Preparation and application of polydopamine-derived carbon-based tar cracking catalyst

A polydopamine carbon-based tar and cracking catalyst technology, which is applied in the direction of physical/chemical process catalysts, cracking, metal/metal oxide/metal hydroxide catalysts, etc., to achieve enhanced catalytic effects, increased reaction time, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

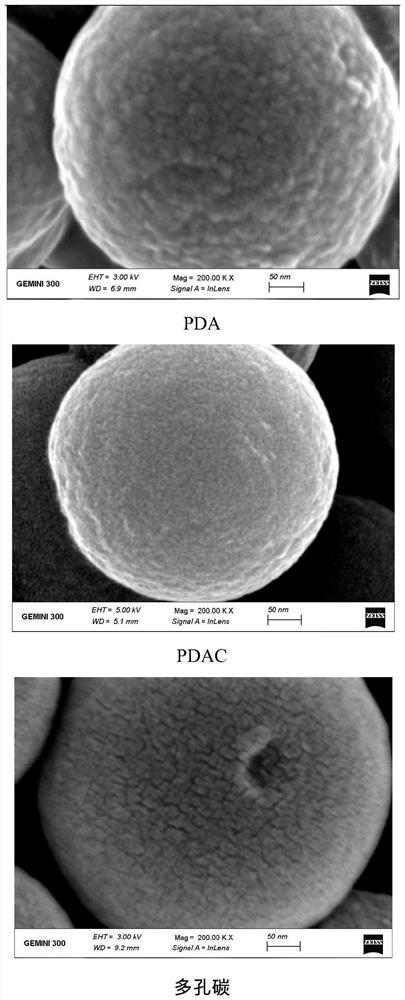

[0026] Figure 1 to Figure 5 An embodiment of the preparation method of a novel polydopamine carbon-based tar cracking catalyst of the present invention is shown.

[0027] A preparation method of a novel porous carbon-based tar catalyst, the catalyst is based on a polydopamine carbon material as a carrier, and the surface supports Fe3O4, and its preparation steps are as follows:

[0028] a) Preparation of polydopamine: firstly, a mixed solution of absolute ethanol-deionized water was prepared at a volume ratio of 2:5, and then a certain amount of ammonia water was added to the above solution. Add a certain amount of dopamine hydrochloride under the condition of slow stirring. The reaction was stirred slowly at room temperature for 24 h, the obtained solution was centrifuged at 6000 rpm for 10 min, and the obtained solid was washed three times with deionized water. Finally, the washed sample was dried in a vacuum oven at 60°C for 12 hours, and the obtained sample was designat...

Embodiment 2

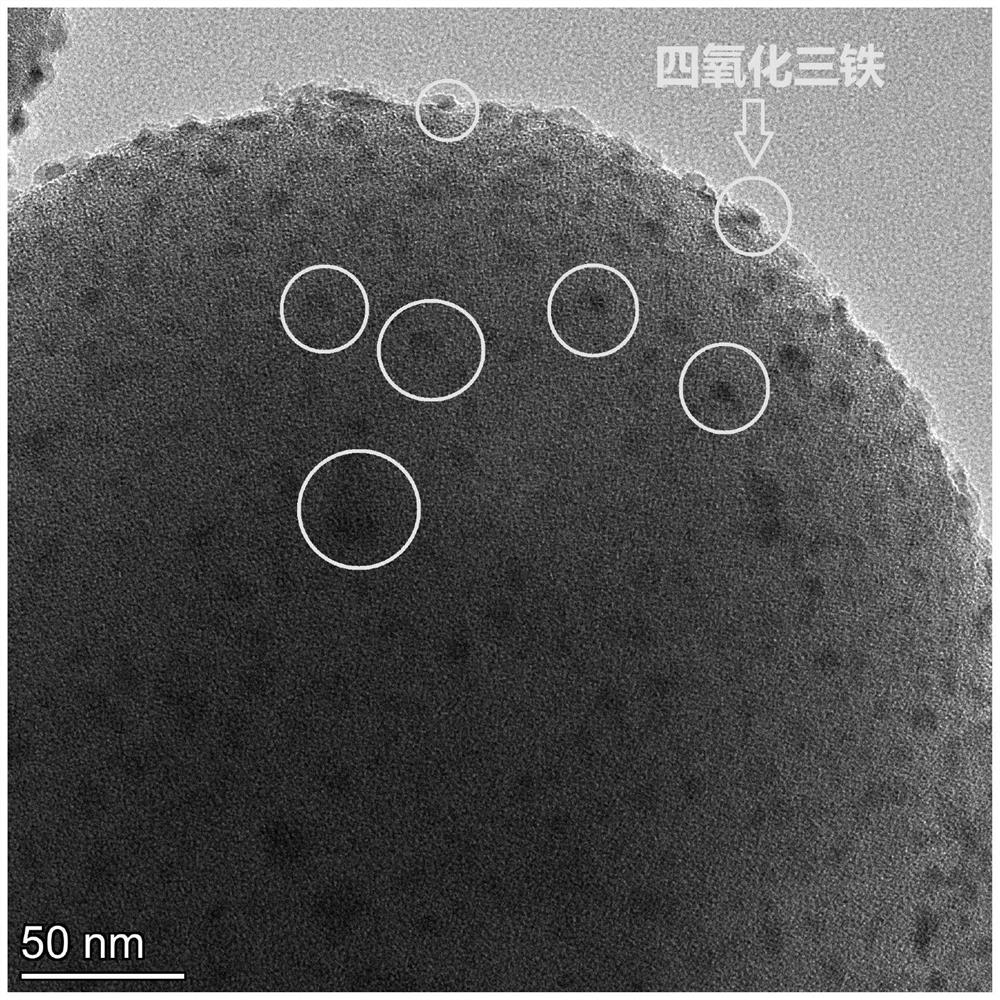

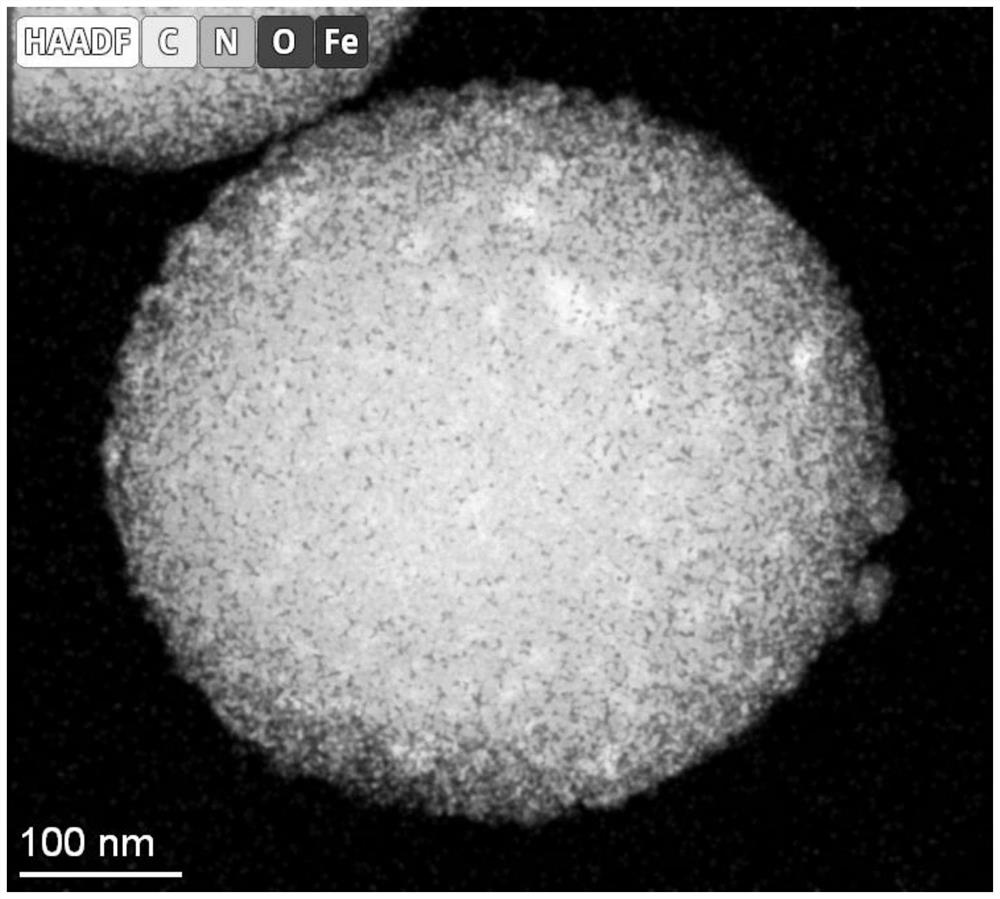

[0034] This example shows the novel porous carbon-Fe3O4 tar cracking catalyst obtained by the preparation method described in the example of the present invention.

[0035] The organic combination of porous carbon and Fe3O4 not only overcomes the problem of insufficient tar catalytic performance of porous carbon at medium and low temperatures, but also improves the agglomeration / sintering of Fe3O4 during the catalytic process, expanding the application potential of porous carbon in tar catalysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com