Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce slurry viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite materials and methods of making the same

InactiveUS20090169867A1Reduce slurry viscosityLow viscosityProtein adhesivesFibre treatmentEmulsionFormaldehyde free

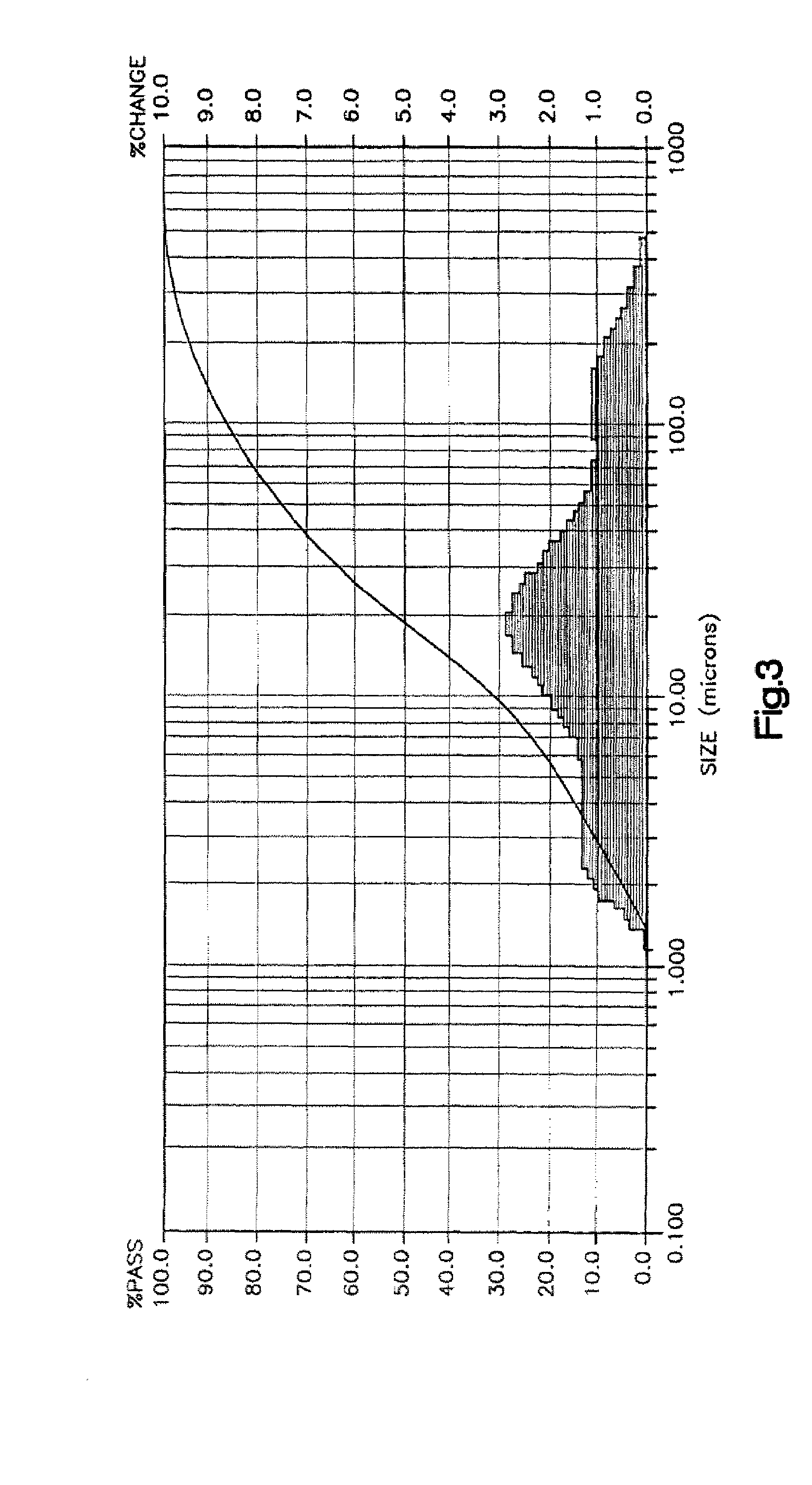

The present invention provides composite materials that contain formaldehyde-free aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size and polymer particles of at least one emulsion (co)polymer. Preferably, the defatted soy flour is present as an aqueous dispersion, or is in denatured form. Also provided are methods of making and using composite materials containing the formaldehyde-free binder compositions.

Owner:ROHM & HAAS CO

Soy composite materials comprising a reducing sugar and methods of making the same

InactiveUS20100129640A1Reduce slurry viscosityLow viscosityLayered productsPretreated surfacesEmulsionSoy flour

The present invention provides composite materials derived from formaldehyde-free aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size, polymer particles of at least one emulsion (co)polymer, and one or more reducing sugar. Also provided are methods of making and using composite materials containing the formaldehyde-free binder compositions.

Owner:ROHM & HAAS CO

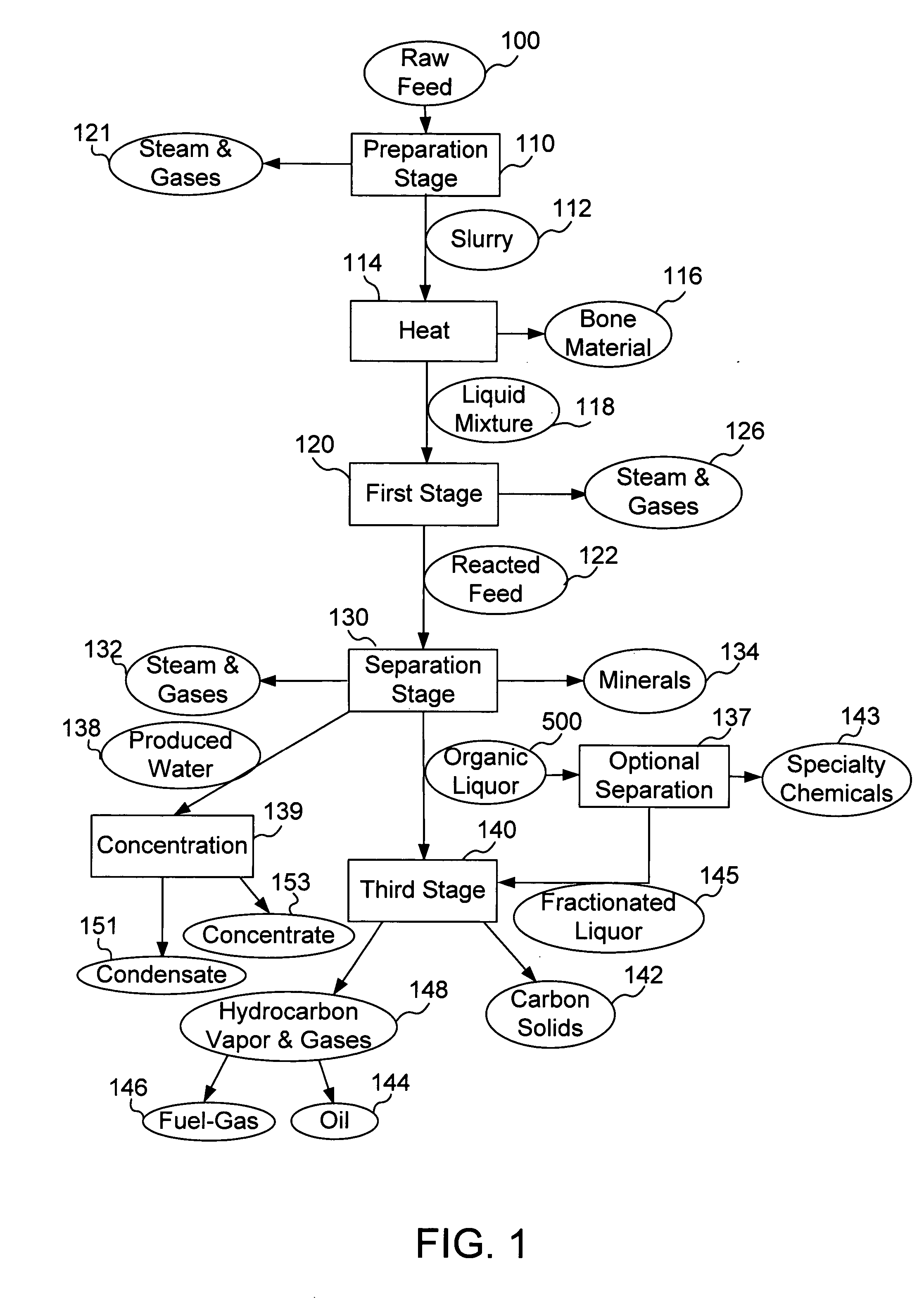

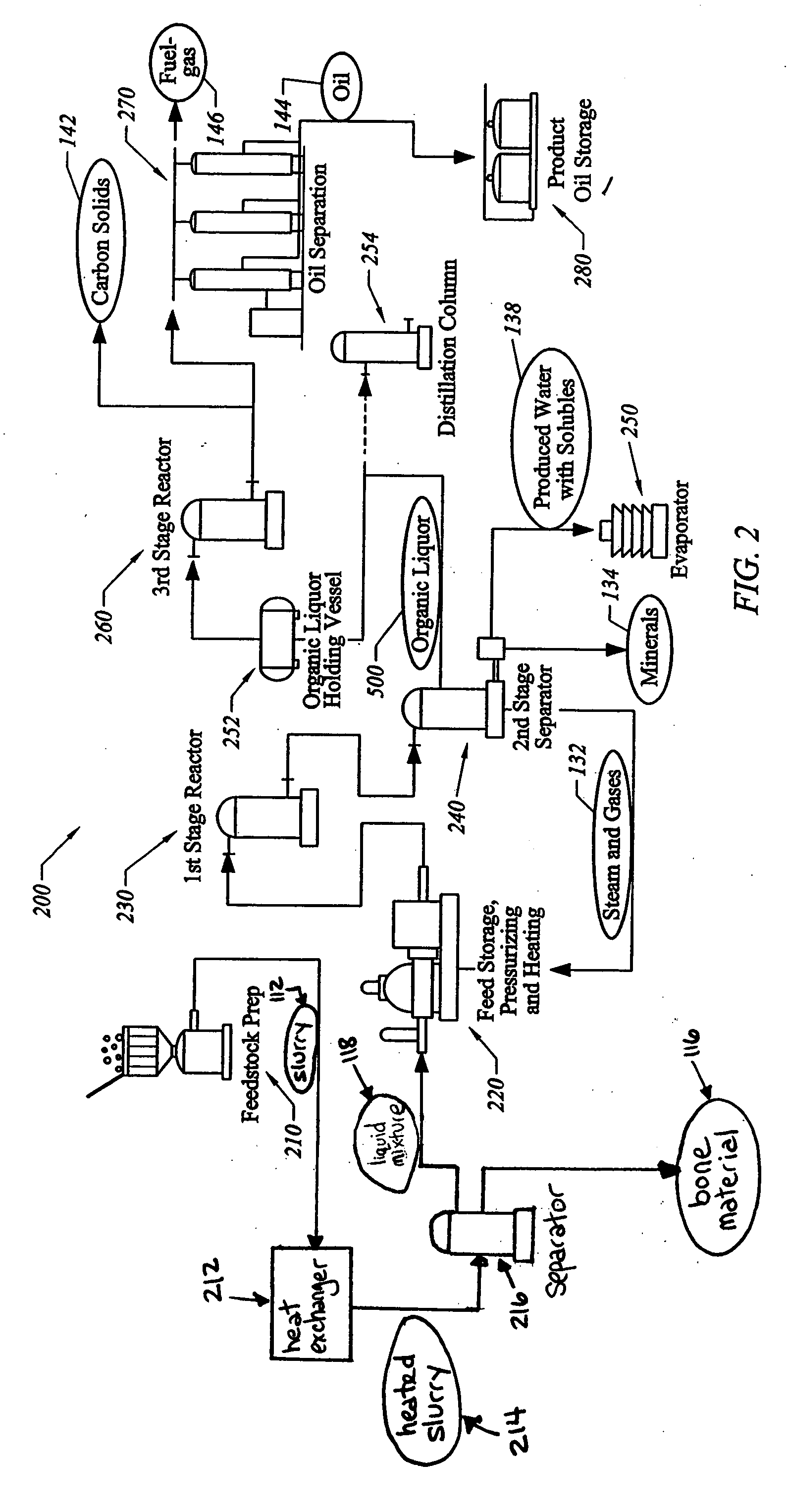

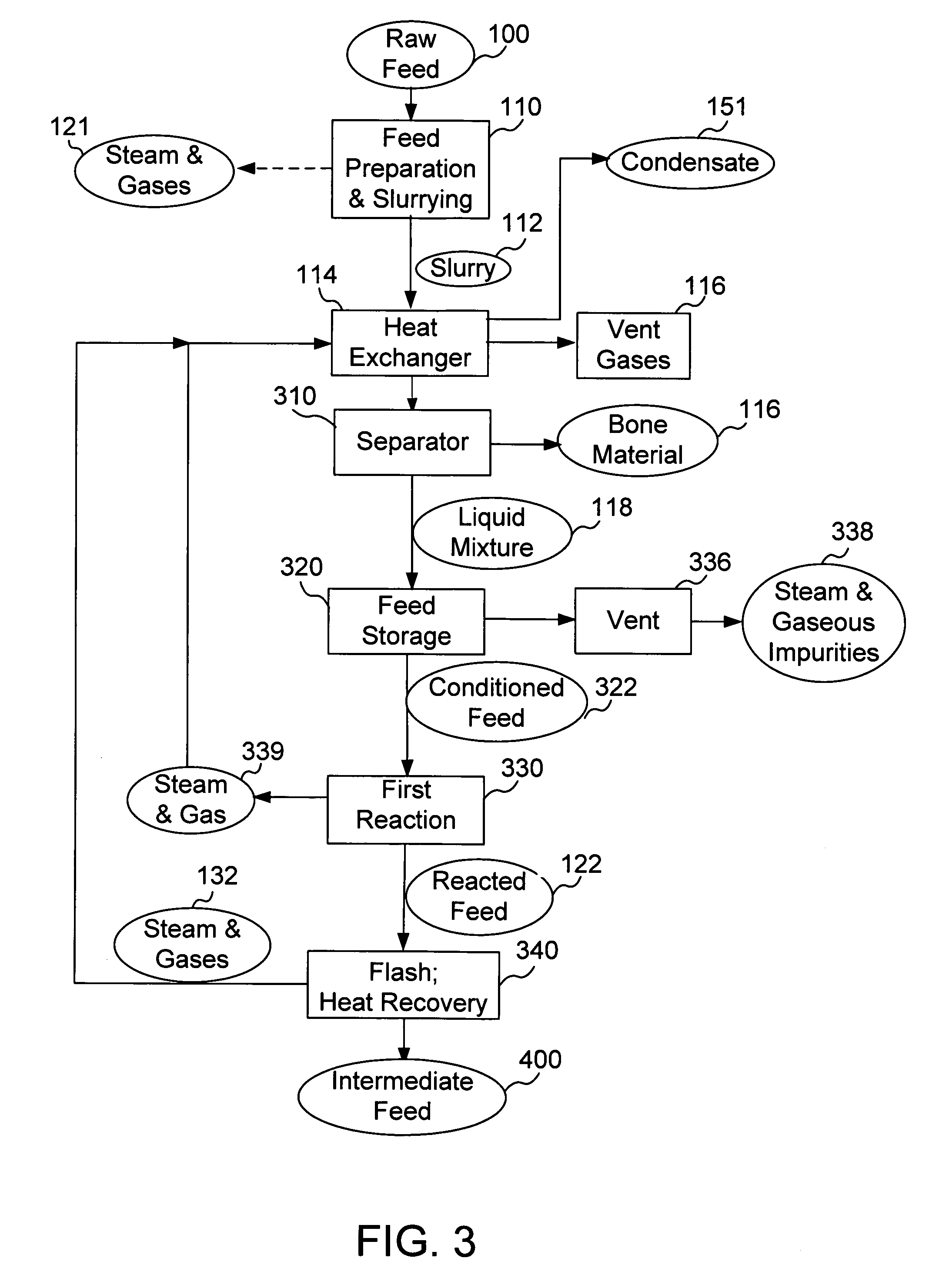

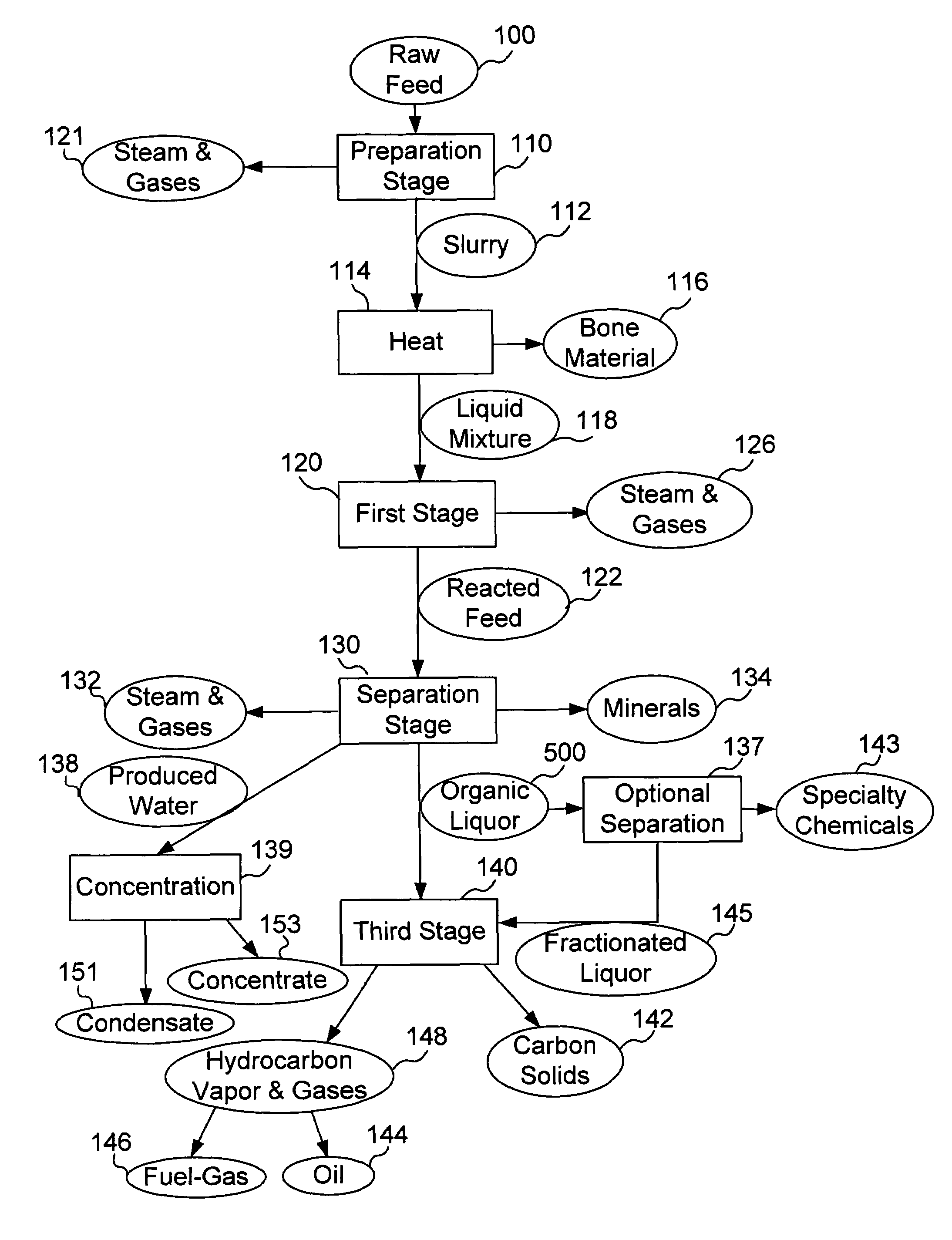

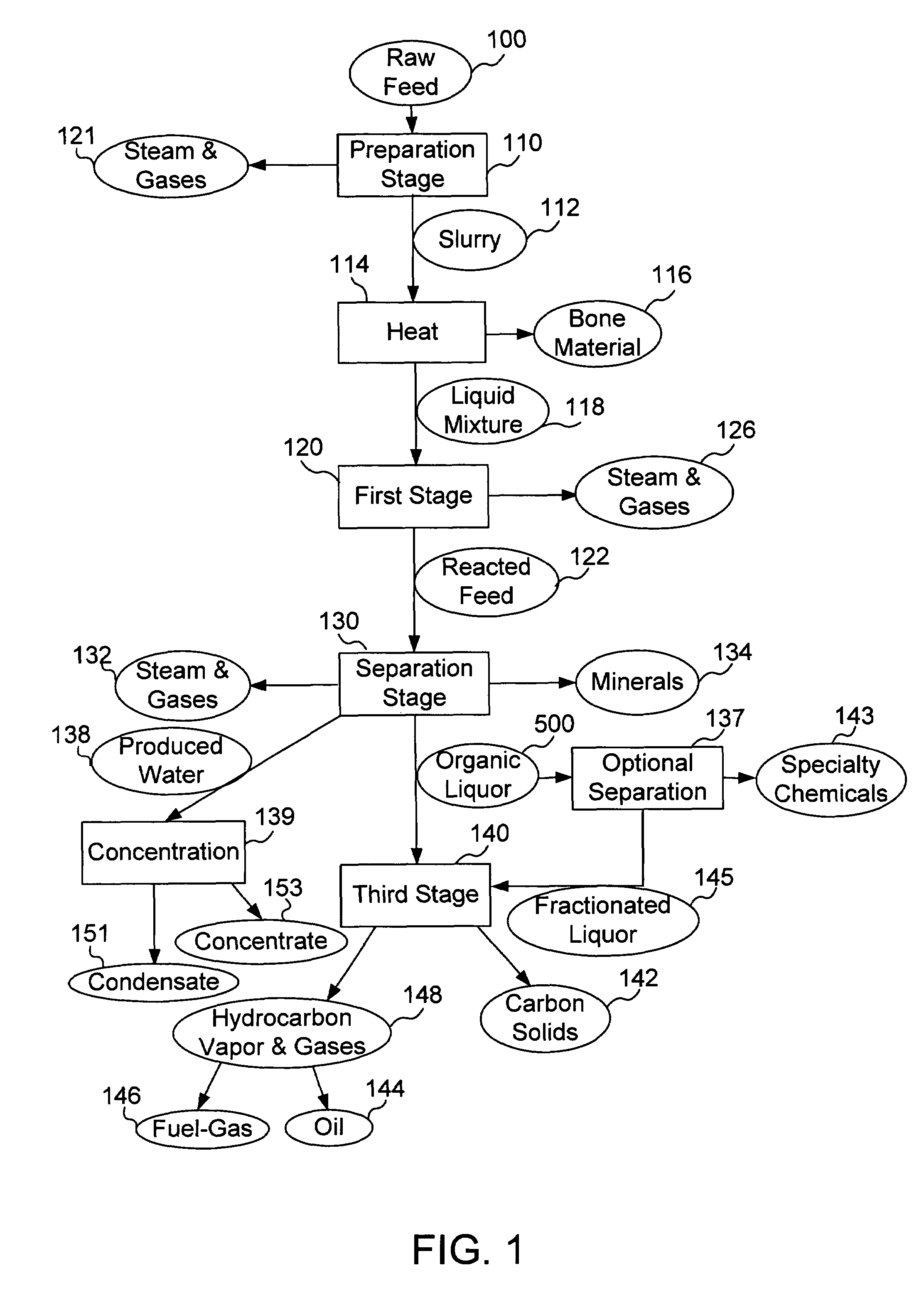

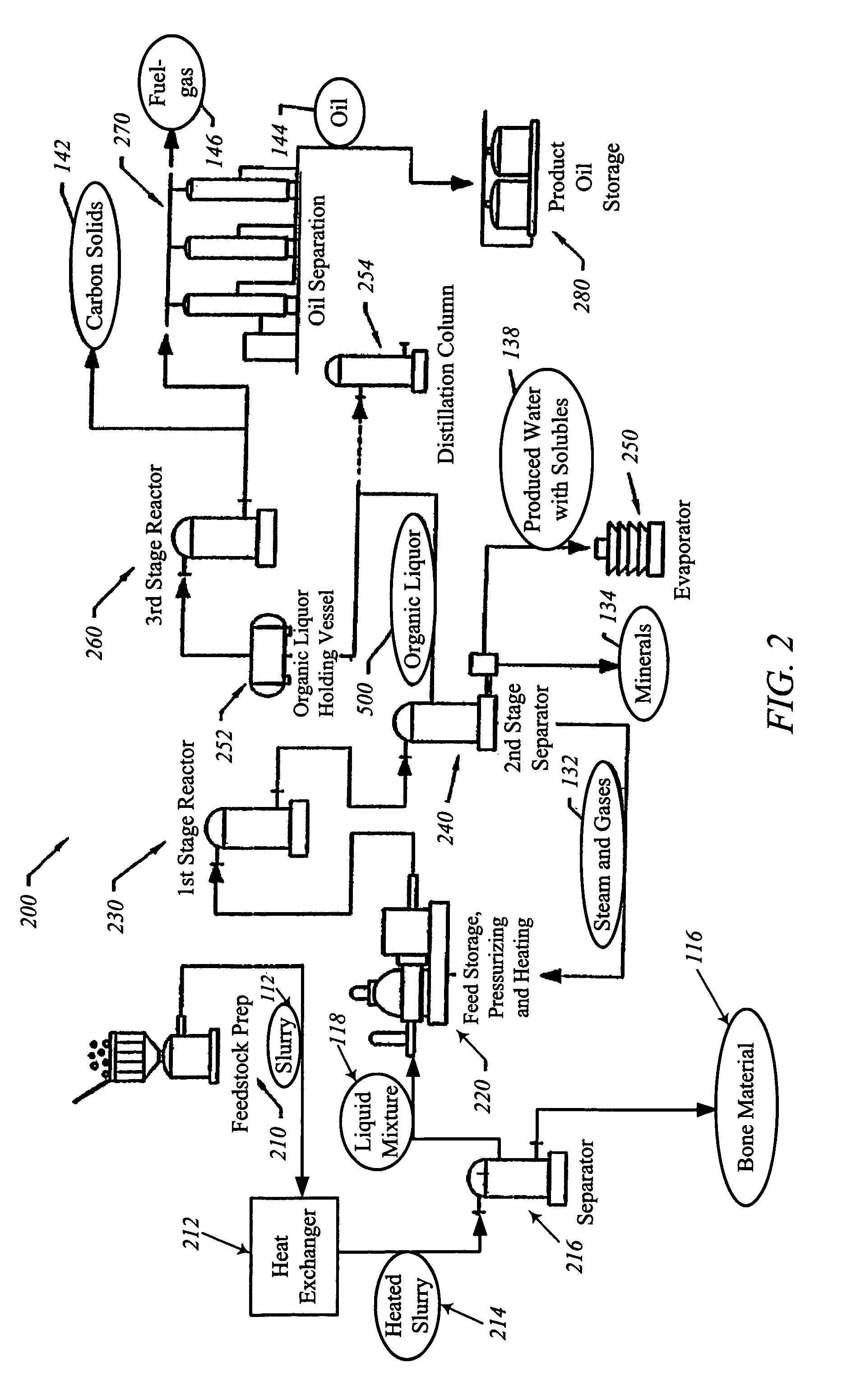

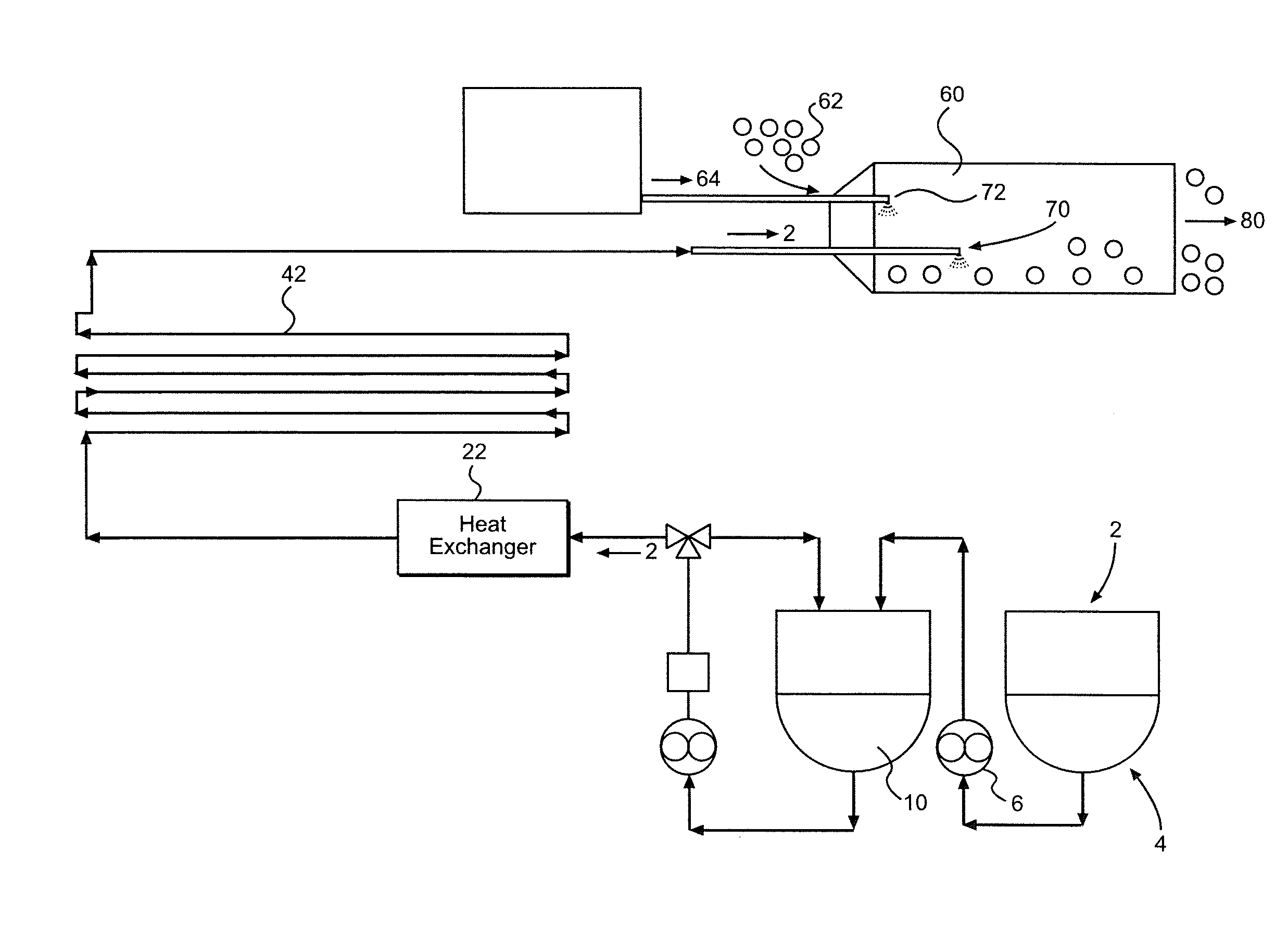

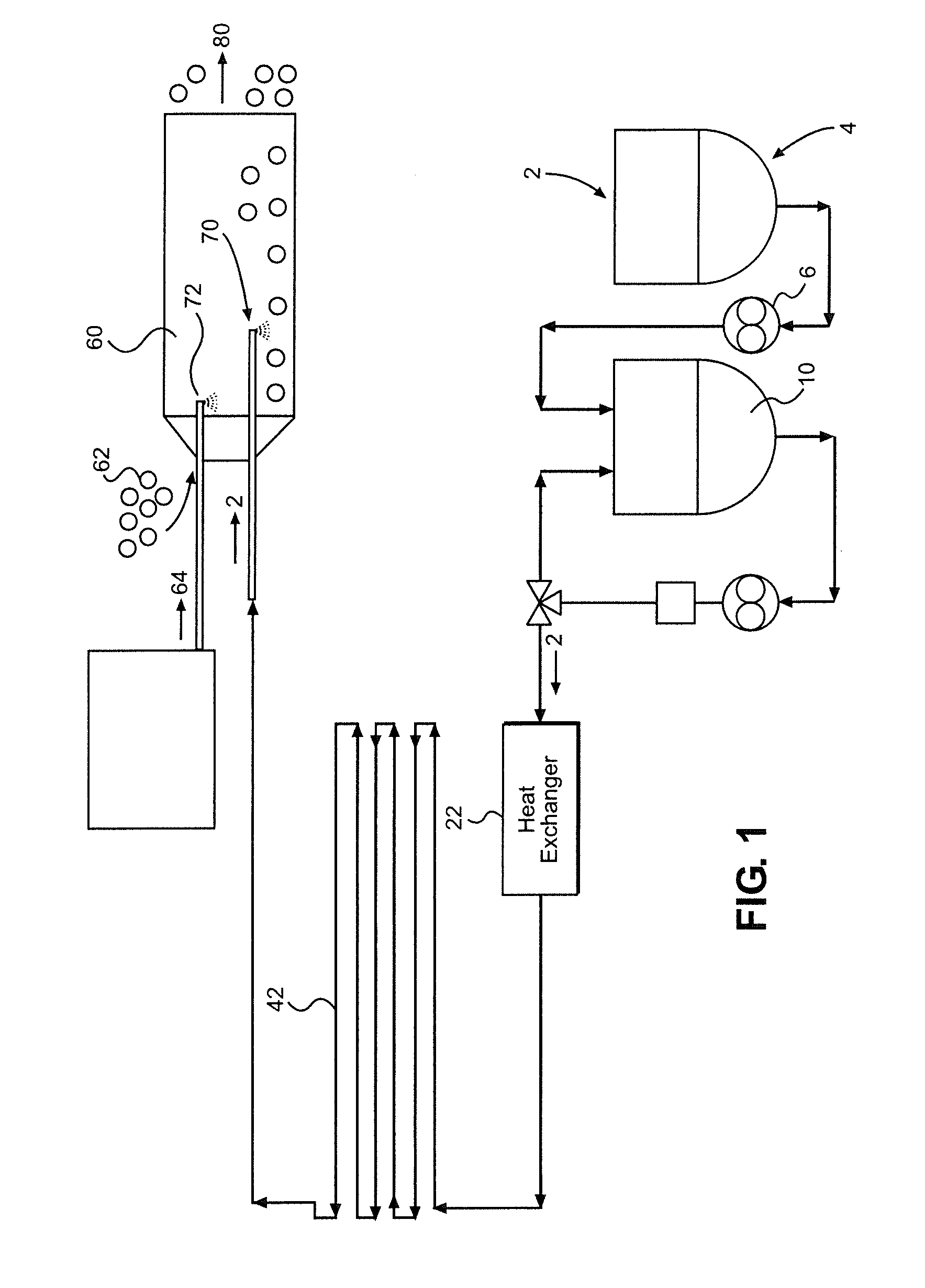

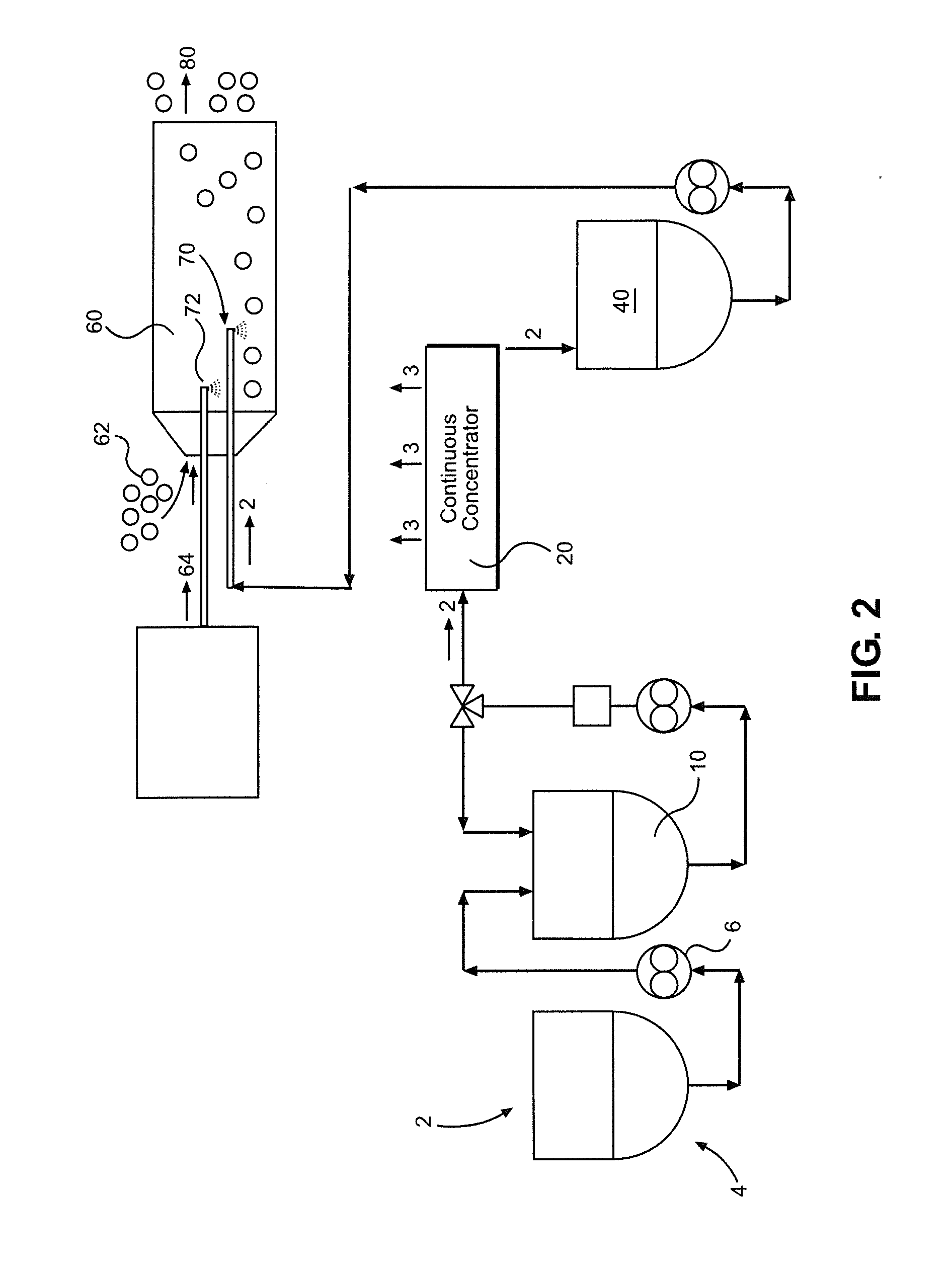

Apparatus and process for separation of organic materials from attached insoluble solids, and conversion into useful products

InactiveUS20050113611A1Efficient removalReduce slurry viscosityMechanical conveying coke ovensSolid waste disposalHigh energyWaste product

The present invention addresses the processing of waste and low-value products that contain bone material to produce useful materials in reliable purities and compositions, at acceptable cost, and with high energy efficiency. In particular, the invention comprises a process that converts various feedstocks such as offal, animal manures, and municipal sewage sludge, to useful materials including gas, oil, specialty chemicals, and carbon solids. The process heats the feedstock in order to breakdown proteins and separate organic material from bone material, applies further heat and pressure to the resulting liquid mixture, separates out various components, then further applies heat and pressure to one or more of those components. The invention further comprises an apparatus for performing a process of converting waste products into useful materials, and an oil product that arises from the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

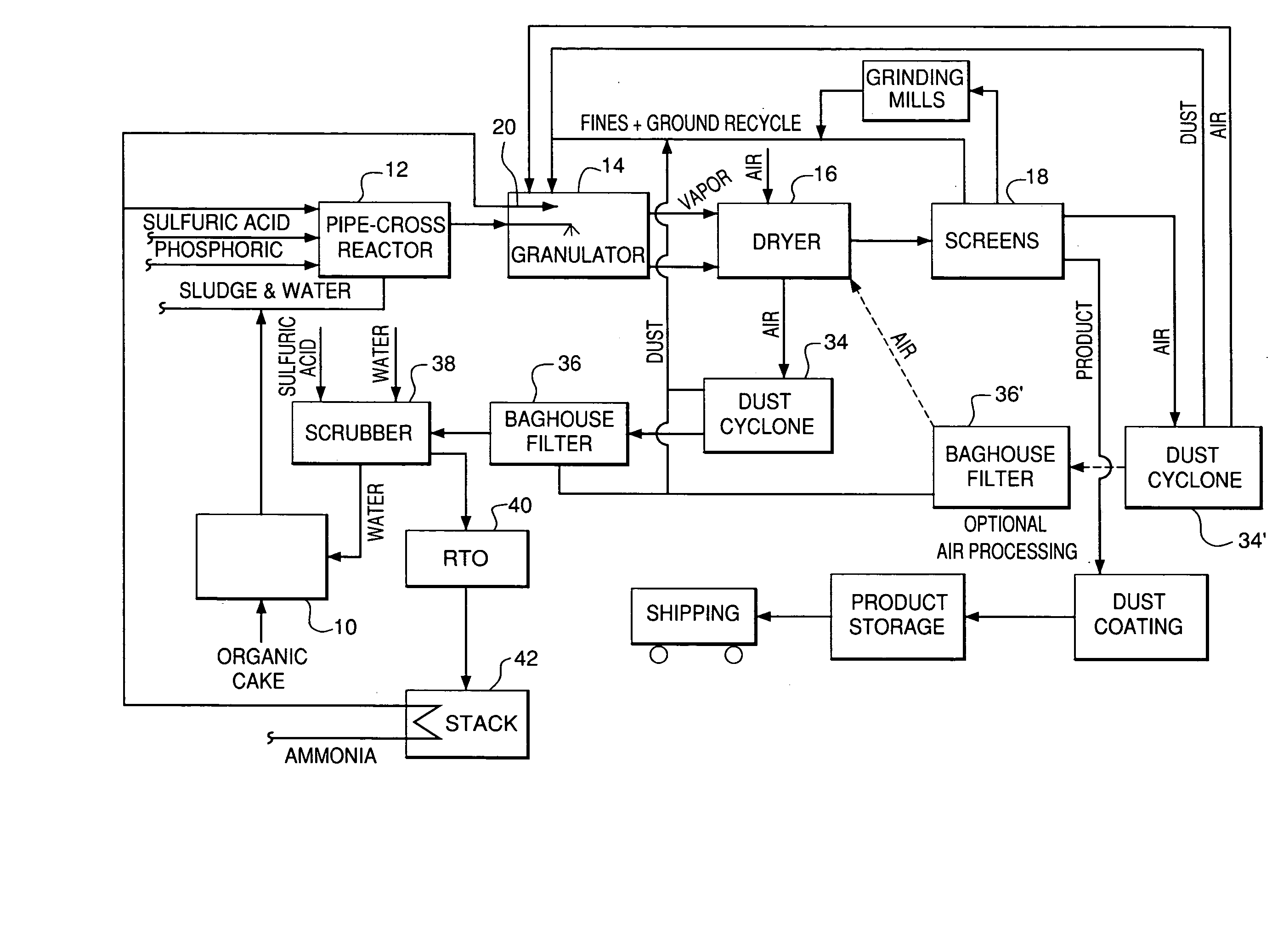

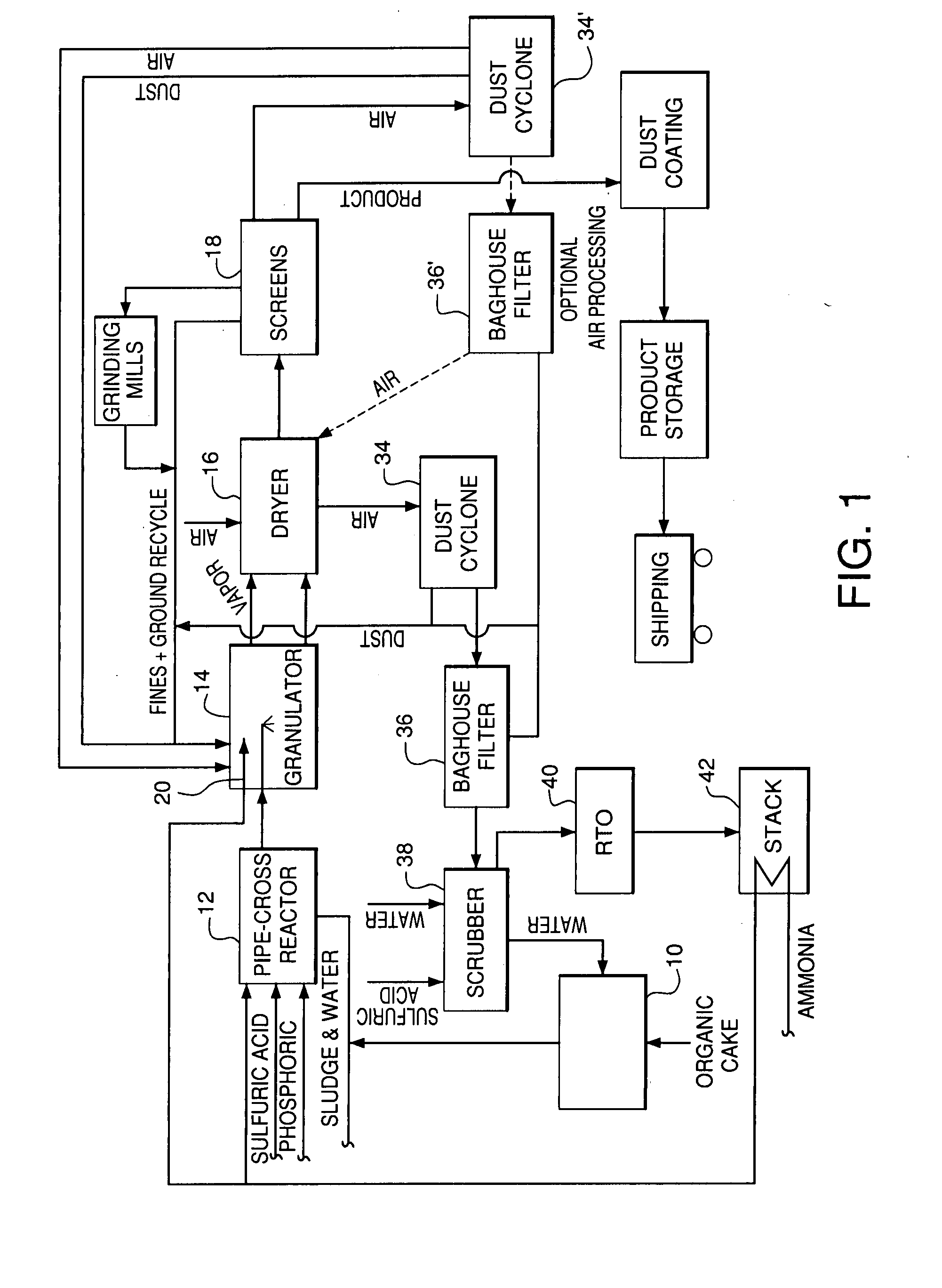

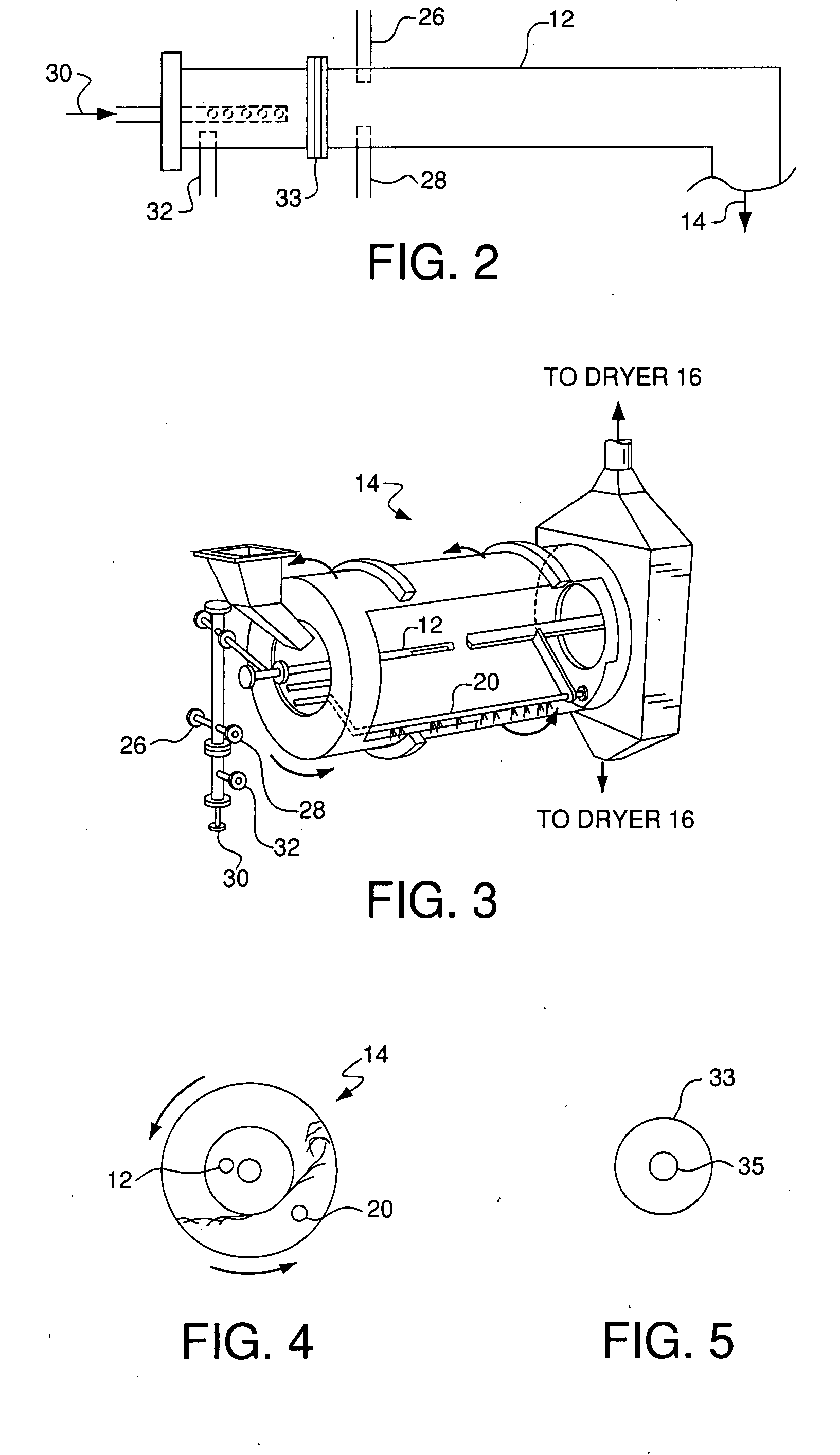

Organic recycling with metal addition

InactiveUS20050039508A1Reduce slurry viscosityAvoid flowAnimal corpse fertilisersAlkali orthophosphate fertiliserSolubilityIron sulfate

The invention is directed to methods for producing a granular nitrogen fertilizer from an organic material comprising adding a metallic salt to said organic material to form a slurry. Preferably the organic material comprises dewatered biosolids and contains water from a scrubber. Metallic salts that can be used comprise a salt of iron, zinc, or a mixture thereof. Preferred iron salts comprises ferric sulfate or ferric oxide, and preferred zinc salts comprises zinc sulfate or zinc oxide. Preferably, the metallic salt is mixed with an acid such as sulfuric acid to form an acidified metal salt. Slurry pH ranges from approximately 2-2.5. The acidified metal salt is added to the organic material in sufficient quantity to lower viscosity of the slurry such that the resulting fluid does not hinder fluid flow during operation. When the metallic salt comprises acidified ferric sulfate or ferrous sulfate, sufficient iron can be present to produce a fertilizer product with 0.1 weight percent to 10 weight percent iron sulfate calculated on a dry weight basis. The invention is also directed to fertilizer products made by the methods of the invention. Preferred products are granules and the metallic salt increases product hardness. Fertilizer granules preferably contain metal that is bioavailable to a plant when used as a fertilizer. Solubility of the metal of the product in water is enhanced, and the product is low staining.

Owner:UNIFIED ENVIRONMENTAL SERVICES GROUP +1

Organic recycling with metal addition

InactiveUS20080034822A1Reduce slurry viscosityAvoid flowAnimal corpse fertilisersAlkali orthophosphate fertiliserSolubilityIron sulfate

Owner:UNITY FERTILIZER LLC

Apparatus and process for separation of organic materials from attached insoluble solids, and conversion into useful products

InactiveUS7692050B2Reduce slurry viscosityInhibition formationMechanical conveying coke ovensSolid waste disposalSpeciality chemicalsHigh energy

The present invention addresses the processing of waste and low-value products that contain bone material to produce useful materials in reliable purities and compositions, at acceptable cost, and with high energy efficiency. In particular, the invention comprises a process that converts various feedstocks such as offal, animal manures, and municipal sewage sludge, to useful materials including gas, oil, specialty chemicals, and carbon solids. The process heats the feedstock in order to breakdown proteins and separate organic material from bone material, applies further heat and pressure to the resulting liquid mixture, separates out various components, then further applies heat and pressure to one or more of those components. The invention further comprises an apparatus for performing a process of converting waste products into useful materials, and an oil product that arises from the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

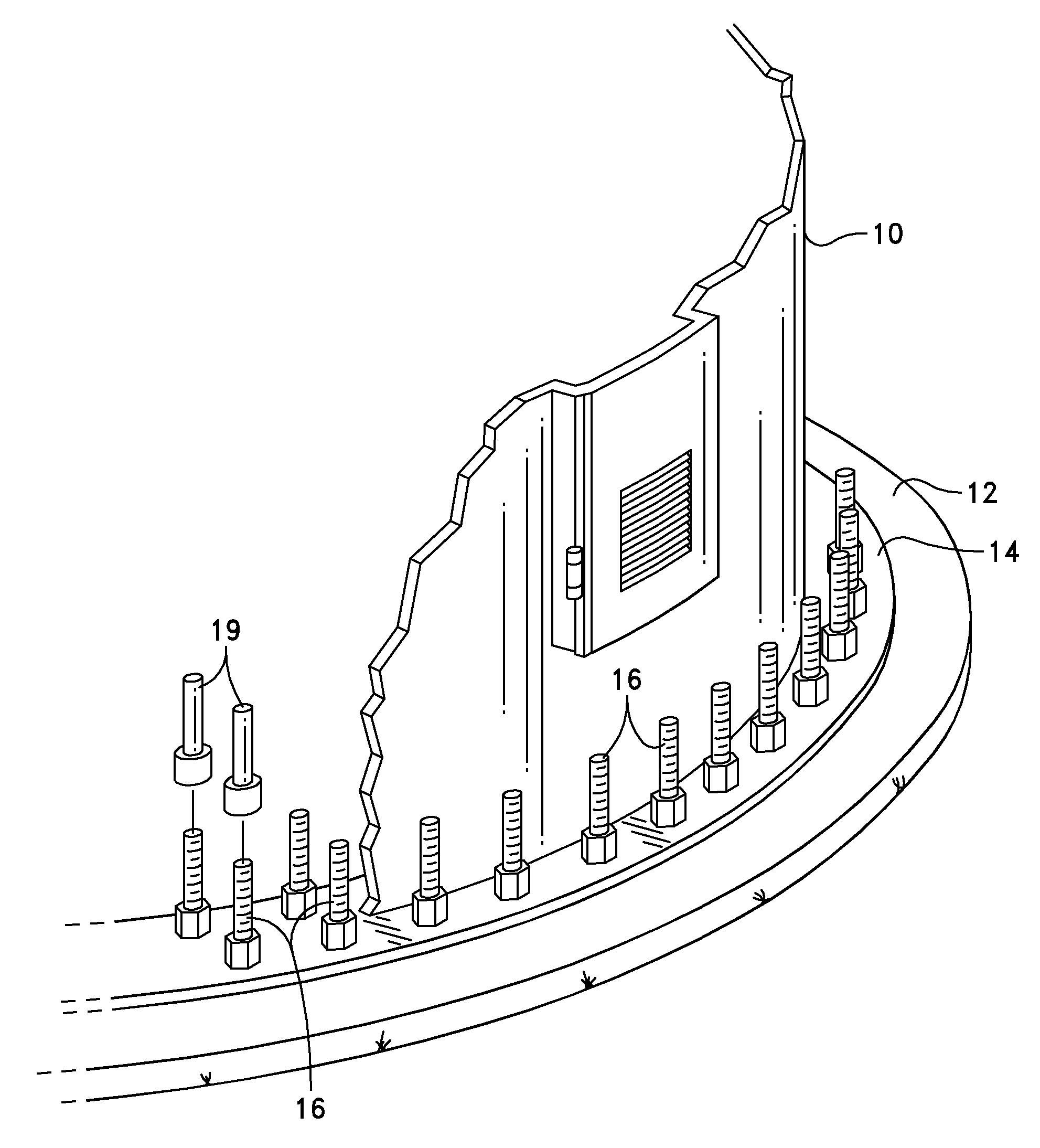

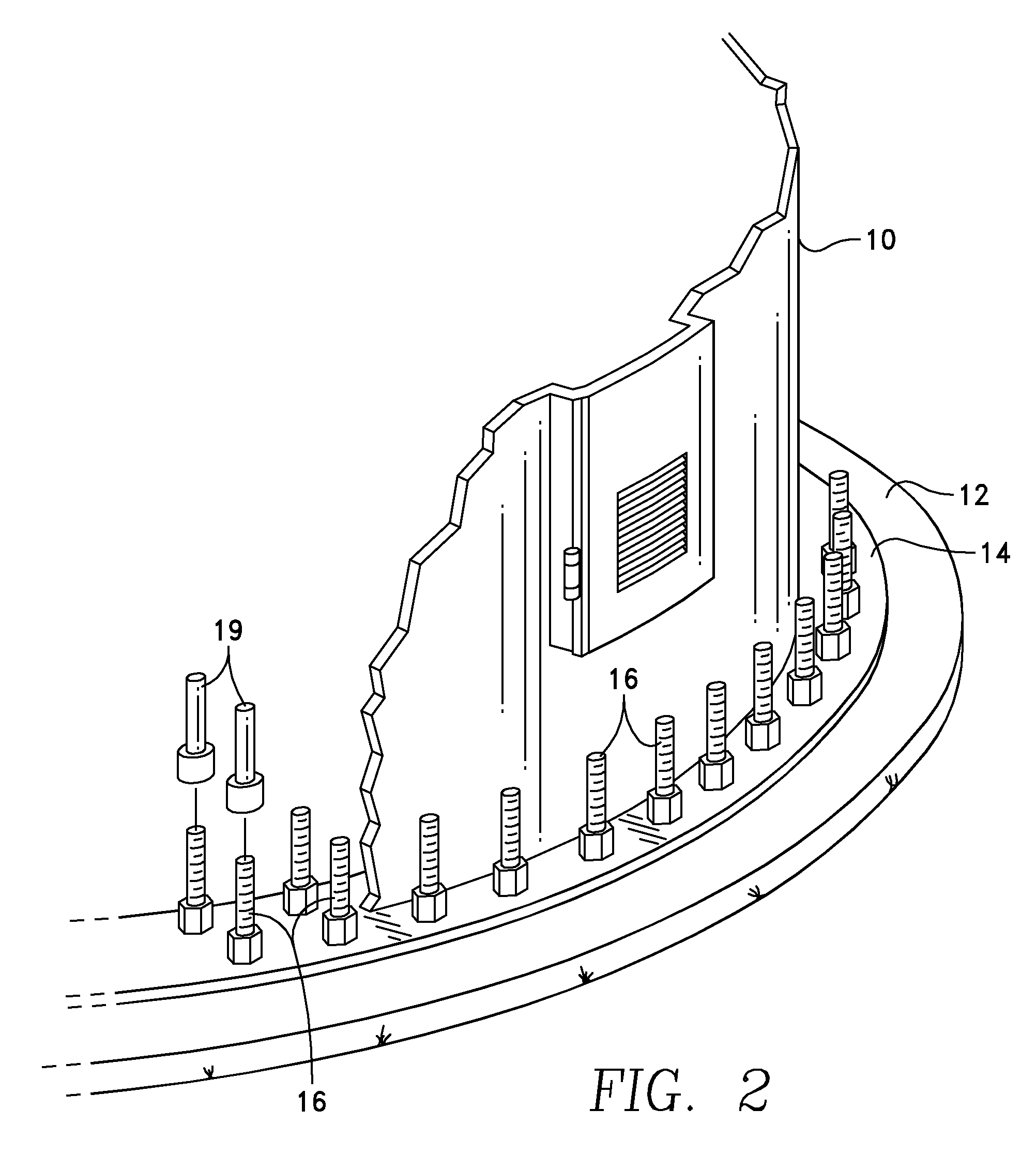

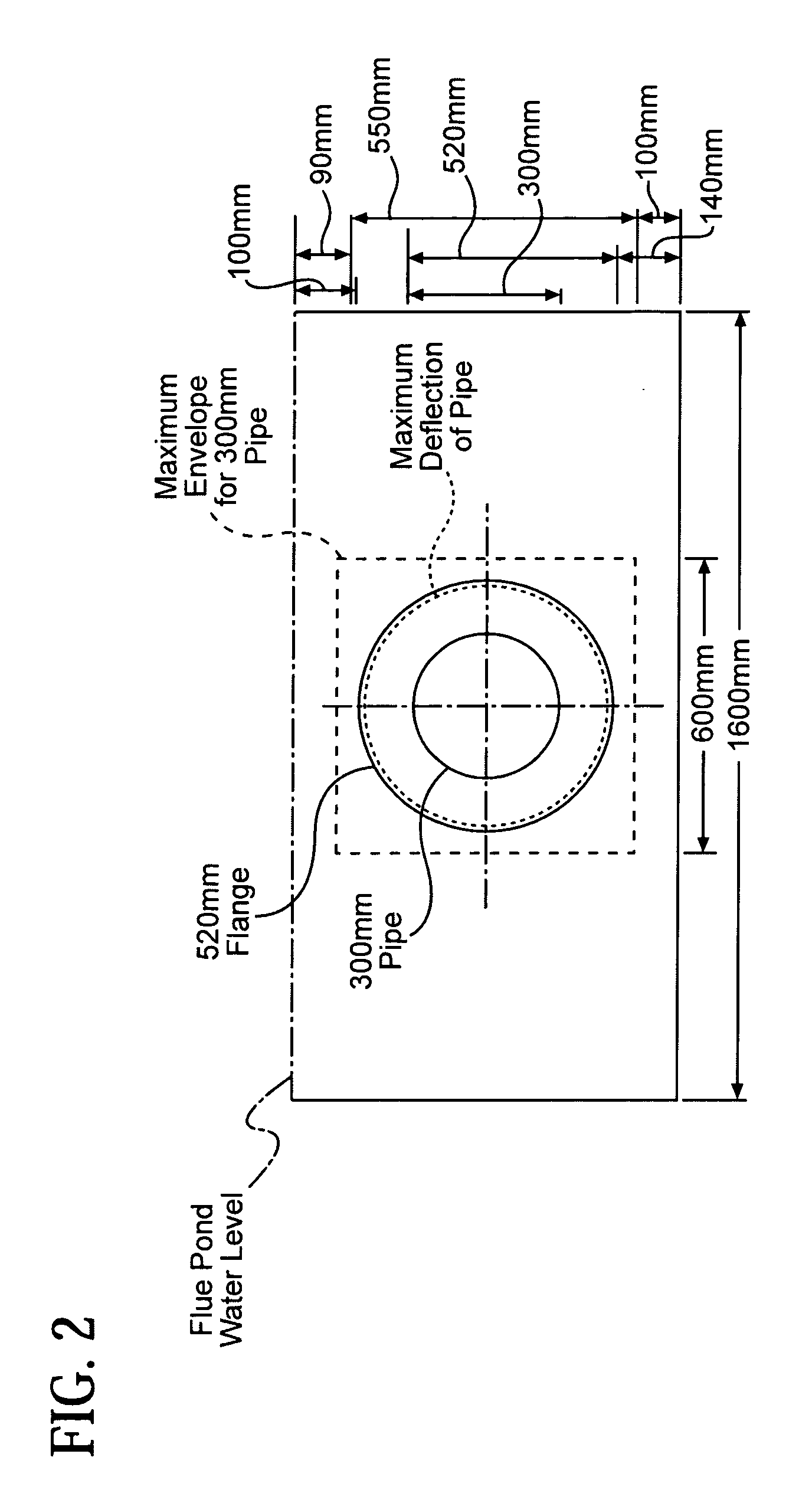

Foundation for a Wind Turbine Utilizing a Slurry of Low Viscosity Grout

InactiveUS20120291380A1Speeding up erectionReduce equipment costsBuilding repairsProtective foundationSlurryTower

A self-leveling grout provides a level surface for the disposition of a wind turbine base. The self-leveling grout is placed within the foundation grout trough as an initial slurry having a viscosity at ambient temperature approximately the same as the viscosity of known grout slurries utilized in turbine foundations. After placement in the grout trough, elevated temperature is applied to the grout slurry, which lowers the viscosity of the slurry such that the slurry becomes self-leveling and the top surface assumes a nearly perfectly level surface. Additional elevated temperature is applied which initiates the curing of the grout to the required compressive strength for supporting the turbine tower.

Owner:TOOMAN NORMAN

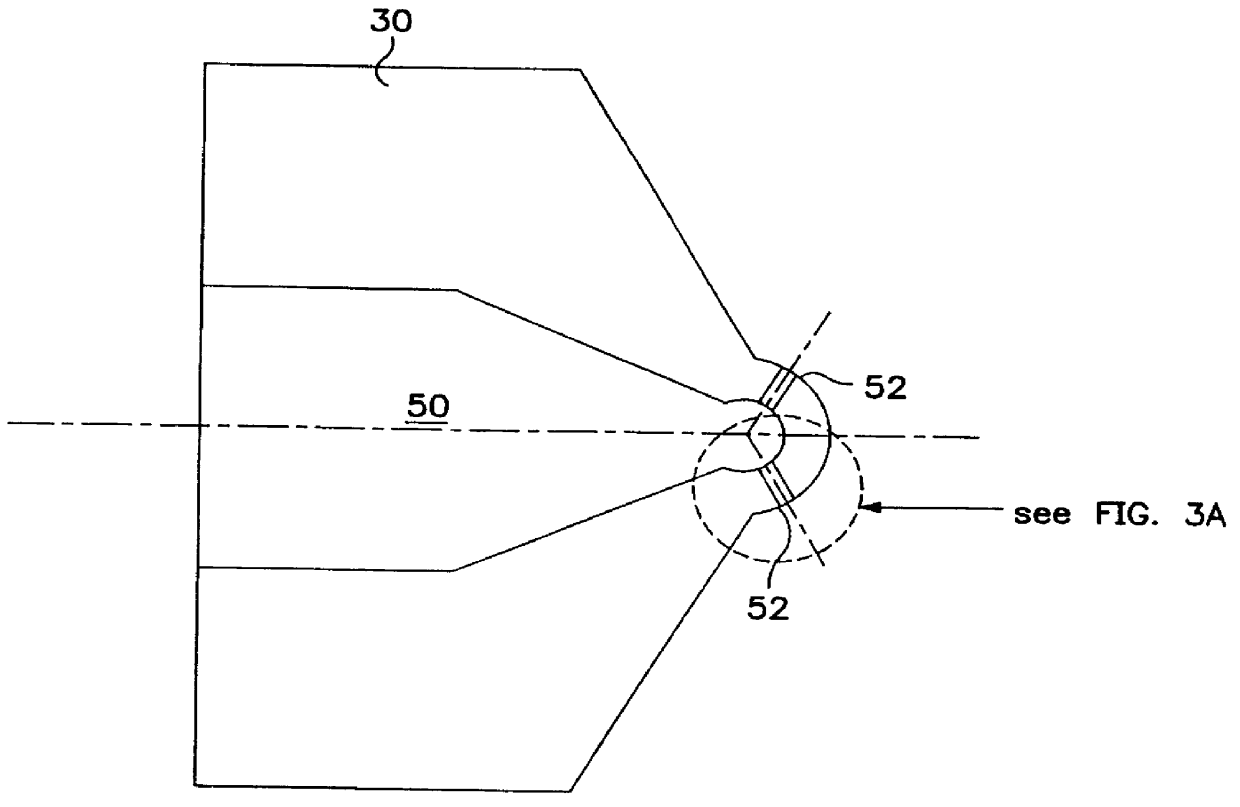

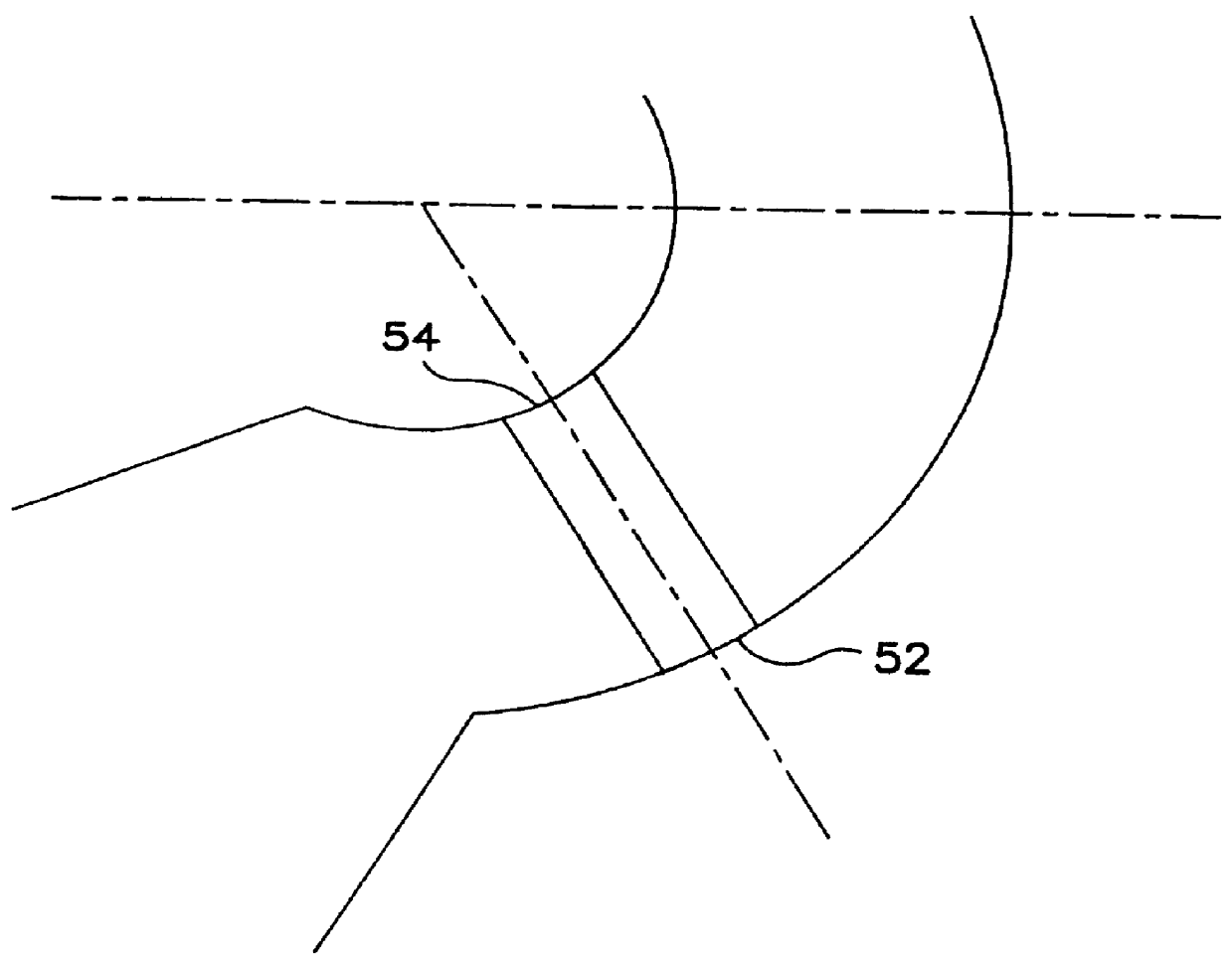

Abrasive liquid slurry for polishing and radiusing a microhole

InactiveUS6132482AImprove economyImprove efficiencyEdge grinding machinesPigmenting treatmentViscosityStreamflow

A system and method for radiusing and sizing microholes in diesel fuel injectors. A liquid abrasive slurry with rheological properties is used. As the slurry approaches and flows through the microhole, it is at first at a lower viscosity. Subsequently, the slurry is characterized by a high viscosity which enables the use of a flow meter in the slurry flow path which directly and accurately monitors slurry flow rate and mass flow in real time. This allows for the individual slurry processing of nozzles to their specified flow rate in a continuous process.

Owner:EXTRUDE HONE CORP

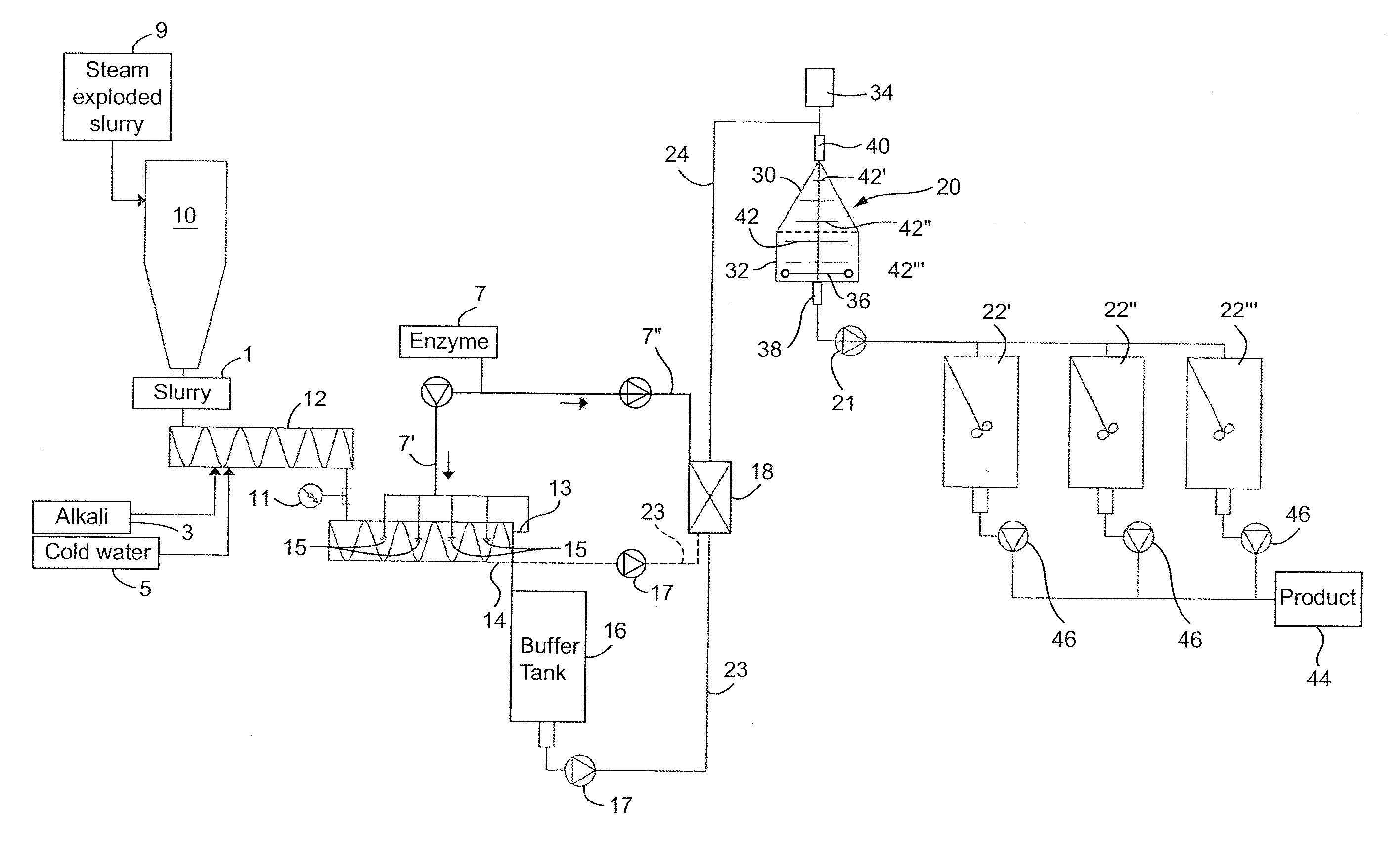

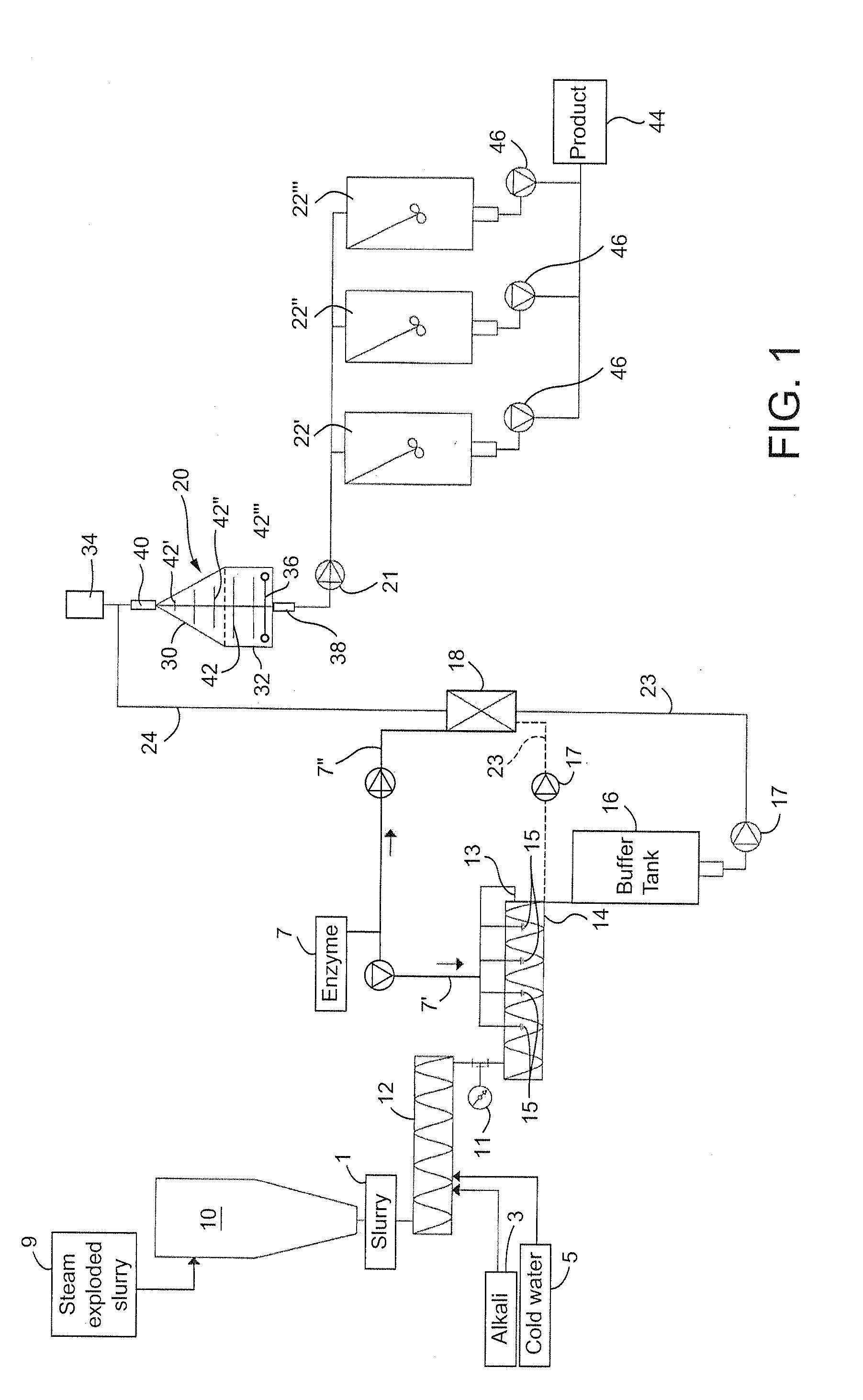

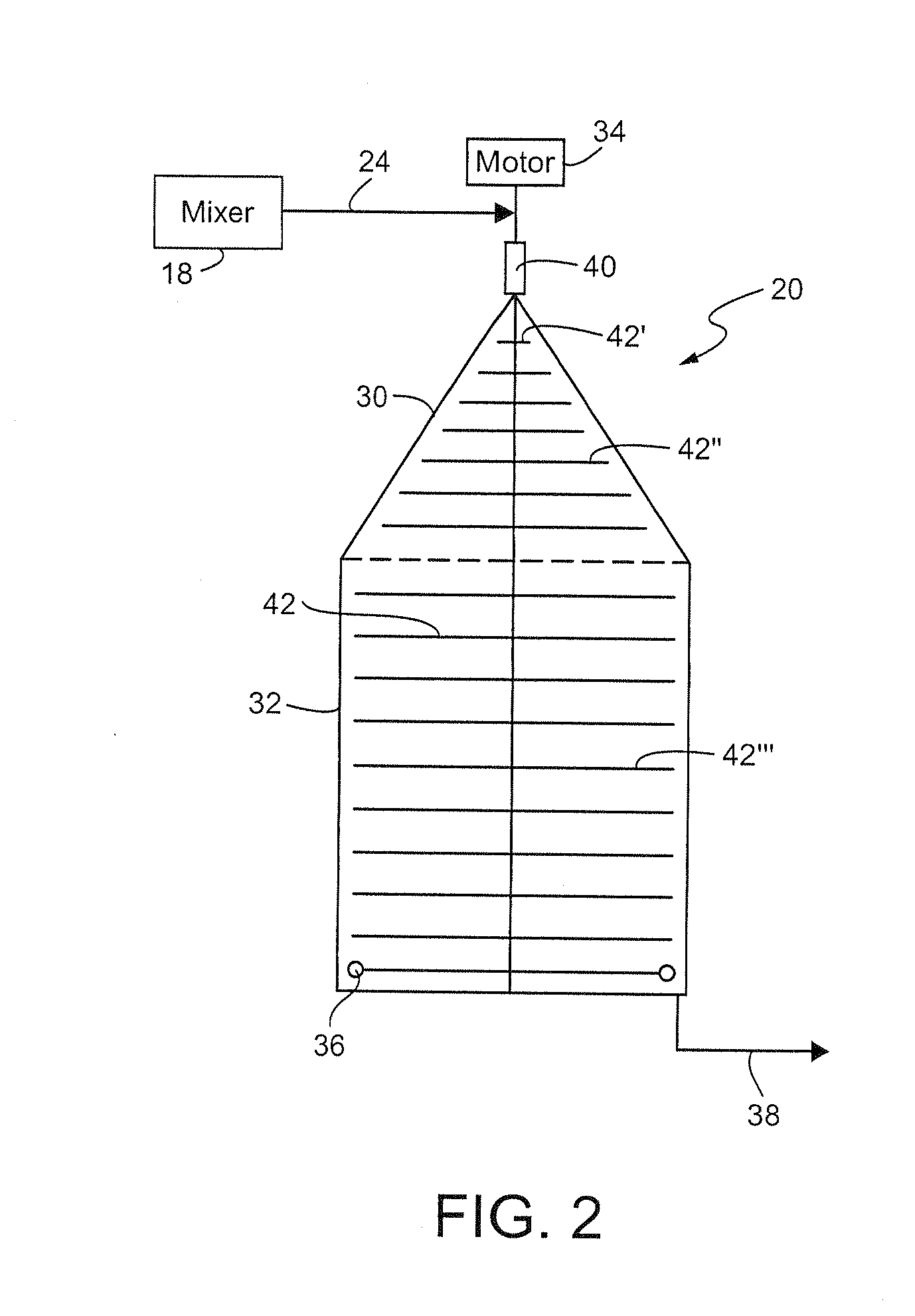

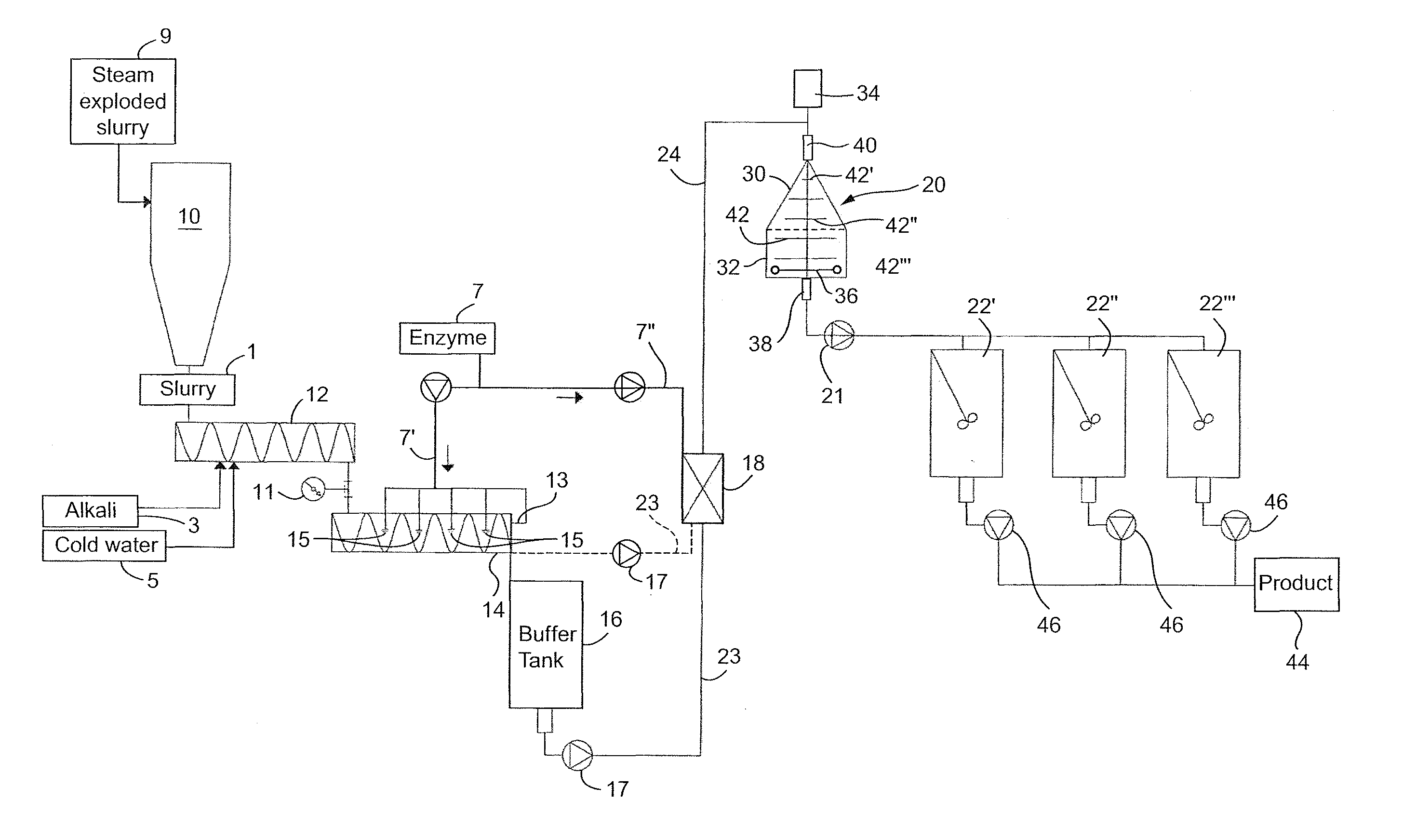

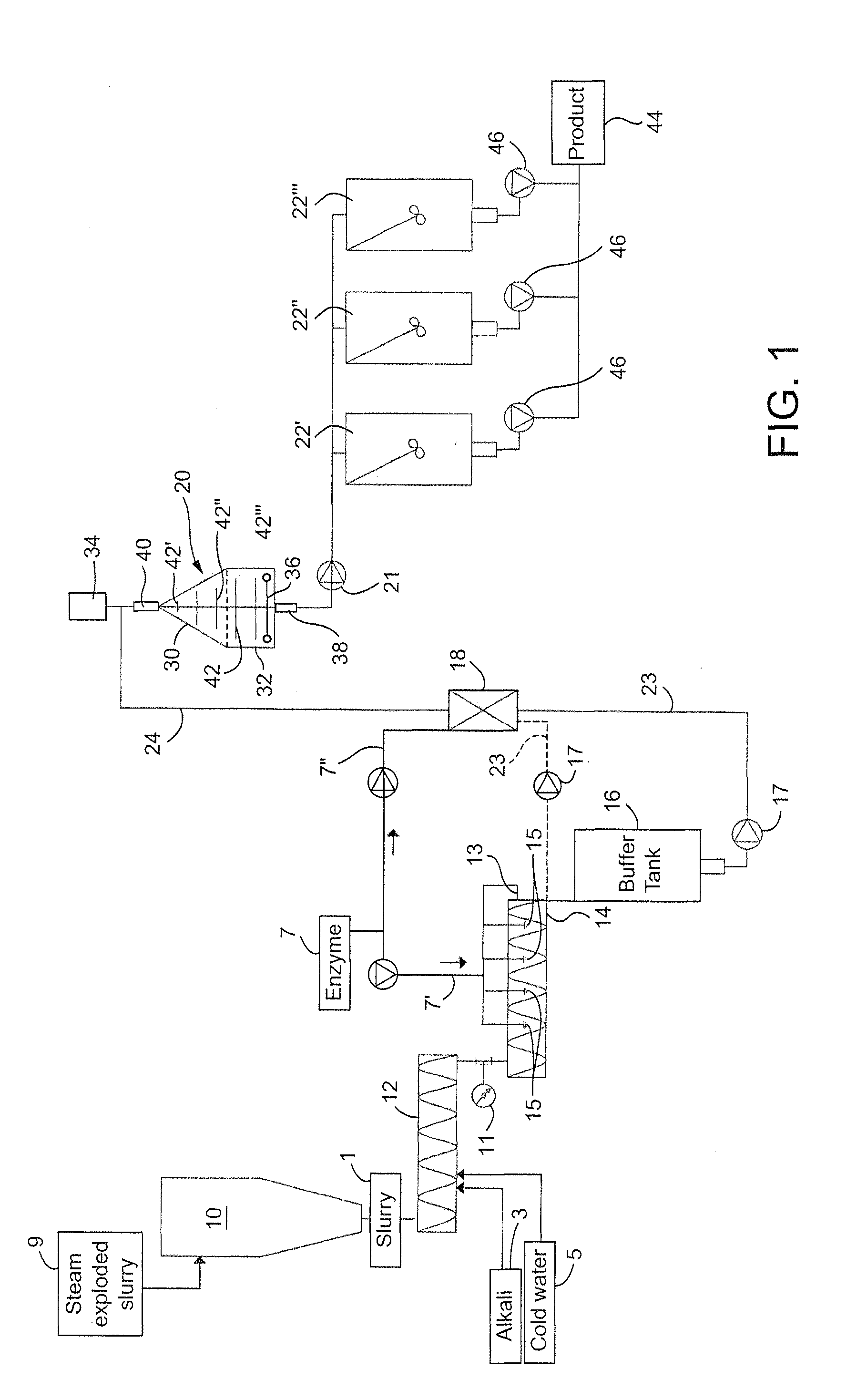

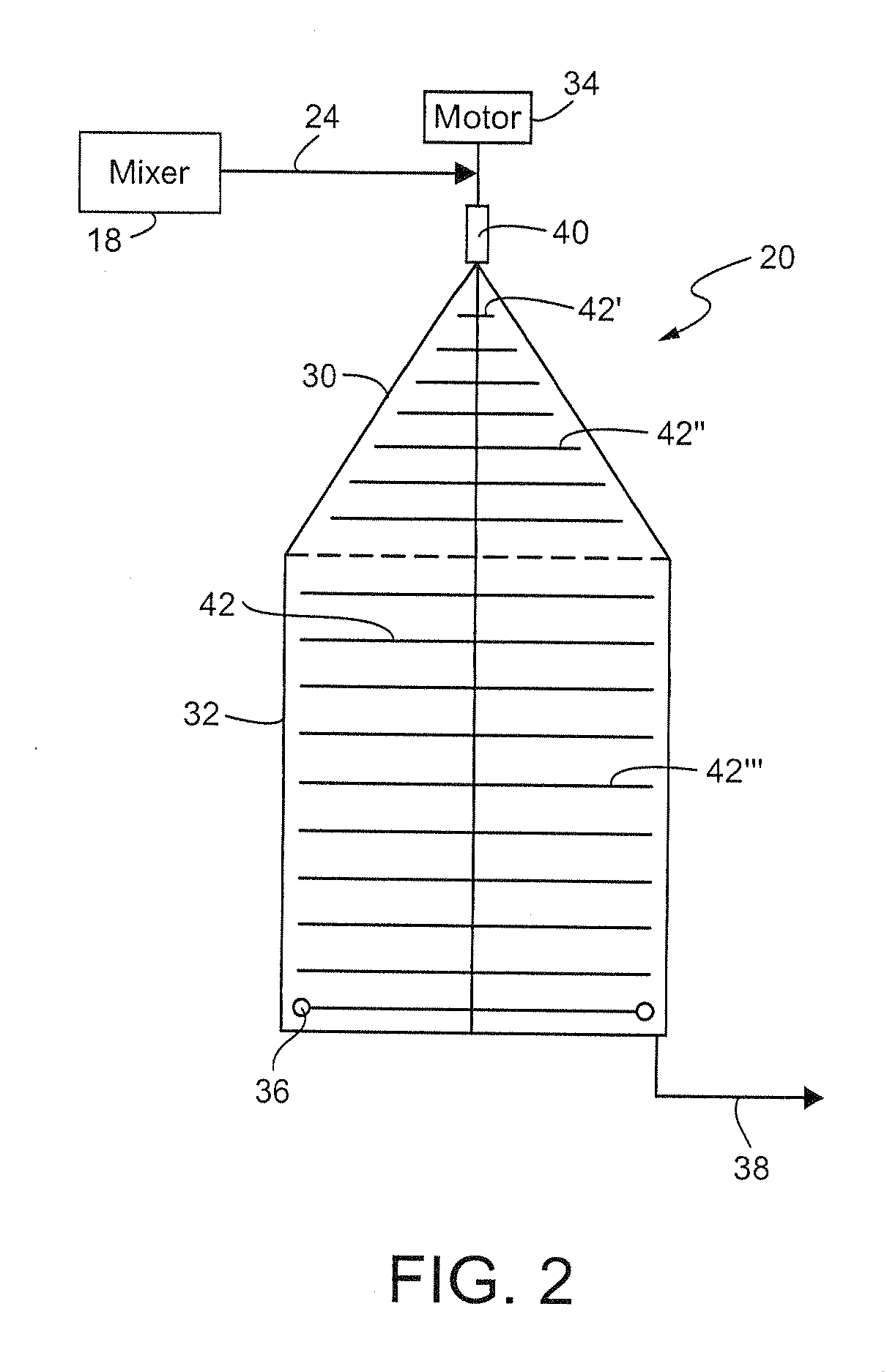

Method and apparatus for mixing a lignocellulosic material with enzymes

ActiveUS20120125549A1Improve liquidityReduce slurry viscosityCellulosic pulp after-treatmentBiological substance pretreatmentsCelluloseEnzymatic hydrolysis

A method to treat a lignocellulosic material including: performing a steam explosion reaction on the lignocellulosic material and discharging a slurry from the; adding an alkali material to the slurry in a first conveyor; transferring the slurry with the alkali material from the first conveyor to a second conveyor; adding an enzyme solution to the slurry while in, entering or at the discharge of the second conveyor; transferring the slurry with the enzyme solution from the second conveyor slurry to a mixer; mixing the slurry in the mixer, wherein a second portion of the enzyme solution is added to the slurry during the mixing, and transferring the slurry with the enzyme solution from the mixer to a first reactor vessel wherein the slurry in the first reactor vessel undergoing enzymatic hydrolysis such that the viscosity of the slurry is reduced in the first reactor vessel.

Owner:ANDRITZ INC

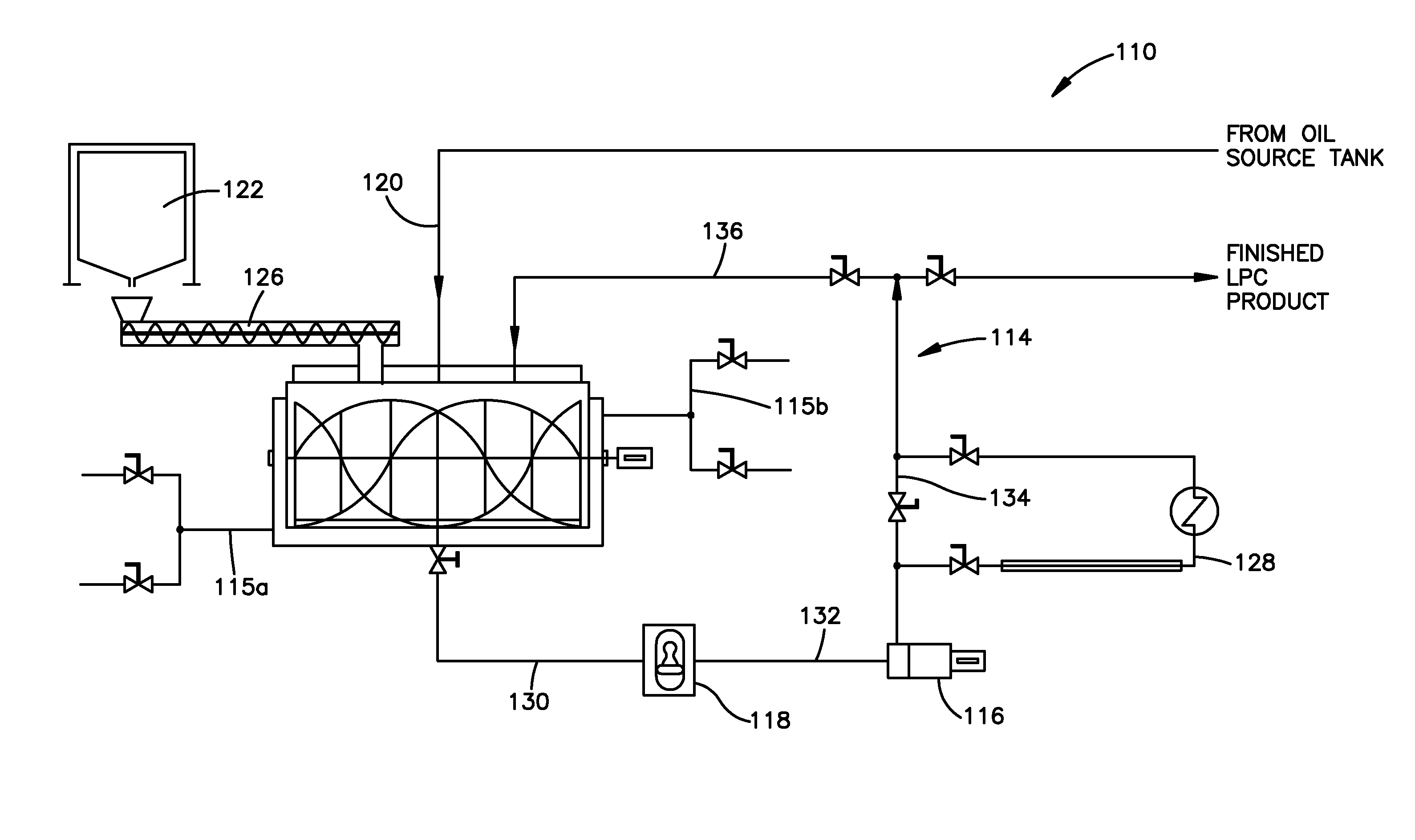

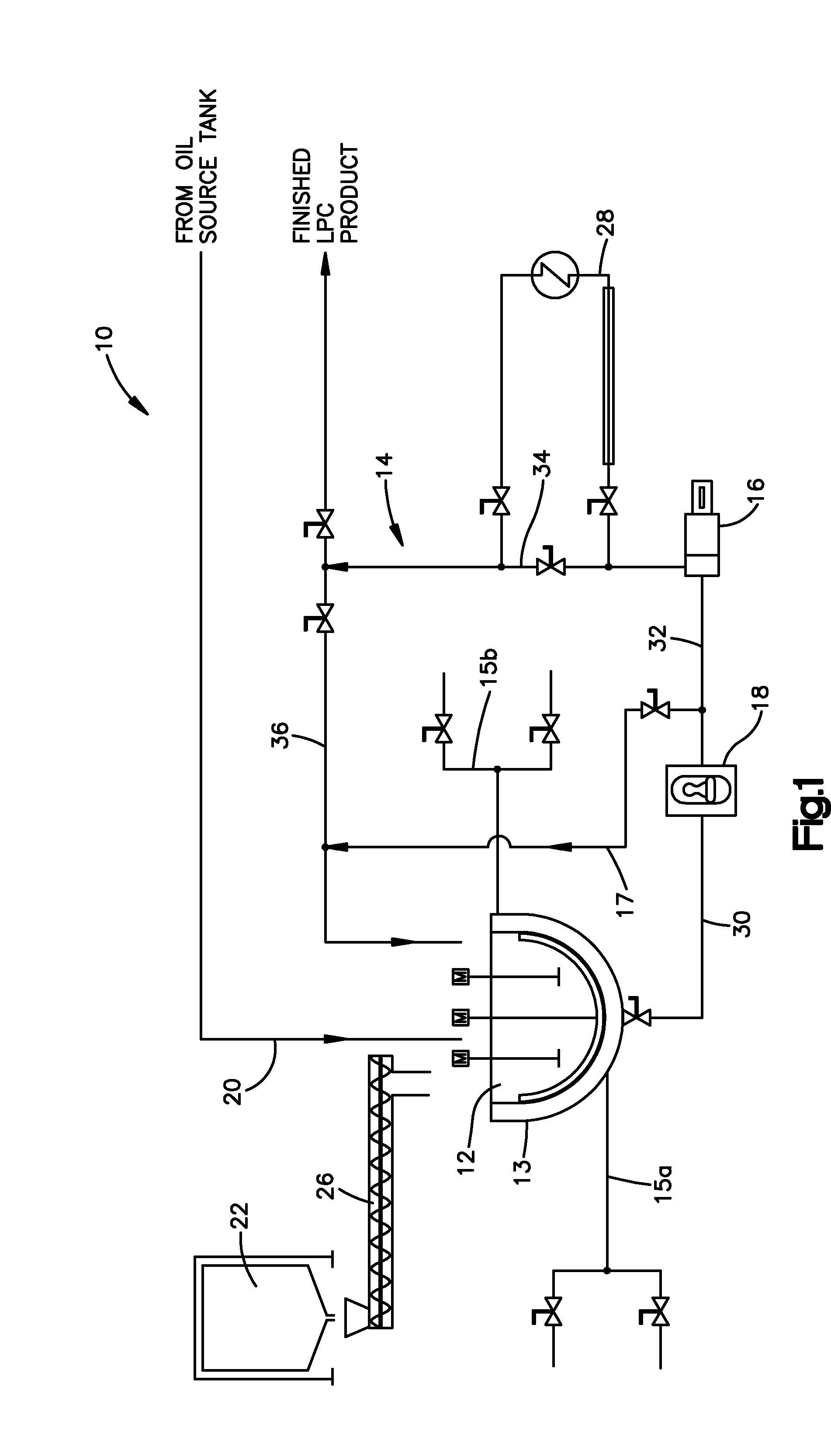

Protein-Containing Food Product and Coating for a Food Product and Method of Making Same

InactiveUS20080113067A1Thin coatingHigh in proteinEdible oils/fats ingredientsConfectioneryLipid formationNutritive values

A method for forming a complex of a protein-containing material and a lipid-based material comprises the steps of admixing said protein-containing material into said lipid material, applying heat and a shear force to said admixture to form an emulsion of protein material in said lipid material, and cooling said admixture to form a lipid-protein complex. Optionally, a liquid grinding step also may be used. The complex comprises at least about 10-50 net weight % protein, preferably no more than about 1% of an emulsifier, and an amount of a lipid-containing material sufficient to form an emulsion with the protein containing material. It is believed that higher proportions of protein could be obtained in the emulsion with high capacity pumps and shear apparatus. The complex can be used as a coating composition for a food product, or as an ingredient in a coating composition for a food product, or as an ingredient in a food article. When used as or in a coating for a snack food item such as a protein-containing energy bar, the coating can add to the nutritive value of the bar, and maintain the moisture content of the bar.

Owner:BUNGE OILS INC

Novel dispersant, preparation method thereof and application thereof

InactiveCN102115511AImprove function and effectReduce slurry viscosityTransportation and packagingMixingMaleic anhydrideChemistry

The invention discloses a preparation method of a novel dispersant, which comprises the steps of: taking crylic acid as a main reaction monomer; adding at least one of monomers such as methacrylic acid, maleic anhydride, fumaric acid, itaconic acid and methyl sodium allylsulfonate as comonomer; taking r-methacryloxypropyl trimethoxy silane, vinyl trimethoxy silane or vinyl triethoxysilane as organic silicon monomer to participate in polymerization; taking a redox system as an initiating system; and polymerizing by water solution, and neutralizing by alkaline substance to obtain the novel dispersant. Due to the novel dispersant, the grinding of calcium carbonate has the characteristics of being low in sizing agent viscosity, small in grain size, good in dispersibility and high in stability.

Owner:山东永港伟方环保材料科技有限公司

Soy composite materials comprising an amino resin and methods of making the same

InactiveUS20120149813A1Reduce slurry viscosityLow viscosityOrganic detergent compounding agentsFibre treatmentEmulsionSoy flour

The present invention provides composite materials derived from aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size, polymer particles of at least one emulsion (co)polymer, one or more amino resin, and, optionally, one or more reducing sugar. Also provided are methods of making and using composite materials containing the binder compositions.

Owner:ROHM & HAAS CO

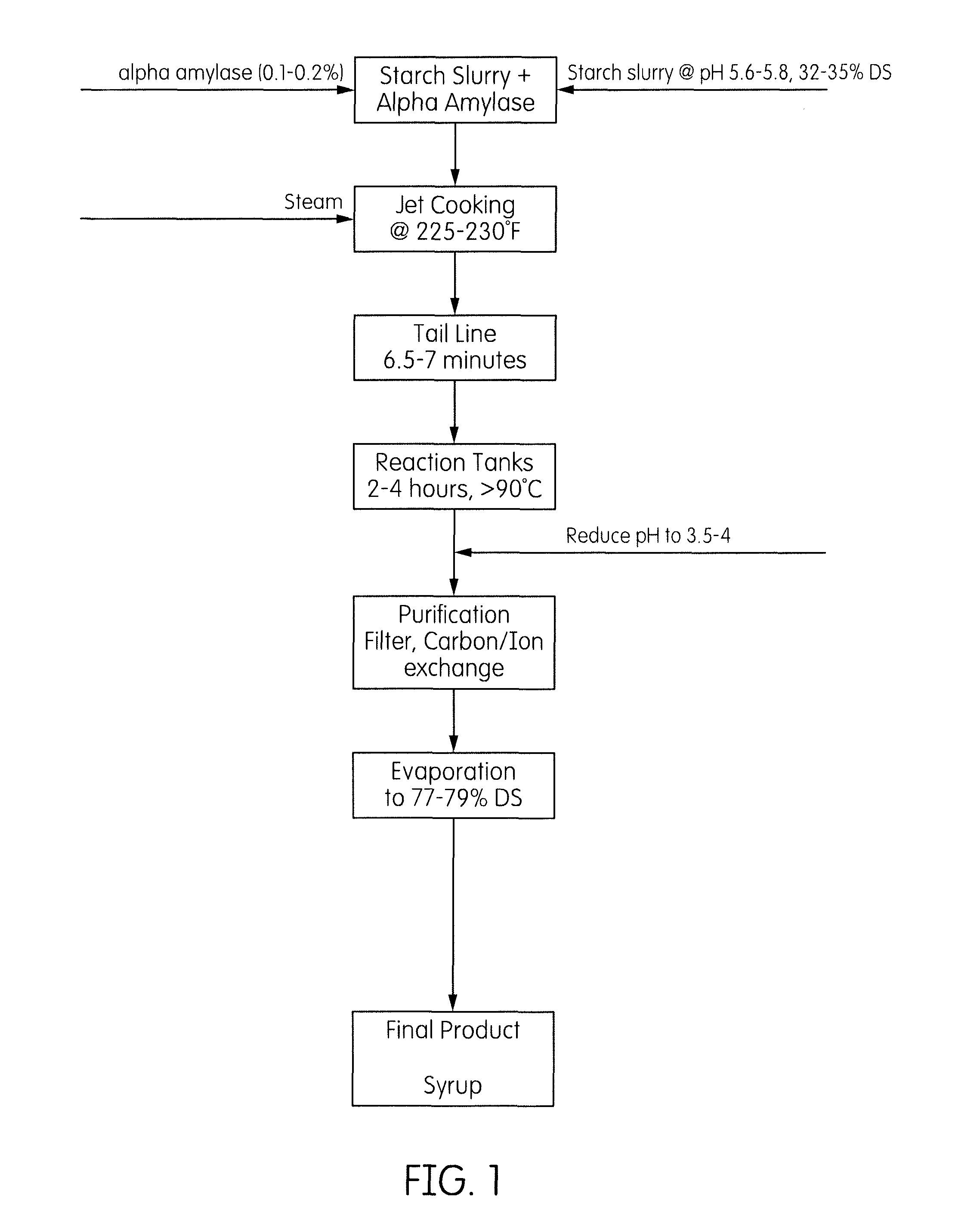

Reduced sugar syrups and methods of making reduced sugar syrups

ActiveUS20130197104A1Increase shearImprove solubilityBiocideCosmetic preparationsAlpha-amylaseSweetness

A reduced sugar syrup having an advantageously low viscosity is prepared by hydrolysis of starch or starchy material using a particular type of alpha amylase enzyme which yields a saccharide distribution having a low DP1-2 and low DP11+ content. The DP4 content of the syrup may be favorably increased by using a maltotetragenic alpha amylase enzyme in combination with the aforementioned alpha amylase enzyme. The syrup is useful in the production of food, beverage, animal feed, animal health and nutrition, pharmaceutical, and cosmetic compositions and may be combined with a high intensity sweetener to provide a composition capable of being substituted for conventional corn syrups.

Owner:BASF ENZYMES +1

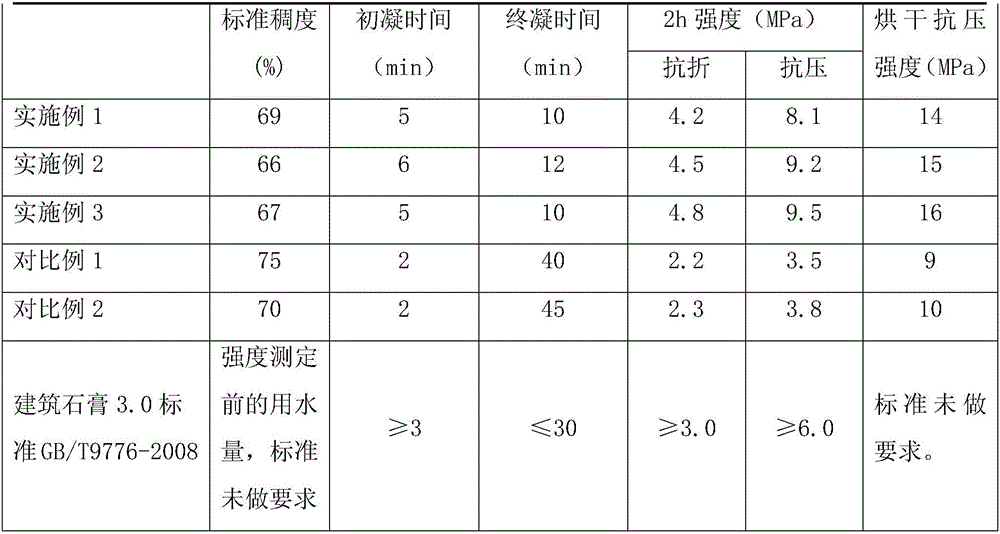

Method for preparing phosphoric acid and co-produced gypsum powder by hemihydrate process

ActiveCN106348266AIncrease the liquid-solid ratioReduce slurry viscosityCalcium/strontium/barium sulfatesPhosphorus compoundsChemical industryPhosphoric acid

The invention belongs to the technical field of phosphorus chemical industry production, and particularly relates to a method for producing phosphoric acid and co-produced gypsum powder by a hemihydrate process. The method for producing the phosphoric acid and co-produced gypsum powder by the hemihydrate process, provided by the invention, is used for solving the problem that co-produced gypsum of the existing hemihydrate processes cannot reach standards of building gypsum. The method provided by the invention comprises the following steps: returning slurry of a crystallizing tank to a pre-reaction tank, and enabling the slurry to make a pre-reaction with phosphorite; in a reaction tank, enabling SO4<2-> remaining in the returned slurry to make a further full reaction with CaO in the phosphorite; adding H2SO4 into the crystallizing tank so as to obtain semi-hydrated gypsum, and carrying out filtrating, washing and free-water removal, thereby obtaining the gypsum powder, of which the length-diameter ratio is (2 to 10): 1. The setting time, breaking strength and compression strength of the gypsum powder prepared by adopting the process are superior to those required in the standards of the building gypsum. The method has the advantages that the energy consumption is lowered, process flows are shortened, the difficulty of subsequent treatment of gypsum produced during the preparation of phosphoric acid by the hemihydrate process is lowered, the range of utilization of ardealite is widened, and the pile-up pressure of gypsum storage yards is lightened.

Owner:GUIZHOU CHANHEN CHEM CO LTD

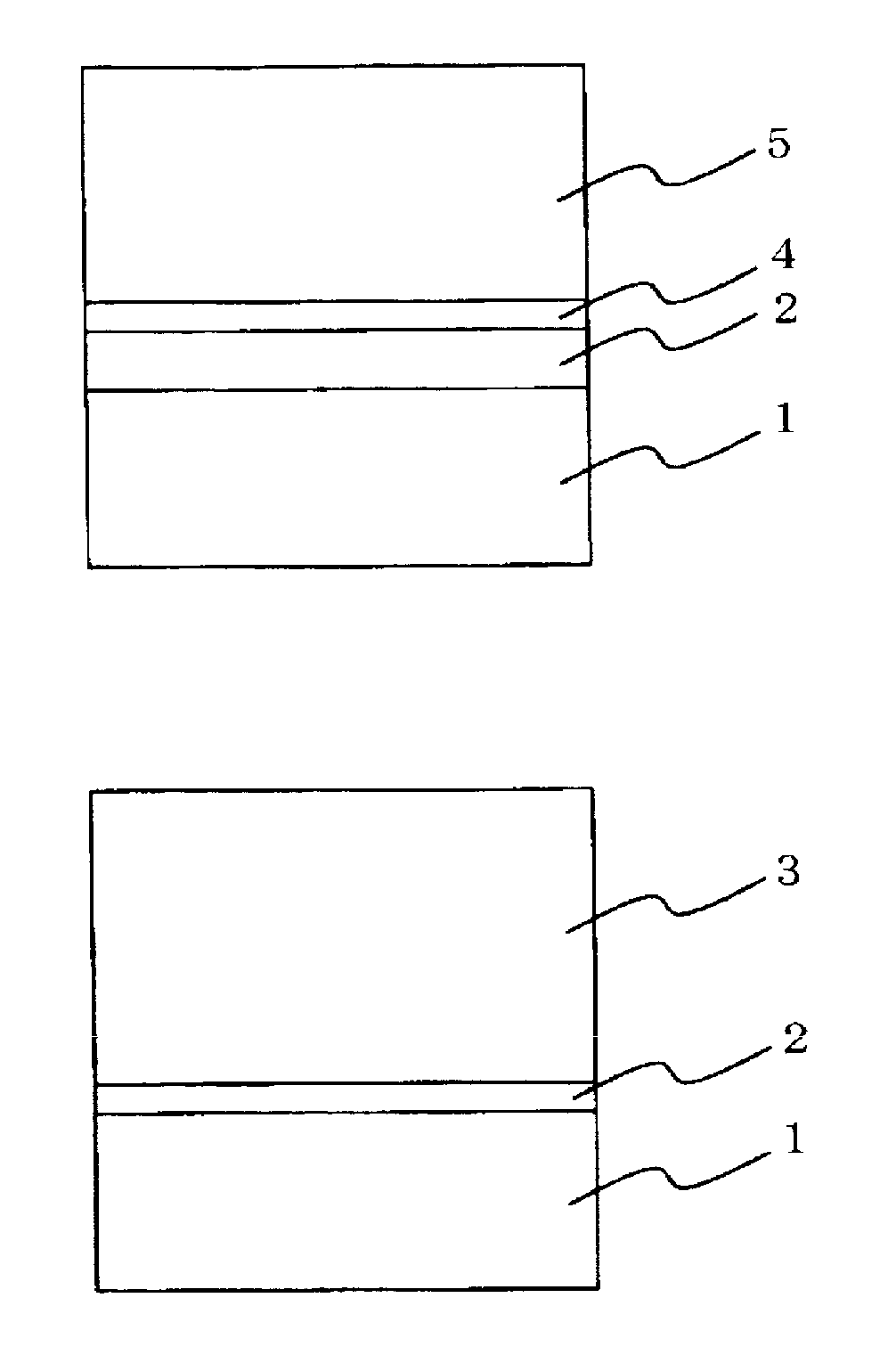

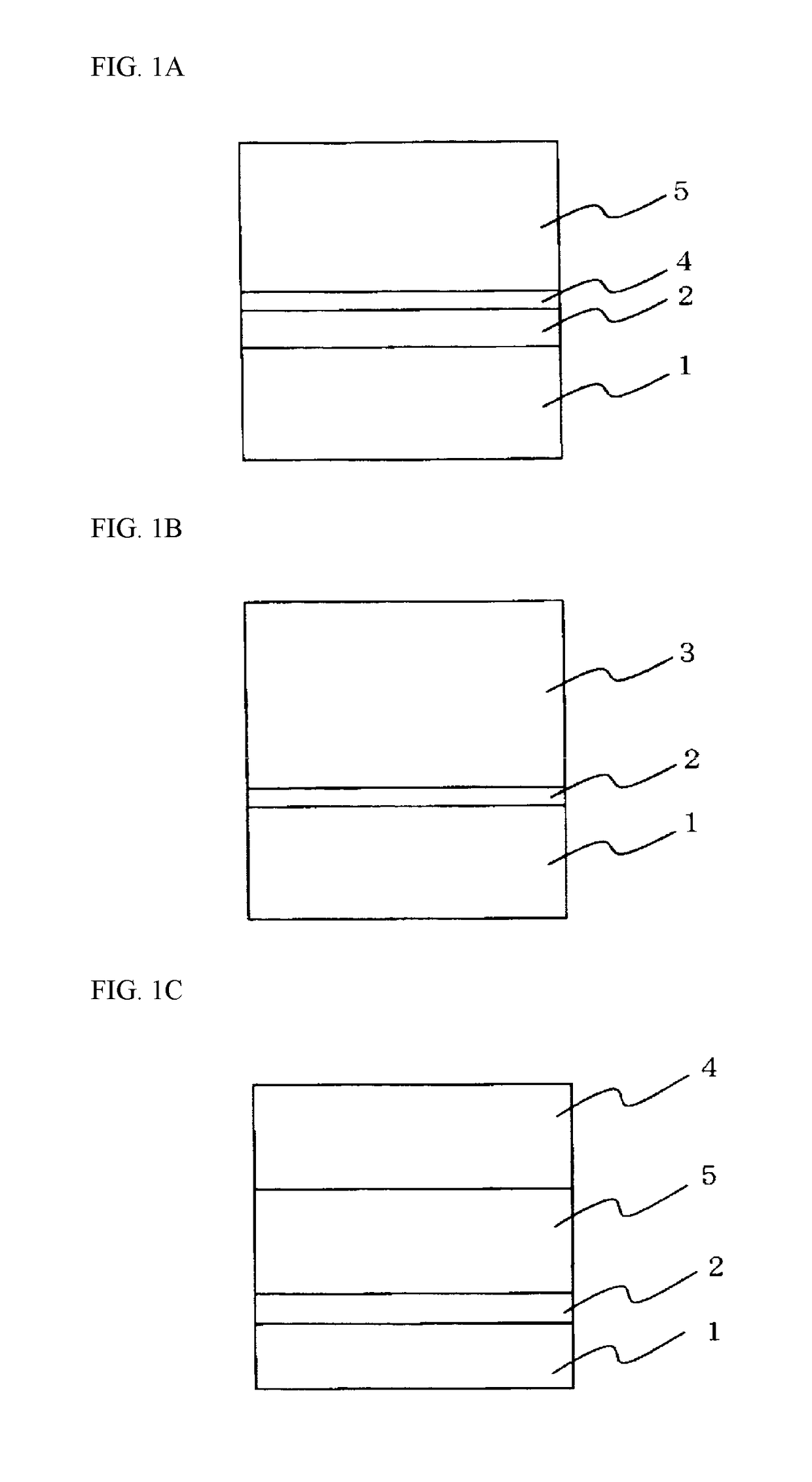

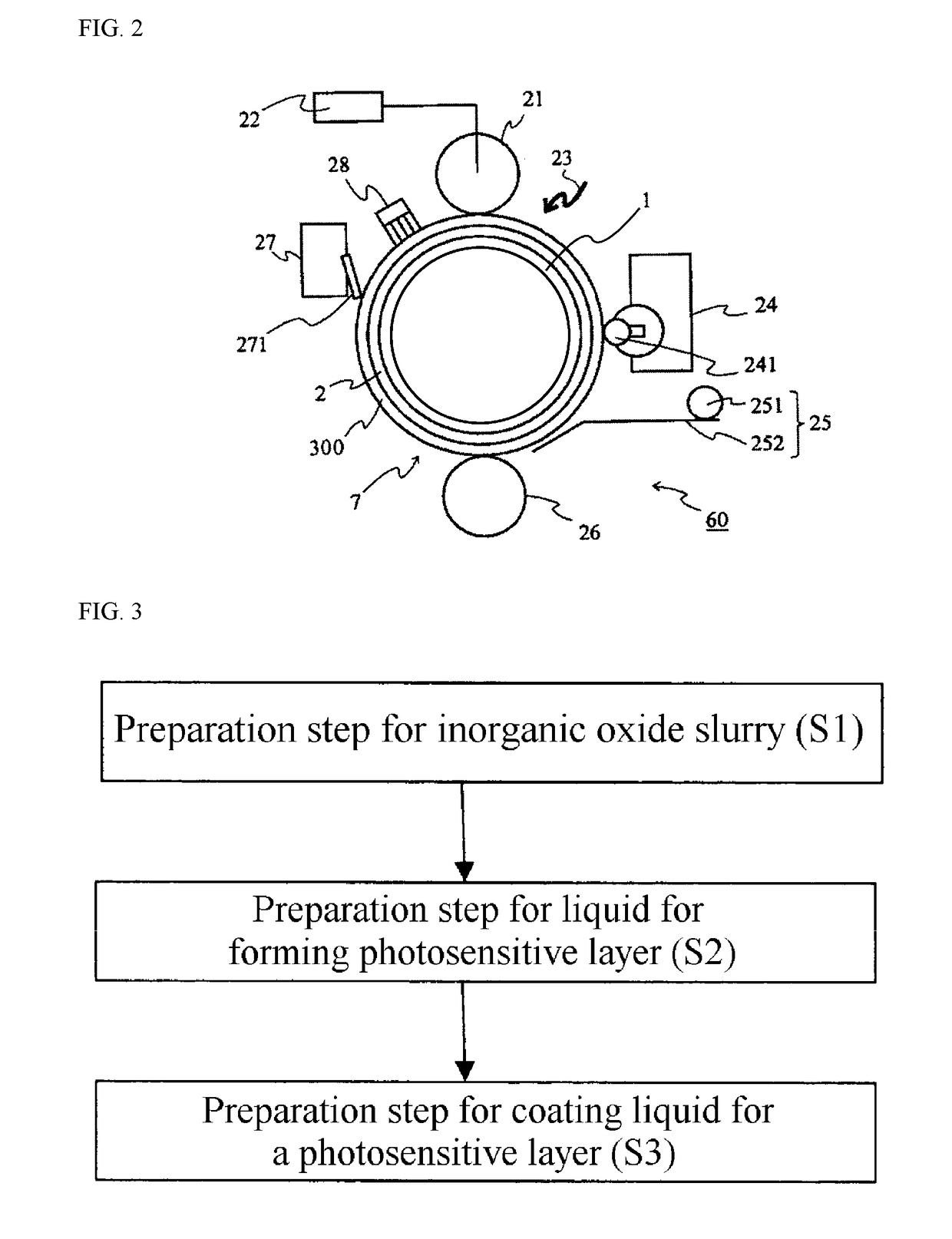

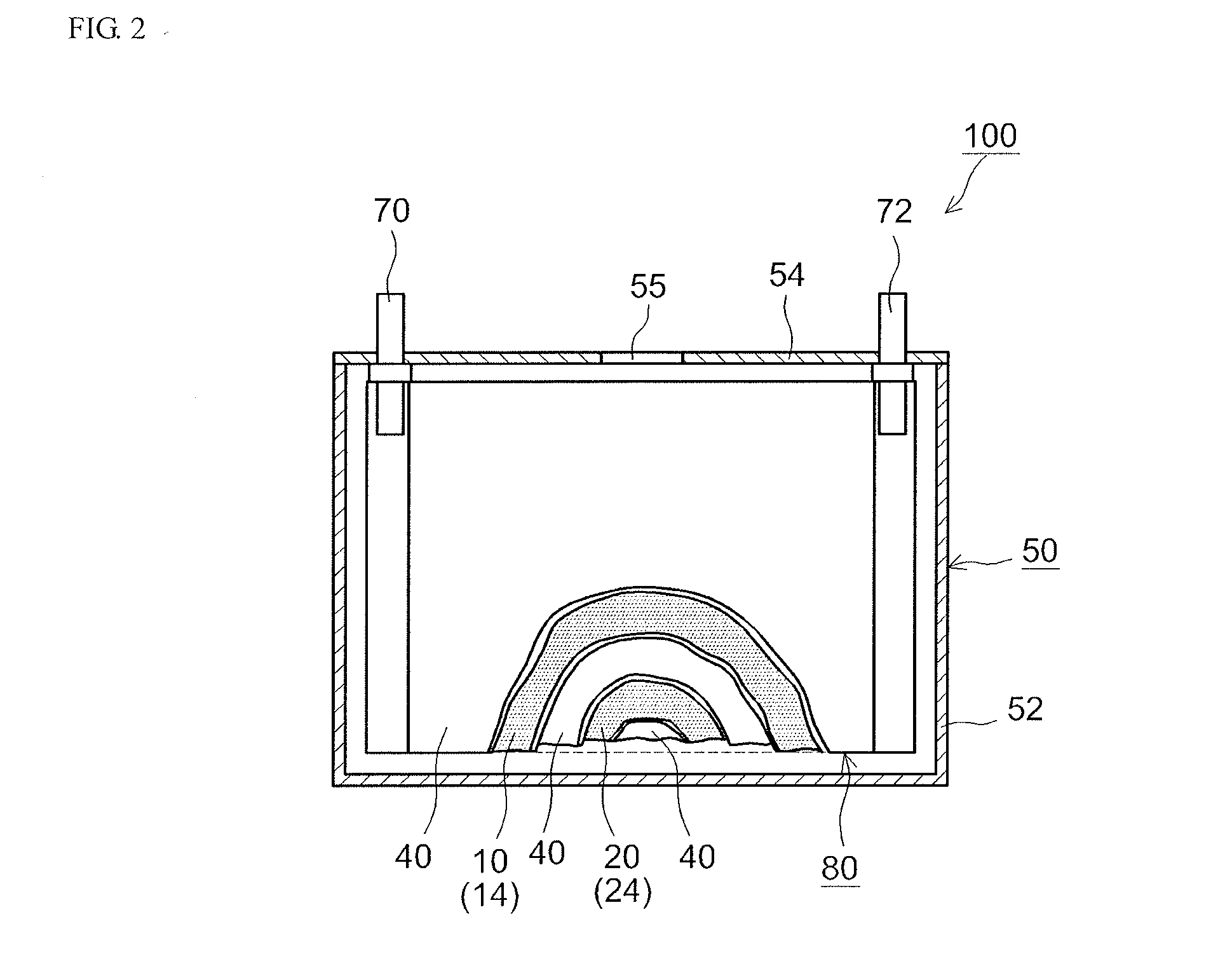

Electrophotographic photoreceptor, method for producing the same, and electrophotographic device including the same

ActiveUS20180224760A1High image qualityControl abrasion propertyElectrography/magnetographySolventOptical transmittance

The invention provides an electrophotographic photoreceptor, which undergoes little abrasion over long term use and is able to develop a stable image, as well as a method of producing the same and an electrophotographic device including the same. The electrophotographic photoreceptor includes a conductive substrate; and a photosensitive layer that contains an inorganic oxide and that is formed on the conductive substrate from a coating liquid. A test slurry containing 20% by mass of the inorganic oxide dispersed in a solvent for forming the coating liquid has a light transmittance of 40% or more in a test case where light having a wavelength of 780 nm irradiates the test slurry.

Owner:FUJI ELECTRIC CO LTD

Decontamination of sediments through particle size reduction and stabilization treatment

InactiveUS20100303551A1Degree of reductionReduce direct impactBiocidePowder deliveryMedicinePARTICLE SIZE REDUCTION

A process of decontamination of sediment particles to reduce active pollutant components through particle size reduction and stabilization treatment.

Owner:CHANG YUN FENG

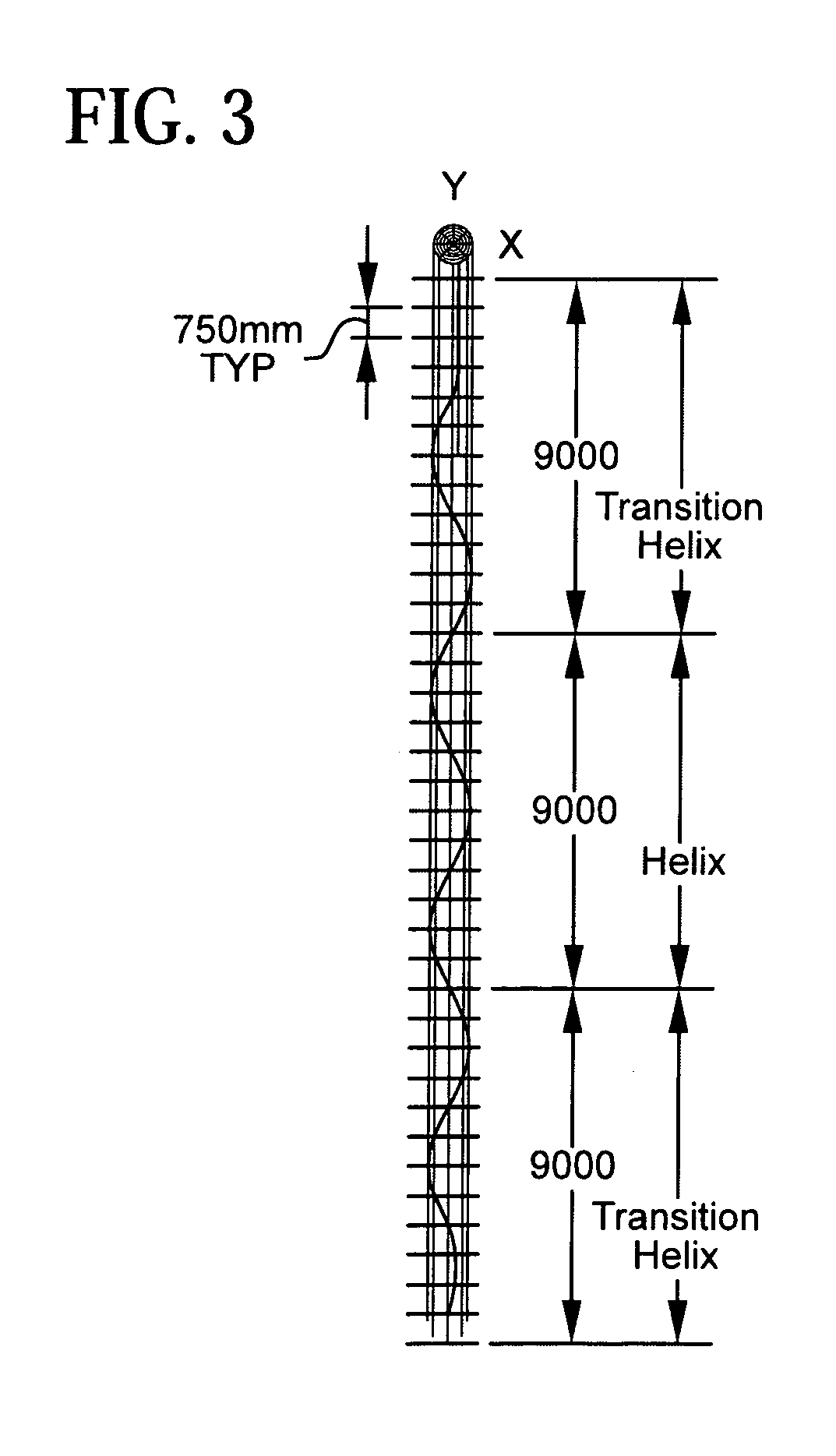

Process and device for cooling inorganic pigments

InactiveUS20060133989A1Improve cooling effectUse minimizedPigmenting treatmentStationary conduit assembliesOxygenInorganic pigments

The present invention provides articles of manufacture and methods for making inorganic pigments. In one embodiment, the present invention provides a method for making titanium dioxide, said method comprising: (a) reacting titanium tetrachloride with oxygen in the presence of heat to produce titanium dioxide; and (b) cooling the titanium dioxide in a conduit having a helix, wherein said helix comprises at least one helical bend. Preferably the conduit comprises at least three helical bends, wherein the helix comprises at least three 360 degree spiral turns, and wherein the helix comprises an angle of from one to ten degrees. In a second embodiment, the present invention also provides a helical pipe for manufacturing pigment, comprising a conduit for receiving an inorganic pigment, wherein said conduit comprises a helix and wherein said conduit is capable of withstanding temperatures greater than about 650° C.

Owner:MILLENNIUM INORGANIC CHEM

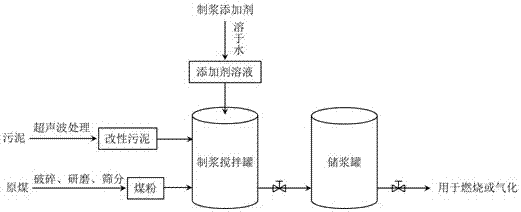

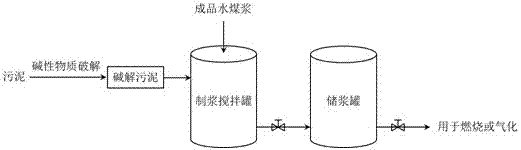

Method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves

InactiveCN107164003ASmall granularityReduce slurry viscositySludge treatmentLiquid carbonaceous fuelsCoal waterFlocculation

The invention discloses a method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves. The ultrasonic waves are used for modifying sludge, microbial cell walls in a sludge floc structure and the sludge are broken by high-temperature high-pressure environments and shearing action generated by ultrasonic cavitation action, sludge particle granularity is reduced, part of interstitial water is released, the modified sludge is mixed with coal, slurry-forming additives, water and the like to prepare the sludge and coal-water slurry, or finished coal-water slurry is doped into the modified sludge and uniformly stirred to prepare the sludge and coal-water slurry. Compared with the prior art, the method has the advantages that the slurry-forming viscosity of the sludge and coal-water slurry can be obviously reduced, slurry-forming concentration is increased, the sludge and coal-water slurry with excellent slurry-forming ability is obtained, treatment time is short, operation is convenient, and the method is applicable to large-scale popularization and application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method of making tungsten carbide based hard metal tools or components

InactiveUS7094821B2Reduce slurry viscosityImprove milling efficiencyTransportation and packagingMetal-working apparatusSlurryStearic acid

Preparation, handling, and spray drying, in an economic and environmentally-friendly way, of slurries for the production of tungsten carbide based hard metal tools or components by the powder injection molding or extrusion route is disclosed. The slurry used is based on ethanol-water and contains metal carbide and metallic raw materials as well as stearic acid and a low concentration of polyethylenimine (PEI). The concentration of PEI is 0.01–1 wt % of the raw material weight. This combination results in low-viscous slurries, which require less use of ethanol, energy, manpower, and equipment time in their preparation, handling, and spray drying. The invention also relates to the powder obtained by using the method.

Owner:SECO TOOLS AB

Method and apparatus for mixing a lignocellulosic material with enzymes

ActiveUS8617355B2Improve liquidityReduce slurry viscosityCellulosic pulp after-treatmentBiological substance pretreatmentsCelluloseEnzymatic hydrolysis

A method to treat a lignocellulosic material including: performing a steam explosion reaction on the lignocellulosic material and discharging a slurry from the; adding an alkali material to the slurry in a first conveyor; transferring the slurry with the alkali material from the first conveyor to a second conveyor; adding an enzyme solution to the slurry while in, entering or at the discharge of the second conveyor; transferring the slurry with the enzyme solution from the second conveyor slurry to a mixer; mixing the slurry in the mixer, wherein a second portion of the enzyme solution is added to the slurry during the mixing, and transferring the slurry with the enzyme solution from the mixer to a first reactor vessel wherein the slurry in the first reactor vessel undergoing enzymatic hydrolysis such that the viscosity of the slurry is reduced in the first reactor vessel.

Owner:ANDRITZ INC

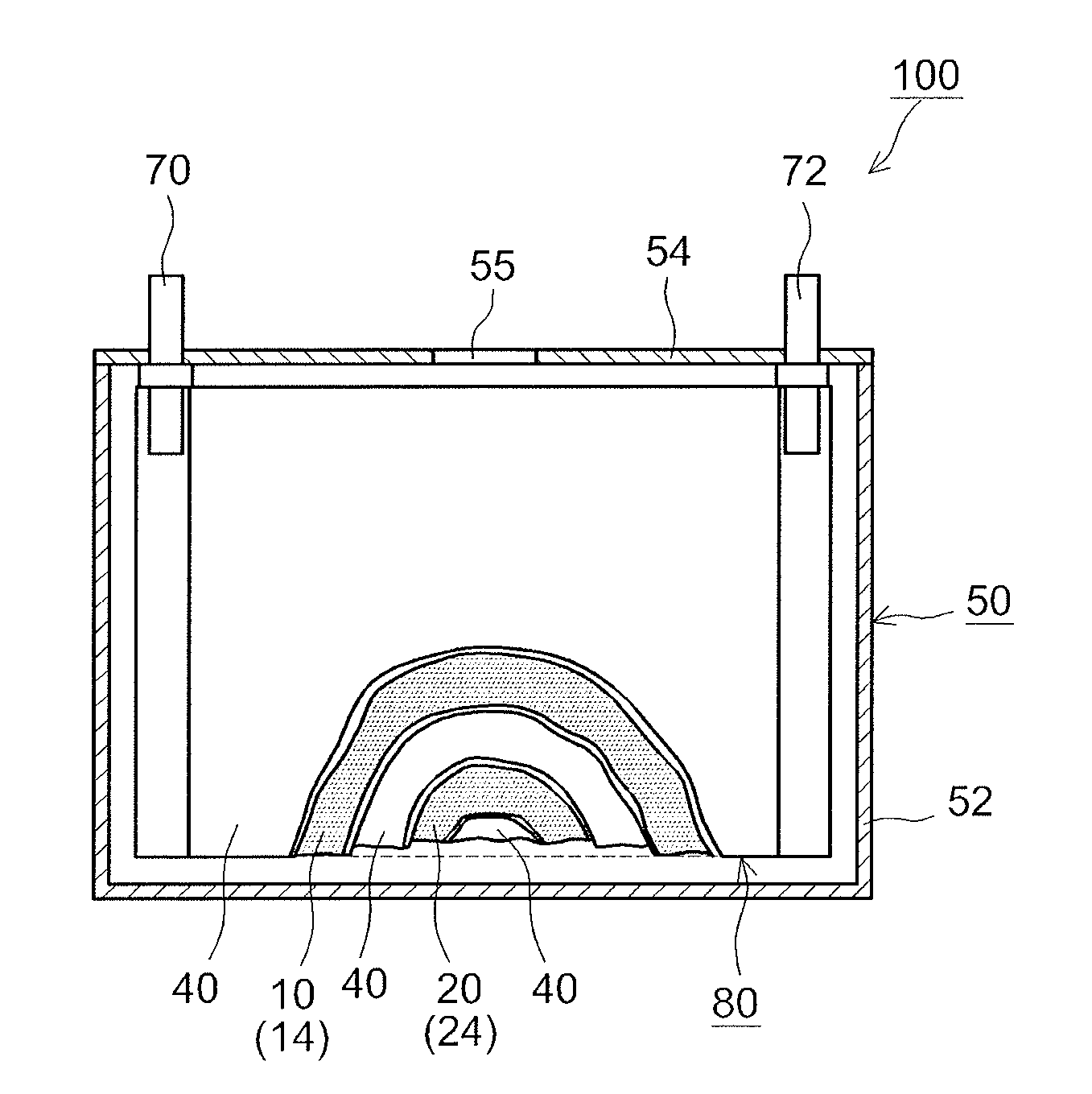

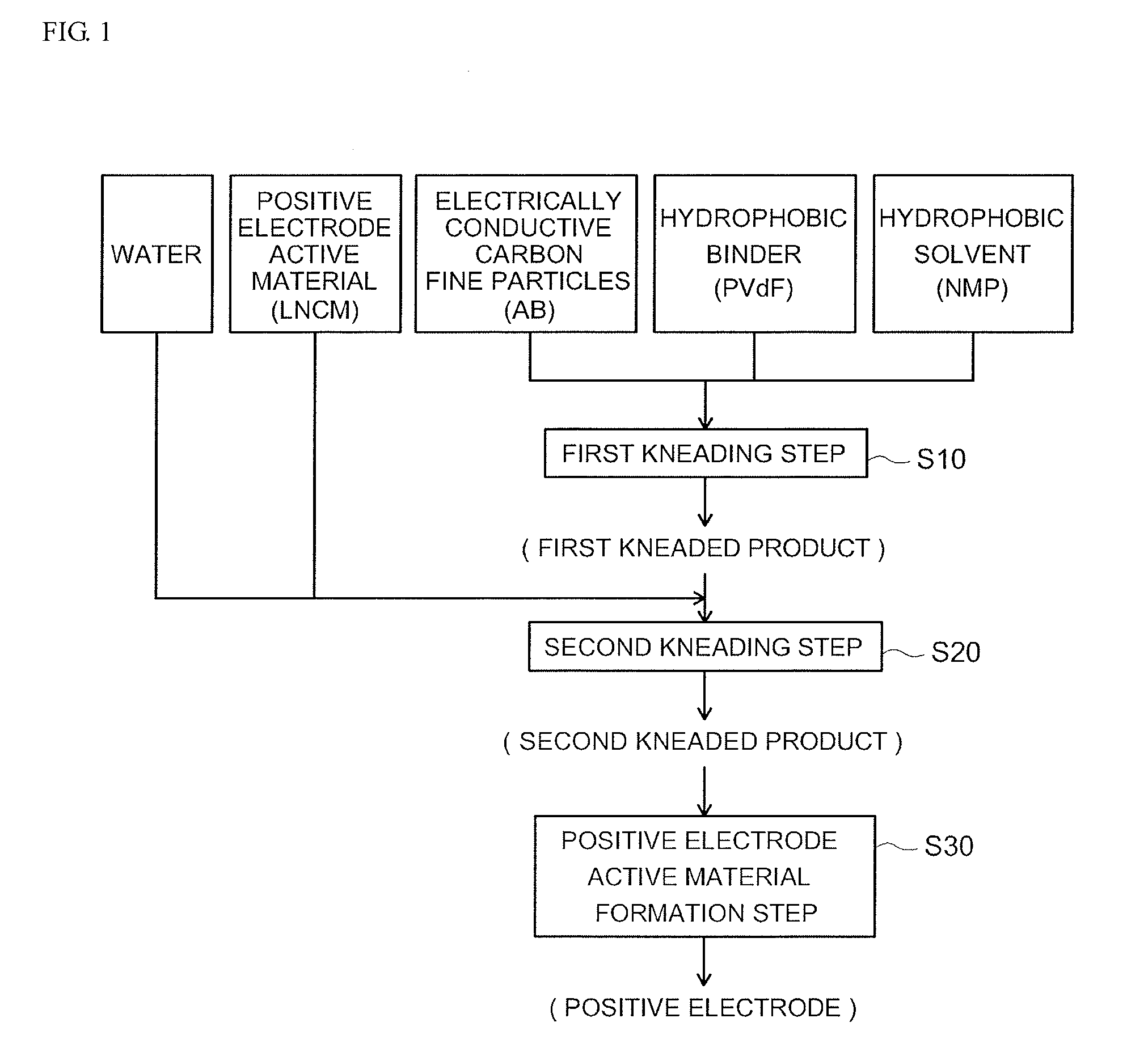

Positive electrode for nonaqueous electrolyte secondary battery and production method thereof

ActiveUS20150303480A1Low resistanceSuperior electrical conductivityPositive electrodesElectrode collector coatingElectrically conductiveProduction rate

Provided is a method for producing a positive electrode for a nonaqueous electrolyte secondary battery having superior electrical conductivity with high productivity. The production method disclosed herein includes the following steps: a first kneading step (S10) for kneading electrically conductive carbon fine particles and a hydrophobic binder that gels when contacted by water, in N-methyl-2-pyrrolidone (NMP); a second kneading step (S20) for adding a positive electrode active material and water to a first kneaded product obtained in the first kneading step followed by additional kneading; and a step (S30) for forming a positive electrode active material layer on the surface of a positive electrode current collector by coating a second kneaded product obtained in the second kneading step on the positive electrode current collector. The first kneaded product contains moisture, and the ratio of the mass of the moisture to the mass of the NMP is 0.002 or less in the first kneaded product, while in the second kneading step (S20), the water is added at a mass ratio of 0.0022 to 0.0115 based on the mass of the NMP.

Owner:TOYOTA JIDOSHA KK

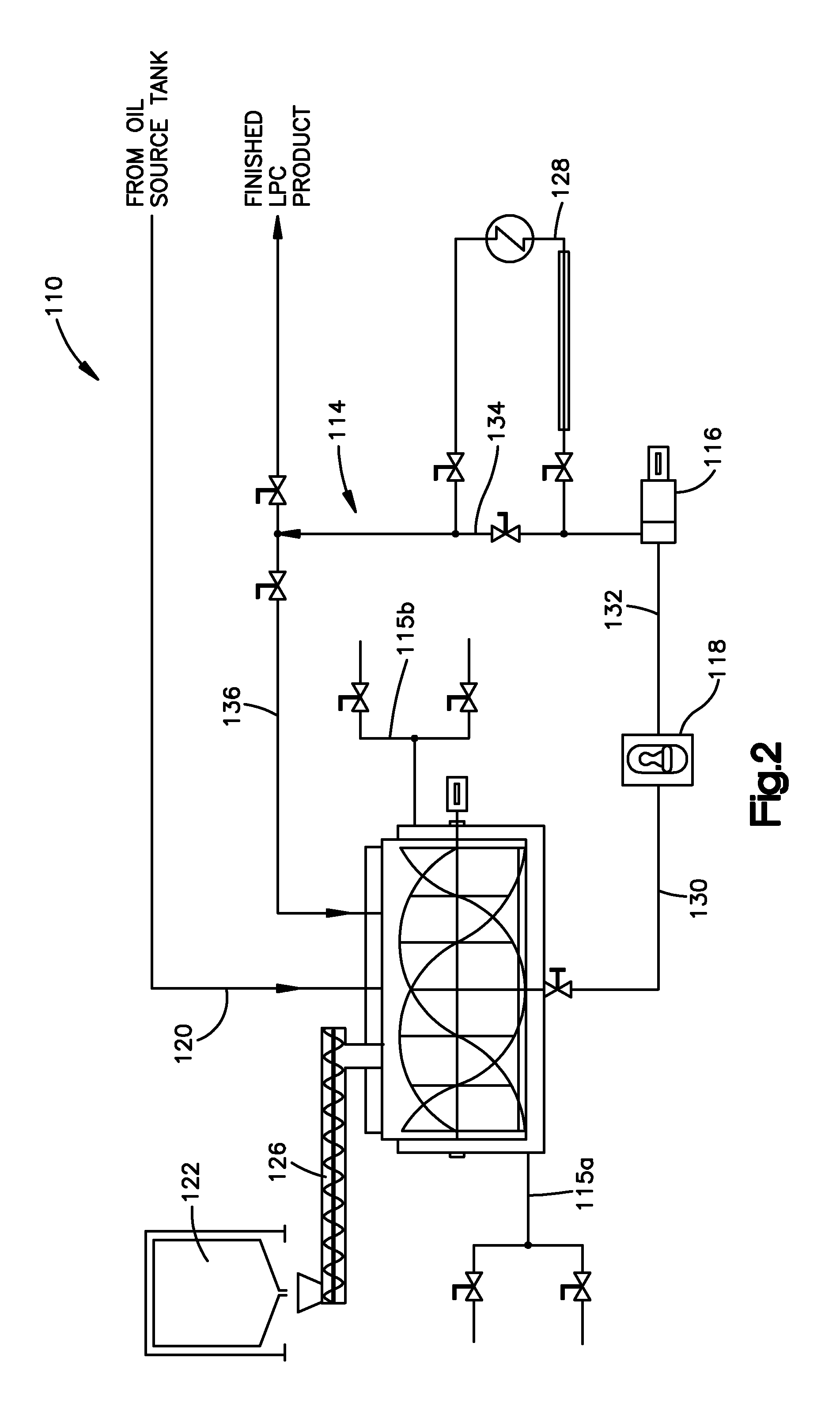

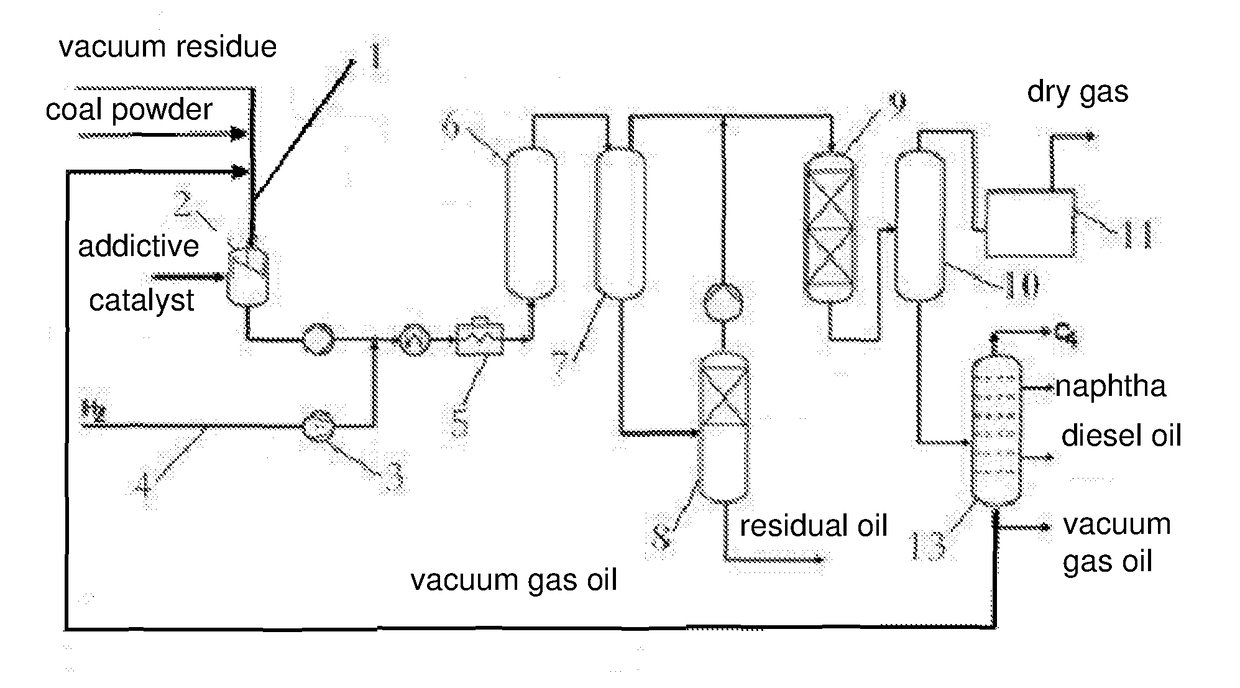

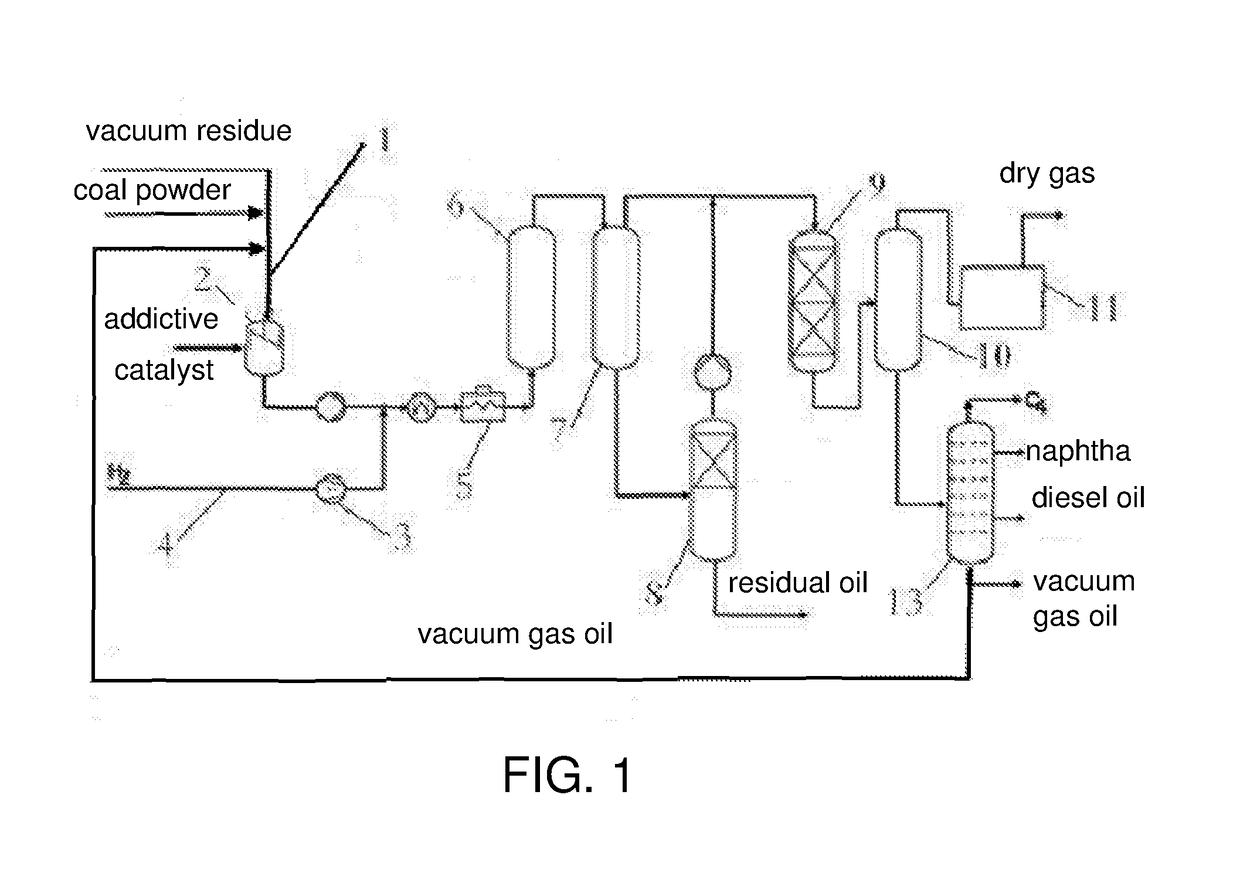

A coal and oil co-hydrotreating processing technology and equipment

ActiveUS20180023014A1Increase partial pressureImprove abilitiesGaseous fuelsSolid fuelsHydrogenation reactionFixed bed

An oil-coal co-hydrotreating processing includes the following steps: pulverized coal, vacuum residue and recycle oil are mixed to prepare coal slurry. After mixed with hydrogen, catalyst and additive, oil-coal slurry is preheated into a slurry bed reactor with high reacting pressure for thermal cracking and hydrogenation reaction. After reaction, all the products go into the hot high pressure separator for separation of solid from the bottom and gas from the top. The gas obtained goes into the fixed bed reactor for further hydrocracking or refining, and the distillate obtained enter the fractionating tower. The vacuum gas oil from the bottom of fractionating tower is taken as recycle oil piped to the oil-coal slurry mixing device as solvent.

Owner:CATECH TECH

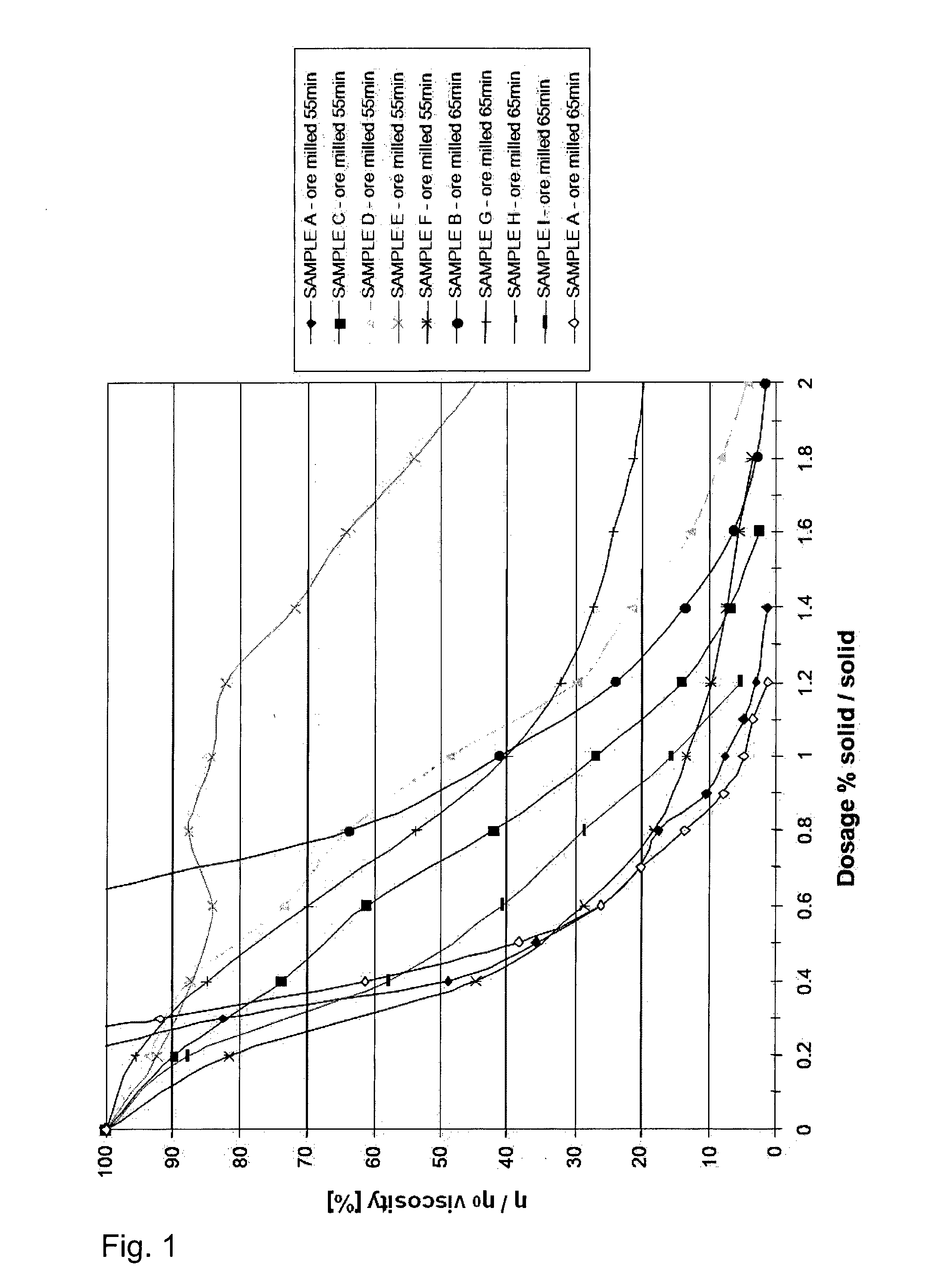

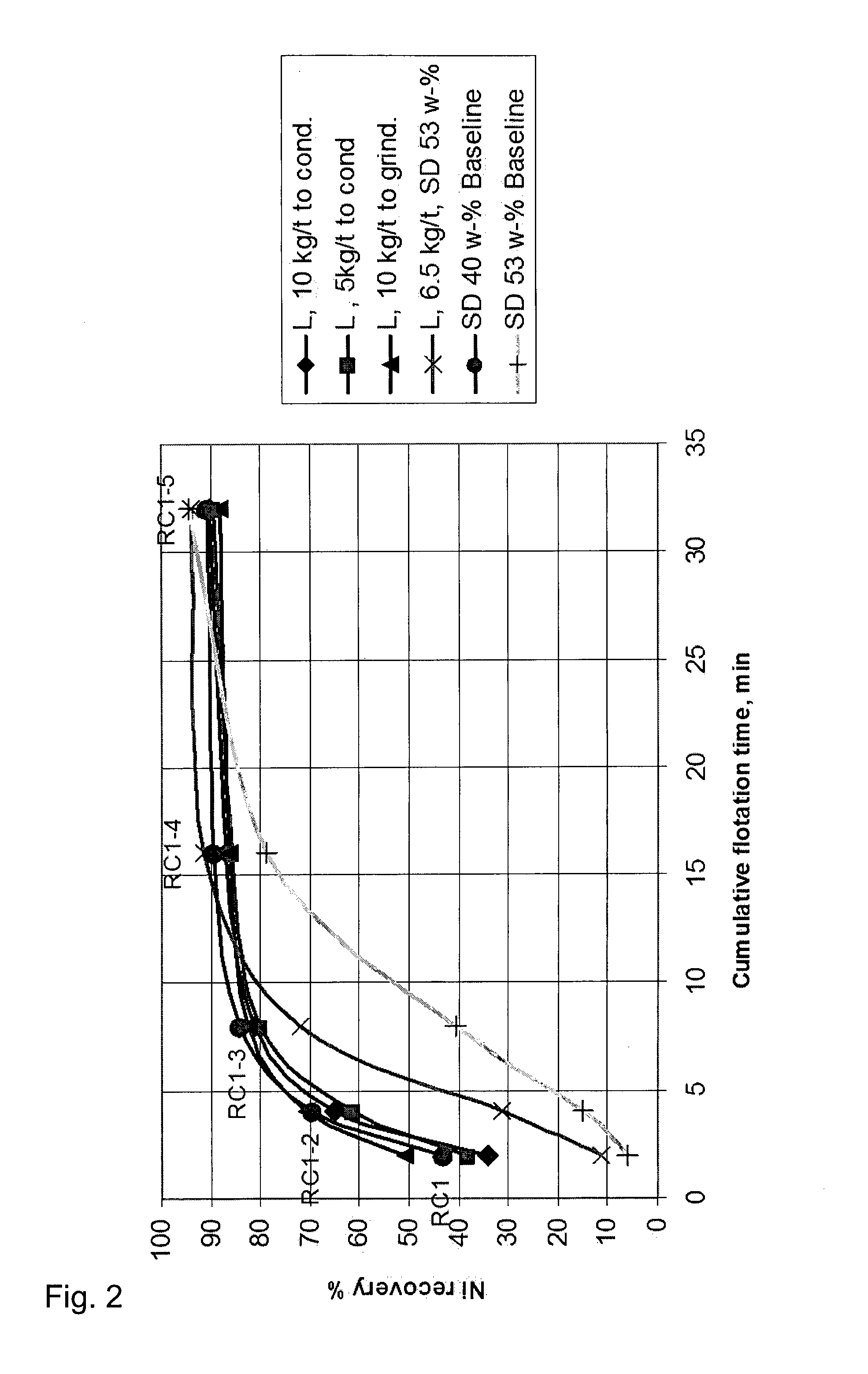

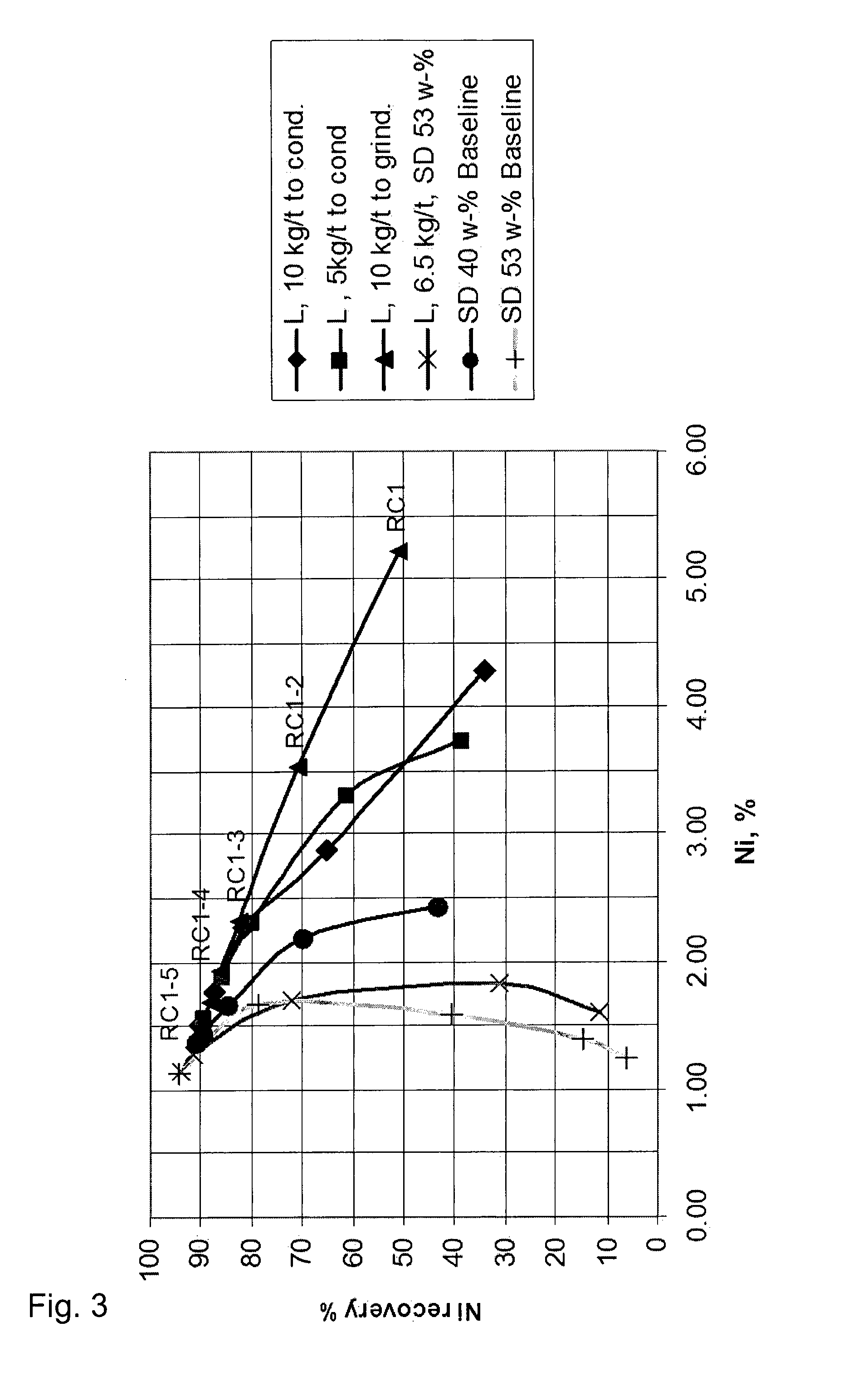

Method for Improving Rheological Properties of Mineral Slurry

InactiveUS20130338295A1Improve flotation effectReduce slurry viscosityTransportation and packagingAlkaline-earth metal silicatesSlurrySilicate minerals

Owner:MOORE LUCAS R +1

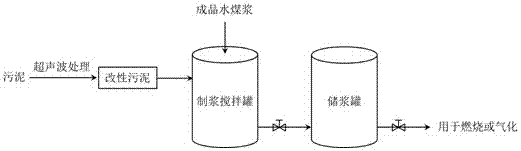

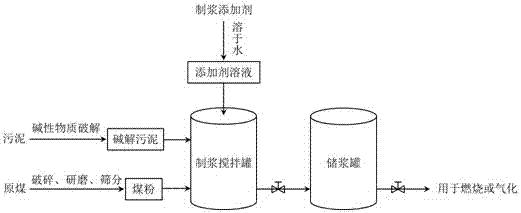

Method for using sludge floccules decomposed by alkaline substances to promote slurry forming of sludge and coal-water slurry

InactiveCN107164004ALow costEasy to operateSludge treatmentLiquid carbonaceous fuelsCoal waterSludge

The invention discloses a method for using sludge floccules decomposed by alkaline substances to promote slurry forming of sludge and coal-water slurry. The method comprises the following steps: (1) firstly, adding the alkaline substances to sludge, and fully stirring for a certain time to obtain alkali-decomposed sludge; (2) crushing, grinding and sieving raw coal sequentially to obtain pulverized coal having a particle size of smaller than 150 microns; and (3) fully dissolving a slurry preparing additive in water to obtain an additive solution, adding the alkali-decomposed sludge in the step (1) and the pulverized coal in the step (2) to the additive solution, and fully stirring by a slurry preparing and stirring device to obtain uniform sludge and coal-water slurry; or, directly doping the alkali-decomposed sludge in the step (1) into a finished product of coal-water slurry, and fully stirring to obtain the uniform sludge and coal-water slurry. Compared with the prior art, the method provided by the invention has advantages of low cost and convenient operation, and can effectively reduce slurry forming viscosity of the sludge and coal-water slurry, improve a slurry forming concentration, acquire the sludge and coal-water slurry with excellent slurry forming performance, and being suitable for large-scale promotion and application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cooked Caramel Compositions and Related Food Products

ActiveUS20160353764A1Reduce crystallinityIncrease moisture contentConfectionerySweetmeatsSlurryFood products

Owner:GENERAL MILLS INC

Method for producing terephthalic acid-alkylene glycol mixture

InactiveCN101535370AGood slurry propertiesImprove stabilityPreparation from carboxylic acid esters/lactonesSlurryHydrolysis

A terephthalic acid-alkylene glycol mixture suitable as a raw material mixture for polyester polycondensation reaction is obtained by preparing a liquid mixture having a temperature of 100-130 DEG C and containing terephthalic acid obtained by hydrolysis of dialkyl terephthalate and at least one alkylene glycol, and stirring this liquid mixture for 15 minutes to 3 hours while maintaining the liquid mixture within the above-mentioned temperature range, thereby adjusting the slurry characteristics of the liquid mixture.

Owner:TEJIN FIBERS LTD

Protein-containing food product and coating for a food product and method of making same

InactiveUS20100034940A1Thin coatingHigh in proteinConfectionerySweetmeatsNutritive valuesAdditive ingredient

A method for forming a complex of a protein-containing material and a lipid-based material comprises the steps of admixing said protein-containing material into said lipid material, applying heat and a shear force to said admixture to form an emulsion of protein material in said lipid material, and cooling said admixture to form a lipid-protein complex. Optionally, a liquid grinding step also may be used. The complex comprises at least about 10-50 net weight % protein, preferably no more than about 1% of an emulsifier, and an amount of a lipid-containing material sufficient to form an emulsion with the protein containing material. It is believed that higher proportions of protein could be obtained in the emulsion with high capacity pumps and shear apparatus. The complex can be used as a coating composition for a food product, or as an ingredient in a coating composition for a food product, or as an ingredient in a food article. When used as or in a coating for a snack food item such as a protein-containing energy bar, the coating can add to the nutritive value of the bar, and maintain the moisture content of the bar.

Owner:BUNGE OILS INC

Long-life iron runner quick-dry castable and production method thereof

InactiveCN110272267AImprove breathabilityImprove explosion-proof performanceDischarge devicesCeramicwareSuperplasticizerAluminum metal

The invention discloses a long-life iron runner castable and a production method thereof. The long-life iron runner castable comprises the following components: 900-1100 parts of fused corundum, 260-500 parts of silicon carbide micro-powder, 90-100 parts of alumina micro-powder, 100-110 parts of tabular corundum micro-powder, 60-80 parts of aluminate cement, 2-4 parts of aluminum metal powder, 2-6 parts of an efficient water reducer and 60-80 parts of a carbon source. The production method comprises the steps of firstly, mixing and stirring the alumina micro-powder, the tabular corundum micro-powder, silicon metal powder, the aluminum metal powder, the efficient water reducer and silica fume for 20-30 minutes to produce a premix; and then mixing and stirring the premix, the fused corundum, the silicon carbide micro-powder, the aluminate cement and ball pitch for 8-12 minutes to produce the iron runner castable used for a blast furnace. The long-life iron runner castable has the advantages that the thermal conductivity is low, the explosion-proof performance is excellent, and the service life is long.

Owner:武汉市科达耐火有限责任公司

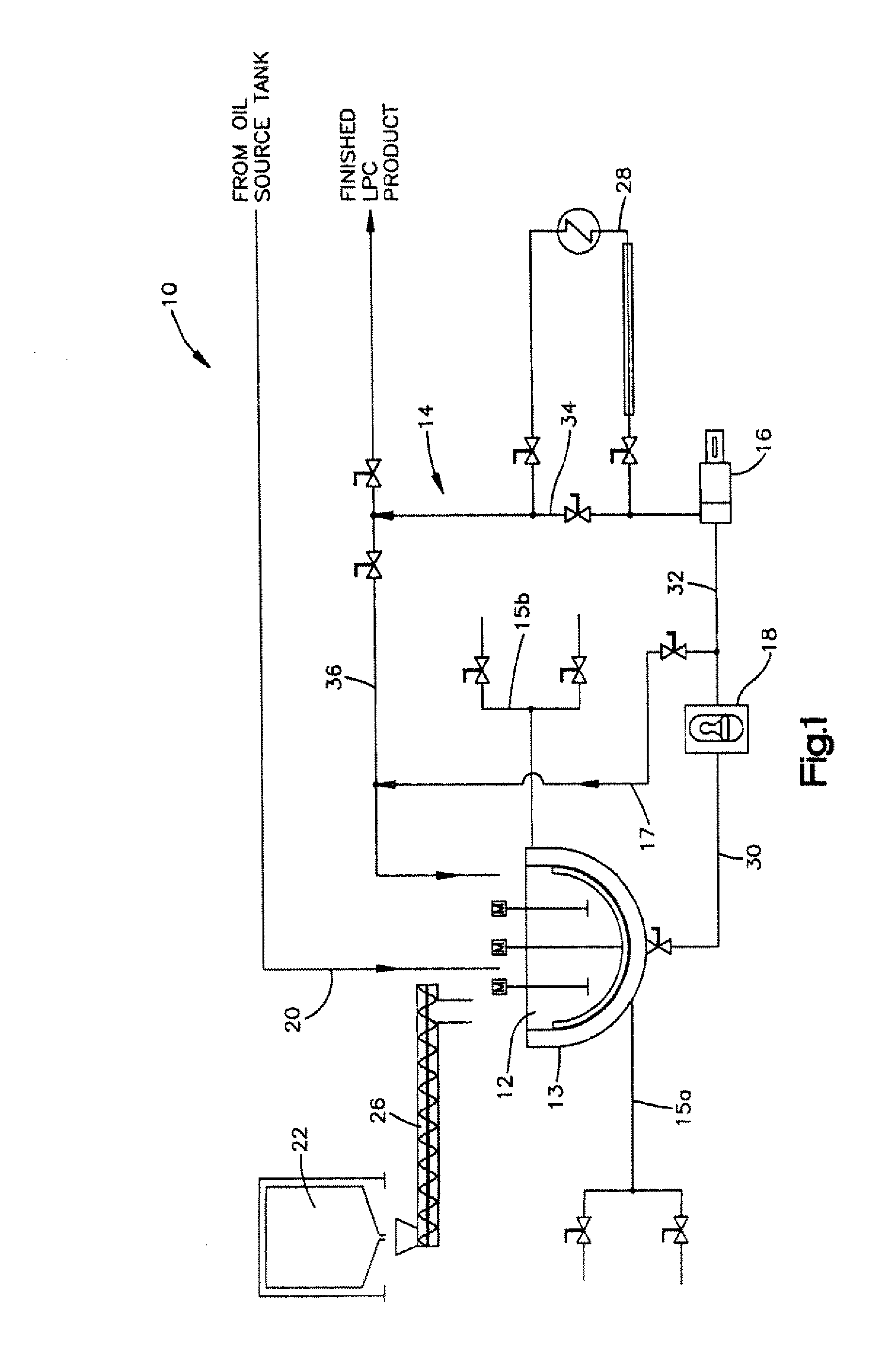

Method and apparatus for obtaining strong white liquor and lime mud with low residual alkali level

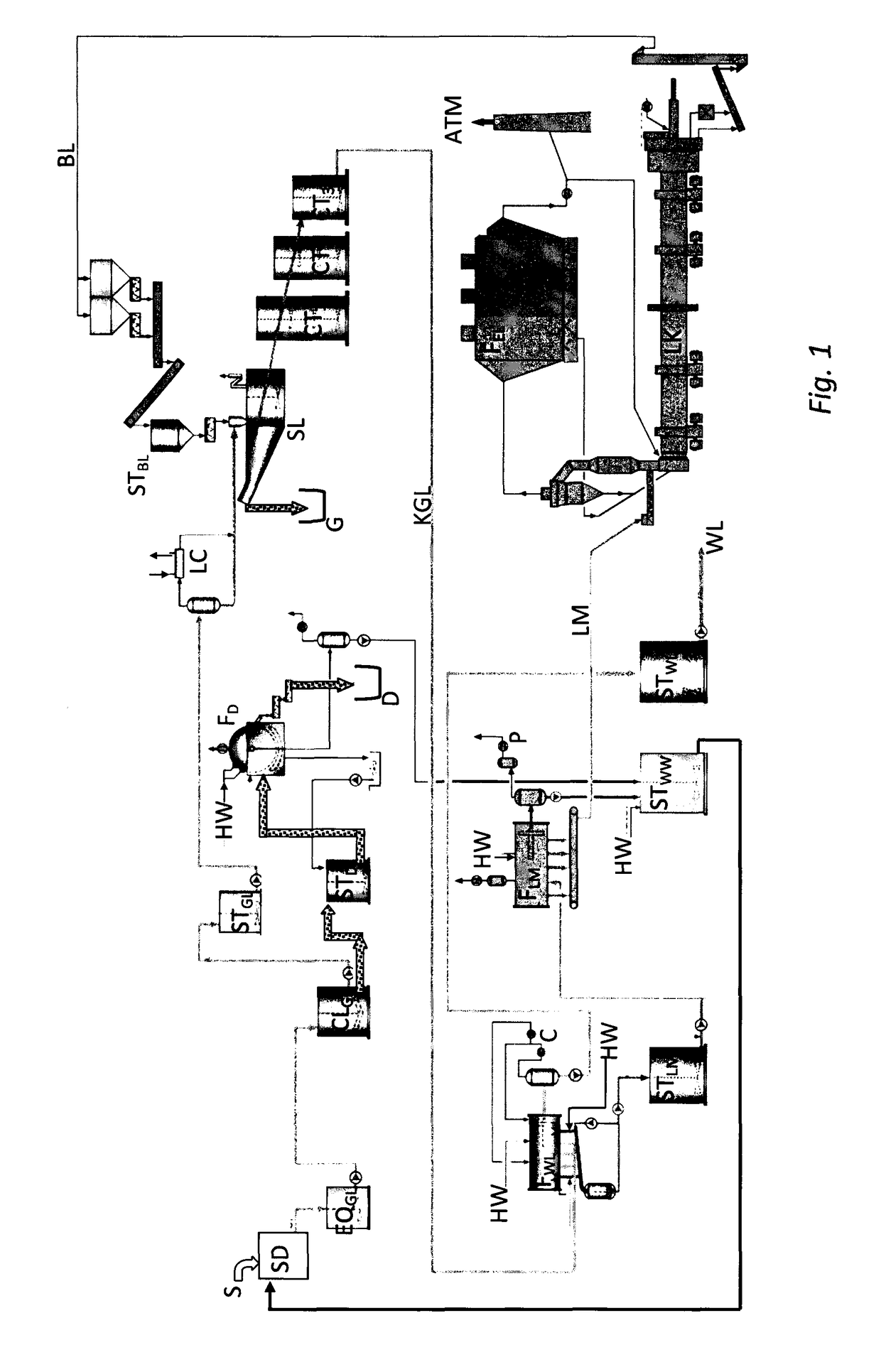

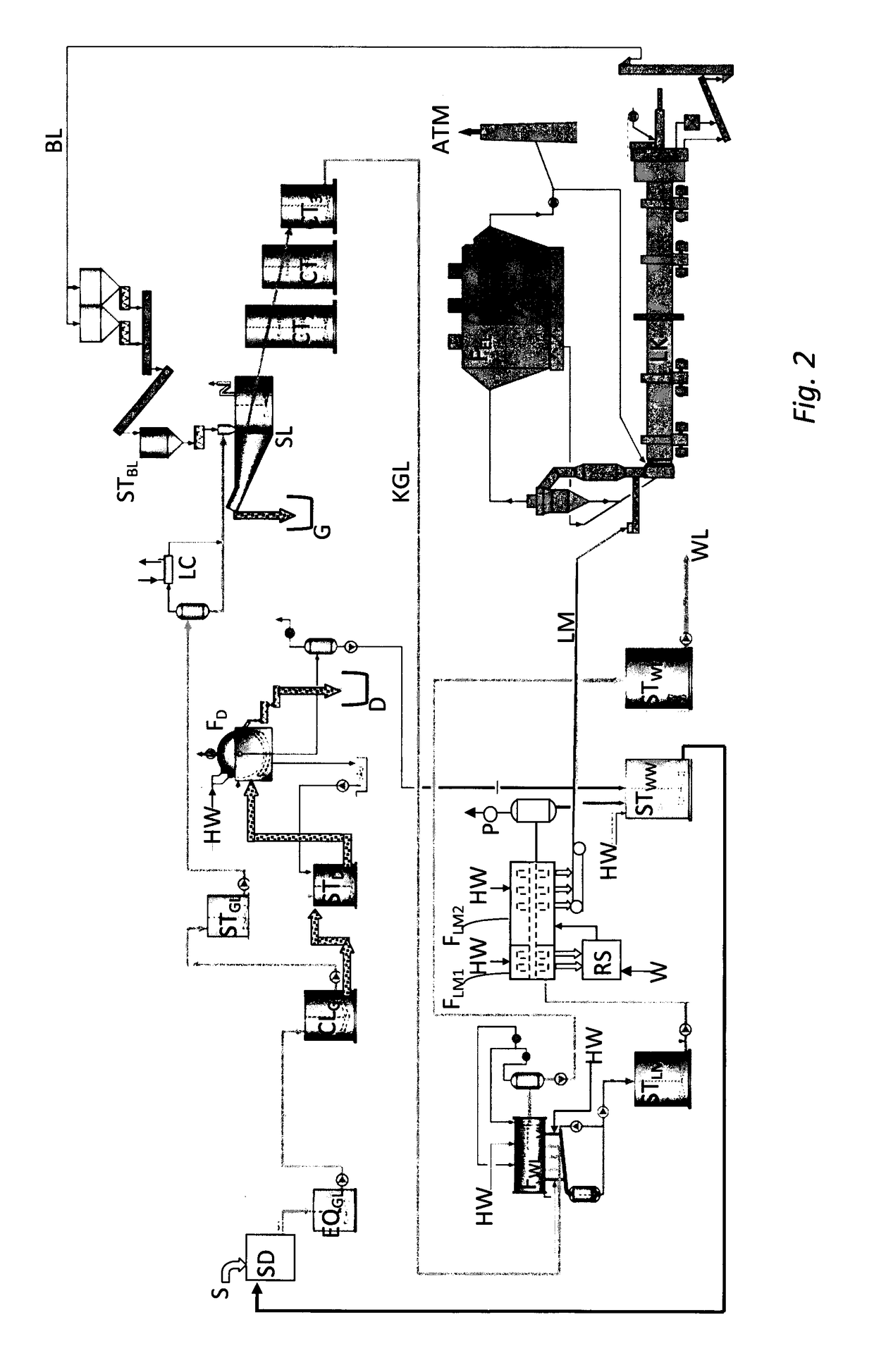

InactiveUS10011947B2Emission reductionIncrease loadRegeneration of alkali lyeLime productionWhite liquorEngineering

The method and apparatus are for obtaining strong white liquor and lime mud with low residual alkali content from causticized liquor. The first filter (FWL) receives causticized liquor from causticizing vessels (CT1-CT2-CT3) and is designed as pressurized two stage disc filter with 2 separate vat parts. In the first vat part non-diluted white liquor is obtained as a filtrate from the causticized liquor. The first lime mud cake accumulated on the filter discs in the first vat part is scraped off and diluted before being fed to the second vat part. In the second vat part weak liquor is obtained as a filtrate from the re-slurried first lime mud cake. The second lime mud cake accumulated on the filter discs in the second vat part is washed before being scraped off and diluted before being fed to subsequent lime mud handling.

Owner:VALMET AB

Method and apparatus for obtaining strong white liquor and lime mud with low residual alkali level

InactiveUS20150225895A1Emission reductionIncrease loadPulp liquors combustionMachine wet endWhite liquorPulp and paper industry

The method and apparatus are for obtaining strong white liquor and lime mud with low residual alkali content from causticized liquor. The first filter (FWL) receives causticized liquor from causticizing vessels (CT1-CT2-CT3) and is designed as pressurized two stage disc filter with 2 separate vat parts. In the first vat part non-diluted white liquor is obtained as a filtrate from the causticized liquor. The first lime mud cake accumulated on the filter discs in the first vat part is scraped off and diluted before being fed to the second vat part. In the second vat part weak liquor is obtained as a filtrate from the re-slurried first lime mud cake. The second lime mud cake accumulated on the filter discs in the second vat part is washed before being scraped off and diluted before being fed to subsequent lime mud handling.

Owner:VALMET AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com