Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1652results about How to "Easy to clamp and fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

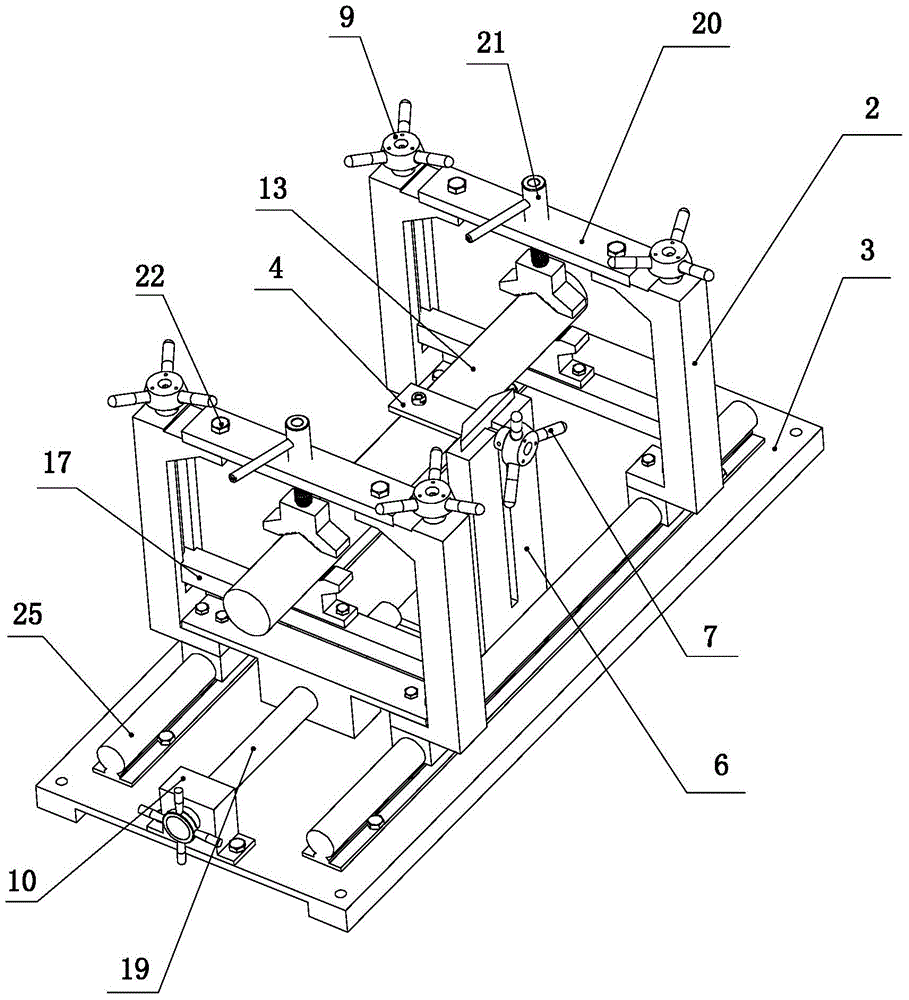

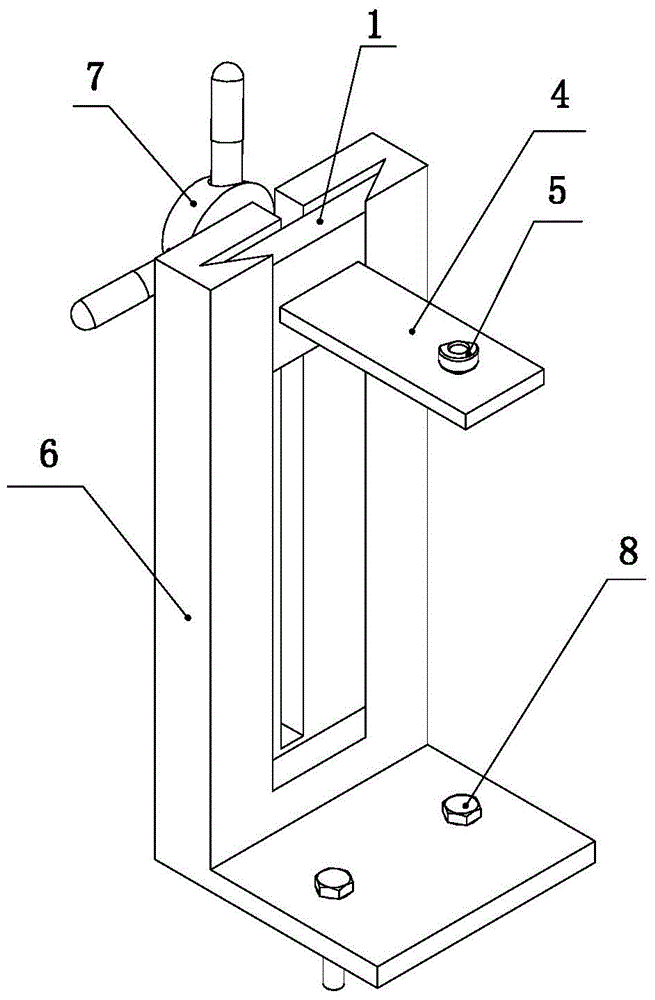

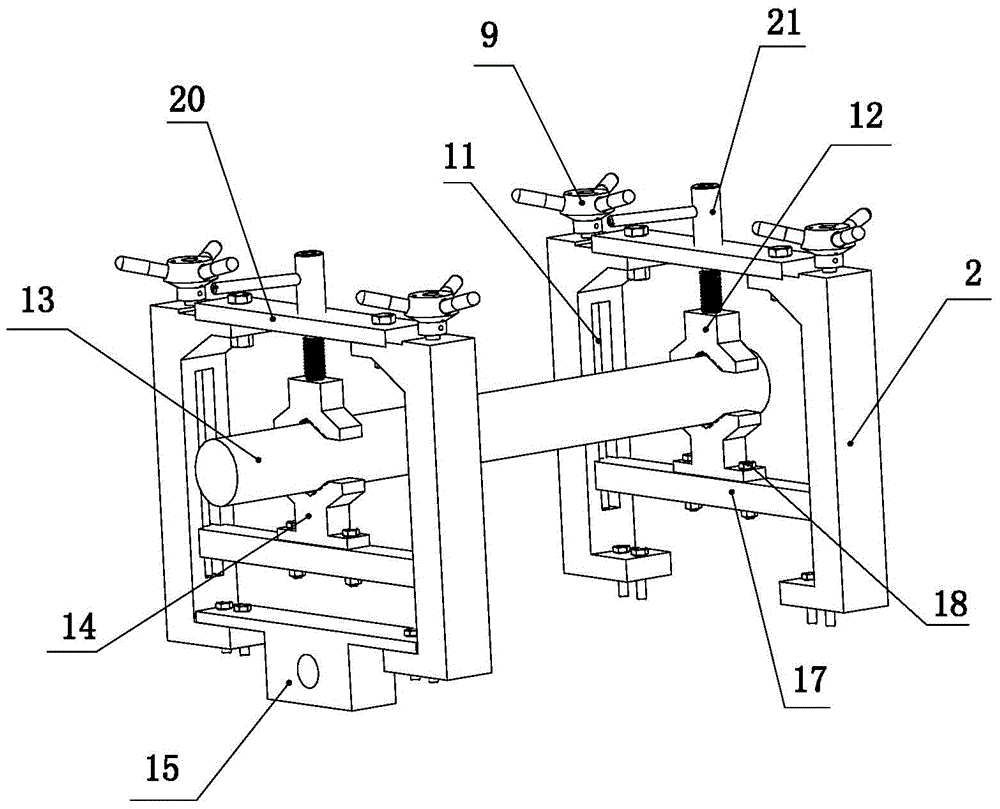

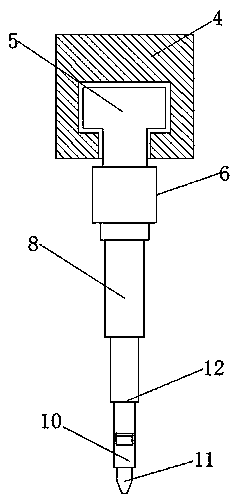

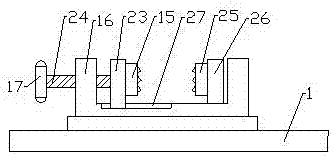

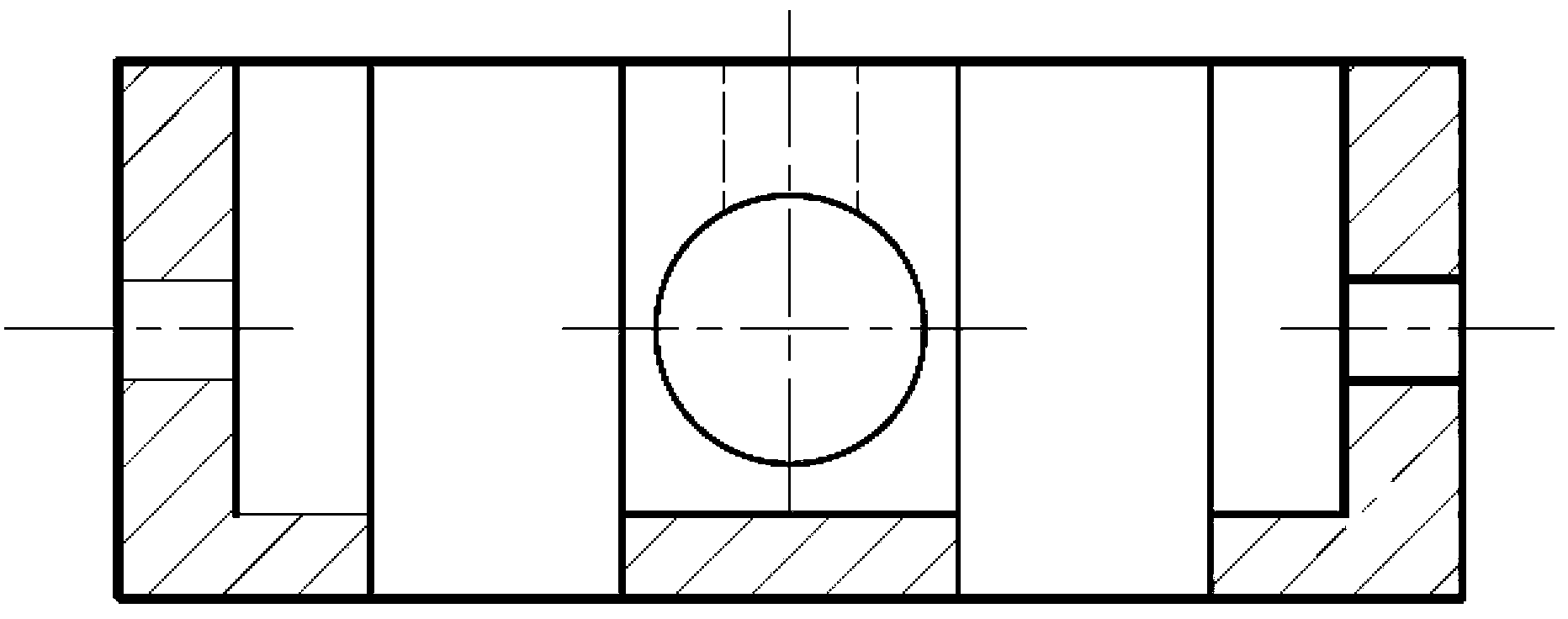

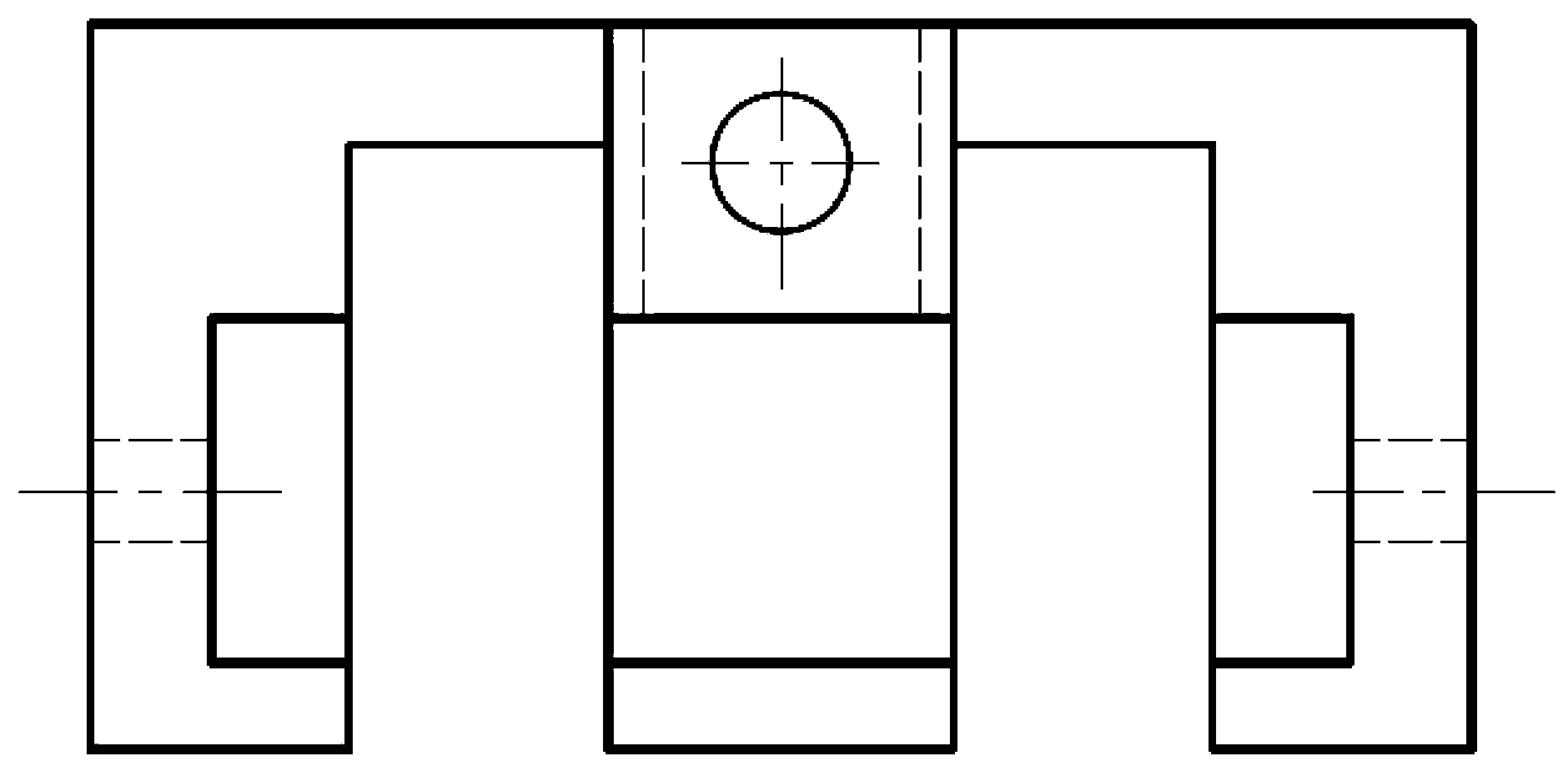

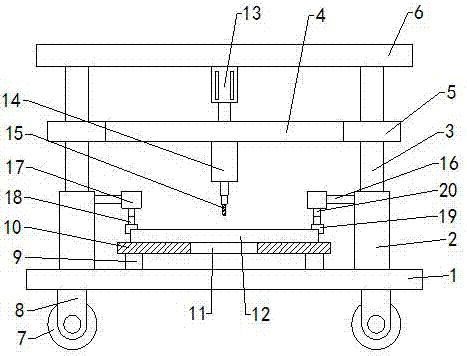

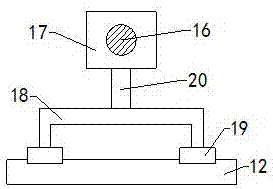

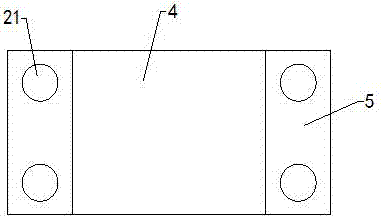

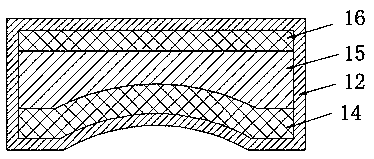

Novel drill jig for processing radial hole of bar

InactiveCN104400499AEasy to clamp and fixEasy to operateLarge fixed membersPositioning apparatusDrilling machinesEngineering

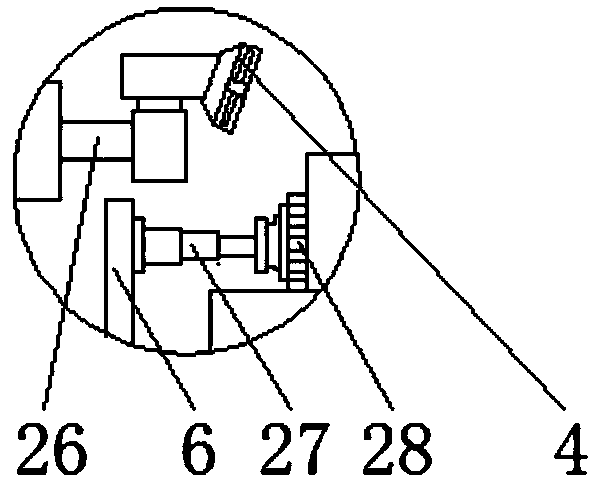

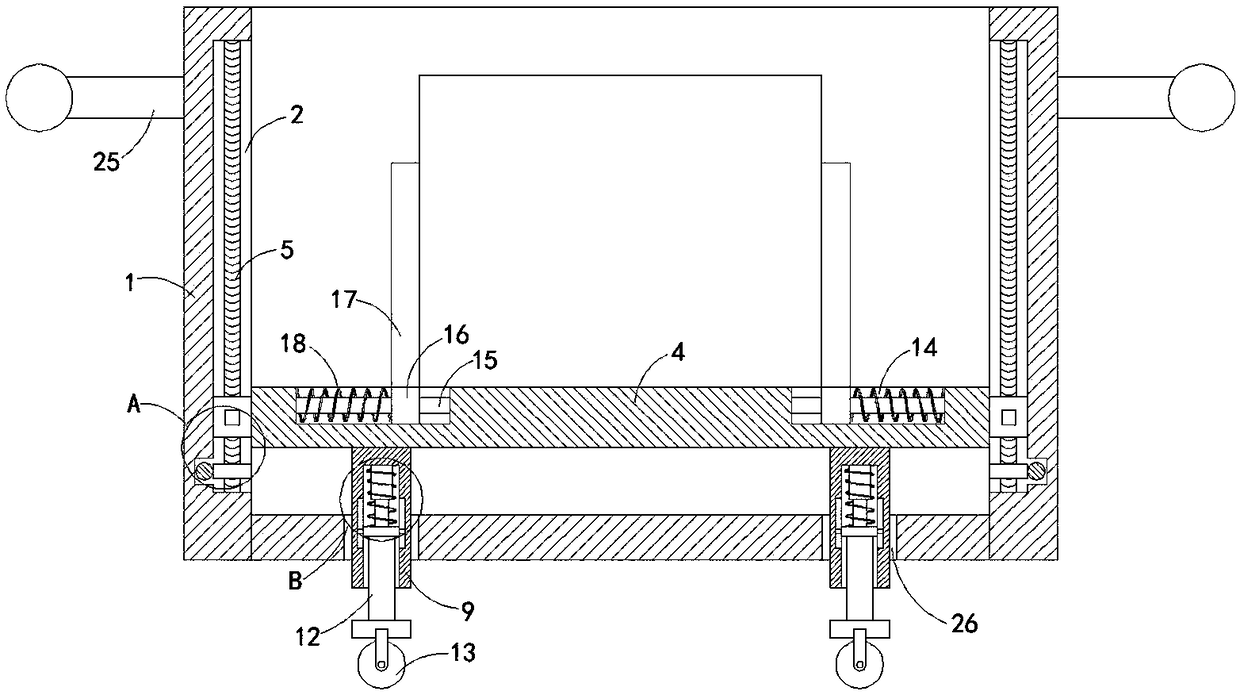

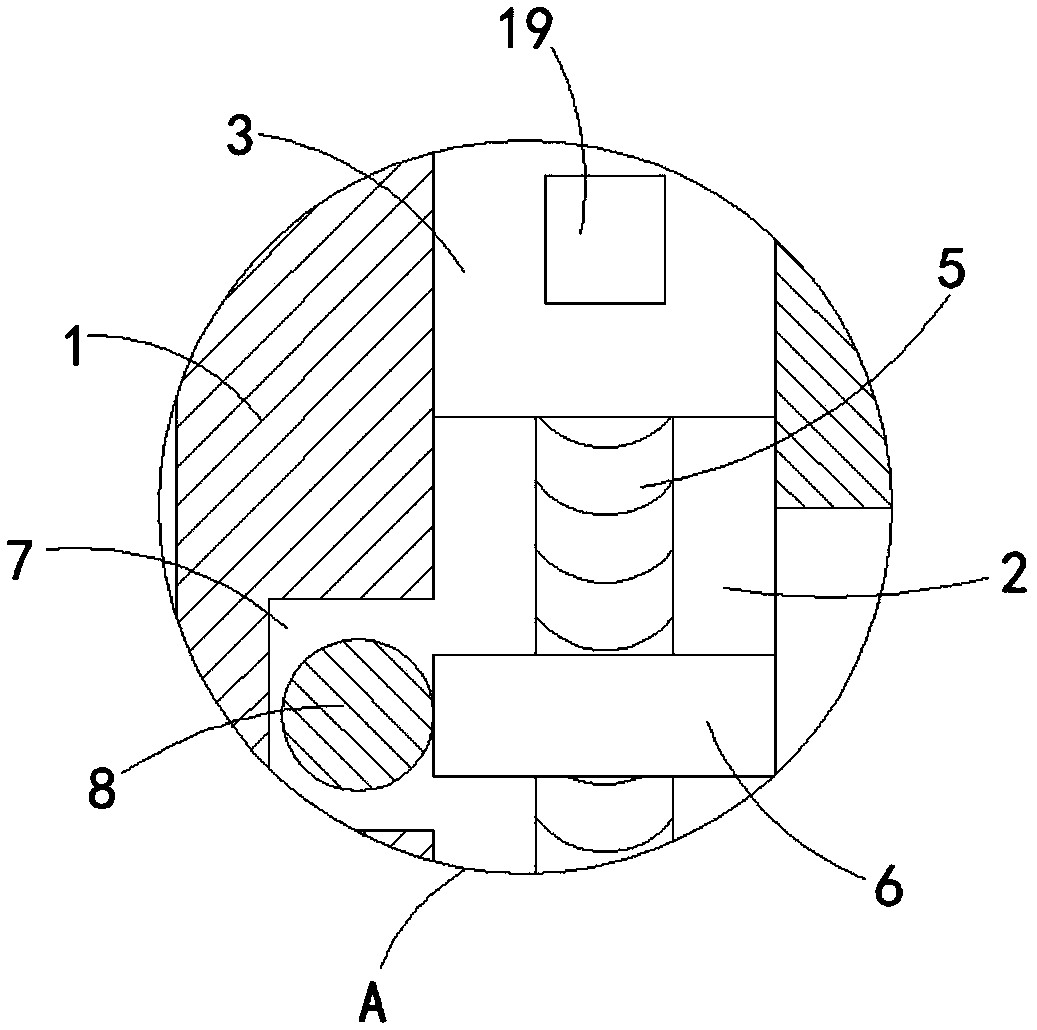

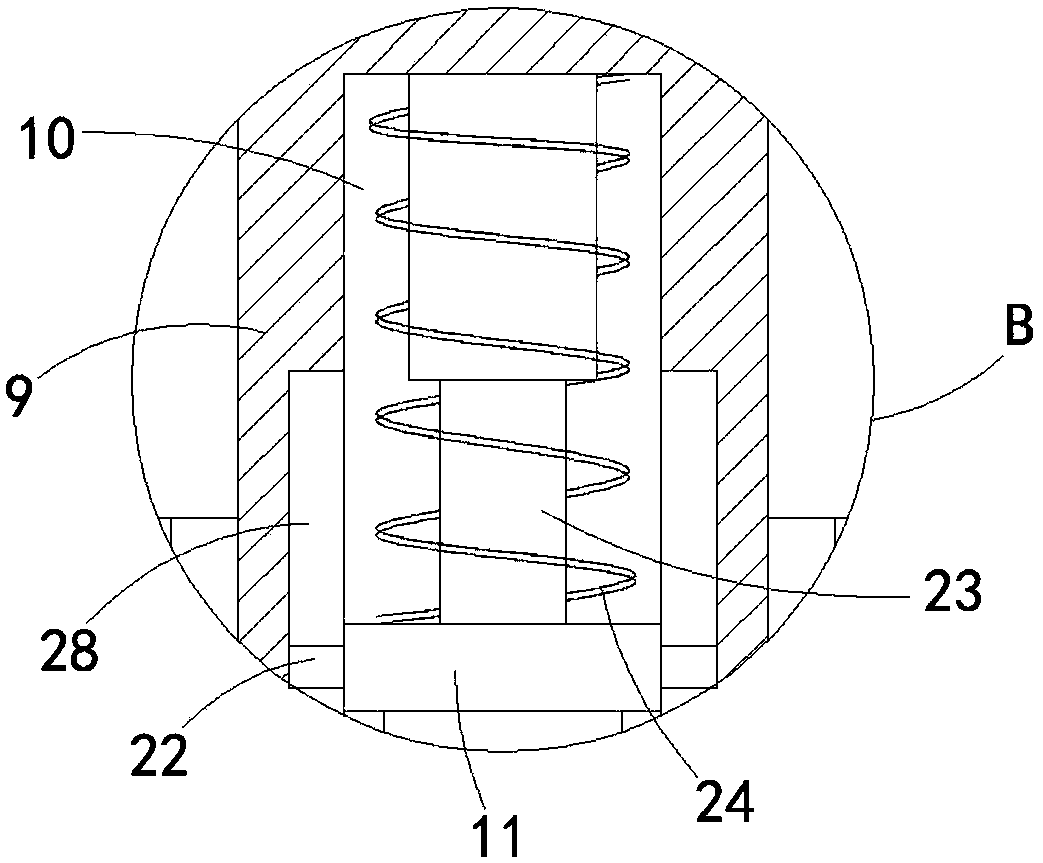

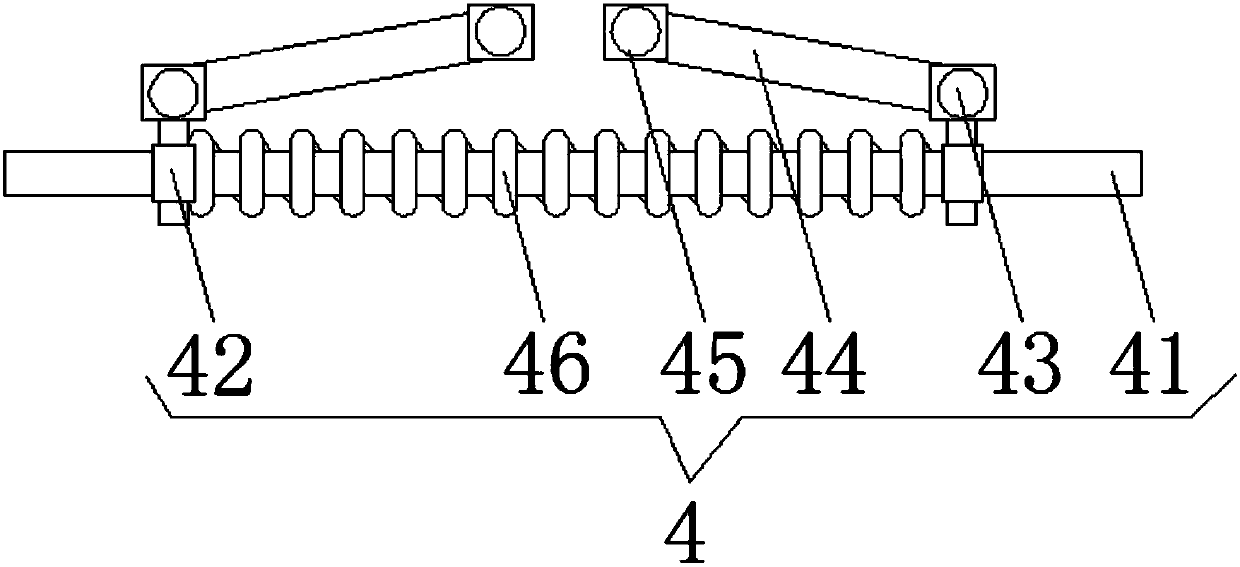

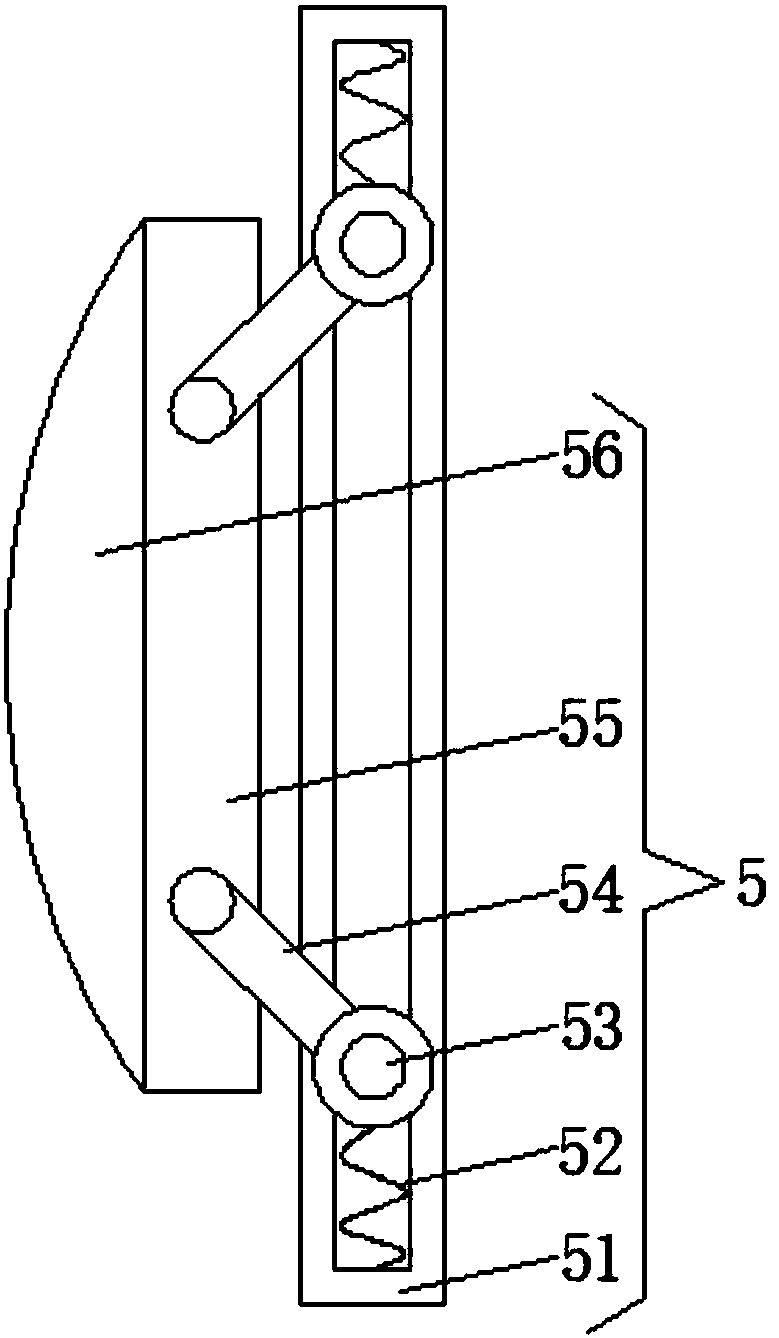

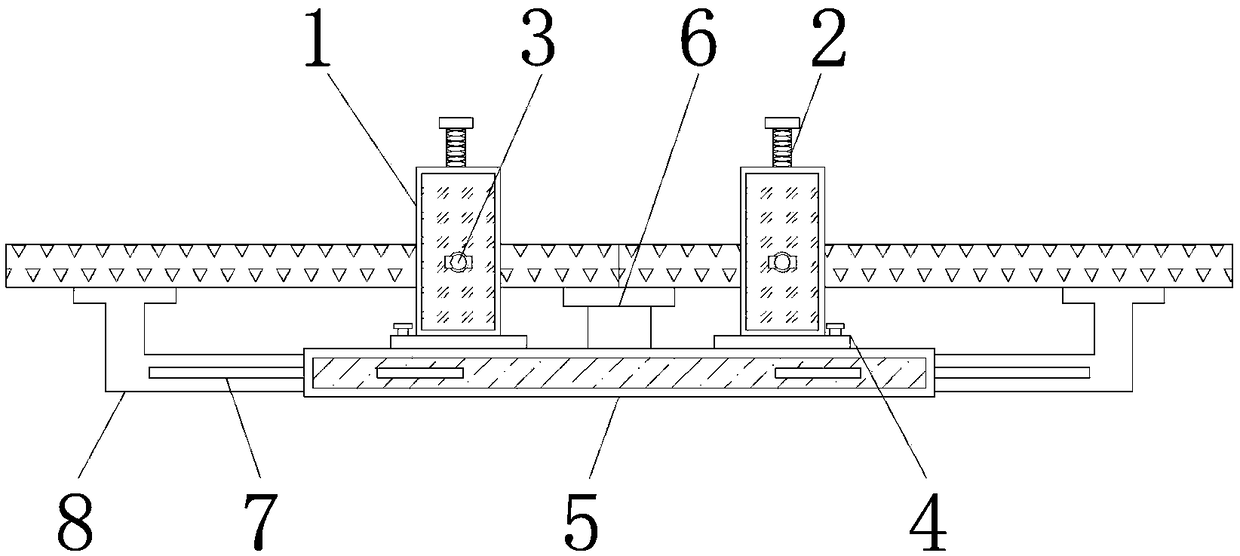

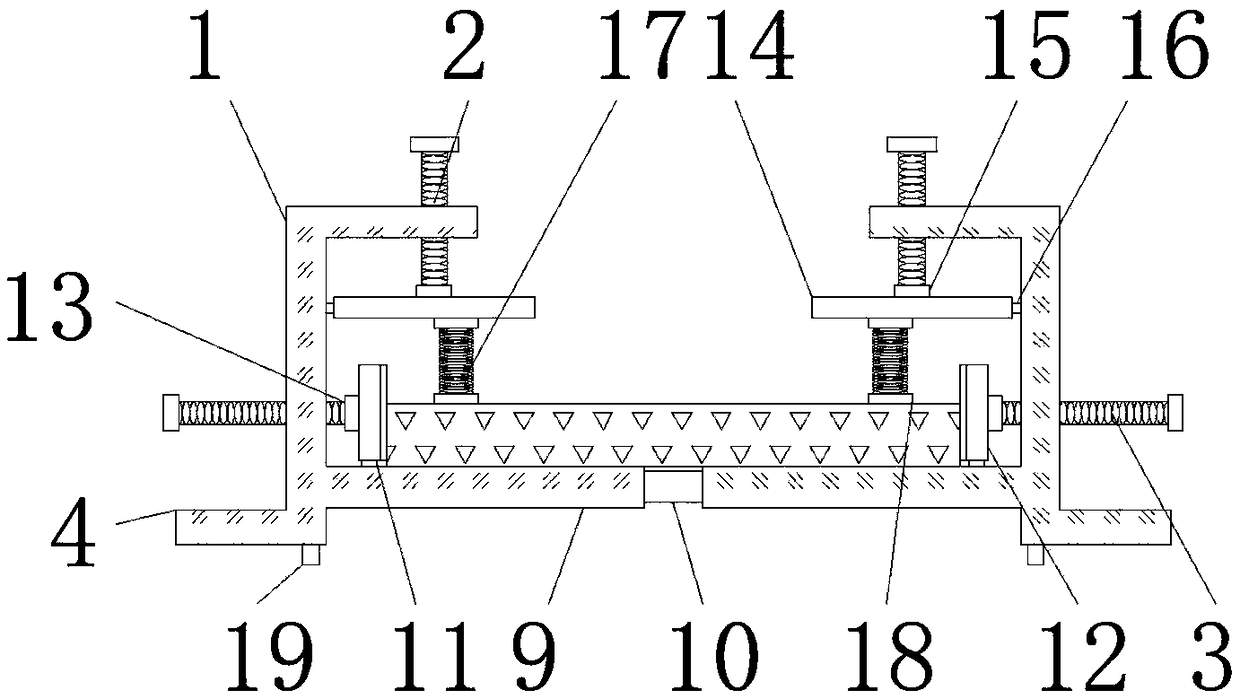

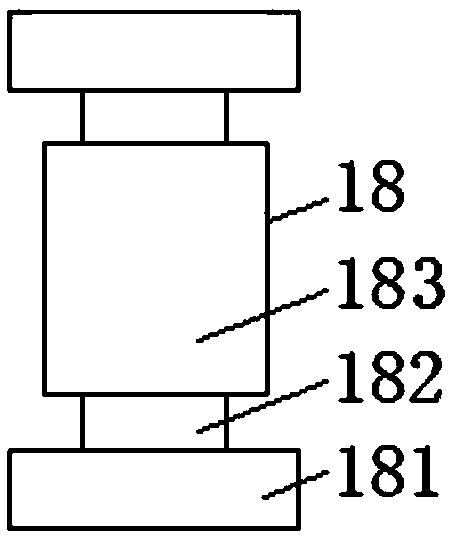

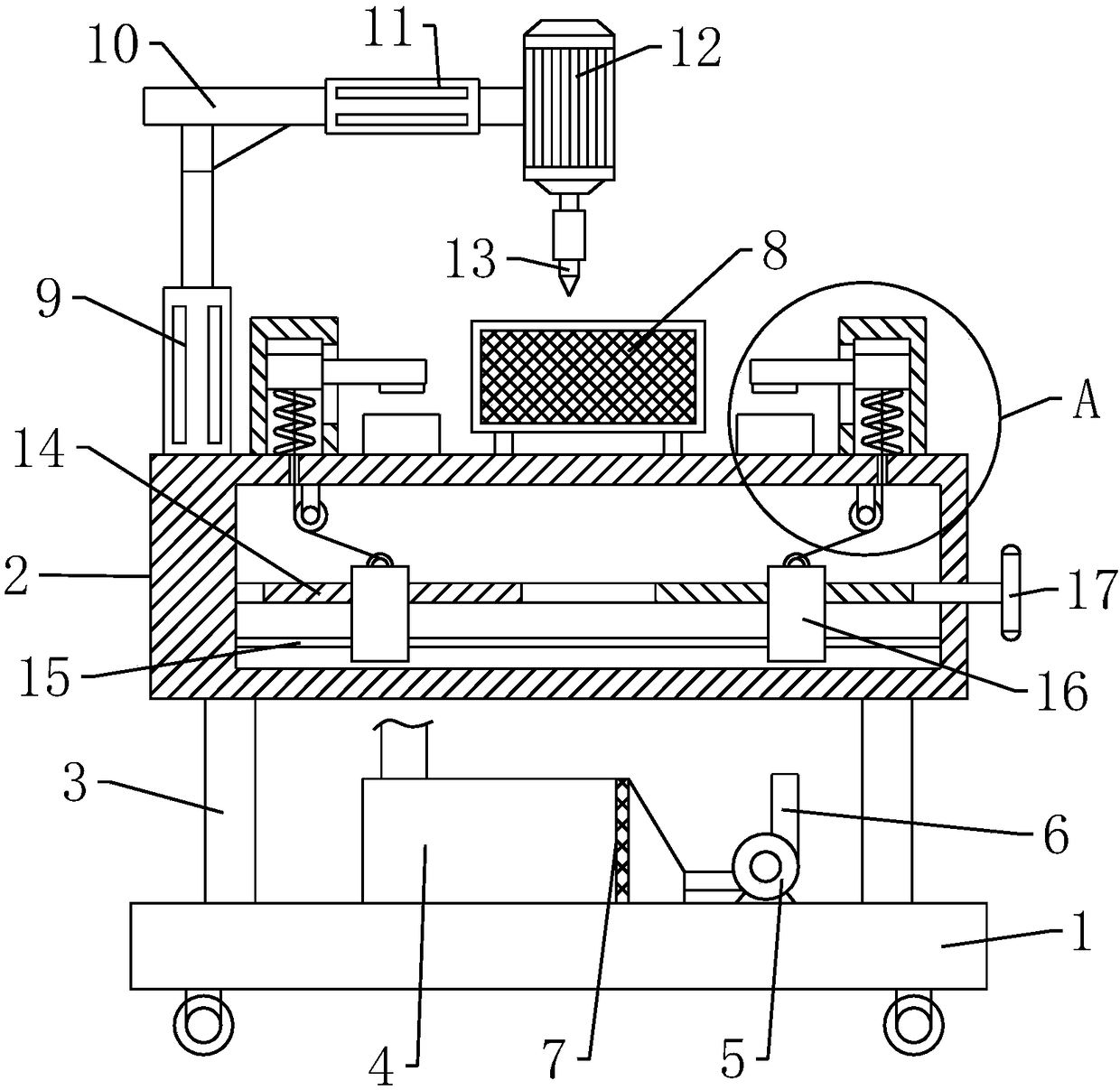

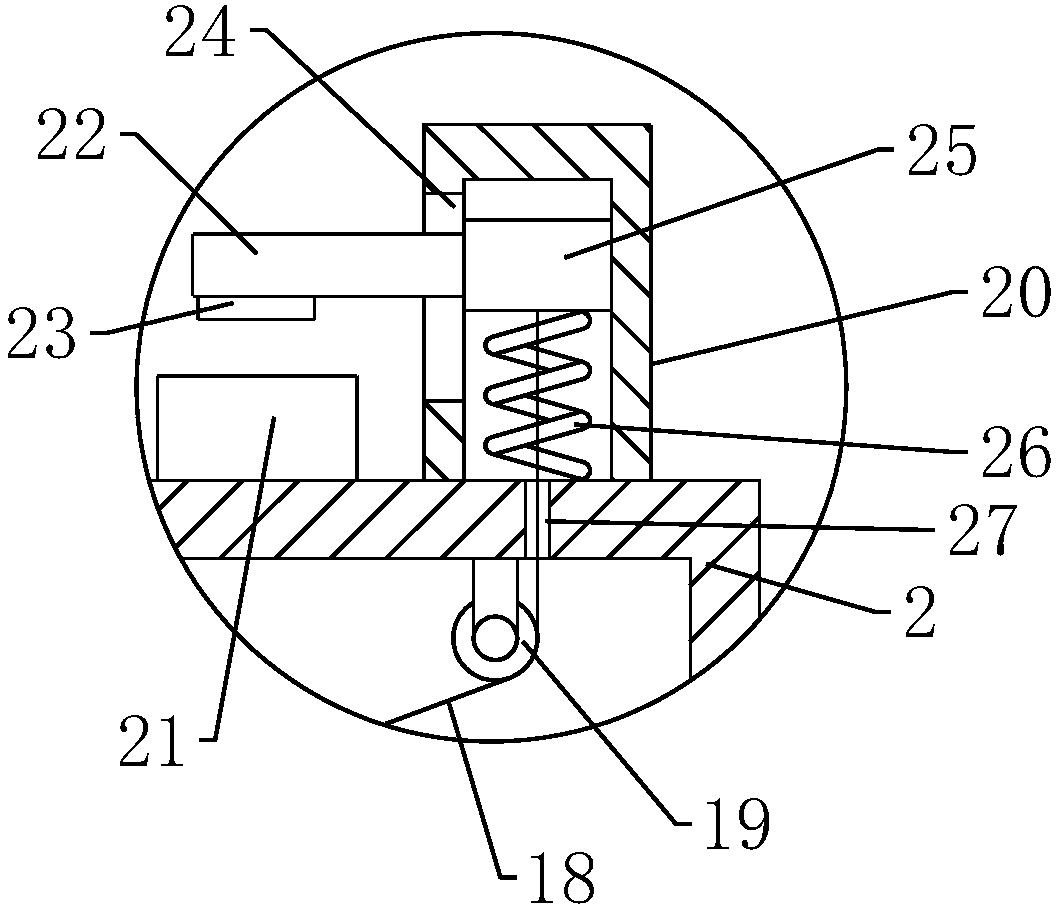

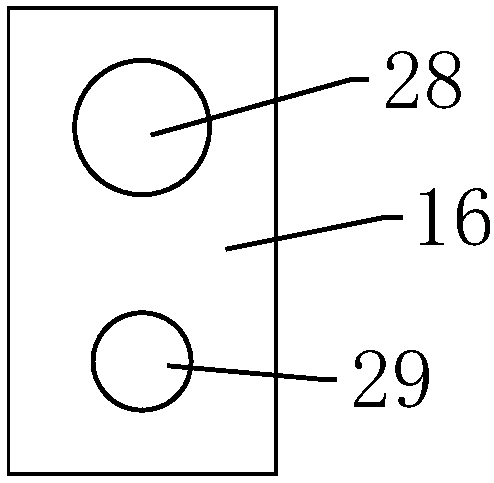

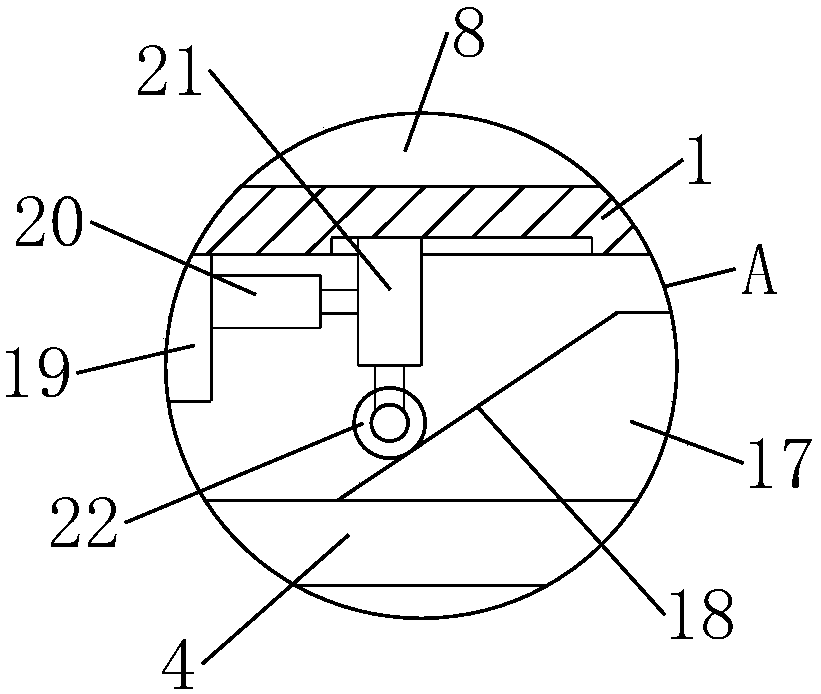

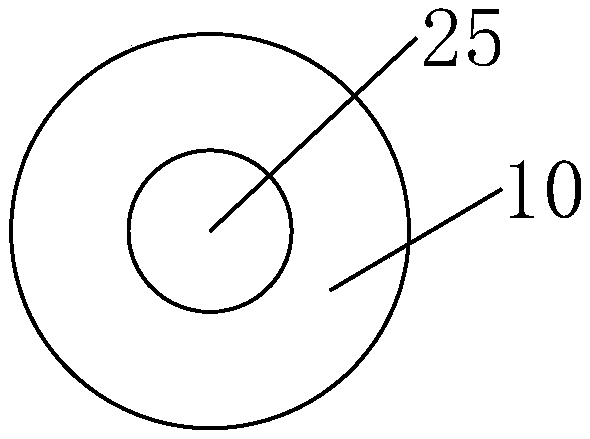

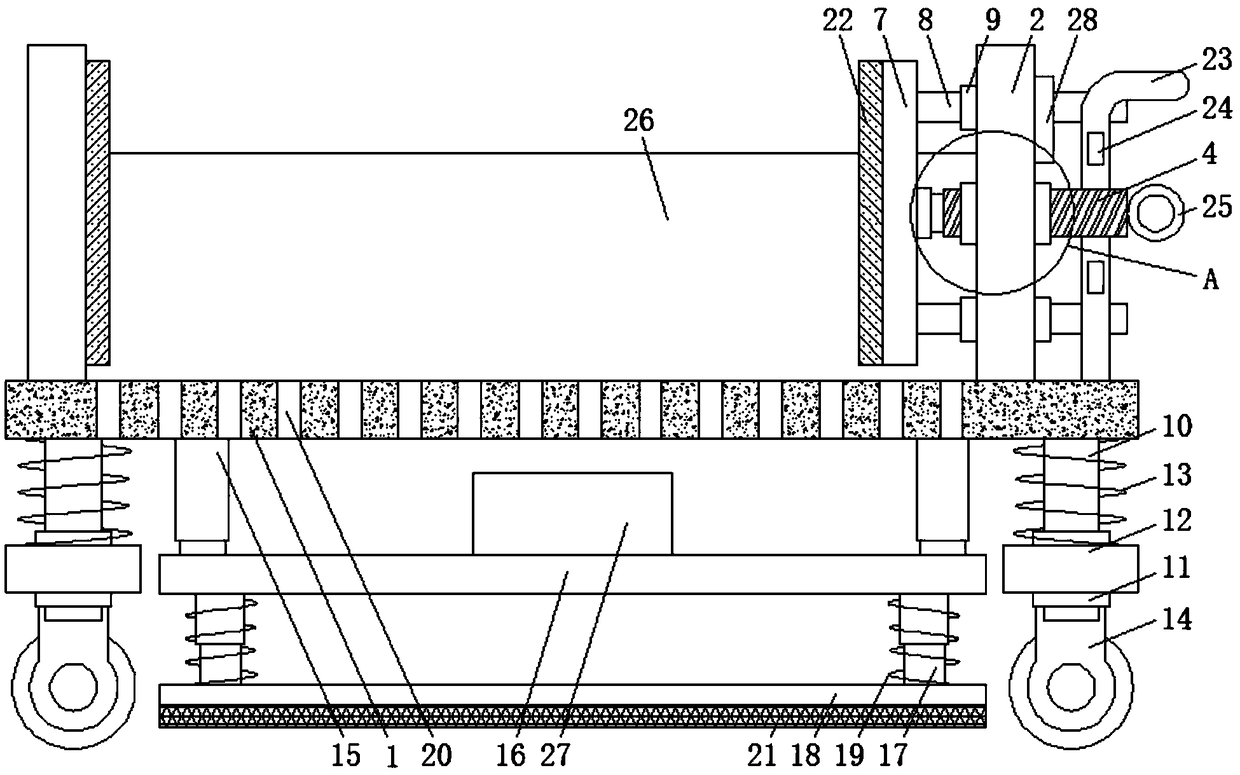

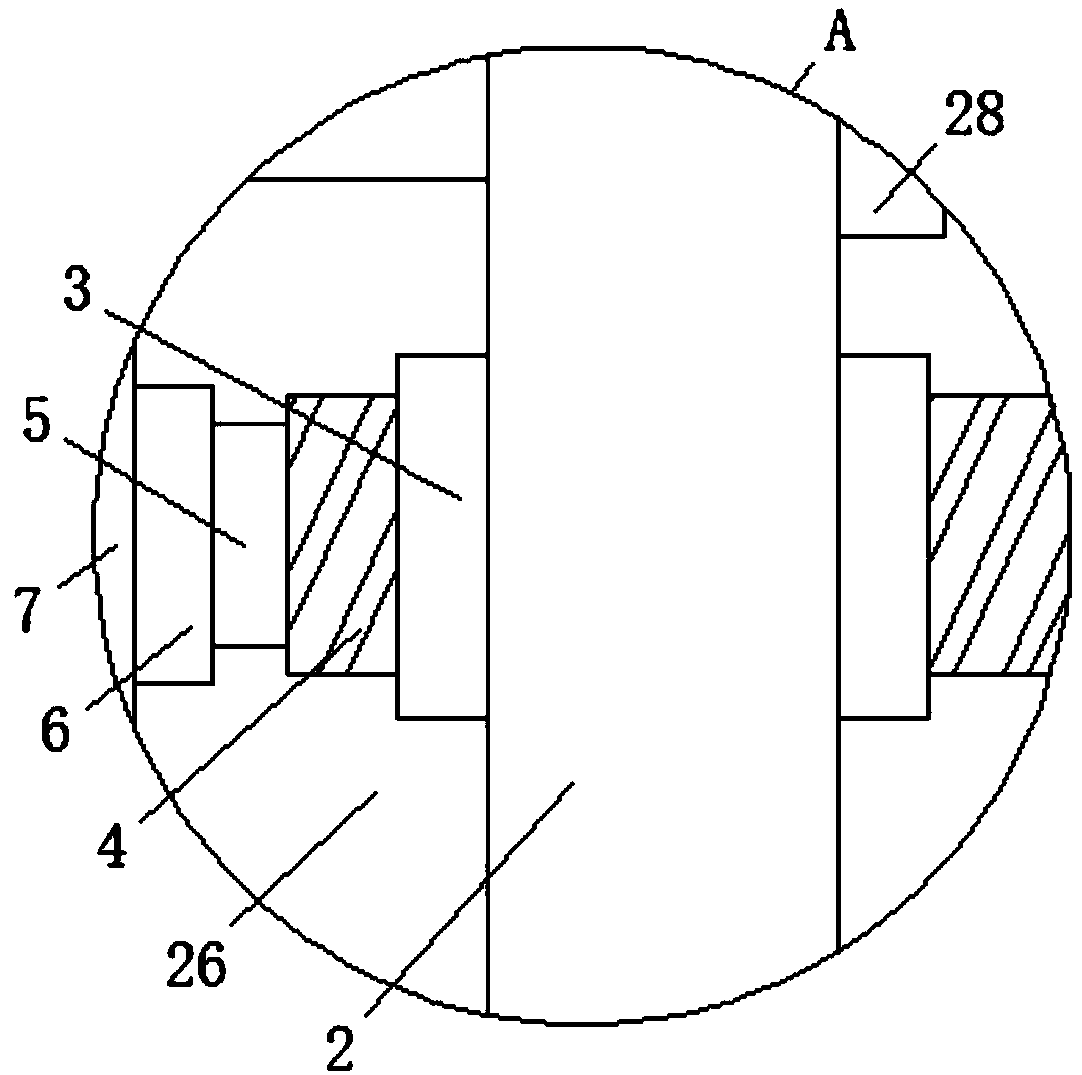

The invention provides a novel drill jig for processing a radial hole of a bar, relates to the technical field of mechanical processing clamps, and aims at solving the problem of inconvenient clamping and fixing of the bars during radial drilling. The novel drill jig for processing the radial hole of the bar is characterized in that a second lead screw is driven to rotate according to the axial position of a hole to be drilled in the bar, so as to enable a second lead screw nut to drive a clamping assembly to move left and right; the bar can be clamped and fixed through an upper clamping block and a lower clamping block by rotating a first lead screw nut and a second lead screw; the height of a guide sleeve can be determined through the opposite moving of a first sliding block and a second sliding block. With the adoption of the drill jig, the bar can be conveniently clamped and fixed; the second lead screw nut can be simply driven to move to drill a plurality of holes in the axial direction; the drill jig is simple in structure and convenient to operate.

Owner:UNIV OF JINAN

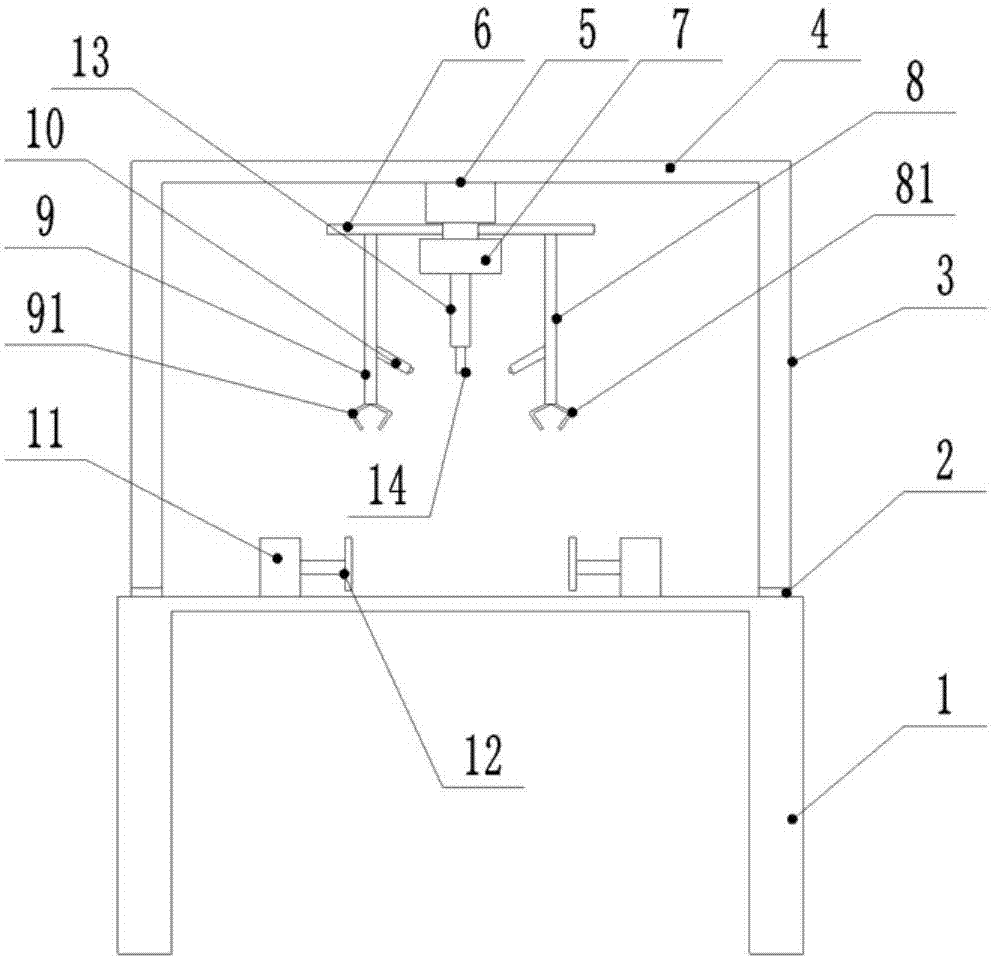

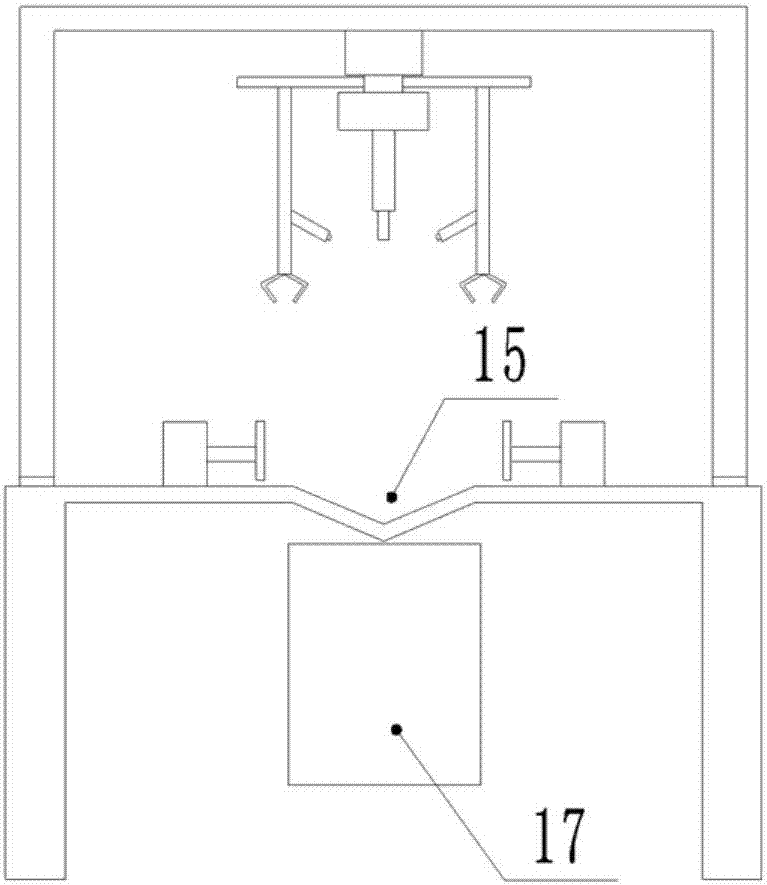

Automatic welding manipulator for automobile assembly

ActiveCN109807520AEasy to weldWelding free movementWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to the technical field of automation equipment and discloses an automatic welding manipulator for automobile assembly. The automatic welding manipulator comprises a base and support plates arranged on two sides of the upper end of the base. The two support plates are symmetrically arranged. Longitudinal sliding rails are correspondingly arranged at the upper ends of two opposite side walls of the two support plates. Longitudinal sliding blocks are correspondingly and slidably connected into the two longitudinal sliding rails. A cross beam transversely arranged is arrangedin the front of the two support plates. The two ends of the cross beam are fixedly connected with the two longitudinal sliding blocks. A transverse sliding rail is arranged at the lower end of the cross beam. A transverse sliding block is slidably connected into the transverse sliding rail. The lower end of the transverse sliding block is fixedly connected with a reduction box. One side of the reduction box is fixedly connected with a driving motor. The automatic welding manipulator for automobile assembly can weld automobile parts from multiple angles and can clamp and fix and rotate and lift automobile parts in different shapes, the welding efficiency is improved and the use is facilitated for people.

Owner:武汉市双新汽车零部件有限公司

Polishing device for automobile parts

InactiveCN107322473AEasy to holdEasy to clamp and fixEdge grinding machinesGrinding work supportsLitterArchitectural engineering

The invention discloses a grinding device for auto parts, which comprises a working platform, a dust collection box, a waste box, a grinding wheel, a movable splint, a fixture seat and a fixed splint. The inner end of the fixed plate is fixedly provided with a slide plate, the movable splint is fixedly arranged on the surface of the right side wall of the slide plate, the right part of the fixture seat is fixedly installed with a fixed plate, the surface of the left side wall of the fixed plate is fixedly provided with a fixed splint, the inner cavity of the dust box A dust filter is arranged in the middle, and a fan is fixedly installed on the upper surface of the left part of the support base, and the air intake end of the fan communicates with the left inner cavity of the dust collection box. The invention is simple in structure, easy to use, has good clamping and fixing effect on the auto parts to be polished, improves the grinding quality of the auto parts, and can effectively collect and separate the dust and iron filings generated in the grinding process, improving the quality of the auto parts. The comfort of the processing environment.

Owner:叶巧敏

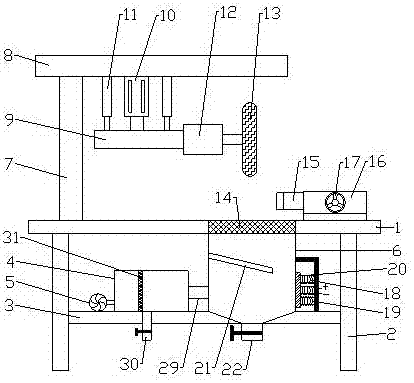

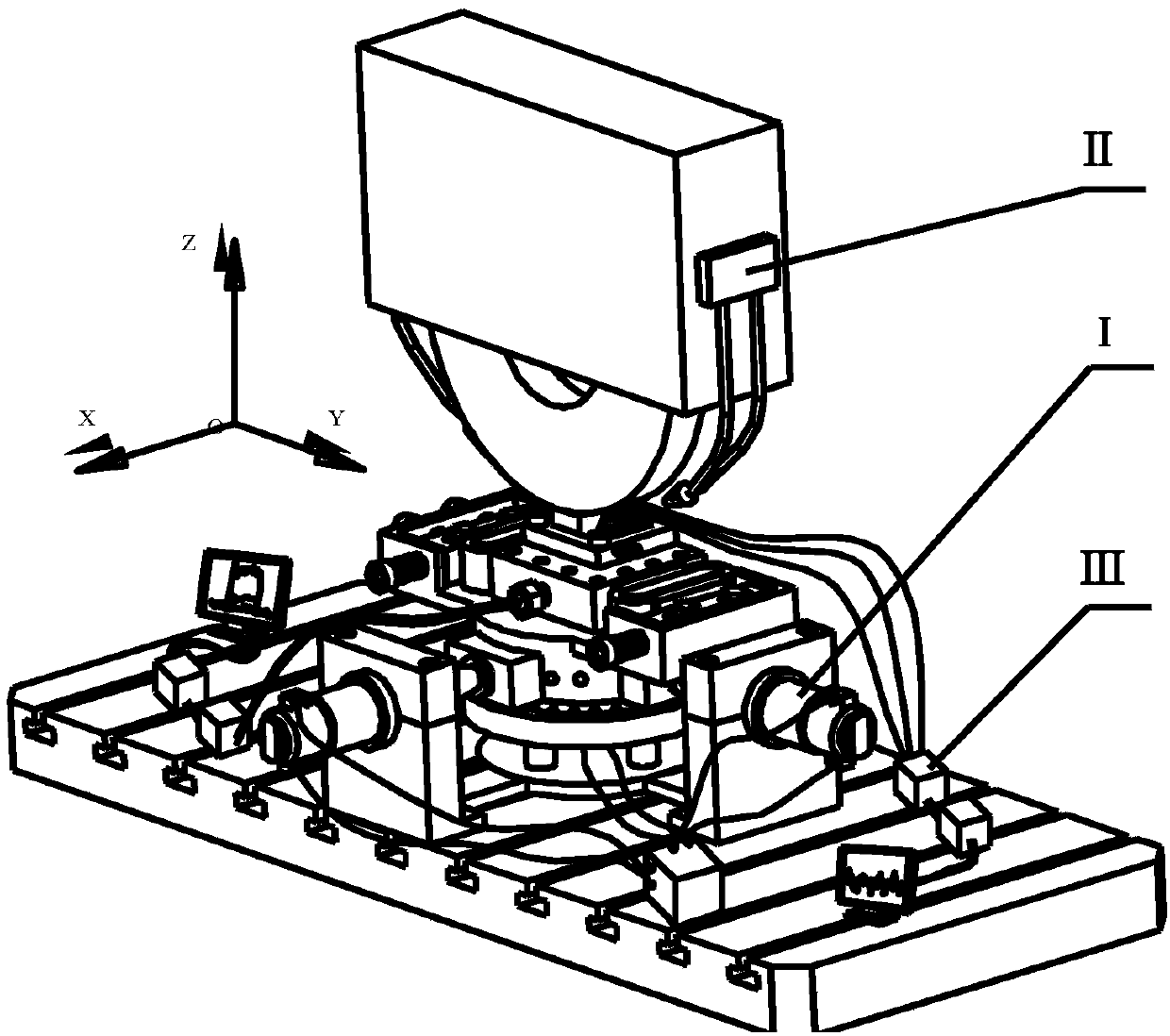

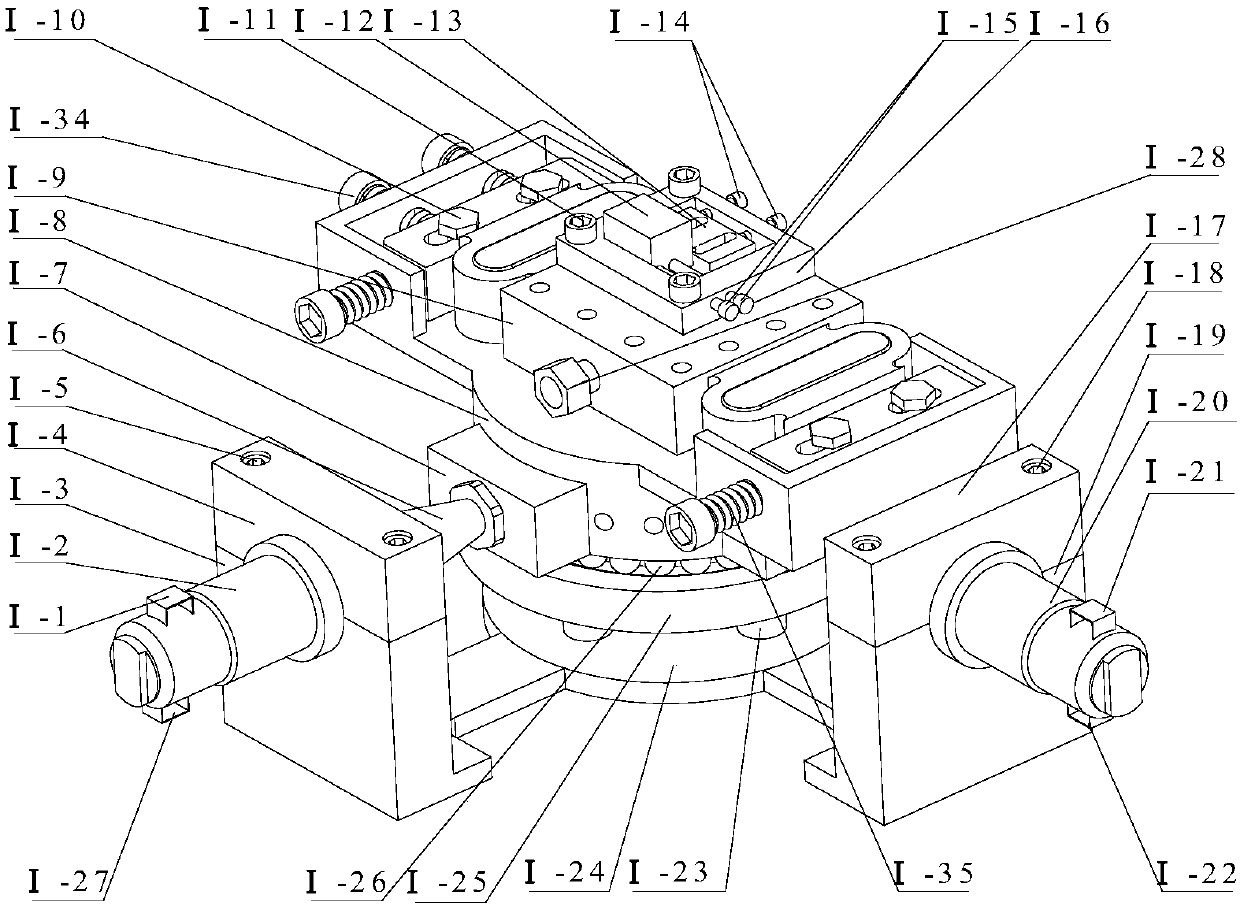

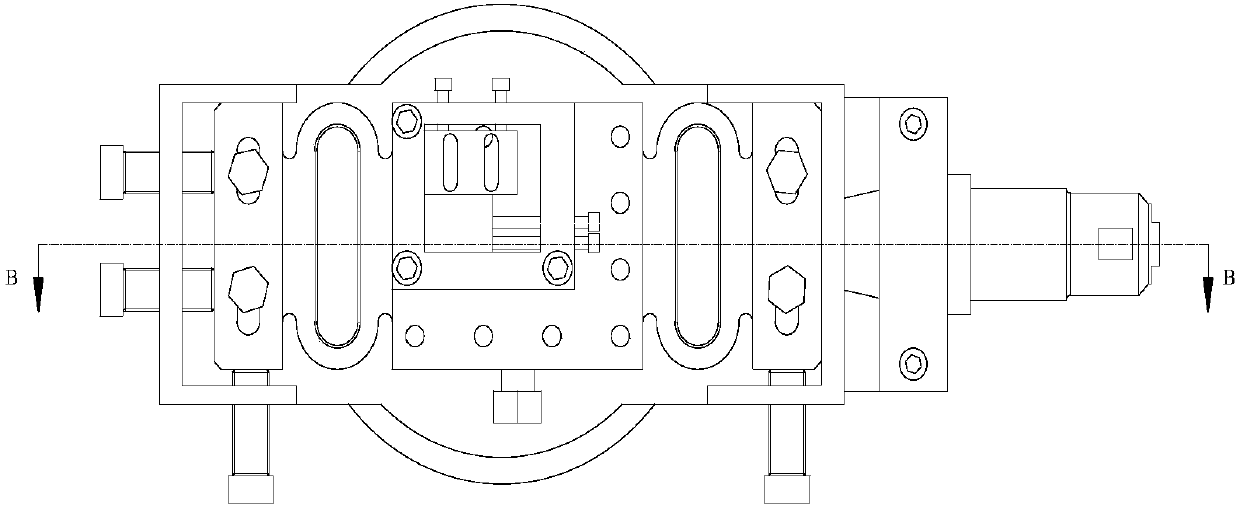

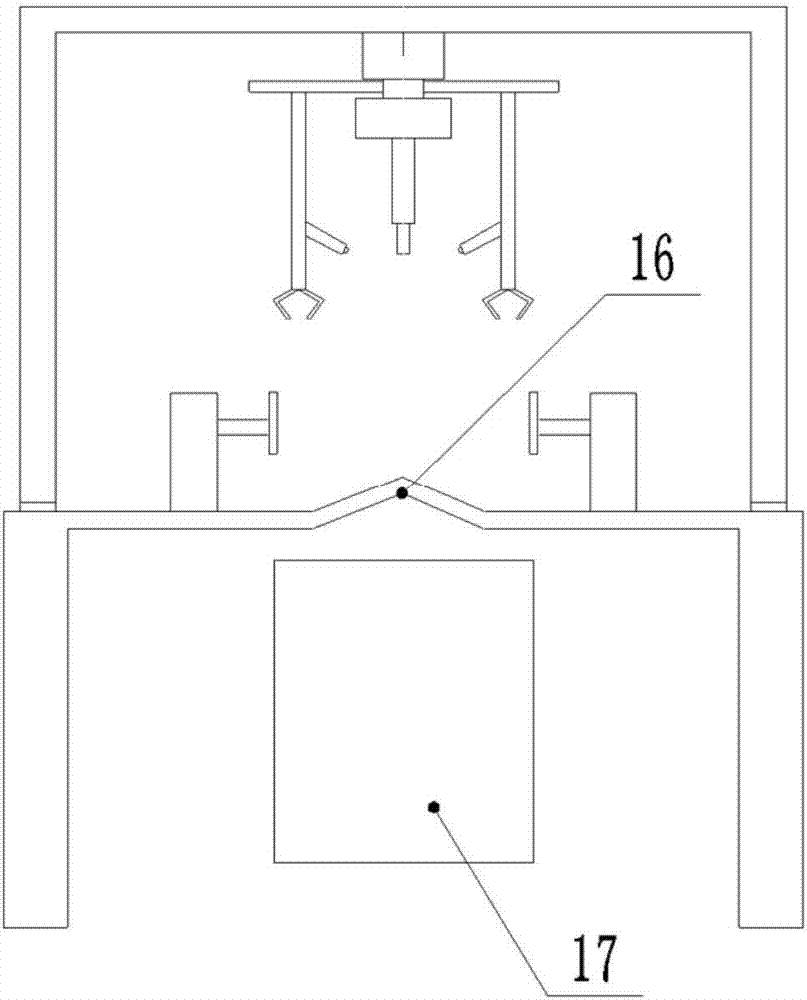

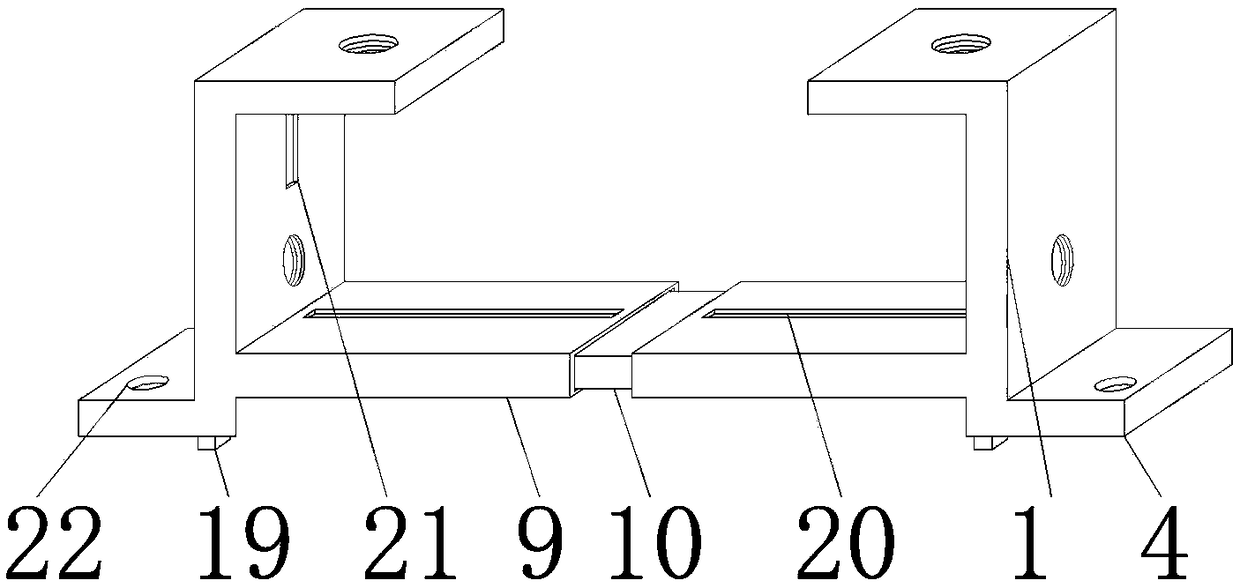

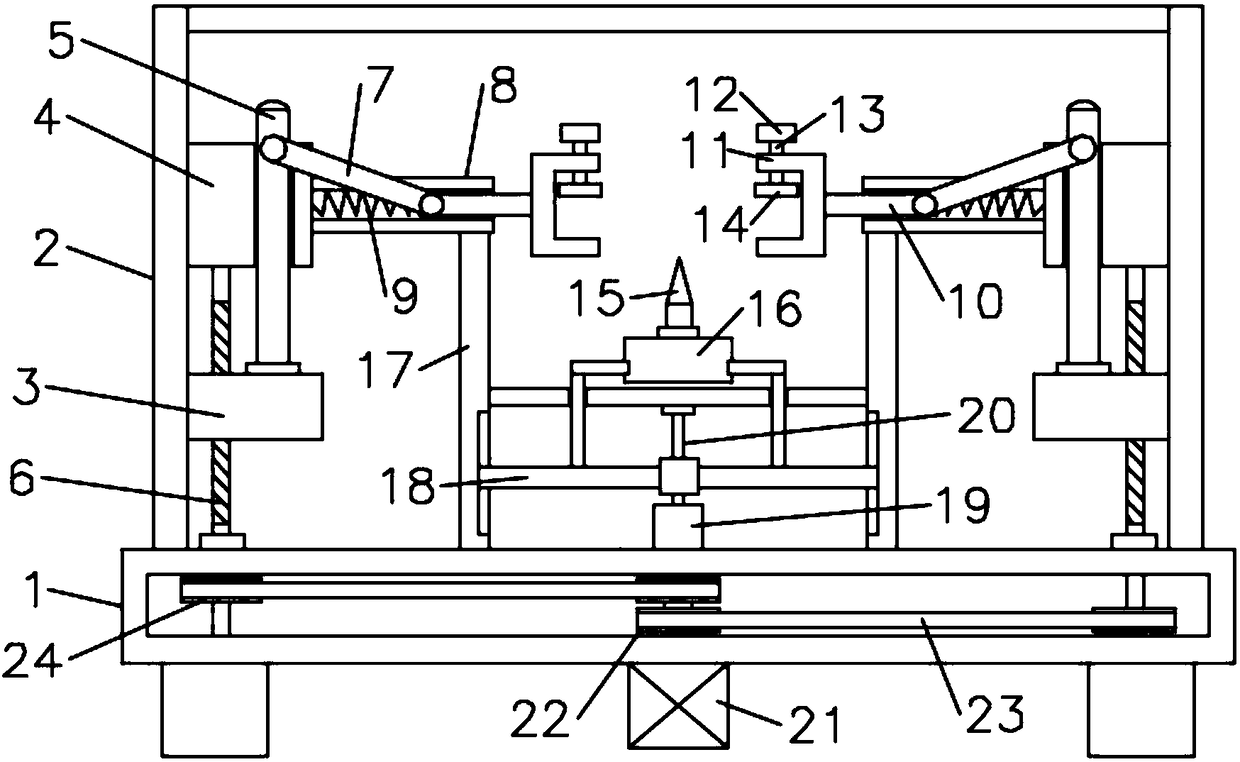

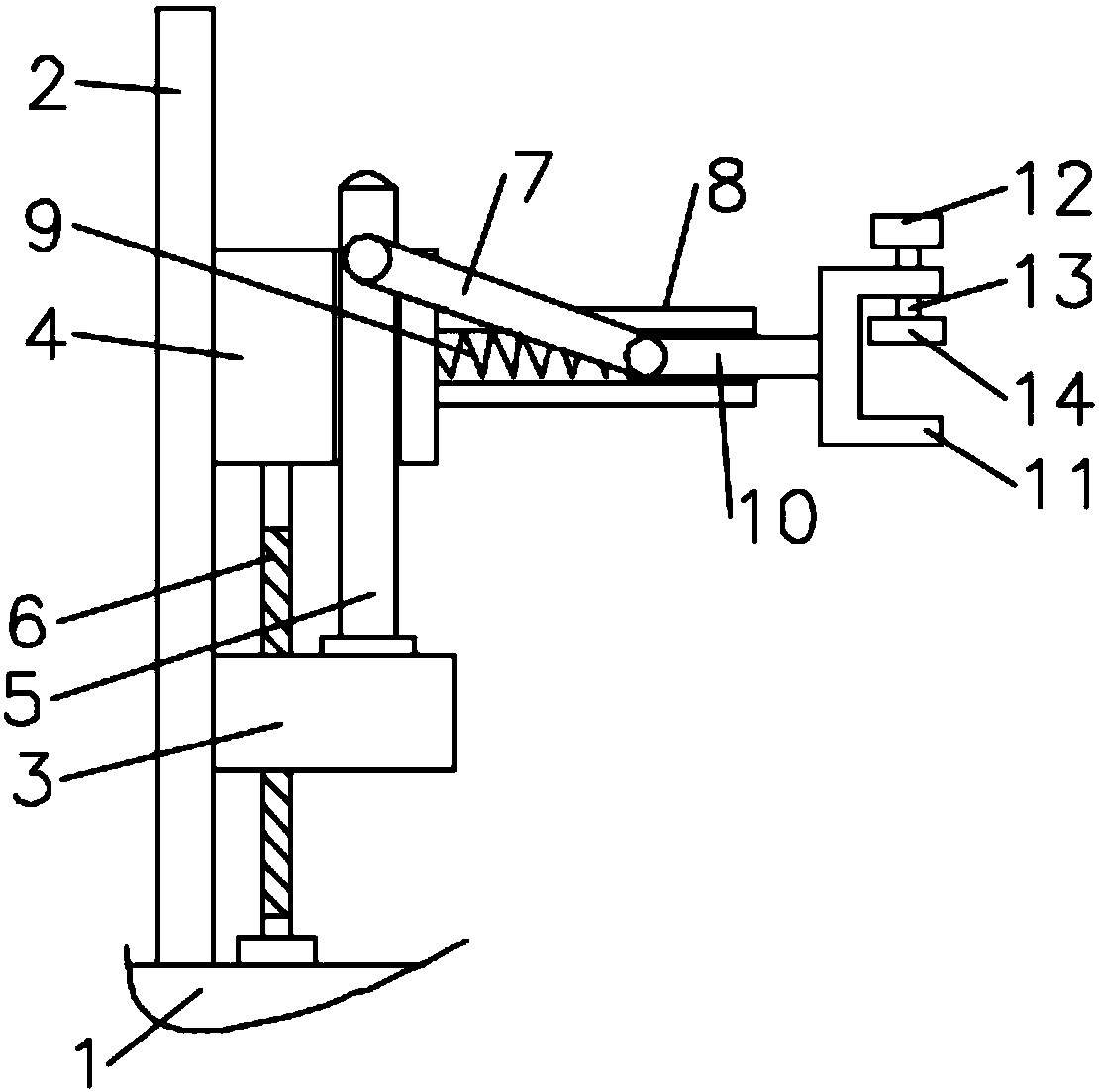

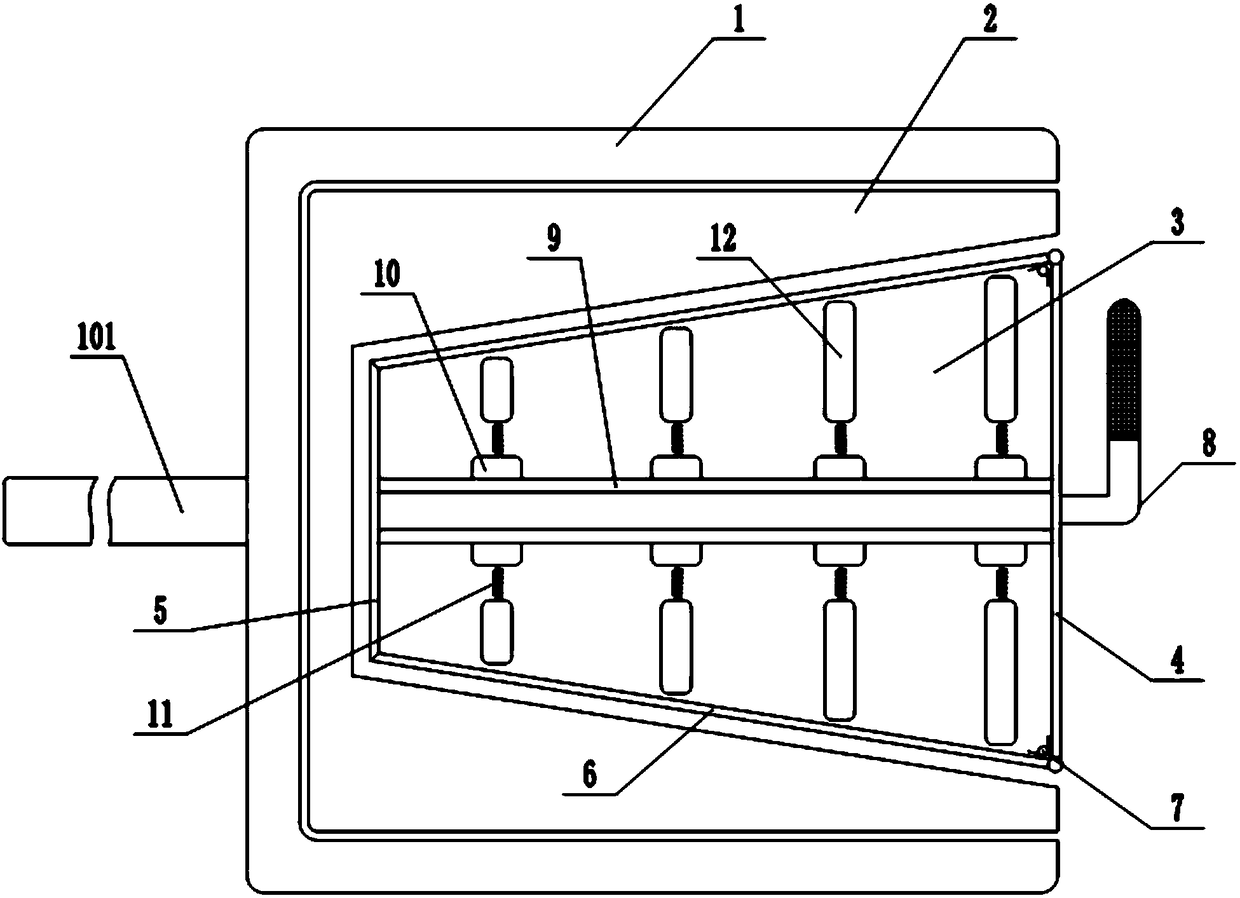

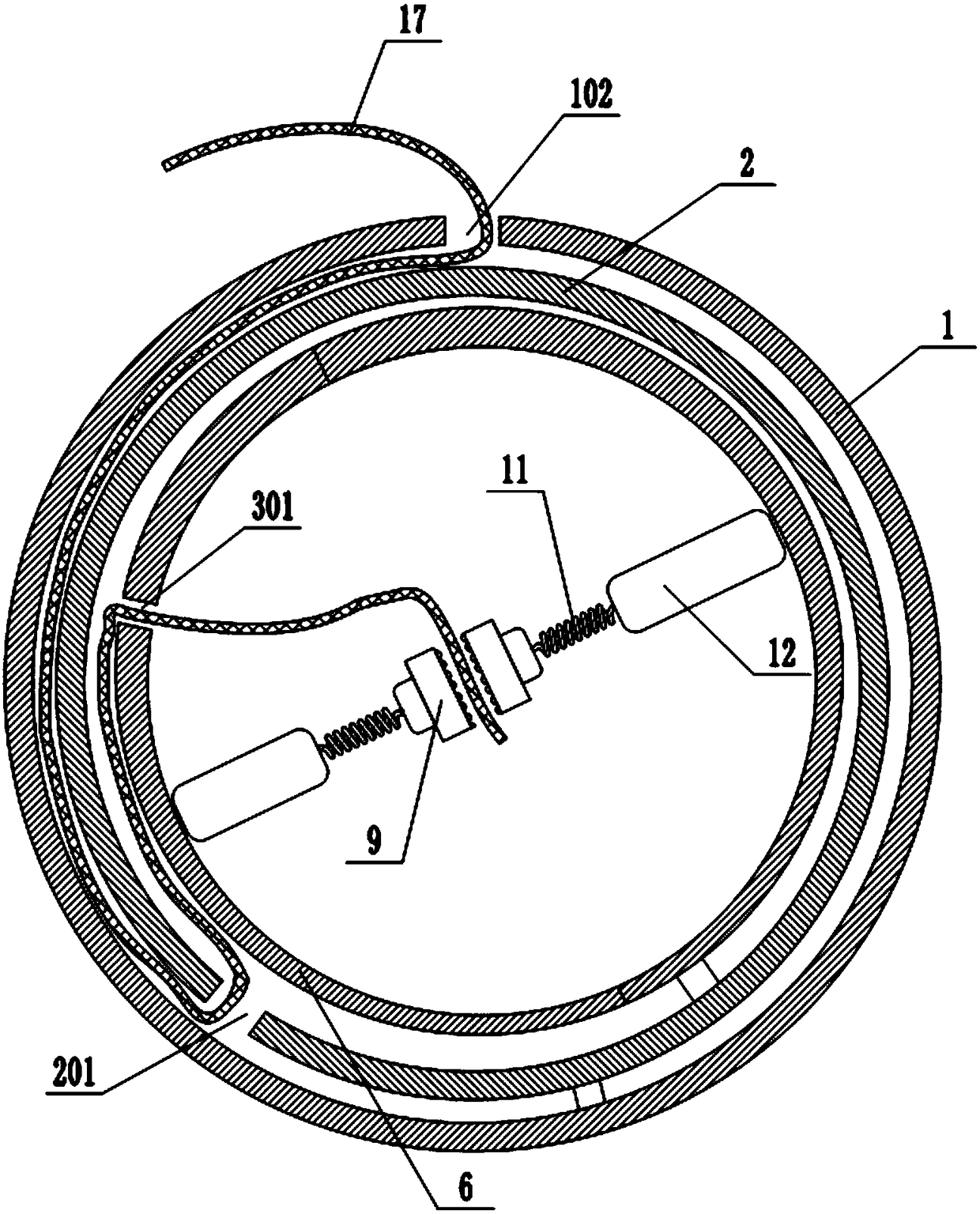

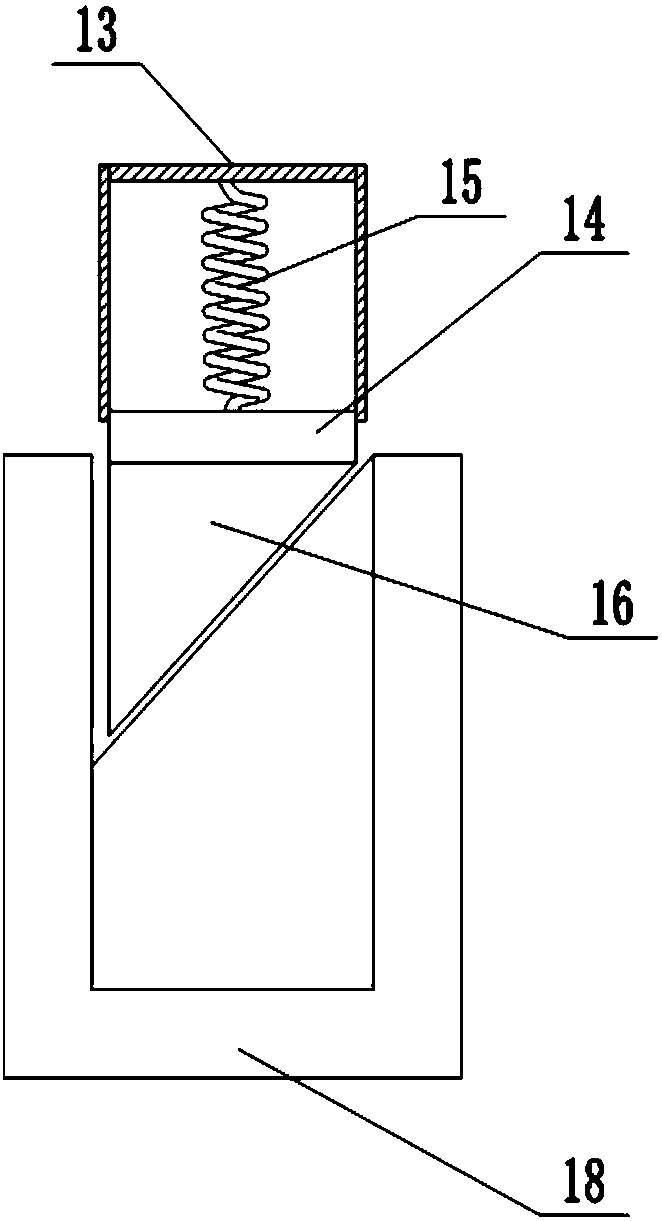

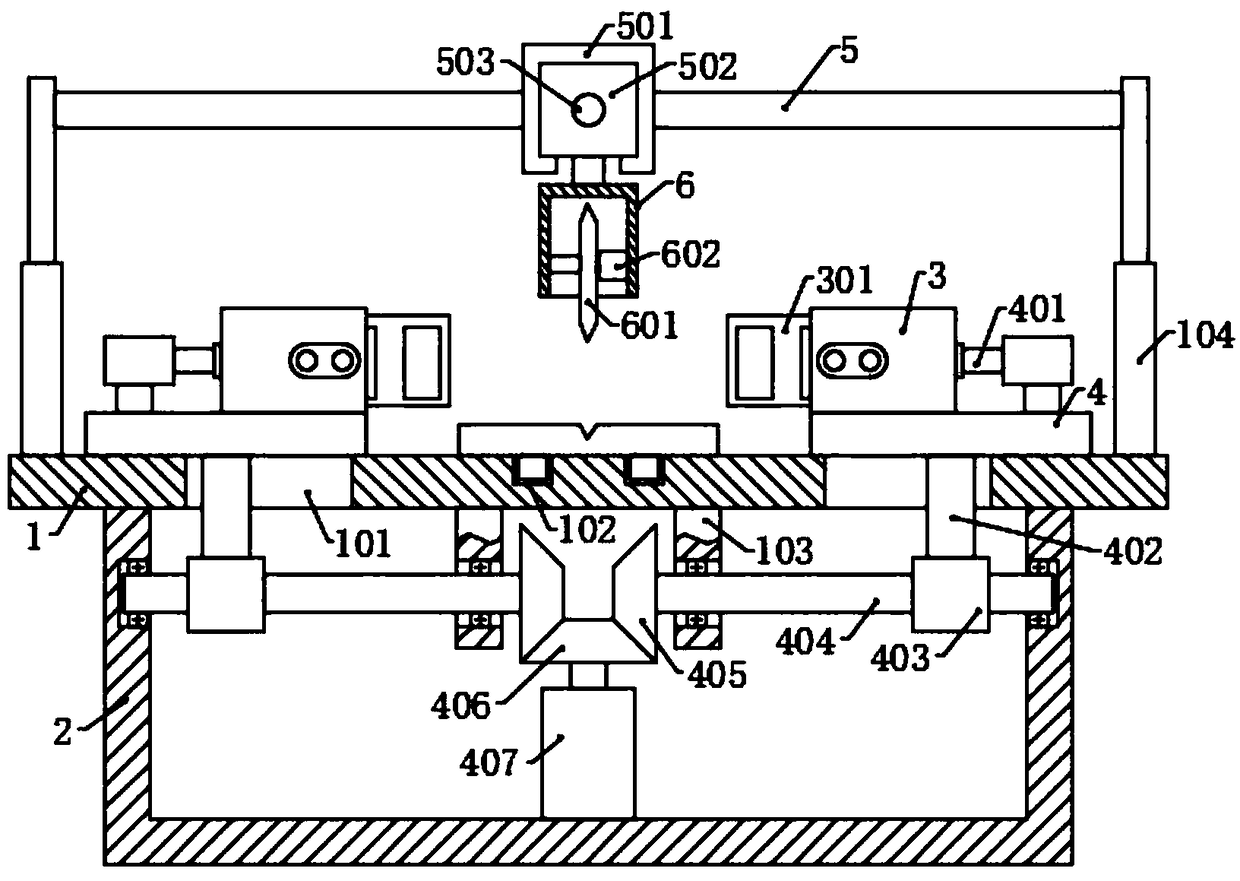

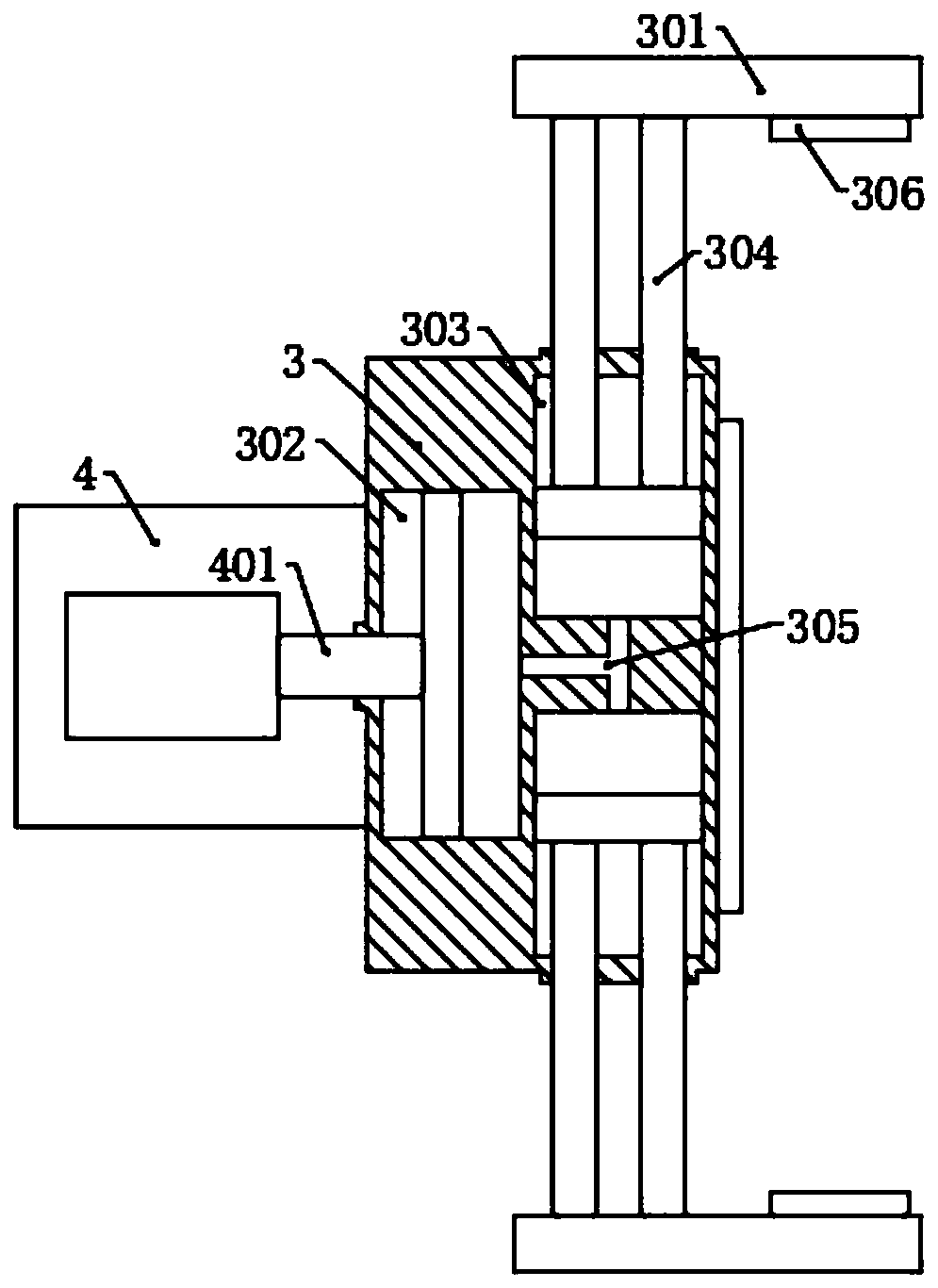

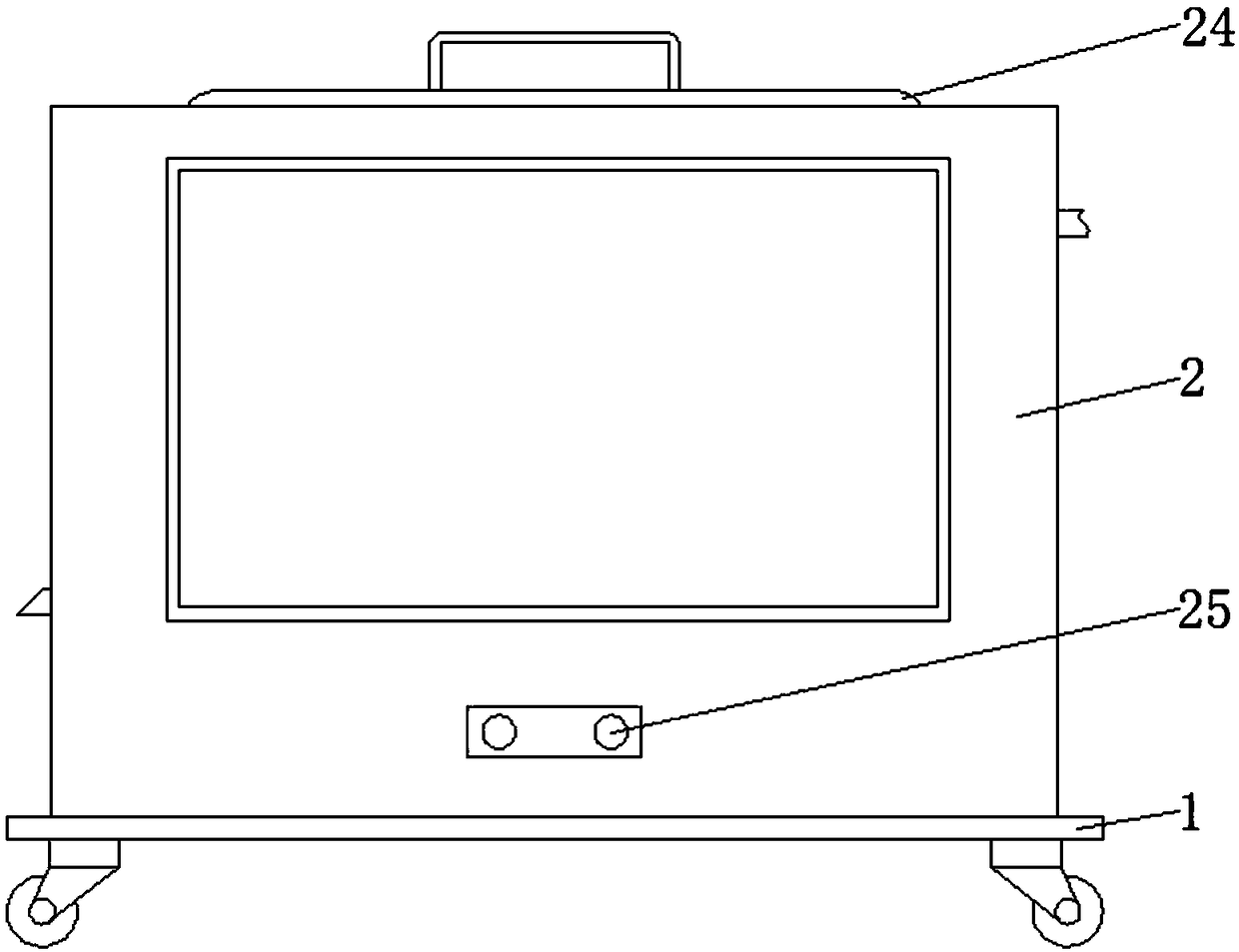

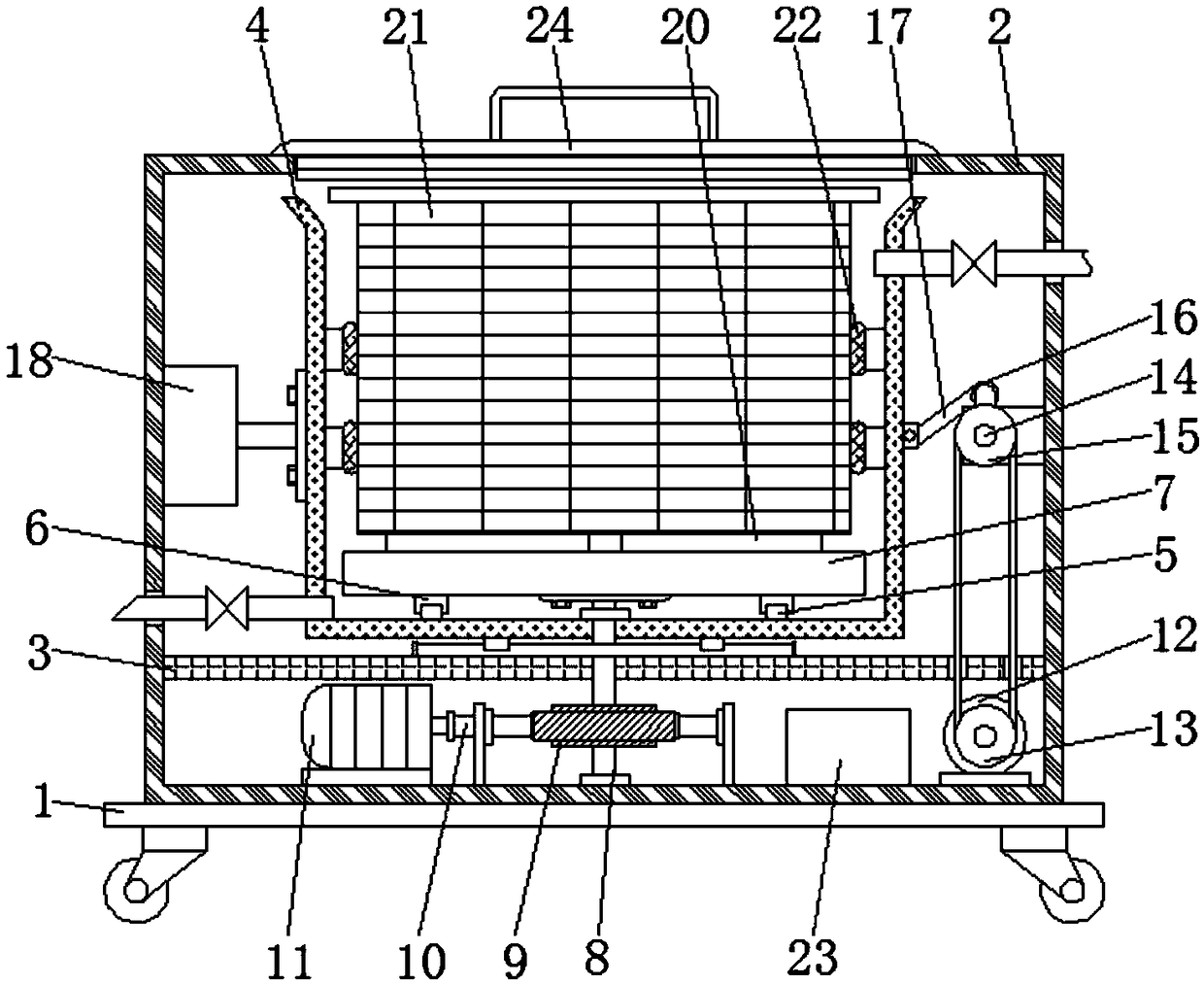

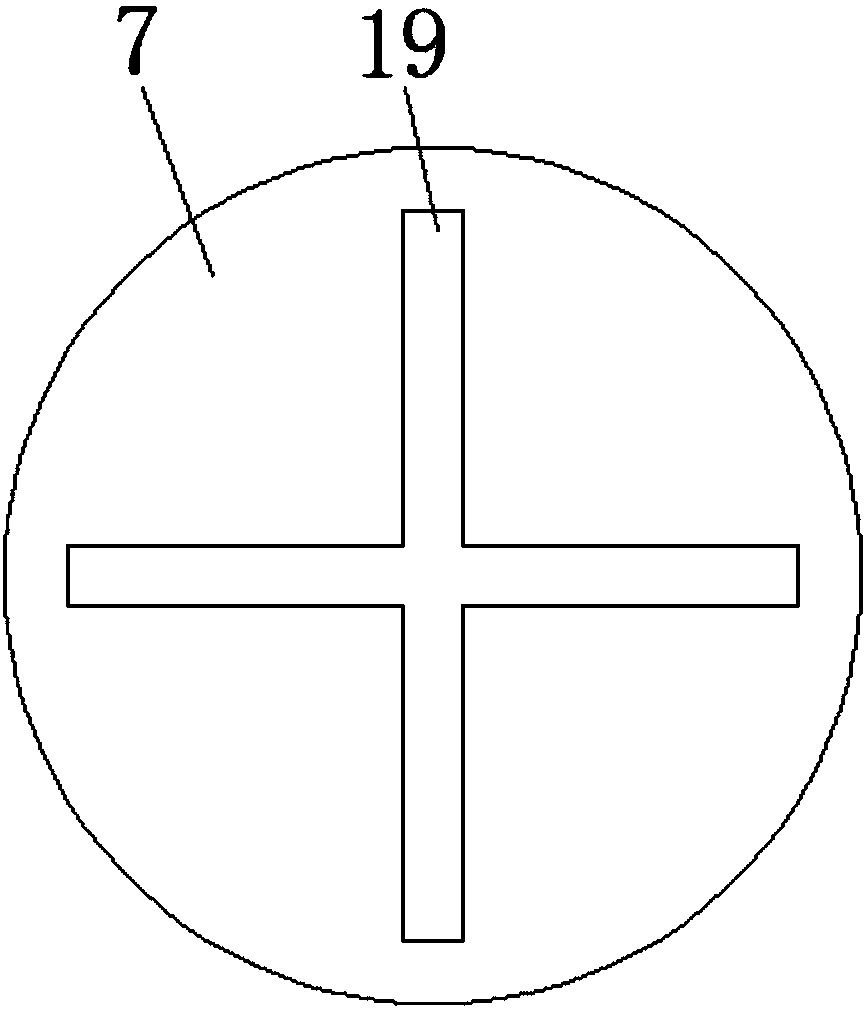

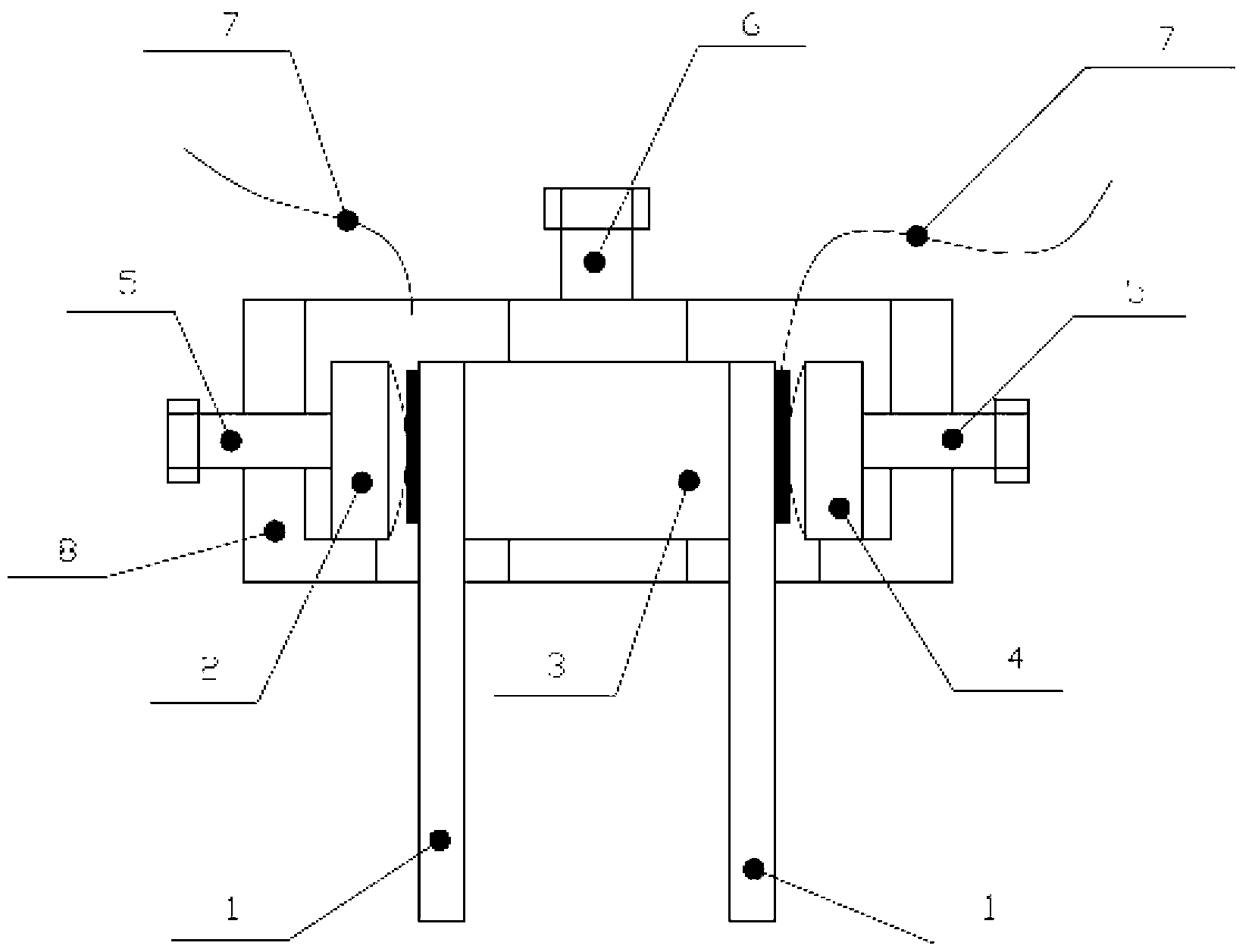

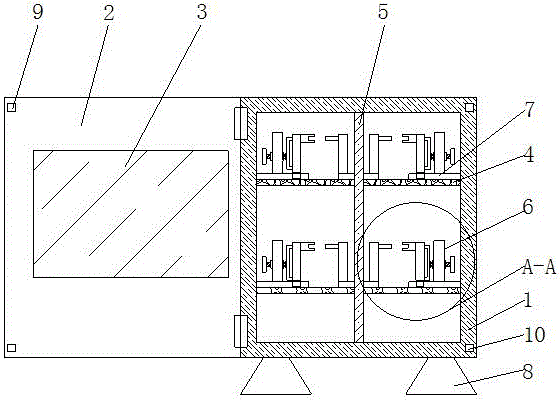

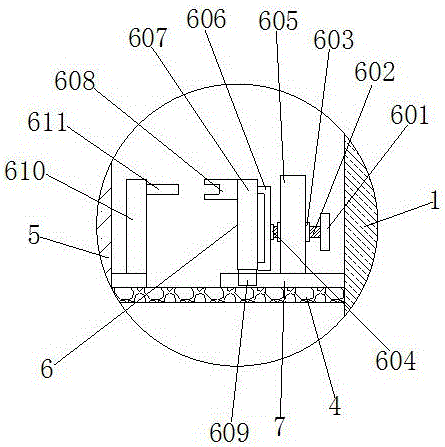

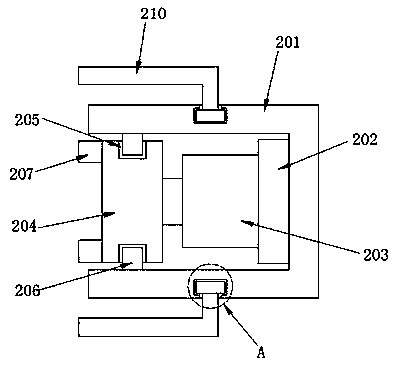

Nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding

InactiveCN107336086AImprove surface qualityDifferent grinding effectsUltrasonic vibrationLubrication

The invention discloses a nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding. The system comprises a magnetism worktable, a workpiece clamp, a measuring cell and an ultrasonic vibration device; the ultrasonic vibration device comprises a tangential ultrasonic vibration device, an axial ultrasonic vibration device, a vibrating base and radial piezoelectric ceramic pieces fixed on the vibrating base; the tangential ultrasonic vibration device and the axial ultrasonic vibration device are respectively fixed on the vibrating base and meanwhile, are respectively fixed on the magnetism worktable by supports, the measuring cell is fixed on the vibrating base and the workpiece clamp is fixed on the measuring cell. The nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding have the advantages that simultaneous online detection of a grinding force and a grinding temperature are realized, time is saved, and the machining errors caused by assembling for multiple times are also avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

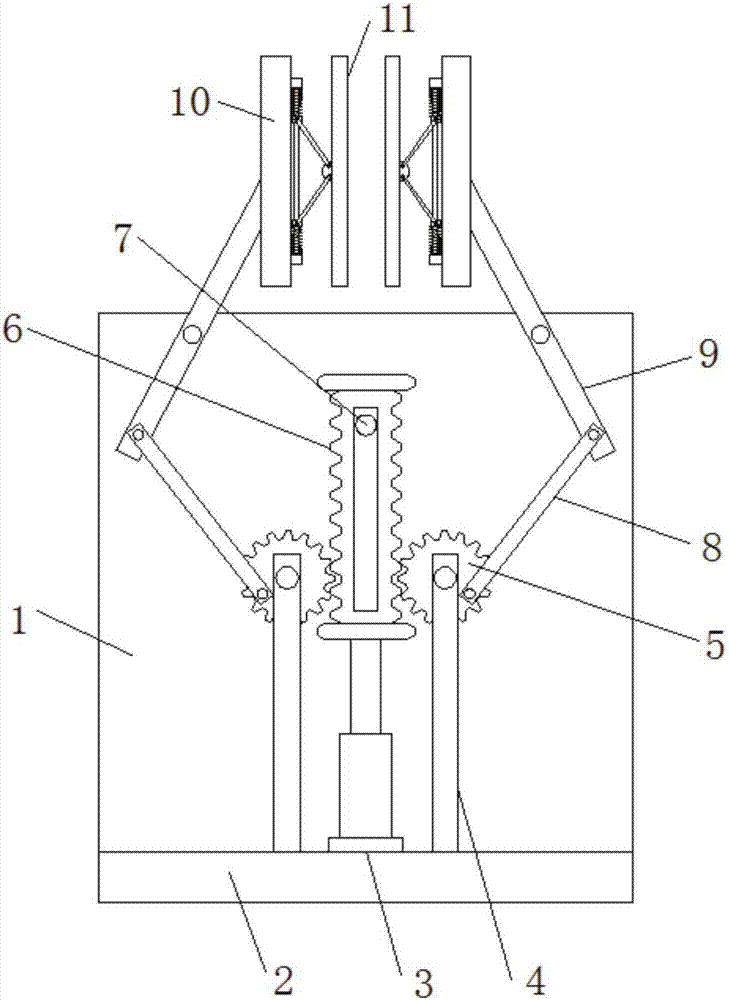

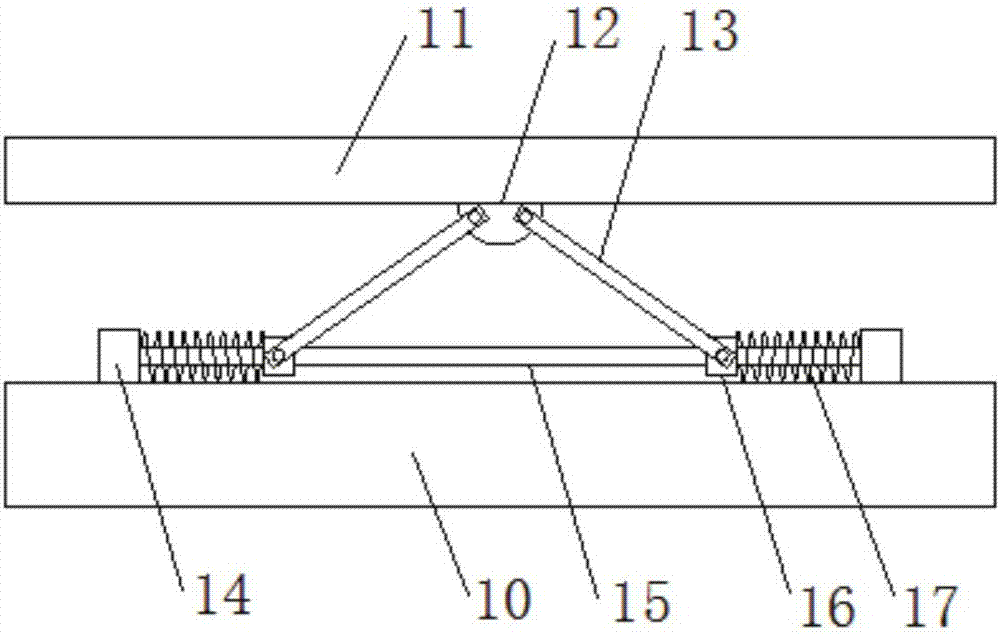

Special numerical control machine tool short shaft part auxiliary clamp

PendingCN107470954AEasy to clamp and fixEasy to adjust the interval widthPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a special auxiliary fixture for short-axis parts of a numerical control machine tool, which comprises a fixed plate, a vertical support plate is arranged on one side of the top of the fixed plate, and a side of the support plate close to the fixed plate is respectively fixedly installed with Horizontally arranged cylinder and limit plate, wherein the limit plate is located on both sides of the cylinder, one end of the limit plate is rotated and installed with a gear, and a rack on the same level as the cylinder is arranged between the two gears, and the edge of the gear A movable rod is connected for rotation, and one end of the movable rod is connected with a swing rod for rotation, and the middle position of the swing rod is connected with the top of the fixed plate for rotation, one end of the swing rod is fixedly installed with a splint, and the two splints are arranged on the side close to each other. There is a buffer plate parallel to the splint, and a buffer mechanism is arranged between the buffer plate and the splint. The invention has a reasonable design, is convenient for clamping and fixing short-axis parts of different sizes, relieves the vibration force received by the machine tool during the working process, and improves the machining accuracy.

Owner:JINGYIHENGZHUN TIANJIN CNC EQUIP CO LTD

Machine part drilling device

InactiveCN107999805AEasy to clamp and fixEasy to rinseWork clamping meansMetal working apparatusMachine partsBiochemical engineering

The invention belongs to the technical field of drilling equipment, and particularly discloses a machine part drilling device. The device comprises a rack, a guide rail is arranged on the rack, a supporting frame is arranged on the guide rail in a sliding connection manner, a cross beam connected with a telescopic device is arranged on the supporting frame, a motor is arranged on the telescopic device, a drill bit is arranged at the output end of the motor, and the device is characterized in that a transverse rod is arranged on the telescopic device, a first supporting rod and a second supporting rod are arranged on the transverse rod, and are hinged with a first clamp and a second clamp correspondingly, two opposite air cylinders are arranged in the middle of the rack, a clamping plate isarranged on piston rods of the air cylinders, and a first spraying head and a second spraying head connected with a water pipe are arranged in the middle of the first supporting rod and the middle ofthe second supporting rod. The device is mainly used for machine part drilling, and the problem that after drilling, sweeps easily remain in holes is solved.

Owner:宁波德深机械设备有限公司

Wire splitting device of winding machine

InactiveCN109775447ACompact structureUnified winding lengthFilament handlingWinding machineEngineering

The invention discloses a wire splitting device of a winding machine. The wire splitting device of the winding machine comprises a winding mechanism and a wire splitting mechanism. The wire splittingmechanism is arranged above the winding mechanism and is composed of a fixed base, a winding motor, a speed reducer, a first belt wheel, a first supporting column, a second supporting column, a firstrotary shaft, a second belt wheel, a second rotary shaft, a third belt wheel, a meter counter, a controller, a winding roller and a first transmission belt. The wire splitting device of the winding machine is compact in structure; the winding mechanism and the meter counter are arranged, and the winding length can be measured and calculated through the meter counter, so that the winding lengths are kept uniform; the wire splitting mechanism is arranged, a wire can be sorted automatically through a wire guide hole under the effect of a reciprocating lead screw, and the situation that the wire is knotted and disordered in the winding process is prevented; and the wire can be clamped and fixed through a clamping cylinder; and the wire is cut to be split through a cutting blade, so that strength is saved, and the labor intensity of workers is relieved.

Owner:南安市瑞创科技有限公司

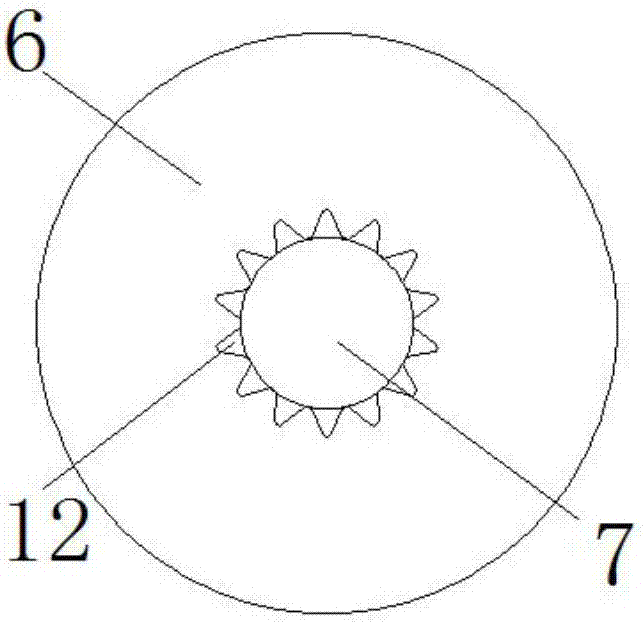

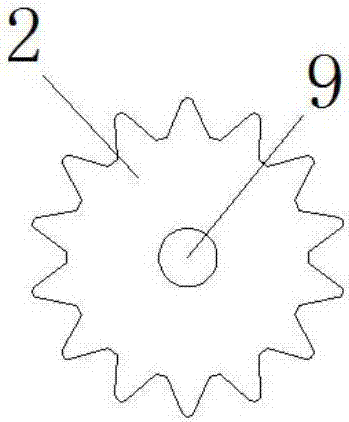

Shaft sleeve continuous vertical lifting mechanism

InactiveCN108861542AAdjust reciprocating rangeAvoid inertia shockLifting framesConveyor partsMechanical equipmentSprocket

The invention discloses a shaft sleeve continuous vertical lifting mechanism, and belongs to the field of workpiece machining mechanical equipment. The shaft sleeve continuous vertical lifting mechanism comprises a fixing bracket, a shaft sleeve transferring mechanism and a lifting mechanism. Buffers are fixedly arranged on the fixing bracket on both ends of one side of a swinging cylinder separately, and the buffers are arranged vertically upwards. A shaft sleeve receiving connection plate is horizontally and fixedly arranged on one side of a translation bracket, rotating sprockets are connected to the upper and lower sides of a lifting bracket, and the upper and lower sides of a lifting chain separately mesh with the rotating sprockets in a winding mode. A lifting guide plate is slidablyarranged on a lifting guide rod in the vertical direction, limiting switches are separately arranged on the lifting bracket on the upper and lower sides of a limiting connecting plate, and a shaft sleeve clamping mechanism is horizontally arranged on one side of the lifting guide plate. The shaft sleeve continuous vertical lifting mechanism is reasonable in structural design, can clamp and fix shaft sleeves of various sizes and specifications conveniently and firmly, and can vertically lift the shaft sleeves more stably and efficiently so that the shaft sleeves can be transferred to requiredworking positions, the automation degree of shaft sleeve transferring is improved, and the needs of processing and use are met.

Owner:晋正正

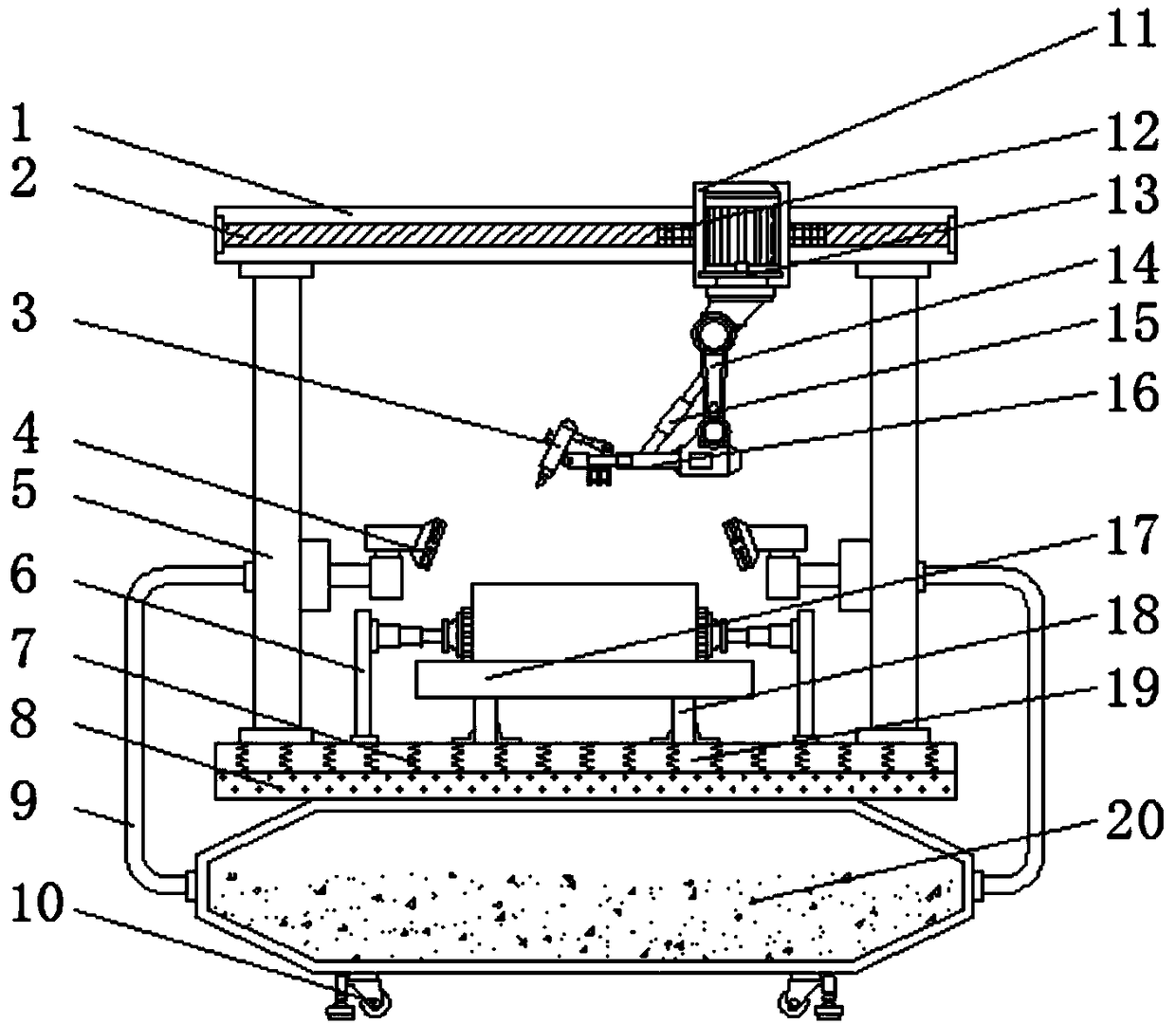

Intelligent welding robot

InactiveCN109015675AImprove adsorption capacityEasy to disassembleWelding/cutting auxillary devicesAuxillary welding devicesIdler-wheelWelding process

The invention discloses an intelligent welding robot which comprises a top plate, stand columns, a supporting base and a tank; a door body is installed on one side of the tank through hinge shafts; acontrol panel is installed at the end, away from the hinges, of the door body; a handle is installed on the side, away from the hinge shafts, of the control panel; idler wheels are installed at four corners of the bottom end of the tank; a supporting seat is welded to the top end of the tank; the stand columns are vertically installed at the two ends of the top of the supporting base; the top plate is installed at the top ends of the stand columns transversely; an electromagnetic sliding rail is arranged inside the top plate; a shell is installed on the electromagnetic sliding rail through a sliding block; and a motor is installed inside the shell. According to the intelligent welding robot, through installation of supporting rods, a hydraulic telescopic rod and clamping plates, products can be clamped and fixed conveniently before the robot performs welding, and the phenomenon that offset occurs in the welding process and consequently the product welding quality is affected is avoided.

Owner:合肥阅辞科技有限公司

Cargo transportation device

InactiveCN108569464AEasy loading and unloadingEasy to clamp and fixDischarging meansRigid containersEngineeringMechanical engineering

The invention discloses a cargo transportation device which comprises a box body, wherein first grooves are formed in the left and right inside walls of the box body, connecting blocks are slidably connected in the first grooves; a placing plate is fixedly connected between the two connecting blocks; a threaded hole penetrating up and down is formed in each connecting block; a threaded rod is in threaded connection in the threaded hole; two ends of the threaded rod are rotatably connected to the upper and lower side walls of each first groove separately; a worm wheel is coaxially and fixedly connected to each threaded rod; a second groove is formed in the side wall of each first groove; a worm engaged to the worm wheel is arranged in each second groove; one end of the worm is rotatably connected to the side wall of each second groove; the other end of the worm runs through the box body; the two worms are in transmission connection through a transmission mechanism; supporting blocks arefixedly connected to four corners of the lower end of the placing plate; openings matched with the supporting blocks are formed in the bottom surface of the box body; and third grooves are formed inthe lower end surfaces of the supporting blocks. The cargo transportation device disclosed by the invention is low in operating difficulty and can be helpful for workers to improve the work efficiency.

Owner:惠安县文雕石业有限公司

Forging press used for metal machining

InactiveCN107999676AEasy to clamp and fixAvoid affecting the effect of processingUpsetting pressesSwagging pressesMetal machiningEngineering

The invention discloses a forging press used for metal machining, and relates to the technical field of metal forging. The forging press used for metal machining comprises a base plate. Fixed columnsare fixedly connected to the two sides of the top of the base plate correspondingly, and a workbench is movably connected to the surfaces of the two fixed columns. A vertical plate is fixedly connected to the left side of the top of the workbench. A lead screw is rotatably connected to the right side of the vertical plate. Movable blocks are connected to the two sides of the surface of the lead screw in a threaded mode, and clamping plates are fixedly connected to the surfaces of the movable blocks. A transverse plate is fixedly connected to the top ends of the fixed columns. A moving device is fixedly connected to the top of the transverse plate. According to the forging press for metal machining, a workpiece can be clamped and fixed conveniently, the situation that the machining effect is affected due to deviation of the workpiece in the machining process is avoided, and the safety in the machining process is improved; and the position of a forging device can be changed convenientlyso that different positions of the workpiece can be forged, the operating mode is flexible, manual operation is facilitated, and working efficiency is improved.

Owner:王传忠

All-terrain vehicle storage battery heat dissipation mounting box

InactiveCN107946498AAchieve the purpose of integrationImprove stabilitySecondary cellsElectric connector introductionOperations managementElectric wire

The invention discloses an all-terrain vehicle storage battery heat dissipation mounting box. The all-terrain vehicle storage battery heat dissipation mounting box comprises an outer frame; a heat dissipation plate is fixedly connected between the two sides of the inner wall of the outer frame; the two sides of the top of the heat dissipation plate are fixedly connected with inner frames respectively; the bottom of the inner wall of each inner frame is glidingly connected with a damping apparatus; the top of each damping apparatus is fixedly connected with a buffer plate; the top of each buffer plate is fixedly connected with a storage battery; and fixed apparatuses are fixedly connected between the two sides of the inner walls of the inner frames. The invention relates to the technical field of the all-terrain vehicle. By virtue of the all-terrain vehicle storage battery heat dissipation mounting box, the storage battery can be clamped and fixed conveniently; and in the use process ofthe all-terrain vehicle, collision and damage of the storage battery can be prevented, normal driving of the all-terrain vehicle is ensured, damage of the storage battery due to overheat can be prevented, the normal temperature of the storage battery is maintained, the service life of the storage battery is prolonged, disorder arrangement of electric wires is avoided, the wires can be arranged more tidily, mutual tangling of the electric wires can be avoided, and wiring stability is improved.

Owner:NINGBO CHAORUITE IND & TRADE CO LTD

Panel welding clamping device convenient to adjust

InactiveCN108637565APrecision weldingEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a panel welding clamping device convenient to adjust. The panel welding clamping device convenient to adjust comprises fixing bases, containing plates, pressing plates, side edge sliding grooves and connecting sliding grooves. The upper portions of the fixing bases are in penetrating connection with first threaded rods. A bearing table is fixed to the upper portion of a base. The containing plates are fixed to the lower portions of the inner side walls of the fixing bases. The upper portions of the containing plates are connected with bottom sliding blocks fixed to thebottoms of side clamping plates. The pressing plates are arranged above the side clamping plates. Connecting springs are arranged below the pressing plates. Surface sliding grooves are reserved in theupper surfaces of the containing plates, and the side edge sliding grooves are formed in the inner side walls of the fixing bases. The connecting sliding grooves are formed in the upper surface of the base, and limiting holes are reserved in the base. According to the panel welding clamping device convenient to adjust, the upper end faces of the bearing table, a supporting table and the containing plates are located at the same horizontal line position, and therefore panels can be well supported when placed on the device; and the situation of unevenness is avoided, and welding between the panels becomes more accurate.

Owner:ANHUI ORIGINAL POWER PRODUCTIVITY PROMOTION CENT CO LTD

Stamping drilling device for production of automobile parts

InactiveCN108544269AAchieve clamping and fixingRealize stamping drillingLarge fixed membersPositioning apparatusMachiningDriving mode

The invention discloses a stamping drilling device for production of automobile parts. The stamping drilling device for production of automobile parts comprises a supporting bottom case, lifting sliding blocks, vertical rails, horizontal rails, workpiece grooves, a drill, a lifting plate, a forward and reverse rotating motor and a screw rod. Supporting posts are fixedly erected on the tops of thetwo ends of the supporting bottom case in a welded mode, clamping mechanisms for clamping and fixing automobile parts are arranged on the two supporting posts correspondingly, supporting vertical plates are symmetrically and fixedly arranged at the top end of the middle of the supporting bottom case, and the lifting plate is arranged between the two supporting vertical plates in a vertical slidingmode. The screw rod is installed in the middle of the lifting plate in a threaded connection mode, the forward and reverse rotating motor for driving the screw rod to rotate is fixedly installed at the top end of the middle of the supporting bottom case, a drilling motor is erected on the lifting plate in a fixedly connected mode, and the top end of an output shaft of the drilling motor is connected with the drill in a driving mode. The stamping drilling device for production of automobile parts facilitates clamping and fixing of automobile parts, is beneficial to drilling machining of automobile parts, and greatly reduces the manual labor intensity.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

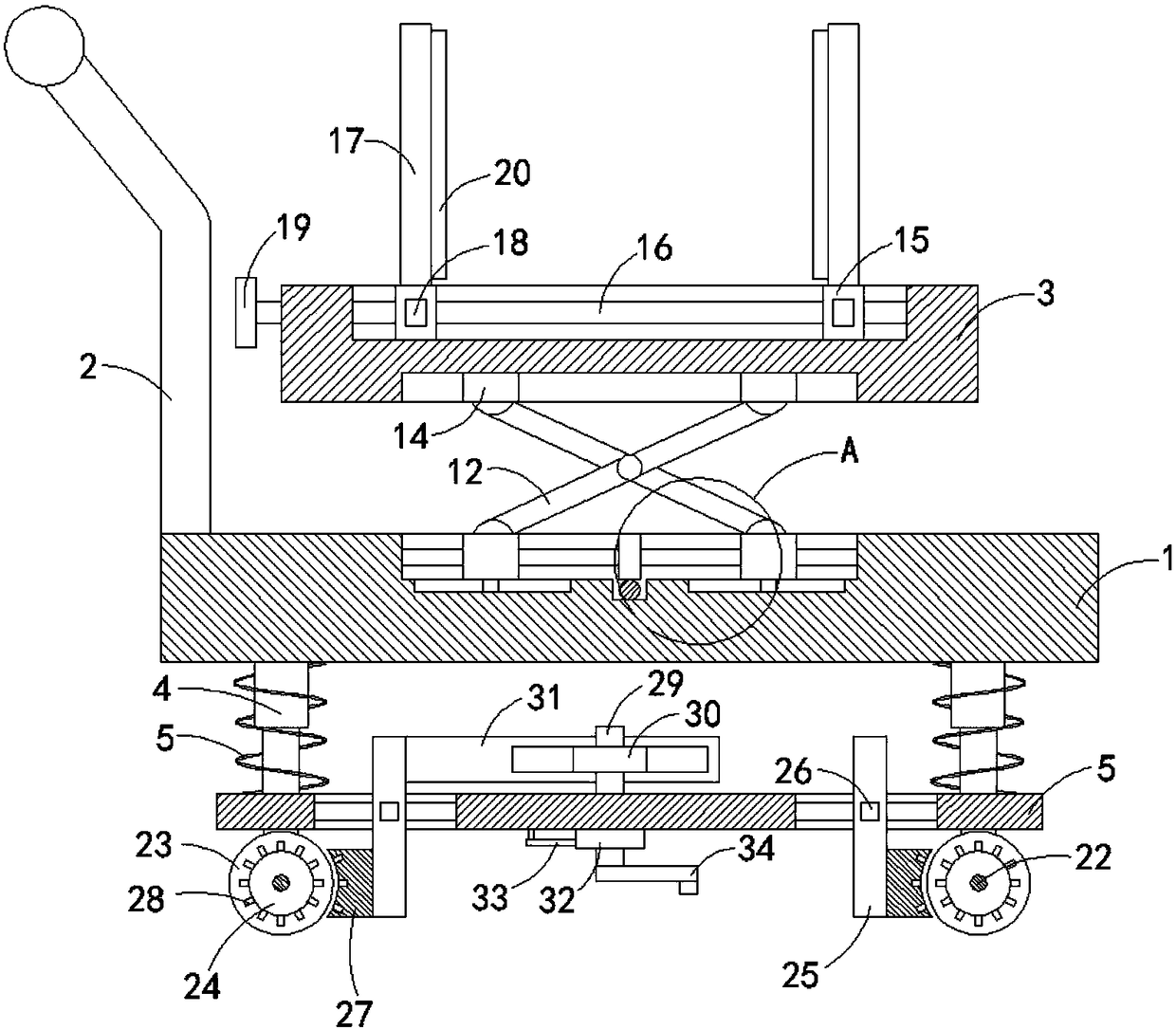

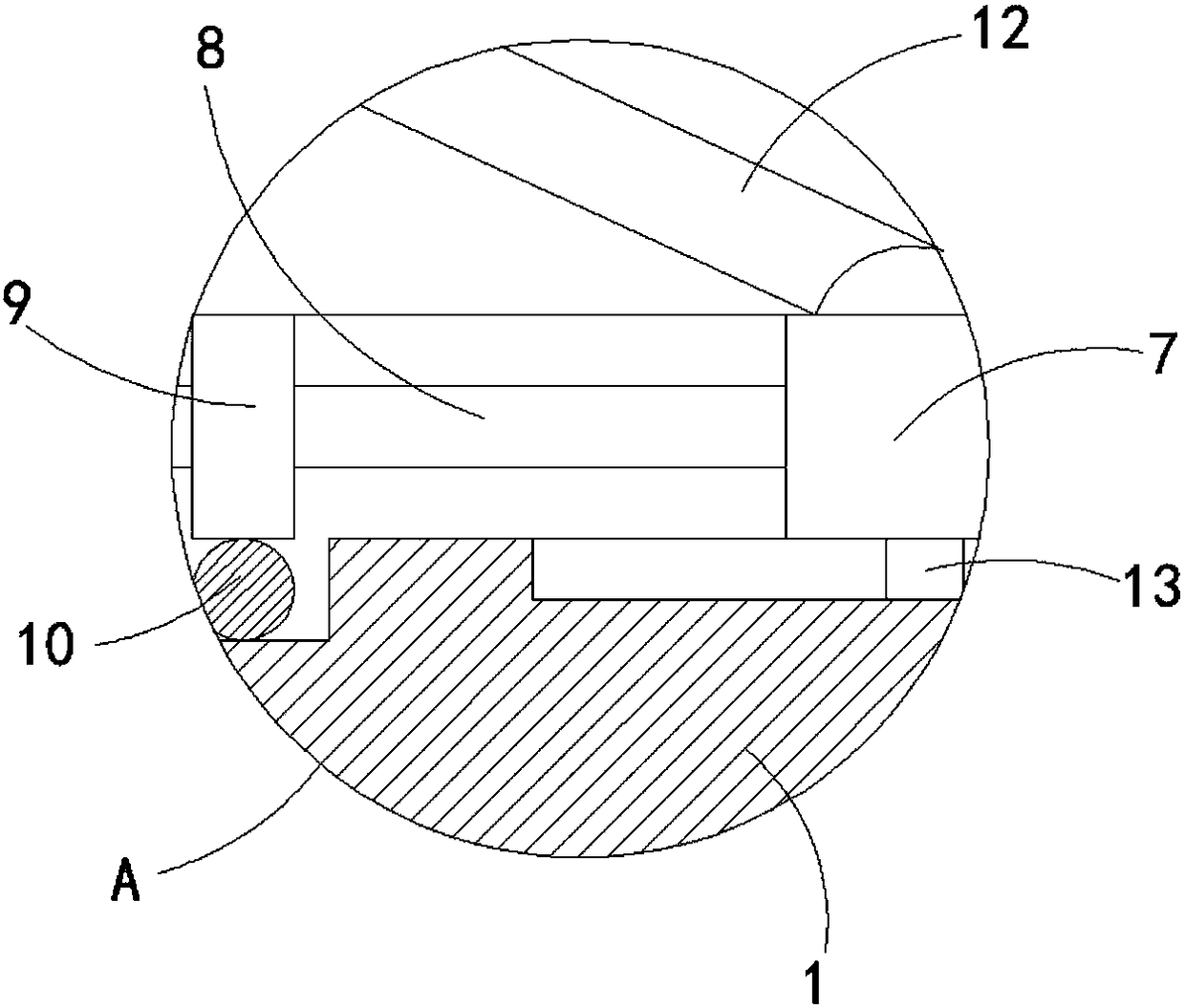

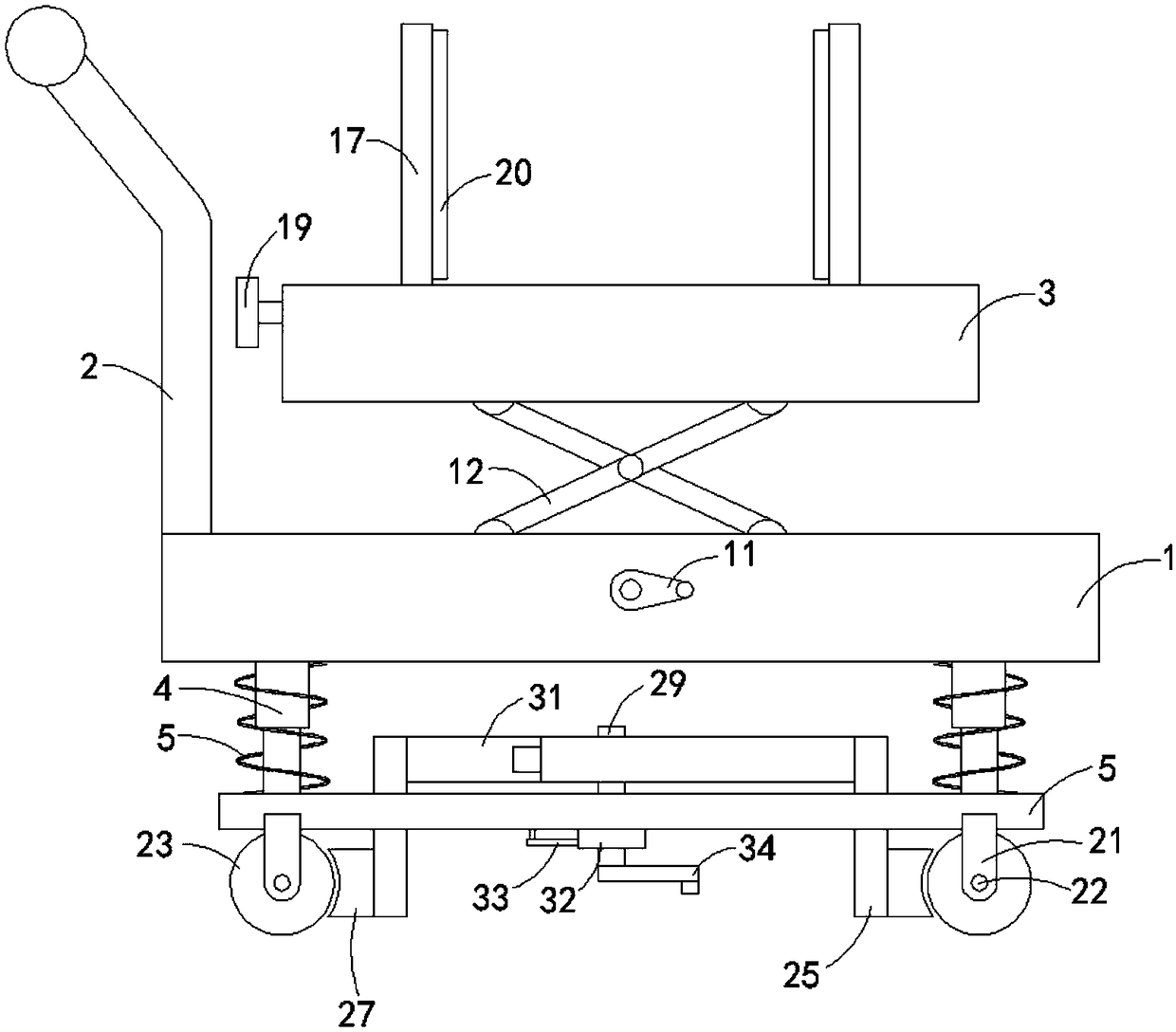

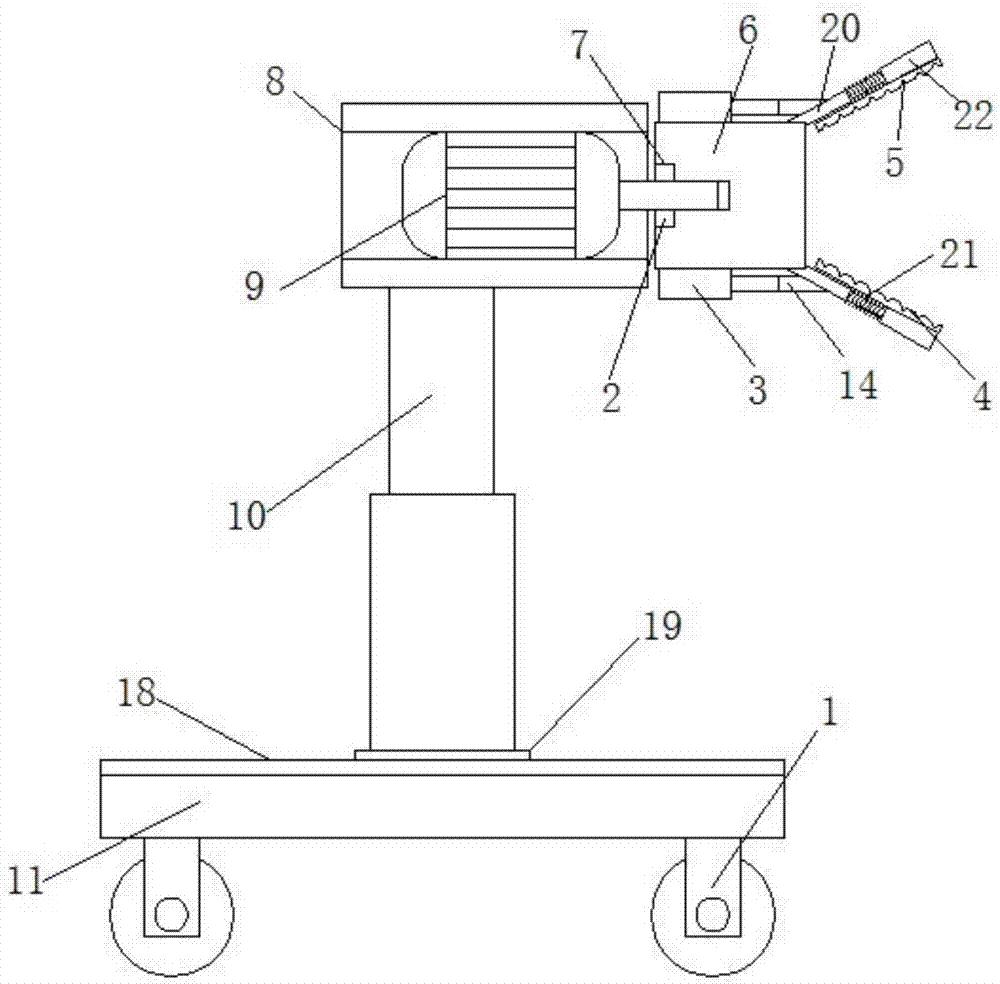

Power equipment transporting vehicle convenient to load and unload

InactiveCN108545104AReduce height differenceEasy to carrySupporting partsHand carts with multiple axesHeight differencePower equipment

The invention belongs to the technical field of power equipment and in particular relates to a power equipment transporting vehicle convenient to load and unload. The power equipment transporting vehicle convenient to load and unload comprises a base; a handrail is fixedly connected to the upper end of the base; a lifting plate is arranged at the upper end of the base; a lifting mechanism is arranged between the lifting plate and the base; a clamping mechanism is arranged at the upper end of the lifting plate; telescopic rods are fixedly connected to the four corners of the lower end of the base; a same mounting plate is fixedly connected to the lower ends of the multiple telescopic rods; springs sleeving the telescopic rods; the two ends of the spring are fixedly connected with the base and the mounting plate; and running mechanisms are arranged on the two sides of the lower end of the mounting plate. The power equipment transporting vehicle convenient to load and unload has the advantages that the height difference between the power equipment transporting vehicle and a large-sized transporting vehicle is reduced by using the lifting plate to be convenient for conveying and transferring power equipment; as the clamping plate is arranged, the power equipment is convenient to clamp and fix so that additional fixing tools such as ropes do not need to use; and the vehicle is simple and convenient.

Owner:STATE GRID CORP OF CHINA +1

Winding drum device

Owner:宁波希奇服饰有限公司

New energy resource automobile battery buffer support frame

The invention discloses a new energy resource automobile battery buffer support frame, which comprises a support plate, wherein a first slide sleeve is clamped and connected in each of positions nearfour corners of the upper surface of the support plate; a first slide rod is sleeved in each of the four first slide sleeves; the top ends of the four first slide rods are respectively and fixedly connected with the lower surface of two first connecting rods; a first spring is sleeved on the surface of each of four first springs; the two ends of the four first springs are respectively and fixedlyconnected with the support plate and the lower surface of the two first connecting rods. The new energy resource automobile battery buffer support frame has the advantages that through the arrangementof the support plate, the first springs, a threaded tube, a threaded post, a clamping plate, a bearing plate, second springs a connecting block and third springs, the first springs, the second springs and the third springs are used for buffering the force generated by the battery shaking; the vibration generated by the battery when an automobile runs on a road with poor road conditions can be effectively avoided, so that the damage can be avoided; the service life of the battery is guaranteed.

Owner:力量知识产权天津有限公司

Drilling device for building construction decorative board

InactiveCN108161078AAchieve clamping and fixingEasy to clamp and fixPositioning apparatusBoring/drilling componentsArchitectural engineeringScrew thread

The invention discloses a drilling device for a building construction decorative board. The drilling device comprises a base, a drilling platform, a collection box, a drill bit, a lead screw, movablesliding blocks, pull ropes, fixed sleeves, support seats and pressure plates. The outer peripheries of the two sides of the lead screw are correspondingly sleeved with the upper portions of the two movable sliding blocks through inner threaded through holes in a threaded manner. The fixed sleeves are fixedly arranged on the upper surfaces of the two ends of the drilling platform. A lifting slidingblock is arranged in an inner cavity of the upper portion of each fixed sleeve. A spring is fixedly arranged in an inner cavity in the lower portion of each fixed sleeve. The other ends of the pressure plates are fixedly mounted on the lifting sliding blocks. The support seats are correspondingly and fixedly arranged on the upper surfaces of the two ends of the drilling platform. The support seats are located under the ends of the pressure plates. One end of each pull rope is fixedly connected with the corresponding lifting sliding block, and the other ends of the pull ropes are fixedly connected with the movable sliding blocks. The drilling device is simple in structure, convenient and fast to operate, capable of clamping and fixing the decorative board conveniently, high in safety and suitable for application and popularization, and the drilling efficiency is improved.

Owner:长沙双合盛企业管理有限公司

Cutting device for mould production

ActiveCN108621309AEasy to clamp and fixAvoid situations such as movingShearing machinesWorking accessoriesEngineeringMechanical engineering

The invention discloses a cutting device for mould production in the technical field of mould production. The cutting device for mould production comprises a workbench, a supporting base and a cuttingmechanism; moving boards are symmetrically arranged on the workbench and provided with fixing blocks and electric pushing rods; and a first oil cavity and a second oil cavity are arranged in the fixing blocks. A first lead screw and a second lead screw drive the moving boards and the fixing blocks to move, so that the left side and the right side of a mould are fixed through the fixing blocks; the electric pushing rods drive a first piston to move, so that a second piston drives a piston rod and fixed boards to move through an oil guide pipe, the front side and the rear side of the mould arefixed through the fixed boards, the mould clamping and fixing effect is improved, and the situations like movement of the mould in the cutting process are avoided; and the fixing blocks on the two sides and the fixed boards on the two sides of the fixing blocks can move towards the middle at the same time, so that the mould is located in the middle of the top face of the workbench all the time andis aligned with a cutter in position, and the cutting precision is improved.

Owner:HEFEI DINGXIN MOLD

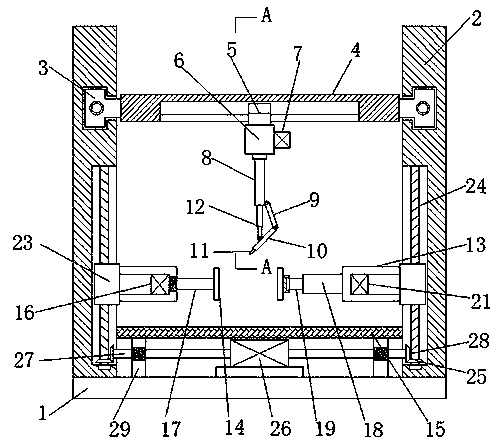

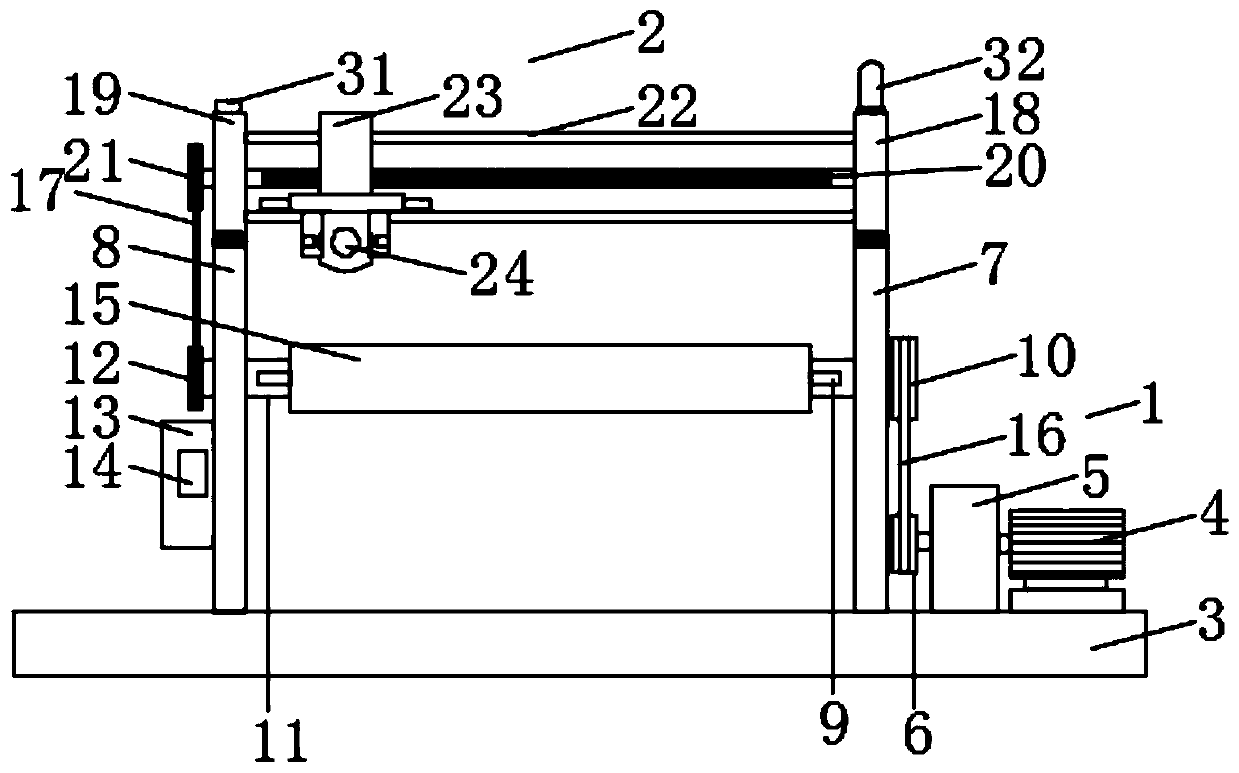

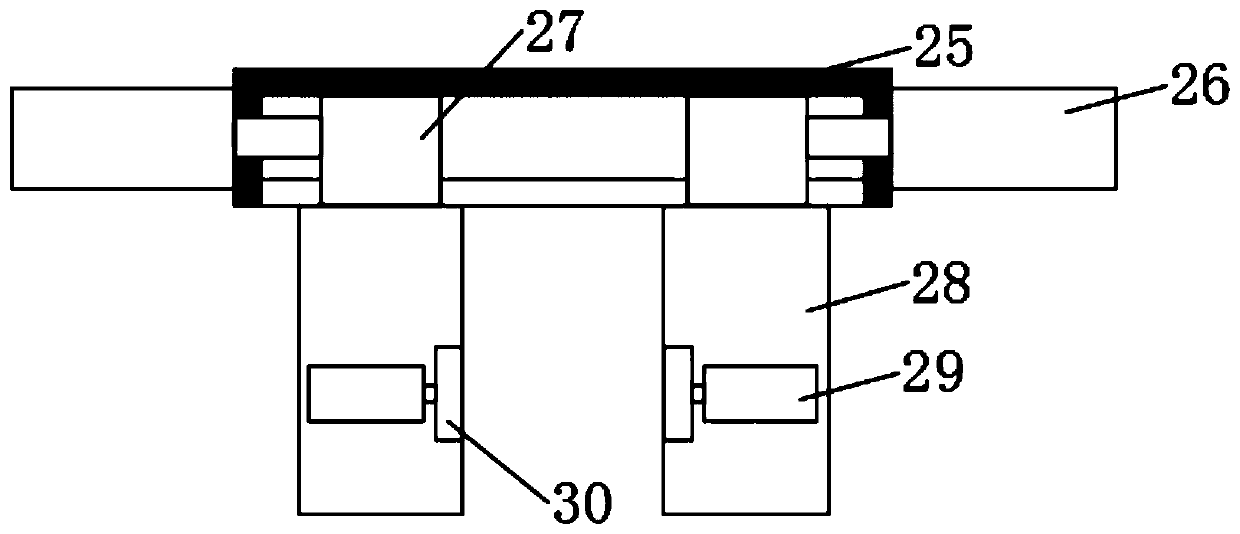

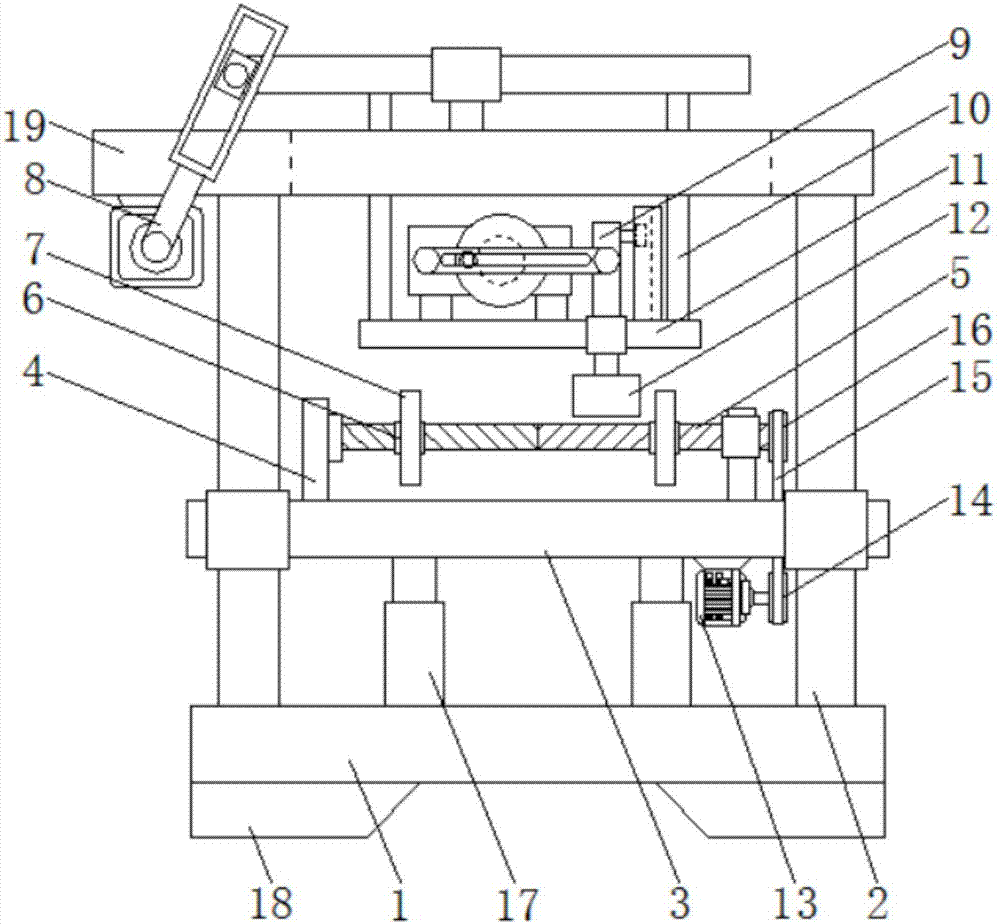

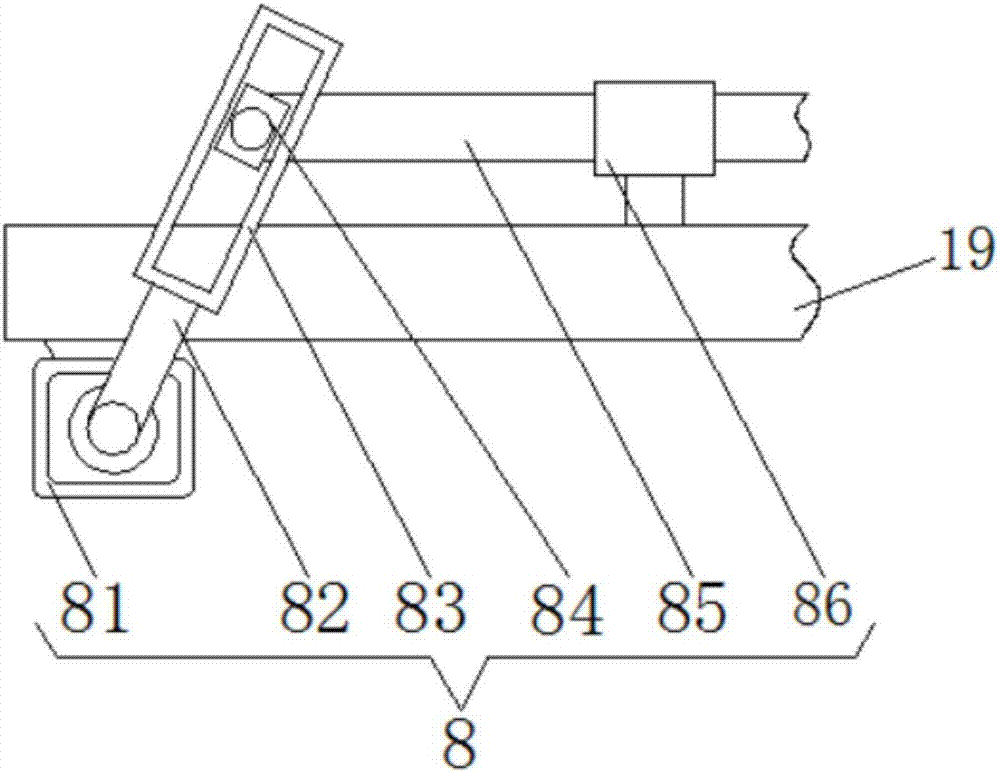

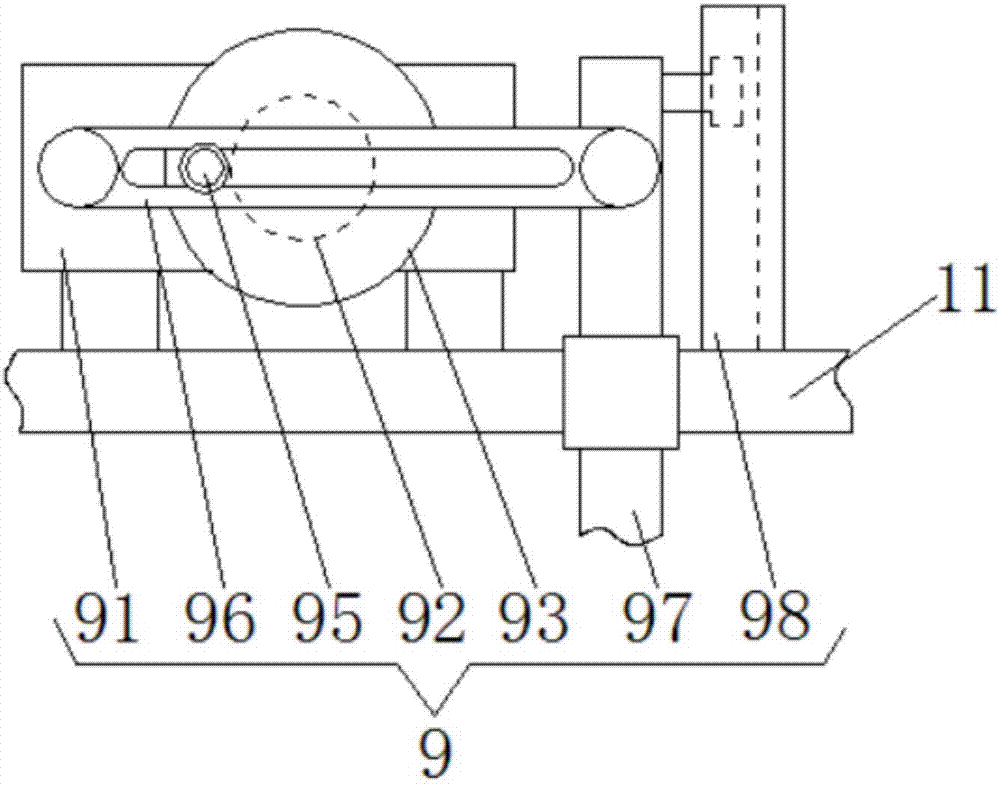

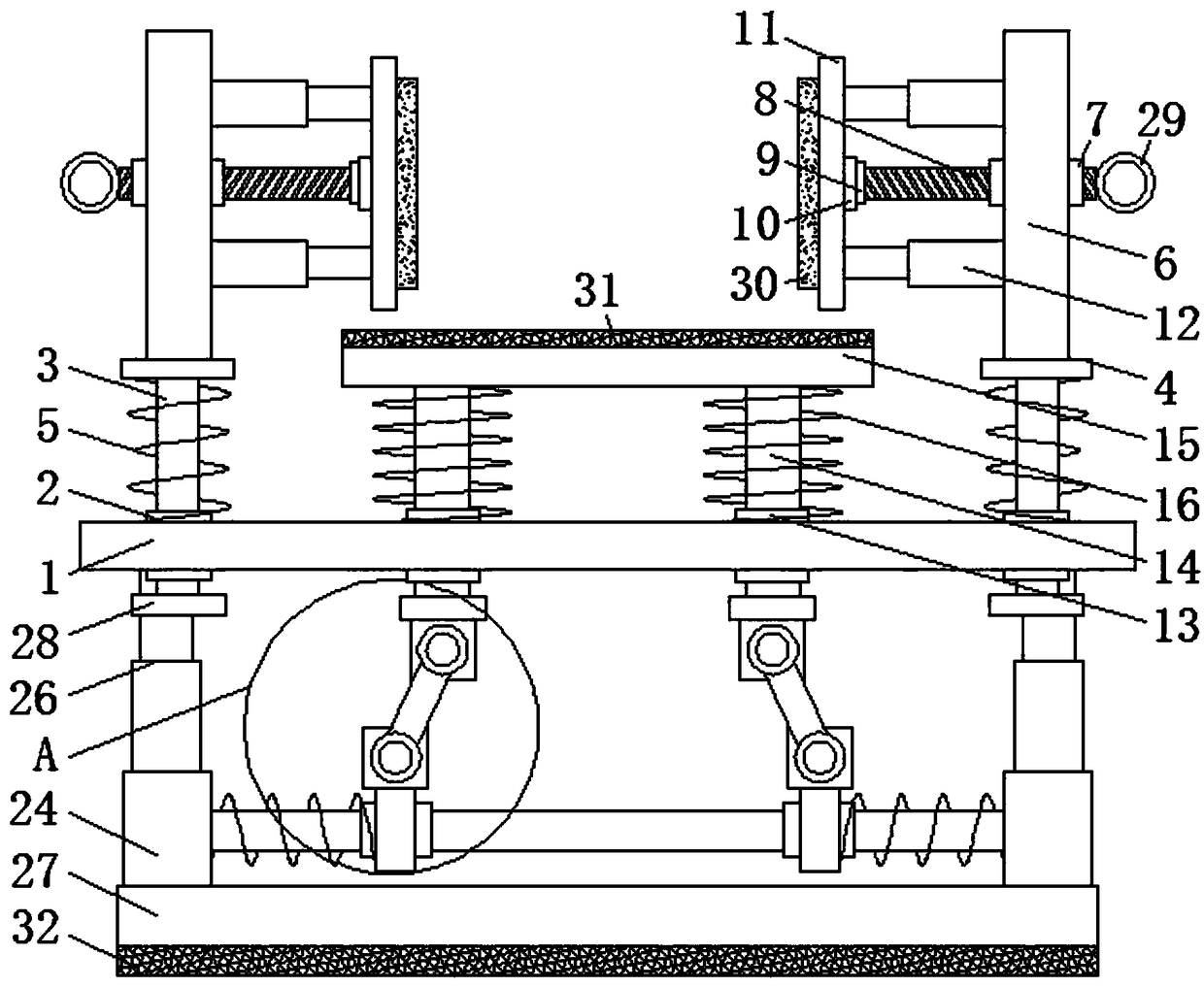

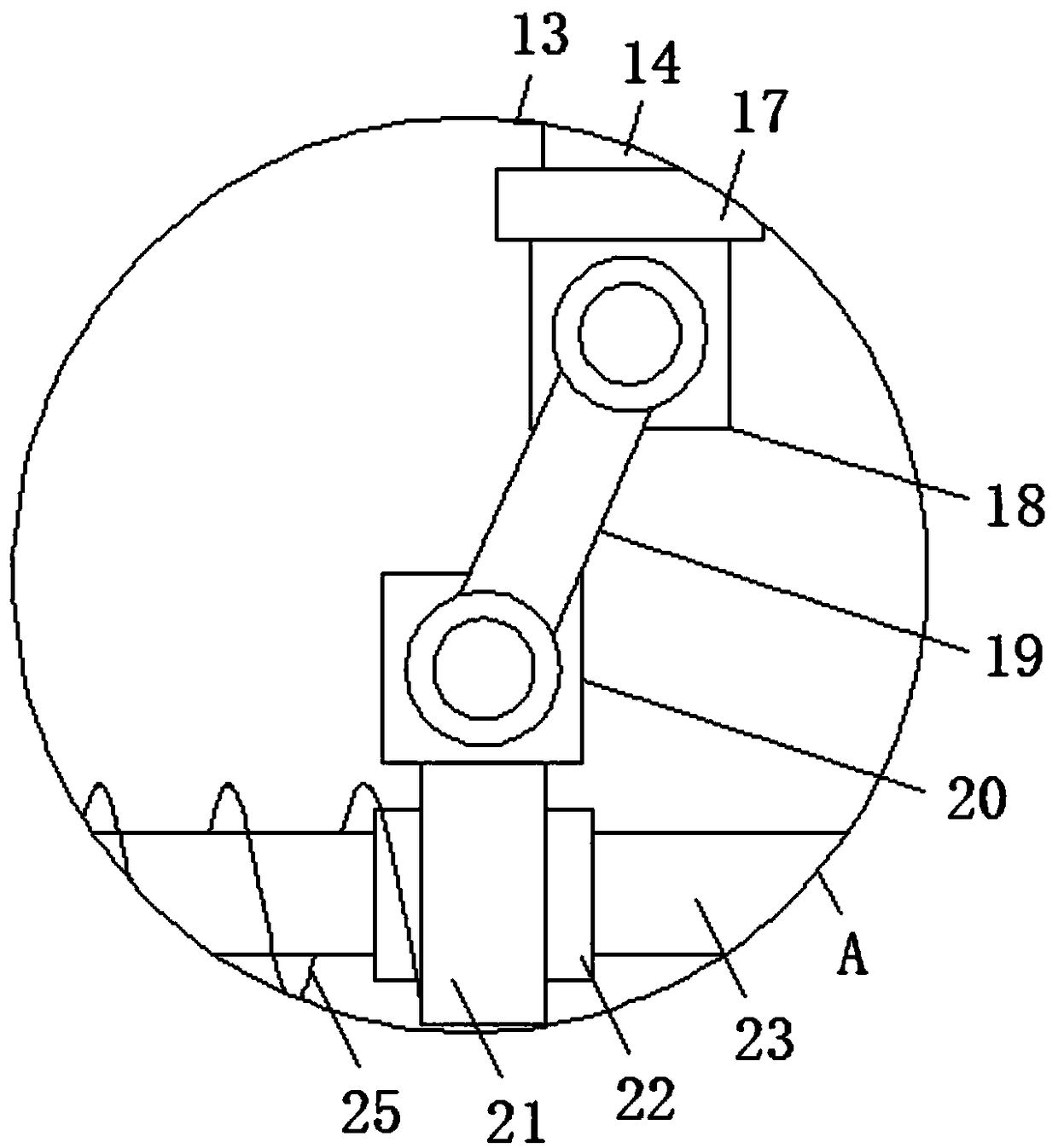

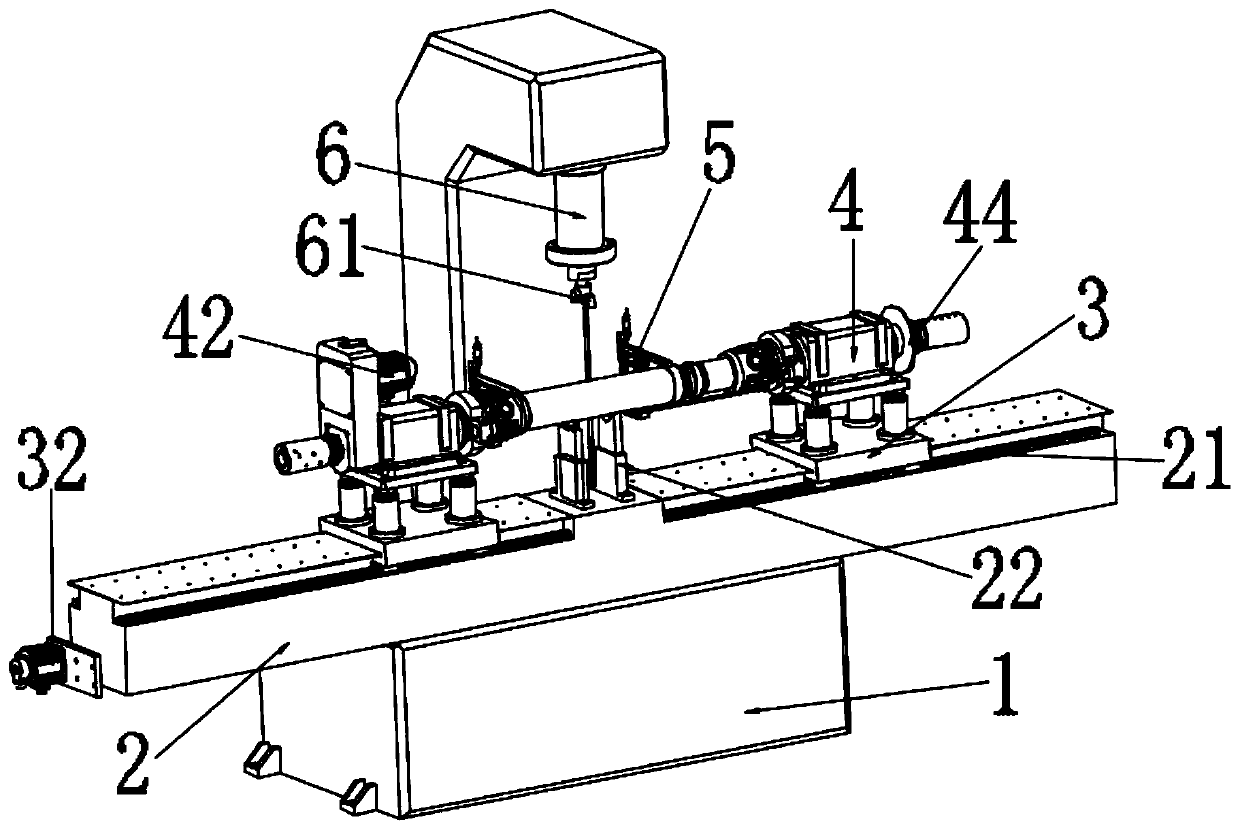

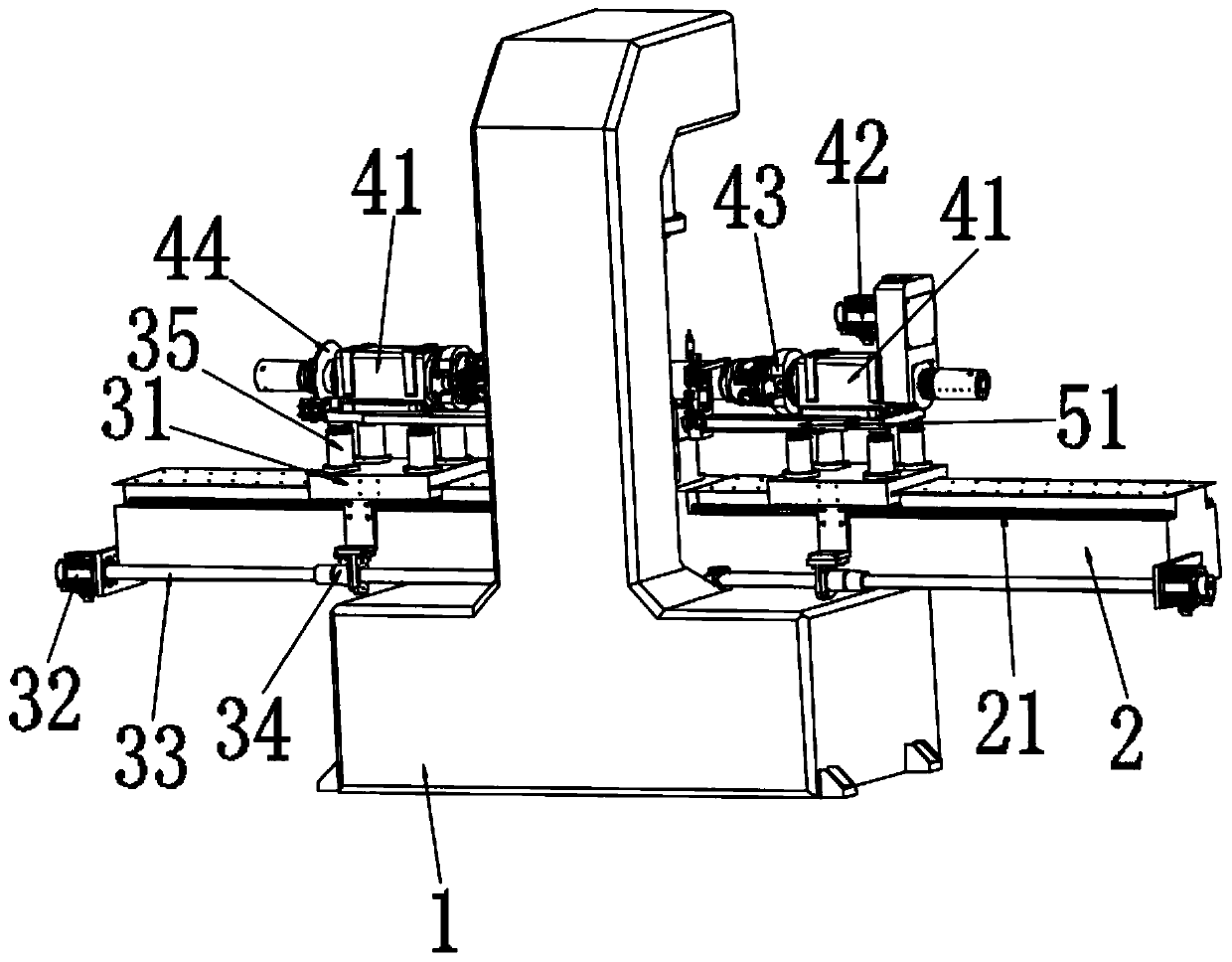

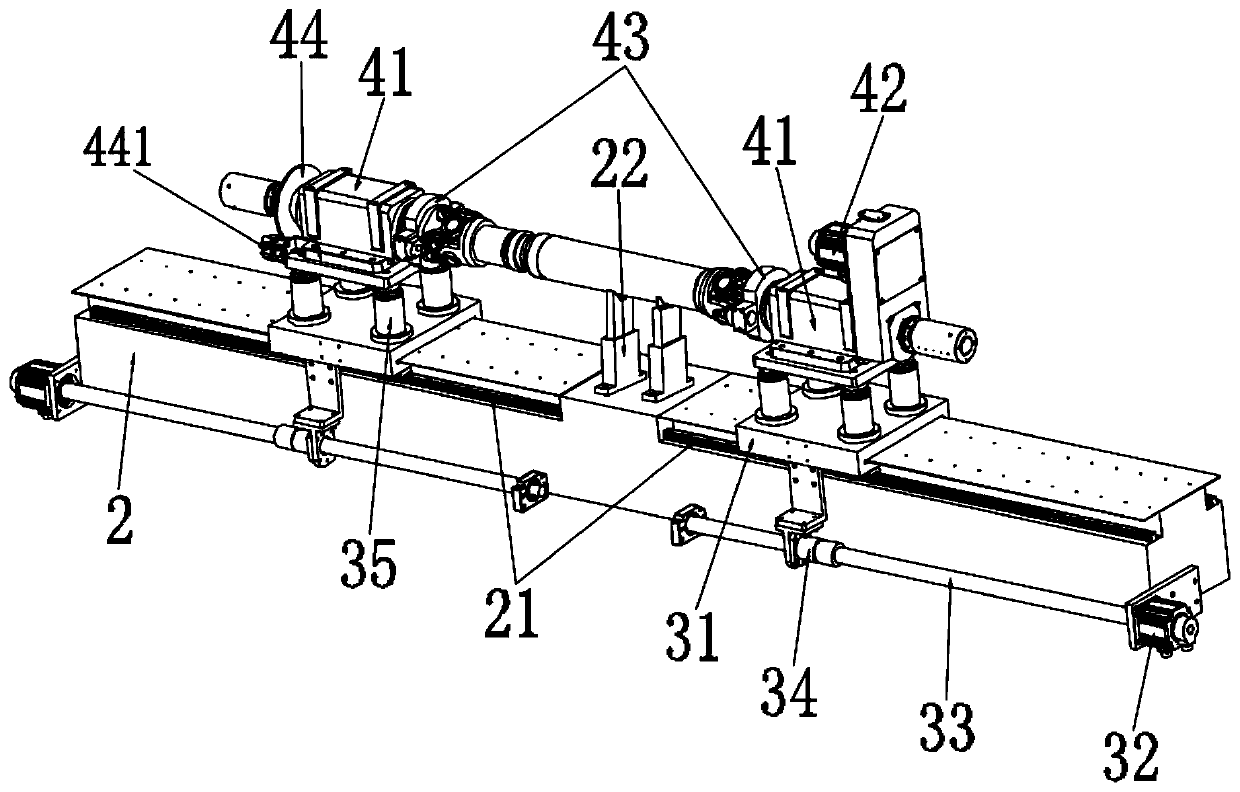

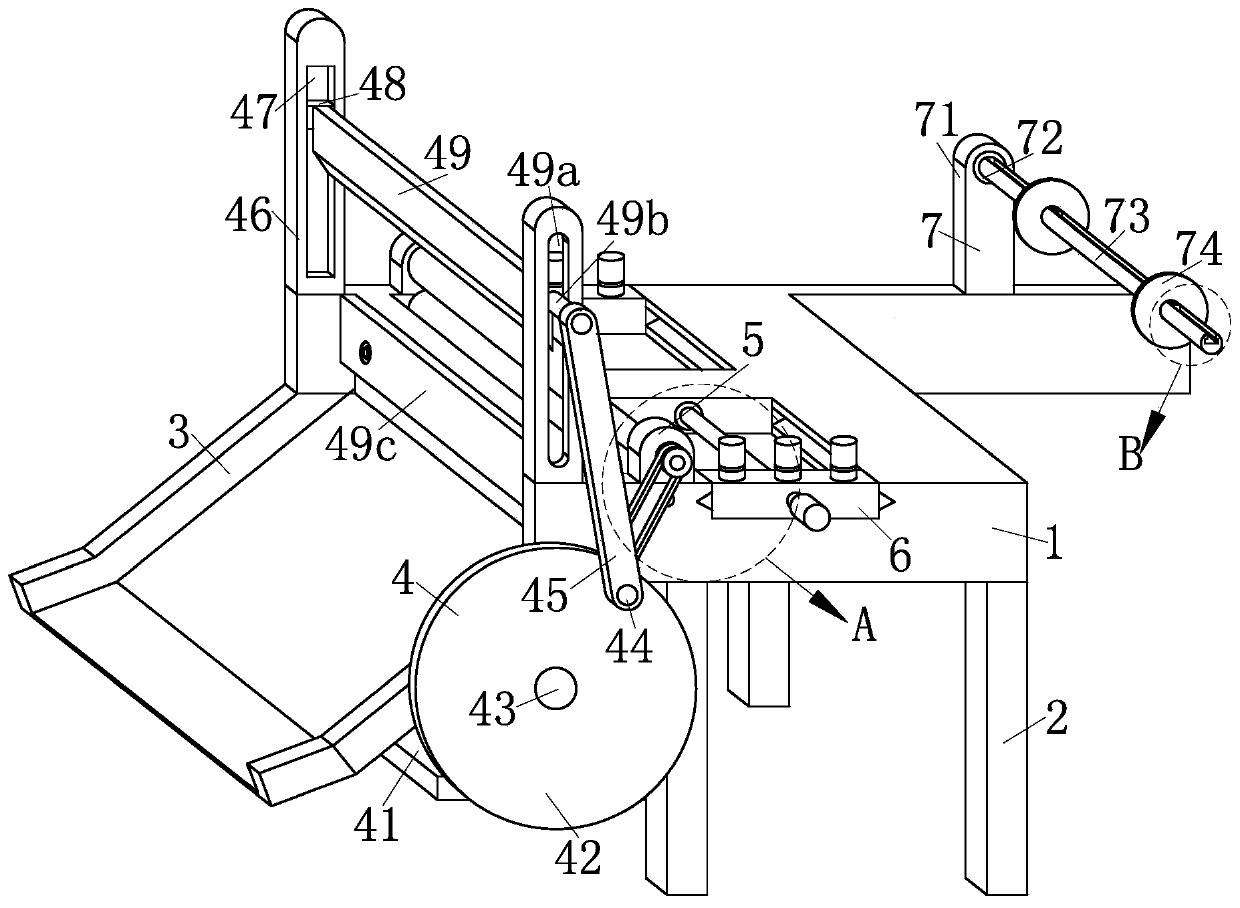

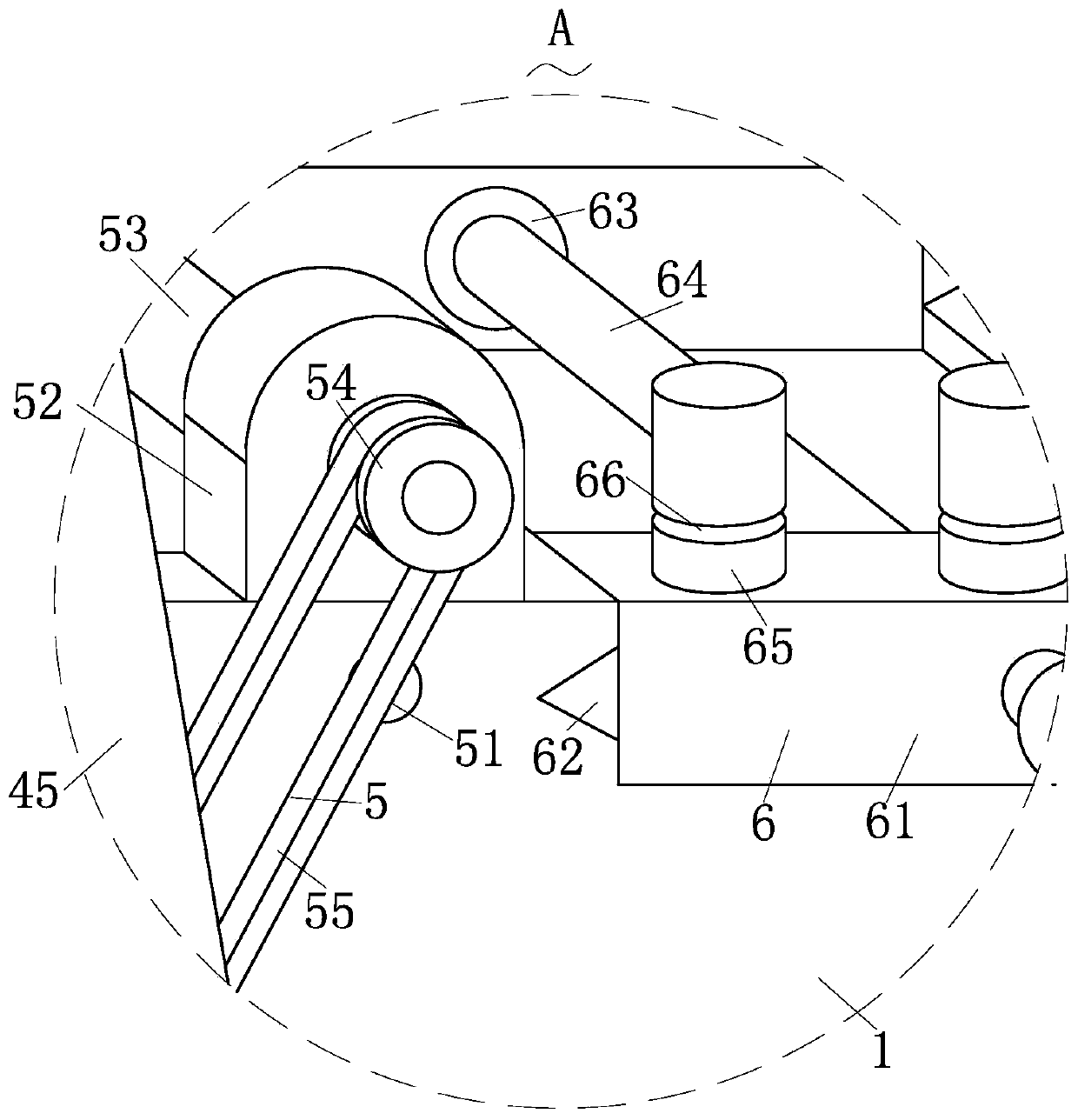

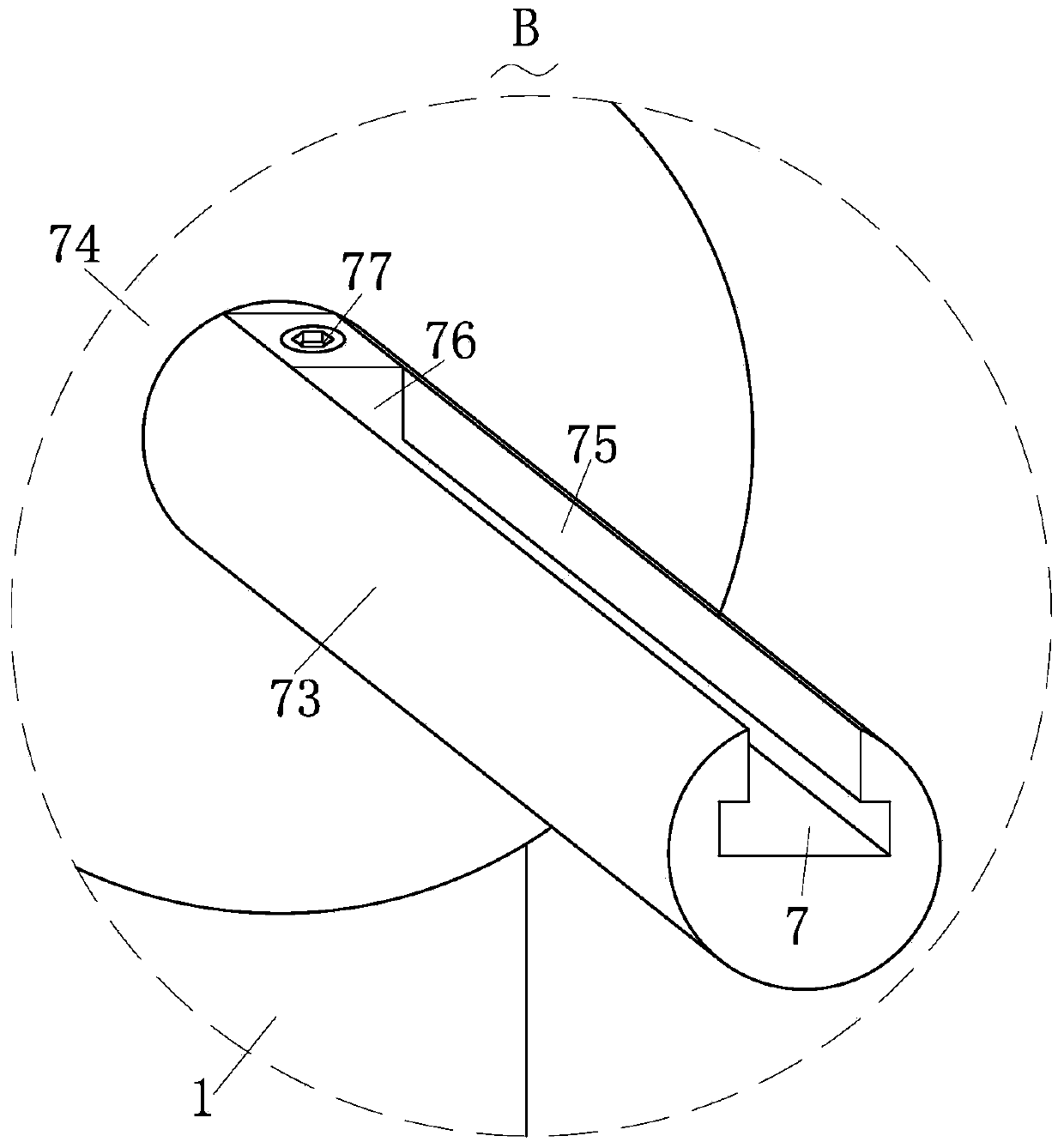

Transmission shaft straightening machine

PendingCN110538895AGuaranteed Alignment AccuracyQuality assuranceMetal-working feeding devicesMetal working apparatusDrive shaftEngineering

The invention relates to a transmission shaft straightening machine. The straightening machine comprises a rack, a workbench connected to the center of the rack, a pressing cylinder connected above the rack and used for straightening a transmission shaft, and a detection mechanism used for detecting circumferential run-out of the transmission shaft. A clamping mechanism used for fixing the transmission shaft is arranged above the workbench, and a driving mechanism used for driving the clamping mechanism to slide is arranged on the side part of the workbench; the detection mechanism used for detecting the circumferential run-out of the transmission shaft is connected to the side part of the clamping mechanism, and the clamping mechanism comprises a main shaft head, and a main machine and adisc brake mechanism which are connected to the side part of the main shaft head; and the driving mechanism comprises a frame plate, a screw rod and an auxiliary machine, wherein the screw rod and theauxiliary machine are connected to the side part of the workbench, and the center of the screw rod is movably connected with a nut connected with the frame plate. The transmission shaft straighteningmachine can be used for straightening the transmission shaft, the operation complexity of conventionally manual straightening, by an operator, on the transmission shaft is changed, and the straightening accuracy and convenience of the transmission shaft are effectively improved.

Owner:ZHEJIANG FOERTAI INTELLIGENT EQUIP CO LTD

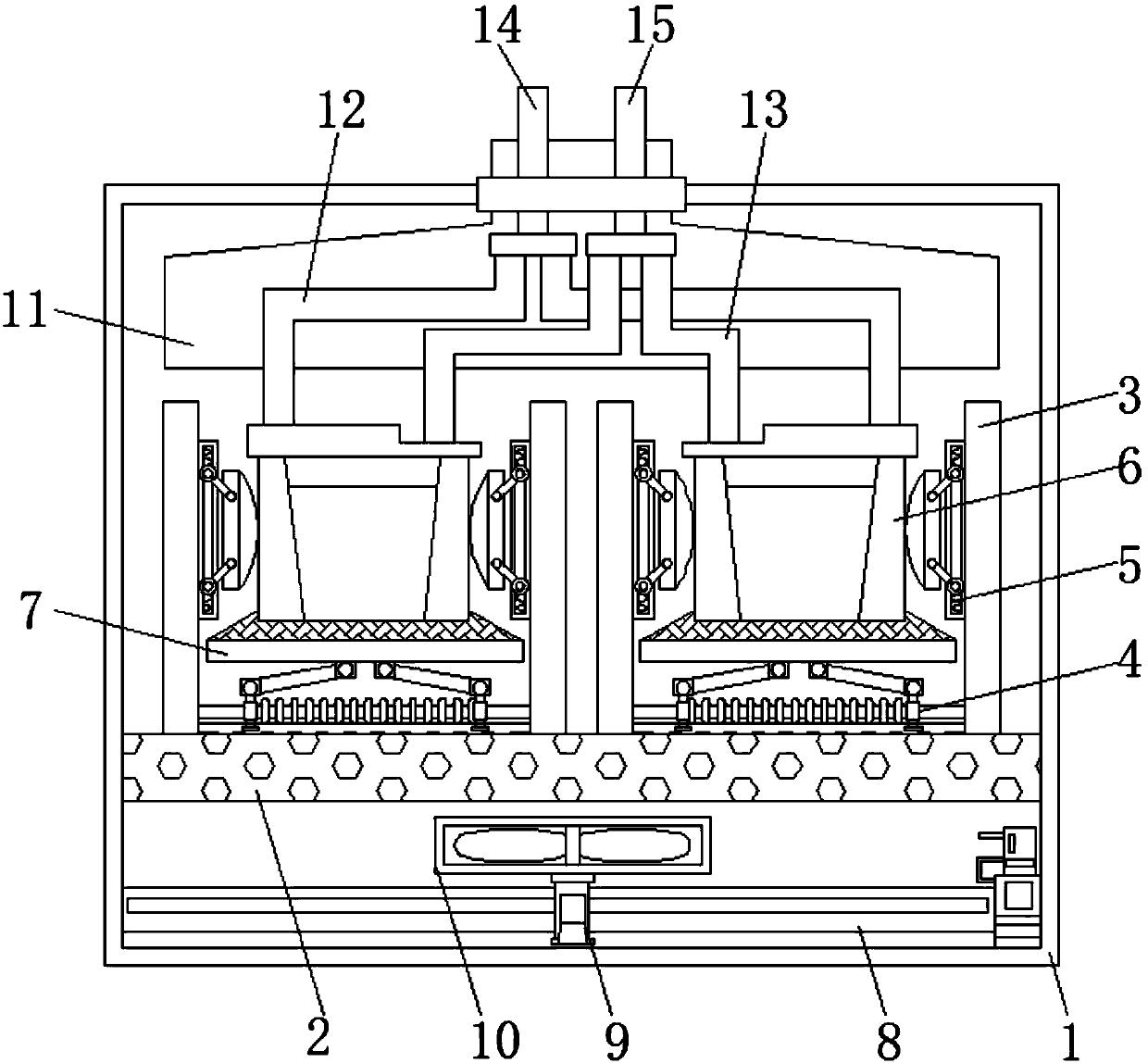

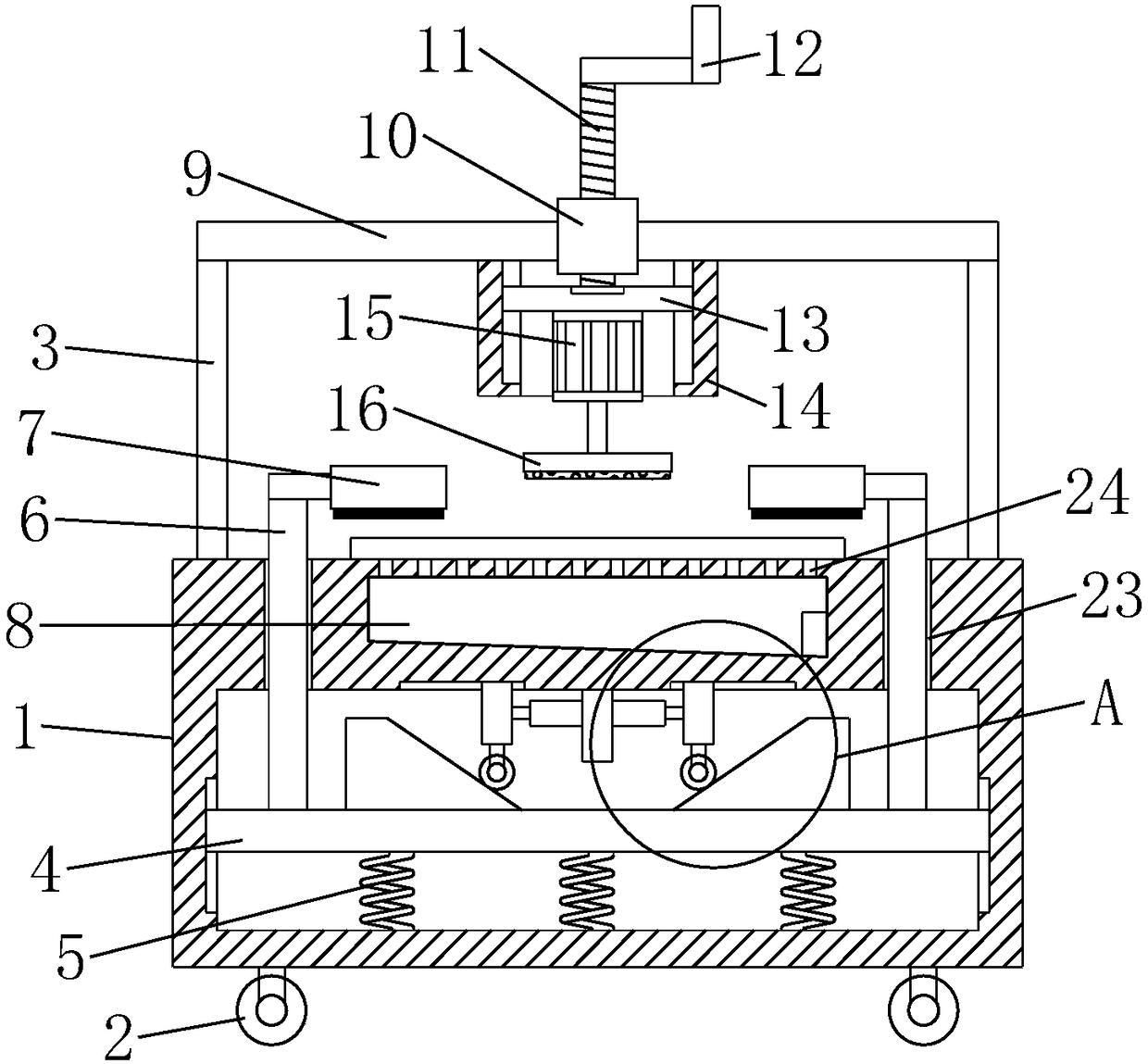

Pressure testing machine for building quality detection

InactiveCN112082864AScientific and reasonable structureEasy to useMaterial strength using tensile/compressive forcesArchitectural engineeringElectric machinery

The invention discloses a pressure testing machine for building quality detection. The pressure testing machine comprises a base, portal frames are symmetrically and fixedly connected to the top end of the base, pressure measuring and buffering mechanisms are movably connected to the interiors of the portal frames, and power transmission and clamping fixing mechanisms are installed at the positions, corresponding to the two sides of the portal frames, in the base, and one end of the base is fixedly connected with a material recovery and crushing mechanism. The pressure testing machine is scientific and reasonable in structure and safe and convenient to use, the pressure measuring and buffering mechanisms are arranged, lead screws are driven by a driving motor to rotate, and through cooperation of a first belt, the two lead screws rotate together to push a lifting block to move; therefore, the lifting block drives a movable plate and a pressing plate to move along a groove, the distancebetween the pressing plate and a building material is adjusted, the pressing plate is attached to the top end of the building material, the pressing plate is pushed to press downwards through cooperation of an air cylinder and a piston rod, and a pressure bearing test is conducted on the building material on a bearing plate.

Owner:张瑞麟

Cutting machine with guiding function for gauze element production and processing

ActiveCN110861132AAvoid creasesAvoid offsetMetal working apparatusWebs handlingMechanical engineeringIndustrial engineering

The invention relates to the field of gauze element production and processing devices, in particular to a cutting machine with a guiding function for gauze element production and processing. The cutting machine comprises a base, supporting legs, a discharge sleeve, a cutting structure, a feeding structure, a guiding structure and a discharging structure; the cutting structure can synchronously drive the feeding structure to work while the cutting structure is working, through the setting of the feeding structure, the feeding operation can be automatically conducted on a gauze element, the workintensity of manual feeding is reduced, the cut gauze element can further be leveled and limited, namely the wrinkle of the gauze element during cutting is avoided, the deviation of the gauze elementcaused by difficult fixation of the gauze element during cutting is also avoided, the guiding structure is arrange at the top end, close to one end of the feeding structure, of the base, the gauze element entering the feeding structure can be guided, the gauze element of the feeding structure is prevented from wrinkling and deviating, the guiding structure can be adjusted, and thus gauze elementswith different width can further be guided.

Owner:LIXIN FUYA GAUZE CO LTD

General mechanical arm robot teaching tool

The invention relates to the technical field of robot teaching tools, in particular to a general mechanical arm robot teaching tool. The general mechanical arm robot teaching tool comprises a baseplate; the baseplate is movably connected with a second electric extension rod; a metal pipe fitting is mounted at the top end of the second electric extension rod; a motor is mounted in the metal pipe fitting; a rotating end of the motor extends to the outer side of the metal pipe fitting, and is sleeved with a movable block; multiple first electric extension rods are arranged along the surface of the movable block; grooves opposite to the first electric extension rods are formed in one surface, far from the metal pipe fitting, of the movable block; and fixed shafts are mounted in the grooves, and are sleeved with second connecting rods. The general mechanical arm robot teaching tool is simple in structure and convenient to use, is not only used for clamping and fixing real objects to improve the stability of the positions of the real objects, but also can be convenient to correct and adjust the positions of the real objects so as to improve the learning efficiency.

Owner:武汉知青年教育咨询有限公司

Surface grinding device convenient for wood clamping and fixing

InactiveCN108247484ARealize clamping and fixingEasy to clamp and fixGrinding machinesGrinding work supportsScrew threadSurface grinding

The invention discloses a surface grinding device convenient for wood clamping and fixing. The surface grinding device comprises a box body, a first lifting plate, springs, clamping blocks, a supportseat, a screw rod, a grinding disc, guide seats and guide pulleys. The bottom of the first lifting plate is connected with the bottom of an inner cavity of the box body through the springs. The guideseats are symmetrically and fixedly arranged on the top of the first lifting plate. Inclined surfaces are correspondingly arranged on the tops of the two guide seats. The guide pulleys are correspondingly arranged at the bottom ends of two sliding blocks. Lifting rods are fixedly erected at the top end of the first lifting plate. The clamping blocks are horizontally and fixedly erected on the inner sides of the top ends of the lifting rods. The screw rod is arranged on the support seat through an inner thread through hole in a threaded manner. A second lifting plate is rotationally erected atthe bottom end of the screw rod. A grinding motor for driving the grinding disc to rotate is fixedly mounted at the bottom of the second lifting plate. The surface grinding device is simple in structure, convenient to move, capable of conveniently clamping and fixing a wood plate, beneficial to the grinding treatment of the wood plate and suitable for application and popularization.

Owner:SUICHANG YUDING TECH SERVICES CO LTD

Damping pedestal with movement function applied to installation of electric cabinet

InactiveCN108767699AEasy to clamp and fixImprove mobile efficiencyAnti-seismic devicesEngineeringIdler-wheel

The invention discloses a damping pedestal with a movement function applied to the installation of an electric cabinet. The damping pedestal comprises a support plate, wherein first fixing plates arefixedly connected with left and right sides of the upper surface of the support plate, a screw cylinder is connected with the right side face of the first fixing plate on the right side in a clampingmanner, a screw column is in threaded connection with the interior of the screw cylinder, the left end of the screw column is fixedly connected with the right end of a rotation shaft, and bearing is connected with the surface of the rotation shaft in a sleeving manner. The damping pedestal with the movement function applied to the installation of the electric cabinet, through the arrangement of the screw cylinder, screw column, clamping plate, first spring, idler wheels, electric push rod and second spring, the support plate and the electric cabinet can be better moved via the idler wheels, the labor intensity of the staffs is reduced, the movement efficiency of the electric cabinet is improved, and meanwhile, the impact force generated by vibration of the support plate can be buffered byusing the first spring and the second spring, so that the elements in the electric cabinet can be prevented from vibrating, and thus the electric cabinet can be better normally used.

Owner:陈汉军

Cleaning device for hardware precision parts

InactiveCN108080345AEasy to cleanFast and efficient cleaning of precision hardware partsCleaning using liquidsBlock matchMachining

The invention discloses a cleaning device for hardware precision parts, and relates to the technical field of hardware precision part machining equipment. The cleaning device comprises a bottom plate,wherein a cleaning case is fixedly connected to the top of the bottom plate, a separation plate is fixedly connected between the two sides of the inner wall of the cleaning case, a cleaning cylinderis fixedly connected to the top of the separation plate, annular sliding rails are fixedly connected to the bottom of the inner wall of the cleaning cylinder, a sliding block matched with each annularsliding rail is slidably connected to the top of the annular sliding rail, and a rotating circular plate is fixedly connected to the tops of the sliding blocks. According to the cleaning device for the hardware precision parts, the cleaning effect is greatly improved, the cleaning efficiency is improved, production personnel do not need to spend a large amount of time cleaning the hardware precision parts, the working load of the production personnel is better relieved, comprehensive cleaning can be conducted on the hardware precision parts rapidly and efficiently, and therefore the production personnel can conduct the cleaning work on the hardware precision parts conveniently.

Owner:方建松

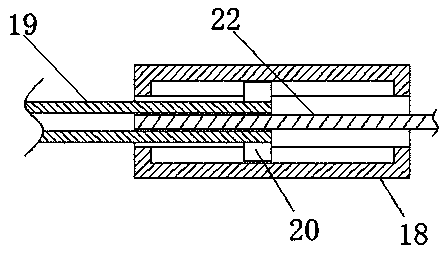

Metal material galvanic couple corrosion test fixture apparatus

InactiveCN103234893AEasy to clamp and fixFirmly connectedWeather/light/corrosion resistanceAccuracy improvementMetallic materials

The invention relates to a metal material galvanic couple corrosion test fixture, and belongs to the technical field of experiment apparatuses and methods. The fixture comprises a main fixture body (8) and three insulating blocks such as an insulating block 1 (2), an insulating block 2 (3) and an insulating block 3 (4), the main fixture body (8) tightly presses the three insulating blocks to form the galvanic couple corrosion test fixture, the main fixture body (8) is provided with a rectangular concave groove, the three insulating blocks are aligned in a straight row manner, and placed into the rectangular concave groove, the bottom surface of the rectangular concave groove for placing the insulating block is provided with two hollow through holes for passing-through of two test specimens, shapes and sizes of cross sections of the three insulating blocks and a shape and a size of a cross section of the rectangular concave groove are the same, and a test specimen is clamped among the three insulating blocks. The present invention provides a fixture capable of effectively reducing influence of external factors on a metal material galvanic couple corrosion test, wherein advantages of high reliability, simple operation, and significant test accuracy improvement are provided.

Owner:BEIJING UNIV OF TECH

Distribution box with electric meter clamping function

ActiveCN106159740AEasy clampingEasy to fixSubstation/switching arrangement detailsEngineeringThreaded rod

The invention discloses a distribution box with an electric meter clamping function. The distribution box comprises a main box body, wherein one side of the main box body is movably connected with one side of a box door through hinges, a glass window is embedded in the box door, supporting plates are fixedly connected onto an internal wall of the main box body, one end of each supporting plate is fixedly connected with one side of a partition plate, the top of each supporting plate is fixedly connected with a clamping device, each clamping device comprises a screwing handle, and one side of each screwing handle is fixedly connected with one end of a threaded rod. According to the distribution box with the electric meter clamping function, through arranging the screwing handles, the threaded rods and threaded sleeves, electric meters can be better clamped, and the circumstance that the electric meters are fixed by screws is avoided, so that the electric meters can be better fixed, and the time for mounting the electric meters is saved; through arranging supporting rods, push rods and movable extruding plates, the electric meters can be better clamped and fixed and be quickly arranged, so that the efficiency of fixing the electric meters is increased.

Owner:NANTONG HAIWANG ELECTRIC

Drilling device for automobile spare part machining

InactiveCN107378041AEasy to clamp and fixImprove work efficiencyPositioning apparatusBoring/drilling componentsTelescopic cylinderDrill bit

The invention discloses a drilling device for automobile spare part machining. The drilling device comprises a supporting platform, supporting stand columns, supporting sliding rods, a lifting plate, a supporting platform, a first electric telescopic cylinder, a drilling motor and a clamping device. The supporting stand columns are symmetrically and fixedly welded to the upper surface of the supporting platform. The supporting sliding rods are fixedly welded and erected to the top ends of the supporting stand columns. A supporting top plate is fixedly erected to the top ends of the supporting sliding rods. The first electric telescopic cylinder used for driving the lifting plate to do the lifting movement is fixedly arranged on the lower surface of the middle portion of the supporting top plate. A drilling motor used for driving a drill bit to rotate at a high speed is fixedly arranged on the lower surface of the middle portion of the lifting plate. The supporting platform is fixedly erected at the top end of the support. The clamping device is fixedly erected on the inner walls of the supporting stand columns through support rods. The drilling device is simple in structure and convenient and fast to operate, automobile spare part clamping and fixing are convenient, the automobile spare part drilling machining work efficiency is improved, the drilling precision is high, and the drilling device is suitable for usage and popularization.

Owner:丽水市正明机械科技有限公司

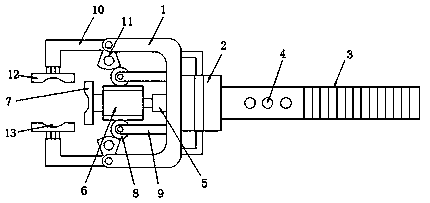

Clamping forceps for forging

ActiveCN110153351AAvoid operator fatigueAvoid the phenomenon of weak clampingForging/hammering/pressing machinesGear wheelForceps

The invention discloses clamping forceps for forging. The clamping forceps for forging comprise a bracket; a rotating mechanism is arranged on one side of the bracket; a handheld rod is arranged on one side, far away from the bracket, of the rotating mechanism; an air cylinder is arranged on one side of the internal part of the bracket; the top end of a piston rod of the air cylinder is fixedly connected with a rack; a first clamping plate is arranged on one side, far away from the air cylinder, of the rack; gears matched with the rack are arranged at the top and the bottom of the rack; forceparms matched with the bracket are arranged at the top and the bottom of the other side of the bracket; fan-shaped gears matched with the gears are arranged on the inner sides of the forceps arms; a second clamping plate is arranged on one side, far away from the bracket, of each forceps arm; and a fine adjustment mechanism matched with each second clamping plate is arranged in each forceps arm. The clamping forceps for forging has the following beneficial effects: through use, a worker can clamp force pieces tightly without continuous operation by double hands, so that operation fatigue caused by continuous operation of the worker can be effectively avoided.

Owner:重庆市綦江区宏利汽配有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com