Machine part drilling device

A technology for drilling equipment and mechanical accessories, which is applied in the direction of drilling/drilling equipment, metal processing machinery parts, boring/drilling, etc., which can solve the problem that waste chips are not easy to remove, and achieve guaranteed results. The operation process is simple and The effect of preventing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

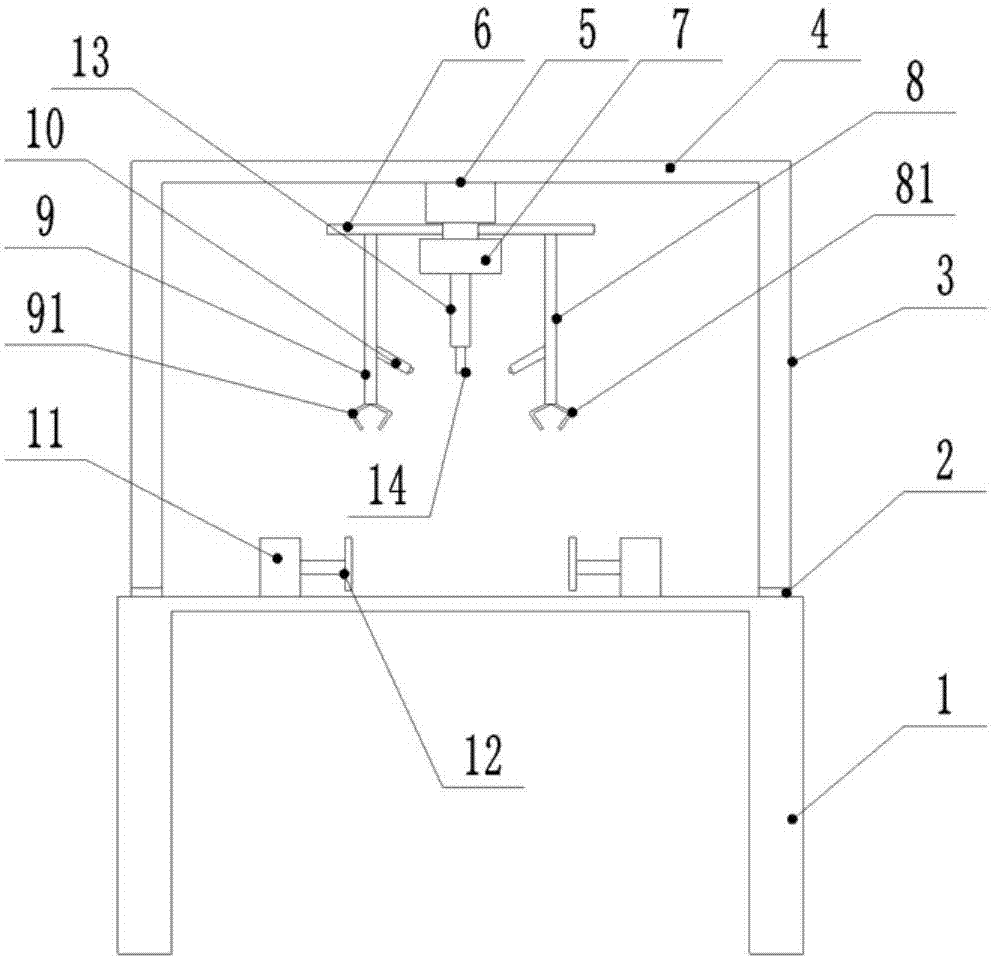

[0022] Such as figure 1 As shown, the drilling equipment for mechanical accessories includes a frame 1, a guide rail 2 is installed on the upper surface of the frame 1, a support frame 3 with rollers is installed on the guide rail 2, a beam 4 is installed on the upper end of the support frame 3, and a beam 4 is installed on the beam 4. The telescopic device 5 with the telescopic shaft facing downward is preferably a hydraulic cylinder in the present embodiment; the telescopic end of the hydraulic cylinder is equipped with a motor 7 with the output end facing downward, and the output end of the motor 7 is connected with a drill bit 14, and one of the telescopic shafts of the cylinder 11 The side is equipped with a cross bar 6, and the left and right ends of the cross bar 6 are equipped with a first support rod 8 and a second support rod 9 symmetrical to the motor 7, and the first support rod 8, the second support rod 9 and the cross bar 6 Rollers are installed between them, whi...

Embodiment 2

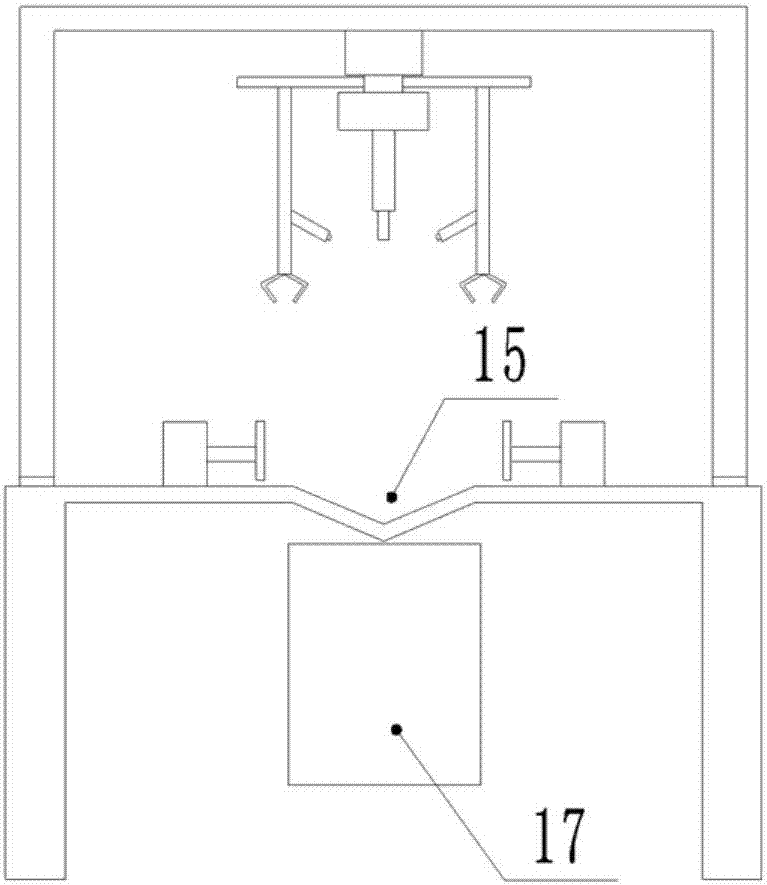

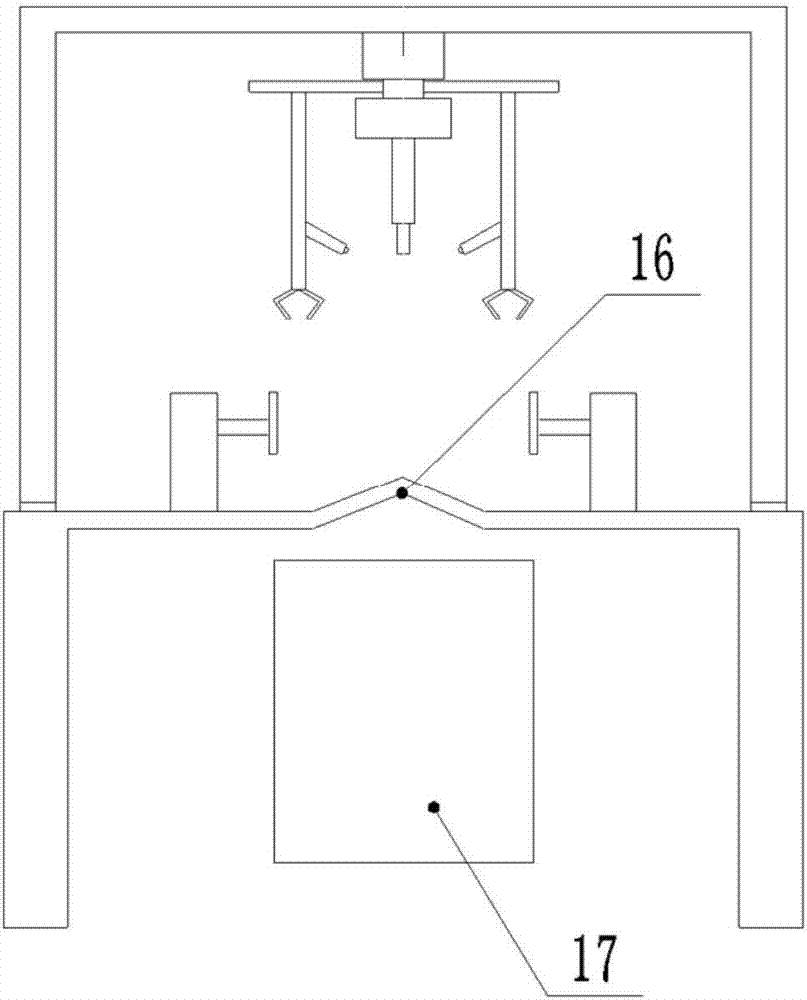

[0025] Such as figure 2 As shown, on the basis of Embodiment 1, a downwardly recessed "V"-shaped water guide groove 15 is processed in the middle part of the frame 1, and a water collection box 17 is installed below the water guide groove 15 of the frame 1. The water collection box 17 A filter screen is installed at the upper port, and the filter screen can filter out the waste debris generated during drilling; image 3 As shown, an upward inverted "V"-shaped protrusion 16 can also be set in the middle of the frame 1, and when the debris falls on the slope, the debris can be easily washed into the filter screen by water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com