Epoxy resin composition for semiconductor encapsulation and semiconductor device

A technology of epoxy resin and semiconductor, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc. It can solve the problems of not being obtained, wiring short circuit, etc., and achieve the effect of excellent laser marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Epoxy resin 1, phenolic resin 1, fused spherical silica 1, fused spherical silica 2, curing accelerator 1, colorant 1, coupling agent 1, coupling agent 2, 2,3-dihydroxynaphthalene and The molding agent was mixed with a mixer according to the compounding ratio shown in Table 1, kneaded at 95° C. for 8 minutes with a hot roll, cooled, and pulverized to obtain an epoxy resin composition. The obtained epoxy resin composition was evaluated by the following method. In addition, from the above-mentioned components, only the colorant 1 was removed, mixed with a mixer in the same manner as above, kneaded at 95° C. for 8 minutes with a hot roll, cooled, and pulverized to prepare a sample, which was used as the following The above-mentioned high-temperature leakage test samples were used for evaluation. The results are shown in Table 1.

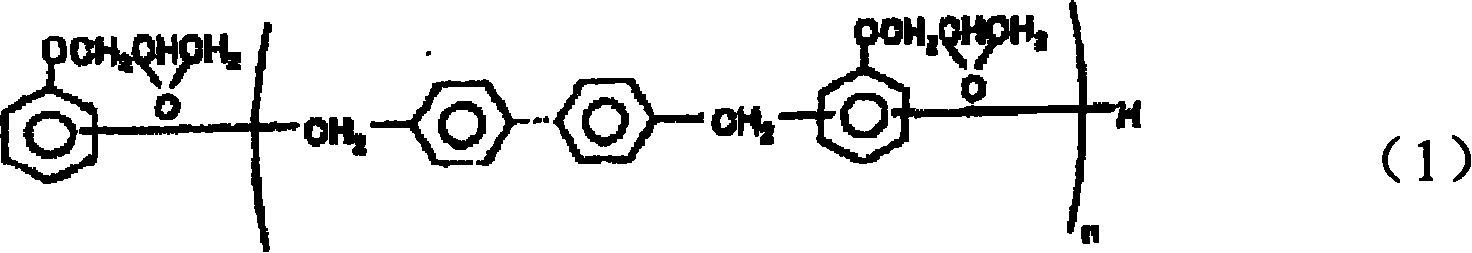

[0051] Epoxy resin 1 is a phenol aralkyl type epoxy resin having a biphenylene skeleton represented by the following formula (1) (58° C. of so...

Embodiment 2~5、 comparative example 1~4

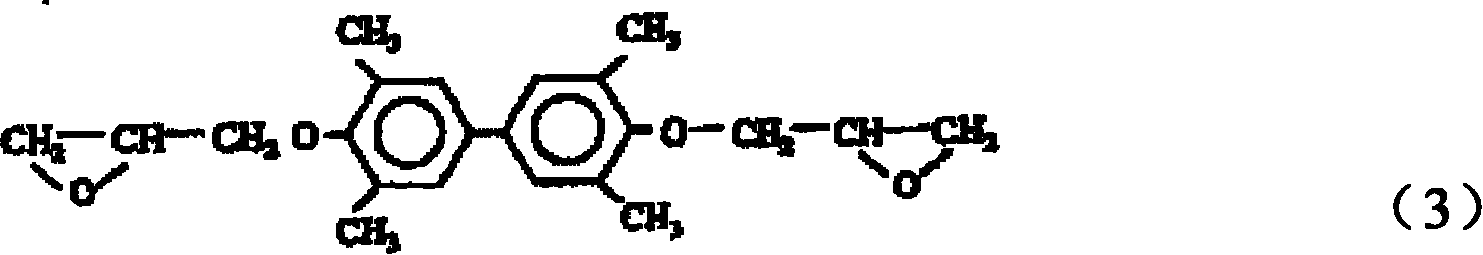

[0072] According to the compounding ratio of Table 1, it operated similarly to Example 1, obtained the epoxy resin composition, and evaluated similarly to Example 1. The results are shown in Table 1. In addition, the epoxy resin 2 is a biphenyl type epoxy resin represented by the following formula (3) with an epoxy equivalent of 190 and a melting point of 105° C. (trade name YX-40000; manufactured by Japan Electronics Co., Ltd.).

[0073]

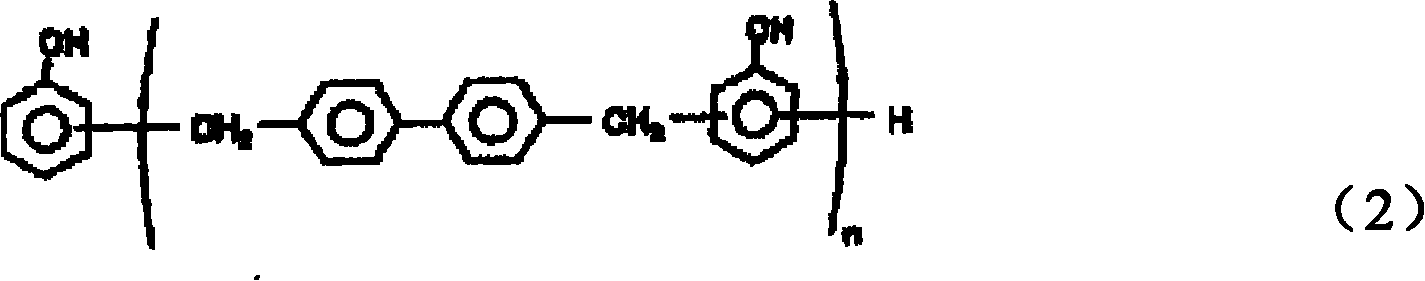

[0074] The phenolic resin 2 is a phenol aralkyl resin represented by the following formula (4) with an epoxy equivalent of 165 and a softening point of 79° C. (trade name XLC-LL; manufactured by Mitsui Chemicals Co., Ltd.).

[0075]

[0076] The curing accelerator 2 is triphenylphosphine (trade name PP-360; manufactured by Kei Ai Chemical Co., Ltd.).

[0077] Table 1

[0078] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com