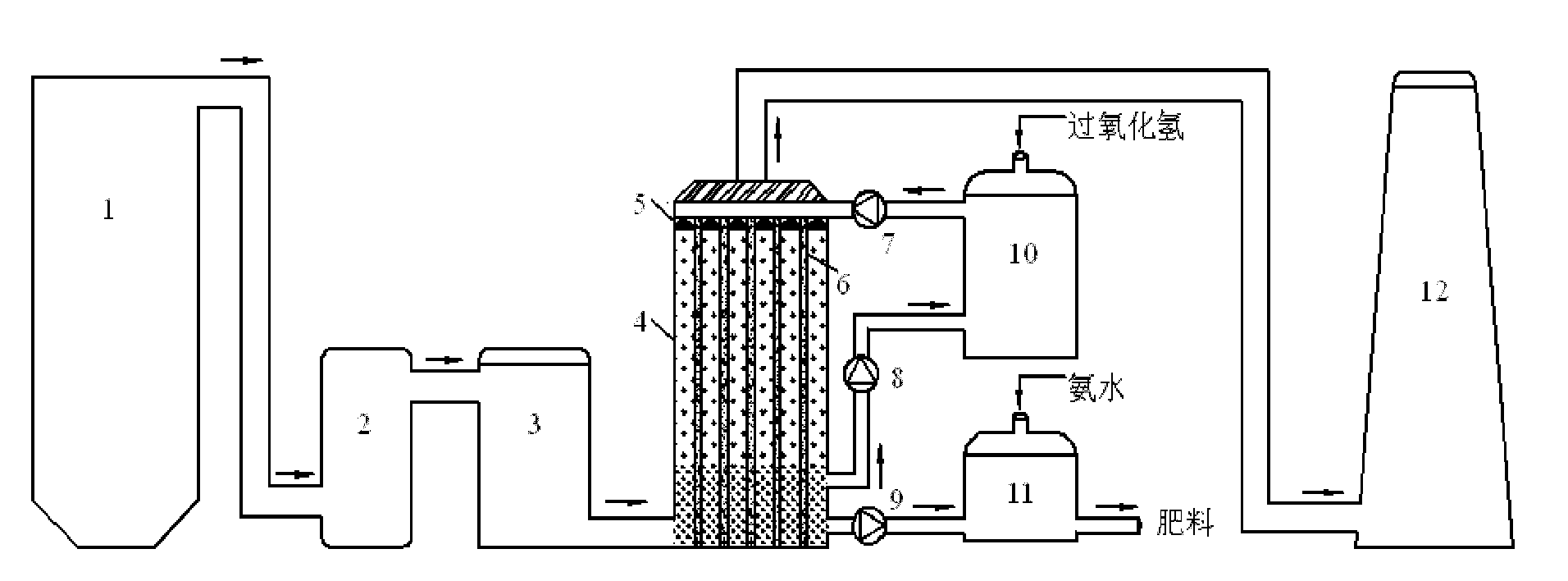

Photochemical advanced oxygenation-based simultaneous desulfuration and denitration system

A technology of advanced oxidation, desulfurization and denitrification, applied in chemical instruments and methods, dispersed particle separation, air quality improvement, etc. Simple and reliable, small footprint, low initial investment and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]

Embodiment 2

[0046]

Embodiment 3

[0048]

[0049] As can be seen from Examples 1, 2, and 3, the upper part of the table is the operating parameters, and the lower part is the variation of the pollutant removal efficiency. The specific operation method is: only change the wavelength of ultraviolet light, and other parameters remain unchanged. It can be seen from the results that the best removal efficiency can be obtained by ultraviolet light at 253.7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com