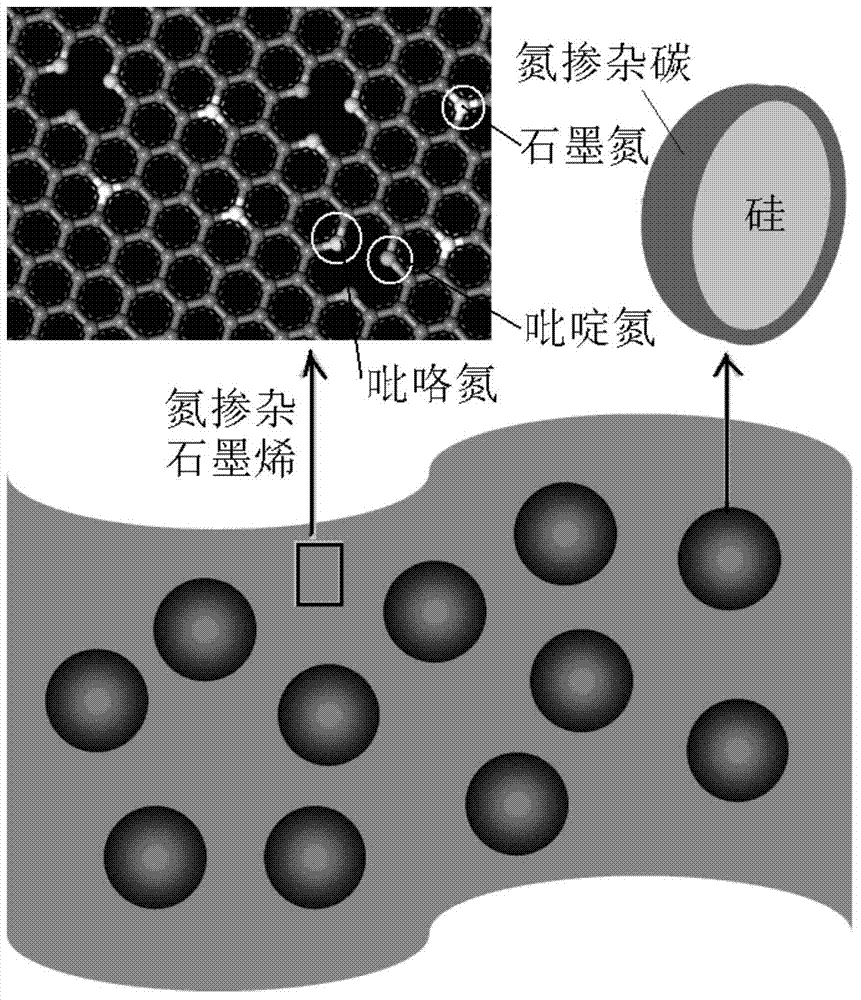

Silicon-nitrogen doped carbon-nitrogen doped graphene composite material, and preparation method and application thereof

A technology of nitrogen-doped graphene and nitrogen-doped carbon, applied in electrical components, electrochemical generators, battery electrodes, etc., to achieve excellent electrochemical performance, suppress volume change, and improve electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

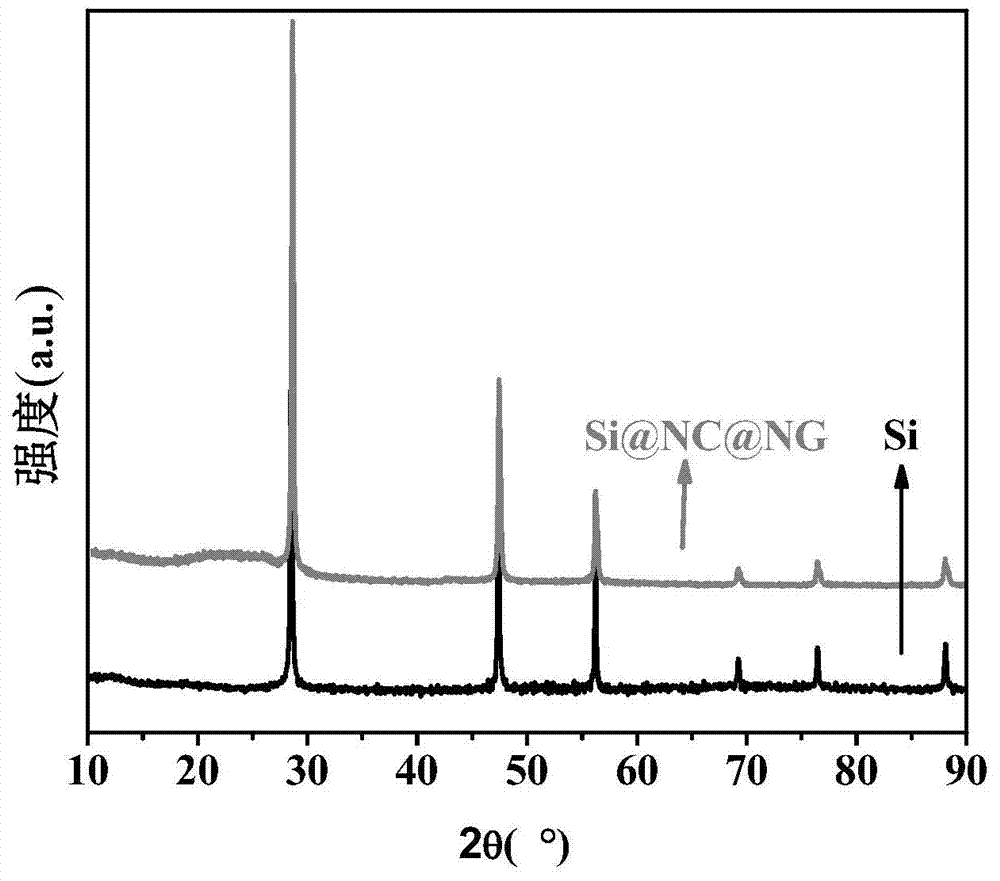

[0028] Embodiment 1, silicon-nitrogen-doped carbon-nitrogen-doped graphene composite material, wherein the mass ratio of graphene oxide: nitrogen-containing carbon source: silicon is 1:2:3, and its preparation steps are as follows:

[0029] 1) Disperse 0.3g of silicon powder in 100mL of water and ultrasonically treat it for 1 hour to obtain an aqueous dispersion of silicon;

[0030] 2) Dissolve 0.2g of glucosamine in 20mL of water to obtain a glucosamine solution;

[0031] 3) Add the glucosamine solution to the aqueous silicon dispersion, stir at room temperature for 6 hours, and ultrasonically for 30 minutes to obtain a mixed solution A for use;

[0032] 4) Prepare a graphene oxide aqueous dispersion with a concentration of 1 mg / mL with deionized water, take 100 mL of graphene oxide aqueous dispersion for ultrasonic dispersion for 1 hour, and add the graphene oxide aqueous dispersion to the mixed solution during ultrasonic dispersion In A, continue to sonicate for 1 hour and...

Embodiment 2

[0037] Embodiment 2, silicon-nitrogen-doped carbon-nitrogen-doped graphene composite material, wherein the mass ratio of graphene oxide: nitrogen-containing carbon source: silicon is 1:2:4, and its preparation steps are as follows:

[0038] Step 1) Disperse 0.4g of silicon powder in 200mL of water, and ultrasonically treat it for 1 hour to obtain an aqueous dispersion of silicon;

[0039] Step 2) dissolving 0.2g glucosamine into 20mL water to obtain a glucosamine solution;

[0040] Steps 3) to 6) are the same as in Example 1.

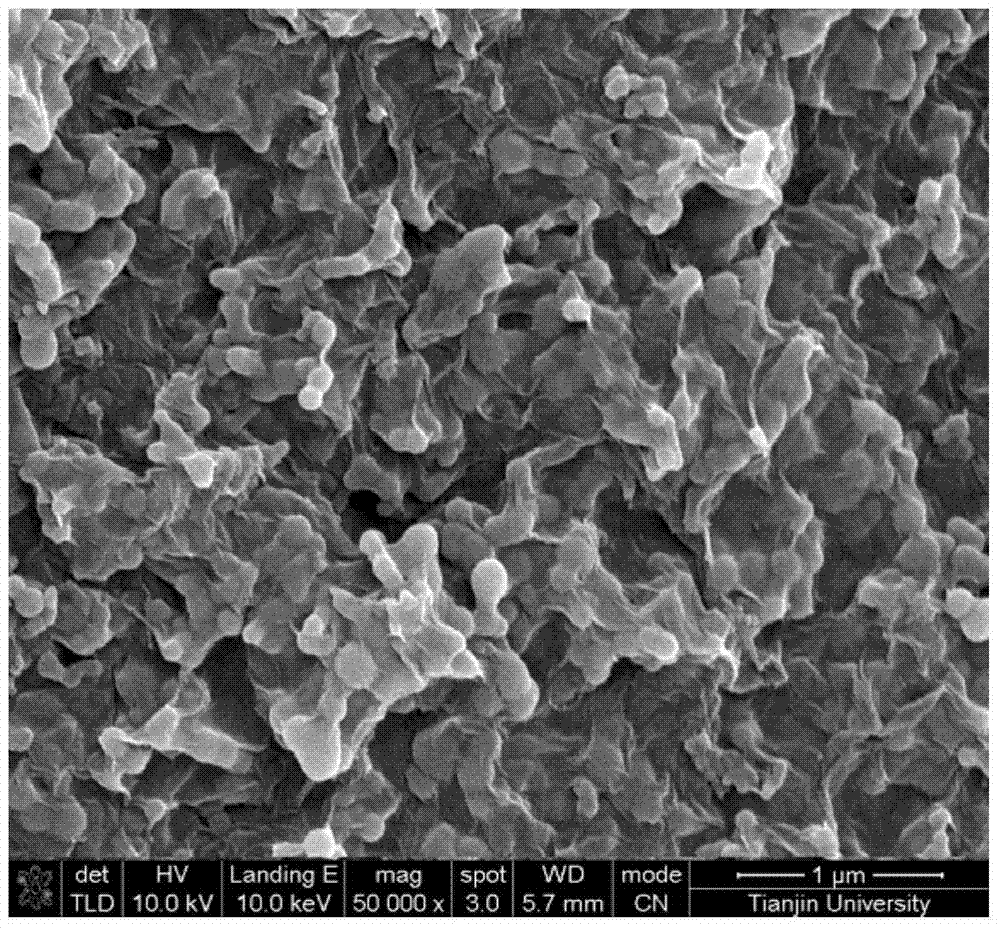

[0041] (a) and (b) in Fig. 7 show the transmission electron microscope picture of the silicon-nitrogen-doped carbon-nitrogen-doped graphene composite material that present embodiment 2 prepares, and (b) is (a) partial enlarged view, It can be seen from FIG. 7( b ) that the thickness of the carbon layer on the surface of the silicon particles in the composite material prepared in Example 2 is about 6 nm.

Embodiment 3

[0042] Embodiment 3, silicon-nitrogen-doped carbon-nitrogen-doped graphene composite material, wherein the mass ratio of graphene oxide: nitrogen-containing carbon source: silicon is 1:2:6, and its preparation steps are as follows:

[0043] Step 1) Disperse 0.6g of silicon powder in 100mL of water, and ultrasonically treat it for 1 hour to obtain an aqueous dispersion of silicon;

[0044] Step 2) Dissolving 0.2g of glucosamine into 20mL of water to obtain a glucosamine solution;

[0045] Steps 3) to 6) are the same as in Example 1.

[0046] (a) and (b) in Fig. 8 show the transmission electron microscope picture of the silicon-nitrogen-doped carbon-nitrogen-doped graphene composite material that embodiment 3 prepares, and (b) is (a) partial enlarged view, It can be seen from FIG. 8( b ) that the thickness of the carbon layer on the surface of the silicon particles in the composite material prepared in Example 3 is about 3 nm.

[0047] Through the transmission electron microsc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com