A laser drilling steel plate clamping mechanism

A clamping mechanism and laser drilling technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unevenness on the board surface, low accuracy of drilling position, and influence on processing effect, etc., to achieve guaranteed The effect of the drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

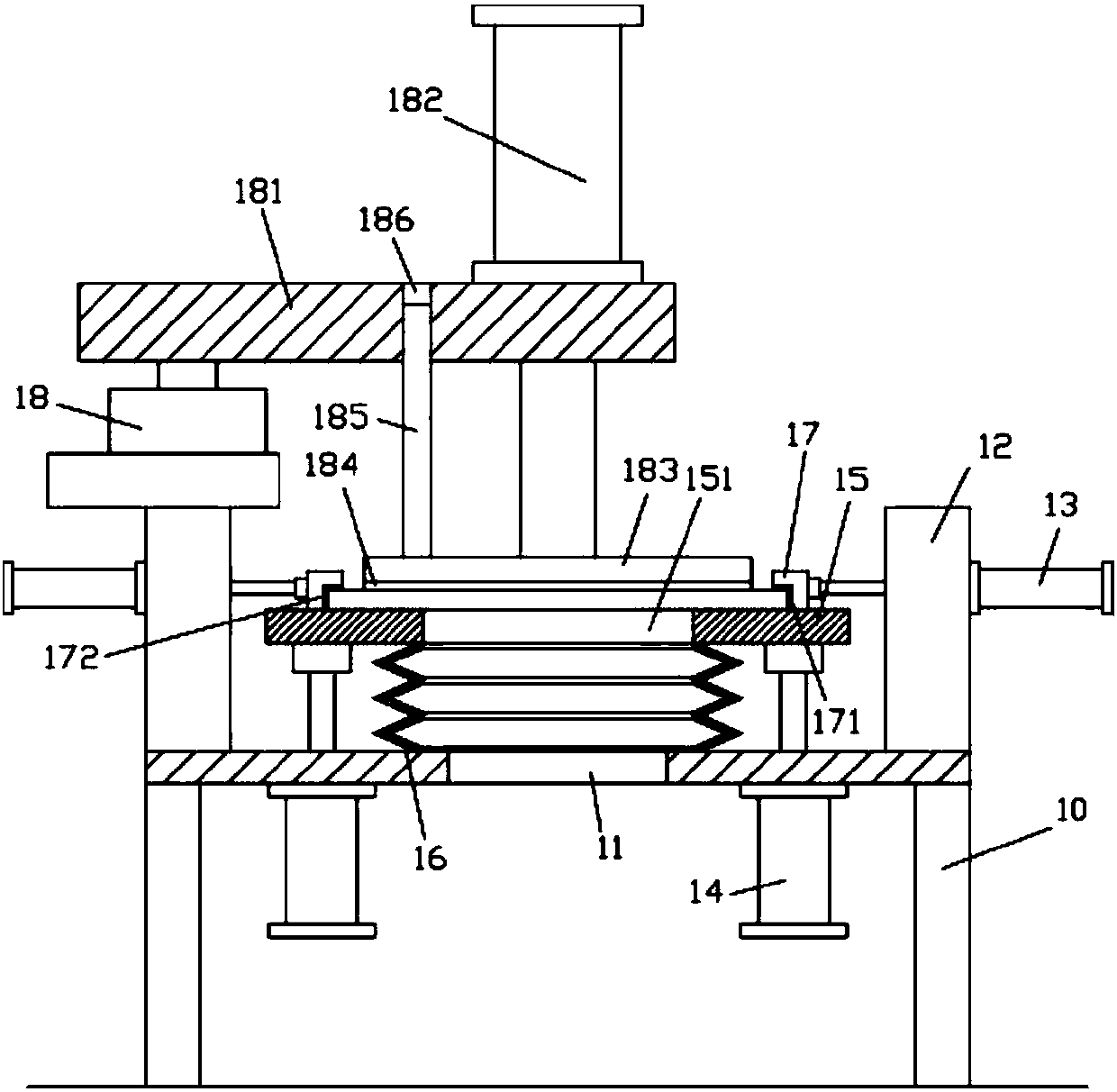

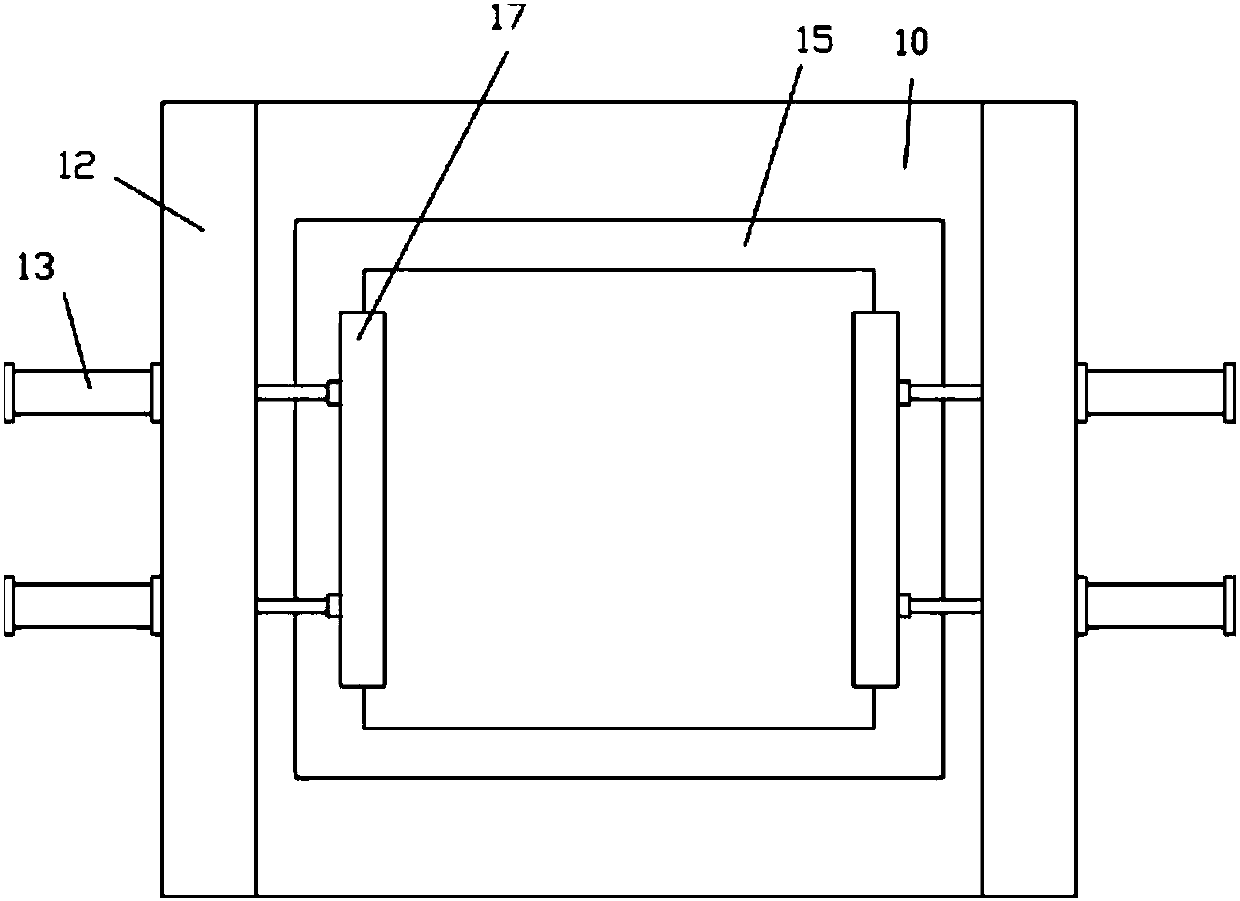

[0017] Examples, see e.g. Figure 1 to Figure 2 As shown, a laser drilling steel plate clamping mechanism includes a frame 10, the middle part of the top plate of the frame 10 has a discharge through hole 11, and the left and right top surfaces of the top plate of the frame 10 are fixed with vertical Support plate 12, a plurality of clamping cylinders 13 are fixed on the outer wall of the vertical support plate 12, lifting cylinders 14 are fixed on both sides of the bottom surface of the top plate of the frame 10, and the push rod of the lifting cylinder 14 passes through the frame vertically upwards 10 and is fixed on the bottom surface of the support plate 15, the support plate 15 is above the top plate of the frame 10, the middle part of the support plate 15 has a blanking through hole 151, and the blanking through hole 151 is aligned with the discharge through hole 11 up and down , the upper end of the corrugated protective cover 16 is fixed on the bottom surface of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com