Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

408results about "Apparatus for feeding conductors/cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

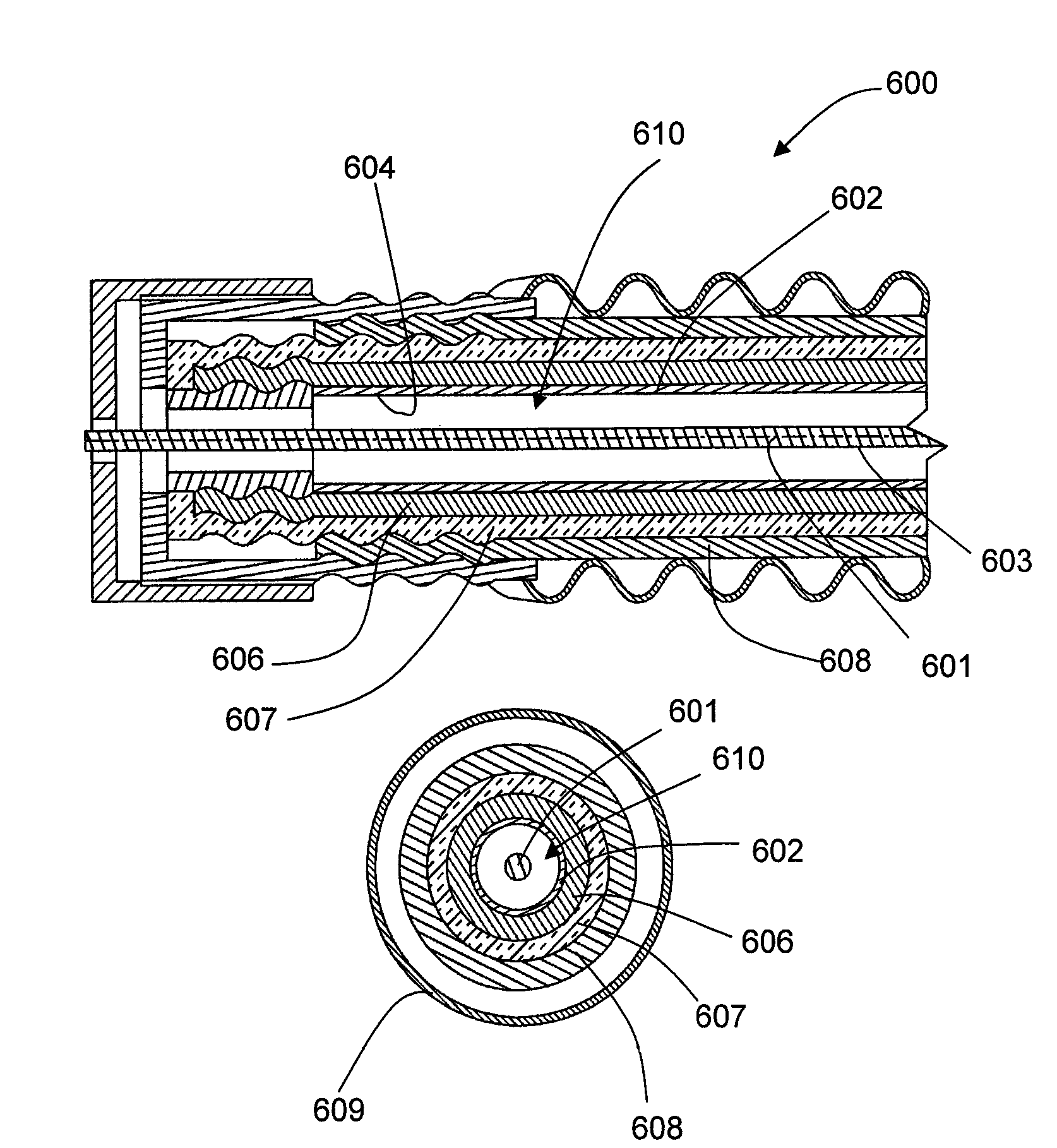

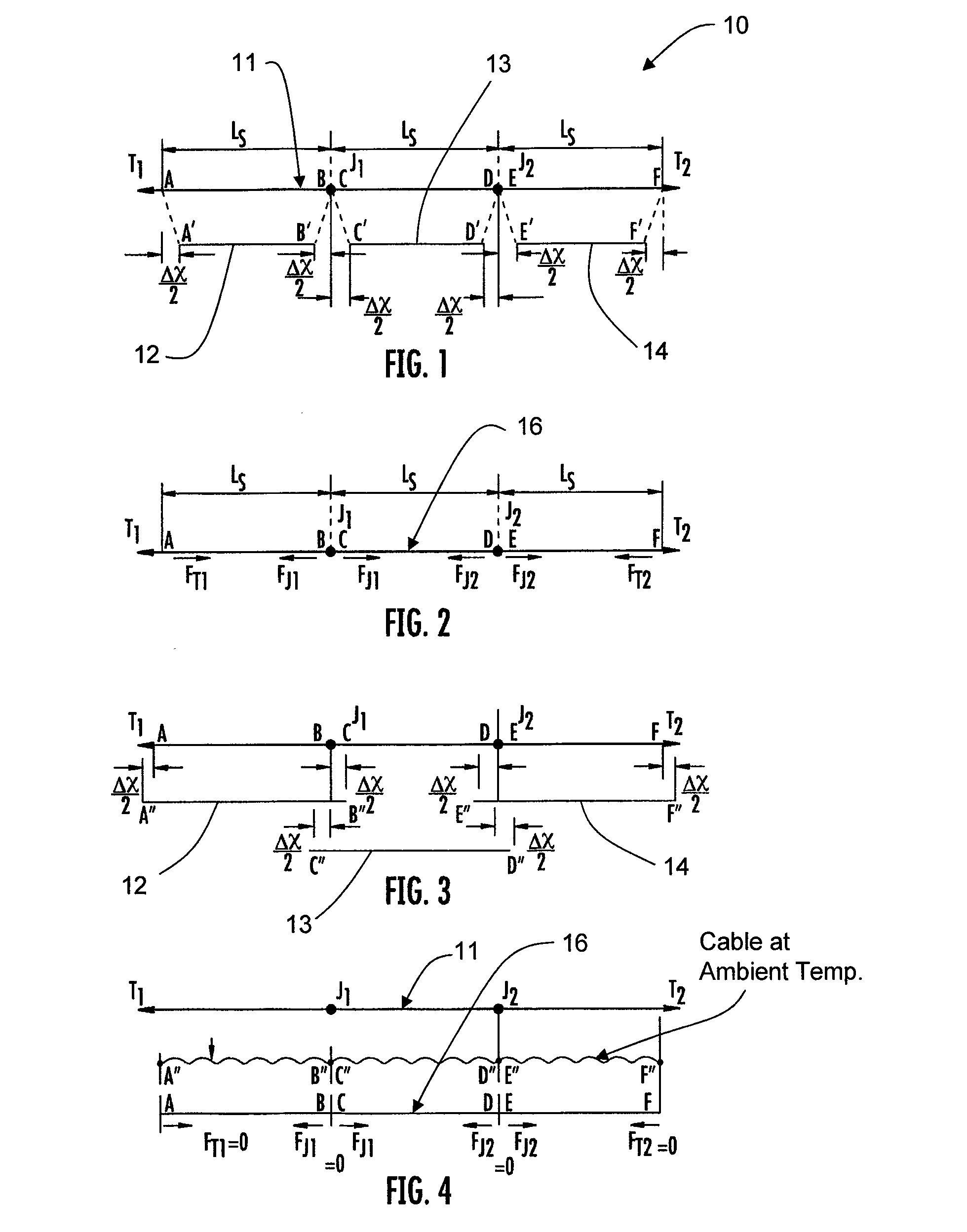

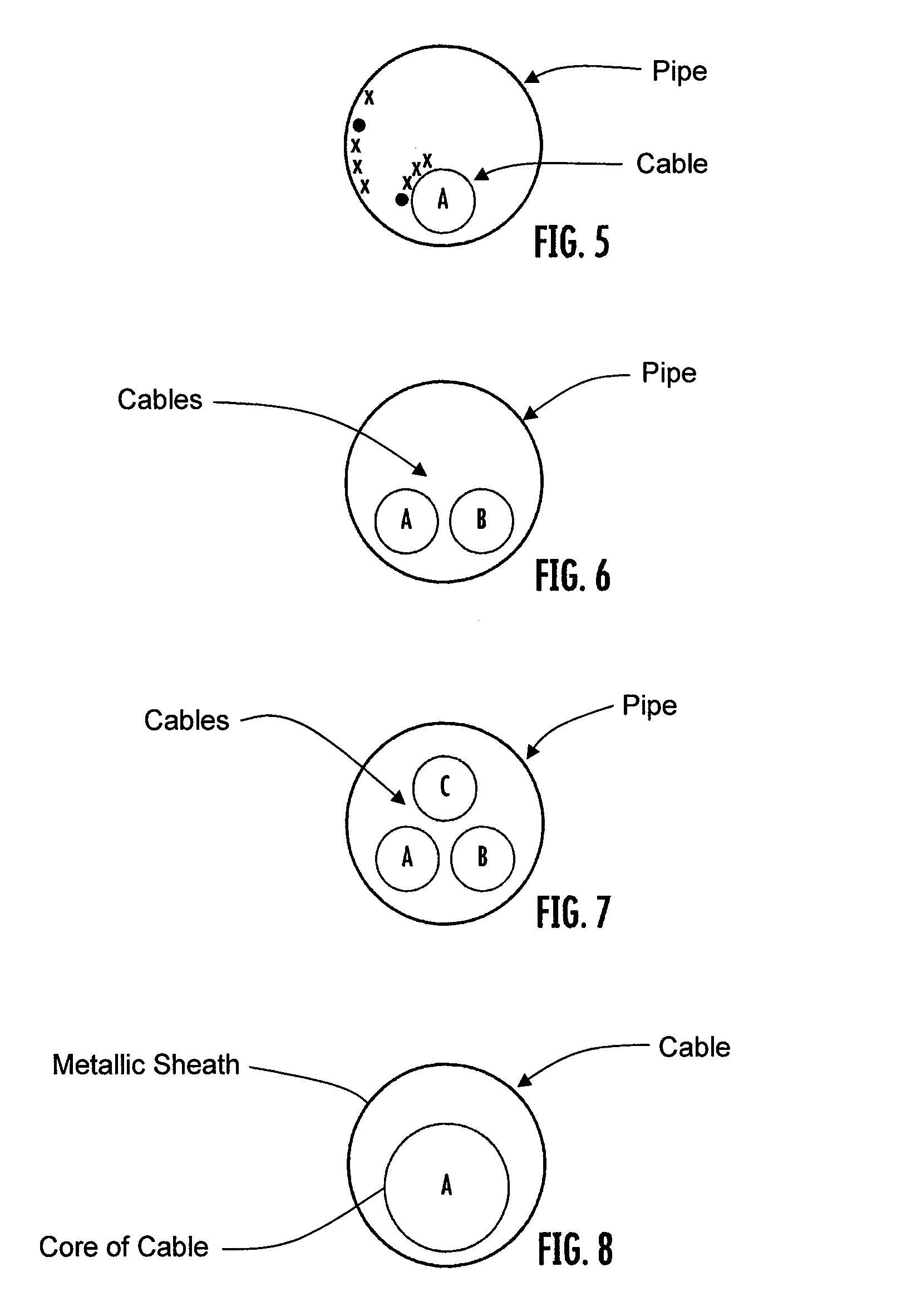

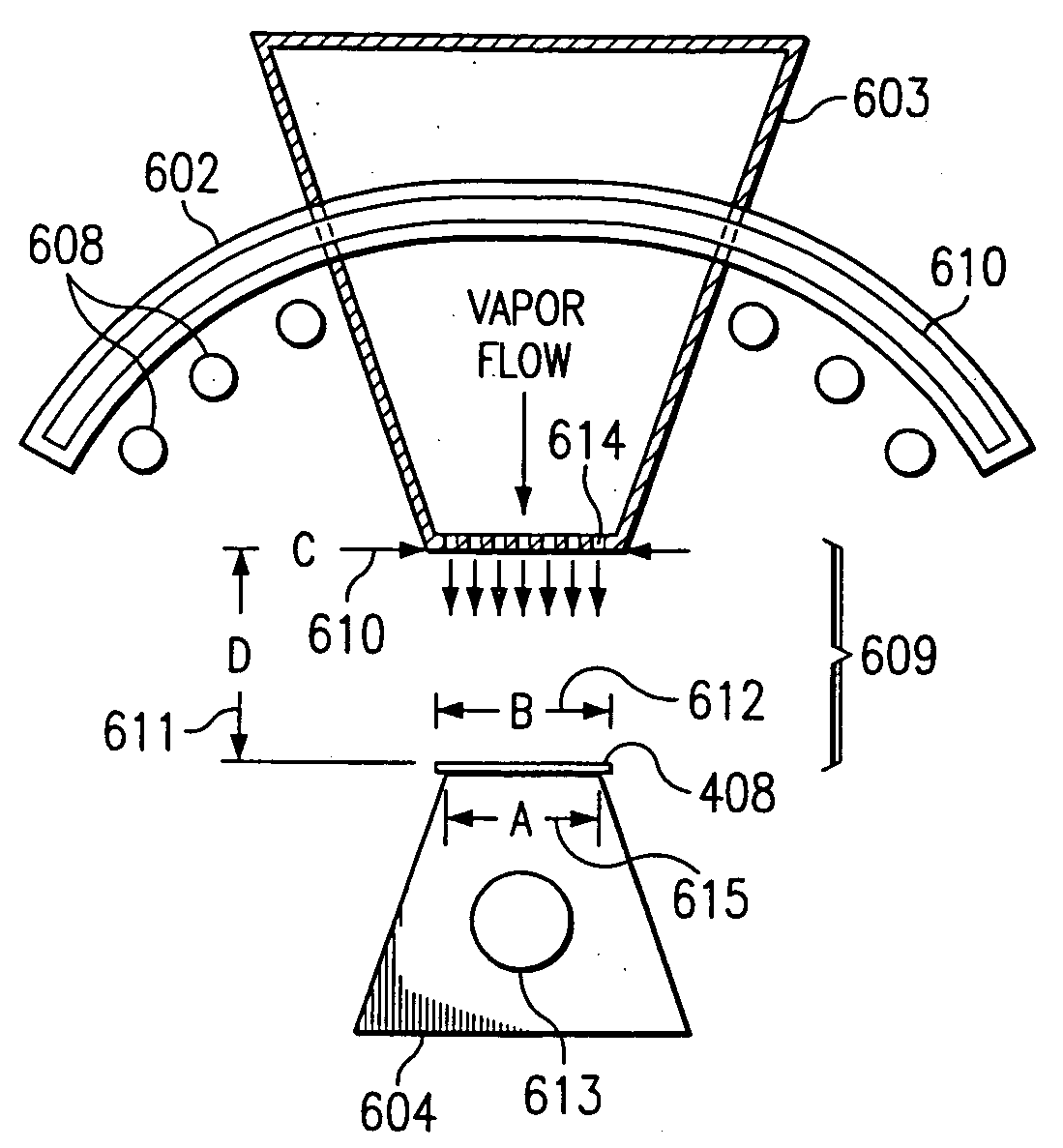

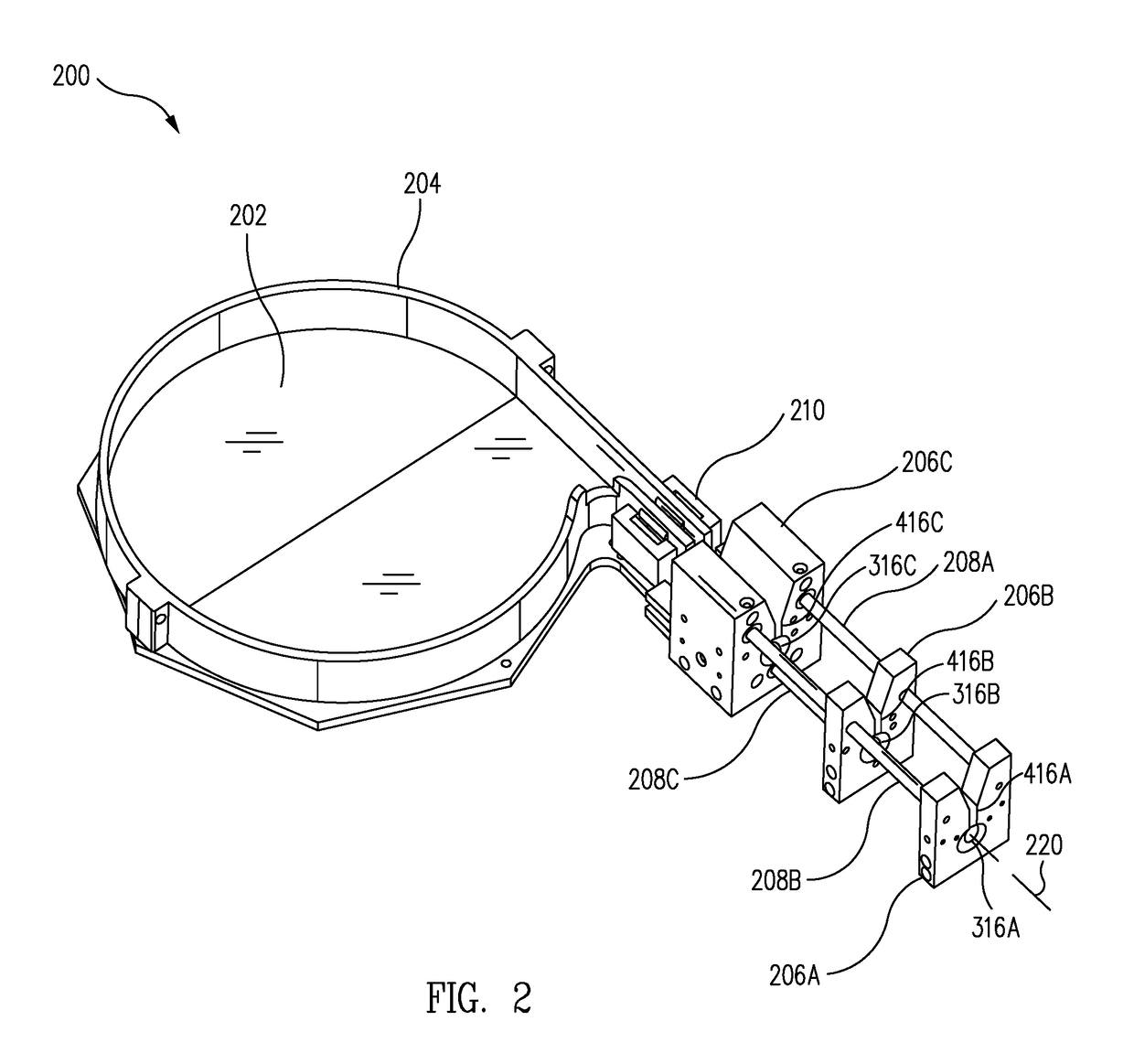

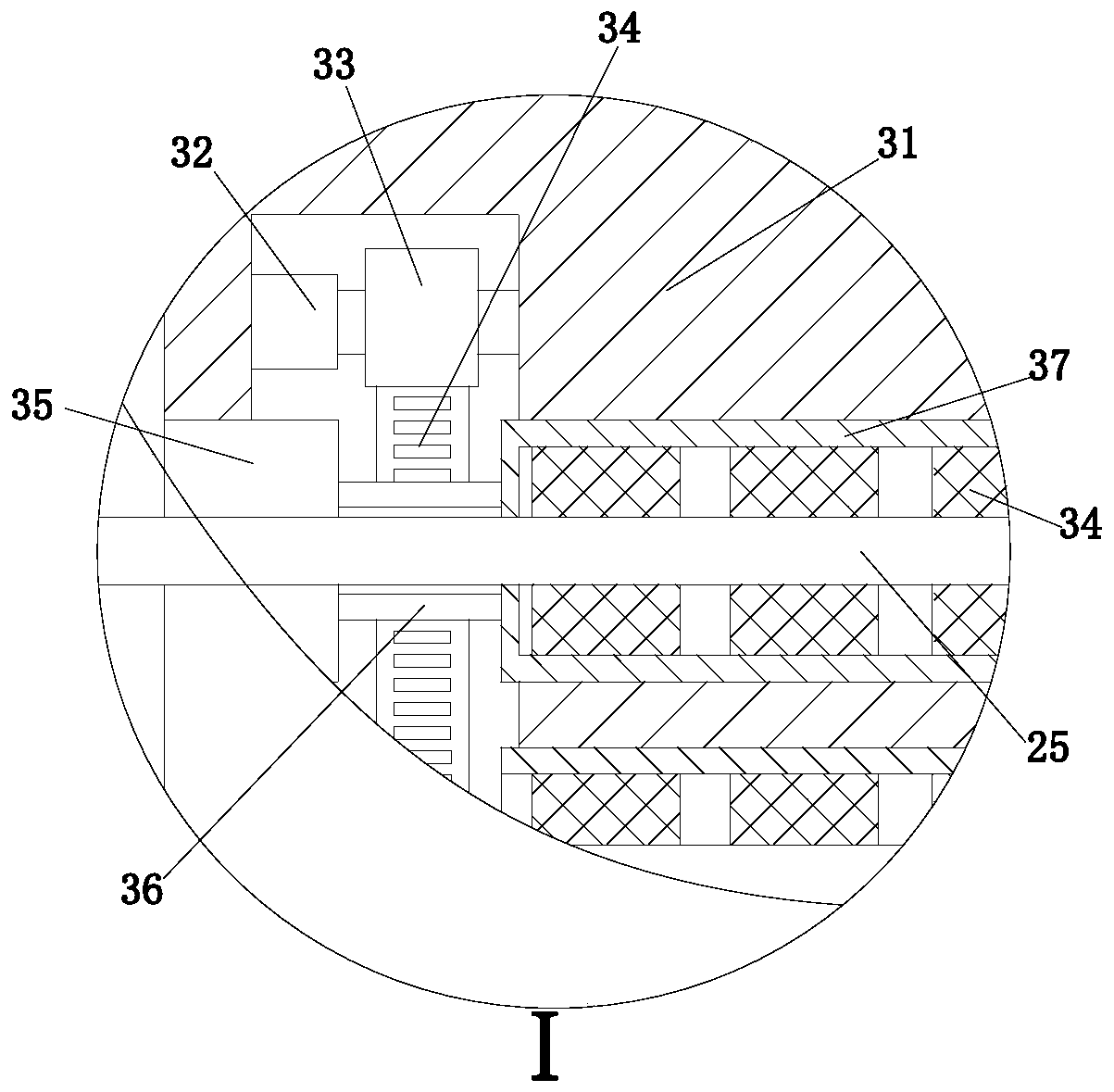

Thermal contraction compensation for superconducting and cryo-resistive cables

InactiveUS20100285968A1Eliminate and reduce magnitude of thermomechanicalSuperconductors/hyperconductorsApparatus for feeding conductors/cablesEngineeringThermal contraction

A method of compensating for thermal contraction of superconducting and cryo-resistive cables. The method includes the steps of determining a compensation length for a cable such that when the cable is subjected to an operating temperature, the cable is in or near a stress-free state, and installing the cable into a pipe such that portions of the cable extend outwardly past ends of the pipe. The method further includes the steps of marking each end of the cable such that the determined compensation length is visibly shown, forcing the cable into the pipe at an ambient installation temperature such that a cable pattern is formed therein, and maintaining the cable in the pipe to prevent the cable from being pushed out of the pipe.

Owner:ELECTRIC POWER RES INST INC

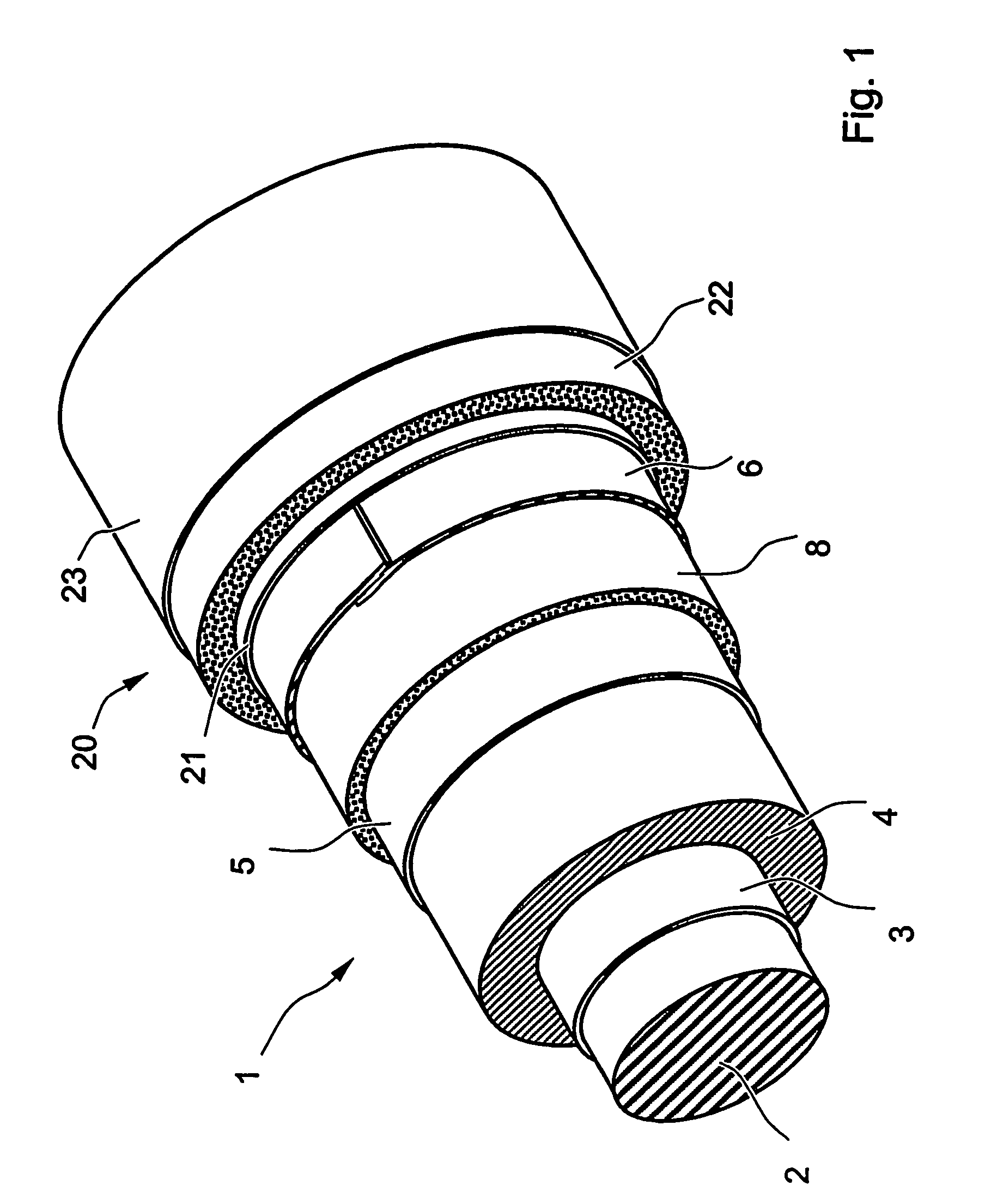

Continuous process for manufacturing electrical cables

InactiveUS7459635B2Increase in costExtended production timeNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorEngineering

A process for manufacturing an electric cable. In particular, the process includes the steps of: a) feeding a conductor at a predetermined feeding speed; b) extruding a thermoplastic insulating layer in a position radially external to the conductor; c) cooling the extruded insulating layer; and d) forming a circumferentially closed metal shield around the extruded insulating layer. The process may be carried out continuously, i.e., the time occurring between the end of the cooling step and the beginning of the shield forming step is inversely proportional to the feeding speed of the conductor.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Method for producing conductive film

InactiveCN104903981AEasy to adjust the diameterEasy to prepareSpecific nanostructure formationMaterial nanotechnologyMetal catalystCarbon nanotube

Provided is a method for producing a conductive film in which a size of a particle of a metal catalyst for synthesizing carbon nanotubes is adjusted to adjust a minor axis diameter of the carbon nanotube, such that the conductive film containing the carbon nanotube having an adjusted diameter may have excellent film properties.

Owner:HANWHA CHEMICAL CORPORATION

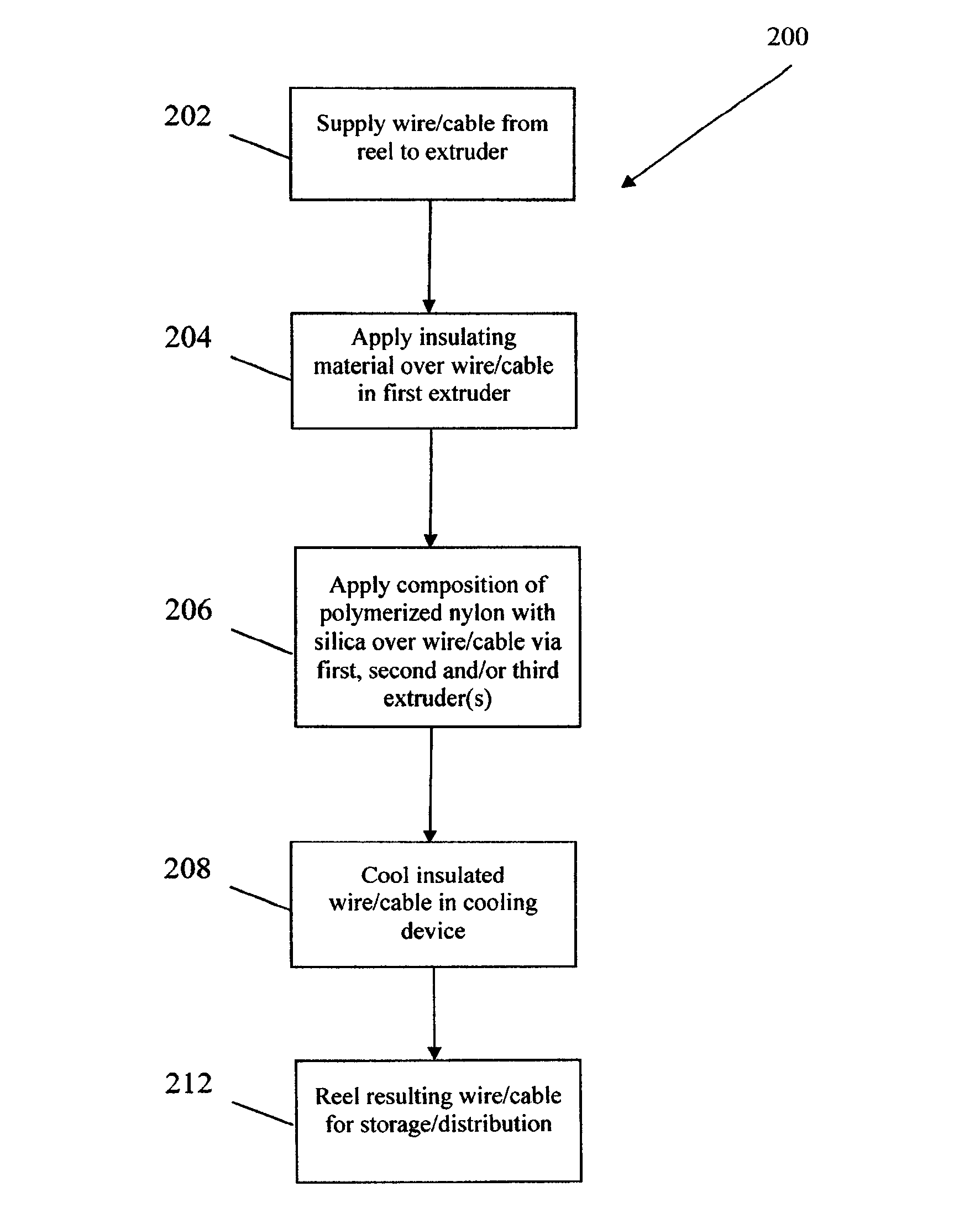

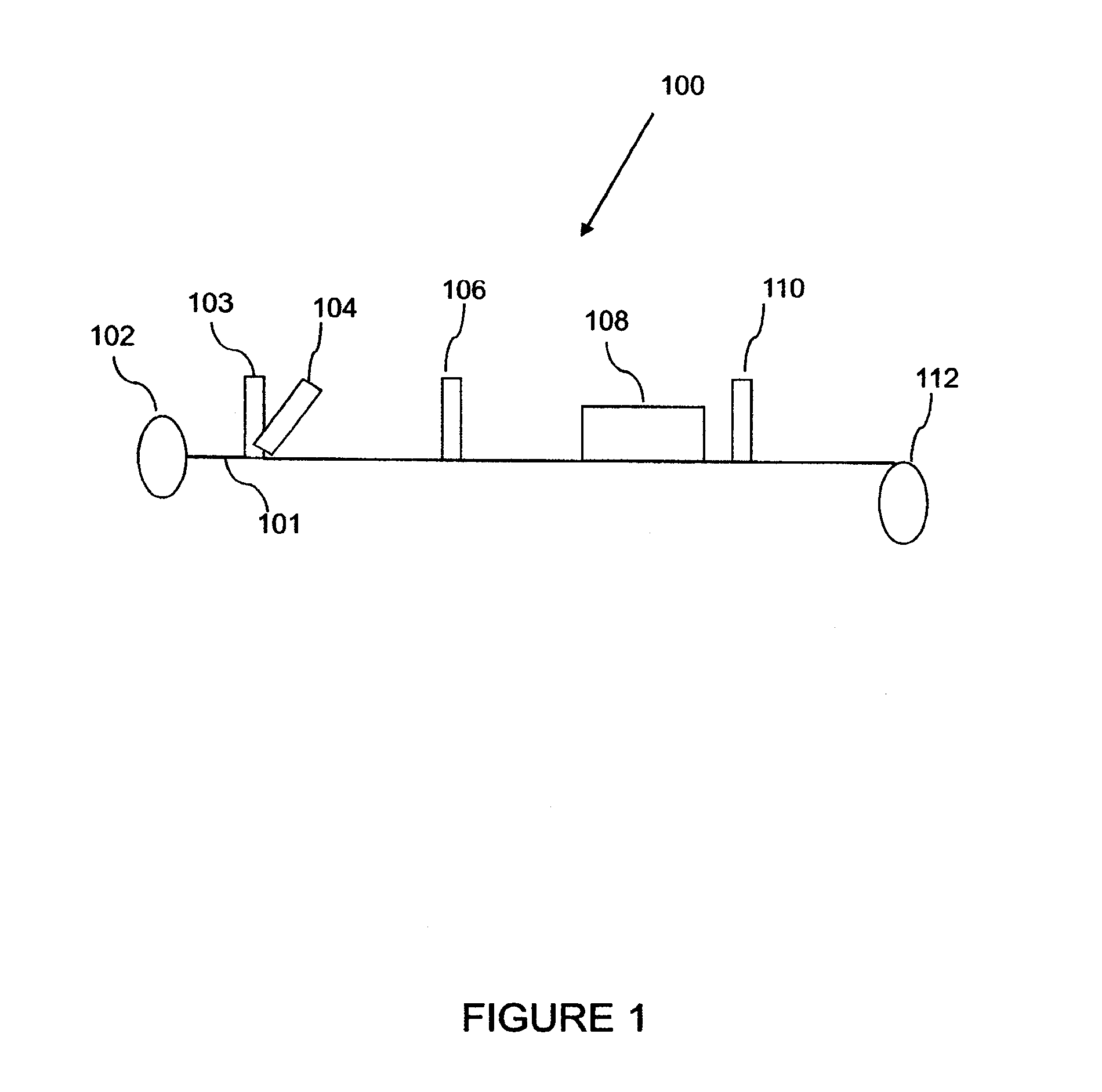

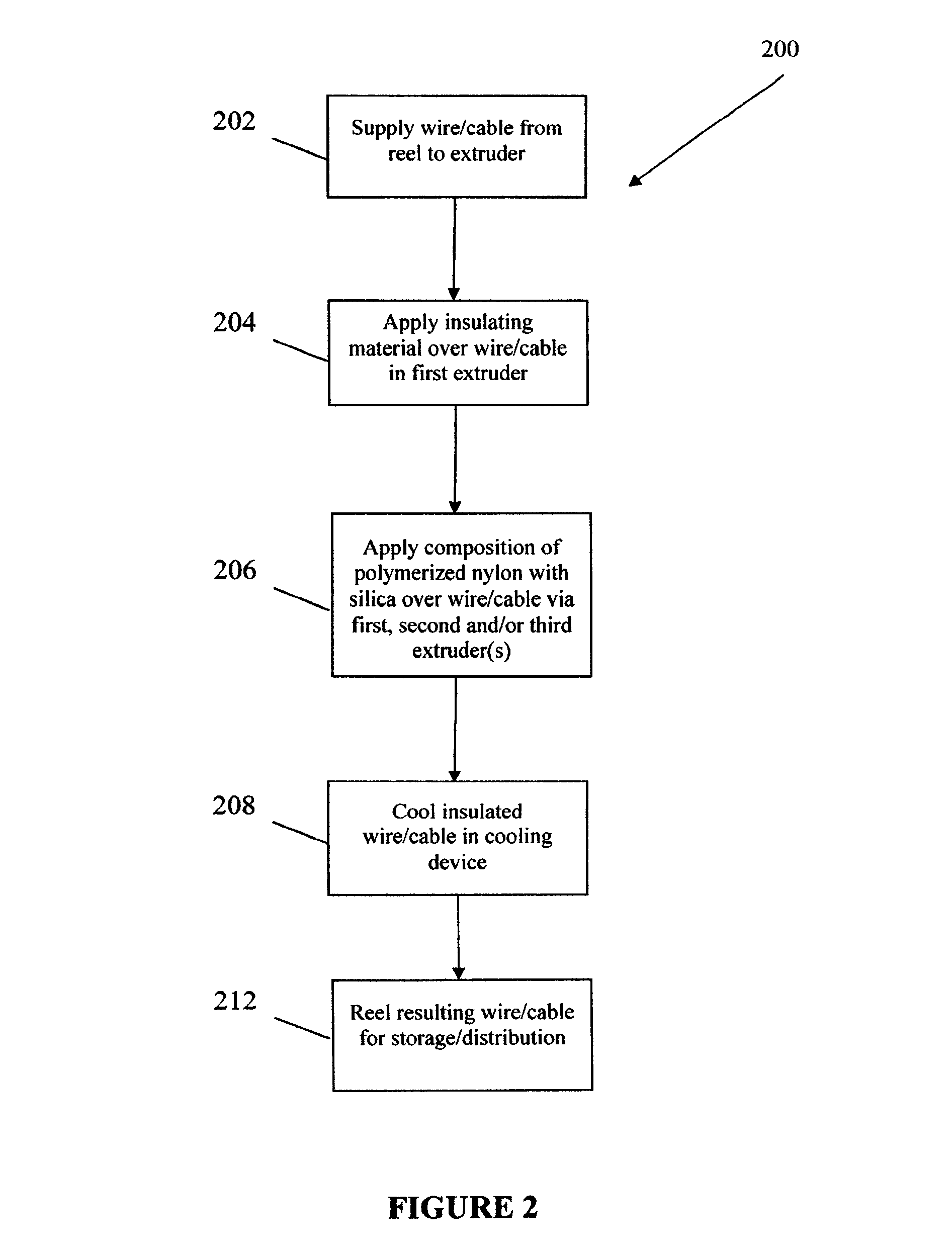

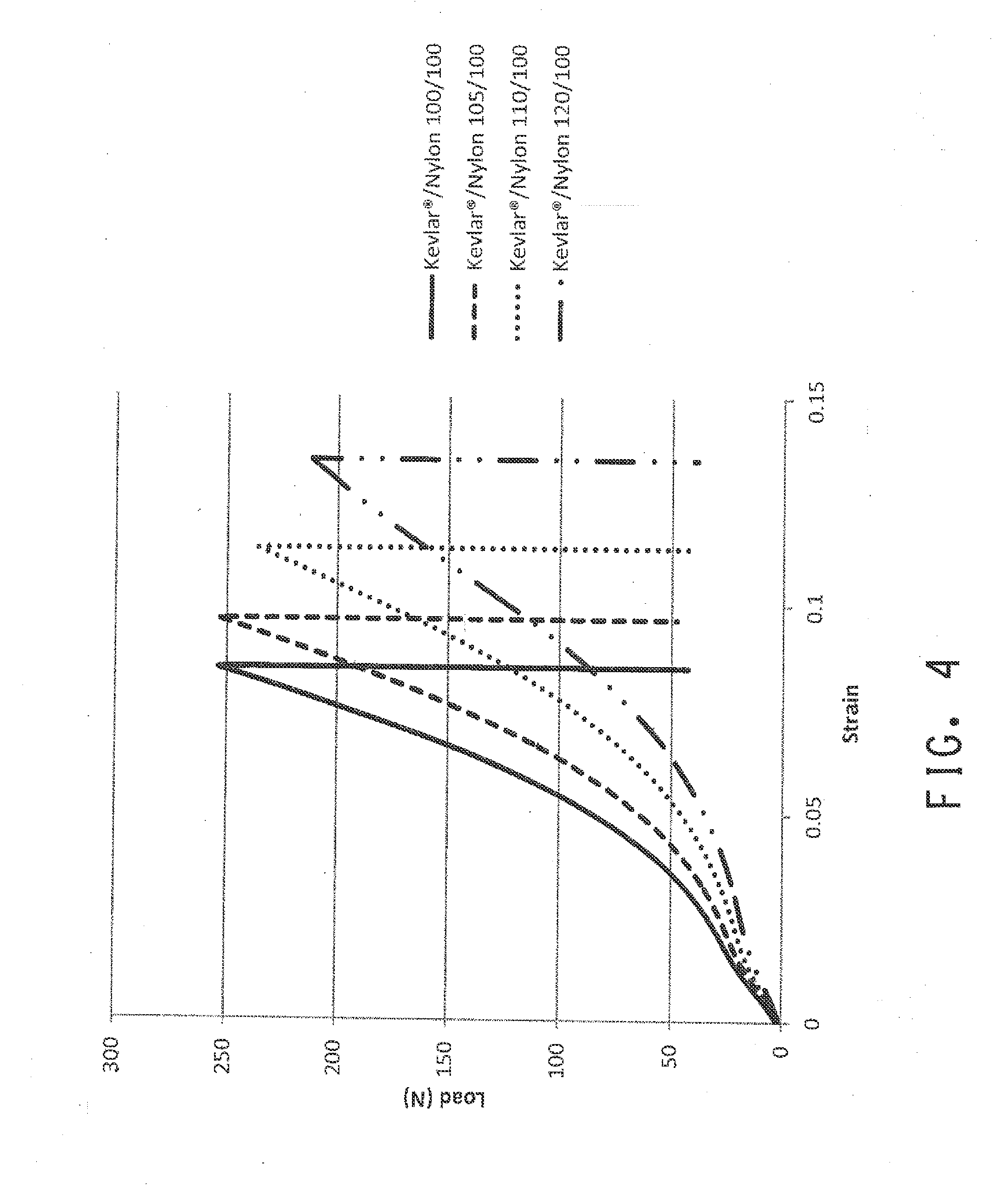

Method of manufacture of electrical wire and cable having a reduced coefficient of friction and required pulling force

ActiveUS9352371B1Reduce tensionReduce coefficient of frictionApparatus for feeding conductors/cablesInsulated cablesPull forceElectrical conductor

A process for manufacturing finished wire and cable having reduced coefficient of friction and pulling force during installation, includes providing a payoff reel containing at least one internal conductor wire; supplying the at least one internal conductor wire from the reel to at least one extruder; providing the least one extruder, wherein the at least one extruder applies an insulating material and a polymerized jacket composition over the at least one internal conductor wire, wherein the polymerized jacket composition comprises a predetermined amount by weight of nylon; and at least 3% by weight of a silica; providing a cooling device for lowering the temperature of the extruded insulating material and the polymerized jacket composition and cooling the insulating material and the polymerized jacket composition in the cooling device; and, reeling onto a storage reel the finished, cooled, wire and cable for storage and distribution.

Owner:ENCORE WIRE CORP

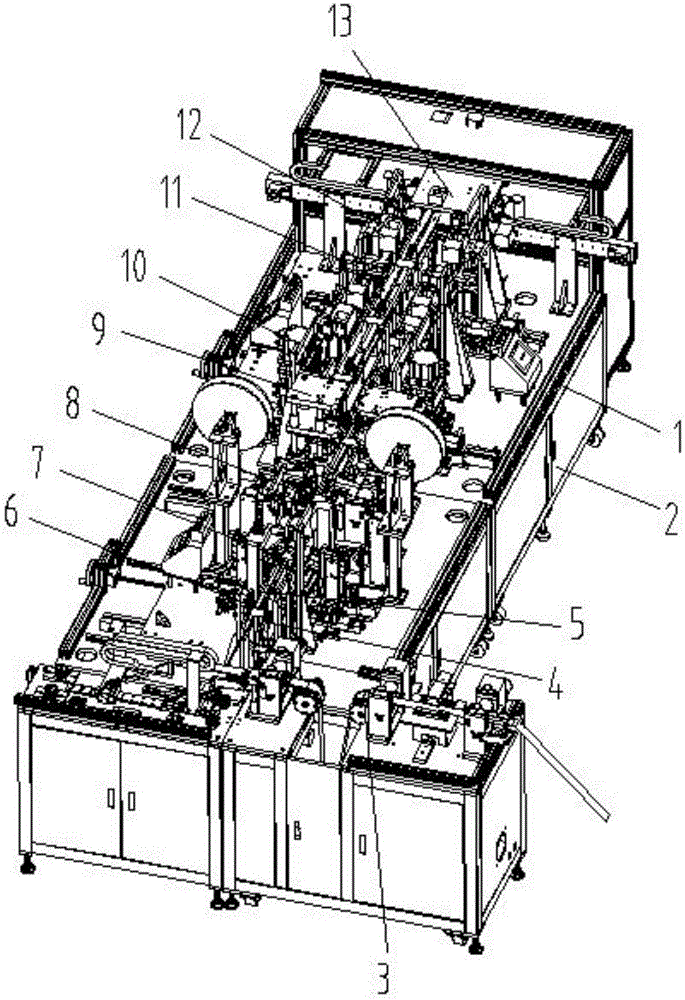

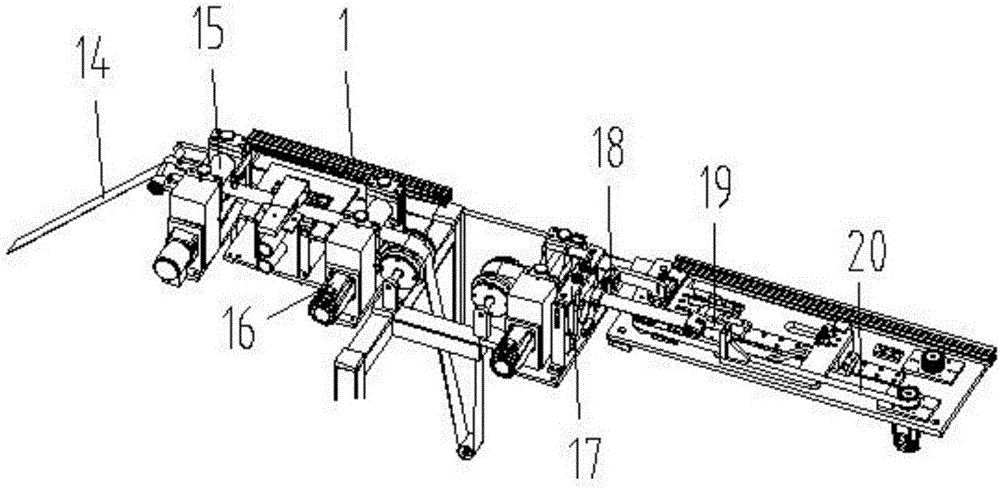

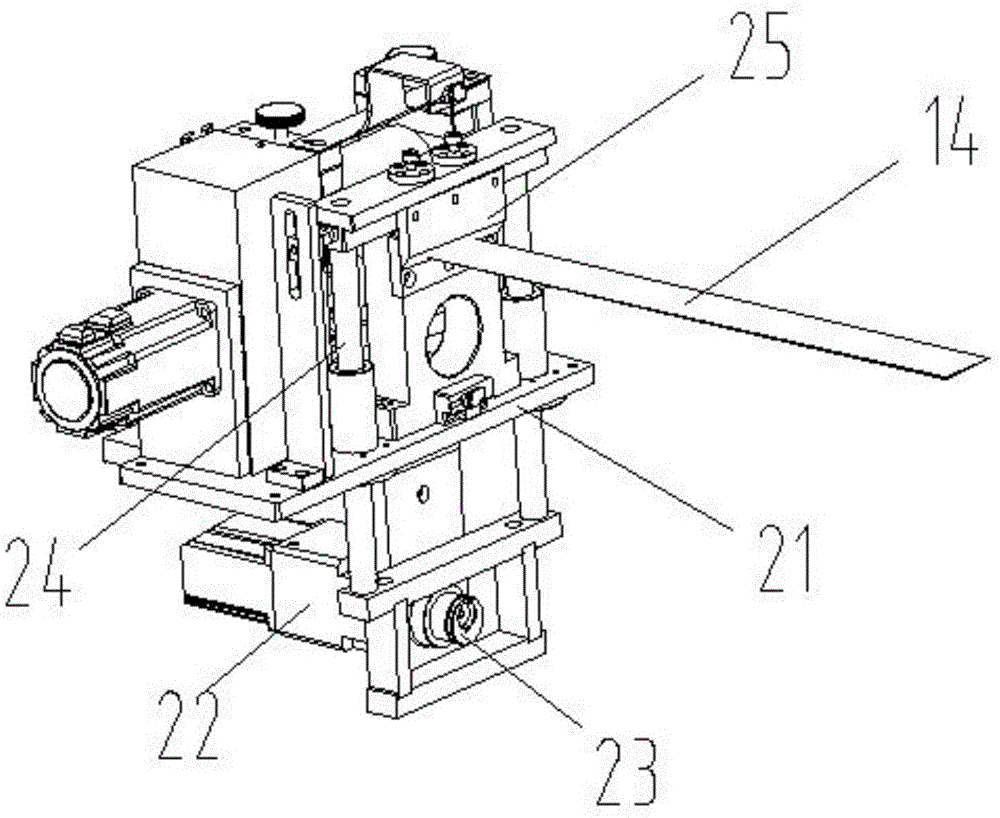

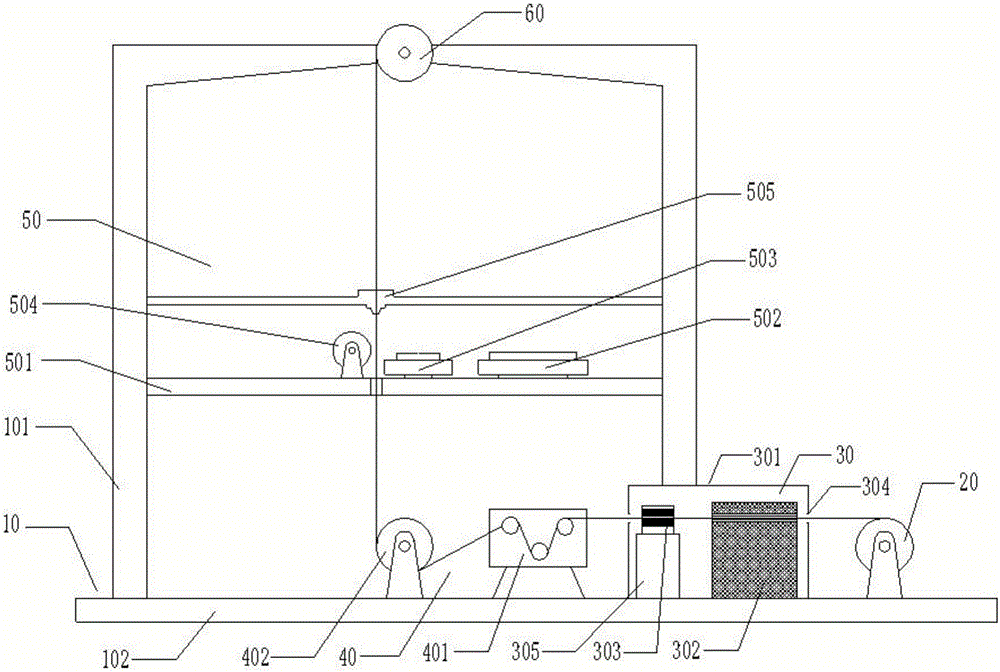

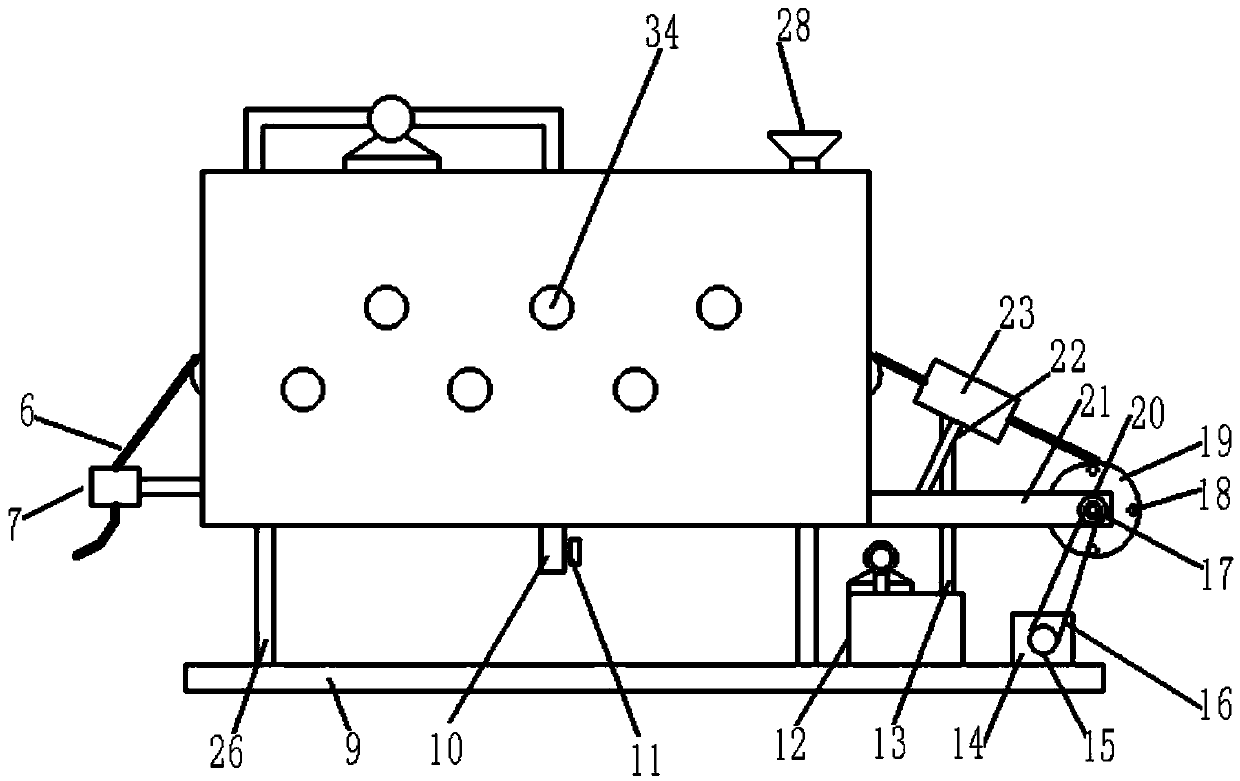

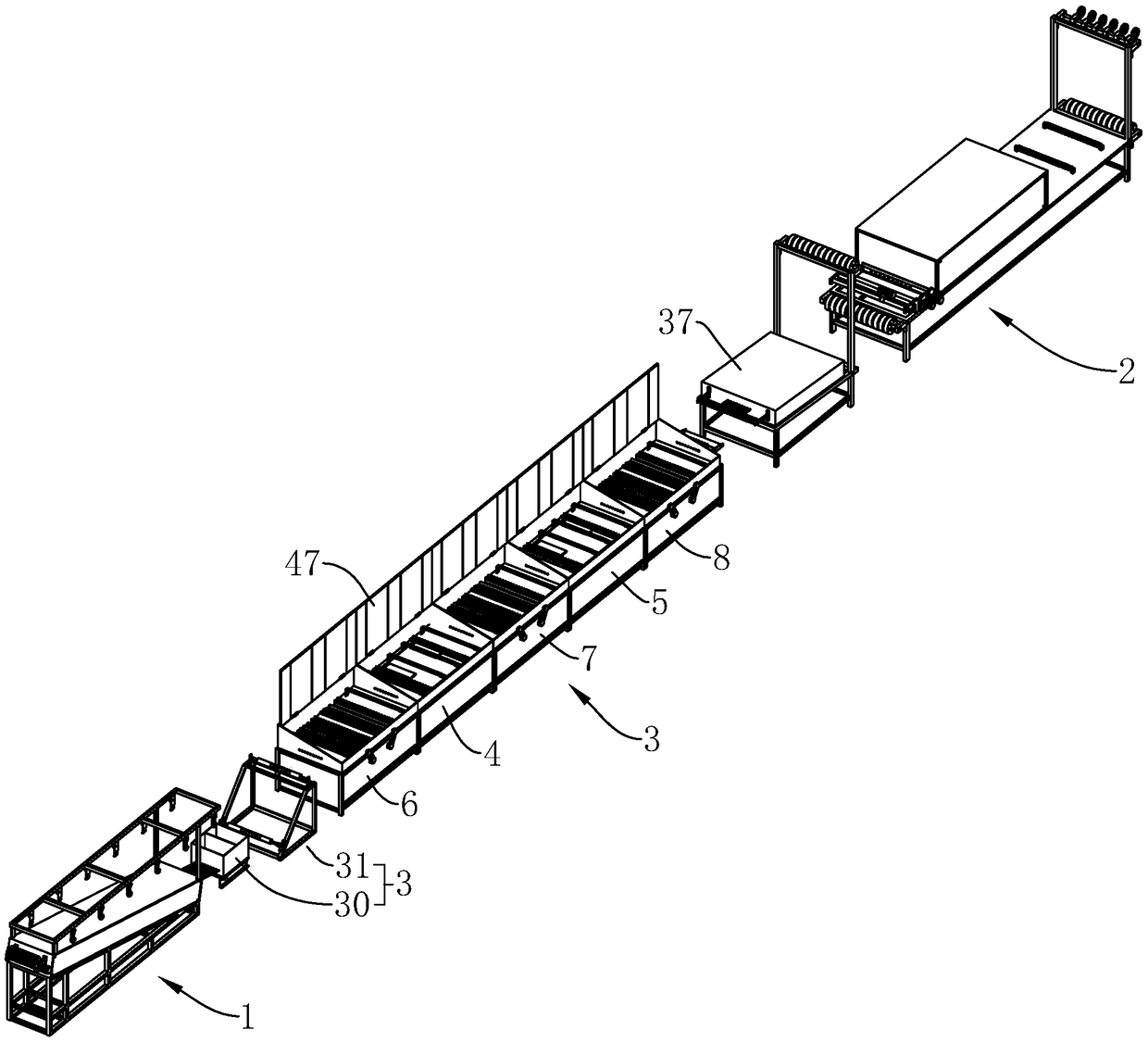

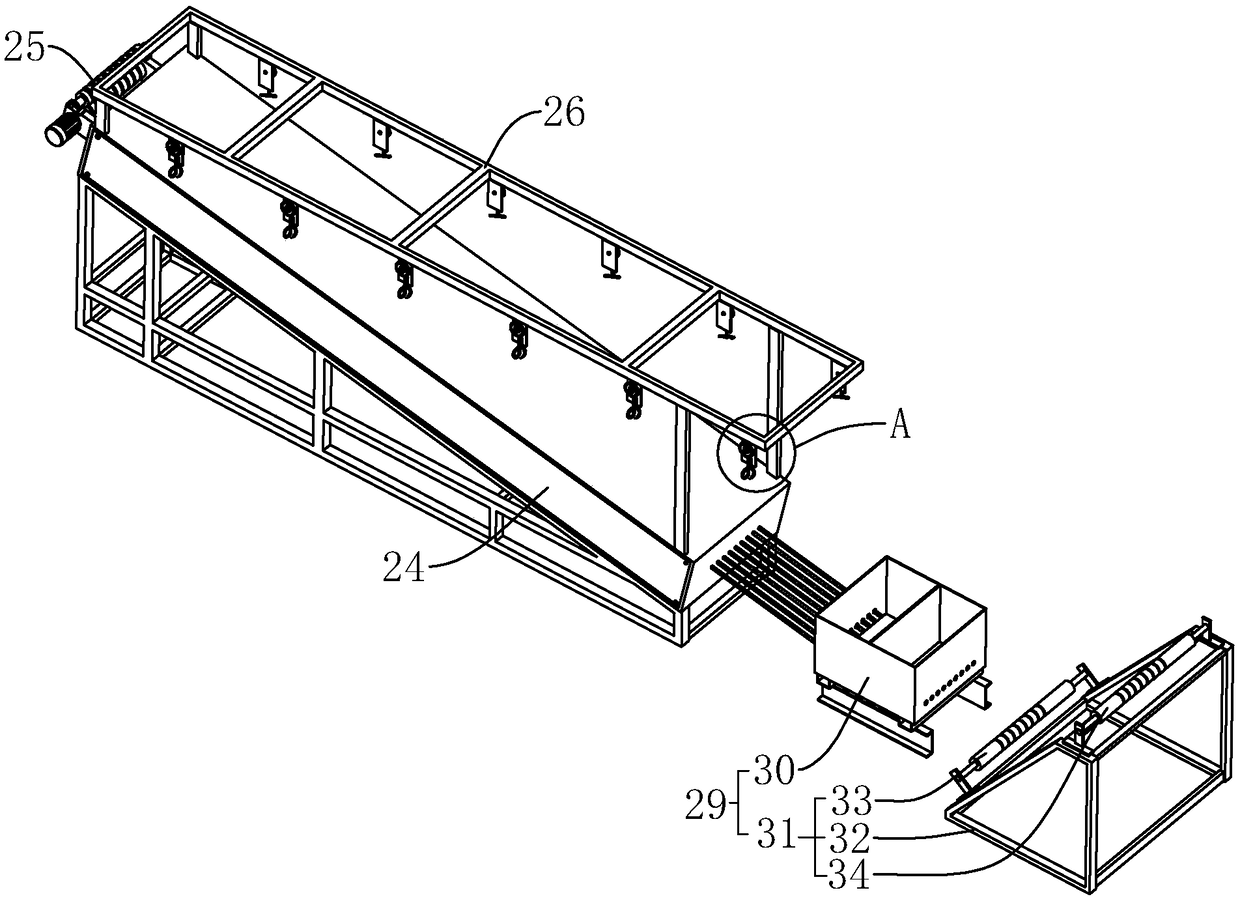

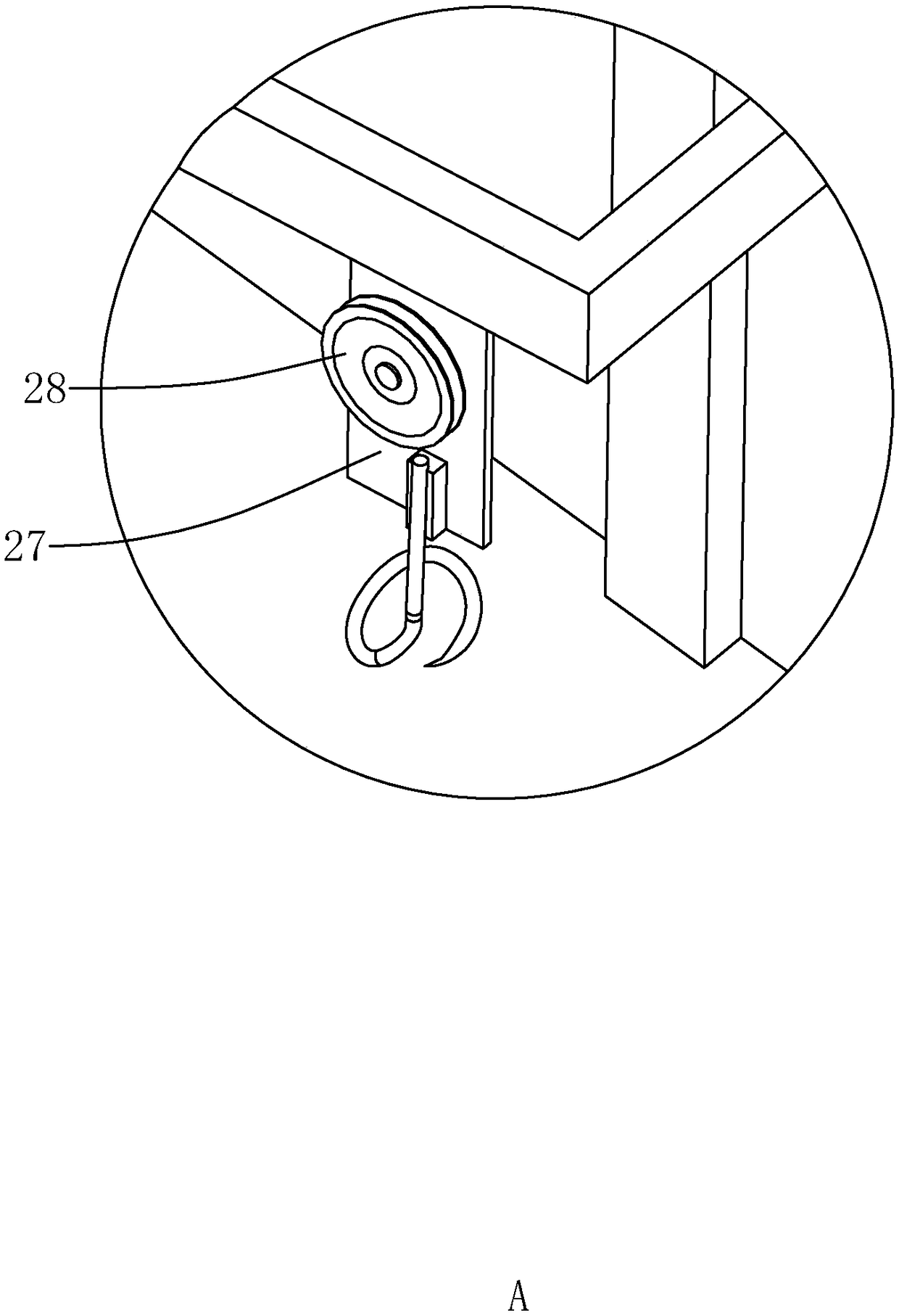

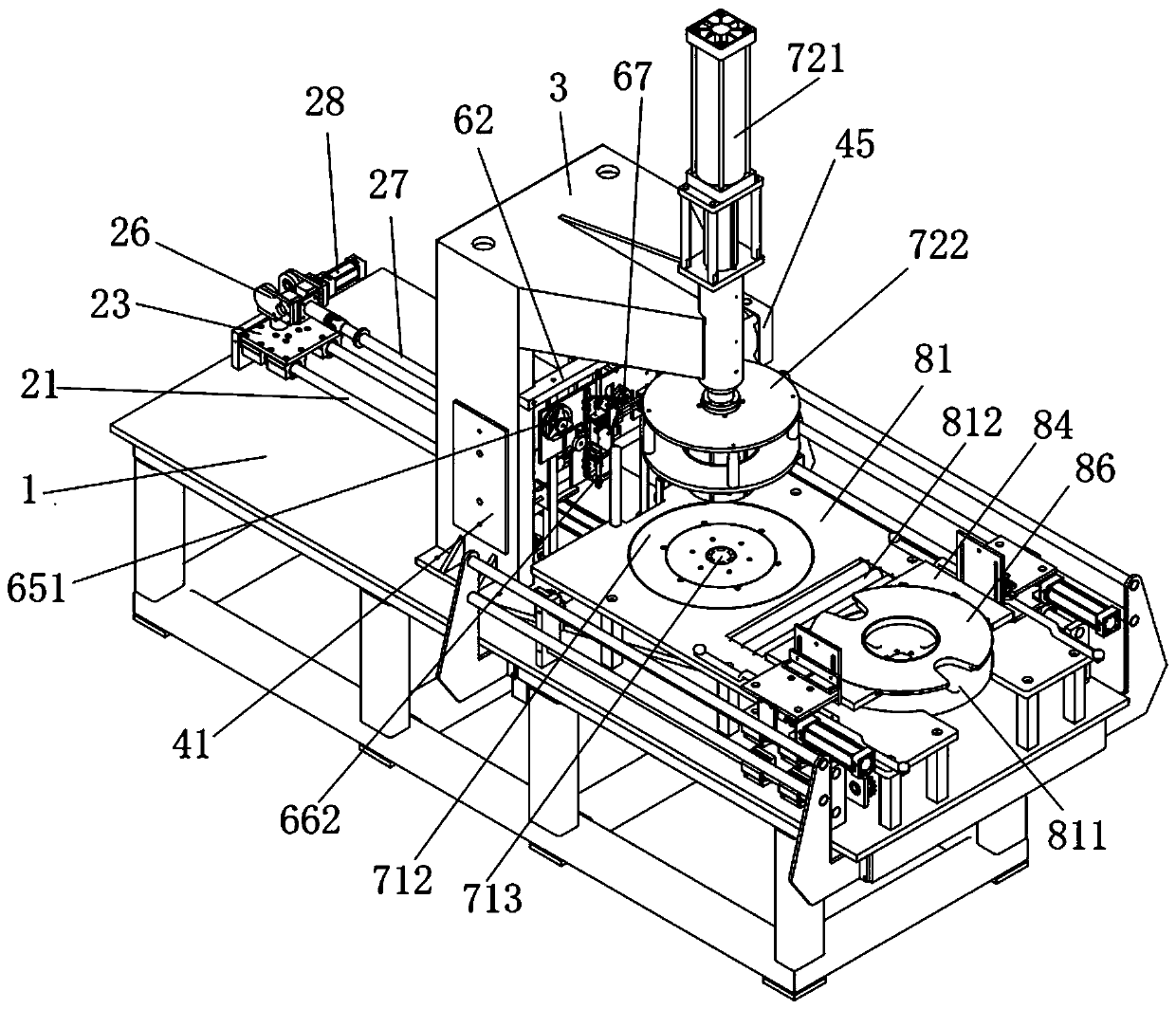

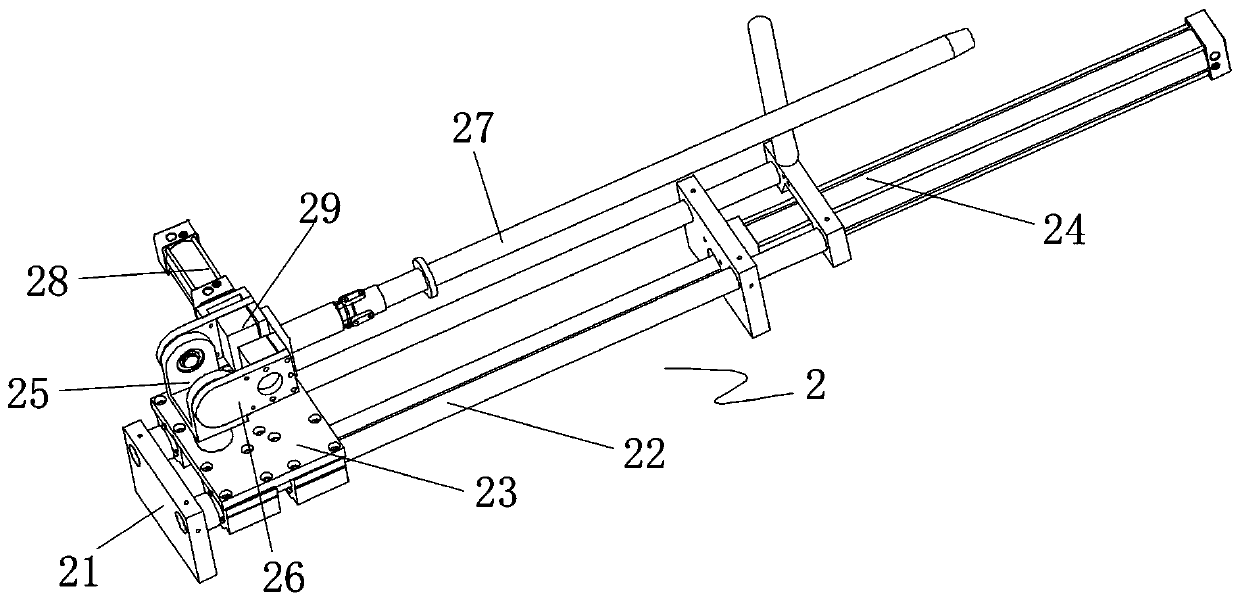

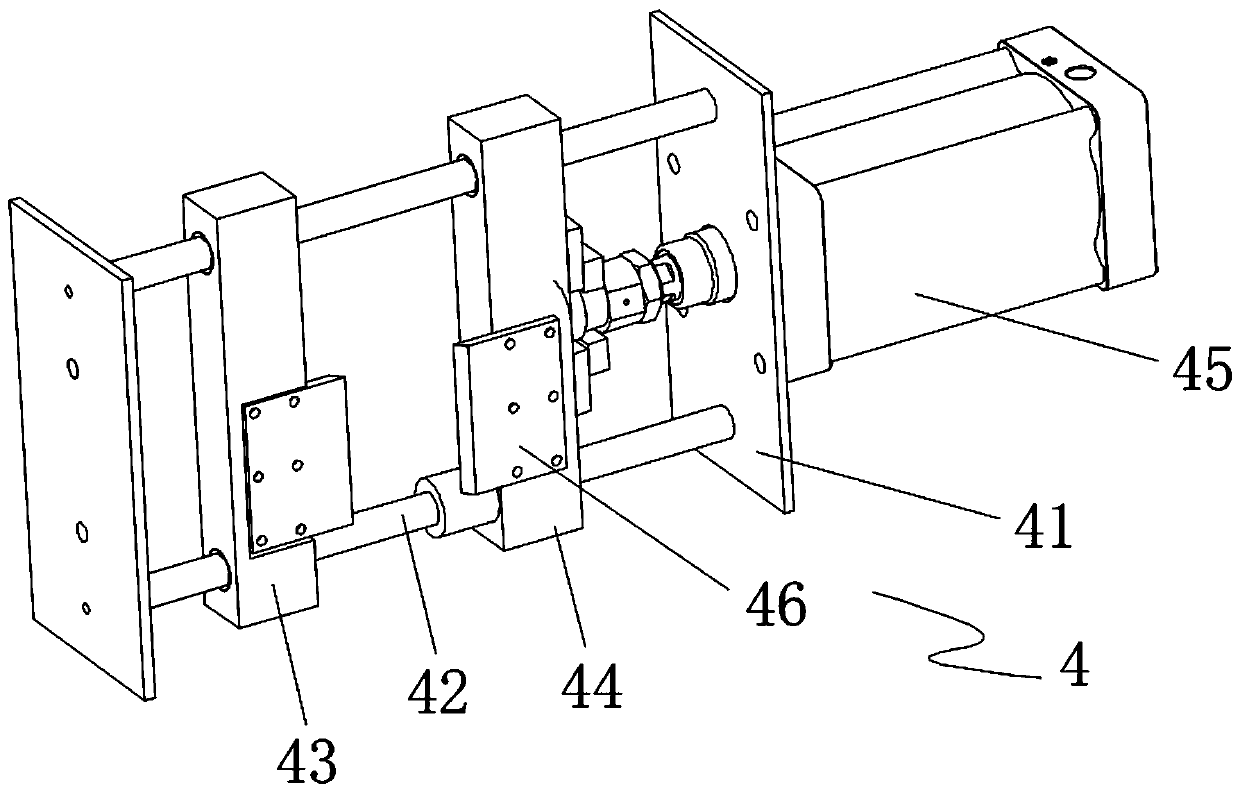

Fully-automated flexible flat cable pipe processing machine

ActiveCN106782888AImprove processing efficiencyImprove yield rateApparatus for feeding conductors/cablesDistribution controlVisual inspection

The invention relates to a fully-automated flexible flat cable pipe processing machine. The fully-automated flexible flat cable pipe processing machine comprises a frame and a power distribution control cabinet, wherein the frame is provided with a conveying chute and a feeding device which are matched with each other; the feeding device comprises a feeding forward-backward movement device, and the feeding forward-backward movement device is provided with a feeding left-right movement device; a feeding lifting device is arranged on the feeding left-right movement device, uniformly provided with a feeding clamp matched with products, and provided with a feeding guide rod matched with the conveying chute; the frame is sequentially provided with an edge spacing detecting device, a wire stripping device, an adhesive applying device, a heat pressing device, a trimming device, a visual inspection device and a circuit detecting device, which are matched with the products on the conveying chute. The fully-automated flexible flat cable pipe processing machine achieves fixed-distance product feeding through matching between the feeding device and the conveying chute and further achieves continuous and integrated flexible flat cable processing, thereby greatly improving the processing efficiency and the yield rate.

Owner:大千纺织(安徽)有限公司

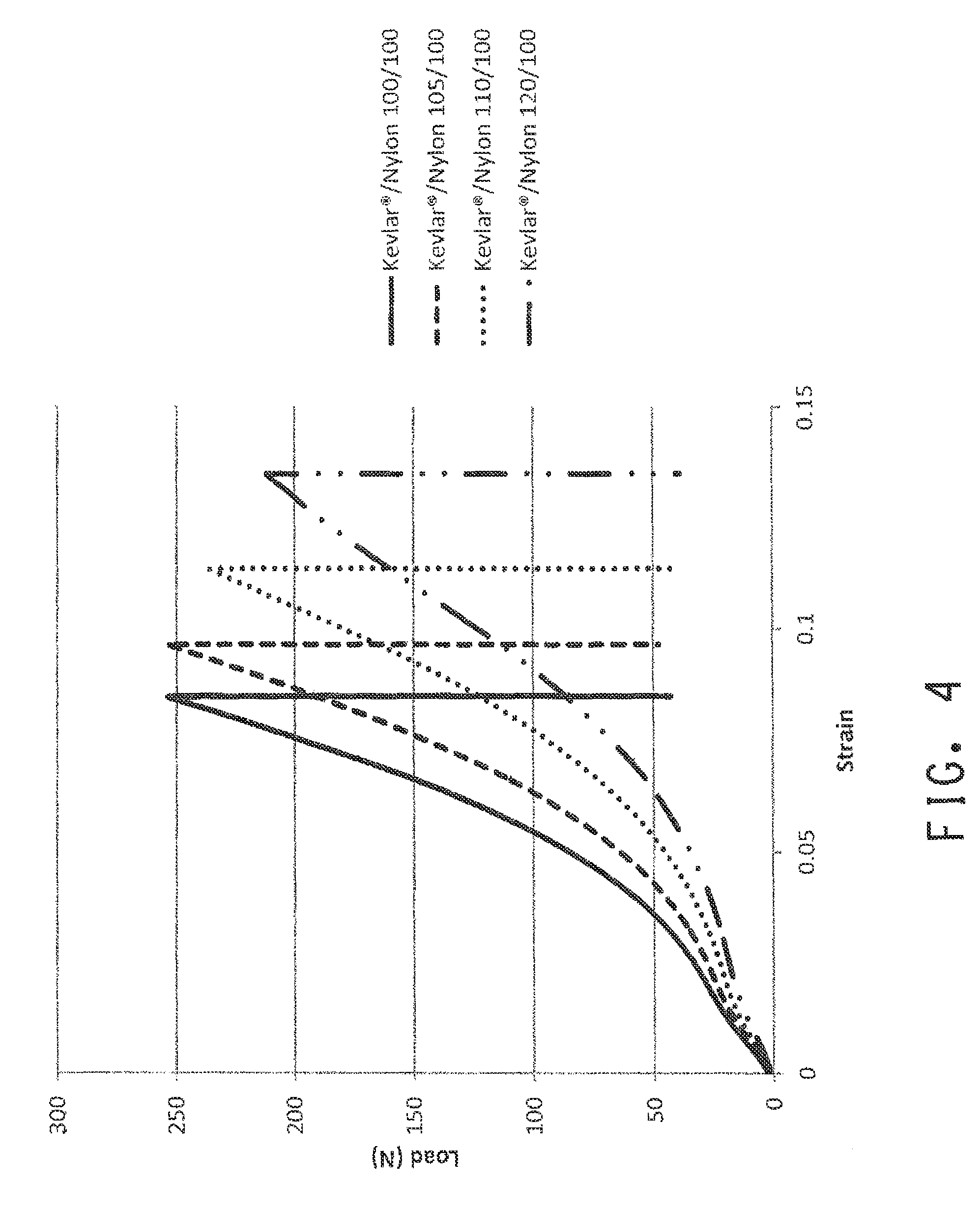

Unbalanced Hybrid Cords and Methods for Making on Cable Cording Machines

A hybrid cord formed from a plurality of component plies wherein at least one of the plies has a length that is from 1 to 50 percent longer than the other plies and a method of providing a cord with predetermined twist and component ply lengths.

Owner:DUPONT SAFETY & CONSTR INC

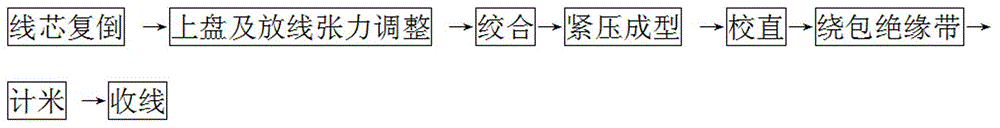

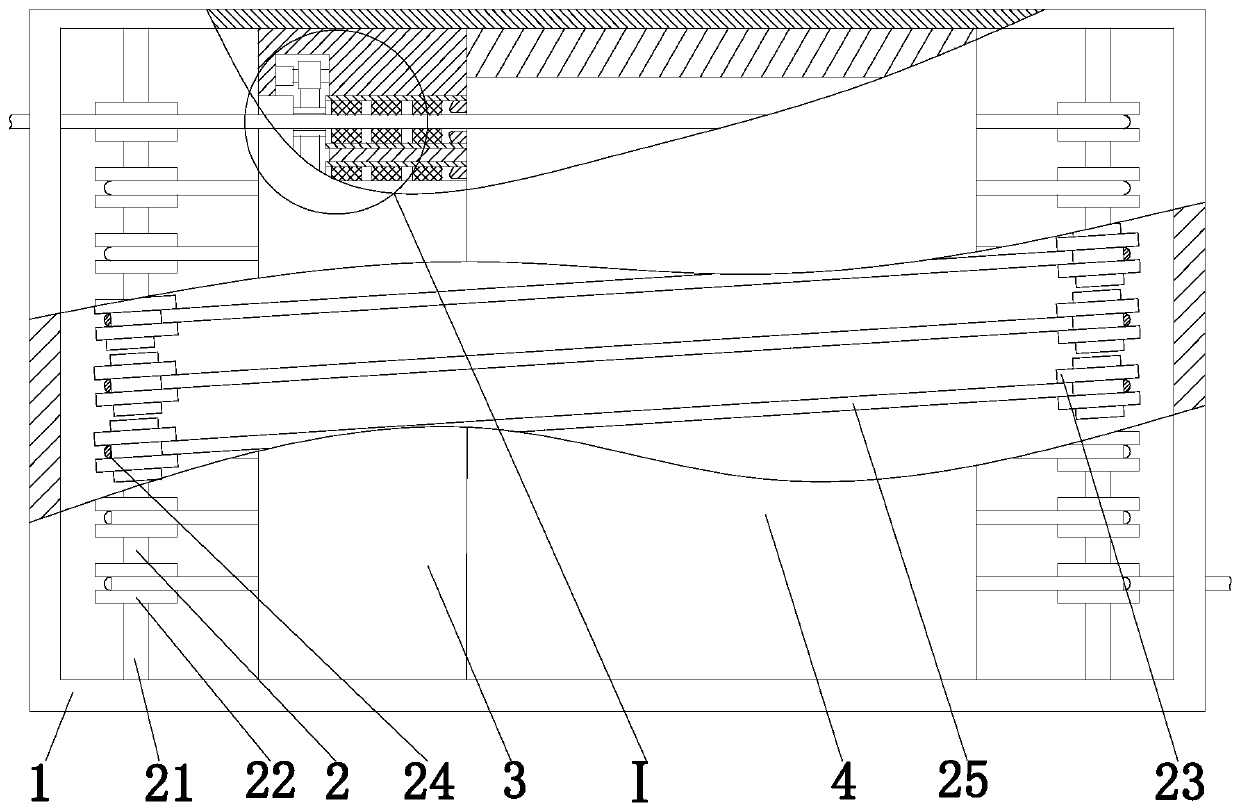

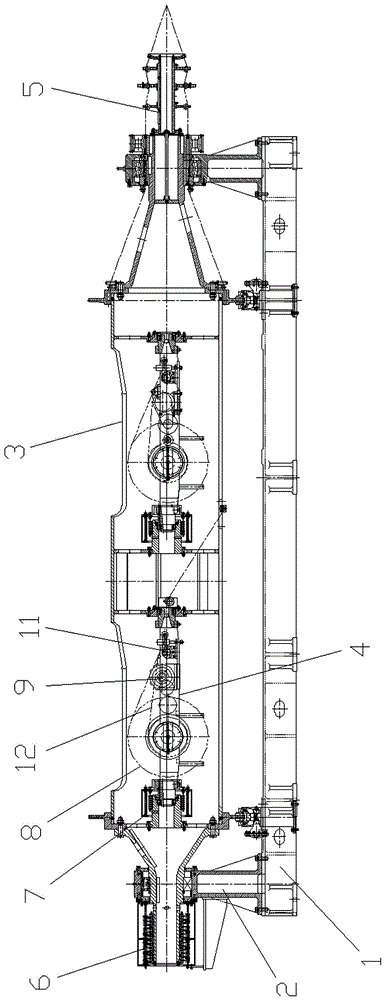

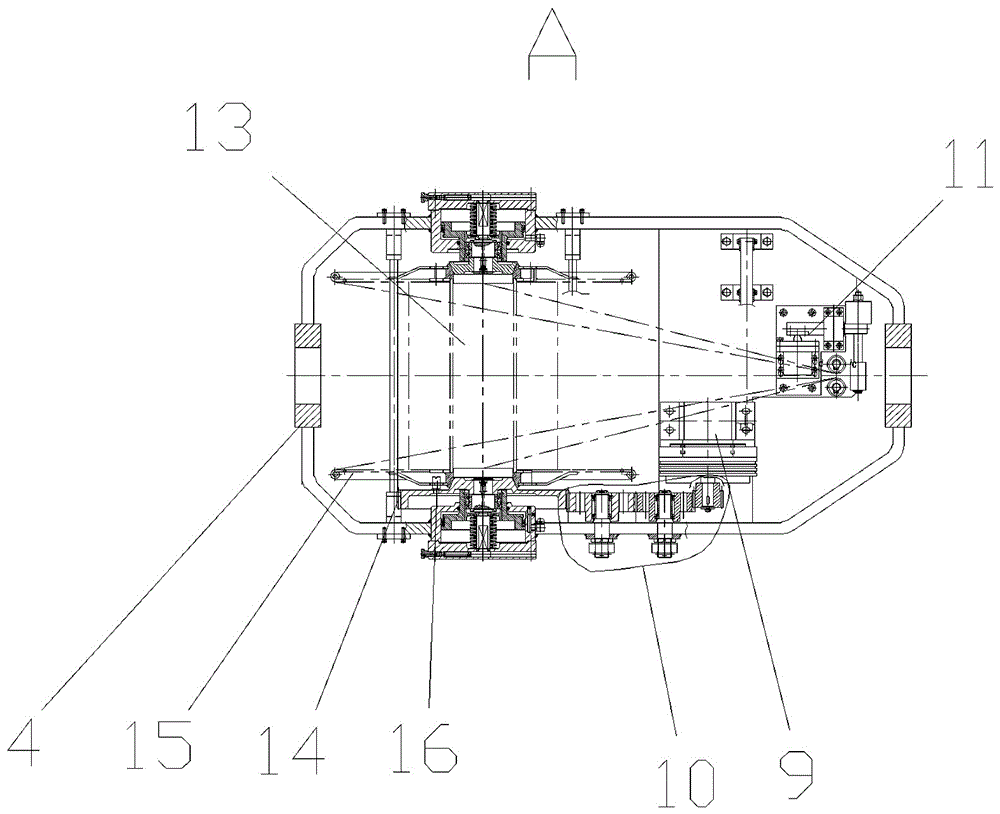

Device and method for producing special-shaped superconducting cable for magnet

ActiveCN106098252AUniform pay-off tensionImport smoothlyApparatus for feeding conductors/cablesCompression moldingWinding machine

The invention discloses a device for producing a special-shaped superconducting cable for a magnet. The device comprises an inner supporting core fixing frame, a stranding cage, a compression mould, a cable straightening machine, an insulated strip winding machine, a crawler traction machine, a pay-off and take-up control machine and a take-up reel, wherein the above parts are arranged in sequence. The stranding cage comprises a stranding cage main shaft, and a stranding cage pay-off rack is arranged on the stranding cage main shaft. The stranding cage pay-off rack is provided with a stranding cage pay-off reel. An inner supporting core is arranged in the stranding cage main shaft. The rear end of the inner supporting core is connected with the inner supporting core fixing frame. In the front end area of the inner supporting core, a fixing region, a small branching ring mounting region, a superconducting compound yarn stranding region, a superconducting compound yarn stabilizing region, a superconducting compound yarn deformation transition region and a superconducting compound yarn deformation stabilizing and forming region are sequentially arranged from back to front. According to the technical scheme of the invention, the gradual and stable transition of each superconducting strand during the stranding process can be ensured, so that each superconducting strand can sequentially enter the compression mold to be subjected to compression molding in the regular and bounce-free manner. Therefore, the problem that each superconducting strand can not regularly enter the compression mold to be damaged can be solved.

Owner:白银有色长通电线电缆有限责任公司

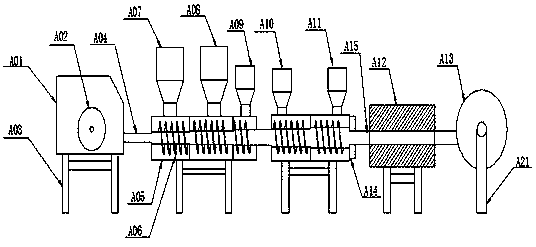

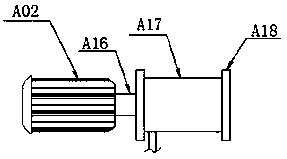

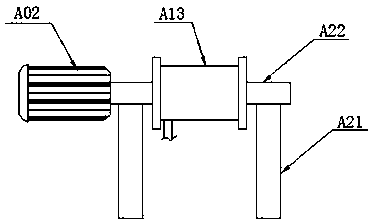

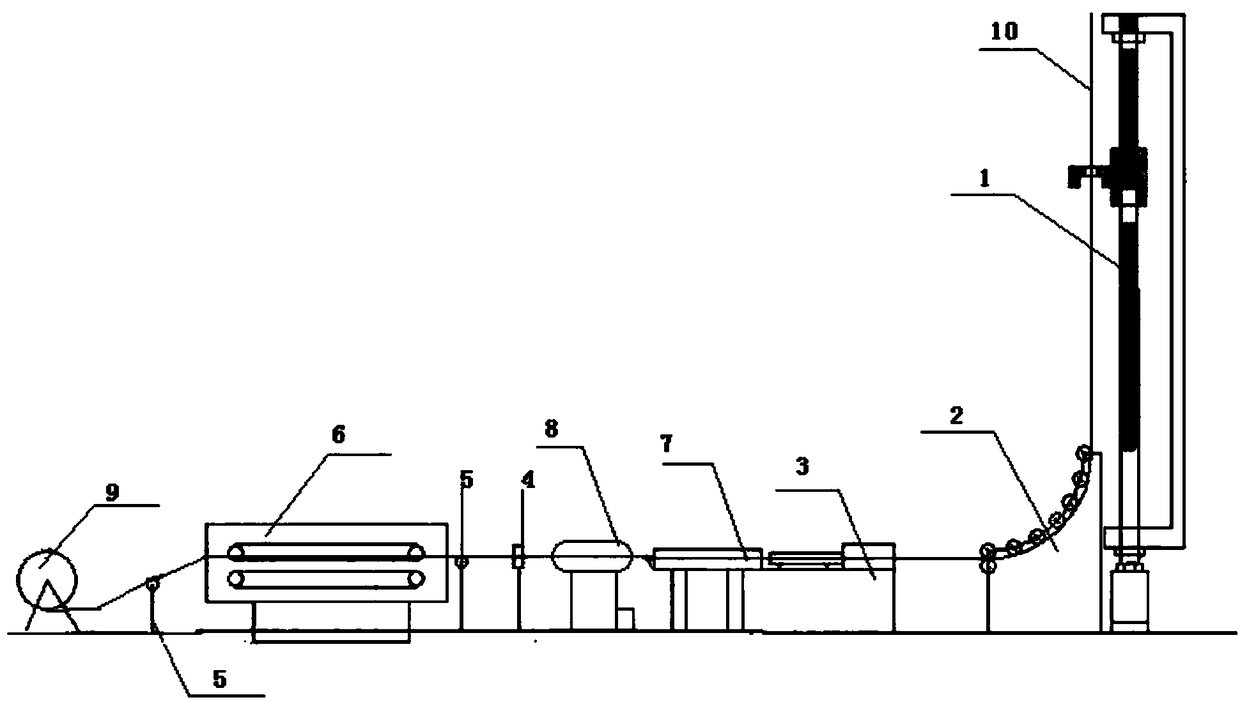

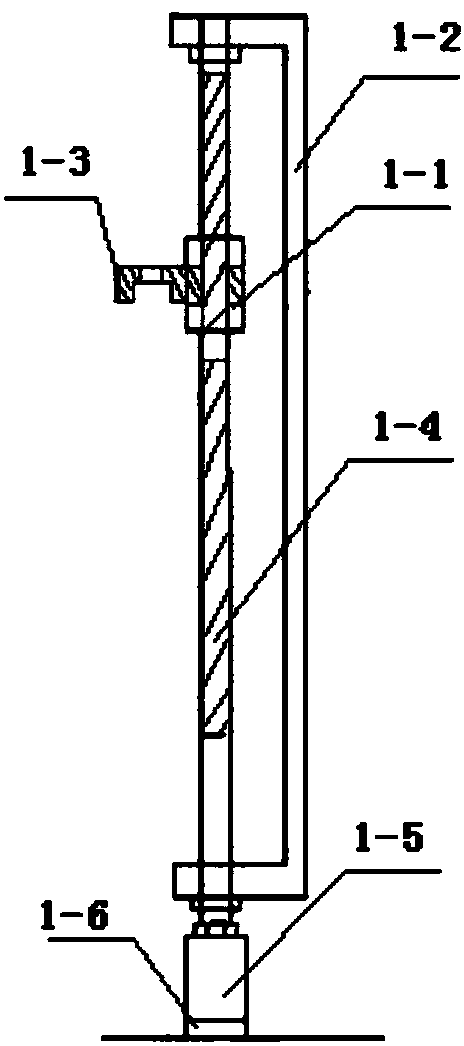

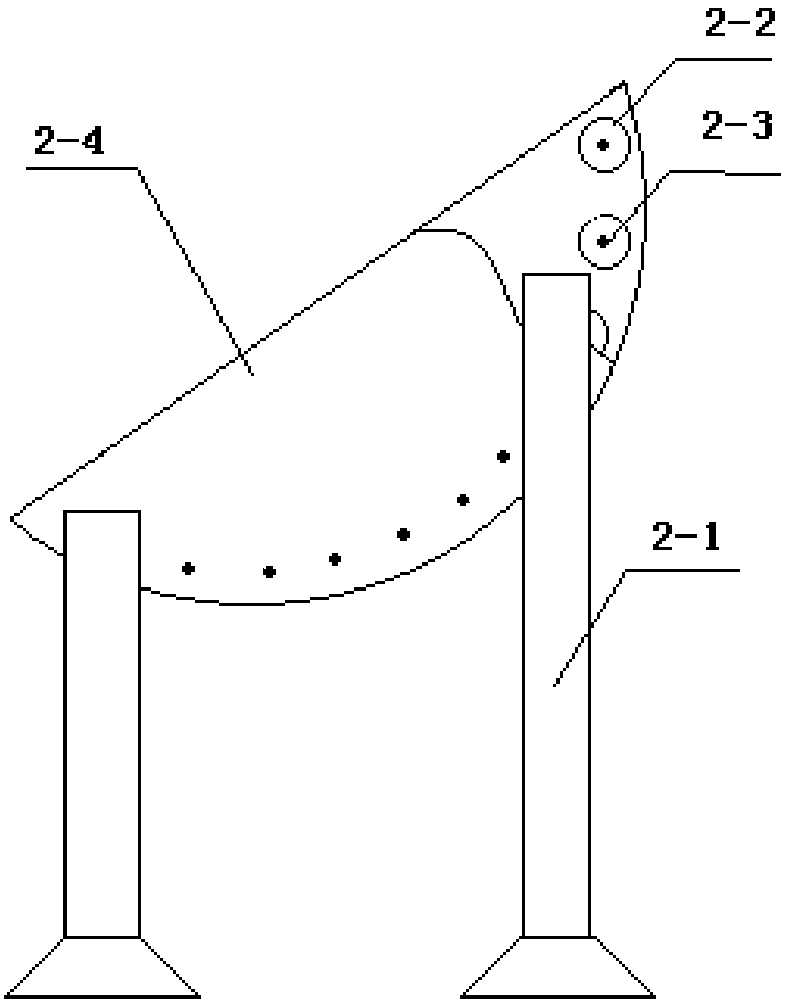

Multifunctional horizontal type aluminum wire enamelling machine

ActiveCN106205860AAvoid cloggingReduce frictionApparatus for feeding conductors/cablesInsulating conductors/cablesComing outAir volume

The invention discloses a multifunctional horizontal type aluminum wire enamelling machine. The multifunctional horizontal type aluminum wire enamelling machine comprises a pay-off apparatus, a wiredrawing apparatus, a cleaning apparatus, an annealing furnace, a painting apparatus, a baking furnace, a cooling apparatus and a take-up apparatus. The multifunctional horizontal type aluminum wire enamelling machine provided by the invention is applicable to painting and processing of metal wires of various different core materials, particularly the aluminum wire; online wiredrawing is realized, so that aluminum wire wiredrawing and enamelling can be carried out at the same time; the pay-off apparatus tightly compresses and brakes the wire through soft wheels, so that a bare wire is in a tensioned state; after the aluminum wire is subjected to online wiredrawing, the aluminum wire is cleaned by an ultrasonic cleaning machine first to remove aluminum powder and lubricating grease on the surface; a wire supporting roller is arranged between the baking furnace and the cooling apparatus, so that friction between the aluminum wire and the pipe wall can be prevented; the cooling apparatus is used for forcedly cooling a high-temperature wire coming out of the baking furnace; the air flow direction in an air channel is opposite to the marching direction of the wire; the air is large in air volume and high in air speed, so that a sufficient cooling effect can be ensured; in addition, the take-up apparatus is provided with a constant-speed apparatus; a constant-speed wheel is equipped with a wire pressing wheel, so that the take-up speed is stable.

Owner:佛山市顺德区盛永机械有限公司

Aluminum armored power cable as well as production equipment and production technology of cable

ActiveCN106782848AGood flexibilityApparatus for feeding conductors/cablesInsulated cablesPower cableEngineering

The invention provides an aluminum armored power cable as well as production equipment and a production technology of the cable. The production equipment is a twisting and wrapping device of the cable, wherein the twisting and wrapping device twists an insulated wire core of forming the cable and sequentially wraps the twisted cable core with a refractory layer and an aluminum armored layer; the twisting and wrapping device comprises a conveying mechanism, a twisting mechanism, a refractory layer wrapping mechanism and an aluminum armored layer wrapping mechanism; the conveying mechanism drags the cable core, so that the cable core sequentially passes through the twisting mechanism, the refractory layer wrapping mechanism and the aluminum armored layer wrapping mechanism; the aluminum armored power cable is sequentially provided with the cable core, the refractory layer and a self-locking aluminum armored layer from inside to outside; the cable core is formed by twisting the insulated wire core and a filling rope; the refractory layer is formed by multiple groups of refractory strips wrapping the cable core; and the self-locking aluminum armored layer is formed by multiple groups of aluminum strips wrapping the cable core refractory layer. According to the produced aluminum armored power cable, the fire resistance, the corrosion resistance and the flexibility of the cable can be strengthened and the bending radius value of the cable can be reduced.

Owner:FUZHOU YONGTONG WIRE & CABLE

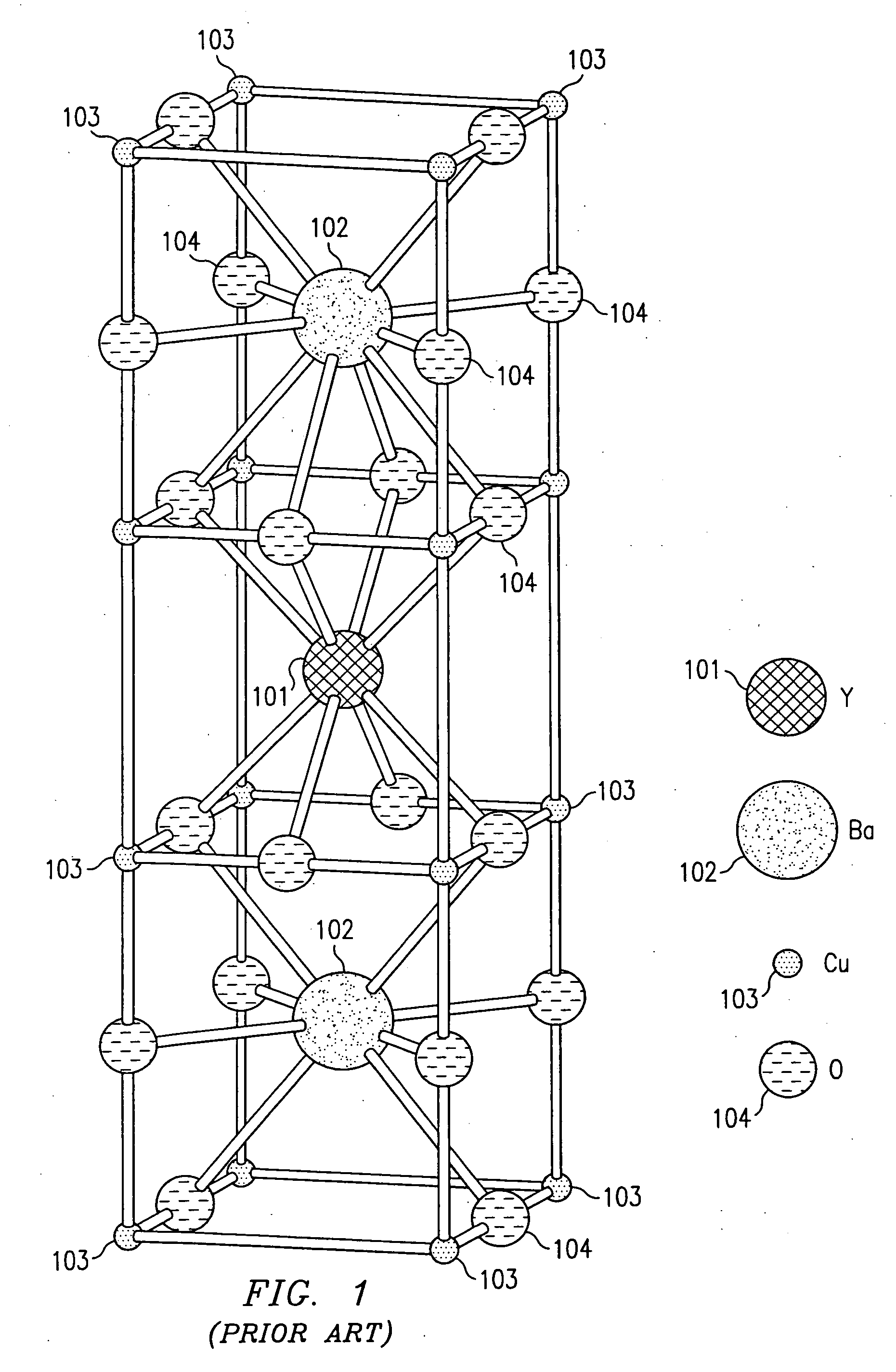

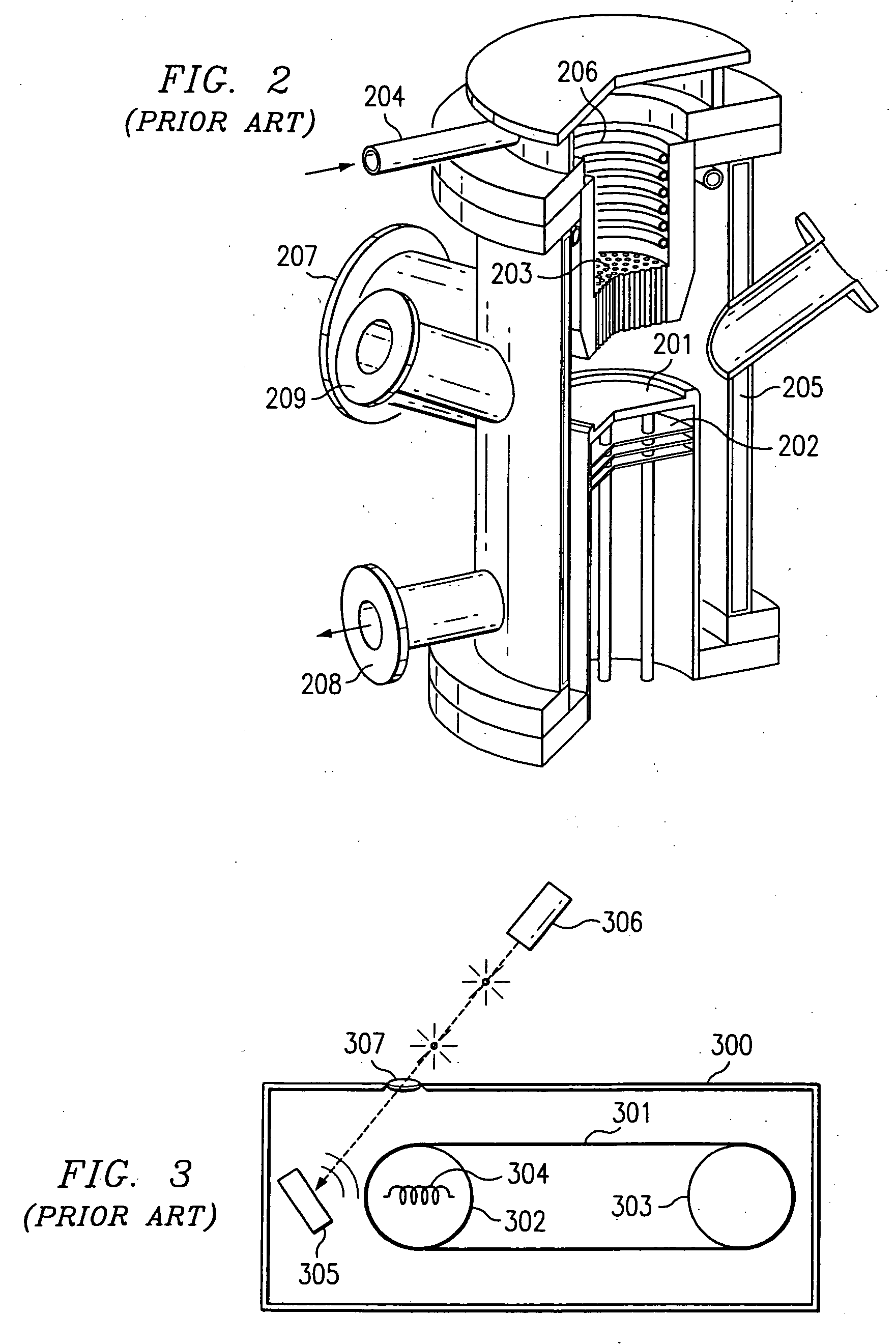

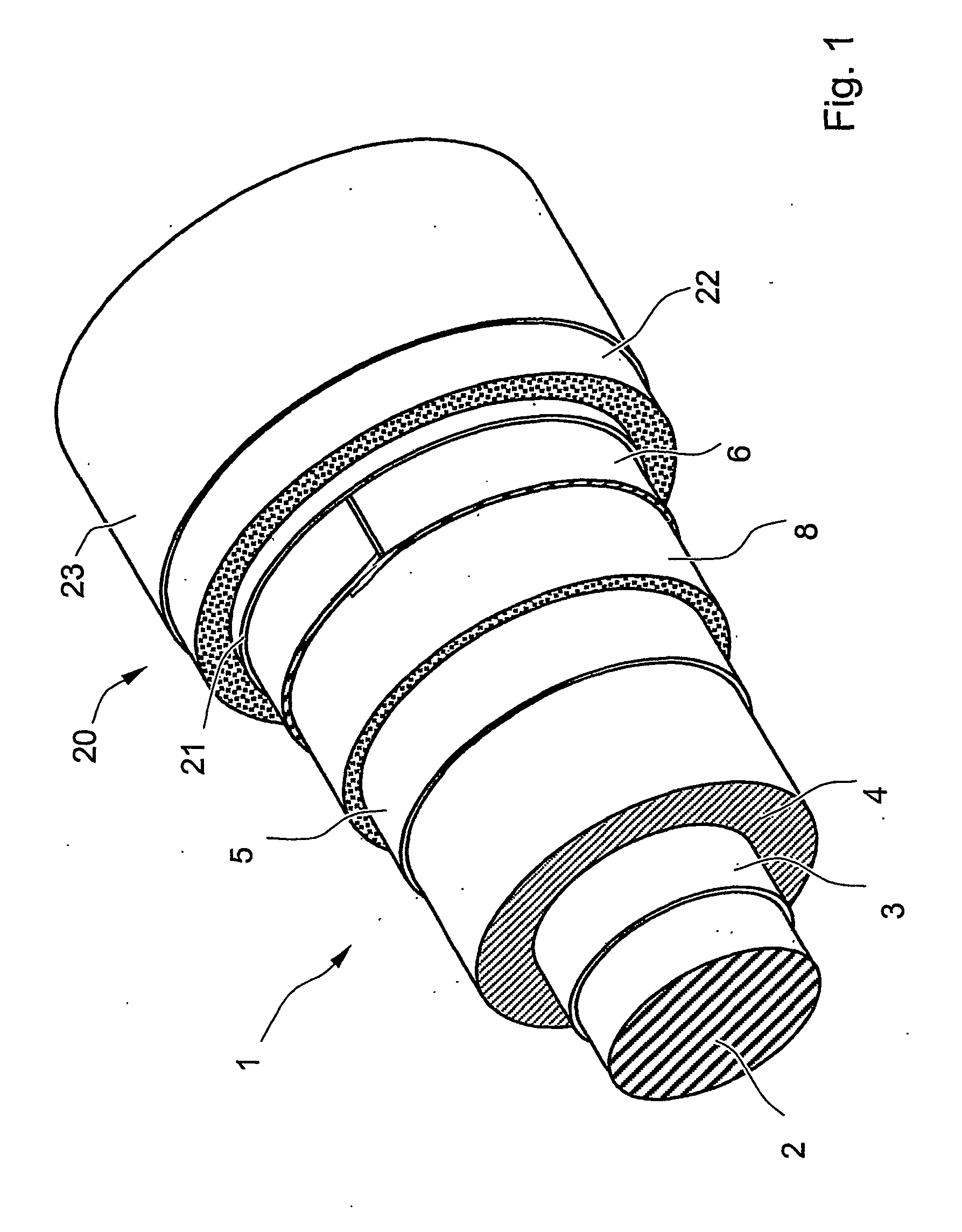

Superconductor material on a tape substrate

InactiveUS20080103052A1Superconductors/hyperconductorsApparatus for feeding conductors/cablesMetallurgyMagnetic tape

The inventive superconducting wire comprises a substrate and a continuous layer of atomically ordered superconducting material. The inventive wire has a length greater than 10 meters.

Owner:IGNATIEV ALEX +5

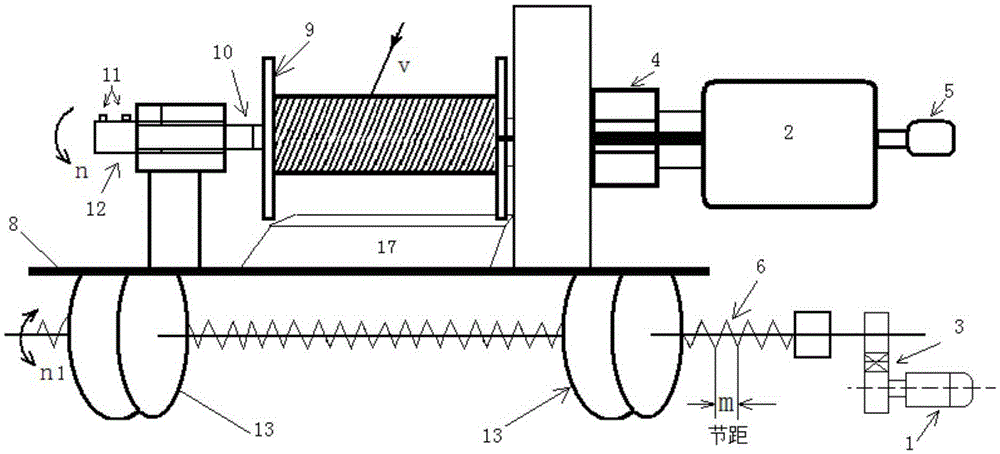

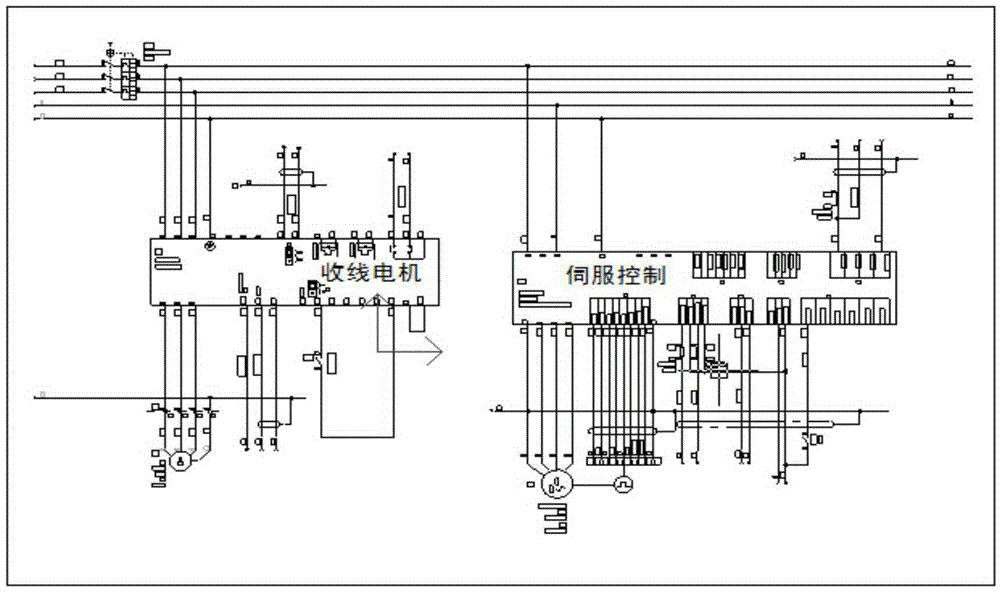

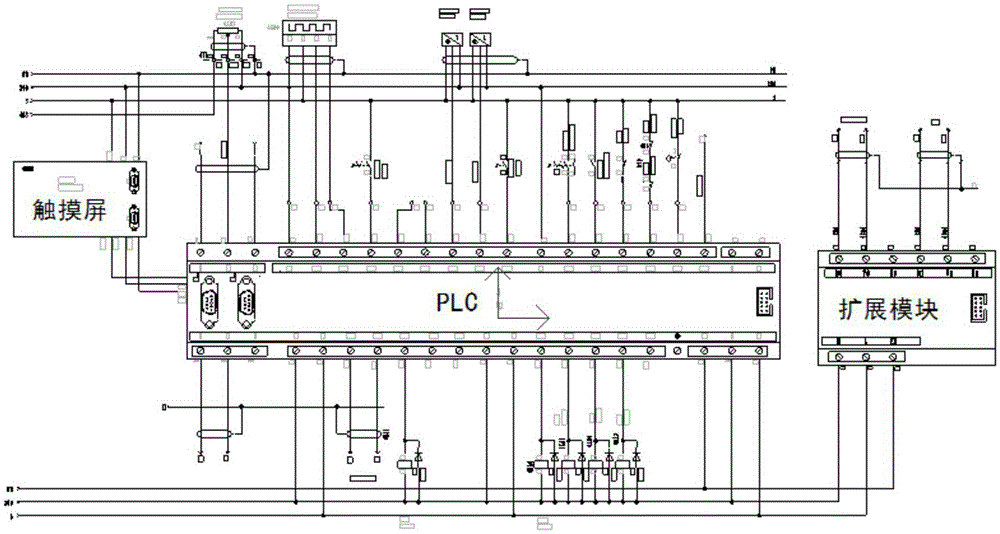

Automatic control system for gathering and laying of cables

ActiveCN105417283APlay a protective effectTight and even wiringApparatus for feeding conductors/cablesFilament handlingAutomatic controlAutomatic train control

The invention relates to an automatic control system for gathering and laying of cables. The control system comprises a main controller; a laying servo control unit for controlling a laying mechanism and a gathering control unit for controlling a gathering mechanism are connected to the main controller, respectively; drivers, motors and relevant parts in the control system provided by the present invention are employed to realize constant-speed gathering and tight and uniform laying of cables, and automatically and accurately adjust a laying pitch, such that a rotating speed of a laying motor is capable of changing along with change of a rotating speed of a gathering motor; besides, the automatic control system guarantees accurate reversing of a cable when the cable is laid to a coil edge and avoids sinking or piling of the coil edge due to manual adjustment; as a result, the production efficiency and the product quality are improved while much labor is saved.

Owner:HENAN COMM CABLE +1

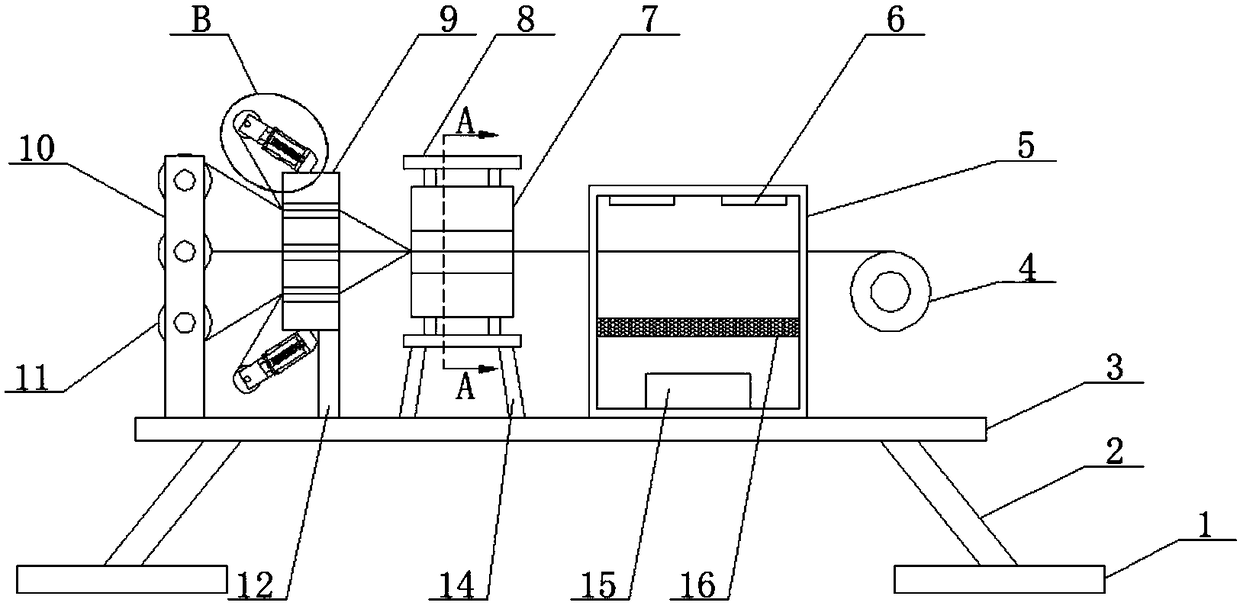

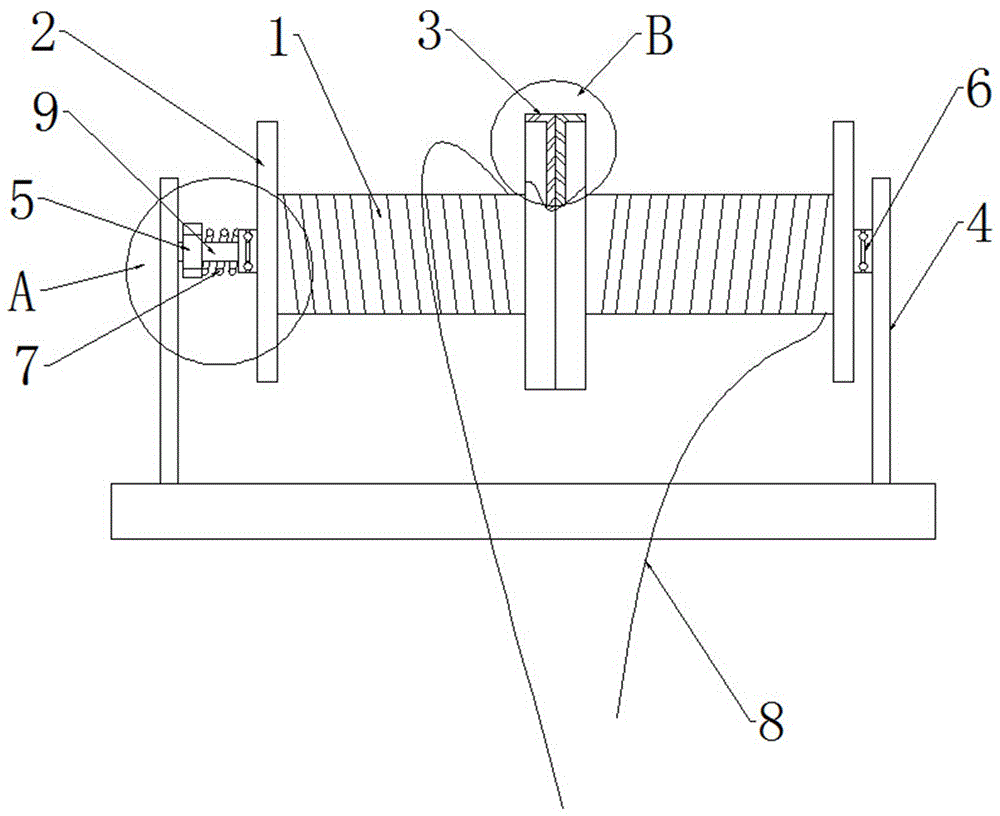

Production equipment for new energy transformer cable

ActiveCN108305714ALow costReasonable structural designApparatus for feeding conductors/cablesProduction lineNew energy

The invention discloses production equipment for new energy transformer cables. The production equipment includes a pedestal. A cable holding device, a cable winding device, a rubber extrusion deviceand a drying device are sequentially arranged on the pedestal in a horizontal direction. The cable holding device includes a fixing support fixedly connected on the pedestal. The fixing support is provided with multiple first cable holding buckets at equal intervals in a vertical direction. The cable winding device includes a supporting rod fixed on the pedestal. The upper end of the supporting rod is fixedly connected with a cable winding disc. The cable winding disc is circumferentially provided with cable holes that are arranged at equal intervals and correspond to the first cable holding buckets in quantity. The sidewall of the cable winding disc is circumferentially provided with damping devices that are arranged at equal intervals and face the cable holes. The production equipment isreasonable in structural design and low in cost and is easy to operate. Cables are low in cost and are quite easy to obtain. The production equipment, easy to operate, needs no quite professional technicians and can be quite easily promoted and used on production lines. Moreover, extra training costs and manpower costs are not needed.

Owner:TONGLING SANJIA TRANSFORMER

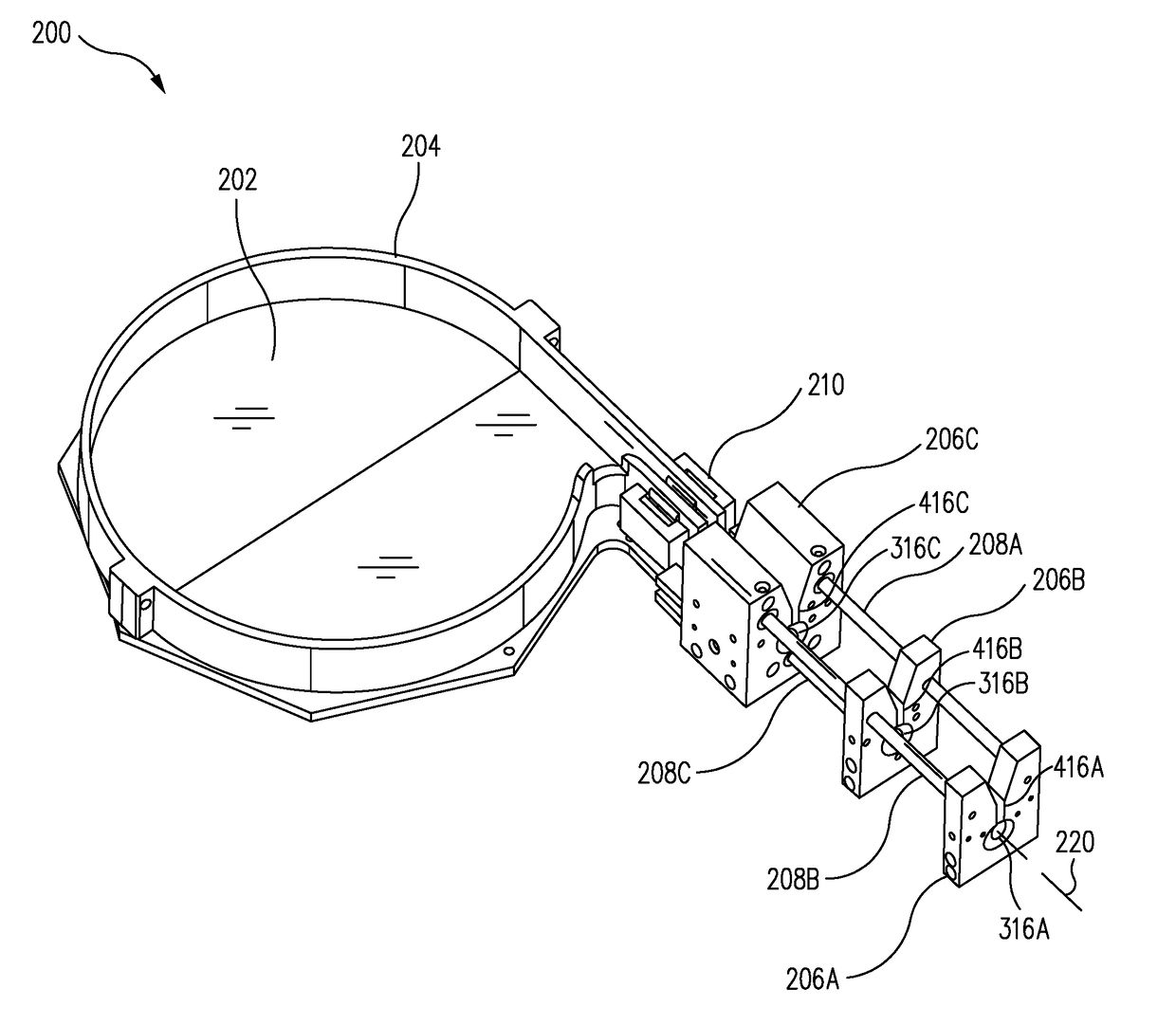

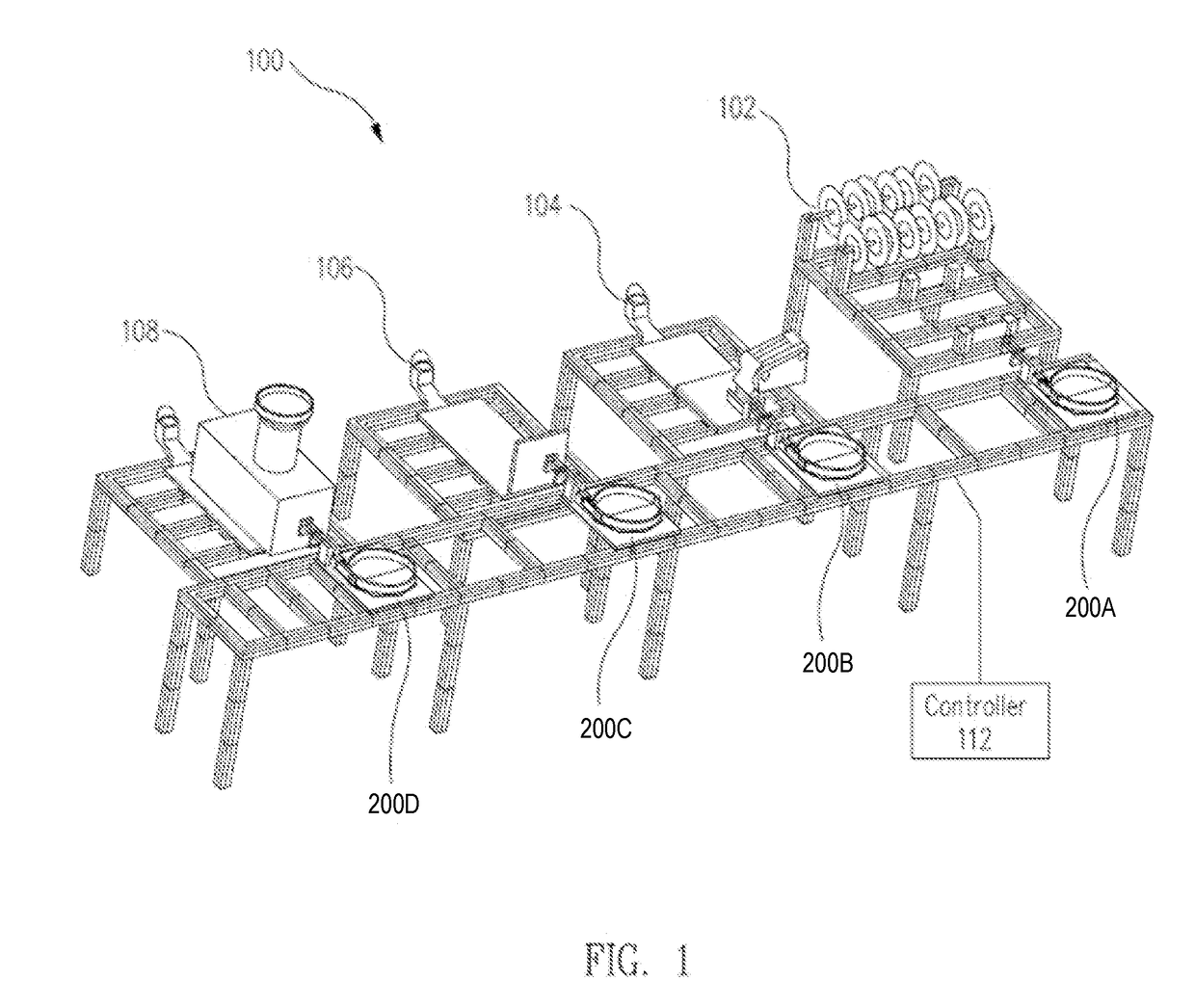

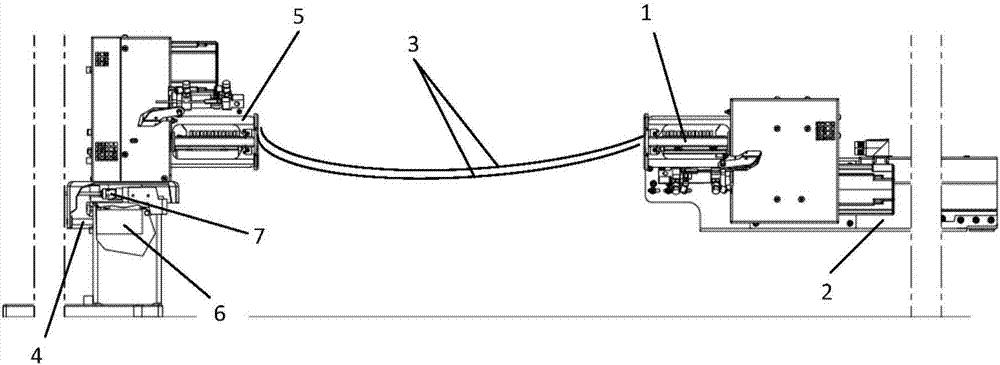

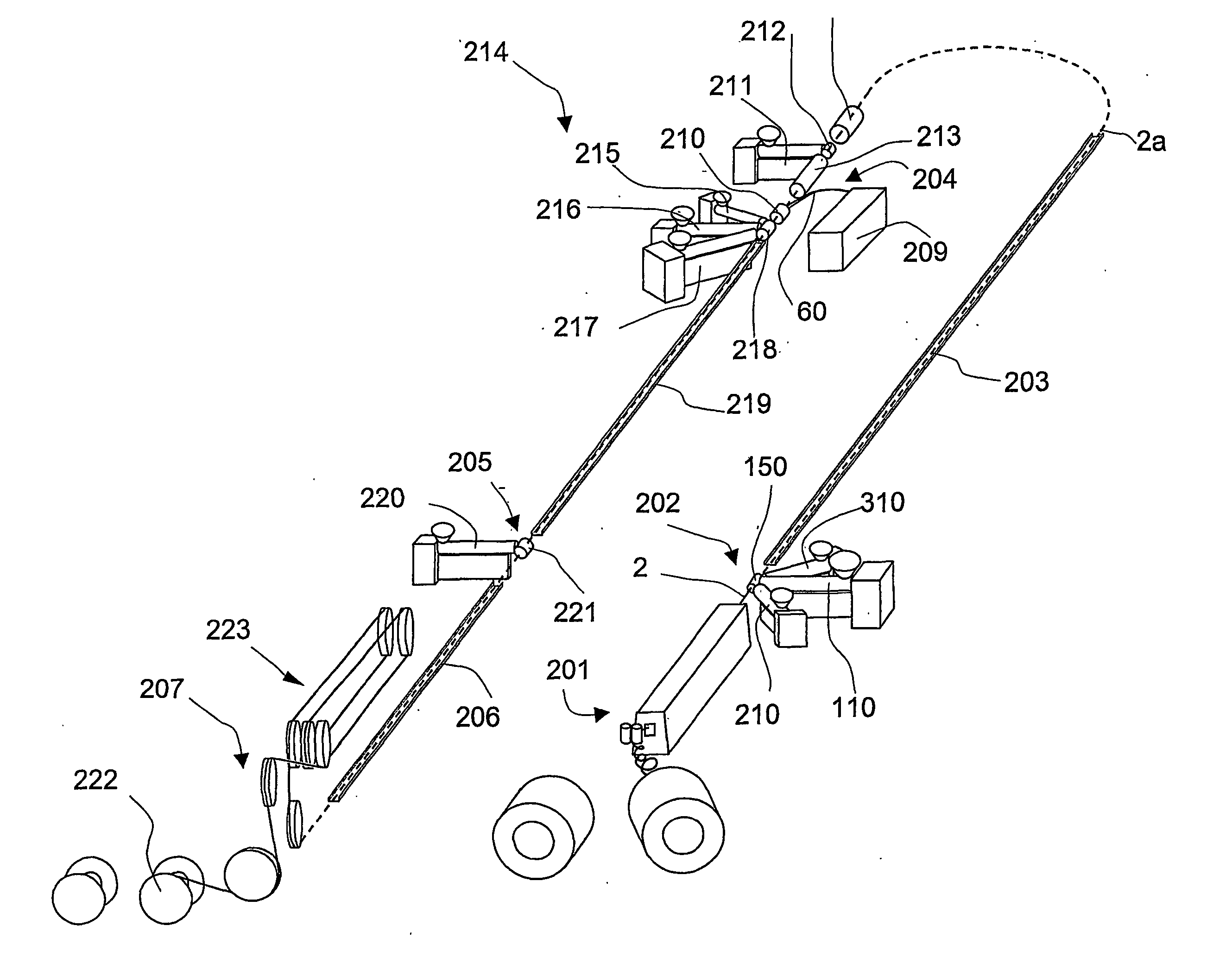

Automated wire processing system and methods

ActiveUS20180174715A1Complete understandingLine/current collector detailsApparatus for feeding conductors/cablesElectricityMachining system

Systems and methods are provided for wire processing. In certain examples, a wire processing system may be disclosed. The wire processing system may include a wire transport, a processing station that may provide wire to the wire transport, a processing station that may move an electrical component threaded onto the wire, and a processing station that may move the electrical component to a position on the wire for further processing.

Owner:THE BOEING CO

Equipment for coating cable

InactiveCN107437443ARealize a reasonable qualifyingSeamless connectionApparatus for feeding conductors/cablesBiochemical engineeringImpurity

The invention provides a device for cable covering. The equipment for cable coating includes a frame, a wire releasing device, a removal device, a guide device, a coating device and a wire take-up device, the wire release device, the removal device, the guide device, Both the coating device and the wire take-up device are arranged on the frame, and the frame is configured to be composed of a bracket and a bottom plate, the bracket is set as a door-shaped structure, and the bracket is vertically arranged across the bottom plate , one side of the upper surface of the bottom plate is provided with the line release device, the impurity removal device and the guide device in sequence, and the line release device, the impurity removal device and the guide device are all arranged under the bracket The cladding device is arranged horizontally across the two vertical arms of the bracket, and the wire take-up device is arranged on the beam of the bracket. The present invention adopts the coating machine, which has a simple structure, can effectively level and clean the surface of the cable to be processed, makes the shielding layer and the surface of the cable close to each other, and ensures good coating quality of the cable.

Owner:天津市宝鼎线缆有限公司

Twisting device for electrical conductors

InactiveCN106952693AImprove twisting processQuality improvementApparatus for feeding conductors/cablesElectrical conductorEngineering

The invention relates to a twisting device for electrical conductors. The twisting device has at least one twisting head that rotates about an axis of rotation and a clamping device. The twisting head is movable in the direction of its axis of rotation toward the clamping device and is mounted on a first, motorised length compensation carriage, while the clamping device is mounted on a travel compensation carriage that is movable towards the length compensation carriage parallel to the axis of rotation of the twisting head. After the conductors have been cut to size and transferred to the twisting head and the clamping device, they are placed under tension. Then, the twisting head is activated to rotate about an axis of rotation parallel to the conductors while simultaneously moving towards the clamping device. Simultaneously, the clamping device is subjected to a force directed away from the twisting head and the travel / force profile for the clamping device is evaluated.

Owner:SCHLEUNIGER HLDG

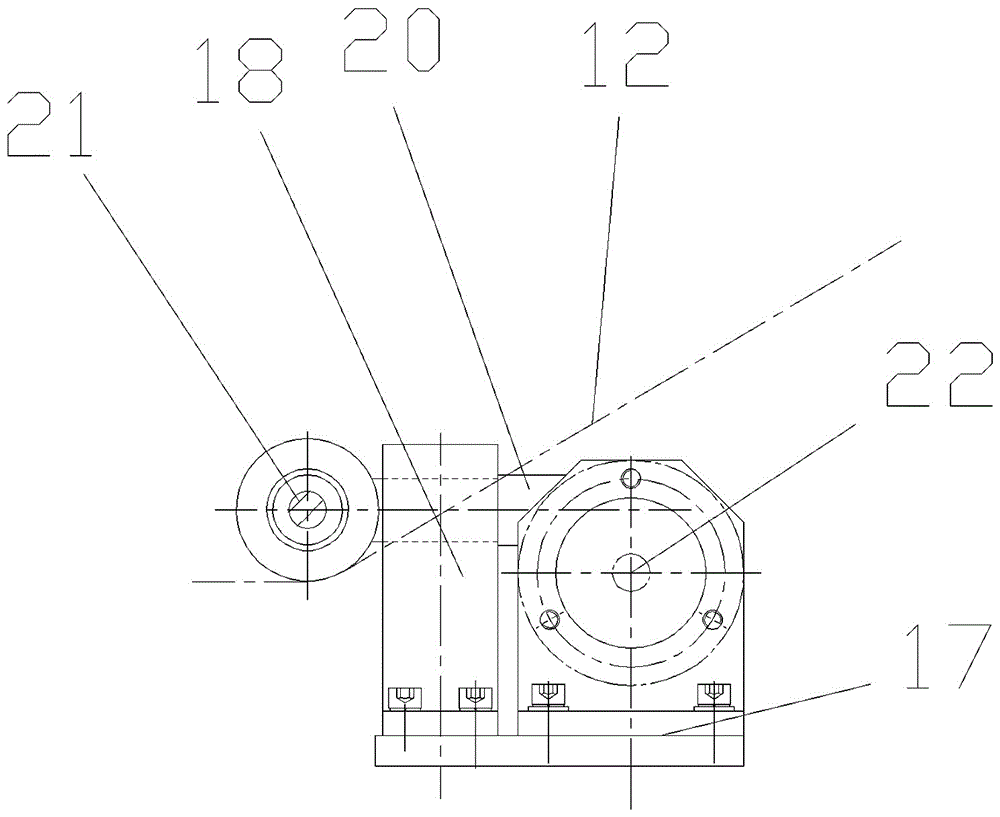

Efficient device for traction machine

InactiveCN105775896ASimple structureEasy to assembleApparatus for feeding conductors/cablesFilament handlingElectric machineEngineering

The invention discloses an efficient device for a traction machine. The device comprises a traction table which is characterized in that combination tables, an electronic clutch and a motor are successively mounted on the upper surface of the traction table from left to right, and the bottom ends of the combination tables are located in fixed slots formed in the traction table, wherein one end of an output shaft of the motor is connected to one end of the electronic clutch, one end of the electronic clutch is connected to one end of a rotating shaft above a fixed plate through a model shaft which penetrates through one combination table, and one end of the rotating shaft is connected to a chute on one side of the combination table through a pulley. The efficient device for the traction machine is simple in structure and convenient to assemble. By driving the rotating shaft connected to the model shaft through the motor to drive engaged high-speed gears to drive two groups of traction wheels and mounting anti-skidding grains at notches of the traction wheels, a cable quickly passes through the middle parts of the two groups of traction wheels where the anti-skidding grains are mounted, so that the circumstance of skidding and falling is avoided, and therefore, the efficiency is improved.

Owner:李明科

Device for drawing, spraying, cleaning, drying, and collecting cable

InactiveCN108682515AEasy to operateAchieve recyclingApparatus for feeding conductors/cablesEngineeringMechanical engineering

The invention relates to a device for drawing, spraying, cleaning, drying, and collecting a cable. The device comprises a cleaning drying box, a cleaning brush, a guiding device, an air heating device, a collecting roller, a drying cylinder and a plurality of spraying pipes. The cleaning drying box is welded on the upper ends of four support frames. The guiding device is welded on the lower end ofthe left sidewall of the cleaning drying box. The collecting roller sleeves the right end of a collecting reel. The drying cylinder is welded on the upper end of a connecting support rod. The air heating device is fixedly disposed on the upper end face of a fixed bottom plate. The air heating device is disposed on the left side of a first motor. The cleaning brush sleeves a rotating shaft. Fastening is performed by screwing a fastening nut on an end of the rotating shaft having external threads. The plurality of spraying pipes are fixedly disposed in the lower end wall of a spraying box. Thedevice is reasonable in design and convenient to use, can clean the dust and the dirt on the cable, and can immediately dry and coil the cable after the cleaning, thereby improving the cable processing efficiency.

Owner:合肥亚卡普机械科技有限公司

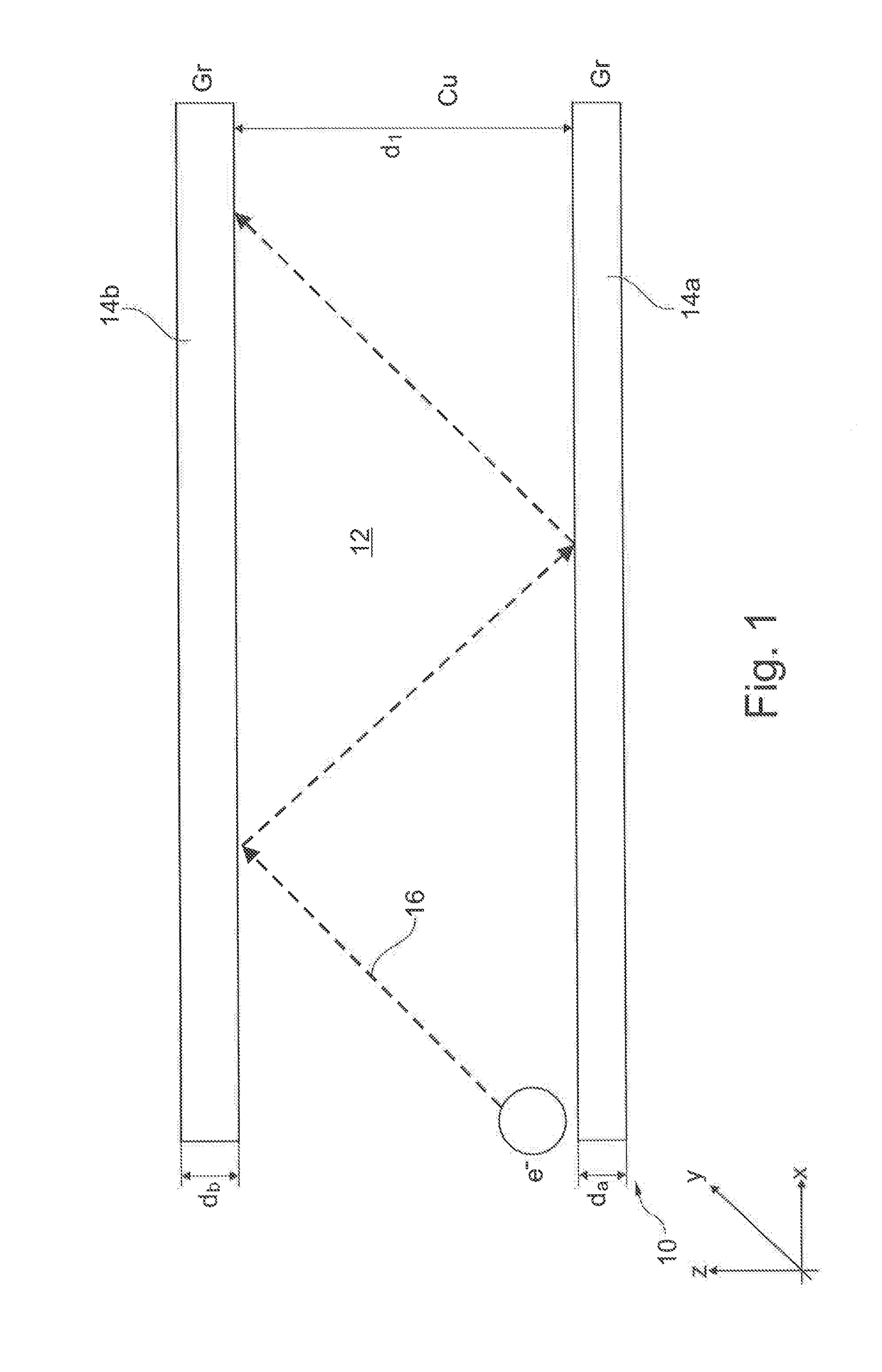

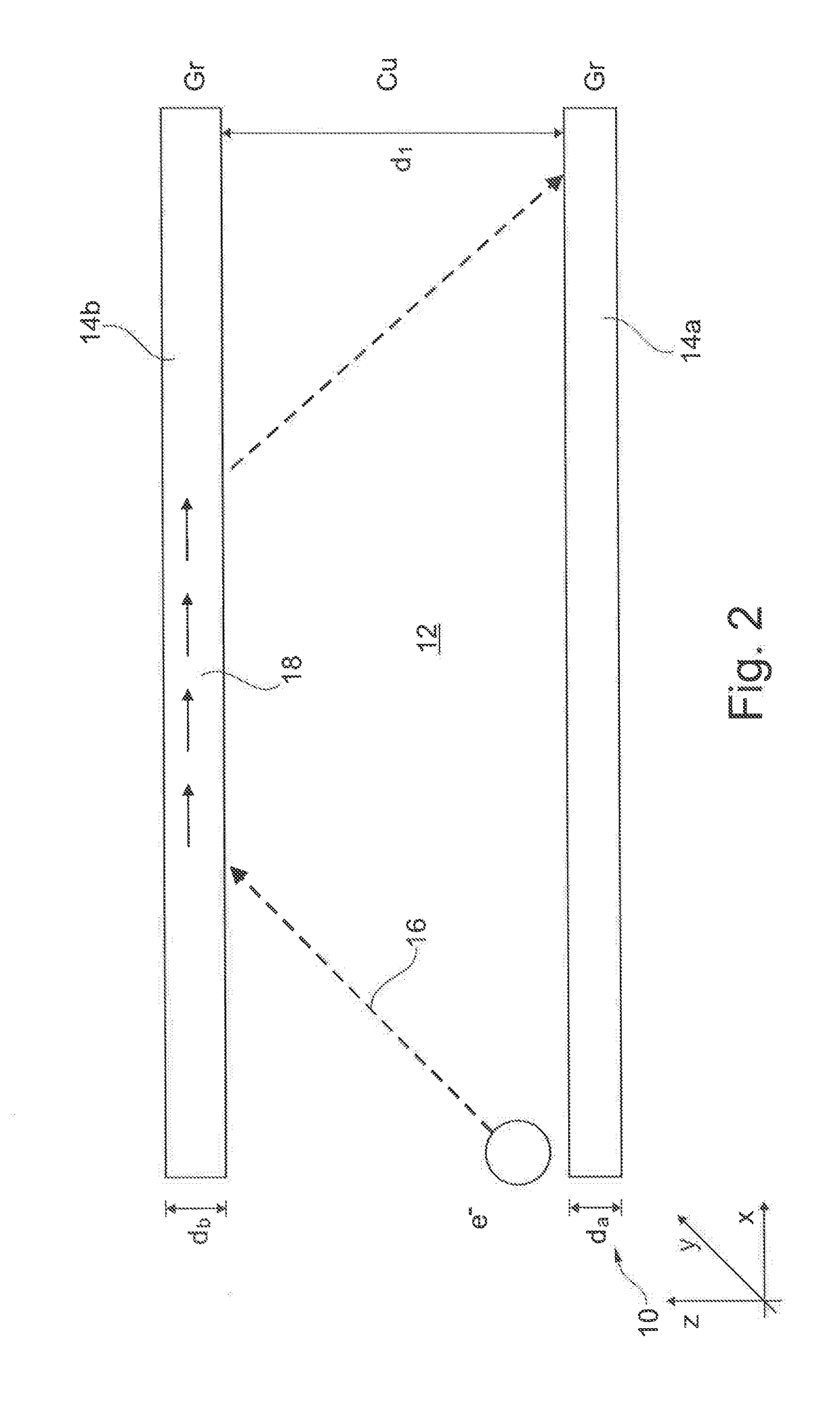

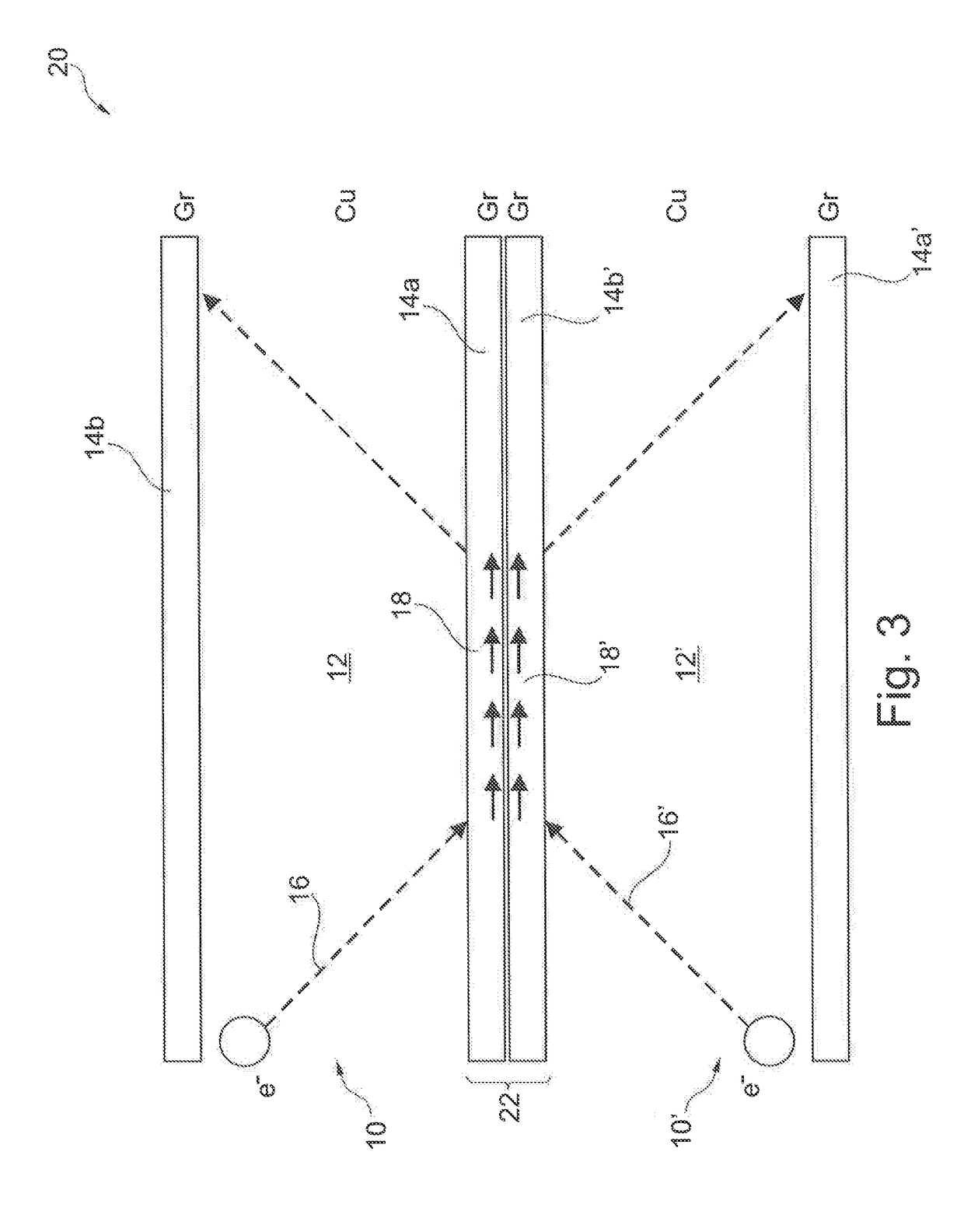

Method and System for Forming a Multilayer Composite Structure

ActiveUS20190066879A1Efficient mass productionHigh volume percentageApparatus for feeding conductors/cablesSingle bars/rods/wires/strips conductorsGrapheneMaterials science

A method for forming a multilayer composite structure comprises providing a first sheet comprising a copper-comprising layer sandwiched by first and second graphene layers, wrapping the first sheet to form a first rod, and compacting the first rod to form a first multilayer composite structure.

Owner:ULTRA CONDUCTIVE COPPER CO INC

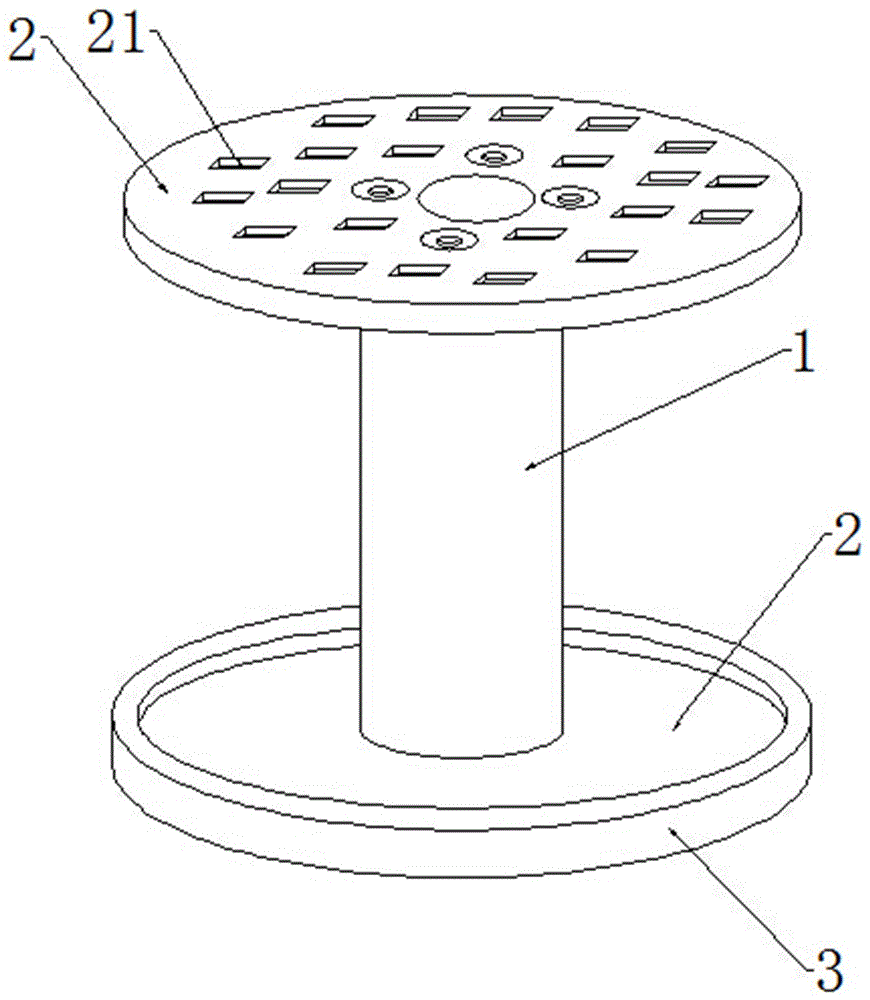

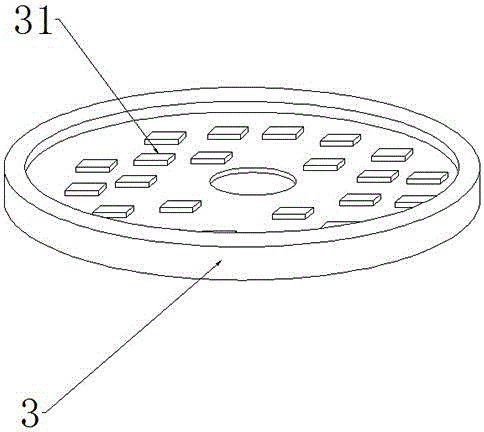

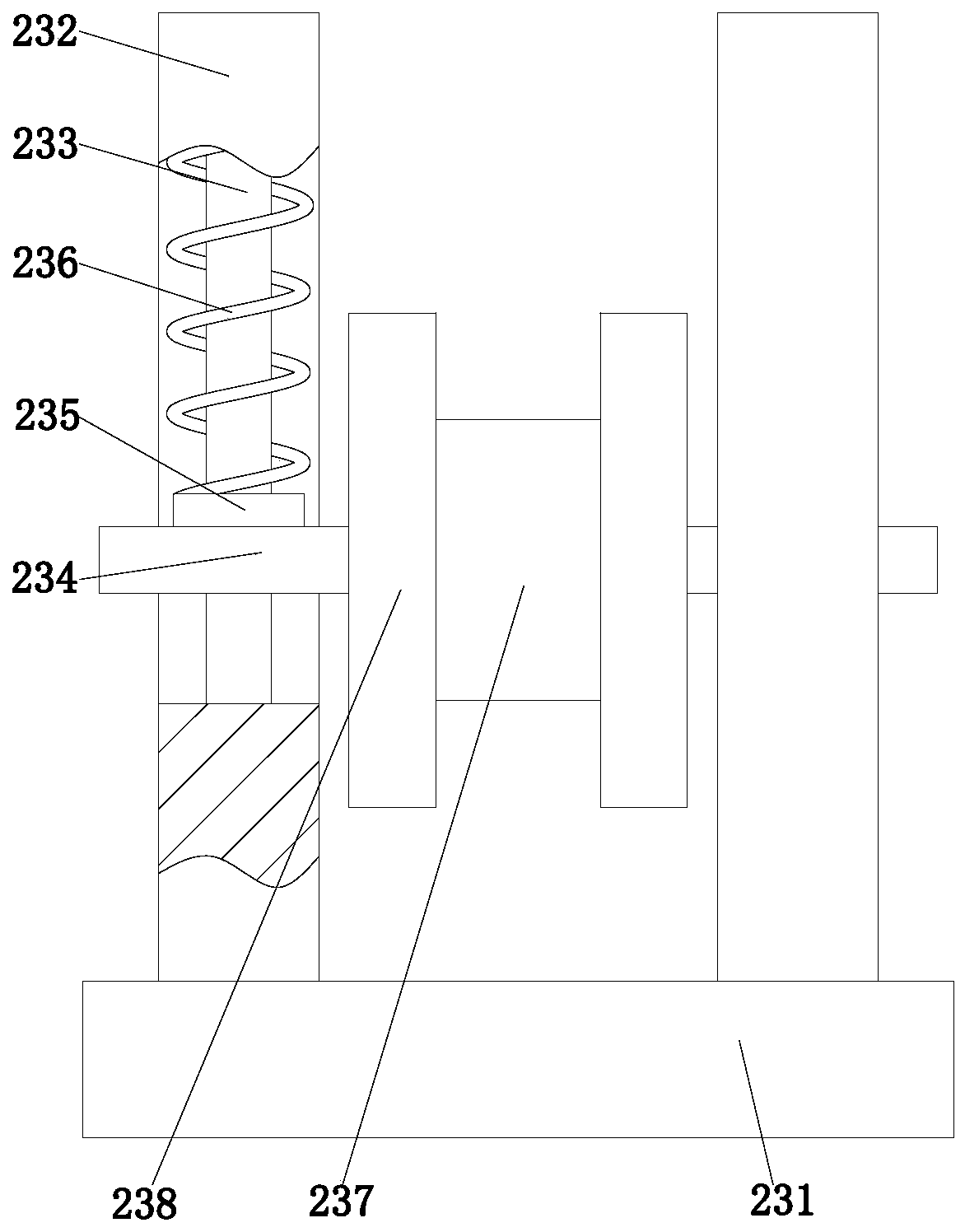

Self-damping double-reel pay-off device and application method thereof

InactiveCN106251978AIncrease resistanceImprove stranding qualityApparatus for feeding conductors/cablesEngineeringMechanical engineering

Owner:ZHENGZHOU YIFANG ELECTRIC

Flexible graphite anti-thunder grounding wire conveying device

InactiveCN109205228AAchieve tensionRealize up and down adjustmentConveyorsApparatus for feeding conductors/cablesGraphiteMechanical engineering

The invention discloses a flexible graphite anti-thunder grounding wire conveying device and relates to the technical field of flexible graphite anti-thunder grounding wire processing. The flexible graphite anti-thunder grounding wire conveying device comprises a left base, a right base, a supporting column I, a supporting column II, a screw rod, a first cross rod, a hand wheel, a second cross rod, a nut, a first rotary shaft, a conveyor belt, a second rotary shaft, a supporting rod I, a supporting rod II and guide rolls. The flexible graphite anti-thunder grounding wire conveying device is simple in structure, fast and convenient to operate, capable of adjusting the conveying distance through a driving device, also capable of tensioning the conveyor belt, capable of implementing up-down adjustment through the hand wheel and suitable for meeting different requirements for conveying graphite grounding wires. Meanwhile, when the conveying device is not in use, the right base can be driven to slide to the left base through the driving device. The flexible graphite anti-thunder grounding wire conveying device is small in occupied space and convenient to store and maintain.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

Cable producing device for improving cable safety performance and using method thereof

InactiveCN108231275AImprove securityHigh strengthApparatus for feeding conductors/cablesInsulating conductors/cablesElectrical conductorWear resistant

The invention provides a cable producing device for improving cable safety performance and a using method thereof. The cable producing device comprises a wire conveying box and a first support, wherein the first support is arranged at the bottom of the wire conveying box; a servo motor is arranged on one side of the wire conveying box; the servo motor is rotationally connected with a first connecting shaft through a motor shaft; the first connecting shaft is rotationally connected with a wire discharging roll; a conductor wire inside a cable is suitably conveyed, so that processing of the periphery of the conductor wire inside the cable is facilitated, and cable production is facilitated; a first conductor wire pipe is arranged at one end of the wire conveying box; coating boxes are connected to one end of the first conductor wire pipe; the first supports are arranged at the bottoms of the coating boxes. Through arrangement of five mixing hoppers, the outer side of the conductor wire is sequentially coated with an insulating material, a composite material, a shielding material, a flame-retardant material and a wear-resistant material, so that the strength, the fire resistance and the wear resistance of the cable are improved, the service life of the cable is prolonged, and the working efficiency of the cable is improved.

Owner:ANHUI DEYUAN CABLE GRP

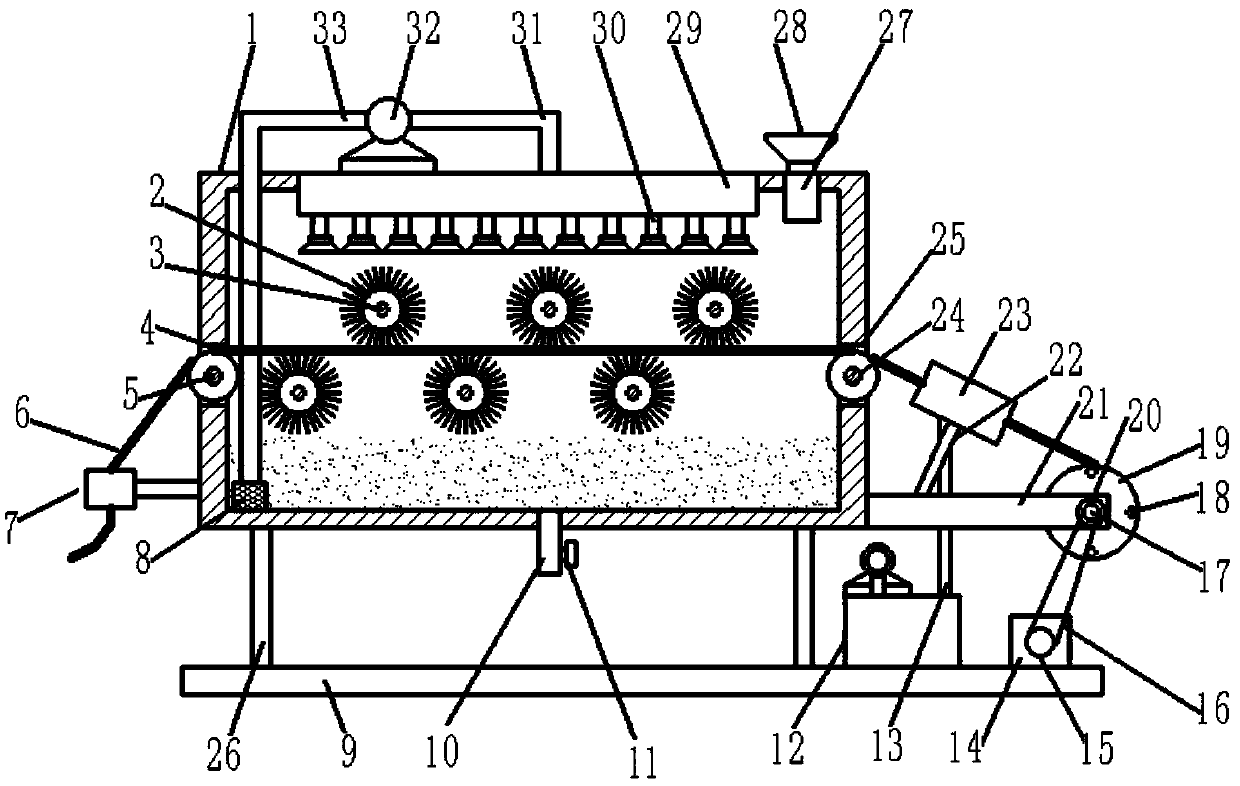

Electric appliance enameled wire manufacturing and processing system

ActiveCN110675995AReduce wasteInhibit sheddingApparatus for feeding conductors/cablesApparatus for heat treatmentMechanical engineeringIndustrial engineering

The invention relates to an electric appliance enameled wire manufacturing and processing system. The system comprises a box body, a lead unit, a painting unit and a baking unit. The lead unit is arranged in the box body, and the painting unit and the baking unit are successively arranged on an inner wall of an upper end of the box body from left to right. Through guiding of the lead unit to an enameled wire and a structural design of the painting unit, the painting unit and the baking unit carry out repeated painting treatment and baking treatment on the enameled wire so that the repeated painting treatment and baking treatment are completed by one device. A paint liquid is more uniform through repeated smearing, and wastes of the paint liquid is reduced. In the invention, through the arranged lead unit, a problem that a plurality of devices are needed to paint and bake the enameled wire is solved; a lead wheel guides the enameled wire to go in and out of the painting unit and the baking unit, a tensioning guide wheel and a wire return wheel guide the enameled wire, the enameled wire enters into a next wire inlet column, and meanwhile, the tensioning guide wheel further tensions the enameled wire.

Owner:瑞安市中德电工器材有限公司

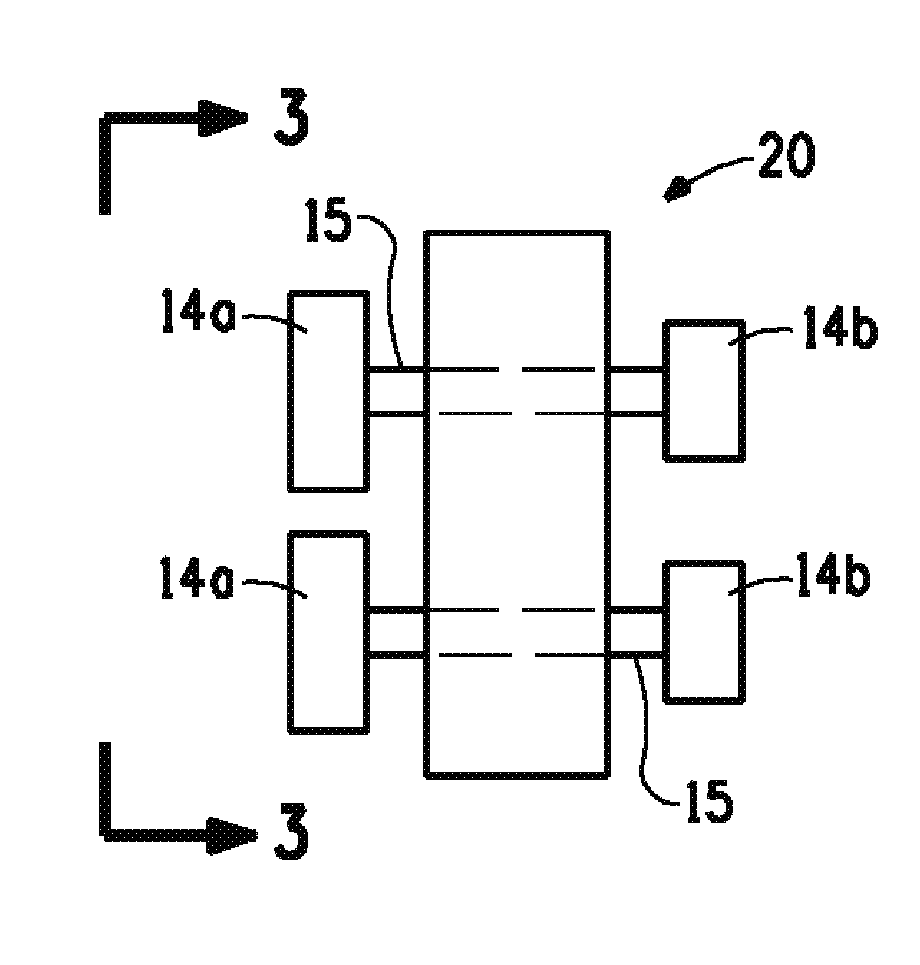

Unbalanced hybrid cords and methods for making on cable cording machines

ActiveUS9175425B2Apparatus for feeding conductors/cablesFlexible pipesEngineeringStructural engineering

A hybrid cord formed from a plurality of component plies wherein at least two of the plies are of unequal ply length regardless of the twist of the plies and at least one of the plies has a length that is from 1 to 50 percent longer than the other plies and a method of providing a cord with predetermined twist and component ply lengths.

Owner:DUPONT SAFETY & CONSTR INC

Paying-off device for enameled wire production

ActiveCN110240002AHeight adjustableEasy to replaceApparatus for feeding conductors/cablesFilament handlingUltimate tensile strengthPulley

The invention discloses a paying-off device for enameled wire production. The paying-off device for the enameled wire production comprises an installation block, a feeding mechanism, a wire roller clamping structure and a wire roller height adjusting mechanism. The upper end of the mounting block is provided with a feeding mechanism, and a supporting frame is fixed to one side of the mounting block. A first servo motor is disposed at the top end of the supporting frame. A first belt pulley is disposed on an output shaft of the first servo motor. A first belt pulley is in transmission connection with second belt pulleys. The second belt pulleys are in key connection to the top ends of first lead screws. The first lead screws are in transmission connection with first transmission nuts, and the first transmission nut are embedded in first fixing blocks. A second mounting box is fixed between the two first fixing blocks. A second servo motor is fixed to the bottom end in the second mounting box through a bolt, and an output shaft end of the second servo motor is in key connecting portion with a connecting sleeve. The outer side of the connecting sleeve is sleeved with the wire roller. Through the above structure, the replacement of the wire roller is convenient during paying off. The paying-off device for enameled wire production is simple in structure, convenient to operate and low in labor intensity.

Owner:江西博能上饶线材有限公司

A manufacture device of an enameled wire

ActiveCN109243708AReduce lossImprove product qualityApparatus for feeding conductors/cablesApparatus for heat treatmentProduction lineSilver plate

The invention discloses a manufacture apparatus for an enameled wire, and relates to the technical field of enamelled wire production equipment, The main points of the technical scheme include an annealing mechanism, a painting mechanism, a plating mechanism;, the electroplating mechanism comprises a nickel plating bath, a silver plating bath, a first cleaning bath, a second cleaning tank, a thirdcleaning tank; a plurality of rows of first wire transmission mechanisms are arranged in a first cleaning tank, the second cleaning tank and the third cleaning tank; the first wire conveying mechanism includes a plurality of first wire conveying rollers, a first wire transmission gap is arranged between two adjacent first wire transmission rollers, a plurality of rows of second wire transmissionmechanisms are arranged in the nickel plating bath and the silver plating bath, the second wire transmission mechanism comprises a plurality of second wire transmission rollers, a second wire transmission gap is arranged between the two adjacent second wire transmission rollers, the nickel plating bath is further provided with a nickel plate, and the silver plate is also arranged in the silver plating bath; By annealing, electroplating and painting on the same production line, the loss of electroplated metal on the conductor surface can be reduced and the production quality of enamelled wire can be improved.

Owner:浙江涌金线材股份有限公司

Automatic winding labeling machine of cable coil

InactiveCN107799234AMeet the needs of automated productionSame lengthApparatus for feeding conductors/cablesConductor/cable markingEngineeringConductor Coil

An automatic winding and labeling machine for cable reels, including a machine platform and a wire feeding mechanism, the machine platform on the right side of the wire feeding mechanism is provided with a frame, a wire cutting device, a wire arranging device, and a labeling device in sequence , a winding device and a blanking mechanism; the labeling device includes a labeling guide column, a cross bar, a labeling press cylinder, a labeling bottom plate, a label feeding component, a labeling bottom, a label cutting component, a labeling Roller, clipping assembly and wire assembly, the position of the clipping assembly corresponds to the position of the label feeding assembly; the middle position of the labeling bottom plate is provided with a first opening and a second opening; the labeling The sticking rollers are arranged on both sides of the second opening. The invention has a high degree of automation and strong practicability, and can process two cable reels at one time, realizing the feeding of cables, winding of cables into cable reels, labeling, cable cutting and cable reels Fully automated production and processing of blanking improves the efficiency of cable processing into cable reels.

Owner:汇聚科技(惠州)有限公司

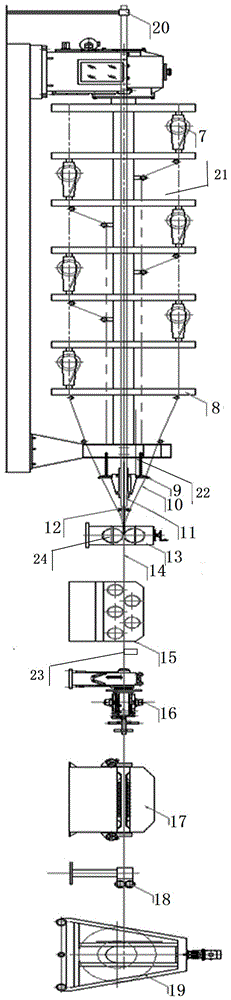

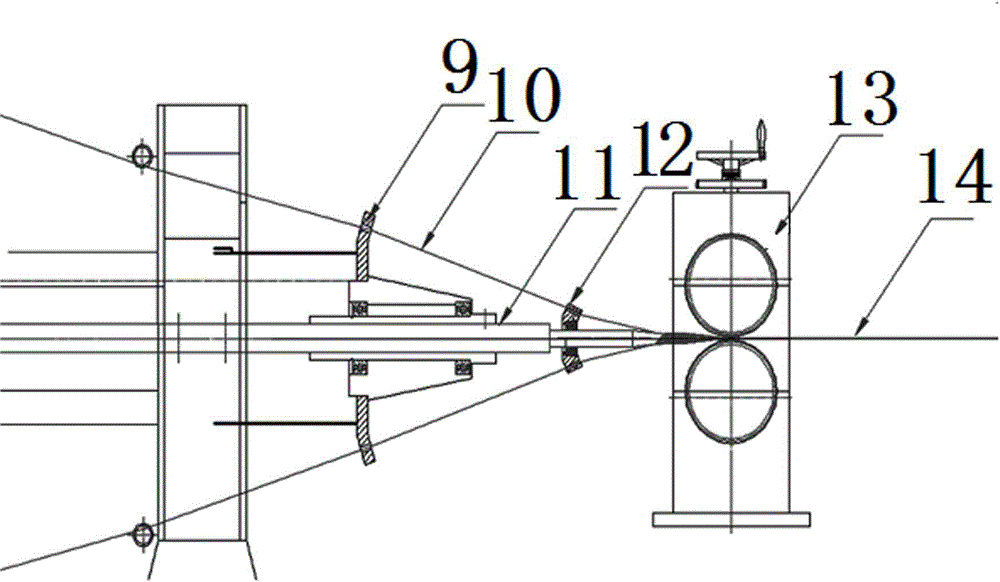

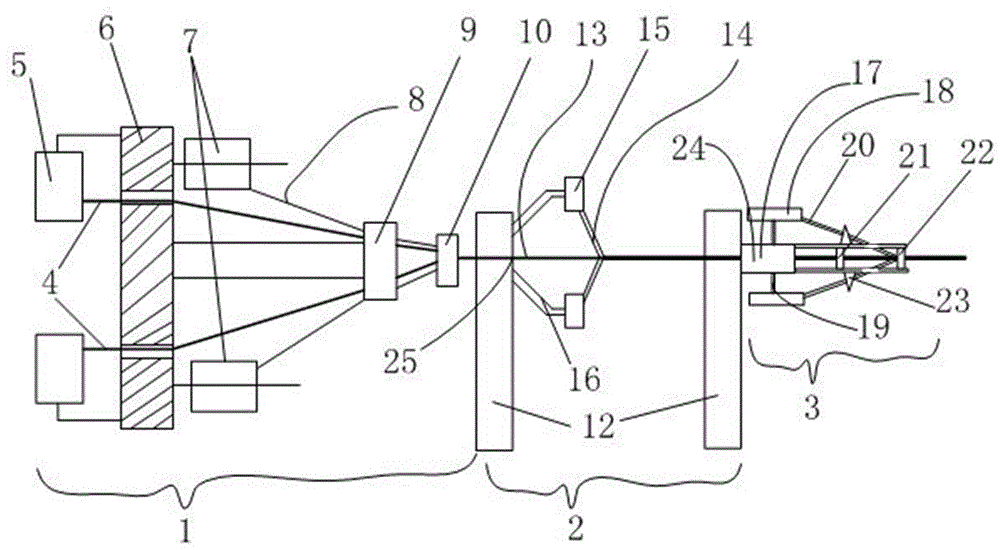

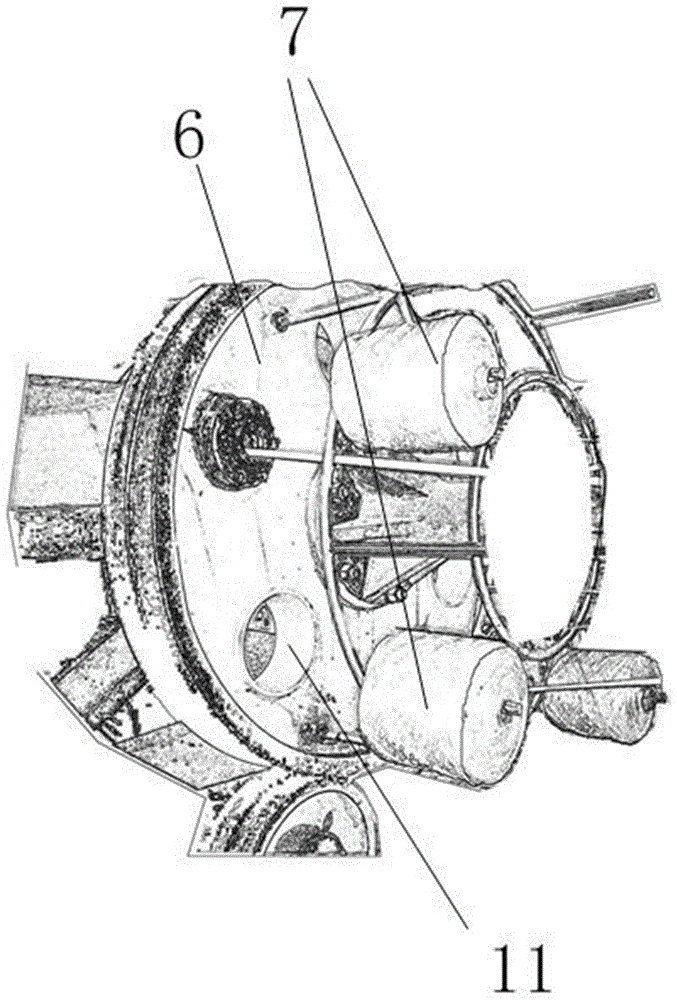

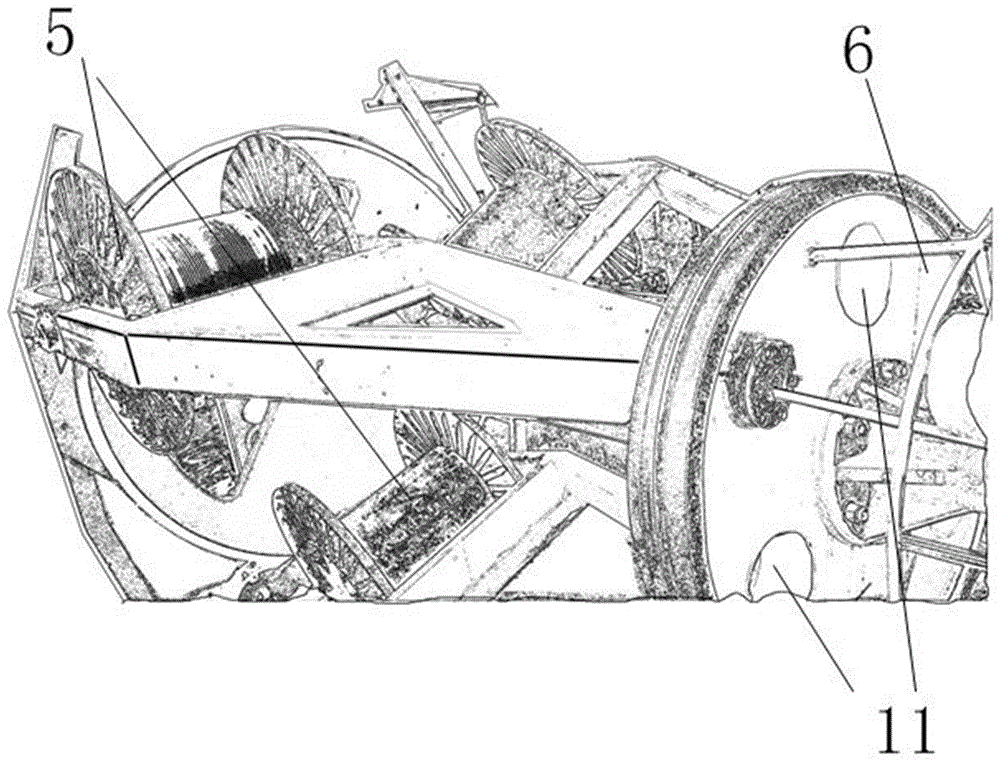

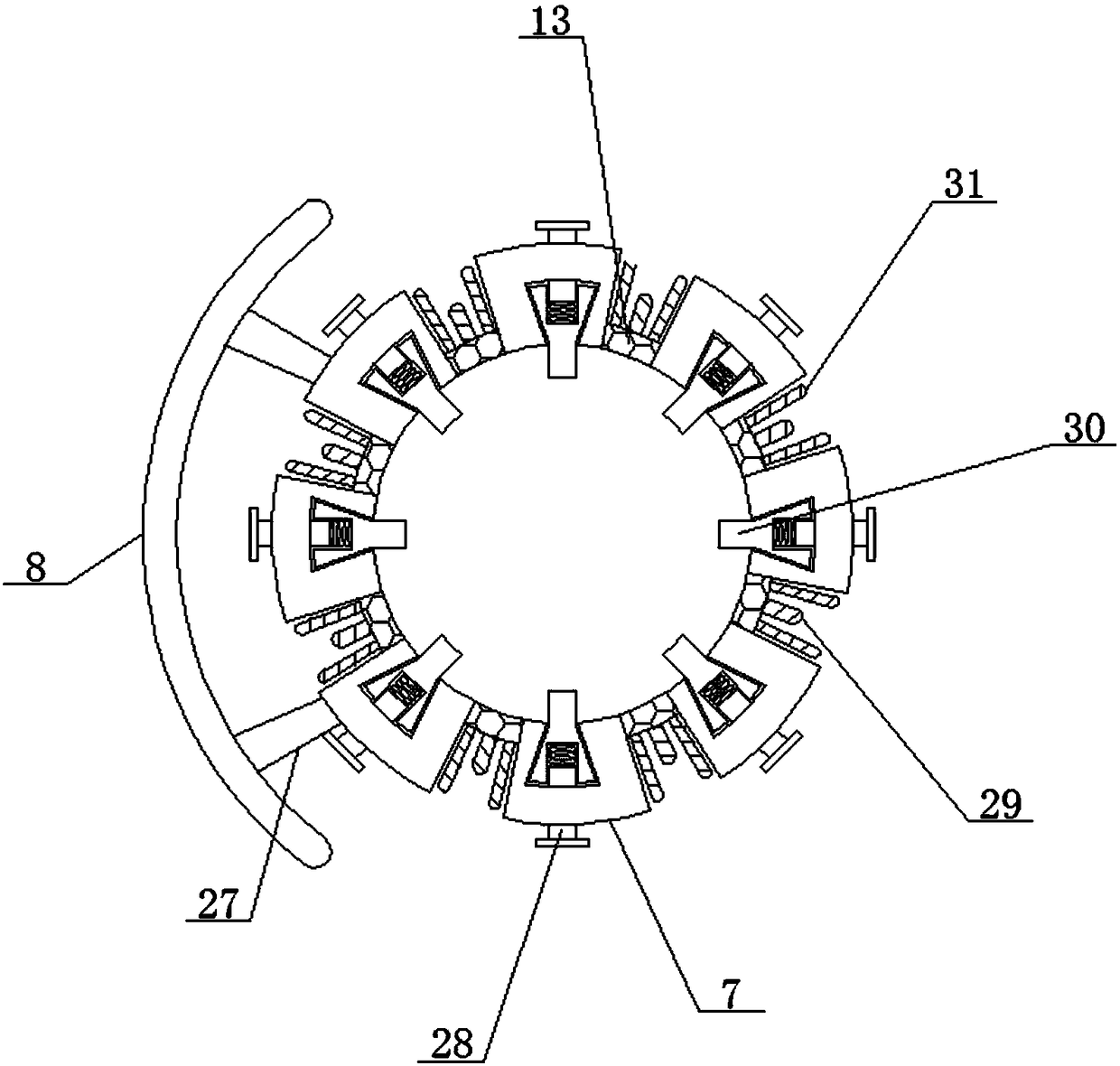

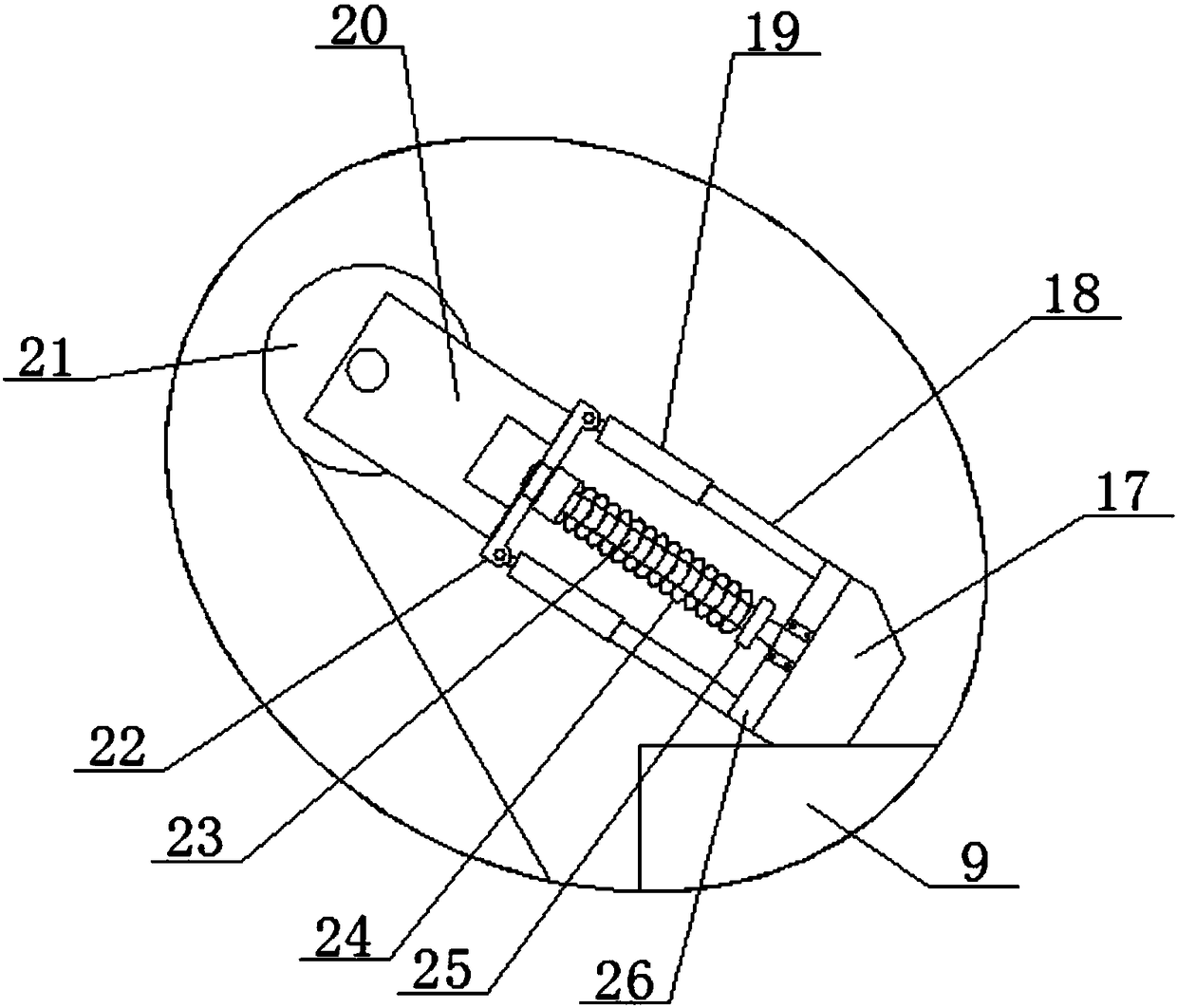

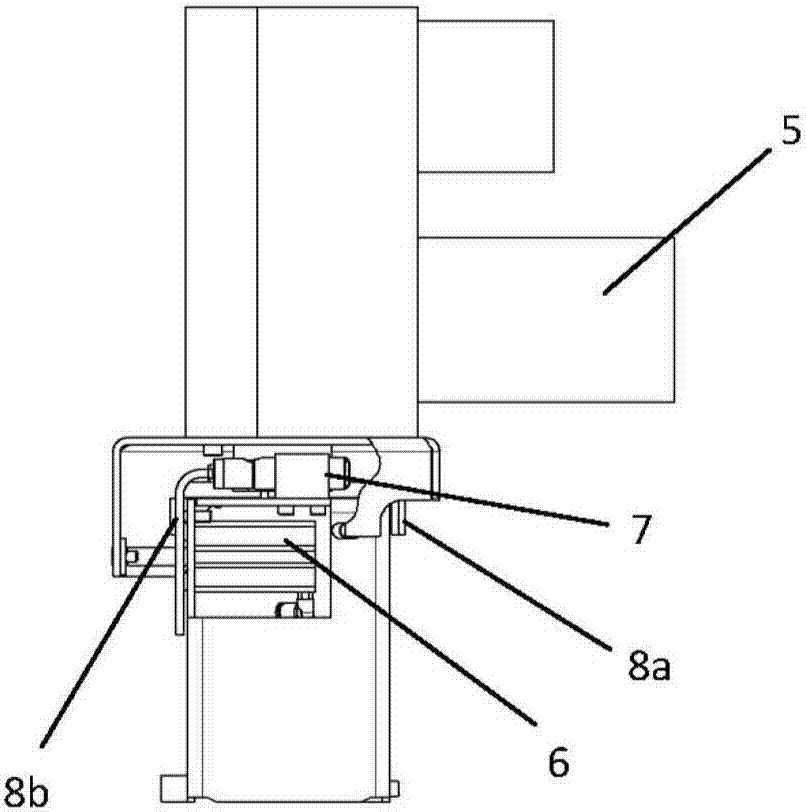

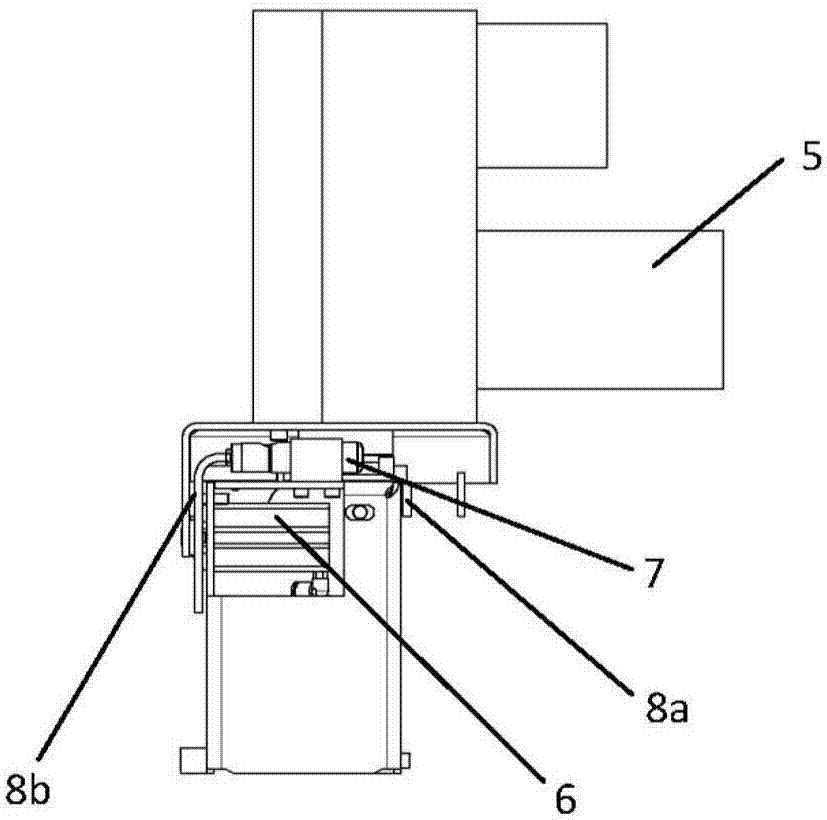

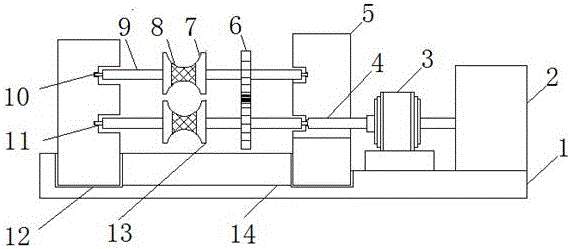

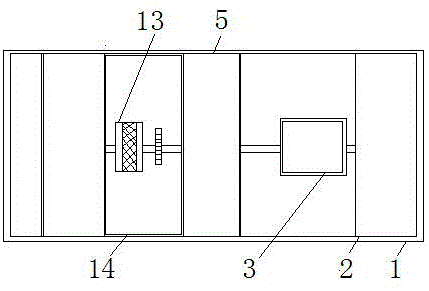

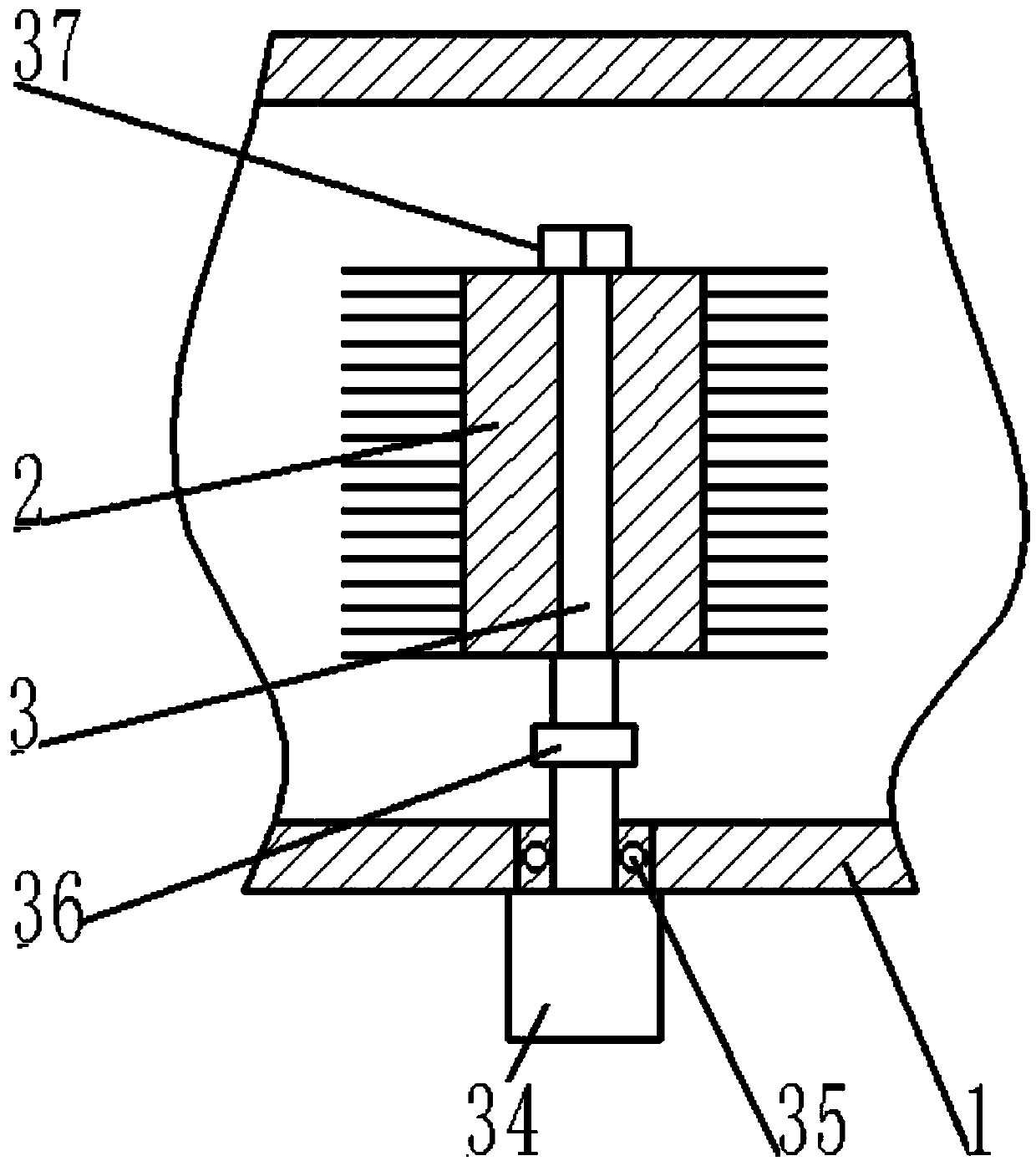

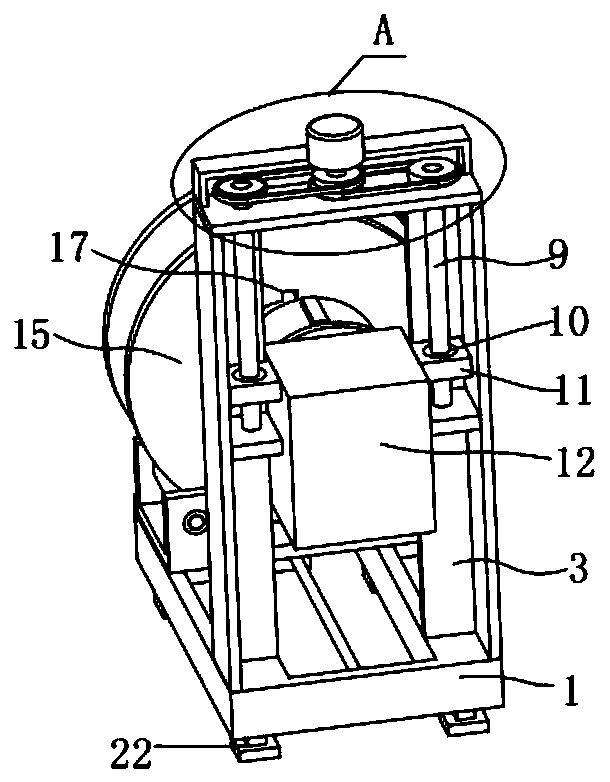

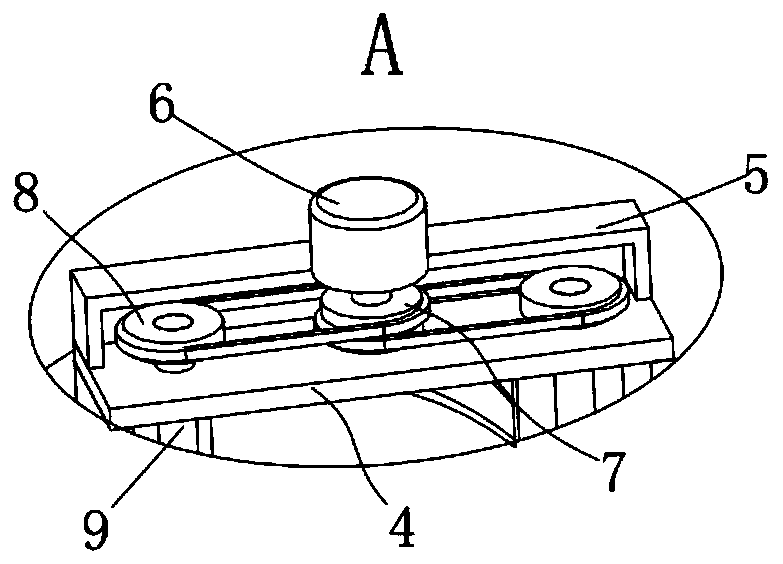

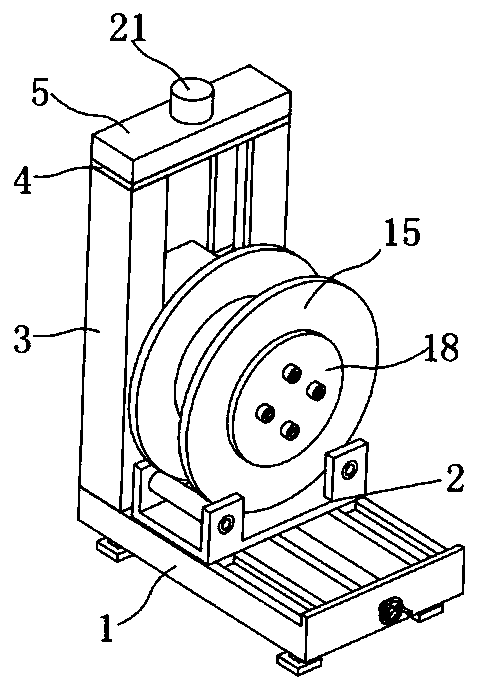

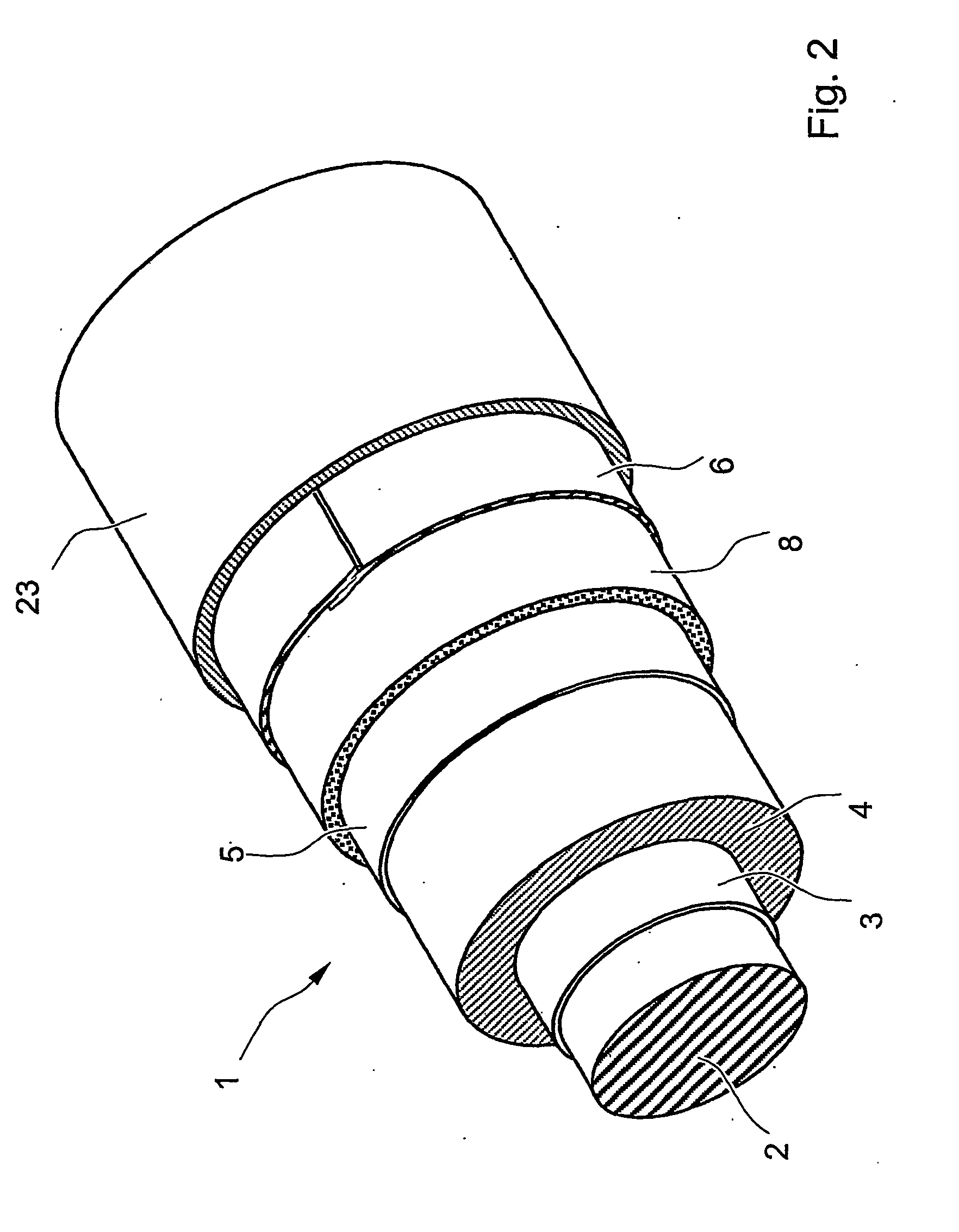

Paying-off device with hysteresis tension and feedback device

InactiveCN106782887AUniform tensionReduce labor intensityApparatus for feeding conductors/cablesHysteresisBobbin

The invention relates to a paying-off device with hysteresis tension and a feedback device. The paying-off device with the hysteresis tension and the feedback device comprises a base (1). The base (1) is connected with a rotation cylinder by a support seat (2). The rotation cylinder (3) is internally provided with a group of bobbin loaders (4). One side of the rotation cylinder is connected with a pre-torsion device (5), and the other side is connected with a main conduction ring (6). The rotation cylinder is internally provided with an assistant conduction ring (7) connected with the main conduction ring. Each bobbin loader (4) is connected with a bobbin (8), a hysteresis brake (9) and a tension detecting device (11). The hysteresis brake is connected with the bobbin (8). Guide wires (12) on each bobbin are connected to the pre-torsion device (5) through the transmission of the corresponding tension detecting device, and twisted to form a cable. The paying-off device is capable of using the hysteresis tension brake to realize the closed-loop control, guaranteeing the uniform tension of each bobbin without the manual intervention, improving the automation degree and the production efficiency of the device, and guaranteeing the stability and reliability of the twisting quality of a product.

Owner:安徽长江精工装备科技有限公司

Electric cable traction forming system and electric cable traction forming pulling method

PendingCN108428514AReduce concentrated stressGood flexibilityApparatus for feeding conductors/cablesReduction of cables/conductors sizeWater coolingElectric cables

The invention discloses an electric cable traction forming system. The electric cable traction forming system comprises an electric cable straightening machine, a guide wheel device, an annealing cooling device, a roundness correction mold rack, an electric cable support, a traction device, a spray bin, a cooling blow-dryer and a transportable take-up gantry stand. The subsequent vertical operation for electric cable forming is transformed into horizontal operation, cost is reduced, and the operation difficulty is simplified; in the traction take-up process, an electric cable is subjected to annealing, roundness correction, oxidation layer elimination and cable diameter adjustment, while the quality of the electric cable is ensured, the shape of the electric cable can be round and attractive, and the electric cable is not prone to deformation. The electric cable obtained after annealing is subjected to air cooling, water cooling and wind cooling drying many times in sequence, which isunprecedented, the quality of the electric cable is ensured, and the appearance of the electric cable keeps attractive.

Owner:沈阳伊思特机器人自动化科技有限公司

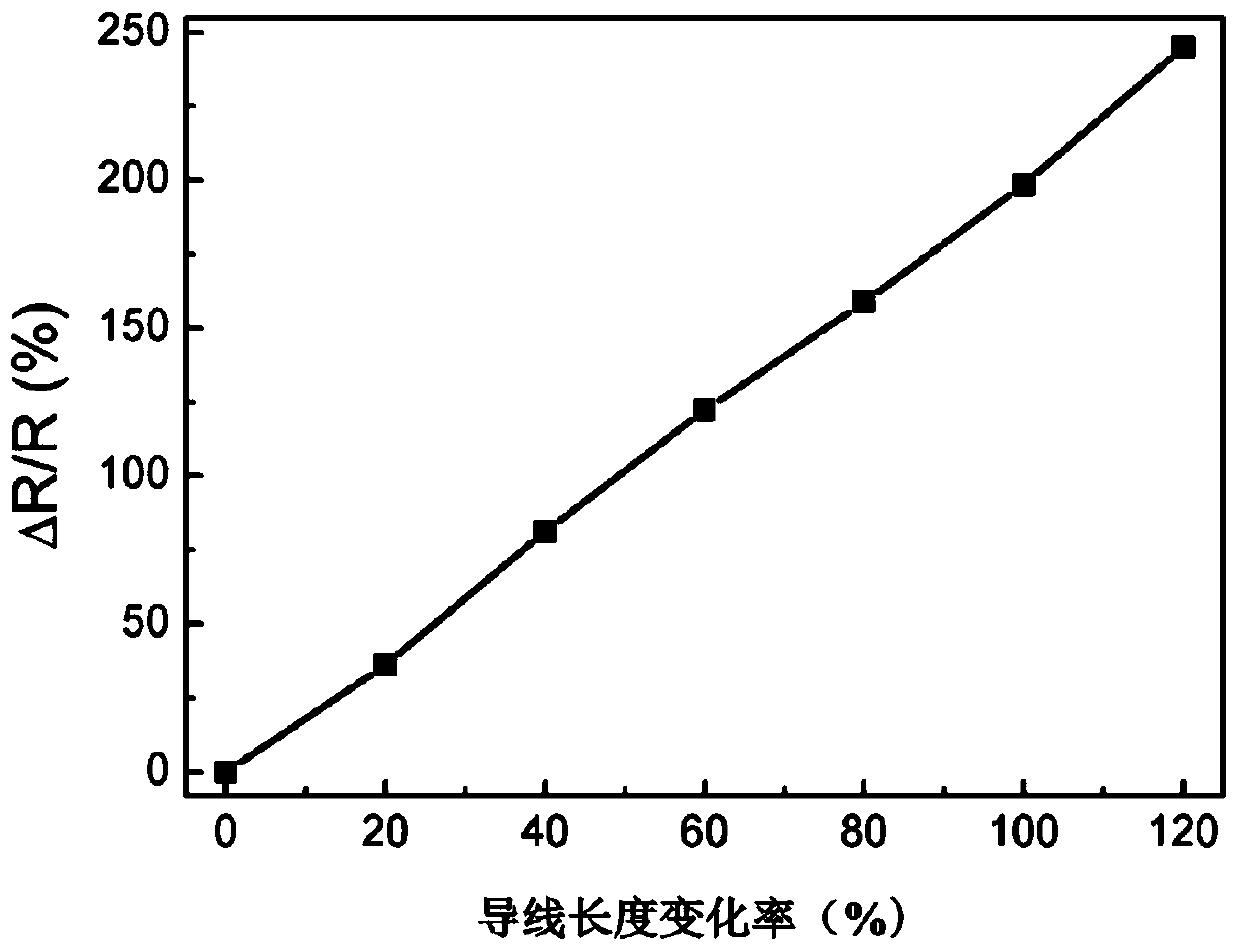

Stretchable lead and preparation method thereof

ActiveCN110729072AShape adjustableEasy to prepareApparatus for feeding conductors/cablesLiquid conductorsLiquid stateHemt circuits

The invention discloses a stretchable lead and a preparation method thereof. The specific embodiment of the stretchable lead comprises: a substrate made of a semi-cured flexible material, wherein thesubstrate is provided with a groove; a cover plate made of the semi-cured flexible material, wherein the cover plate is bonded and connected with the substrate and is used for encapsulating the grooveto form a sealed hollow pipeline; and a metal circuit layer formed by liquid metal and distributed in a flowing state in the hollow pipe and used for conducting a circuit. The sealed hollow pipe is formed by attaching the cover plate of the semi-cured flexible material to the semi-cured flexible material substrate with the groove, and the metal circuit layer is formed through combination with theliquid metal injected into the hollow pipe so that the stretchable wire with adjustable shape can be obtained through the action of physical force and then the stretchable wire with extremely fine diameter can be obtained.

Owner:SHANGHAI MI FANG ELECTRONICS LTD

Continuous process for manufacturing electrical cables

InactiveUS20070051450A1Extends cable manufacturing timeIncrease costApparatus for feeding conductors/cablesInsulated cablesElectrical conductorEngineering

A process for manufacturing an electric cable. In particular, the process includes the steps of: a) feeding a conductor at a predetermined feeding speed; b) extruding a thermoplastic insulating layer in a radially outer position with respect to the conductor; c) cooling the extruded insulating layer at a temperature not higher than 70° C.; and d) forming a circumferentially closed metallic screen around the extruded insulating layer. The process is carried out continuously, i.e., the time occurring between the end of the cooling step and the beginning of the screen forming step is inversely proportional to the feeding speed of the conductor.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com