Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Guaranteed drilling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

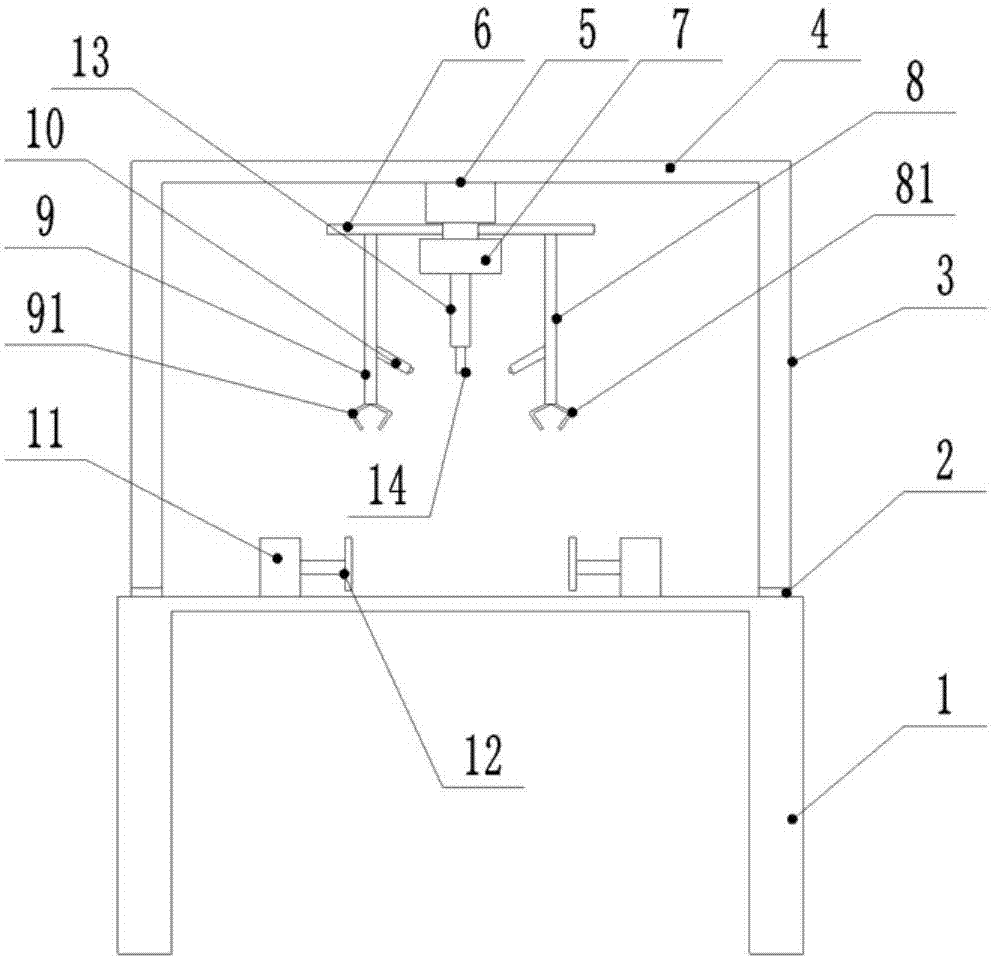

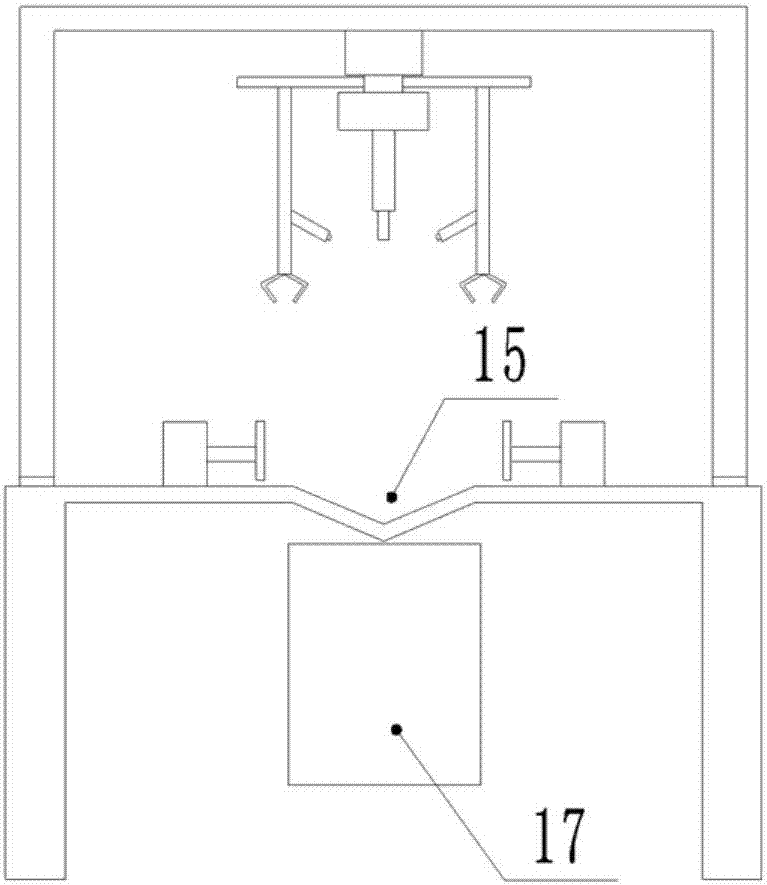

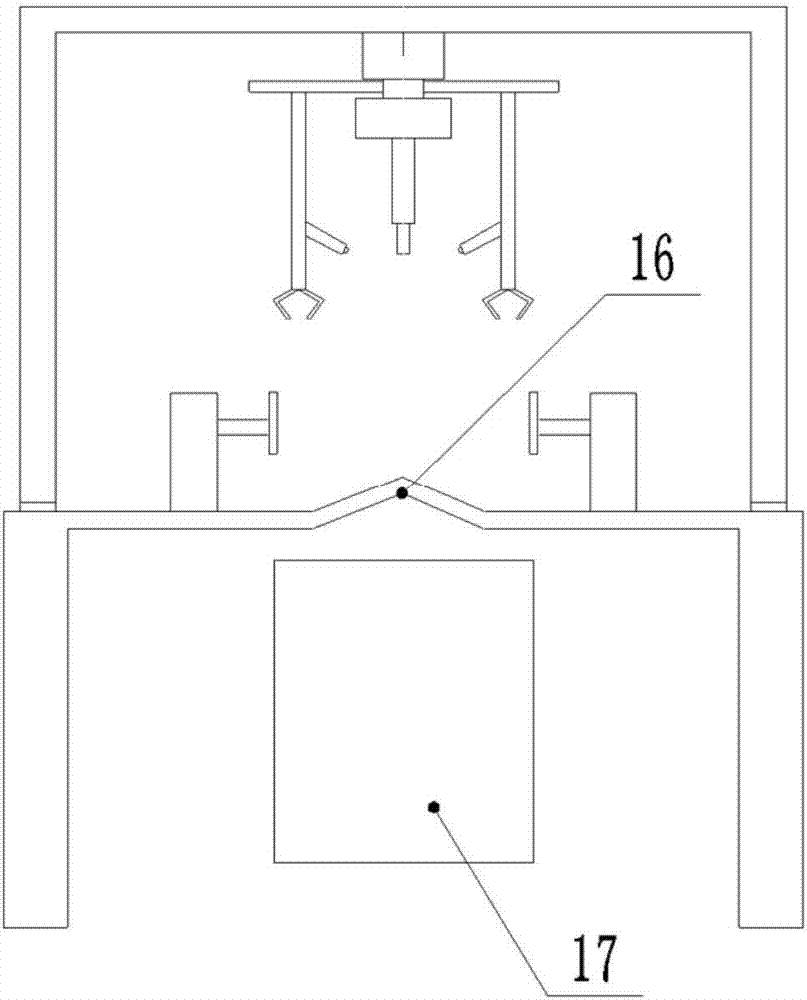

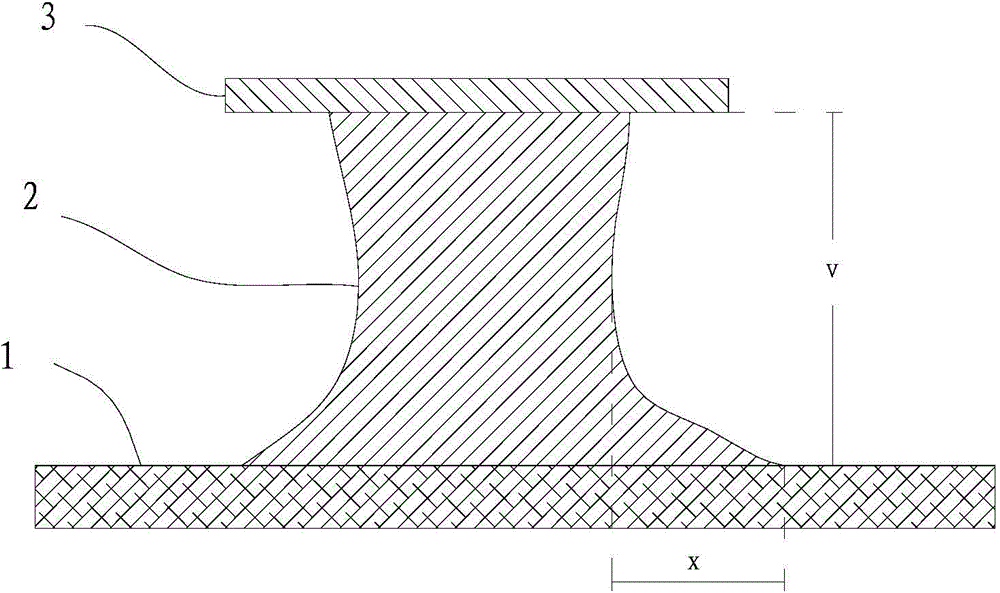

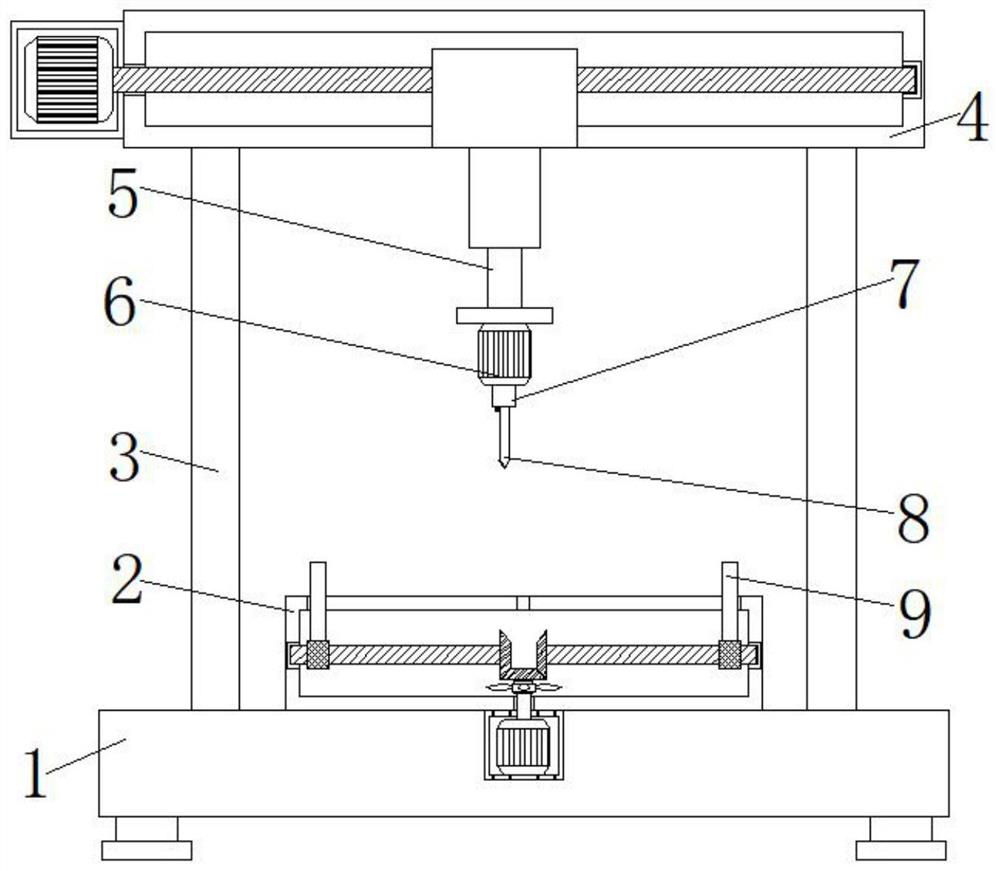

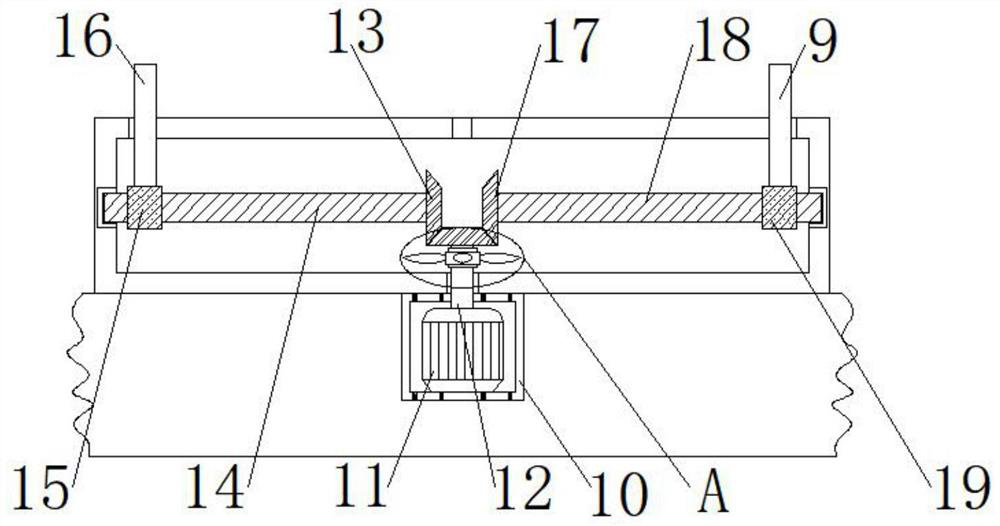

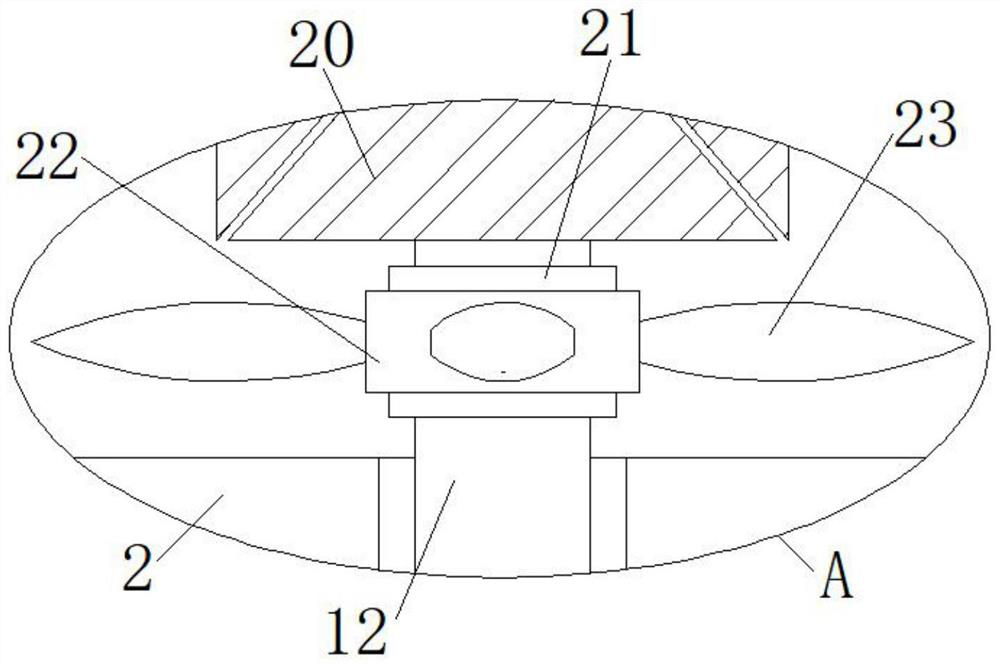

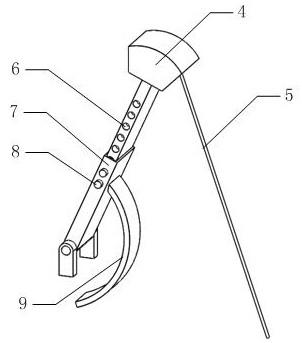

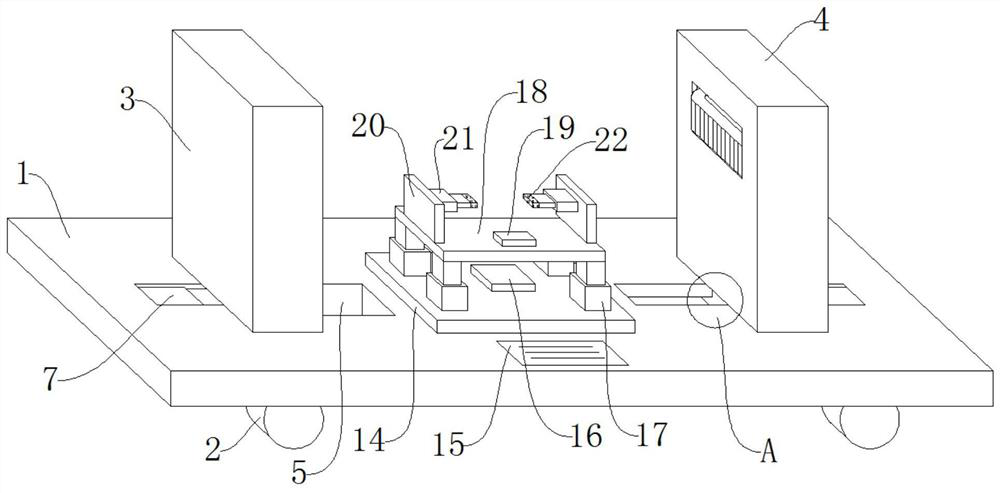

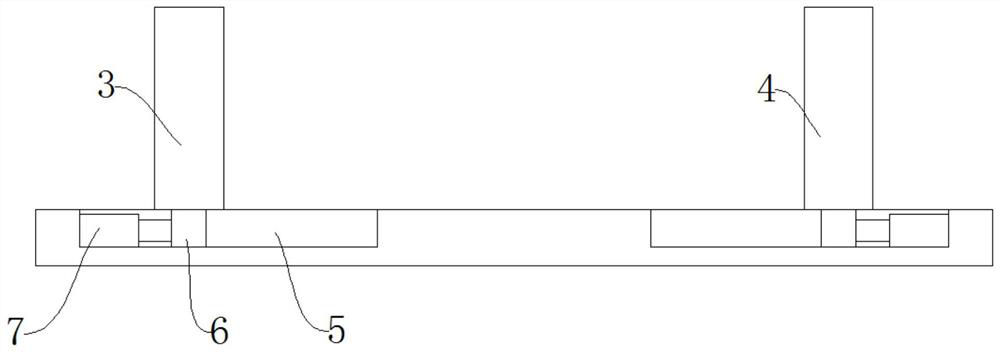

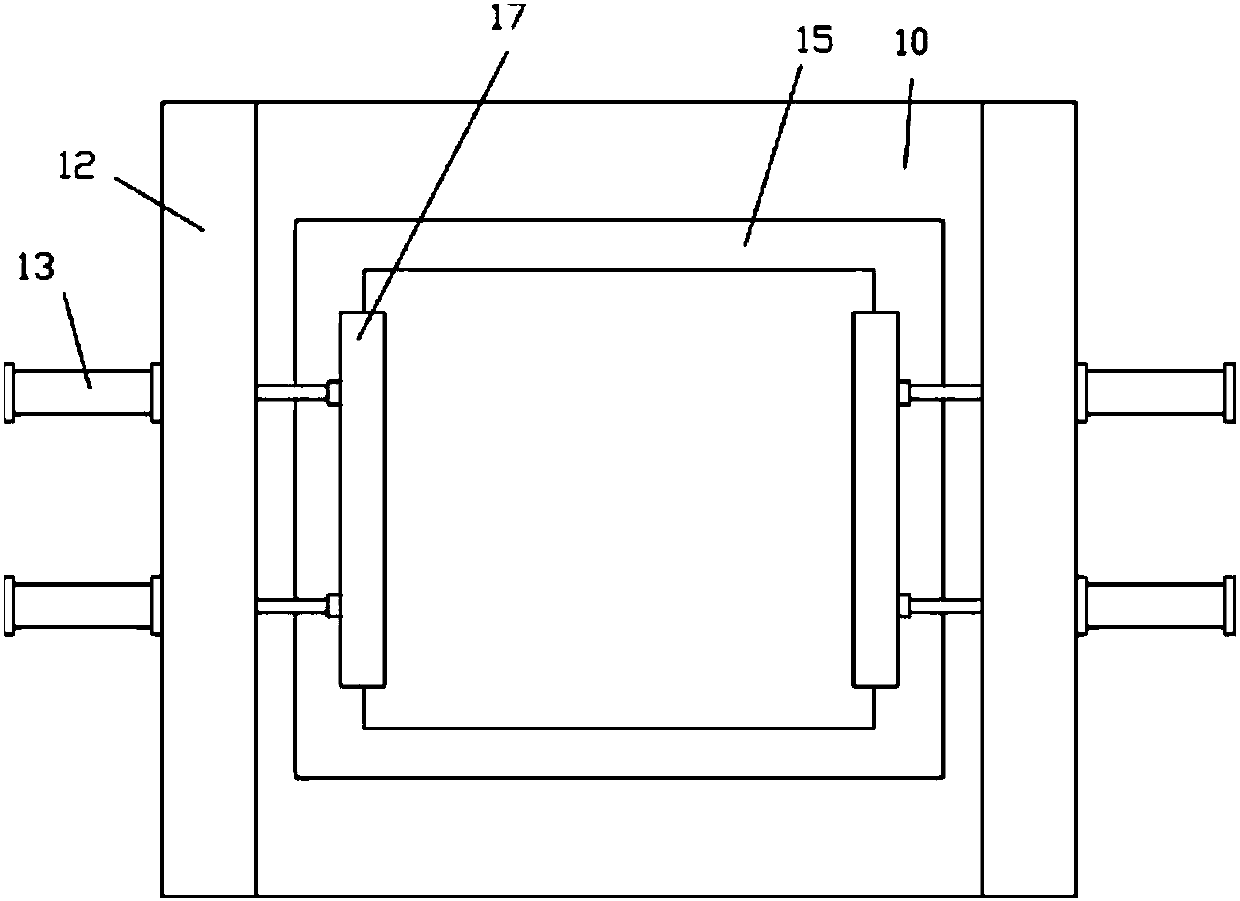

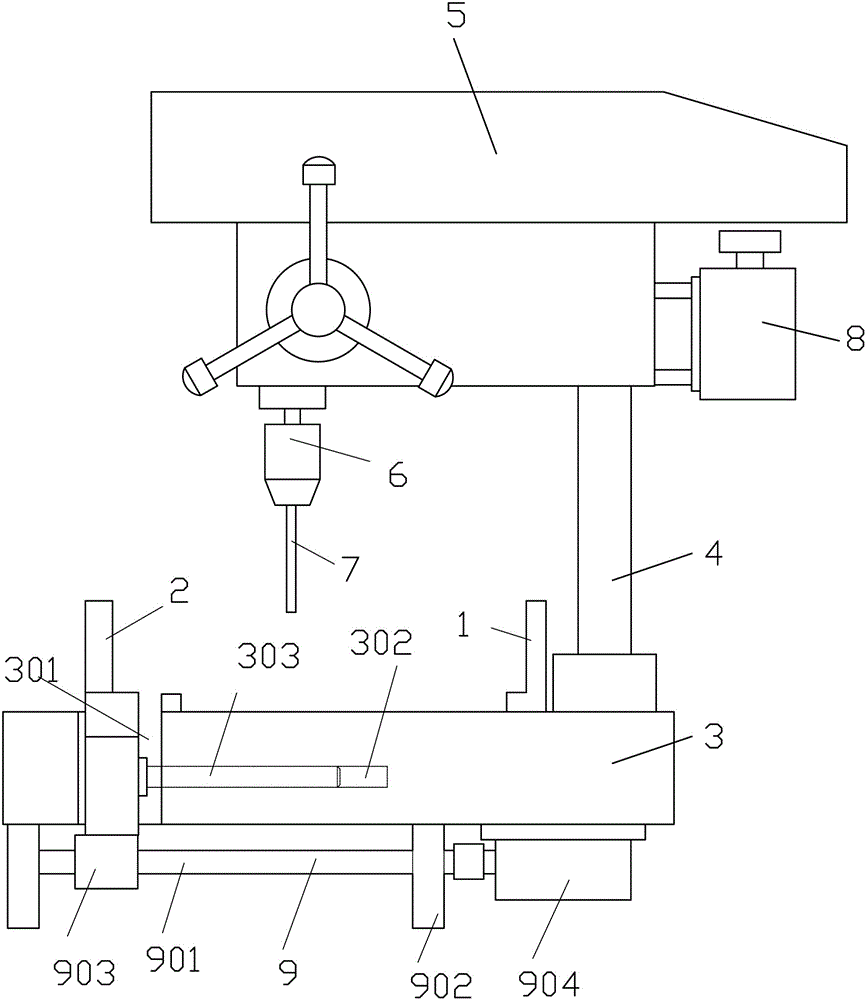

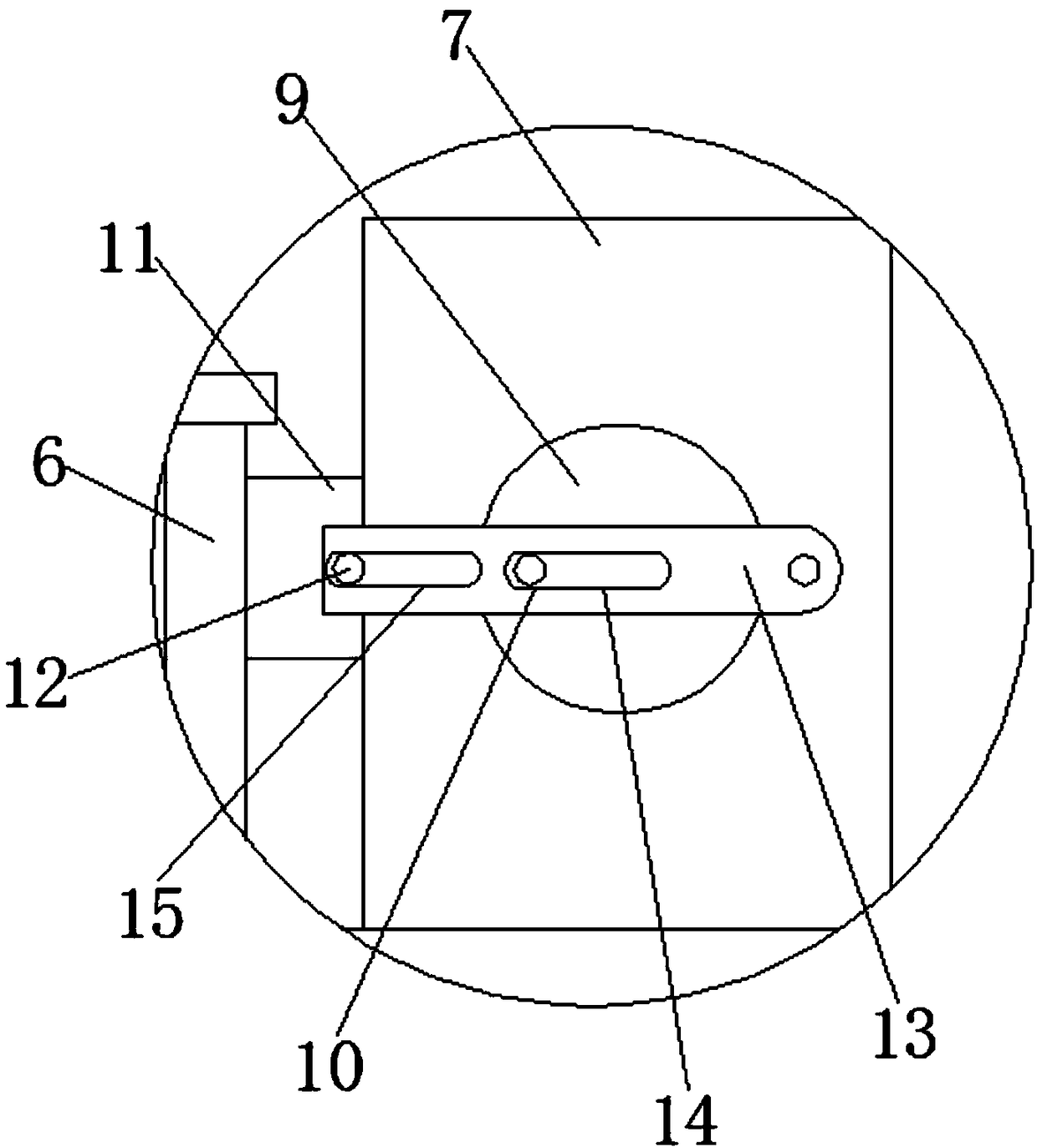

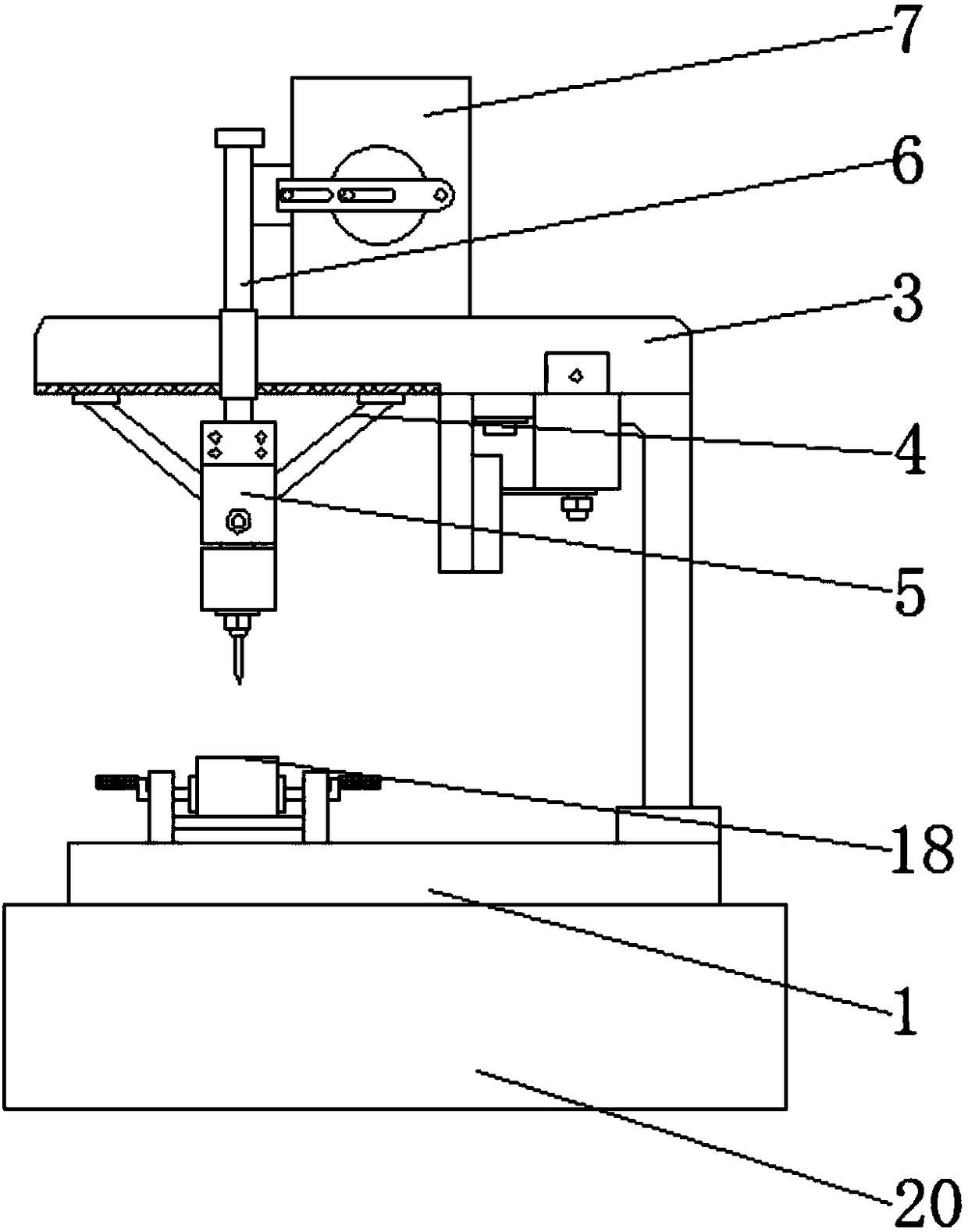

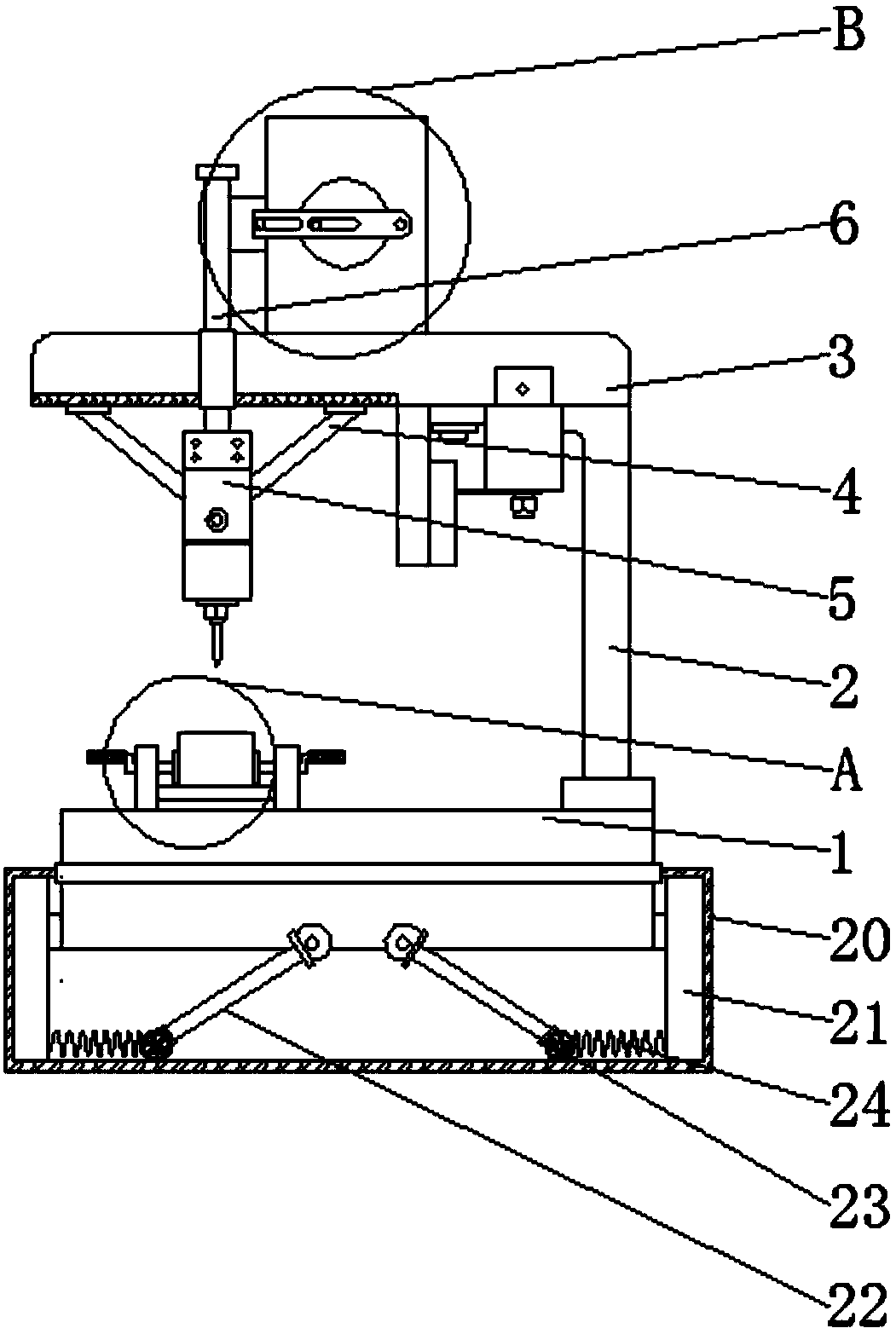

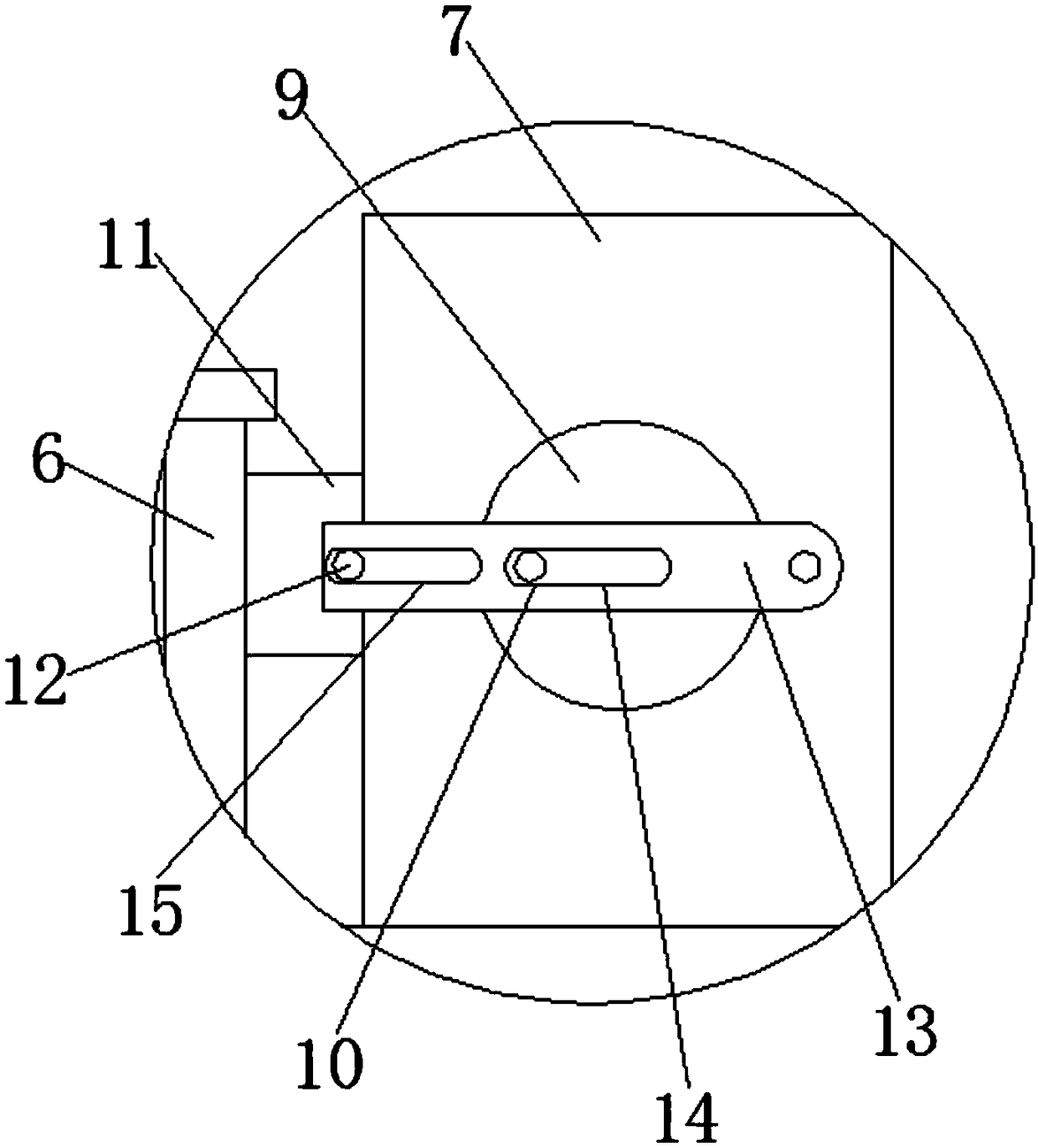

Machine part drilling device

InactiveCN107999805AEasy to clamp and fixEasy to rinseWork clamping meansMetal working apparatusMachine partsBiochemical engineering

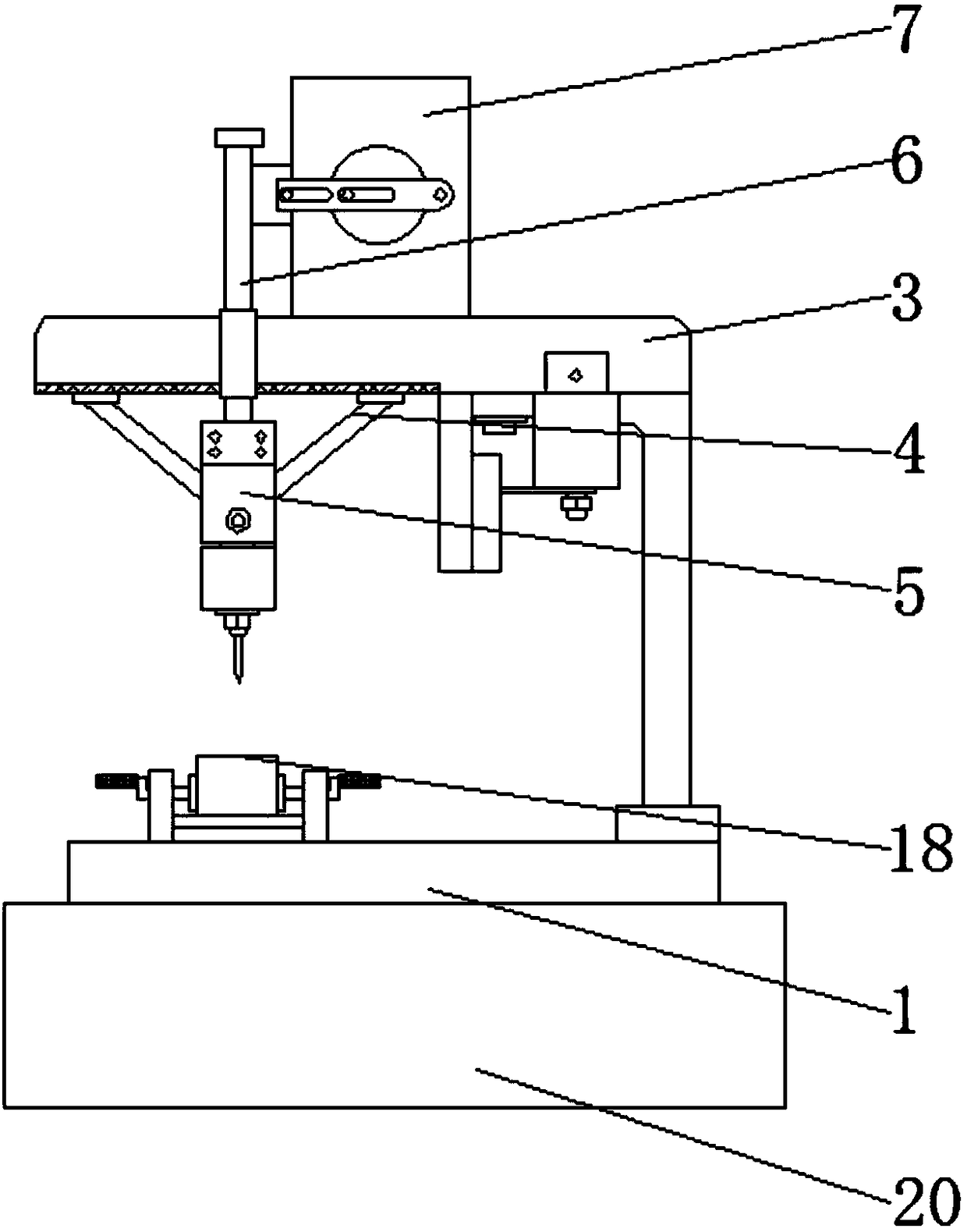

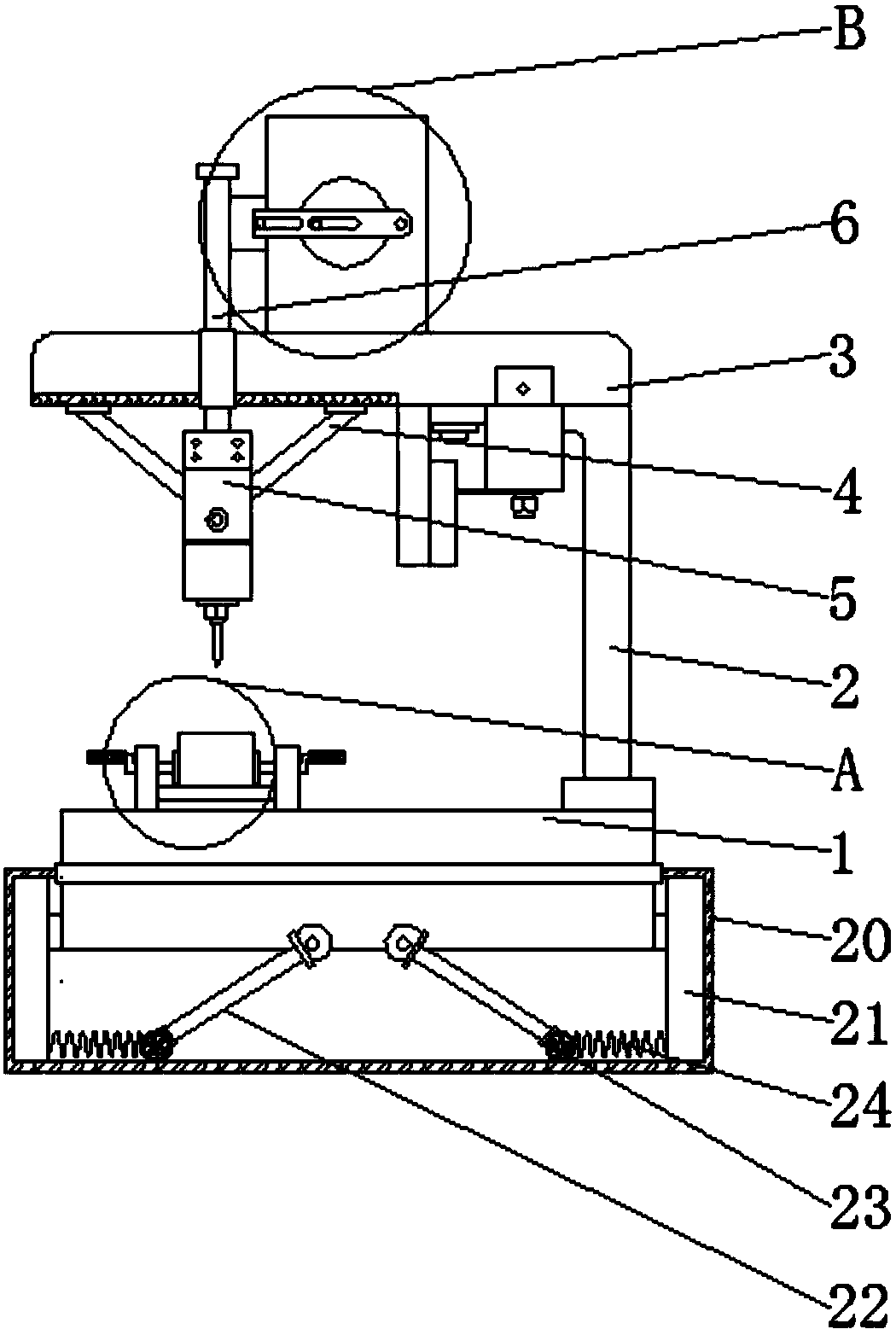

The invention belongs to the technical field of drilling equipment, and particularly discloses a machine part drilling device. The device comprises a rack, a guide rail is arranged on the rack, a supporting frame is arranged on the guide rail in a sliding connection manner, a cross beam connected with a telescopic device is arranged on the supporting frame, a motor is arranged on the telescopic device, a drill bit is arranged at the output end of the motor, and the device is characterized in that a transverse rod is arranged on the telescopic device, a first supporting rod and a second supporting rod are arranged on the transverse rod, and are hinged with a first clamp and a second clamp correspondingly, two opposite air cylinders are arranged in the middle of the rack, a clamping plate isarranged on piston rods of the air cylinders, and a first spraying head and a second spraying head connected with a water pipe are arranged in the middle of the first supporting rod and the middle ofthe second supporting rod. The device is mainly used for machine part drilling, and the problem that after drilling, sweeps easily remain in holes is solved.

Owner:宁波德深机械设备有限公司

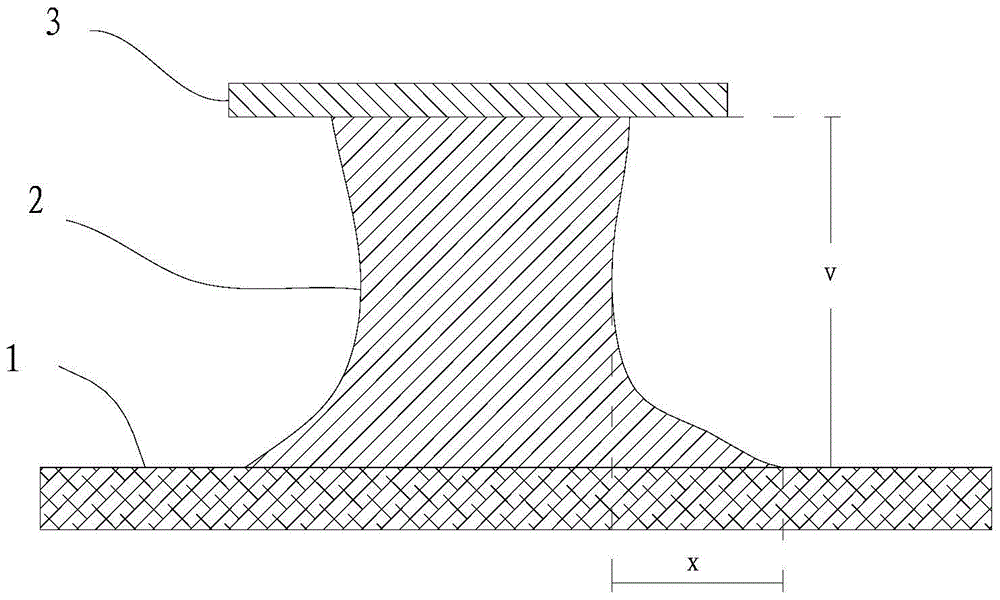

Inner and outer layer copper thickness-differentiated thick copper circuit board and preparation method thereof

ActiveCN104486914AEvenly filledUniform pressure distributionConductive material chemical/electrolytical removalMultilayer circuit manufactureProcess engineeringMechanical engineering

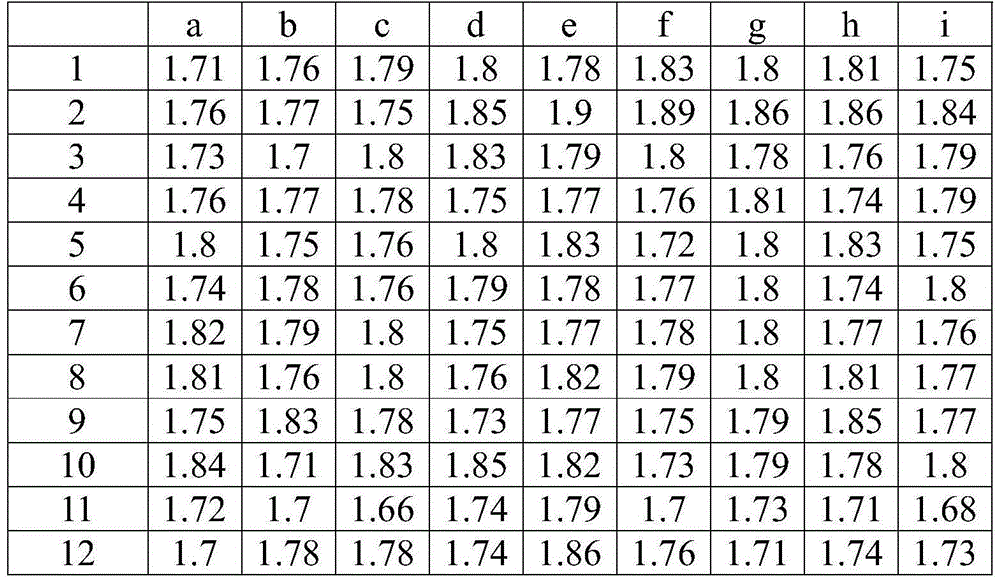

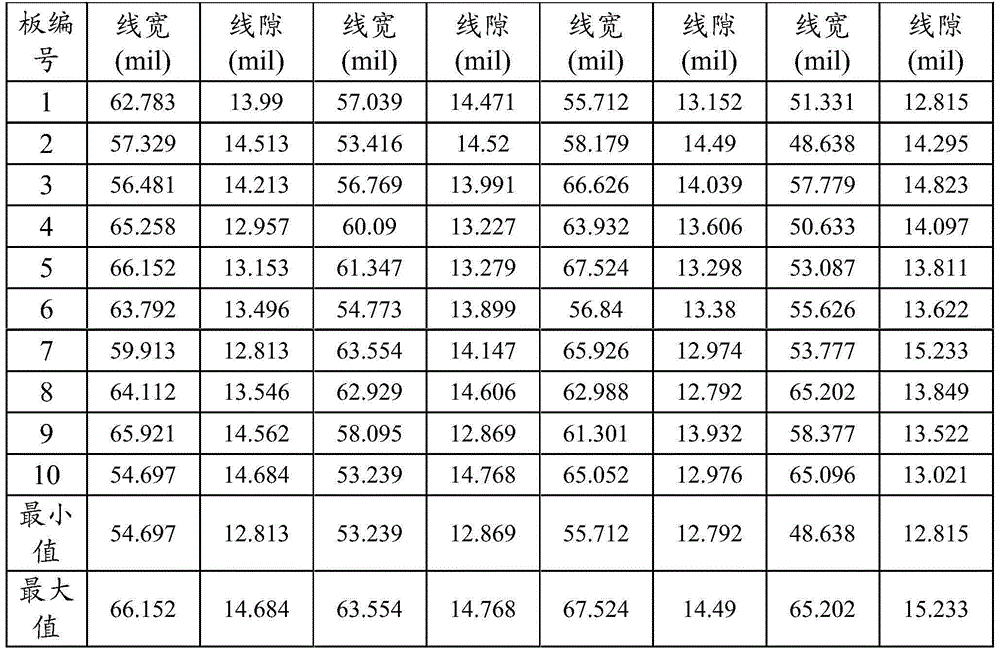

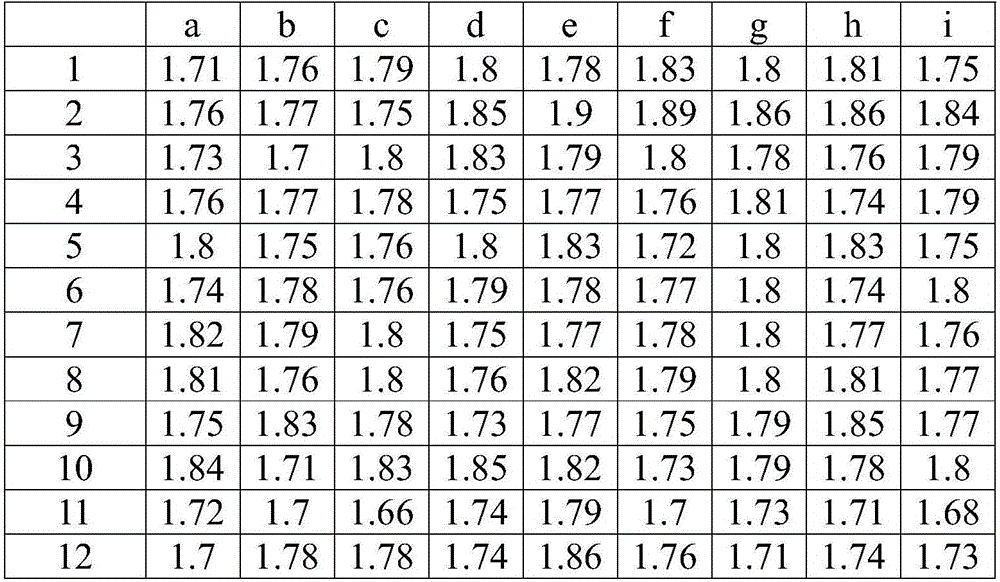

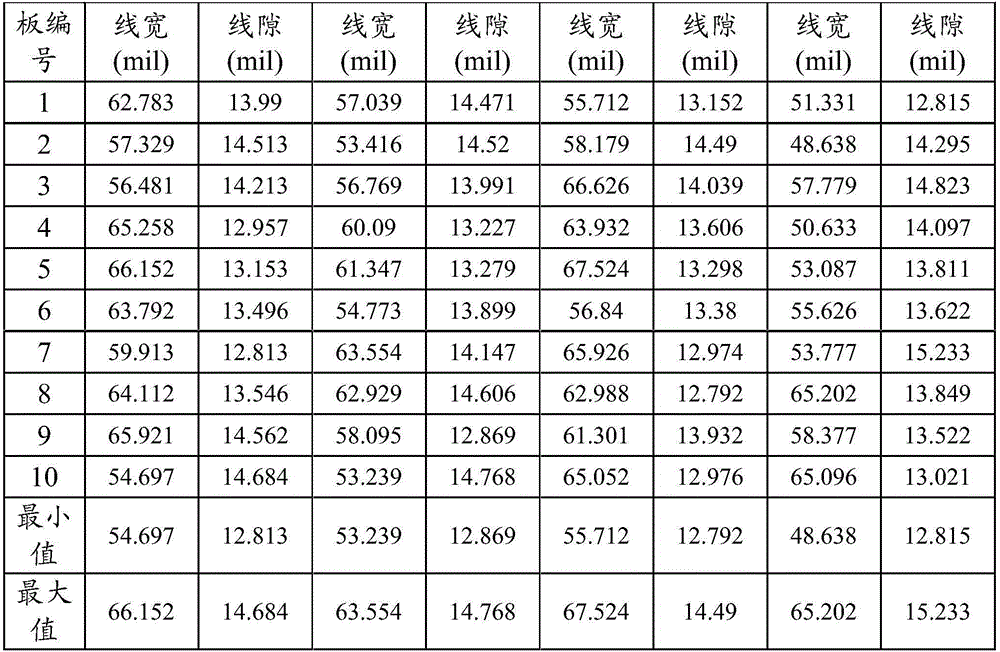

The invention discloses an inner and outer layer copper thickness-differentiated thick copper circuit board and a preparation method thereof and belongs to the PCB technical field. The method includes the steps of board pressing process, drilling process and etching process. According to the board pressing process, a prepreg of which the resin content is equal to or larger than 65% is selected; hot pressing process and cold pressing process are sequentially adopted to perform board pressing; the parameter conditions of the hot pressing process are as follows: pressure ranges from 250 to 450 PSI, temperature ranges from 175 to 220 DEG C, vacuum degree ranges from 0 to 68 cm Hg, and time ranges from 90 to 150 min; and the parameter conditions of the cold pressing process are as follows: pressure ranges from 50 to 450 PSI, temperature ranges from 165 to 220 DEG C, and time ranges from 130 to 230 min. According to the preparation method, a laminated structure and a board lamination mode are adopted, and temperature rising and pressurization control are utilized in cooperation, and therefore, the filling of flowing resin can be uniform, and pressure distribution is uniform when board pressing is performed, and an excellent filling effect can be realized, and air bubble generation can be avoided, and press fit can be excellently realized.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

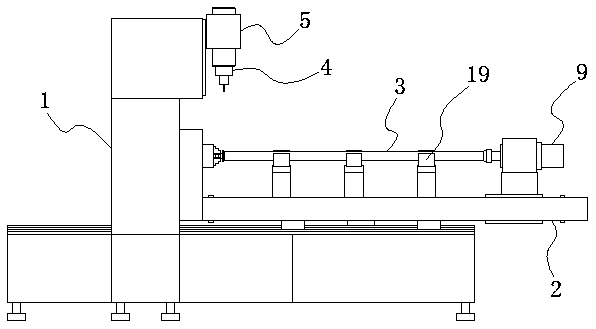

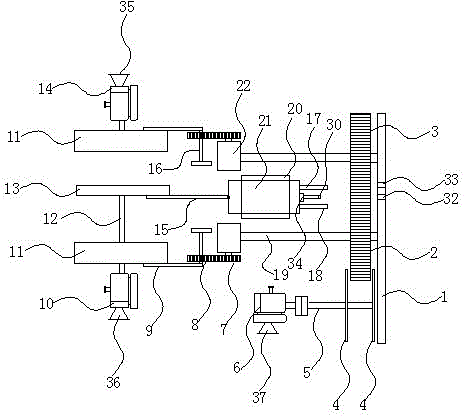

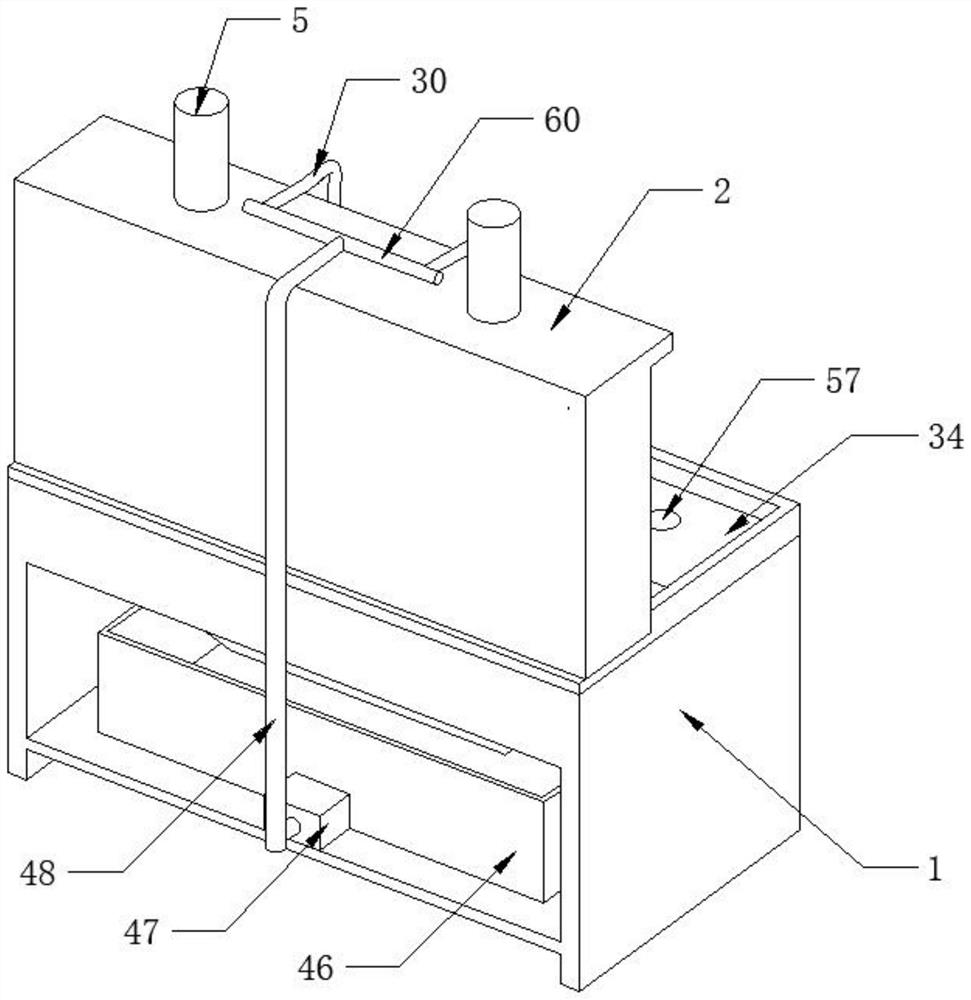

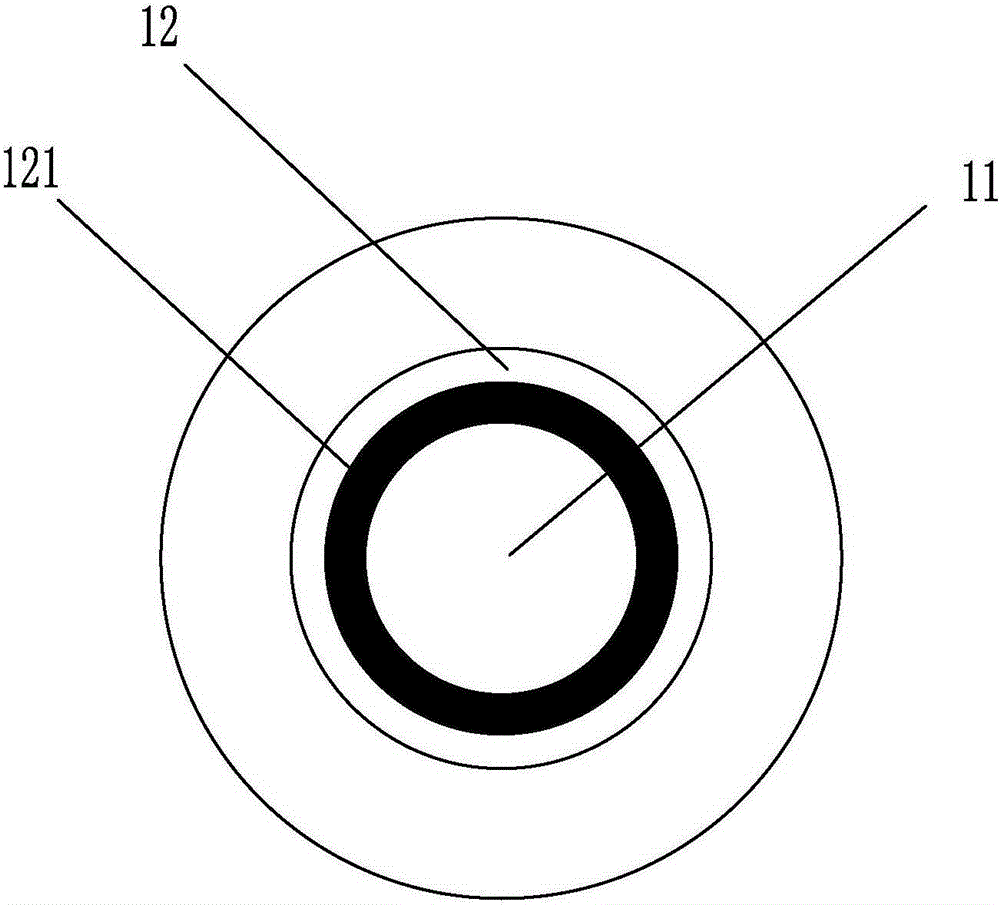

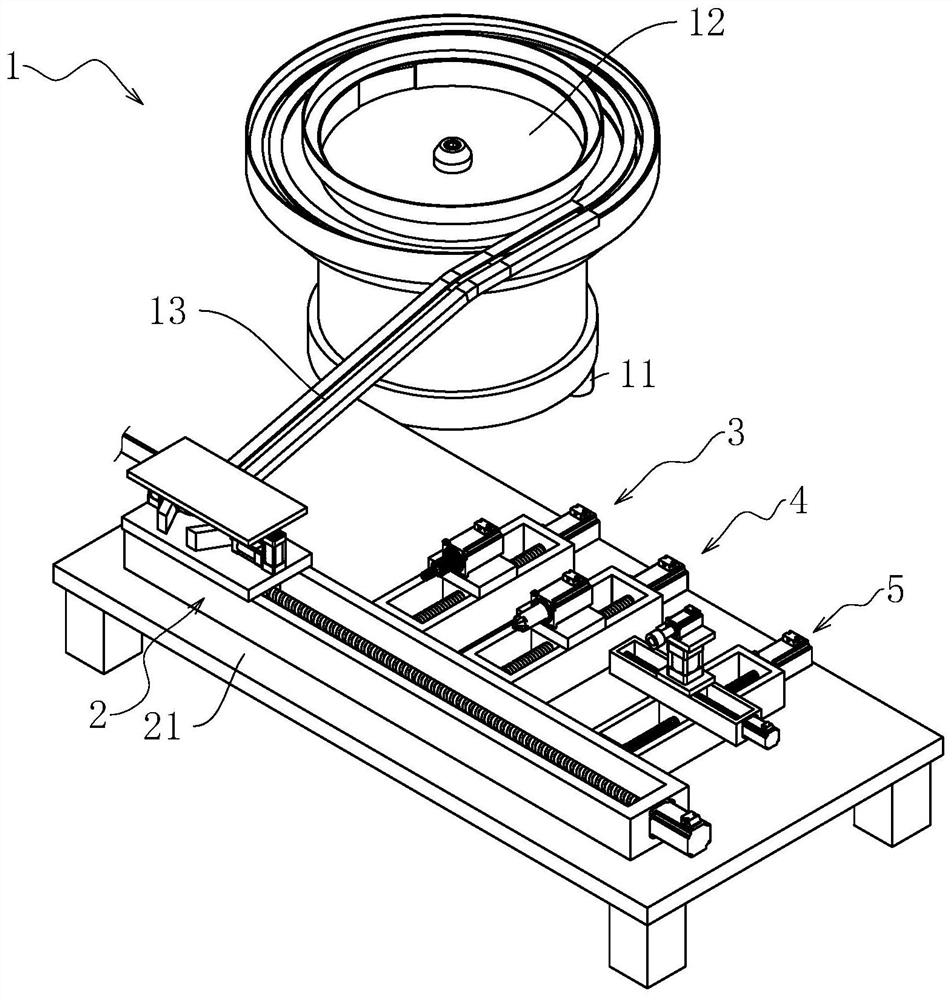

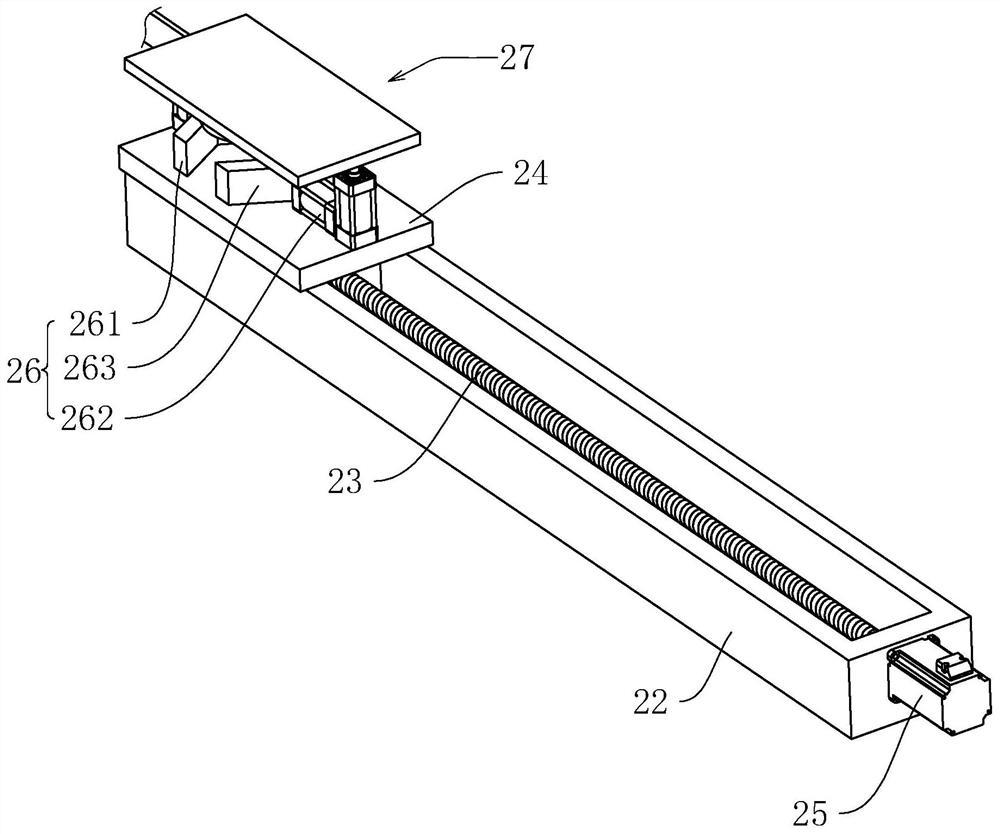

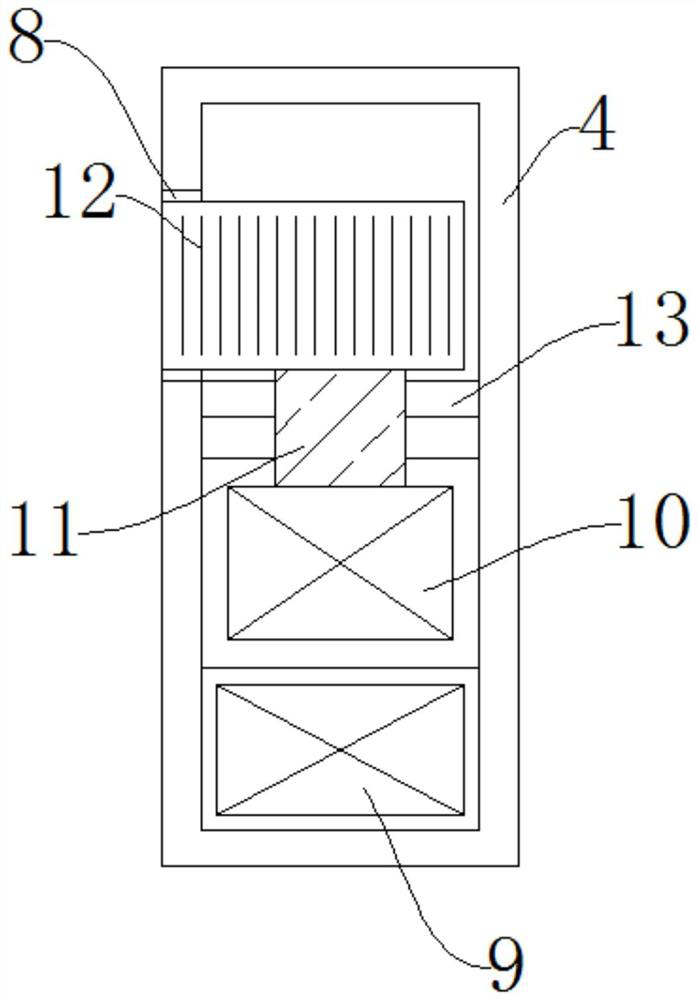

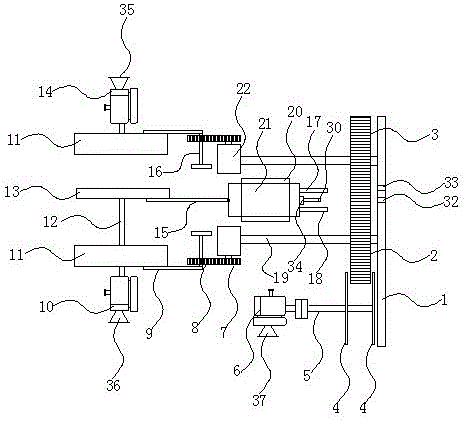

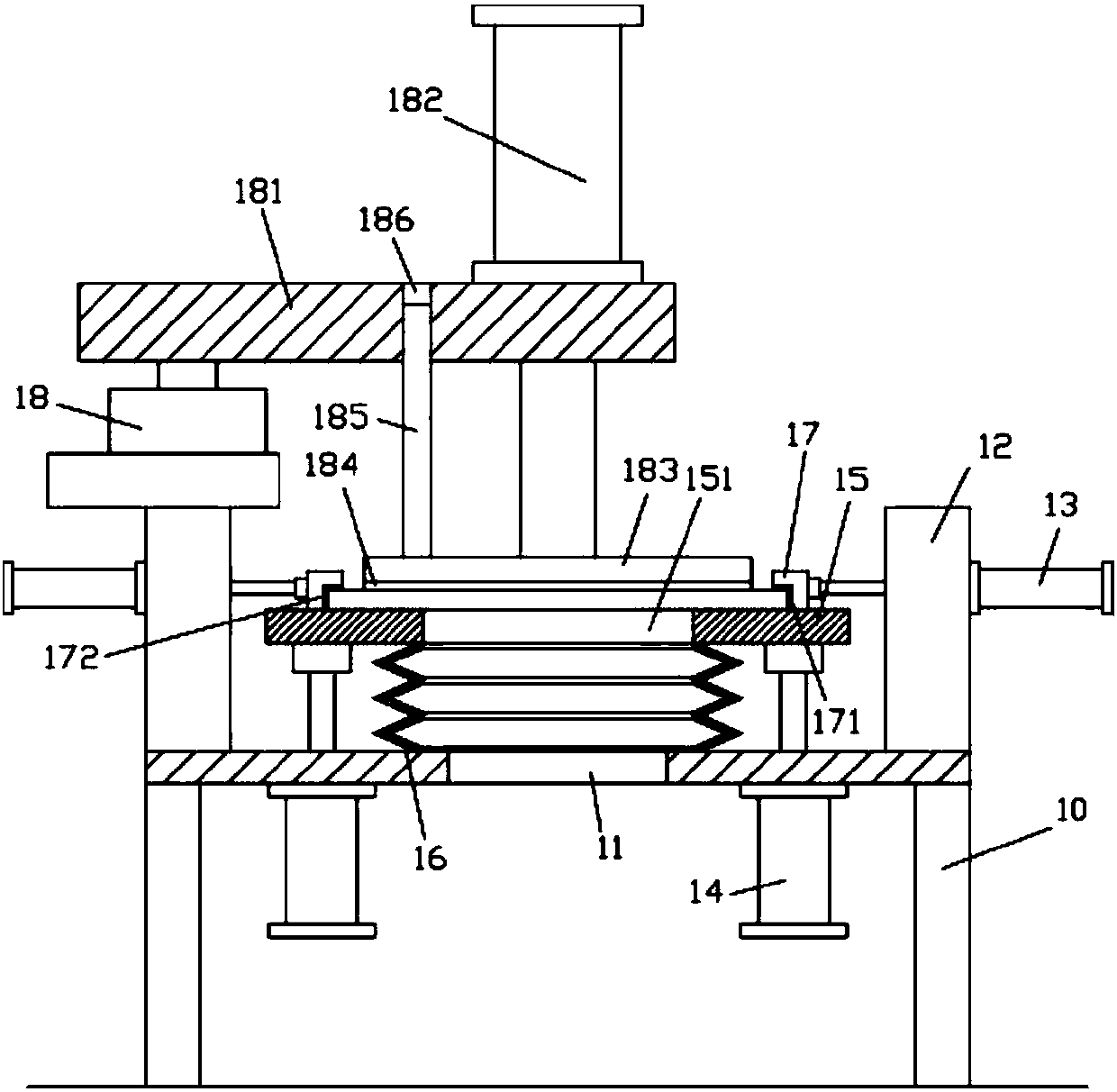

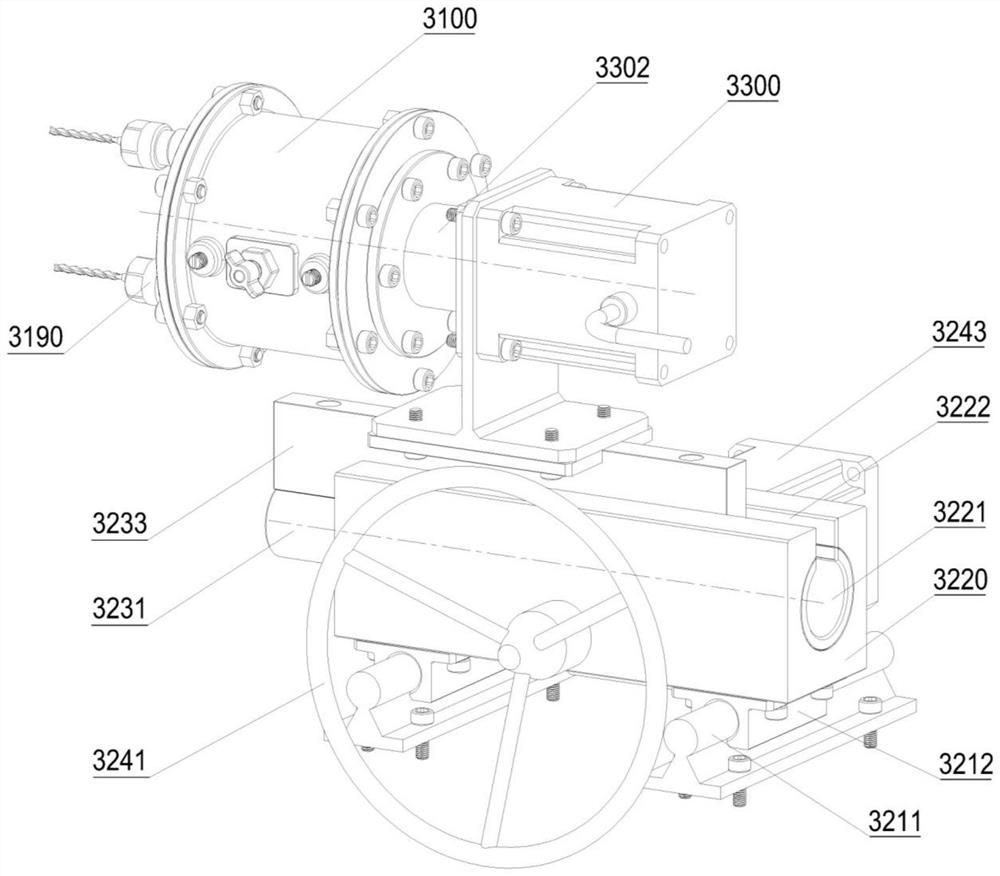

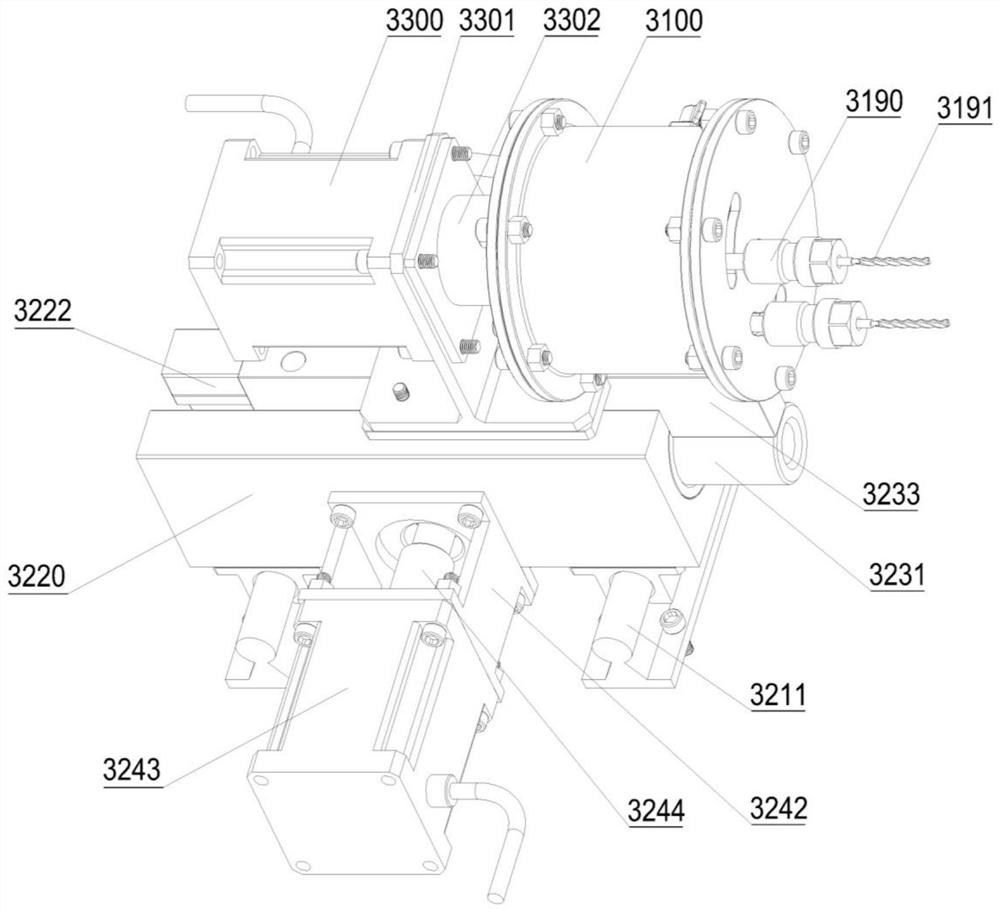

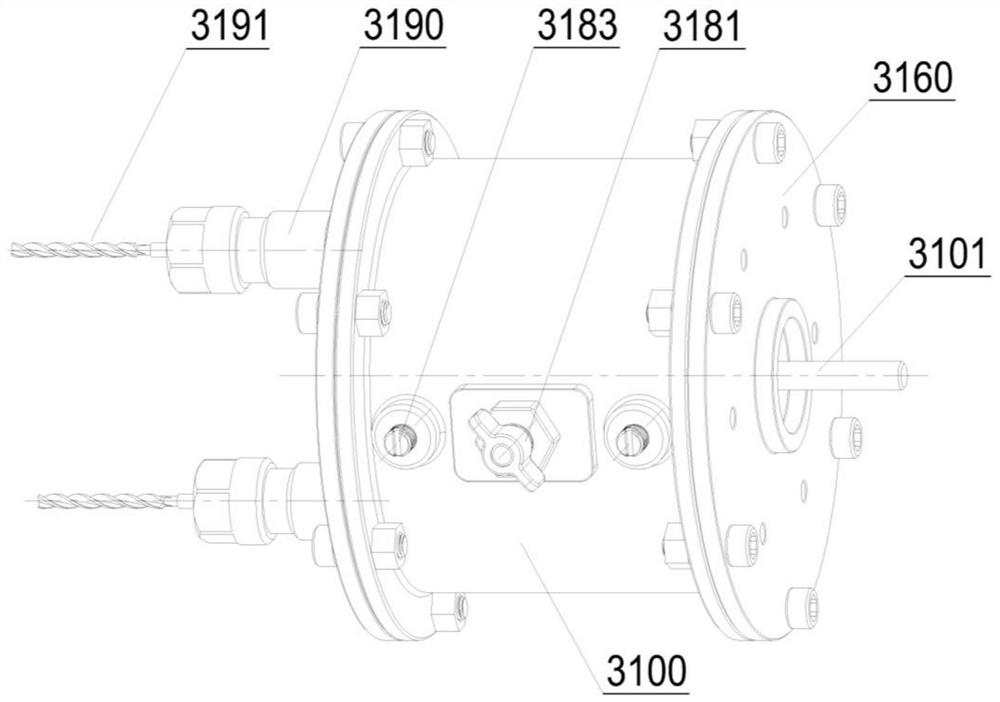

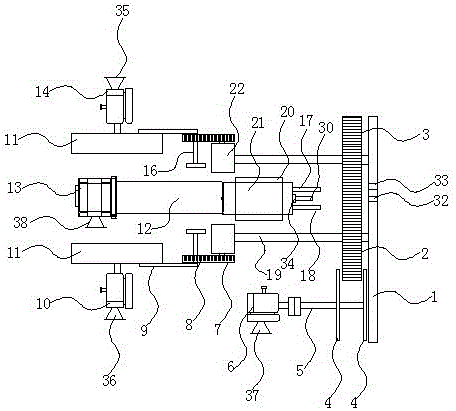

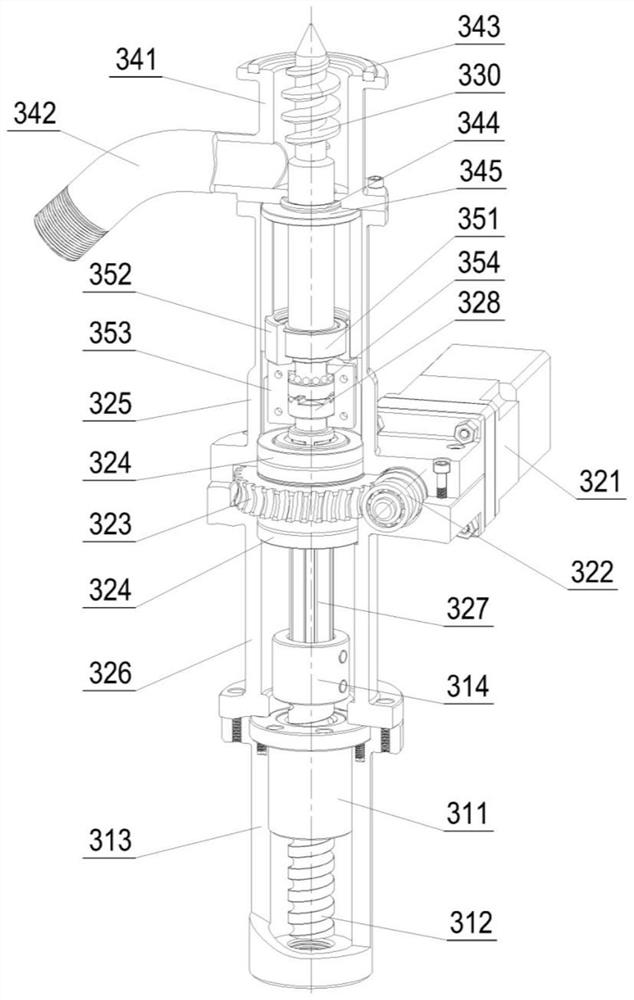

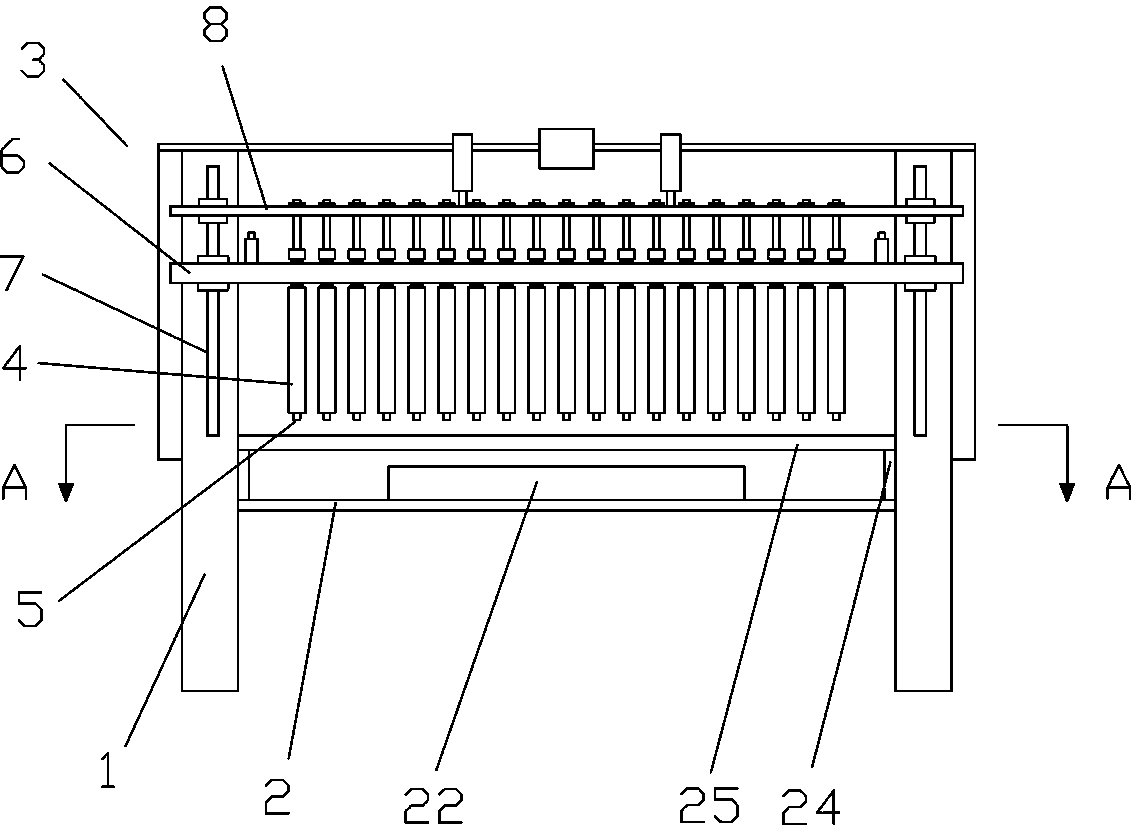

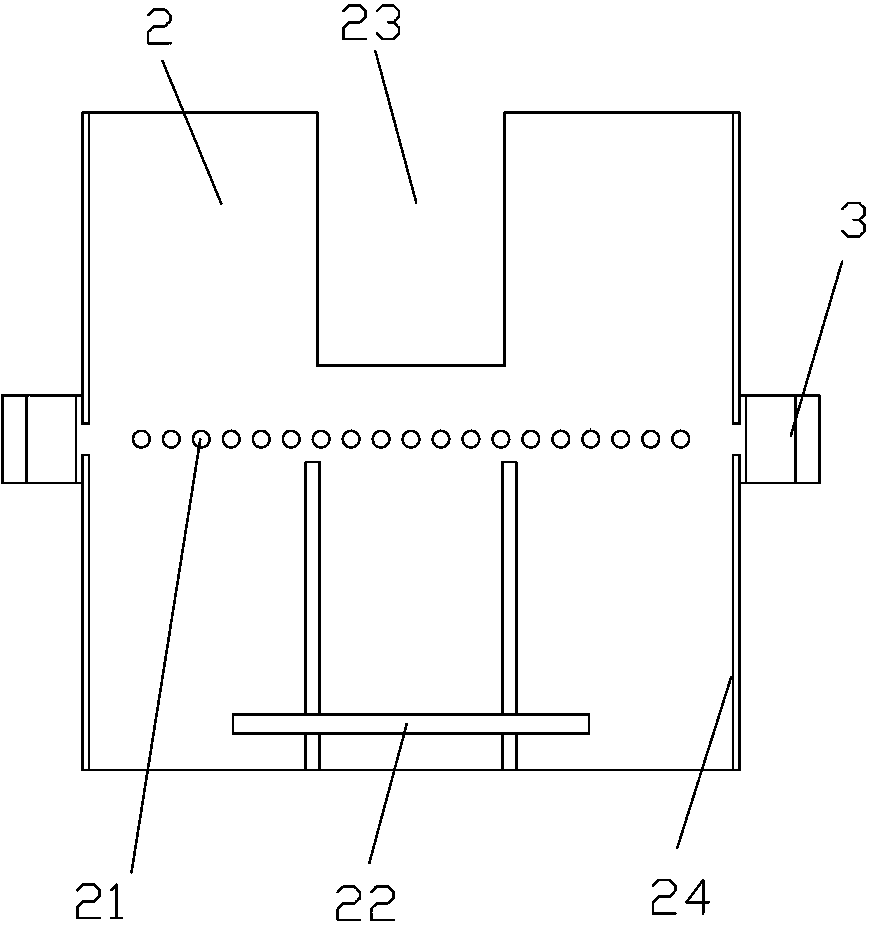

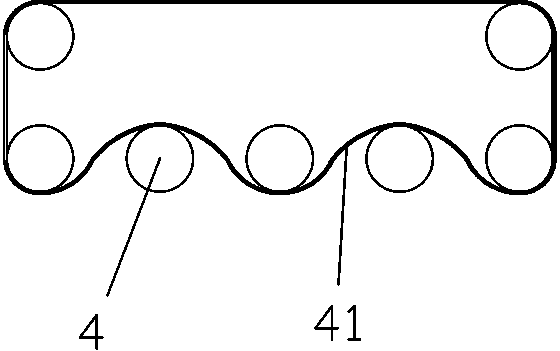

Intelligent pipe drilling control system and method

InactiveCN110000854AEnsure stabilityGuaranteed drilling effectMetal working apparatusElectricityControl system

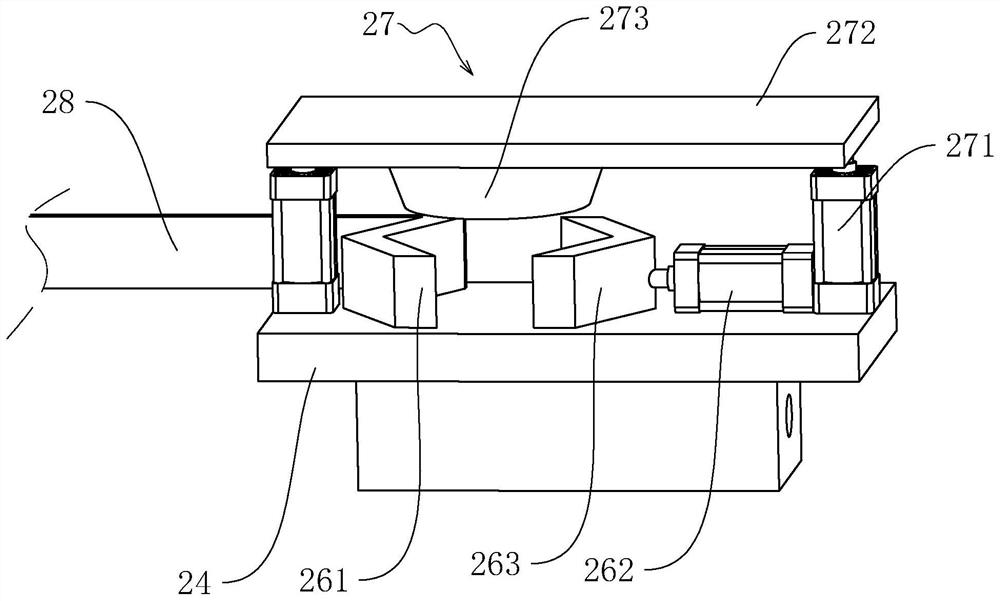

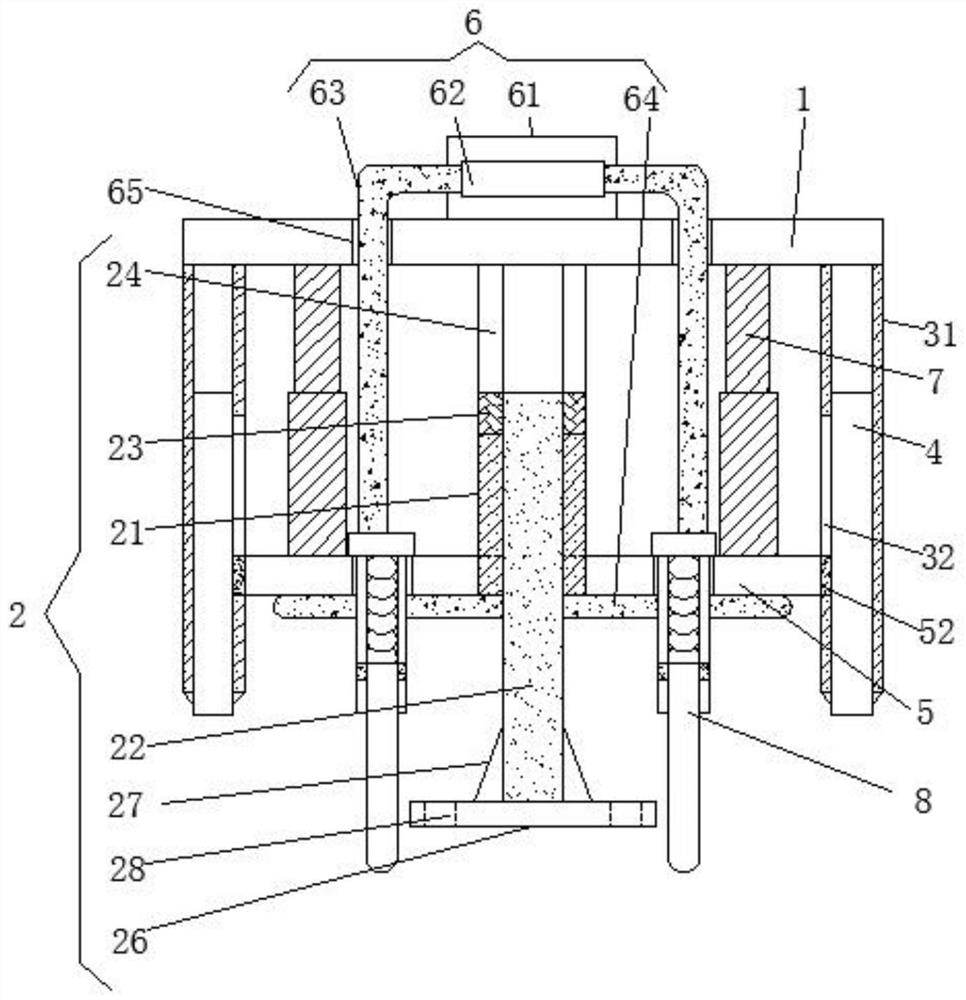

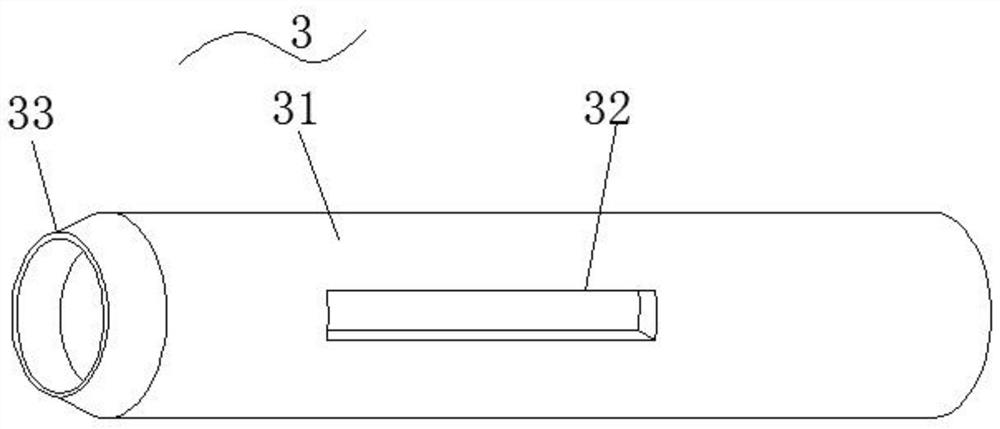

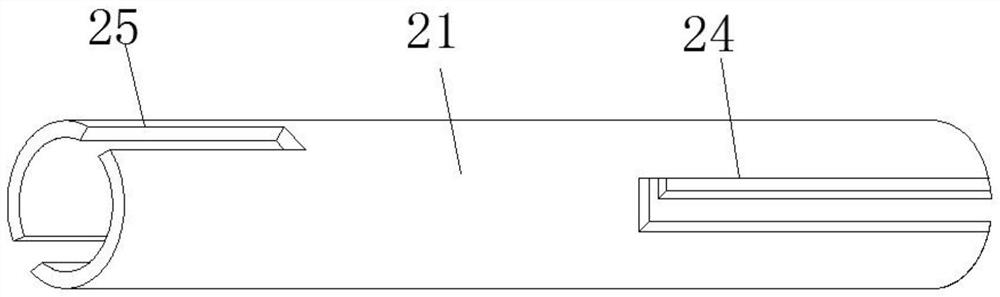

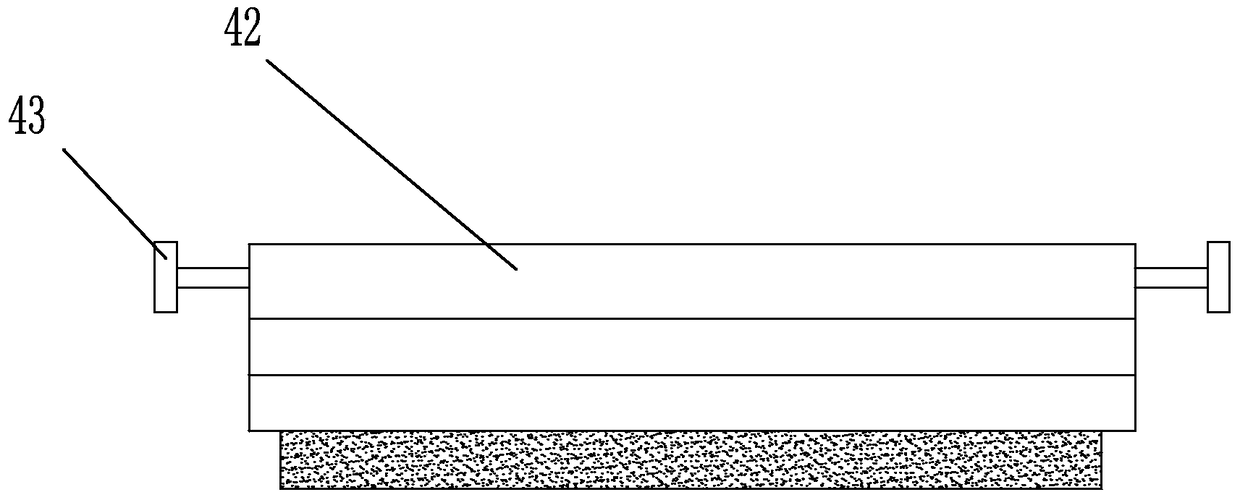

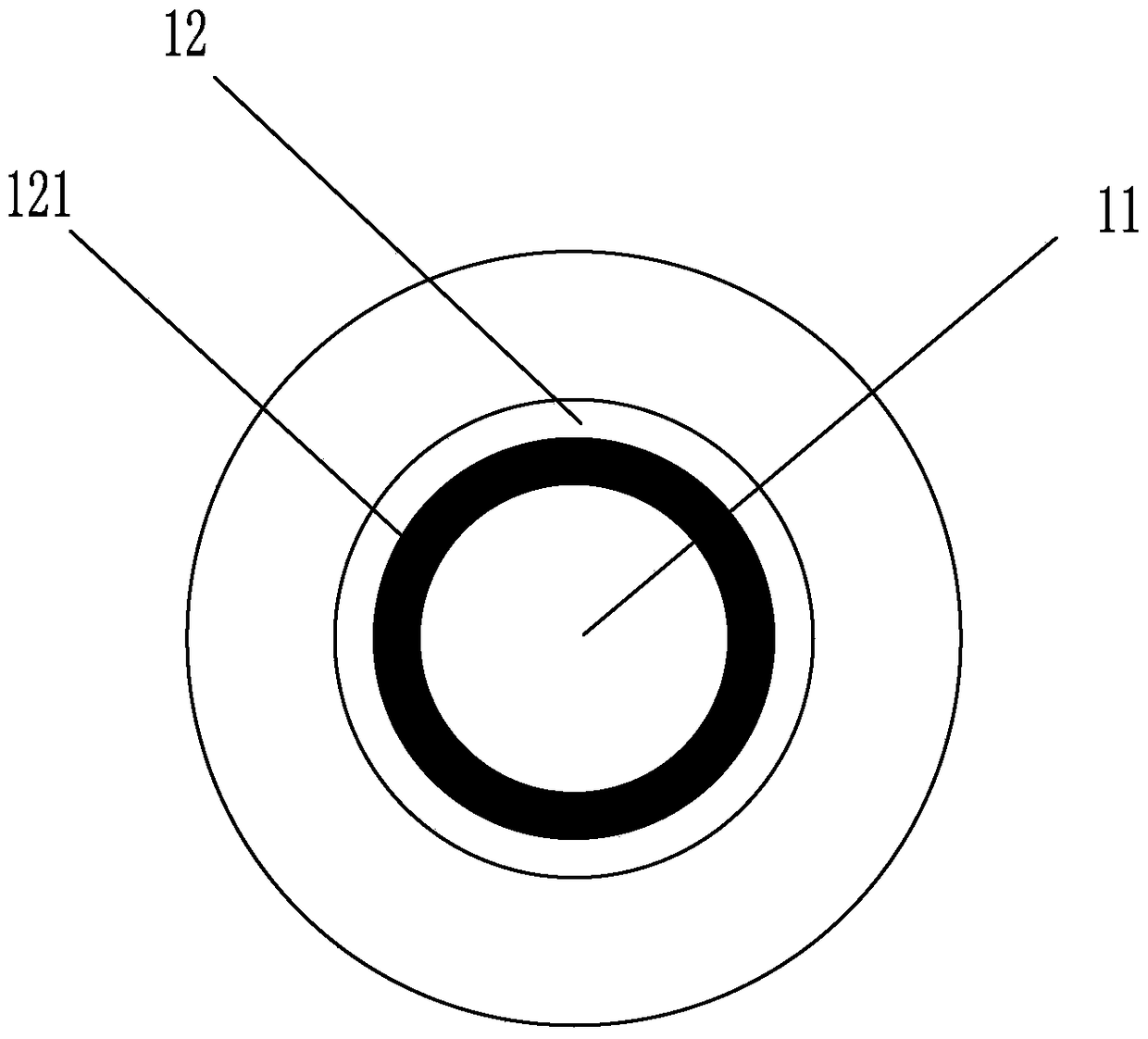

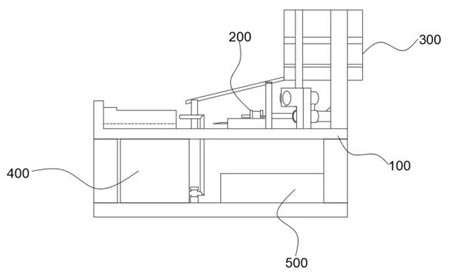

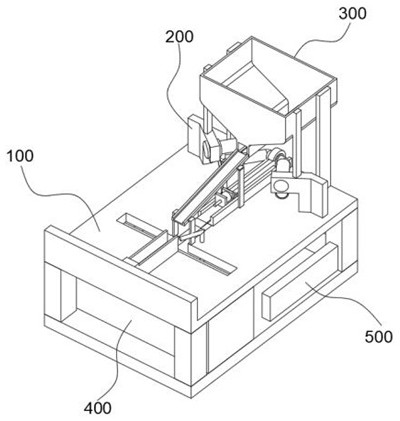

The invention discloses an intelligent pipe drilling control system and method. The intelligent pipe drilling control system comprises a PLC control system and an axial clamping electromagnetic valve,a horizontal movement driving device and an electromagnetic switch which are electrically connected to the PLC control system; the axial clamping electromagnetic valve is connected to a high-molecular pipe clamping device, and is used for controlling the high-molecular pipe clamping device to axially clamp a plurality of high-molecular pipes along the axial direction of the high-molecular pipe; the horizontal movement driving device is arranged between a rack main body and the high-molecular pipe clamping device, and the horizontal movement driving device can drive the rack main body and thehigh-molecular pipe clamping device to move relative to each other; and a plurality of main shaft power drilling bits are arranged on the rack main body, the electromagnetic switch is connected to theplurality of main shaft power drill bits and is used for simultaneously controlling opening or stopping of the multiple main shaft power drill bits. The system and the method can be suitable for batch drilling processing of high-molecular pipes, the production efficiency can be improved, and the production requirements of high-speed development are met.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

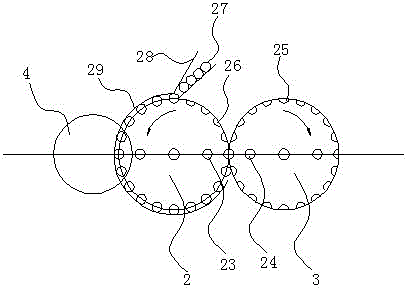

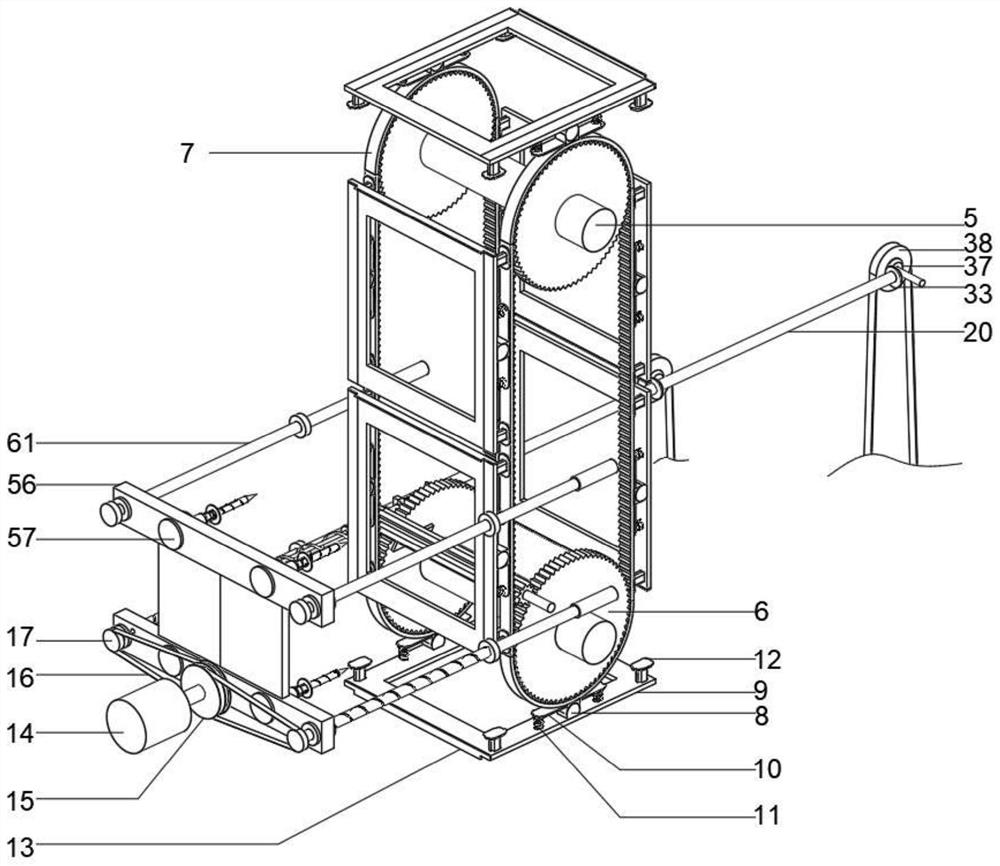

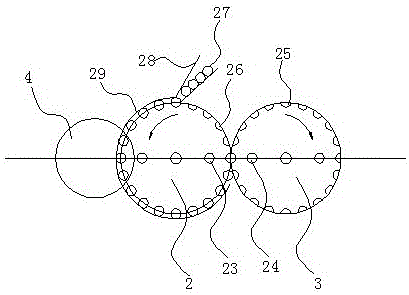

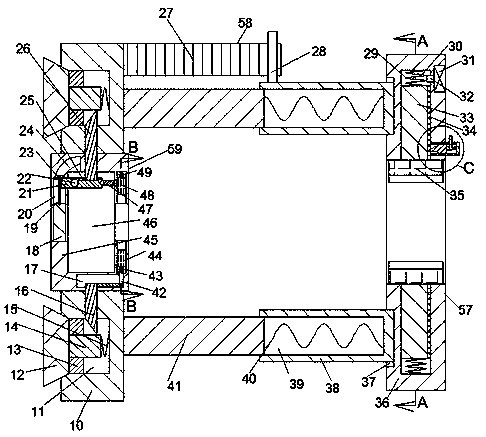

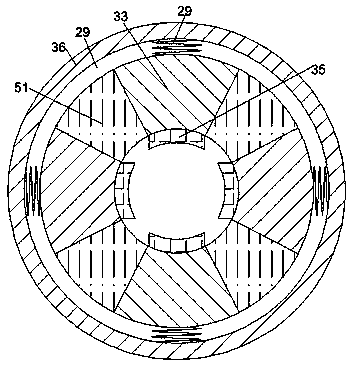

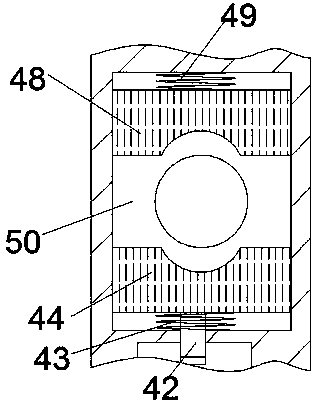

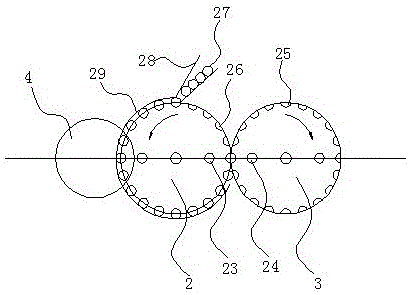

Drilling device of spherical jade

InactiveCN104802324AEnsure drilling qualityGuaranteed drilling effectWorking accessoriesFine working devicesEngineeringCrankshaft

The invention discloses a drilling device of spherical jade. The drilling device comprises a machine frame, a main turntable, a sub turntable, a main transmission device, a sub transmission device, a main motor and a sub motor, wherein the main transmission device is connected with the main turntable, the sub transmission device is connected with the sub turntable, the main motor is used for driving the main transmission device to work, the sub motor is used for driving the sub transmission device to work, the main turntable and the sub turntable are in parallel arrangement and are rotationally arranged on the machine frame, the rotating directions of the main turntable and the sub turntable are opposite, a plurality of main round grooves are formed in the main turntable, a plurality of sub round grooves are formed in the sub turntable, the main round grooves and the sub round grooves are matched in the tangent positions of the main turntable and the sub turntable for forming a clamping part used for clamping the jade, the main transmission device is in transmission connection with a crankshaft through a first rotating shaft, a first connecting rod is connected onto the crankshaft, and a drilling assembly used for jade hole drilling work is hinged to the first connecting rod. The drilling device has the advantages that the drilling quality of the jade can be effectively ensured, and the processing efficiency is greatly improved.

Owner:河南嘉豪珠宝股份有限公司

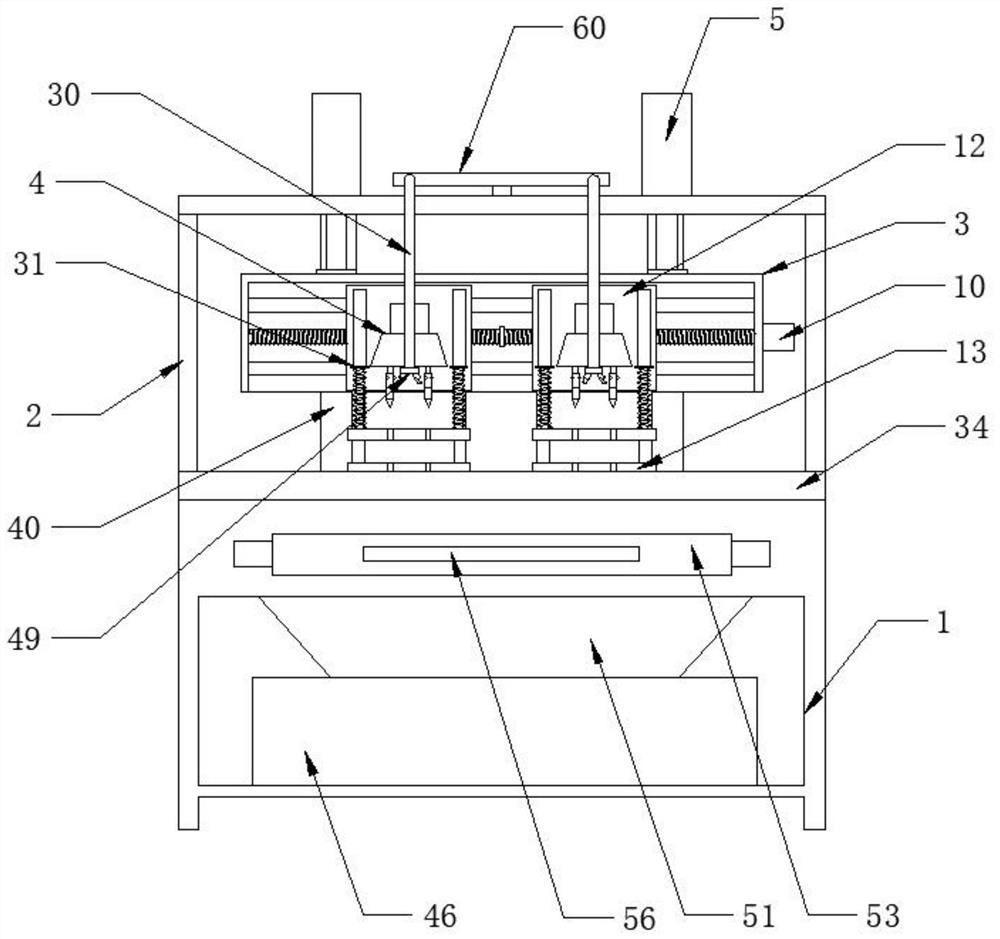

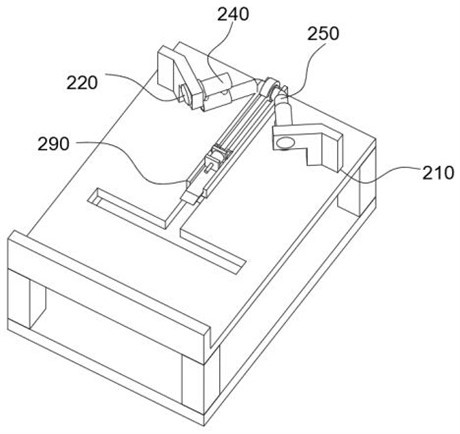

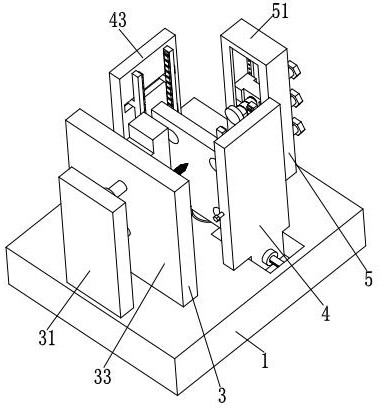

Tibia outer side locking plate finish machining positioning and drilling device

PendingCN111940786AGuaranteed positioningAdjustable spacingPositioning apparatusMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses a tibia outer side locking plate finish machining positioning and drilling device. The device comprises a base, a workbench is fixed to the surface of the top end of the base,a mounting frame is fixed to a cavity of the base, a forward and reverse rotation motor is fixed to the inner side of the mounting frame, and an output shaft of the forward and reverse rotation motoris rotationally connected with a rotating shaft. The rotating shaft rotationally penetrates through the outer wall of the bottom end of the workbench, the rotating shaft extends to a cavity of the workbench, a third bevel gear is fixed to the tail end of the rotating shaft, and the two sides of the third bevel gear are in engaged connection with a first bevel gear and a second bevel gear correspondingly. Through the arrangement of the forward and reverse rotation motor, the distance between clamping mechanisms can be conveniently and rapidly adjusted, and the positioning effect of the clampingmechanisms on a locking steel plate is guaranteed; through the arrangement of fan blades, wind power generated when the fan blades rotate can cool the forward and reverse rotation motor in a workingstate; and through the arrangement of the fan blades, a drill bit can be conveniently and rapidly replaced, and the drilling effect of the drill bit on the locking steel plate is guaranteed.

Owner:上海翰利医疗科技有限公司

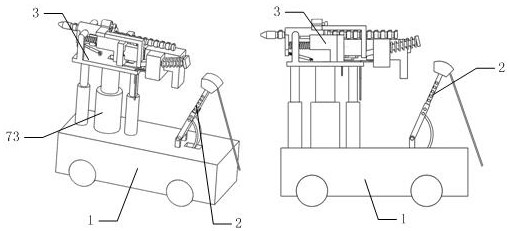

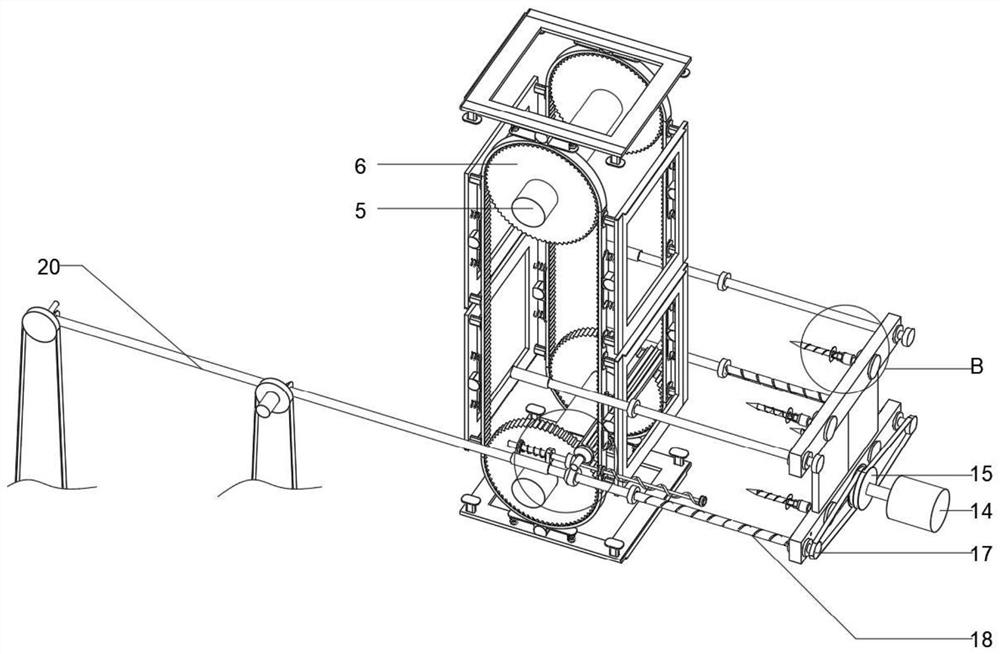

Drilling equipment for earth-rock blasting

ActiveCN112252991AGuaranteed drilling effectImprove drilling efficiencyEarth drilling toolsDerricks/mastsRock blastingImpact

The invention belongs to the technical field of earth-rock blasting, and particularly relates to drilling equipment for earth-rock blasting. The drilling equipment comprises a traveling platform, a pendulum bob mechanism, an adjusting mechanism and a hole drill, one end of a gear adjusting block is step-shaped, each step corresponds to a gear, if the gear adjusting block is adjusted, when an impact block is matched with one step face, after the impact block is stressed, a fourth spring is extruded firstly, then the gear adjusting block is impacted, part of impact force is transmitted to the hole drill through the gear adjusting block to impact and crush a hard layer, and residual energy is converted into pressure of impact on the hard layer, and the hard layer is subjected to rotary cutting by utilizing the pressure. The design aims to select impact force and drilling pressure distribution according to stone mountains with different hardness.

Owner:ZHEJIANG HUADONG ENG CONSTR MANAGEMENT +1

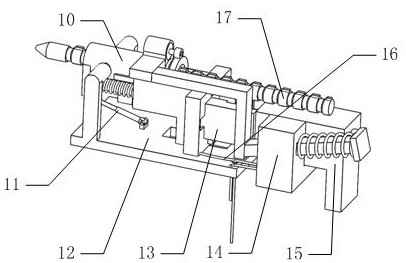

Steel plate drilling and grinding device for automobile machining

InactiveCN112935830AGuaranteed drilling effectOther manufacturing equipments/toolsSteel platesDrill hole

The invention discloses a steel plate drilling and grinding device for automobile machining. The steel plate drilling and grinding device comprises a supporting frame, wherein a first limiting plate is arranged on the inner side of the supporting frame, a conveying belt is arranged on the inner side of the first limiting plate, a support is fixed to one end of the supporting frame, a plurality of first transmission rods are arranged on the support, first tooth discs are arranged at the two ends of the plurality of first transmission rods, and a transmission belt is arranged on the first tooth discs. During drilling, when a reciprocating lead screw slowly rotates, a moving plate is driven to do continuous reciprocating motion, a drilling machine carries out hole forming operation on a steel plate through a drill bit, the steel plate obtained after hole forming is driven by a grinding disc which continuously advances to move forwards, and therefore the grinding disc carries out grinding operation on the steel plate obtained after hole rotating; and when the moving plate is reset through the reciprocating lead screw, a third spring is separated from pressing, a second spring rebounds, and therefore a second gear is engaged to a first gear which slowly rotates to enable a third gear to rotate, a tooth roller drives the first tooth discs to rotate, and the reciprocating lead screw continuously works to keep the continuous drilling effect.

Owner:刘晓娜

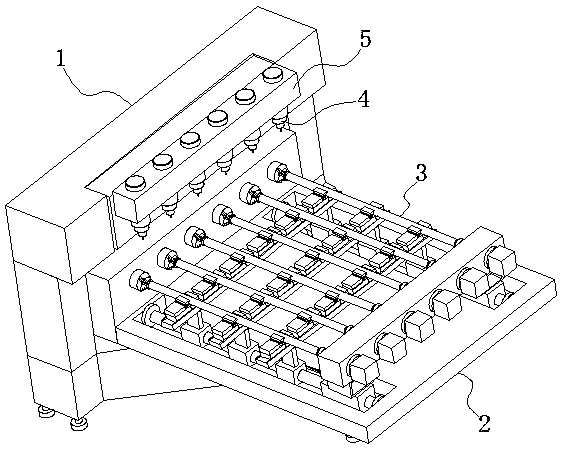

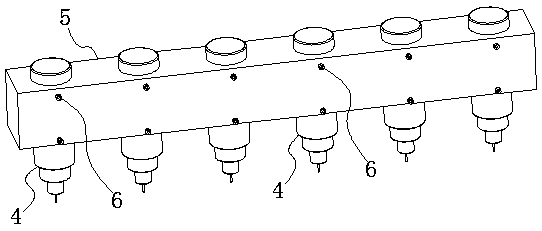

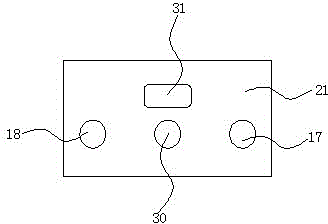

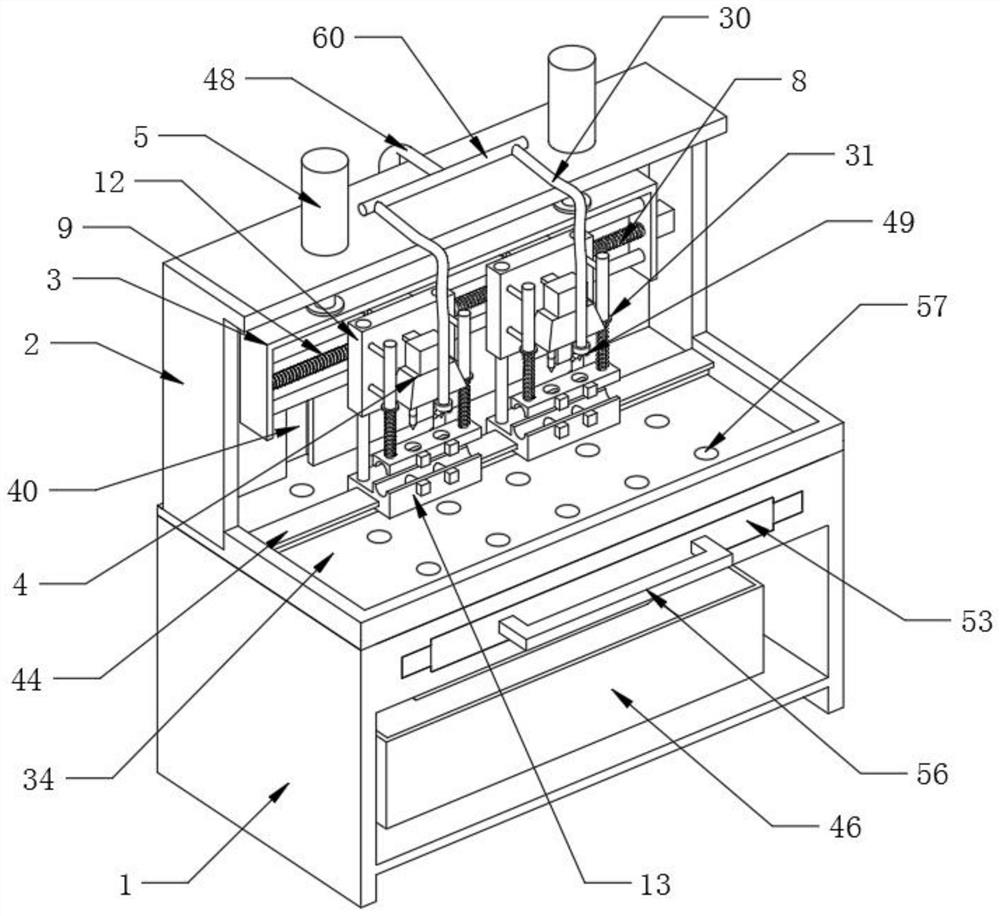

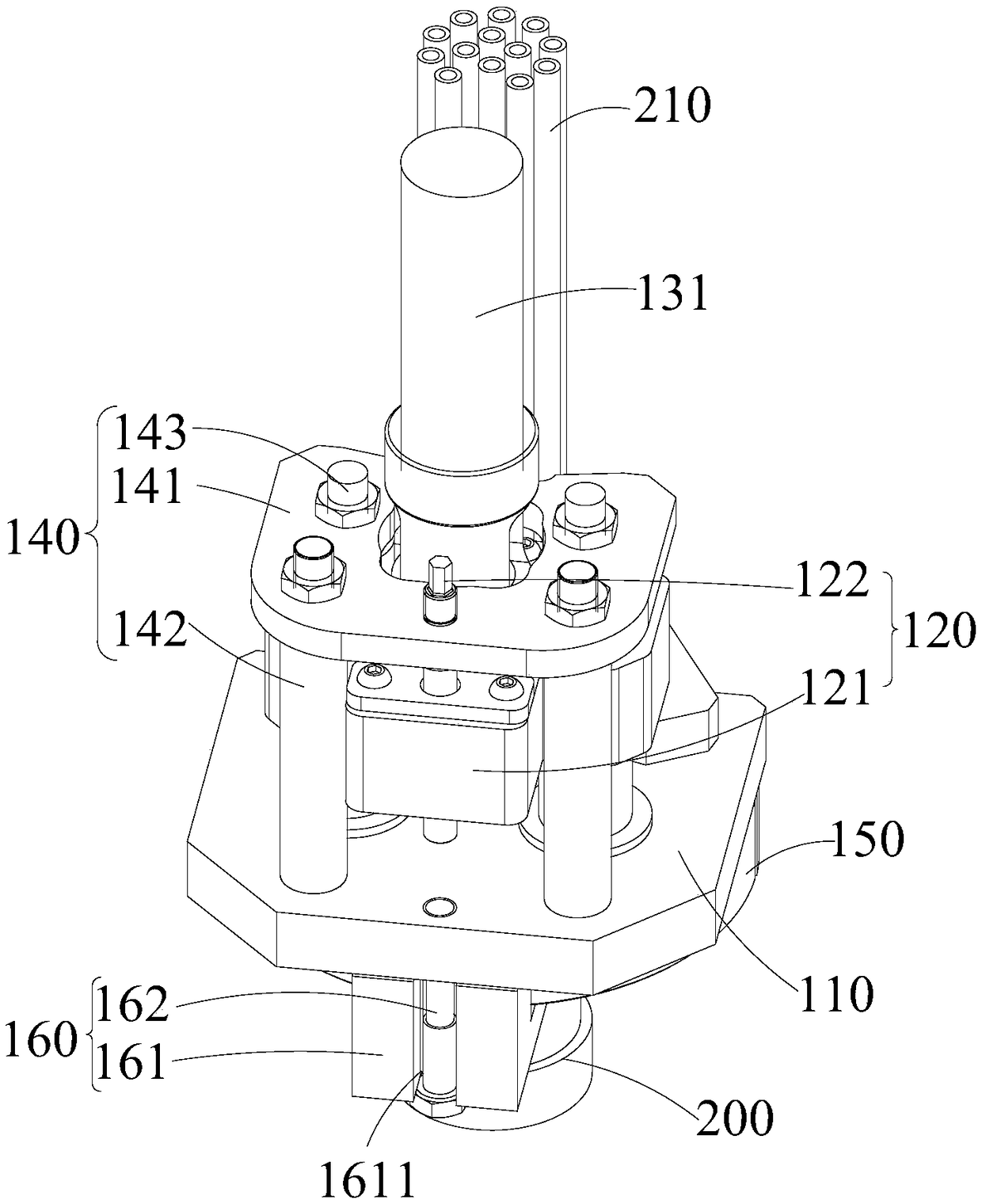

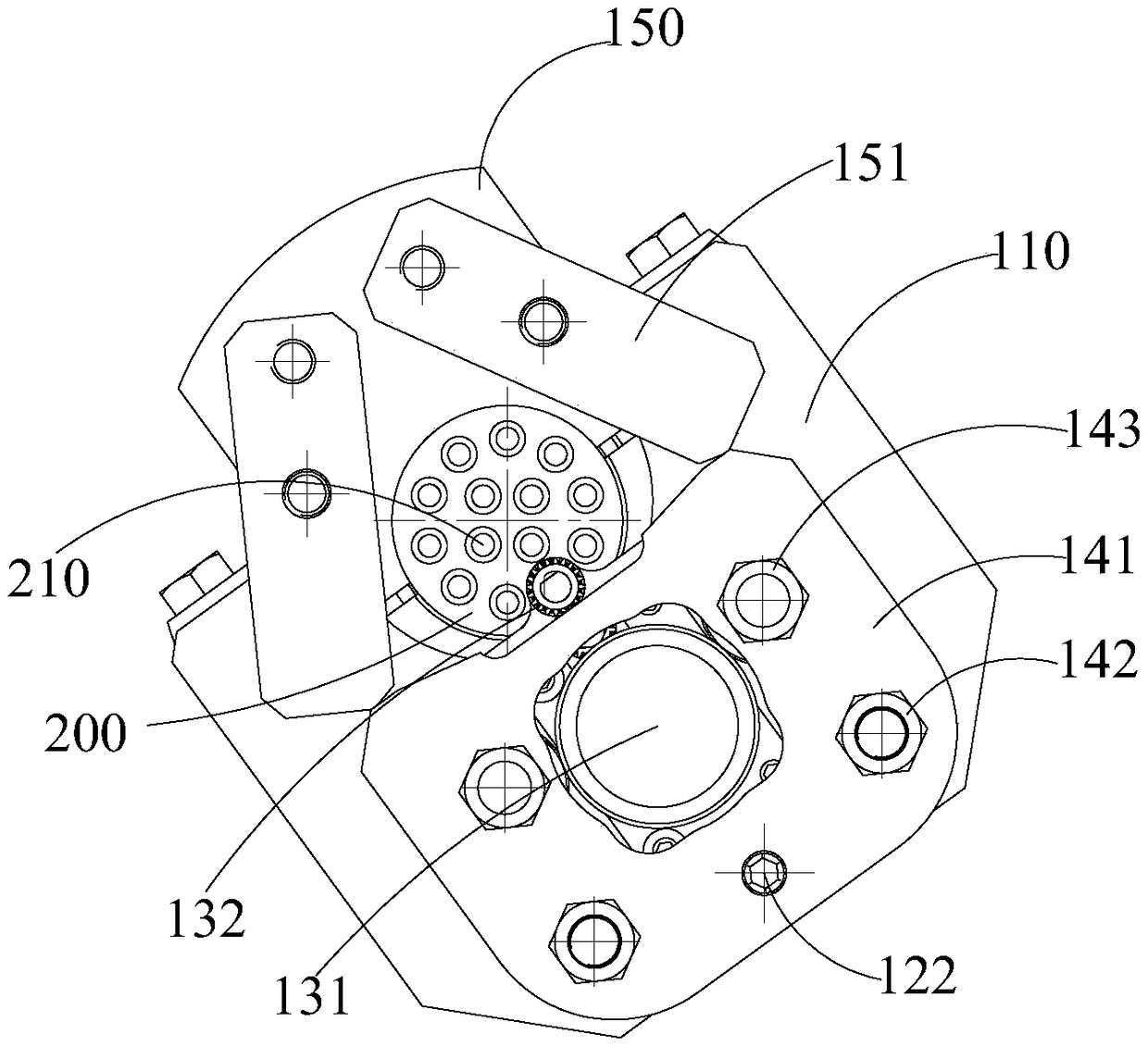

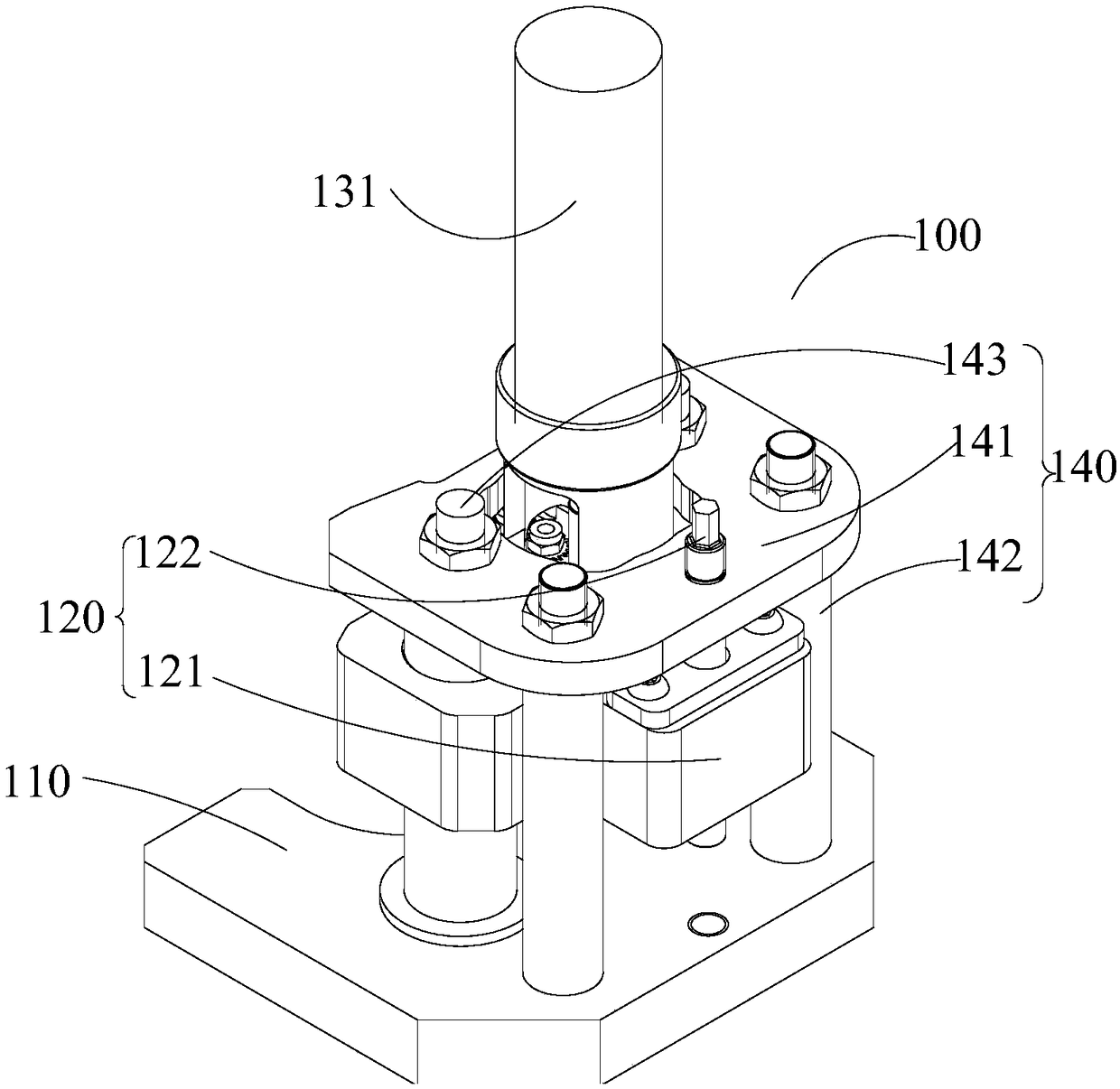

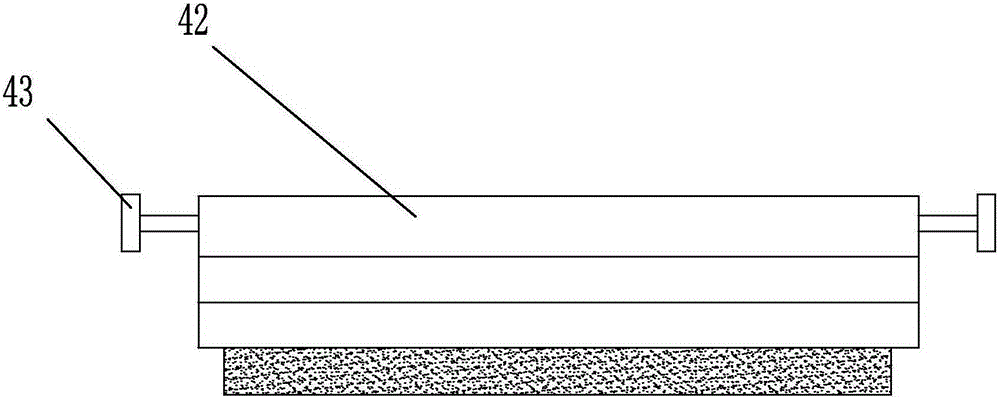

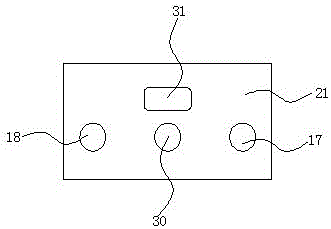

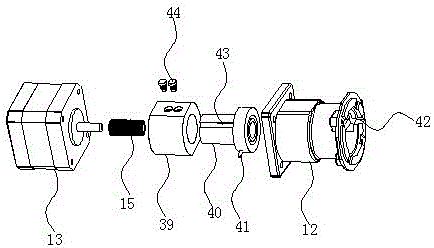

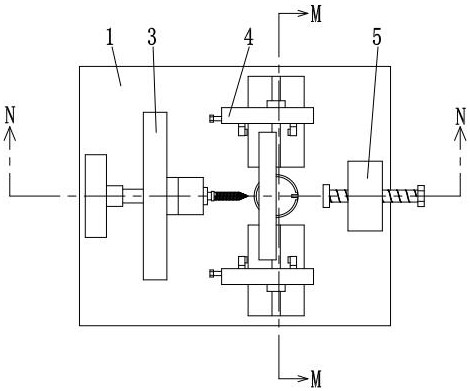

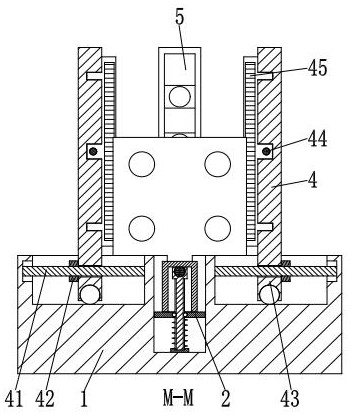

Novel multi-shaft drilling mechanism for steel bar connecting structural member

PendingCN113751747AHigh precisionAccurate distance adjustmentBoring/drilling componentsMaintainance and safety accessoriesElectric machineryDrive motor

The invention discloses a novel multi-shaft drilling mechanism for a steel bar connecting structural member. The novel multi-shaft drilling mechanism comprises a rack; a working table plate is fixed to the upper side of the rack; a supporting frame is installed on the upper side of the working table plate; a distance adjusting mechanism is installed in the supporting frame; drilling assemblies are arranged on the distance adjusting mechanism; the number of the drilling assemblies is two; each drilling assembly comprises a driving motor, a transmission box and two drill bit mechanisms; the two drill bit mechanisms are arranged at the bottom of the corresponding transmission box side by side; each drill bit mechanism comprises a rotating shaft; and a connecting block is fixed to the lower end of each rotating shaft; and a drill bit is arranged at the bottom of each connecting block. The distance between the two drilling assemblies can be accurately adjusted; the drilling effect is improved; the positions, needing to be drilled, of the steel bar connecting structural member can be positioned through first positioning protruding strips on the front sides of containing bases and second positioning protruding strips on the front sides of lower pressing blocks; and the drilling accuracy is further improved.

Owner:卓冠(宿迁)智能科技有限公司

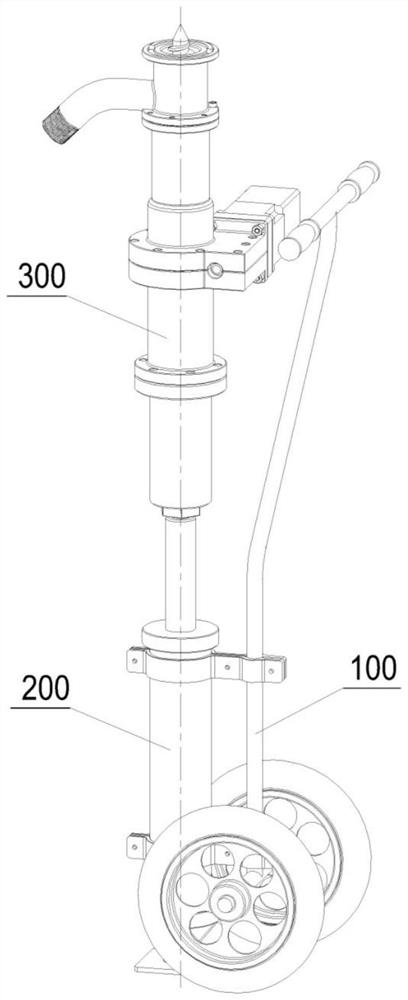

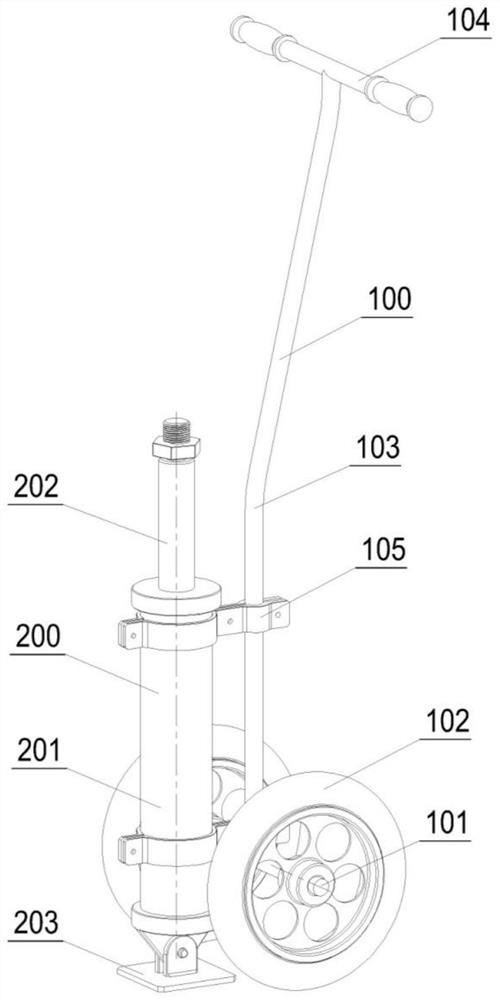

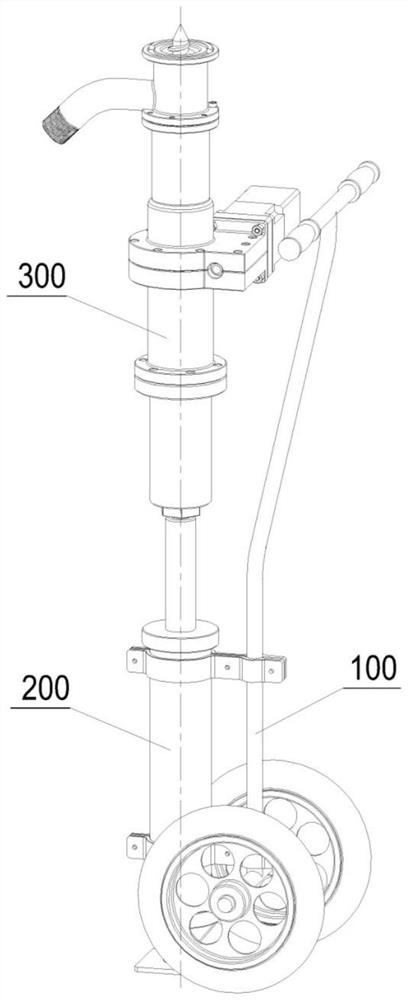

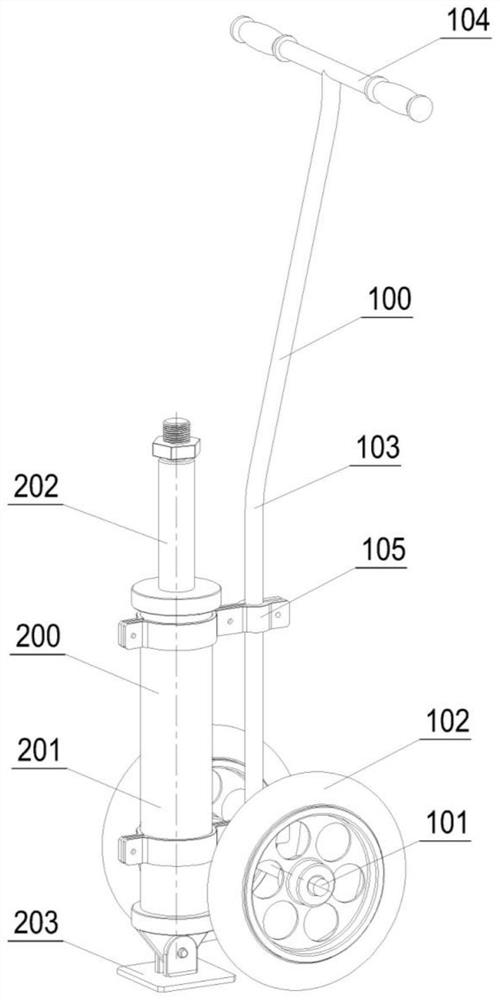

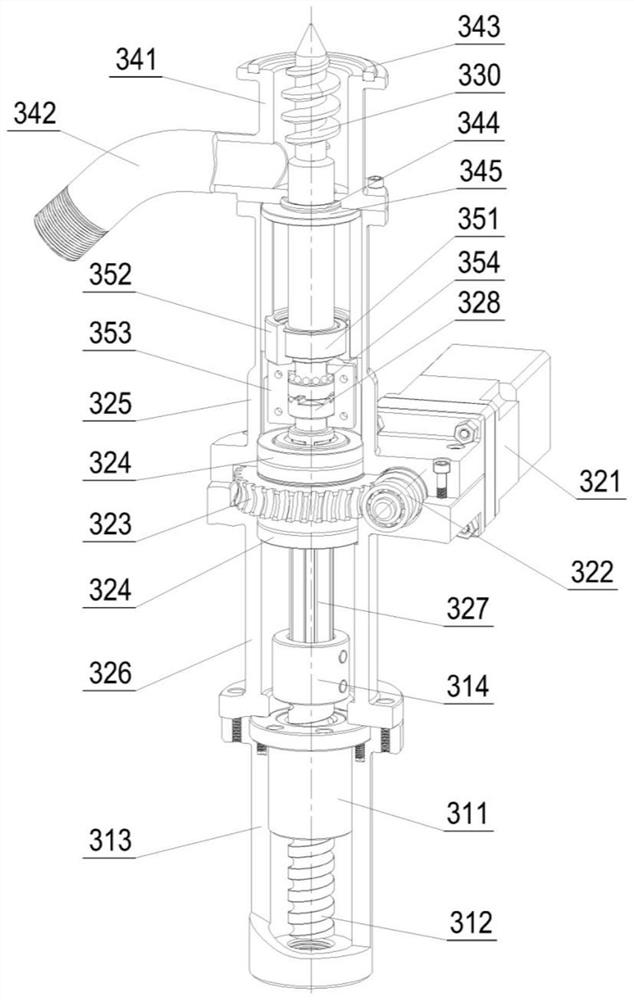

drilling device

ActiveCN107363295BAvoid touchingRealize the feed functionWork benchesPortable drilling machinesDrillPetroleum engineering

The invention provides a drilling device which comprises a base fixed on a workpiece to be drilled, a body mounted on the base, a moving mechanism which is arranged on the body and can move towards or away from the base, and a drilling mechanism arranged on the moving mechanism, wherein the moving mechanism can drive the drilling mechanism to move towards or away from the base; the drilling mechanism comprises a driving member and a drill; the driving member is connected with the drill in a transmission manner; the drill extends towards the workpiece to be drilled; and the driving member drives the drill to drill the workpiece to be drilled. The drilling device realizes drilling work of the workpiece to be drilled; all the parts of the drilling device are fully distributed in a height space, and are compactly distributed in a horizontal space, so that the size of the drilling device in the horizontal space is reduced, and the drilling device is particularly suitable for the drilling work in a small space; and therefore, the drilling effect is guaranteed, contact with an adjacent workpiece to be drilled can be effectively avoided, and equipment safety is guaranteed.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

Manufacturing method for printed circuit board for portable card type equipment

InactiveCN110868804AIncrease the maximum thicknessMeet the punching needsPrinted circuit manufactureSurface oxidationPrinted circuit board

The invention provides a manufacturing method for a printed circuit board for portable card type equipment. The manufacturing method comprises the following steps of S1, mechanically drilling a positioning hole in a TF board substrate, S2, thinning copper on the surface of the TF board substrate, S3, carrying out oxidation treatment on the thinned copper surface so that the copper surface is in adark rough state, and S4, positioning the TF board substrate on a laser tabletop according to positioning holes, and performing laser drilling to obtain required via holes. A laser drilling mode is used for replacing a mechanical drilling mode, a drill point is not needed, and the problems that the drill point is difficult to manufacture due to the fact that the hole diameter of a hole to be drilled is reduced, and meanwhile the drilling effect is greatly reduced due to change of the drill point are solved; copper reduction treatment and copper surface oxidation treatment are carried out on the TF board substrate, and the laser drilling effect is guaranteed.

Owner:QUZHOU SUNLORD CIRCUIT BOARD CO LTD

Drilling device for sheet glass drilling

InactiveCN105216122AHas the effect of fixing flat glassPlay a cleaning roleWorking accessoriesStone-like material working toolsFlat glassEngineering

The invention discloses a drilling device for sheet glass drilling. The drilling device for sheet glass drilling comprises a drilling machine, a fixing mechanism, a feeding mechanism and a cleaning mechanism, wherein the fixing mechanism is located between the drilling machine and the feeding mechanism; the cleaning mechanism is located above the fixing mechanism; the drilling machine comprises a drill bit and a moving mechanism; the drill bit comprises a drill bit body and a heating device; the heating device is arranged around the drill bit body; the moving mechanism comprises an X-axis moving mechanism and a Y-axis moving mechanism; the fixing mechanism comprises a clamping device and a detecting device; an upper clamping handle and a lower clamping handle are disposed on a clamping device body and are matched with each other; the feeding mechanism comprises a feeding channel, a feed conveying plate and a feed conveying belt; the cleaning mechanism comprises a moving track and cleaning brushes. The drilling device for sheet glass drilling is simple in structure and high in practicability; the stability of the drilling device during operation is improved; the drilling effect of the drilling device is guaranteed; side effects caused during drilling are reduced; the effects are remarkable and the working efficiency is improved.

Owner:浙江大可安全玻璃有限公司

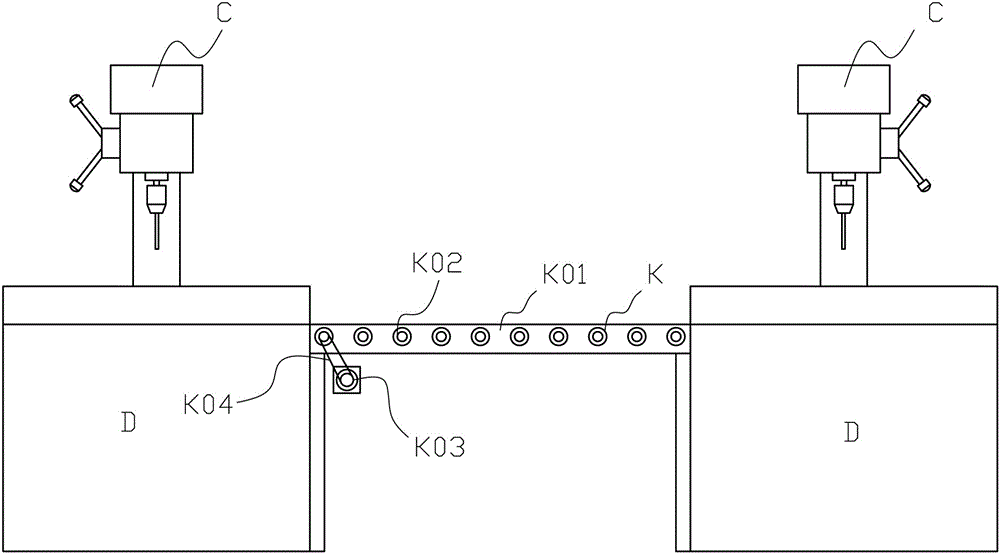

Valve body transverse drilling equipment and drilling method thereof

PendingCN113333808AGuaranteed processing efficiencyEnsure drilling qualityOther manufacturing equipments/toolsMetal working apparatusHole drilling methodMachining

The invention relates to the field of valve body drilling, in particular to valve body transverse drilling equipment. The equipment comprises a conveying mechanism, and a coarse drilling mechanism and a fine drilling mechanism are sequentially arranged on the two sides of the conveying mechanism in the conveying direction; and the conveying mechanism comprises a workbench, a conveying rail is arranged on the workbench, a bearing plate is arranged on the conveying rail, a conveying driving part for driving the bearing plate to move along the conveying rail is arranged on the workbench, and a limiting assembly for fixing the valve body is arranged on the bearing plate. The valve body transverse drilling equipment has the effect of improving the valve body drilling machining efficiency.

Owner:SUZHOU ENVIL MACHINERY

Anti-blocking cutter for paperboard drilling

InactiveCN112873399AKeep hollow designAchieve relative motionMetal working apparatusPaper dustPaperboard

An anti-blocking cutter for paperboard drilling comprises a top plate, a connecting piece is fixedly connected to the circle center of the top plate, cutter cylinders are evenly arranged at the bottom of the top plate and located on the periphery of the connecting piece, fixing rods are arranged in the cutter cylinders, the interiors of the cutter cylinders are dredged, a stabilizing plate is arranged between the fixing rods and the connecting piece to limit and stabilize the cutter cylinders, an exhaust mechanism is arranged between the top plate and the stabilizing plate, a retractable air cylinder is arranged between the stabilizing plate and the top plate, and a limiting assembly is arranged on the surface of the stabilizing plate to limit and stabilize the overall stability of a cutter. Through cooperation of the cutter cylinders and the fixing rods, the fixing rods can clean the interior of the cutter cylinders after drilling of the cutter cylinders, paper scraps entering the interior of the cutter cylinders are discharged, in addition, the end openings of the fixing rods are located on the outer side of the cutter cylinders through relative movement between the fixing rods and the cutter cylinders, and therefore the cutter cylinders are not affected by the paperboard scraps.

Owner:马鞍山章鱼心网络科技服务有限公司

Brake pad automatic drilling drill bit positioning and installation mechanism and installation method thereof

InactiveCN113211116AEasy to installReduce laborMeasurement/indication equipmentsPositioning apparatusControl engineeringStructural engineering

The invention discloses a brake pad automatic drilling drill bit positioning and installation mechanism and an installation method thereof. The brake pad automatic drilling drill bit positioning and installation mechanism comprises a base, a first clamping column, a second clamping column and a horizontal sensor, and rolling wheels are arranged at the four corners of the lower end of the base. The brake pad automatic drilling drill bit positioning and installation mechanism and the installation method have the beneficial effects that through the design of the first clamping column, the second clamping column and a toothed belt, the installation mechanism can replace manual work, it can be ensured that a drill bit is firmly installed, and the labor amount of workers can be decreased. Through the design of a PLC, second electric push rods and the horizontal sensor, the installation mechanism can have a horizontal adjustment function, the drill bit can be horizontally installed, and therefore the drilling effect of the drill bit is ensured. Through the design of third electric push rods and rubber clamping blocks, the installation mechanism can be temporarily fixed in a clamping mode, the abrasion degree can be reduced, and replacement can be convenient and fast. Therefore, the positioning and installation precision of the drill bit can be ensured.

Owner:湖北龙兴腾达汽车零部件有限公司

A drilling device for drilling flat glass

InactiveCN105216122BIncrease temperatureAchieve softening effectWorking accessoriesStone-like material working toolsFlat glassDrilling machines

The invention discloses a drilling device for sheet glass drilling. The drilling device for sheet glass drilling comprises a drilling machine, a fixing mechanism, a feeding mechanism and a cleaning mechanism, wherein the fixing mechanism is located between the drilling machine and the feeding mechanism; the cleaning mechanism is located above the fixing mechanism; the drilling machine comprises a drill bit and a moving mechanism; the drill bit comprises a drill bit body and a heating device; the heating device is arranged around the drill bit body; the moving mechanism comprises an X-axis moving mechanism and a Y-axis moving mechanism; the fixing mechanism comprises a clamping device and a detecting device; an upper clamping handle and a lower clamping handle are disposed on a clamping device body and are matched with each other; the feeding mechanism comprises a feeding channel, a feed conveying plate and a feed conveying belt; the cleaning mechanism comprises a moving track and cleaning brushes. The drilling device for sheet glass drilling is simple in structure and high in practicability; the stability of the drilling device during operation is improved; the drilling effect of the drilling device is guaranteed; side effects caused during drilling are reduced; the effects are remarkable and the working efficiency is improved.

Owner:浙江大可安全玻璃有限公司

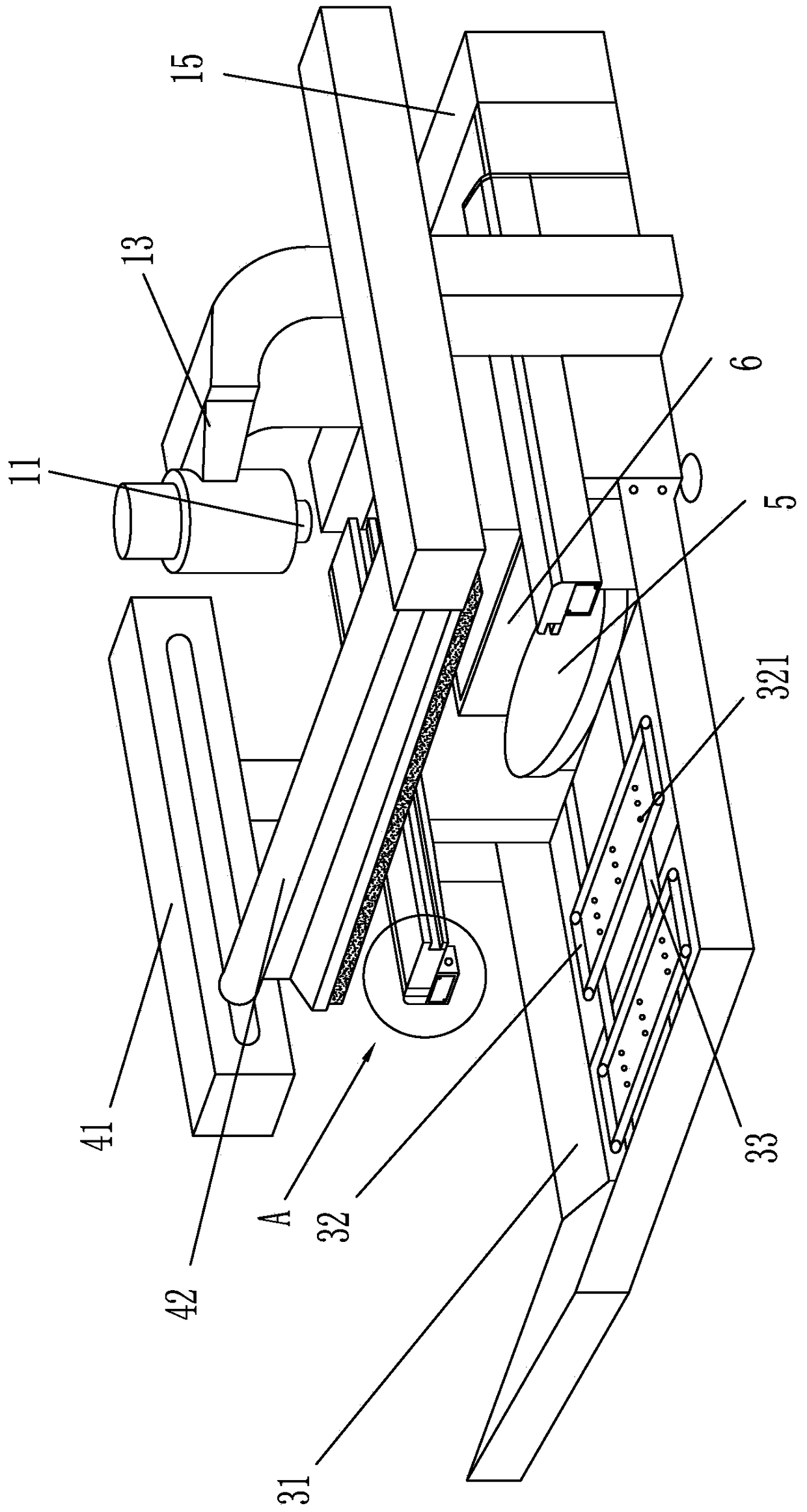

Machine tool for machining spindle hole of five-axis linkage low-temperature motor

ActiveCN114769648AGuaranteed drilling effectStrong linkageMaintainance and safety accessoriesBoring/drilling machinesPhysicsElectric machinery

The invention relates to the technical field of emulsion preparation and production, in particular to a five-axis linkage low-temperature motor spindle hole machining tool which comprises a machining table, and a machining module, a feeding module and a flushing module are arranged on the machining table. According to the drilling device, the motor output shaft drives the rotating part connected with the motor output shaft to rotate, then the rotating part drives the connecting shafts to rotate, the connecting shafts are limited by the rotating part connected with the cylinder, so that the connecting shafts can only penetrate between the two connecting shafts, the motion trail of the connecting shafts is O-shaped, and the connecting shafts enable the inserting plate and the drilling machine to enter and exit the limiting plate in a reciprocating mode through the connecting rods; then the connecting shaft moving in an O shape indirectly drives the arc-shaped rubber plate to rub with the motor shaft at the bottommost part in the material frame, then the motor shaft is driven to be conveyed into the slide, then the motor shaft is conveyed into the limiting plate in a sliding mode along the slide to be limited, then the motor shaft is inserted through the inserting plate in the limiting plate, the axis of the motor shaft is aligned with the output end of the drilling machine, and the motor shaft is driven to rotate. And the motor shaft drilling effect is guaranteed, the linkage performance is high, and more time and labor are saved during use.

Owner:常州市昌隆电机股份有限公司

A drilling device for spherical jade

InactiveCN104802324BEnsure drilling qualityGuaranteed drilling effectWorking accessoriesFine working devicesRotational axisElectric machinery

Owner:河南嘉豪珠宝股份有限公司

Auxiliary punching and powder collecting device

InactiveCN111391155AGuaranteed accuracyAvoid affecting the efficiency of processingWorking accessoriesStone-like material working toolsPunchingClassical mechanics

The invention discloses an auxiliary punching and powder collecting device. The auxiliary punching and powder collecting device comprises a clamping box, wherein a clamping cavity is formed in the clamping box; a clamping mechanism is arranged in the clamping cavity; a connecting mechanism is arranged in the clamping box; the connecting mechanism comprises a rotating groove formed in the left endface of the clamping box; a moving block which is symmetrical up and down relative to the circle center of the clamping box and is in sliding fit with the clamping box is arranged in the rotating groove; and a moving groove is formed in the moving block. A wall surface needing to be punched is attached through a suction cup, the counter-acting force generated during punching can be reduced duringwall surface machining, the wall surface punching accuracy is guaranteed, a hole opening is perpendicular to the interior of the wall surface, and the drilling effect is guaranteed.

Owner:FUZHOU TAIJIANG AIQISHI ELECTRONICS TECH CO LTD

A laser drilling steel plate clamping mechanism

ActiveCN106271133BStable clampingGuaranteed drilling effectLaser beam welding apparatusSheet steelArchitectural engineering

Owner:江苏九九铝业有限公司

A device for drilling double holes with adjustable spacing

ActiveCN112792918BSolve the problem that the drilling spacing cannot be adjustedGuaranteed adjustabilityStationary drilling machinesCane mechanical workingGear wheelElectric machinery

Owner:NANJING COLLEGE OF INFORMATION TECH

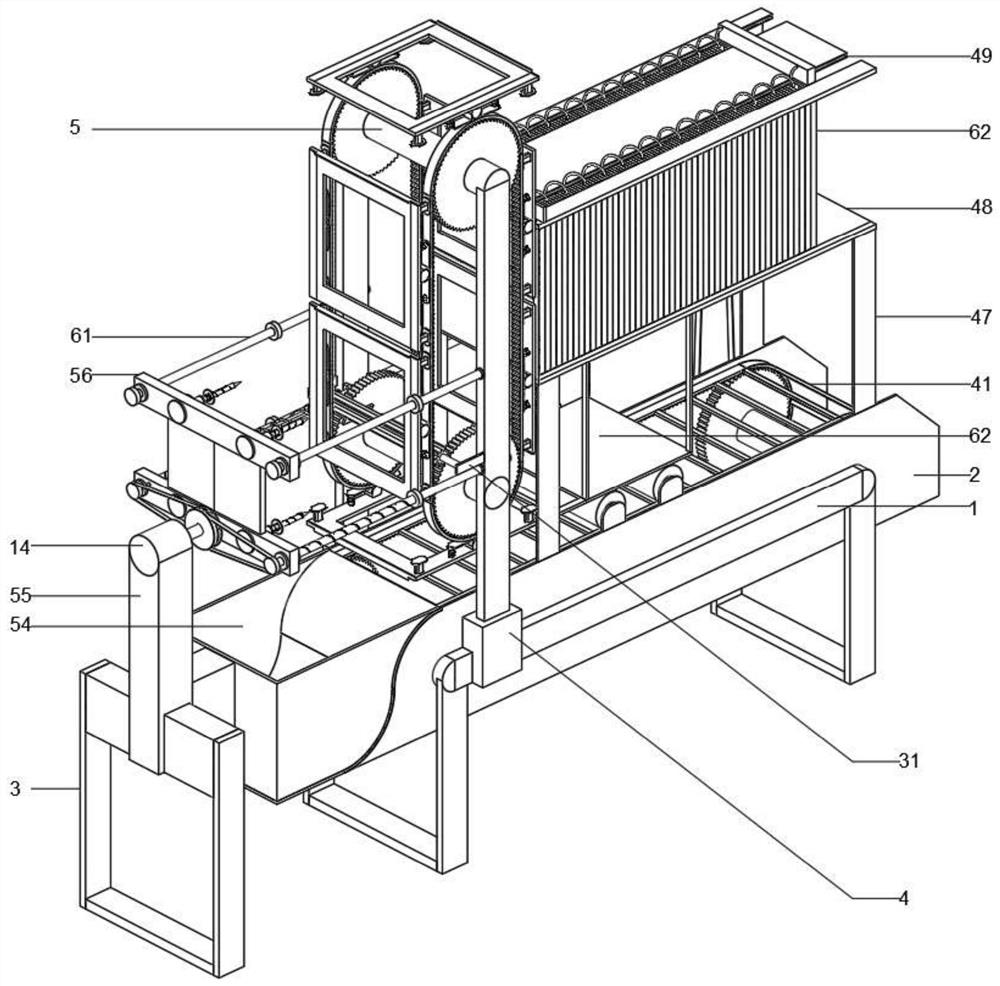

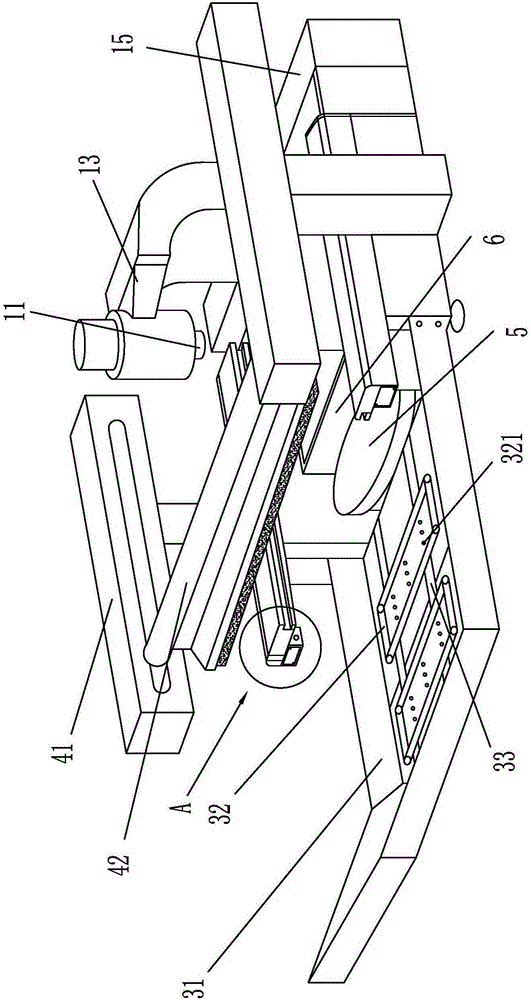

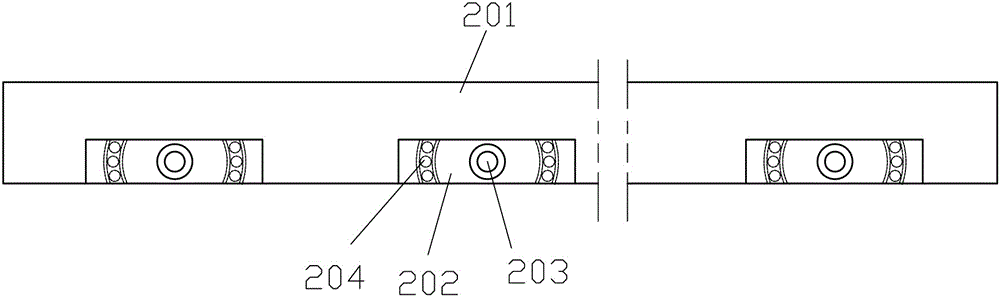

Drilling line for chair cushions

ActiveCN104308909BGuaranteed positionGuaranteed stabilityDrilling machinesProduction lineChair cushion

The invention discloses a drilling production line for chair cushions. The drilling production line comprises a conveying line, a workbench located at the two ends of the conveying line and drilling devices arranged on the workbench; the drilling device comprises a workbench, a supporting shaft fixed on the workbench, an installation platform fixed on the supporting shaft, a drill pipe arranged on the installation platform, a drill bit arranged on the drill pipe and a motor fixed on the installation platform for driving the drill pipe to rotate. The drilling production line is characterized in that a push plate device, a propping device and a driving mechanism used for driving the push plate device to move on the workbench are further arranged on the workbench. The drilling production line disclosed by the invention is used for drilling chair cushions by using two drilling devices, the conveying line is arranged between two drilling devices to convey the processed chair cushion to the next drilling device for processing, and the drilling production line is simple in structure and convenient to operate.

Owner:ZHEJIANG HAOGUO FURNITURE

Thick copper circuit board with inconsistent inner and outer layer copper thickness and preparation method thereof

ActiveCN104486914BEvenly filledUniform pressure distributionConductive material chemical/electrolytical removalMultilayer circuit manufactureTime rangeCopper-wiring

The invention discloses an inner and outer layer copper thickness-differentiated thick copper circuit board and a preparation method thereof and belongs to the PCB technical field. The method includes the steps of board pressing process, drilling process and etching process. According to the board pressing process, a prepreg of which the resin content is equal to or larger than 65% is selected; hot pressing process and cold pressing process are sequentially adopted to perform board pressing; the parameter conditions of the hot pressing process are as follows: pressure ranges from 250 to 450 PSI, temperature ranges from 175 to 220 DEG C, vacuum degree ranges from 0 to 68 cm Hg, and time ranges from 90 to 150 min; and the parameter conditions of the cold pressing process are as follows: pressure ranges from 50 to 450 PSI, temperature ranges from 165 to 220 DEG C, and time ranges from 130 to 230 min. According to the preparation method, a laminated structure and a board lamination mode are adopted, and temperature rising and pressurization control are utilized in cooperation, and therefore, the filling of flowing resin can be uniform, and pressure distribution is uniform when board pressing is performed, and an excellent filling effect can be realized, and air bubble generation can be avoided, and press fit can be excellently realized.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Drilling machine for machining hardware precision parts

InactiveCN108127457AAvoid damageExtended service lifeDriving apparatusPositioning apparatusReduction functionDrill hole

The invention discloses a drilling machine for machining hardware precision parts and relates to the technical field of drilling machines. The drilling machine comprises a base plate. A support rod isfixedly connected to one side of the top of the base plate, and in addition, a fixing plate is fixedly connected to the top end of the support rod. Movable rods are connected to the two sides of thebottom of the fixing plate in a sliding manner, wherein the movable rods are matched with the fixing plate to be used. An electric drill bit is movably connected to the ends, far away from the fixingplate, of the movable rods, and a fixing rod is fixedly connected to the top of the electric drill bit. By means of the drilling machine for machining the hardware precision parts, the base plate canbe well protected; the electric drill bit is prevented from damaging the base plate; the service life of the drilling machine is prolonged; safety and reliability are achieved; the base plate can be prevented from being damaged; the drilling effect of the electric drill bit is guaranteed; drilling errors are reduced; the drilling machine can achieve the good fixing function; the vibration influence on drilling of the electric drill bit is reduced; and the drilling machine can achieve the good vibration reduction function, convenience and fastness.

Owner:方建松

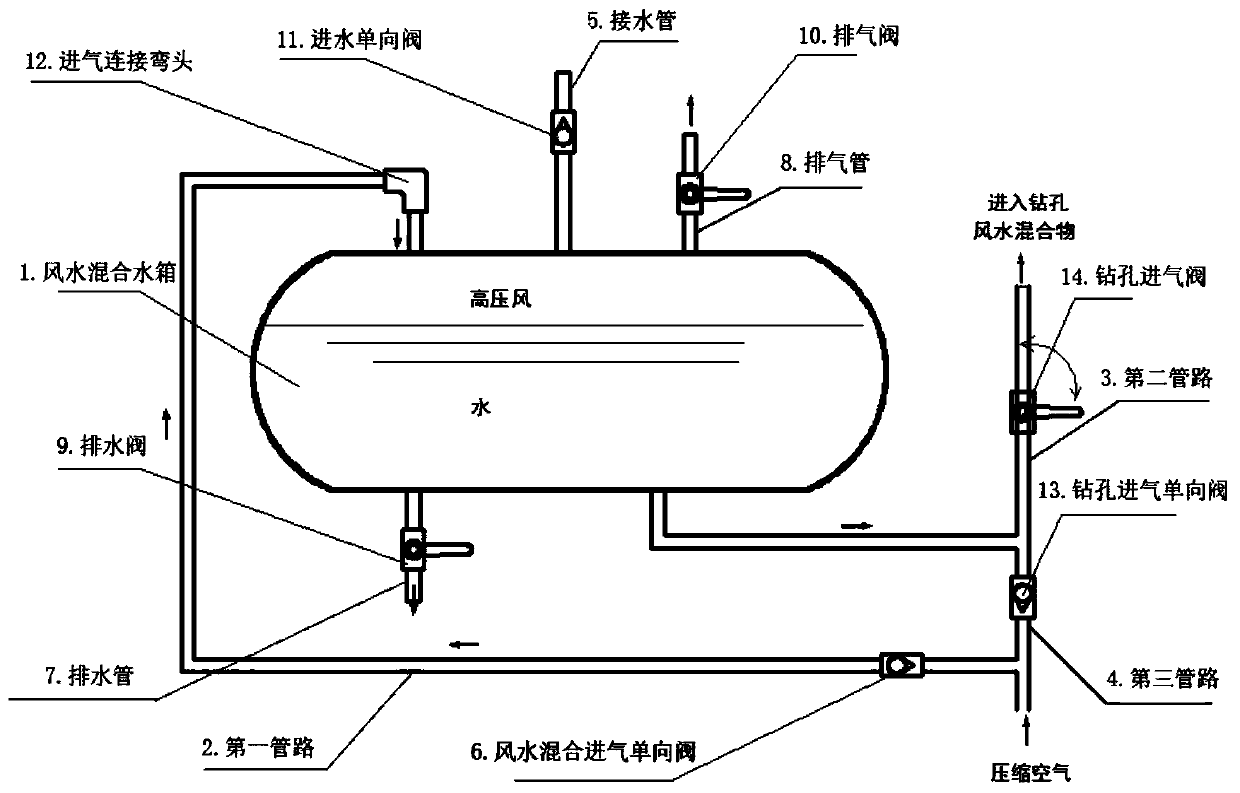

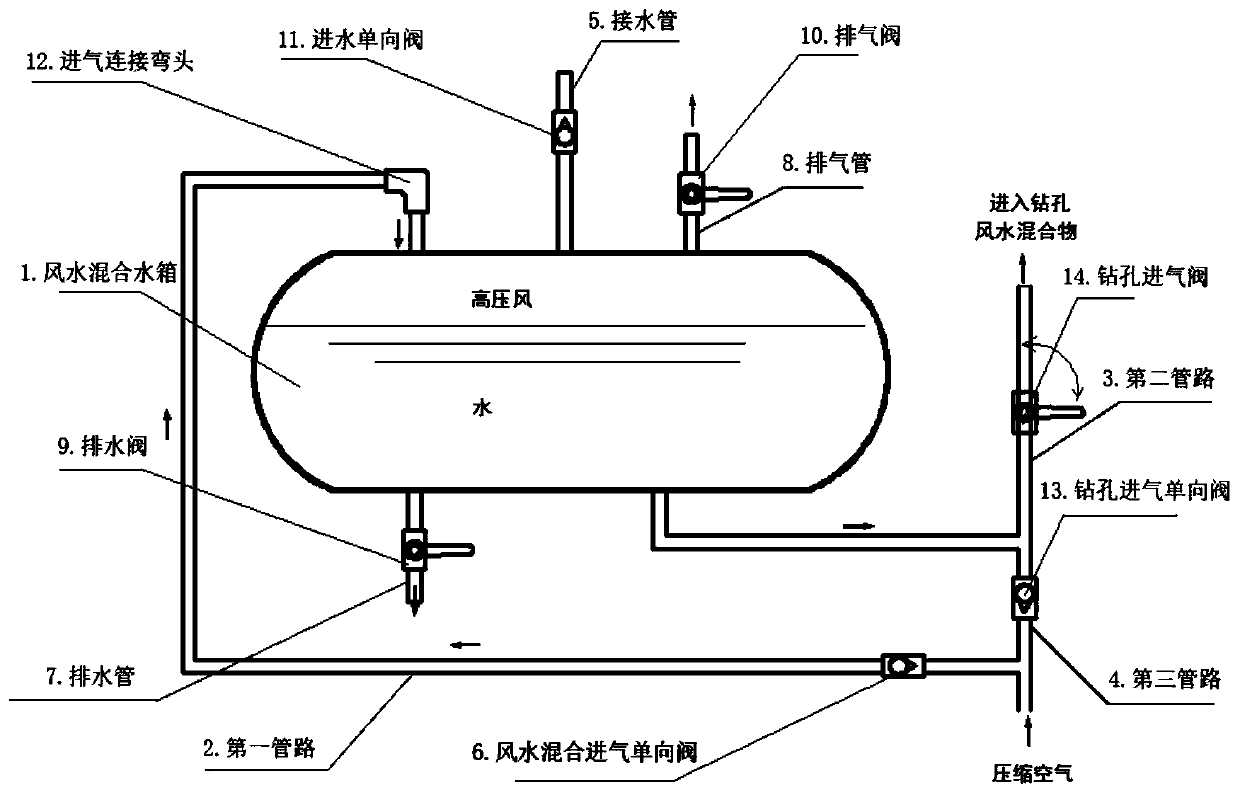

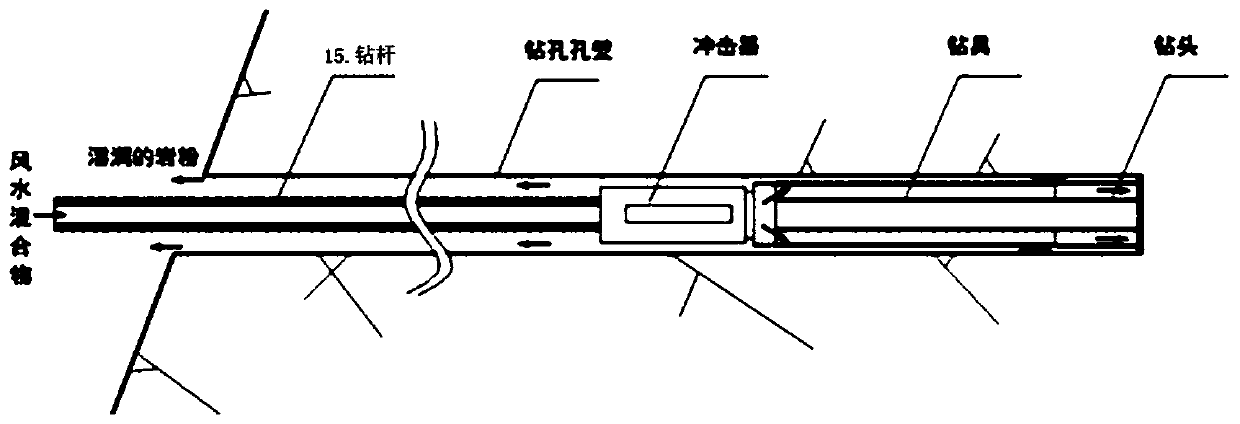

Dust removal device with wind-water mixing function and drilling rig thereof

PendingCN110685729AReduce rock dust flyingAvoid reverse flowDust removalFire preventionPipingDrill hole

The invention provides a dust removal device with a wind-water mixing function and a drilling rig thereof. The dust removal device comprises a compressed air system, a wind-water mixing box, a first pipeline, a water containing pipe, a second pipeline, a third pipeline, and a drilling air inlet one-way valve, wherein an inlet of the first pipeline is connected with the compressed air system, an outlet of the first pipeline communicates with the top of the wind-water mixing box, the water containing pipe communicates with the wind-water mixing box, and supplies water to the wind-water mixing box, the second pipeline is arranged at the bottom of the wind-water mixing box and communicates with a drill rod of the drilling rig, the third pipeline is connected between the first pipeline and thesecond pipeline, the drilling air inlet one-way valve is arranged on the third pipeline, and an inlet of the drilling air inlet one-way valve faces the first pipeline. High-pressure blast and water are synchronously fed into a drilling impactor, the high-pressure blast provides power for impacting coring drilling, rock powder and rock debris generated in the drilling process are wetted by the water, the drilling effect of an impacting drilling coring sample is guaranteed, and the flying situation of the rock powder is reduced; and the dust removal device has very high practical value and promotional value in the field of tunnel geological advance impacting coring drilling.

Owner:四川中铁二院环保科技有限公司 +1

An improved drilling device for spherical jade

ActiveCN104802312BEnsure drilling qualityGuaranteed drilling effectEdge grinding machinesWorking accessoriesEngineeringSpherical shaped

The invention discloses an improved hole drilling device for ball-shaped jade. The improved hole drilling device comprises a machine frame, a main turntable, a sub turntable, a main transmission device, a sub transmission device, a main motor, a sub motor, a hole drilling assembly and a third transmission device, wherein the main transmission device is connected with the main turntable, the sub transmission device is connected with the sub turntable, the main motor is used for driving the main transmission device to work, the sub motor is used for driving the sub transmission device to work, the hole drilling assembly is used for carrying out hole drilling work on the jade, the third transmission device is connected with the hole drilling assembly, the main turntable and the sub turntable are in parallel arrangement and are rotationally arranged on the machine frame, the rotating directions of the main turntable and the sub turntable are opposite, a plurality of main circular grooves are formed in the main turntable, a plurality of sub circular grooves are formed in the sub turntable, the main circular grooves and the sub circular grooves are matched with the tangent position parts of the main turntable and the sub turntable, and a clamp part used for clamping the jade is formed. The improved hole drilling device has the advantages that the hole drilling quality of the jade can be effectively ensured, and the processing efficiency is greatly improved.

Owner:山东益华生物科技有限公司

A four-hole bergamot power line clamp drilling machine

ActiveCN113681054BImprove drilling efficiencyEasy to fixPositioning apparatusMetal-working holdersPilot holePower cable

Owner:江苏恒康电力科技有限公司

Electric spiral cone rod extrusion oil tank oil drain hole equipment

ActiveCN111618068BSmooth oil dischargeDrain oil thoroughlySolid waste disposalTransportation and packagingCouplingFuel tank

The invention discloses an electric screw taper rod extruding oil tank oil discharge hole equipment, which includes a lifting device and a working host connected to the output end of the lifting device; the working host includes a driving mechanism, a spiral cone and an oil cup; the driving mechanism includes a spline shaft, a spline The top surface of the key shaft is provided with a first end tooth; the bottom surface of the spiral cone is provided with a second end tooth, and the first end tooth and the second end tooth are connected through a coupling sleeve; the spiral cone has a first state and a second state. In the first state, the top of the spiral cone is located in the oil cup; in the second state, the top of the spiral cone is located above the oil cup; the device drives the spiral cone to rotate and rise through the driving mechanism, and the spiral cone can quickly Pierce the fuel tank, drive the mechanism and drive the spiral cone to descend, so that the oil in the fuel tank flows into the oil cup; when the spiral cone descends, the upward flange at the opening of the fuel tank will be pulled back downward through the outer spiral to make the fuel tank turn over The side is downward, which ensures the smooth and thorough oil discharge.

Owner:NANJING COLLEGE OF INFORMATION TECH

Furniture sponge drilling machine

InactiveCN102729291BAvoid deformationImprove work efficiencyMetal working apparatusMechanical engineeringDrilling machines

Owner:李钊怀

Drain hole equipment of electrical spiral cone rod protrusion oil tank

ActiveCN111618068ASmooth oil dischargeDrain oil thoroughlySolid waste disposalFluid-pressure actuator componentsEngineeringMechanical engineering

The invention discloses drain hole equipment of an electrical spiral cone rod protrusion oil tank. The equipment comprises a lifting device and a working main machine connected to an output end of thelifting device, wherein the working main machine comprises a driving mechanism, a spiral cone body and an oil cup. The driving mechanism comprises a spline shaft, and a first end tooth is arranged onthe top surface of the spline shaft; a second end tooth is arranged on the bottom surface of the spiral cone body, and the first end tooth and the second end tooth are connected through a coupling band; the spiral cone body has a first state and a second state, the top end of the spiral cone body in the first state is located in the oil cup, and the top end of the spiral cone body in the second state is located above the oil cup. According to the device, the spiral cone body is driven by the driving mechanism to rotate and rise, so that the spiral cone body can pierce the oil tank quickly, and the driving mechanism drives the spiral cone body to descend, so that oil in the oil tank flows into the oil cup; when the spiral cone body descends, an upward turnup at an opening of the oil tank is pulled back downward by means of rotation outside, so that the turnup of the oil tank is downward, and therefore, it is ensured that oil is drained smoothly and thoroughly.

Owner:NANJING COLLEGE OF INFORMATION TECH

Application method of drilling machine for hardware precise part machining

InactiveCN108262501AImprove protectionAvoid damageFeeding apparatusPositioning apparatusDamping functionDrilling machines

The invention discloses an application method of a drilling machine for hardware precise part machining. The drilling machine comprises a base plate; one side of the top of the base plate is fixedly connected with a support rod; the top end of the support rod is fixedly connected with a fixed plate; the two sides of the bottom of the fixed plate are slidingly connected with movable rods matched for use; the ends, far from the fixed plate, of the movable rods are movably connected with electric drill bits; the tops of the electric drill bits are fixedly connected with fixed rods; and the drilling machine relates to the technical field of drilling machines. The drilling machine for hardware precise part machining can preferably protect the base plate, prevents damage of the base plate by theelectric drill bits, prolongs the service life, is safe and reliable, can prevent damage of the base plate, guarantees the drilling effect of the electric drill bits, reduces drilling errors, achieves excellent fixing function, reduces influence on the electric drill bits by vibration during drilling, and achieves excellent damping function and excellent convenience.

Owner:方建松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com