Automatic laminating machine and cutting device thereof

A laminating machine and automatic technology, applied in the direction of lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of uneven tearing, high labor costs, and low efficiency, so as to improve the yield and prevent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

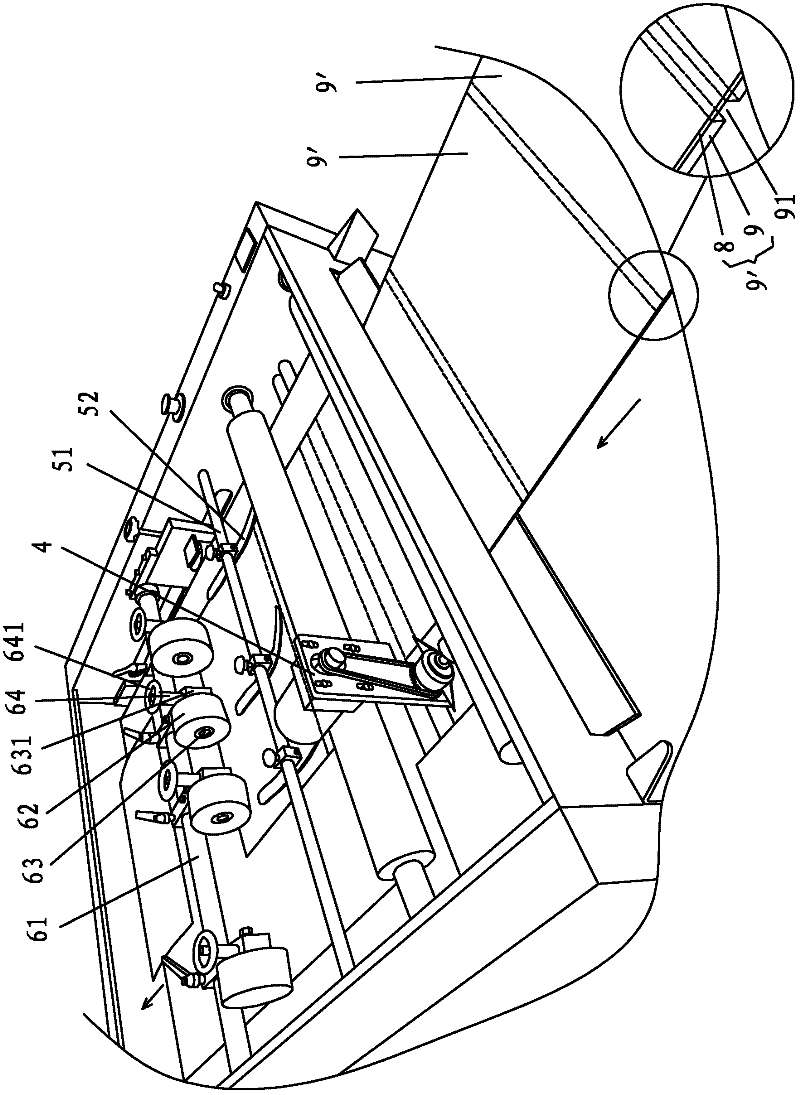

[0042] Such as Figure 1-3 As shown, the automatic laminating machine of the present invention includes a film feeding device 1 , a conveyor belt 2 , a hot pressing device 3 , a cutting device 4 , an introducing device 5 , a pressing device 6 and a receiving platform 7 .

[0043] The film feeding device 1 includes a plurality of reels, one of which is equipped with a roll of plastic film with glue, and after being tensioned by several reels, it is exported to the feeding port of the conveyor belt 2 through the other reel. The discharge port of the conveyor belt 2 passes through the hot pressing device 3 , the cutting device 4 , the introducing device 5 and the compacting device 6 in turn, and then is set at the receiving platform 7 . In addition, plastic film rolls without glue can also be installed on the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com