Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve laser marking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encapsulant epoxy resin composition and electronic device

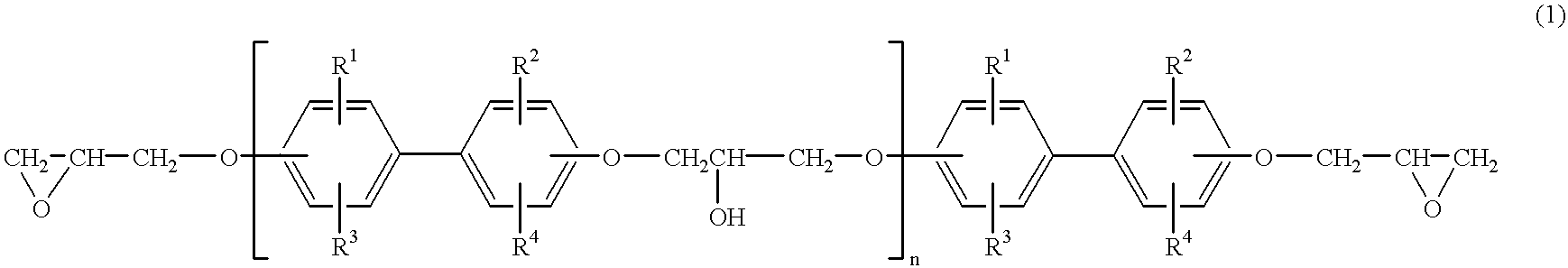

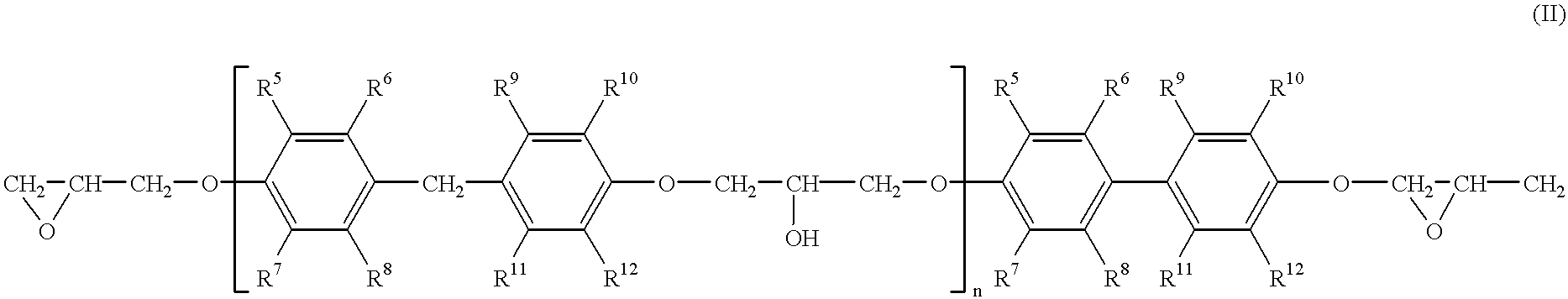

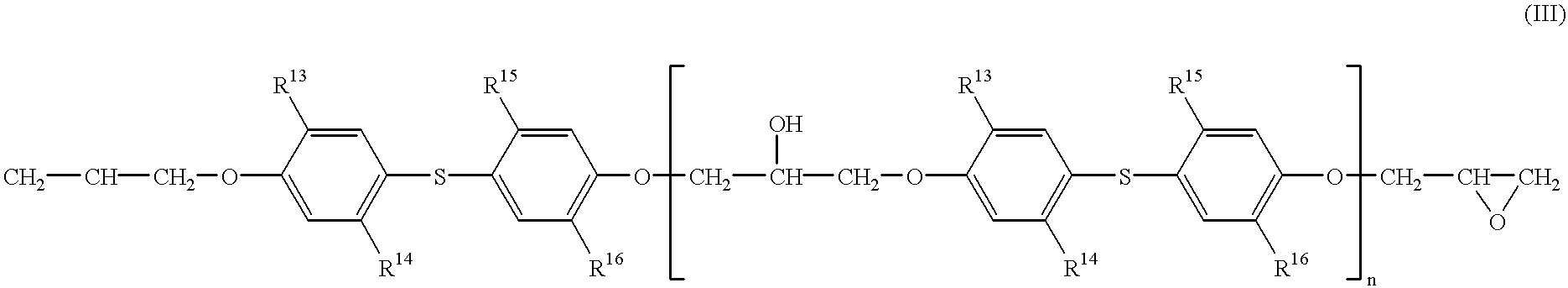

InactiveUS6372351B1Good molding effectImprove laser marking effectMechanical apparatusOther chemical processesEpoxyInorganic filler

In the present invention, provided are i) an encapsulant epoxy resin composition comprising an epoxy resin, a curing agent, a non-conductive carbon and an inorganic filler, and ii) an electronic device having an encapsulating member comprising a cured product of this composition.

Owner:HITACHI CHEM CO LTD

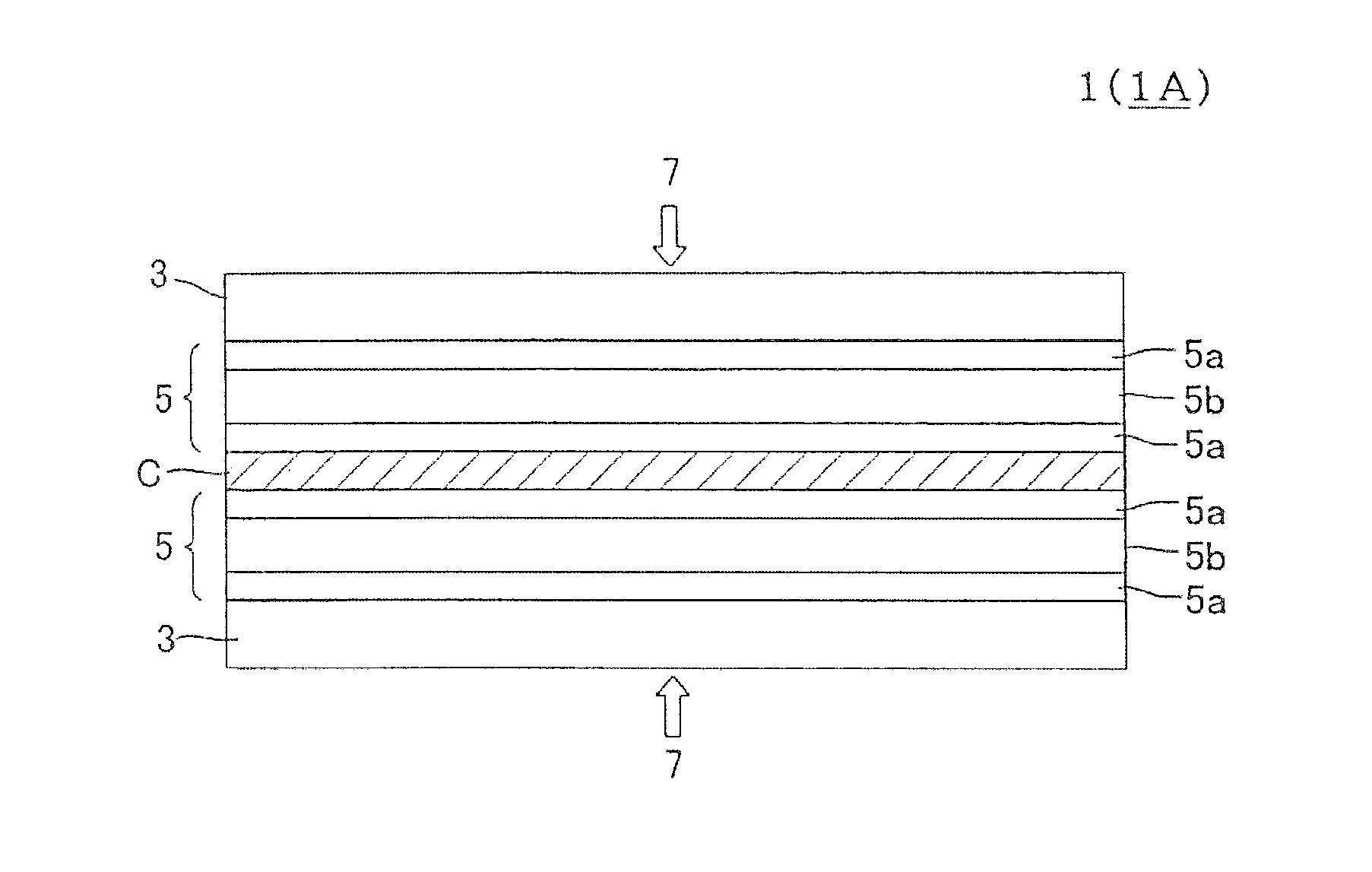

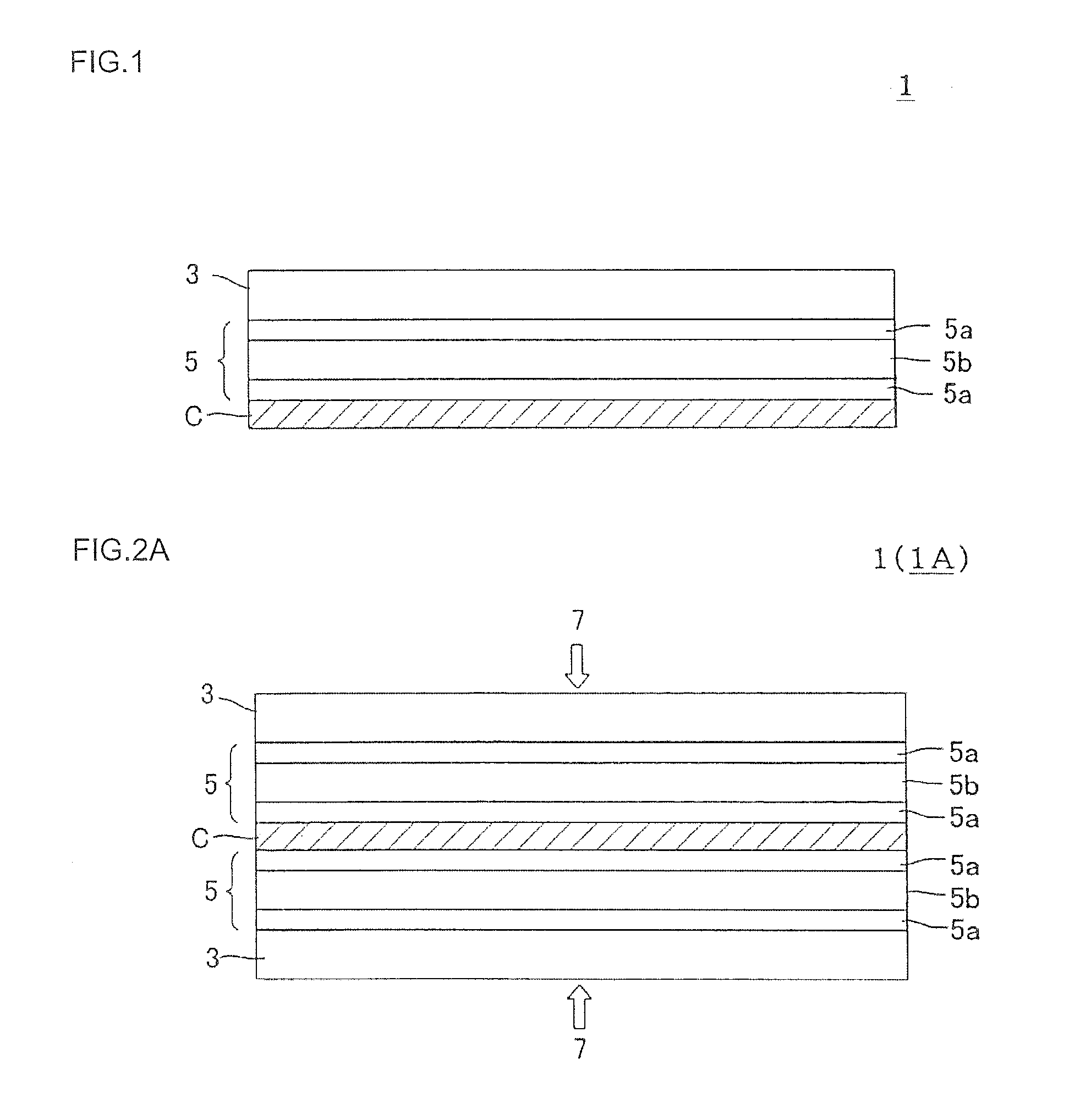

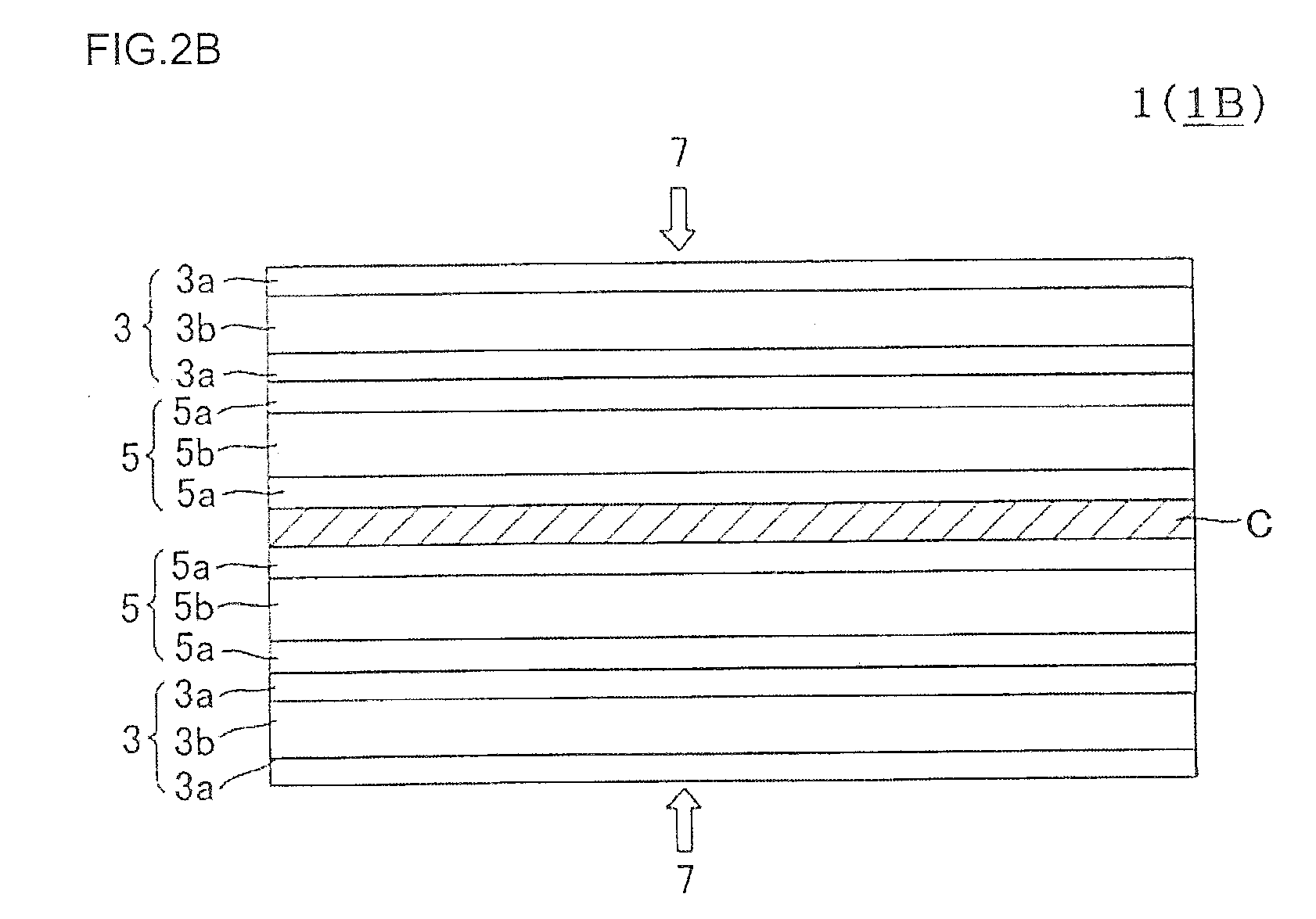

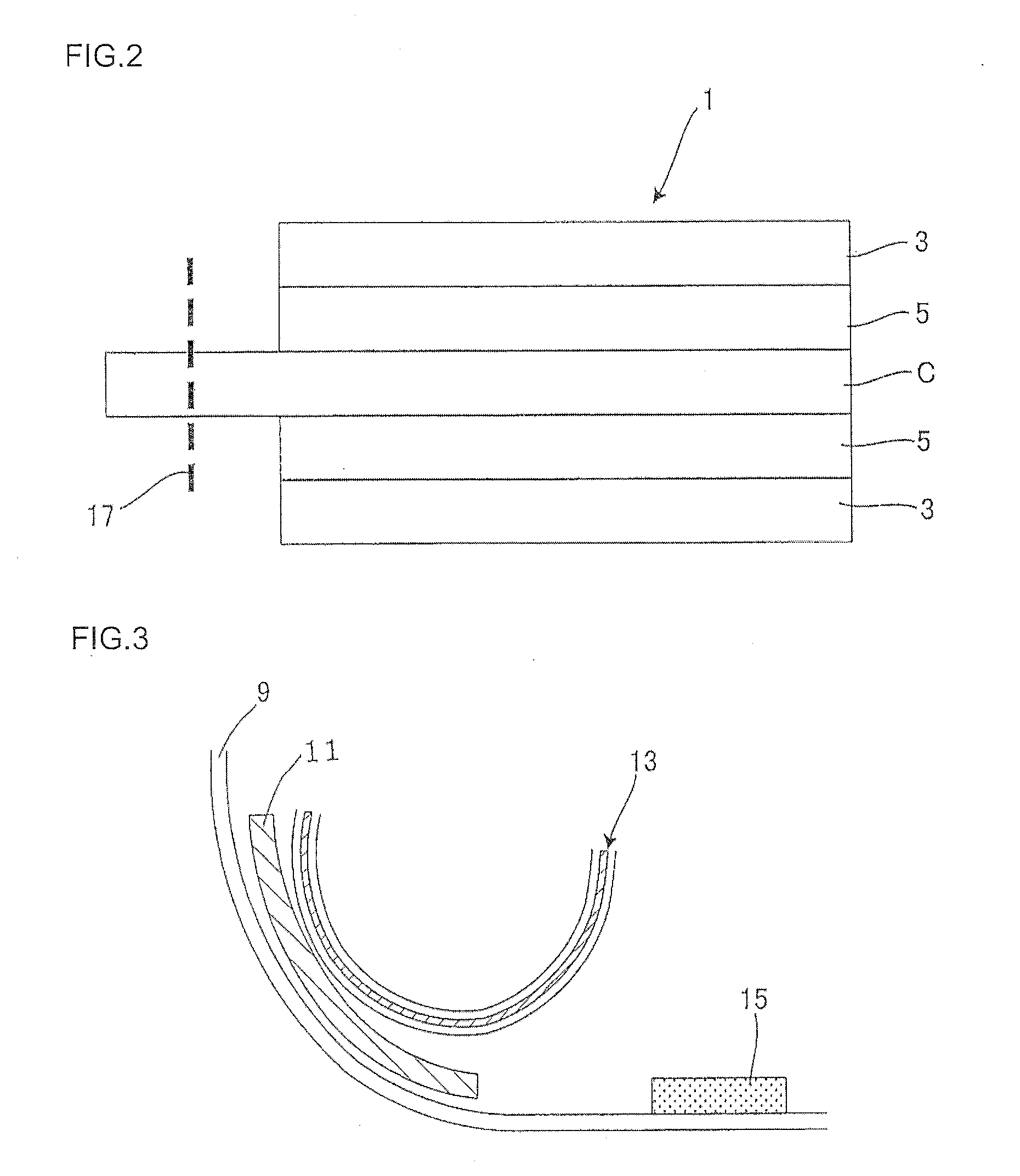

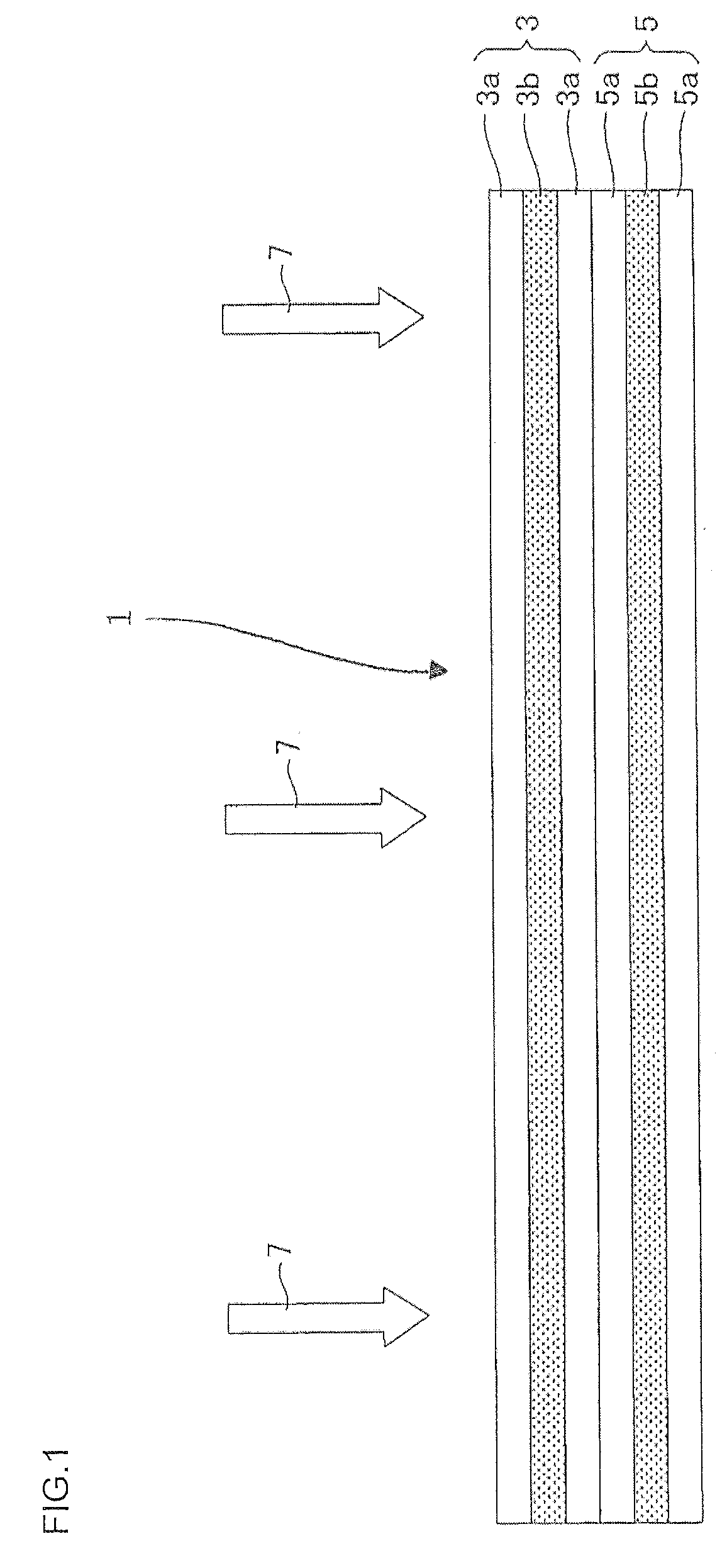

Multilayer laser-markable sheet for electronic passport and electronic passport

InactiveUS20120164419A1Improve laser marking effectIncrease contrastOther printing matterDuplicating/marking methodsEngineeringLaser light

A multilayer laser-markable sheet for an electronic passport includes three sheets of a sheet A / a multilayer sheet B / a sheet C as a basic constitutional unit. The sheet A includes a transparent polycarbonate resin composition including a thermoplastic polycarbonate resin and a laser light energy absorbing agent, the multilayer sheet B includes a transparent thermoplastic resin including a thermoplastic polycarbonate resin, at least one layer of the skin layers and the core layer of the multilayer sheet B including at least one selected from a dye and a pigment. The sheet C includes a sheet or a laminate sheet. The multilayer laser-markable sheet for an electronic passport has excellent laser markability and high contrast, can achieve clear letters, symbols and images, and further has excellent thermal adhesiveness, transparency, sheet conveyance property, releasability from a die after thermal press, thermal resistance, foldability and wear resistance.

Owner:JAPAN COLORING

Laser markable microporous material

ActiveUS20110198837A1Improve laser marking effectOther printing matterFilm/foil adhesivesPolyolefinWater insoluble

Provided is a microporous material including a polyolefin matrix material; finely divided, substantially water-insoluble filler distributed throughout the matrix material, where the filler includes a positive amount of titanium dioxide; a network of interconnecting pores communicating throughout the microporous material; and optionally, a contrasting enhancing amount of a contrast enhancing material. The sum of the weight percent of the titanium dioxide and the weight percent of the optional contrast enhancing material is at least 3 weight percent based on total weight of the microporous material. Multilayer articles having a layer of the microporous material also are provided.

Owner:PPG IND OHIO INC

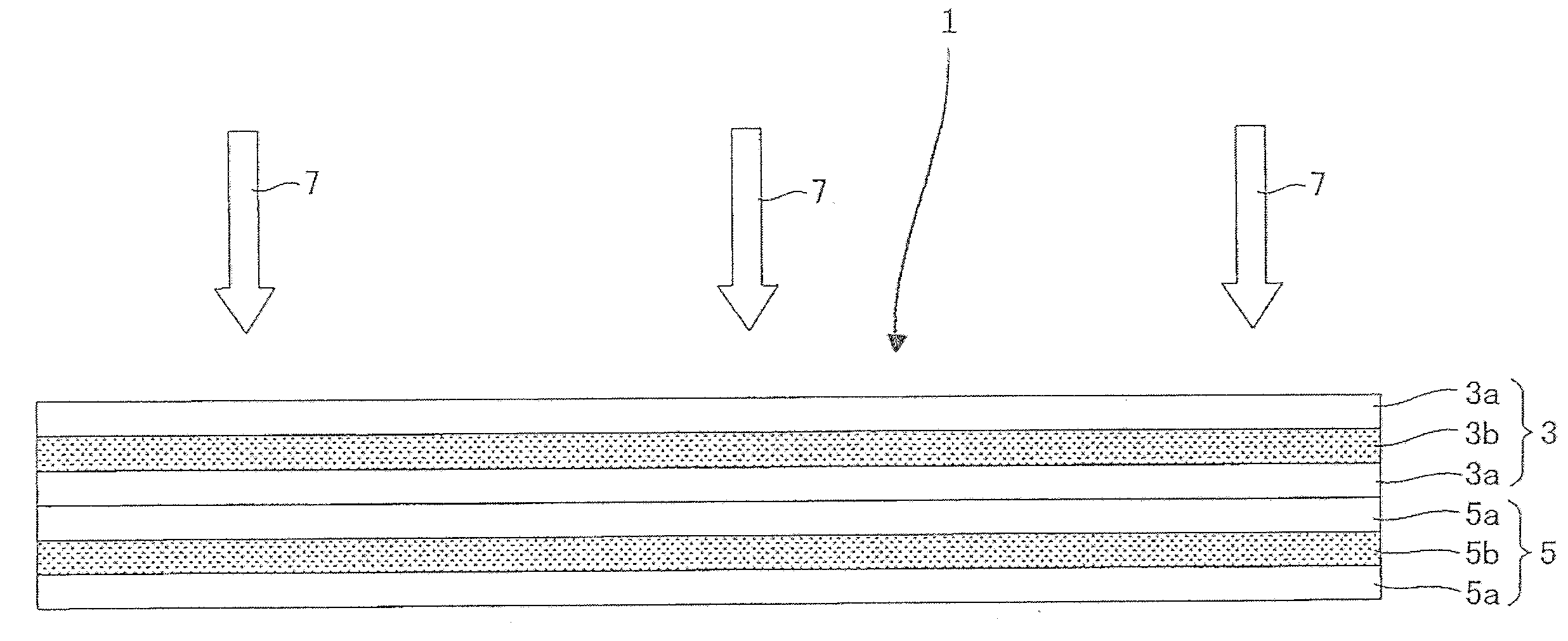

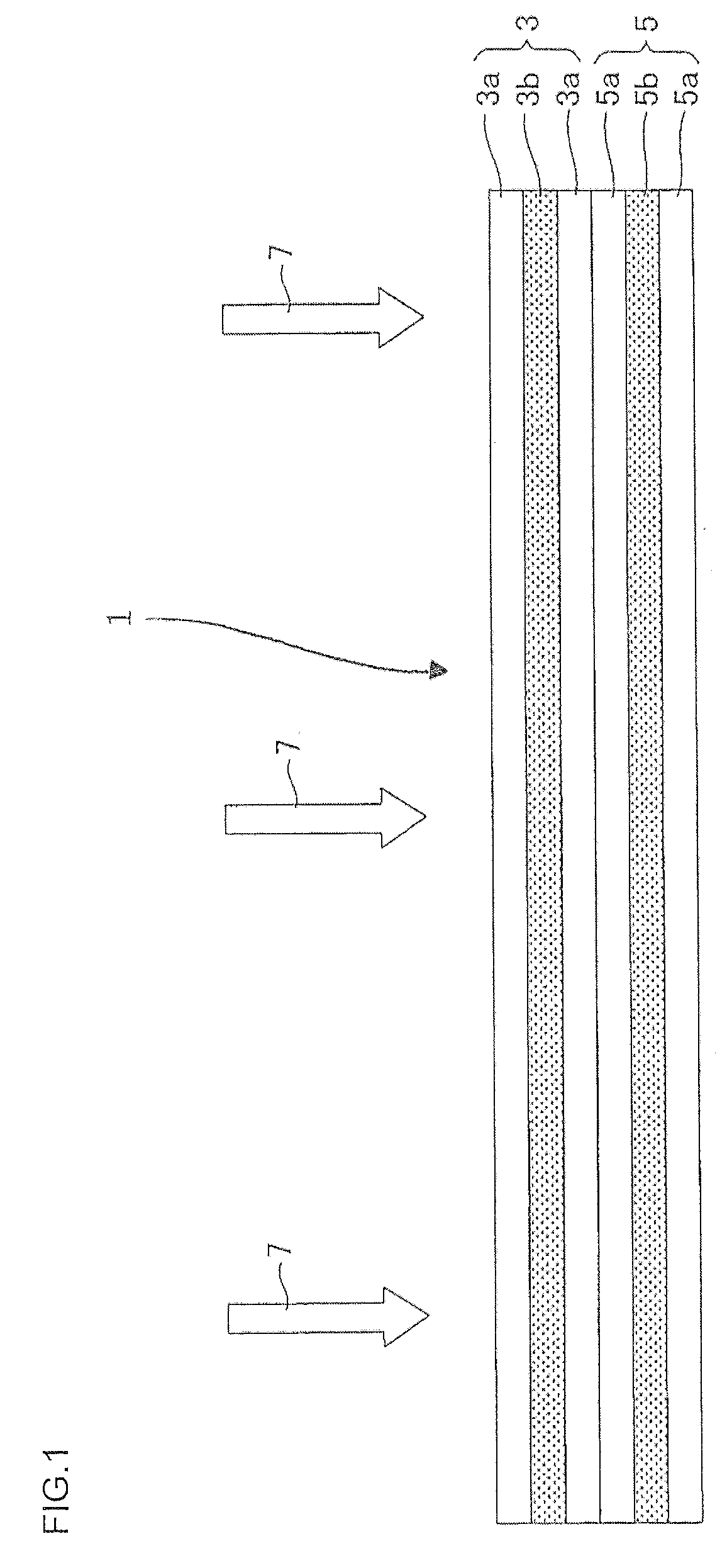

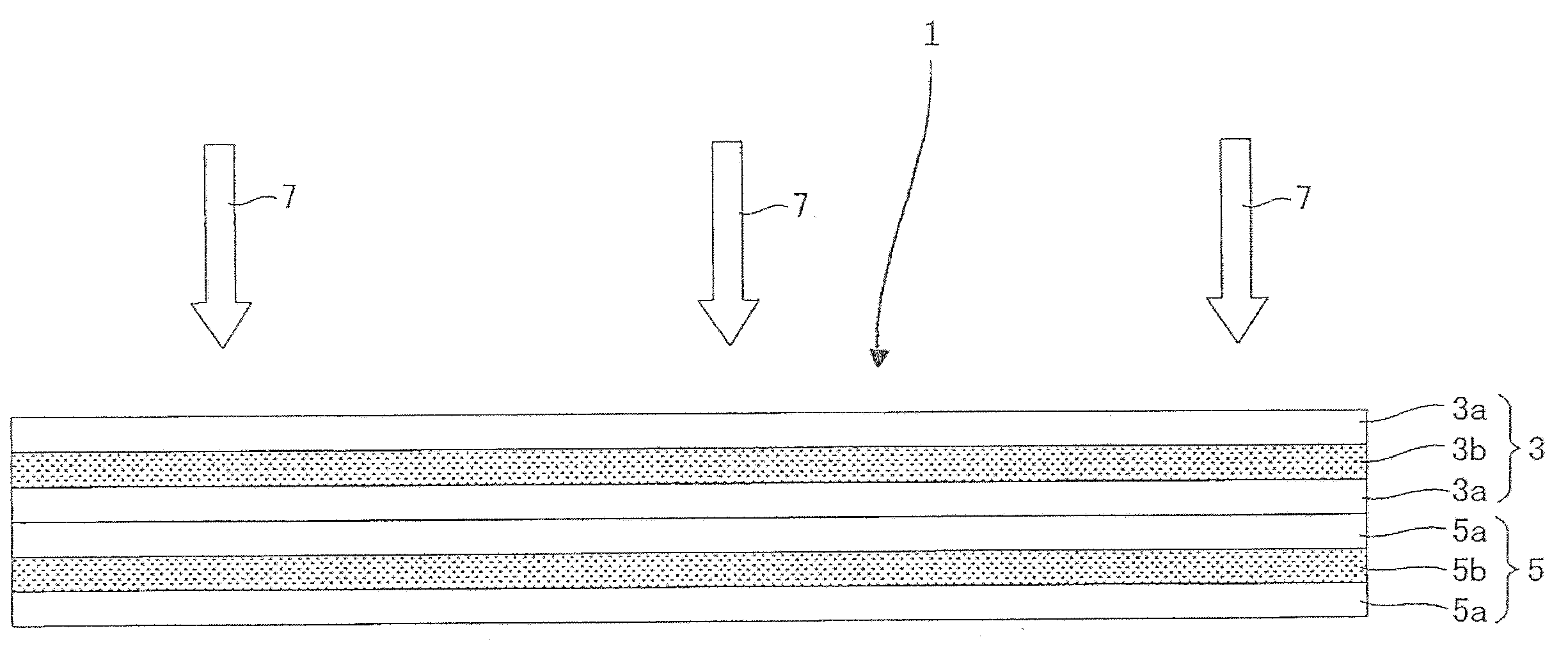

Multilayer sheet for laser marking

ActiveUS20110076452A1Excellent thermal adhesionIncrease contrastSynthetic resin layered productsRecord information storagePolyester resinOptoelectronics

A laser marking multilayer sheet includes a multilayer sheet A, and a multilayer sheet B that is stacked under the multilayer sheet A. The multilayer sheet A is a transparent laser marking multilayer sheet. A skin layer that forms each outermost layer of the multilayer sheet A is formed of a noncrystalline aromatic polyester resin composition, and a core layer of the multilayer sheet A is formed of a polycarbonate resin composition. The multilayer sheet B is a colored laser marking multilayer sheet. A skin layer that forms each outermost layer of the multilayer sheet B is formed of a noncrystalline aromatic polyester resin composition, and a core layer of the multilayer sheet B is formed of a polycarbonate resin composition.

Owner:JAPAN COLORING

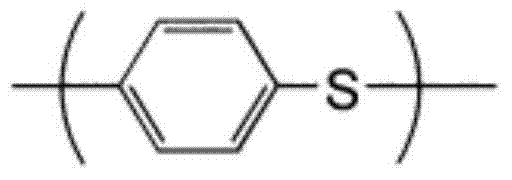

Thermoplastic resin composition and molded article thereof

InactiveCN103717672AImprove heat resistanceImprove laser marking effectLiquid crystal compositionsDuplicating/marking methodsLiquid crystallinePolyester

To provide: a thermoplastic resin composition which has high laser marking properties and heat resistance; and a molded article which is formed from the thermoplastic resin composition. A thermoplastic resin composition which contains 0.001-10 parts by weight of a metal complex (b) that is configured of a monodentate or bidentate ligand and at least one metal selected from the group consisting of copper, zinc, nickel, manganese, cobalt, chromium and tin and / or a salt thereof per 100 parts by weight of a thermoplastic resin (a) that is a liquid crystalline polyester and / or a polyphenylene sulfide.

Owner:TORAY IND INC

Oversheet for card

ActiveUS20110123766A1Good effectSharp contrastSynthetic resin layered productsRecord information storagePolyesterPolycarbonate

There is provided an over-sheet for a card, the sheet being formed of at least three layers including a skin layer and a core layer and laminated by a coextrusion technique. The skin layer, which is an outermost layer on both sides of the three-layer sheet, is formed of a substantially amorphous aromatic polyester-based resin composition containing 0.01 to 3 parts by mass of at least one lubricant selected from the group of fatty acid ester, fatty acid amide, and fatty acid metal salt. The core layer is formed of a polycarbonate resin.

Owner:JAPAN COLORING

Polyamide Resin Composition for Laser Marking and Laser-Marked Polyamide Resin Molded Product

InactiveUS20090306262A1Improve flame retardant performanceImprove laser marking effectFilm/foil adhesivesDuplicating/marking methodsHalogenHeat resistance

There is provided a polyamide resin composition capable of not only maintaining inherent properties of polyamide resins including moldability, mechanical properties, thermal stability, heat resistance and electrical properties but also exhibiting a good flame retardance and an excellent laser marking property, as well as a resin molded product for laser marking which is molded from the composition. The polyamide resin composition for laser marking according to the present invention includes 100 parts by weight of a polyamide resin and 0.1 to 100 parts by weight of a halogen-containing organic compound and / or an antimony compound, wherein when subjecting a molded product obtained from the composition to laser marking, a color tone of a laser-marked portion of the molded product exhibits a darker color than that of a surface of a laser-non-irradiated portion of the molded product.

Owner:MITSUBISHI ENG PLASTICS CORP

Epoxy resin composition for semiconductor encapsulation and semiconductor device

InactiveCN101133120ANo deformationNo short circuitPigmenting treatmentSemiconductor/solid-state device detailsEpoxyPhenol formaldehyde resin

An epoxy resin composition for sealing semiconductors including (A) an epoxy resin, (B) a phenol resin, (C) an inorganic filler, (D) a curing promoter, and (E) a surface-treated coloring agent, wherein the coloring agent before the surface treatment is a carbon precursor with a carbon content of 90 wt % or more or carbon black having a DBP absorption of 100 cm<3> / 100 g or more, and a semiconductor device sealed with the epoxy resin composition. The epoxy resin composition can produce semiconductors which are free from electrical failures such as a short circuit, a leak current, and the like, do not induce wire deformation, and exhibits excellent laser marking characteristics.

Owner:SUMITOMO BAKELITE CO LTD

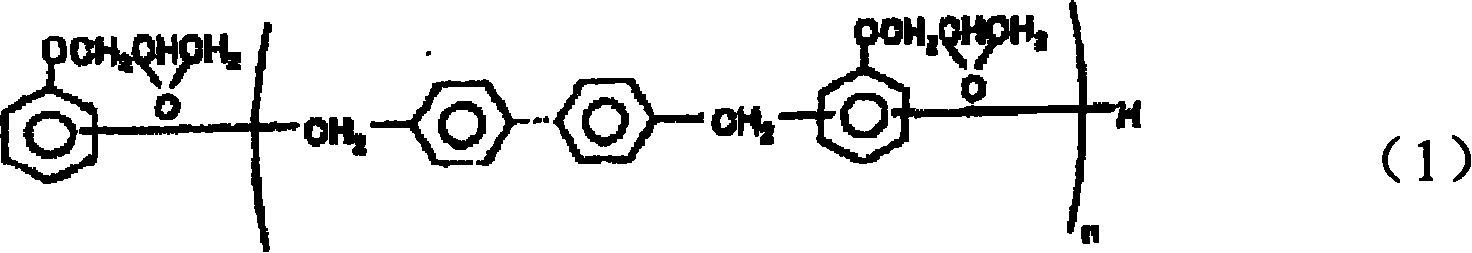

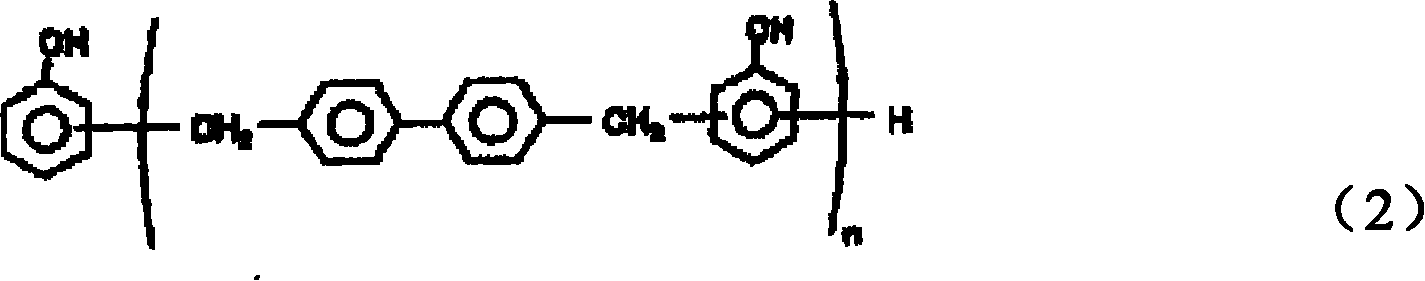

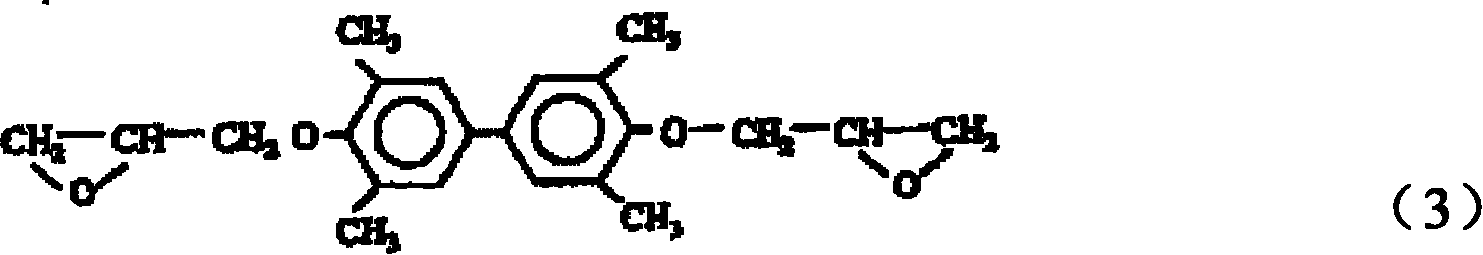

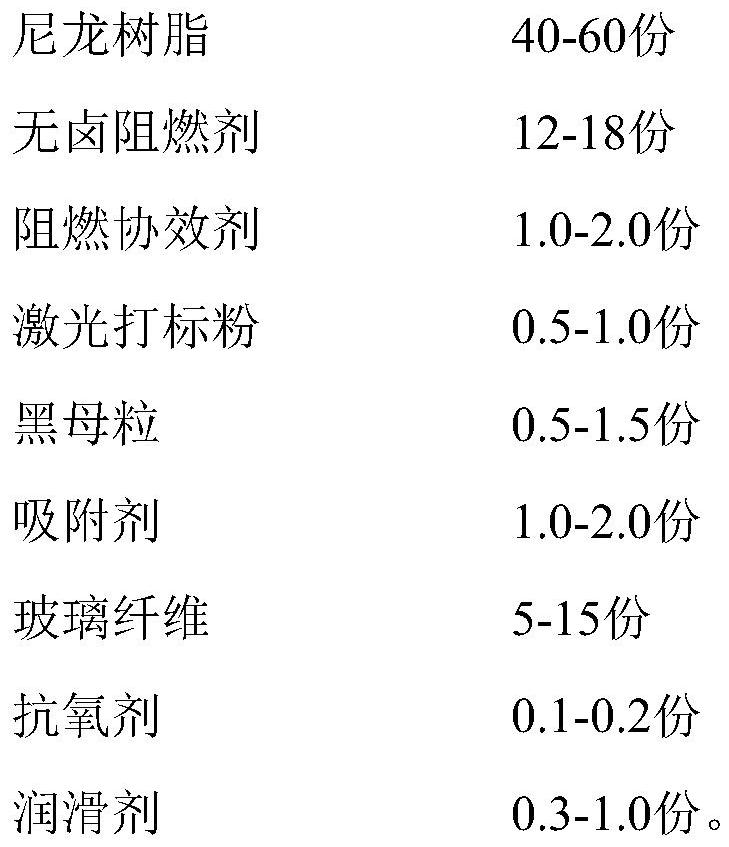

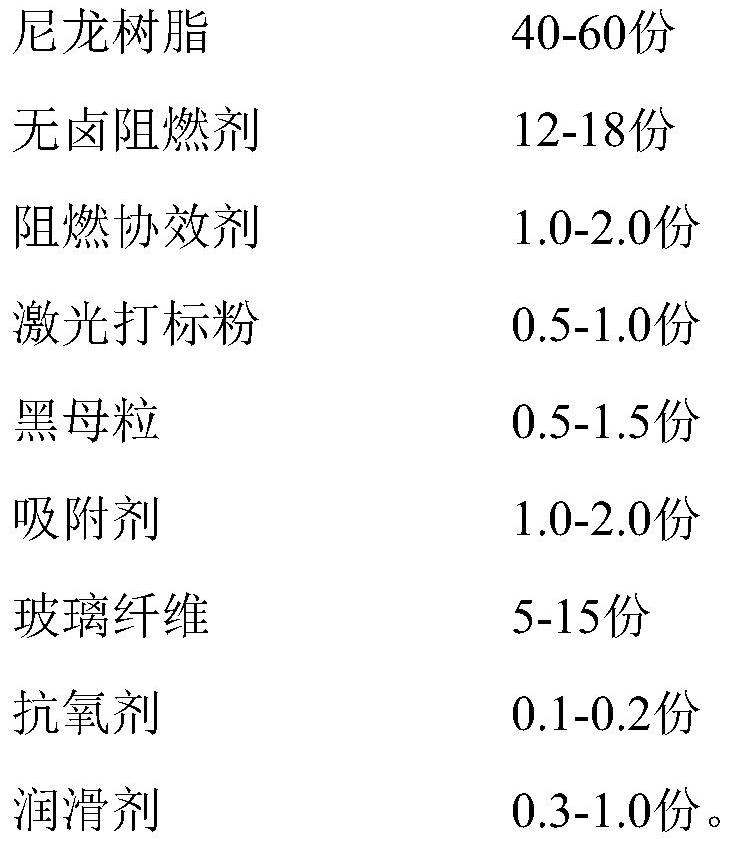

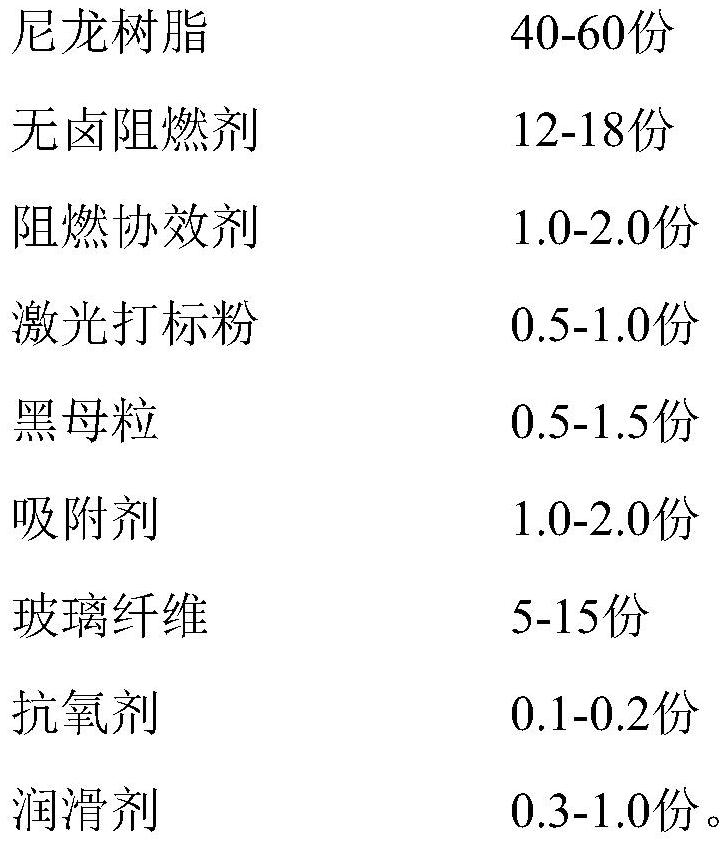

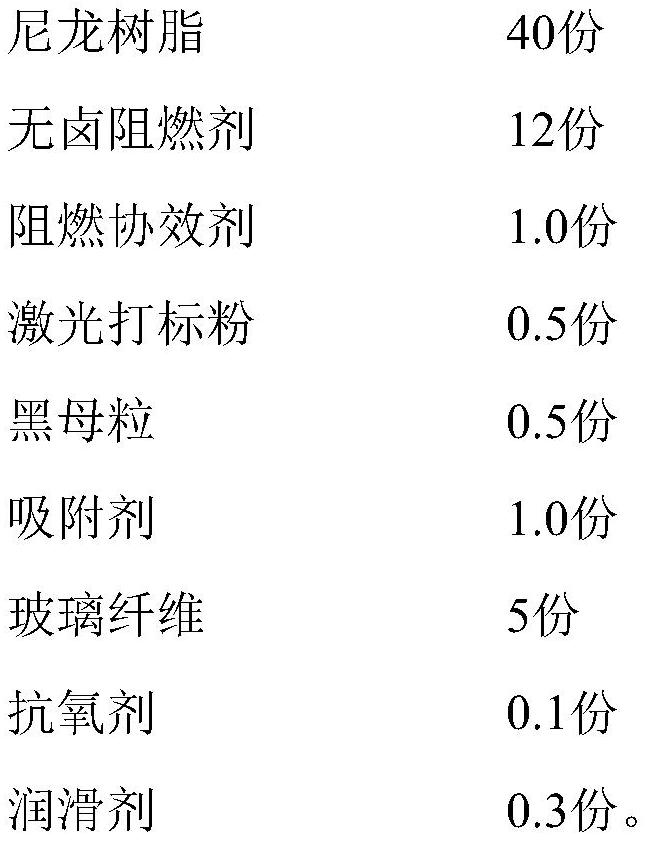

Halogen-free flame-retardant nylon composite material capable of being subjected to laser marking and preparation method thereof

The invention relates to the technical field of laser marking high polymer materials, in particular to a halogen-free flame-retardant nylon composite material capable of being subjected to laser marking and a preparation method thereof. The nylon composite material comprises nylon resin, a halogen-free flame retardant, a flame retardant synergist, laser marking powder, black master batch, an adsorbent, glass fibers, an antioxidant and a lubricant, so that the prepared nylon composite material has excellent flame retardance and high-temperature and high-humidity resistance, relatively good tensile strength and bending strength and a good laser marking effect. The material is simple in preparation process, environment-friendly, clean and low in cost, laser marking can be directly carried out in the product processing process, and continuous and automatic industrial production is realized.

Owner:东莞市东翔塑胶有限公司

Multilayer sheet for laser marking

ActiveUS8603633B2Excellent thermal adhesionIncrease contrastSynthetic resin layered productsRecord information storagePolyester resinOptoelectronics

A laser marking multilayer sheet includes a multilayer sheet A, and a multilayer sheet B that is stacked under the multilayer sheet A. The multilayer sheet A is a transparent laser marking multilayer sheet. A skin layer that forms each outermost layer of the multilayer sheet A is formed of a noncrystalline aromatic polyester resin composition, and a core layer of the multilayer sheet A is formed of a polycarbonate resin composition. The multilayer sheet B is a colored laser marking multilayer sheet. A skin layer that forms each outermost layer of the multilayer sheet B is formed of a noncrystalline aromatic polyester resin composition, and a core layer of the multilayer sheet B is formed of a polycarbonate resin composition.

Owner:JAPAN COLORING

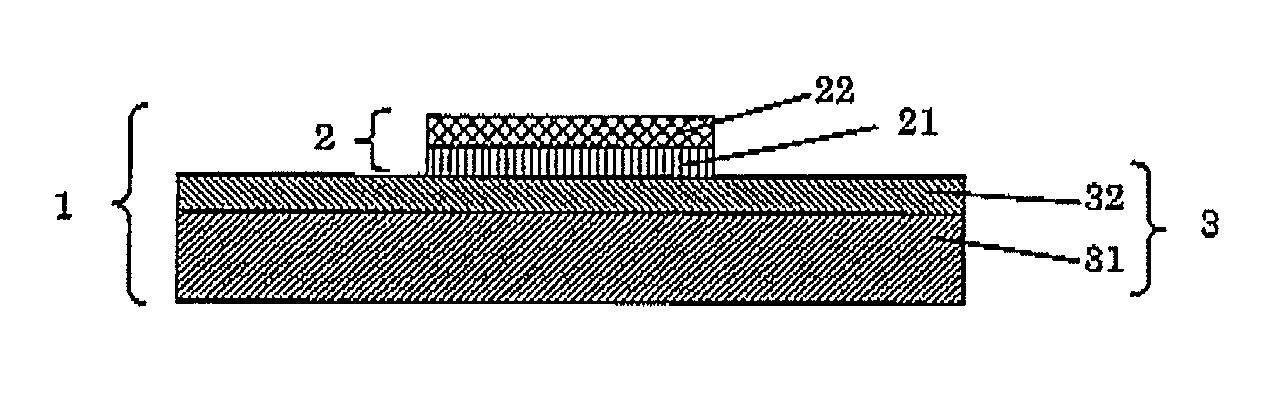

Film for flip chip type semiconductor back surface containing thermoconductive filler

InactiveUS8513816B2Efficient releaseImprove laser marking effectSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceSemiconductor components

The present invention relates to a film for flip chip type semiconductor back surface, which is to be disposed on the back surface of a semiconductor element to be flip chip-connected onto an adherend, the film containing a resin and a thermoconductive filler, in which the content of the thermoconductive filler is at least 50% by volume of the film, and the thermoconductive filler has an average particle size relative to the thickness of the film of at most 30% and has a maximum particle size relative to the thickness of the film of at most 80%.

Owner:NITTO DENKO CORP

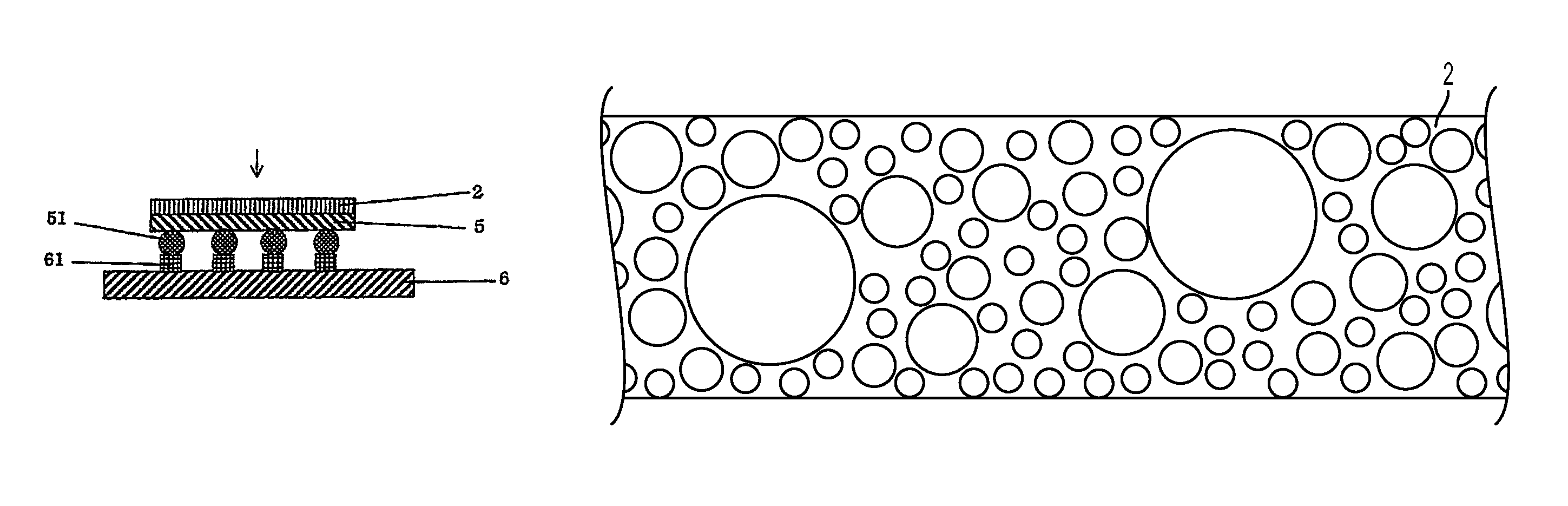

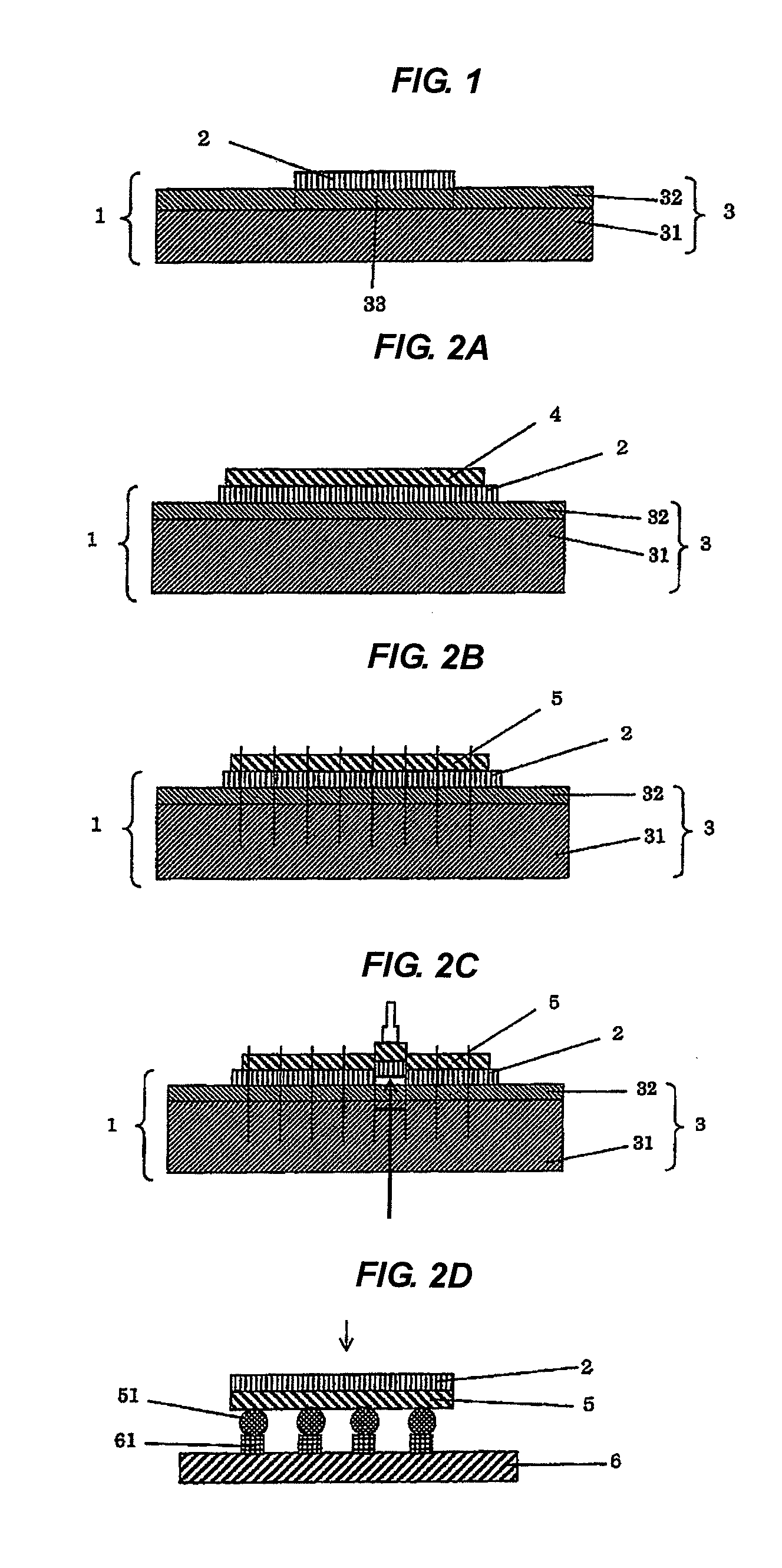

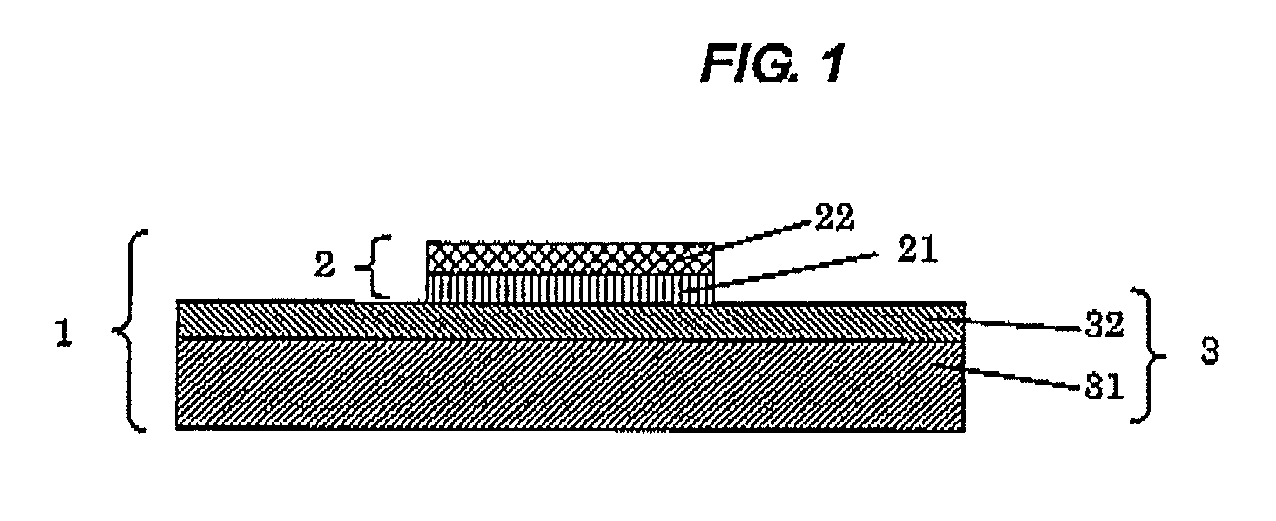

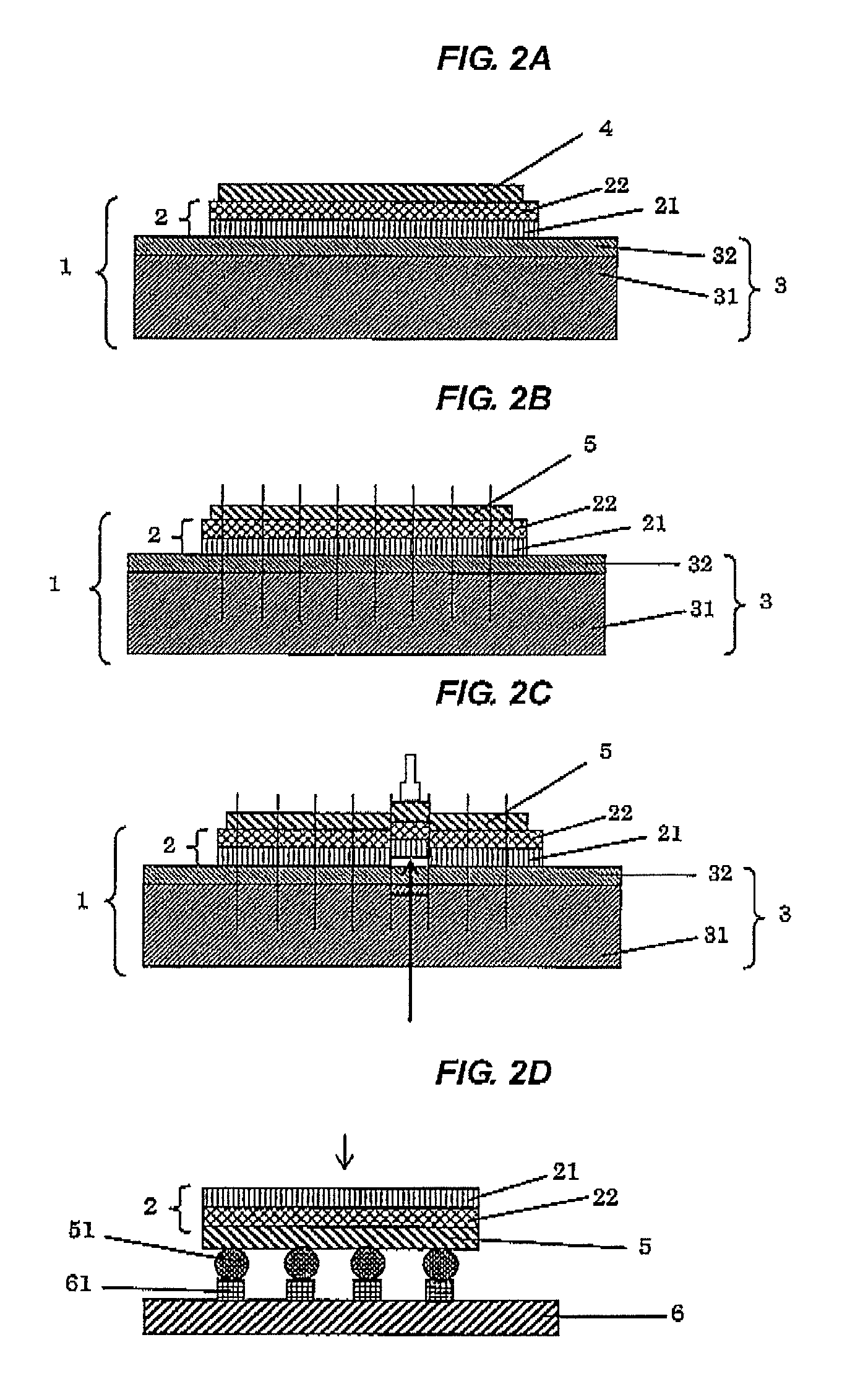

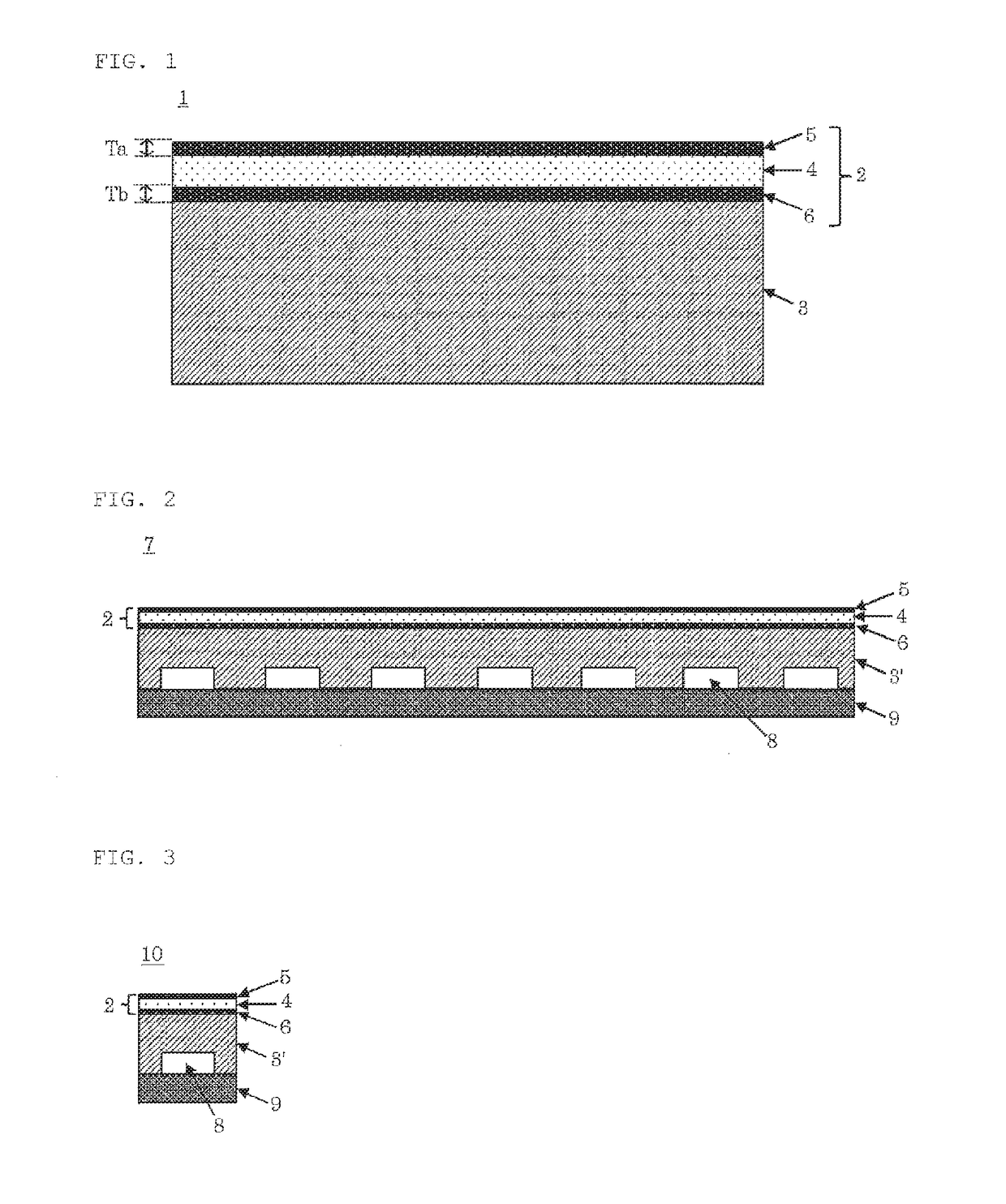

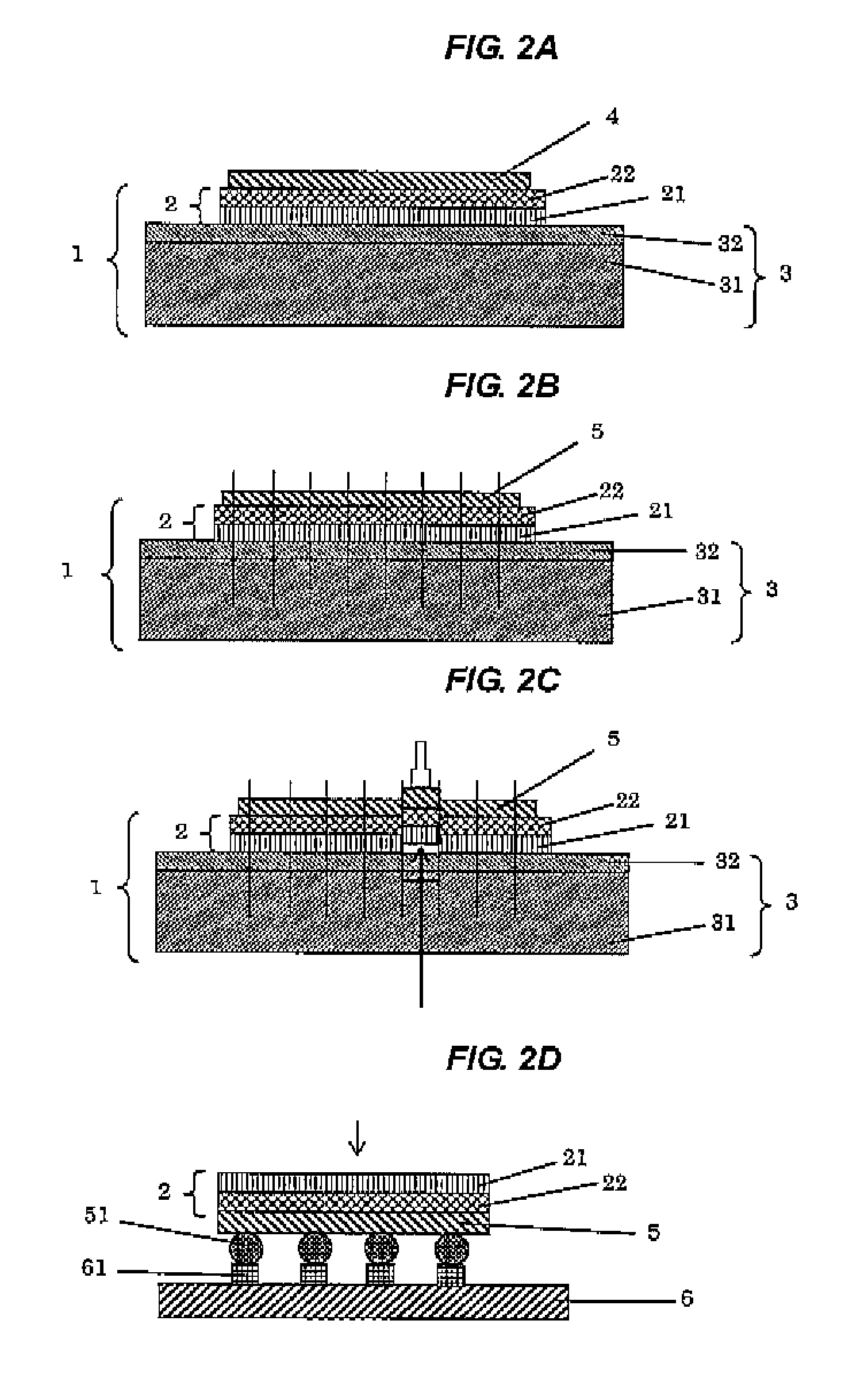

Dicing tape-integrated film for semiconductor back surface

ActiveUS8703584B2Good lookingImprove laser marking effectSemiconductor/solid-state device detailsSolid-state devicesDicing tapeEngineering

The present invention provides a dicing tape-integrated film for semiconductor back surface, which includes: a dicing tape including a base material and a pressure-sensitive adhesive layer provided on the base material; and a film for flip chip type semiconductor back surface provided on the pressure-sensitive adhesive layer, in which the film for flip chip type semiconductor back surface has a multilayered structure including a wafer adhesion layer and a laser mark layer, the wafer adhesion layer is formed of a resin composition containing a thermosetting resin component and, as an optional component, a thermoplastic resin component in an amount of less than 30% by weight relative to the whole amount of resin components, and the laser mark layer is formed of a resin composition containing a thermoplastic resin component in an amount of 30% by weight or more relative to the whole amount of resin components and, as an optional component, a thermosetting resin component.

Owner:NITTO DENKO CORP

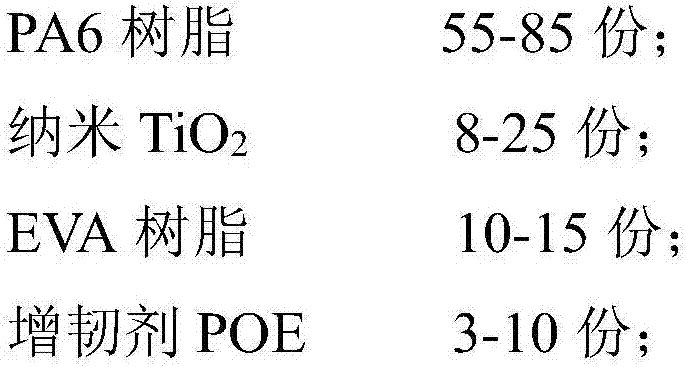

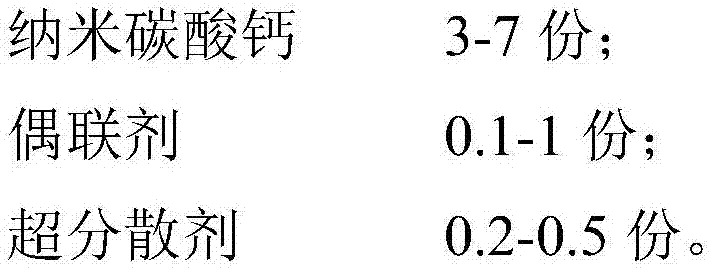

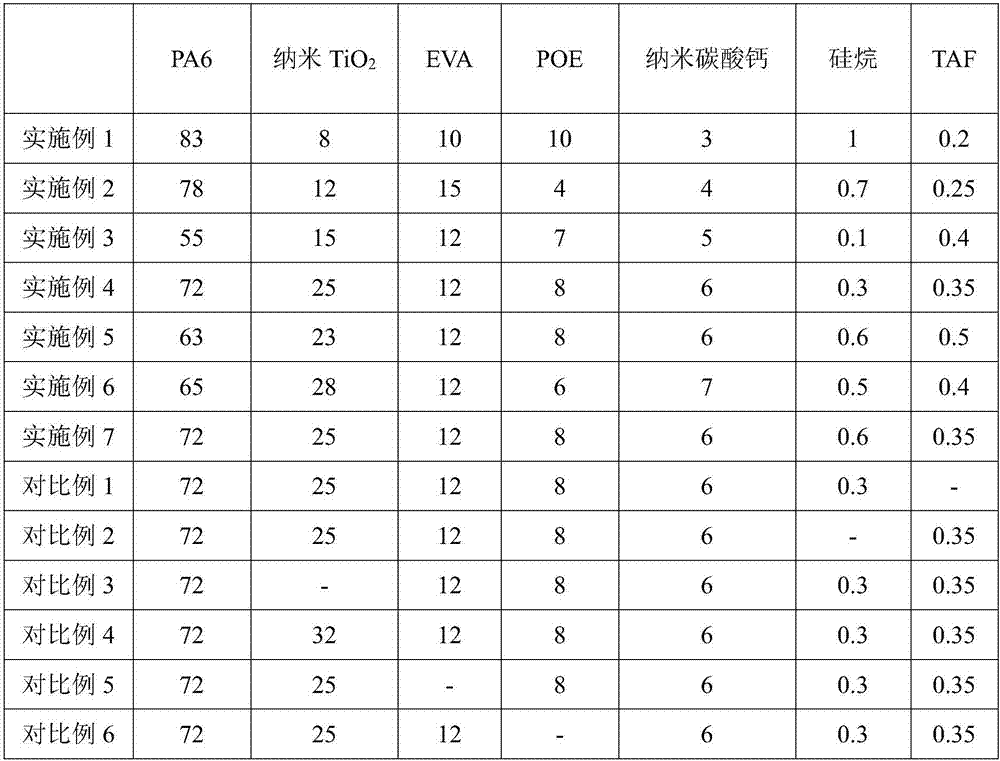

Modified PA6 (Polyamide6) material for laser marker

The invention discloses a modified PA6 material for a laser marker. The modified PA6 material is composed of the following raw materials in parts by weight: 55-85 parts of a PA6 resin, 8-25 parts of nano TiO2, 10-15 parts of an EVA (Ethylene-Vinyl Acetate) resin, 3-10 parts of a flexibilizer POE, 3-7 parts of nano calcium carbonate, 0.1-1 part of a coupling agent and 0.2-0.5 part of a hyperdispersant. The modified PA6 material disclosed by the invention has high laser marking capacity, is high in contrast ratio and clear after marking and has an excellent mechanical property.

Owner:SUZHOU SUNWAY POLYMER

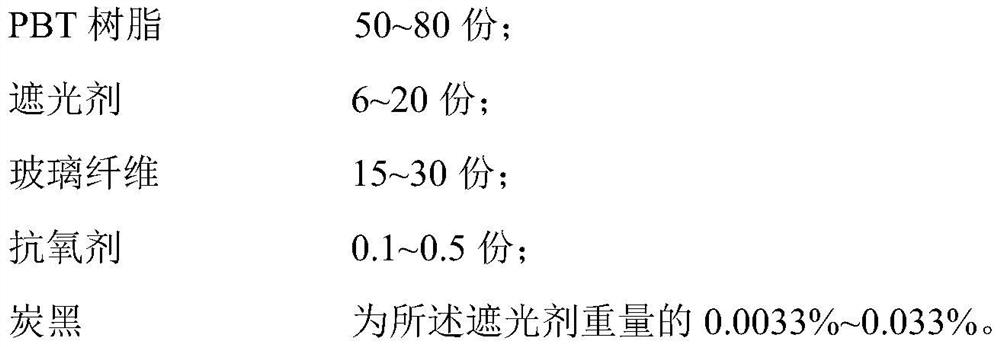

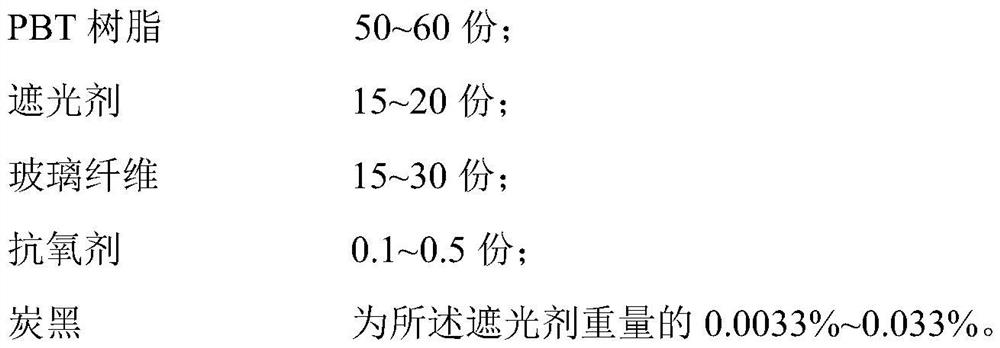

Laser marking shading enhanced PBT composition as well as preparation method and application thereof

ActiveCN112375345APlay the role of reflecting lightImprove laser marking effectGlass fiberAntioxidant

The invention provides a laser marking shading enhanced PBT composition. The composition comprises the following components in parts by weight: 50-80 parts of PBT resin; 6-20 parts of an opacifying agent; 15-30 parts of glass fiber; 0.1-0.5 part of antioxidant; and carbon black accounting for 0.0033%-0.033% of the weight of the opacifying agent. Under the condition that no expensive laser markingagent is used and only the opacifying agent and the trace carbon black are compounded, the composition has the following properties that: a shading effect of which the whiteness value is larger than 90 and of which the thickness is smaller than 3 mm is achieved; and the color difference value before and after laser marking is larger than 15; and therefore, composition can be applied to the field of preparation of lamp cup shells, capacitors, connectors or relay products in the lighting industry.

Owner:KINGFA SCI & TECH CO LTD

Preparation method of laser marking lubricant for ABS (acrylonitrile butadiene styrene) engineering plastics

ActiveCN107266717AImprove compatibilityImprove mechanical properties and laser marking resultsStearic acidNitrogen gas

The invention discloses a preparation method of a laser marking lubricant for ABS (acrylonitrile butadiene styrene) engineering plastics, and belongs to the technical field of a laser marking additive. According to the method, firstly, a Dopamine solution is used for soaking a modified laser absorbent; after filtering and drying are performed, the modified laser absorbent and a treating agent are mixed and react at high temperature, and are then dissolved in ethanediamine to prepare a laser absorbent ethanediamine solution; next, in a nitrogen protection state, heating is performed, so that stearic acid is melted and is then proportionally mixed with the laser absorbent ethanediamine solution for performing dehydration reaction; moisture in the system is taken out by nitrogen gas flow; finally, through extrusion pelletization, the laser marking lubricant for the ABS engineering plastics is obtained. The compatibility of the laser marking lubricant for the ABS engineering plastics with a plastic base body is good; the laser marking lubricant can be stably dispersed in the plastics; the mechanical strength of the product can be effectively improved; in the laser marking process, the formed marks are clear; the contrast is obvious; wide application prospects are realized.

Owner:常州可赛成功塑胶材料有限公司

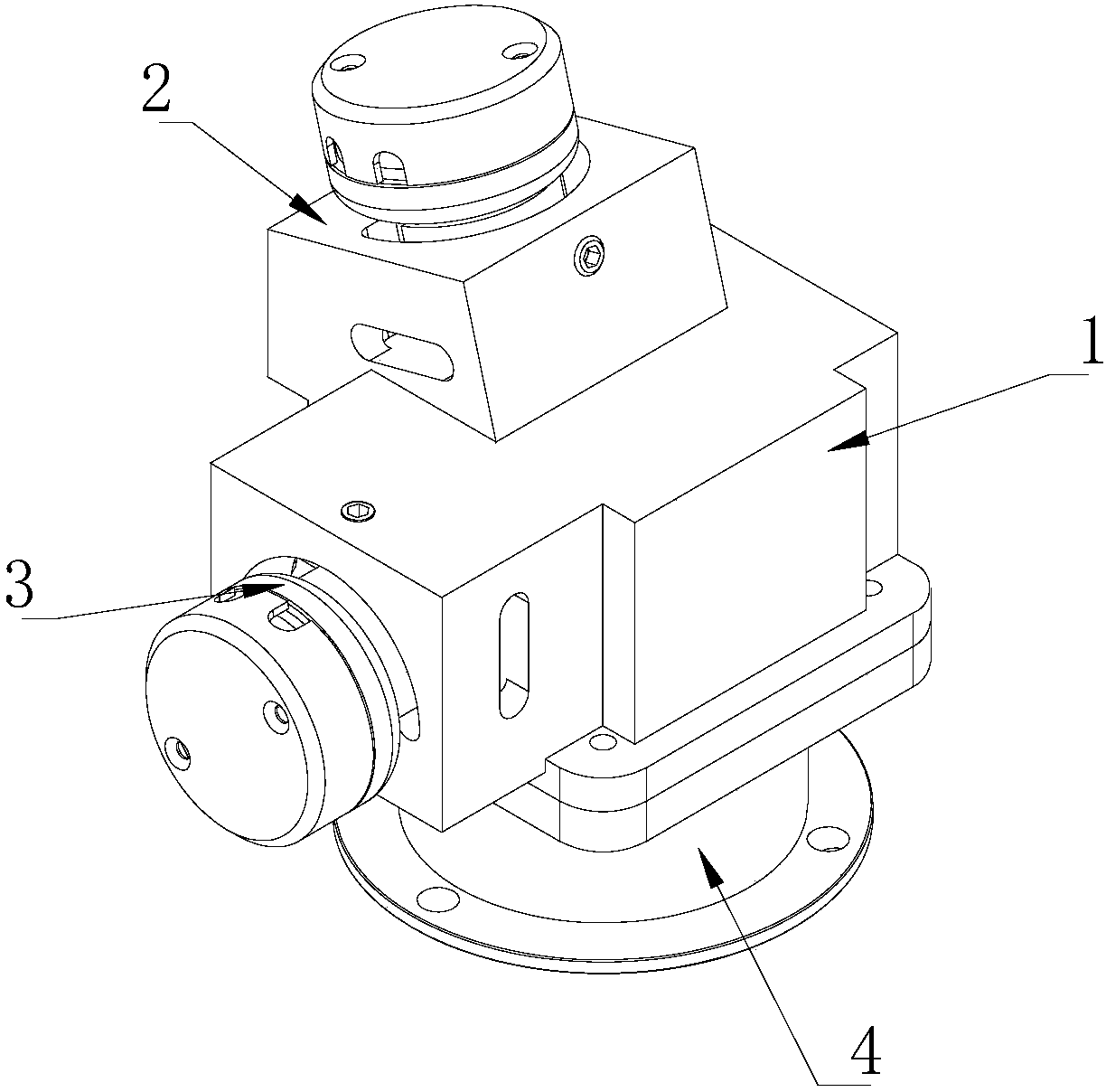

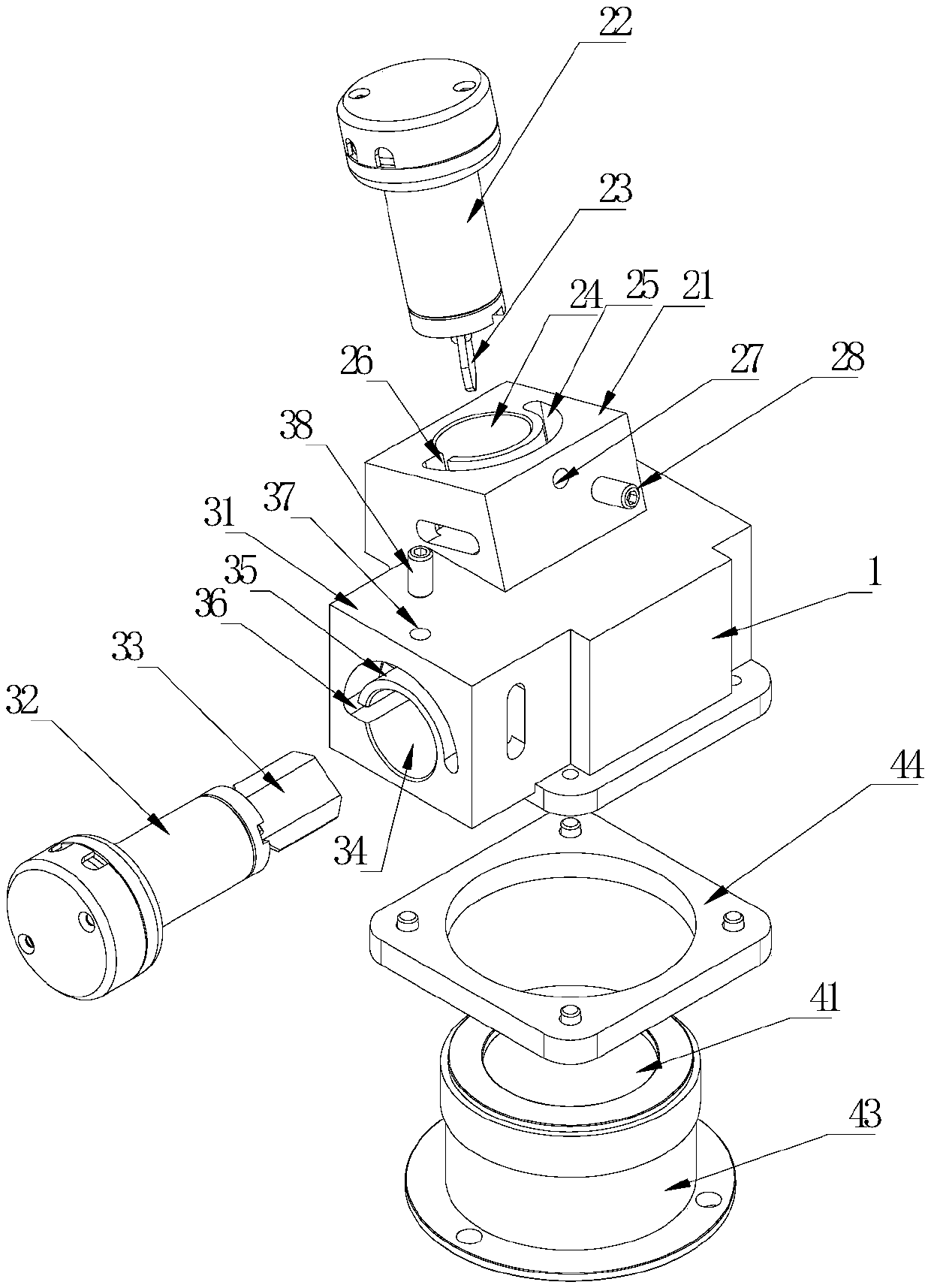

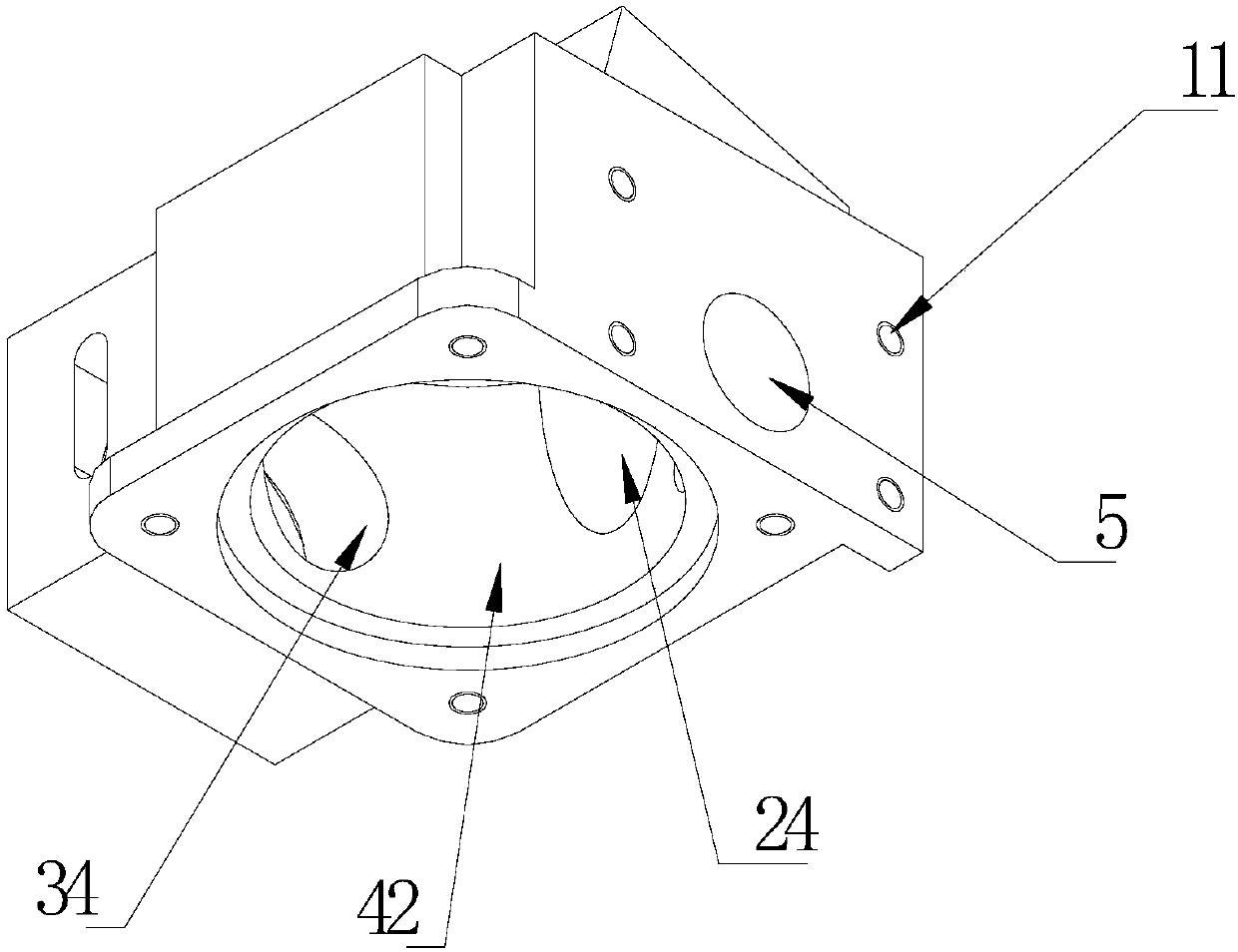

Closed scanning galvanometer device for laser machine

PendingCN107790892AReduce distractionsStable positionLaser beam welding apparatusOptical elementsGalvanometerLaser beams

The invention provides a closed scanning galvanometer device for a laser machine. The device comprises a base, an X galvanometer mechanism, a Y galvanometer mechanism and a field lens mechanism. The Xgalvanometer mechanism comprises an X galvanometer motor, an X galvanometer lens and an X galvanometer base which is provided with an X positioning hole, the Y galvanometer mechanism comprises a Y galvanometer motor, a Y galvanometer lens and a Y galvanometer base which is provided with a Y positioning hole, the field lens mechanism comprises a field lens, the front end of the base is provided with a laser incidence hole, the bottom of the base is provided with a field lens installation hole, the field lens is installed in the field lens installation hole, the X positioning hole, the Y positioning hole, the field lens installation hole and the laser incidence hole are mutually connected in a cavity, and the cavity is provided with no other through hole except for the X positioning hole, the Y positioning hole, the field lens installation hole and the laser incidence hole. The scanning galvanometer device fixes the Y galvanometer motor, the X galvanometer motor and the field lens, therelative positions are more stable, the closed cavity is formed in the base after fixing, and dust pollution is small when a laser beam passes.

Owner:广东铭钰科技股份有限公司

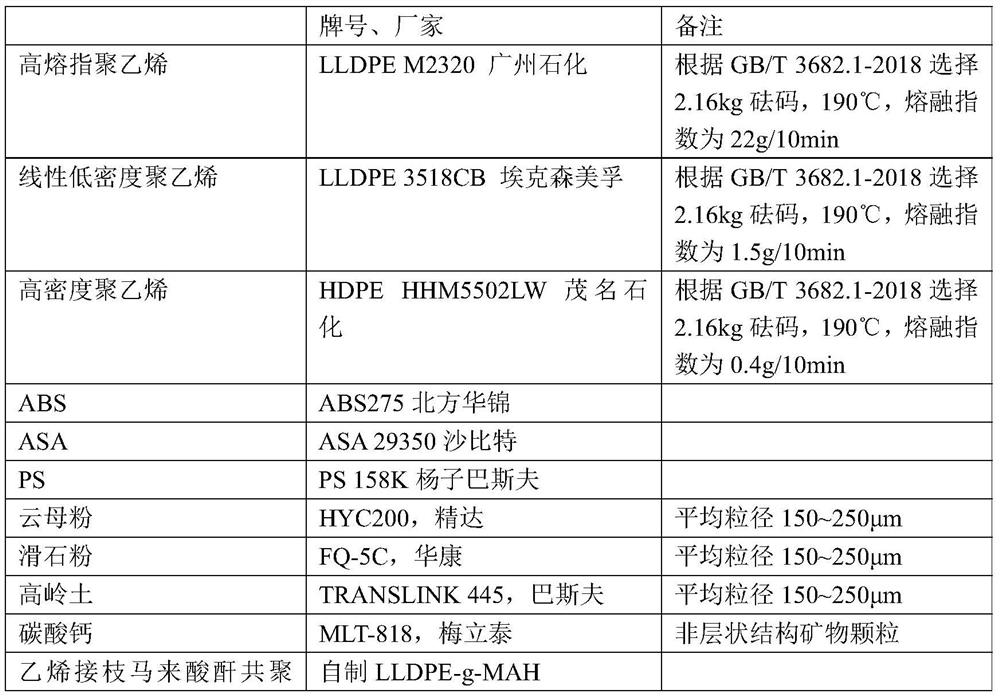

Polyethylene laser marking master batch as well as preparation method and application thereof

The invention discloses a polyethylene laser marking master batch as well as a preparation method and application thereof. The polyethylene laser marking master batch comprises the following components in parts by weight: 45-70 parts of a polyethylene matrix, 10-15 parts of a polystyrene-based copolymer, 15-30 parts of layered-structure mineral particles, 5-10 parts of a compatilizer, 1-2 parts of a lubricant and 0.1-0.3 part of a cross-linking sensitizer, wherein the silicon content of the layered structure mineral particles is greater than or equal to 30 wt.%. The polyethylene laser marking master batch provided by the invention has excellent laser sensitivity. The polyethylene laser marking master batch is added into polyethylene according to a weight ratio of 5-10%, and a prepared polyethylene material has excellent laser marking performance and can be used for preparing an optical cable sheath.

Owner:KINGFA SCI & TECH CO LTD +1

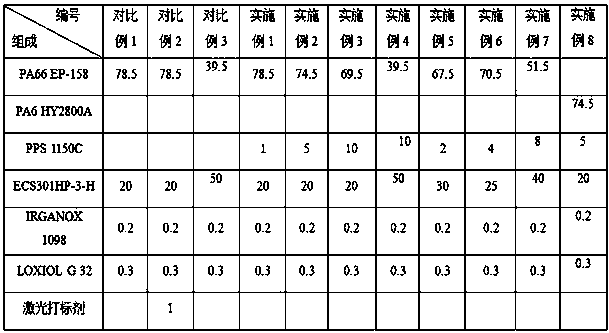

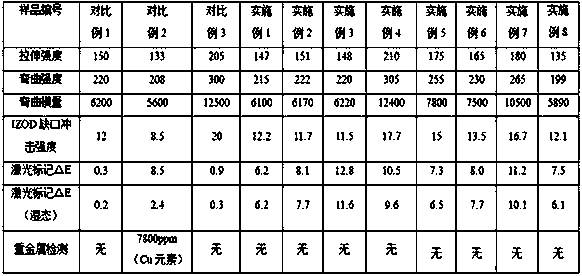

Nylon/polyphenylene sulfide alloy material and preparation method thereof

The invention discloses a nylon / polyphenylene sulfide alloy material and a preparation method thereof. The nylon / polyphenylene sulfide alloy material comprises following components in parts by weight:35 to 80 parts of nylon, 1 to 10 parts of polyphenylene sulfide, and 20 to 50 parts of glass fibers. By adding a certain amount of polyphenylene sulfide resin into nylon resin, and then the mixture is reinforced by glass fibers to prepare the nylon / polyphenylene sulfide alloy material. Compared with a common laser labeling agent modified enhanced nylon material, the provided nylon / polyphenylene sulfide alloy material has a good mechanical property and an excellent laser labeling performance, does not contain any heavy metal, is environmentally friendly and pollution free, and is beneficial for color matching. The alloy material is resistant to fading in a high temperature high humidity environment, and also has a good laser labeling effect, and moreover, the application range is enlarged.

Owner:KINGFA SCI & TECH CO LTD

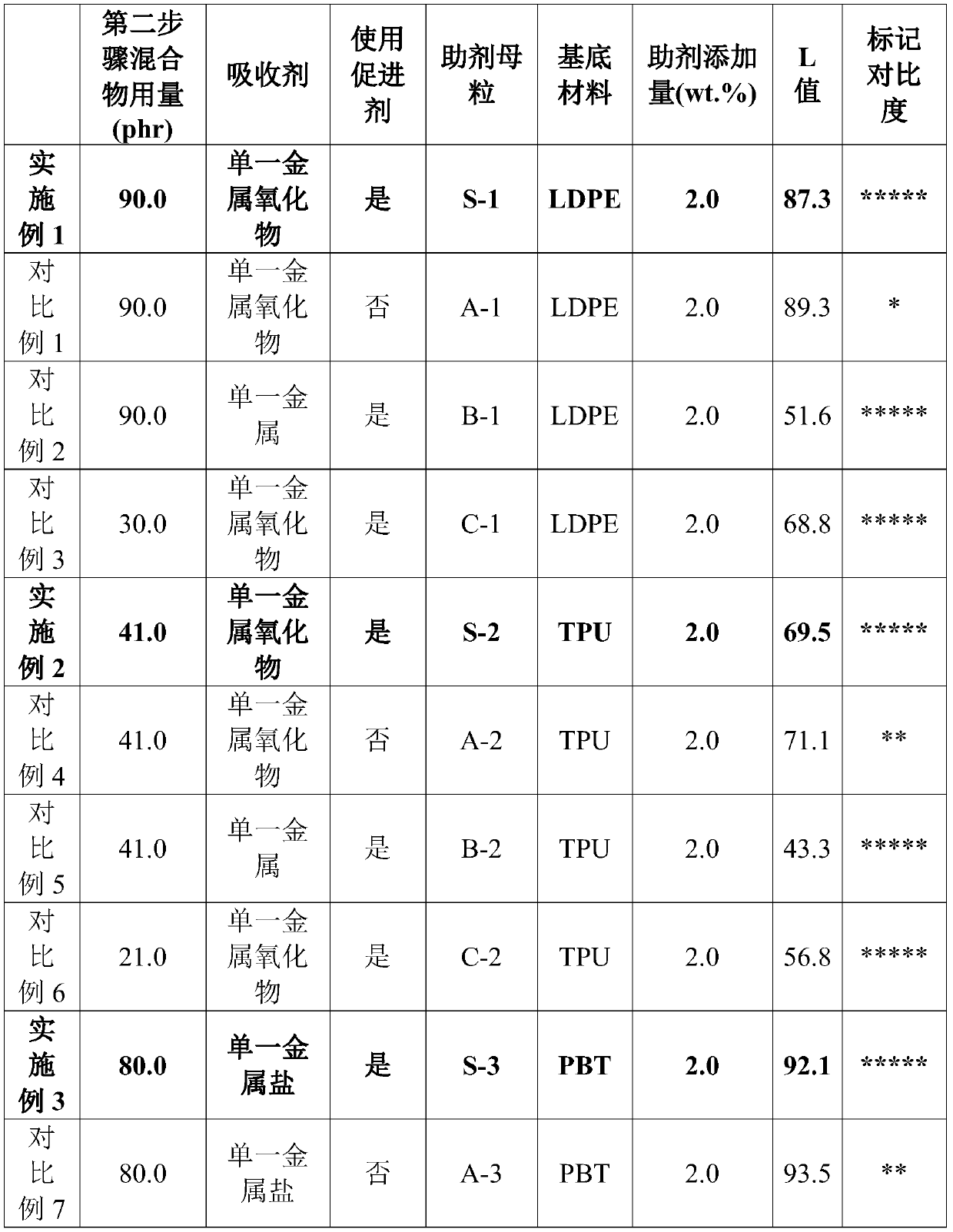

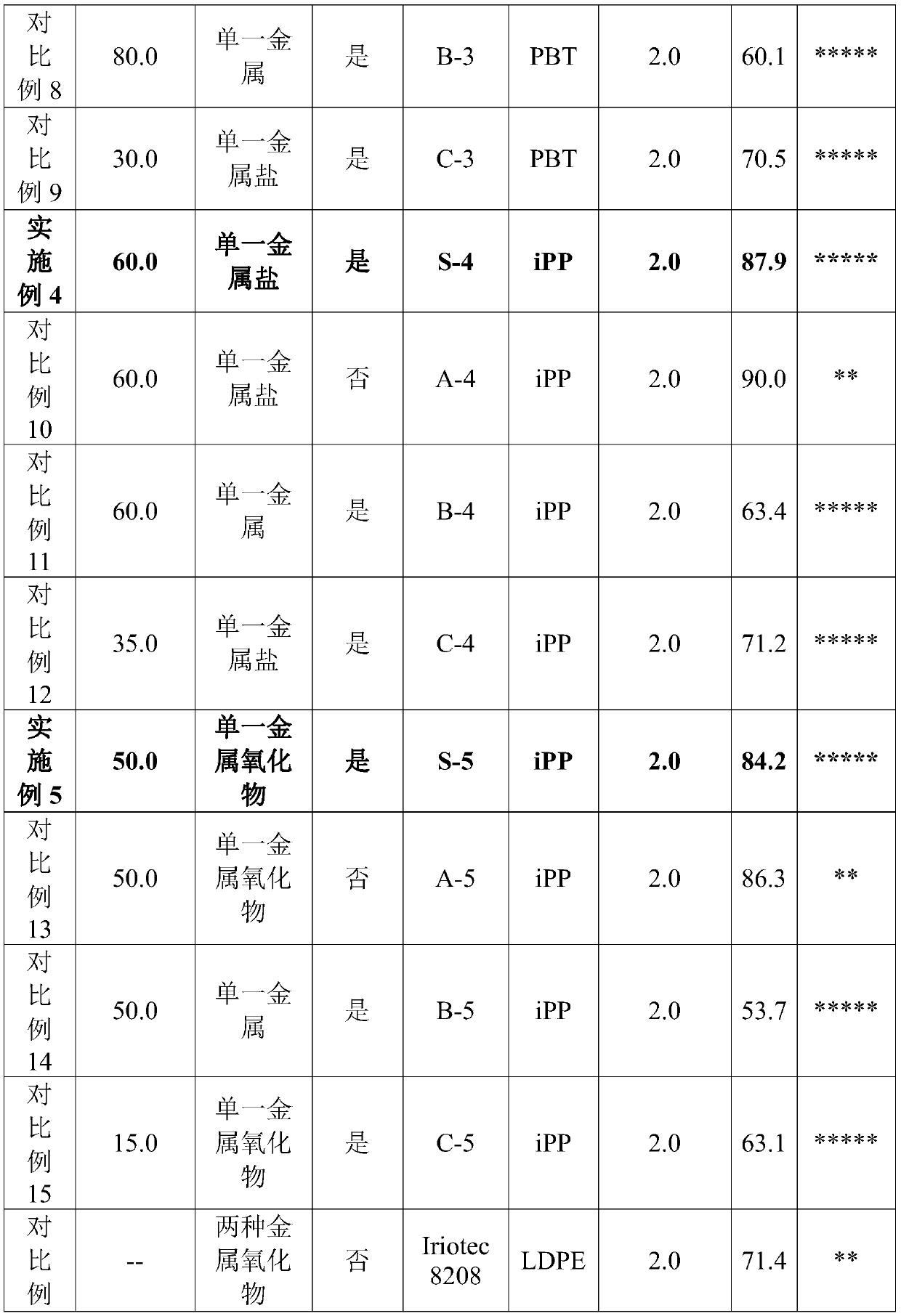

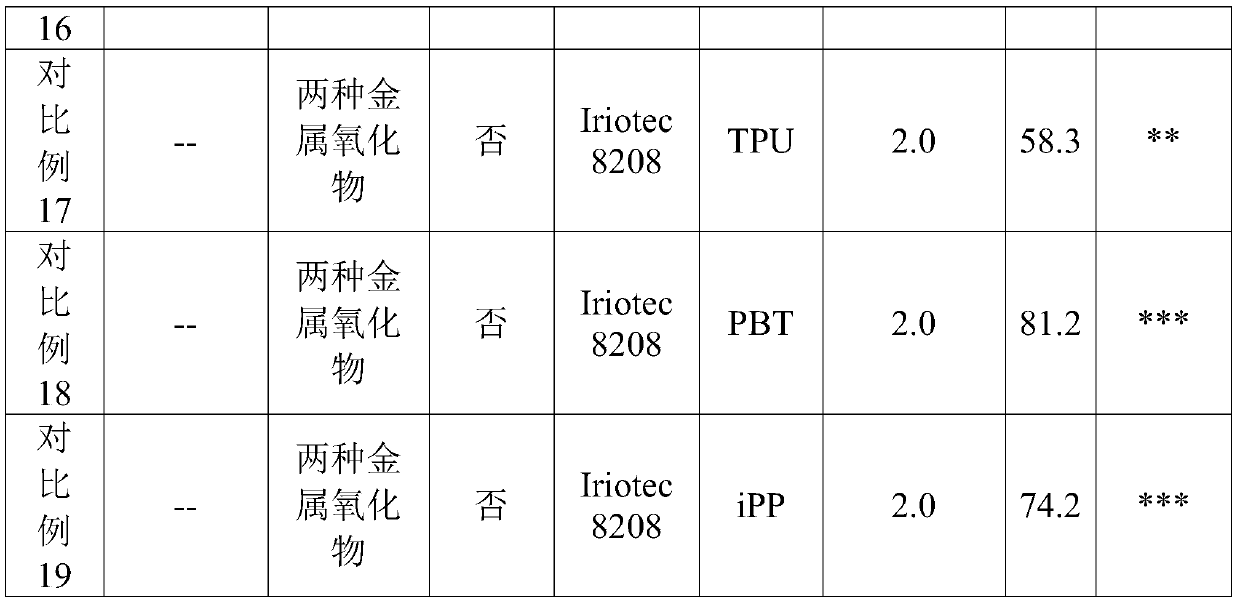

Functional color change additive composition and preparation method thereof

The invention relates to a functional color change additive composition and a preparation method thereof. The functional color change additive composition is prepared from the following components inparts by weight: 41.0 to 90.0 parts of a mixture, 0.5 to 6.0 parts of a bulking agent and 4.0 to 58.5 parts of a carrier polymer, wherein the mixture comprises a metal oxide or a metal salt, a thermoplastic polymer and an accelerant, and the weight ratio of the metal oxide or the metal salt to the thermoplastic polymer to the accelerant is (70.0-90.0): (5.0-29.9): (0.1-5.0). The color change auxiliary agent composition can form a mark with ultrahigh contrast ratio only by one absorbent, and meanwhile, the bottom color of the polymer substrate material cannot be obviously darkened and grayed, and the technical problems in the field are solved. The functional color change additive is suitable for different substrate materials, can meet the requirements for light color products in the industry, can achieve the marking effect of ultrahigh color difference contrast, and is wide in application prospect.

Owner:SICHUAN UNIV

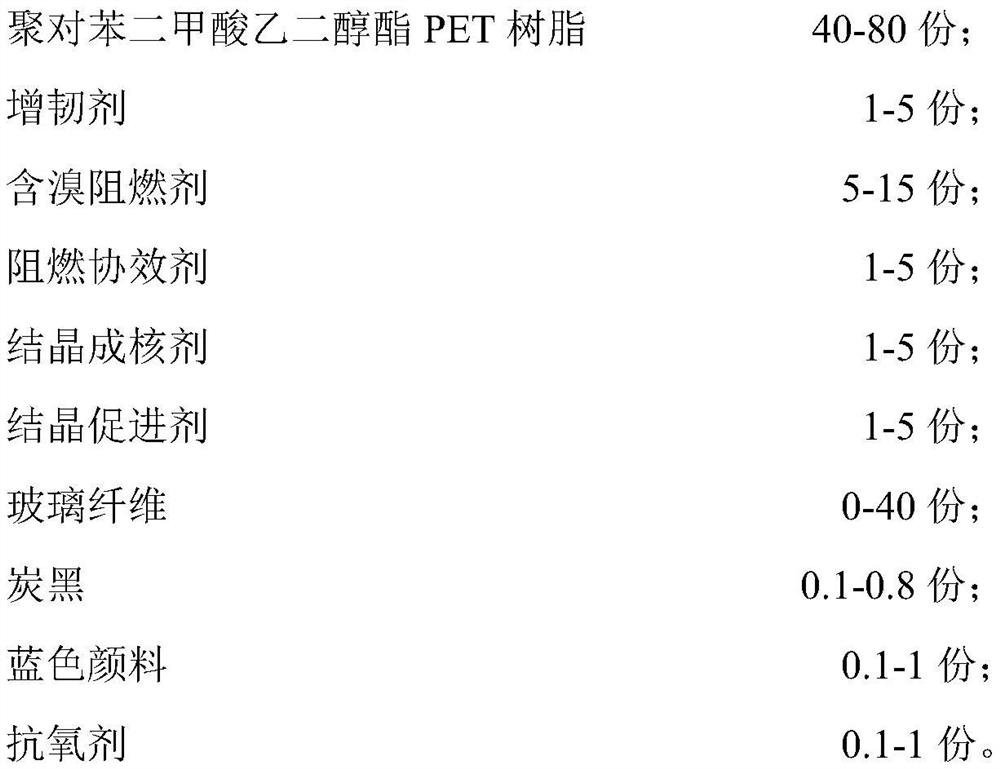

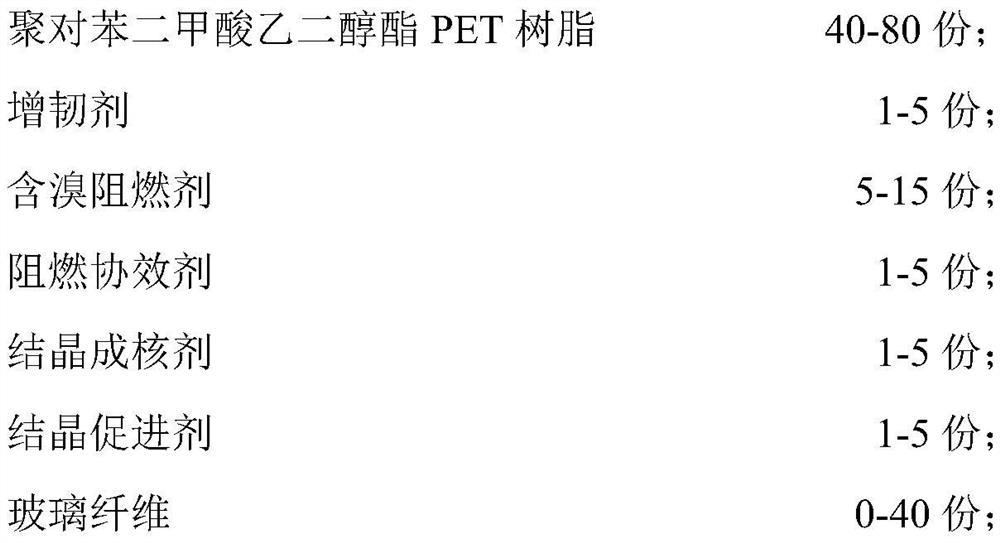

High-fluidity black flame-retardant reinforced polyethylene glycol terephthalate composition and preparation method thereof

The invention relates to a high-fluidity black flame-retardant reinforced polyethylene glycol terephthalate composition and a preparation method thereof. The composition comprises PET resin, a toughening agent, a bromine-containing flame retardant, a flame-retardant synergist, a crystallization nucleating agent, a crystallization accelerator, glass fibers, carbon black, a blue pigment and an antioxidant. By adjusting the viscosity of the PET resin and introducing the crystallization nucleating agent and the crystallization accelerator, the flowability of the material is greatly improved, and the crystallization performance is maintained.

Owner:SHANGHAI KINGFA SCI & TECH +1

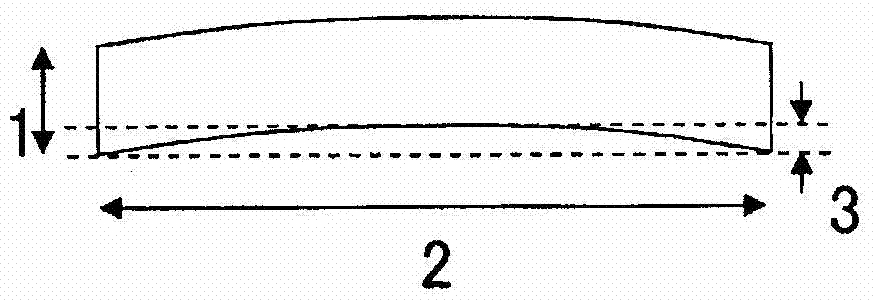

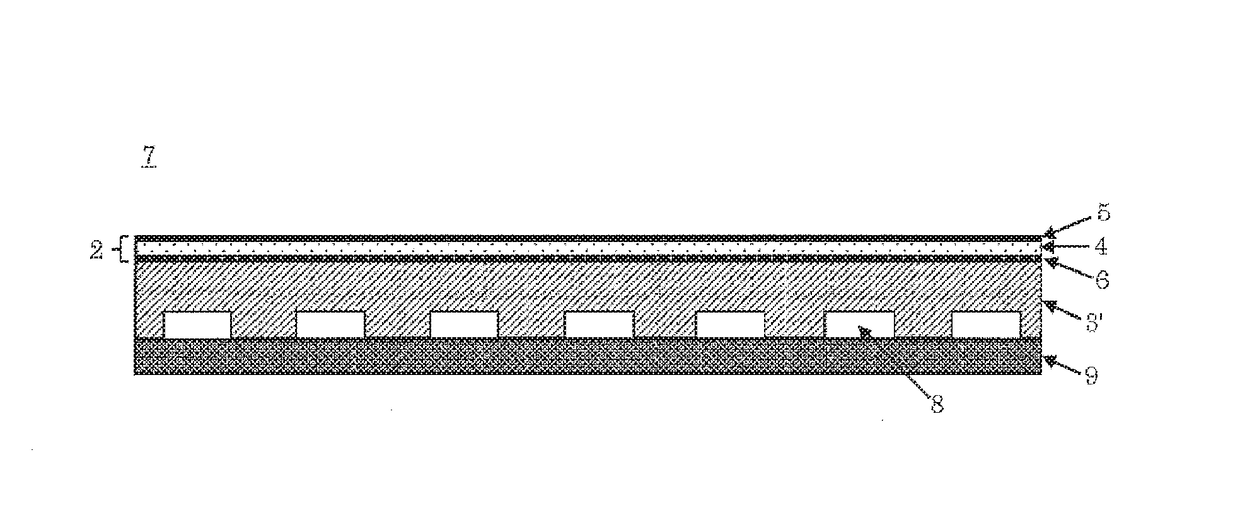

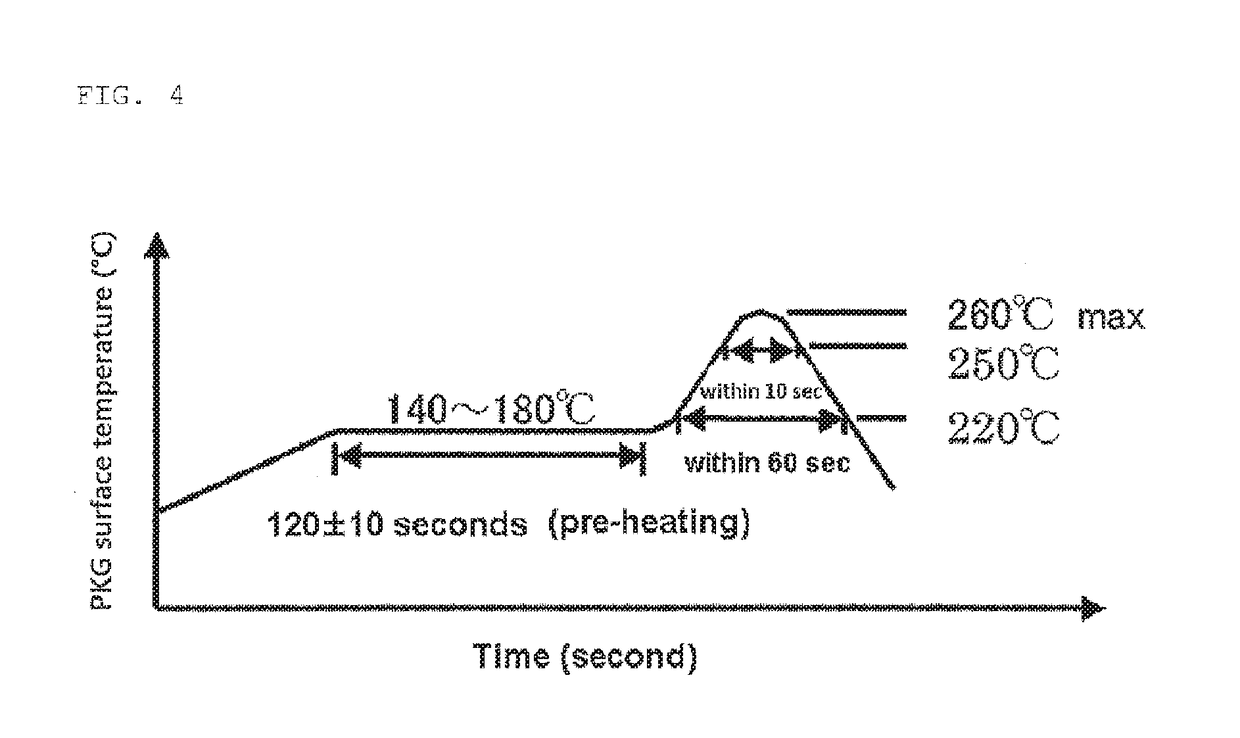

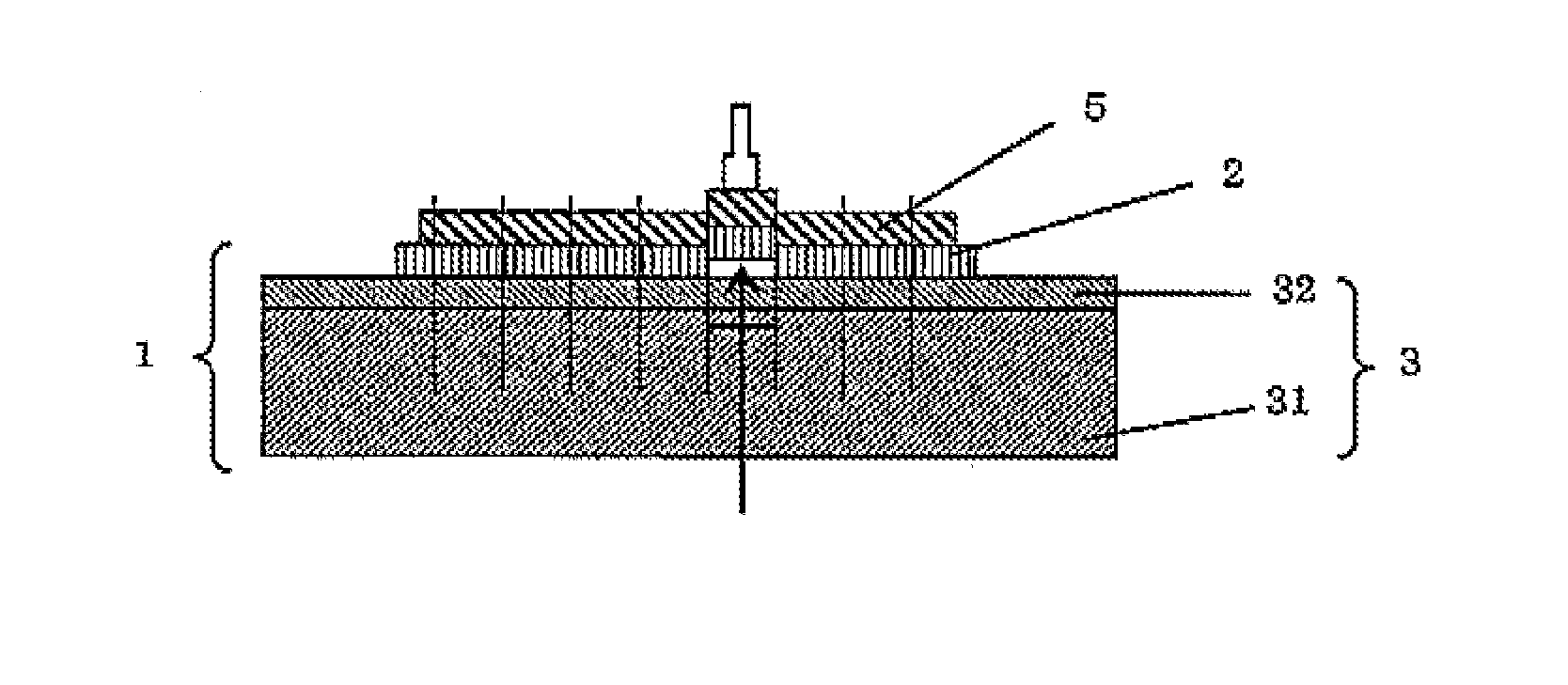

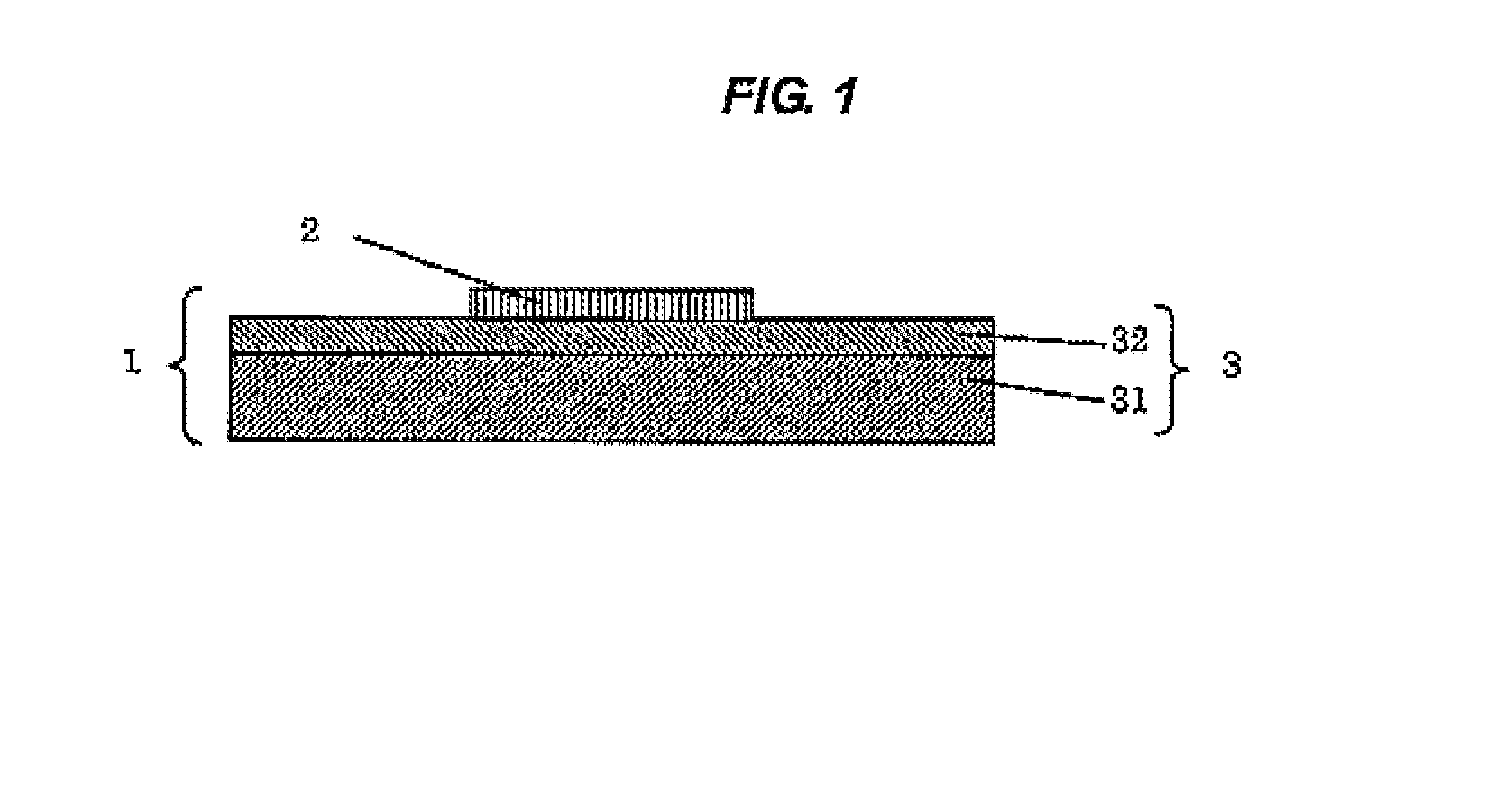

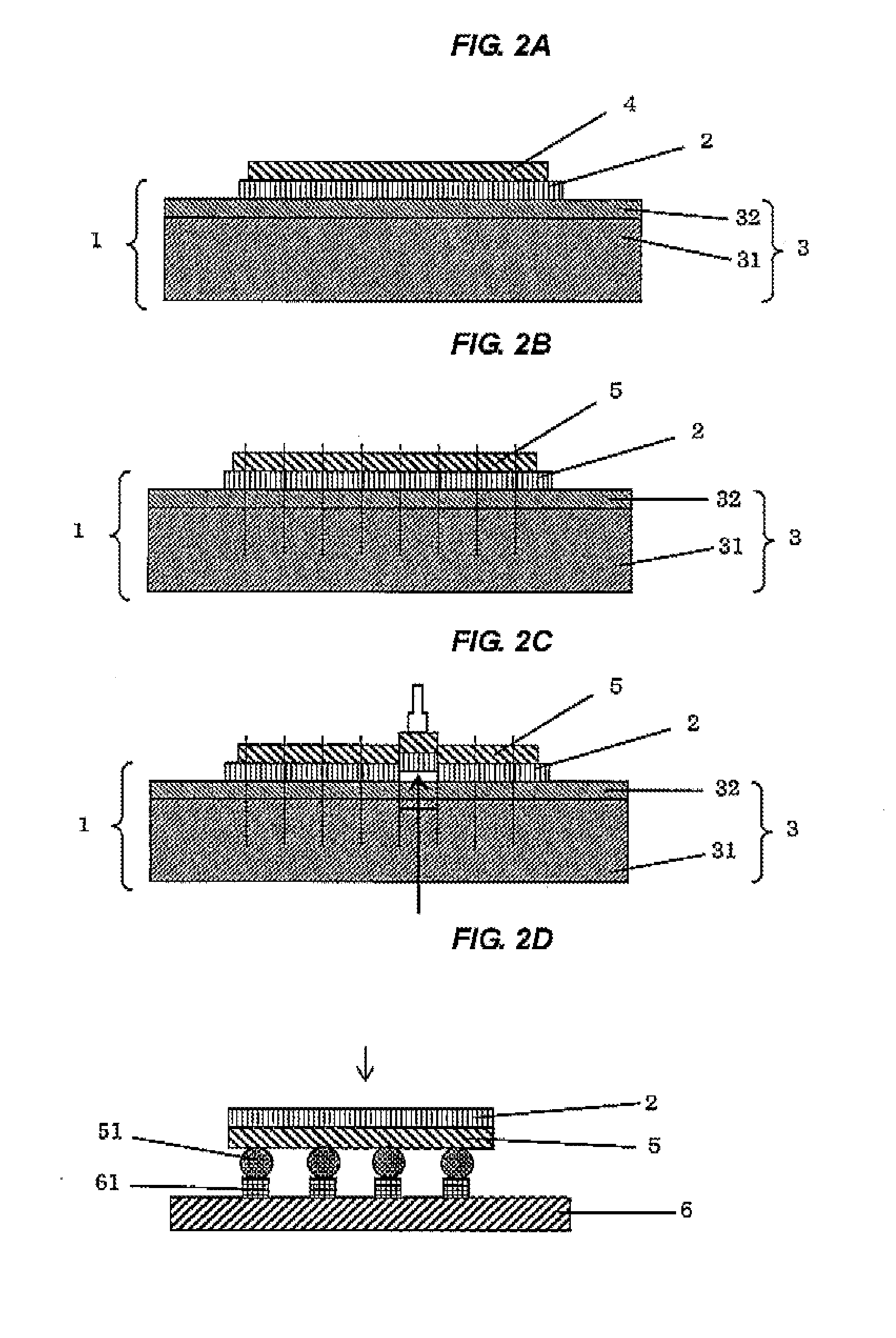

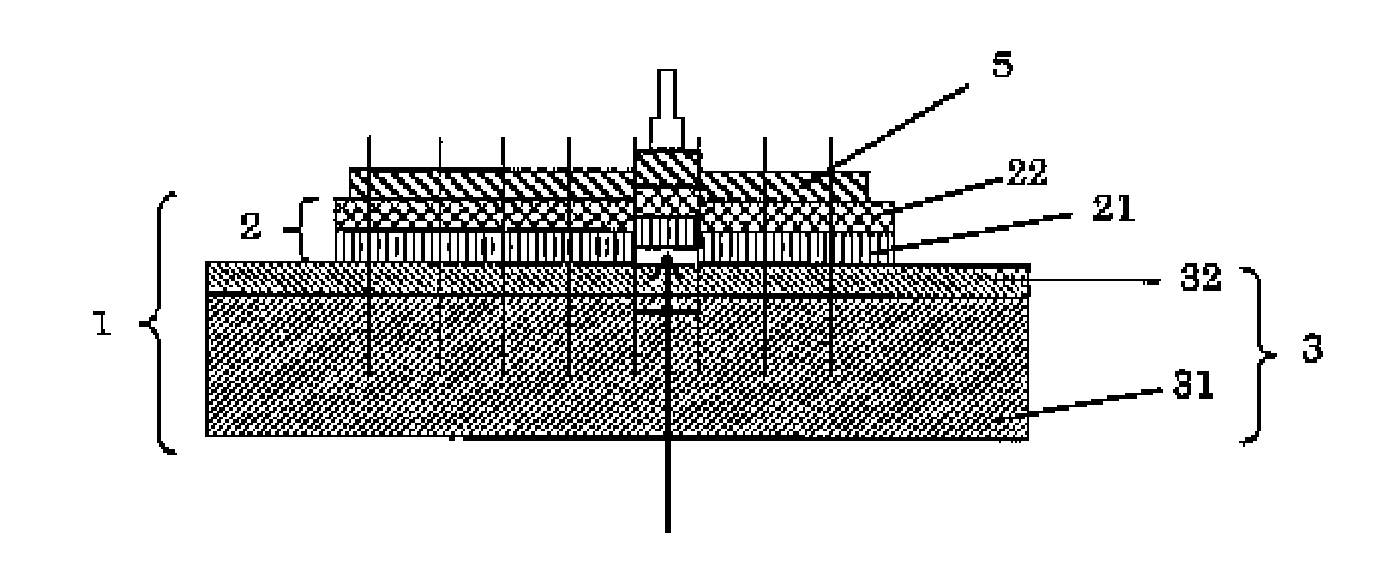

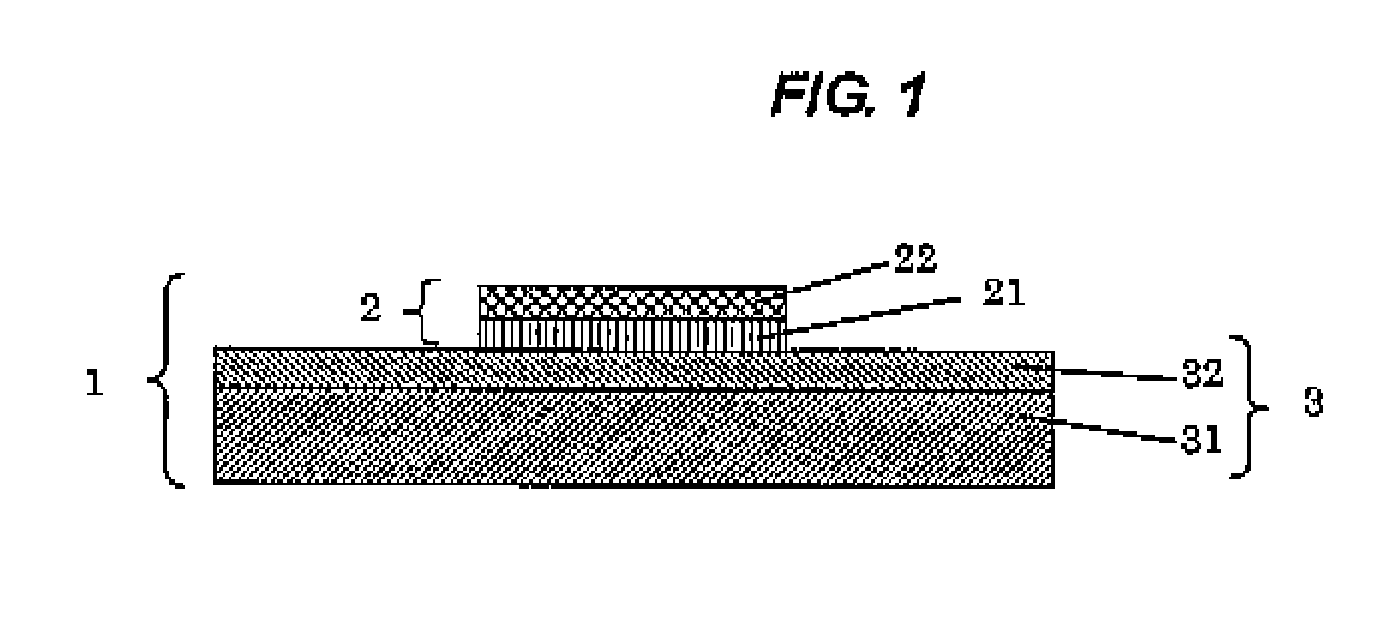

Base-attached encapsulant for semiconductor encapsulation, method for manufacturing base-attached encapsulant for semiconductor encapsulation, and method for manufacturing semiconductor apparatus

InactiveUS20170098551A1Low costGood encapsulation effectLayered productsSemiconductor/solid-state device detailsFiberSemiconductor package

A base-attached encapsulant for semiconductor encapsulation, includes a base and encapsulating resin layer on one surface of the base, the base being composed of a fibrous base layer in which a thermosetting resin composition containing a thermosetting resin is impregnated into a fibrous base and cured, a cured material layer A composed of a cured material of the thermosetting resin composition formed on the fibrous base layer at the opposite side to the encapsulating resin layer, and a cured material layer B composed of a cured material of the thermosetting resin composition formed on the fibrous base layer at the encapsulating resin layer side. The thickness Ta of the cured material layer A is 0.5 μm or more. The ratio Ta / Tb of the thickness Ta of the cured material layer A and the thickness Tb of the cured material layer B is in a range of 0.1 to 10.

Owner:SHIN ETSU CHEM IND CO LTD

Dicing tape-integrated film for semiconductor back surface

InactiveUS20140175677A1Dicing efficiencyEasy to peelSemiconductor/solid-state device detailsSolid-state devicesDicing tapeEngineering

The present invention provides a dicing tape-integrated film for semiconductor back surface, which includes: a dicing tape including a base material and a pressure-sensitive adhesive layer provided on the base material; and a film for flip chip type semiconductor back surface provided on the pressure-sensitive adhesive layer, in which the film for flip chip type semiconductor back surface contains a black pigment.

Owner:NITTO DENKO CORP

Laser-marked and halogen-free flame-retardant polyamide composite material

ActiveCN102093707BWith anti-counterfeiting effectStable temperature resistanceAntioxidantFilling materials

The invention relates to a laser-marked and halogen-free flame-retardant polyamide composite material with excellent flame-retardant property and laser marking effect. The polyamide composite material is characterized by comprising the following substances: at least one or more of polyamide resins, at least one or more of inorganic packing materials, at least one or more of halogen-free flame retardants which can provide the excellent flame-retardant property for the composite material, at least one or more of aids which can provide excellent laser marking for the composite material, and other unessential aids such as lubricants, antioxidants, pigments and the like. The composite material has the comprehensive performance of excellent temperature resistance, flame retardance, and dimensional stability, easiness of processing and molding and the like, and also has clear and attractive laser marking effect at the same time. The composite material is widely applied in the fields of household products, electronic appliances, laser handles and the like and has huge market prospect.

Owner:BENSONG ENG PLASTICS HANGZHOU

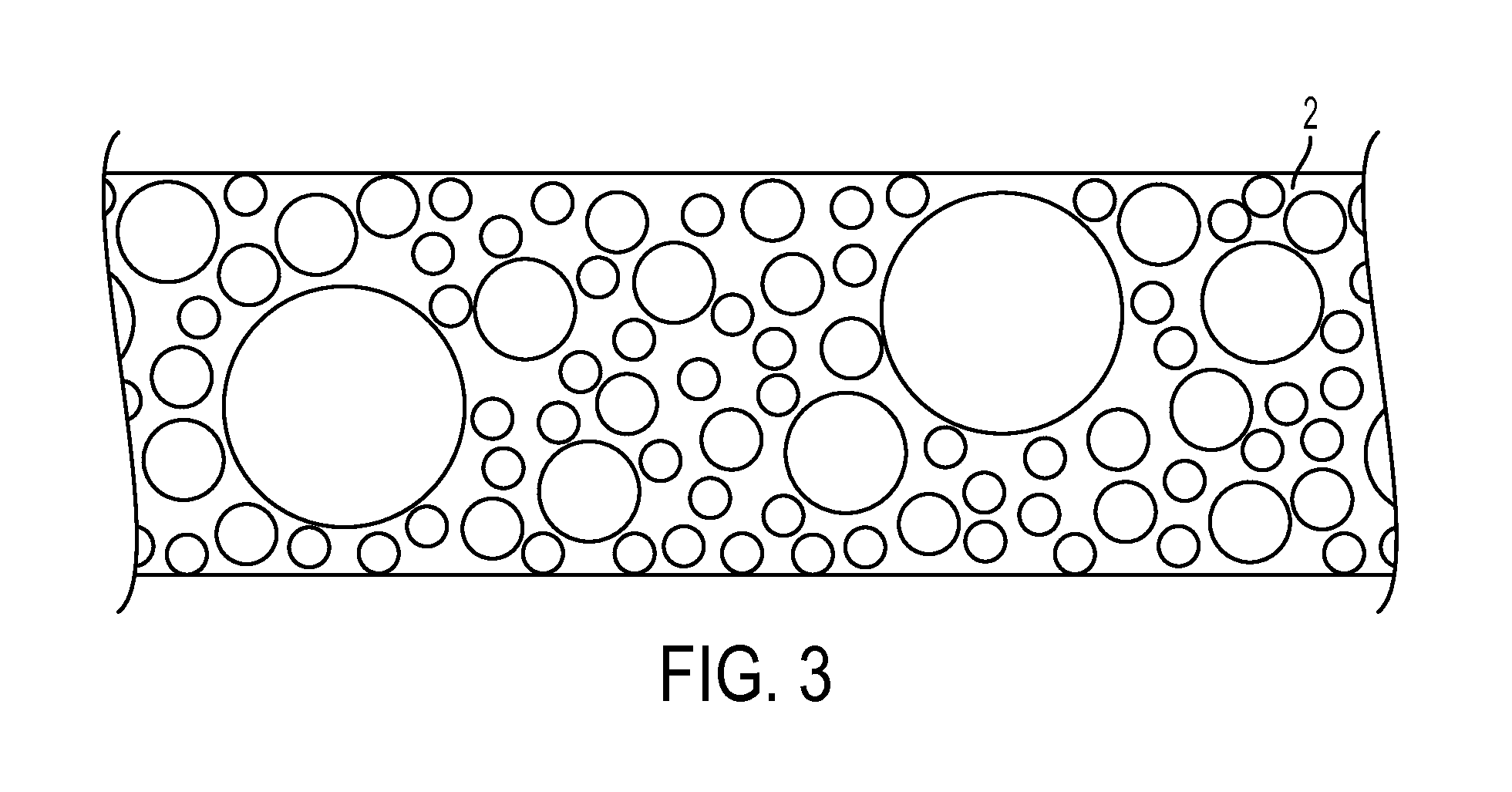

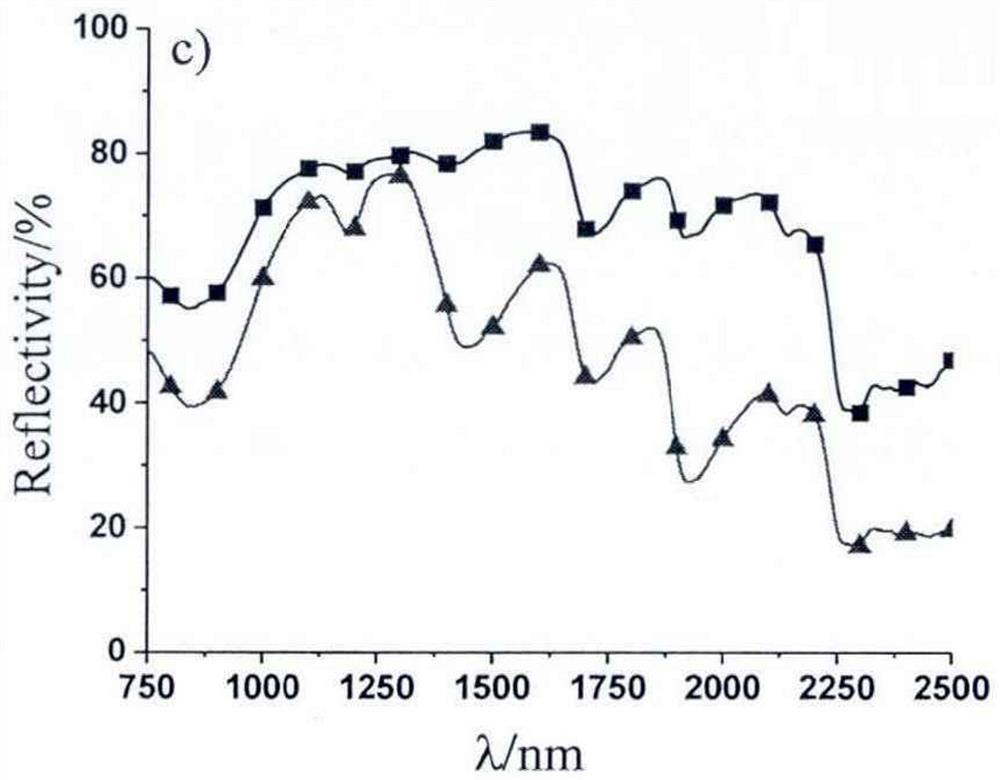

Film for flip chip type semiconductor back surface

ActiveUS8704382B2Improve laser marking effectSemiconductor/solid-state device detailsSolid-state devicesTransmittanceLength wave

The present invention provides a film for flip chip type semiconductor back surface, which is to be formed on a back surface of a semiconductor element flip-chip connected on an adherend, the film including a wafer adhesion layer and a laser marking layer, in which the wafer adhesion layer has a light transmittance of 40% or more in terms of a light having a wavelength of 532 nm and the laser marking layer has a light transmittance of less than 40% in terms of a light having a wavelength of 532 nm.

Owner:NITTO DENKO CORP

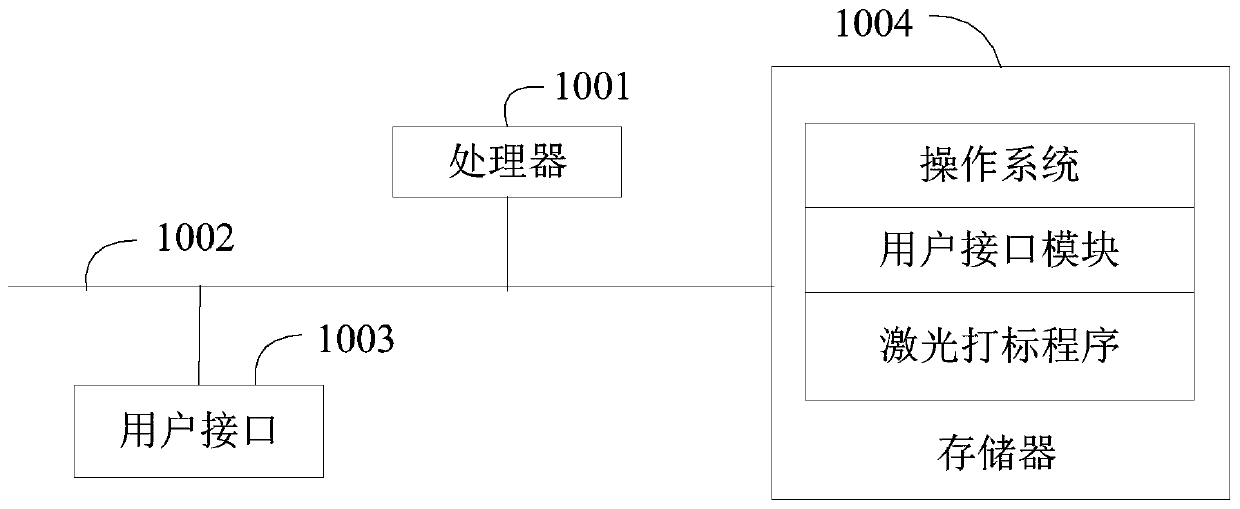

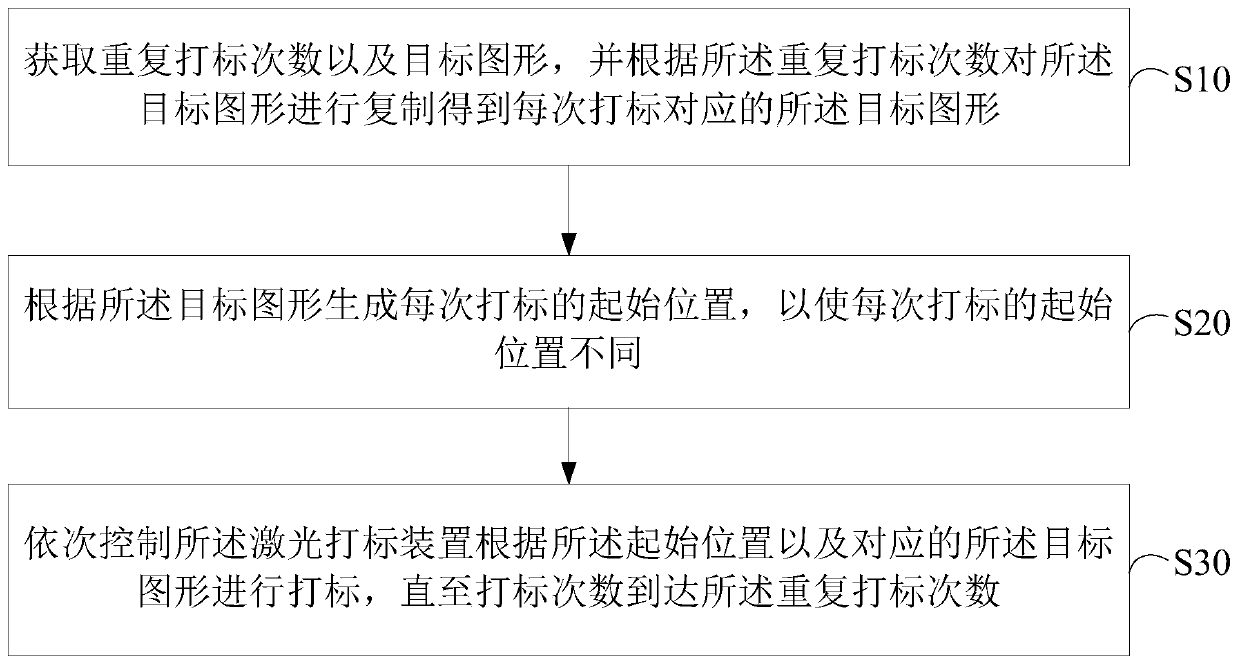

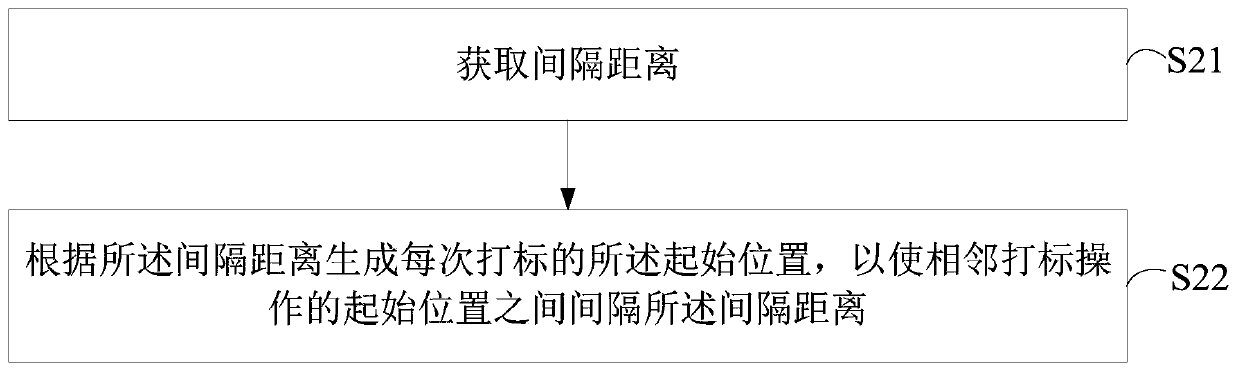

Laser marking method, laser marking device and computer readable storage medium

ActiveCN110588202AAvoid the problem of more visible dentsImprove laser marking effectThermographyLaser beam welding apparatusComputer visionComputer science

The invention discloses a laser marking method. The laser marking method comprises the following steps of obtaining repeated marking times and a target pattern, and copying the target pattern according to the repeated marking times to obtain the target pattern corresponding to each marking; generating an initial position of each marking according to the target pattern, so that the initial positions of marking are different each time; and sequentially controlling a laser marking device to mark according to the initial position and the corresponding target pattern until marking times reach the repeated marking times. The invention further discloses the laser marking device and a computer readable storage medium. The initial positions of marking are generated on the repeated marking pattern,so that the initial positions of marking are different each time; and marking is started according to the initial position of marking, so that the problem that dents are more obvious during a repeatedmarking process is solved, and the laser marking effect is improved.

Owner:深圳泰软软件科技有限公司

A kind of ABS composition and preparation method thereof

Owner:KINGFA SCI & TECH CO LTD +1

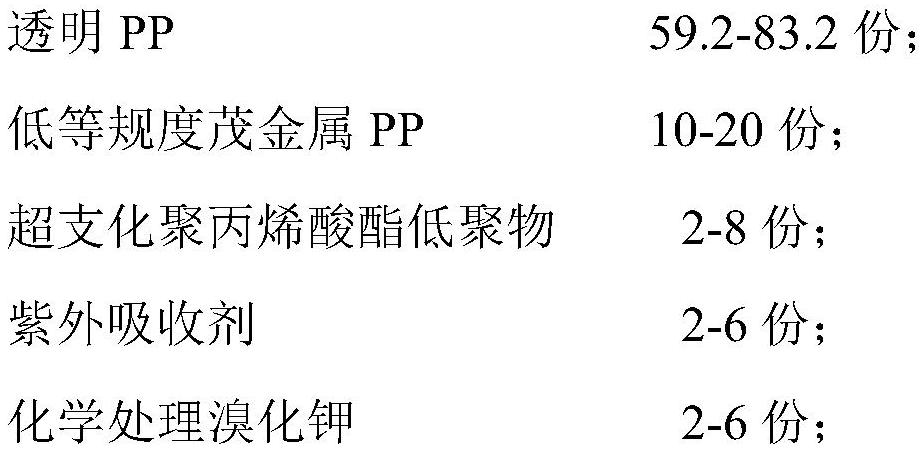

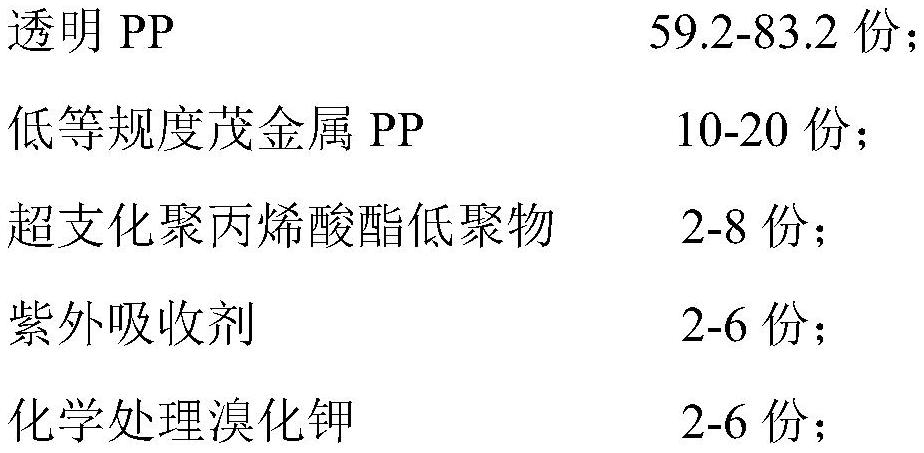

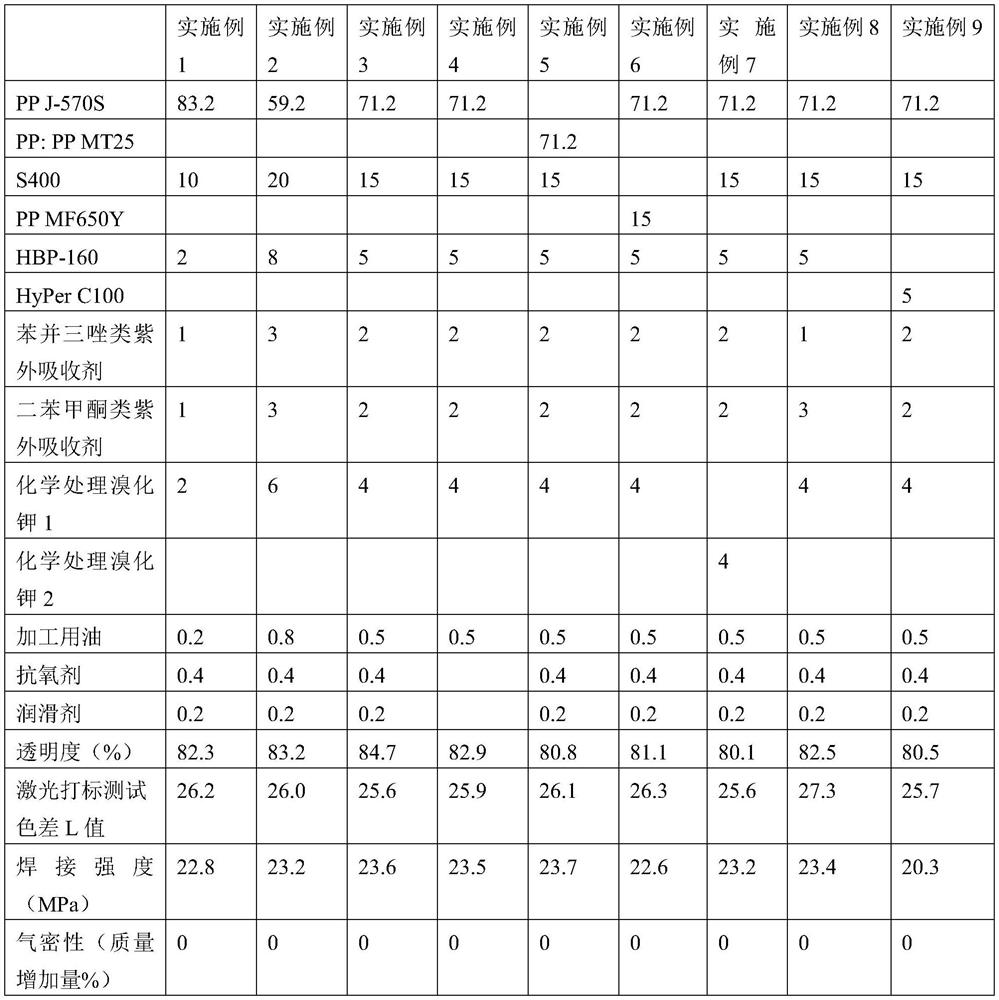

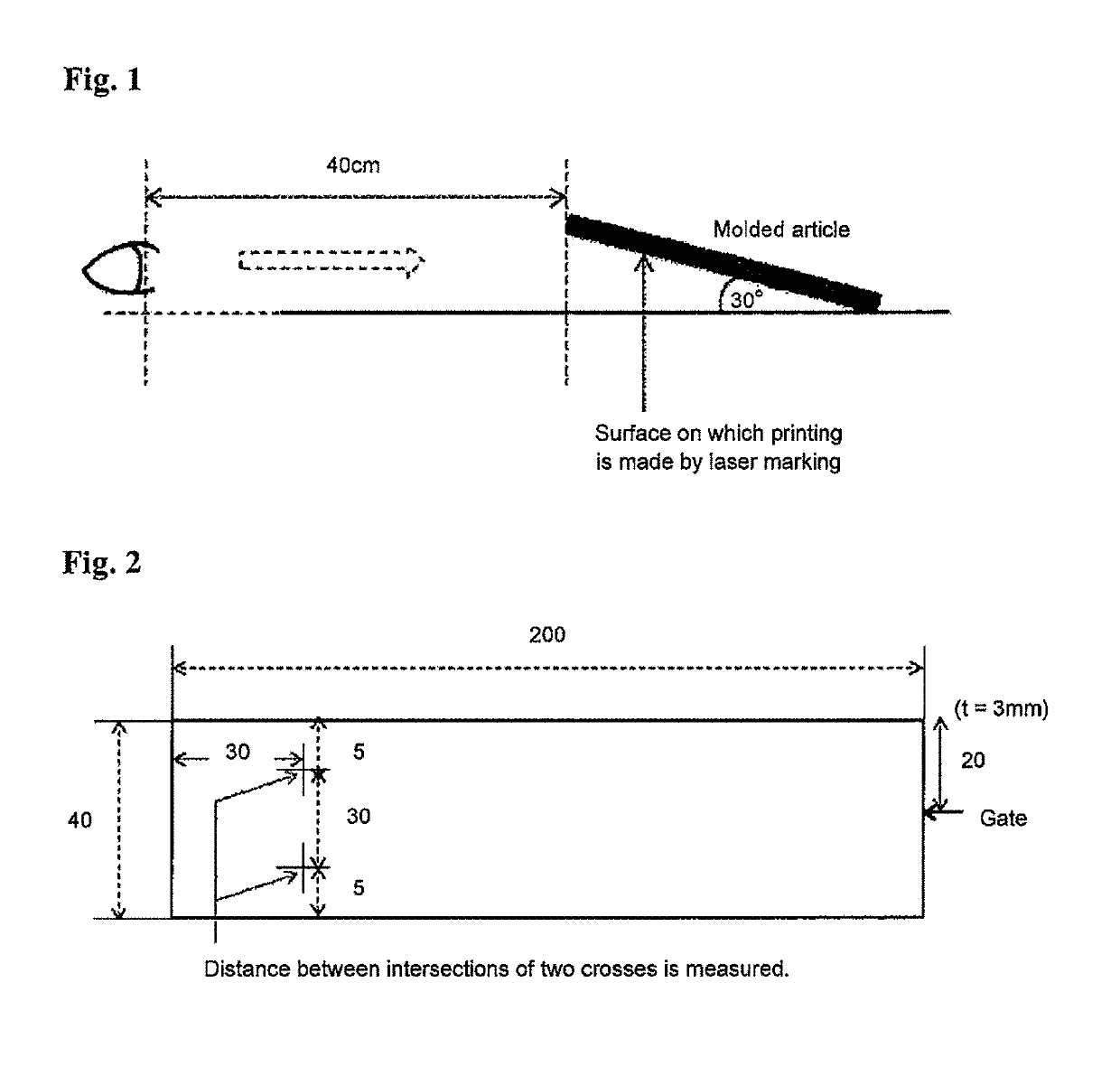

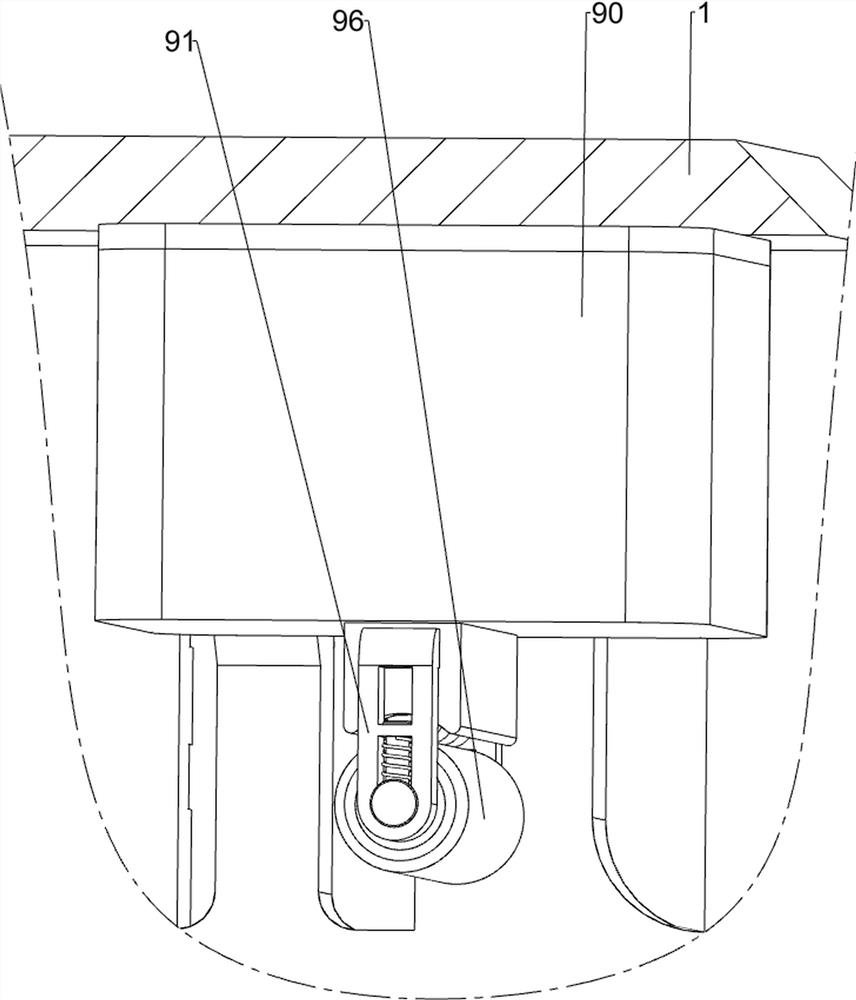

Modified PP (polypropylene) material easy to sweat weld, high in transparency and easy to laser mark as well as preparation method and application of modified PP material easy to sweat weld, high in transparency and easy to laser mark

ActiveCN114316442AGood compatibilityImprove laser marking clarityPackage recyclingChemical treatmentUv absorbance

The invention relates to a modified PP (polypropylene) material easy for hot melting welding, high transparency and easy for laser marking as well as a preparation method and application thereof. The modified PP material comprises the following components in parts by weight: 59.2-83.8 parts of transparent PP; 10 to 20 parts of low isotacticity metallocene PP (Polypropylene); 2 to 8 parts of a hyperbranched polyacrylate oligomer; 2-6 parts of an ultraviolet absorbent; and 2-6 parts of chemically treated potassium bromide. The modified PP material has good sweat soldering performance, transparency and laser marking performance.

Owner:TIANJIN KINGFA NEW MATERIAL

Polyamide composition and molded article produced from the composition

Provided is a polyamide resin composition comprising a polyamide resin, a PAN carbon fiber, carbon black, and a black dye, wherein the polyamide resin composition contains the PAN carbon fiber in an amount of 7.5 to 25% by weight, based on the weight of the composition, contains the carbon black in an amount of 0.01 to 0.55% by weight, based on the weight of the composition, and contains the black dye in an amount of 0.01 to 1.0% by weight, based on the weight of the composition.

Owner:UBE CORP

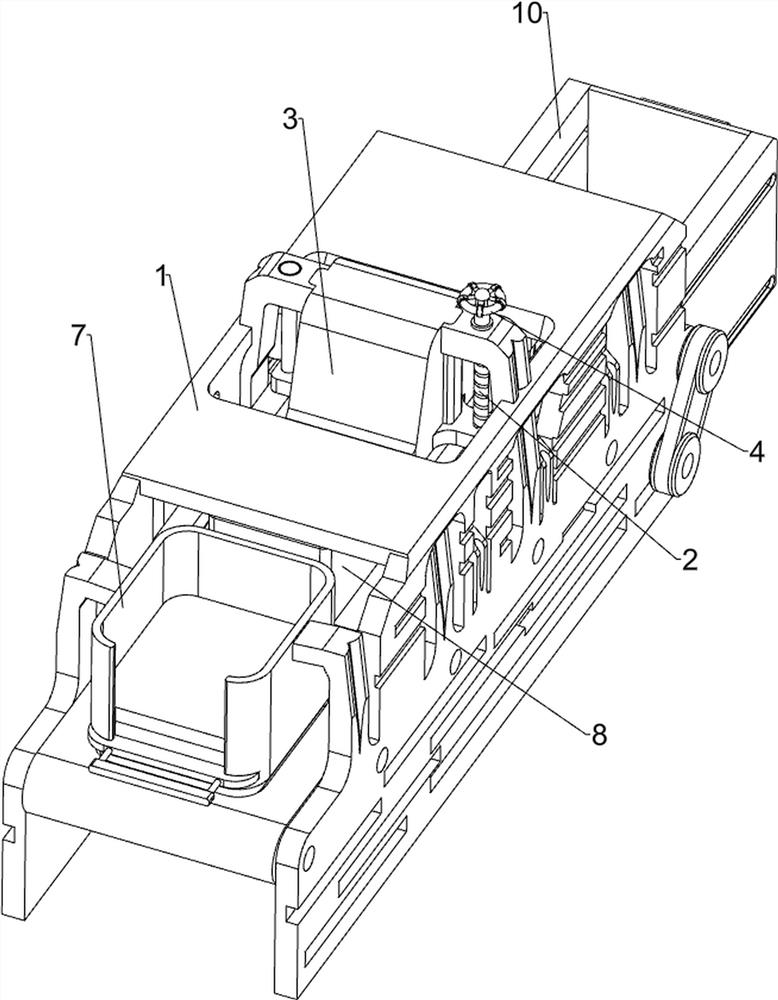

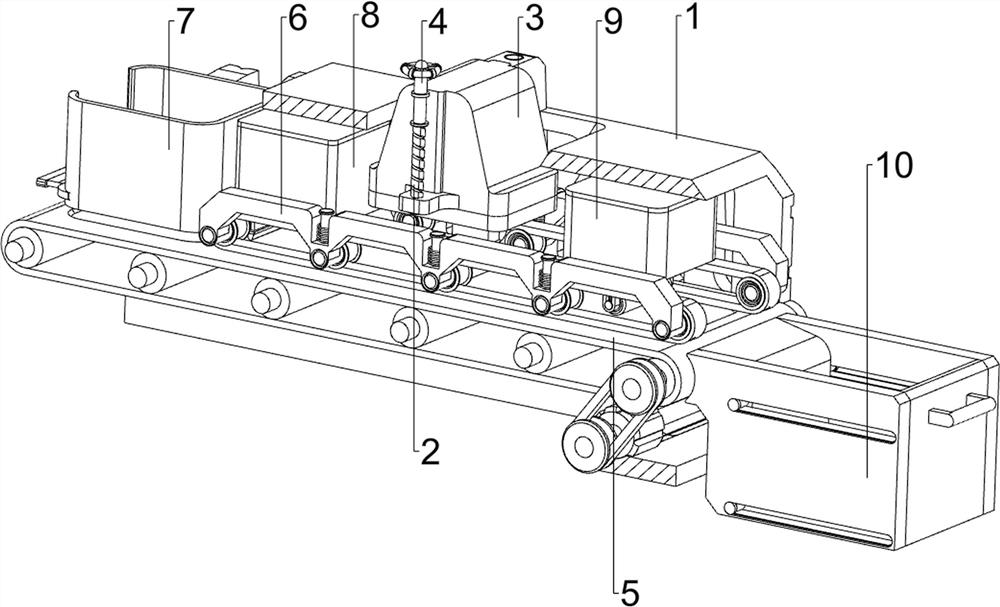

Laser marking equipment for modified heavy-duty motorcycle nameplate

InactiveCN113695753AAvoid affecting the marking effectImprove laser marking effectLaser beam welding apparatusNameplateLeather belt

The invention relates to laser marking equipment, and particularly relates to laser marking equipment for a modified heavy-duty motorcycle nameplate. The technical problem to be solved by the laser marking equipment is to provide the laser marking equipment for the modified heavy-duty motorcycle nameplate, the laser marking equipment for the modified heavy-duty motorcycle nameplate can automatically clean the surface of the modified heavy-duty motorcycle nameplate and can adapt to the modified heavy-duty motorcycle nameplates with different thicknesses. The laser marking equipment for the modified heavy-duty motorcycle nameplate comprises a mounting support, a screw and a marking device, one side of the middle of the mounting support is rotatably connected with the screw, the middle of the mounting support is slidably connected with the marking device, and the marking device is connected with the screw through threads. When the modified heavy-duty motorcycle nameplate is subjected to marking, the modified heavy-duty motorcycle nameplate is in contact with a flat belt, and then the flat belt slightly fixes the modified heavy-duty motorcycle nameplate through resilience force of a first spring, and therefore, the situation that the marking effect is affected due to the fact that the position of the modified heavy-duty motorcycle nameplate deviates when laser marking is carried out is avoided.

Owner:杨允雄

A halogen-free flame-retardant nylon composite material capable of laser marking and preparation method thereof

The invention relates to the technical field of laser-marked polymer materials, in particular to a laser-markable halogen-free flame-retardant nylon composite material and a preparation method thereof. The nylon composite material includes nylon resin, halogen-free flame retardant, flame retardant synergist, laser marking powder, black masterbatch, adsorbent, glass fiber, antioxidant and lubricant, so that the obtained nylon composite material has the following characteristics: It has excellent flame retardancy and high temperature and high humidity resistance, good tensile strength and bending strength, and good laser marking effect. In addition, the material has a simple preparation process, is environmentally friendly and clean, and has low cost, and can be directly laser marked in the product processing process to realize continuous and automatic industrial production.

Owner:东莞市东翔塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com