Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

643results about How to "The process is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

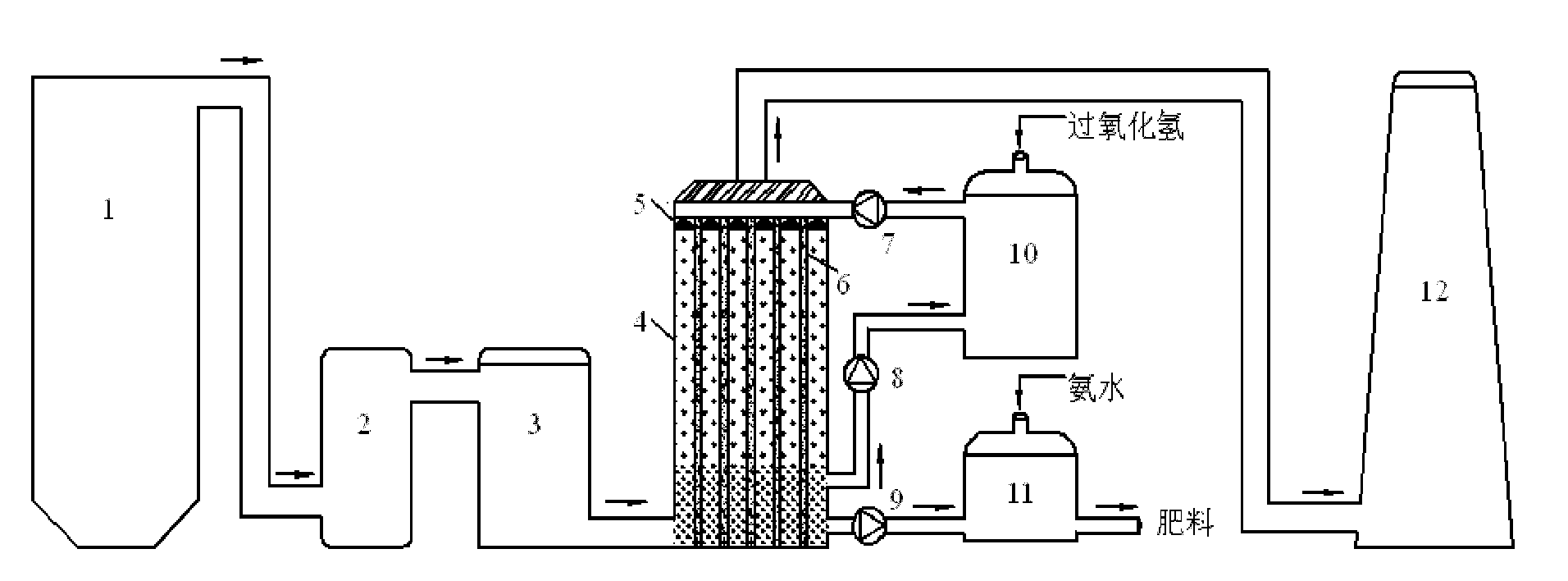

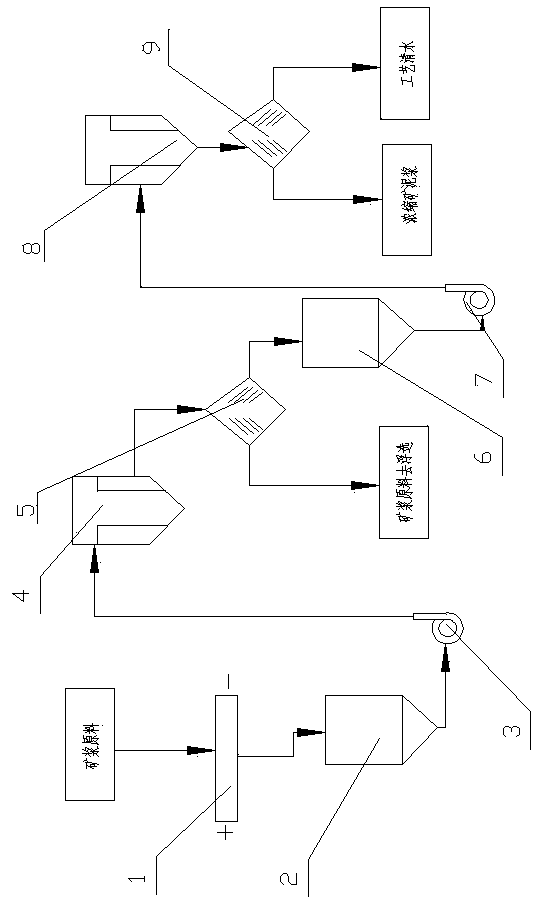

Photochemical advanced oxygenation-based simultaneous desulfuration and denitration system

InactiveCN101940871AThe process is simple and reliableSmall footprintDispersed particle separationAir quality improvementFertilizerAmmonium sulfate

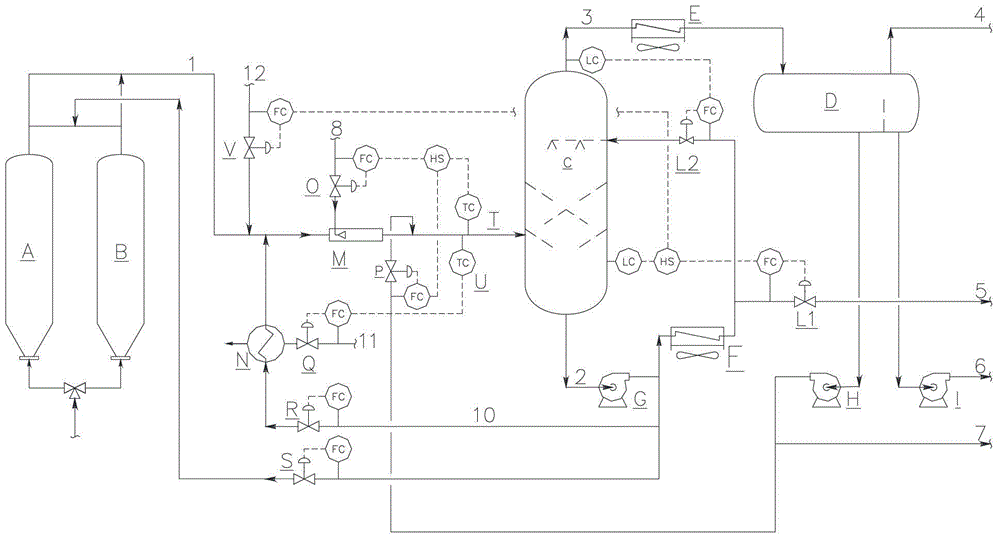

The invention discloses a photochemical advanced oxygenation-based simultaneous desulfuration and denitration system. The system is provided with a burning and exhausting system consisting of a burner, an electrostatic dust collector, a heat exchanger, a spray tower, a liquid adding tower and a chimney, wherein fume generated by the burner enters the electrostatic dust collector, fume particles are removed from the fume by the electrostatic dust collector, the fume enters the heat exchanger and is cooled by the heat exchanger, and then the fume enters the spray tower; an UV light tube is arranged in the spray tower; hydrogen peroxide solution from the liquid adding tower is pumped by a circulating pump, sprayed into the spray tower through an atomizing nozzle and is activated by ultraviolet light to decompose hydrogen peroxide and then generate hydroxyl radicals (.OH) with strong oxidizing property; after being contacted with the fume in the spray tower, the hydroxyl radicals undergoes a gas-liquid absorption reaction with the fume to oxidize and remove NOx and SO2 in the fume; the fume, after being absorbed and washed, enters the chimney from the top of the spray tower and is exhausted; and sulfuric acid solution and salpeter solution generated in the spray tower are pumped into the separating column by the circulating pump and are reacted with added ammonia water to generate agricultural fertilizers including ammonium sulfate and ammonium nitrate.

Owner:SOUTHEAST UNIV

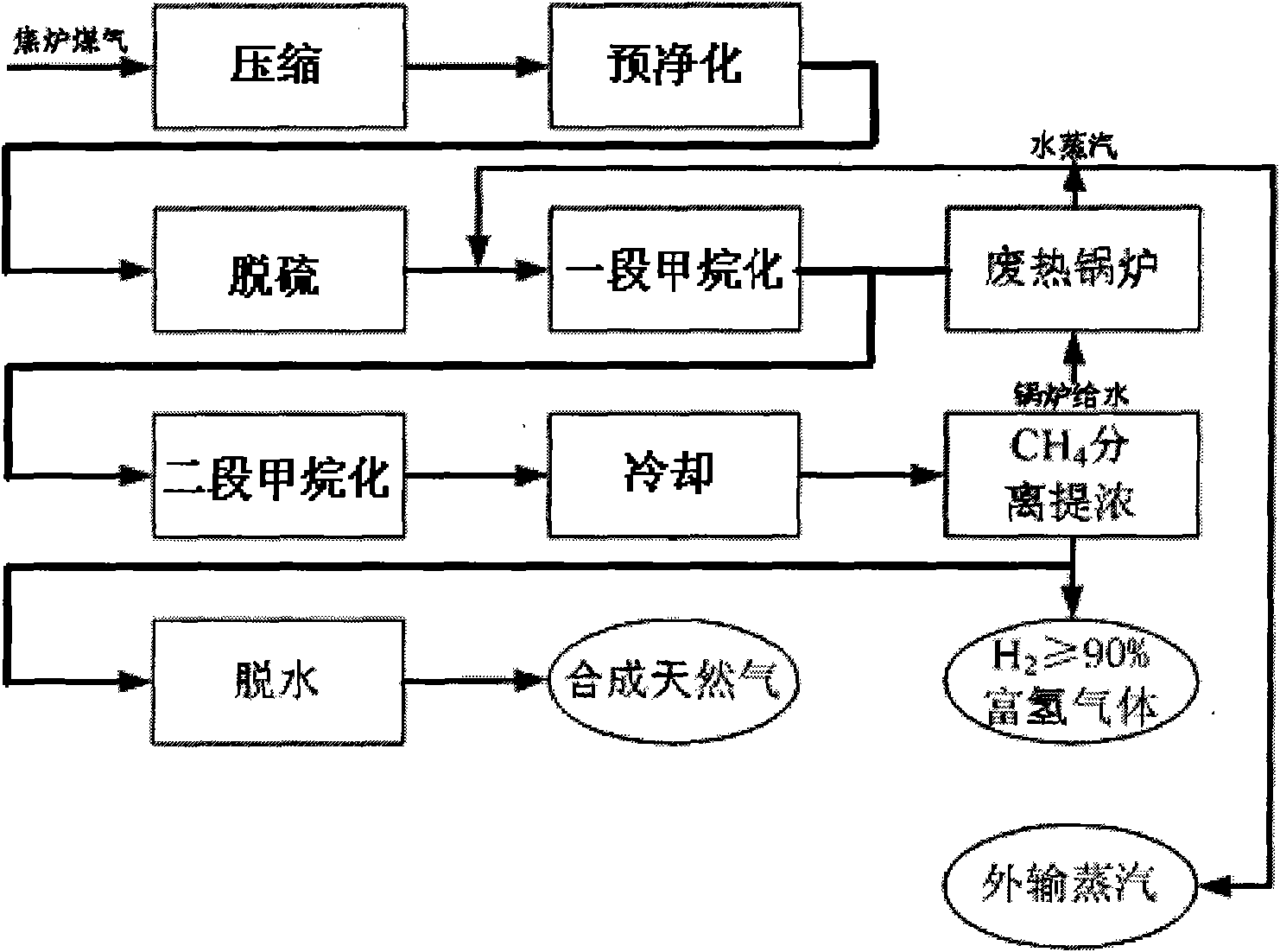

Synthesis process of natural gas employing methanation of coke oven gas

The invention relates to a comprehensive utilization synthesis process of natural gas employing methanation of coke oven gas, belonging to the technical field of new energy utilization. The process comprises the following steps: compressing coke oven gas, preliminary cleaning, removing sulfur, performing first section methanation, performing second section methanation and separating natural gas toprepare natural gas which reaches the grade A technological requirements of natural gas national standard (GB17820-1999). The synthesis process of natural gas employing methanation of coke oven gas reaches the aim of high effective comprehensive utilization of natural gas and provides a new way of preparing and synthesizing natural gas.

Owner:SHANDONG TIEXIONG METALLURGICAL TECH CO LTD +2

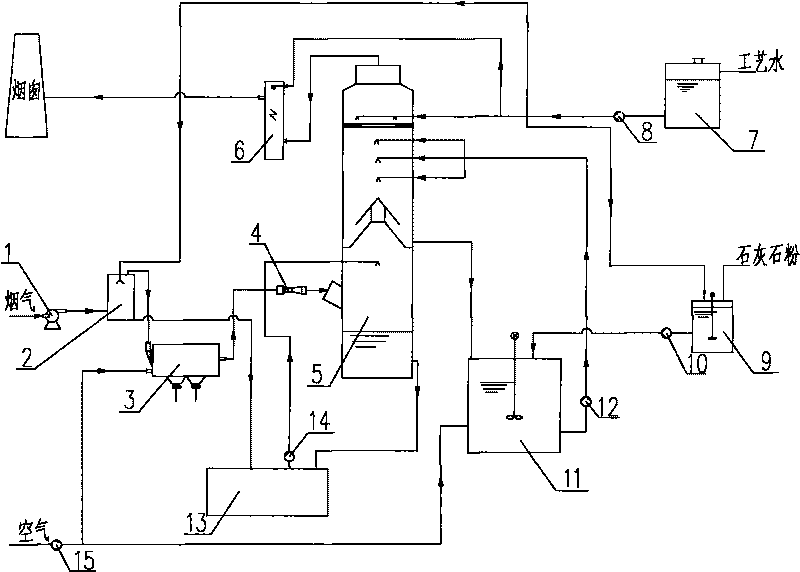

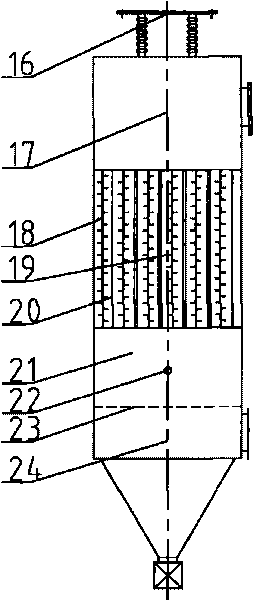

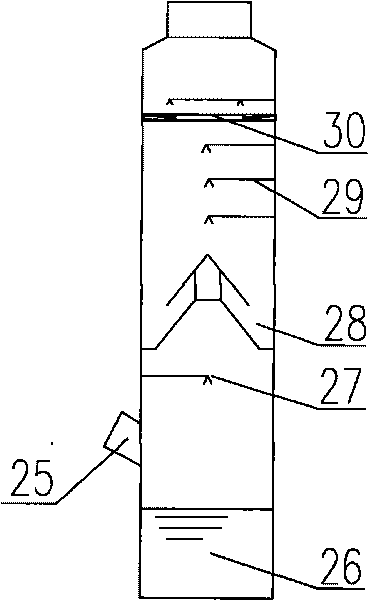

Simultaneous removing device and method of various pollutants by electrocatalytical oxidation combining lime-gypsum method

ActiveCN101716463ALow investment costThe process is simple and reliableUsing liquid separation agentElectricityMulti pollutant

The invention discloses simultaneous removing device and method of various pollutants by an electrocatalytical oxidation combining lime-gypsum method. The device comprises a spraying and cooling device, an electrostatic enhancement reactor, a Venturi device, a double-circulation integrated absorption tower of various pollutants and a wet type electrostatic defroster, wherein after smoke is cooled by the spraying and cooling device, the smoke enters the electrostatic enhancement reactor and is subjected to corona discharge processing in a corona discharge area formed in the electrostatic enhancement reactor; the processed smoke enters the double-circulation integrated absorption tower of various pollutants and is sprayed to remove dust and absorb in the absorption tower; and the purified smoke sequentially enters a corrugated plate defroster and the electrostatic defroster on the upper part of a spraying tower so as to remove aerosol in the smoke. The invention has the advantages that various pollutants can be simultaneously removed, and meanwhile, the pollution of fine granules and the aerosol can be effectively controlled; various pollutants can have higher removal efficiency; and the removal and the absorption of by-products cannot cause secondary pollution to environment.

Owner:ZHEJIANG UNIV

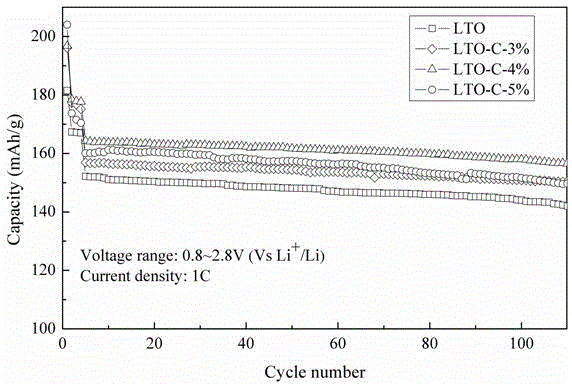

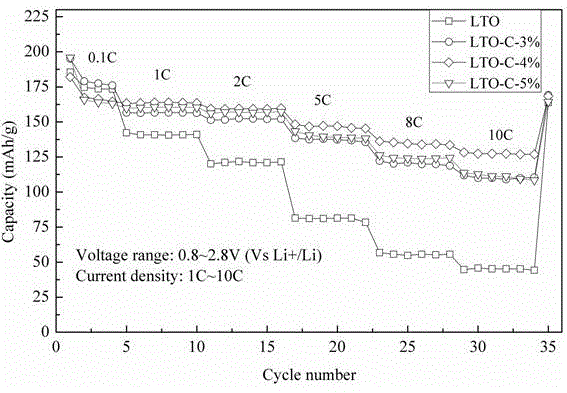

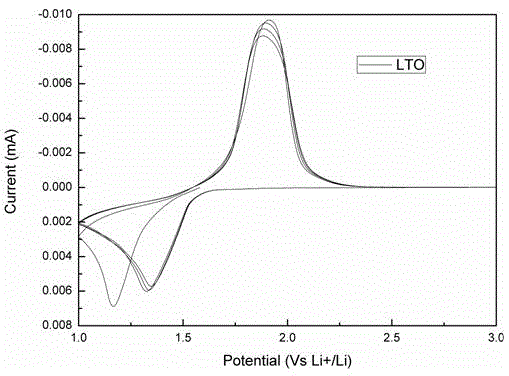

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

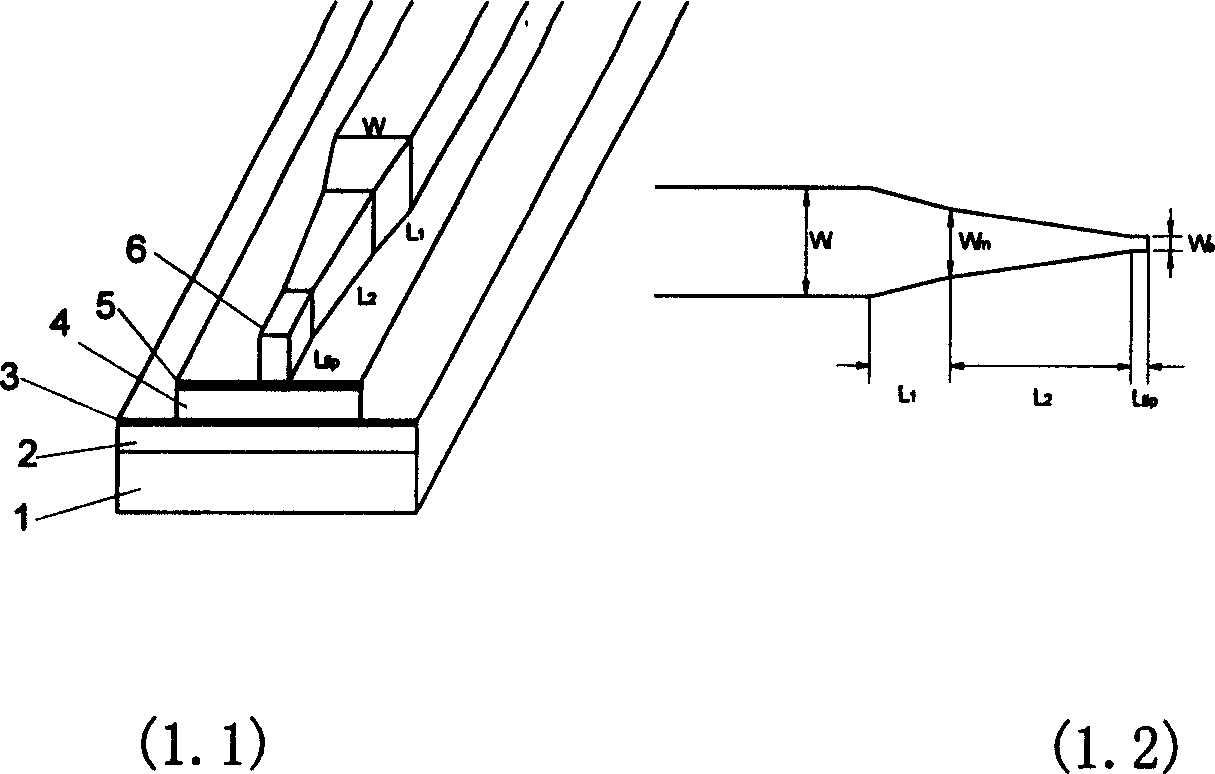

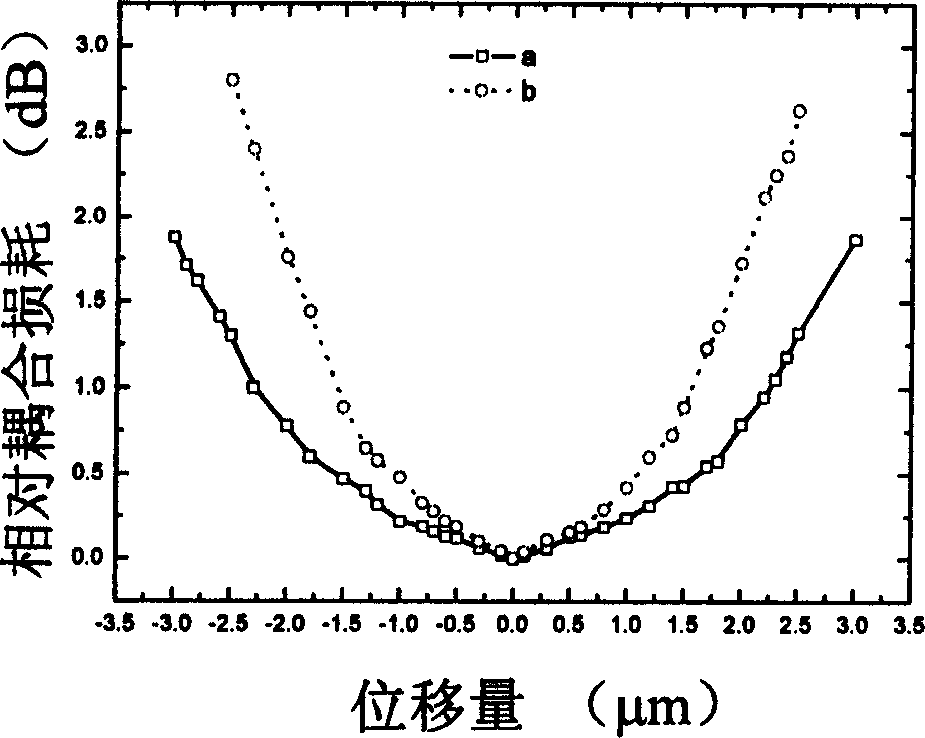

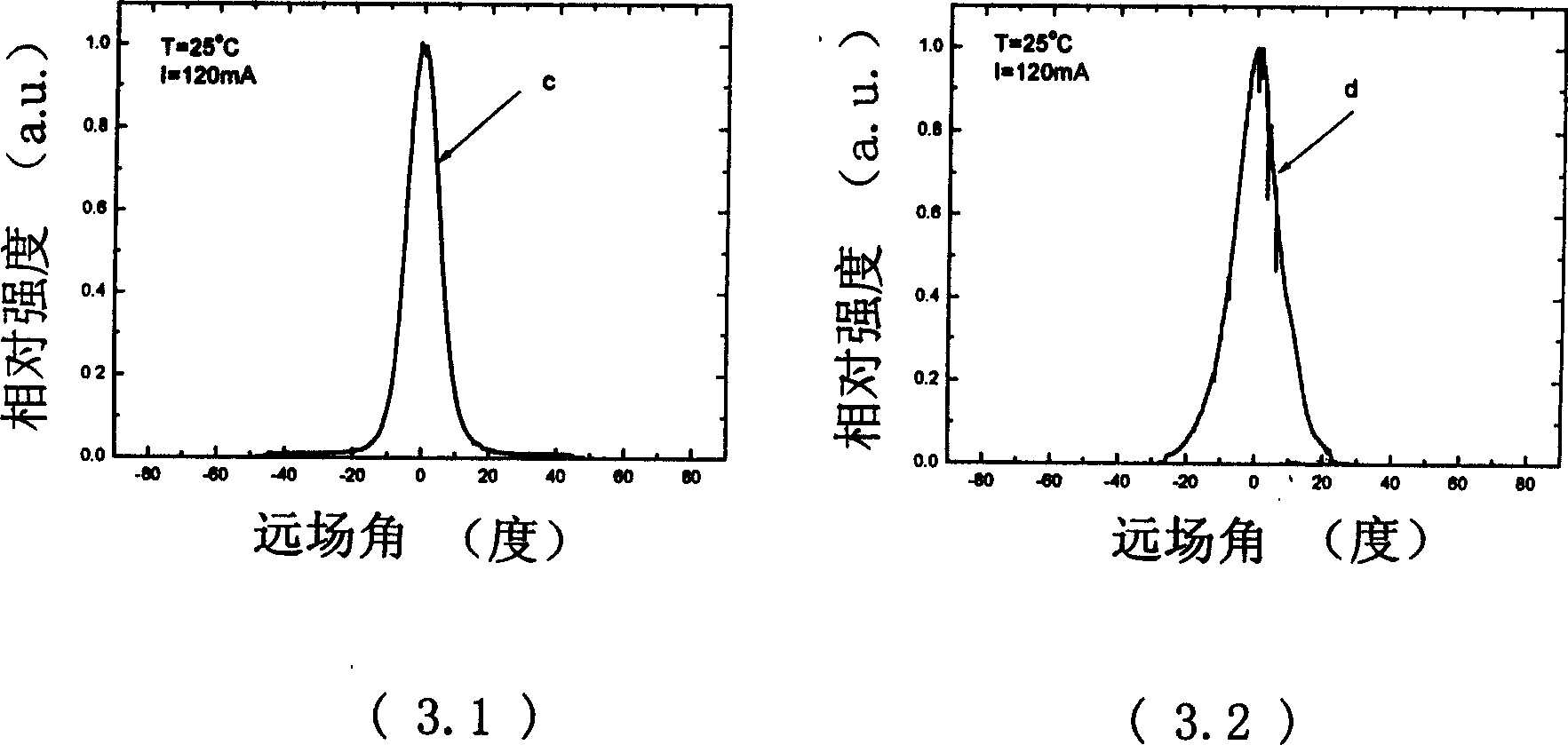

Ridge waveguide polarized don't-care semiconductor optical enlarger of integrated modular spot converter

InactiveCN1564406AImprove yieldThe process is simple and reliableOptical wave guidanceLaser active region structureCoupling efficiencyRidge

The light amplifier includes InP substrate, n type InP buffer layer, passive waveguide layer, active region, ridge type waveguide and electrodes in top and bottom layers. Characters are that second stage wide ridge waveguide is setup between passive waveguide layer and active region. The said ridge type waveguide is lateral taper structure. Ridge type waveguide and second stage wide ridge waveguide together makes light beam match to optical fiber at far field. Ridge type waveguide is divided into three parts: reduced laterally in two stages. Features are: good performance in far field, very high coupling efficiency to waveguide or fiber and alignment tolerance, wide applicable to optical network, optical integration and photoelectron integration.

Owner:HUAZHONG UNIV OF SCI & TECH

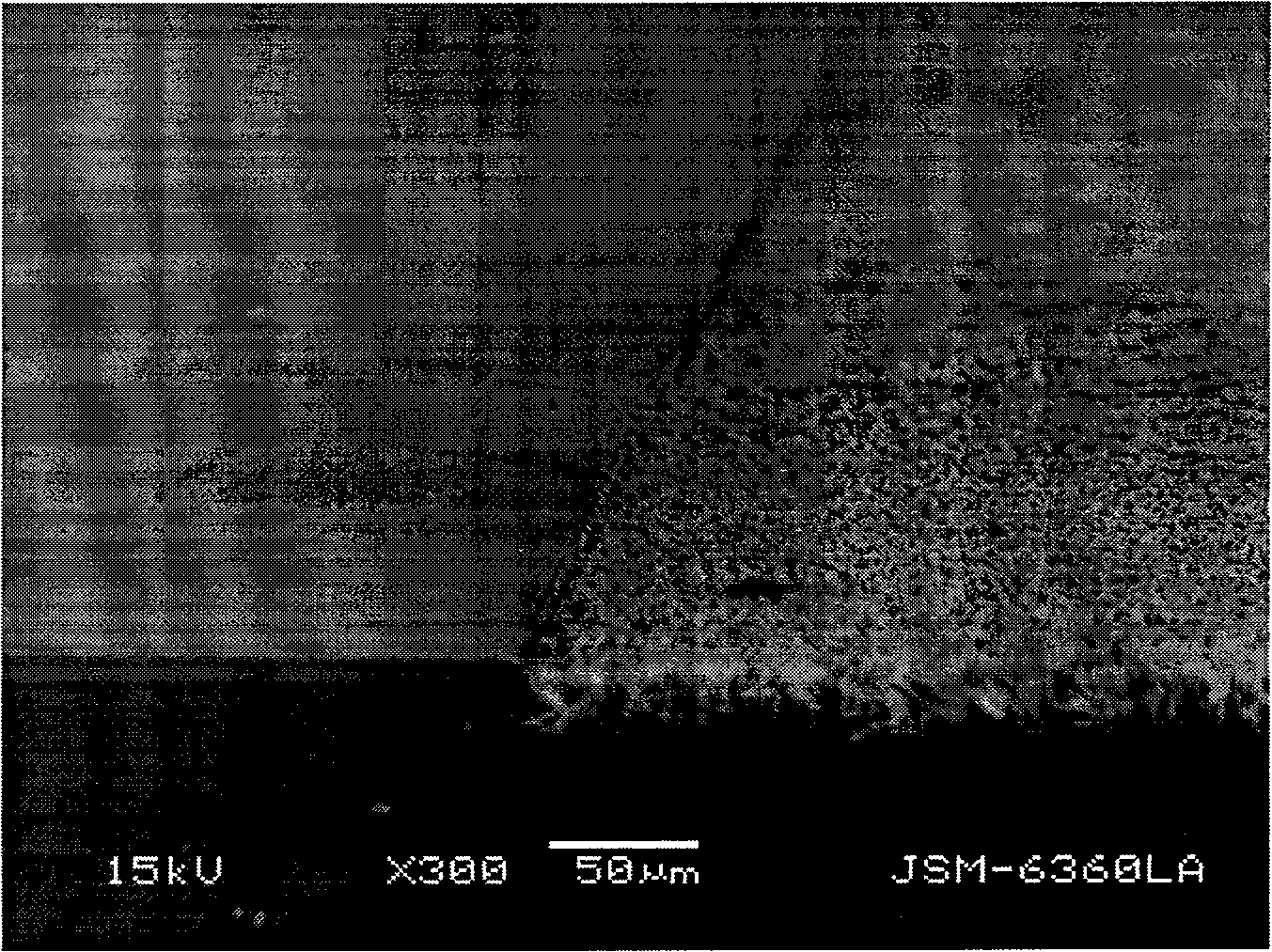

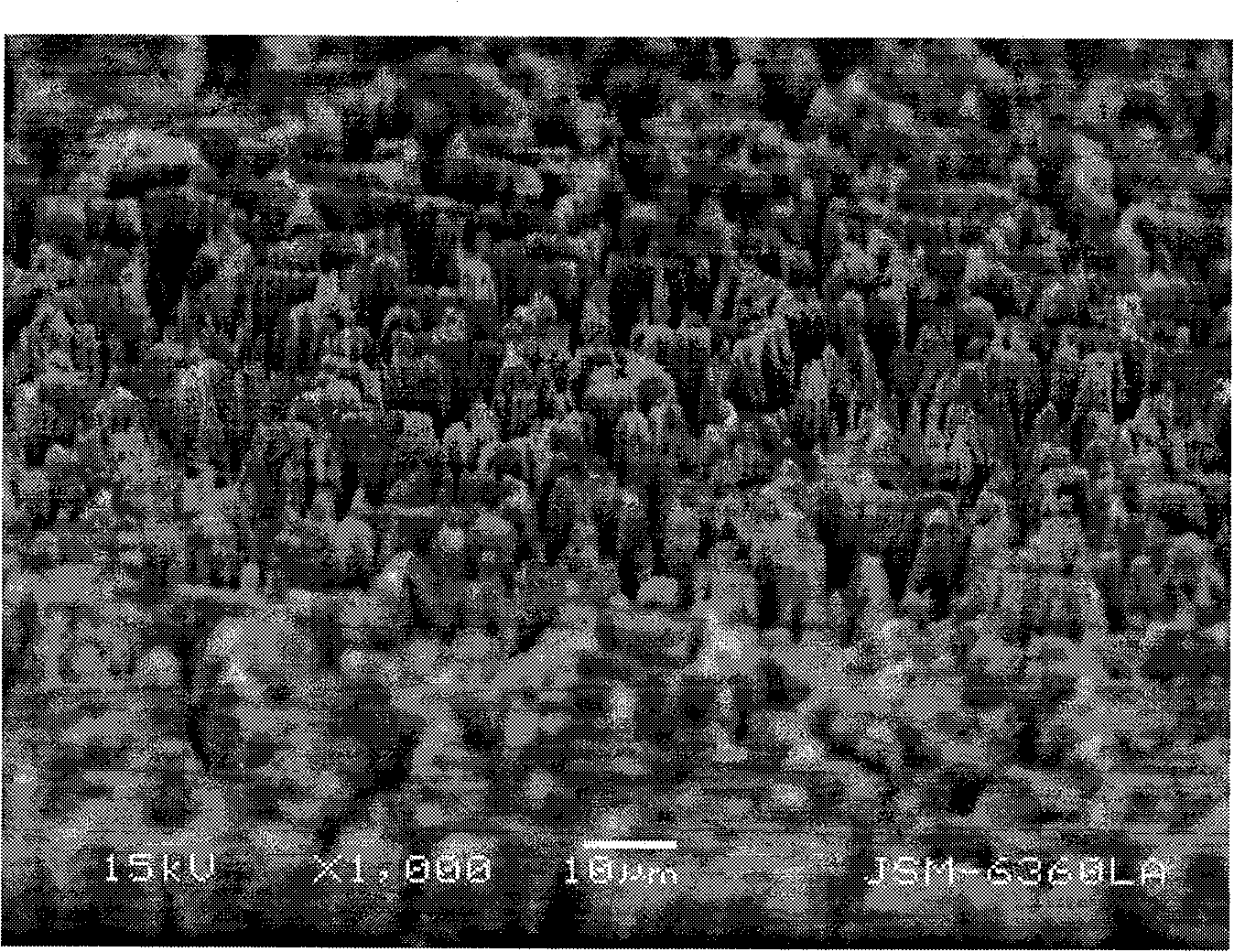

A method for selectively etching silicon nano line

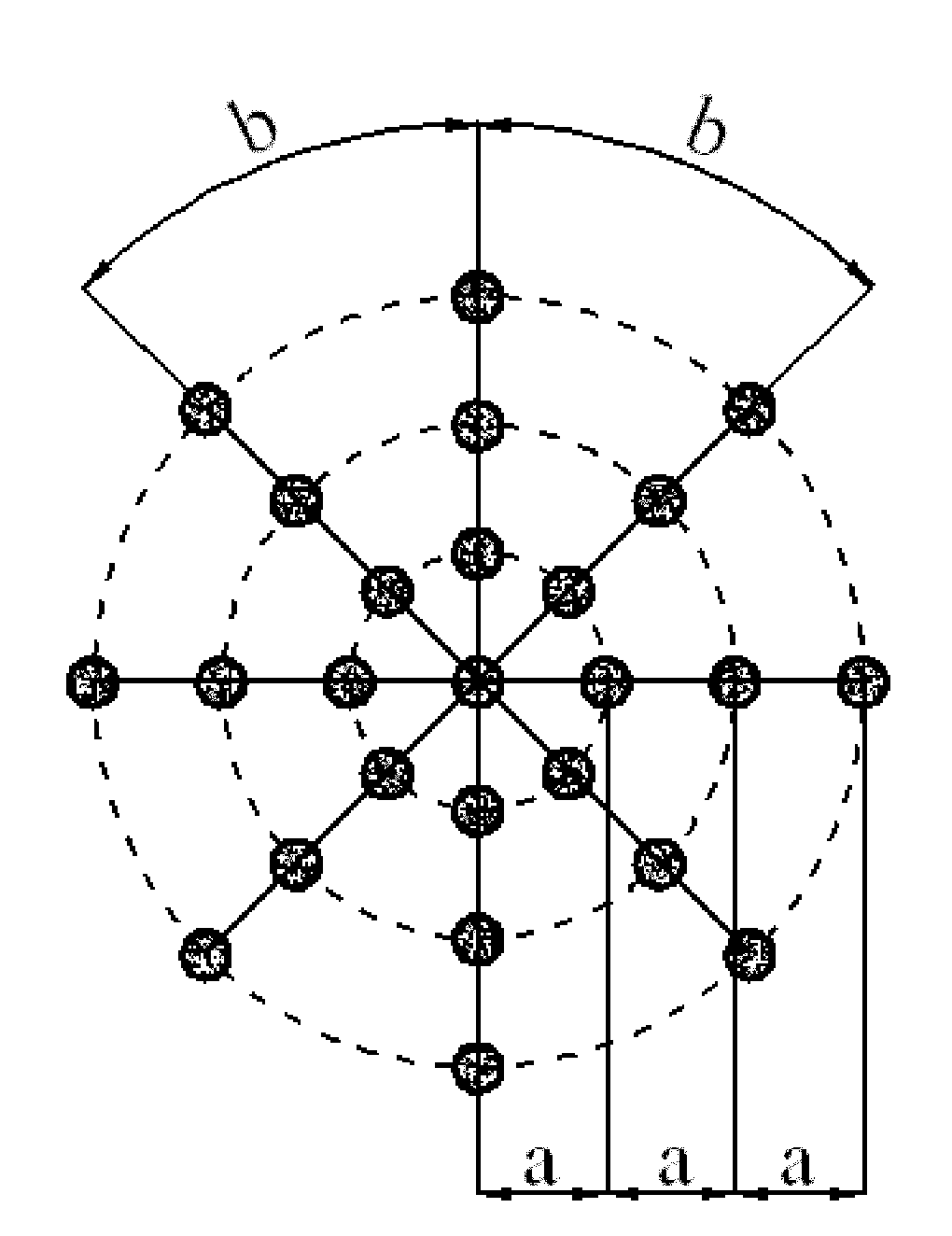

InactiveCN101266919AEvenly distributedThe process is simple and reliableNanostructure manufactureSemiconductor/solid-state device manufacturingSilicon nanowiresNanotechnology

The invention discloses a method for selectively etching silicon nano-wire according to defects in existing technology and market requirement, comprising: a) using ''up to down'' standard microelectronic manufacturing process to open a window on a silicon sheet; b) using ''up to down'' non-electroplating chemical deposition method to etch silicon nano-wires on surface of the silicon sheet with opened window. Compared to the existing technology, the method for selectively etching silicon nano-wire according to the invention can not only make any expected image, but also obtain uniformly arranged silicon nano-wire array with regular size; also it has the advantages of simple manufacturing process, low costs, suitable for batch production, to realize industrial manufacture of silicon nano-wire electrode, and provide a scheme manufacturing nano-electric element based on a plurality of nano-wires.

Owner:EAST CHINA NORMAL UNIV

Lamellar corneal stroma bracket as well as preparation method and application thereof

The invention discloses a lamellar corneal stroma bracket as well as a preparation method and application thereof. The method comprises the following steps: carrying out low-permeability swelling, repetitive freeze-thawing, enzyme digesting, drying and sterilizing treatment on a corneal stroma sheet of a fresh animal eyeball cut down under a sterile condition, wherein the enzyme digesting adopts buffer liquor containing DNA (deoxyribonucleic acid) enzyme and RNA (ribonucleic acid) enzyme to treat, ultrasonic treatment is carried out after the enzyme digestion treatment, and then drying and sterilizing treatment is carried out. The invention further provides application of the lamellar corneal stroma bracket as a corneal stroma substrate. The method disclosed by the invention can be used for reducing damages on a corneal stroma collagen structure to the greatest extent; collagenous fiber arrangement is orderly, holes are uniform and regular, cell residues are avoided, the lamellar structure is kept complete, and the biocompatibility of the bracket material is improved.

Owner:QINGDAO CHUNGHAO TISSUE ENG

Laser marked plastic and preparation method thereof

ActiveCN101418091AImprove marking effectIncrease contrastAdvertisingDisplay meansPolymer sciencePigment

The invention relates to plastic which can be marked by laser, which comprises the following blended components in weight portion: 100 portions of plastic, 0.1 to 10 portions of powder rubber with the average grain diameter of between 50 and 200 nanometers and the gel content of over 60 weight percent, and 0.01 to 5 portions of pearlescent pigment or metallic oxide. The invention also relates to a method for preparing the plastic which can be marked by the laser. The preparation method comprises the steps of melting and blending the components comprising the plastic, the powder rubber and the pearlescent pigment to prepare the plastic which can be marked by the laser. The plastic which can be marked by the laser can obtain a laser mark with higher contrast grade under the action of the laser. The preparation method has the advantages of simple and reliable processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

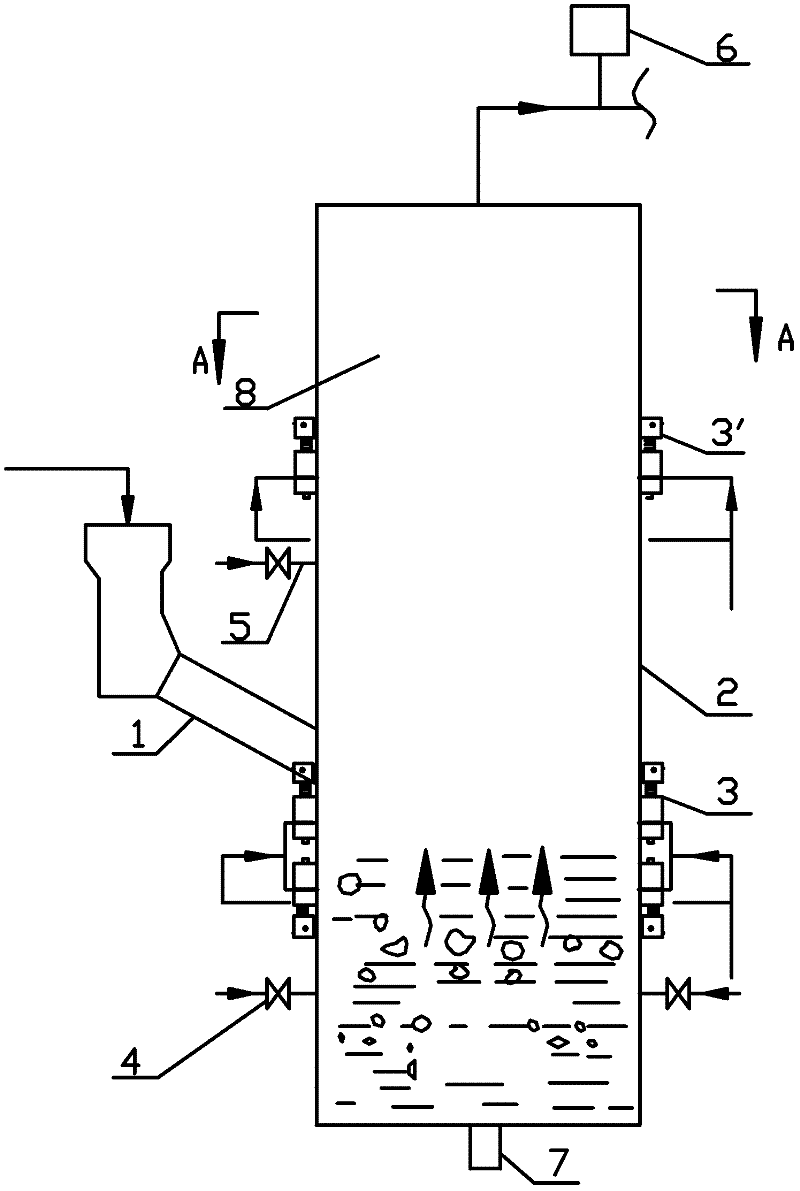

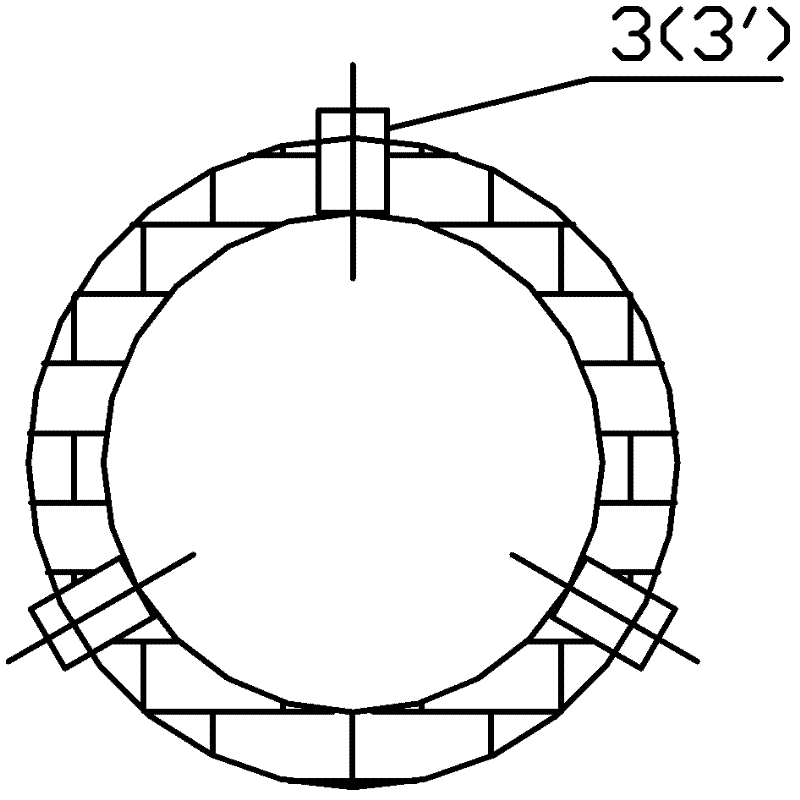

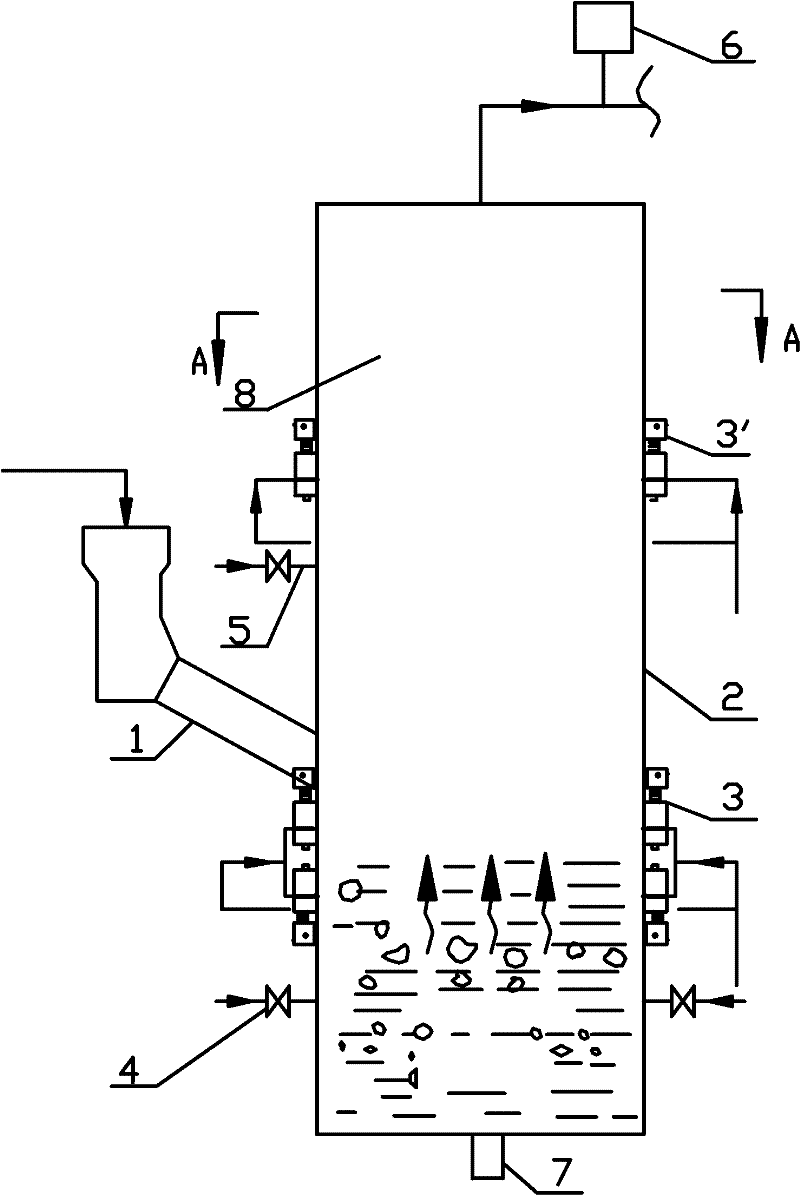

Microwave plasma biomass gasification fixed-bed gasification furnace and process

The invention relates to a microwave plasma biomass gasification fixed-bed gasification furnace and a process, comprising a vertically arranged furnace body; a gasification furnace clearance zone is arranged at the upper part of the furnace body; a fixed bed is arranged at the lowest part of the furnace body; an raw material and fuel inlet, a product gas outlet and an oxygen / steam inlet are arranged on the furnace body; a slag notch is arranged at the bottom of the furnace body, and a synthesis gas monitoring unit is arranged at the position of the product gas outlet. The gasification furnace and the process are characterized in that: at least one microwave plasma generating device is arranged on the furnace body, the characteristics of high dispersion degree and high ionization of microwave plasma are adopted to achieve high-efficiency conversion of biomass fuel chemical energy in the furnace. The cold gas efficiency can be significantly higher than that of the conventional biomass gasification process and can reach more than 85%. Non-equilibrium cleavage reaction is carried out to tar and the like in synthesis gas, so that tar content is very low, direct industrialization utilization can be achieved, and the follow-up process is simple and reliable. No special requirements on the fuel particle size are demanded, simple breaking operation is only needed without complex processing, and the economy is good.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

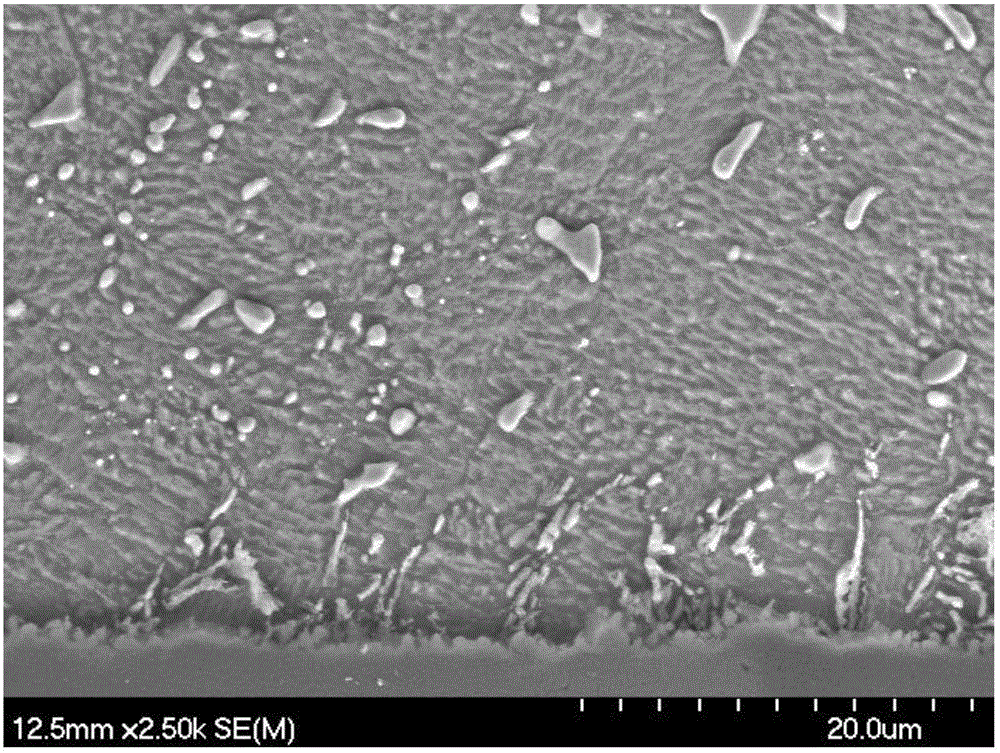

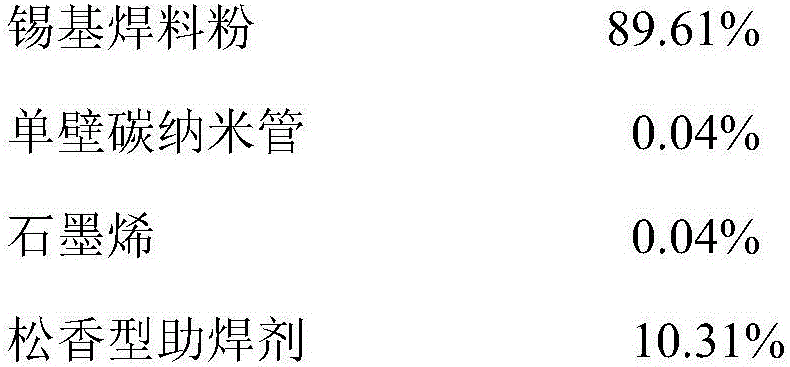

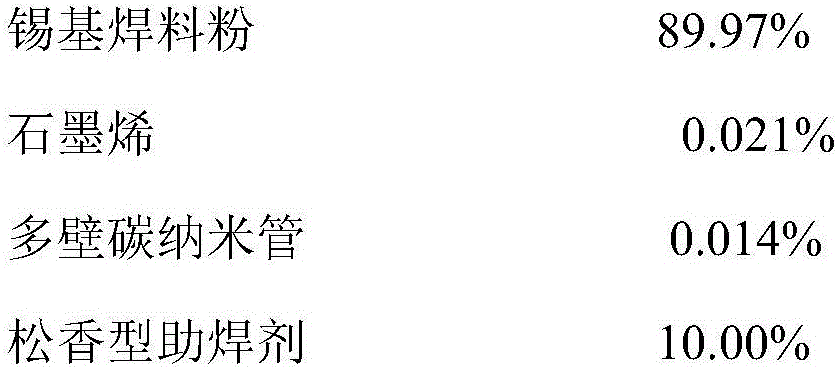

Tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof

ActiveCN106363315AImprove creep resistanceImproved electromigration performanceWelding/cutting media/materialsSoldering mediaTinningAging resistance

The invention provides tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof. The tinned carbon nanomaterial reinforced compound solder alloy comprises, by weight, 84-95 parts of tin-based solder, 0.01-0.2 part of carbon nanomaterials and 5-15 parts of soldering flux. By the adoption of the technical scheme, the creep resistance, electrical conductivity and thermal aging resistance of soldered dots generated by the tinned carbon nanomaterial reinforced compound solder alloy and the solder paste thereof are improved. The carbon nanomaterials in the prepared solder paste are uniform in distribution, the process is simple and reliable, adaptability is high, and cost is low.

Owner:YIK SHING TAT SOLDER MFR KUNSHAN +2

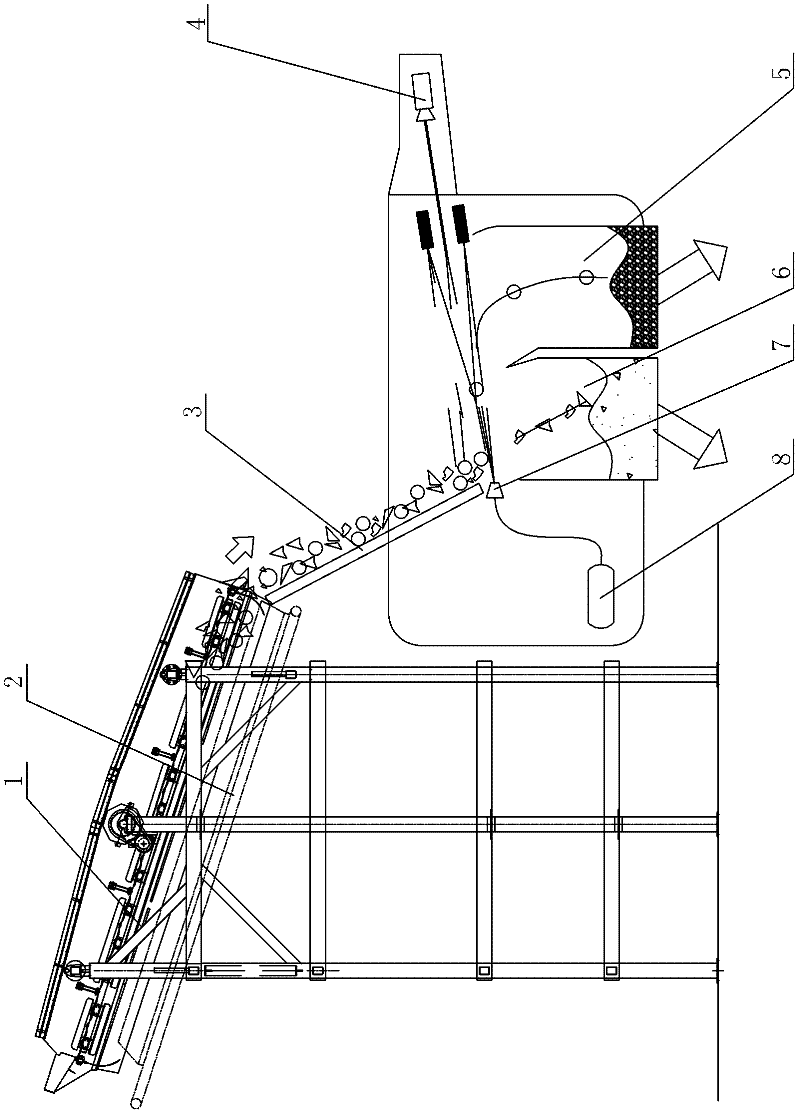

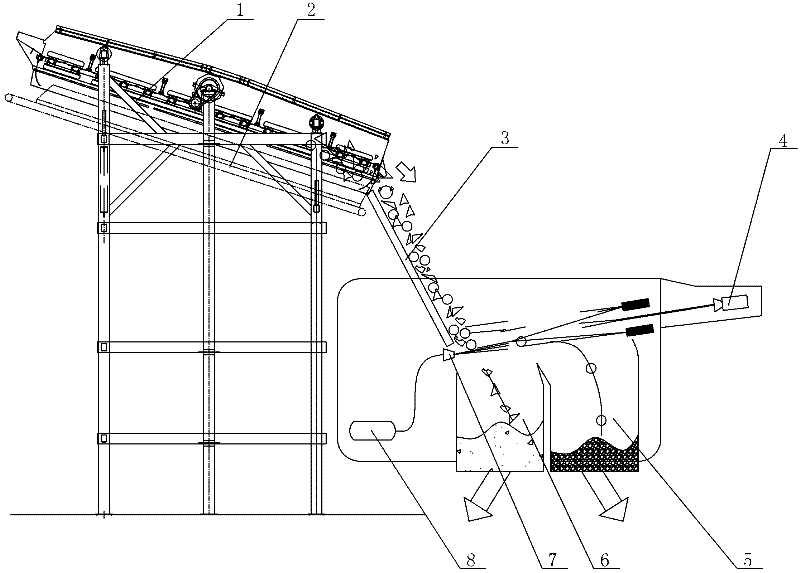

Full automatic pencil lead filling machine and filling technology thereof

ActiveCN108146687ARealize automatic fillingIncrease productivityRod-shaped articlesEngineeringMechanical engineering

The invention relates to the field of pencil lead manufacturing, in particular to a full automatic pencil lead filling machine. The full automatic pencil lead filling machine comprises a pencil lead barrel charging and locating device, a conveying device, a pencil lead charging and locating device, a pencil lead barrel cover charging device, a press-fitting device and a finished product conveyingbelt; the pencil lead barrel charging and locating device, the conveying device and the finished product conveying belt are arranged in the conveying direction of the conveying device; the pencil leadcharging and locating device is perpendicular to the conveying device; the pencil lead barrel cover charging device is located on the side of the pencil lead charging and locating device; the conveying device comprises a first rack and a conveying mechanism; a mounting groove is formed in the top of the first rack; the conveying mechanism is fixed in the mounting groove; the press-fitting deviceis fixed in the mounting groove and is located between the conveying mechanism and the finished product conveying belt; a first supporting block and a second supporting block are arranged on the firstrack symmetrically; and a first slideway is arranged on one side, facing the second supporting block, of the first supporting block. Automatic filling of pencil leads is realized, the production efficiency is improved and the technology is simple and reliable.

Owner:陈信发

Method for recycling water-containing sump oil by utilizing delayed coking device

ActiveCN104419444AReduce cooling effectReduce energy consumptionThermal non-catalytic crackingEconomic benefitsSewage

The invention discloses a method for recycling water-containing sump oil by utilizing a delayed coking device. The method comprises the following steps: (1) injecting water-containing sump oil into a steam blowing exhausting pipeline of a coke chamber when the coke chamber of the delayed coking device is subjected to large steam blowing and coke cooling process, wherein the water-containing sump oil is heated by high-temperature oil gas from the coke chamber; (2) gasifying water and light oil fractions in the water-containing sump oil, mixing the gasified water and light oil fractions with cooled oil, oil gas and steam from the coke chamber, and allowing the mixed oil gas to enter an emptying tower; and (3) distilling off the steam and light oil fractions from the top of the emptying tower, condensing, cooling, allowing the steam and light oil fractions to enter a liquid separation tank on the top of the emptying tower, and separating non-condensable gas, light sump oil and sulfur-containing sewage from the liquid separation tank, wherein heavy oil fractions are extracted from the bottom of the emptying tower. According to the method disclosed by the invention, the water-containing sump oil which is difficultly treated in an oil refinery is treated, the cooling load and energy consumption of the coking device are reduced, and the method is not influenced by the properties of the water-containing sump oil. The energy conservation and emission reduction in a refinery plant are promoted, and a certain economic benefits are created for the refinery plant.

Owner:SINOPEC ENG +1

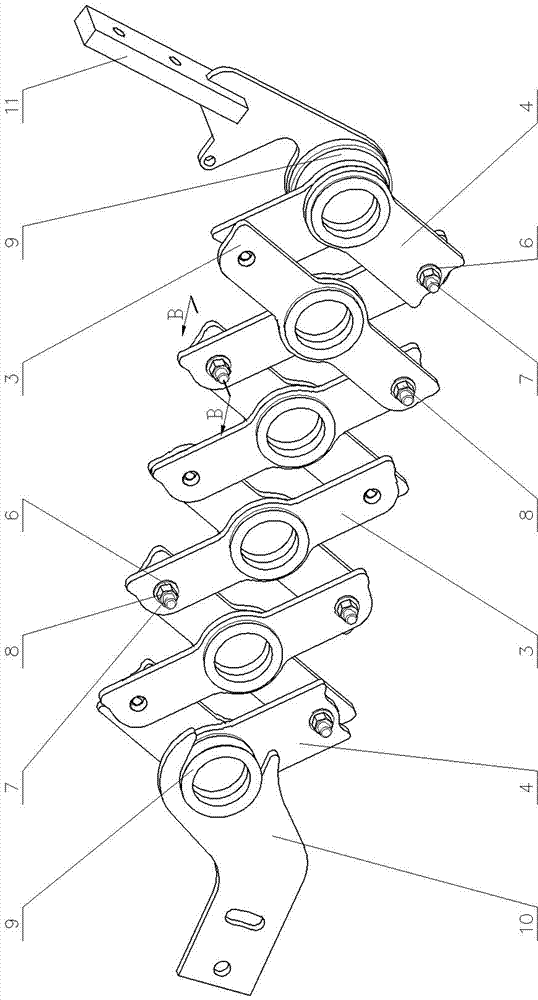

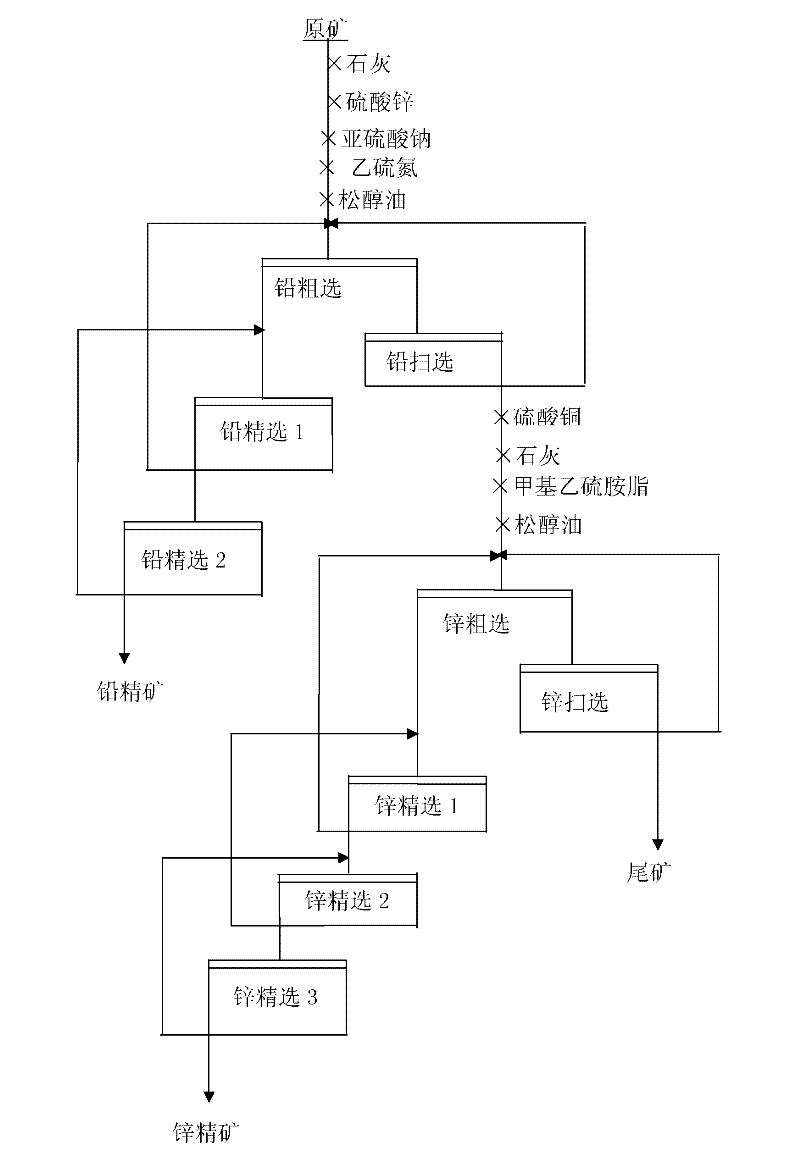

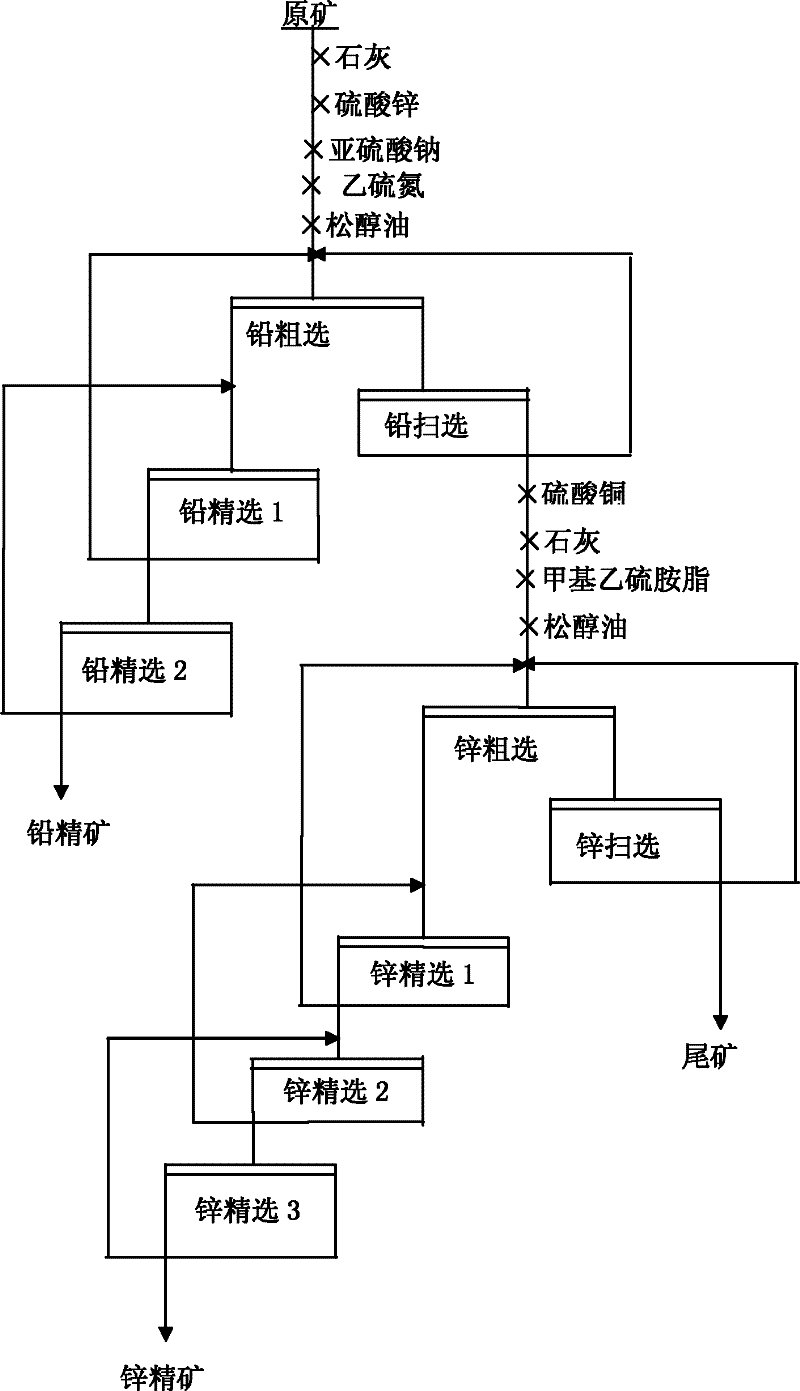

Flotation method for lead and zinc ore difficult to select

InactiveCN103639061AThe process is simple and reliableEasy to operateFlotationDibutyl dithiophosphateSulfite salt

The invention relates to a flotation method for lead and zinc ore difficult to select. The method includes the following steps of lead roughing, two-time lead scavenging, three-time lead fine selection, zinc roughing, two-time zinc scavenging and three-time fine selection. Lime serves as regulators, zinc sulfate and sodium sulfite serve as zinc inhibitor, diethyl dithiocarbamate and ethyl xanthogenate serve as lead collecting agents, copper sulfate serves as zinc activating agents, ammonium dibutyl dithiophosphate serves as zinc collecting agents, and terpenic oil serves as foaming agents. The lead and zinc ore difficult to select is processed by the adoption of lead differential flotation and zinc selection technological processes, and the practical problems that in original technological processes, zinc contains a high content of lead which contains a high content of the zinc, and the lead recovery rate and the zinc recover rate are low are solved. The technological processes are simple, reliable, easy to operate, and good in sorting index. Compared with the original technological processes, the method has the advantages that under the circumstance that raw ore contains the same lead and zinc, mutual containing of the lead and zinc is reduced, and the lead recovery rate and the zinc recovery rate are greatly increased and increased by 9.29% and 9.05% respectively.

Owner:GUANGXI UNIV

Seeding pretreatment method for rape seeds

ActiveCN104641761ATo promote metabolismPromote germinationSeed and root treatmentDry weightPretreatment method

The invention discloses a seeding pretreatment method for rape seeds. The seeding pretreatment method comprises the following steps: (1) finely selecting harvested rape seeds, and then drying the seeds in sunlight for 16-30 hours, wherein the seed drying has the effects of promoting the after-ripening and activity of enzyme, reducing the content of substances for inhibiting the seeds from sprouting, increasing the sprouting rate and sterilizing and the like; (2) soaking the seeds in the step (1), stirring the seeds uniformly by a seed soaking agent with the weight of 0.4-0.8 times of the dry weight of the seeds, and airing for 3-6 hours; (3) magnetizing the seeds from the step (2) in magnetized water, immersing the upper surfaces of the seeds by magnetized water so as to enclose the seeds in the magnetized water, and magnetizing in a magnetic field of 200-600 gauss for 2-6 hours; and (4) sowing the seeds treated in the step (3) within 2-3 days. According to the seeding pretreatment method, the activity of the enzyme at the seed germination stage by utilizing the interaction of magnetization and biological tissues; the metabolism of the substances and energy is accelerated; the method is simple, reliable, rapid and effective.

Owner:CHAOHU XINYU BREEDING FARMER PROFESSIONAL COOP

Wood pulp non-woven fabrics in use for tobacco

InactiveCN101003925AExcellent adsorptionImprove filtering effectTobacco smoke filtersNon-woven fabricsPulp and paper industryNonwoven fabric

The present invention relates to a wood pulp nonwoven fabric for manufacturing filter tip of cigarette. Said invention uses wood pulp fiber and high-melting point synthetic fiber or / and artificial fiber as raw material and adopts air laying mode to make them into fiber web, then utilizes adhesive to make crosslinking reaction so as to obtain the invented nonwoven fabric for manufacturing filter tip of cigarette.

Owner:DARE TECH

Anti-static/conductive fabric and manufacture method thereof

ActiveCN101845753AGuaranteed validityGuaranteed stabilityDry-cleaning apparatus for textilesVegetal fibresFiberYarn

The invention discloses an anti-static / conductive fabric and a manufacture method thereof. The anti-static / conductive fabric is a terylene pure yarn fabric or a polyester-cotton blend fabric the fiber surface layer of which is uniformly compounded with conductive high molecular particles. The manufacture method comprises the following steps of: (1) destaticization: putting the terylene pure yarn fabric or the polyester-cotton blend fabric into a conductive high molecular particle dispersing solution to carry out wet dip dyeing treatment; (2) reduction cleaning: putting the fabric subjected to destaticization into a mixed solution of sodium hydrosulfite and alkali for cleaning; (3) rinsing: rinsing the fabric subjected to reduction cleaning by using water; and (4) drying and sizing: drying and sizing the rinsed fabric to obtain the anti-static / conductive fabric. The anti-static / conductive fabric effectively reduces the frication voltage and the resistance on the surface of the fabric and has good air permeability, enduring anti-static property and better uniformity. The manufacture method has simple process, easy operation, high quality of produced products and low cost.

Owner:SHENZHEN KINGKYLIN ENVIRONMENT TECH CO LTD

Weaving process of hemp towel

InactiveCN101671905ARetain antibacterial health care performanceSoft and comfortableBiochemical fibre treatmentBleaching apparatusRadiation resistantPerspiration

The invention discloses a weaving process of a hemp towel, comprising the steps of cheese winding, warping, weaving and grey cloth post treatment. The rotating speed of a cheese winding grooved drum is 1,200+ / -5r / min; the concentration of caustic soda in desizing boiled bleaching liquor subjected to the grey cloth post treatment is 5ml / L; the concentration of FLOW preliminary treatment agent is 3ml / L; the concentration of hydrogen peroxide is 7.8ml / L; and the temperature of the desizing is 95 DEG C and the boiled bleaching is carried out for 50 minutes. The towel manufactured by the manufacturing process has few filoplume and easy degradation as well as excellent moisture absorbing perspiration performances, natural bacteriostasis and health-care performances reservation of hemp, favorablesoft and comfortable performances, excellent uvioresistant and radiation-resistant performance, high-temperature resistant performance and odor-absorbing and blowdown performances, and is new generation of natural environment-friendly products.

Owner:SUNVIM GROUP

Semi-hydrated-two-hydrated wet process phosphoric acid production process and system thereof

The invention relates to a semi-hydrated-two-hydrated method wet process phosphoric acid production process and a system thereof, which solve the problems of high investment, small device scale, high energy consumption, low device operation rate and low raw material yield of the existing processing process. The technical solution comprises: performing semi-hydrated reaction and filtering by taking phosphorite as a raw material to obtain a product phosphoric acid and semi-hydrated gypsum, and then performing two-hydrated reaction and filtering on the semi-hydrated gypsum to obtain water-hydrated dry gypsum. The system comprises a semi-hydrated reaction and filtering system and a two-hydrated reaction and filtering system. The process is reliable, product phosphoric acid concentration is high, quality of side products fluosilicic acid and dry gypsum is good, energy consumption is low, equipment investment and operation cost are low, and environment friendliness and continuous stable large-scale production (more than or equal to 0.3 million tons / year) are realized.

Owner:WUHUAN ENG

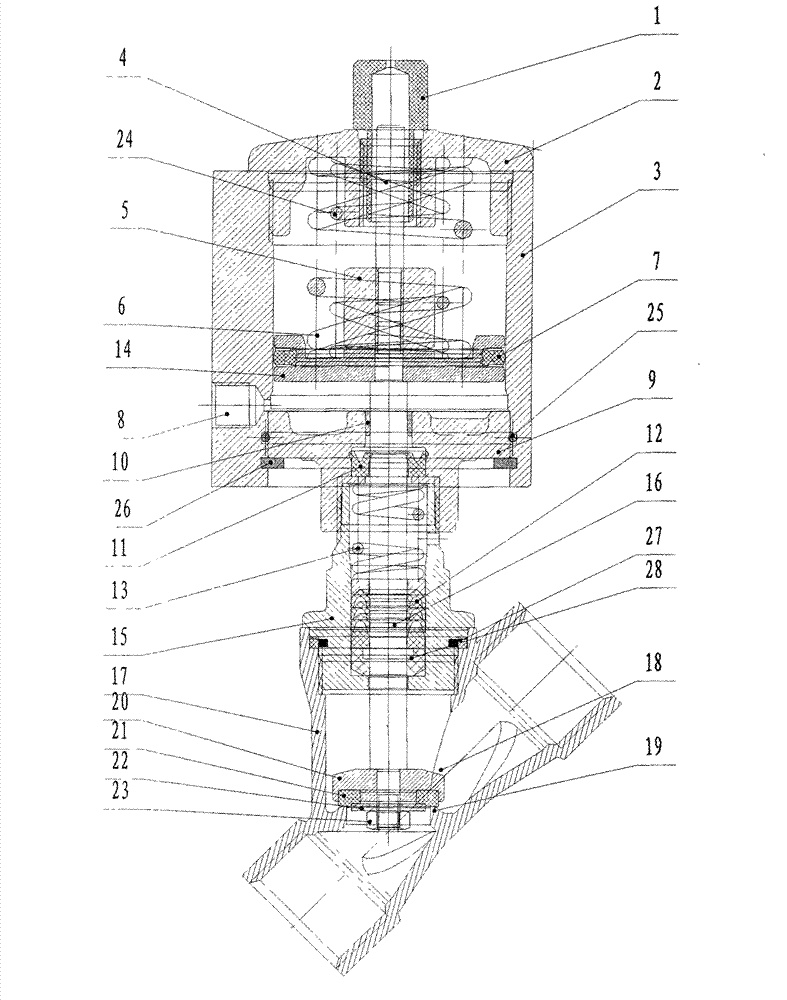

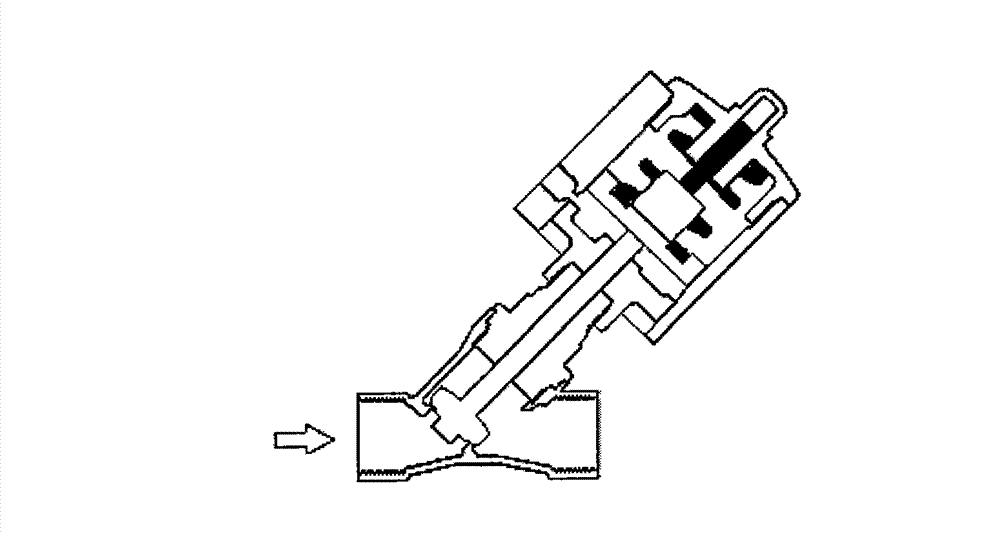

Pneumatically controlled angle seat valve

InactiveCN102878302AReliable workmanshipEasy to makeOperating means/releasing devices for valvesLift valveAluminium alloyAngle seat piston valve

The invention relates to a valve, and discloses a pneumatically controlled angle seat valve. An aluminum alloy upper end cover is connected with an aluminum alloy cylinder barrel through a sealing ring; an observation window is fixed in the center of the aluminum alloy upper end cover; one end of an indicating rod is positioned in the observation window, and the other end of the indicating rod is connected with a locking nut; the locking nut is connected with a valve rod; the valve rod is fixed in the center of a piston; one end of a spring presses against the aluminum alloy upper end cover, and the other end of the spring presses against the piston; an air inlet is positioned on the lower part of the aluminum alloy cylinder barrel; the valve rod is connected with an aluminum alloy lower end cover through an oil bearing; a Y-shaped ring is arranged between the valve rod and the aluminum alloy lower end cover; the aluminum alloy lower end cover is connected with a connecting seat; the connecting seat is connected with a valve body; a macromolecular sealing assembly and a sealing spring are arranged between the valve rod and the connecting seat; the end of the valve rod is connected with a valve core; and the valve core is positioned at the upper end of a valve port. The angle seat valve is compact in structure, safe, reliable, long in service life and easy to manufacture.

Owner:青岛海菲勒气控阀门有限公司 +1

Process and system for sorting coal by discharging coal gangue through dry method

ActiveCN102416386ACompact structureSmall footprintSievingGas current separationCoal briquetteControl system

Owner:BIRTLEY TIANJIN IND EQUIP

Method for preparation of aluminum scandium alloy by alumino-thermic reduction method

The thermit reduction process of preparing Al-Sc alloy has Sc2O3 as main material, NH4HF2, NaF and alkali metal chloride as fluorinating agent and flux, and metal aluminum as reductant and main alloy component, and through heating inside aluminum or graphite crucible at 850-1100 deg.c for some period and casting into Al-Sc alloy ingot. The Al-Sc alloy contains Sc 1-3 wt%, Al+Sc over 99 wt% and small amount of Fe, Si, Ca, C and F, each of which less than 0.05 wt%, and the process has Sc yield over 80 %. The technological process is simple and reliable, and the Al-Sc alloy has low impurity content and excellent performance, and is suitable for use as additive for various Al, Mg and other precise alloy to raise their performance obviously.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

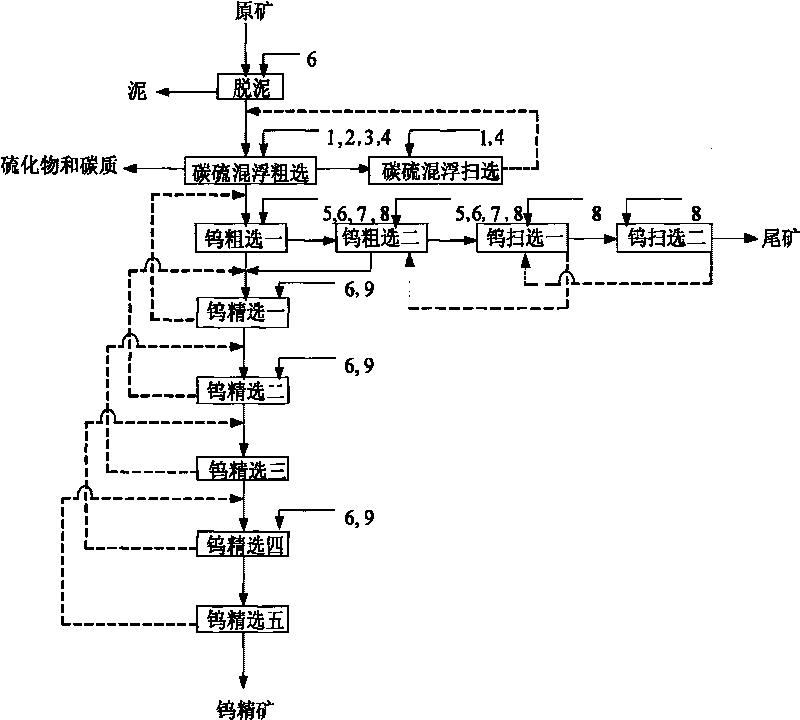

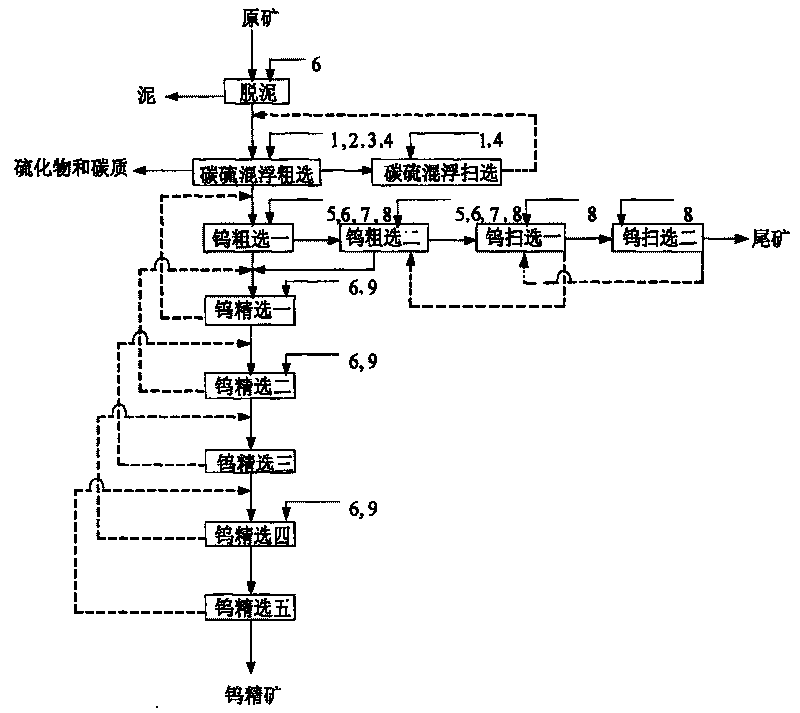

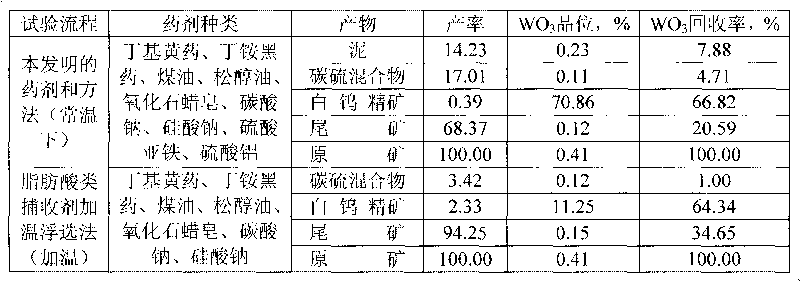

Beneficiation reagent and method for separating scheelite from complex tungsten ore

The invention relates to a beneficiation reagent and a method for separating scheelite from complex tungsten ore; the beneficiation reagent adopts oxidized paraffin soap, kerosene, butyl xanthate, dithiophosphate BA as collectors, adopts sodium carbonate as modifier and terpenic oil as foaming agent, and also adopts one or the combination of Sodium silicate and ferrous sulfate or aluminum sulfate as inhibitor; the method employing the beneficiation reagent for separating scheelite from complex tungsten ore includes: desliming in normal temperature, carbon-sulfide bulk rough floatation, secondary tungsten rough floatation and quintic tungsten concentration, so tailings and tungsten concentrate product are obtained; besides, the invention has the advantages of high sorting efficiency, high yield rate, wide reagent resource, low price, low cost and dosage, simple and reliable process, easy operation and normal temperature working, and is particularly applicable to the beneficiation application of complex tungsten ores.

Owner:ZIJIN MINING GROUP

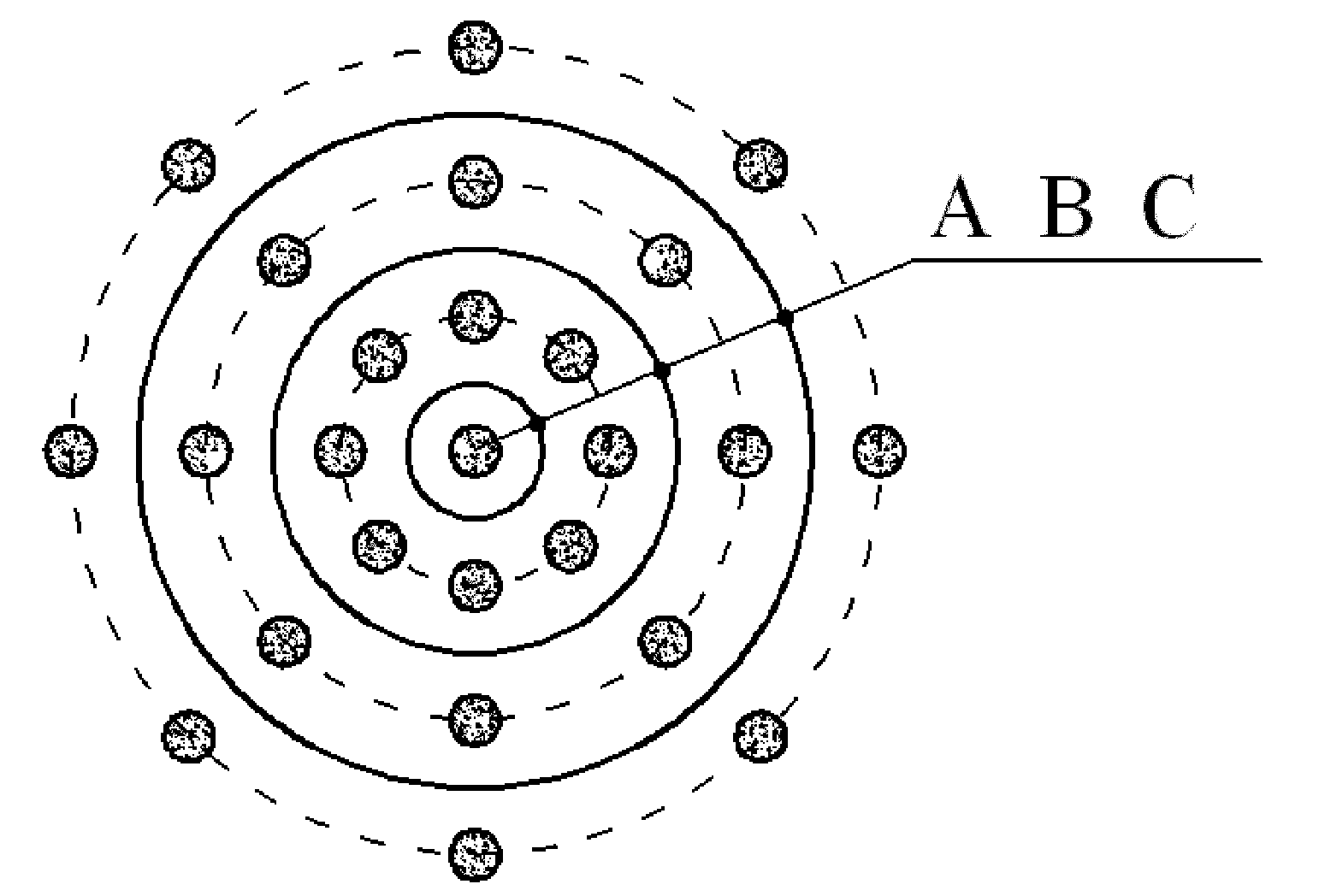

Method for synchronously feeding powder to prepare ceramic based thermal barrier coating of continuous and gradual variation structure

ActiveCN105951028AImprove coating qualityEfficient depositionMolten spray coatingEfficient propulsion technologiesThermal insulationCeramic coating

The invention provides a method for synchronously feeding powder to prepare a ceramic based thermal barrier coating of a continuous and gradual variation structure. The obtained ceramic based thermal barrier coating of the continuous and gradual variation structure is stable in structure and excellent in thermal shock resistance and thermal insulation. The method comprises the following steps that firstly, a bonding layer is prepared on a high-temperature alloy matrix, specifically, the thickness of the bonding layer is 50-200 [mu]m; and secondly, independently researched and developed dual-powder-feeding nozzles are adopted, and the ceramic coating of the continuous and gradual variation structure and made of two kinds of materials of A and B is sprayed on the bonding layer obtained in the first step. Through the method, a continuous and gradual variation thermal barrier coating system which is stable and reliable in quality and excellent in high-temperature shock resistance is obtained finally, and has wide application prospects in the national defense sophisticated industries such as air-turbine motors and heavy duty gas turbines.

Owner:XI AN JIAOTONG UNIV

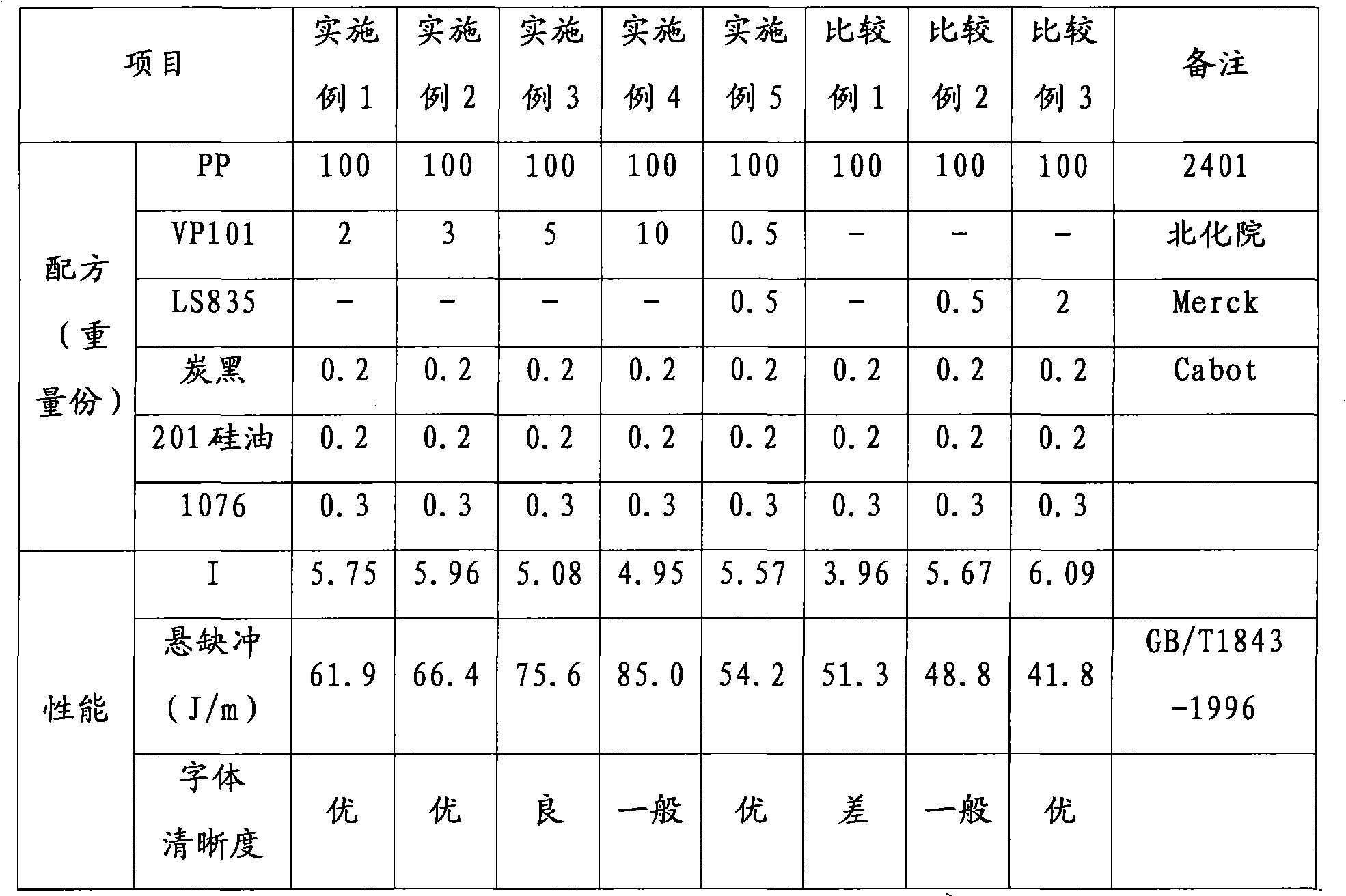

Polypropelene composition capable of making with laser and preparation method thereof

The invention relates to a polypropylene compound which forms bright white (yellow) marks on dark background and a preparation method thereof. The polypropylene compound includes the following components which are blended: 100 weight portions of polypropylene; 0.1 weight portion to 20 weight portions of powdered rubber; 0.01 weight portion to 0.5 weight portion of carbon black; wherein, the powdered rubber includes SBR powdered rubber or / and carboxylated styrene butadiene powdered rubber. The preparation method includes the following step: the components including polypropylene, powdered rubber and carbon black are melted and blended by the proportion of components. The polypropylene compound of the invention can overcome the problems that polypropylene is difficult to produce laser marks, poorer physical performance and more expensive price of materials produced by too much laser promoter in the prior art; the preparation method of the invention has simple and reliable process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for ore pulp desliming and ore slurry dehydration

The invention provides a process for ore pulp desliming and ore slurry dehydration, which relates to a mineral processing process. The process comprises the steps of: a, removing large dreg of ore pulp raw materials by using a dreg separation sieve; b, removing impurities of the ore pulp raw materials without the large dreg by adopting a sorting filter and enabling the ore pulp raw materials to enter a sorting machine to be subjected to desliming and selection to obtain deslimed ore pulp and ore slurry; c, enabling the deslimed ore pulp to enter a floating selection procedure; after removing the impurities of the ore slurry with a dehydrating filter, enabling the ore slurry to enter a dehydrating machine to be concentrated and dehydrated so as to obtain concentrated ore slurry and reusable process pure water. The process is simple and reliable; the concentration and the grade of the ore slurry are improved and the desliming is complete; rapid concentration and dehydration of the ore slurry are realized; the process has important effects in the aspects of improving the stability of selection work and the grade and the recovery rate of ore concentrates, reducing the use amounts of a floating selection medicament and pure water and the like.

Owner:江苏迈安德智能装备有限公司

Package structure of semiconductor light-emitting chip with airtight window free of silica gel

ActiveCN106449542AIncrease luminous fluxIncrease optical powerSemiconductor/solid-state device detailsSolid-state devicesLuminous fluxSoldering

The invention provides a package structure of a semiconductor light-emitting chip with an airtight window free of silica gel and relates to the technical field of illumination. A package device comprises a ceramic body, wherein the ceramic body is a plate-like object; a metal frame placement area, a chip placement area and a gold wire welding area are arranged on the surface of the ceramic body; the metal frame placement area, the chip placement area and the gold wire welding area are coated with a weldable material capable of carrying out welding; the surface of the metal frame is coated with the weldable material; a die bonding material is arranged between the semiconductor light-emitting chip and the ceramic body; a gold wire is arranged in the gold wire welding area; a first preset soldering lug is arranged between the ceramic body and the metal frame; a second preset soldering lug is arranged between the metal frame and glass; and the melting point of the second preset soldering lug is lower than that of the first preset soldering lug. According to the package structure, input of the cost is greatly reduced; the packaging process is simple; the air tightness and the reliability are further improved; and furthermore, the luminous flux and the luminous power can be improved.

Owner:深圳市五矿发光材料有限公司

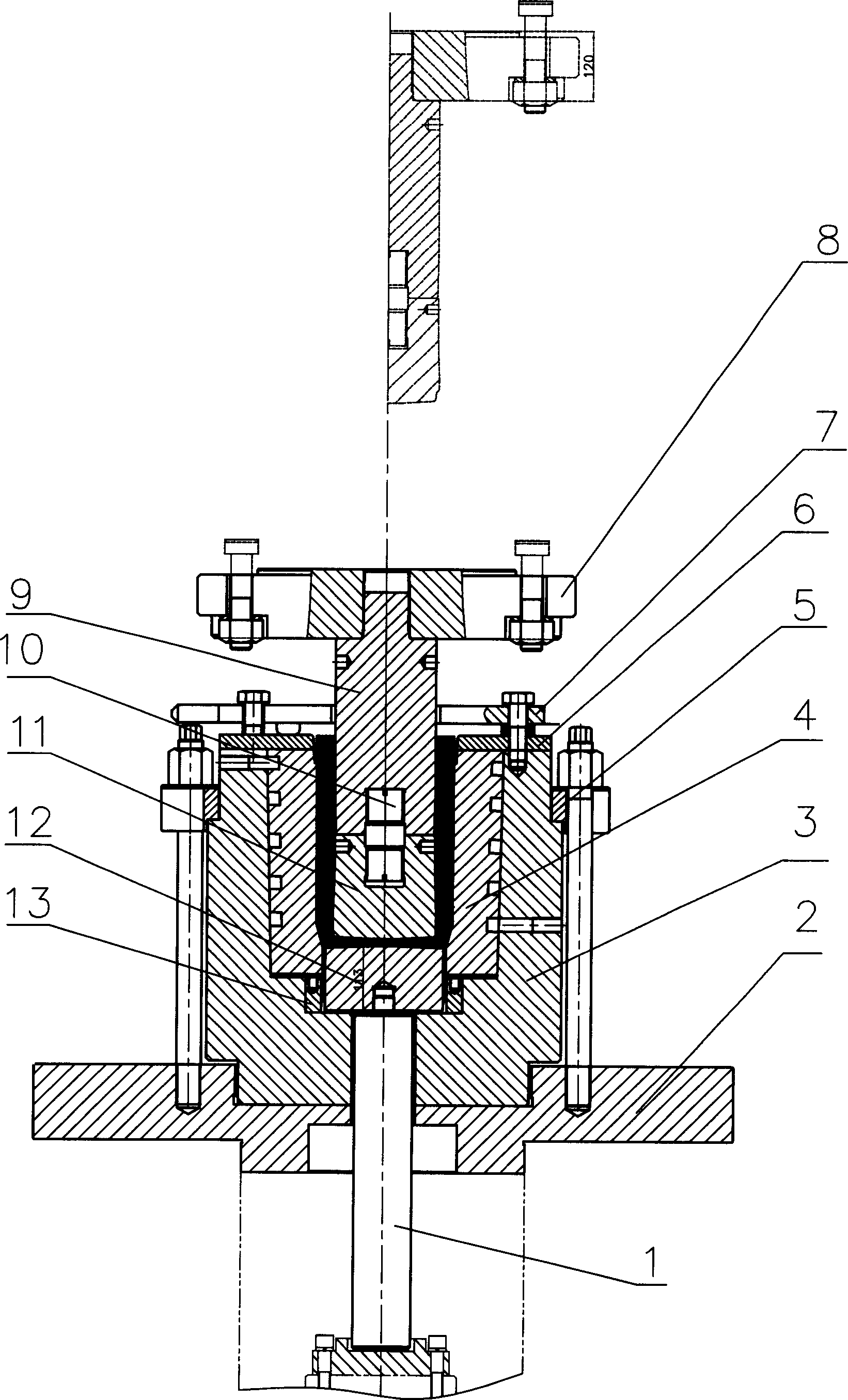

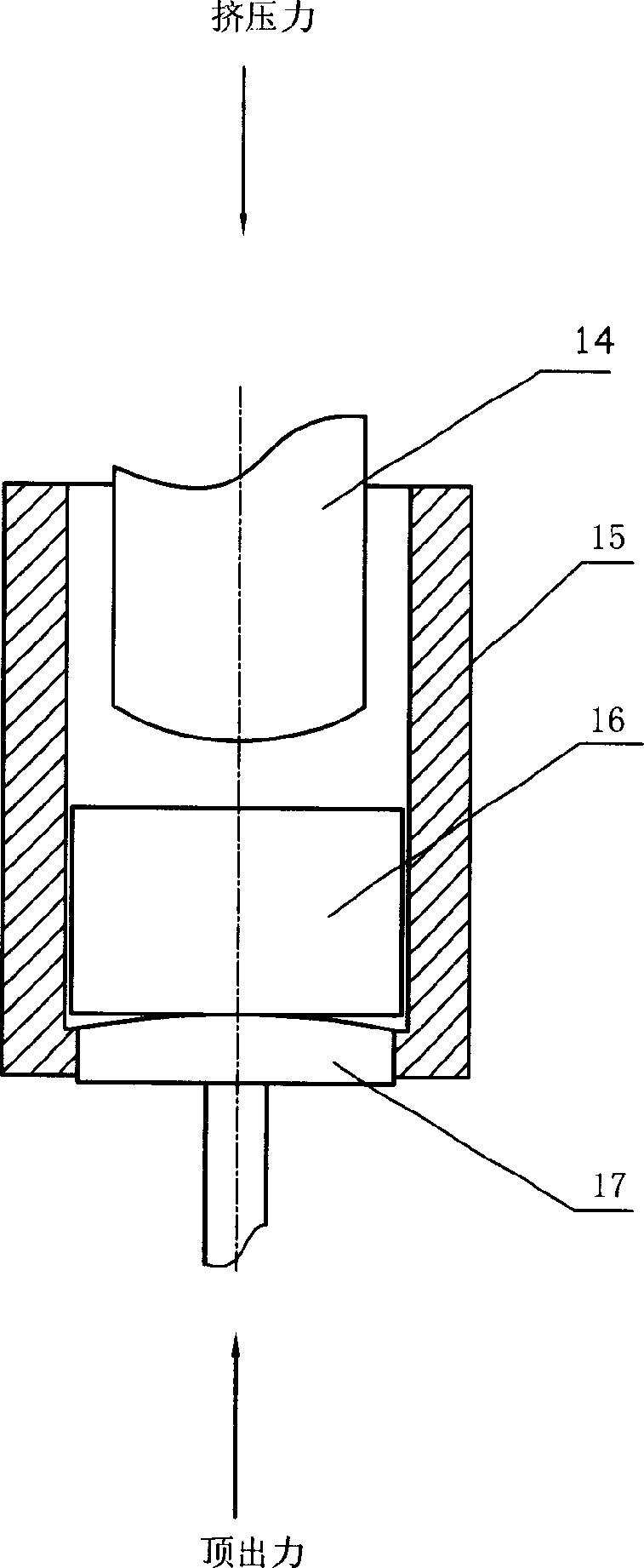

Adjustable mold employing reverse extrusion and draw forming for raw copper tube of mould, reverse extrusion and draw forming method thereof

InactiveCN1799721ASolve the problem of raw material supplyMeet the needs of small batch productionDrawing diesExtrusion diesScrew threadTailstock

The invention discloses a replaceable mold which uses indirect extrusion and drawing to mold crystallizer blank copper pipe. Wherein, said replaceable mold comprises: an upper supporting board and a upper punch body mounted on the machine head; a chassis, a mould sheath, a compression ring, a compression plate, a discharge board, a material underlay and a material underlay ring mounted on the operation board. The invention is characterized in that: a screw is arranged at the lower end of upper punch body to be connected with the screw thread of upper punch pin via double-ended binding bolt; a cavity die is mounted inside the taper hole of mould sheath, while the circumference of said cavity die has spiral groove which contains electrical heating element and the heating element is connected to external circuit via the taper hole of mould sheath; the bottom of material underlay has a screw hole connected with material beating rod of tail block; and the top of upper punch body is connected with upper supporting board key. Said mold has better adjustable ability, which can realize the replacement between punch pin and cavity die, improve the final forging environment of blank copper pipe, and improve the producing efficiency and the rate of finished products, while it can apply the corporation for processing single multi-variety copper pipe.

Owner:大连冶金结晶器有限公司

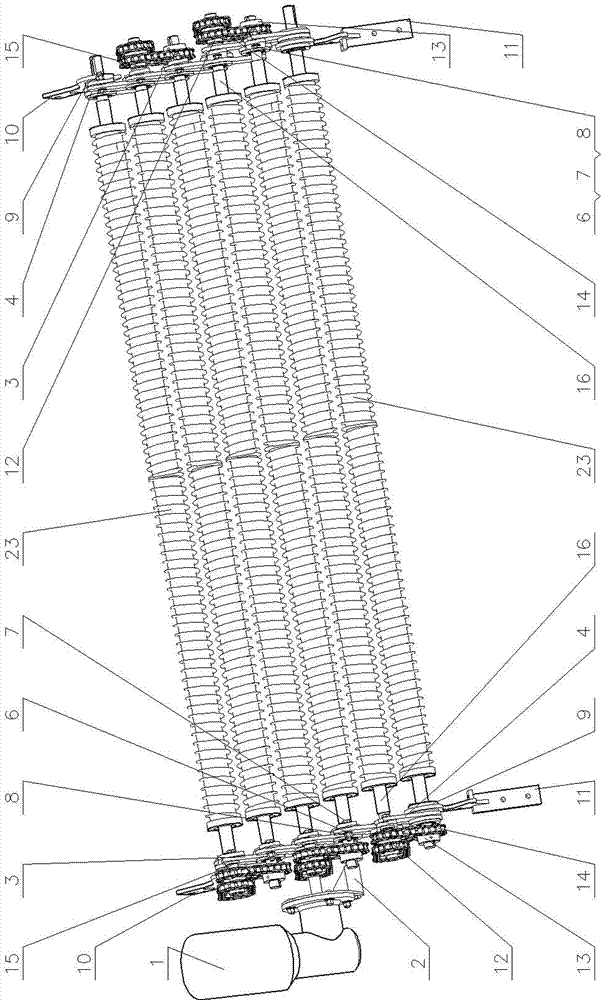

Elastic sorting device of potato separator

The invention provides an elastic sorting device of a potato separator. The device is characterized in that long and short connecting pieces of an extension frame are overlapped and connected to form five rhombuses with sequence numbers of I, II, III, IV and V; a motor frame is mounted in the hinged place of end parts of the long connecting piece of the rhombus III; a speed reducing motor is connected with a flange of the motor frame, and drives each elastic sorting roller, supported on the extension frame by two ends, to rotate through a transmission device; after two ends of one elastic sorting roller I and one elastic sorting roller II respectively penetrate through circular holes in short connecting piece bosses of the rhombuses I and V, extension ends in the direction of the speed reducing motor are connected with single-row chain wheels; the extension ends, penetrating through the extension frame, of the rest elastic sorting rollers are all connected with the single-row chain wheels, and penetrate through the single-row chain wheels in the hinged place of the rhombuses II and III; and the extension ends towards the speed reducing motor are connected with the speed reducing motor. The device can conveniently classify cleaned potatoes, and is low in skin breakage rate, stable and reliable in work, uniform and thorough in sorting and wide in application range.

Owner:山东希成农业机械科技有限公司 +1

High-efficiency antibiotic, anti-crease, anti-ultraviolet full cotton and polyester cotton special finishing method

InactiveCN101349011AIncreased durabilityImprove washabilityFibre treatmentLiquid/gas/vapor textile treatmentPolyesterUltraviolet

The invention provides a special method for finishing efficiently antibacterial, crease resistant and anti-ultraviolet all cotton terylene textile, comprising the following steps that: the fabric is subjected to padding by an antimicrobial FBR-5 mixing solution, an FSA softening agent and a uv resistant agent, after the high temperature preliminary drying and baking, each effect of the material is intensified, the three resisting effects are excellent; moreover, the textile processed by the method has the antibacterial protecting function and the function of blocking the radiation of ultraviolet radiation on human body, the antibacterial grade is up to seven, the anti-ultraviolet grade is up to five, and the water washing is up to the fourth after the crease resisting process for 12 times. The textile has good durability and washability, feels cool and refreshing if a person wears the textile in the summer, ensures that skin feels comfortable and moderate and has fresh and clean as well as lasting odorant.

Owner:JIANGSU YUHAO TEXTILE

Beneficiation reagent for separating lead zinc ores from lead zinc sulphide ores containing carbon and beneficiation method

InactiveCN102513219ASuitable for sorting applicationsImprove sorting efficiencyFlotationLeadhilliteSulfate

Beneficiation reagent for separating lead zinc ores form lead zinc sulphide ores containing carbon and a beneficiation method resolve the problem that existing beneficiation reagent for separating lead zinc is poor in effect and high in cost. The beneficiation reagent includes, by weight, 1 part of lime, 600 parts of copper sulfate, 40 parts of methyl ethionine ester and 5 parts of terpenic oil. The beneficiation method comprises following steps: lead roughing: adding 3kg / t of lime, 1500g / t of zinc sulfate, 500g / t of sodium sulphite, 80g / t of dithiocarbamate and 5g / t of terpenic oil into raw ores; lead scavenging; twice lead concentration; zinc roughing: adding 1kg / t of lime, 600g / t of copper sulfate, 40g / t of methyl ethionine ester and 5g / t of terpenic oil into tailings of lead scavenging; zinc scavenging; and primary, secondary and tertiary zinc concentration. The beneficiation reagent and the beneficiation method are good in beneficiation effect and low in cost.

Owner:云南澜沧铅矿有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com