Tinned carbon nanomaterial reinforced compound solder alloy and solder paste thereof

A technology of carbon nanomaterials and enhanced compounding, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problem of non-wetting between carbon nanomaterials and solder matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

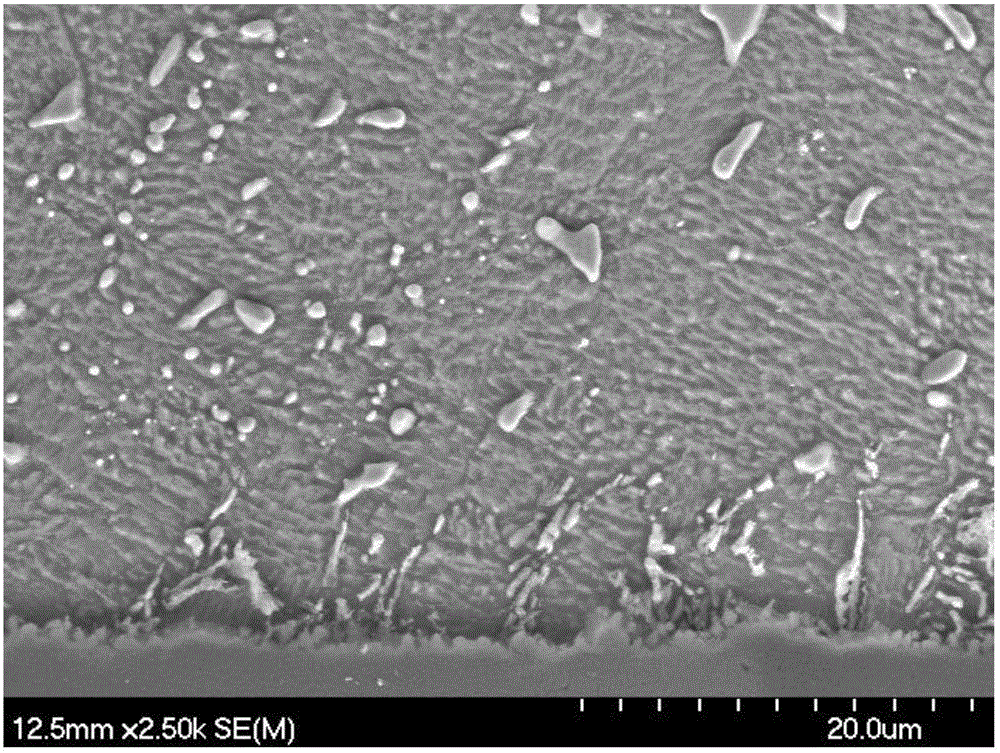

Image

Examples

Embodiment 1

[0055] The material composition of the tin-plated carbon nanomaterial reinforced composite solder paste of the present embodiment comprises tin-based solder powder of commercially available No. 5 Sn52Bi, multi-walled carbon nanotubes, and rosin-type flux composition, and the total mass is 50g; wherein, the tin The particle size of the base solder powder is 15-25 μm, the inner diameter of the multi-walled carbon nanotube is 3-5nm, the outer diameter is 8-15nm, and the length is 3-12um; the components of the tinned carbon nanomaterial reinforced composite solder paste are calculated as :

[0056] Tin-based solder powder 89.95%

[0057] Multi-walled carbon nanotubes 0.05%

[0058] Rosin type flux 10%

[0059] Adopt following preparation method to prepare:

[0060] (1) Place the multi-walled carbon nanotubes in acetone and apply ultrasonic cleaning for 10 minutes, and repeat 5 times.

[0061] (2) The cleaned multi-walled carbon nanotubes were uniformly mixed with tin-based sol...

Embodiment 2

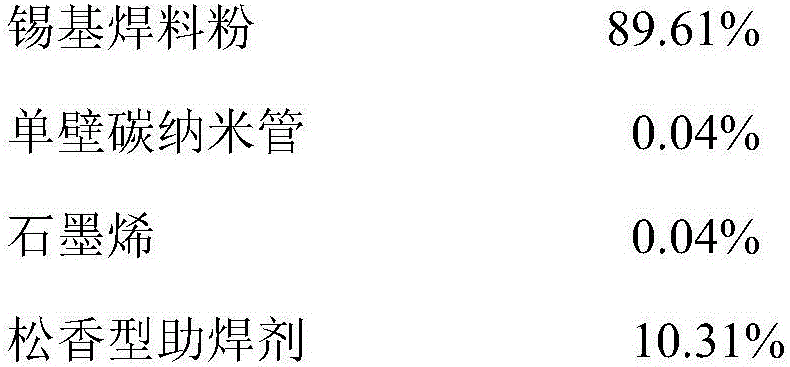

[0067] The tinned carbon nanomaterial-reinforced composite solder paste of this embodiment is composed of commercially available No. 3 Sn64Bi35Ag1 tin-based solder powder, single-walled carbon nanotubes, graphene, and rosin-type flux, with a total mass of 50 g. Wherein, the commercially available No. 3 Sn64Bi35Ag1 tin-based solder powder has a particle size of 25-45 μm, and the single-walled carbon nanotubes have an inner diameter of 0.8-1.6 nm, an outer diameter of 1-2 nm, and a length of 1-2 um. The components of the tin-plated carbon nanomaterial reinforced composite solder paste are calculated by mass fraction as:

[0068]

[0069] Adopt following preparation method to prepare:

[0070] (1) Mix single-walled carbon nanotubes and graphene uniformly according to the mass ratio of 1:1 to obtain mixed carbon nanomaterials, place the mixed carbon nanomaterials in alcohol and apply ultrasonic cleaning for 8 minutes, and repeat 3 times.

[0071] (2) The cleaned carbon nanomat...

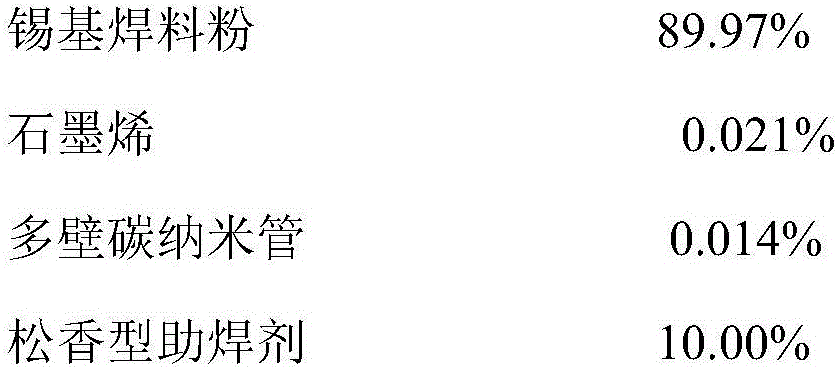

Embodiment 3

[0077] The tin-plated carbon nanomaterial reinforced composite solder paste of this embodiment is composed of tin-based solder powder, graphene, and rosin-type flux of commercially available No. 4 Sn0.7Cu, with a total mass of 50g, wherein commercially available No. 4 Sn0. The particle size of 7Cu tin-based solder powder is 20-28μm. The components of the tin-plated carbon nanomaterial reinforced composite solder paste are calculated by mass fraction as:

[0078]Tin-based solder powder 90.18%

[0079] Graphene 0.018%

[0080] Rosin type flux 9.80%

[0081] Adopt following preparation method to prepare:

[0082] (1) Place the graphene in acetone and apply ultrasound to clean it. The ultrasonic cleaning time is 5 minutes, and it is repeated 4 times.

[0083] (2) The cleaned graphene was uniformly mixed with tin-based solder powder at a mass ratio of 1:7 by mechanical stirring, and the composite solder powder was placed in a crucible and rapidly heated to 260°C, and left to st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com