion. The resulting emulsion was pre-cured for 15 minutes under sealed conditions at 40°C; then the sample was placed in a desiccator with the open open, and vacuumed at room temperature until a transparent sample was obtained, then the sample was taken out, and the temperature was raised to 40°C for curing for 1 day . A dynamically reversible macroporous polymer in a solid state is obtained after curing.

[0103] The reversible dynamic macroporous elastomeric polymer material obtained in this embodiment is a transparent material.

Embodiment 3

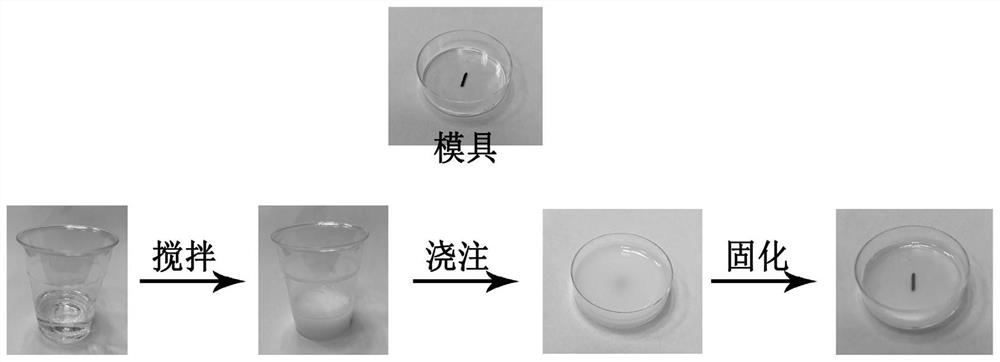

[0105] In this embodiment, the preparation method for preparing a reversible dynamic macroporous elastomeric polymer through a crosslinkable polymer precursor includes:

[0106] A mixture of 10 g of A and 10 g of B was used to obtain a silicone precursor. The silicone precursor and 3 g of an aqueous solution containing 1 wt % polyvinyl alcohol were mixed and stirred for 30 min, and the obtained emulsion was poured on the substrate and cured at room temperature for 6 days to obtain a reversible dynamic macroporous elastomeric polymer material.

[0107] The reversible dynamic macroporous elastomeric polymer material obtained in this embodiment is a transparent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com