Intelligent pipe drilling control system and method

A control system and pipe technology, applied in the direction of metal processing, etc., can solve the problem of not being suitable for batch drilling processing, and achieve the effect of ensuring stability, meeting production requirements, and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

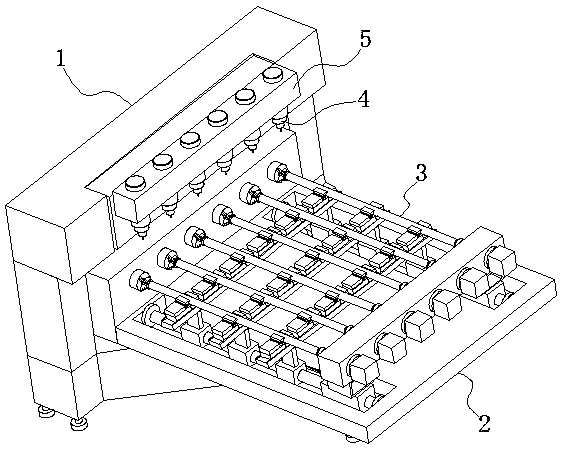

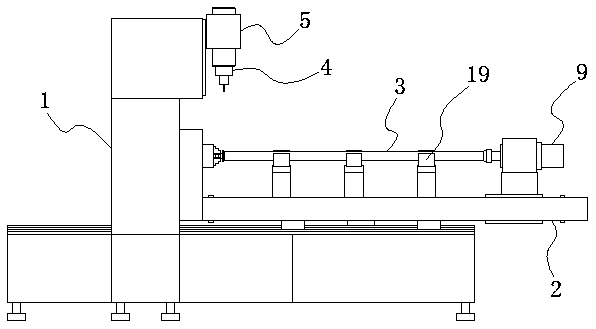

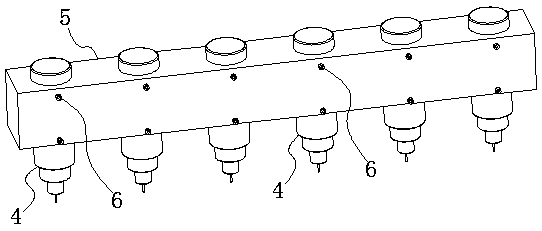

[0044] Embodiment 1: as figure 1 with figure 2 As shown, an intelligent drilling control system for pipes includes a PLC control system and an axial clamping solenoid valve electrically connected to the PLC control system, a horizontal movement drive device and an electromagnetic switch, and the axial clamping solenoid valve and the polymer pipe The clamping device 2 is connected to control the polymer tube clamping device 2 to simultaneously clamp multiple polymer tubes along the axial direction of the polymer tube, and the horizontal movement drive device is arranged on the frame main body 1 and the polymer tube clamping device Between 2, the relative movement between the frame main body 1 and the polymer pipe clamping device 2 can be driven by the horizontal moving drive device, and a plurality of spindle power drills 4 are arranged on the frame main body 1, and the electromagnetic switch and the multiple spindle power The drill bit 4 is connected, and is used to simultan...

Embodiment 2

[0082] Embodiment 2: Compared with Embodiment 1, the difference is: as Figure 13 As shown, the polymer pipe clamping device also includes a loading and unloading manipulator 27 for automatically clamping the polymer pipe 3 and a lever mechanism 28 arranged near the top cone 2 10, through which the high One end of the molecular pipe 3 is pulled away from the top cone 2 10, and a detection sensor for detecting whether the polymer pipe is placed in place is also provided on the working platform. The loading and unloading manipulator, the lever mechanism and the detection sensor are all connected with the PLC control system electrical connection; in this embodiment, the detection sensor can be an infrared sensor.

[0083] Before the drilling process, the loading and unloading manipulator 27 is controlled by the PLC control system to place multiple polymer pipes 3 on the working platform 7. When the detection sensor detects that the polymer pipes are placed in place, a signal is s...

Embodiment 3

[0085] Embodiment 3: Compared with Embodiment 1, the difference is that: the polymer pipe clamping device also includes a loading and unloading manipulator for automatically clamping the polymer pipe.

[0086] The fixation of the transverse guide rail on the guide column does not use limit parts, but a power cylinder mechanism is set on the working platform, and the power cylinder mechanism can be an air cylinder or an oil cylinder. The power cylinder mechanism is connected with the slider, driven by the power cylinder mechanism, the slider can move back and forth along the guide column or fixed, and the power cylinder mechanism is also electrically connected with the PLC control system.

[0087] Before the drilling process, multiple polymer pipes can be placed on the working platform through the loading and unloading manipulator. After the drilling process is completed, when the telescopic power cylinder drives the top cone to retract, one end of the polymer pipe is aligned wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com