Winding drum device

A reel and drum technology, applied in the field of textiles, can solve the problems of inconvenient rolls and sub-packaging, unable to fix one end of the cloth on the reel, etc., so as to improve the utilization rate and improve the effect of clamping and fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

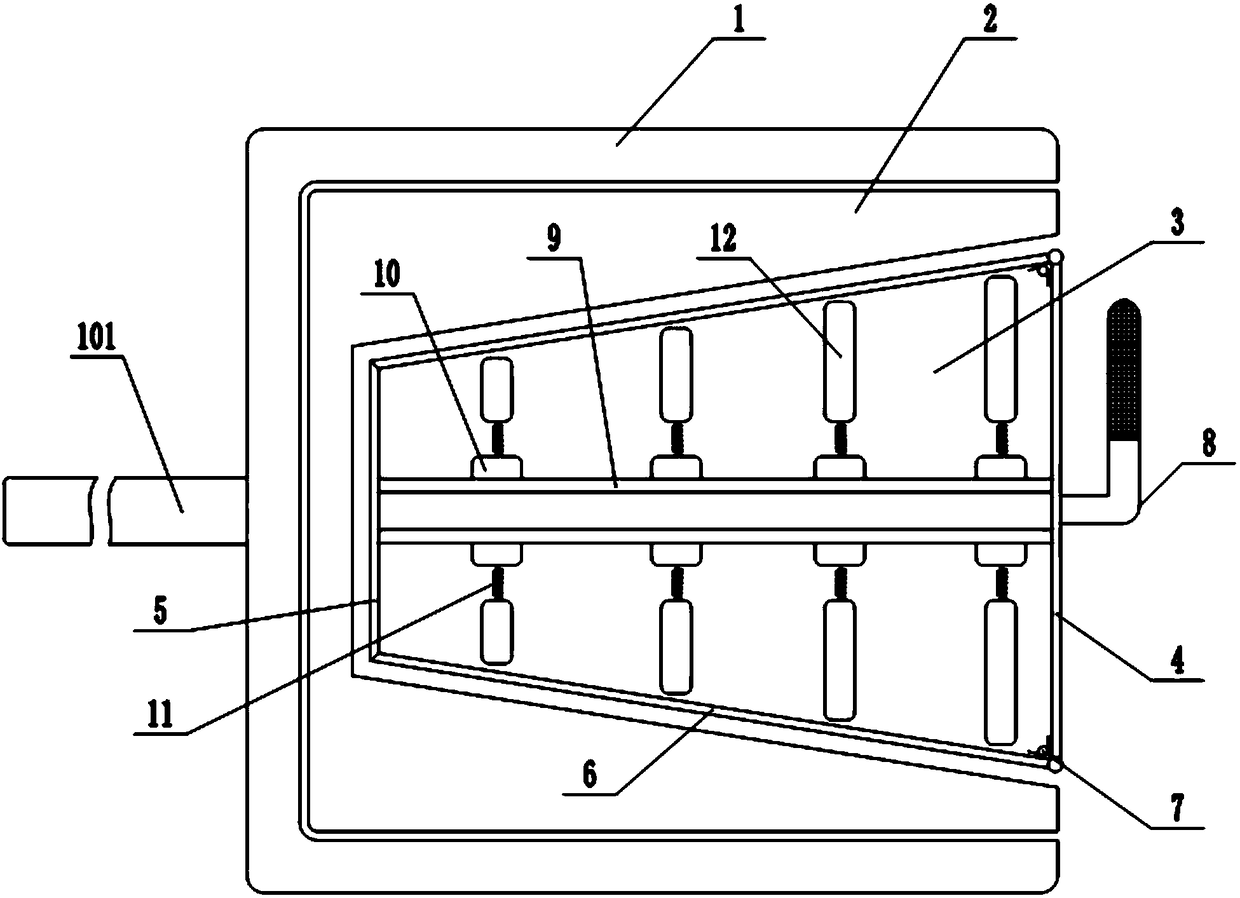

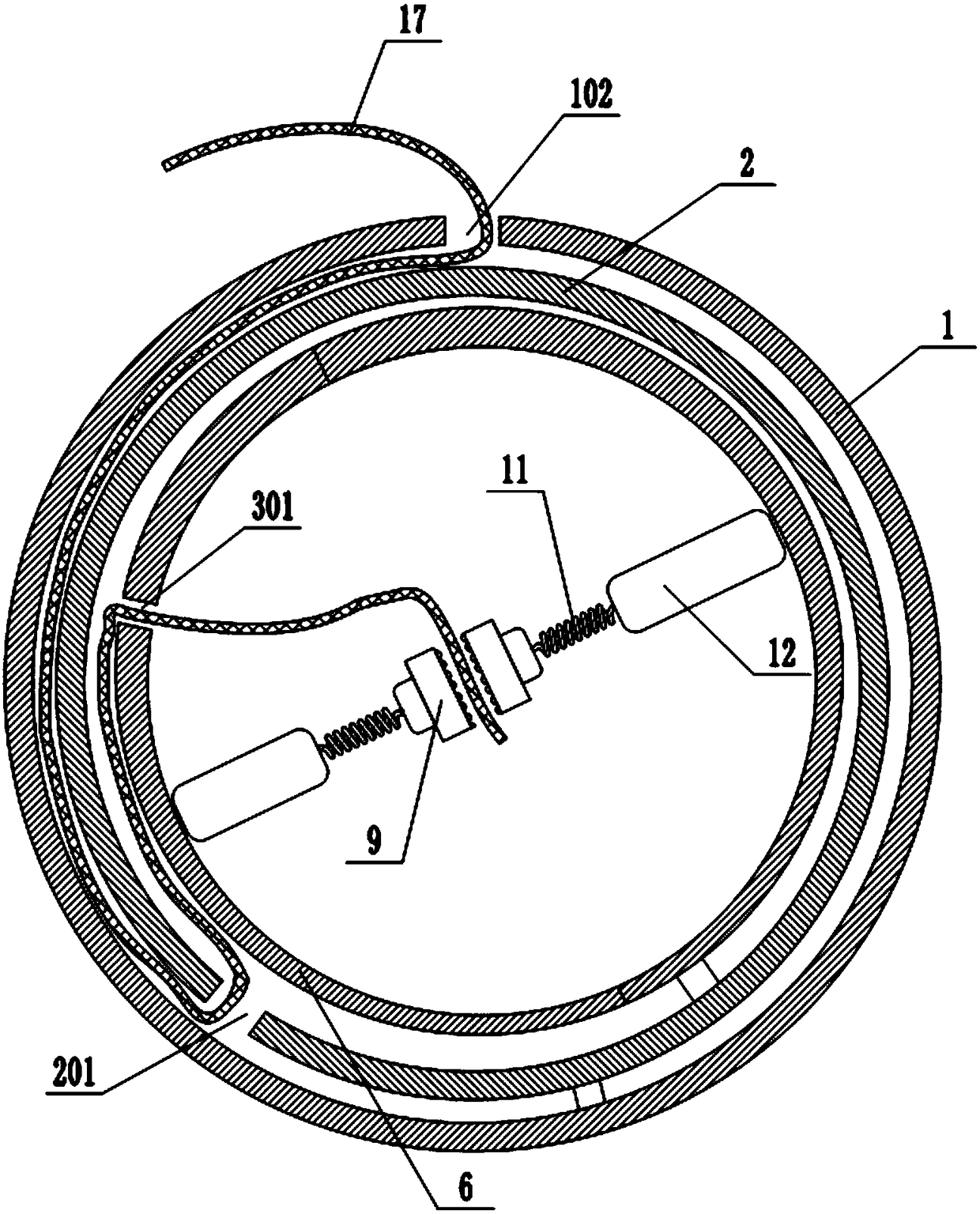

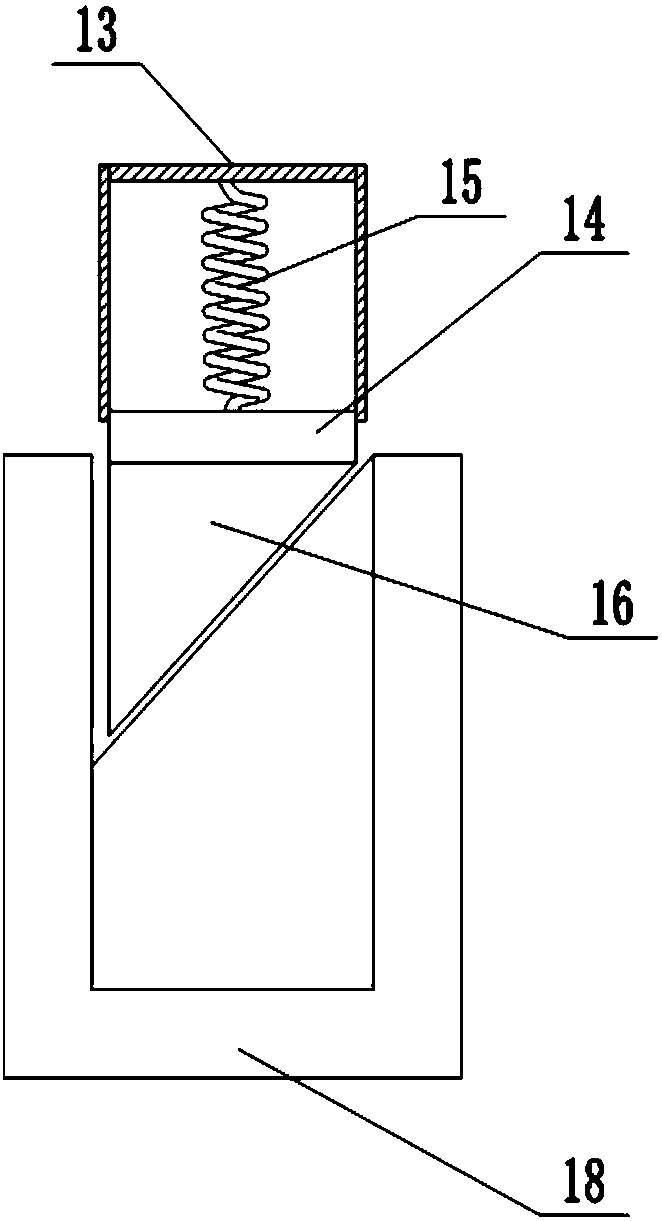

[0019] The reference signs in the accompanying drawings of the specification include: the reel body 1, the drive shaft 101, the first strip-shaped opening 102, the first drum 2, the second strip-shaped opening 201, the second drum 3, and the third strip-shaped opening 301. First end cap 4, second end cap 5, arc plate 6, torsion spring 7, handle 8, clamping plate 9, fixed block 10, first spring 11, sliding rod 12, sleeve 13, connecting rod 14. The second spring 15, the wedge block 16, the cloth 17, and the first strip groove 18.

[0020] The embodiment is basically as attached Figure 1 to Figure 3Shown: a reel device, including a cylindrical reel body 1, the interior of the reel body 1 is a hollow structure, the left end of the reel body 1 is connected to a drive shaft 101, the drive shaft 101 is connected to a drive motor, and the reel body 1 The right end is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com