Roller blind device and wind blocker and motor vehicle with a roller blind device

A technology for roller blinds and automobiles, applied to vehicle parts, transportation and packaging, roofs, etc., can solve the problems of troublesome windshield partitions and space requirements, and achieve low material cost, economical and favorable manufacturing and assembly, simple and reliable rolling The effect of winding and unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

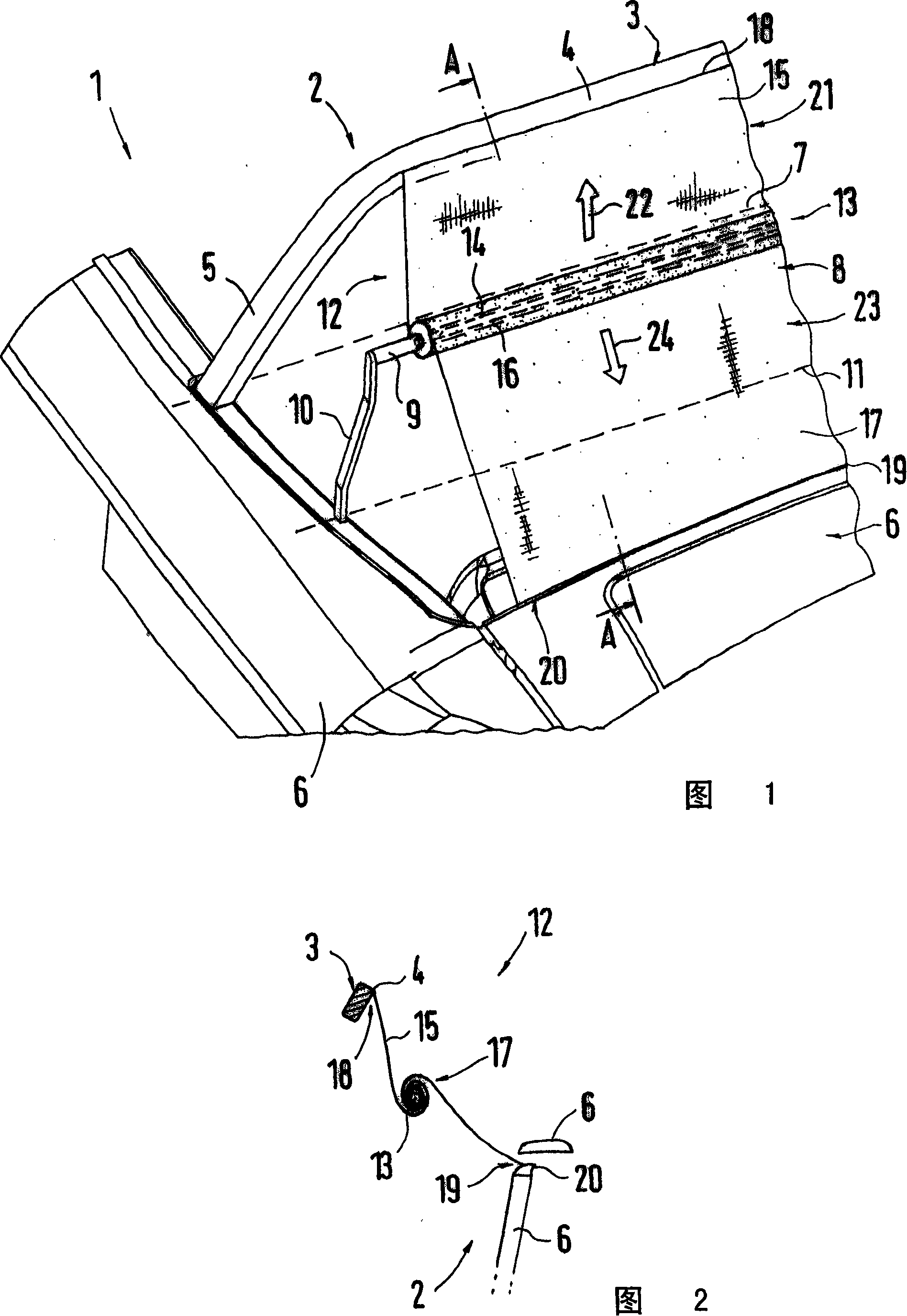

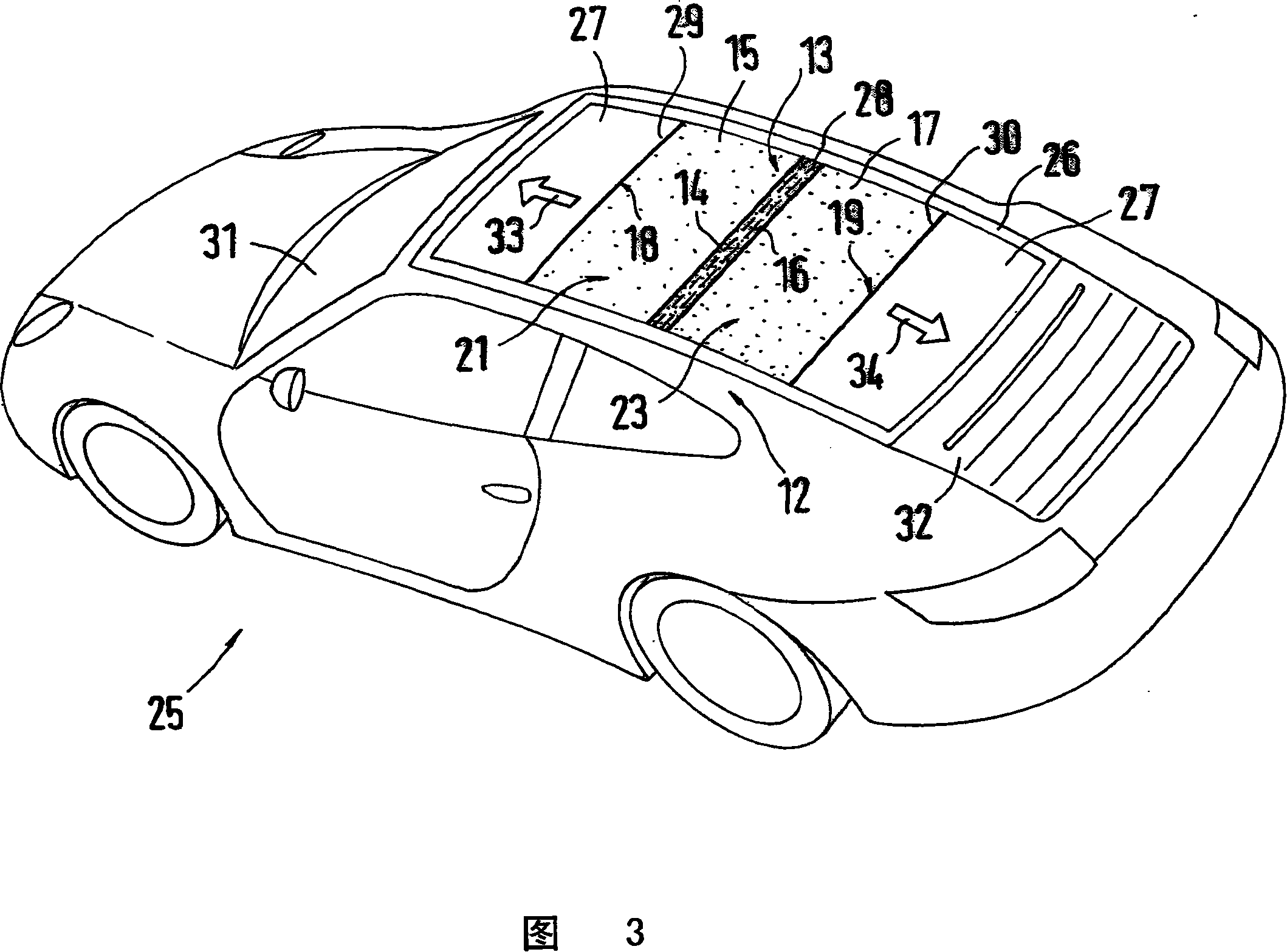

[0025] The same reference symbols are used below for elements that are identical or have the same effect.

[0026] FIG. 1 shows a schematic perspective view of a part of a coupe 1 according to the invention, which is arranged between the driver's seat and the driver's seat and the rear of the vehicle. A windshield 2 according to the invention is arranged in this part of the coupe 1 . In the transverse direction of the passenger car 1 , the windshield bulkhead 2 is substantially mirror-symmetrical about an axis arranged through its center in the longitudinal direction. Therefore, only the left side part of the coupe 1 and the left side part of the windshield 2 are shown in FIG. 1 for the sake of clarity. The windshield bulkhead 2 includes a tensioning bow 3 which comprises two spaced-apart, opposite side bars which are advantageously integrally connected to one another by means of a transverse web 4 . FIG. 1 shows a left-hand lever 5 of the tensioning bow 3 . The tensioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com