Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "Easy to unwind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

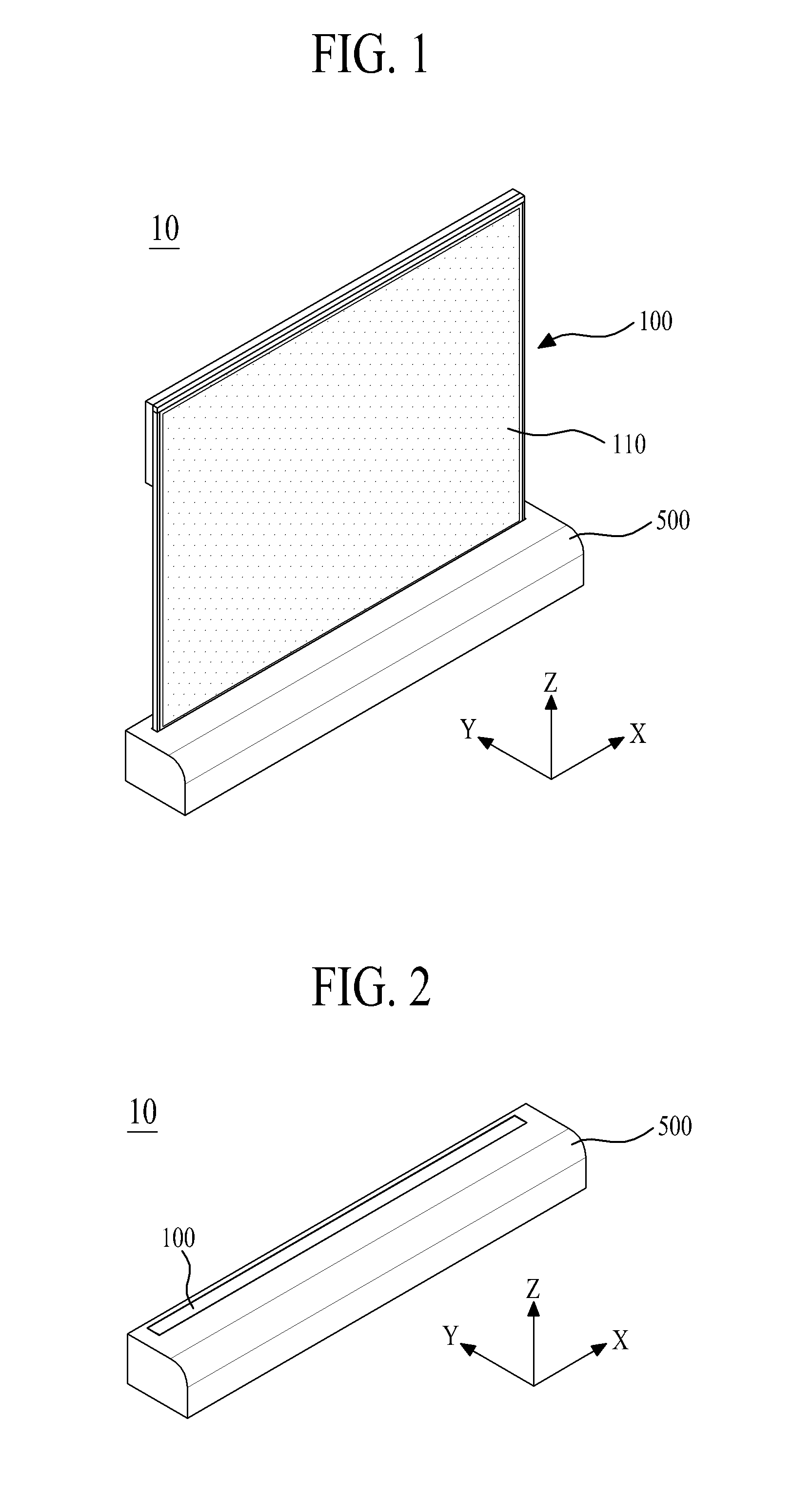

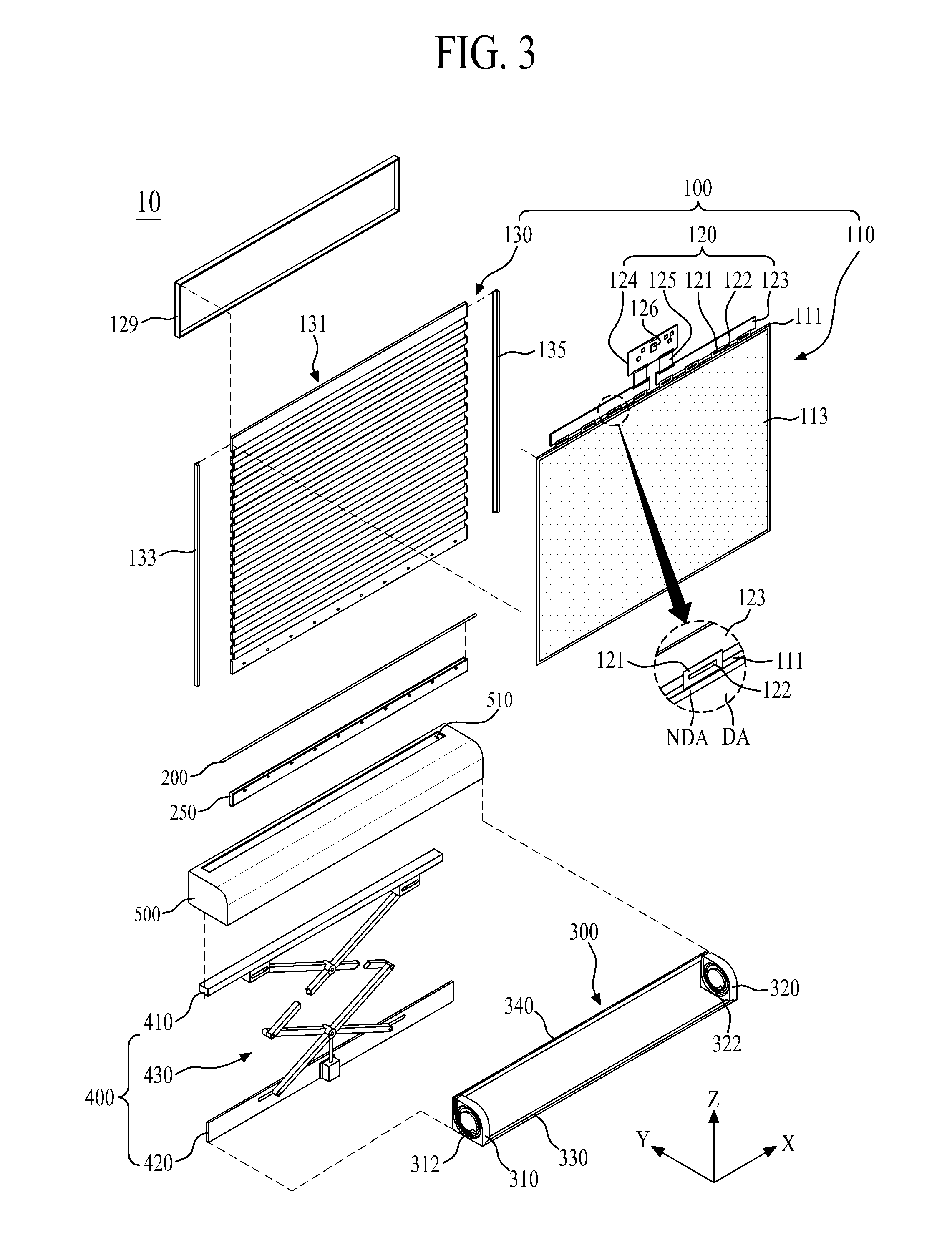

Flexible display apparatus

ActiveUS20160363960A1Easy to unwindImprove reliabilityDigital data processing detailsBoardsEngineeringConductor Coil

A flexible display apparatus includes a frame module having a sliding path to guide the winding or unwinding of a flexible display module, and a sliding shaft configured to slide along a spiral sliding path via vertical movement of the flexible display module. The flexible display apparatus makes it easy to wind or unwind a large flexible display panel.

Owner:LG DISPLAY CO LTD

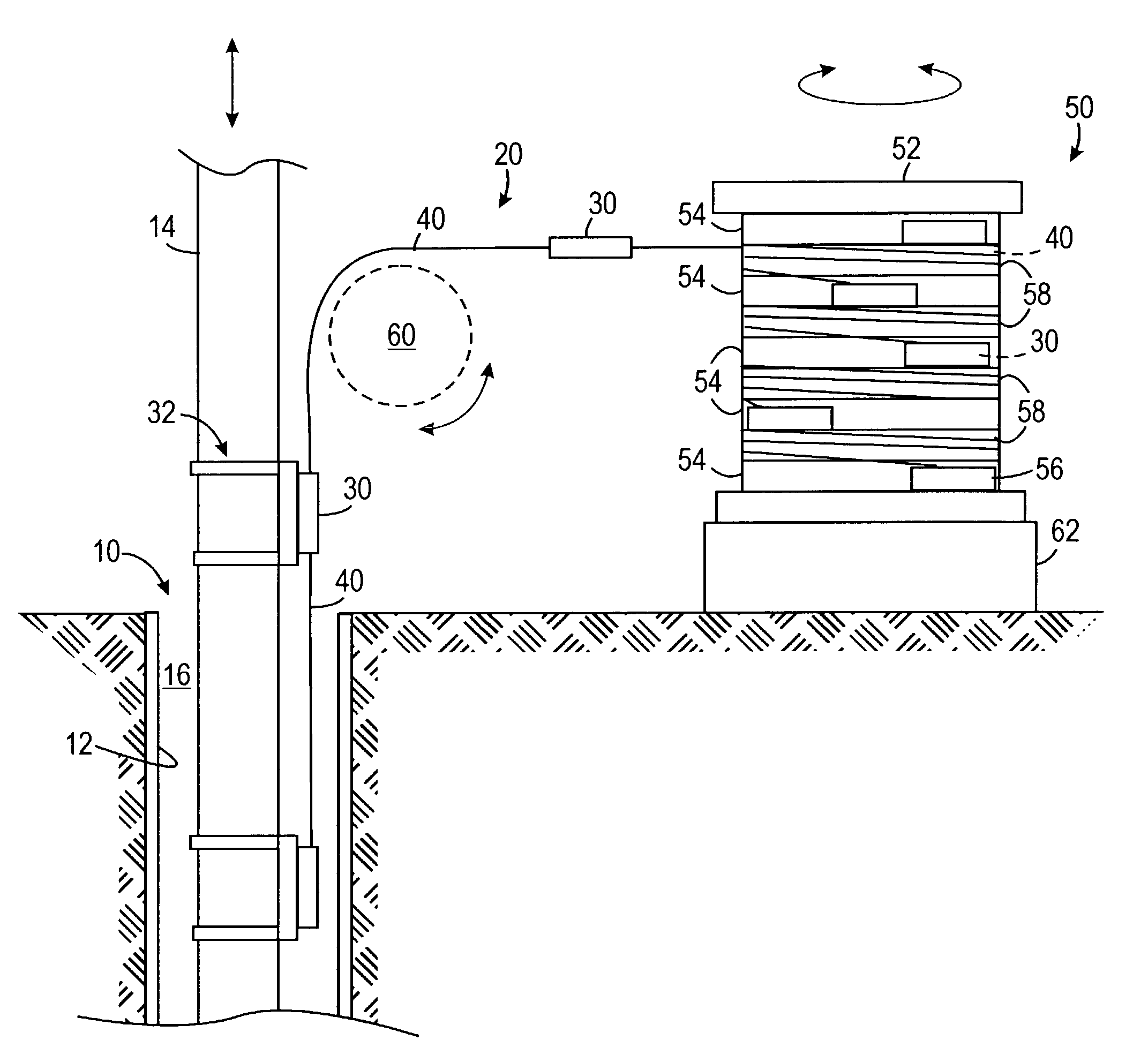

Apparatus and method for transporting, deploying, and retrieving arrays having nodes interconnected by sections of cable

InactiveUS7036601B2Tight windingEasy to unwindSurveyDrilling rodsEngineeringElectrical and Electronics engineering

Owner:WEATHERFORDLAMB

Flexible display apparatus

ActiveUS9756757B2Small thicknessEasy to unwindCasings with display/control unitsMounting boards securingComputer moduleEngineering

A flexible display apparatus has a small thickness which makes it easy to wind or unwind a flexible display module. The flexible display apparatus includes a frame module, into or from which a flexible display module is wound or unwound, and a panel elevating module configured to vertically move the flexible display module via folding or unfolding of at least one retractable unit. The retractable unit includes joint members provided at ends of first and second links intersecting each other, and elastic members installed to the respective joint members and supported by the ends of the first and second links.

Owner:LG DISPLAY CO LTD

Flexible display apparatus

ActiveUS9864412B2Easy to unwindImprove reliabilityDigital data processing detailsBoardsEngineeringFlexible display

Owner:LG DISPLAY CO LTD

Low-smoke FDY (Fully Drawn Yarn) oiling agent and preparation method thereof

The invention discloses a low-smoke FDY (Fully Drawn Yarn) oiling agent and a preparation method thereof. The low-smoke FDY oiling agent comprises the following materials in percentage by weight: 50-60% of emulsifying agent, 10-30% of smoothing agent, 6-10% of antistatic agent, 1-3% of beam concentrating agent, 9-11% of moisture, and 0.1-0.2% of preservative. The low-smoke FFY oiling agent provided by the invention has such functions of lubricating fiber, concentrating beam, preventing static electricity and the like in a production process of FDY, has the characteristics of reducing broken yarns, broken filaments, reducing dyeing and the like in a pre-spinning process, and further has the characteristics of reducing broken yarns, broken filaments, static electricity and the like in a post-processing (weaving) process, and is an important auxiliary ingredient which is essential in the production process of chemical fiber.

Owner:ZHEJIANG TIANSHENG HLDG GROUP

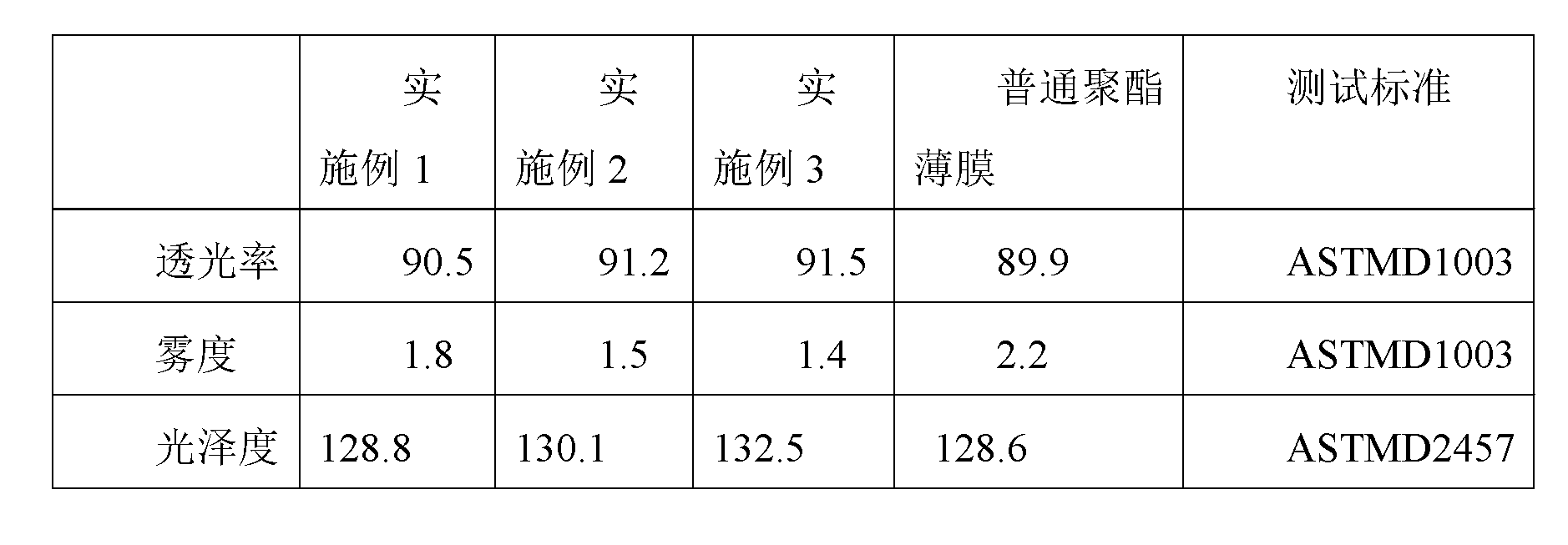

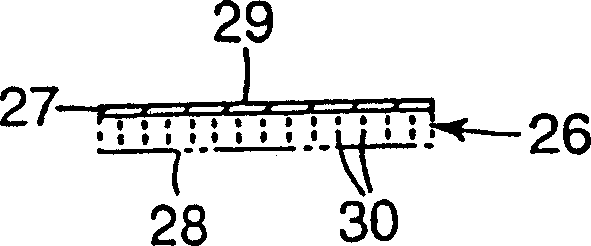

Bidirectional-stretching online-coating optical base film and its making method

InactiveCN103171223AGood anti-adhesionImprove smoothnessSynthetic resin layered productsPolyesterSurface layer

The invention relates to a bidirectional-stretching online-coating optical base film and its making method. The optical base film comprises a three-layer co-extruded bidirectional-stretching polyester film, and a coat having a thickness of 1-10mum and coated on at least one surface of the polyester film. The three-layer co-extruded polyester base film has an A / B / A structure and is formed by two co-extruded surface layers (the A layers) and a core layer (the B layer) positioned between the two surface layers. The coat adopts an aqueous polyurethane coating liquid, and includes a silica colloid having a particle size of 40-50mum, and micron-sized silica having a particle size of 1-6mum. The optical base film having the above structure has the characteristics of high light transmittance, low haze, good adhesion resistance and the like, and is suitable for the use in optical films comprising diffusion films, whitening films and protection films for the optical use.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

Horticultural greenhouse with removable cover

InactiveUS6843019B2Easy to unwindSimple structureBuilding roofsClimate change adaptationGreenhouseCovering system

A roll-up cover system includes a tarpaulin (30) having a fixed edge (30-1) and a free edge (30-2) secured to a winding shaft (31), in which the tarpaulin is of the double-membrane inflatable type (30a, 30b) and all or part of the unwinding of the tarpaulin is carried out by inflating the tarpaulin, the inflating pressure occurring in the tarpaulin unwinding the tarpaulin or contributing to the unwinding force. The roll-up cover system has particular application to horticultural greenhouses.

Owner:MERCURIO JOSEPH +1

Method for producing a casing

InactiveUS7059102B2Small sizeCan be without delayWrapper twisting/gatheringSausage makingBand shapeEngineering

Owner:POLY CLIP SYST

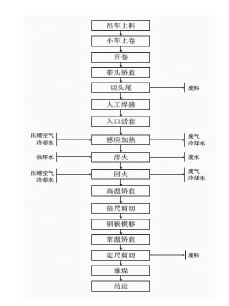

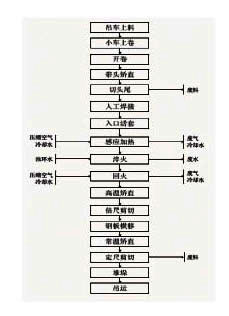

Production process for high-performance steel plate thermal treatment unit

ActiveCN101935750AEasy to unwindUnwinding and other processes are reliableFurnace typesProcess efficiency improvementHigh intensityThermal treatment

The invention relates to the technical field of high-performance steel plate thermal treatment, in particular to a production process for a high-performance steel plate thermal treatment unit. The process comprises the following steps of: carry out the following controls after hot-rolling steel coils are transported into a rolling cylinder of an uncoiler through a coil car and then fed into a pinch roll: regulating a deep bending roll to enter a preset position and straightening in a No.1 straightener after passing through a No.1 side guide device; cutting off the head waste materials of the straightened steel plates in the cutting position of an opening, and carrying out the centring welding and the manual welding in the position of a welding platform; feeding the welded steel plates into an entrance loop; pulling the steel plates out from the loop and transferring to a process section; then sequentially carrying out the thermal treatments of induction heating, quenching, tempering, and the like so as to reach mechanical performances required for the steel plates; then carrying out straightening and slitting; carrying out the multiple feet cutting on the steel plates by a pair of plasma scissors; and transferring the cut steel plates to a finished product storage. The invention can ensure that the yield strength of the steel plates produced by adopting the process can reach above 1000MPa; and the steel plates can reach the performance requirements on high strength, high toughness and cold bending.

Owner:LIAONING HENGYE HI TECH NEW MATERIAL

Peel-away security covering for a ticket

InactiveUS20110272934A1Easy to unwindImprove adhesionRecording apparatusOther printing matterAdhesiveComputer printing

A solution for concealing confidential information that is printed at the point of sale in a game of chance utilizing a more common type printer designed for printing on a standard grade and biodegradable direct thermal paper. This system can print and cut each individual ticket in variable lengths. The unique and innovative concept of this new system allows a second and separate biodegradable substrate to be collated in a continuous stream over top of the printed ribbon before it is cut away and delivered into the presenter. The second substrate contains a strip of a specially formulated adhesive and is adhered to the top surface of the printed ribbon as the two substrates join together while passing through mechanical nip rollers. The confidential printed information is now covered and the combined substrates are cut and delivered as one ticket unit. The ticket information is revealed by easily peeling away the adhered top layer.

Owner:MAX INT CONVERTERS

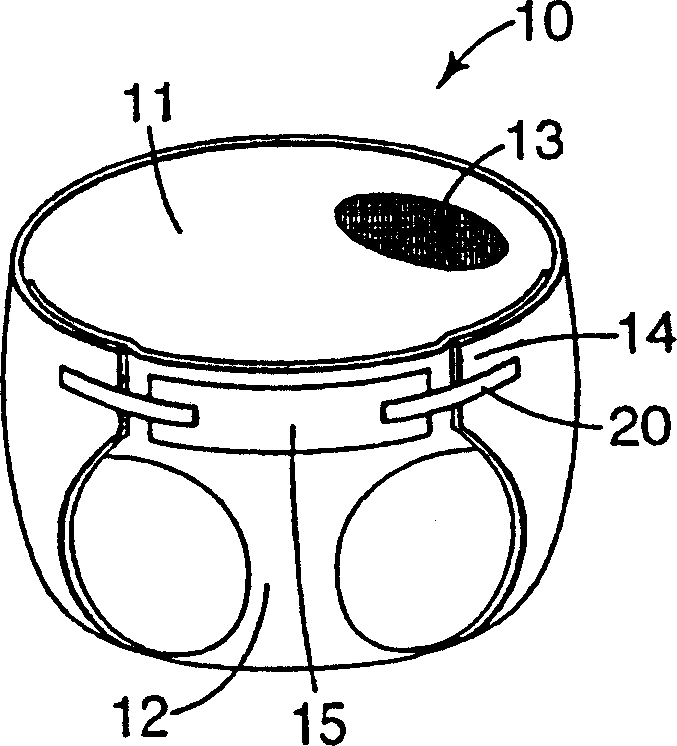

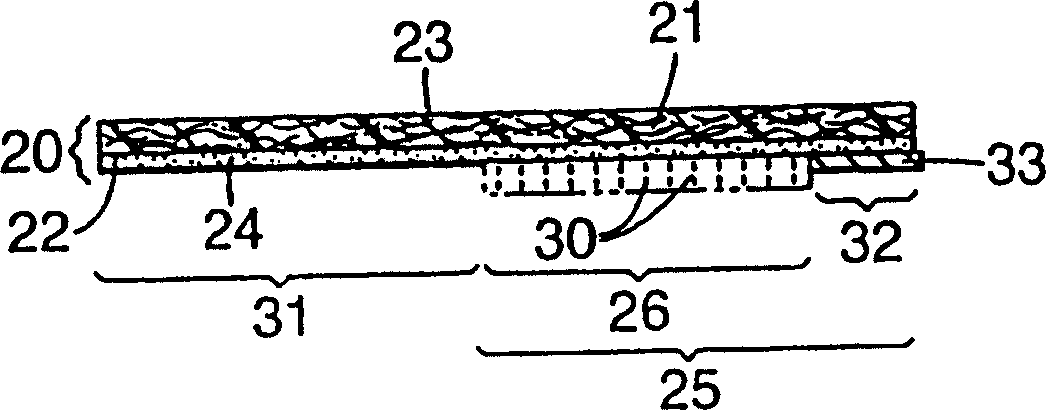

Non-woven adhesive band for making diaper closing part

InactiveCN1508204AEasy to unwindStay cohesiveOther chemical processesFilm/foil adhesivesMethacrylateAdhesive belt

The present invention provides an adhesive tape comprising a backing comprising a fibrous layer of woven fibers or of non-woven fibers of a thermoplastic polymer, said backing comprising on said fibrous layer a silicone release layer and the side of the backing opposite to the side comprising said silicone release layer comprises a pressure sensitive adhesive layer, said silicone release layer comprising a cured reaction product of a curable composition comprising (i) a polydialkylsiloxane having acrylate and / or methacrylate groups and (ii) an organic compound free of silicon and comprising at least two reactive groups selected from the group consisting of an acrylate and a methacrylate group, said adhesive tape having a 90 DEG peel adhesion of at least 6 N / 2.54 cm relative to a polyethylene film surface and said adhesive tape having a Keil test value of not more than 1 N / 2.54 cm. The adhesive tape is suitable for making cloth-like closure systems for absorbent articles such as diapers.

Owner:3M INNOVATIVE PROPERTIES CO

Machine of pressing yarn for cheese yarn on cones

InactiveCN1600937AAdaptableSolving Density Compensation IssuesTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentYarnColour difference

A Cheese pressure consists of motor, oval rotary disc, top pressing basin, lifting bar, link and bottom pressing basin. The presser has double functions of pressing and chamfering and can eliminate inner, middle and outer layer colour difference caused by unevenness of cylinder density in existing loose cylinder dyeing process.

Owner:金国周

Linear unstretched polyethylene film easy to tear

InactiveCN105313414AWith linear easy tear performanceRegular tearSynthetic resin layered productsDomestic containersInter layerSurface layer

The invention provides a linear unstretched polyethylene film easy to tear, and relates to the technical field of films. The linear unstretched polyethylene film easy to tear is of a three-layer compound structure comprising an outer surface layer, a middle layer and an inner surface layer. The outer surface layer is mainly prepared from one or a mixture of at least two of linear low-density polyethylene, low-density polyethylene, high-density polyethylene and medium-density polyethylene; the middle layer is mainly prepared from low-density polyethylene and / or linear low-density polyethylene and cyclic olefin copolymers; the inner surface layer is mainly prepared from one or a mixture of at least two of metallocene polyethylene, linear low-density polyethylene and low-density polyethylene. The linear unstretched polyethylene film easy to tear can overcome the defect that an existing film is difficult to tear or a torn opening is in a zigzag shape.

Owner:安徽双津实业有限公司

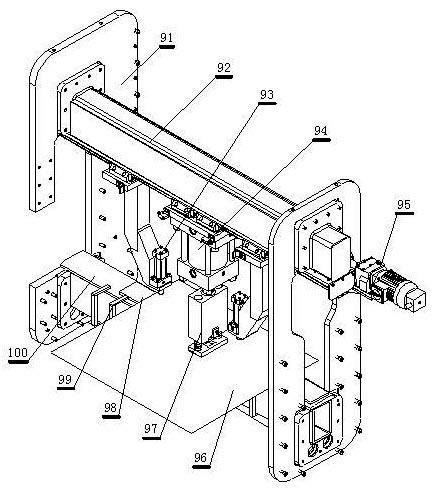

Winding pin mechanism of winding machine and winding machine

InactiveCN105514479AEasy to unwindFacilitate strippingAssembling battery machinesFinal product manufactureWinding machineEngineering

The invention discloses a winding pin mechanism for a winding machine and the winding machine. The winding pin mechanism comprises a winding pin seat, a winding pin assembly and a winding pin tailstock. The winding pin assembly is inserted into the winding pin seat and the winding pin tailstock and comprises a first outwards-winding pin, a first inwards-pressing pin, a second inwards-pressing pin and a second outwards-winding pin, wherein the first outwards-winding pin and the second outwards-winding pin are arranged on the same circumference at 180 degrees, the first inwards-pressing pin is arranged in the first outwards-winding pin, and the second inwards-pressing pin is arranged in the second outwards-winding pin. The winding pin tailstock comprises a fixing seat, a driving device for controlling a sliding block to slide is arranged in the fixing seat and can drive the first inwards-pressing pin and the second outwards-winding pin to get close to or be away from the first outwards-winding pin and the second inwards-pressing pin to clamp or release a base material penetrating through the part between the first inwards-pressing pin and the second inwards-pressing pin. The cross section of a winding core formed by the first outwards-winding pin and the second outwards-winding pin is oval or diamond. The winding pin mechanism for the winding machine and the winding machine are simple in structure and capable of reliably winding high-quality battery cores.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

fall protection system

InactiveCN102281923AControl rotation speedReduce rotation speedLiquid resistance brakesSafety beltsFall protectionRotation velocity

A fall protection system comprising a line wound onto a rotatable pulley having a centrifugal clutch which activates a gearbox which in turn drives an input shaft of a hydraulic actuator whereby the hydraulic actuator controls the rate of rotation of the pulley, and a secondary brake which slows the rotational speed of the pulley should it exceed a predetermined speed, whereby in use, the line isattached to a user to restrain a fall and then the system facilitates unwinding of the line at a controlled speed to effect descent.

Owner:FALLSAFE TECH PTY LTD

Crosslinked solid type pressure-sensitive adhesive composition, pressure-sensitive adhesive sheet comprising the composition, and pressure-sensitive adhesive sheet for waterproofing/airproofing comprising the sheet

InactiveUS20040258936A1Increase forceEvenly dispersedFilm/foil adhesivesSynthetic resin layered productsQuinoneOrganic solvent

A solid type pressure-sensitive adhesive composition capable of being applied without the necessity of using an organic solvent or water and a pressure-sensitive adhesive sheet, which are excellent in both adhesive force and holding power and, in particular, undergo no decrease in low-temperature adhesive force even when the adhesive layer thickness is small. The crosslinked solid type pressure-sensitive adhesive composition comprising (a) a rubbery polymer, (b) a tackifier, and (c) a crosslinking agent comprising at least one member selected from the group consisting of thiuram vulcanizing agents, quinoid vulcanizing agents, quinone dioxime vulcanizing agents, and maleimide vulcanizing agents.

Owner:NITTO DENKO CORP

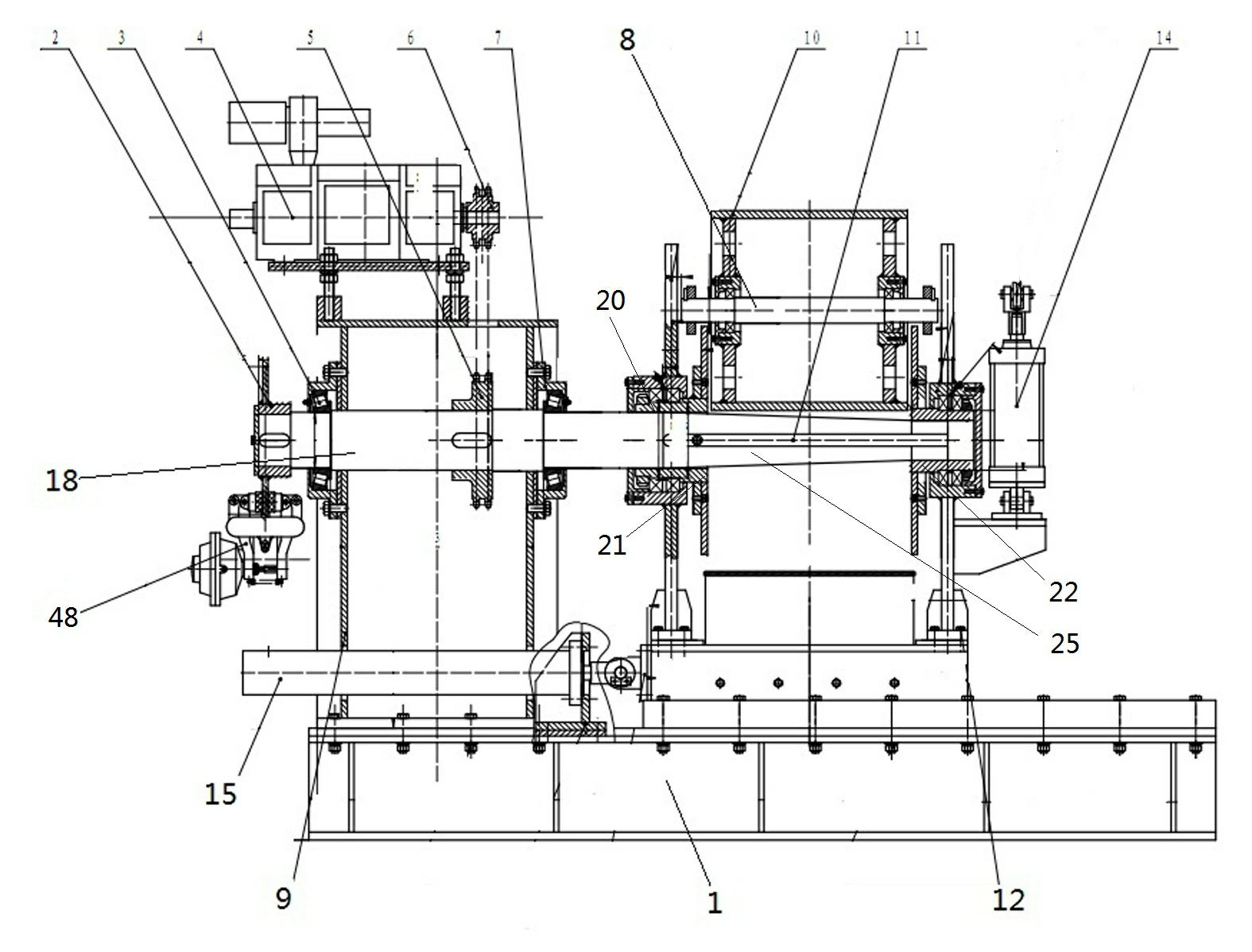

Foil-type coiling machine with cold pressure welding device

InactiveCN102315013AGuarantee product qualityMake sure tightCoils manufactureNon-electric welding apparatusWinding machineControl vector

The invention discloses a foil-type coiling machine with a cold pressure welding device. A cold pressure welding mode replaces the traditional pneumoelectric welding mode for connecting outgoing lines of workpiece copper (aluminum) foils and copper (aluminum) bars; copper (aluminum) metals are subjected to plastic deformation only by means of pressure without any external heat source, so that oxide films and other impurities between welding joints are extruded out, thus the pure metal forms solid welding, thereby ensuring the product quality of coils. A foil material feeding device, a foil material decoiling device, a deflection regulating device, a pre-welding cleaning device, a cold pressure welding device, an edge belt decoiling device, a layer insulation transmission device, an insulation shearing device, a coiling device, a layer insulation decoiling device, a trimming device, an end supporting device, a release plate recoiling machine and other components are connected with a main framework, and control signal output and input ends of the coiling machine are connected with control signal output and input ends of a control device; and the stepless frequency control of a motor is controlled through a Siemens motion and vector control module.

Owner:LIAONING XINTAI

Device and method for covering yarn

The invention relates to a device for covering yarn, which comprises an unwinding device, a twisting device, a drafting device and a winding device, at least one number-one rotary plate is arranged below a number-two rotary plate, the number-two rotary plate is arranged above an axis line in the number-one rotary plate by a driven shaft, a driving shaft is arranged below the axis line in the number-one rotary plate, the number-one rotary plate is internally provided with an intermediate shaft and a balancing shaft which are parallel to the driving shaft respectively at the two sides of a shaft driving the number-two rotary plate, a tangential belt drives the driving shaft which is provided with a driving belt wheel, the driving belt wheel transmits a first intermediate belt wheel below the intermediate shaft by the belt wheel, a second intermediate belt wheel above the intermediate shaft drives the driven shaft, the driven shaft drives the number-two rotary plate to rotate, and the driving shaft drives the number-one rotary plate to rotate. The device utilizes the transmission ratio of the belt wheel to enhance the shaft rotational speed, has simple structure, is improved based on the original mechanical yarn covering machine, enhances the production efficiency, adopts the shape of a single cone in packaging outer yarn, reduces the original winding procedure and reduces the production cost.

Owner:DONGHUA UNIV

High dust holding filter material for filter bag

ActiveCN103638747AImprove breathabilityEasy to processDispersed particle filtrationSynthetic resin layered productsPorosityCarding

The invention discloses a high dust holding filter material for a filter bag. The high dust holding filter material is in a three-layer overlap structure formed by clamping a middle dust holding layer clamped by an upper protective layer and a lower protective layer, wherein the three layers are compounded into a whole by adopting a punching or ultrasonic welding process; the total gram weight of the high dust holding filter material is 50-200g / m<2>; the upper protective layer and the lower protective layer are made of polypropylene spunbond nonwoven fabrics with the gram weight of 10-30g / m<2>. The invention aims to give a certain strength to the high dust holding filter material, the dust holding layer is clamped, and the effects of fixing fibers and preventing the fibers from dropping are achieved. Moreover, the dust holding layer is a key layer of the high dust holding filter material, has the gram weight of 30-140 g / m<2> and is made of a polypropylene short fiber raw material, and a high-bulk high-porosity three-dimensional stereoscopic structure is manufactured by utilizing the mechanical carding and mechanical wet forming technology. The high dust holding filter material has the characteristics of high dust holding capacity, high processing performance and the like.

Owner:桐乡市朗裕净化科技股份有限公司

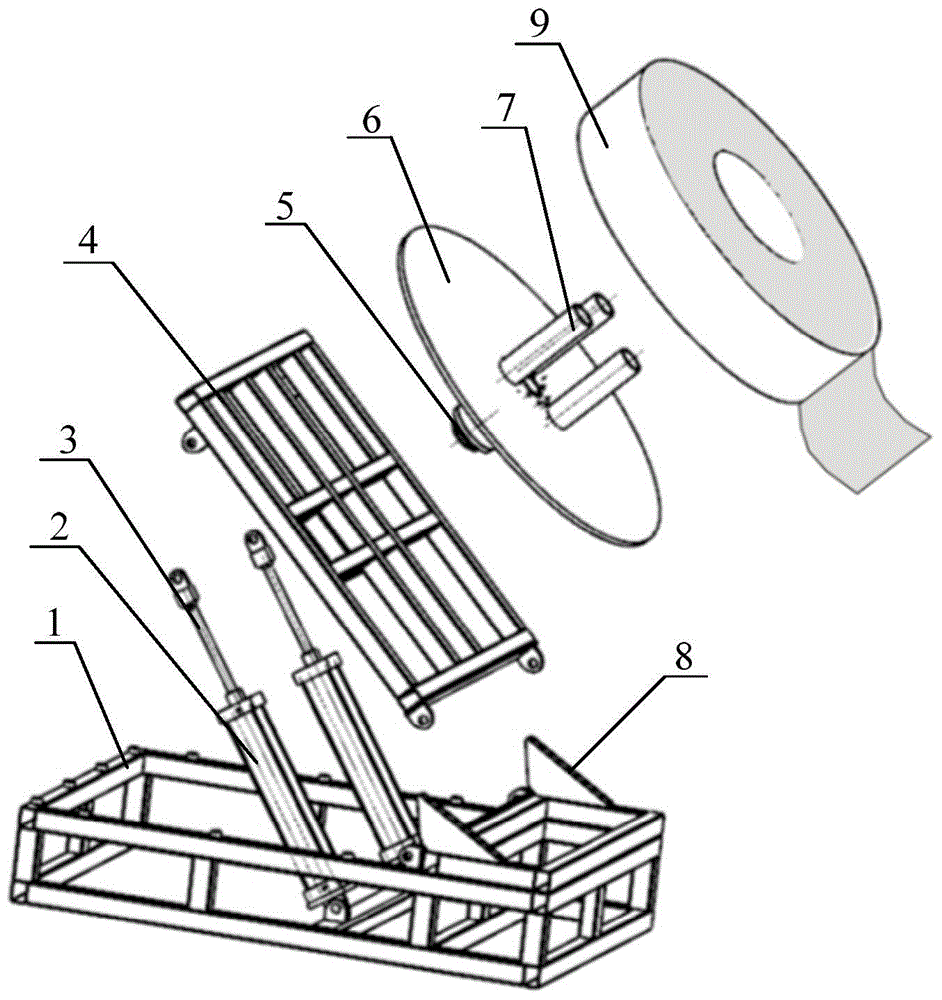

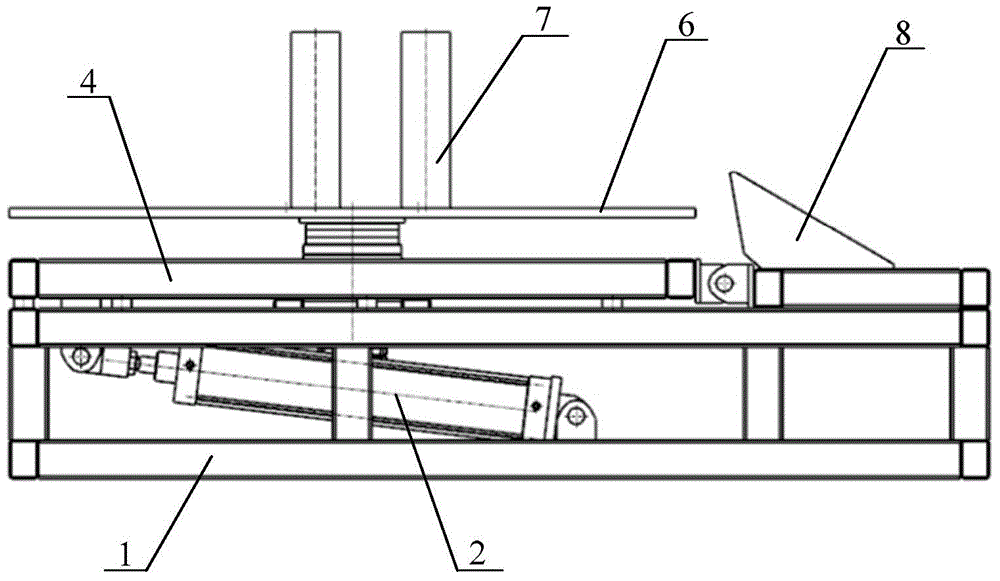

Coil stock unrolling feeding device

The invention discloses a coil stock unrolling feeding device. The coil stock unrolling feeding device is characterized by comprising a base (1), a rotary support (4) with one end connected to the base (1), and a rotary table (6) which is arranged on the support (4) and can rotate, fixing columns (7) are fixed to the rotary table (6), and the base (1) is provided with a power device pushing the support (4) to rotate. The coil stock unrolling feeding device is simple in structure and low in cost. According to the coil stock unrolling feeding device, the loading work can be finished within a very short time, the coil stock loading difficulty can be lowered, one-time loading success is ensured, and therefore the material loss, the occupational injury hidden danger and other accidental situations are reduced, safety and reliability are achieved, meanwhile, the input of manpower and material resources is reduced, accordingly, cost is reduced, and the coil stock unrolling feeding device is suitable for usage and popularization.

Owner:CHENGDU HELE DOORS

Surface protective film

InactiveCN101679816AEasy to unwindGood unwinding effectFilm/foil adhesivesSynthetic resin layered productsElastomerPolyolefin

Disclosed is a surface protective film comprising a base layer and an adhesive layer. The adhesive layer contains a styrene elastomer, a polyolefin and a tackifier, and the styrene elastomer containsa hydrogenated or non-hydrogenated vinyl-polyisoprene block. The styrene elastomer has a styrene content of not less than 5% but not more than 30%, a triblock copolymer content of not less than 80%, and a glass transition temperature of not less than -40 DEG C but not more than 20 DEG C.

Owner:IDEMITSU UNITECH CO LTD

Coiler for trimmings of cold-rolling strip steel

The invention relates to a coiler for trimmings of cold-rolling strip steel, which comprises a rack and a recovery rotary shaft rotatably assembled on the rack and is driven by a corresponding power source, wherein a recovery working section for recovering corresponding trimmings is arranged on the recovery rotary shaft; the rack is provided with a guiding structure with a guiding direction extending along a vertical direction on the upper part of the recovery working section; the guiding structure is provided with a bouncing roller capable of bounding up and down in a guiding way; and the bouncing roller comprises a roller body which is in friction rolling fit with the corresponding trimmings when the recovery working section is rotated to recover the trimmings, and bounces up and down under the friction action of the trimmings. The invention provides the coiler for the trimmings of the cold-rolling strip steel with a simple structure.

Owner:郑州市华驰薄板科技有限公司

Cord reel assembly and vacuum cleaner having the same

InactiveUS20070209895A1Easy to unwindEasy to operateSuction cleanersCastorsElectric powerVacuum cleaner

A cord reel assembly according to the present disclosure includes a power cord; and a cord reel around which the power cord is automatically wound when the power cord is separated from an electric power source, the cord reel from which the power cord is automatically unwound when the power cord connected to the electric power source.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

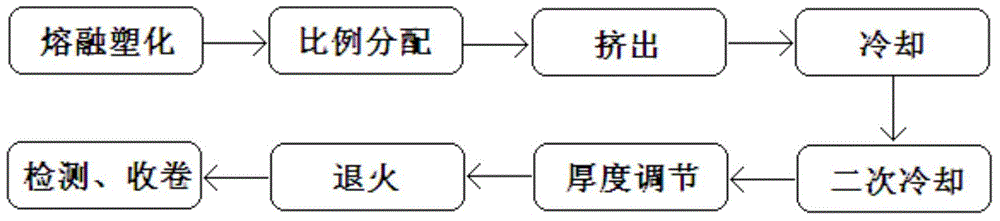

Production technology for high-viscosity CPP self-sticking protection film

InactiveCN105128496AViscous stabilityImprove flatnessLaminationLamination apparatusBlack pointDistributor

The invention relates to a production technology for a high-viscosity CPP self-sticking protection film. The production technology includes the steps that firstly, a sticking-resisting layer raw material, a base layer raw material and a sticking layer raw material are added into a single screw extruder to be melted and plasticized, and the raw materials are filtered through a filter and then conveyed into a distributor to be subjected to interlayer proportional distribution; secondly, melts of the three layers of raw materials are conveyed to a die head to be evenly distributed and plasticized and are then extruded through a die lip, and the melts make contact with a main cooling roller to be cooled; thirdly, an obtained cast film is secondarily cooled through an auxiliary cooling roller, and then thickness adjustment is conducted; fourthly, annealing processing is conducted, flaw detection is conducted, and rolling is conducted. The production technology is simple in design, the operation efficiency is high, losses are small, the stability of the product quality is good, and cost is low. By means of the production technology, the prepared high-viscosity CPP self-sticking protection film can have extremely-low shrinkage, the flatness of a film body is good, viscosity is stable, and rolling and unrolling are convenient. In addition, the transparency of the product can be effectively improved, and the occurrence of problems of fish eyes, crystal points, black points, impurities and the like on the film body is inhibited.

Owner:昆山金华安电子科技有限公司

Warping device

The invention relates to a warping device (1), which has a winding carrier, a rotation drive (8) that rotationally drives the winding carrier, a bearing unit (11) for the winding carrier and a threadband guiding device moved along the winding carrier. For the purpose that the production time can be short in the process of producing warp threads by the warping device, the warping device is designed in the following way: the winding carrier is designed into a yarn beam (2) which can be detachably connected with the rotation drive (8) and bearing unit (11) and has at least one yarn beam plate (24).

Owner:KARL MAYER STOLL R&D GMBH

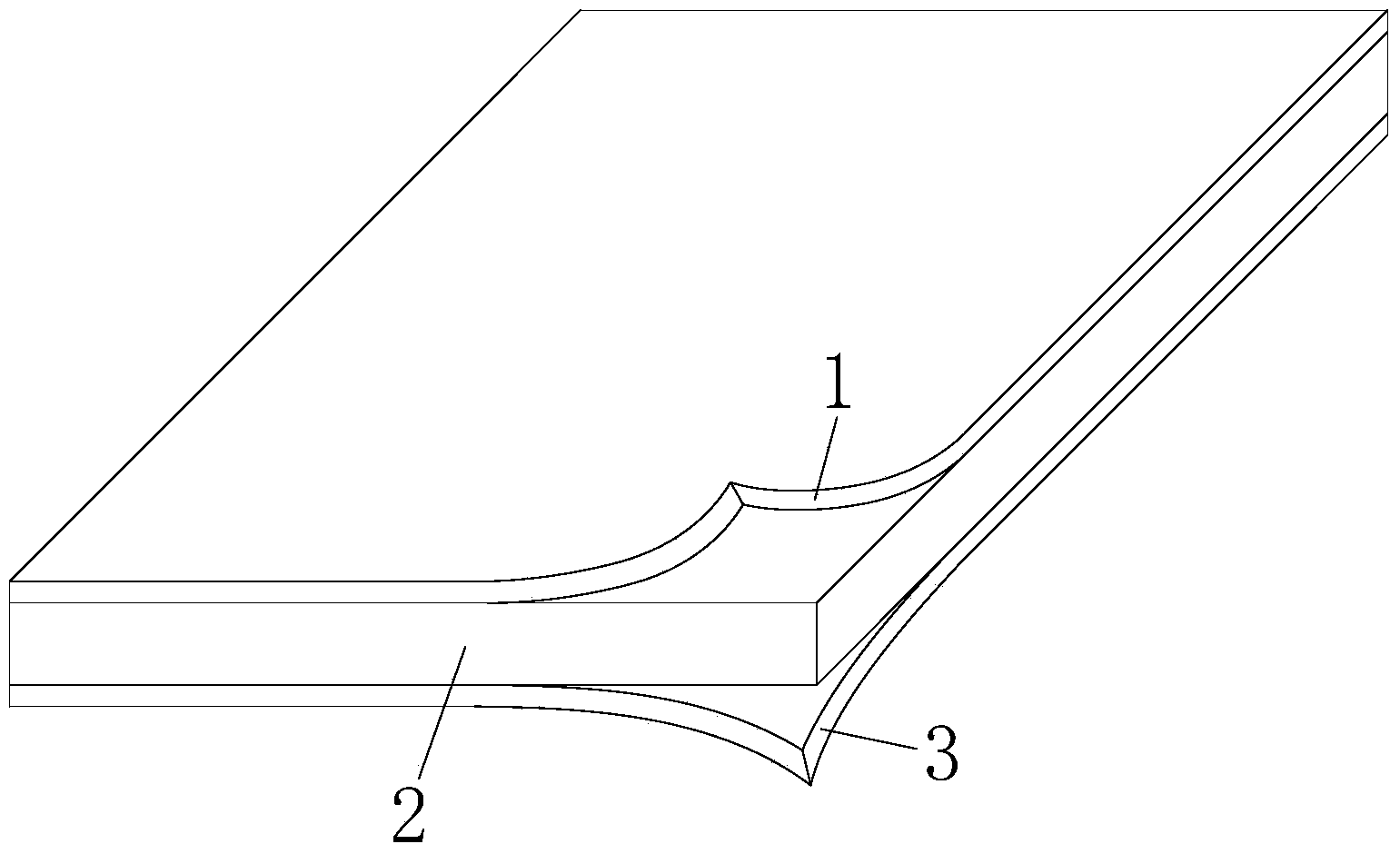

Preparation method of monodirectional preimpregnation narrowband for automatic filament placement

A convenient preparation method of a monodirectional preimpregnation narrowband for automatic filament placement belongs to the composite material laying and forming field, and mainly comprises the following steps: width prepreg uncoiling, back lining paper rewinding, prepreg slitting, preimpregnation narrowband coating, and spiral rewinding of a coated preimpregnation narrowband. The preimpregnation narrowband for automatic filament placement can be prepared by the method, and is continuous in length, constant in width, and good in unwinding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nonwoven adhesive tape for producing diaper closure system

InactiveCN1326493AEasy to unwindStay cohesiveOther chemical processesFilm/foil adhesivesMethacrylateFibrous layer

The present invention provides an adhesive tape comprising a backing comprising a fibrous layer of woven or nonwoven fibers of a thermoplastic polymer, said backing comprising a silicone release layer on said fibrous layer, and comprising The opposite backing side of the silicone release layer comprises a pressure sensitive adhesive layer, the silicone release layer comprising a cured reaction product of a curable composition comprising (i) having Polydialkylsiloxanes of acrylate and / or methacrylate groups, and (ii) silicone-free but containing at least two reactive groups selected from acrylate and methacrylate groups. Compounds, the adhesive tape has a 90° peel adhesion of at least 6 N / 2.54 cm to a polyethylene film surface and a Keil test value of no higher than 1 N / 2.54 cm. The adhesive tape is suitable for making fabric-like closure systems for absorbent articles such as diapers.

Owner:3M INNOVATIVE PROPERTIES CO

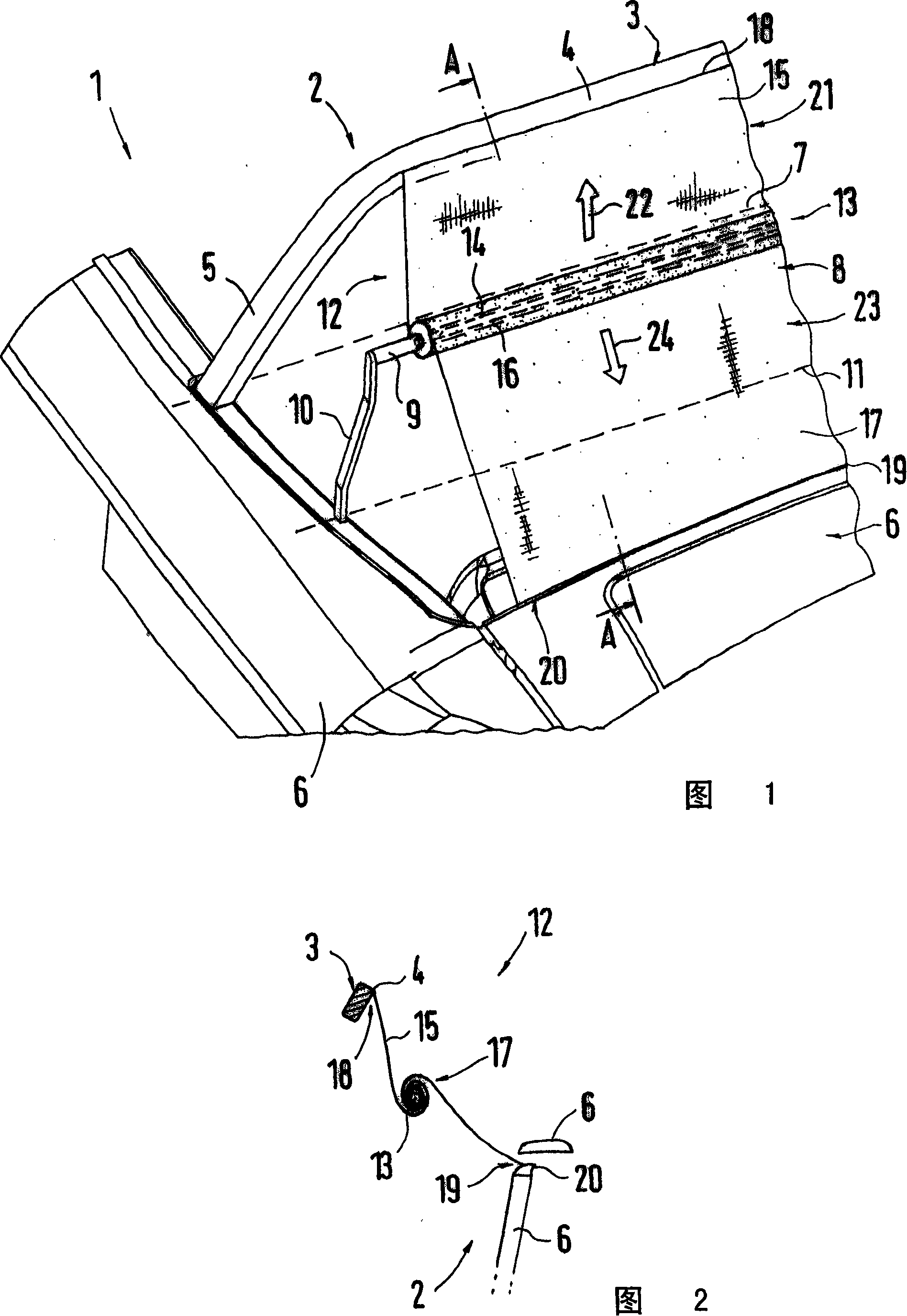

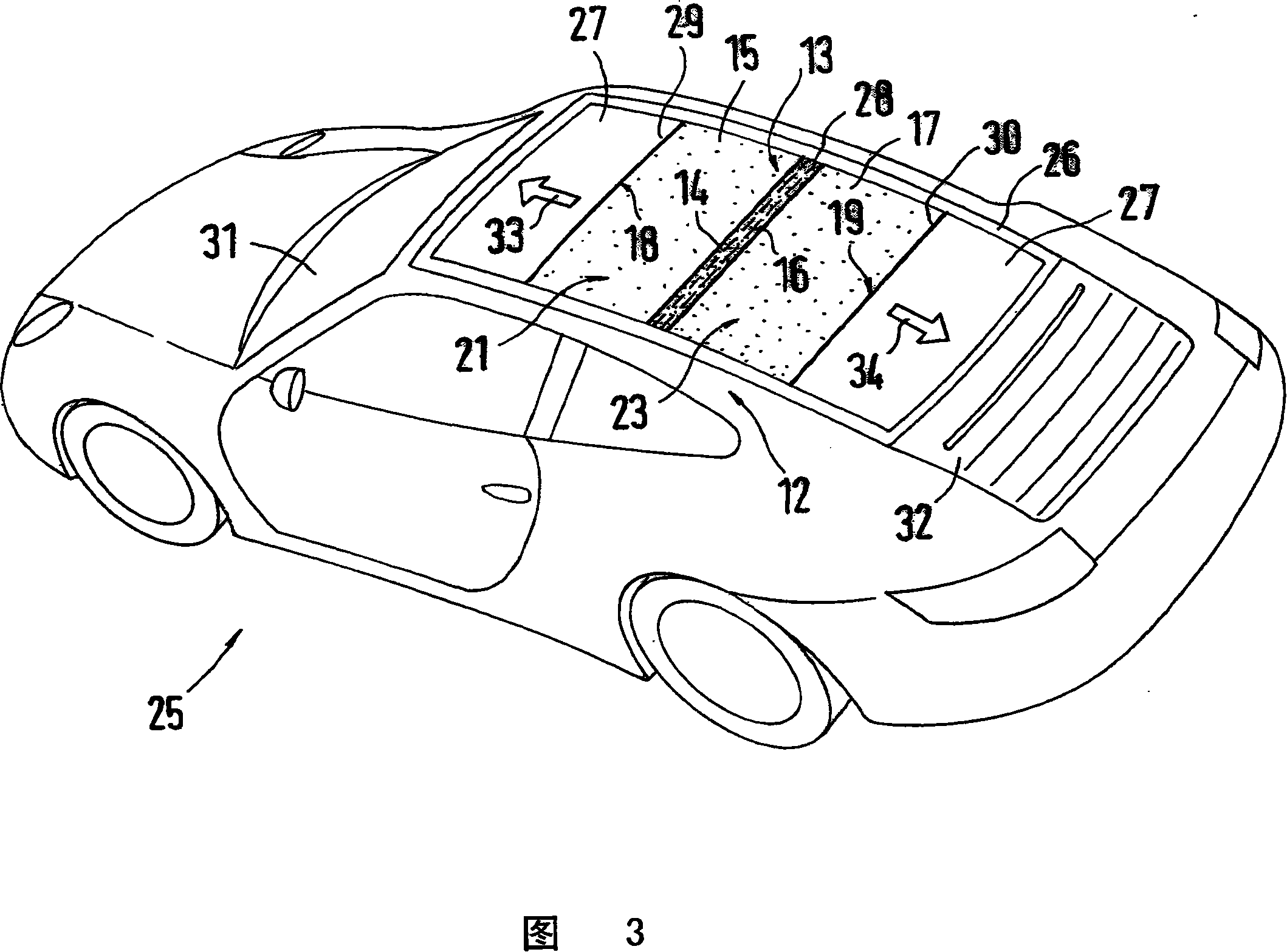

Roller blind device and wind blocker and motor vehicle with a roller blind device

Owner:DR ING H C F PORSCHE AG

Palladium (PD)-coated copper wire for ball bonding

InactiveUS20170057020A1Promote formationEvenly dispersedVacuum evaporation coatingSolid-state devicesCopper wireSulfur

A palladium coated copper wire for ball bonding includes a core formed of pure copper or copper alloy having a purity of 98% by mass or more, and a palladium draw coated layer coated on the core. The copper wire has a diameter of 10 to 25 μm, and the palladium drawn layer contains sulfur, phosphorus, boron or carbon.

Owner:TANAKA DENSHI KOGYO KK

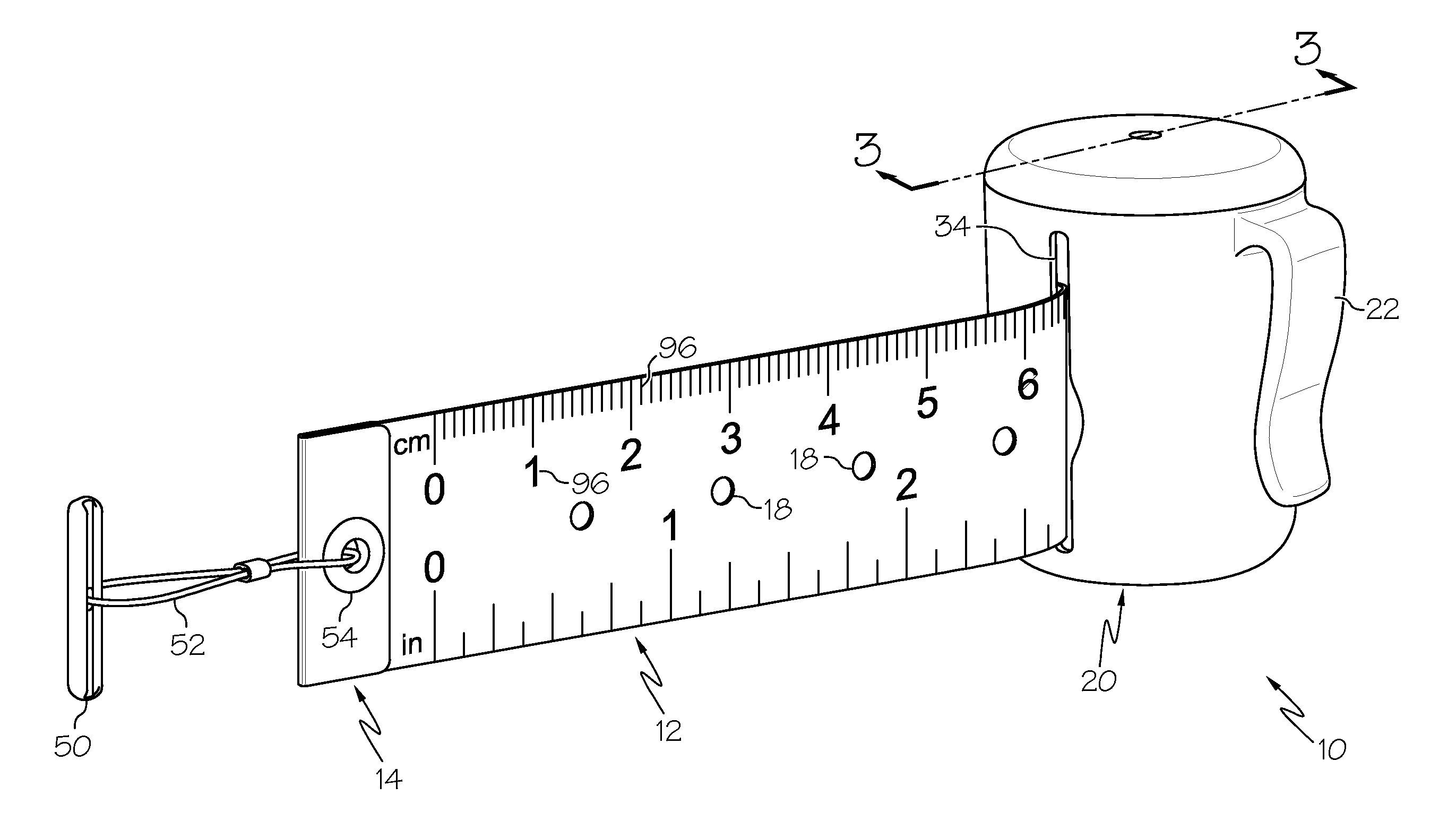

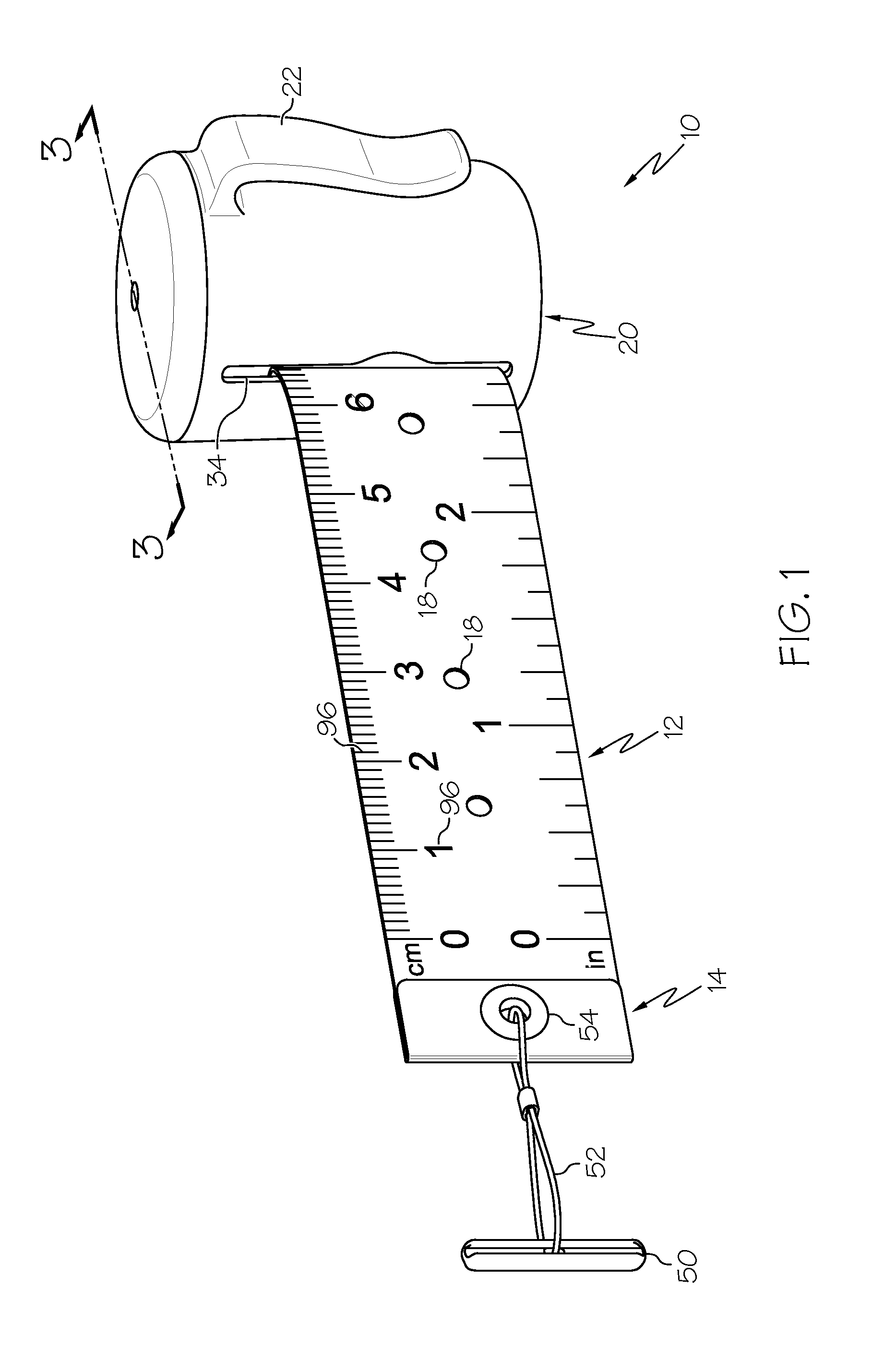

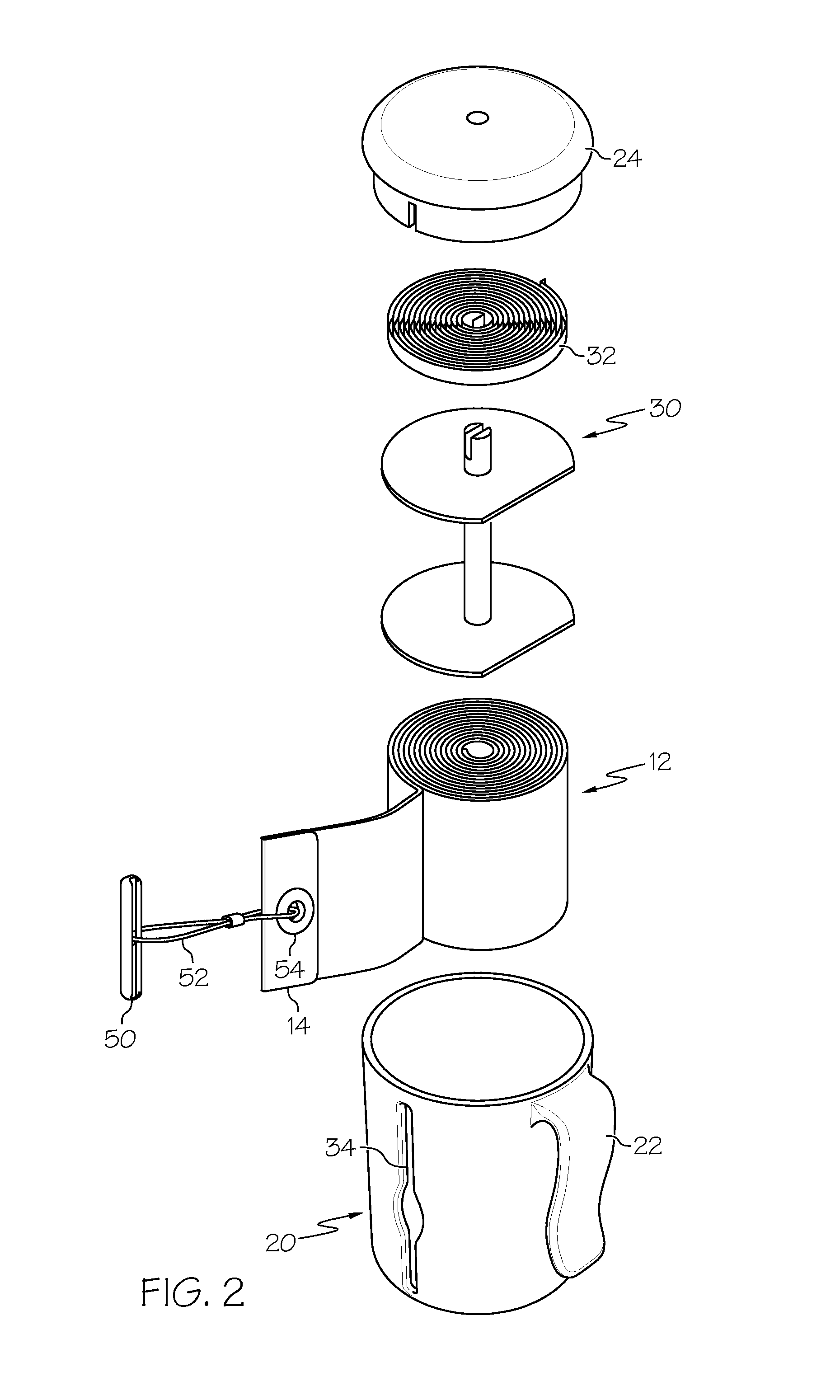

Spring Retractable Transfer Belt Apparatus

InactiveUS20120011649A1Easy to carryImprove securityStampsStretcherMechanical engineeringEngineering

Owner:OPHAUG BRYAN JEFFREY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com