Forming and prestress flattening method for steel plate with ultra wide width and small thickness error

A small-thickness, pre-stressed technology, applied to other manufacturing equipment/tools, jet propulsion devices, rocket engine devices, etc., can solve the problems that cannot satisfy the production of front and rear heads, so as to improve the flattening efficiency and Quality, reduced processing costs, precise thickness control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

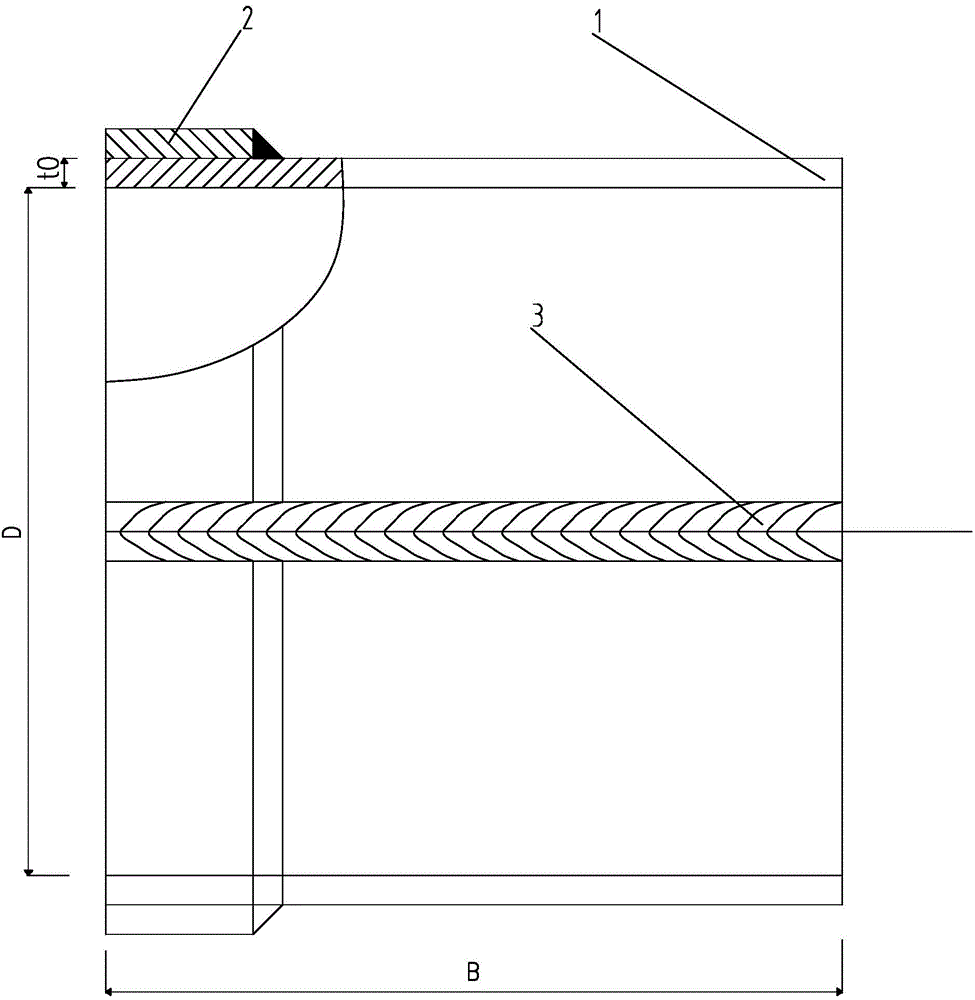

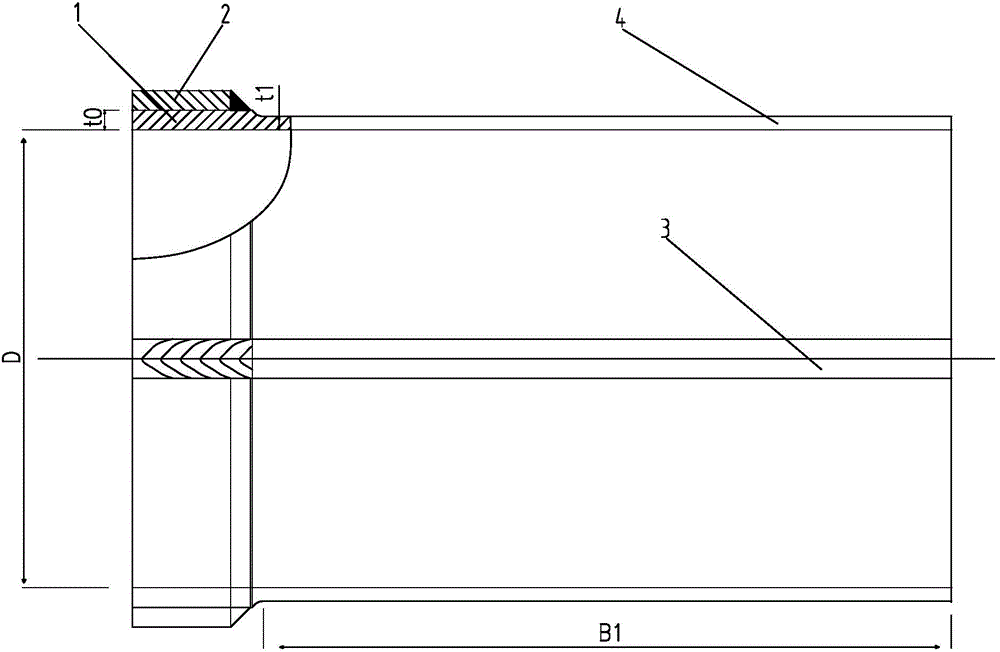

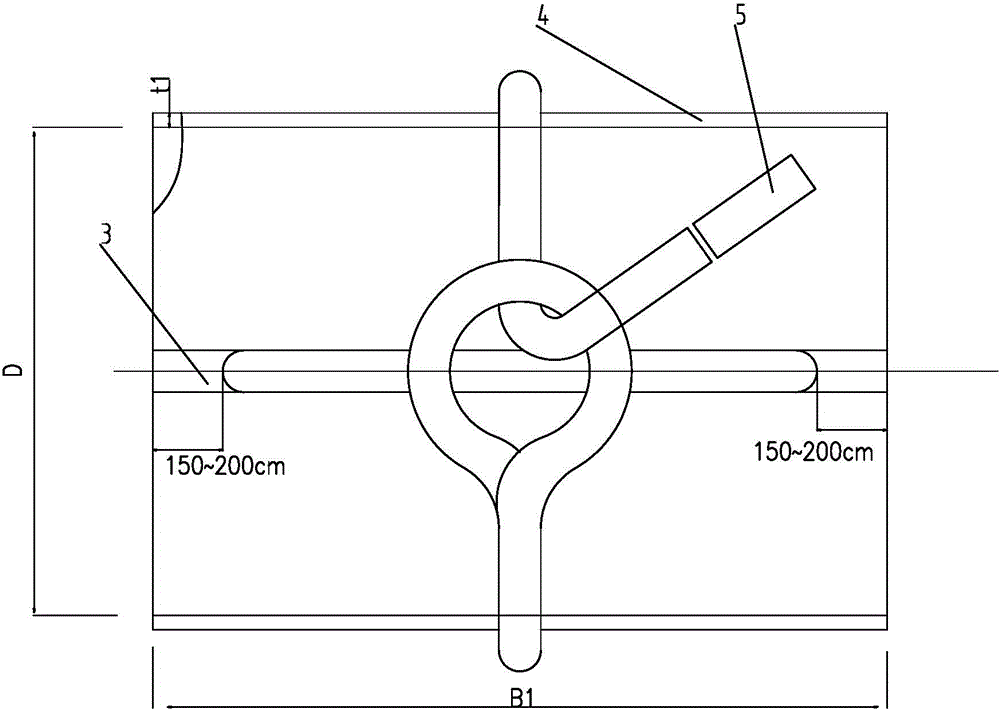

[0031] Embodiment 1: For a rocket combustion chamber shell head with a diameter of Φ1400mm for a certain aircraft, the diameter d required by the stretching process design of the rocket engine combustion chamber casing head is Φ1900mm, and the thickness t of the thin-walled cylinder 4 1 4.1mm, the forming and prestressed flattening process of the ultra-wide, small thickness error steel plate is as follows:

[0032] Step 1: set the width to B (according to B≥(t 1 D+t 1 2 )÷(t 0 D+t 0 2 )×(d+200)+50mm formula is calculated as 1483mm, and the original width B=1500mm is selected according to GB / T709 "Size, Shape, Weight and Permissible Deviation of Hot-rolled Steel Plates and Steel Strips", where, t 1 The thickness of the thin-walled cylinder 4 is 4.1 mm, t 0 The thickness of the narrow thick steel plate is 6mm, D is the diameter of the inner hole of the thin-walled cylinder 4 is Φ1400mm, d is the diameter required by the stretching process design of the shell head of the ro...

Embodiment 2

[0041] Embodiment 2: For a rocket combustion chamber shell head with a diameter of Φ1600mm for a certain aircraft, the diameter d required by the stretching process design of the rocket engine combustion chamber shell head is Φ2150mm, and the thickness of the thin-walled cylinder 4 is t 1 4.5mm, the forming and prestressed flattening process of the ultra-wide, small thickness error steel plate is as follows:

[0042] Step 1: set the width to B (according to B≥(t 1 D+t 1 2 )÷(t 0 D+t 0 2 )×(d+200)+50mm formula is calculated as 1369mm, and the original width B=1400mm is selected according to GB / T709 "Size, Shape, Weight and Permissible Deviation of Hot-rolled Steel Plates and Steel Strips", where, t 1 The thickness of the thin-walled cylinder 4 is 4.5mm, t 0 The thickness of the narrow thick steel plate is 8mm, D is the diameter of the inner hole of the thin-walled cylinder 4 is Φ1600mm, d is the diameter required by the stretching process design of the shell head of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com