Adjustable mold employing reverse extrusion and draw forming for raw copper tube of mould, reverse extrusion and draw forming method thereof

A reverse extrusion and crystallizer technology, applied in the direction of metal extrusion dies, wire drawing dies, etc., can solve the problems of time-consuming, laborious and wasteful adjustment and replacement of dies, and meet the requirements of single-piece small-batch production, fewer production links, and high-quality workmanship. simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

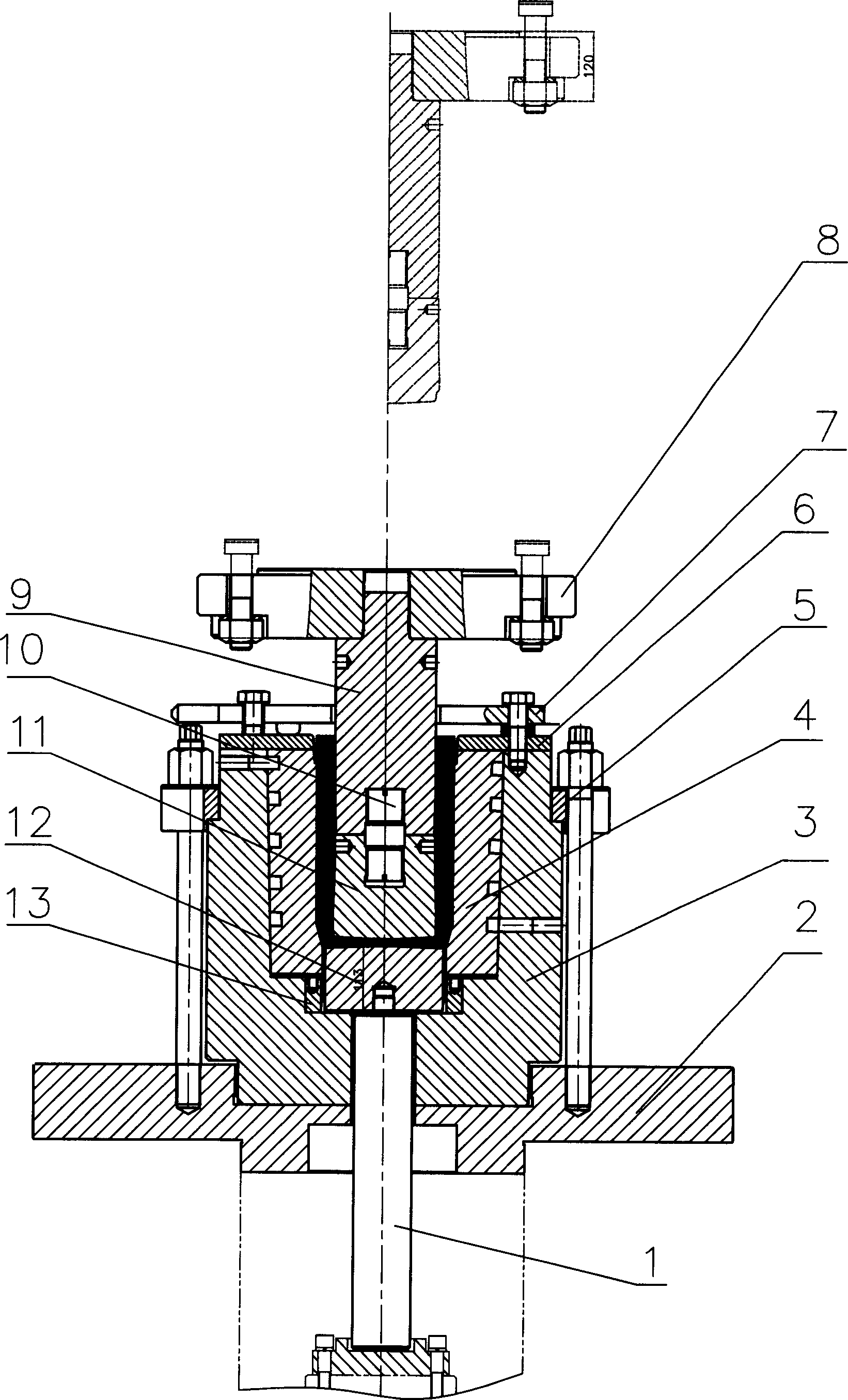

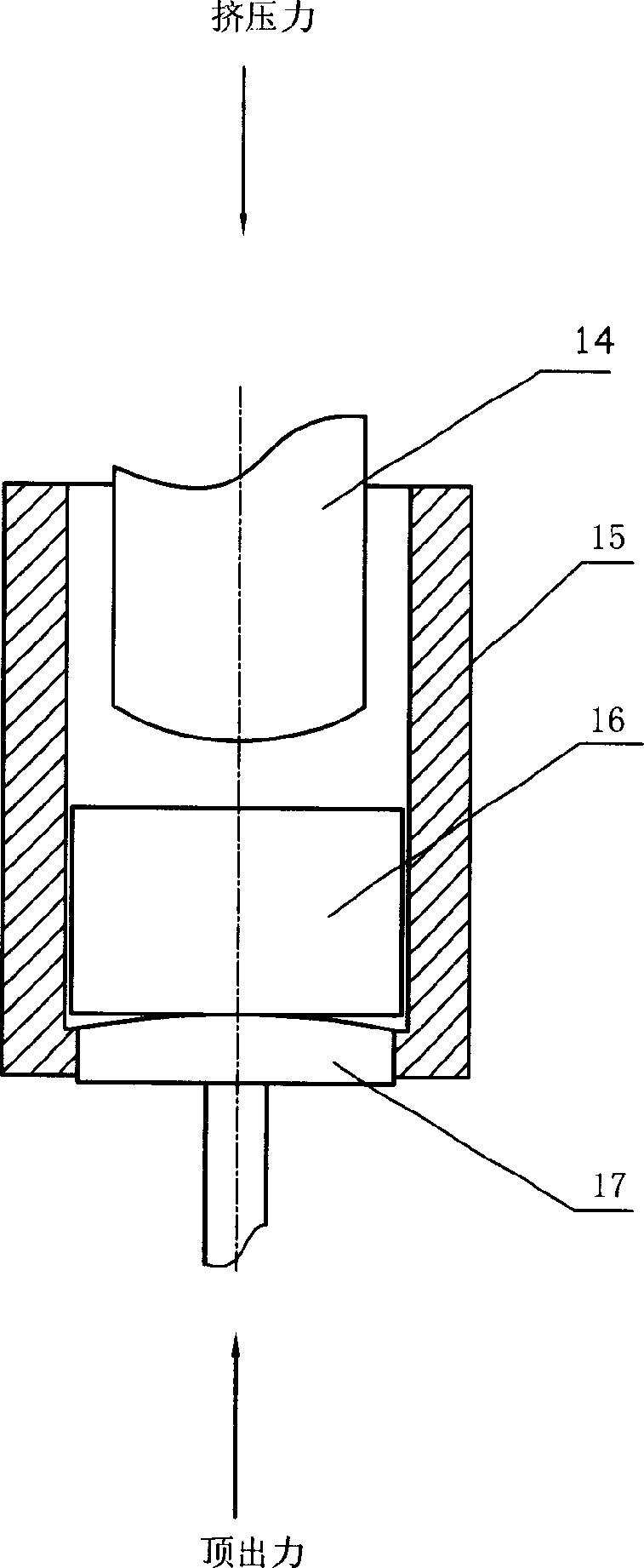

[0019] Such as Figure 1 ~ Figure 4 Shown is an interchangeable mold and method for reverse extrusion and drawing of rough copper tubes, wherein the interchangeable mold includes an upper supporting plate mounted on the head of a bed, an upper punch body and a base mounted on a workbench , die sleeve and material pad, which is characterized in that the lower end of the upper punch body has a screw hole, which is threadedly connected with the upper punch through a stud bolt; there is a die in the die sleeve, which is movably connected with the taper sleeve through a cone; the die of the die There is a spiral groove on the outer surface, and a discharge heating body is placed in the groove. The heating element is connected to the external circuit through the through hole of the mold sleeve; there are bolts on the top of the mold sleeve to fix the stripping plate and the pressure plate on the mold sleeve; the bottom of the pad and the The punch rod installed on the tailstock is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com