Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Facilitated reaction kinetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

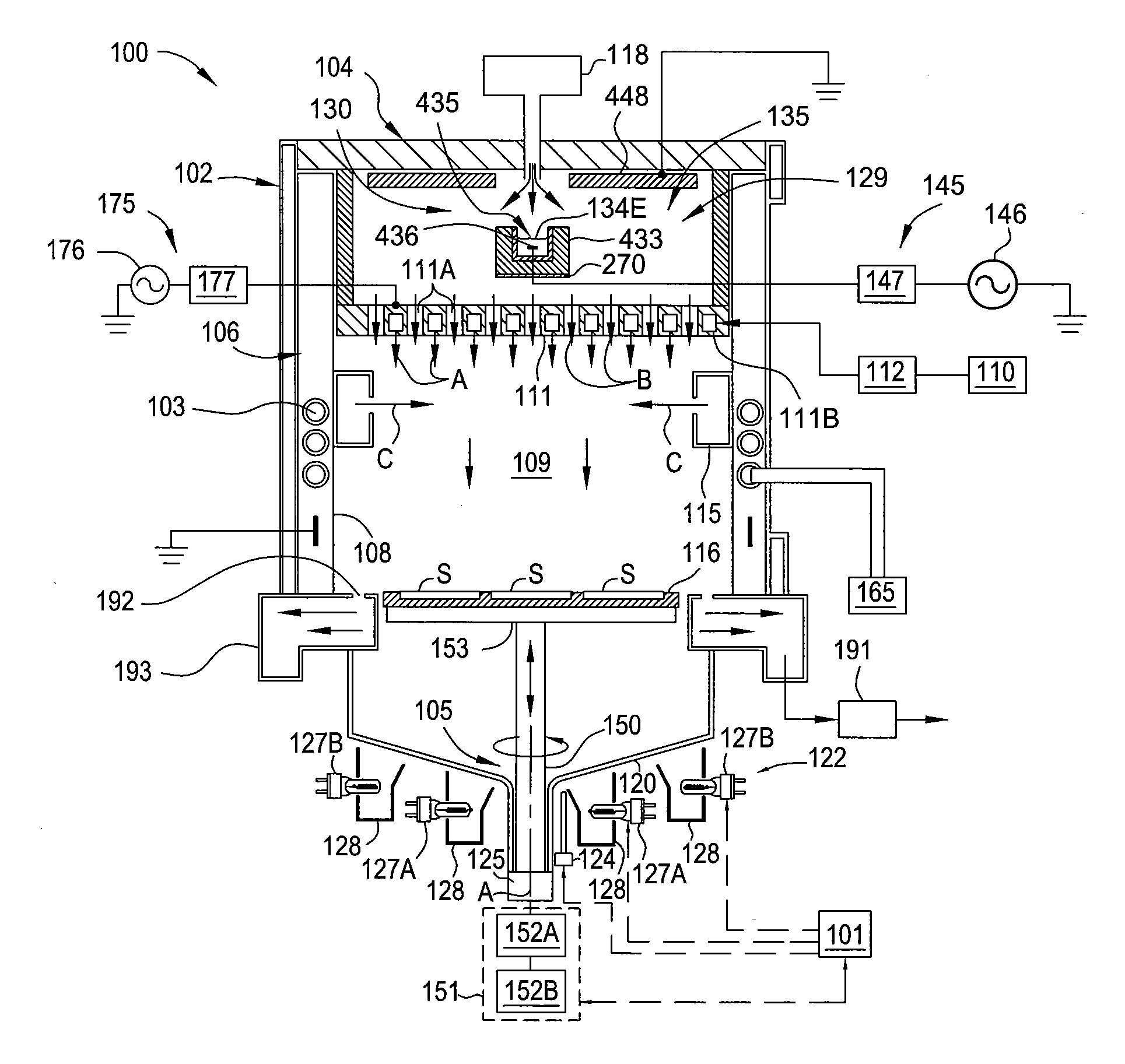

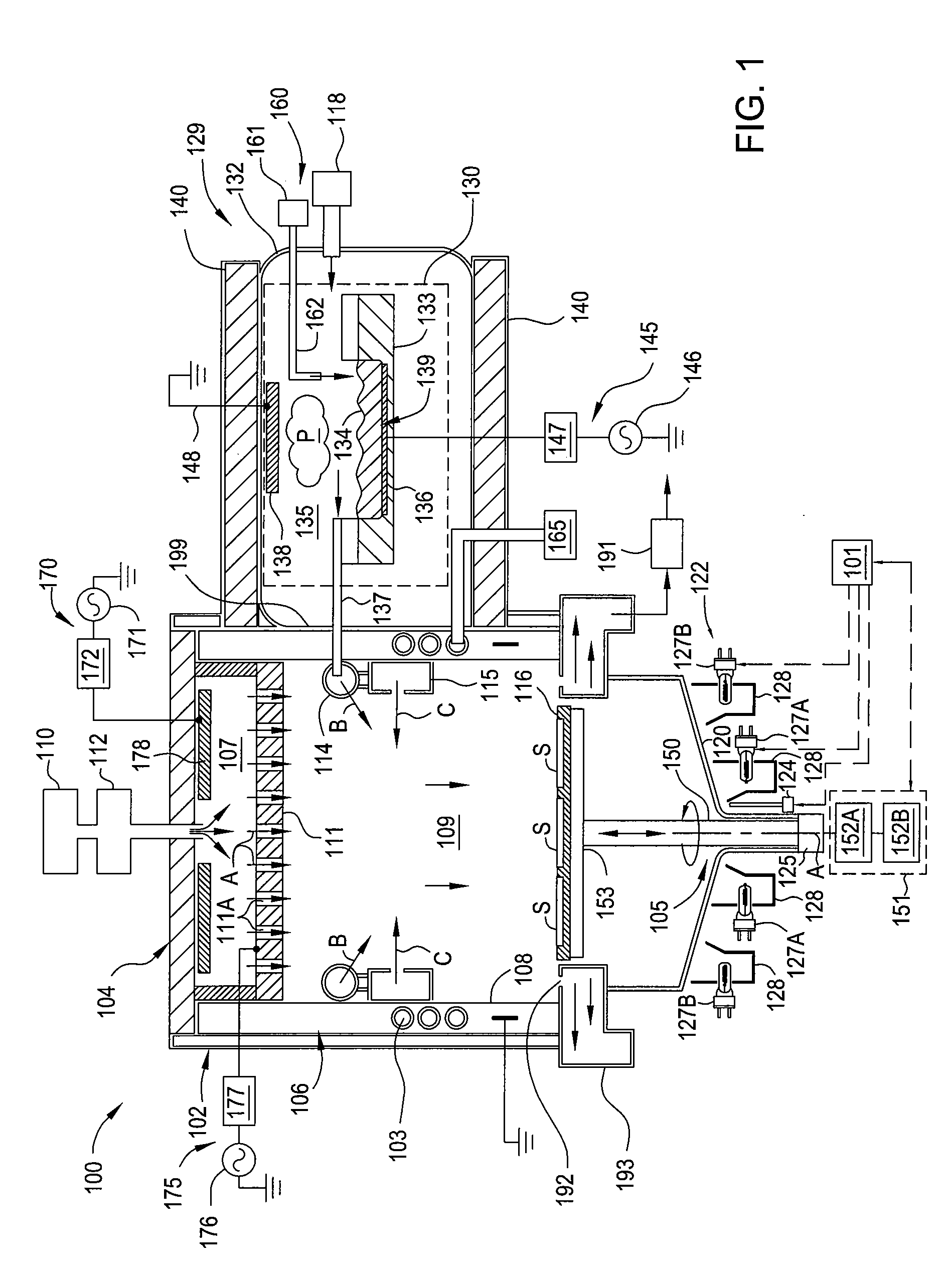

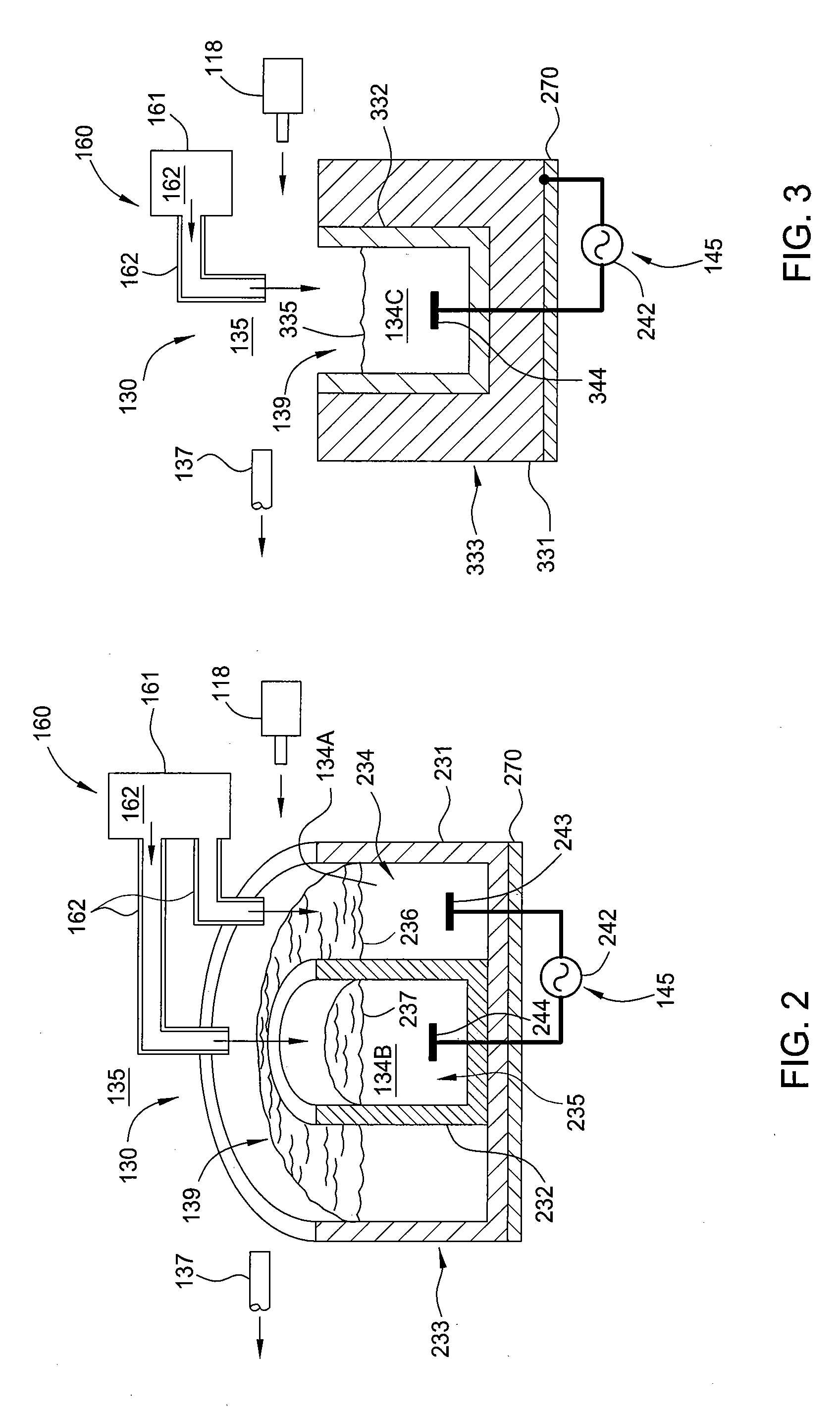

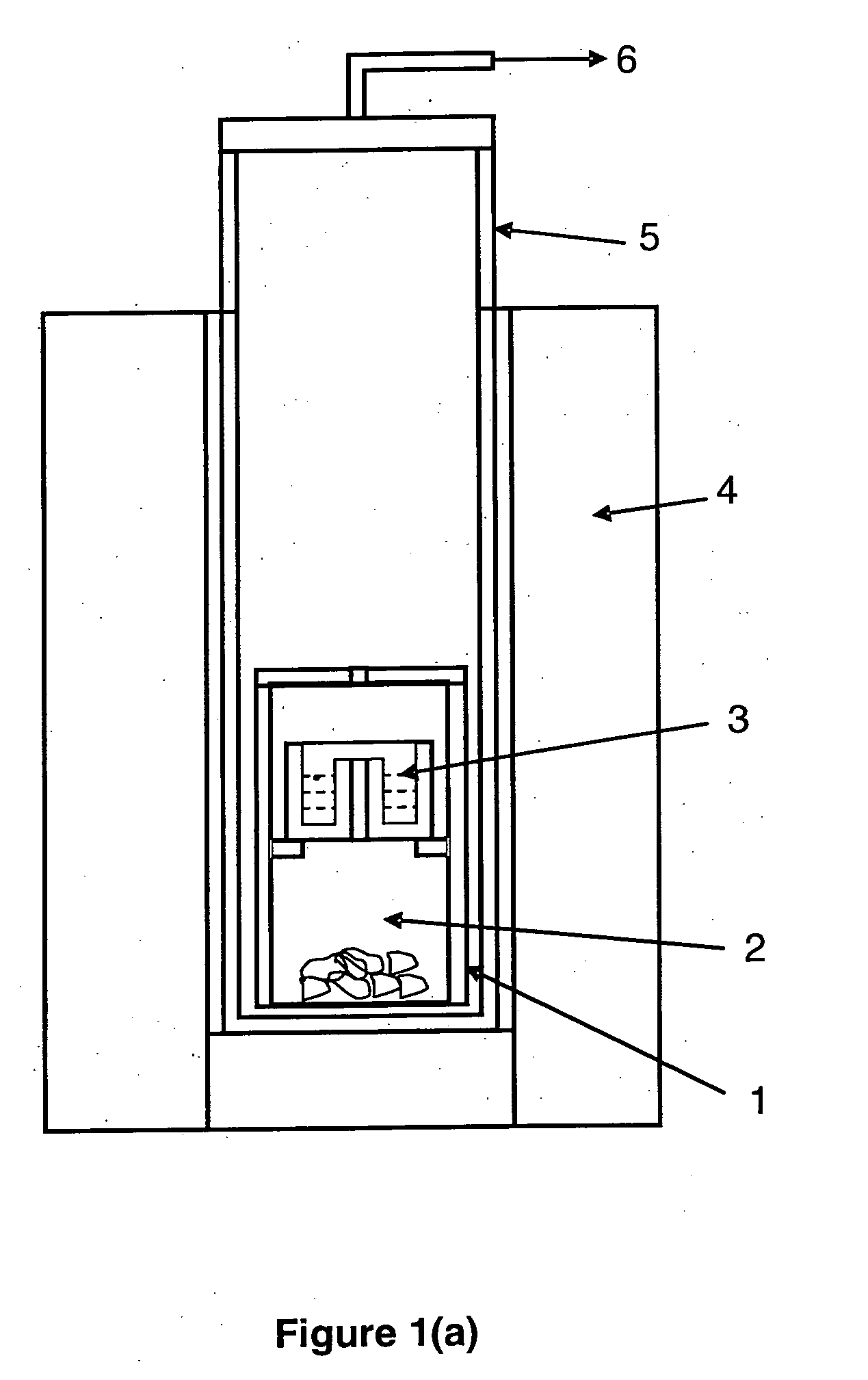

Plasma assisted hvpe chamber design

InactiveUS20130032085A1Enhance deposition reaction kineticsReduce processing timePolycrystalline material growthFrom chemically reactive gasesNitrogenVapor phase

Embodiments of the invention disclosed herein generally relate to a hydride vapor phase epitaxy (HVPE) deposition chamber that utilizes a plasma generation apparatus to form an activated precursor gas that is used to rapidly form a high quality compound nitride layer on a surface of a substrate. In one embodiment, the plasma generation apparatus is used to create a desirable group-III metal halide precursor gas that can enhance the deposition reaction kinetics, and thus reduce the processing time and improve the film quality of a formed group-III metal nitride layer. In addition, the chamber may be equipped with a separate nitrogen containing precursor activated species generator to enhance the activity of the delivered nitrogen precursor gases.

Owner:APPLIED MATERIALS INC

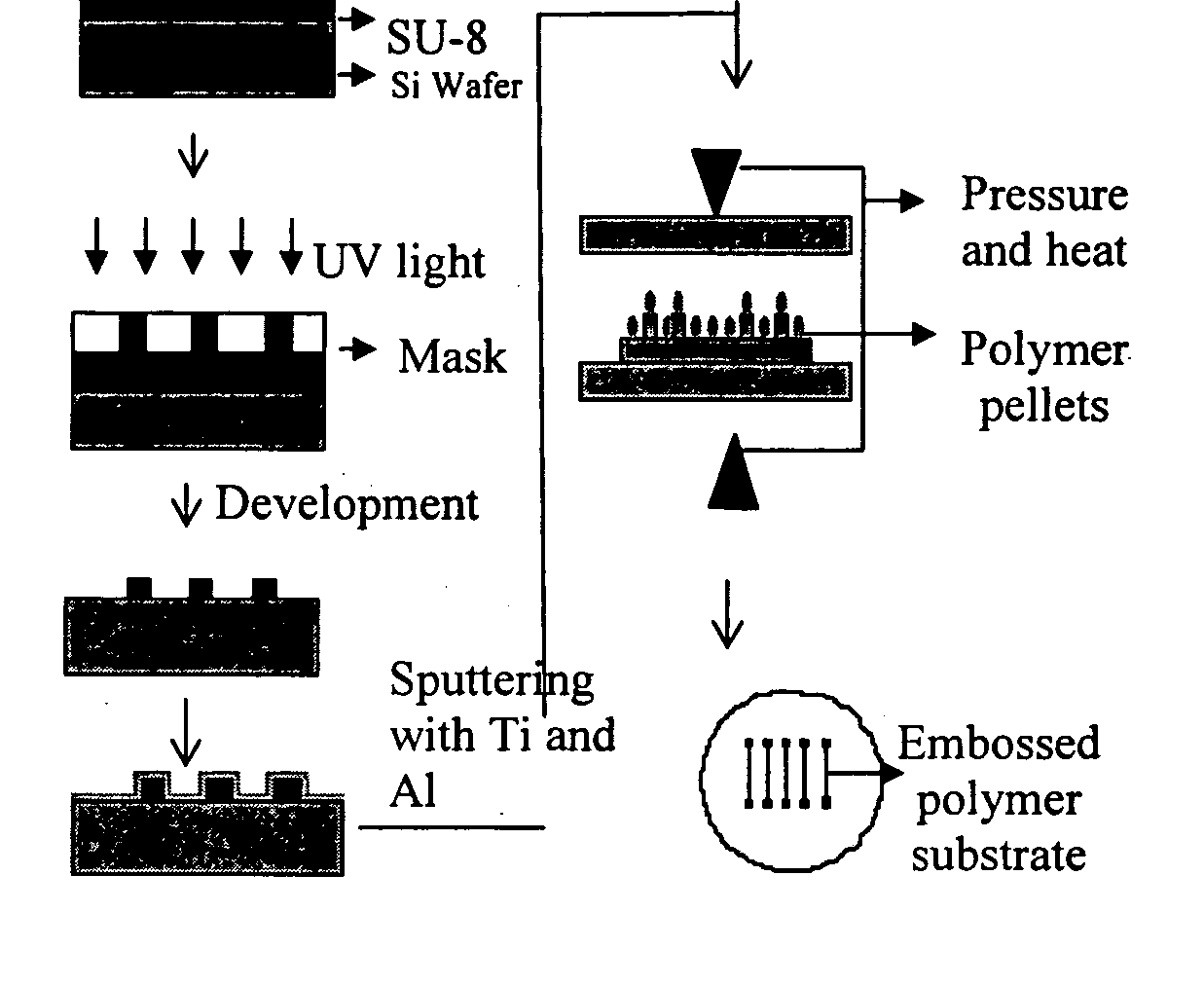

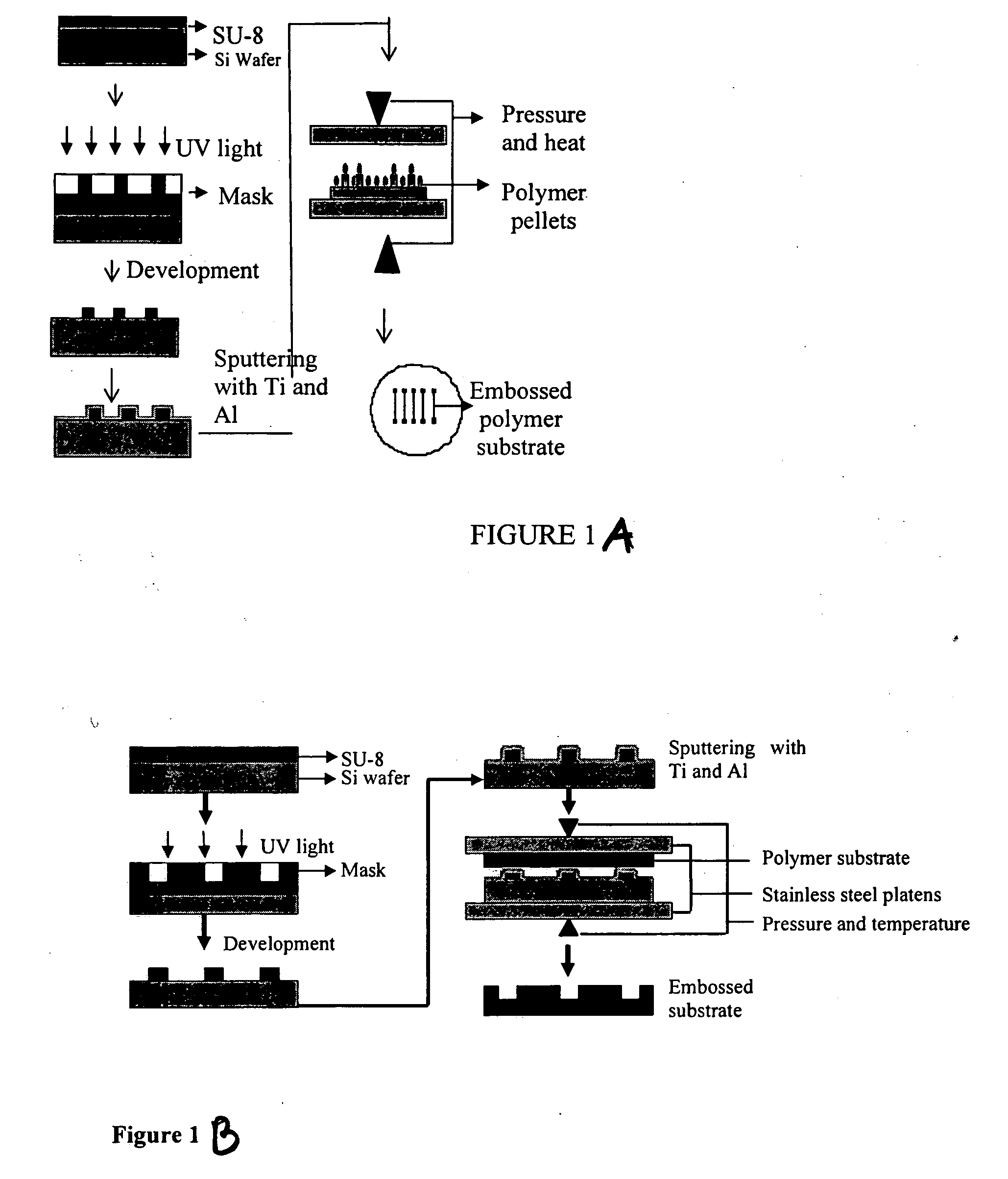

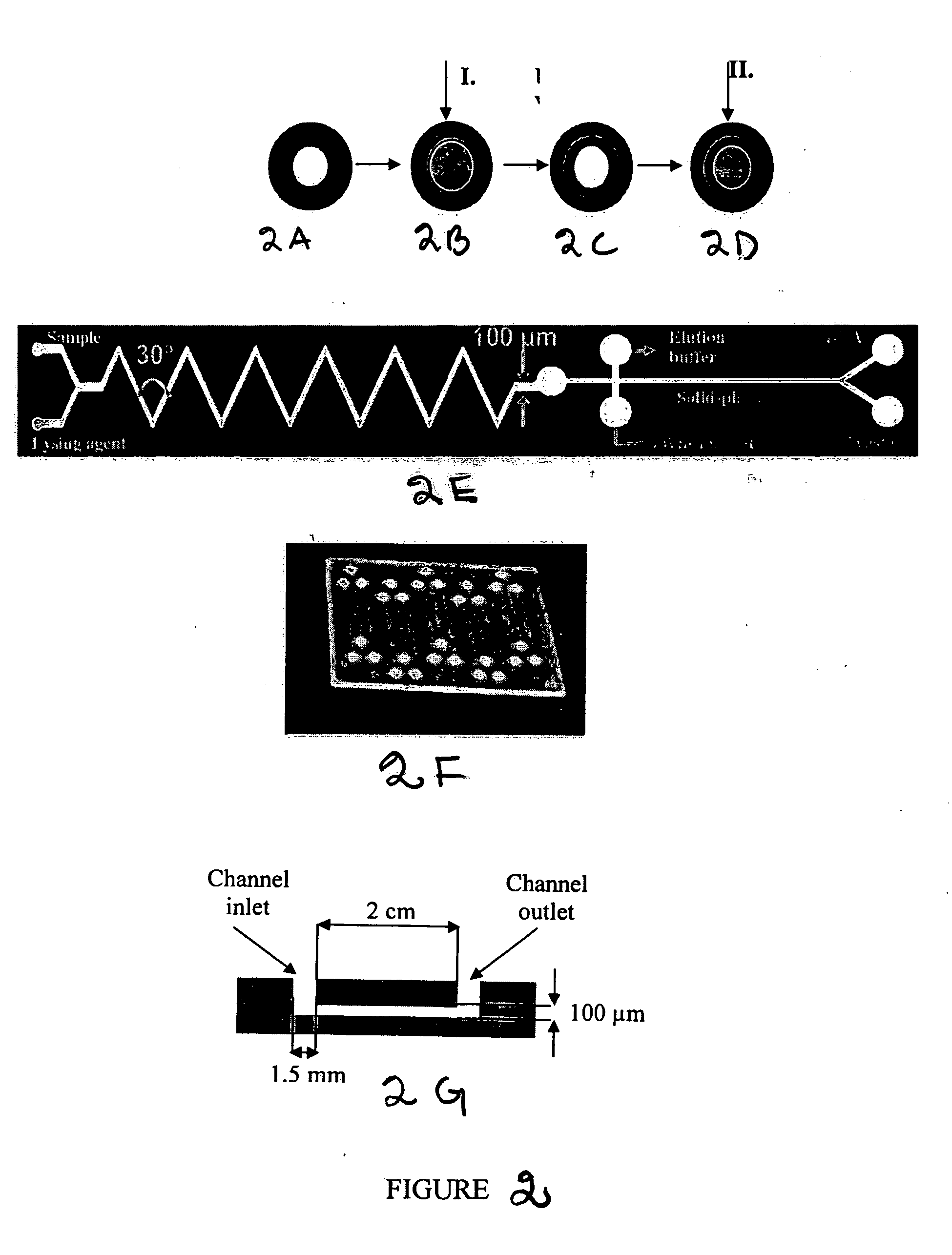

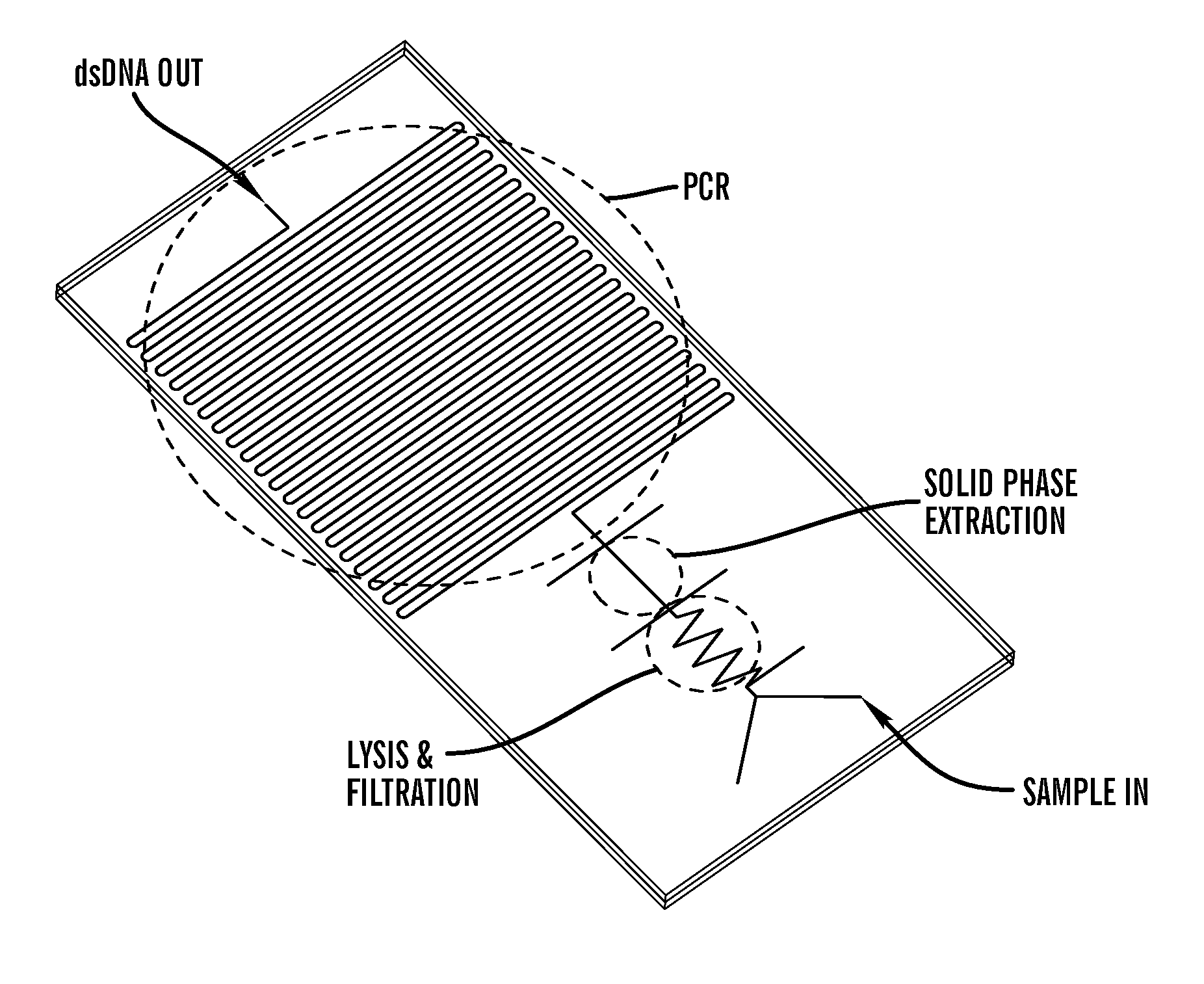

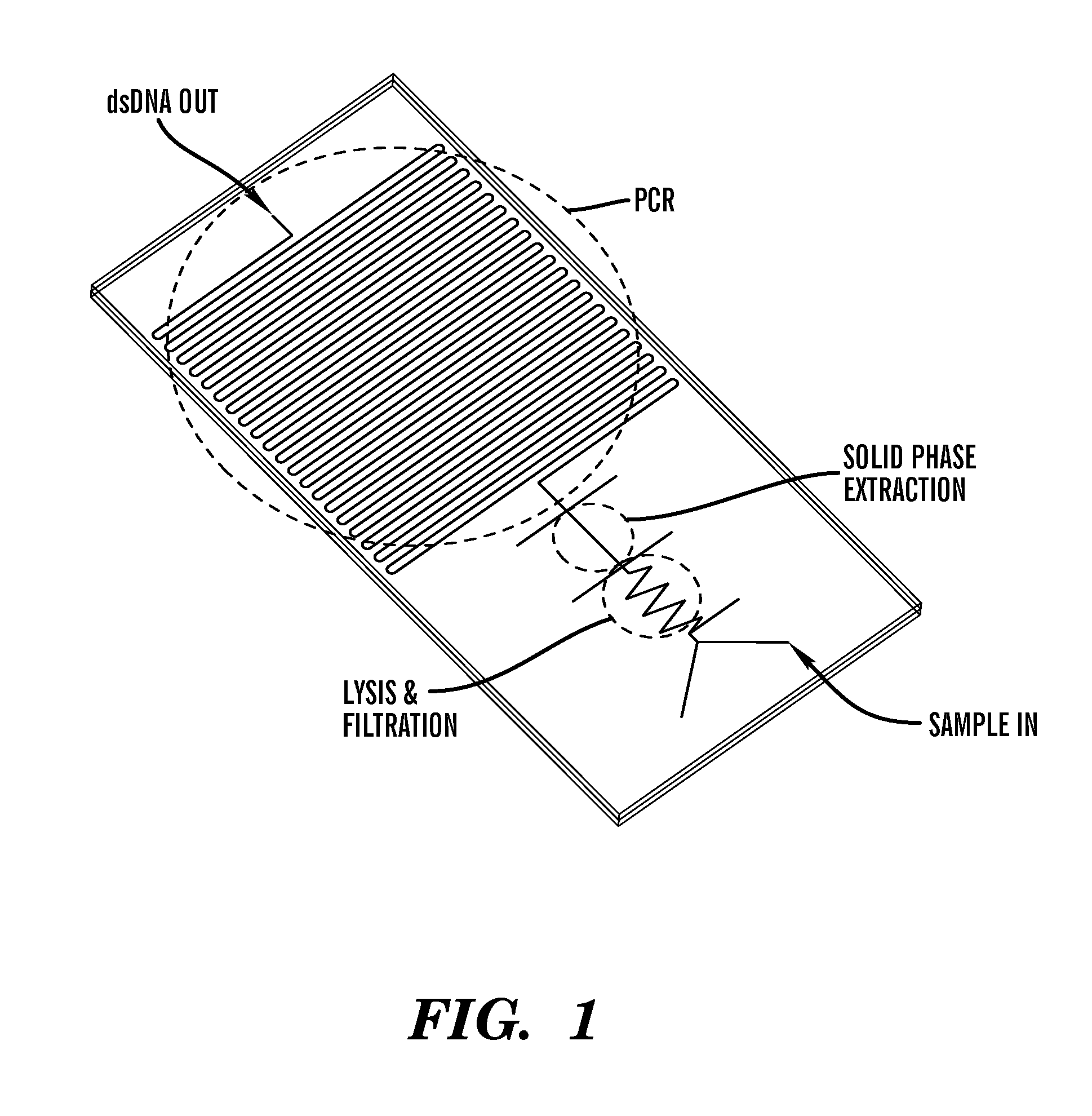

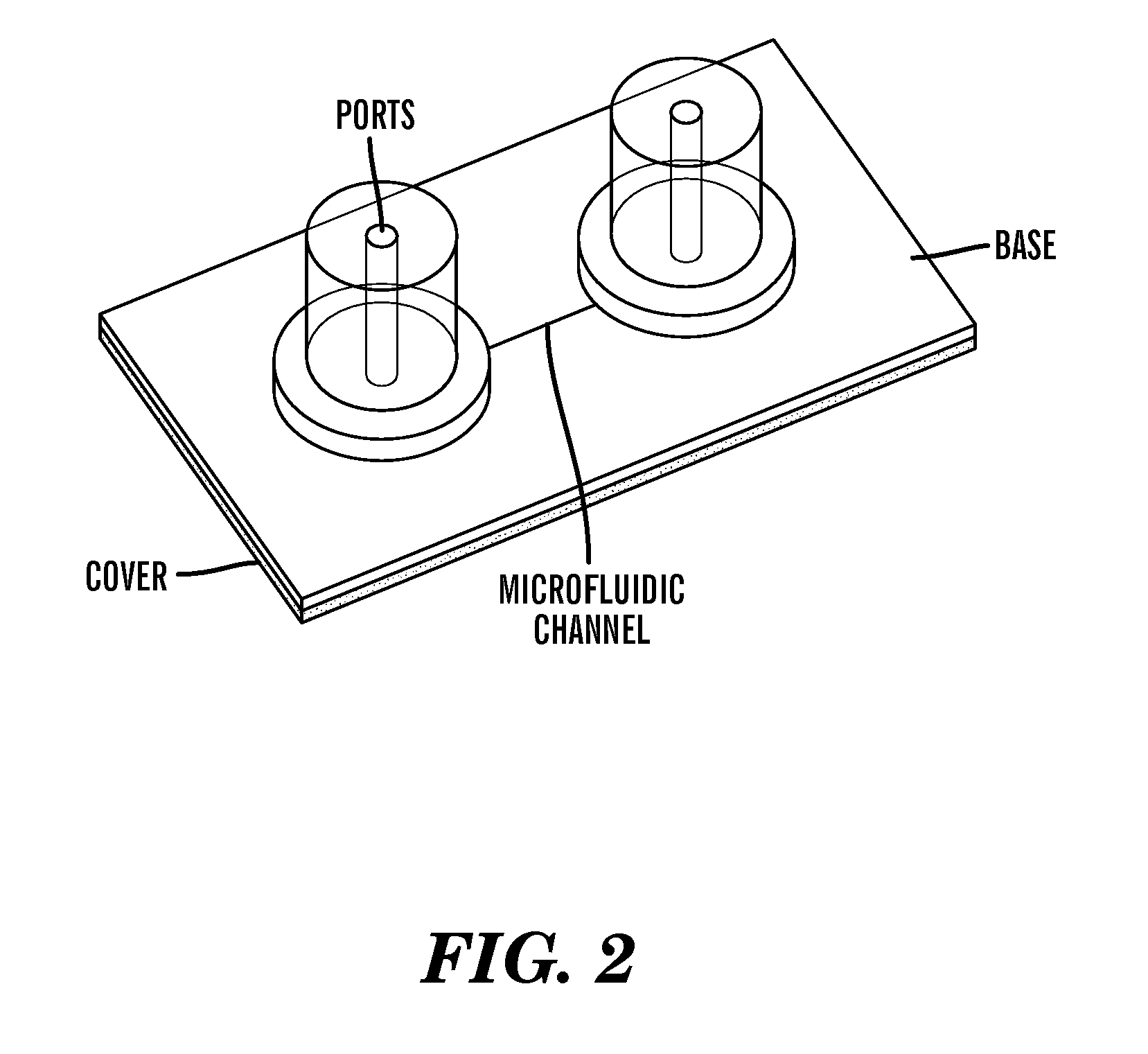

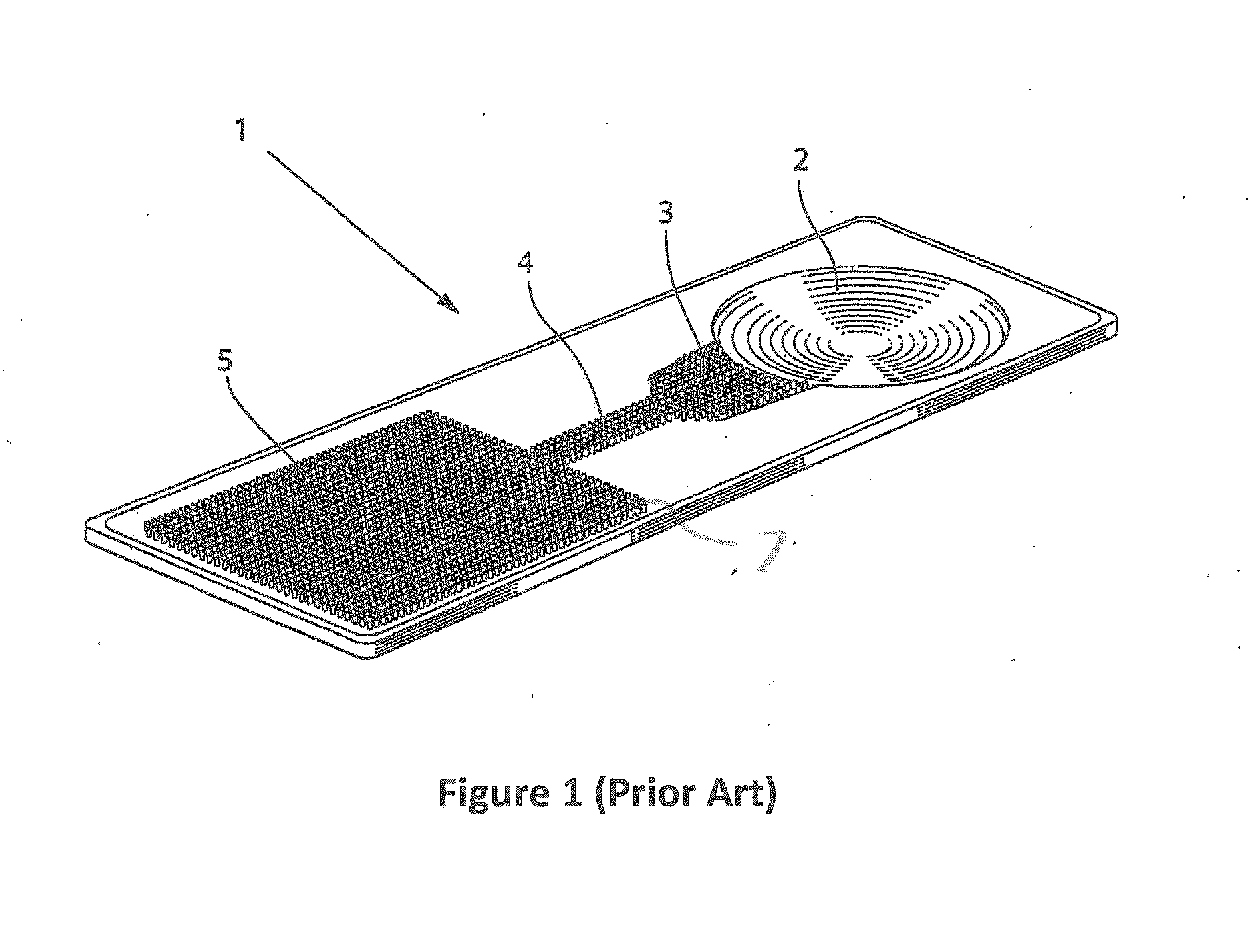

Plastic microfluidic chip and methods for isolation of nucleic acids from biological samples

InactiveUS20070015179A1Facilitated reaction kineticsImprove detection limitBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic chipPeptide

The present invention is directed to methods of manufacture of microfluidic chip such as a plastic microfluidic chips, which has channels packed with polymer-embedded particles and uses thereof. The chip of the present invention is designed for application of an untreated biological sample on the chip thus allowing isolation, purification and detection of biomolecules, such as nucleic acids, proteins or peptides in one step. The invention also provides a microfluidic chip for combined isolation, purification and detection of biomolecules thus providing a complete Lab-on-a-Chip analysis system for biomolecules such as nucleic acids and proteins. The chips of the invention can be adapted to perform highly specific immunoassays and diagnostic test, for example, for diagnosis of infectious agents, such as bacteria, viruses or parasites.

Owner:TRUSTEES OF BOSTON UNIV

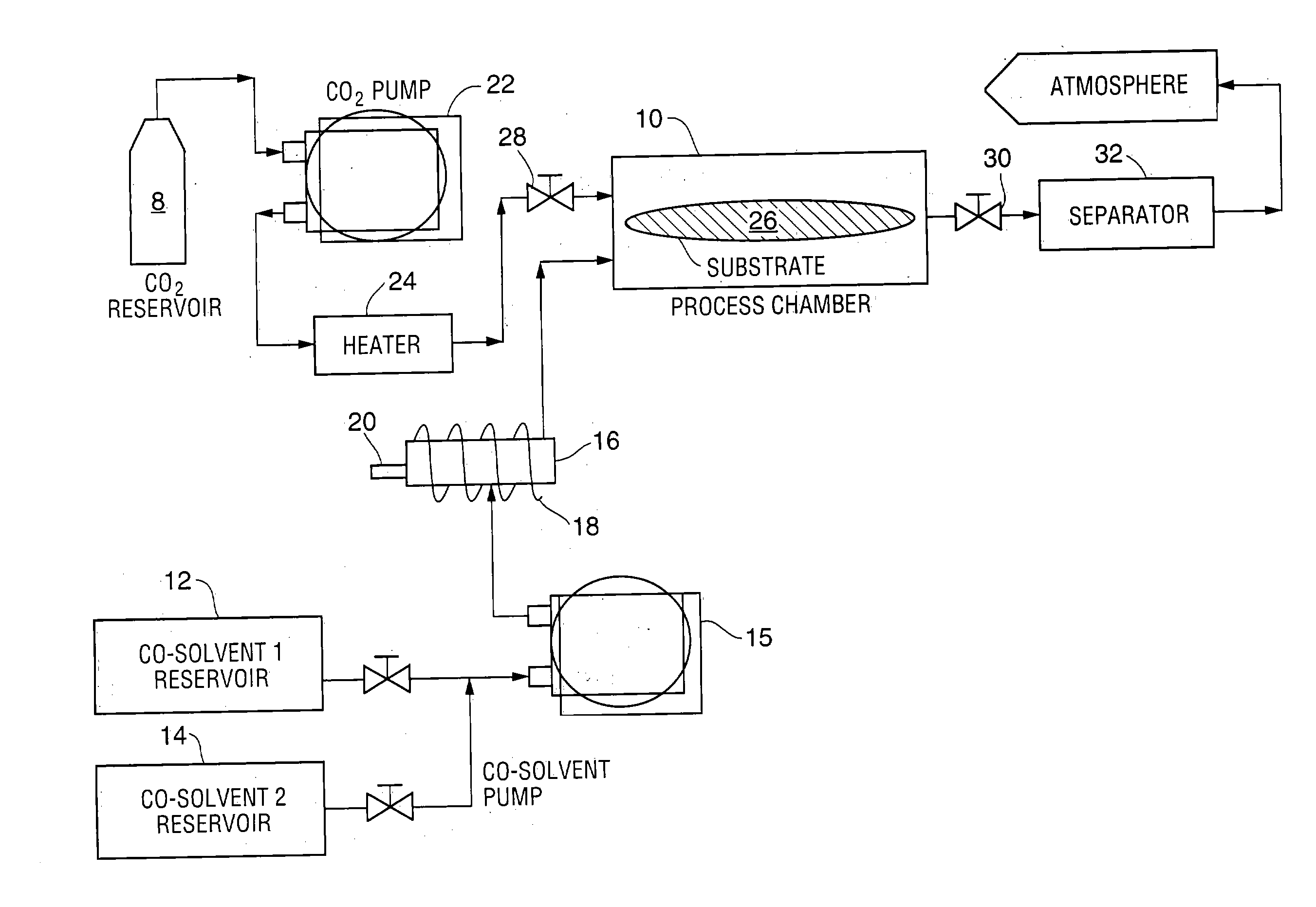

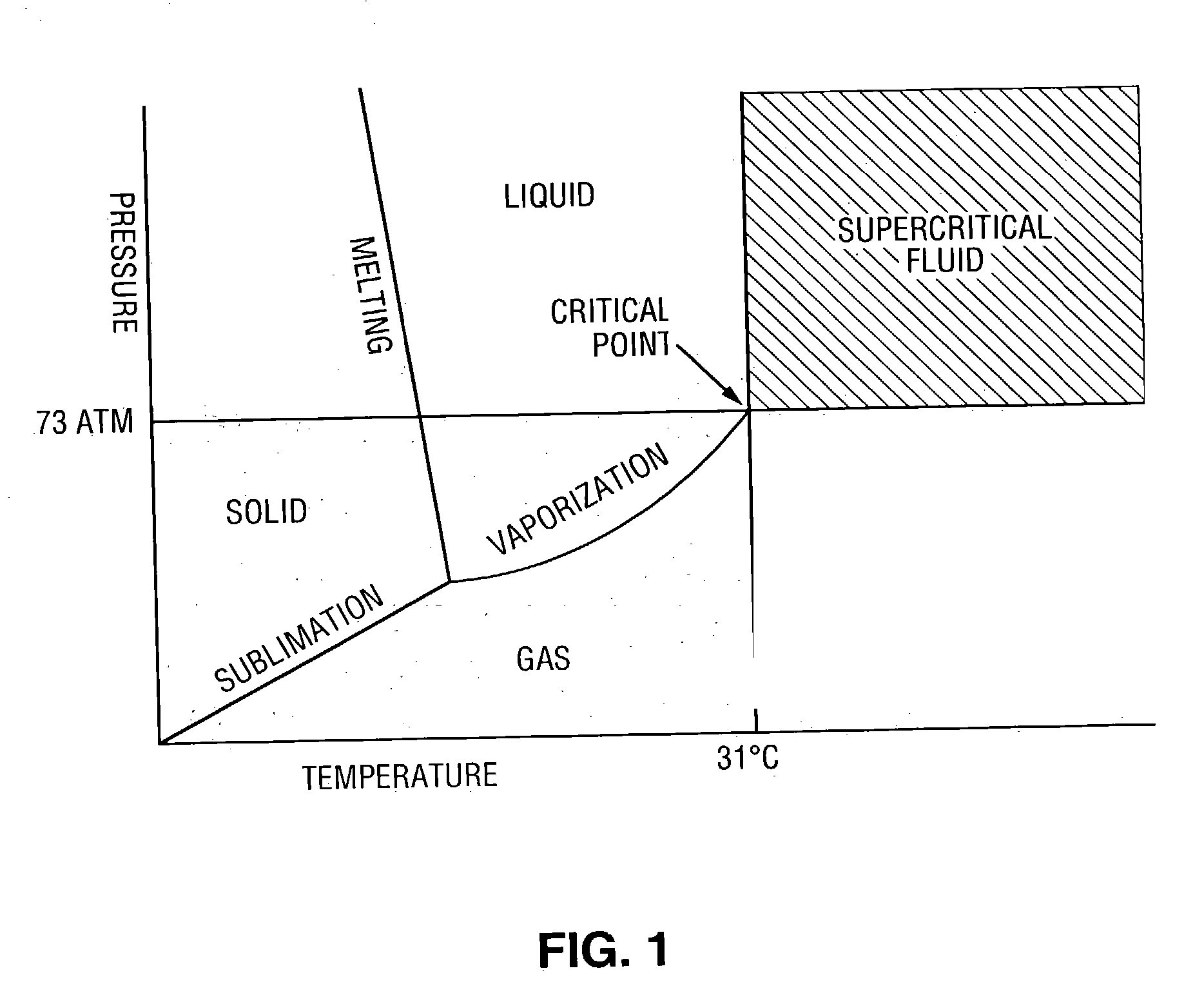

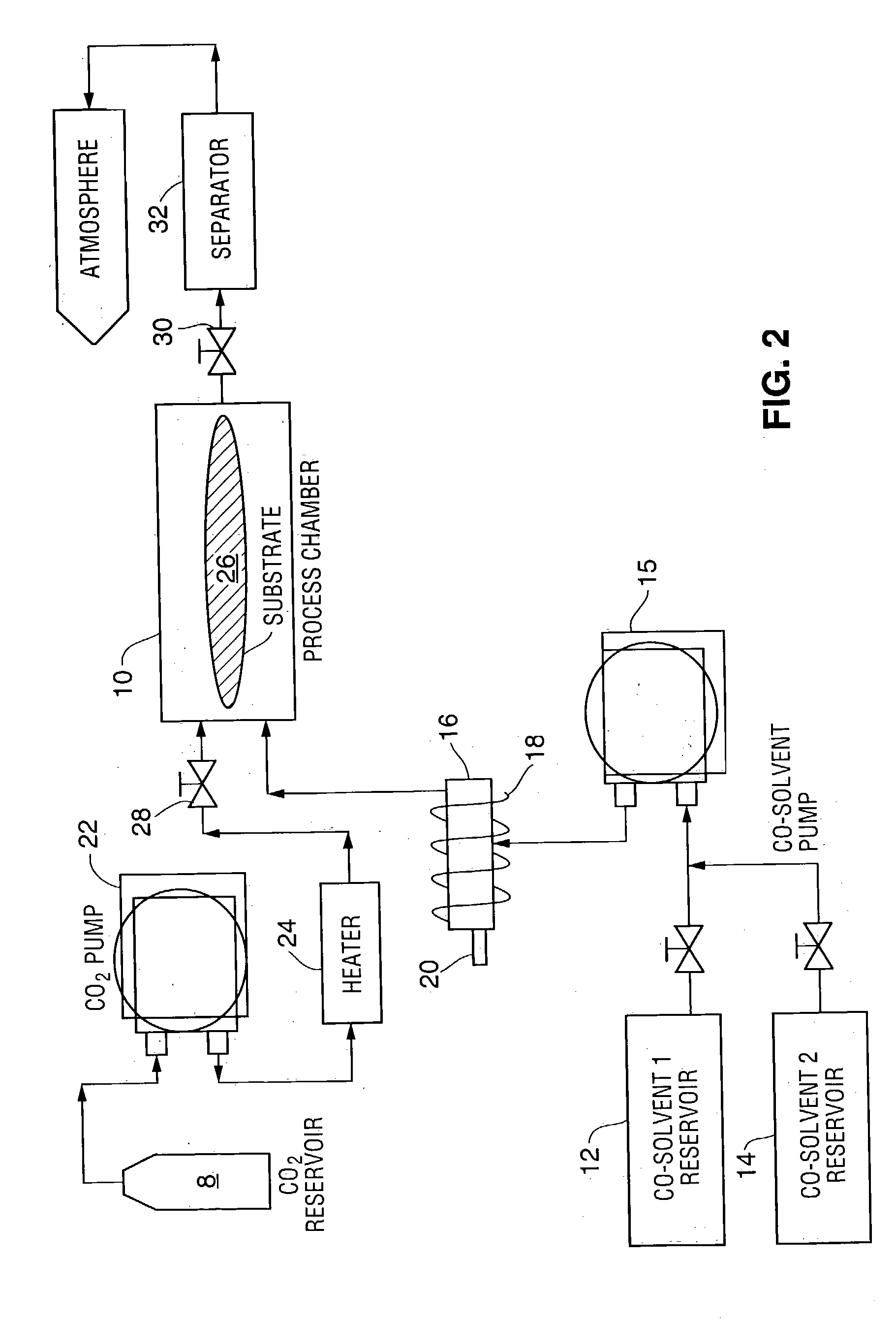

Compositions and method for removing photoresist and/or resist residue at pressures ranging from ambient to supercritical

InactiveUS20040050406A1Accelerate photoresist strippingImprove reaction kineticsNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistAlcohol

A method of enhancing removal of photoresist and / or resist residue from a substrate includes exposing the substrate to an environmentally friendly, non-hazardous co-solvent mixture comprising a carbonate, an oxidizer and an accelerator. The stripping process may be performed under ambient conditions, or in the presence of a supercritical fluid such as supercritical carbon dioxide with the supercritical cleaning step itself being a desirable "green" process. In one embodiment, the co-solvent mixture includes propylene carbonate, benzyl alcohol, hydrogen peroxide and an accelerator such as formic acid. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes a lower alkyl alcohol such as isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

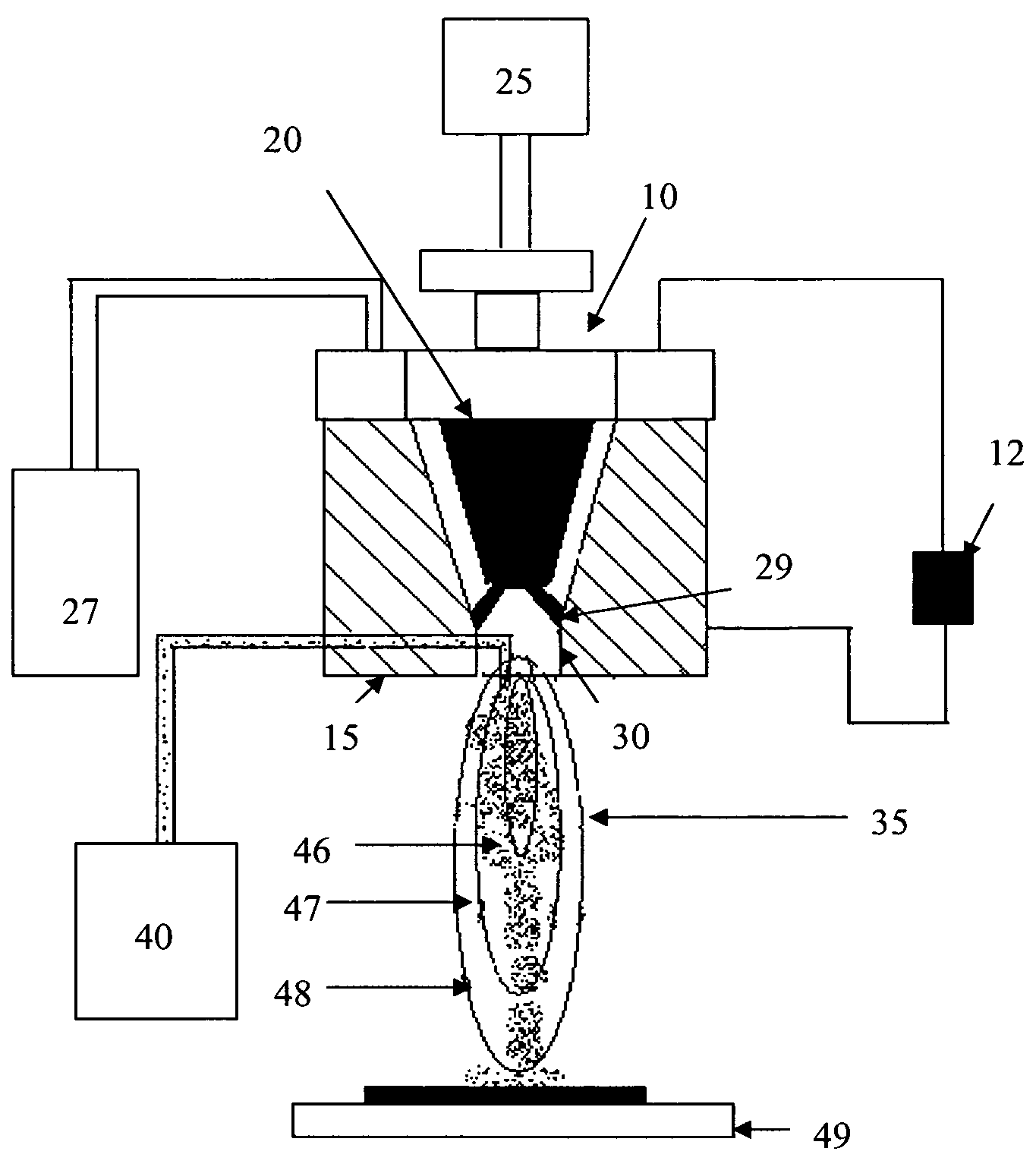

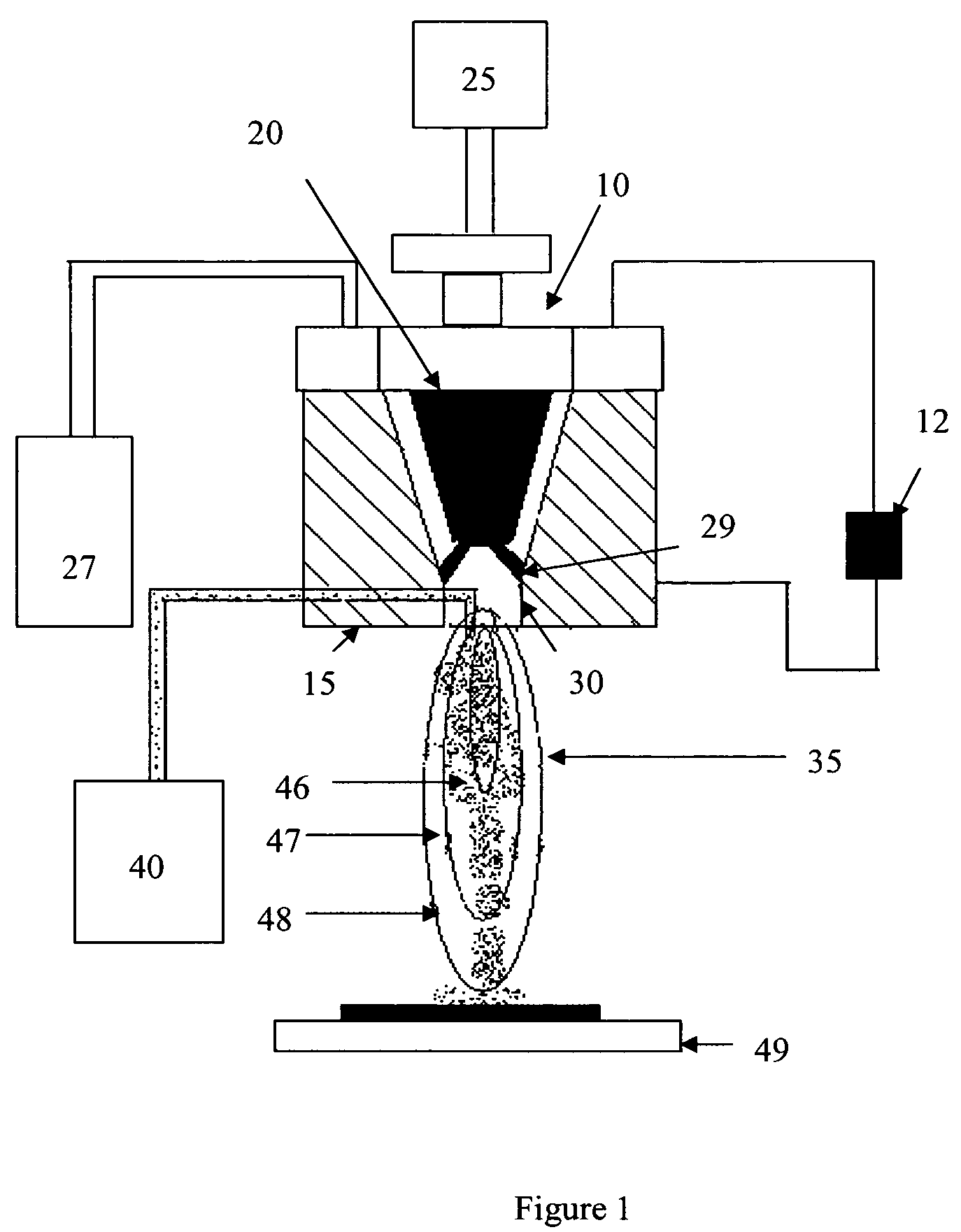

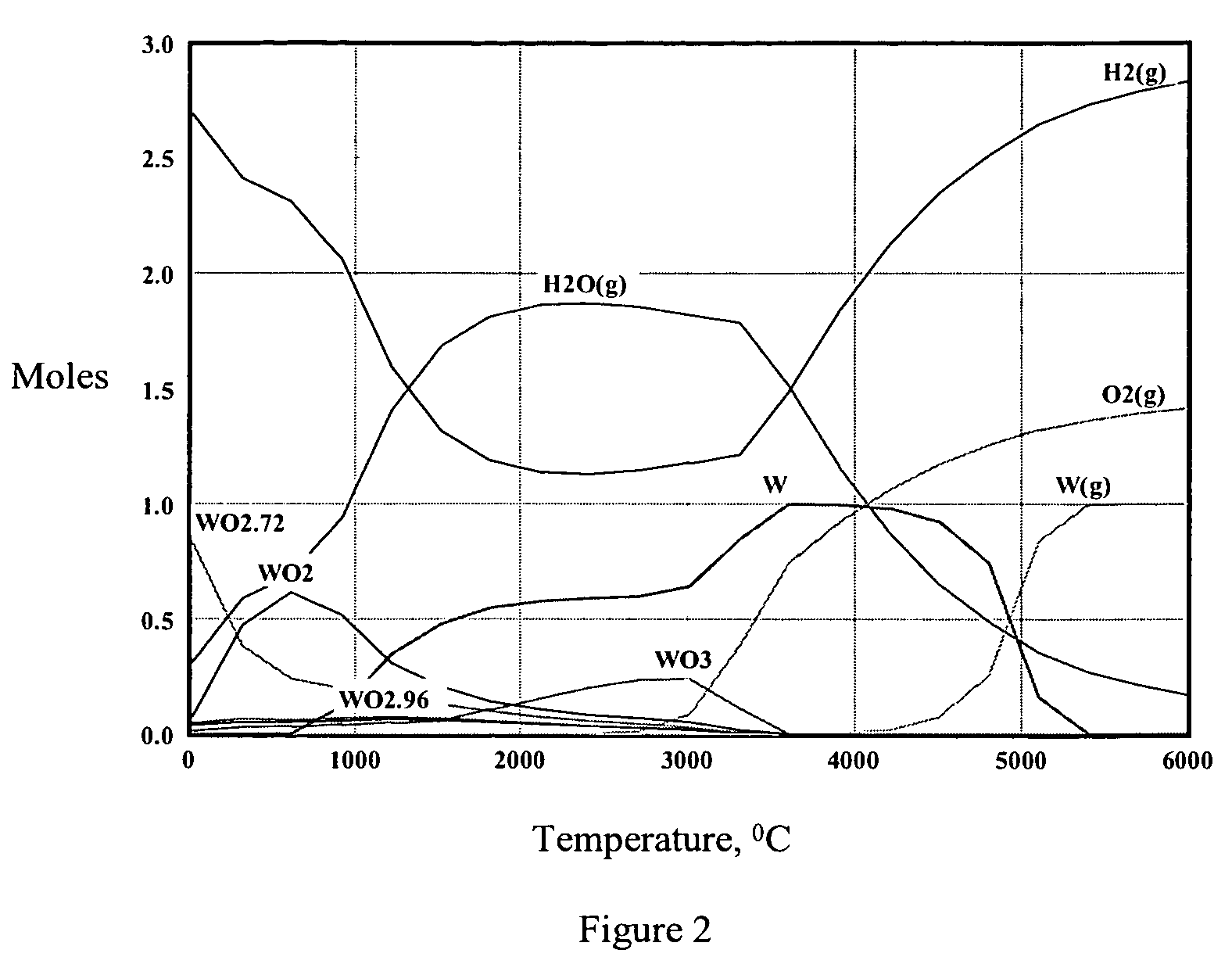

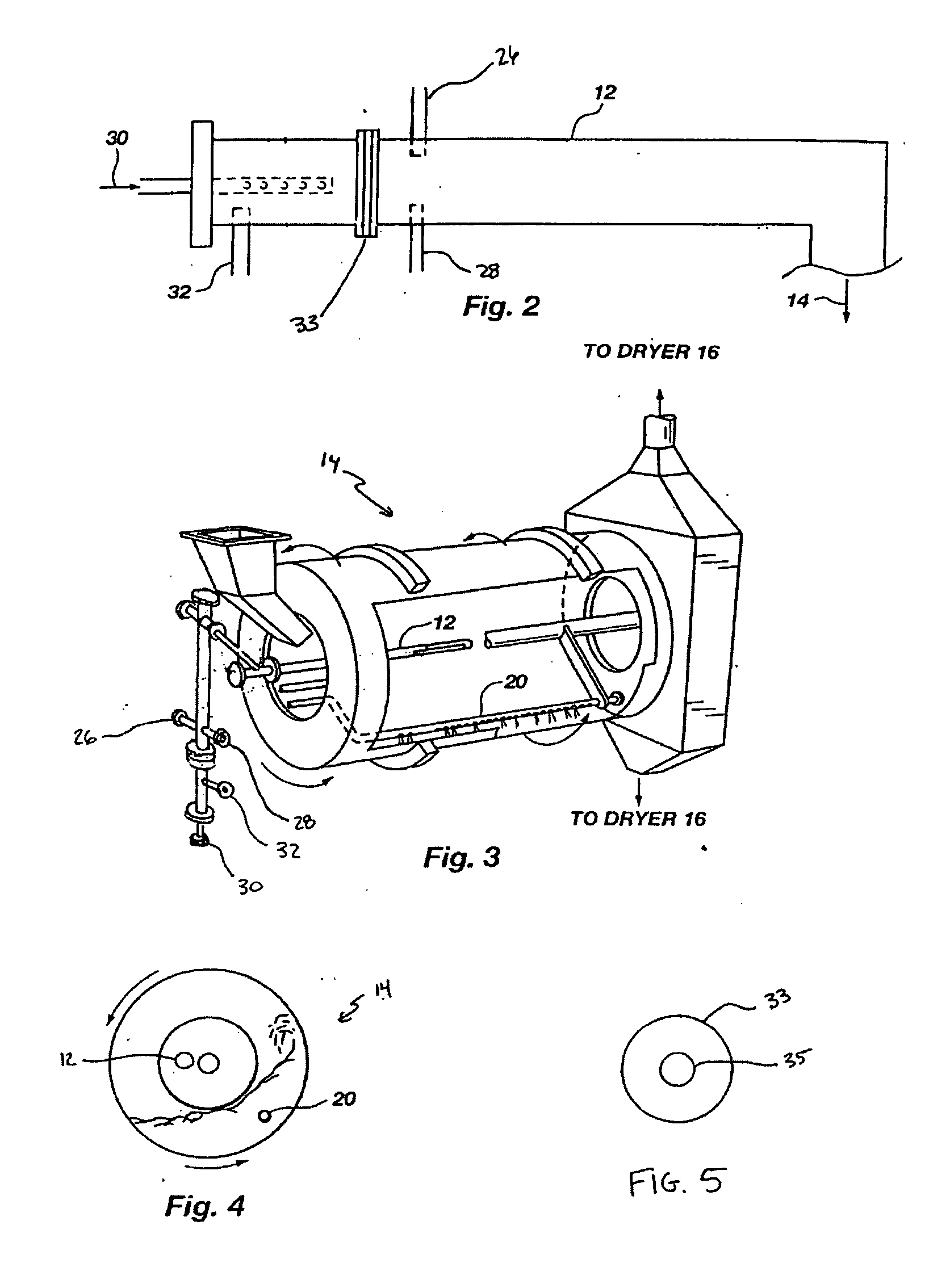

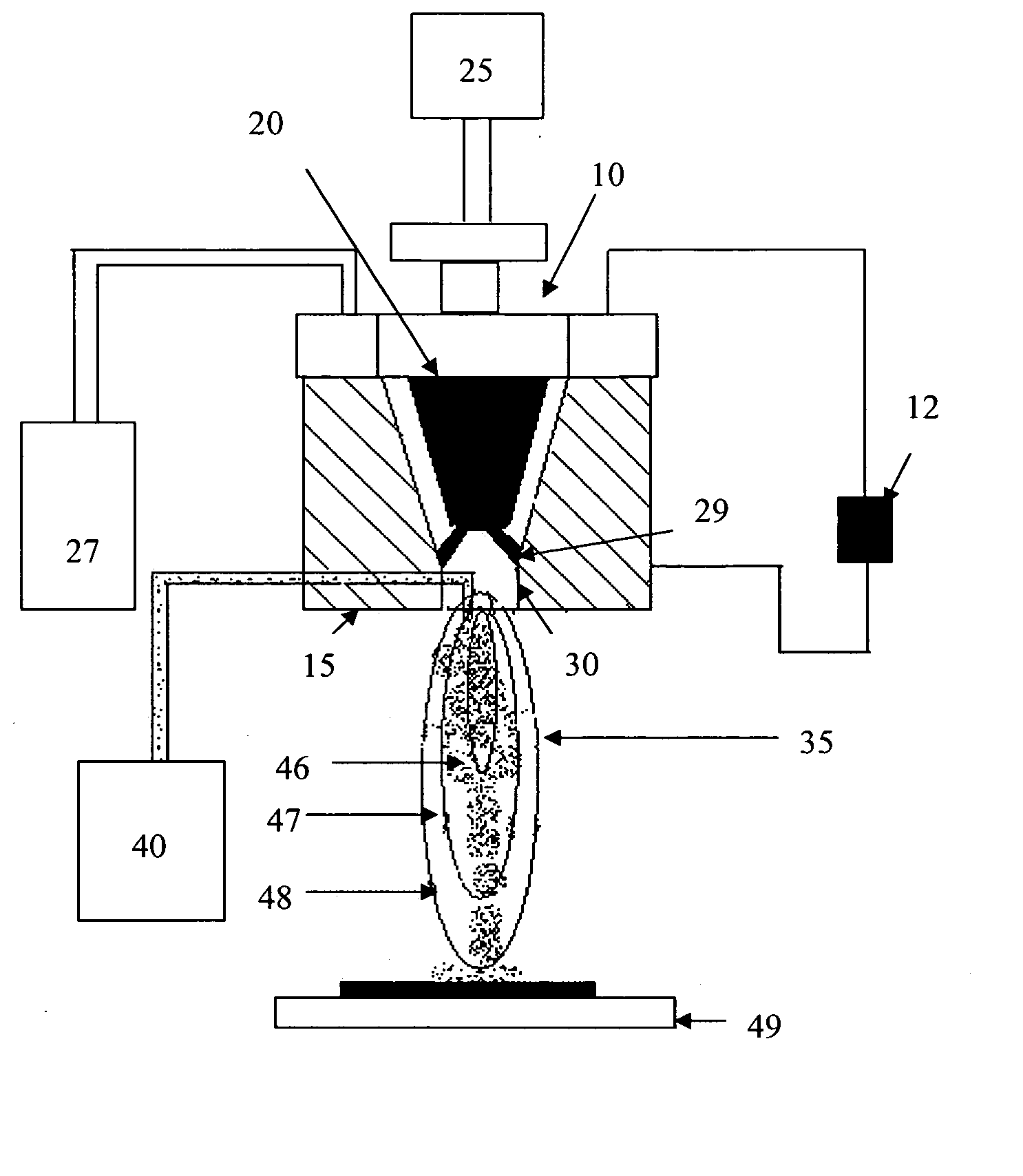

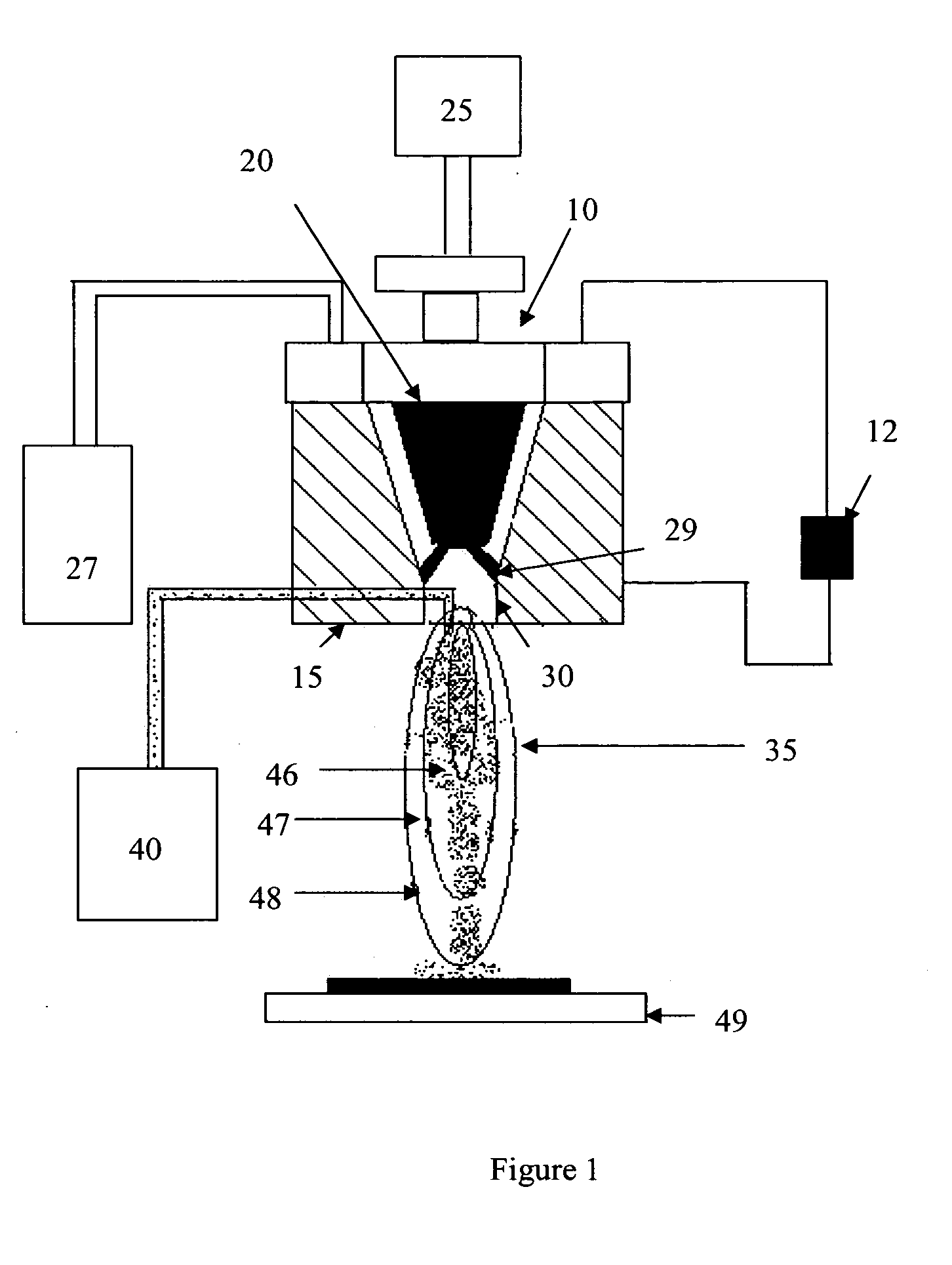

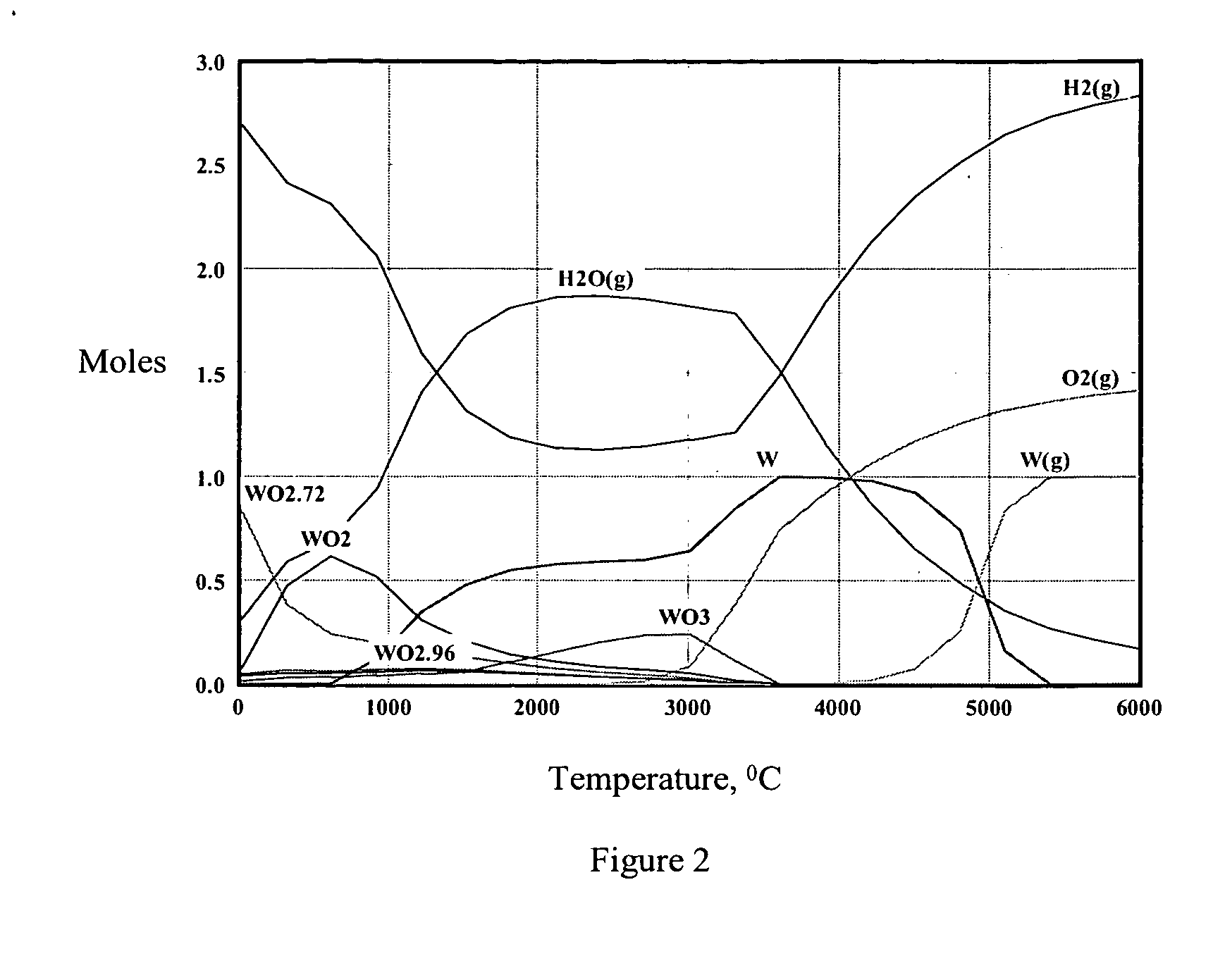

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

Method for bacterial lysis

InactiveUS20100203521A1Reduce needMinimize sample consumptionBioreactor/fermenter combinationsMaterial nanotechnologyPathogenCarbon nanotube

The present invention is directed to a microfluidic device for lysis of cells, such as bacteria and microorganisms. In particular, the present invention relates to microfluidic devices and methods of manufacture of such microfluidic devices comprising a substrate with at least one channel packed with a polymer monolith embedded with carbon particles, for example carbon nanotubes. The microfluidic devices and methods of the present invention are useful for cell lysis of cells within a biological sample, such as a untreated biological sample comprising microorganisms, such as but not limited to gram positive and gram negative bacteria. In some embodiments, the microfluidic devices of the present invention can also optionally comprise other modules enabling further processing of the biological sample, for example isolation, purification and detection of biomolecules released from the lysed cells, such as but not limited to nucleic acids or proteins or peptides from the lysed cells, providing a complete Lab-on-a-Chip analysis system for biomolecules released from difficult to lyse microorganisms in a single step or process. The microfluidic devices of the present invention can also be adapted and are useful to methods to enrich for microorganisms in a biological sample, for example enrich for a desired type of bacteria within a biological sample. The microfluidic devices and methods of the present invention can be adapted to perform highly efficient lysis of microorganisms within a biological sample for diagnostic tests, for example for diagnosis of infectious agents and pathogens, such as bacteria, viruses or parasites.

Owner:BOSTON MEDICAL CENTER INC

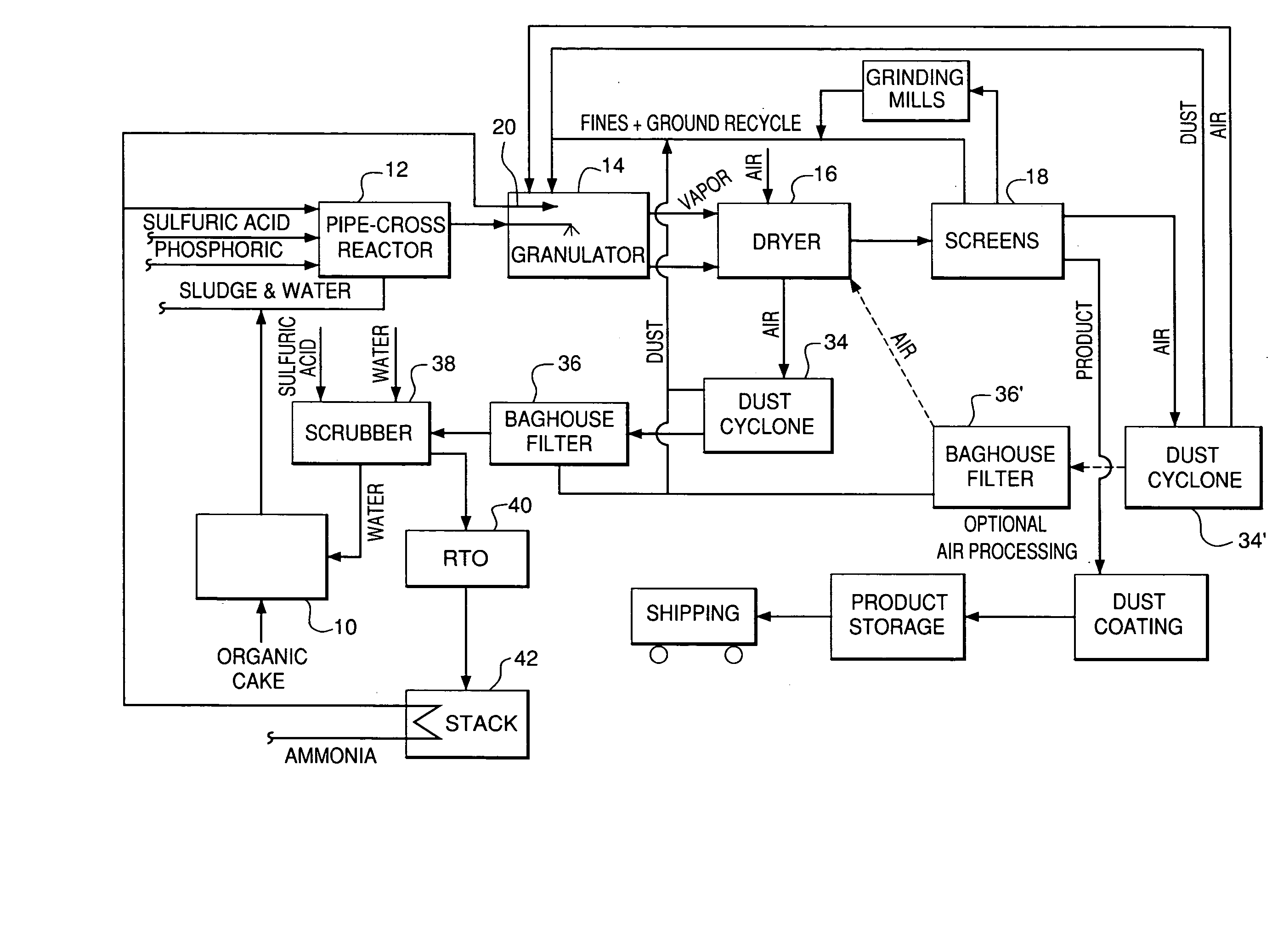

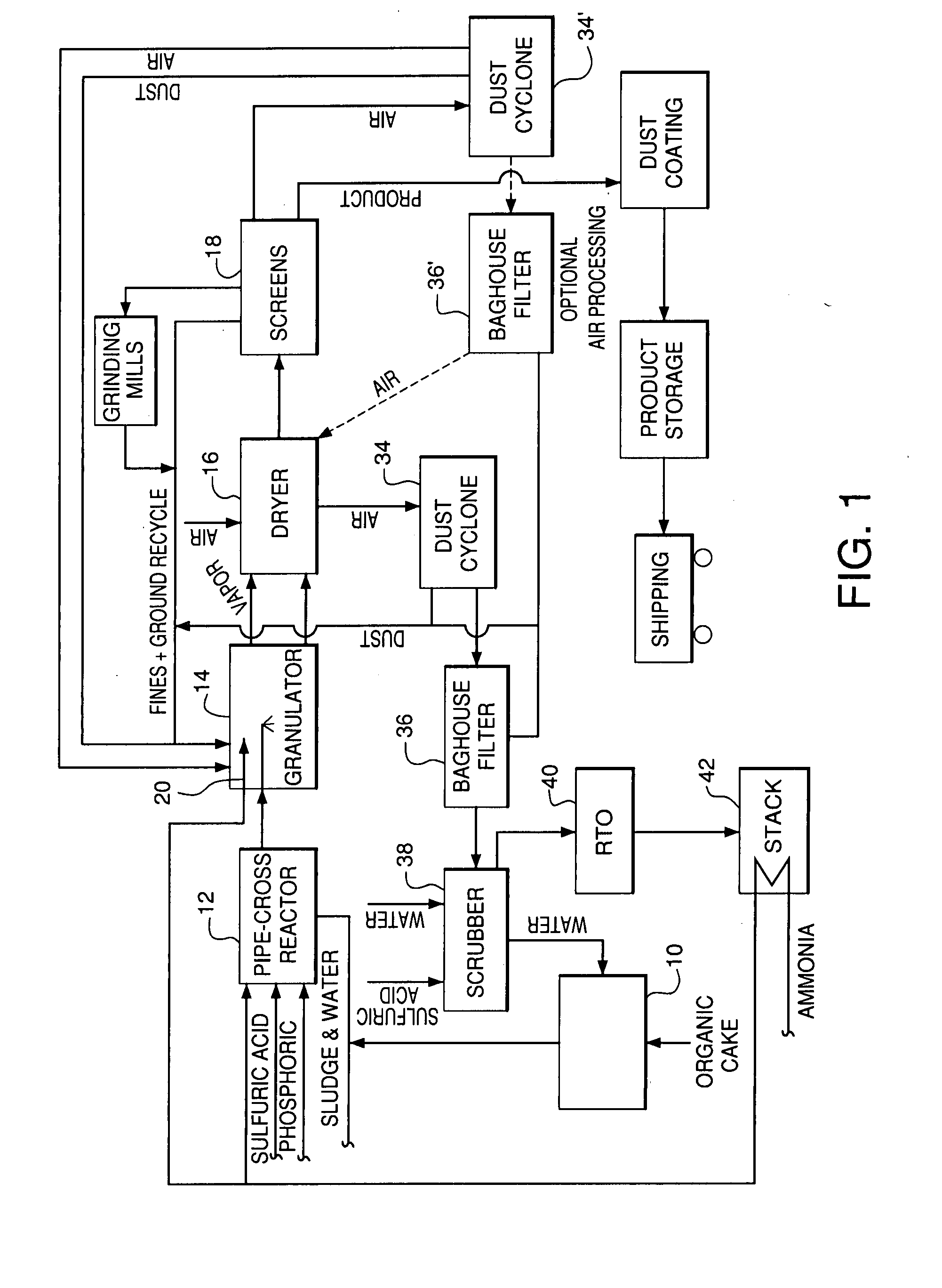

Organic recycling with metal addition

InactiveUS20050039508A1Reduce slurry viscosityAvoid flowAnimal corpse fertilisersAlkali orthophosphate fertiliserSolubilityIron sulfate

The invention is directed to methods for producing a granular nitrogen fertilizer from an organic material comprising adding a metallic salt to said organic material to form a slurry. Preferably the organic material comprises dewatered biosolids and contains water from a scrubber. Metallic salts that can be used comprise a salt of iron, zinc, or a mixture thereof. Preferred iron salts comprises ferric sulfate or ferric oxide, and preferred zinc salts comprises zinc sulfate or zinc oxide. Preferably, the metallic salt is mixed with an acid such as sulfuric acid to form an acidified metal salt. Slurry pH ranges from approximately 2-2.5. The acidified metal salt is added to the organic material in sufficient quantity to lower viscosity of the slurry such that the resulting fluid does not hinder fluid flow during operation. When the metallic salt comprises acidified ferric sulfate or ferrous sulfate, sufficient iron can be present to produce a fertilizer product with 0.1 weight percent to 10 weight percent iron sulfate calculated on a dry weight basis. The invention is also directed to fertilizer products made by the methods of the invention. Preferred products are granules and the metallic salt increases product hardness. Fertilizer granules preferably contain metal that is bioavailable to a plant when used as a fertilizer. Solubility of the metal of the product in water is enhanced, and the product is low staining.

Owner:UNIFIED ENVIRONMENTAL SERVICES GROUP +1

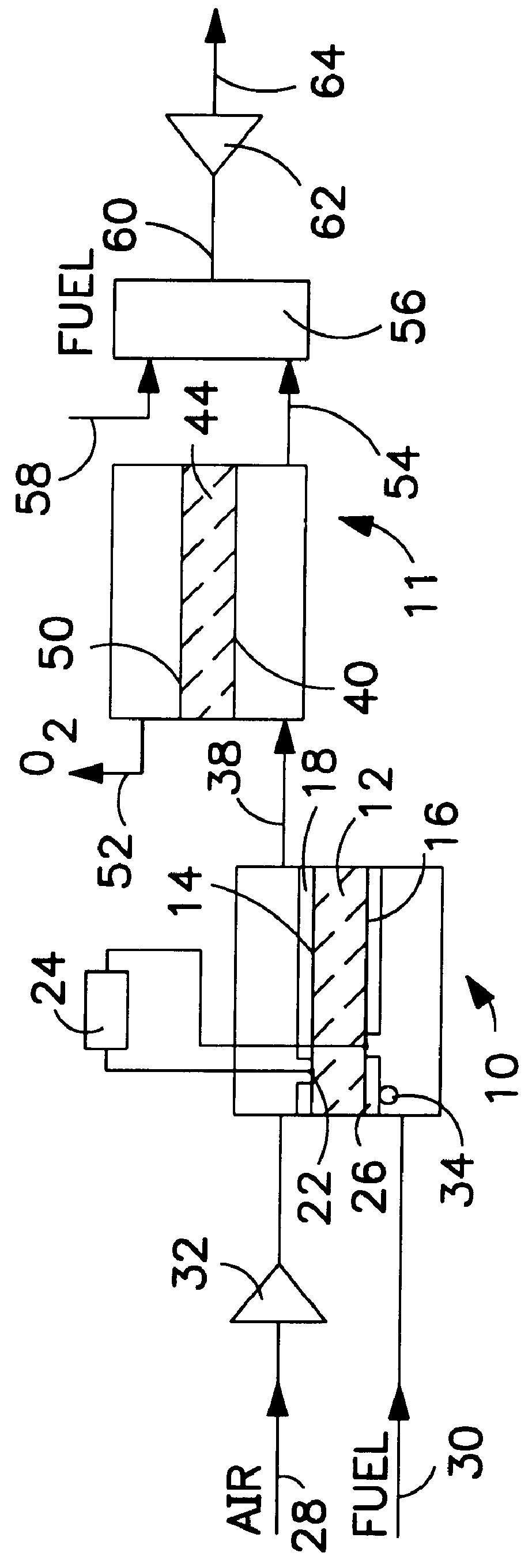

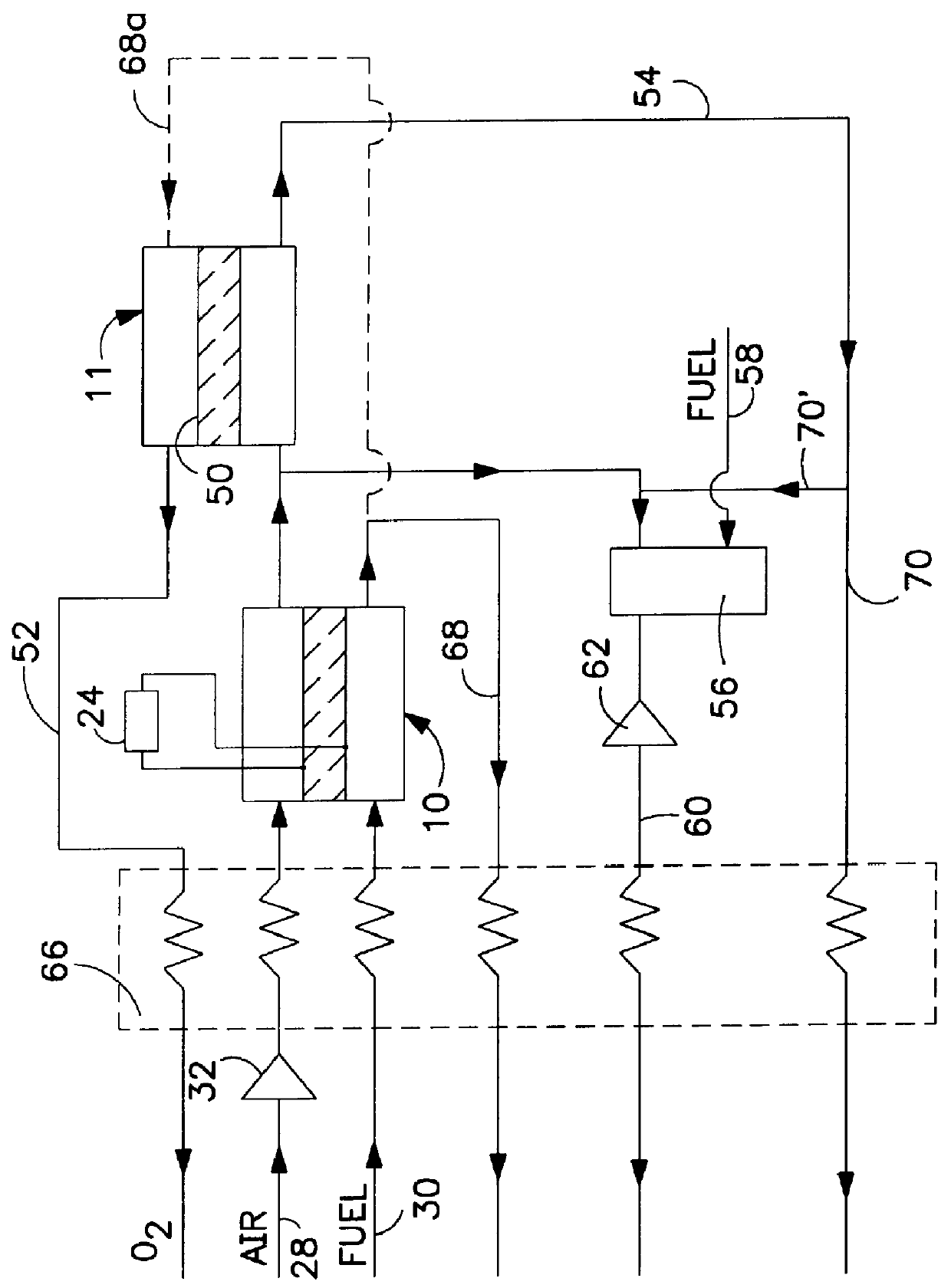

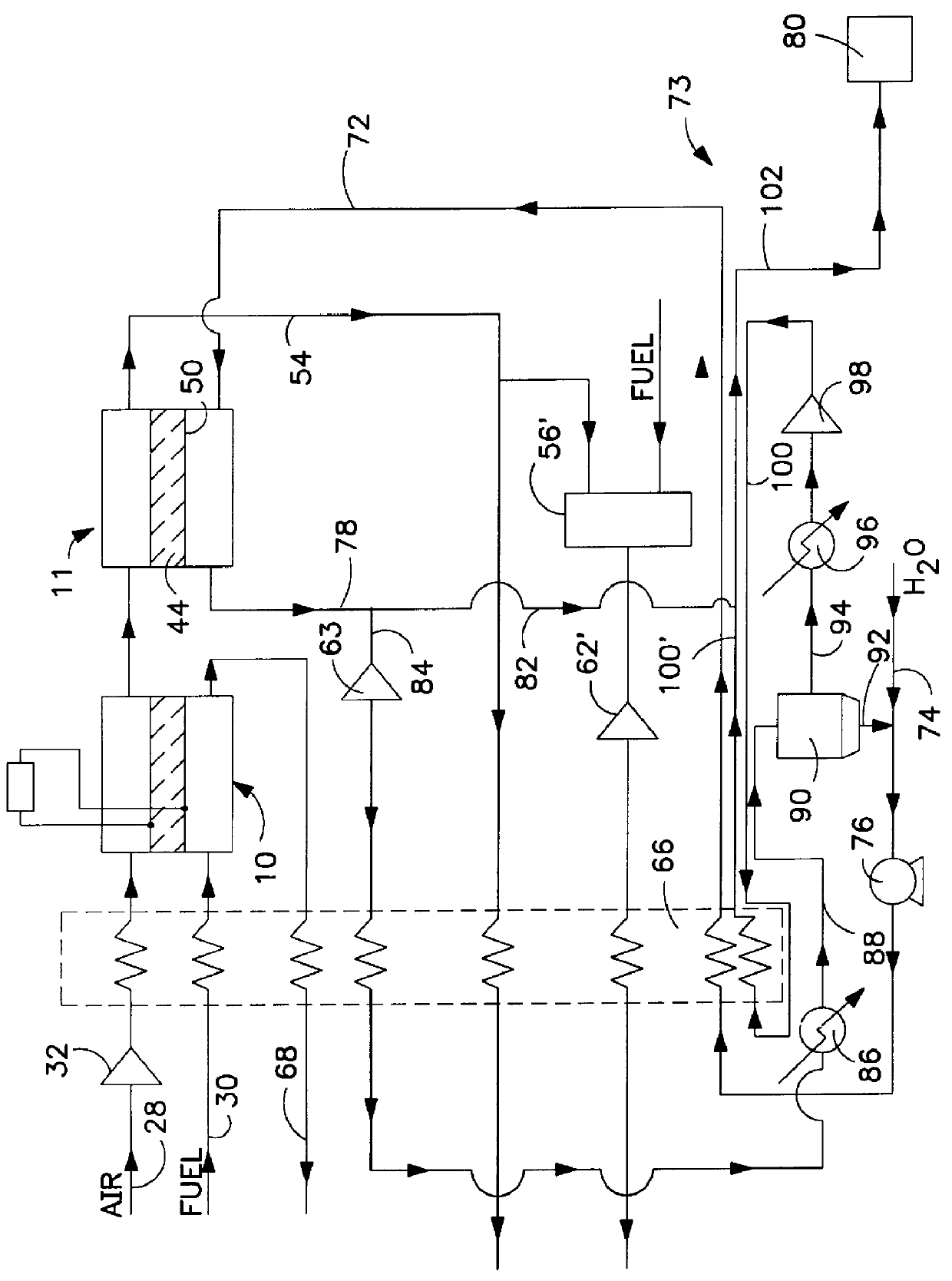

Process integrating a solid oxide fuel cell and an ion transport reactor

InactiveUS6017646AImprove efficiencyMaximize efficiencyHydrogenFuel cell heat exchangeNuclear engineeringOxygen ions

An integrated system utilizing a solid oxide fuel cell and at least one ion transport reactor to generate electric power and a product gas by delivering an oxygen-containing gas, typically air, to a first cathode side of the solid oxide fuel cell and delivering a gaseous fuel to a first anode side. Oxygen ions are transported through a membrane in the fuel cell to the first anode side and exothermally react with the gaseous fuel to generate electric power and heat. The heat and oxygen transport produces a higher-temperature, reduced-oxygen-content gaseous retentate stream exiting the cathode side of the solid oxide fuel cell which is delivered to a first ion transport reactor where a substantial portion of the residual oxygen is transported through an oxygen selective ion transport membrane. A product gas stream is then recovered.

Owner:PRAXAIR TECH INC

Nano powders, components and coatings by plasma technique

ActiveUS20080202288A1Simplify processRapid quenching and generationLiquid surface applicatorsMolten spray coatingSolid phasesTungsten

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

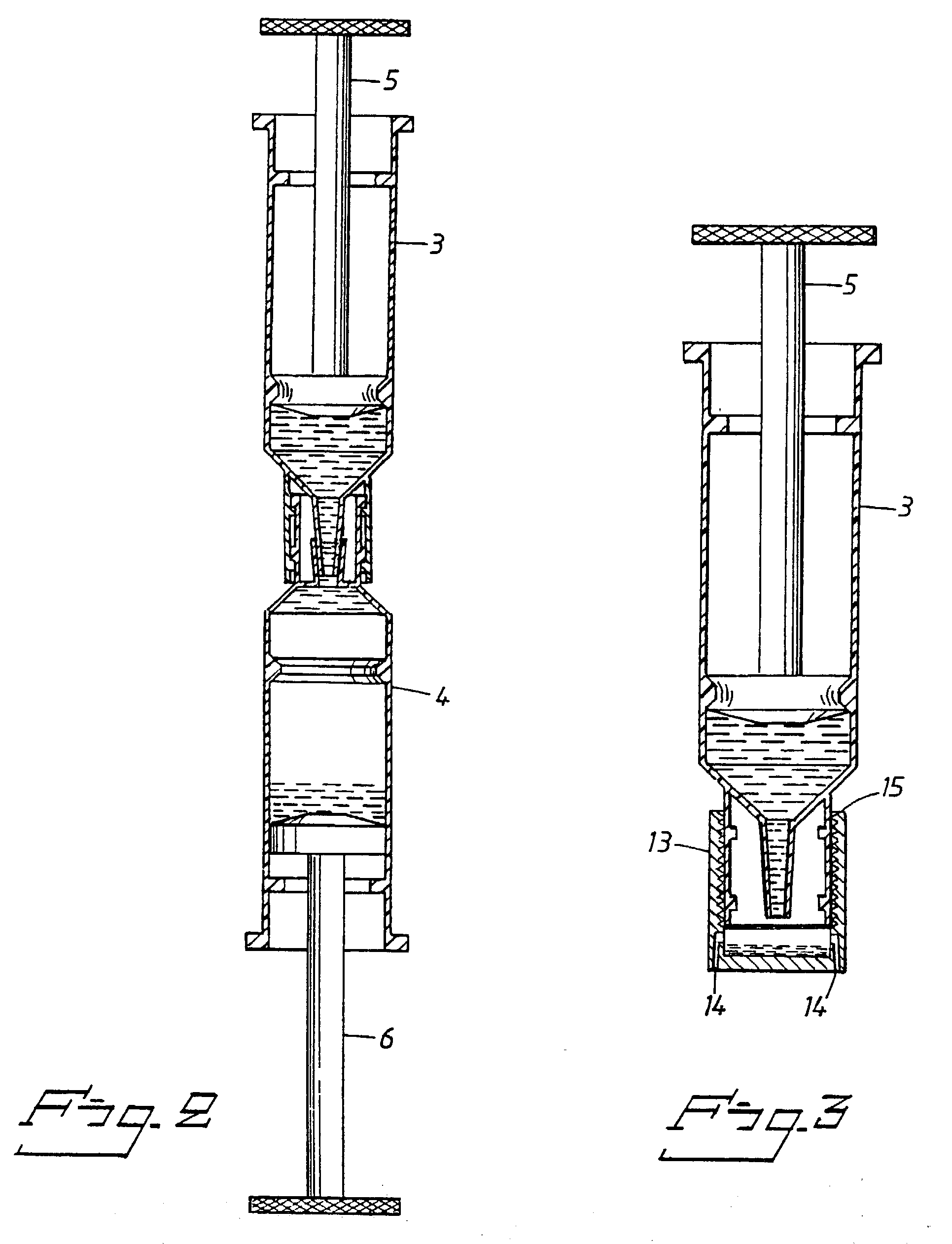

Method and device for the handling of samples and reagents

InactiveUS20020182718A1Facilitated reaction kineticsHigh yieldBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersReagentClosed system

Nucleic acids are extracted rapidly, safely and directly from a sample without pipetting steps by using predispensed, interconnectable vessels. These vessels are used separately or interconnected according to the mictrotiter standard format. The sample is mixed with lysis buffer and the nucleic acids bound to a matrix in a closed system, comprising at least two interconnectable volumes. By forcing the sample and buffer mixture back and forth from one volume to another, passing a narrow passage, thorough mixing is ensured.

Owner:MALMOQVIST MATS +1

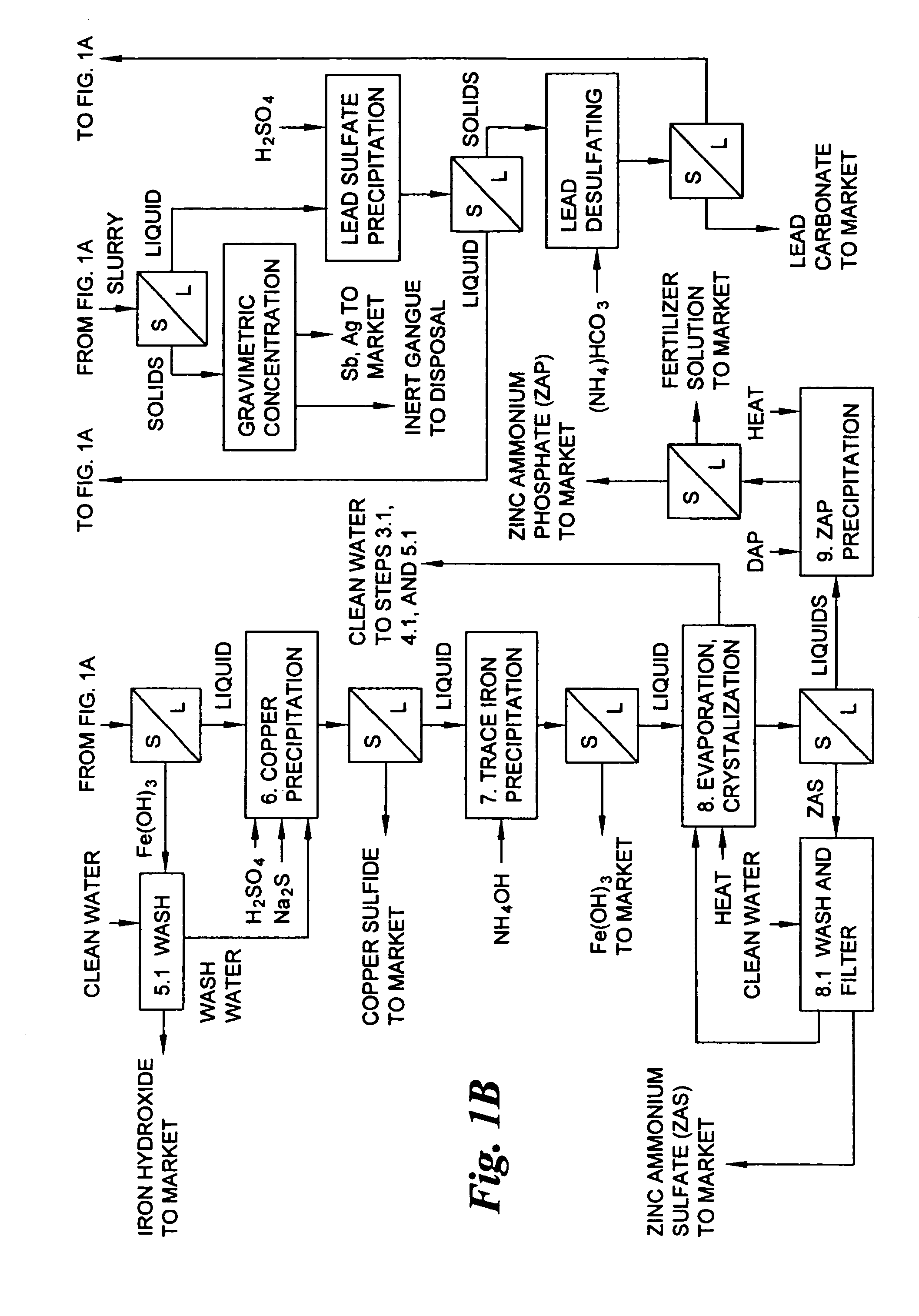

Hydrometallurgical process for the treatment of metal-bearing sulfide mineral concentrates

InactiveUS20070098609A1Improve efficiencyReduce the amount requiredSolvent extractionGold compoundsAmmonium compoundsMetallic sulfide

A hydrometallurgical process for the treatment of complex silver-bearing sulfide ores and concentrates that recovers substantially all silver, lead, antimony, zinc, copper and sulfur, along with the chemical reagents utilized during the process. Finely ground ores and concentrates are leached under heat and pressure with water, sulfuric acid, nitric acid, oxygen, and a catalyst, and are further treated to recover silver in the form of silver chloride; iron in the form of iron hydroxide; copper and all traces of soluble toxic metals as sulfides; zinc as zinc ammonium sulfate and specifically nitric acid, sulfuric acid, oxygen, ammonia, and ammonium compounds as valuable fertilizer products.

Owner:ROYAL SILVER PANAMA

Organic recycling with metal addition

InactiveUS20080034822A1Reduce slurry viscosityAvoid flowAnimal corpse fertilisersAlkali orthophosphate fertiliserSolubilityIron sulfate

Owner:UNITY FERTILIZER LLC

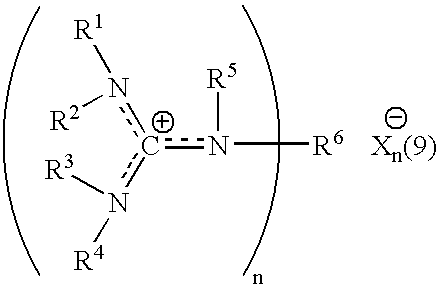

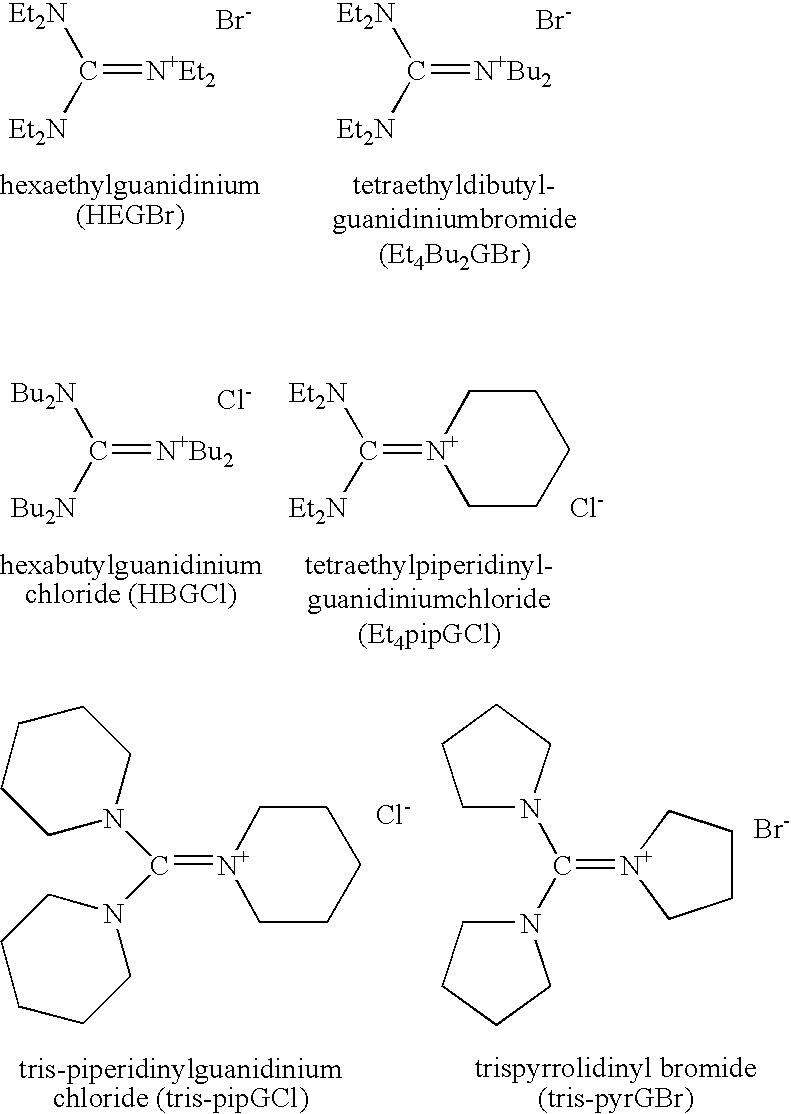

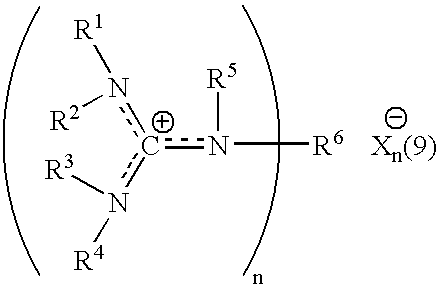

Aqueous catalytic process for the preparation of thiocarboxylate silane

An aqueous process is described in which thiocarboxylate silane is produced from haloalkyl silane by reaction of the haloalkyl silane with an aqueous solution of thiocarboxylate salt in the presence of a catalytically effective amount of alkylguanidinium salt.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

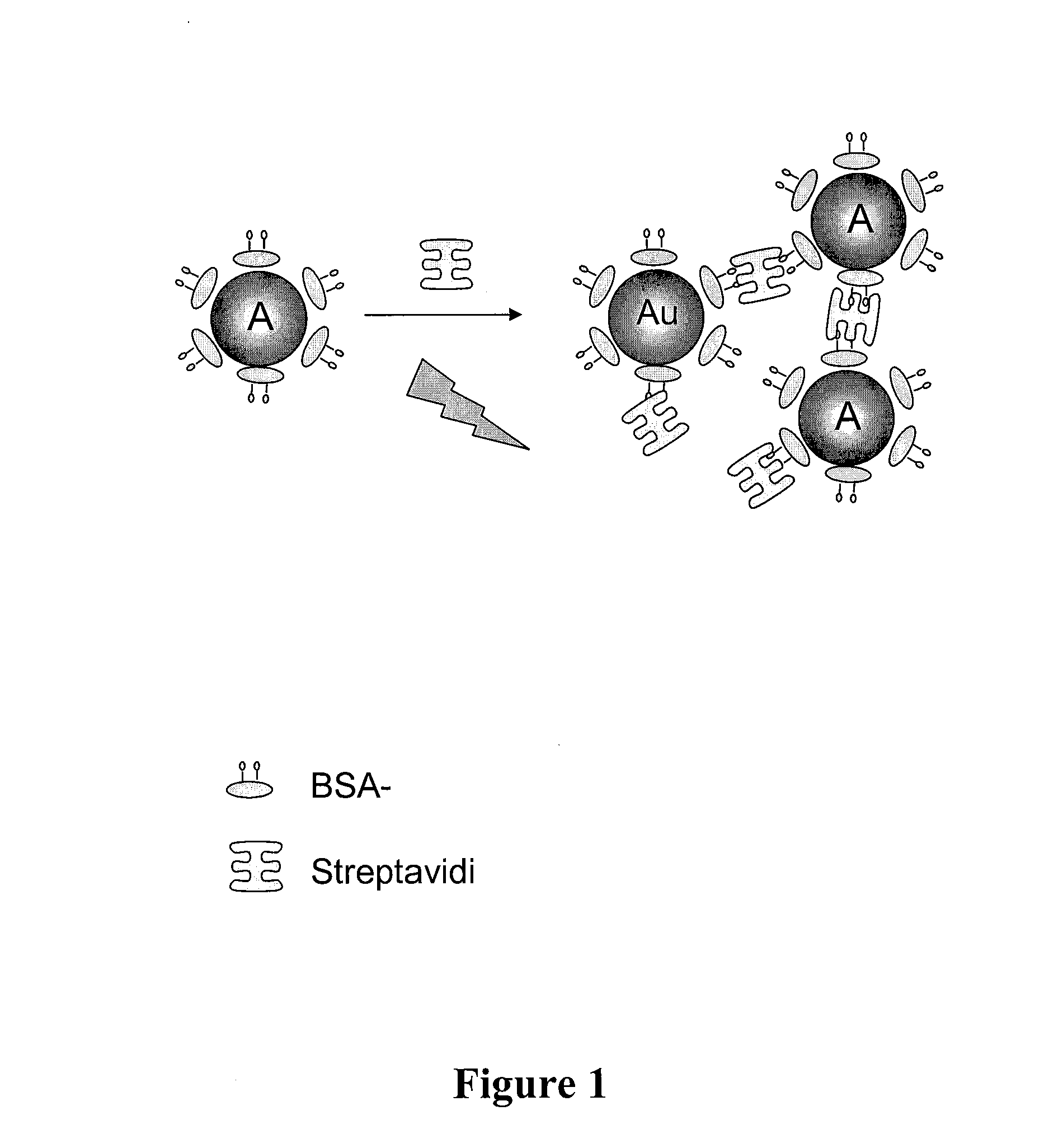

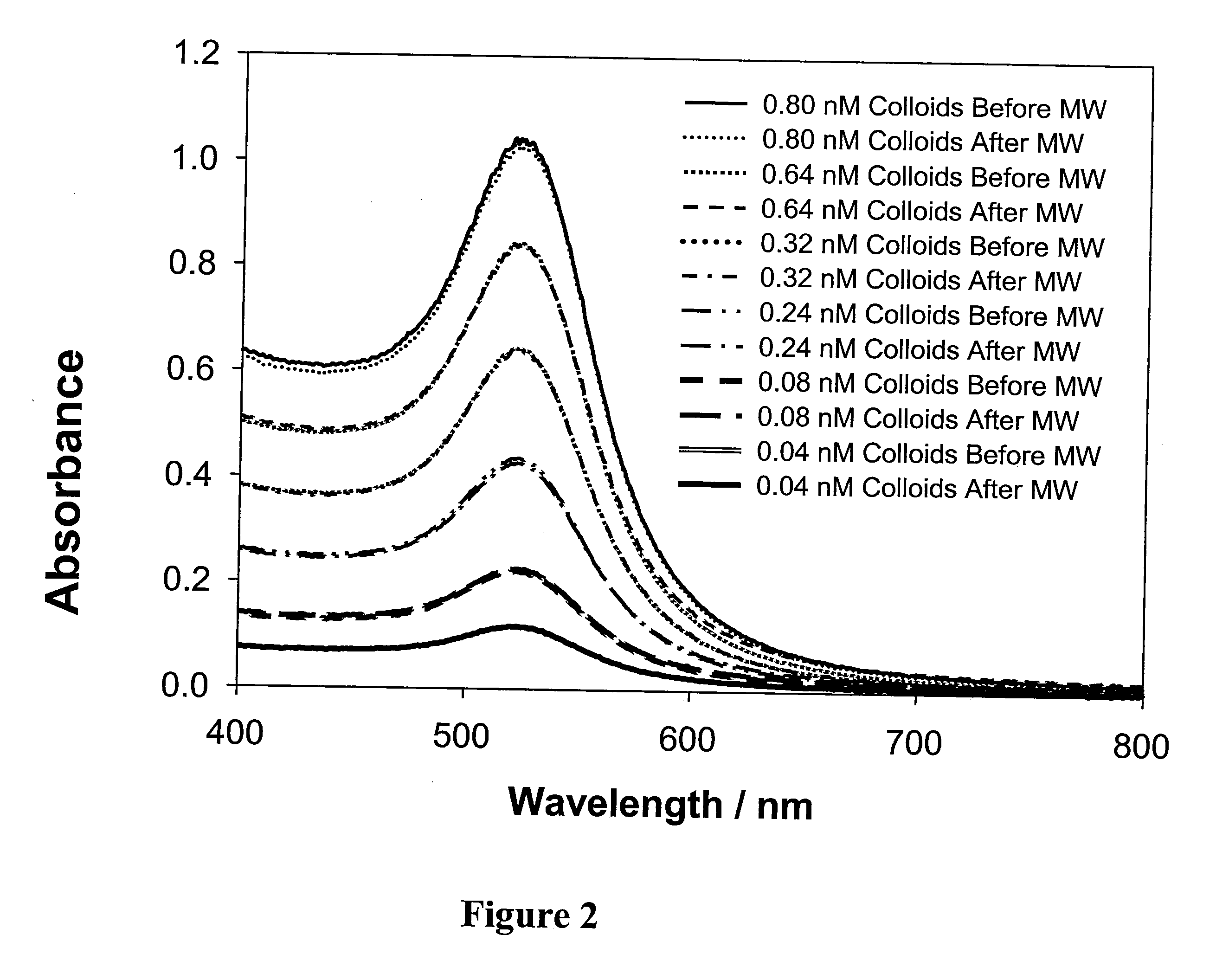

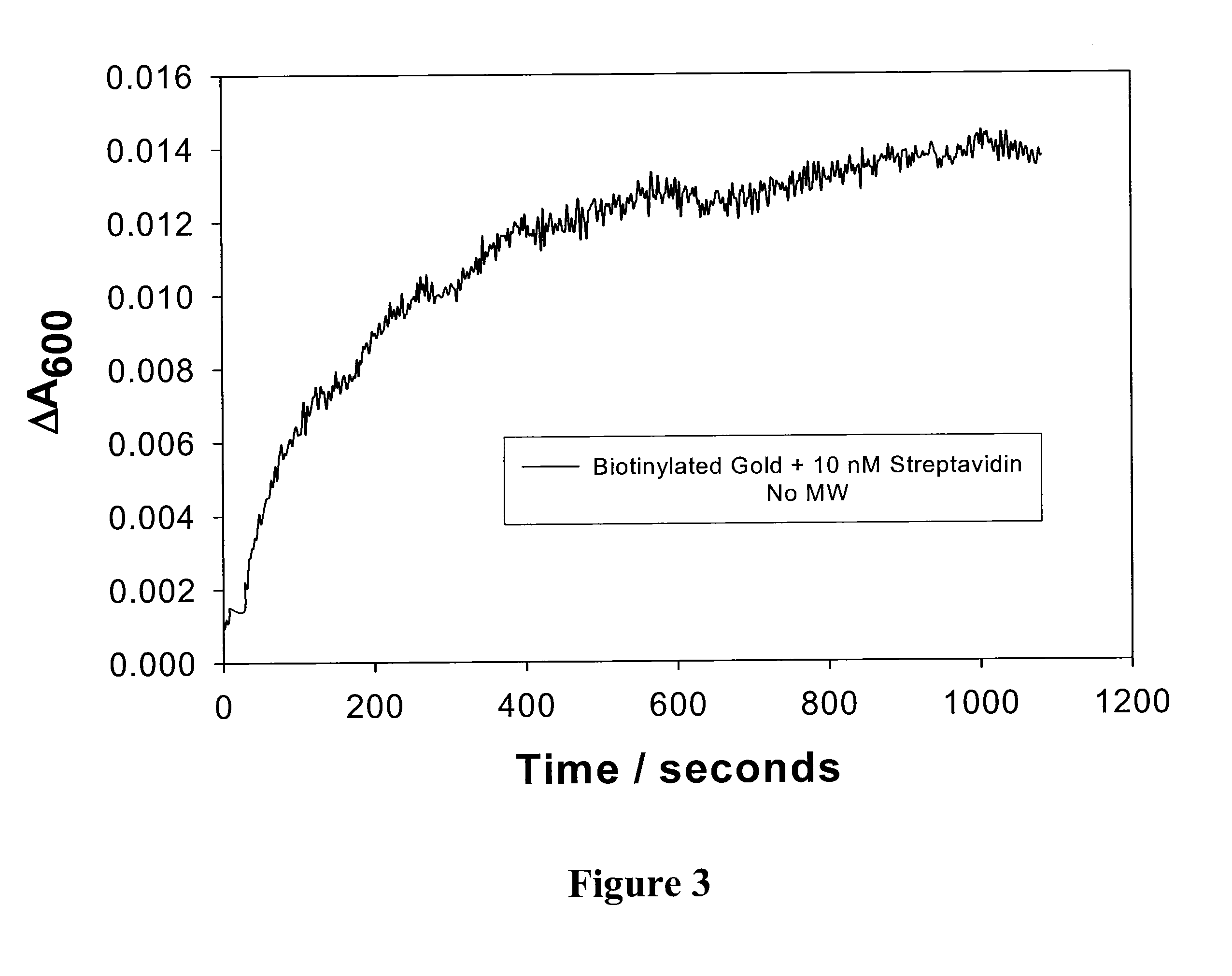

Microwave-accelerated plasmonics

ActiveUS20120107952A1Simple methodFacilitated reaction kineticsComponent separationMaterial analysis by observing effect on chemical indicatorMicrowaveSurface plasmon

The present invention relates to systems and methods using microwave accelerated surface plasmonics for the detection of target species, wherein the system has a metallic surface and the system is exposed to microwave energy for increasing detection time and / or the reaction kinetics of the target species and other interacting participants in the system and wherein plasmonic emissions from the metallic surface alone or coupled with emissions from a luminescing entity are detected.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

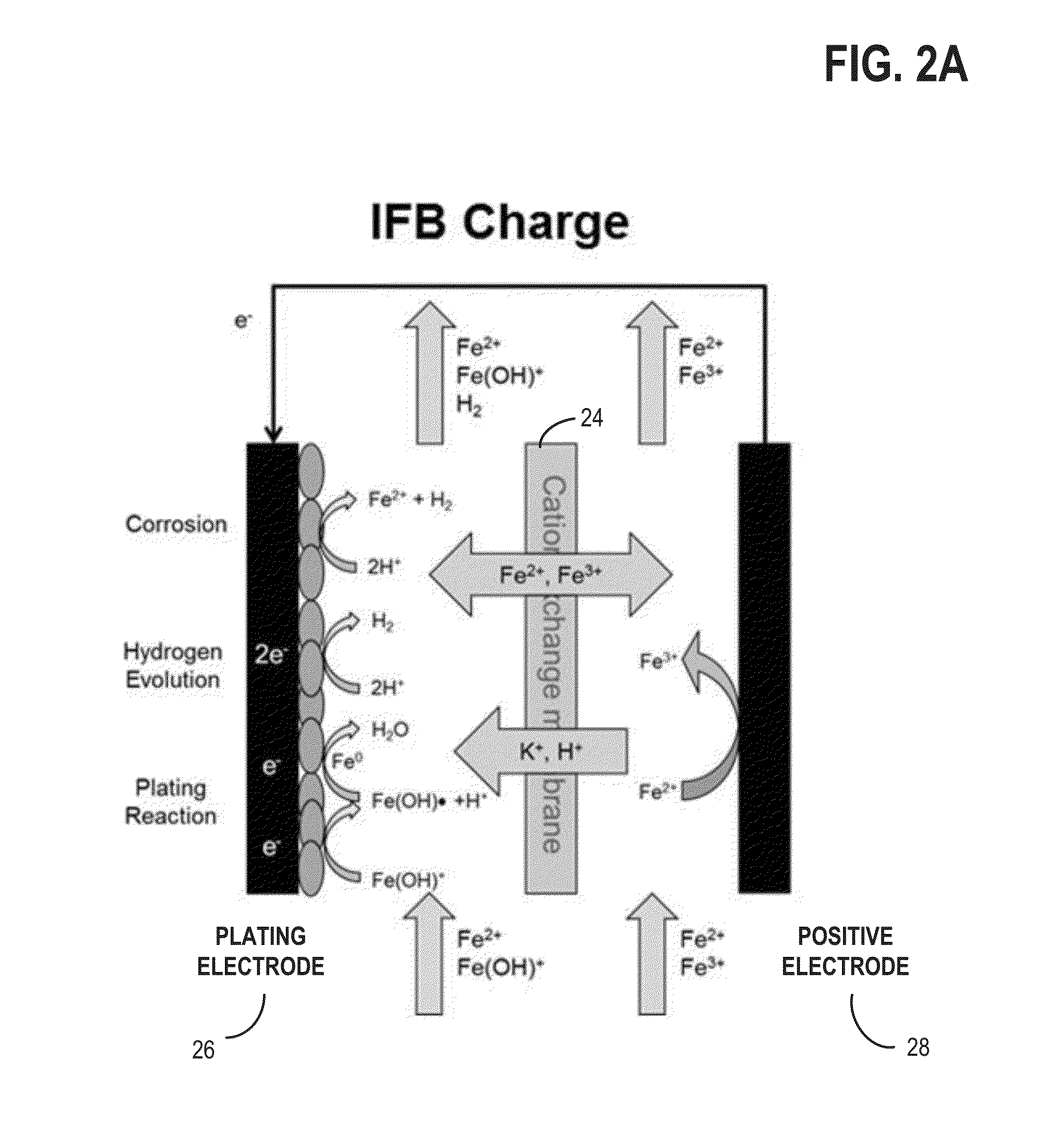

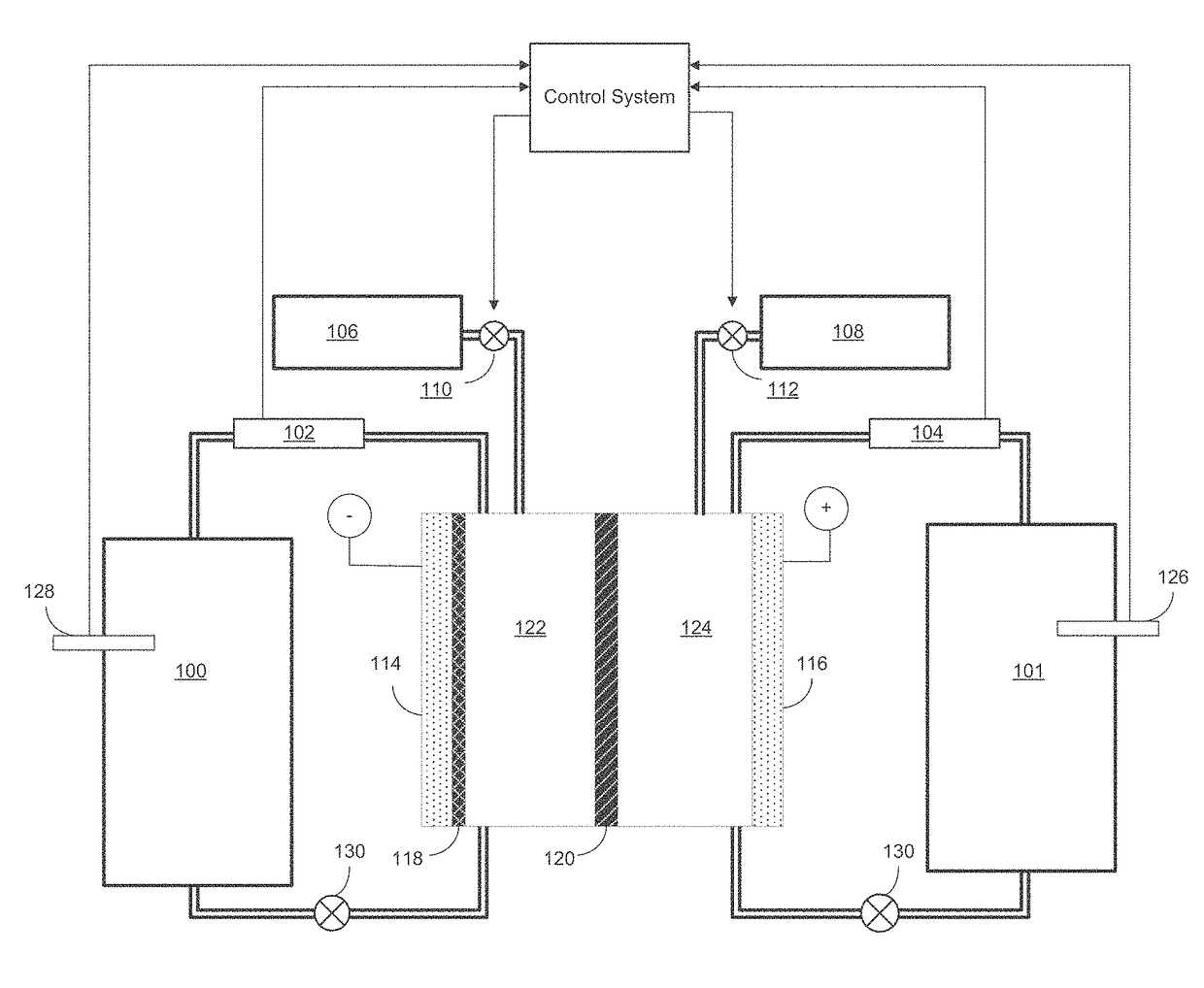

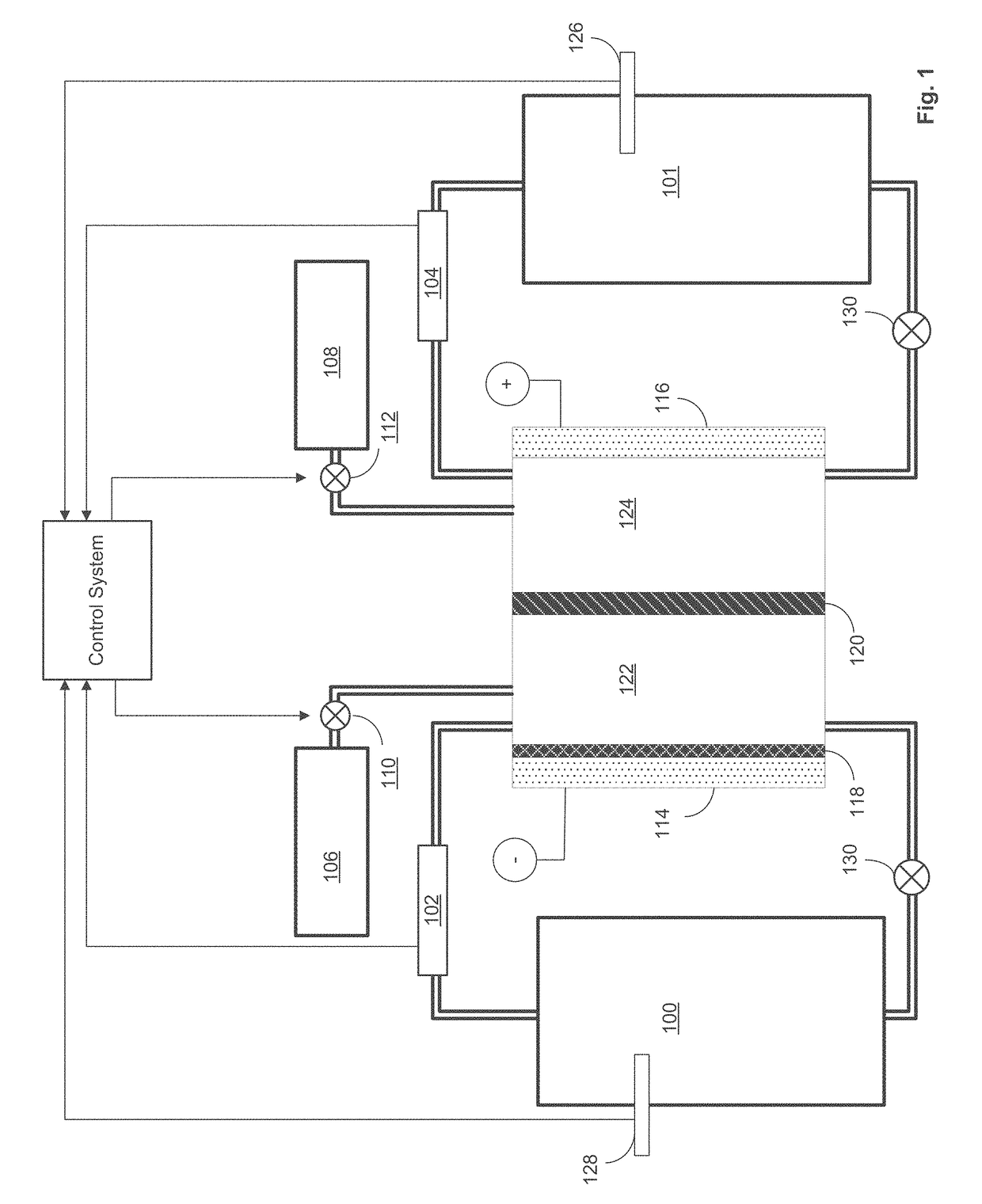

Method and system to maintain electrolyte stability for all-iron redox flow batteries

ActiveUS20150255824A1Reduce efficiencyLoss of capacityRegenerative fuel cellsIndirect fuel cellsIron redoxElectricity

Methods and systems are provided which maintain the positive and negative electrolyte pH and stability of a redox flow battery through the use of electrochemical rebalancing cells. The electrochemical cells may be activated by applying an electrical load to affect changes to the pH of the electrolytes. The use of the electrochemical cells improves long term performance stability redox flow batteries by decreasing and / or eliminating Fe(OH)3 precipitation formation.

Owner:ESS TECHNOLOGY

Method for producing low-sulfur molten iron in one step by smelting and reducing copper slag

InactiveCN101824505ALower oxygen potentialReduce sulfur contentFluidised-bed furnacesMelting tankCyclone

The invention discloses a method for producing low-sulfur molten iron in one step by melting and reducing copper slag. The method is characterized in that the method includes the following processing steps that: the high-temperature molten copper slag is first reduced by reducing agent in a high-temperature reduction furnace, wherein, when the reduction reaction of iron is nearly finished, a certain amount of additive, which is theoretically calculated, is added in a melting bath based on the existing slag system in the reduction furnace, a jet gun is inserted into a slag-iron interface to blow carbon monoxide into the melting bath when the additive is completely molten, the blowing time is 30min to 40min, and desulphurization reaction is almost finished. The melting bath is kept still, and when slag and iron are completely separated, the high-temperature low-sulfur molten iron and the slag are respectively discharged out of a tap hole and a slag hole. In addition, after high-temperature flue gas passes through a secondary combustion chamber, a residual heat boiler recovers residual heat from the flue gas, dust is collected from the flue gas by cyclone, and the flue gas is washed. By sufficiently utilizing the high desulphurization of the refined slag and blowing the carbon monoxide, the invention solves the defect that the content of sulfur in the molten iron produced by melting and reducing the copper slag for ironmaking is high; the processing flow is short, the emission of pollutant is less, and moreover, the applicability is high.

Owner:KUNMING UNIV OF SCI & TECH

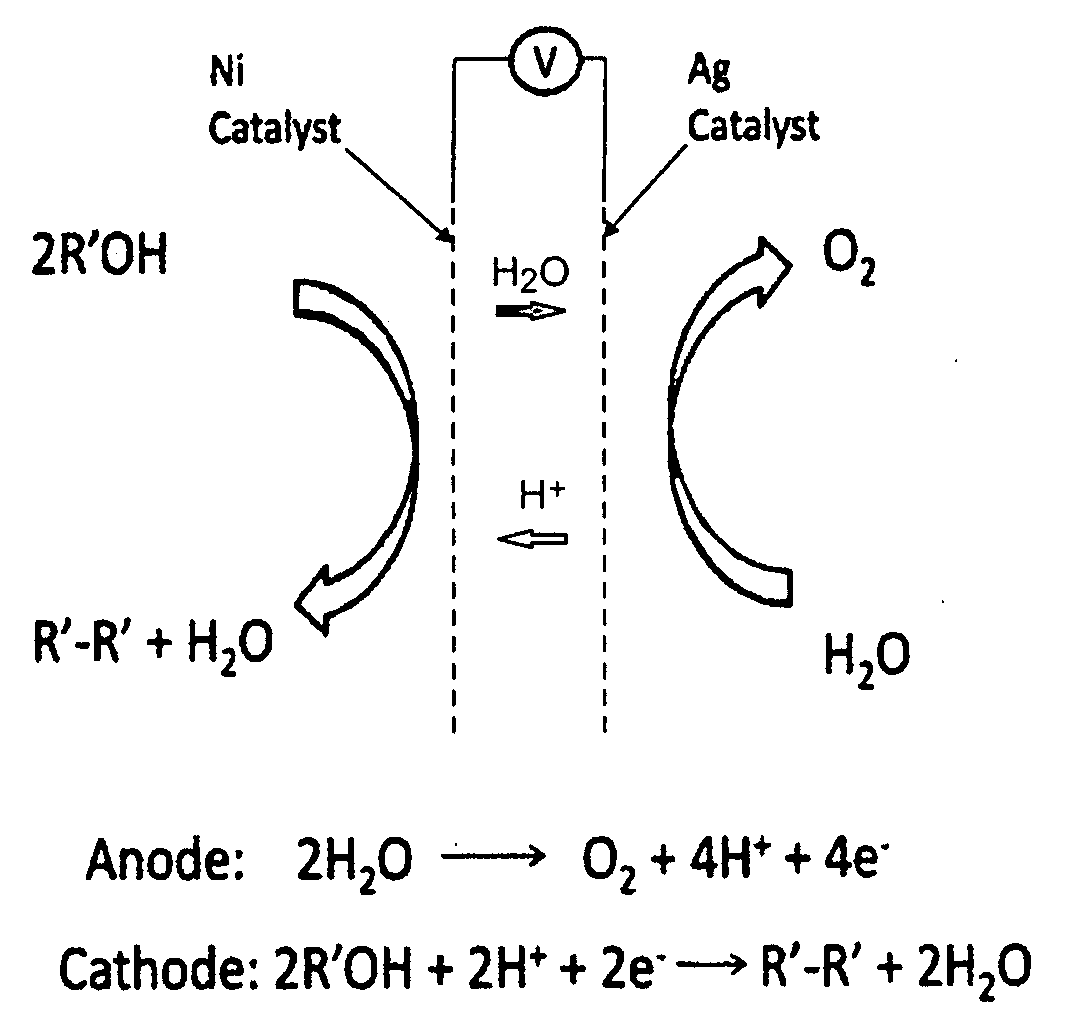

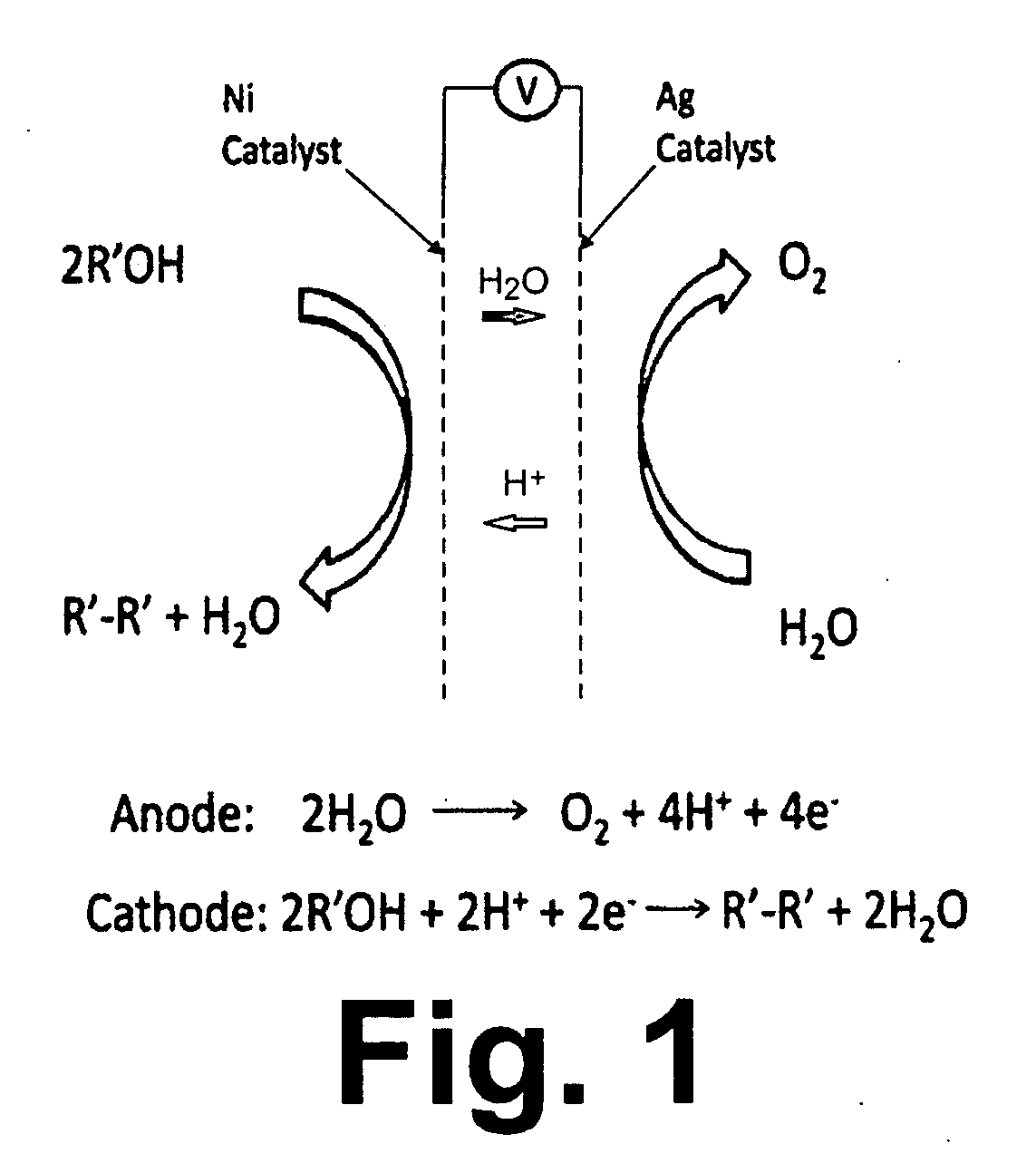

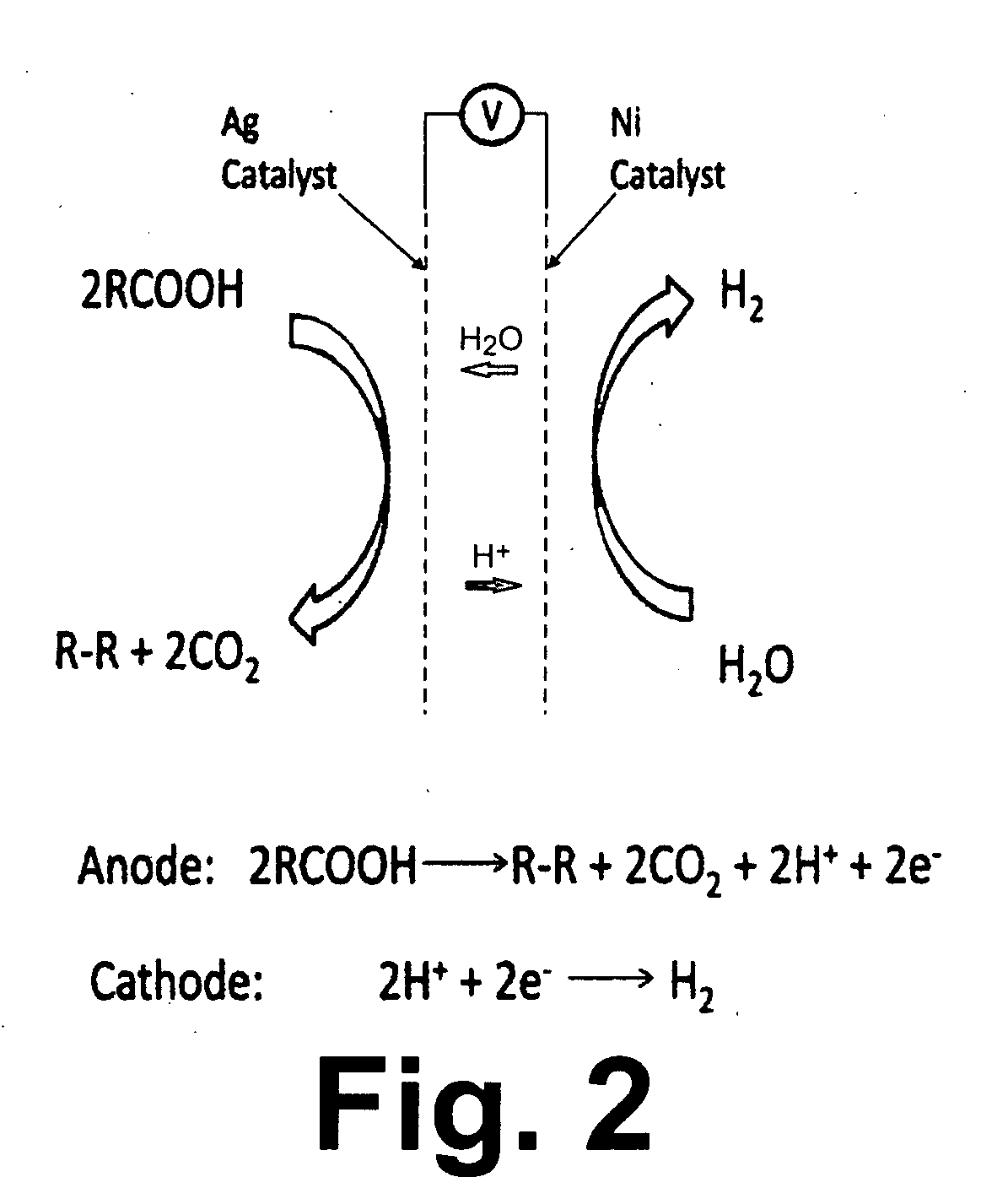

Biofuel production by high temperature non-faradaic electrochemical modification of catalysis

InactiveUS20100258447A1High calorific valueEasy to separateElectrolysis componentsEnergy inputMetallurgyBiofuel

A method for producing biofuels from biomass in which a refined biomass material is introduced into a non-Faradaic electrochemical device, preferably at a temperature greater than or equal to about 150° C., and deoxygenated and / or decarboxylated in said device to produce an increased carbon chain fuel.

Owner:GAS TECH INST

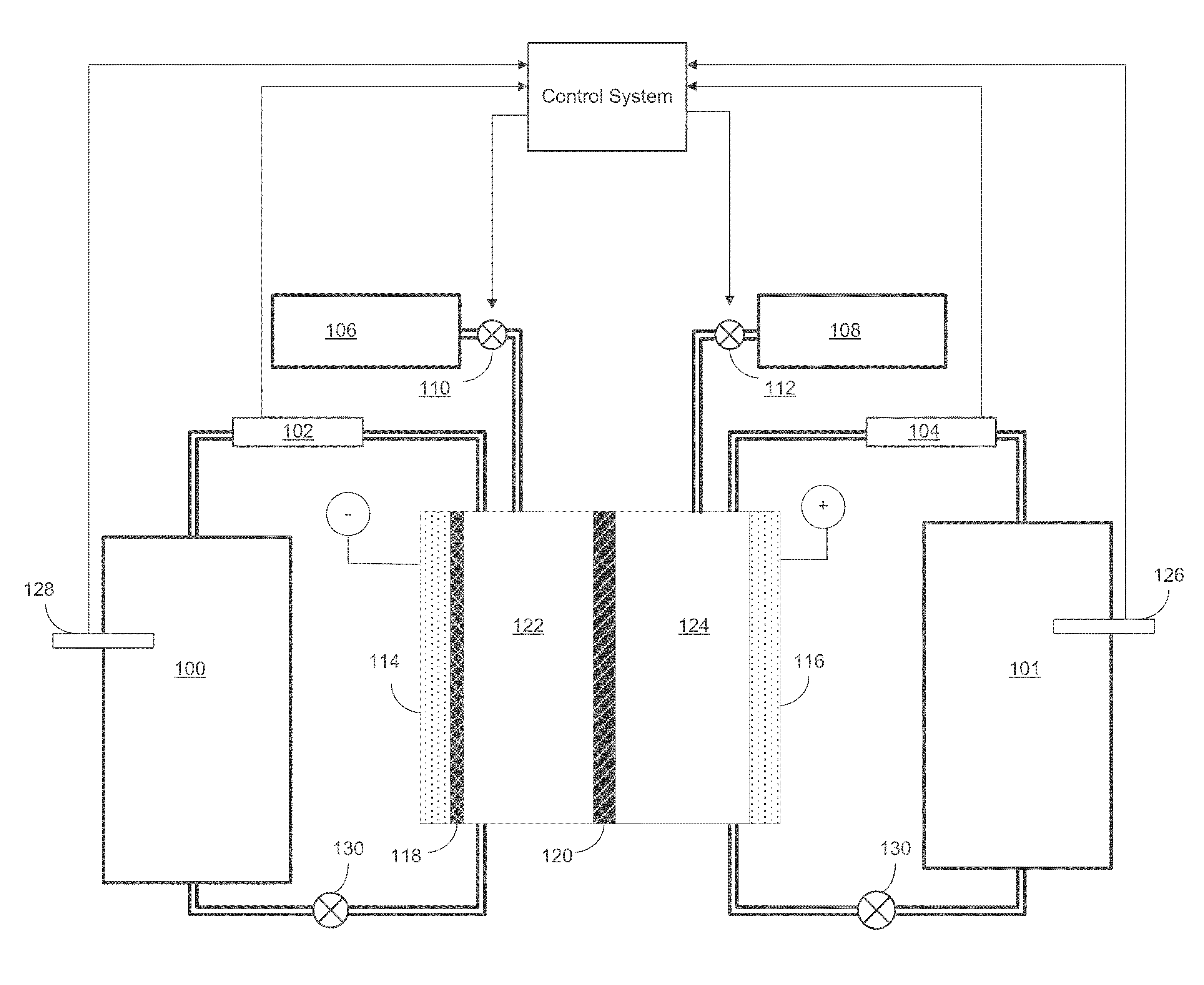

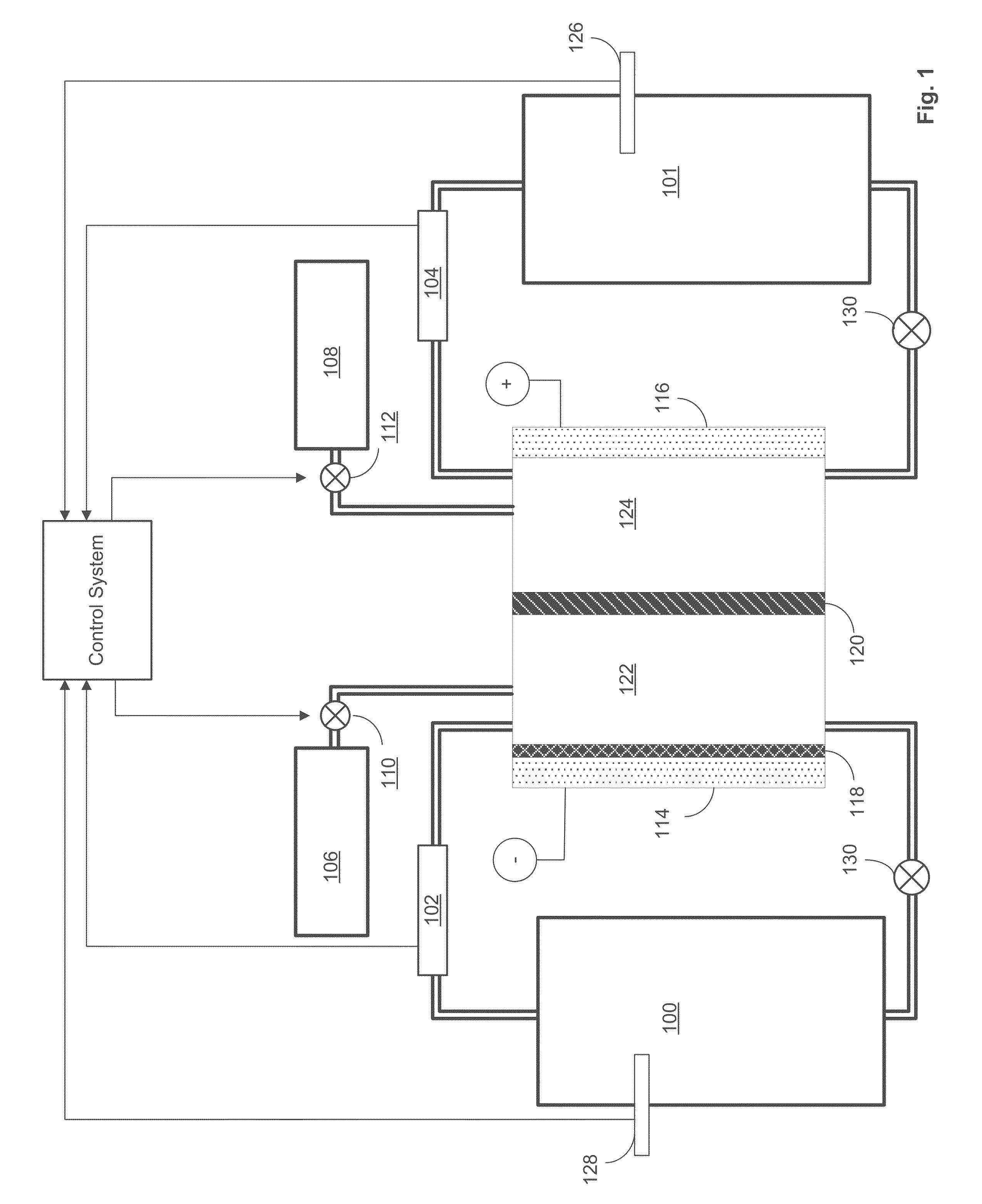

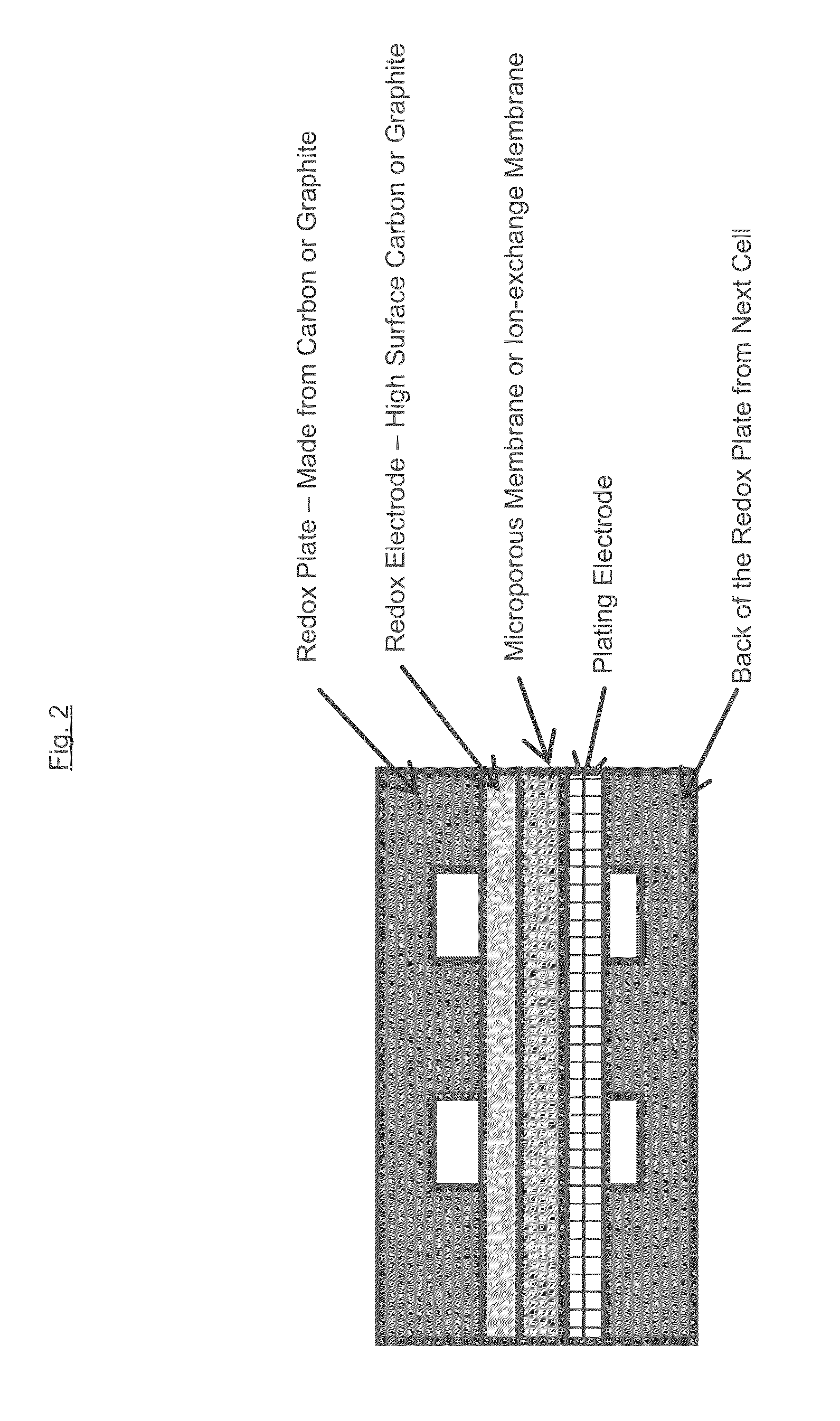

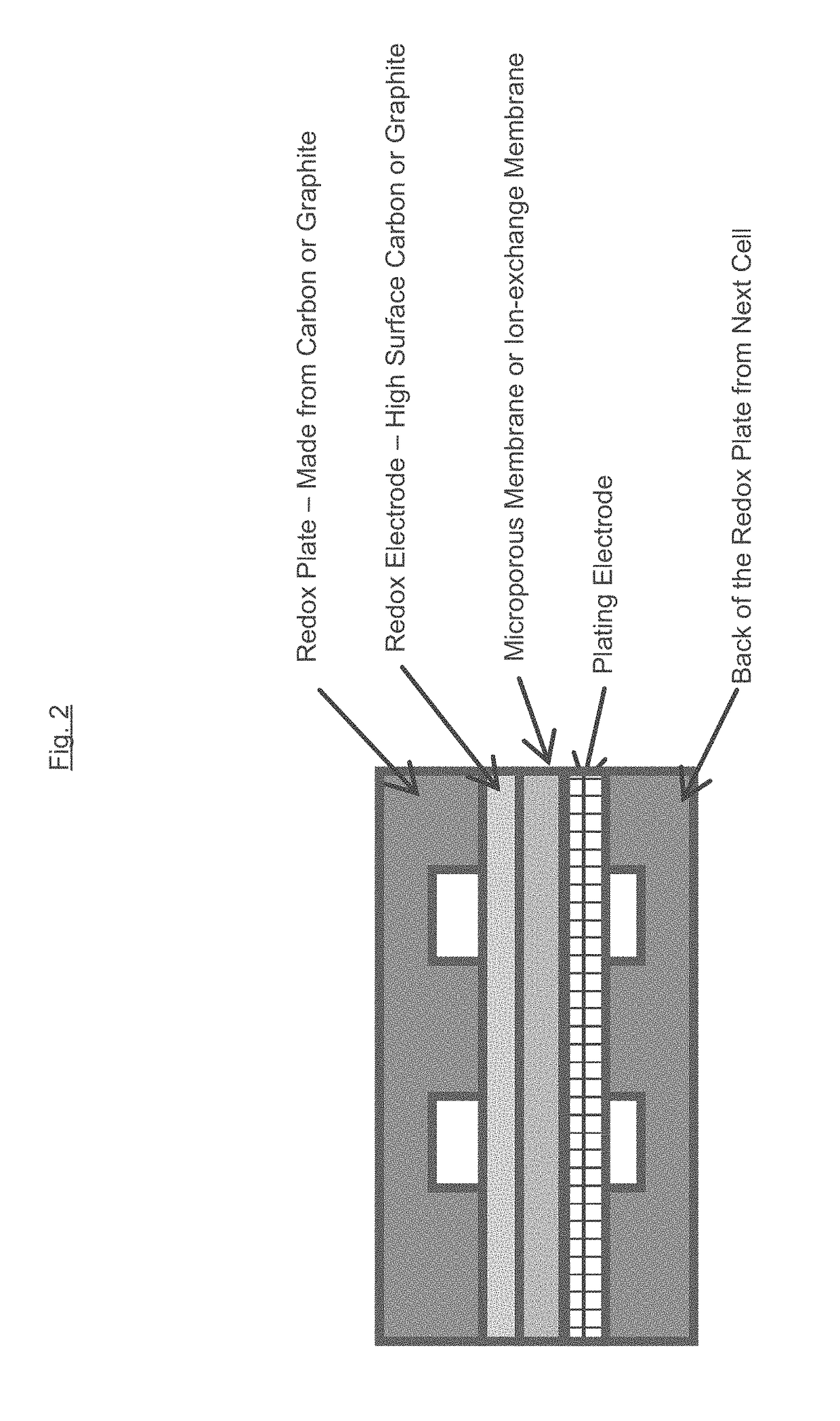

Methods to prepare stable electrolytes for all iron redox flow batteries

ActiveUS20140272493A1Low costHigh recycling valueRegenerative fuel cellsIndirect fuel cellsChemical reactionOxidation-Reduction Agent

An iron redox flow battery system, comprising a redox electrode, a plating electrolyte tank, a plating electrode, a redox electrolyte tank with additional acid additives that may be introduced into the electrolytes in response to electrolyte pH. The acid additives may act to suppress undesired chemical reactions that create losses within the battery and may be added in response to sensor indications of these reactions.

Owner:ESS TECHNOLOGY

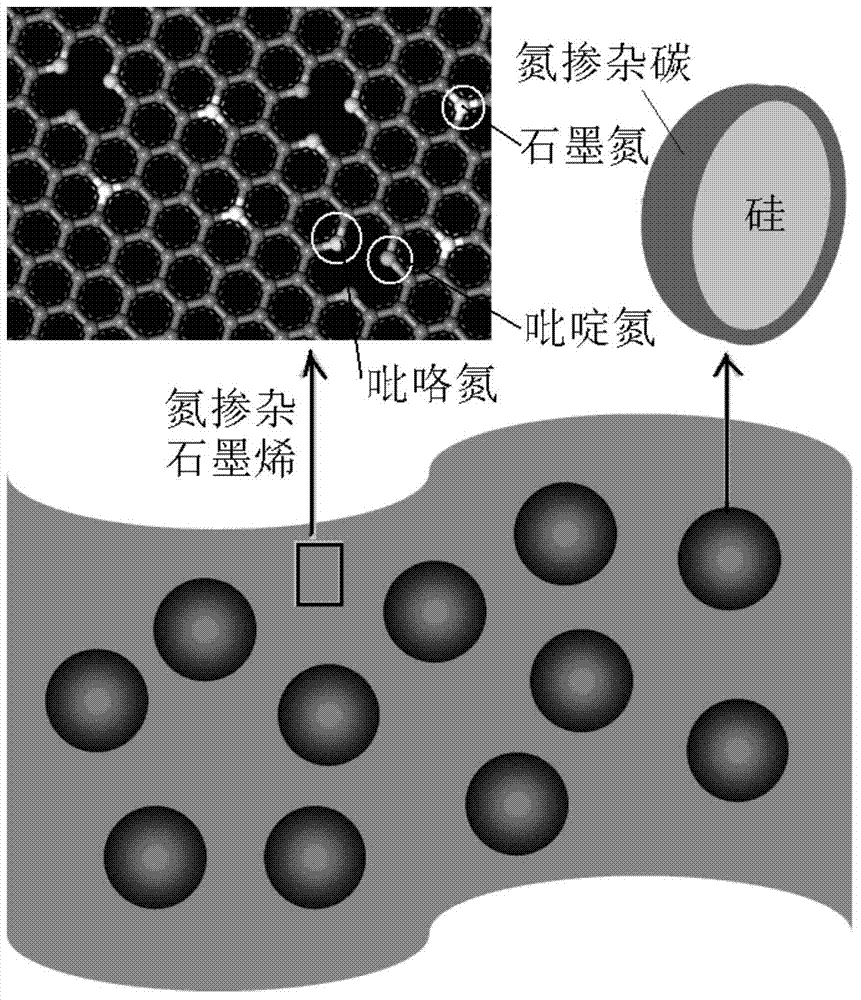

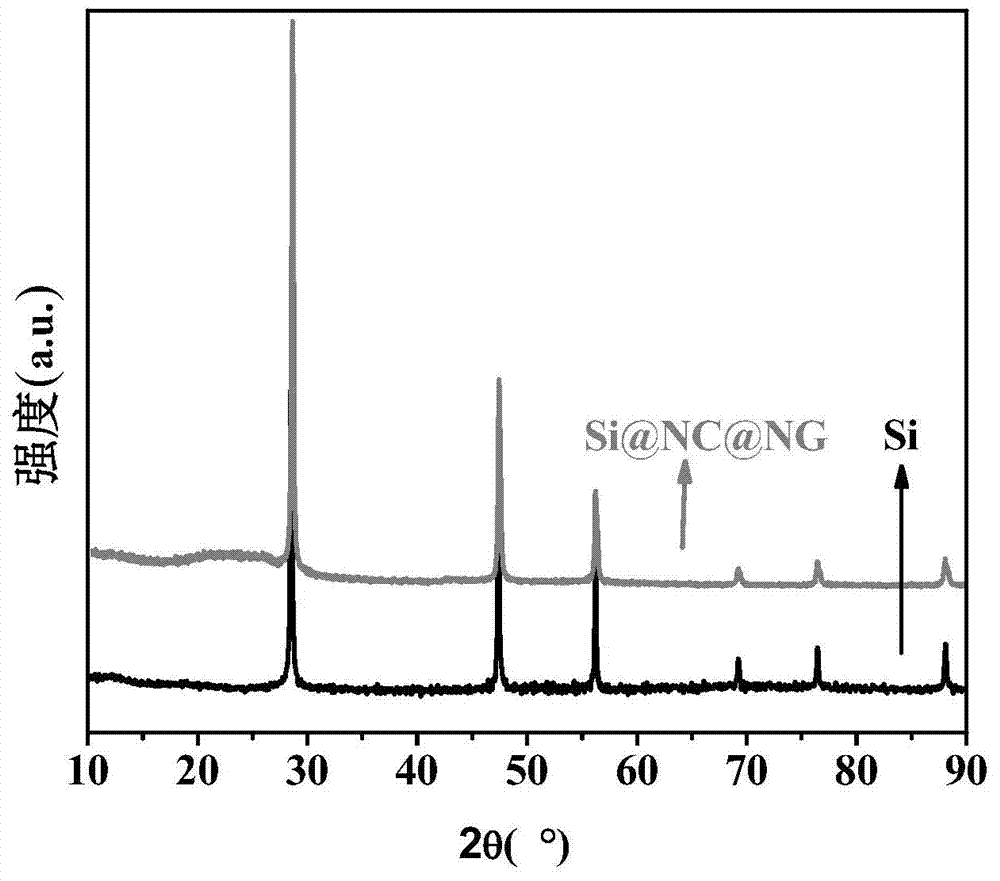

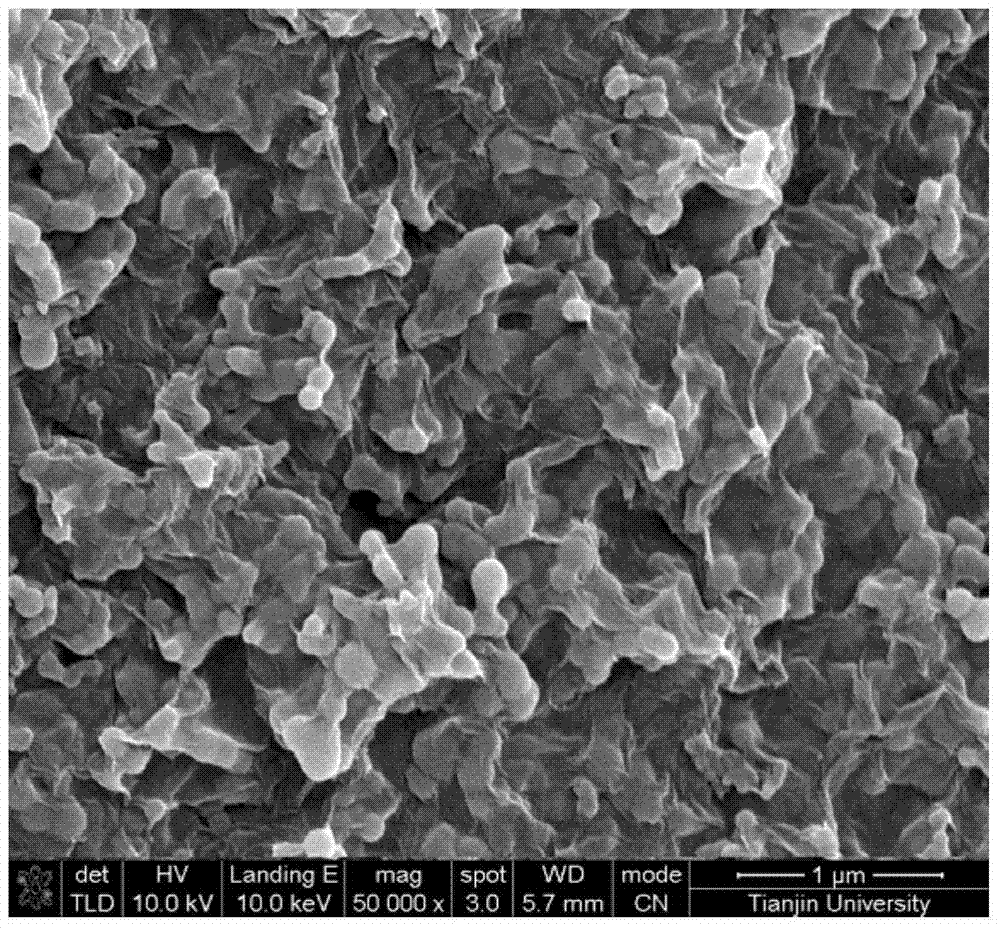

Silicon-nitrogen doped carbon-nitrogen doped graphene composite material, and preparation method and application thereof

InactiveCN104716321AAvoid reunionInhibition of volume changeCell electrodesSecondary cellsCarbon layerDoped graphene

The invention discloses a silicon-nitrogen doped carbon-nitrogen doped graphene composite material. The silicon-nitrogen doped carbon-nitrogen doped graphene composite material is formed by graphene oxide, a nitrogen-containing carbon source and silicon, wherein a mass ratio of graphene oxide to the nitrogen-containing carbon source to silicon is 1-4:2:2-6; and nitrogen doped carbon with a core-shell structure is obtained through a solution mixing process and a high temperature charring process, and coats silicon particles, and the nitrogen doped carbon coated silicon particles are uniformly inlaid in nitrogen doped graphene interlayer. A preparation method of the composite material comprises the following steps: adding a nitrogen-containing carbon source solution into a silicon dispersion, and carrying out stirring ultrasonic treatment; adding a graphene oxide dispersion solution to the above obtained mixed solution in the ultrasonic process; and carrying out stirring heating, evaporation pulping, freeze drying and high temperature charring in order to obtain the silicon-nitrogen doped carbon-nitrogen doped graphene composite material. The nitrogen-containing carbon source is used to form a carbon layer on the surface of silicon particles and realize nitrogen doping of the carbon layer and graphene, the preparation process is simple, controllable and environmentally-friendly, and the composite material greatly improves the integral electrochemical performances.

Owner:TIANJIN UNIV

One part epoxy resin including a low profile additive

InactiveUS20110253943A1Improve abilitiesImprove connection reliability and consistencyPrinted circuit assemblingConductive materialPolymer scienceResin matrix

An adhesive composition comprising: (i) a one part curable epoxy adhesive and (ii) a low profile additive (LPA), the low profile additive being a polymer that is compatible with the epoxy adhesive such that it forms a single phase when admixed with the adhesive composition and that separates from the adhesive to form a network of stress-absorbing nodules therein when the adhesive is cured, the low profile additive being present in an amount sufficient to prevent or reduce shrinkage and / or the formation of voids or cracks when the adhesive is cured. In one embodiment the LPA is a block copolymer including at least one flexible block and at least one rigid block that makes the low profile additive compatible with the epoxy adhesive such that a mixture of the uncured epoxy resin and the low profile additive forms a homogenous solution and as the epoxy resin is cured, the low profile additive forms a stress absorbing network of nodules in the cured epoxy resin matrix.

Owner:TRILLION SCI INC

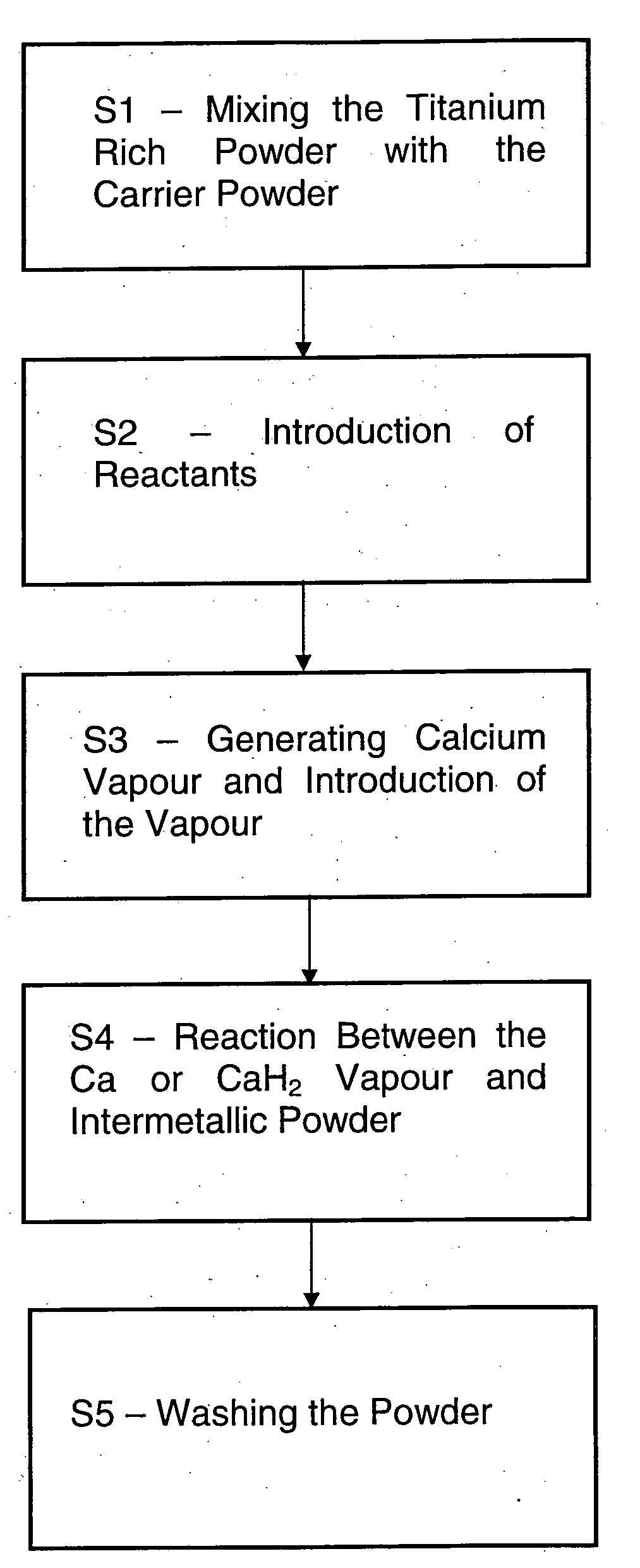

Method for purification of metal based alloy and intermetallic powders

InactiveUS20100064852A1High purityEfficient responseTransportation and packagingMetal-working apparatusMetal alloyCompound (substance)

This invention relates to a method for purifying metal alloy and intermetallic powders. Particularly, the present invention relates to a method for the reduction or elimination of the content of the dissolved oxygen and to remove the metal oxide inclusions from metal alloy and intermetallic powders including the steps of: a) placing the metal in powder form into a reaction apparatus; b) introducing a suitable carrier substance to the metal powder; and c) introducing calcium vapour into the reaction apparatus to create a reaction between the metallic powder and calcium vapour thereby removing inclusions in the metal as shown in FIG. 11.

Owner:WAIKATOLINK LIMITED

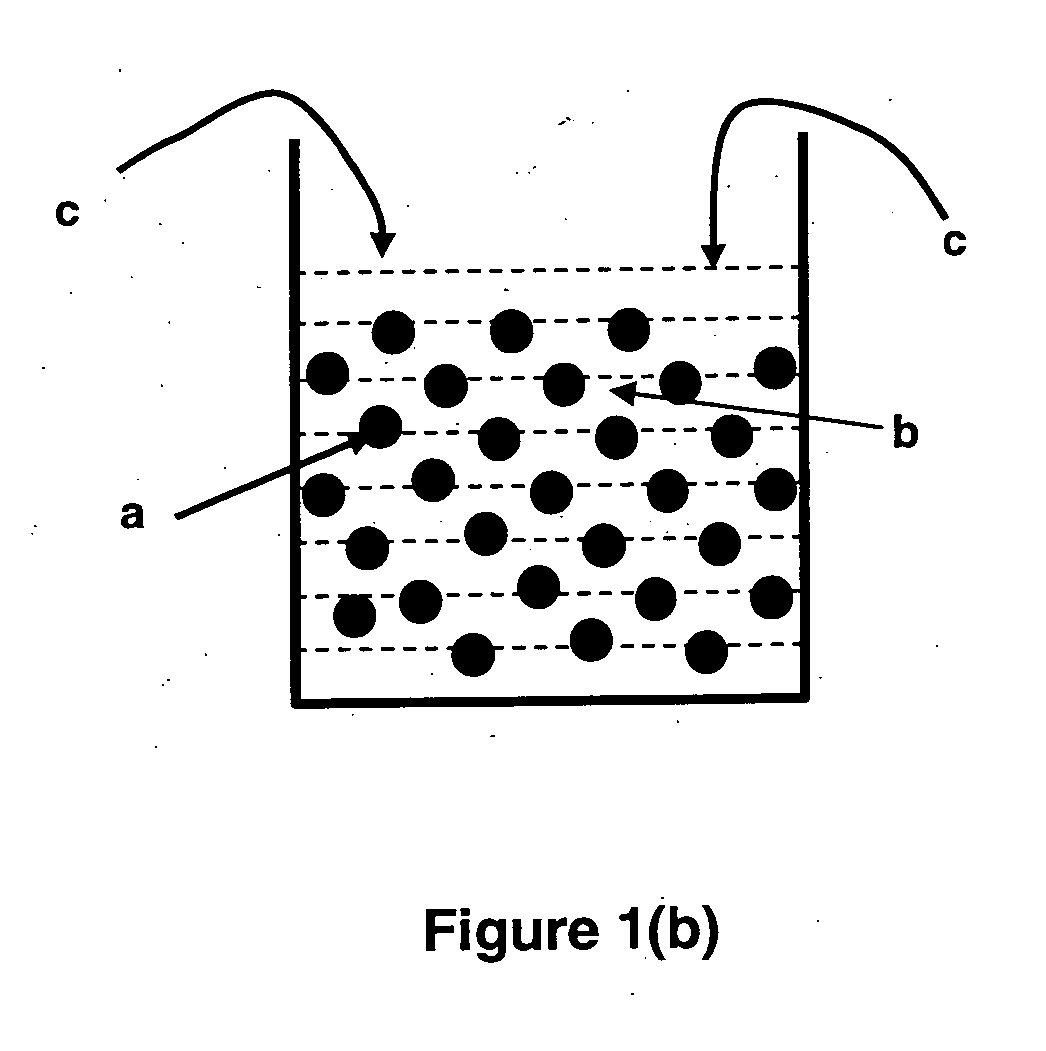

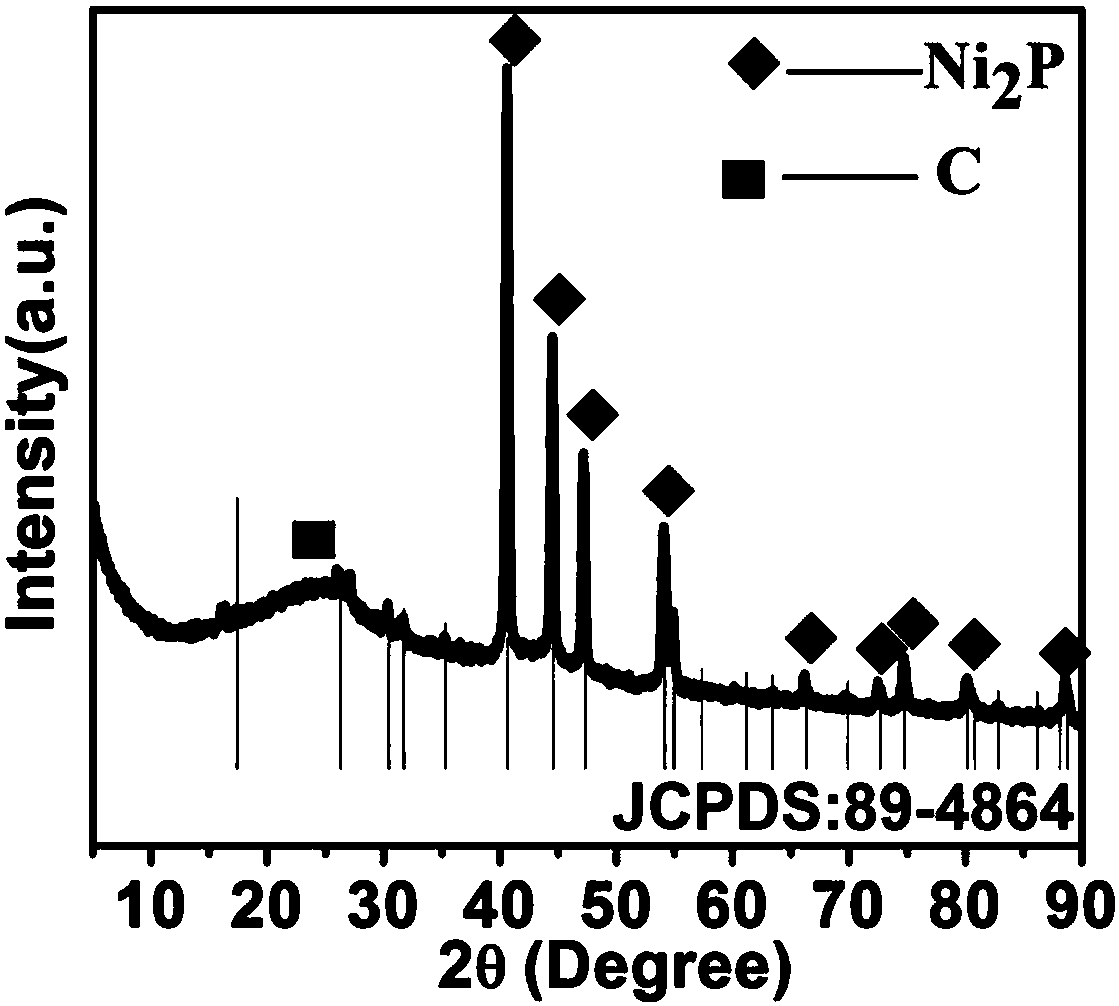

Transitional metal phosphide-carbon composite material as well as preparation method and application thereof

ActiveCN108511714AAvoid reunionImprove reaction kineticsMaterial nanotechnologyCell electrodesCarbon compositesElectrochemistry

The invention provides a transitional metal phosphide-carbon composite material, which belongs to the field of electrochemical energy materials. A carbon precursor is used as a carbon source and a nitrogen source, the transitional metal ions are uniformly dispersed on a carbon precursor substrate by virtue of a complexing effect of the transitional metal ions and the carbon precursor, and the single-dispersed transitional metal phosphide nano particles are in-situ synthesized by virtue of the phosphorization process. The single-dispersed transitional metal phosphide nano particles are embeddedinto the carbon material substrate, so that the volume expansion of the phosphide particles in the charging-discharging process can be alleviated, the cycling stability of the material can be improved, the electric conductivity of the composite material can also be increased, the reaction dynamics process of an electrode is accelerated, the heteroatom-doped carbon is combined with the transitional metal phosphide by virtue of a covalent bond, so that the interaction of the heteroatom-doped carbon and the transitional metal phosphide is improved, the clustering problem of the phosphide particles in the charging and discharging process can be solved, and the synergistic effect between the carbon and phosphide improves the specific capacity and rate capability of the composite material.

Owner:YANSHAN UNIV

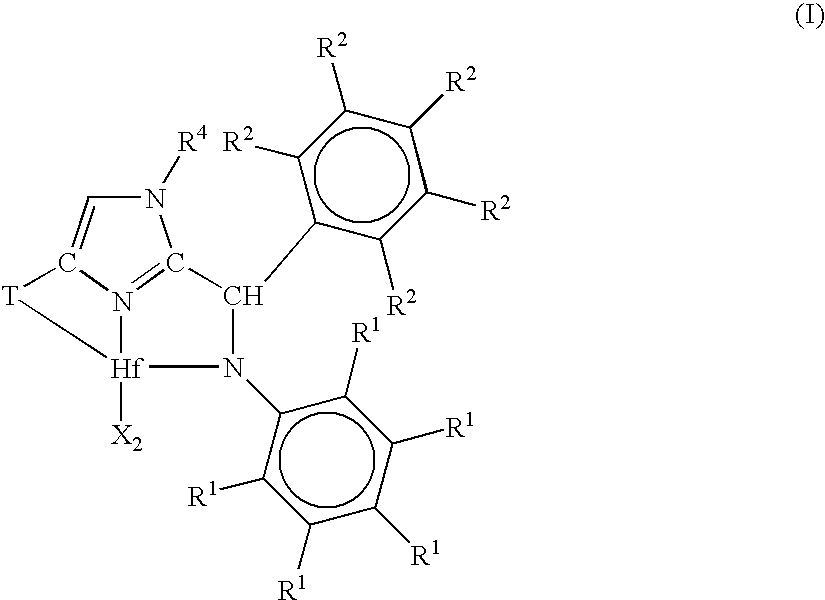

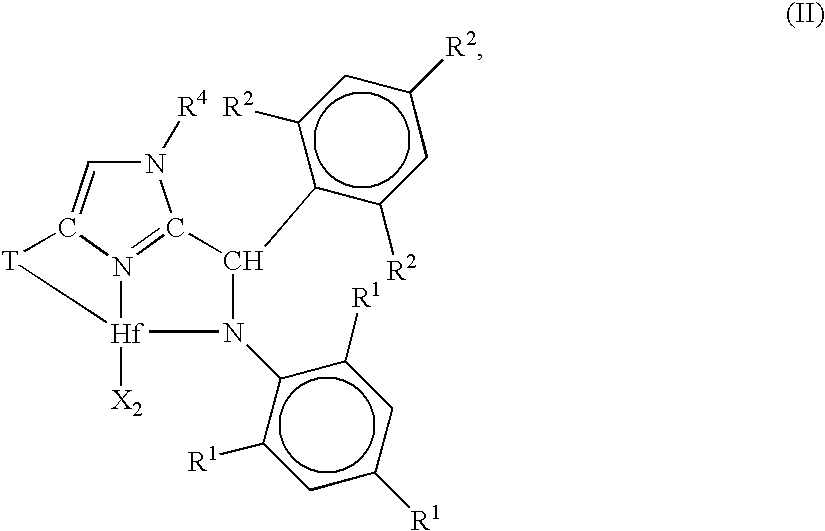

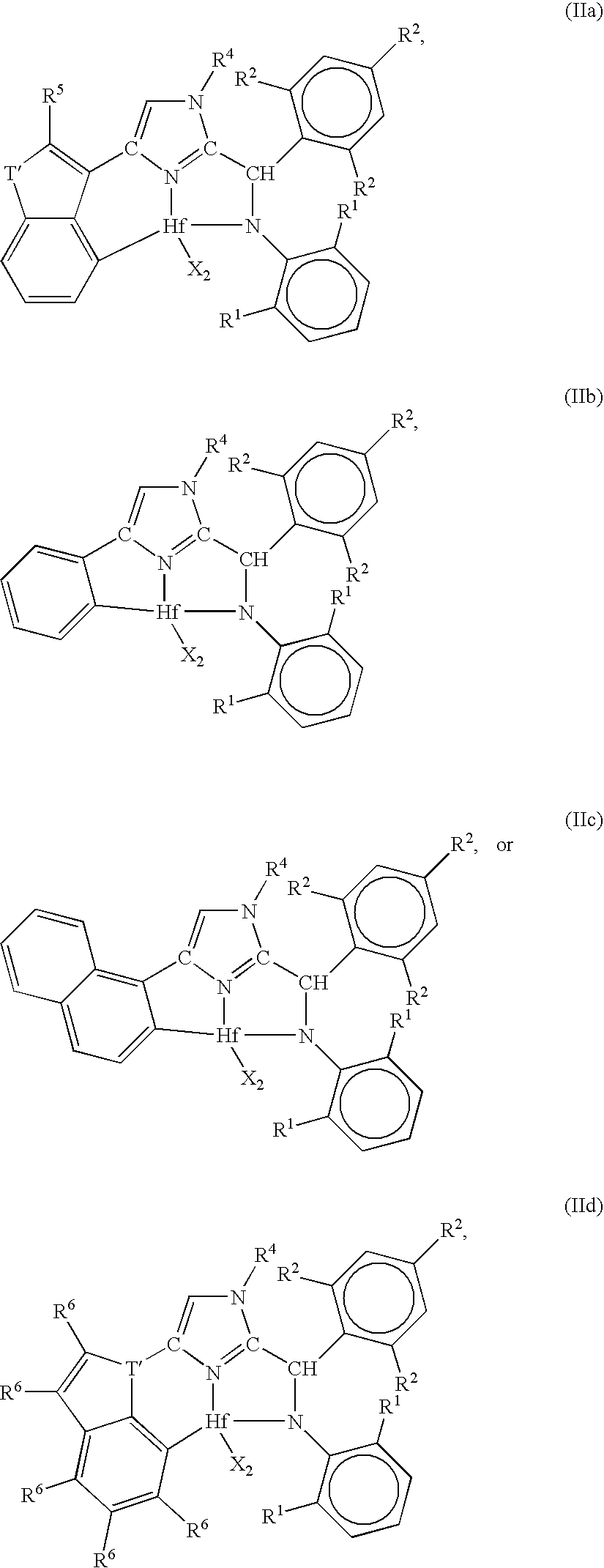

Ortho-metallated hafnium complexes of imidazole ligands

InactiveUS20090306318A1High molecular weightHigh catalytic efficiencyGroup 4/14 element organic compoundsGroup 8/9/10/18 element organic compoundsMetalationHafnium

Hafnium complexes of heterocyclic organic imidazol-2-yl ligands containing internal orthometallation and their use as components of olefin polymerization catalyst compositions, especially supported catalyst compositions, are disclosed.

Owner:DOW GLOBAL TECH LLC

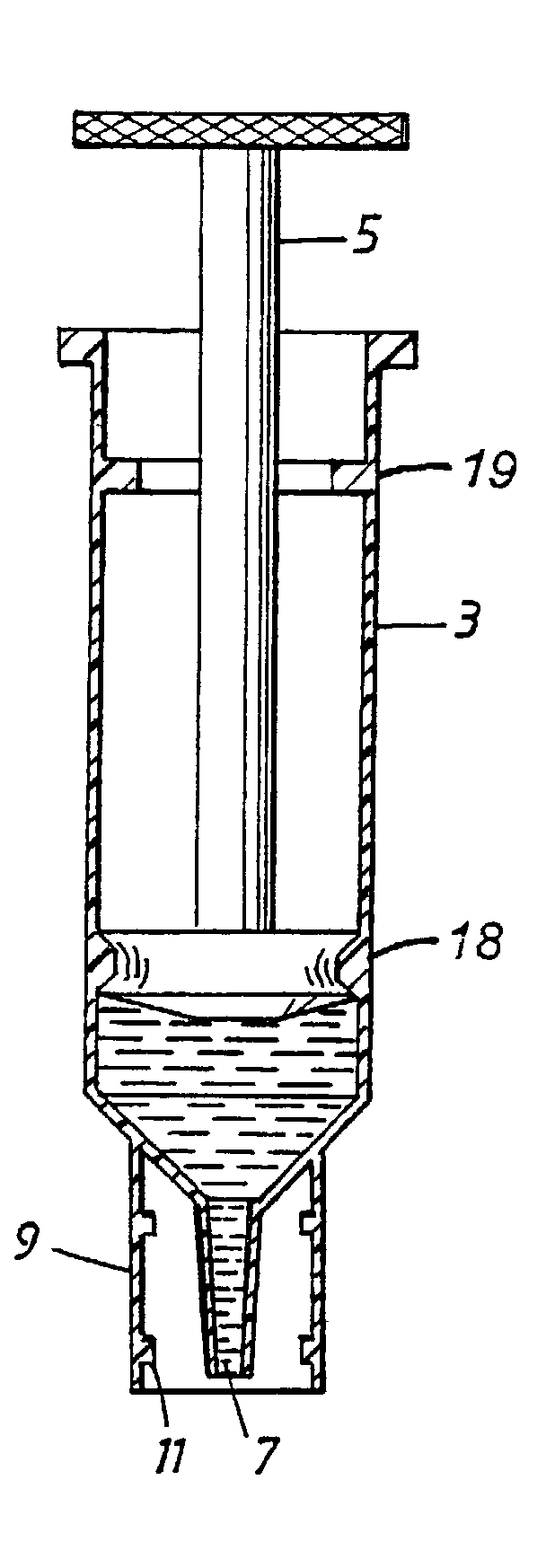

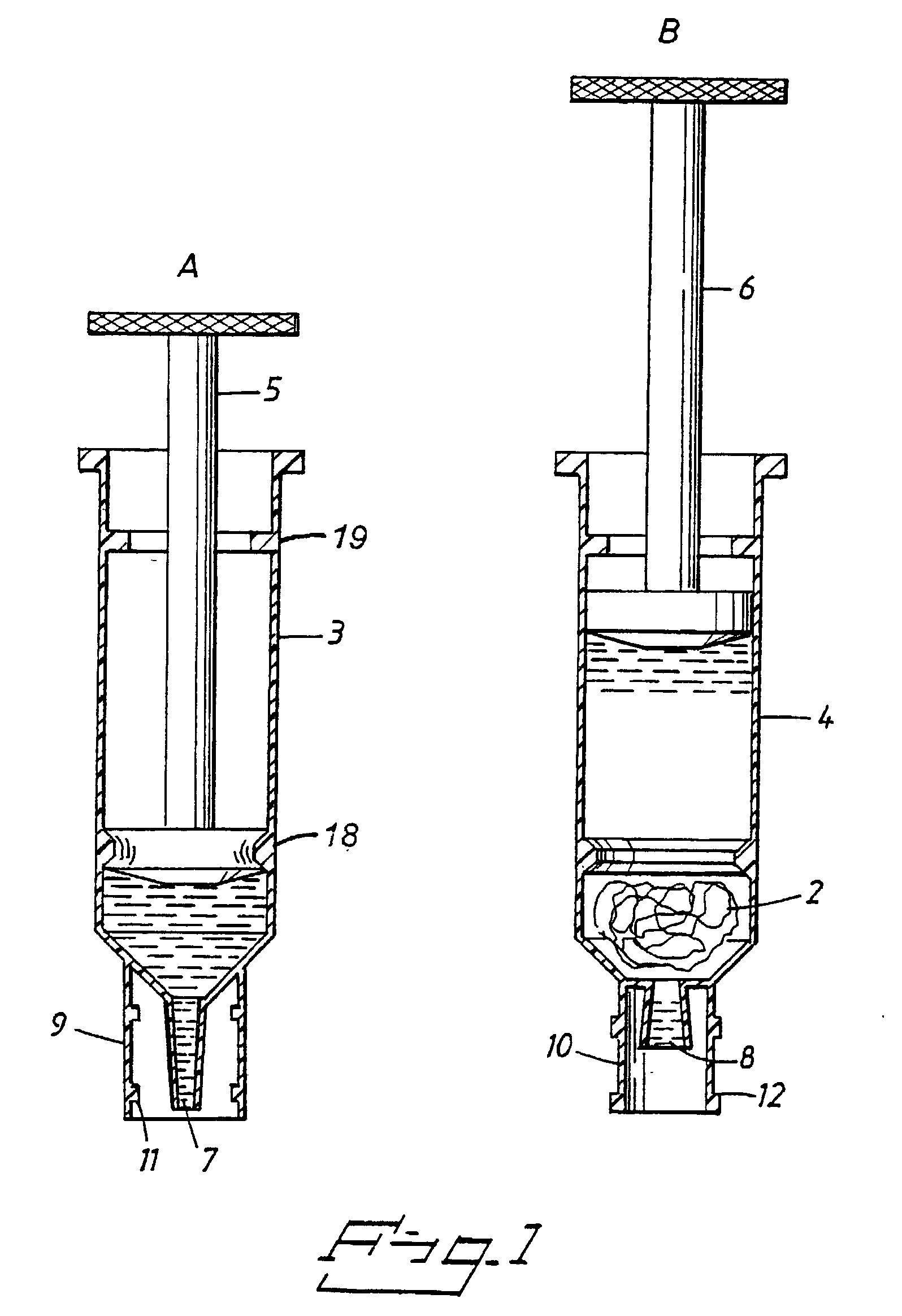

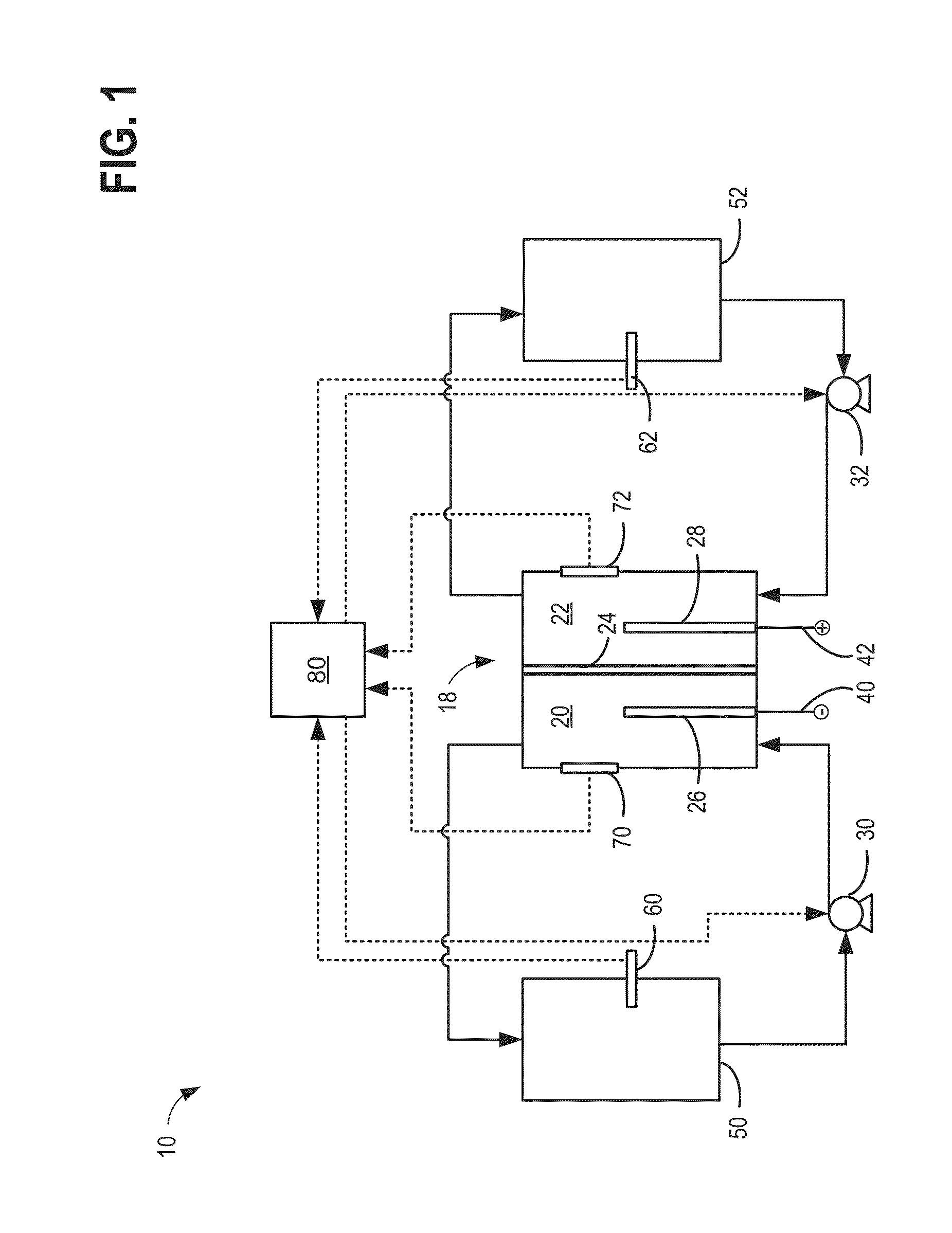

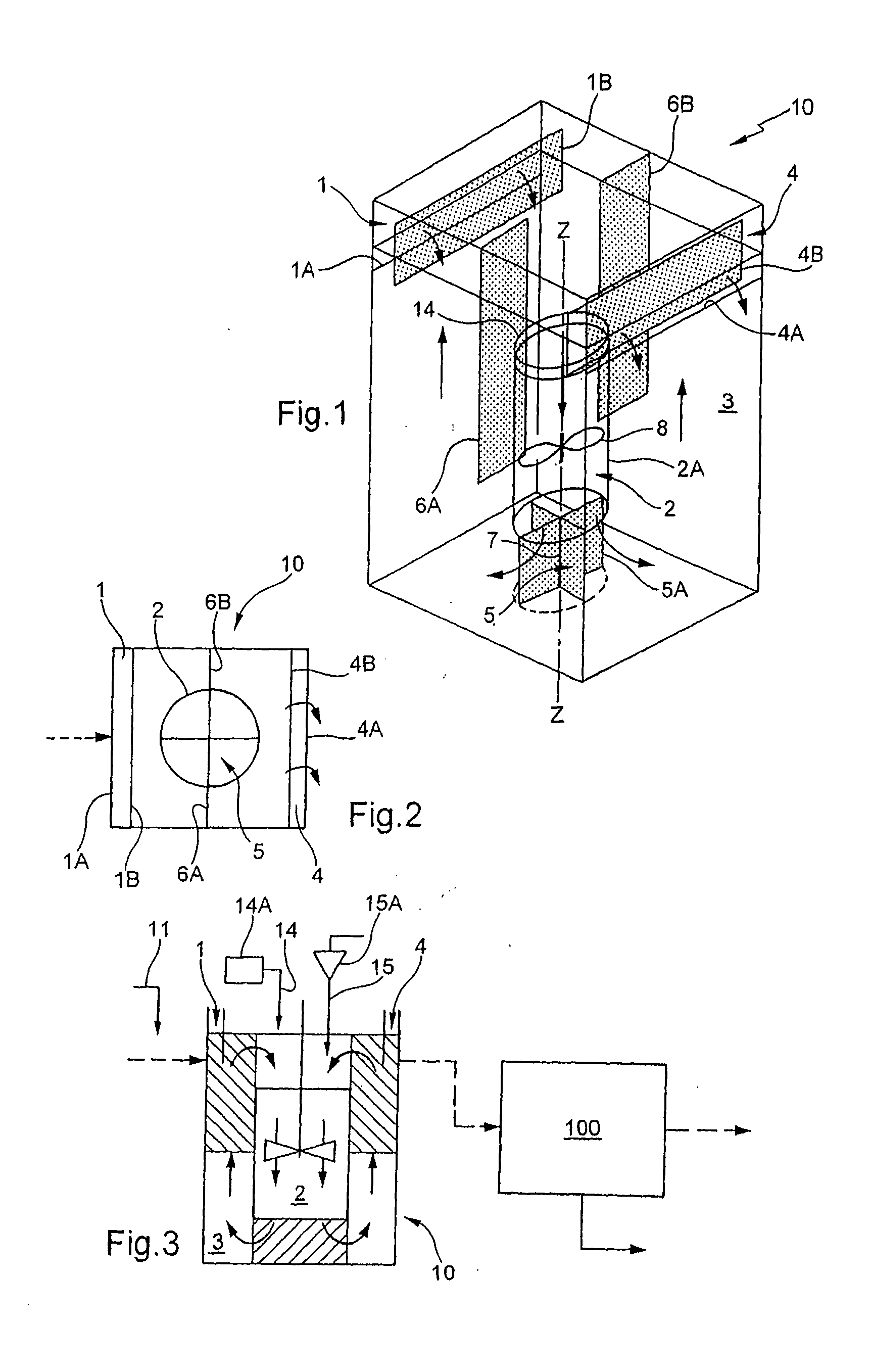

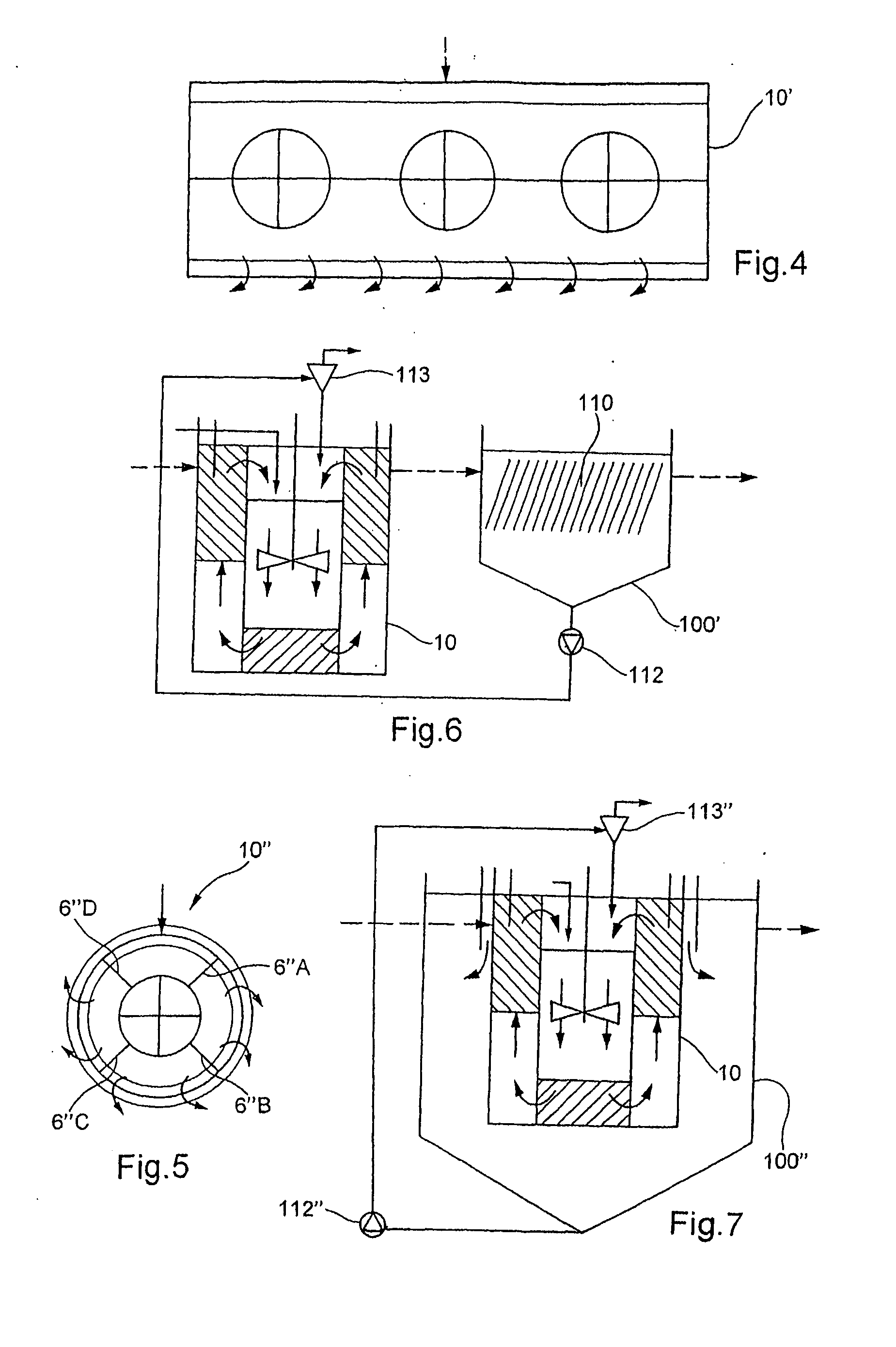

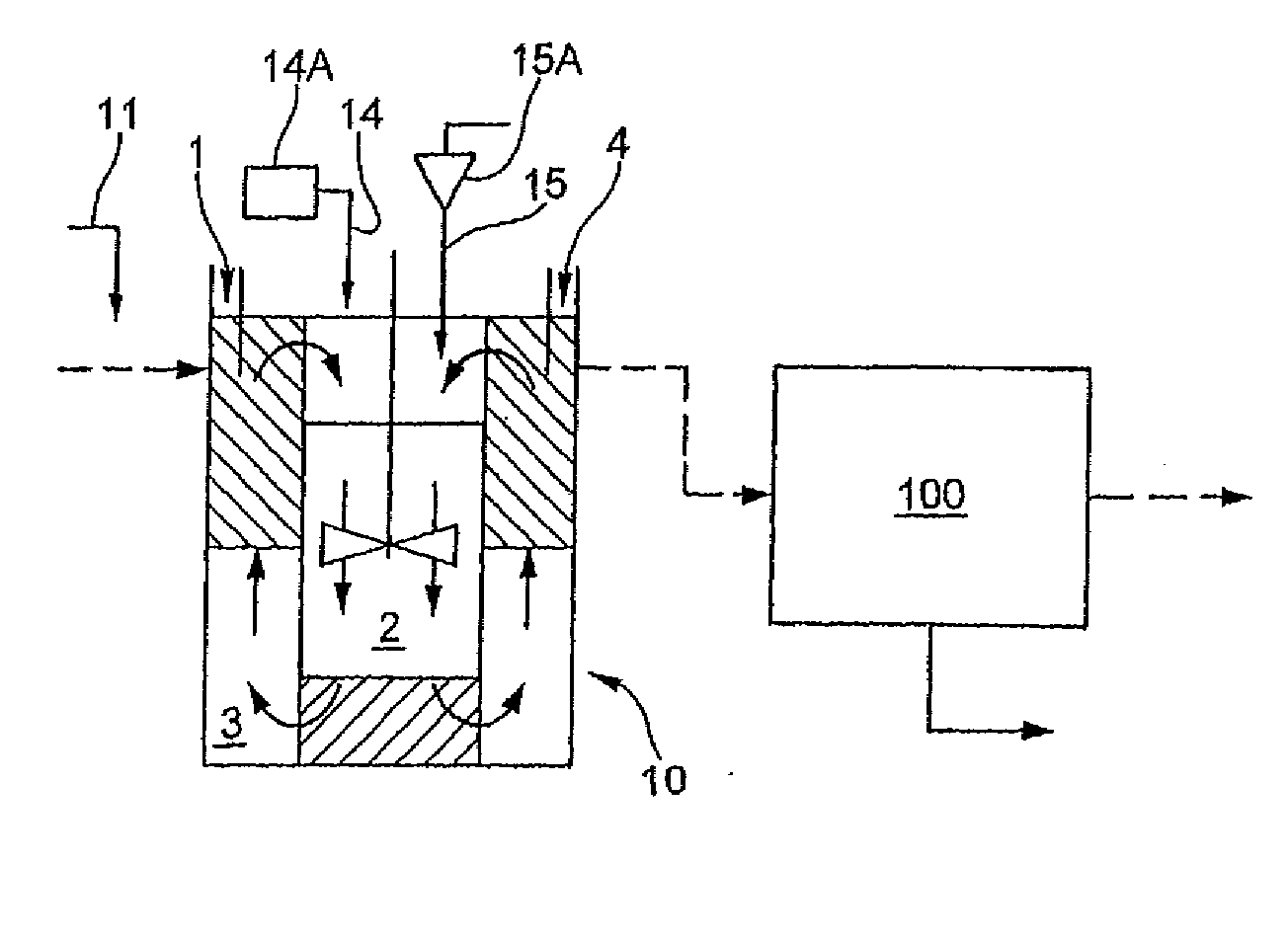

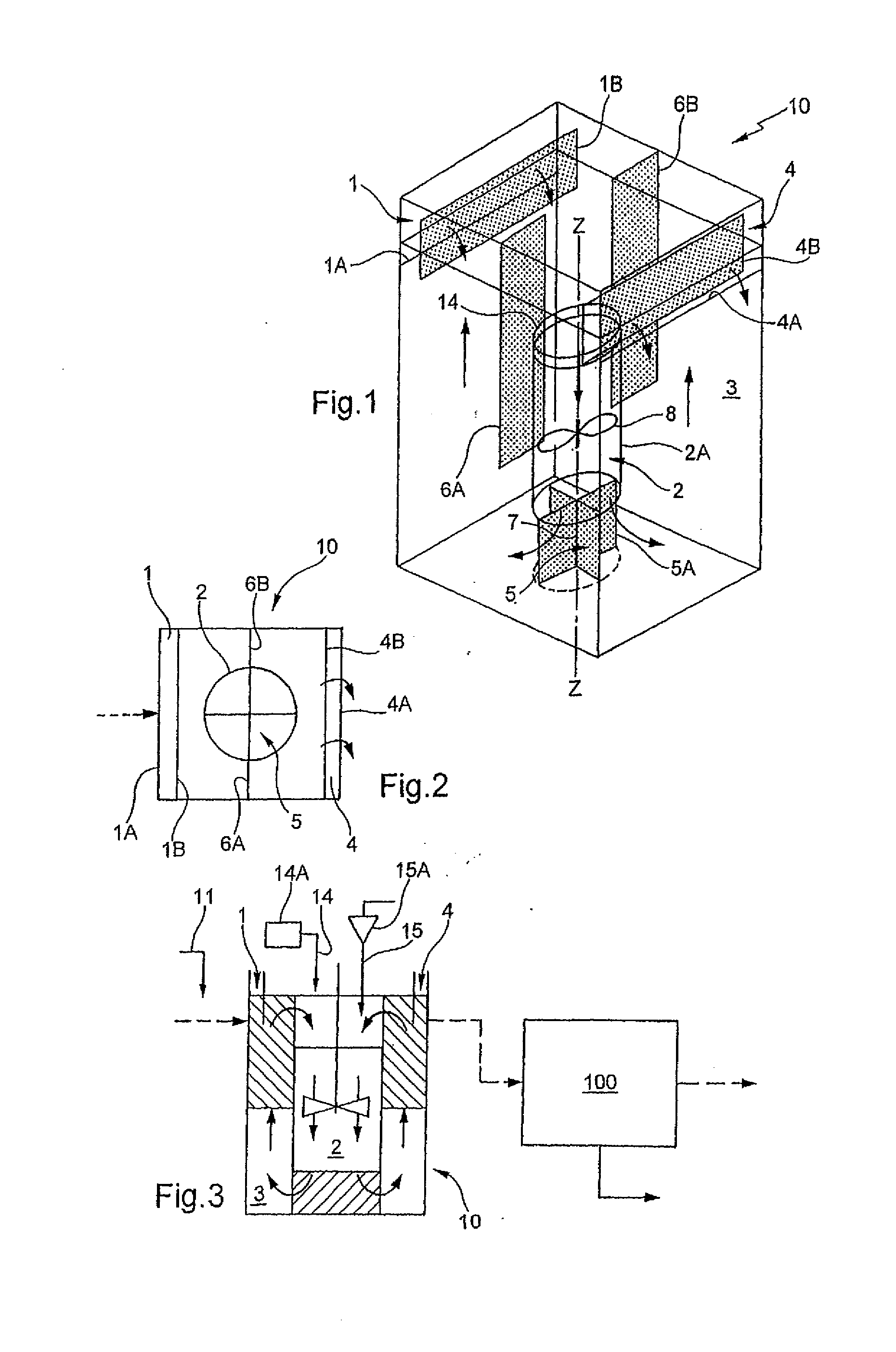

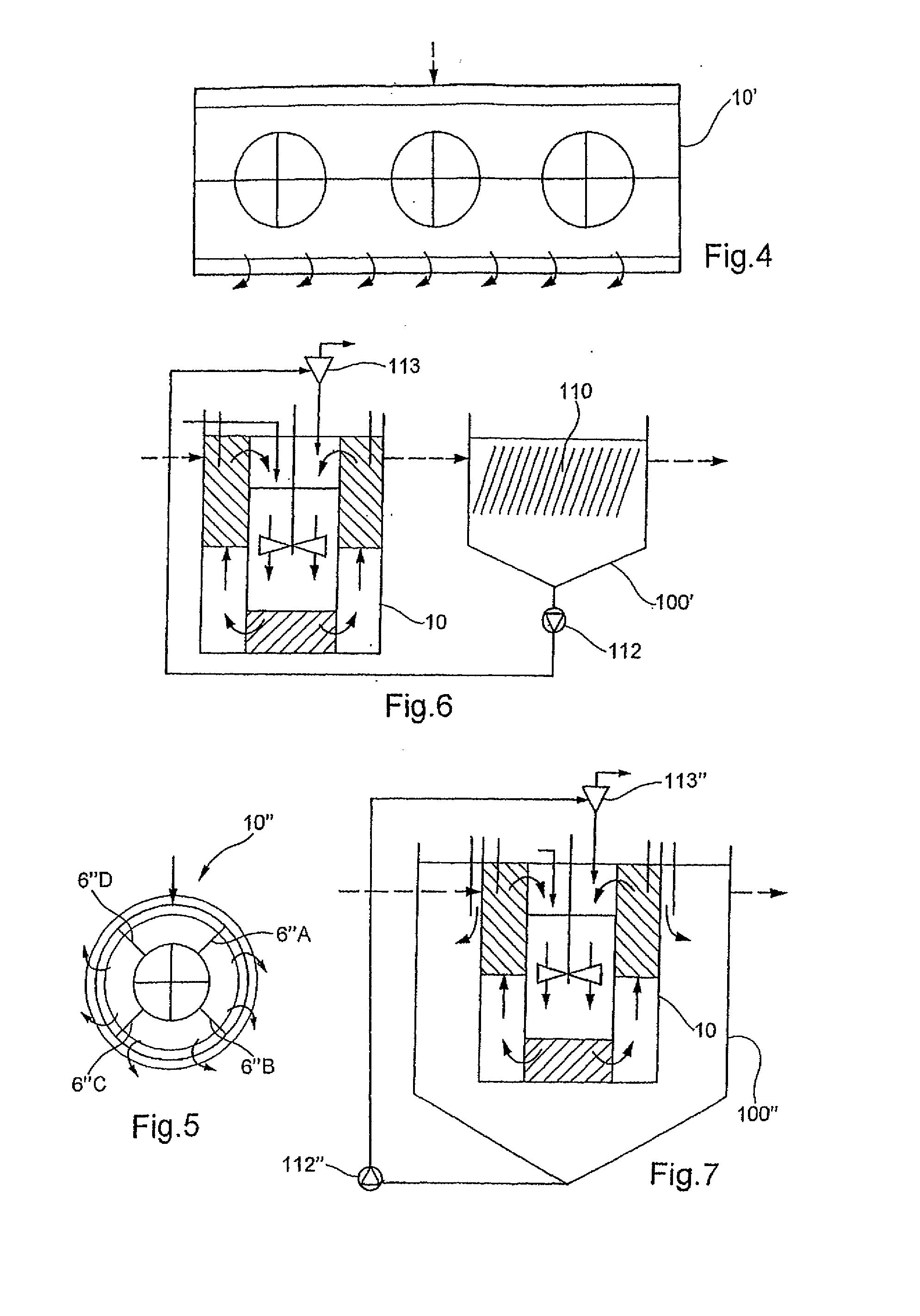

Method and apparatus for treating wastewater

ActiveUS20070114184A1Easy to combineImprove efficacyWater treatment compoundsDifferential sedimentationWastewaterTurbulent blood flow

A method and apparatus for treating wastewater. The apparatus comprises a reactor having a flow channel generally centrally located in a reactor and immersed in the water or wastewater in the reactor. An agitator is disposed within the flow channel and induces water or wastewater to enter the open upper end thereof and to move downwardly through the flow channel where the water or wastewater is discharged via a flow divider. A reagent is injected into the water or wastewater and the agitator within the flow channel serves to mix the reagent with the water or wastewater passing therethrough and in the process causes at least a slightly turbulent and downward axial flow through the flow channel.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

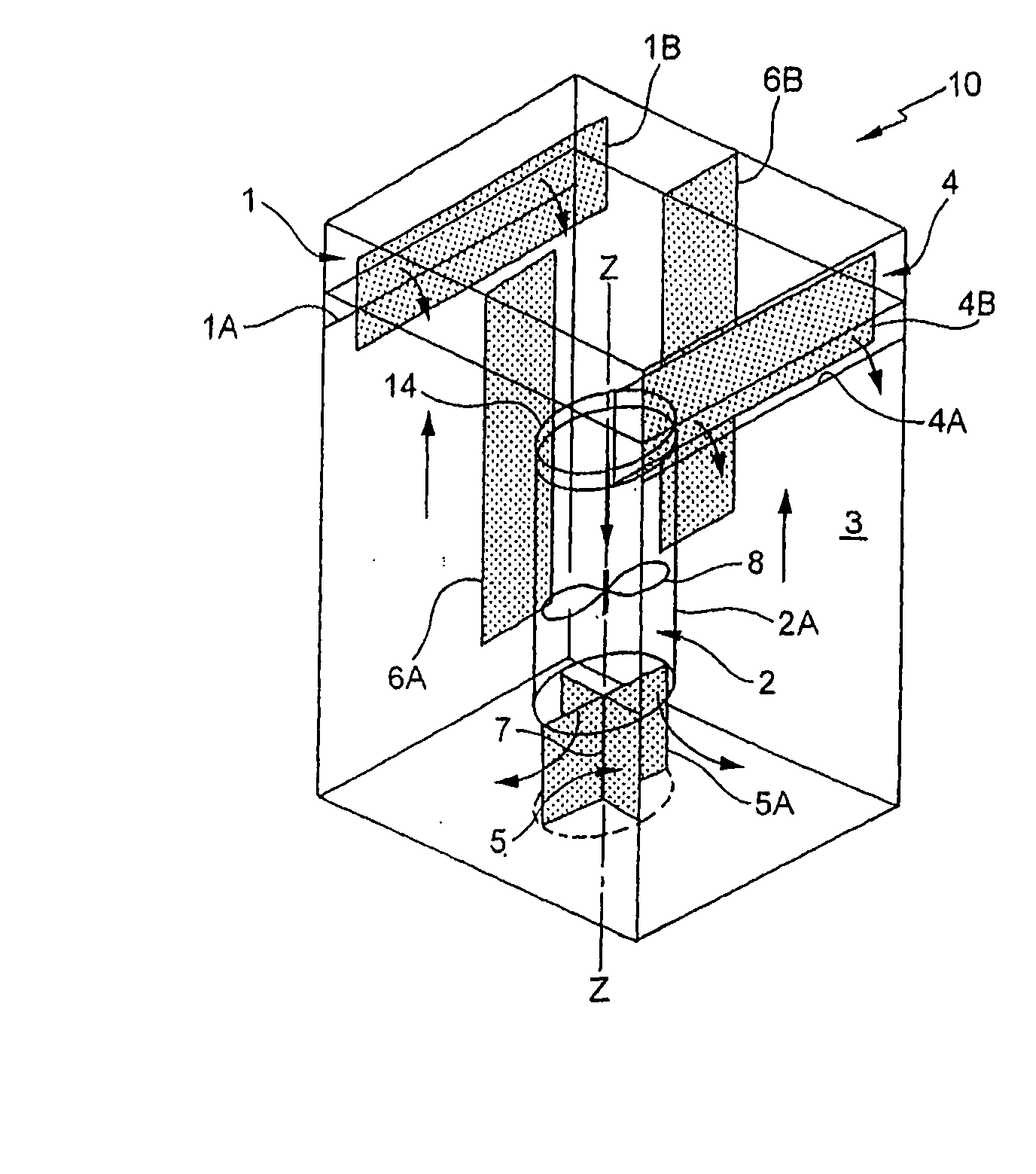

Method and apparatus for treating wastewater

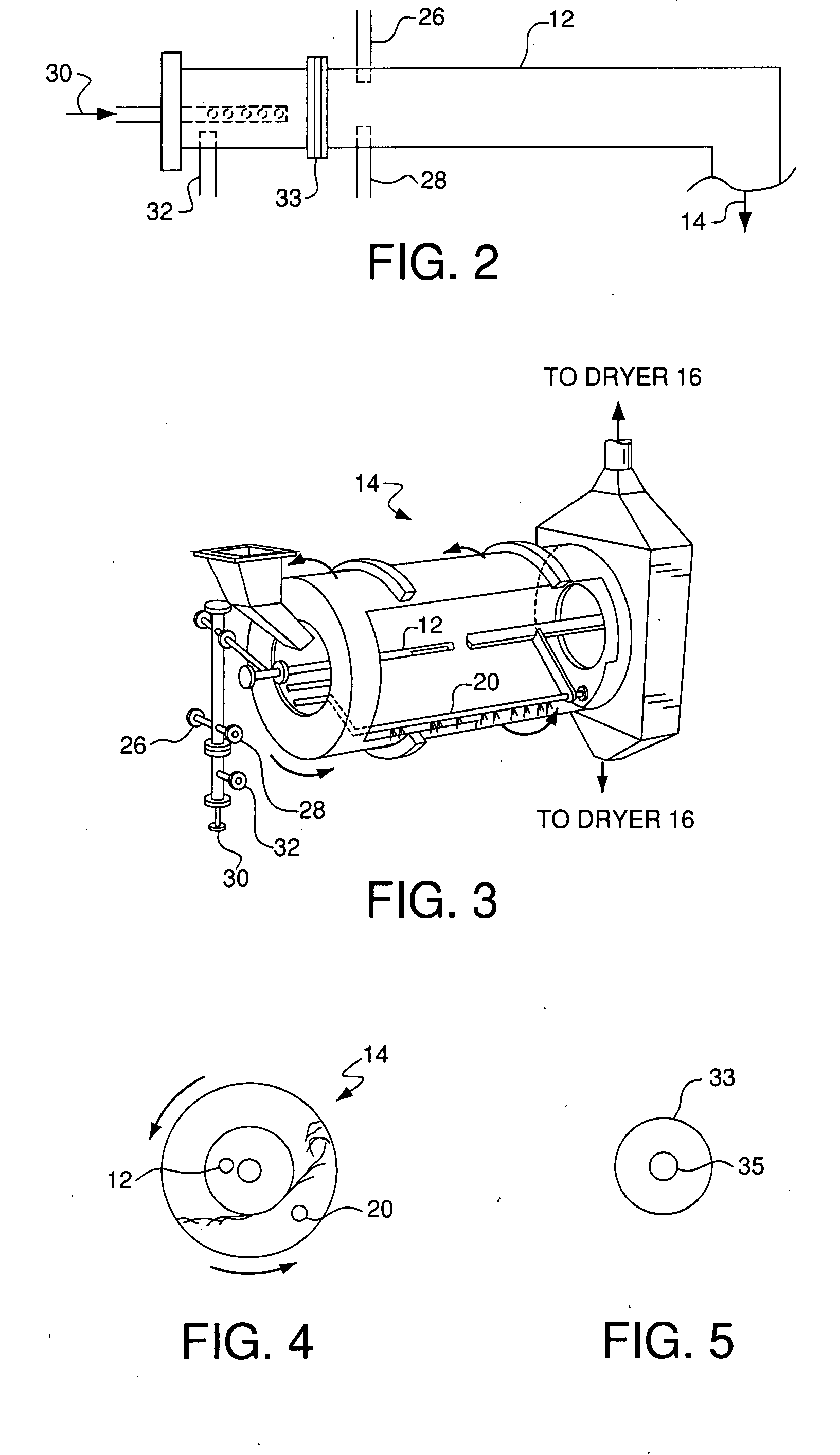

ActiveUS20090301948A1Facilitated reaction kineticsIncreases usable fraction of volume of reactorFlow mixersRotary stirring mixersWastewaterFlow divider

A method and apparatus for treating wastewater. The apparatus comprises a reactor having a flow channel generally centrally located in a reactor and immersed in the water or wastewater in the reactor. An agitator is disposed within the flow channel and induces water or wastewater to enter the open upper end thereof and to move downwardly through the flow channel where the water or wastewater is discharged via a flow divider. A reagent is injected into the water or wastewater and the agitator within the flow channel serves to mix the reagent with the water or wastewater passing therethrough and in the process causes at least a slightly turbulent and downward axial flow through the flow channel.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Devices comprising multiple capillary inducing surfaces

InactiveUS20050147531A1Enhanced assay volumeEasy to operateAnalysis using chemical indicatorsLaboratory glasswaresClassical mechanicsCapillarities

Assay device structures for a device where fluid flows from a one region to another. The device structures comprising one or more capillarity-inducing structures; where the capillarity-inducing structure induces capillary force along an axis that is essentially perpendicular to the axis along which capillary force induced in another region of the device.

Owner:BIOSITE INC

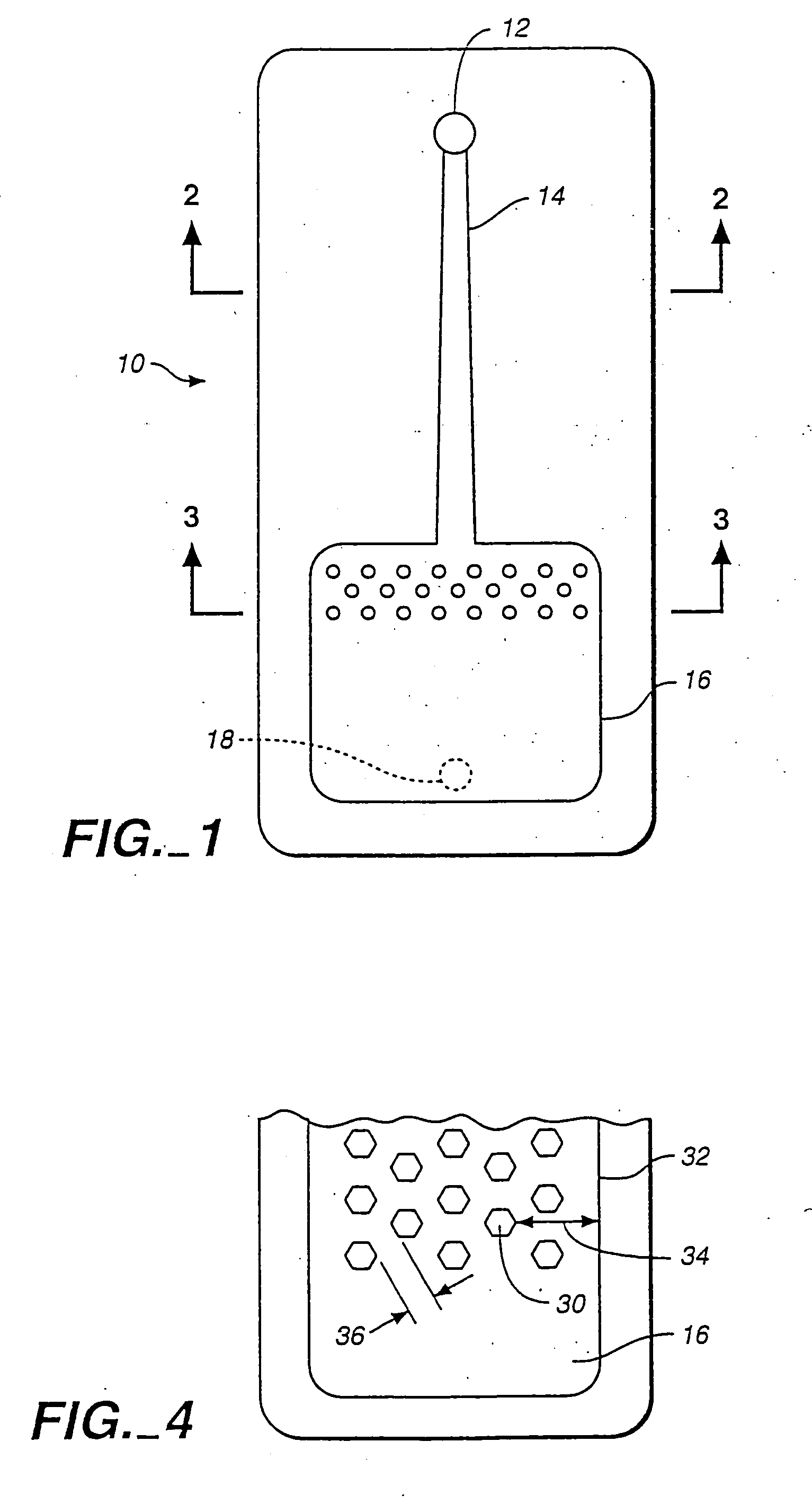

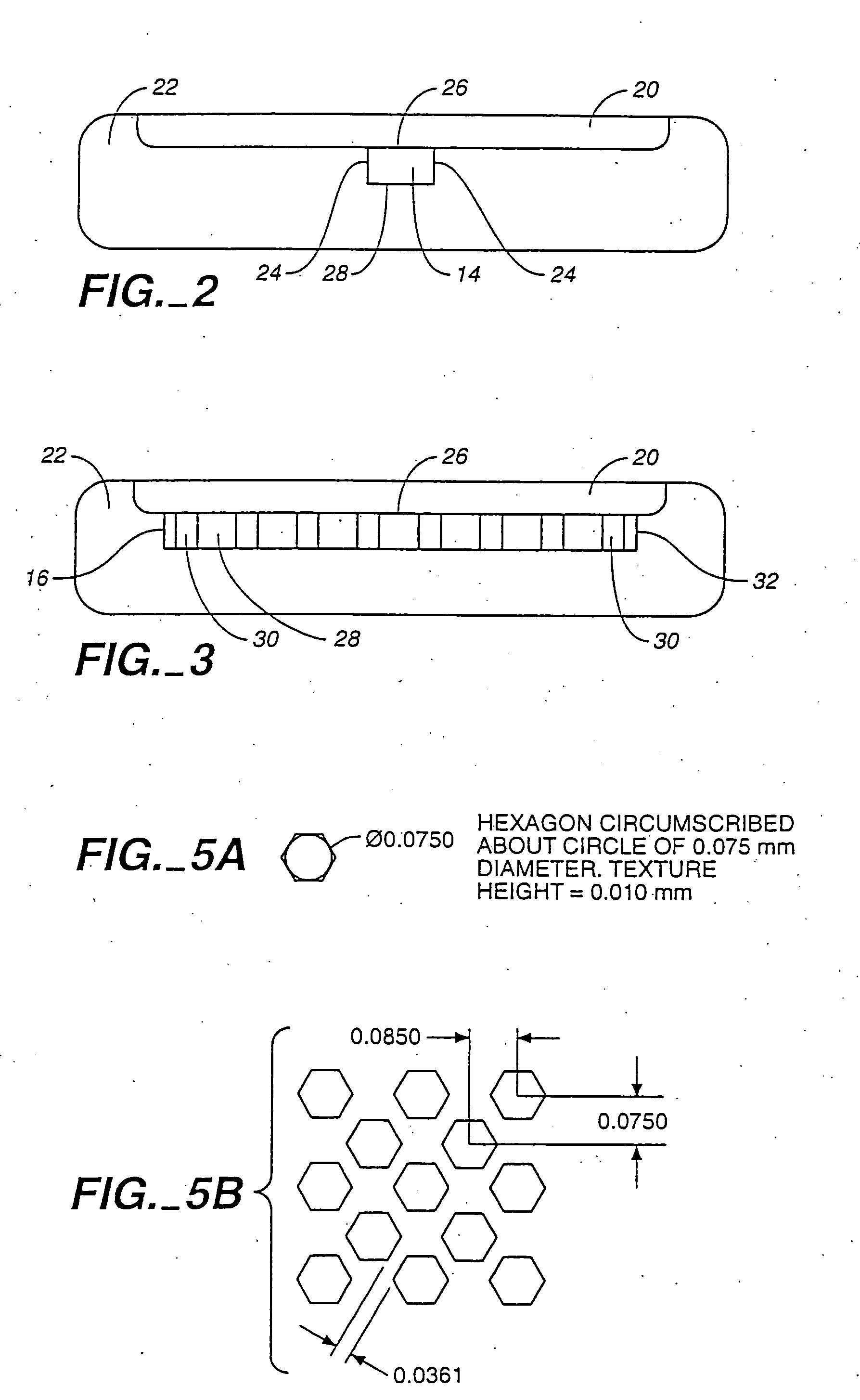

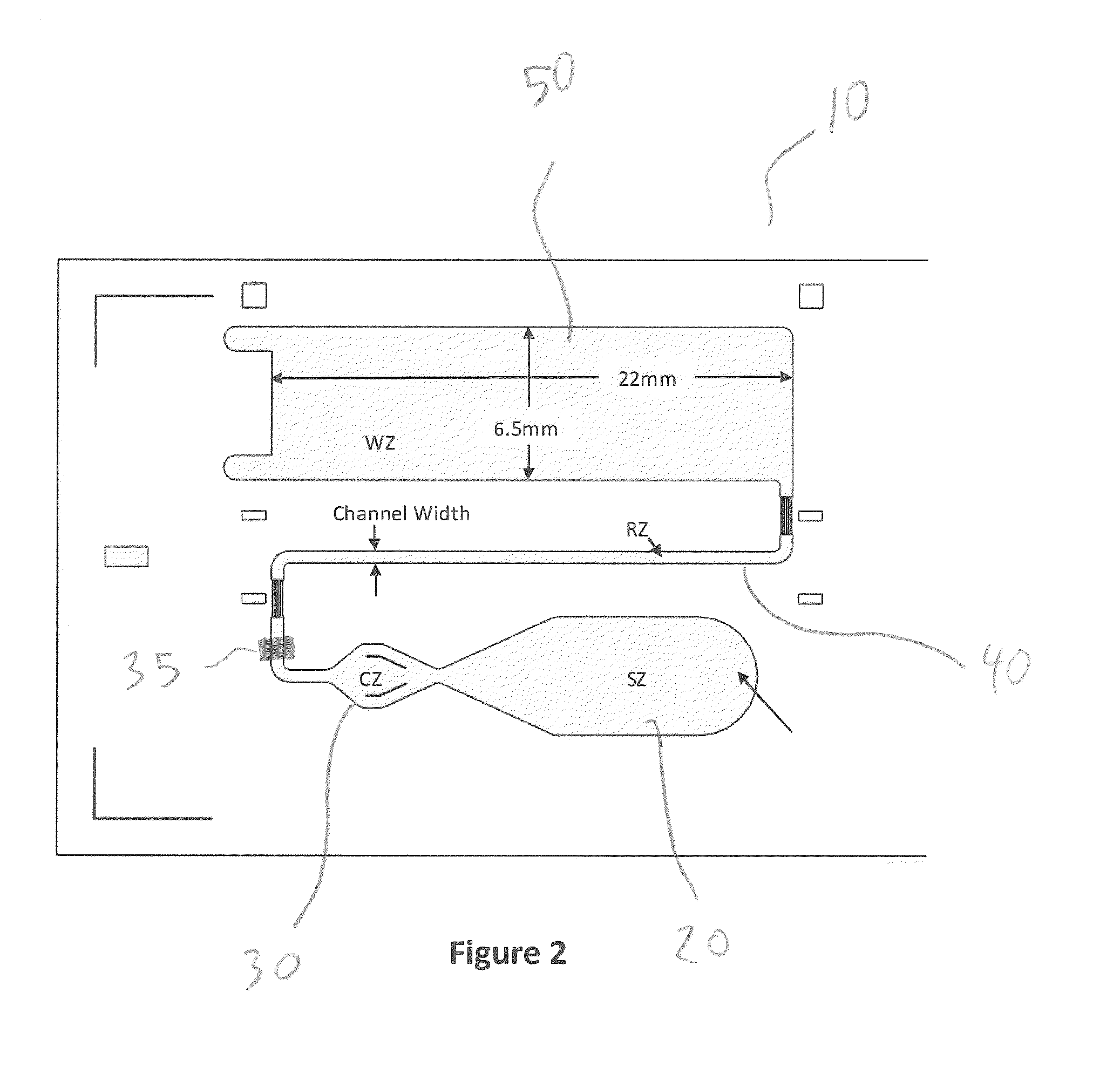

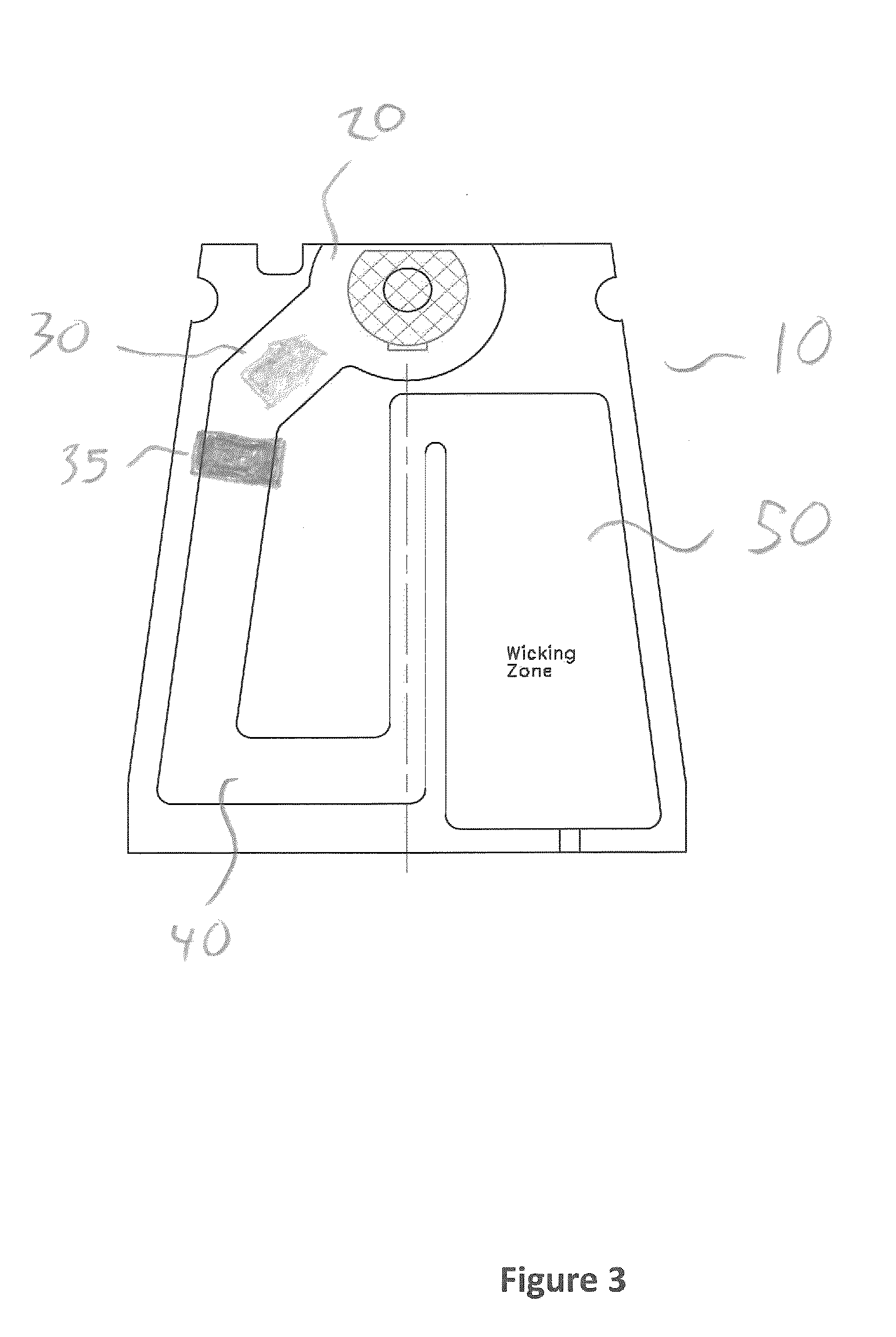

Assay Device Having Uniform Flow Around Corners

ActiveUS20130189796A1Reduce problemFacilitated reaction kineticsComponent separationWithdrawing sample devicesChemistrySubstrate surface

An assay device includes: a liquid sample zone; a reagent zone downstream and in fluid communication with the sample zone containing a reagent material; a detection zone in fluid communication with the reagent zone having capture elements bound thereto; and a wicking zone in fluid communication with the capture zone having a capacity to receive liquid sample flowing from the detection zone. The sample receiving zone, the reagent zone, the detection zone and the wicking zone define a fluid flow path and at least a part of the fluid flow path has a substrate and projections which extend substantially vertically from the substrate, wherein the projections have a height, cross-section and a distance between one another that defines a space between the projections capable of generating capillary flow parallel to the substrate surface. In addition, the fluid flow path having projections includes a corner section which changes the direction of the flow path. The projections in or around the corner section are modified to maintain the configuration of the flow front of the sample flowing through the flow path after the corner is substantially the same configuration as before the corner.

Owner:ORTHO-CLINICAL DIAGNOSTICS

Methods to prepare stable electrolytes for iron redox flow batteries

ActiveUS9865895B2Low costHigh recycling valueRegenerative fuel cellsIndirect fuel cellsChemical reactionOxidation-Reduction Agent

Owner:ESS TECHNOLOGY

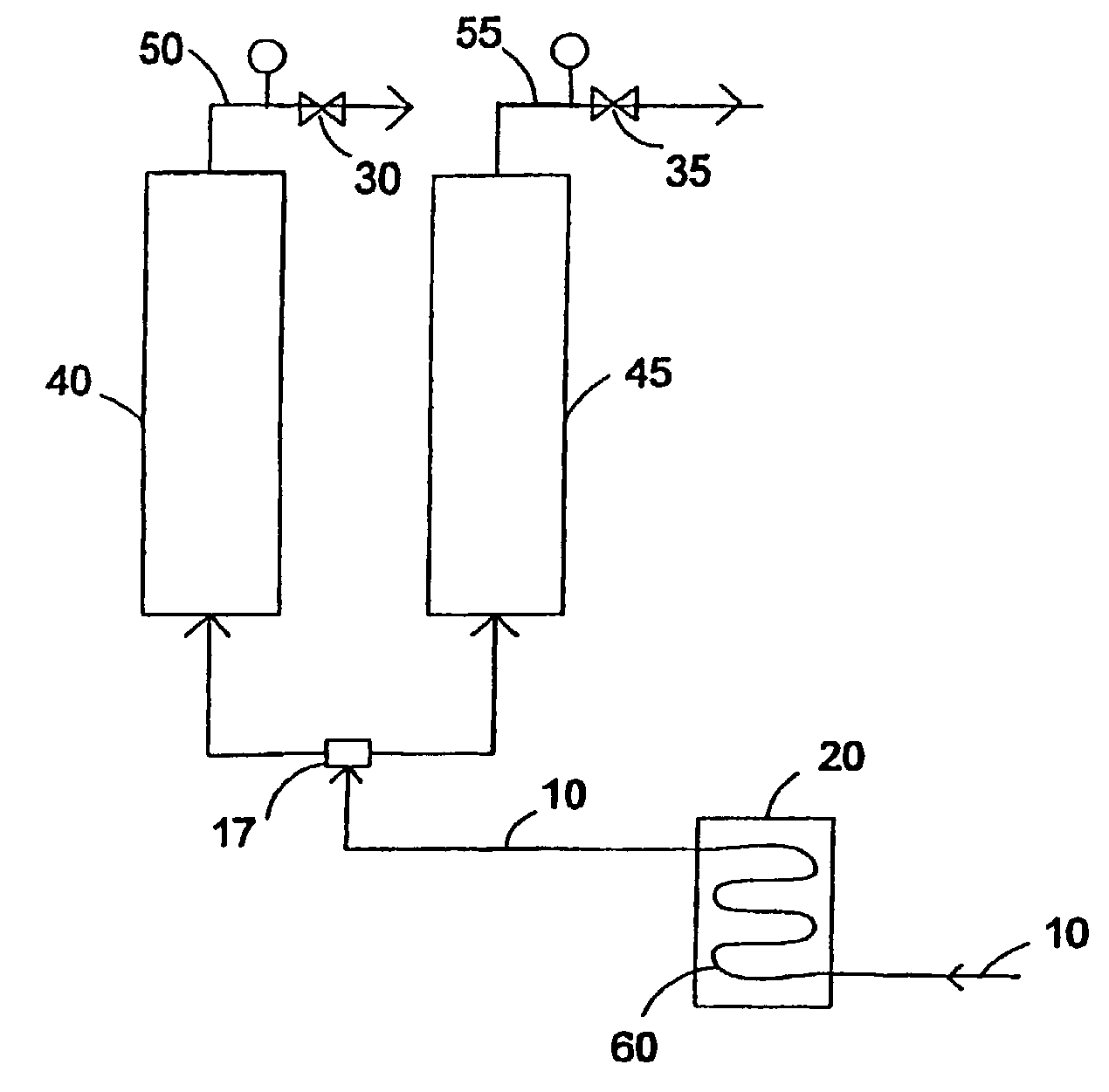

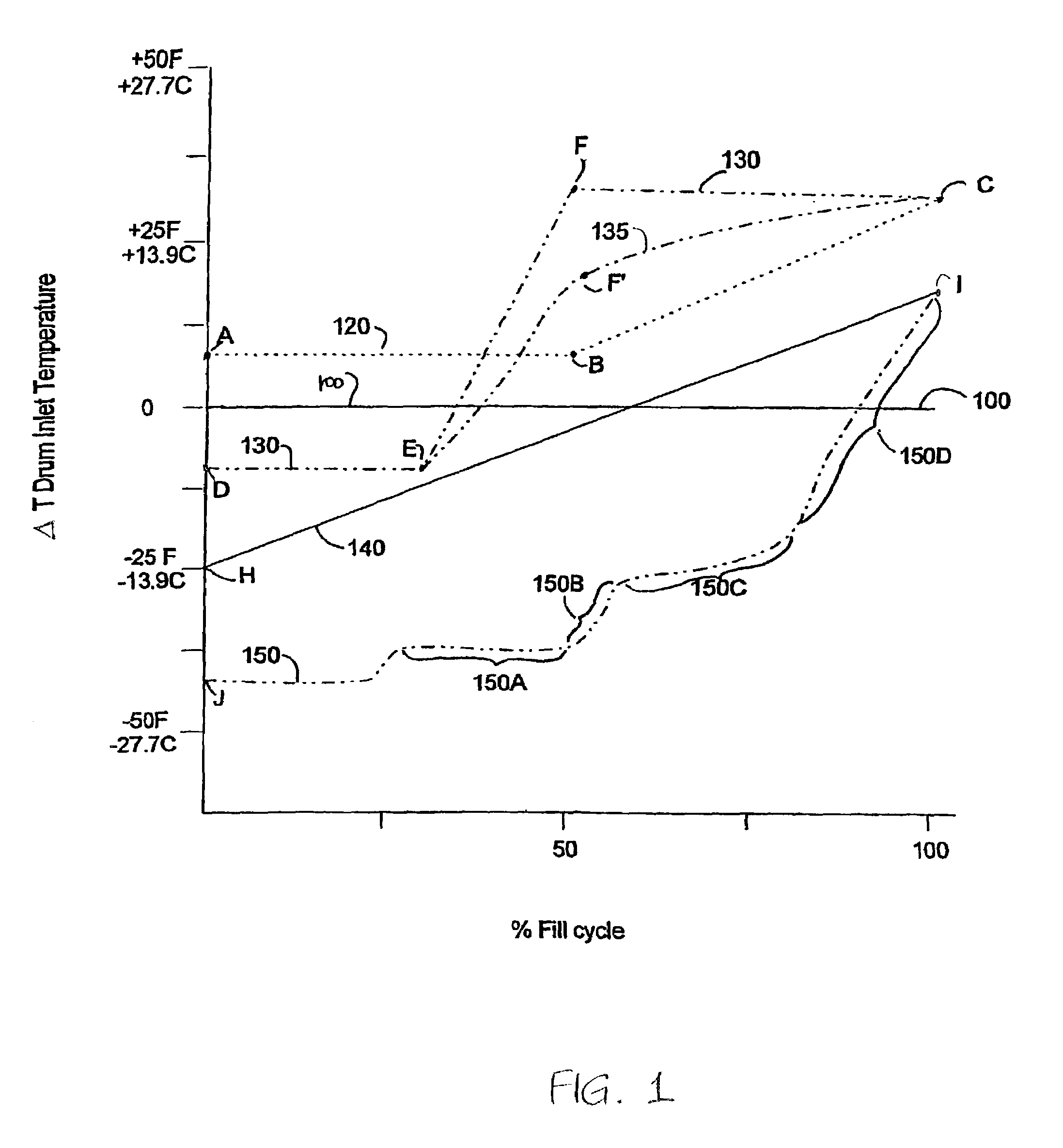

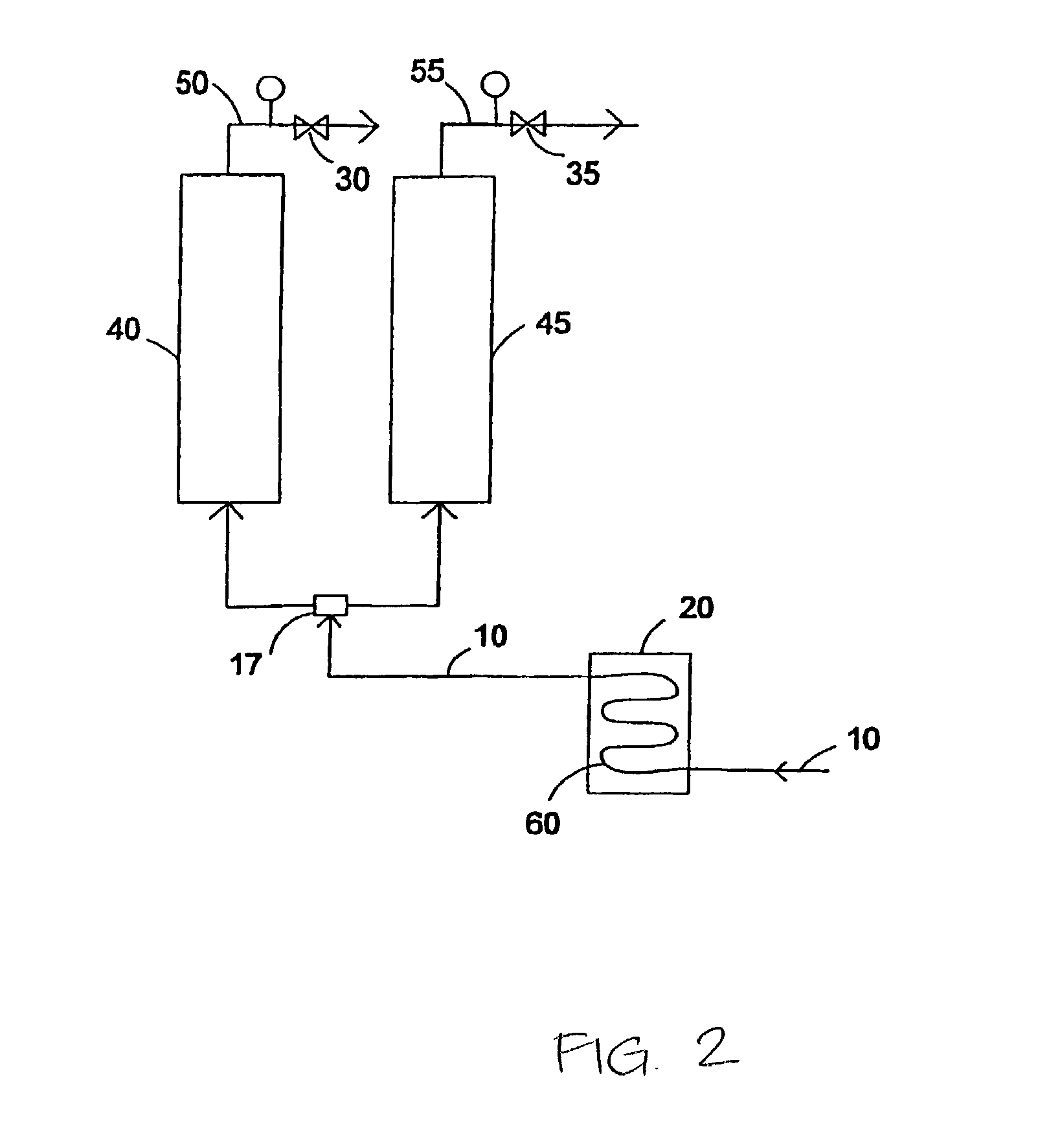

Process for producing coke

InactiveUS7371317B2Improve coke qualityImprove operationThermal non-catalytic crackingCoking carbonaceous materialsProcess engineeringInlet temperature

A delayed coking process for producing more uniform and higher quality coke by increasing the drum inlet temperature of the feedstock at least 2° F. during a fill cycle.

Owner:PHILLIPS 66 CO

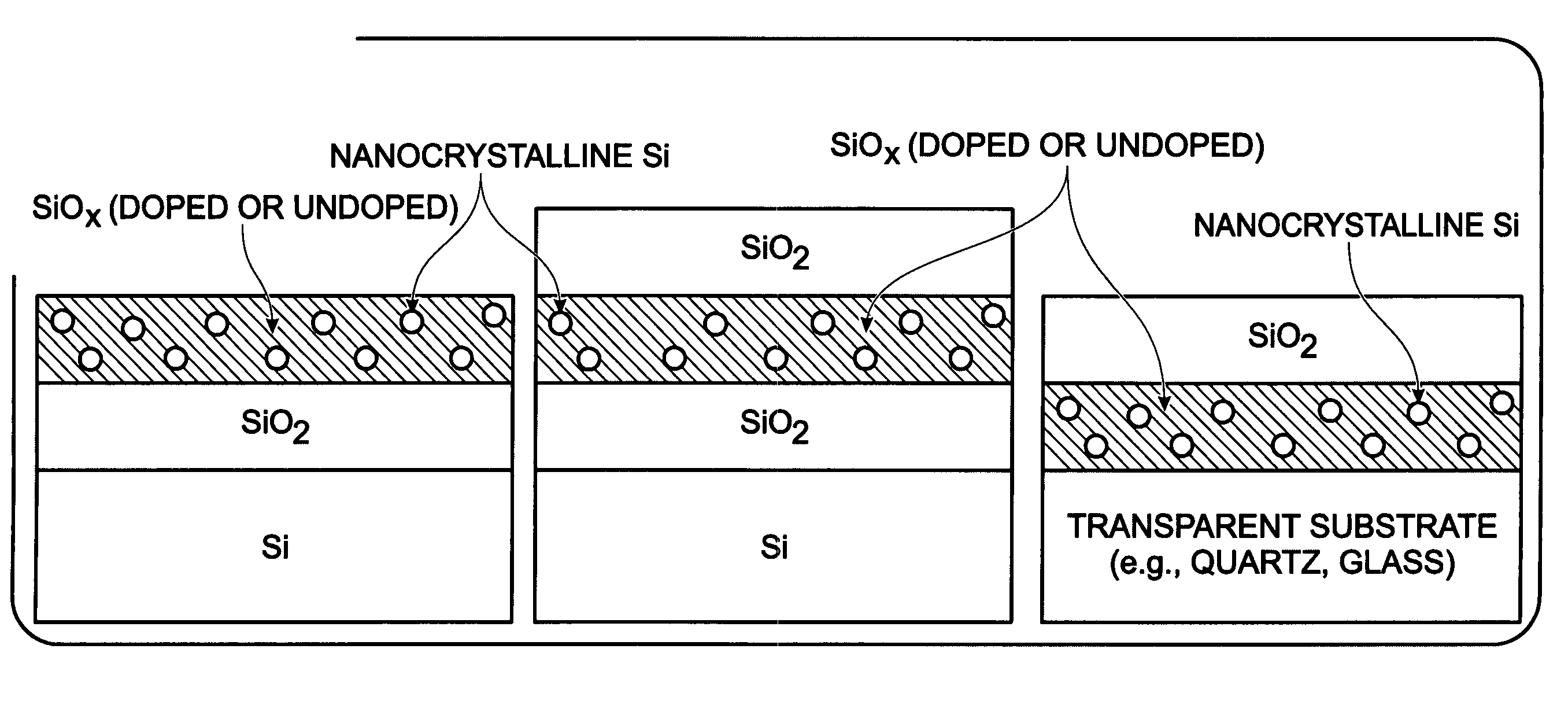

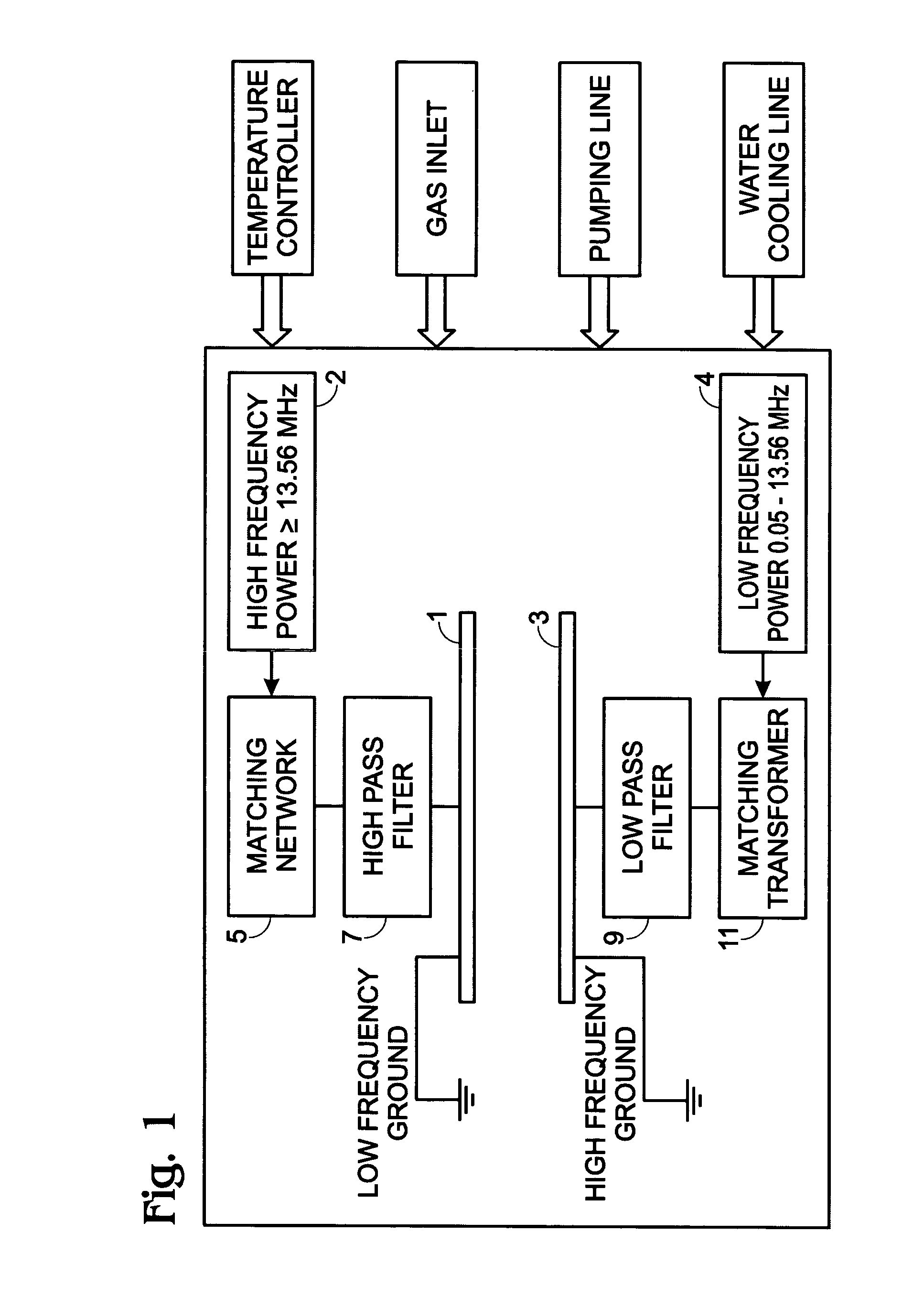

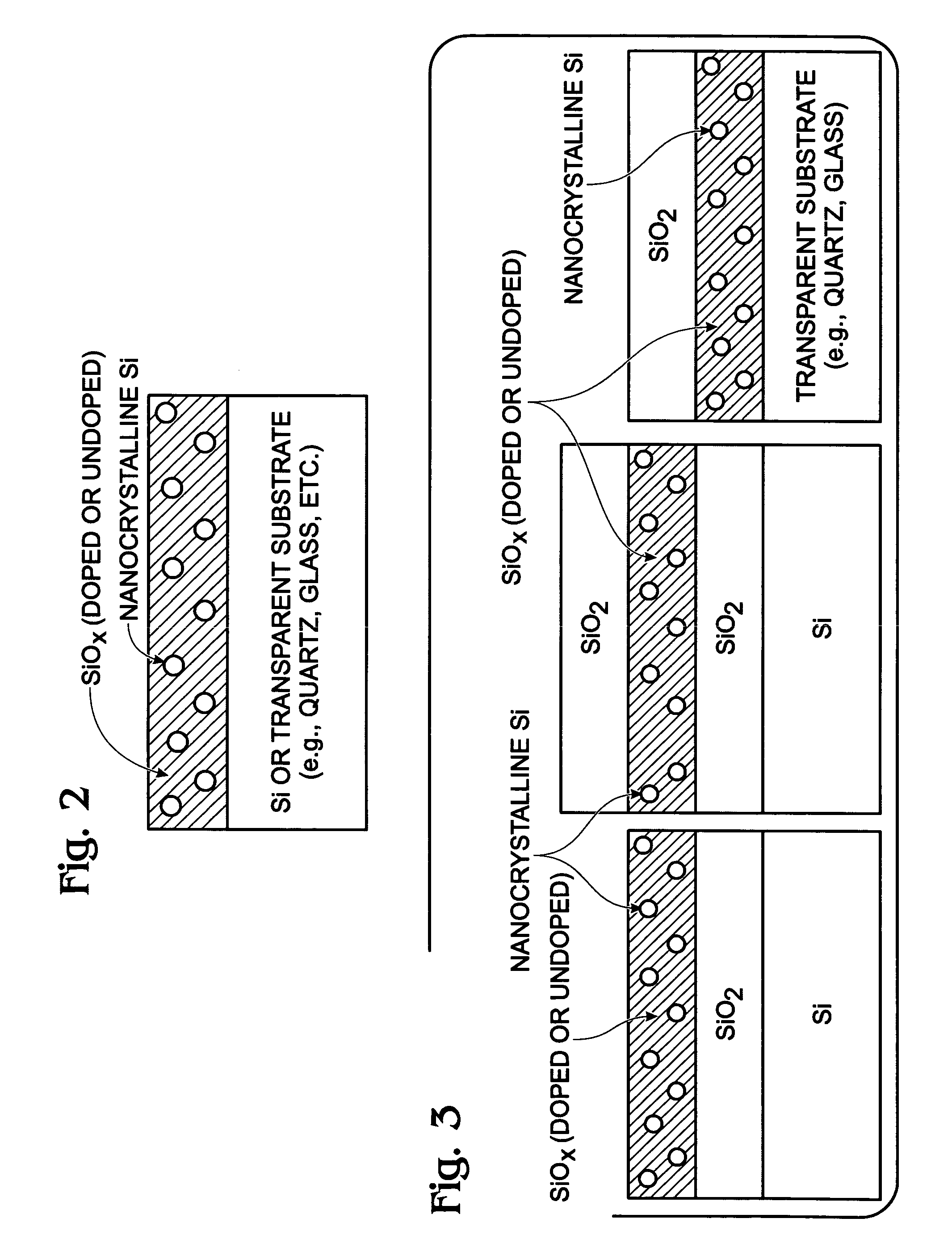

Silicon oxide thin-films with embedded nanocrystalline silicon

InactiveUS7544625B2Controlled microstructural and optical and electrical propertyFacilitated reaction kineticsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenHigh density

Owner:SHARP KK

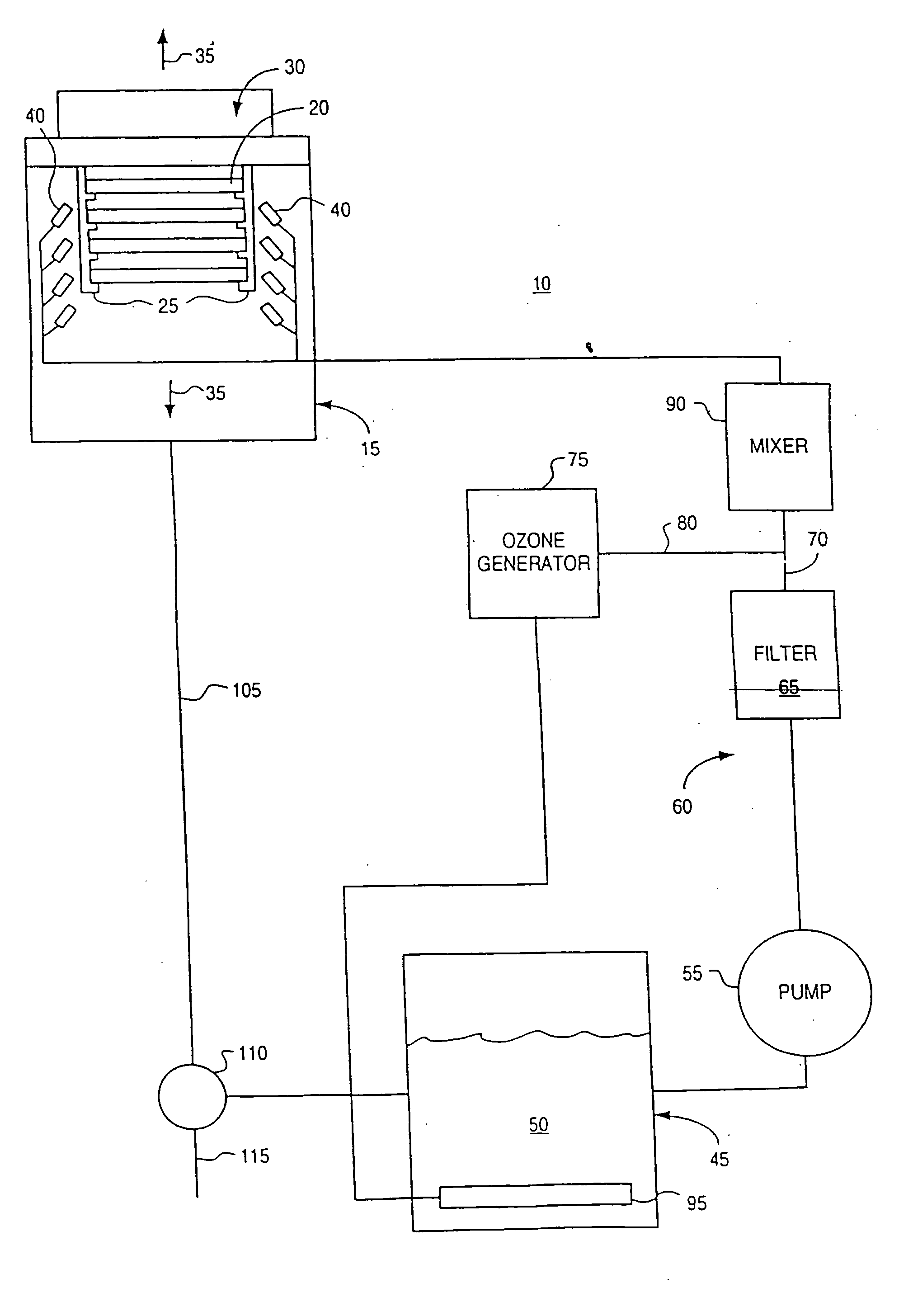

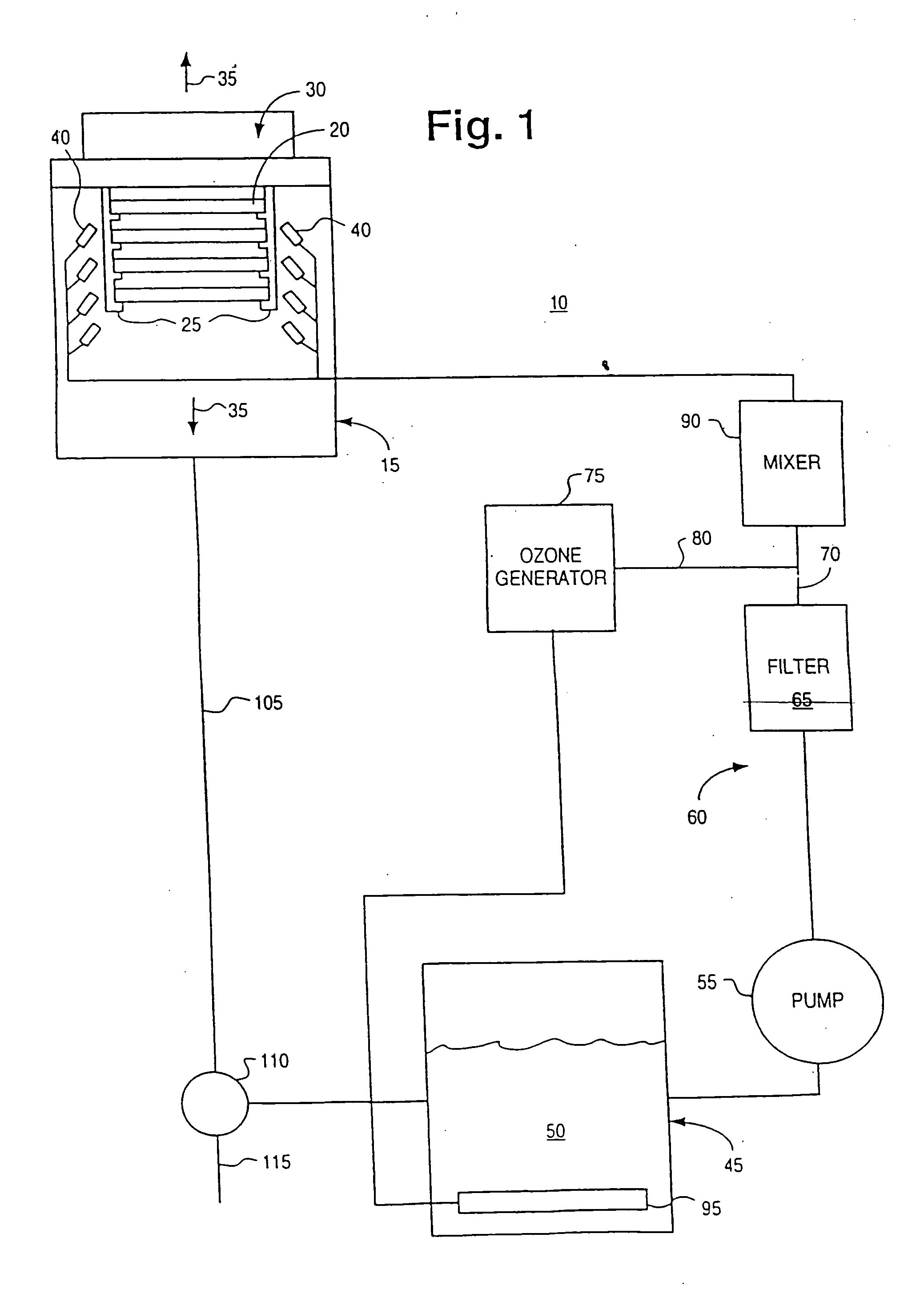

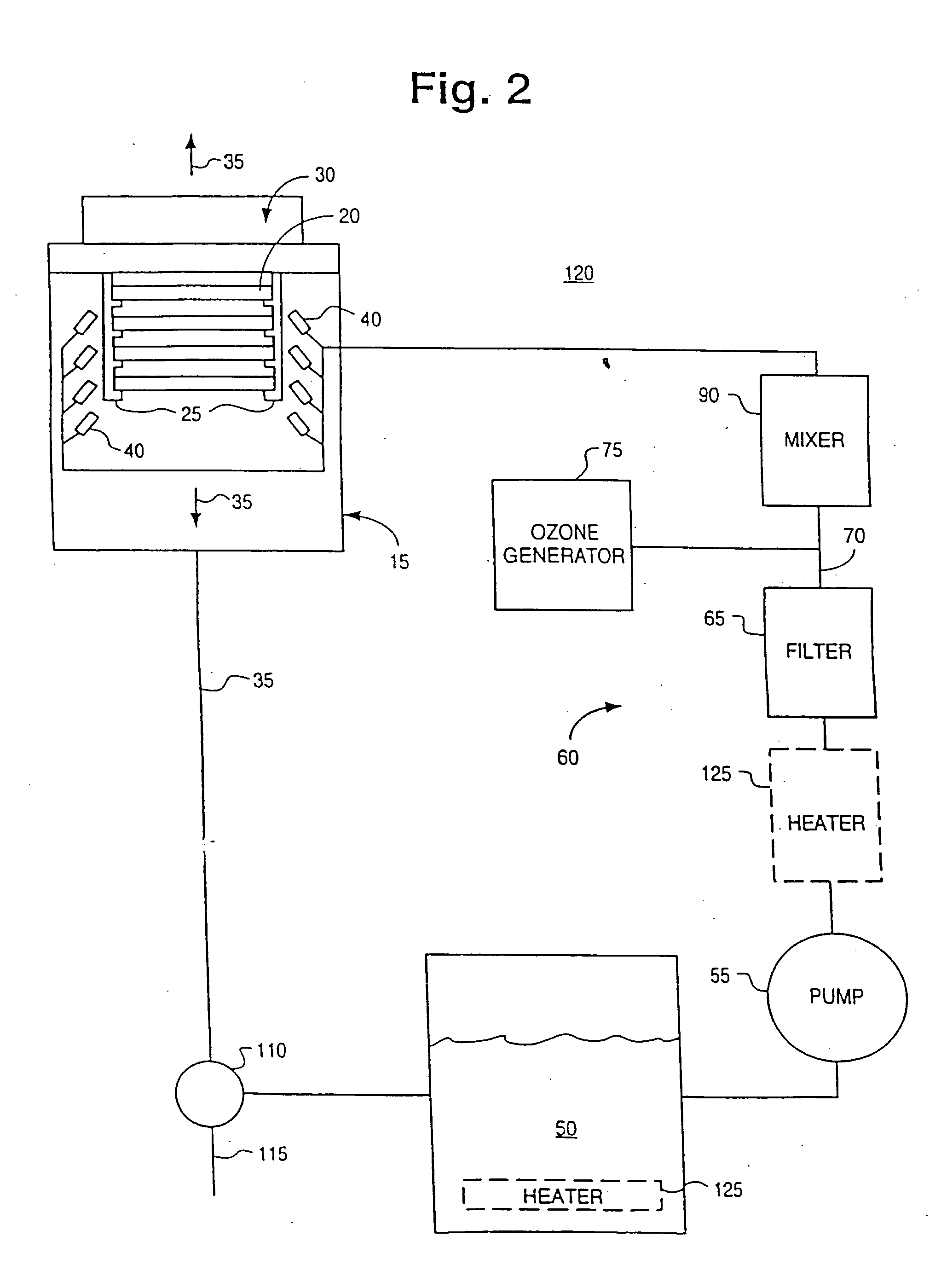

Process and apparatus for treating a workpiece

InactiveUS20050072446A1Temperature stabilityReduce pollutionLighting and heating apparatusSemiconductor/solid-state device manufacturingOzone generatorCompound (substance)

A novel chemistry, system and application technique reduces contamination of semiconductor wafers and similar substrates and enhances and expedites processing. A stream of liquid chemical is applied to the workpiece surface. Ozone is delivered either into the liquid process stream or into the process environment. The ozone is preferably generated by a high capacity ozone generator. The chemical stream is provided in the form of a liquid or vapor. A boundary layer of liquid or vapor forms on the workpiece surface. The thickness of the boundary layer is controlled. The chemical stream may include ammonium hydroxide for simultaneous particle and organic removal, another chemical to raise the pH of the solution, or other chemical additives designed to accomplish one or more specific cleaning steps.

Owner:BERGMAN ERIC J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com