Thermoplastic resin composition and molded article thereof

A thermoplastic resin and composition technology, which is applied in the field of thermoplastic resin composition and its molded products, can solve the problems of complicated processing procedures and insufficient adhesion of coatings, and achieve excellent heat resistance and laser marking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~29

[0174] Examples 1-29, Comparative Examples 1-11

[0175] Using a Toshiba Machine Co., Ltd. TEM35B twin-screw extruder equipped with a side feeder, the compounding amounts shown in Tables 1 to 3 were added from the hopper to 100 parts by weight of the thermoplastic resin (a-1 to a-4). Put in additives (b-1~b-4, z-1~z-4), put in filling materials (c-1, c-2) from the side feeder with the compounding amount shown in Table 1~3, and put the materials into The cylinder temperature was set to the melting point of the thermoplastic resin + 10° C., and melt kneading was performed to form pellets. After drying the obtained pellets of the thermoplastic resin composition with hot air, the following evaluations (1) to (4) were performed. The results are shown in Tables 1-3.

Embodiment 30、 comparative example 12

[0177] Using a Toshiba Machine Co., Ltd. TEM35B twin-screw extruder equipped with a side feeder, with respect to 100 parts by weight of the two thermoplastic resins (a-1:a-4=3:7 (weight ratio)), the following table Additives (b-1, z-2) and Epicott 191P (glycidyl ester type epoxy resin) manufactured by Japan Epoch Resin Co., Ltd. as a compatibilizer are put into the compounding amount shown in 2 to 3 from the hopper, and are shown in Table 2 to The compounding amount shown in 3 was charged into the filler (c-1) from the side feeder, and the temperature of the cylinder was set at the melting point of the higher thermoplastic resin + 10°C, and melt kneaded to form pellets. After drying the obtained pellets of the thermoplastic resin composition with hot air, the following evaluations (1) to (4) were performed. The results are shown in Tables 2-3.

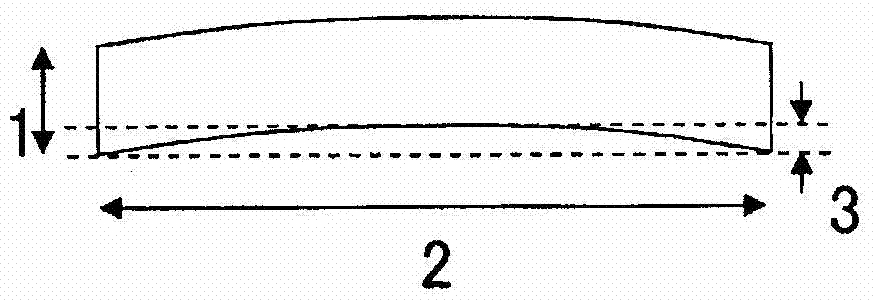

[0178] (1) Laser marking evaluation

[0179] Supply the thermoplastic resin composition to a Fanack α30C injection molding machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com