Method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves

A technology of ultrasonic wave and sludge water, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of poor slurry forming properties, improve slurry forming properties, easy method, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

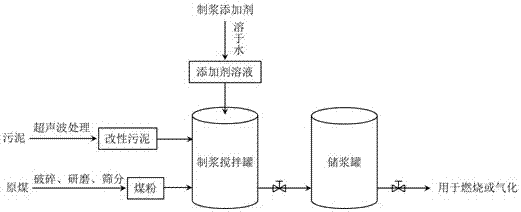

[0035] (1) Implementation method

[0036] Sludge is taken from the surplus sludge produced by a sewage treatment plant. After different degrees of mechanical dehydration, sludge samples with moisture content of 90%, 95% and 98% are formed, which are used for ultrasonic modification and subsequent sewage treatment. Slurry.

[0037] The probe-type ultrasonic chemical treatment system is adopted, and the equipment consists of three parts: generator, transducer and ultrasonic probe. The ultrasonic frequency is 20 kHz, the ultrasonic power is set to 190 W, and the ultrasonic input specific energy is selected as 0 (ie without ultrasonic treatment), 3.8, 7.5, 15, 30, and 75 kJ / g DS.

[0038] When the modified sludge is used to make coal-water slurry, the mass ratio relationship of each raw material component is: sludge converted according to the moisture content of 90%: dry coal powder = 30: 100, additive: dry coal powder = 0.8: 100. The additive is naphthalene sulfonate formaldehy...

Embodiment 2

[0046] (1) Implementation method

[0047] The sludge is taken from the surplus sludge produced by a sewage treatment plant. After a certain degree of mechanical dehydration, sludge samples with a moisture content of 95% are formed, which are used for ultrasonic modification and subsequent sludge coal-water slurry production.

[0048] Same as Example 1, a probe-type sonochemical treatment system is used, which consists of three parts: a generator, a transducer and an ultrasonic probe. The ultrasonic frequency is 20 kHz, the ultrasonic power is set to 114 W, 190 W and 266 W, respectively, and the ultrasonic input specific energy is 75 kJ / g DS.

[0049] When the modified sludge is used to make coal-water slurry, the mass ratio relationship of each raw material component is: sludge converted according to the moisture content of 90%: dry coal powder = 30: 100, additive: dry coal powder = 0.8: 100. The additive is naphthalene sulfonate formaldehyde condensate. The solid mass conce...

Embodiment 3

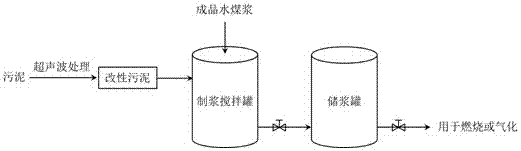

[0056] (1) Implementation method

[0057] The sludge is taken from the surplus sludge produced by a sewage treatment plant. After a certain degree of mechanical dehydration, sludge samples with a moisture content of 95% are formed, which are used for ultrasonic modification and subsequent sludge coal-water slurry production.

[0058] The sludge was modified by a multi-frequency ultrasonic cell breaker. The ultrasonic frequencies were 15 kHz, 25 kHz, and 35 kHz, the ultrasonic power was set to 325 W, and the ultrasonic input specific energy was 4 kJ / g DS and 30 kJ / g DS, respectively.

[0059] Coal water slurry adopts the finished product prepared in advance, the additive is lignin sulfonate when making coal water slurry, and the mass ratio relationship between additive and dry coal powder is 0.8:100.

[0060] The modified sludge is mixed into the coal-water slurry and fully stirred to form a uniform sludge-coal-water slurry sample. The mass ratio of the sludge mixed is: sludge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com