Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

545results about How to "Avoid creases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

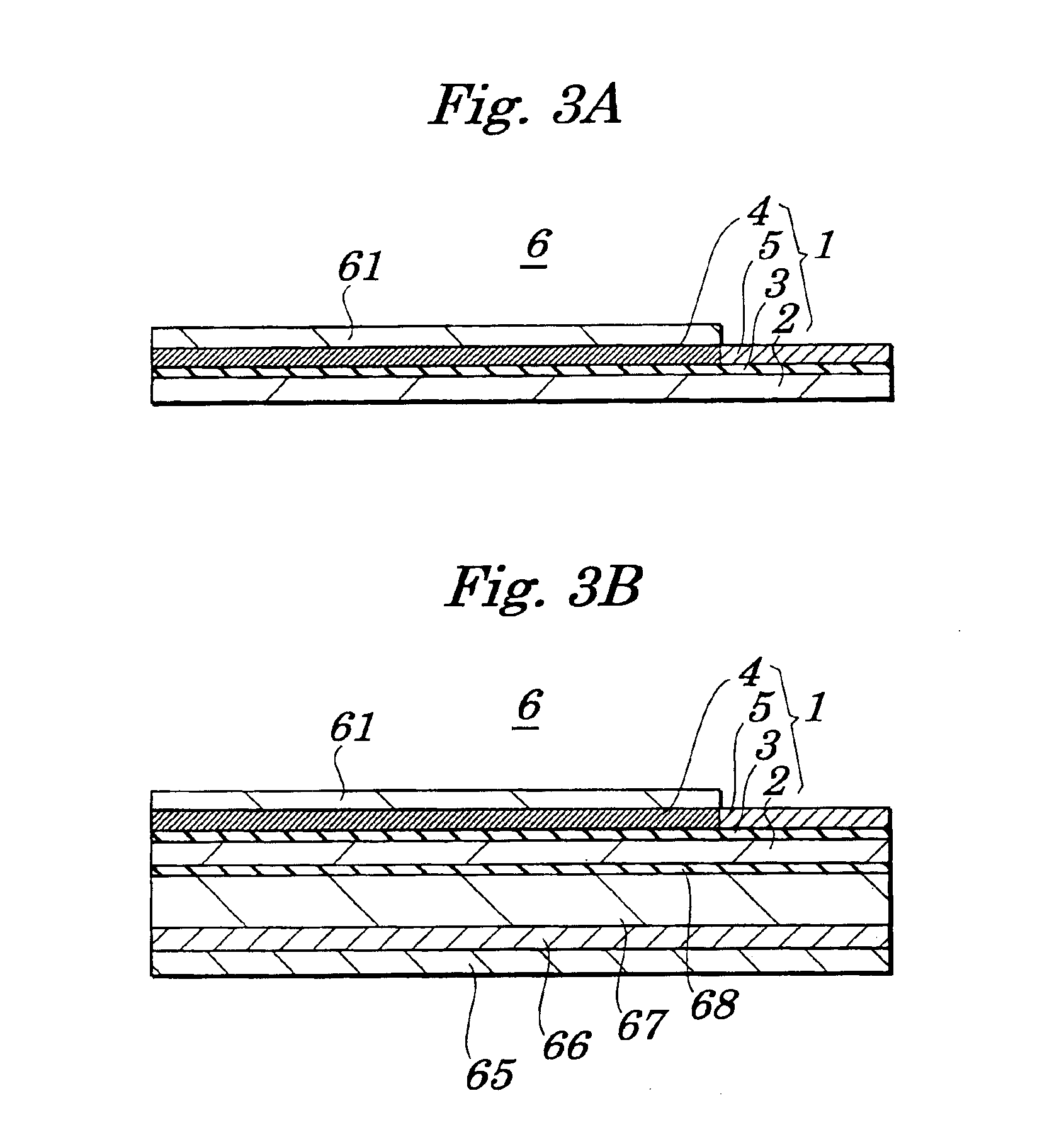

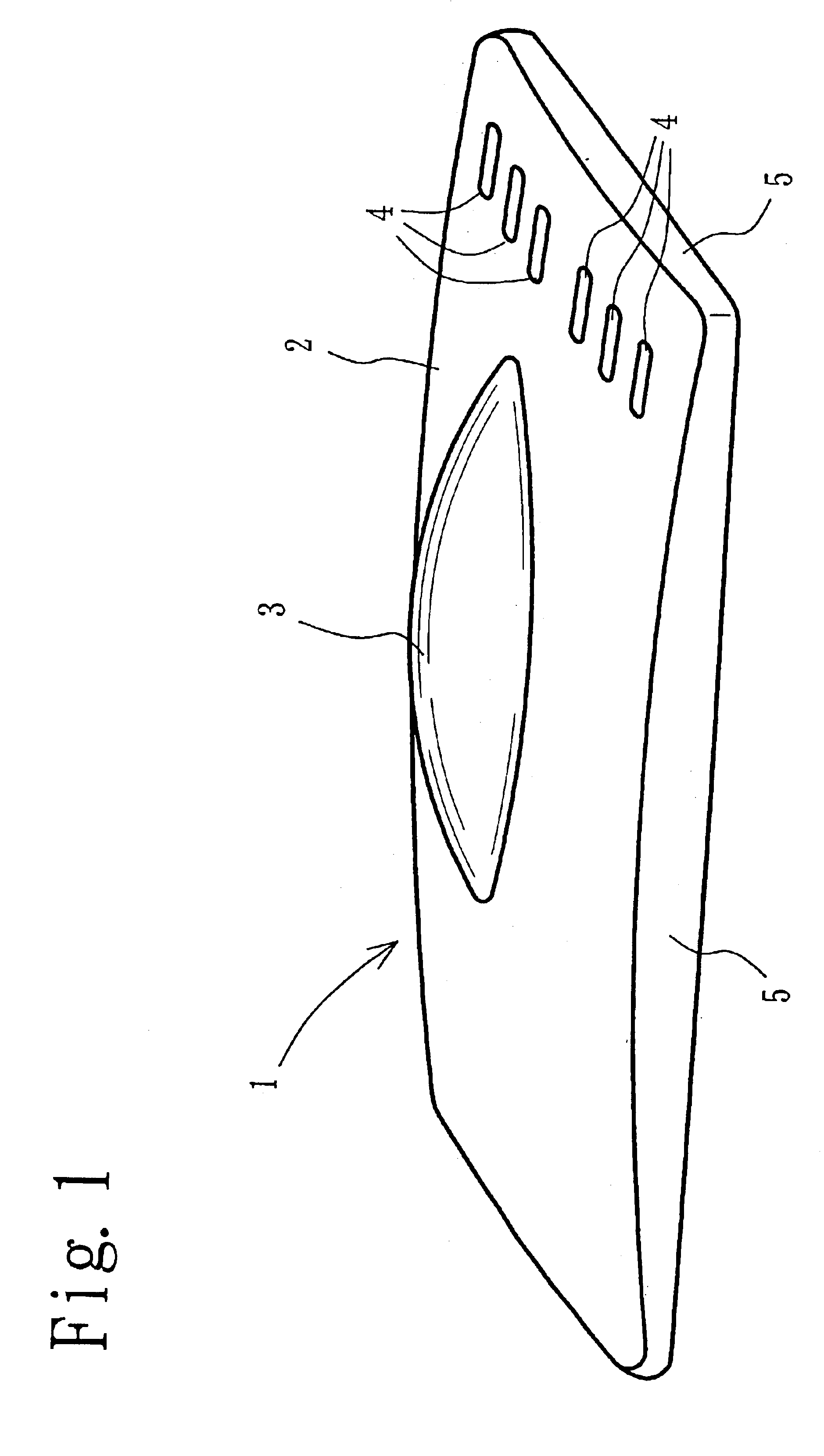

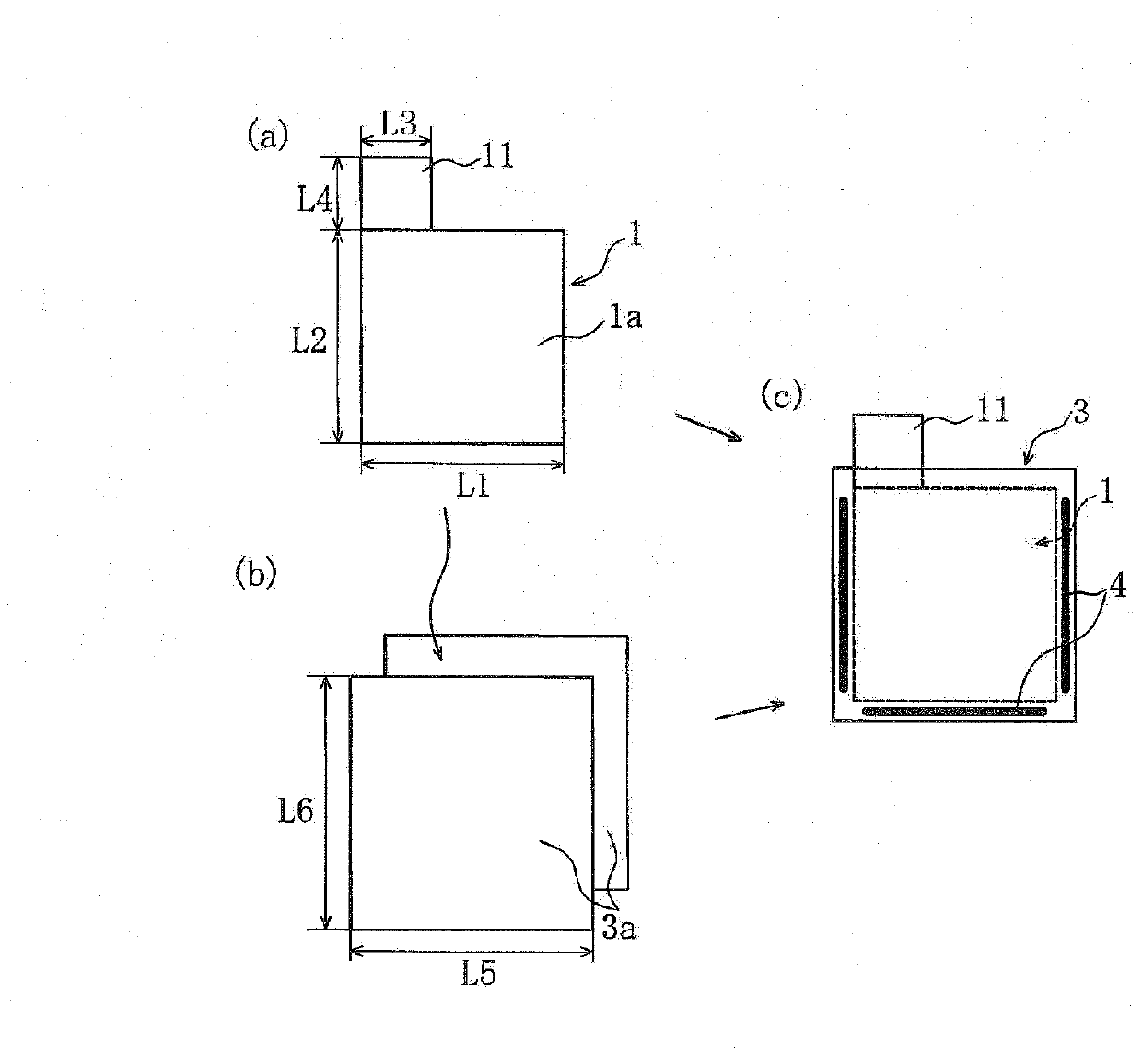

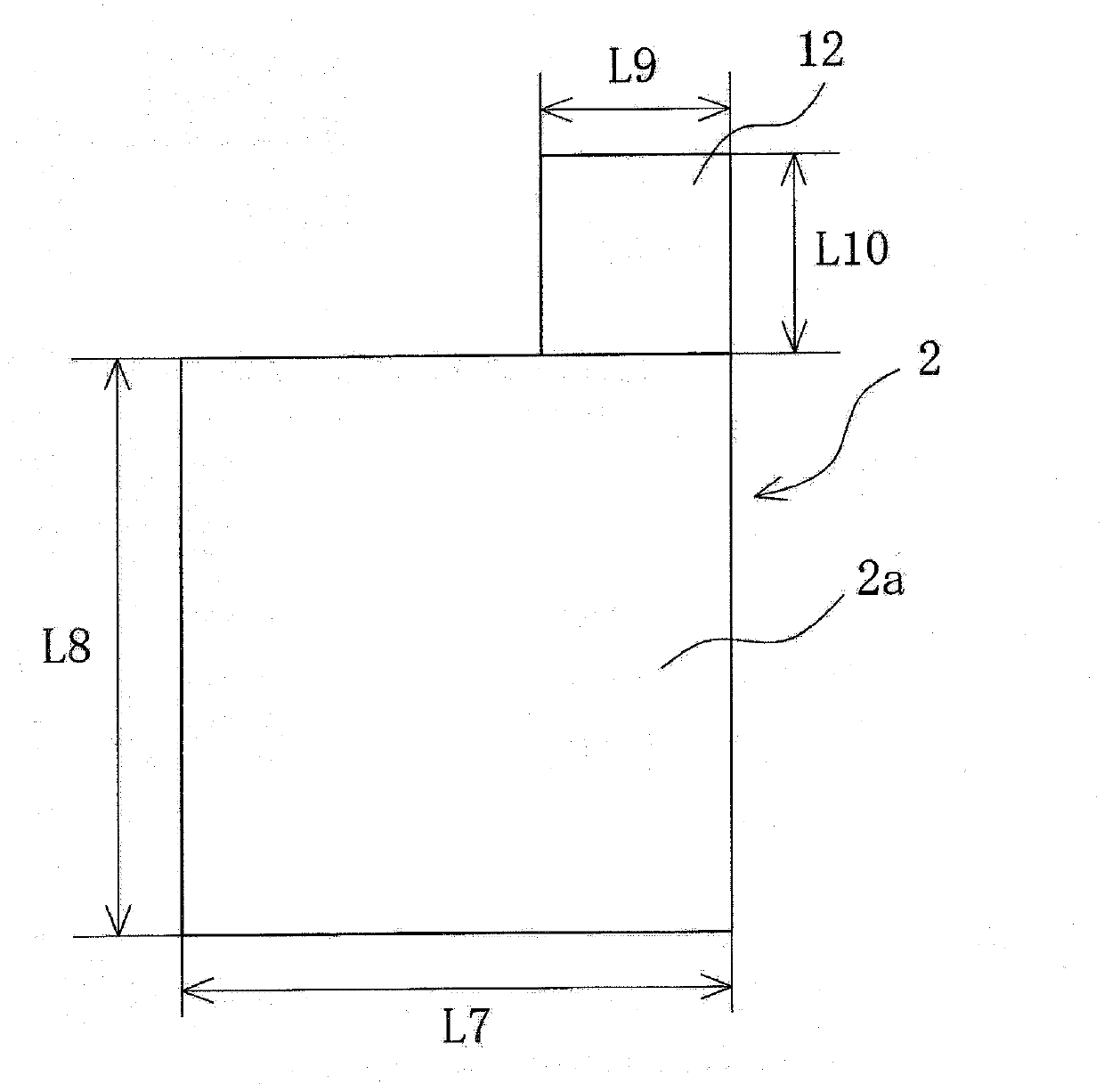

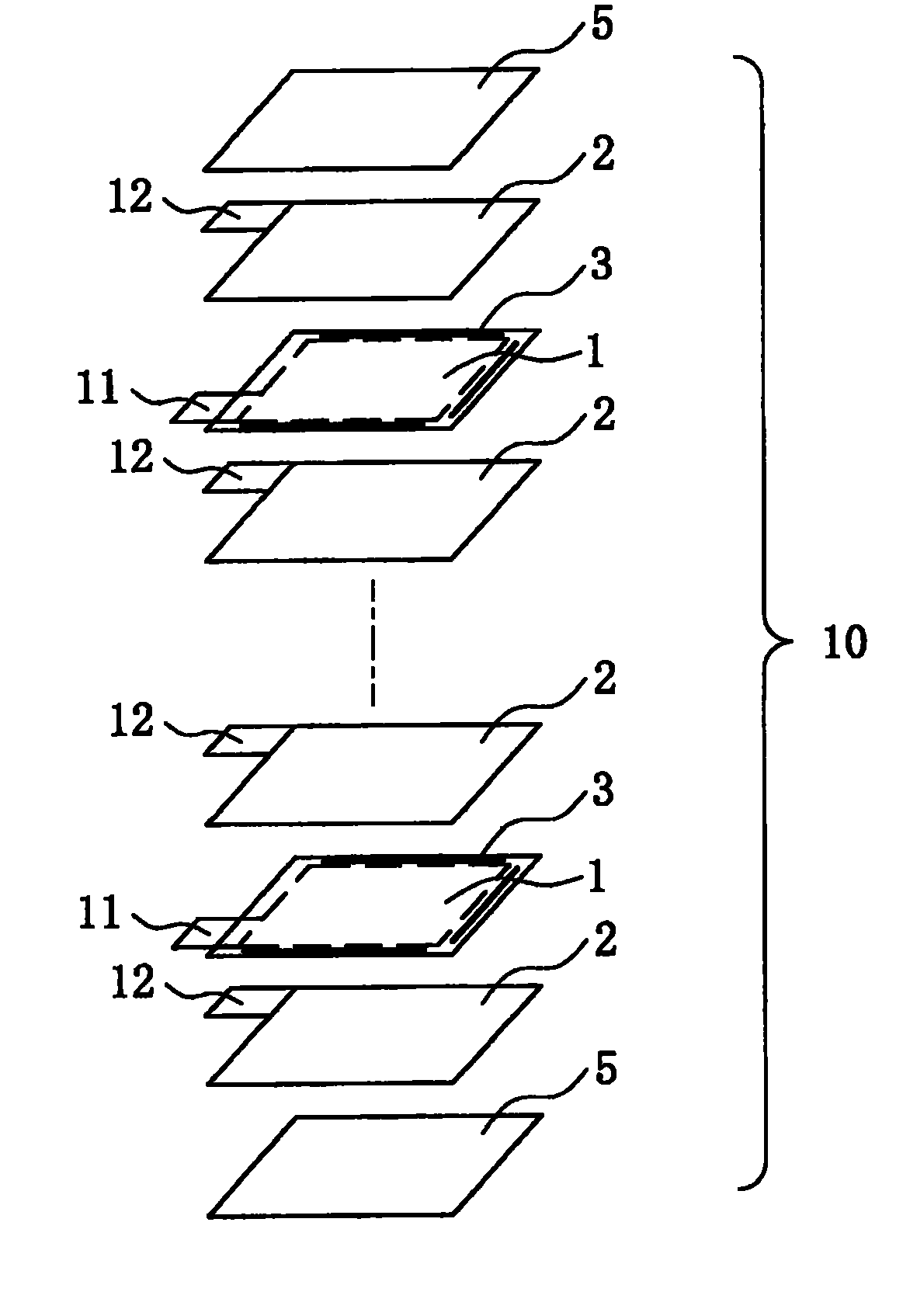

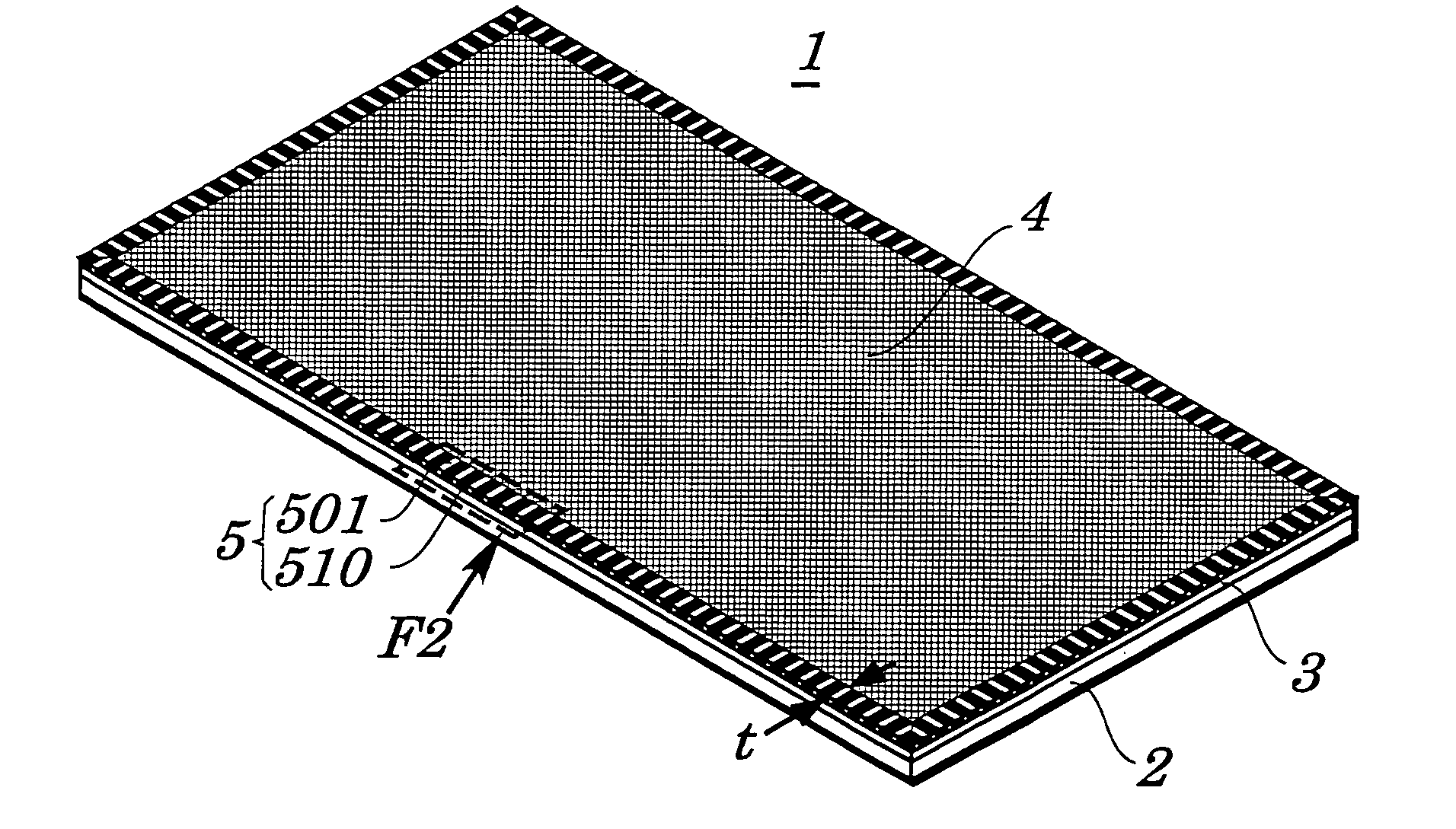

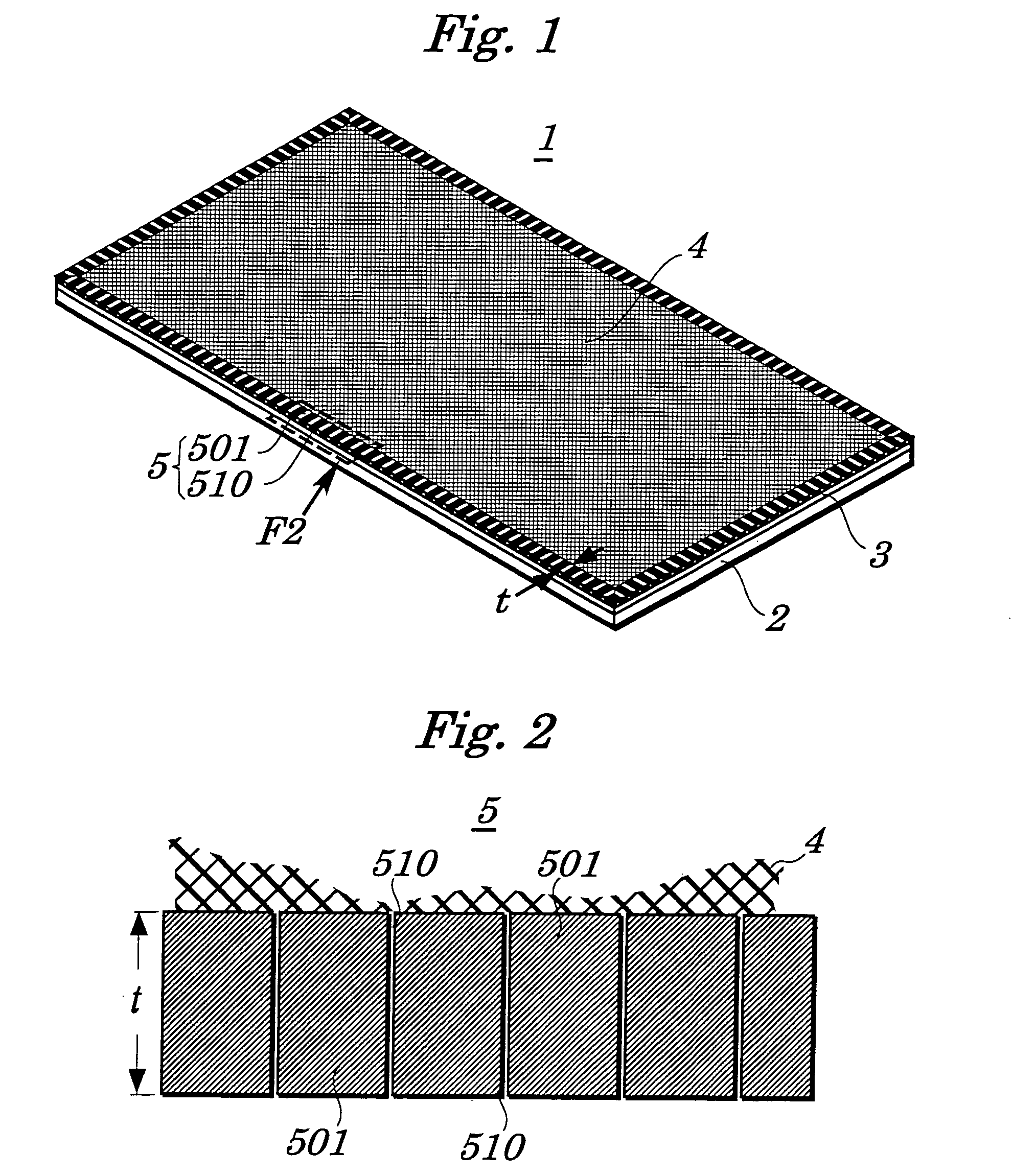

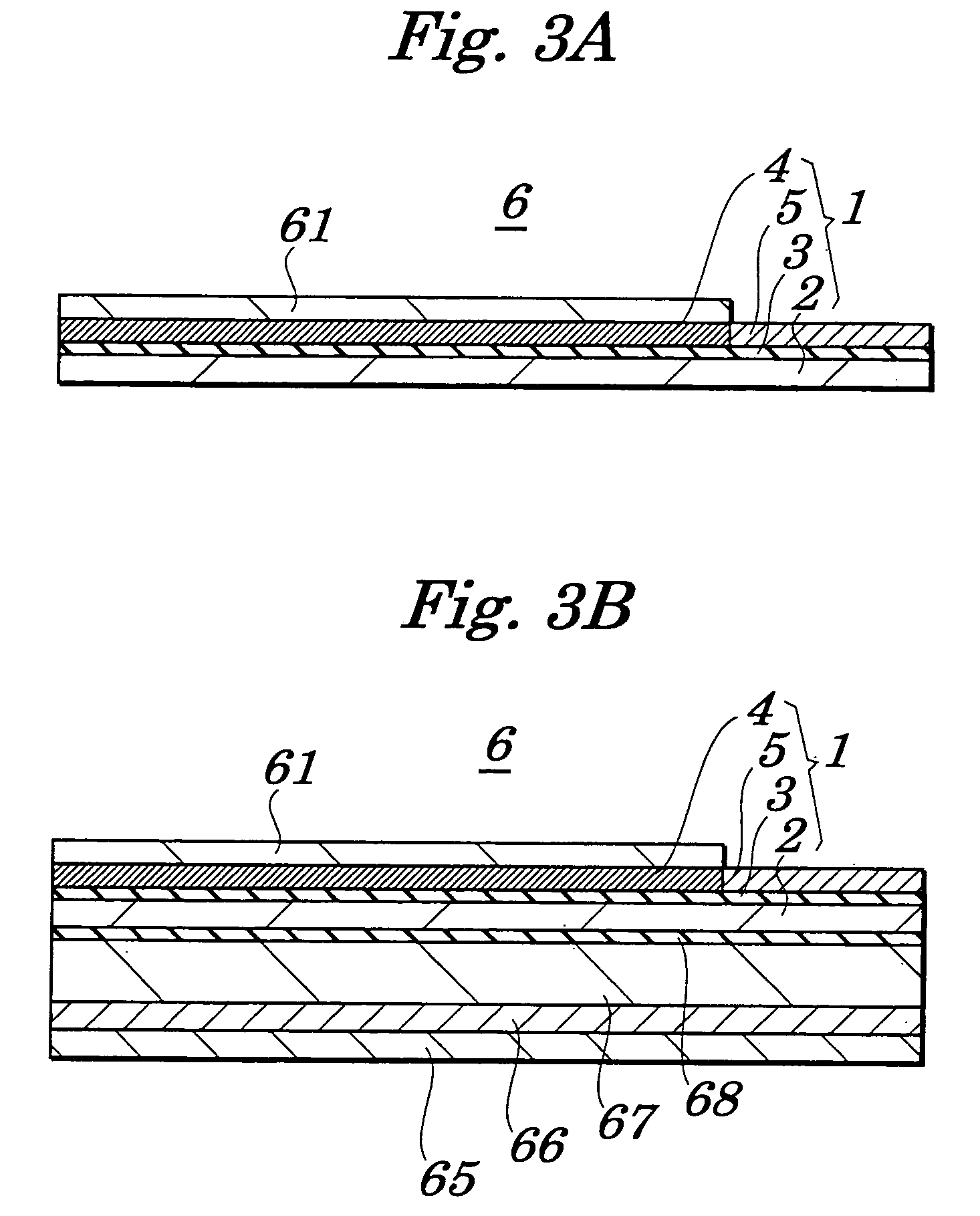

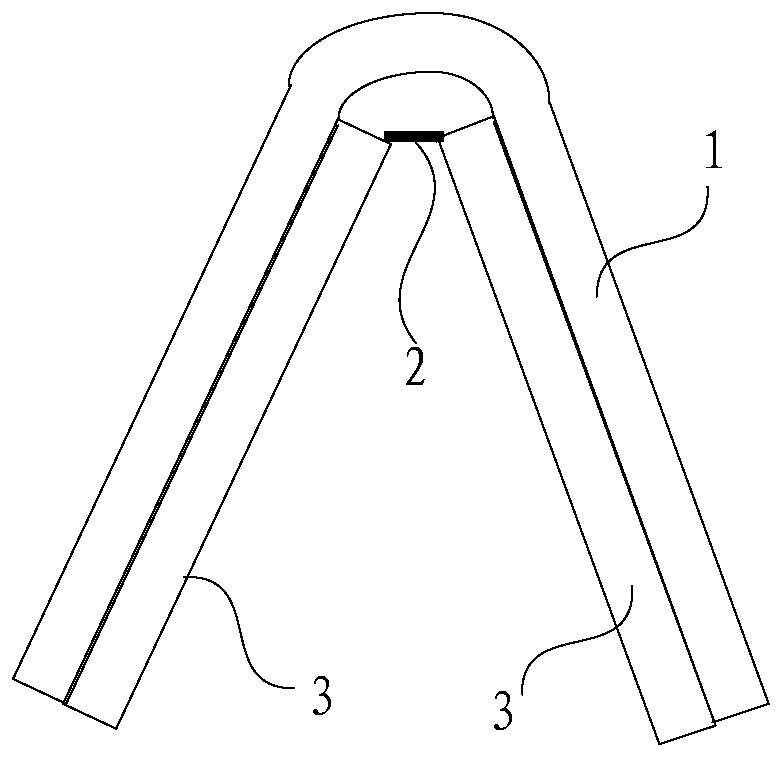

Electromagnetic shield film, electromagnetic shield unit and display

InactiveUS6884936B2Avoid creasesPreventing the earth portion from being creasedTelevision system detailsMagnetic/electric field screeningElectrical conductorAdhesive

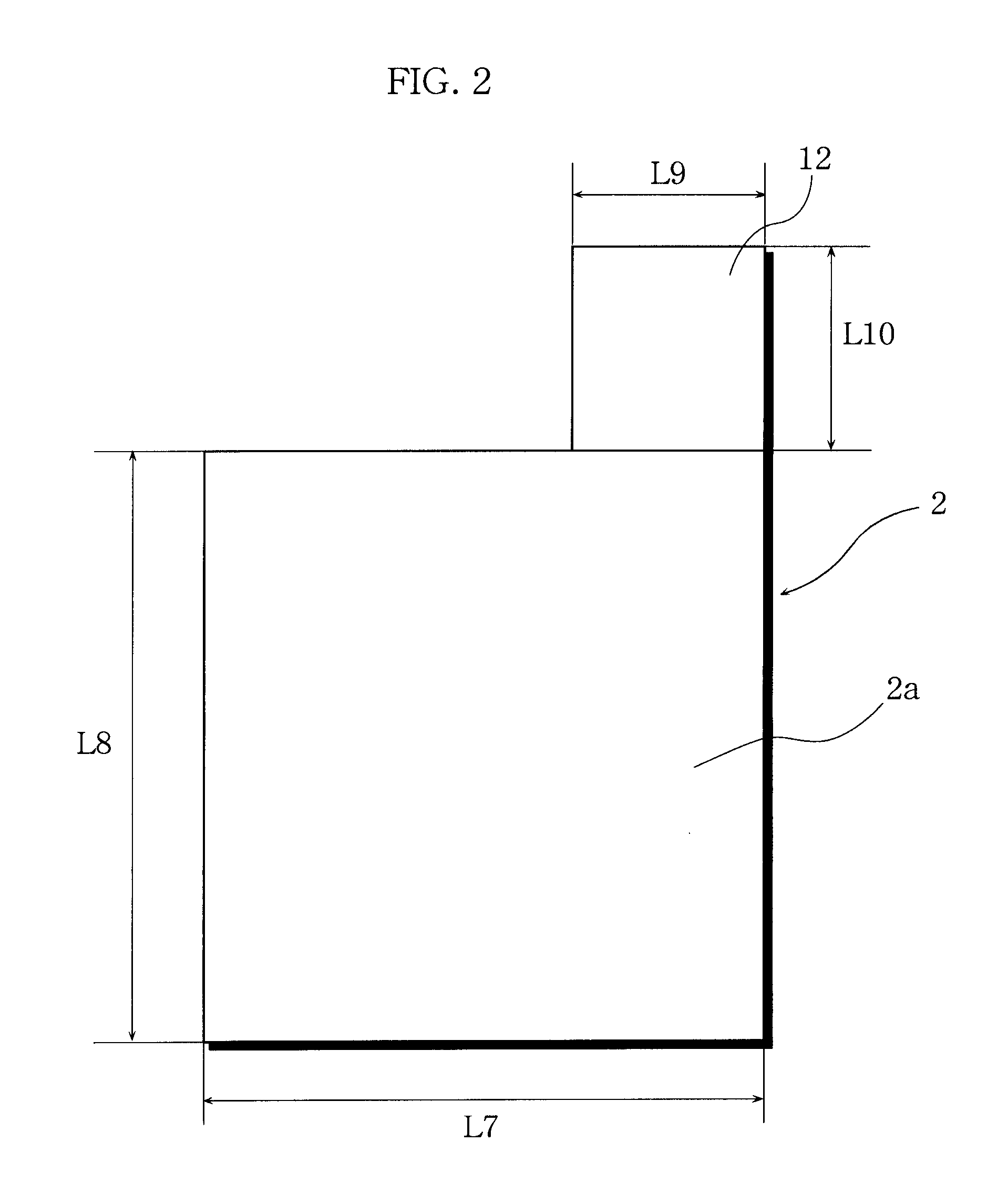

An electromagnetic wave shield film (1) comprises a transparent base (2), a conductor (4) positioned on the transparent base (2) via an adhesive (3) and having a mesh geometric pattern, and an earth portion (5) arranged around the conductor (4) and including conductive regions (501) which absorb electromagnetic waves, and non-conductive regions (510) which prevent the earth portion (5) from being creased.

Owner:HITACHI CHEM CO LTD

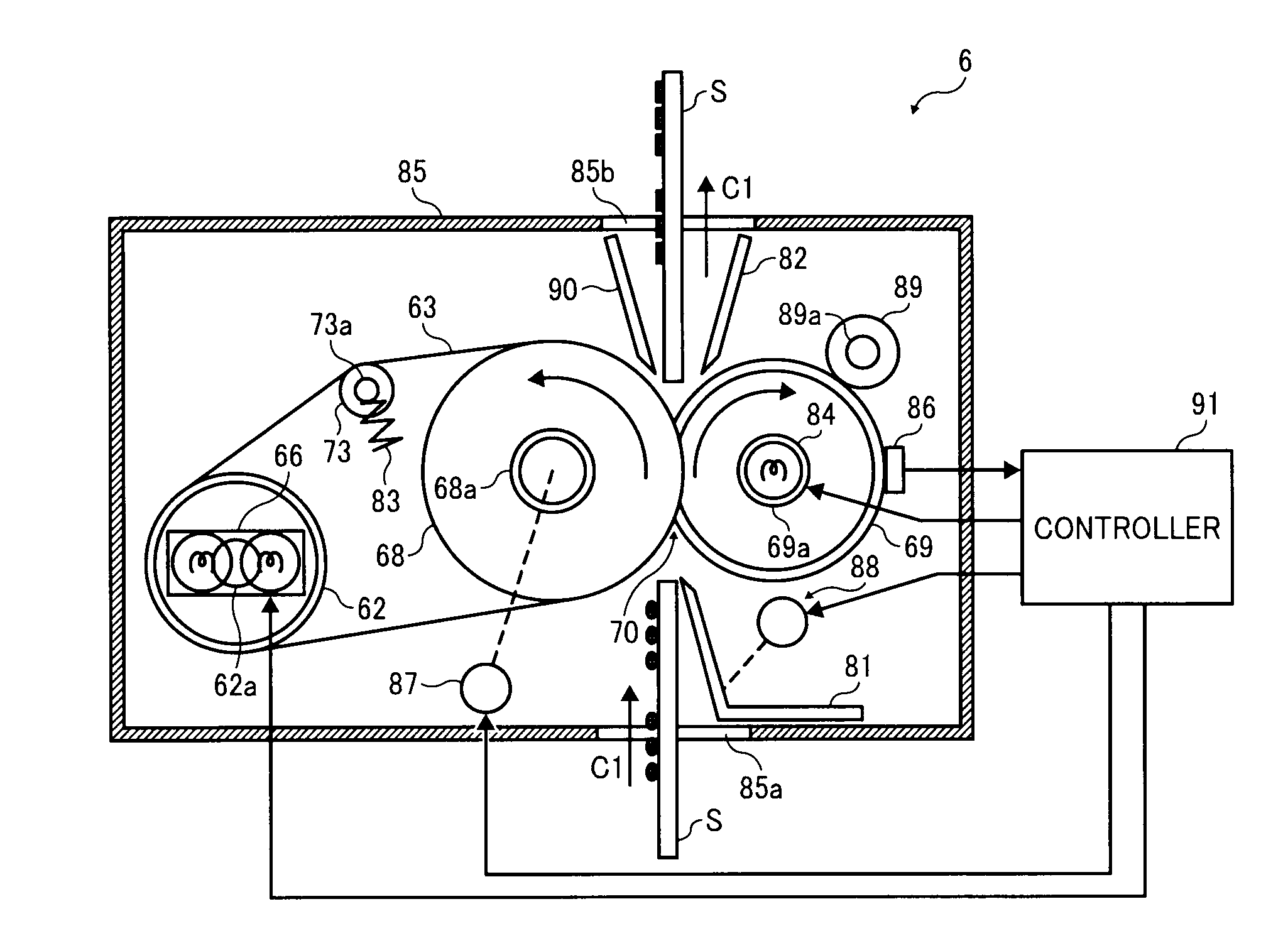

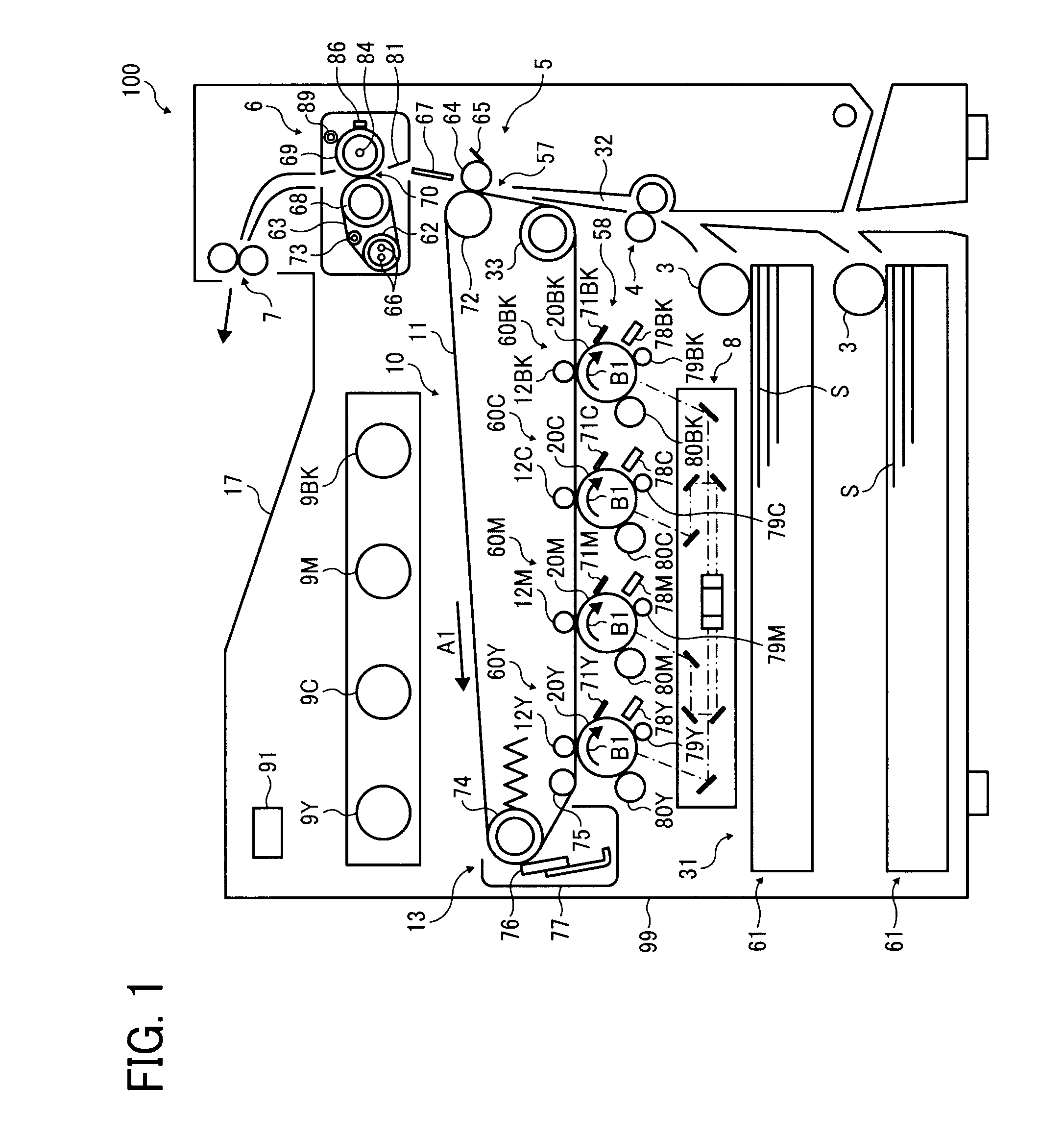

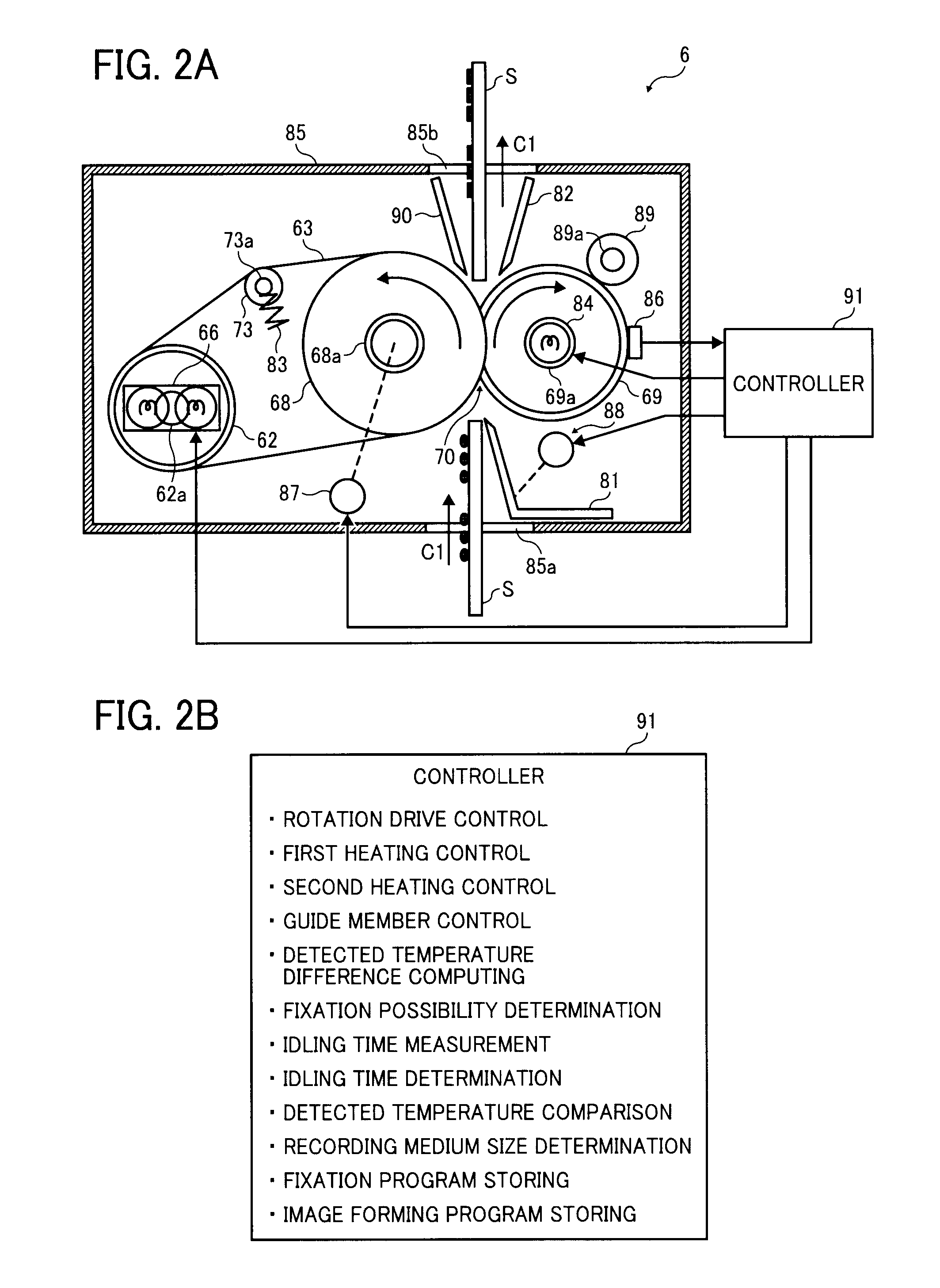

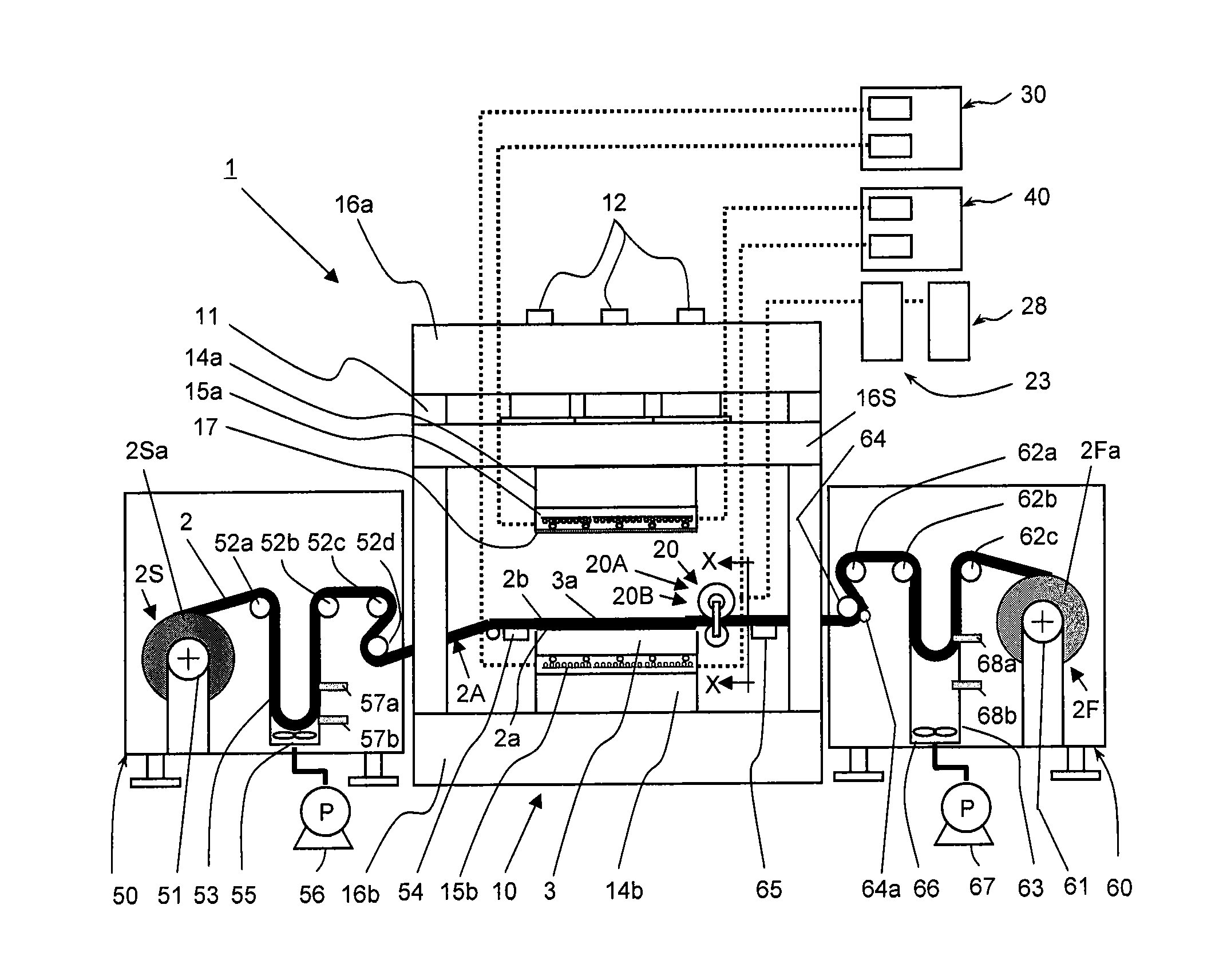

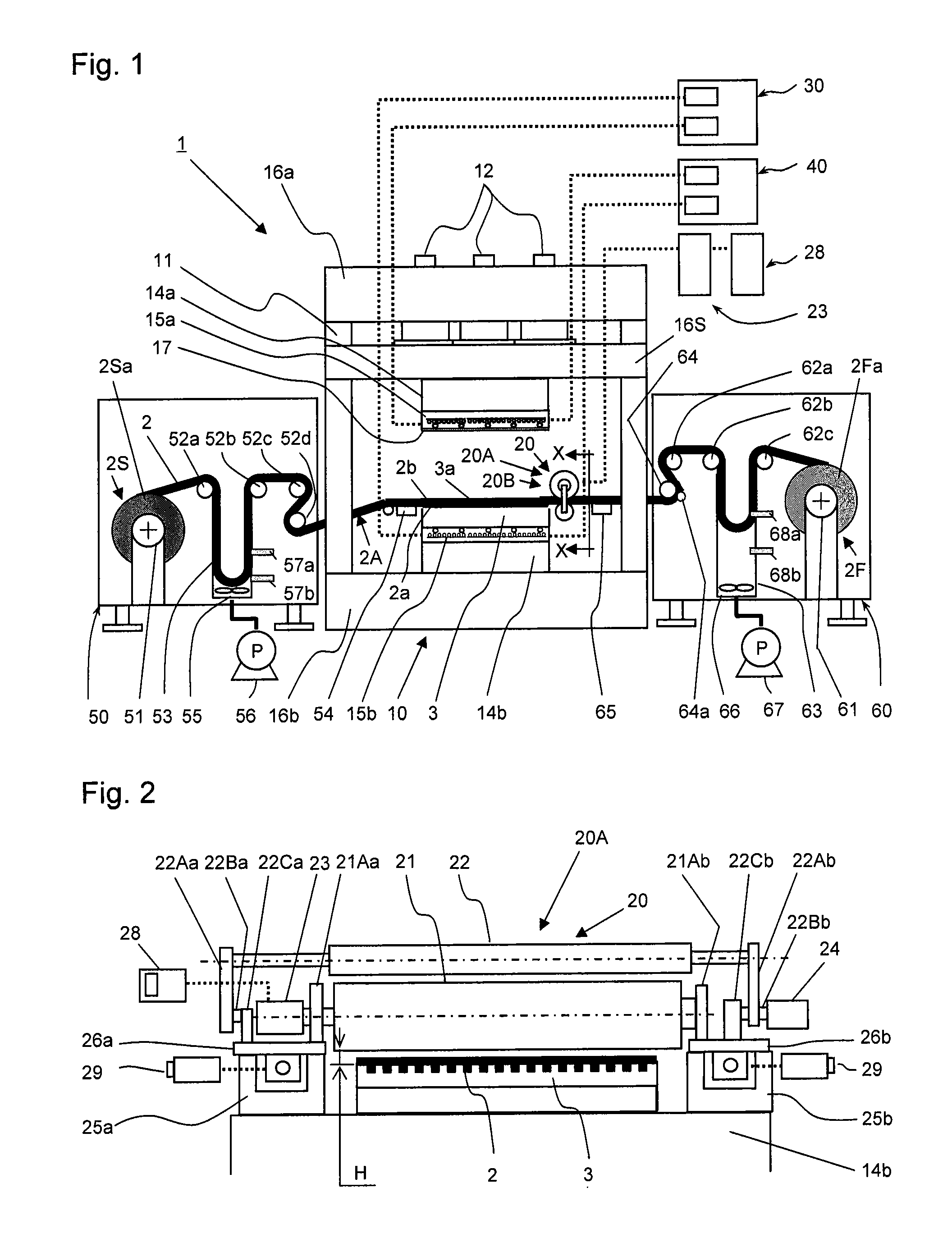

Fixing device, fixing method, image forming apparatus, and image forming method

InactiveUS20110229236A1Prevent crease and curlAvoid creasesElectrographic process apparatusMechanical engineeringTemperature difference

A fixing device in an image forming apparatus includes a conveyance member to convey a recording medium at a fixing nip where an image carried on the recording medium is fixed onto it; a plurality of temperature detectors to detect temperature of the conveyance member, the detectors being disposed at both end portions of the conveyance member outside an area where a maximum-sided recording medium passes through; a guide member to guide the recording medium toward the fixing nip; and a guide plate displacing unit to displace a part of the guide member in a direction orthogonal to a conveyed surface of the recording medium to be conveyed at the fixing nip, based on temperature difference detected by the plurality of temperature detectors.

Owner:RICOH KK

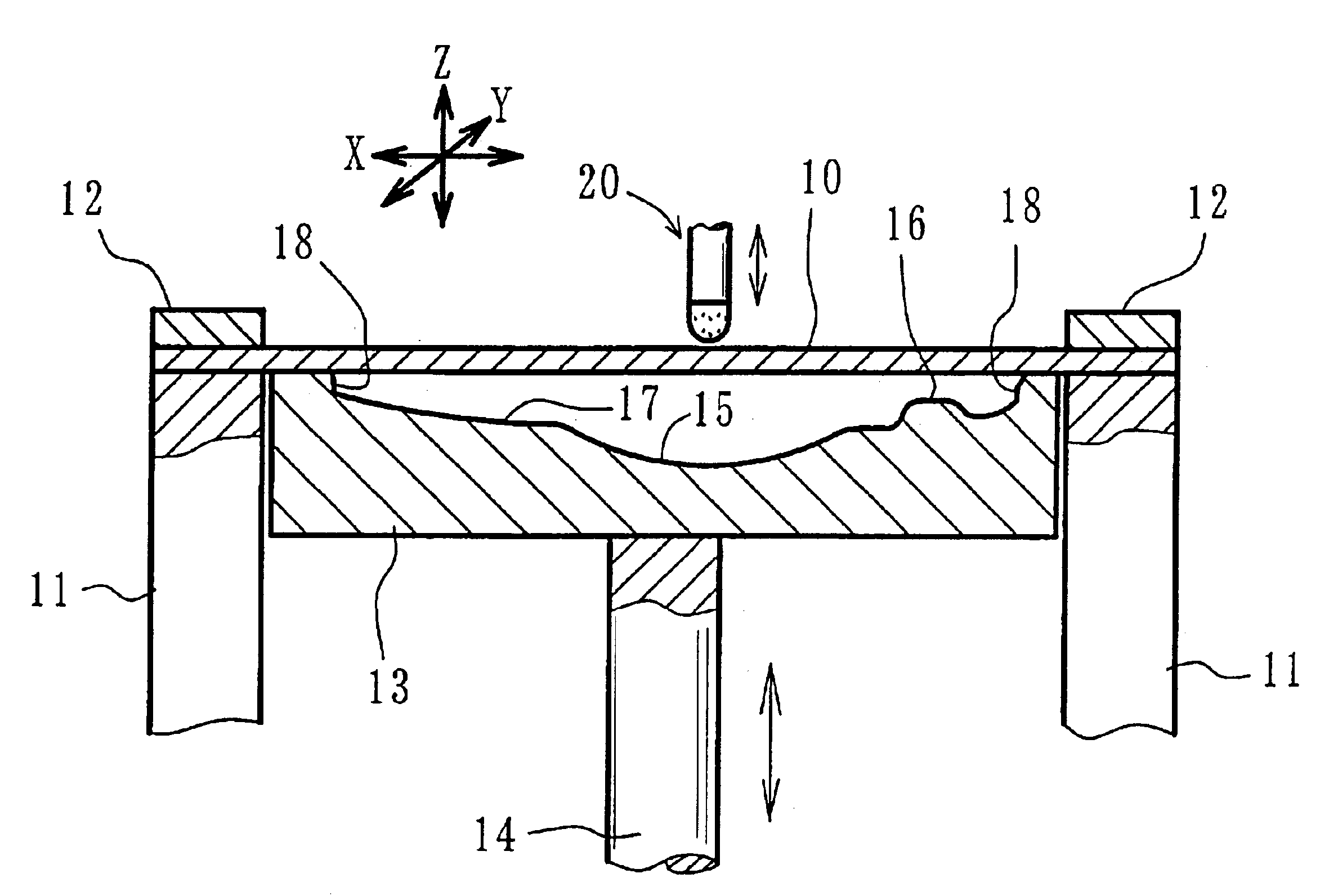

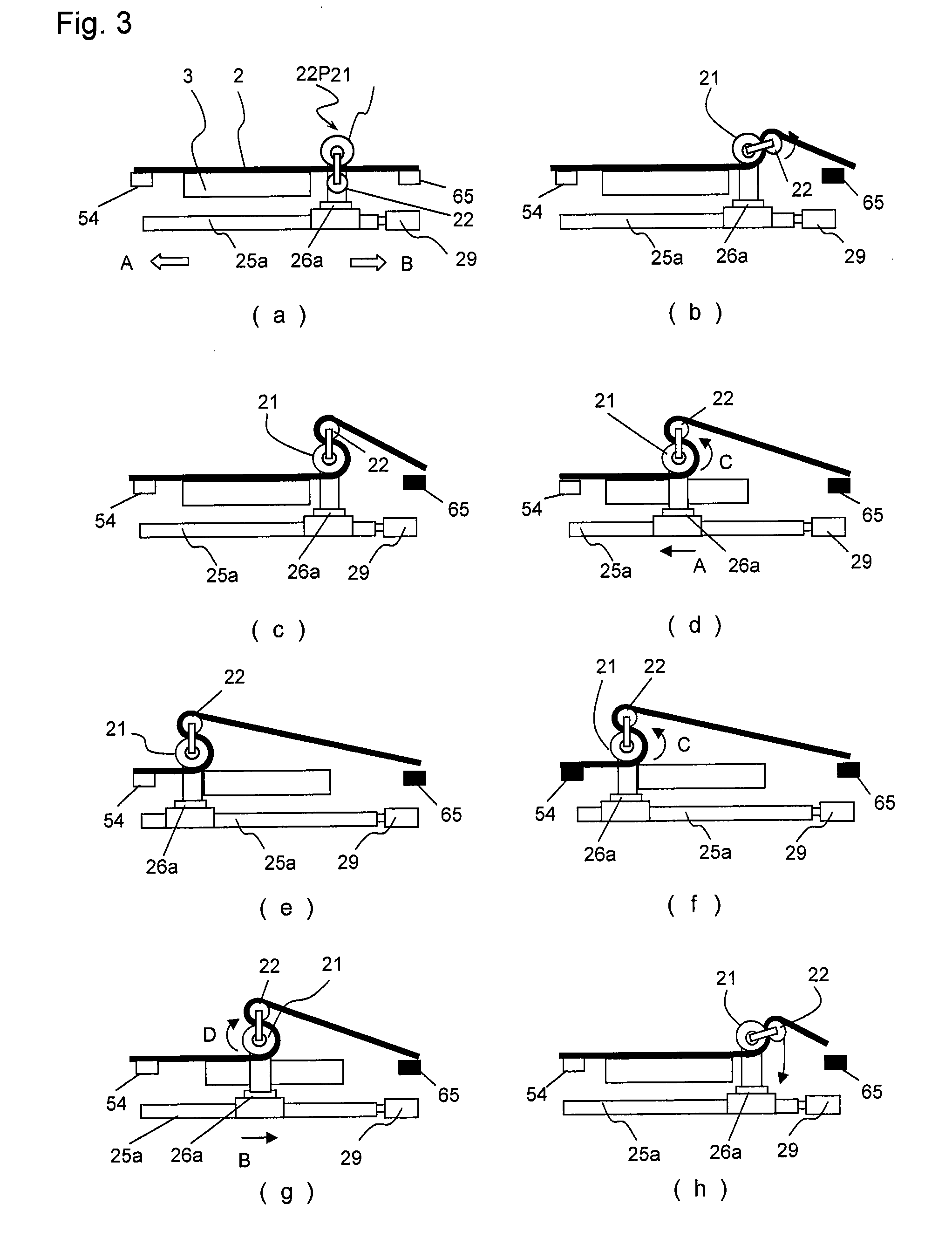

Sequential forming device

A plate member (10) is mounted on a supporting frame (11). The periphery of the plate member (10) is firmly secured by a clamp (12) and a concave die-shaped lower pushing member (13) is caused to rise from below. The lower pushing member (13) is provided with a forming concave area (15) and a forming convex area (16). Disposed above the plate member (10) is a bar-shaped upper pushing member (20) which is lowered to push against the plate member (10). In such a condition, the plate member (10) is caused to rise together with the lower pushing member (13) and move in the directions of X and Y to form convex areas (17) and (18) within the forming concave area (15) and the forming convex area (16). The upper pushing member (20) is provided with a main body (21) of high rigidity and a flexible member (22). The flexible member (22) is formed in a hemispherical shape and made of material more elastic than the main body (21) which is made of hard polyurethane or the like, thereby making spherical contact with the plate member (10).

Owner:HONDA MOTOR CO LTD

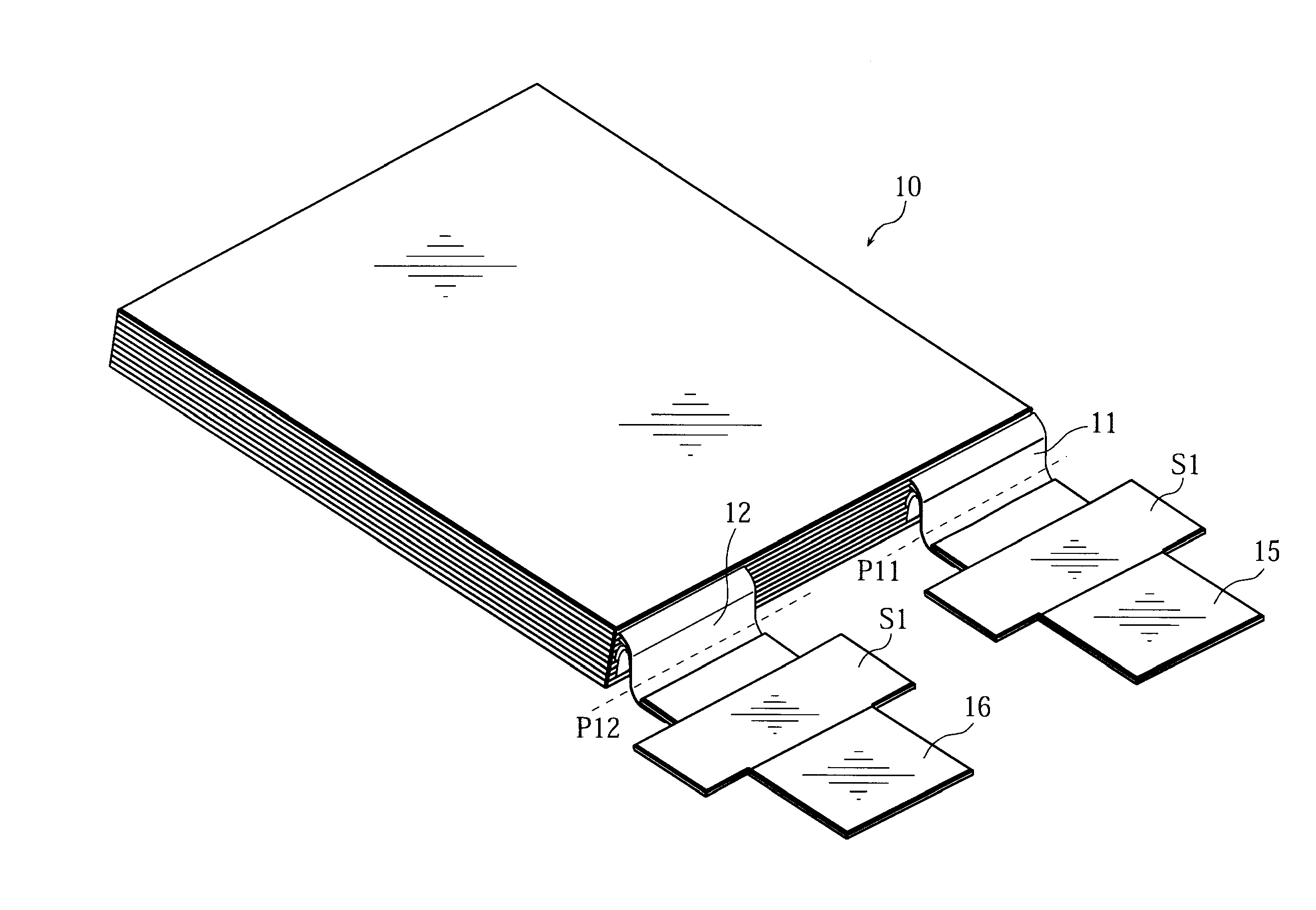

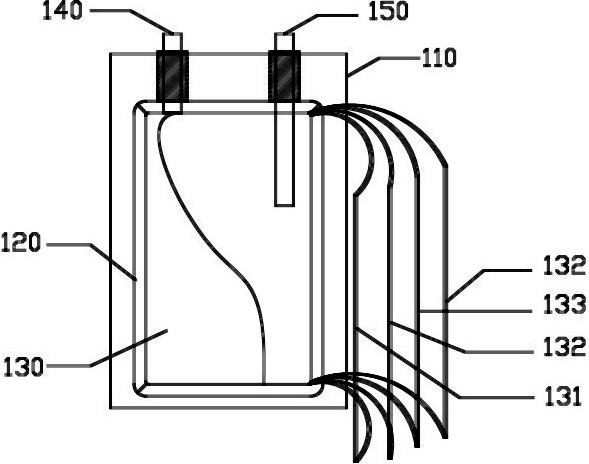

Stack type battery

InactiveUS20110244312A1Avoid constructionAvoid creasesLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery cell

In a stack type battery, stacked positive and negative electrode lead tabs (11, 12) are joined to one another at a location between the current collector terminals and the electrode plates, the positive and negative electrode lead tabs (11, 12) being folded at an intermediate location between positive and negative electrode current collector terminals (15, 16) and positive and negative electrode plates and protruding from the positive and negative electrode plates. A stacked electrode assembly (10) is accommodated in a battery case (18) having flexibility. A first spacer (a first cover portion (52) of an integral-type spacer (5)) is disposed between the battery case (18) and an open side end of the positive and negative electrode lead tabs (11, 12) formed by folding the positive and negative electrode lead tabs (11, 12).

Owner:SANYO ELECTRIC CO LTD

Display device and flexible display panel thereof

ActiveCN109087586AExtended service lifeAvoid failure damageIdentification meansStress concentrationDisplay device

The invention relates to a display device and a flexible display panel thereof. The flexible display panel comprises a screen body and a buffer layer adhering to the lower surface of the screen body,wherein the screen body comprises a display area and a non-display area extending outward from the display area, and the non-display area comprises a bending area and a non-bending area; the buffer layer extends out of the display area and covers the bending area, and the thickness of the buffer layer near the junction of the bending area and non-bending area is greater than the thickness of the buffer layer away from the junction; the buffer layer extends out of the display area and covers the bending area, so that buffer protection is performed on the bending area, and the overall thicknessof the bending area is thickened, thereby avoiding the occurrence of dead folding in the bending area; the thickness of the buffer layer at the junction of the bending area and non-bending area wherethe stress is concentrated is lager, thereby reducing the stress concentration at the position, so that a crease at the position is avoided, thereby preventing the screen body of the bending area anda circuit from being damaged and disabled.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Stack type battery and method of manufacturing the same

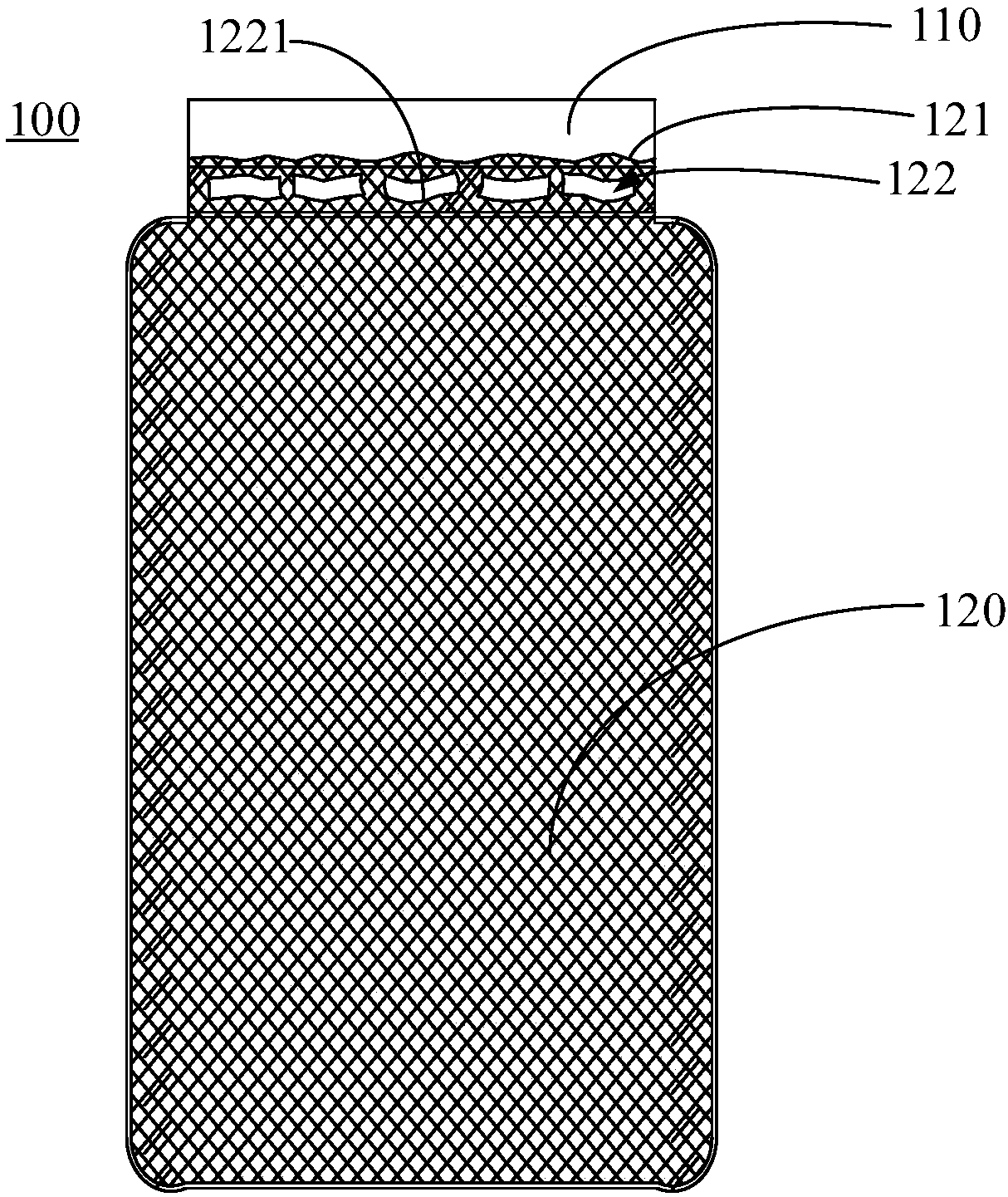

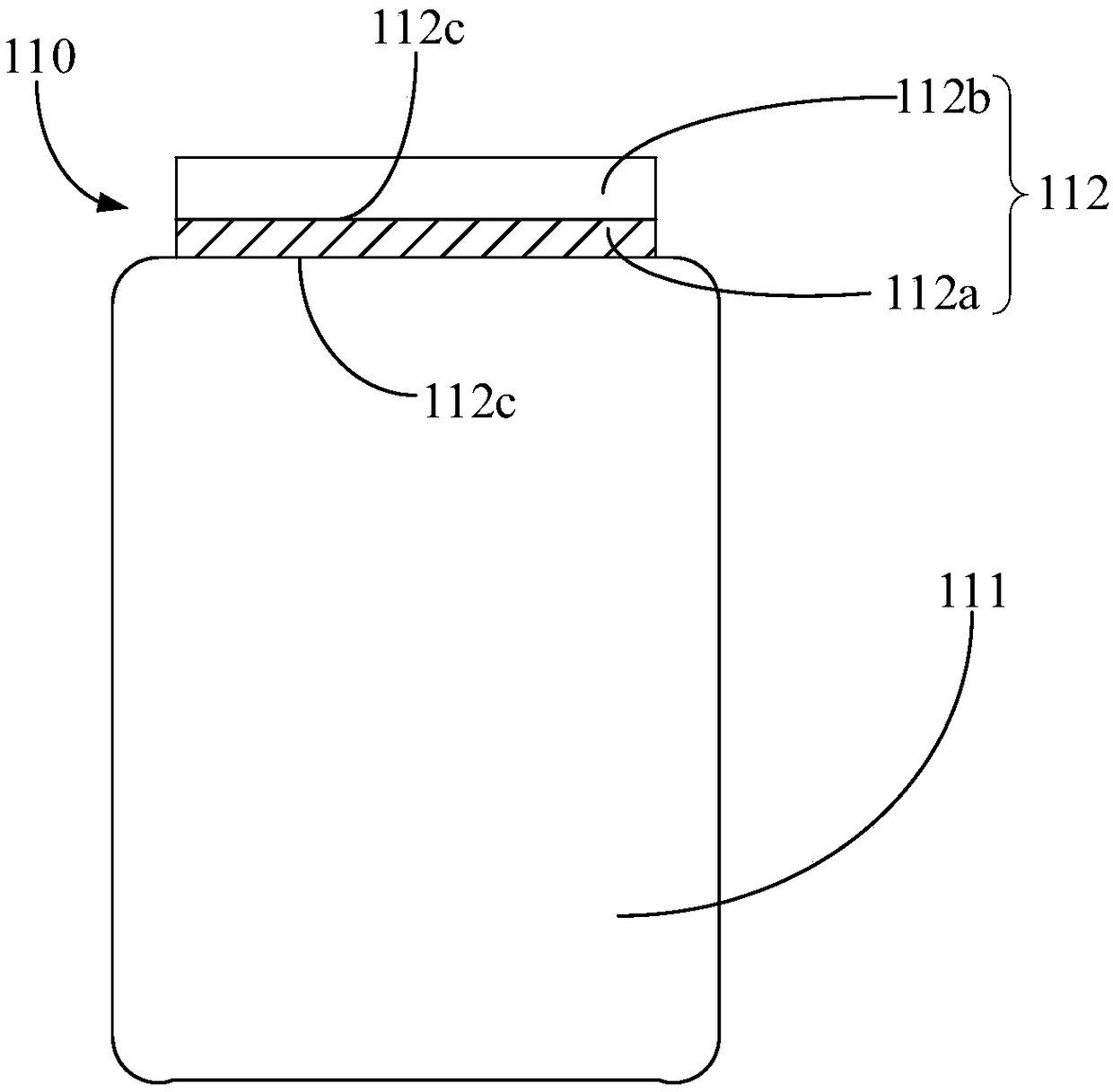

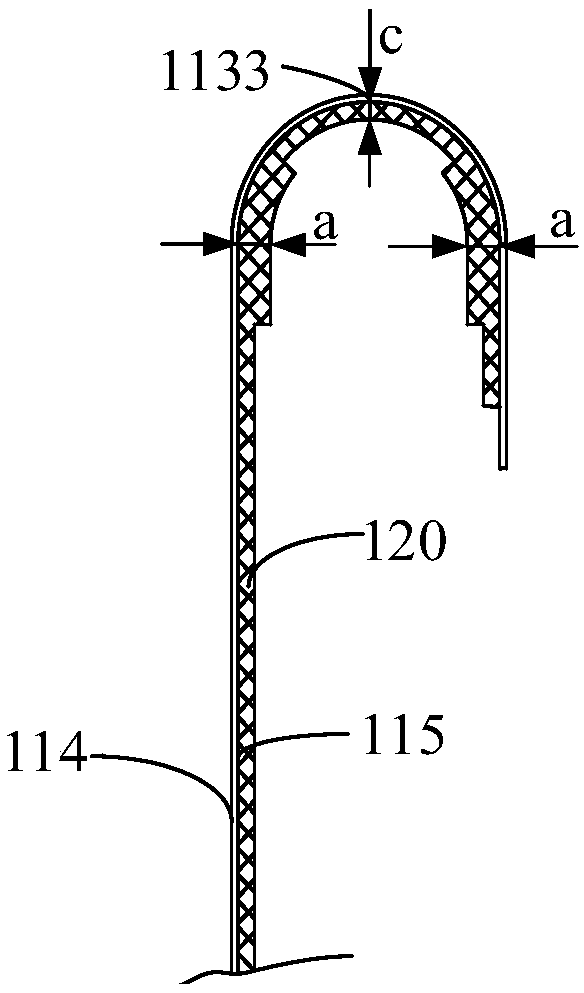

ActiveCN102629678AAvoid creasesLarge-sized flat cells/batteriesFinal product manufactureElectrical batteryElectrical and Electronics engineering

A stack type battery (A1) has a stacked electrode assembly (10) having a plurality of positive electrode plates having respective positive electrode current collector leads (11) protruding therefrom, a plurality of negative electrode plates (2) having respective negative electrode current collector leads protruding therefrom, and separators (3a) interposed between the positive electrode plates (1) and the negative electrode plates (2). The stacked positive electrode current collector leads (11) and the stacked negative electrode current collector leads are bundled at one stacking direction-wise side of the stacked electrode assembly (10), and a portion of the bundled leads is bent toward the other stacking direction-wise side. The positive electrode current collector leads (11) or the negative electrode current collector leads are provided with a fastening tape (46) for retaining a portion of the bundled leads in a folded shape so as to be pulled toward the positive and negative electrode plates (1, 2).

Owner:PANASONIC ENERGY CO LTD MORIGUCHI SHI

Electromagnetic shield film, electromagnetic shield unit and display

InactiveUS20040074655A1Easy to thinAvoid creasesTelevision system detailsMagnetic/electric field screeningElectrical conductorAdhesive

An electromagnetic wave shield film (1) comprises a transparent base (2), a conductor (4) positioned on the transparent base (2) via an adhesive (3) and having a mesh geometric pattern, and an earth portion (5) arranged around the conductor (4) and including conductive regions (501) which absorb electromagnetic waves, and non-conductive regions (510) which prevent the earth portion (5) from being creased.

Owner:HITACHI CHEM CO LTD

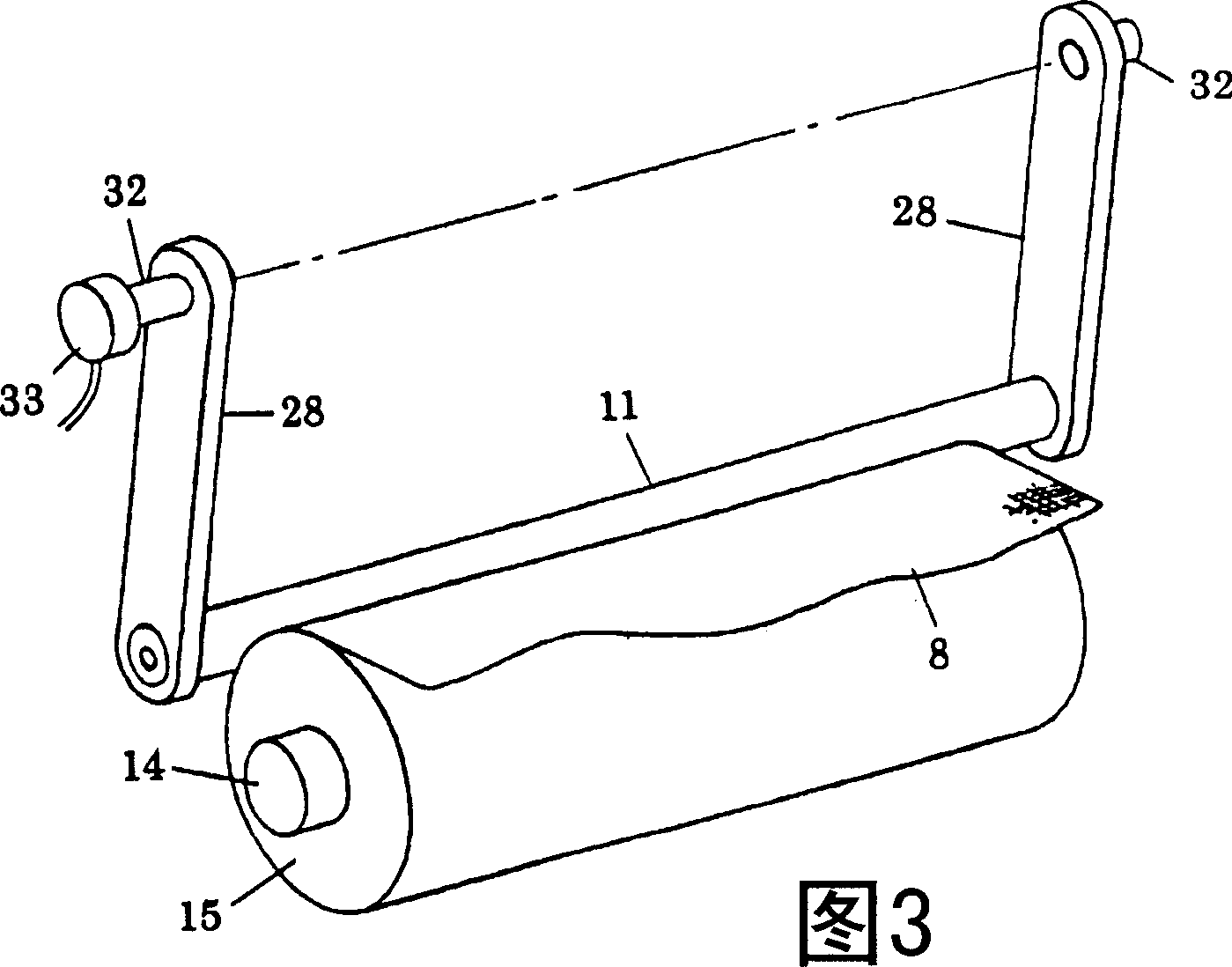

Production method and production device of film having fine irregular pattern on surface

InactiveUS20110001264A1Avoid creasesShorten the timeConfectioneryOptical articlesEngineeringThin membrane

Owner:TORAY IND INC

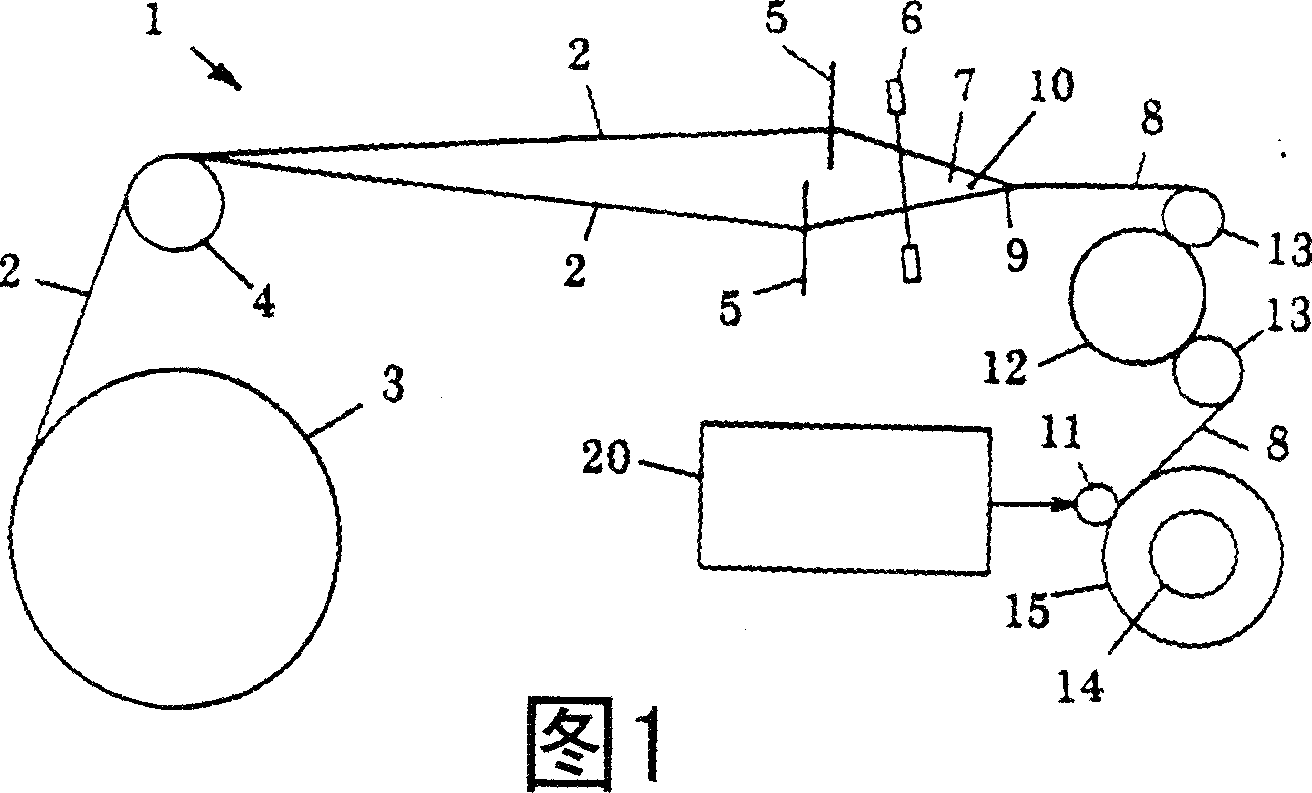

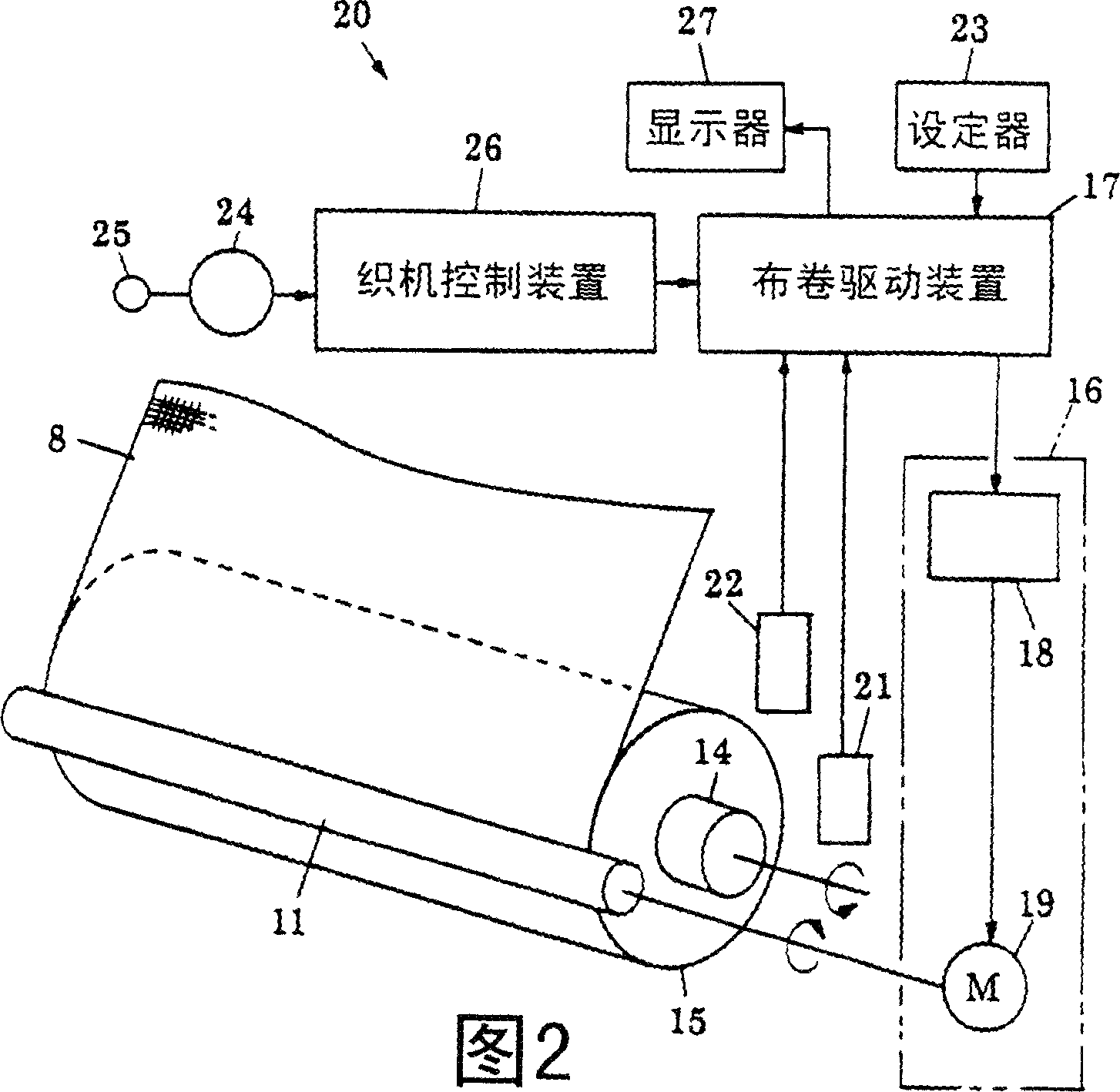

Loom take-up motion

InactiveCN1434161AAvoid creasesAvoid wrinklesLoomsFunction indicatorsConductor CoilMechanical engineering

The present invention provides a loom take-up motion (20) comprises a pressing member (pressure roller) (11) with its axis extended in parallel to that of a take-up roller (14) and pressed against a fabric roll (15) of a fabric (8) wound on the take-up roller (14), a variable-speed driving device (16) for driving the pressing member (11) for rotation about the axis thereof in a fabric winding direction, and a take-up controller(17) capable of controlling the driving device (16) by giving a speed signal produced on the basis of take-up speed at which the fabric (8) is wound round the take-up roller (14) to the driving device (16) to control the surface speed of the pressing member (11) properly according to weaving conditions including the type of the fabric (8) and the diameter of the fabric roll (15). The pressing member (11) is rotated positively while the fabric (8) is being wound round the take-up roller (14) to prevent forming folds and creases in the fabric(8) in the fabric roll (15).

Owner:TSUDAKOMA KOGYO KK

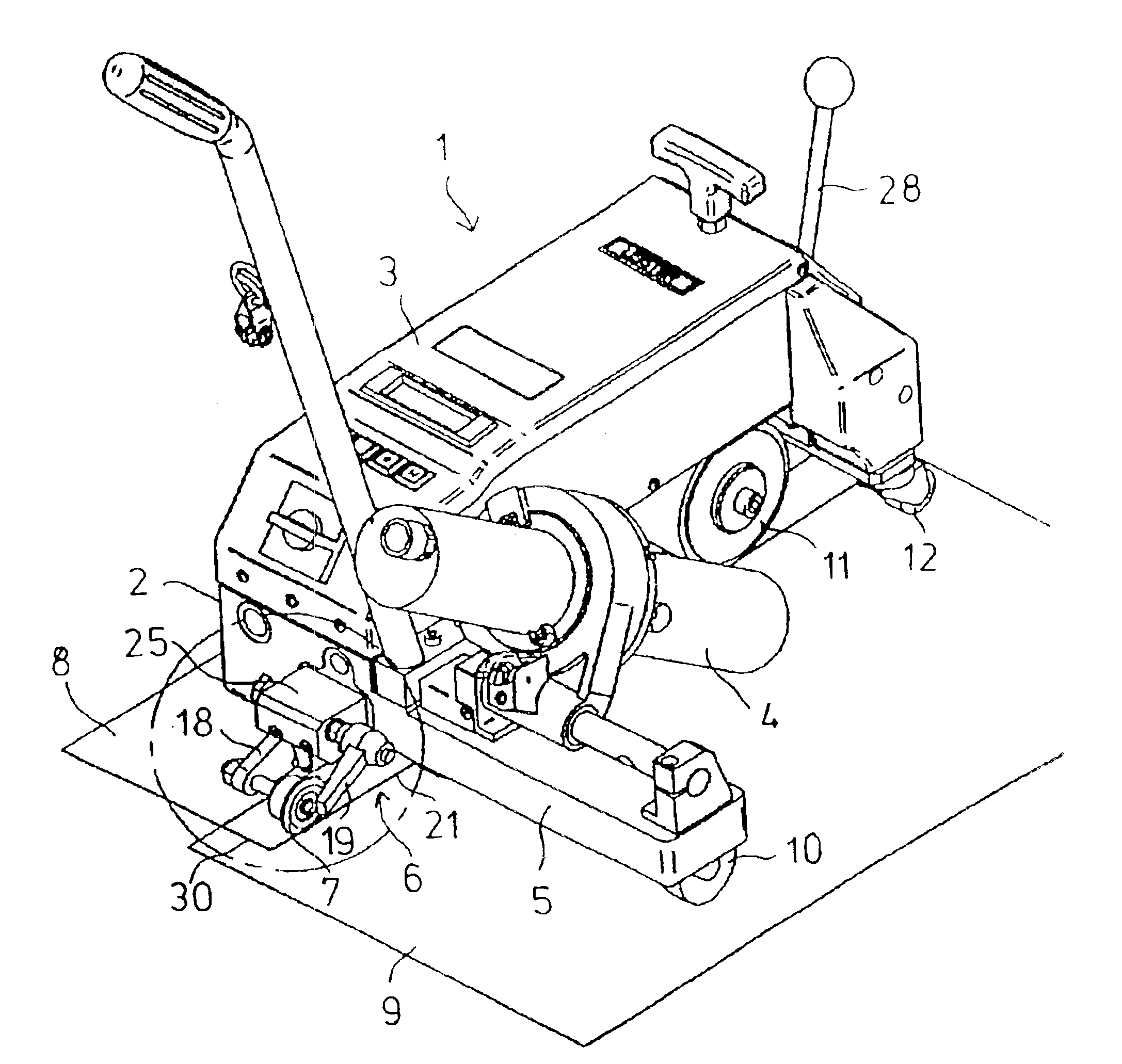

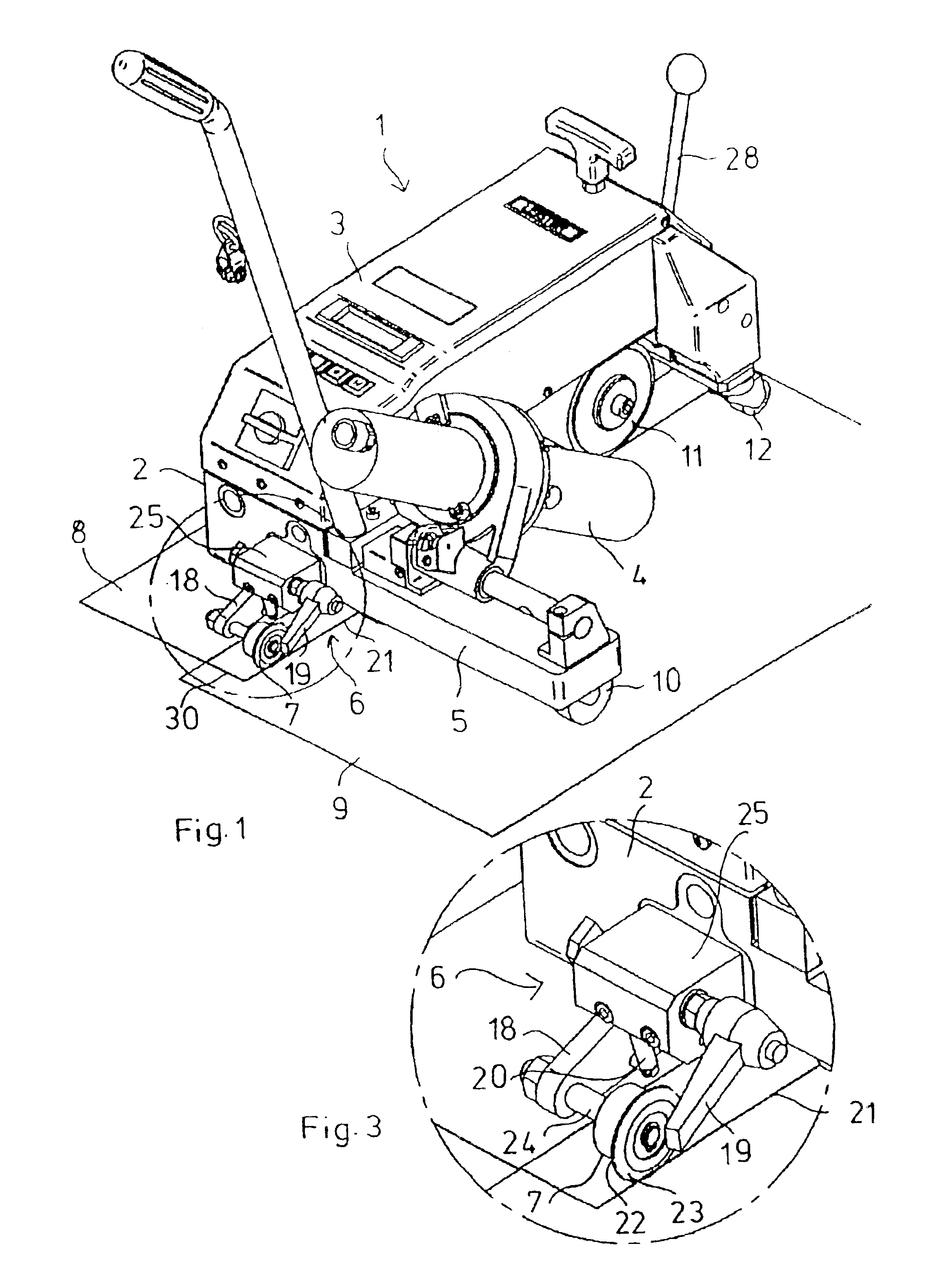

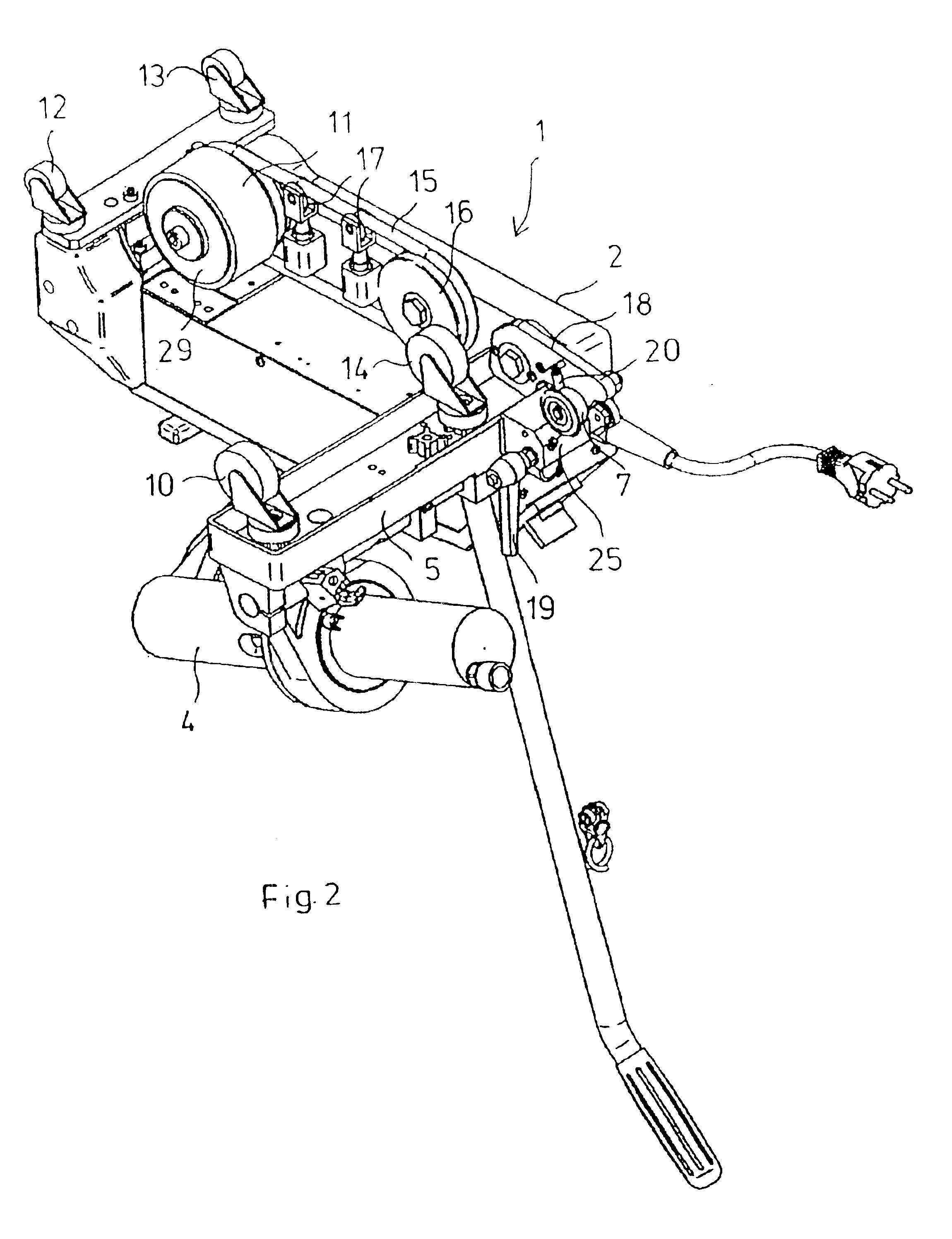

Automatic welding machine

InactiveUS6866077B2Prevent forward movementWeld is also clearly improved visuallyLaminationLamination apparatusPlastic materialsEngineering

An automatic welding machine for planar plastic materials, such as sealing sheets, tarpaulins or films, the chassis, in the welding position, in addition to being carried by the driving unit and the pressure device, also being carried by a rigid guide wheel, preferably in the front region of the chassis. With respect to a pressure roller running essentially on the welded overlap region, the guide wheel is arranged in such a way that, during the welding, it runs along the bottom plastic material parallel to the edge of the top plastic material. In addition, the guide wheel has a narrow running surface. During the welding, the guide wheel runs along the edge of the overlapping plastic material and the pressure roller runs essentially on the weld region. Due to this configuration, the automatic welding machine can follow the edge in such a way as to keep to the track, so that guidance by the operator or frequent corrections of the welding direction are not necessary. This leads to an increased weld quality and also to a higher welding speed. There is less interference from the background or due to the welding device swinging in laterally.

Owner:LEISTER TECHNOLOGIES

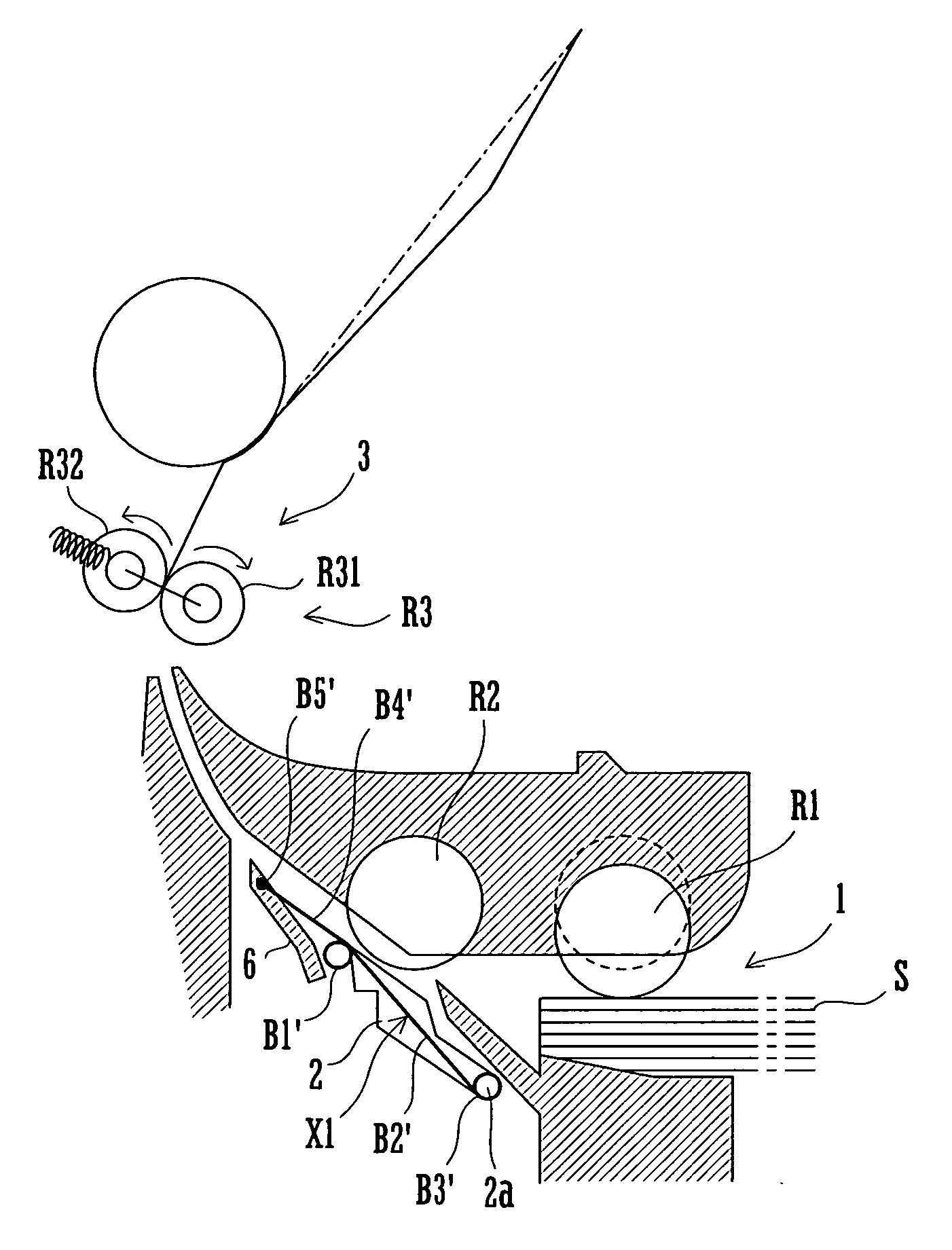

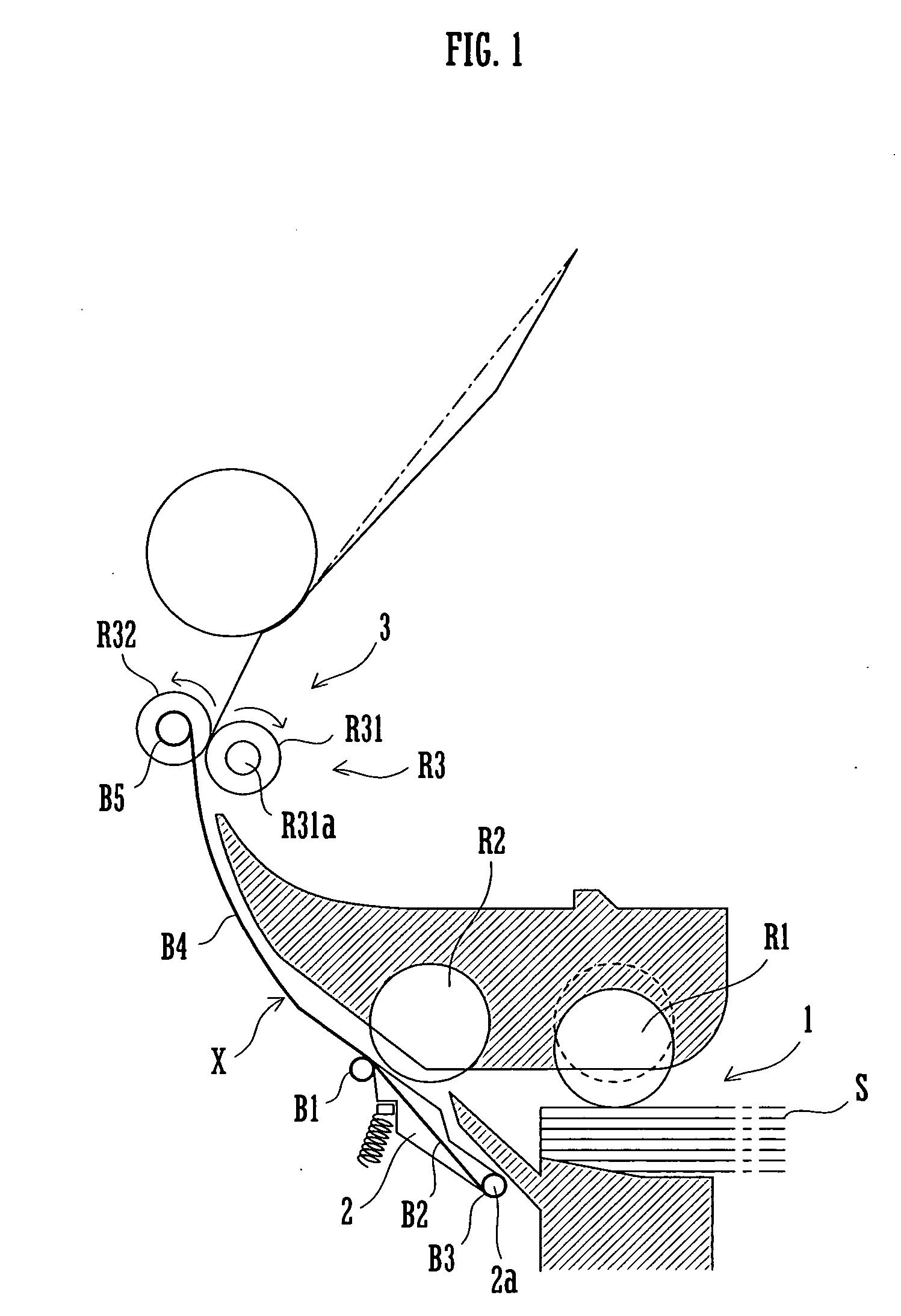

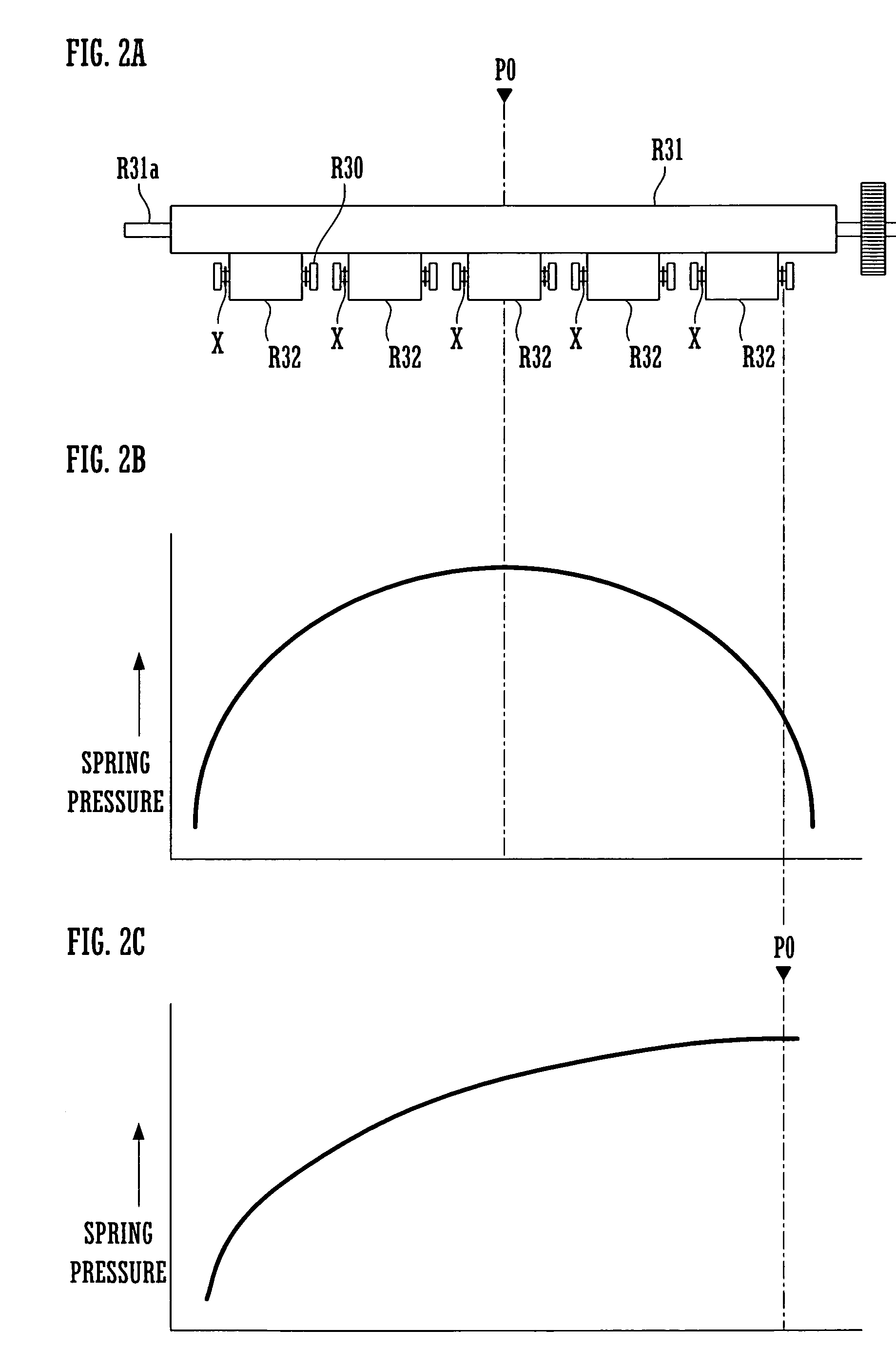

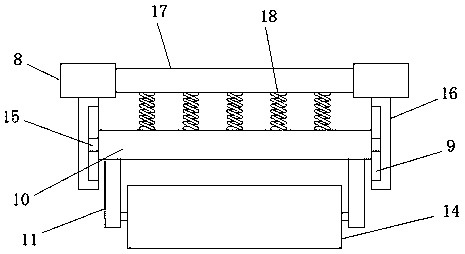

Sheet-conveying mechanism

InactiveUS20060180989A1Smooth trafficBridging the gapArticle feedersArticle separationCoil springEngineering

A sheet transport guide includes a torsion coil spring (X). The spring (X) has a first arm (B4) with an end (B5). Through the end (B5), the spring (X) supports a rotation shaft of driven roller (R32) and applies elastic force to the roller (R32). Through the arm (B4) that is curved, the spring (X) guides a sheet toward a rotation roller R31. The spring (X) has a coil portion (B1) and an end (B3) of a second arm (B3) both fixed to a frame of an apparatus body. A plurality of driven rollers (R32) are aligned approximately parallel to a shaft (R31a) of the roller (R31). The rollers (R32) are each provided with the springs (X). A largest elastic force is applied to the roller (R32) at a predetermined reference position, and smaller elastic forces are applied to the other rollers (R32) at positions distant from the reference position.

Owner:SHARP KK

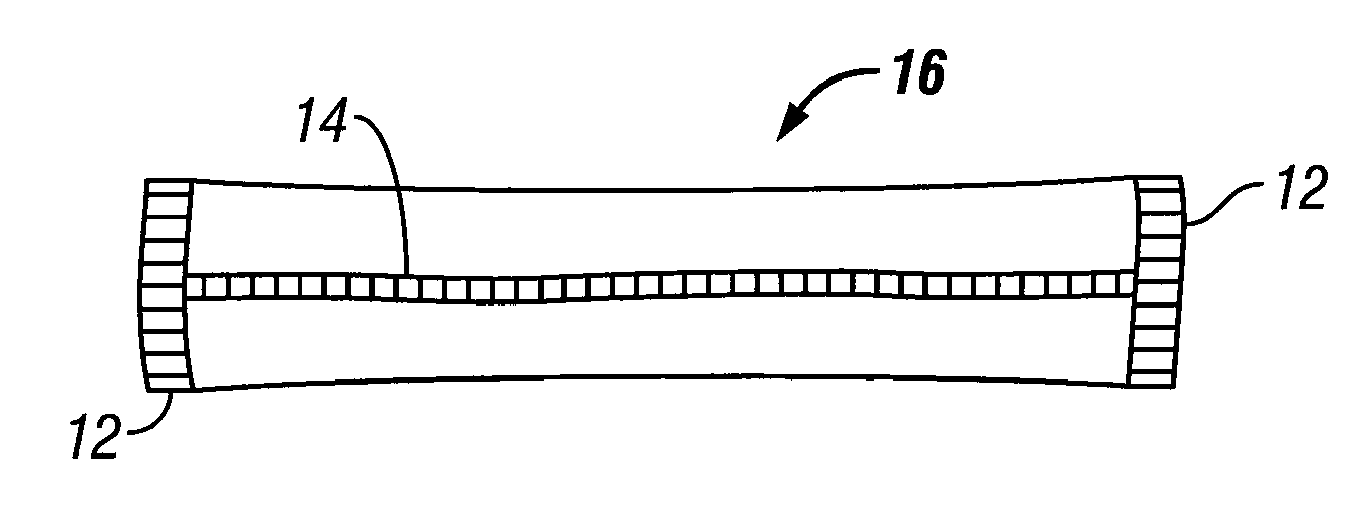

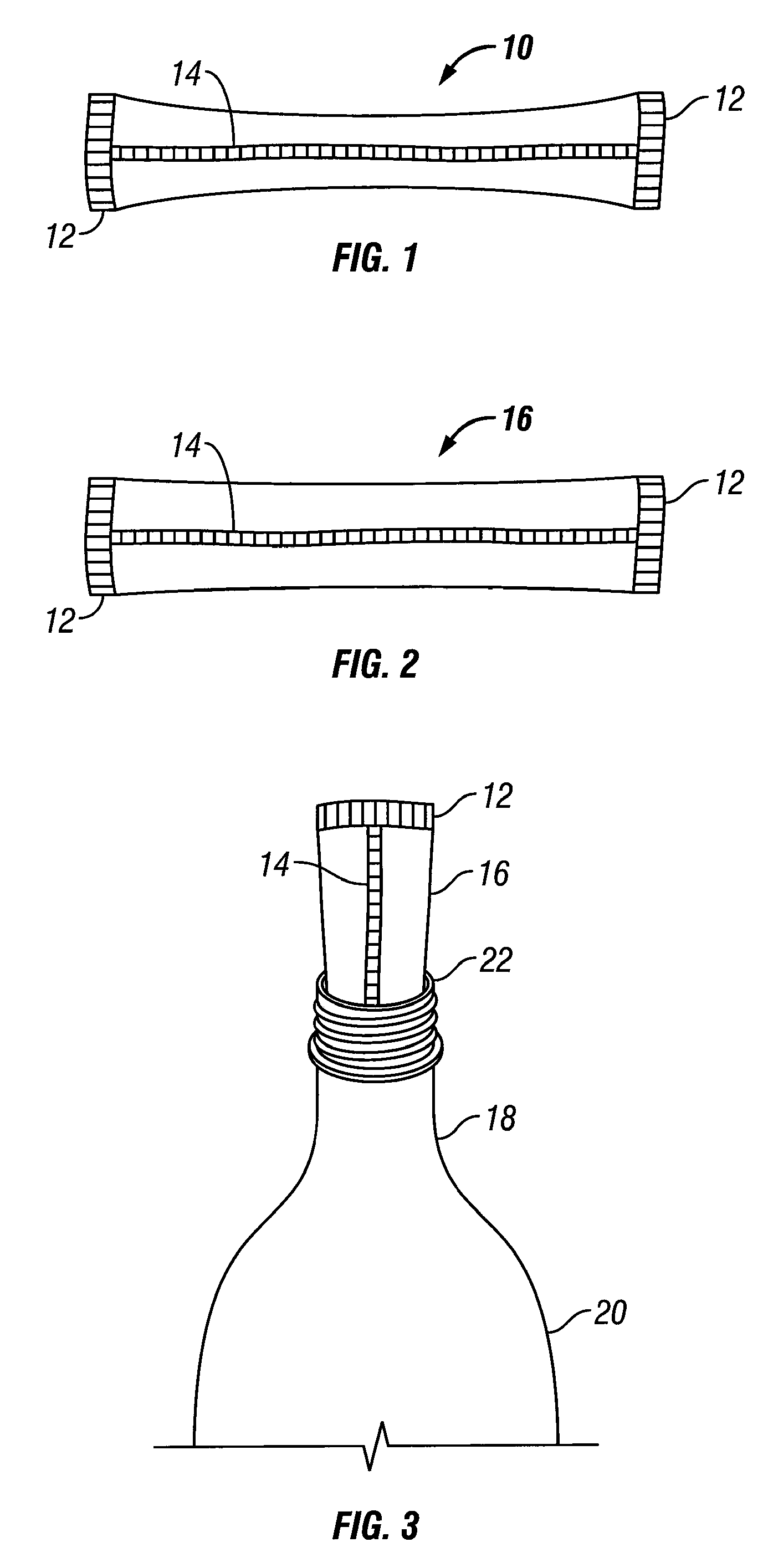

Pressurized water-soluble pouch

InactiveUS7325688B1Easily fitLess susceptible to ruptureFlexible coversWrappersWater solubleAqueous solution

A pressurized pouch is made of a water-soluble material, preferably PVA film, to hold a concentrated product for later mixing in a bottle to provide a water solution. Because of the interior pressure, the water-soluble pouch retains a semi-rigid resilient shape that greatly facilitates its introduction through the neck of the bottle. The pressurized pouch can be made by either VFFS or HFFS machines wherein a puff of air is added prior to sealing. Alternatively, the pouch is made by filling it in a pressurized chamber.

Owner:GOWAN MILLING

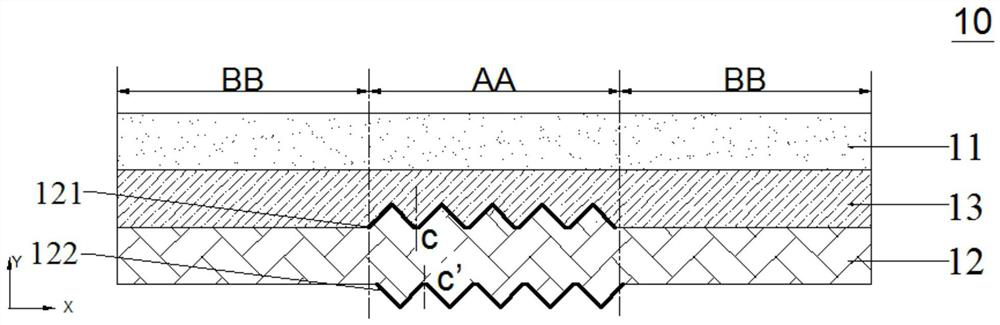

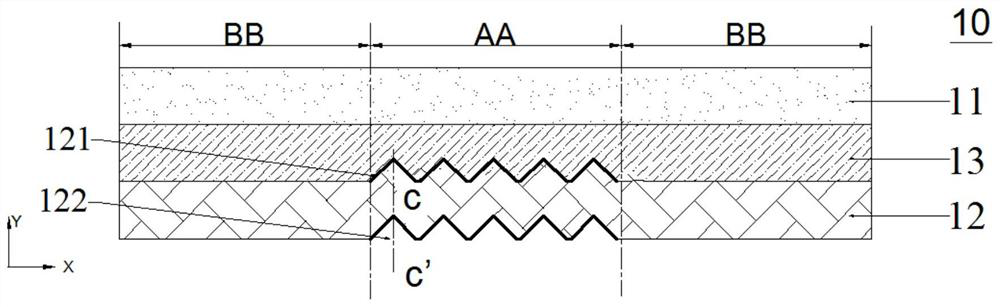

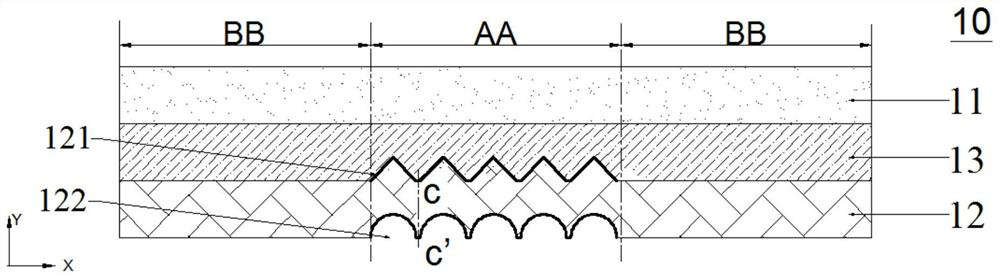

Flexible display module, flexible display device and manufacturing method of flexible display module

The invention discloses a flexible display module, a flexible display device and a manufacturing method of the flexible display module. The flexible display module comprises a bending area and a non-bending area, and further comprises a flexible display panel and a supporting layer arranged on the side, away from a light emitting side, of the flexible display panel, wherein the supporting layer comprises an extensible part corresponding to the bending area, the first surface, close to the flexible display panel, of the extensible part is provided with a first extensible structure, and the second surface, away from the flexible display panel, of the extensible part is provided with a second extensible structure. According to the flexible display module provided by the invention, the stretchable first extensible structure and the stretchable second extensible structure are respectively arranged on the two opposite surfaces of the supporting layer corresponding to the bending area, so that when the supporting layer supports the flexible display panel, adaptive stretching can be achieved through the first extensible structure and the second extensible structure according to the direction and the size of received bending stress, and the problem of folding marks caused by stress concentration of a bending area can be avoided.

Owner:BOE TECH GRP CO LTD +1

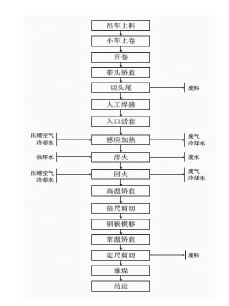

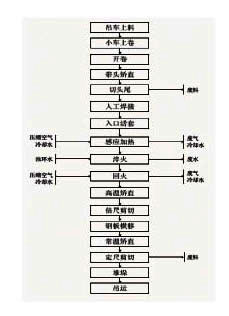

Production process for high-performance steel plate thermal treatment unit

ActiveCN101935750AEasy to unwindUnwinding and other processes are reliableFurnace typesProcess efficiency improvementHigh intensityThermal treatment

The invention relates to the technical field of high-performance steel plate thermal treatment, in particular to a production process for a high-performance steel plate thermal treatment unit. The process comprises the following steps of: carry out the following controls after hot-rolling steel coils are transported into a rolling cylinder of an uncoiler through a coil car and then fed into a pinch roll: regulating a deep bending roll to enter a preset position and straightening in a No.1 straightener after passing through a No.1 side guide device; cutting off the head waste materials of the straightened steel plates in the cutting position of an opening, and carrying out the centring welding and the manual welding in the position of a welding platform; feeding the welded steel plates into an entrance loop; pulling the steel plates out from the loop and transferring to a process section; then sequentially carrying out the thermal treatments of induction heating, quenching, tempering, and the like so as to reach mechanical performances required for the steel plates; then carrying out straightening and slitting; carrying out the multiple feet cutting on the steel plates by a pair of plasma scissors; and transferring the cut steel plates to a finished product storage. The invention can ensure that the yield strength of the steel plates produced by adopting the process can reach above 1000MPa; and the steel plates can reach the performance requirements on high strength, high toughness and cold bending.

Owner:LIAONING HENGYE HI TECH NEW MATERIAL

Lithium ion secondary battery and preparation method thereof

ActiveCN102709592AImprove charge and discharge efficiencyImprove securityCell electrodesFinal product manufactureMetallic lithiumDischarge efficiency

The invention discloses a lithium ion secondary battery and a preparation method thereof, and belongs to the field of lithium ion secondary batteries. The anode layer of the lithium ion secondary battery has a layered structure, and comprises an anode current collector. An anode material layer consisting of two outer hard carbon material layers and a lithium metal layer between the two hard carbon material layers is adhered to one or two surfaces of the anode current collector, wherein the lithium metal layer is plated on the hard carbon material layers by adopting an ion sputtering method. An irreversible capacity compensation layer of the lithium ion secondary battery is the lithium metal layer sandwiched between the hard carbon material layers, is uniformly distributed, and can avoid the risk that a diaphragm is pierced by lithium metal or lithium dendrites, wherein the lithium ion secondary battery has the advantages of high charging and discharging efficiency, high safety and the like.

Owner:DONGFANG ELECTRIC CORP LTD

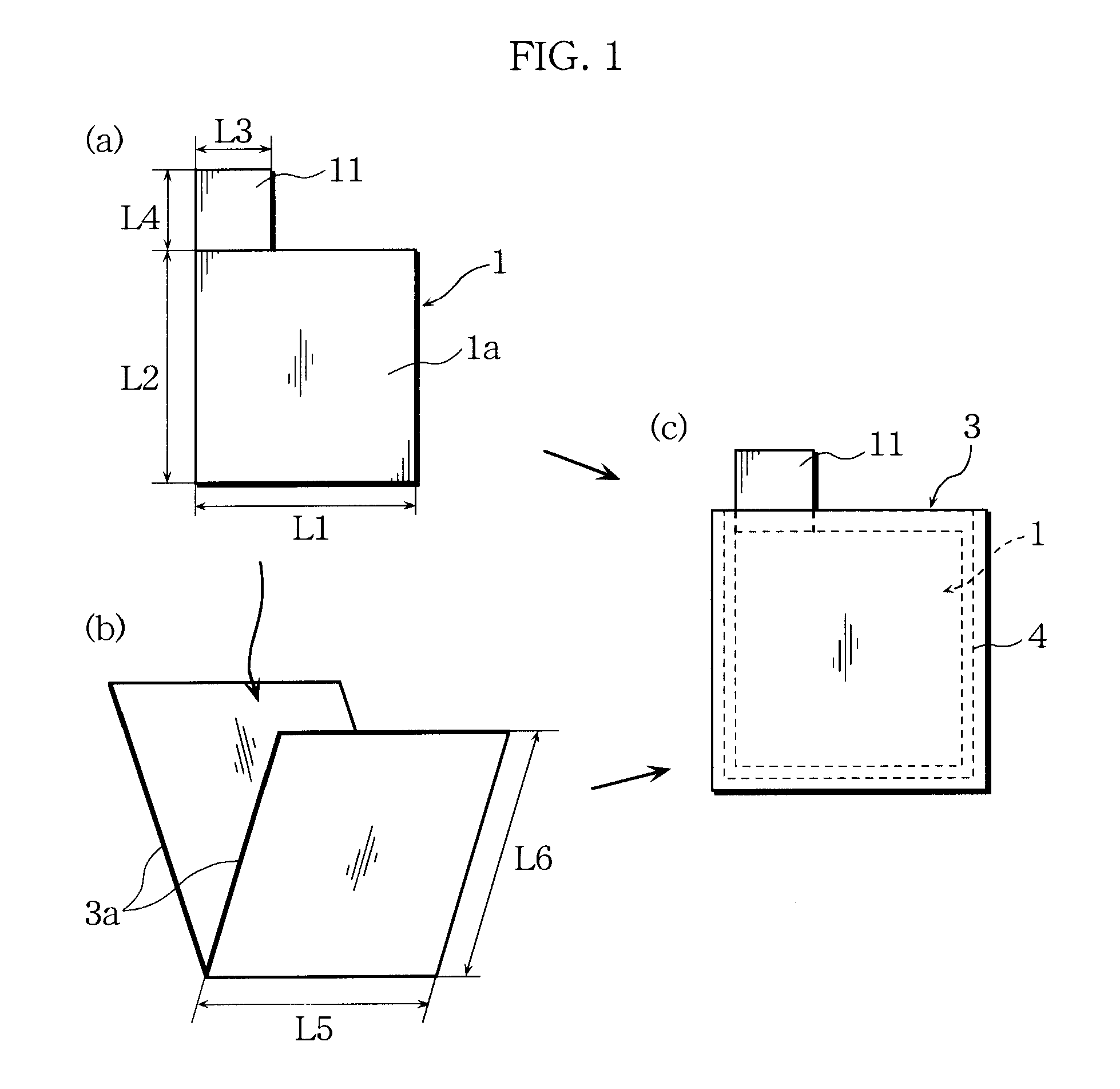

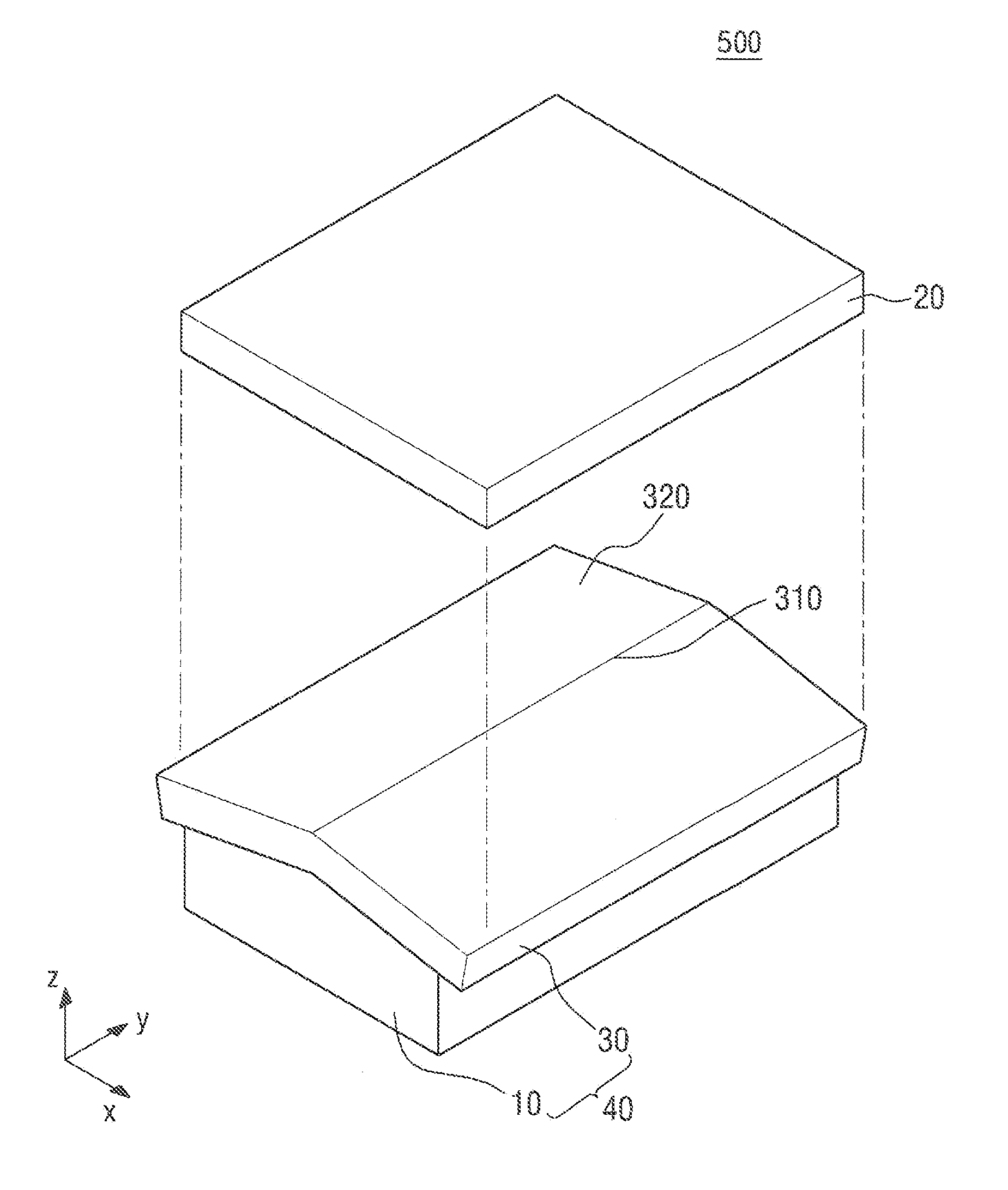

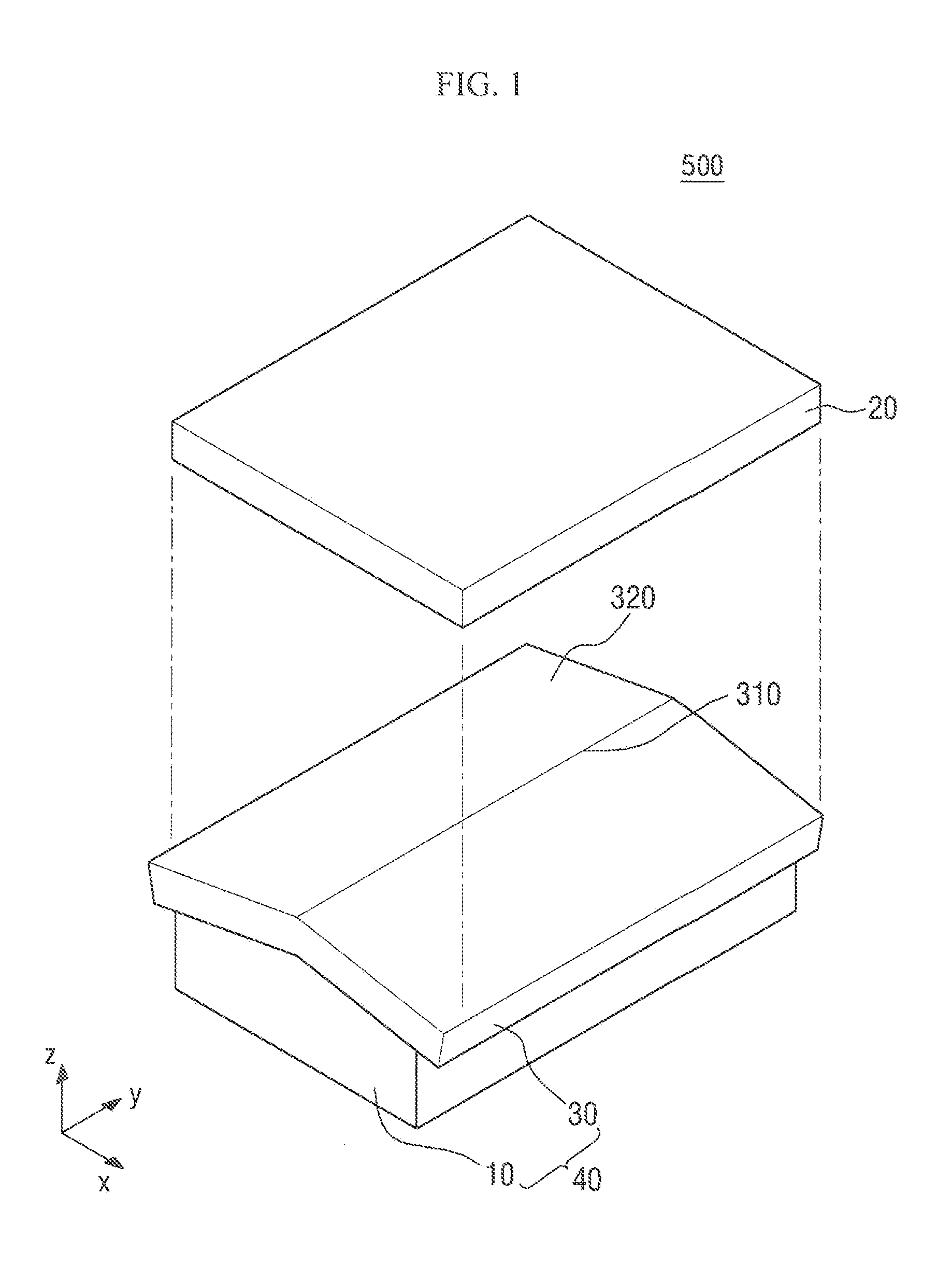

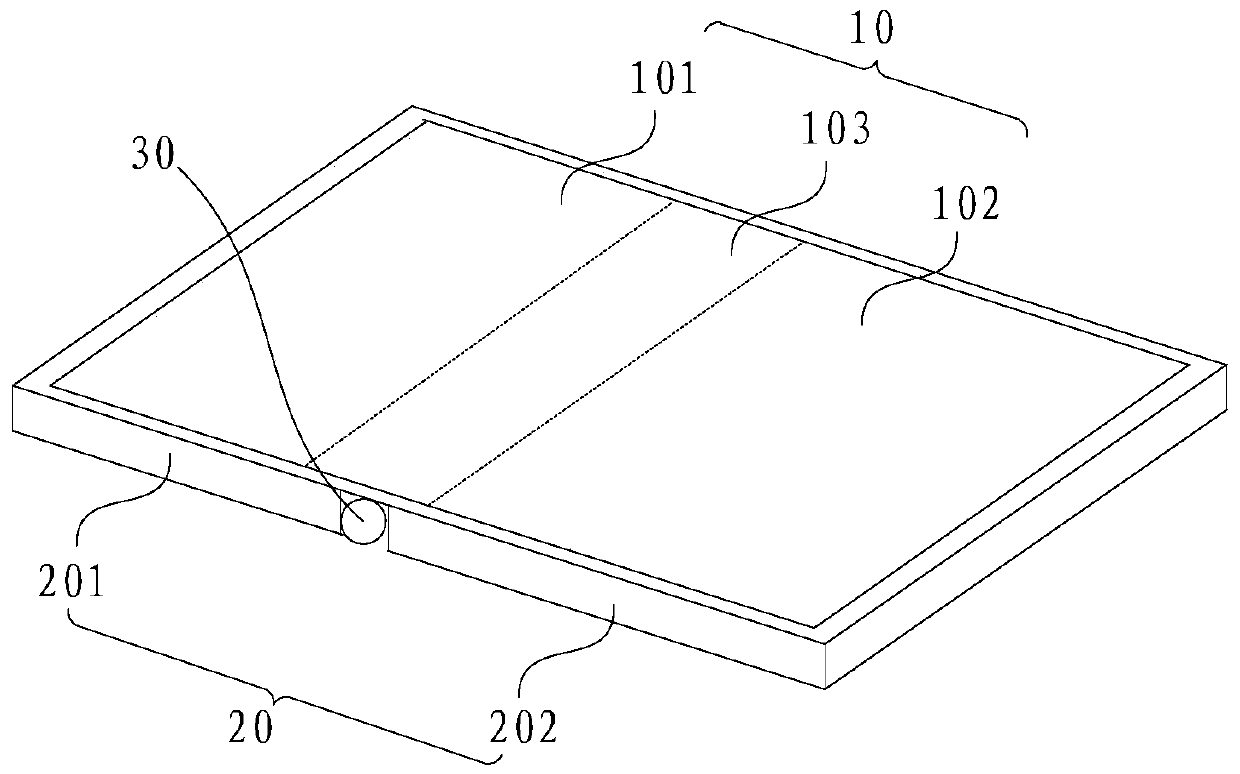

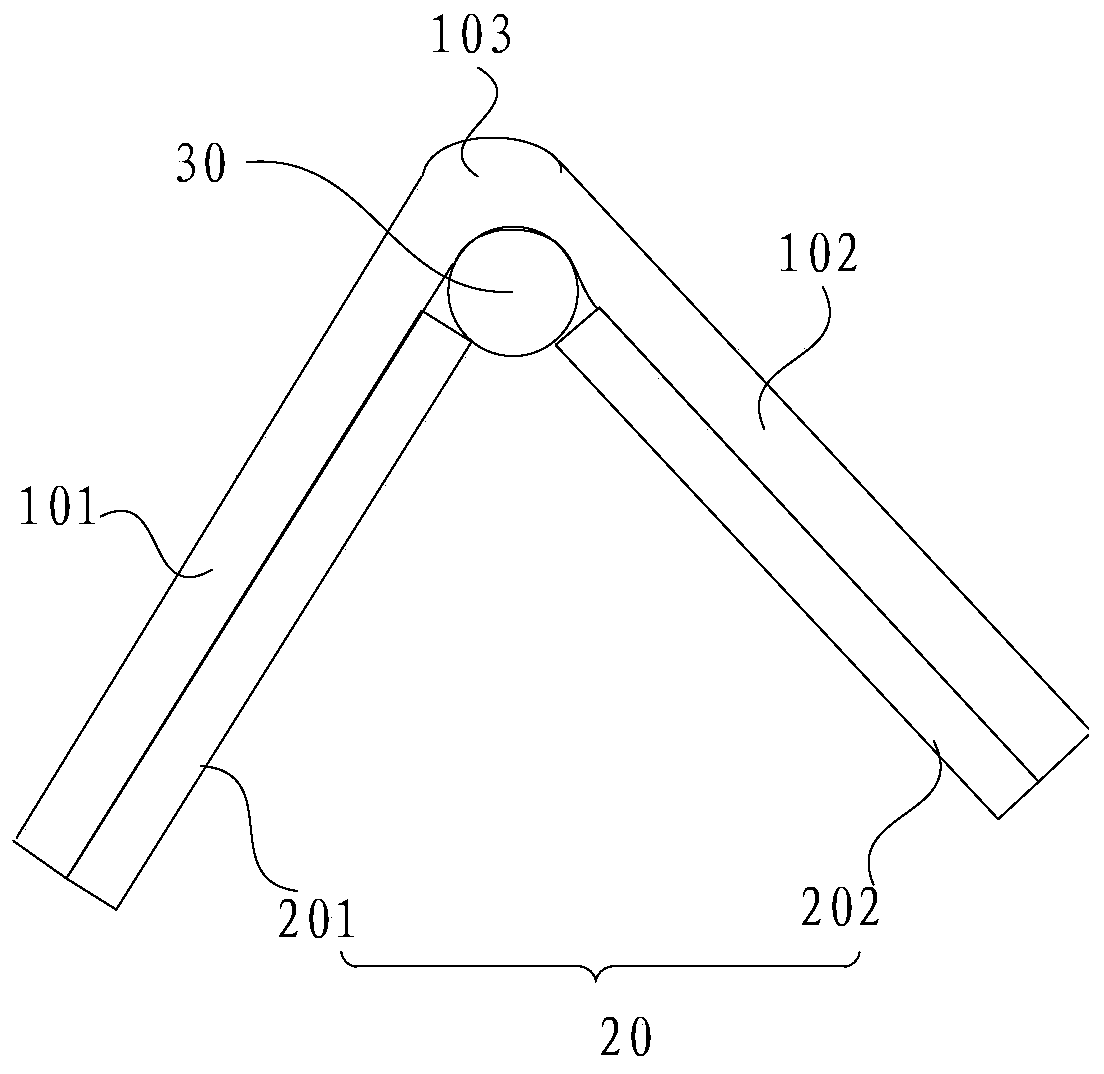

Jig assembly, laminating apparatus, and laminating method using the laminating apparatus

ActiveUS20140299269A1Avoid creasesInhibition formationLayered product treatmentWelding/cutting auxillary devicesEngineeringMechanical engineering

Provided are laminating apparatus and method. A laminating apparatus includes a jig assembly, which includes the first jig and an elastic member, and a second jig. A laminating method includes placing a first plate on a jig assembly, placing a second plate on a second jig which is placed to face the first jig, bringing the second plate into contact with the adhesive layer by making the jig assembly and the second jig approach each other, and, attaching the first plate and the second plate to each other by making the jig assembly and the second jig approach closer to each other. The jig assembly includes a first jig and an elastic member which comprises a top portion and sloping portions sloping downward from the top portion. An adhesive layer is disposed between the first plate and the second plate.

Owner:SAMSUNG DISPLAY CO LTD +1

Drying device for textile use

InactiveCN108217258AEfficient dryingAvoid creasesDrying gas arrangementsDrying machines with progressive movementsEngineeringCotton material

The invention discloses a drying device for textile use. The drying device for textile use comprises a drying box which is of a hollow cuboid structure, wherein air blowers which are symmetrically arranged are arranged on the inner wall of the top end and the inner wall of the bottom end of the drying box; symmetrically arranged electric heating wires are arranged in the drying box; the two electric heating wires are located between the two air blowers; two symmetrically arranged first connecting plates are connected to one side of the drying box; a rotating motor is mounted on one side of oneof the first connecting plates through screws, and a winding roller is rotatably connected between the first connecting plates; and the output shaft of the rotating motor is connected to one end of the winding roller through the first connecting plates. The drying device for textile use disclosed by the invention is novel in structure, can dry textile cloth effectively, can roll the dried textilecloth and can prevent the textile cloth from being wrinkled, so that the attractive degree of the textile cloth is guaranteed while the drying quality is improved.

Owner:江苏爱纺纺织有限公司

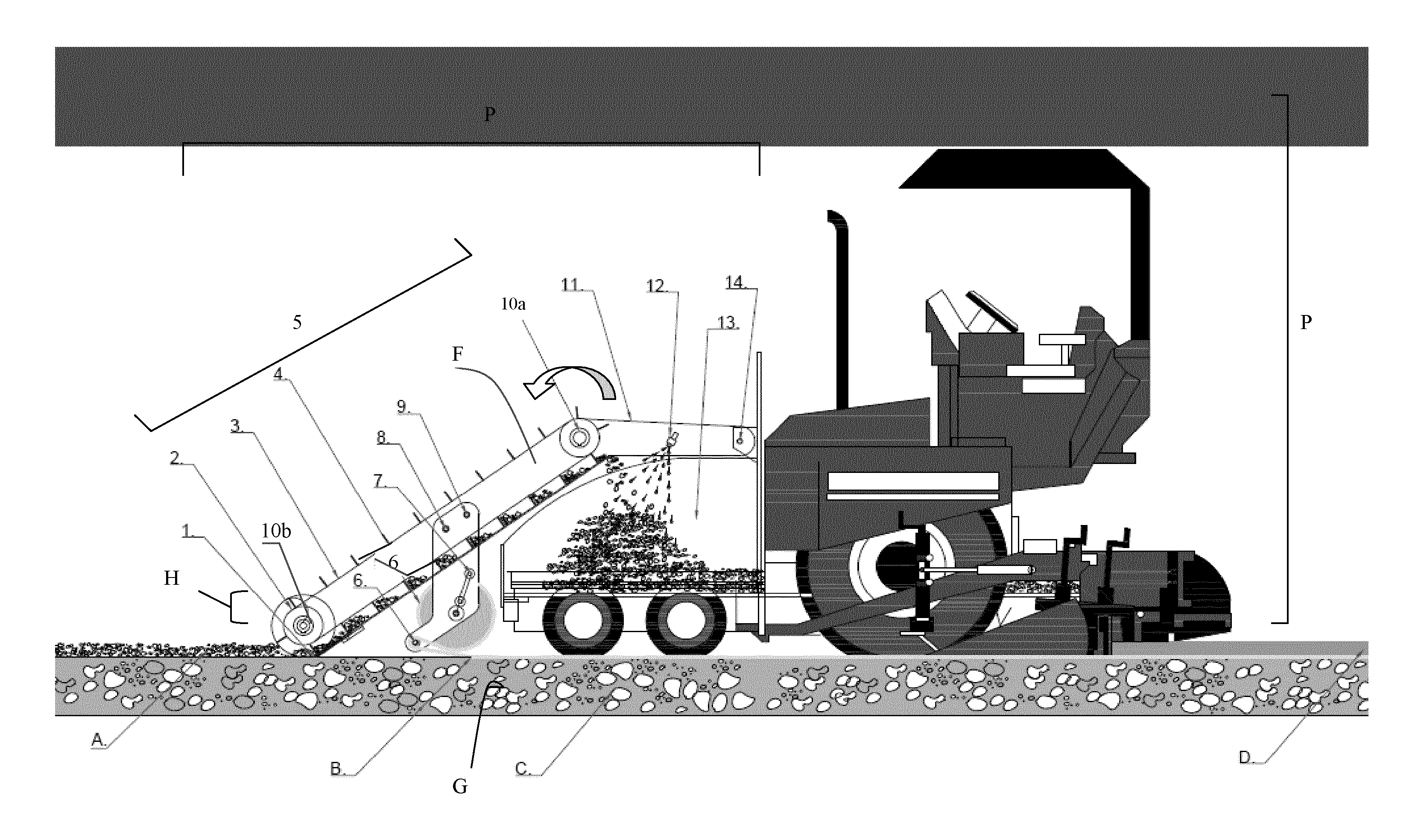

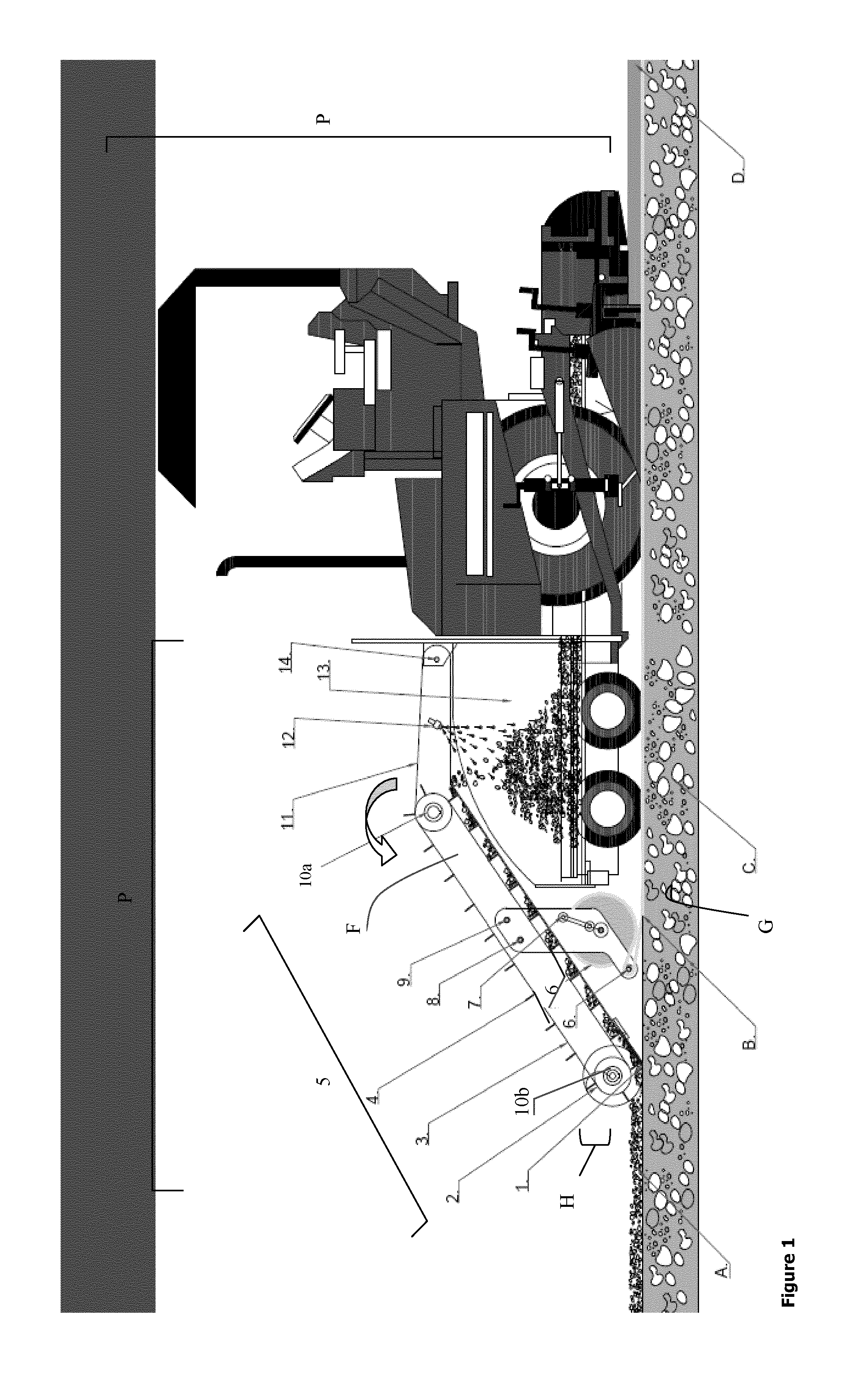

Road strengthening and reinforcement during a recycling process

InactiveUS20140270953A1Prevent kinkingAvoid creasesIn situ pavingsOther manufacturing equipments/toolsCyclic processRoad surface

The invention relates to an optional additional process during routine rehabilitation or recycling of road surfaces. More particularly, the invention relates to a process whereby a geomaterial, whether mesh, membrane, textile, grid or fabric membrane is placed underneath in-situ road surface material, which has been loosened as part of a regenerative or recycling process, as an added structural benefit to the rehabilitated road structure.

Owner:TONY DUFFY ENG

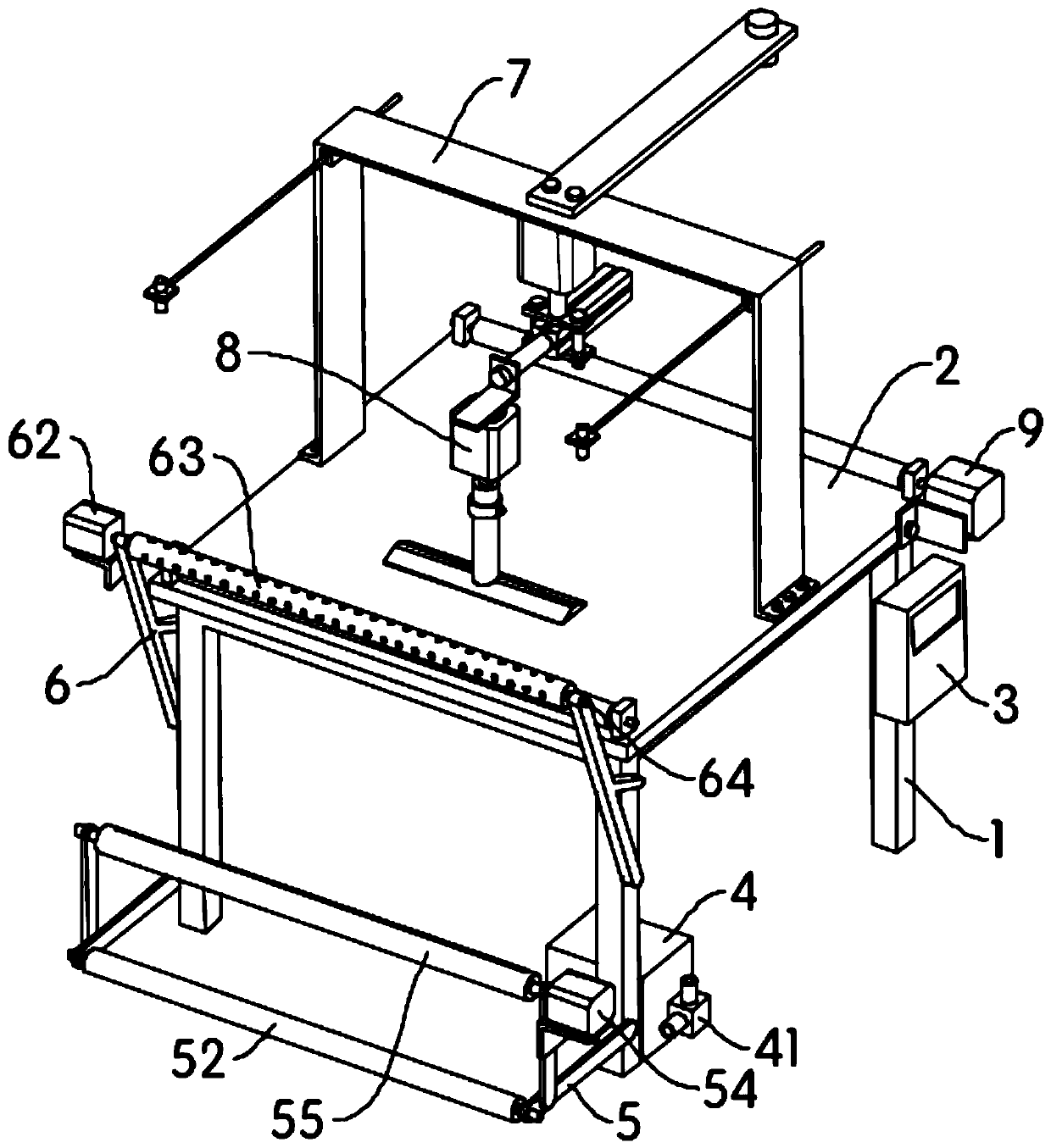

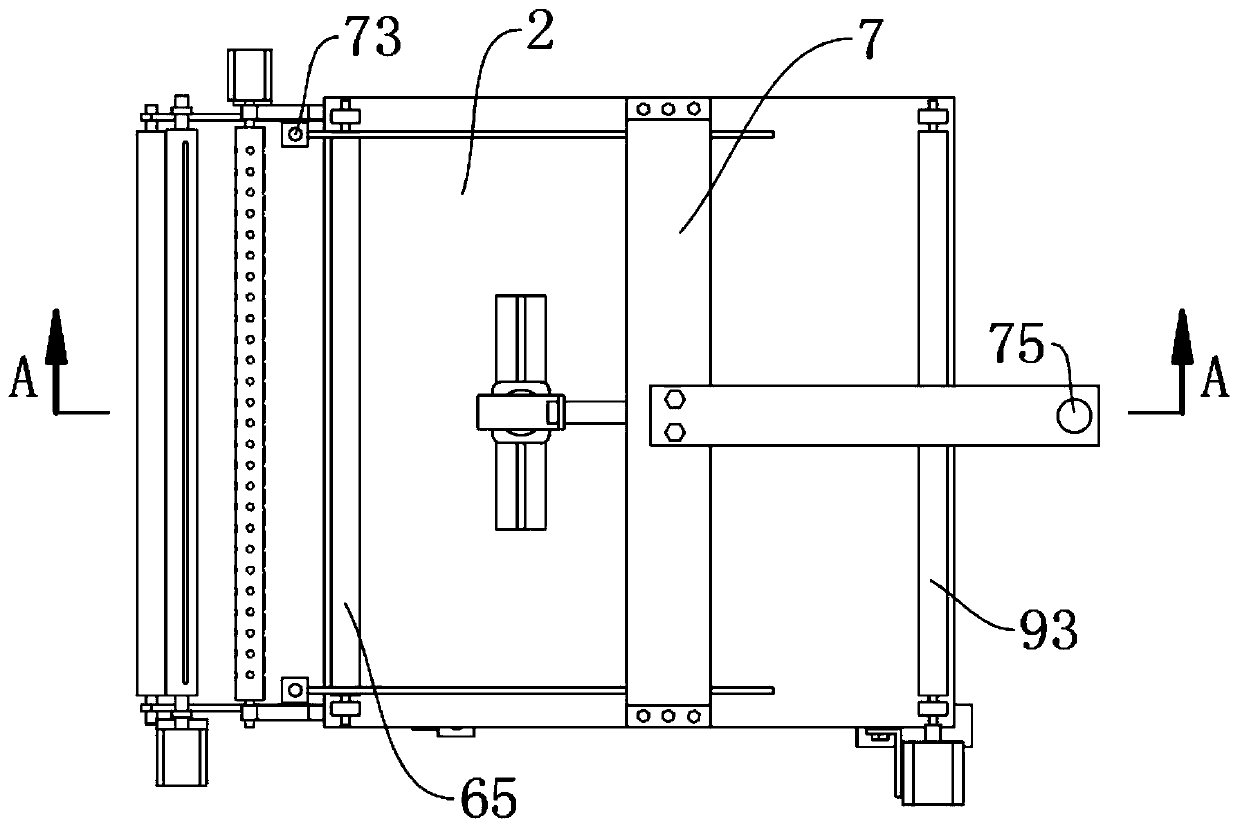

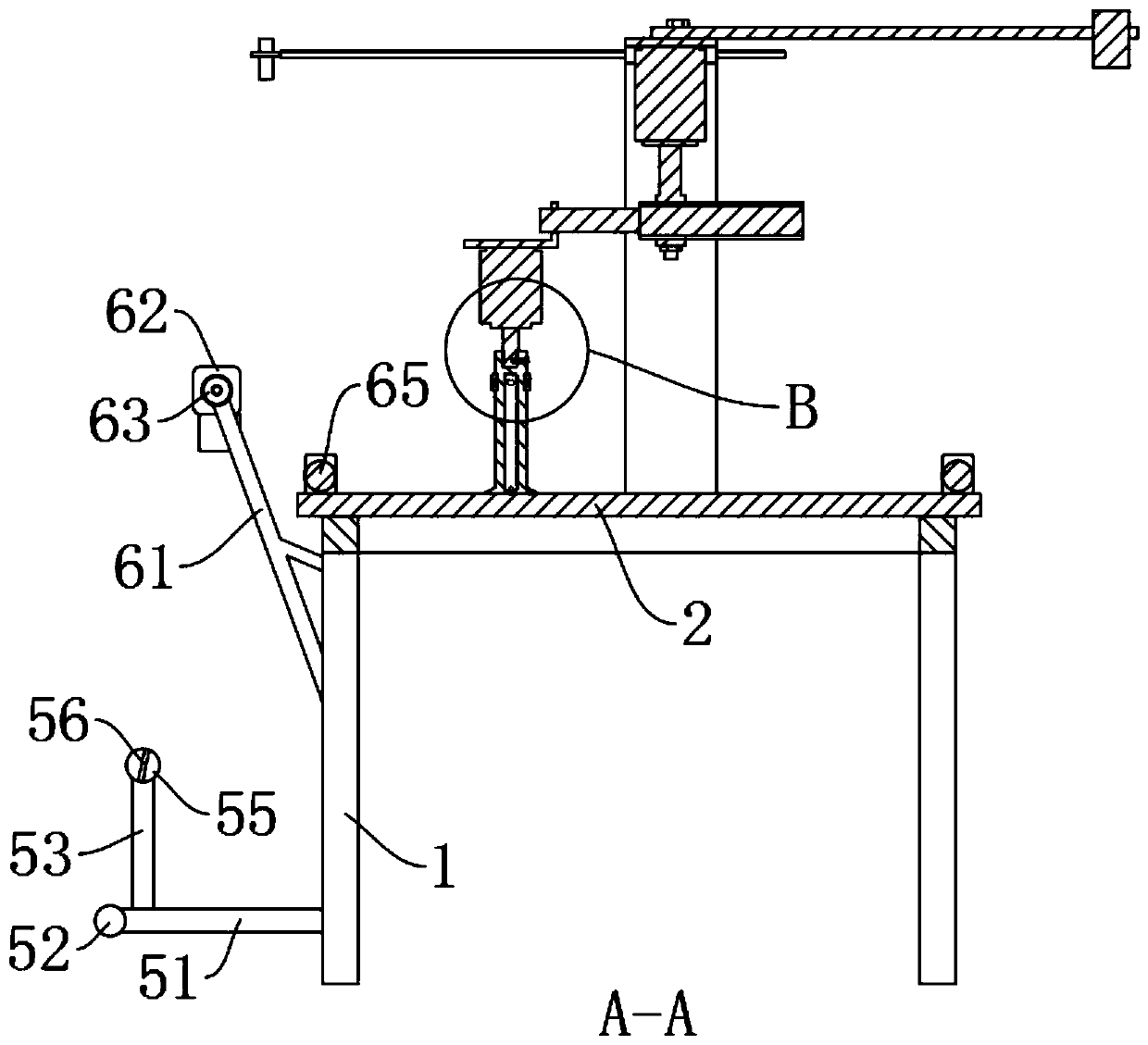

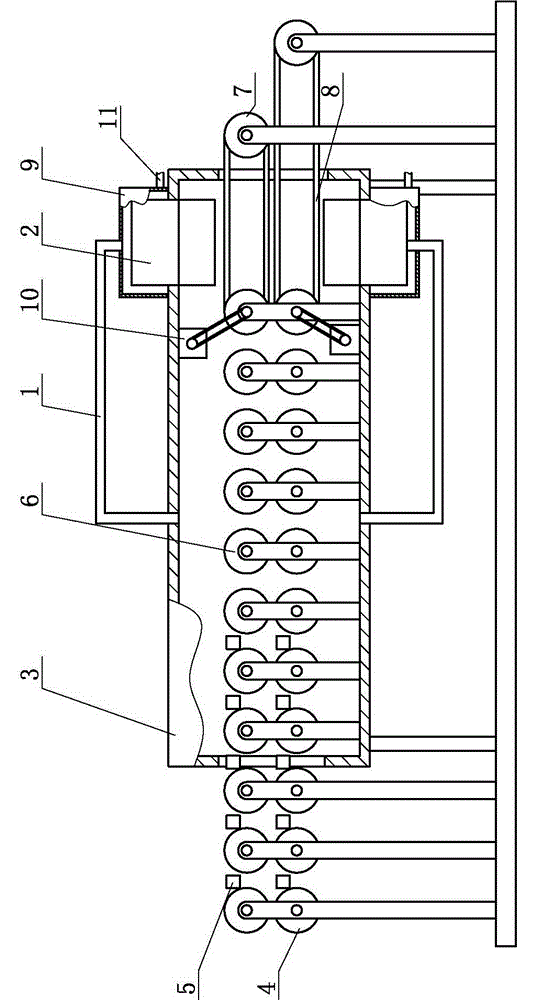

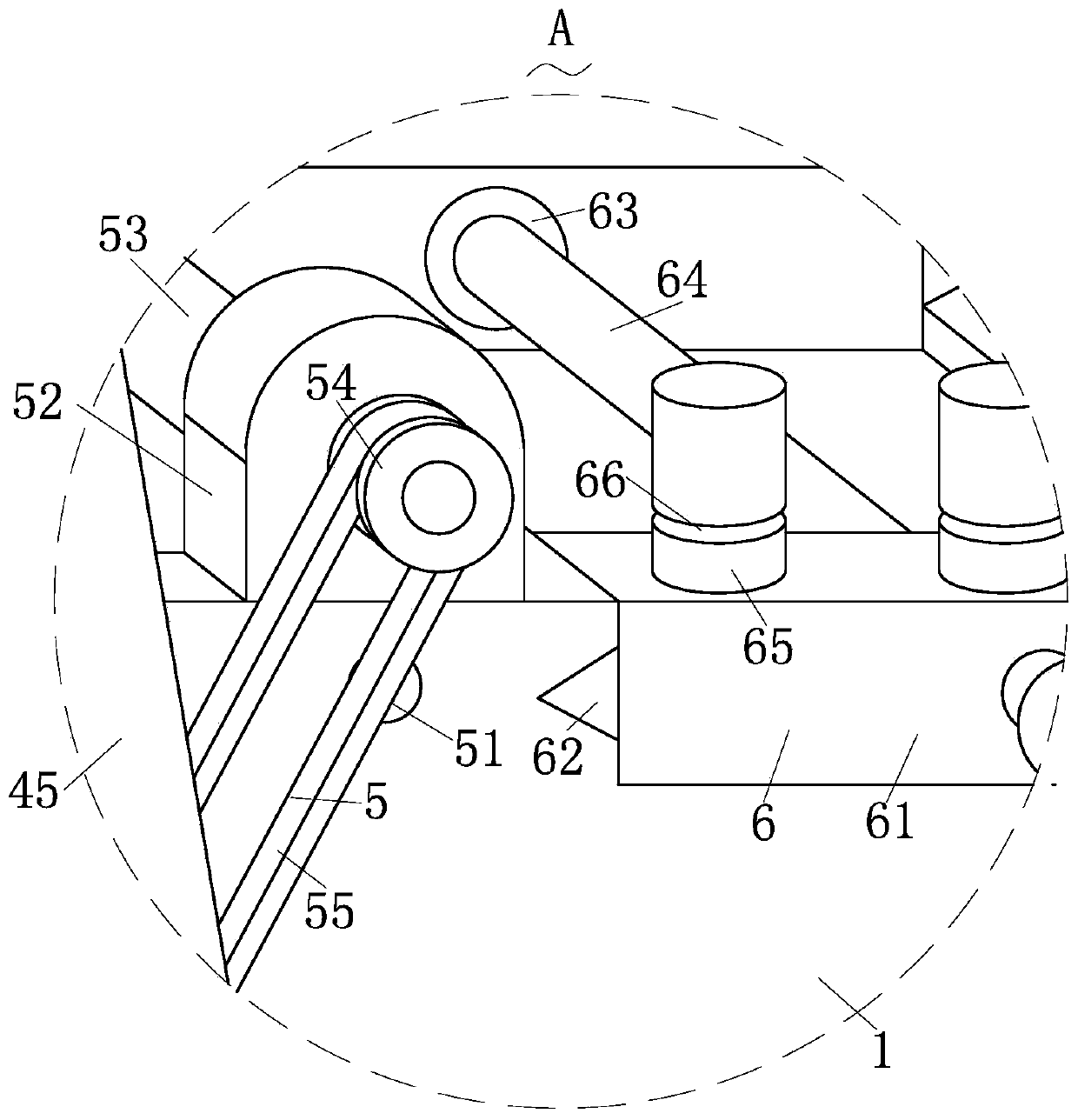

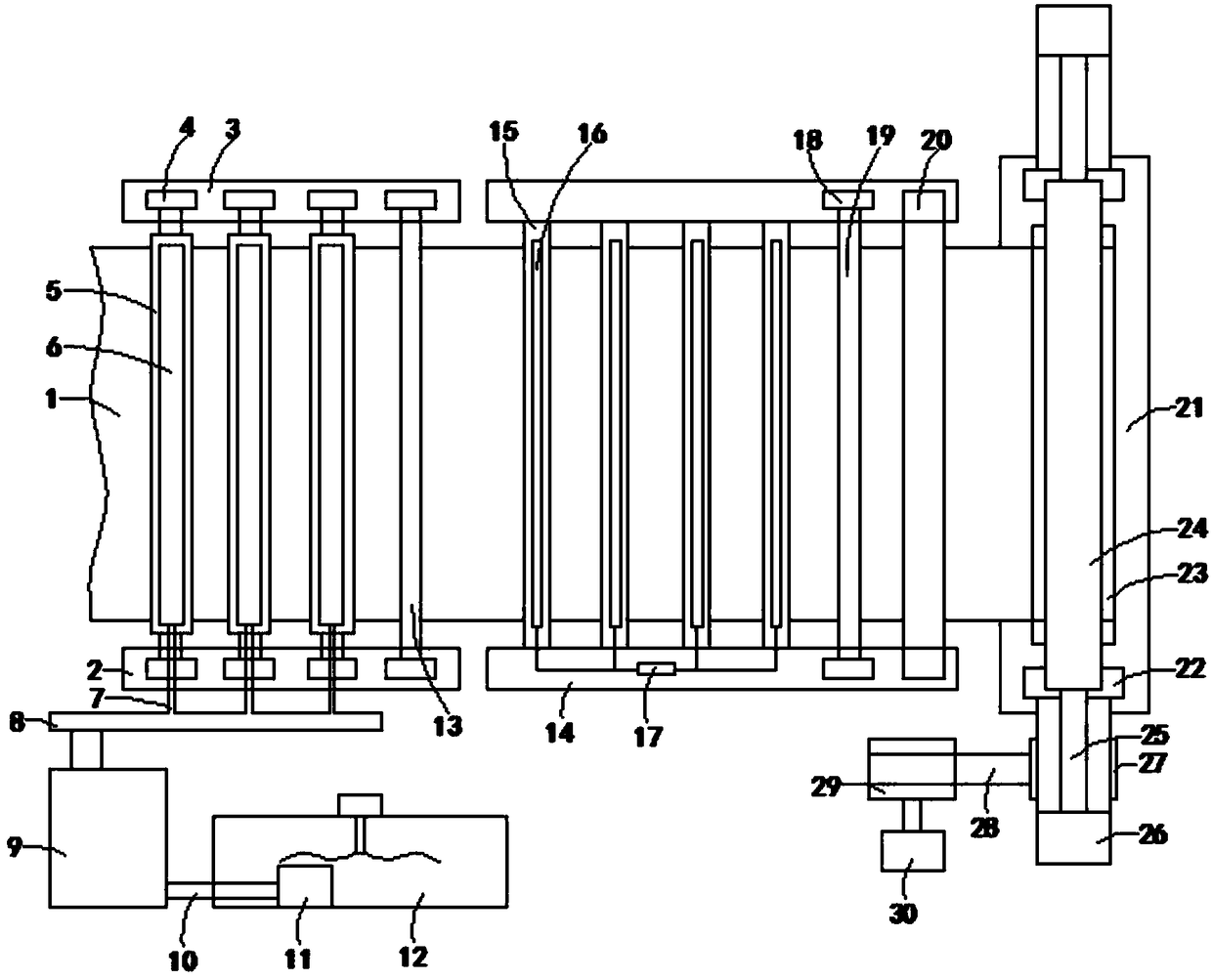

Fully-automated flexible flat cable pipe processing machine

ActiveCN106782888AImprove processing efficiencyImprove yield rateApparatus for feeding conductors/cablesDistribution controlVisual inspection

The invention relates to a fully-automated flexible flat cable pipe processing machine. The fully-automated flexible flat cable pipe processing machine comprises a frame and a power distribution control cabinet, wherein the frame is provided with a conveying chute and a feeding device which are matched with each other; the feeding device comprises a feeding forward-backward movement device, and the feeding forward-backward movement device is provided with a feeding left-right movement device; a feeding lifting device is arranged on the feeding left-right movement device, uniformly provided with a feeding clamp matched with products, and provided with a feeding guide rod matched with the conveying chute; the frame is sequentially provided with an edge spacing detecting device, a wire stripping device, an adhesive applying device, a heat pressing device, a trimming device, a visual inspection device and a circuit detecting device, which are matched with the products on the conveying chute. The fully-automated flexible flat cable pipe processing machine achieves fixed-distance product feeding through matching between the feeding device and the conveying chute and further achieves continuous and integrated flexible flat cable processing, thereby greatly improving the processing efficiency and the yield rate.

Owner:大千纺织(安徽)有限公司

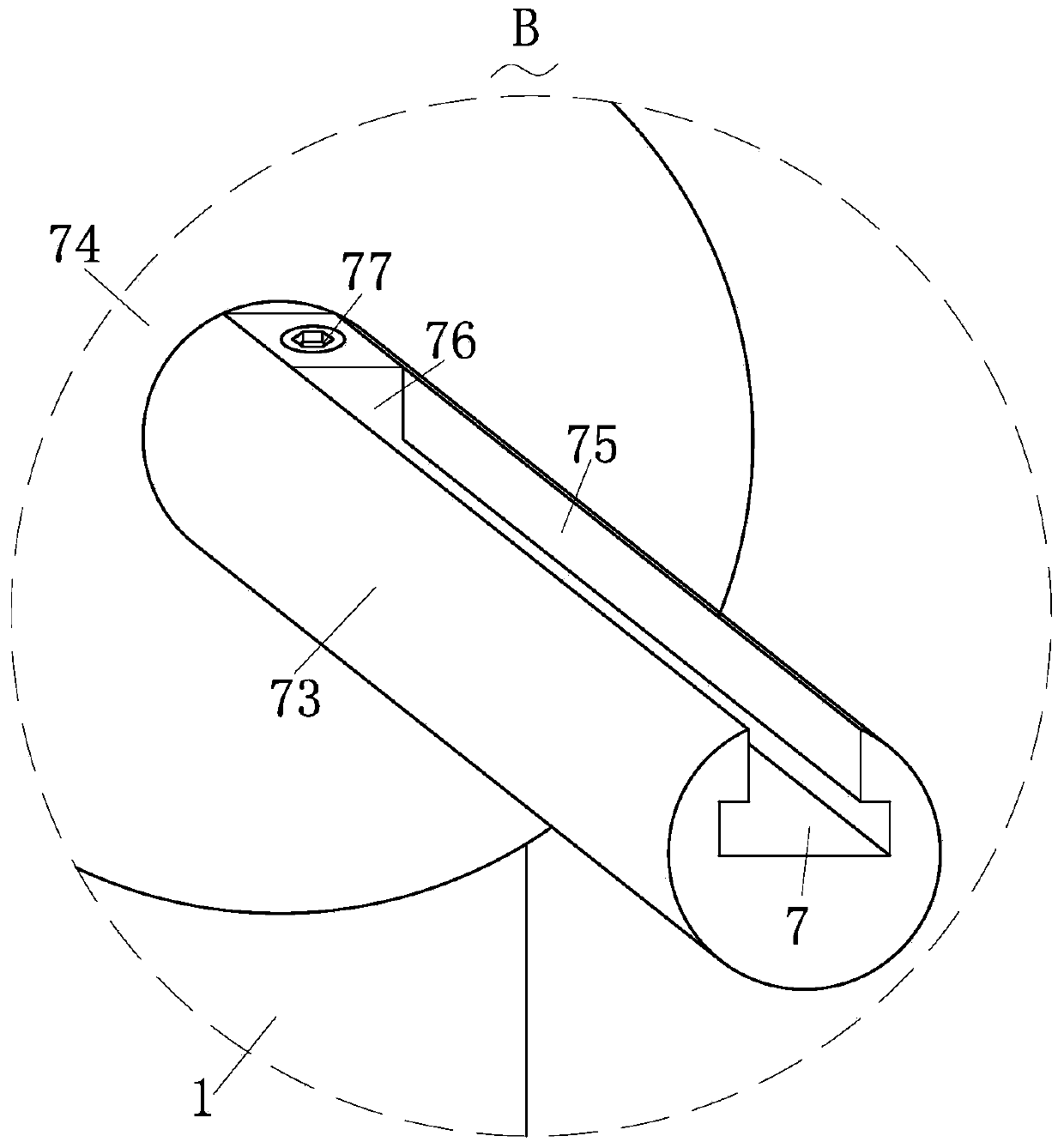

Temporary winding device with cleaning function and used for gauze production and machining

InactiveCN110626838AGood cleaning effectGuaranteed cleanlinessCleaning using toolsCleaning using gasesMachiningBlow out

The invention relates to the field of gauze production and machining devices, and specifically relates to a temporary winding device with a cleaning function and used for gauze production and machining. The temporary winding device with the cleaning function and used for gauze production and machining comprises a bottom plate, a winding structure, a fixed plate, a compression structure, a flatly-laying structure, a guide structure, a cleaning structure and a side plate. The winding structure is capable of synchronously driving the cleaning structure to work during working, so that a better cleaning effect of the cleaning structure can be achieved; two oppositely-arranged brush plates are fixed into a cleaning sleeve, and cleaning working can be carried out on a gauze being wound, so that impurities on the surface of the gauze can be cleaned, and then the cleanliness of the wound gauze can be ensured; gas blowing holes communicate with the interior of a gas storage groove separately, and therefore, gas in the gas storage groove is blown out via the gas blowing holes, so that ash blowing cleaning working can be carried out before the gauze enters the two brush plates, and then the cleanliness of the wound gauze can be ensured.

Owner:LIXIN FUYA GAUZE CO LTD

Cloth wrinkle removing device for spinning

PendingCN111501271AAvoid creasesImprove flatnessTextile treatment by spraying/projectingTextile treatment rollersSpinningWorkbench

The invention discloses a cloth wrinkle removing device for spinning, and relates to the technical field of cloth wrinkle removal. The device comprises four table legs, four top ends are fixedly connected with a worktable, the side walls of the table legs are fixedly connected with controllers, the side walls of the bottoms of the table legs are fixedly connected with steam devices, winding devices are fixedly connected to the side walls, reverse to each other, of the bottoms of the two table legs, ironing devices are fixedly connected to the reverse side walls of the tops of the two table legs, a detection support is fixedly connected to the top face of the worktable, a leveling device is fixedly connected to the center of the inner top of the detection support, an infrared sensor is adopted for detecting the cloth, ironing plates are rotated to carry out tilting and leveling on the cloth folding part, it can be ensured that the cloth cannot be wrinkled, meanwhile, folds generated bycloth overlapping can be prevented, a detection camera is arranged, the cloth after wrinkle removing and leveling can be subjected to secondary detection, the disqualified cloth is re-wound for ironing and leveling, and the reliability of the cloth finished product quality can be ensured.

Owner:陈利平

Singe-plate drying machine

InactiveCN104654758AImprove work efficiencyReduce heatDrying machines with progressive movementsDrying solid materialsEvaporatorEngineering

The invention discloses a single-plate drying machine which comprises a drying chamber. A feeding port and a discharging port are respectively formed in the front end and the rear end of the drying chamber, at least one air conditioning device is arranged on the drying chamber, a condenser of each air conditioning device is located in the drying chamber, an evaporator of each air conditioning device is located outside the drying chamber, an air collecting cover is installed on the periphery of the evaporator of each air conditioning device, an air channel and an exhaust pipe are arranged on the air collecting cover, an air inlet of the air channel is communicated with the drying chamber, and a plurality of groups of heating paired rollers and a plurality of groups of paired roller press wheels are arranged in the drying chamber. The single-plate drying machine is provided with the air channel and an air blower so as to accelerate single-plate drying, is further provided with the air conditioning devices, so that accelerated damp-elimination forming of a single plate is achieved, heat is also saved, energy saving and emission reduction are achieved, the whole drying process of the single plate becomes gradual temperature changing process, and the situation that the single plate is directly heated by the heating paired rollers at high temperature and accordingly crumples are produced on the surface of a plate material is avoided. The single-plate drying machine has the advantages of being simple and compact in structure, low in manufacturing cost and simple and convenient to use.

Owner:黄士苗

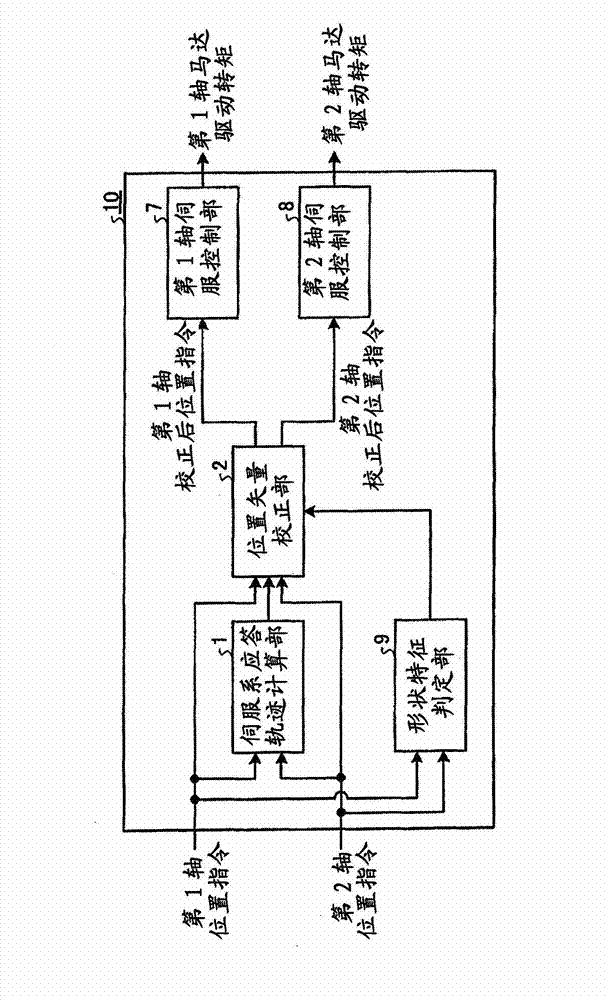

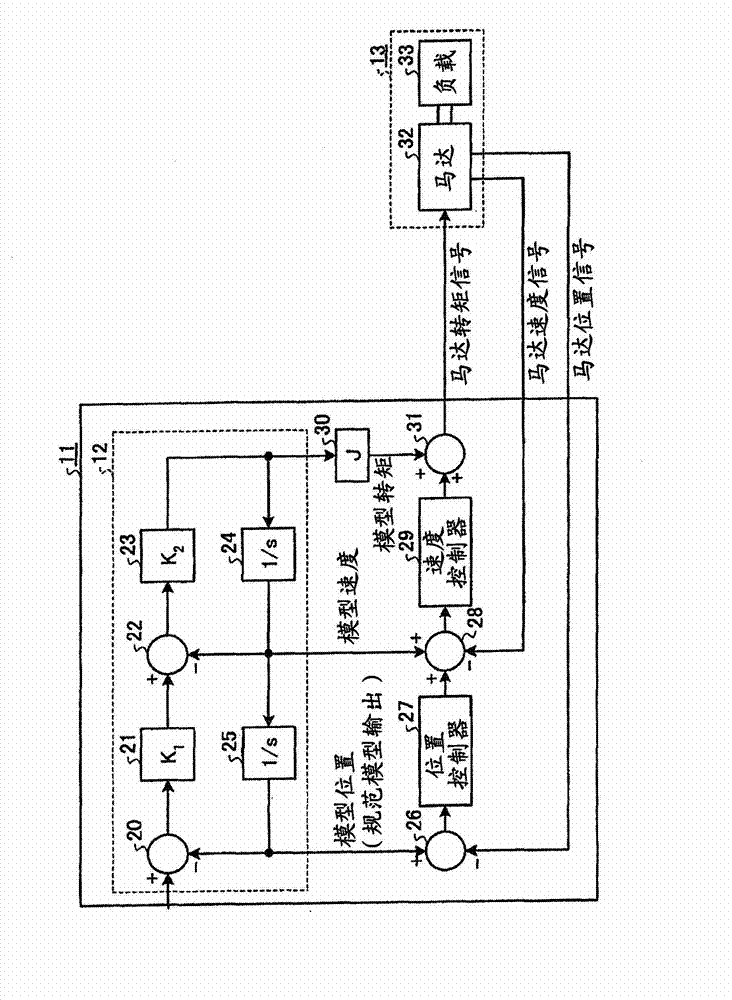

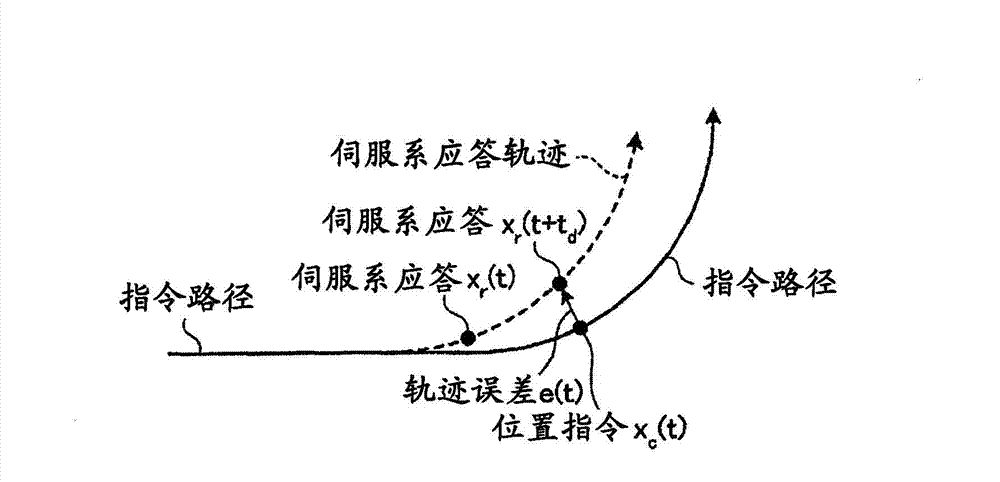

Trajectory control device

ActiveCN103080859AQuality improvementAvoid damageComputer controlSimulator controlMotor driveEngineering

A trajectory control device for controlling the trajectory of a movable portion by simultaneously controlling the motors of a plurality of movable axes comprises: a servo system response trajectory calculation unit (1) for calculating a servo system response trajectory on the basis of the position commands for the respective movable axes; a shape feature determination unit (9) for, on the basis of whether a command route shape is a straight or curved line from the position commands, outputting a shape feature amount including information about movement directions at the position of a boundary point of the route shape and in the vicinity of the boundary point; a position vector correction unit (2) for correcting a position vector on the basis of the position commands, the servo system response trajectory, and the shape feature amount and outputting the corrected position commands; and servo control units (7, 8) for controlling the motors of the respective movable axes by outputting the motor driving torques so that the positions of the respective movable axes follow the corrected position commands. This makes it possible to perform corrections for suppressing a trajectory error to a sufficiently small level, including even at a place, such as a boundary portion between a straight line and a curved line, where the magnitude and direction of the trajectory error change transiently.

Owner:MITSUBISHI ELECTRIC CORP

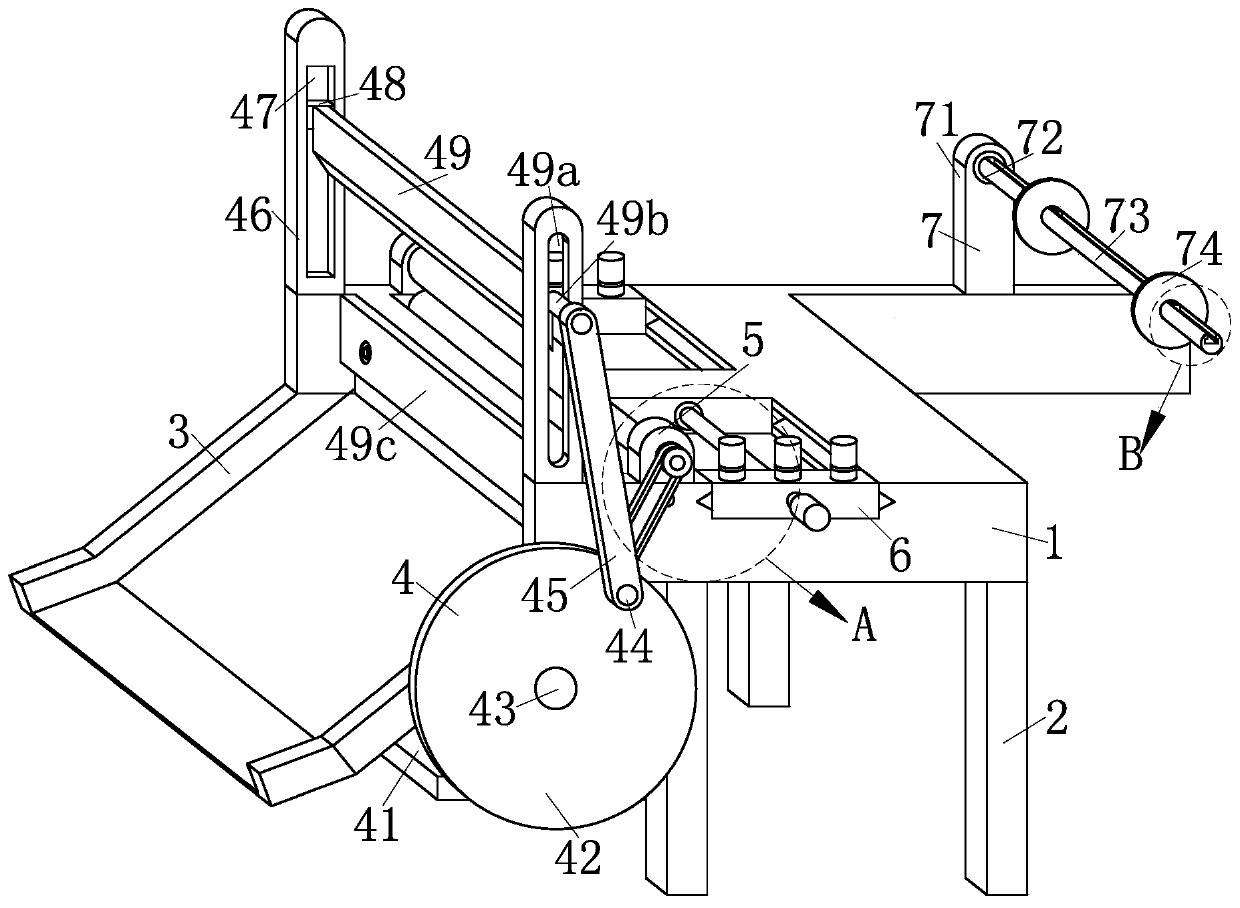

Cutting machine with guiding function for gauze element production and processing

ActiveCN110861132AAvoid creasesAvoid offsetMetal working apparatusWebs handlingMechanical engineeringIndustrial engineering

The invention relates to the field of gauze element production and processing devices, in particular to a cutting machine with a guiding function for gauze element production and processing. The cutting machine comprises a base, supporting legs, a discharge sleeve, a cutting structure, a feeding structure, a guiding structure and a discharging structure; the cutting structure can synchronously drive the feeding structure to work while the cutting structure is working, through the setting of the feeding structure, the feeding operation can be automatically conducted on a gauze element, the workintensity of manual feeding is reduced, the cut gauze element can further be leveled and limited, namely the wrinkle of the gauze element during cutting is avoided, the deviation of the gauze elementcaused by difficult fixation of the gauze element during cutting is also avoided, the guiding structure is arrange at the top end, close to one end of the feeding structure, of the base, the gauze element entering the feeding structure can be guided, the gauze element of the feeding structure is prevented from wrinkling and deviating, the guiding structure can be adjusted, and thus gauze elementswith different width can further be guided.

Owner:LIXIN FUYA GAUZE CO LTD

Adsorption device and method of metal pattern plates, evaporation equipment and evaporation method

ActiveCN108165927AReduce wrinklesAvoid wrinklesVacuum evaporation coatingSputtering coatingWrinkle skinEvaporation

The invention provides an adsorption device and method of metal pattern plates, evaporation equipment and an evaporation method so as to solve the problem that in evaporation, the metal pattern platesare adsorbed, and then an FMM wrinkles. The adsorption method comprises the steps that adsorption begins from a certain area or certain areas of each metal pattern plate, and then the adsorption range is gradually enlarged from the initial adsorption area till the whole metal pattern plates are attached to substrate base plates. The adsorption method is applied to the evaporation process of manufacturing of OLED display panels so as to improved the evaporation quality.

Owner:BOE TECH GRP CO LTD +1

Wall cloth spraying, drying and rolling device

The invention provides a wall cloth spraying, drying and rolling device and relates to the technical field of wall cloth production equipment. The wall cloth spraying, drying and rolling device comprises wall cloth, a left bracket, a right bracket, a fixed seat, a spraying cavity, a coating supply pipe, a feeding pipe, a material supply pipe, a liquid suction machine, a discharge pipe, a filter, amaterial storage box, an extrusion strike plate, a heating cavity bracket, a heating cavity, a heating rod, a power supply interface, a pressure shaft bracket, a pressure shaft, an air cooler, a rolling rack, a bearing pedestal, a rolling roller, a pressure roller, a connecting rod, a support, a driven flywheel, a transmission belt and the like. By arranging the air cooler to heat and dry the wall cloth, cold air blown by the air cooler can cool the cloth wall, so that the wall cloth is prevented from being rolled at a relatively high temperature; by arranging the pressure roller and a tension spring, when the wall cloth is rolled, the pressure roller is in tight contact with the rolling roller all the way under the action of tension spring; as the pressure roller levels the wall cloth, the condition that the rolled wall cloth is wrinkle is prevented, and the levelness of the wall cloth is improved.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

Display device

ActiveCN111047988AFree from damageAvoid creasesMachine supportsCasings with display/control unitsDisplay deviceComputer science

The invention provides a display device, which comprises a flexible screen, a supporting structure and a bendable structure. The flexible screen comprises a first main body, a second main body and a third main body, wherein the third main body is connected between the first main body and the second main body. The supporting structure comprises a first supporting part and a second supporting part,wherein the first supporting part is used for supporting the first main body and the second supporting part is used for supporting the second main body. The bendable structure is overlapped with the third main body; and the first supporting part and the second supporting part are connected through the bendable structure. When the first main body is bent relative to the second main body, the firstsupporting part is bent relative to the second supporting part through the bendable structure, and at least part of the bendable structure makes contact with the third main body and rolls. The displaydevice is used for preventing the flexible screen from being folded and protecting the flexible screen from being damaged.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Folding mechanism, support structure and electronic equipment

PendingCN113067926AStable supportIncrease the display areaTelephone set constructionsDetails for portable computersStructural engineeringMechanical engineering

The invention discloses a folding mechanism, a support structure and electronic equipment, and belongs to the technical field of communication equipment.The folding mechanism comprises a first screen supporting plate, a second screen supporting plate, a third screen supporting plate, a first shell base rotationally arranged on the first screen supporting plate, a second shell base rotationally arranged on the second screen supporting plate and a base part; and the first shell seat and the second shell seat are rotationally connected with the base part; in the unfolded state, the first side edges of the first screen supporting plate and the second screen supporting plate are located between the second side edges, the third screen supporting plate is located between the first screen supporting plate and the second screen supporting plate, and the first surfaces of the first screen supporting plate, the second screen supporting plate and the third screen supporting plate are flush; and in the folded state, the distance between the first side edges is larger than that between the second side edges. According to the folding mechanism, the problem that the service life of the display screen is short due to the fact that creases are easily formed on the display screen of the current inward folding type electronic equipment can be solved.

Owner:VIVO MOBILE COMM CO LTD

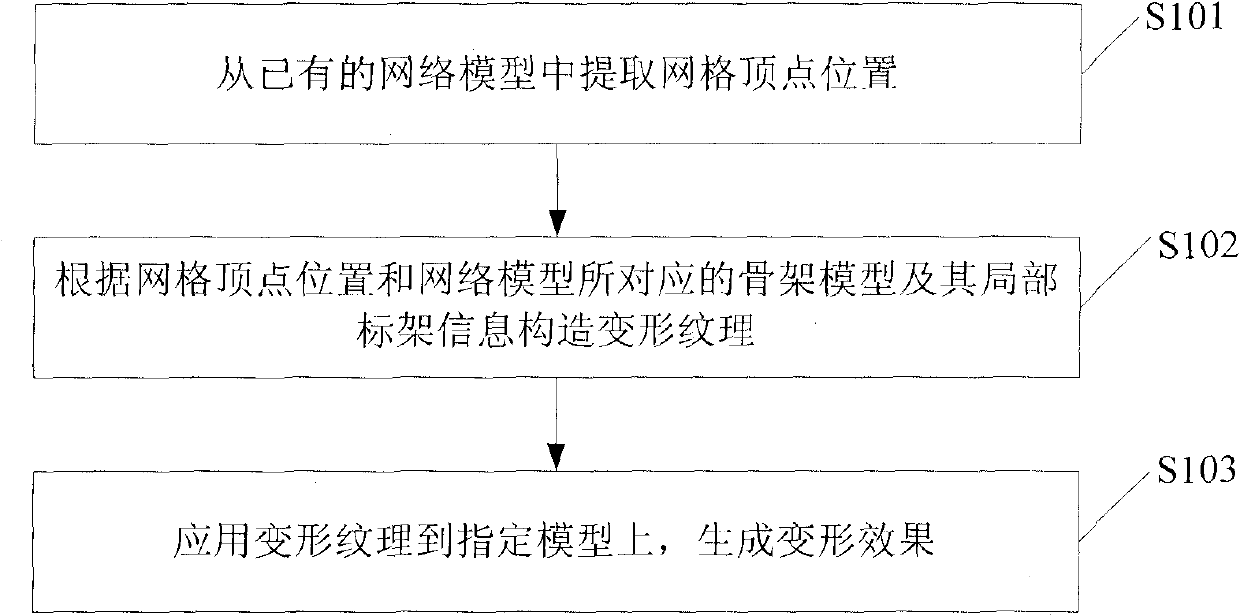

Three-dimensional grid model deformation method and system based on texture

InactiveCN101794462AAvoid wrinklesAvoid creases3D-image rendering3D modellingDeformation effectNetwork model

The implementation of the invention discloses a three-dimensional grid model deformation method based on texture. The method includes the following steps: grid vertex position is extracted from the existing grid model; deformation texture is constructed according to the grid vertex position, skeleton model corresponding to network model and local frame information thereof; the deformation texture is applied to the designated model to generate deformation effect. Accordingly, the implementation of the invention also discloses a three-dimensional network model processing system; by implementing the invention, real time effect can be provided in operation, and faster execution speed can be obtained in practical application.

Owner:SUN YAT SEN UNIV

Inflatable ear piece and a method of its manufacture

ActiveUS9338568B2Reduce noiseAvoid creasesIn the ear hearing aidsHearing aids housingEngineeringHearing aid

An inflatable ear piece is used in a hearing aid. The inflatable ear piece defines an inflatable part, which defines an inflatable cavity. The inflatable cavity, when inflated, defines an inflated state in which the inflatable part abuts an inner wall of an auditory canal when provided therein, and, when deflated to a deflated state, allows for insertion and / or retraction of the ear piece from the auditory canal. The inflatable ear piece comprises one or more biasing means that are arranged to bias the inflatable part away from a totally collapsed state and into the deflated state. The biasing means is secured to an inner wall of the inflatable cavity.

Owner:SONION NEDERLAND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com