Three-connected-arch tunnel double-side cavity construction method for soft geological

A construction method and weak geological technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as large excavation area of a single block, long exposure time of surrounding rock, crack support effect, etc., to save energy, overcome Difficult to deal with waterproofing, reasonable division of excavation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

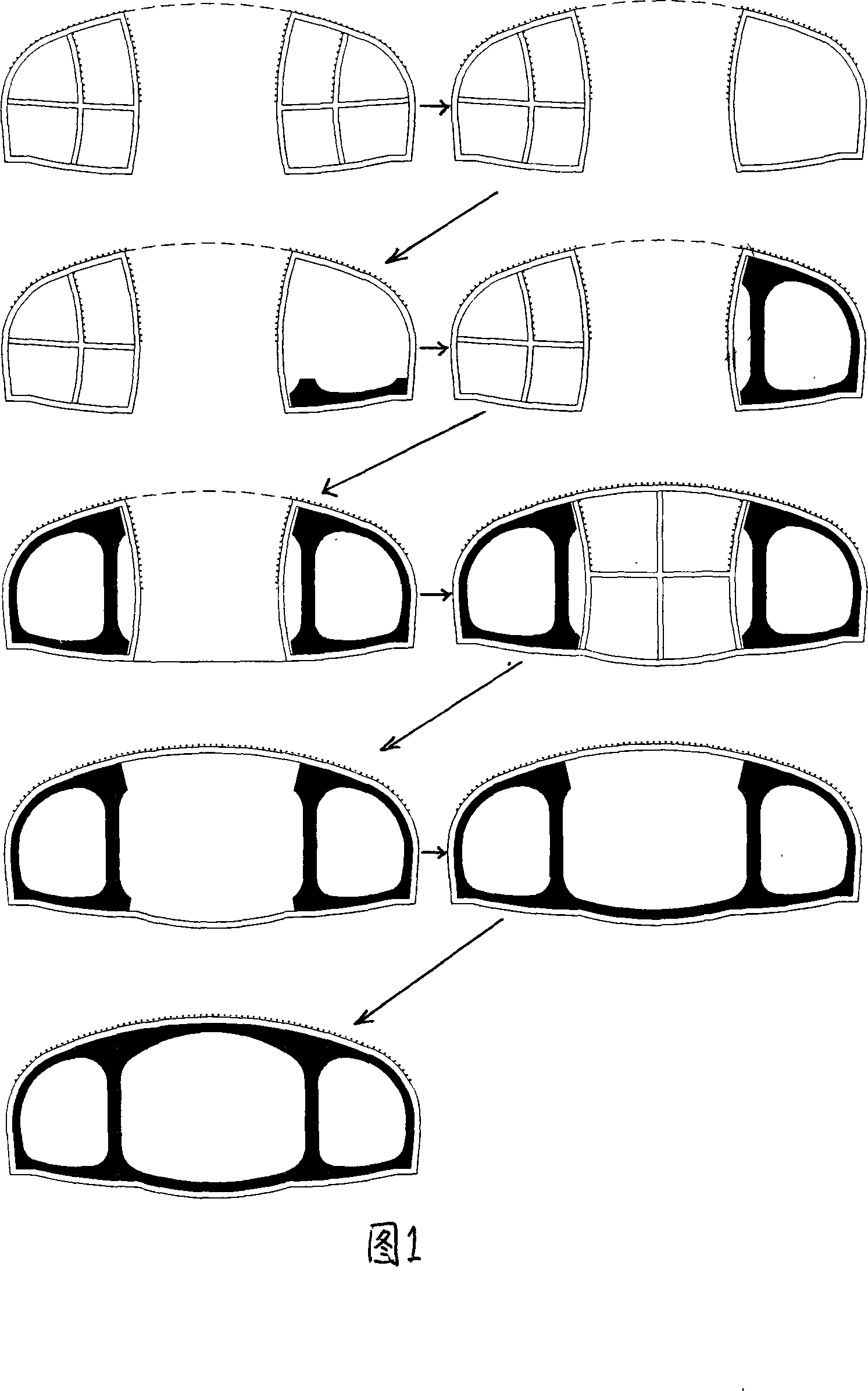

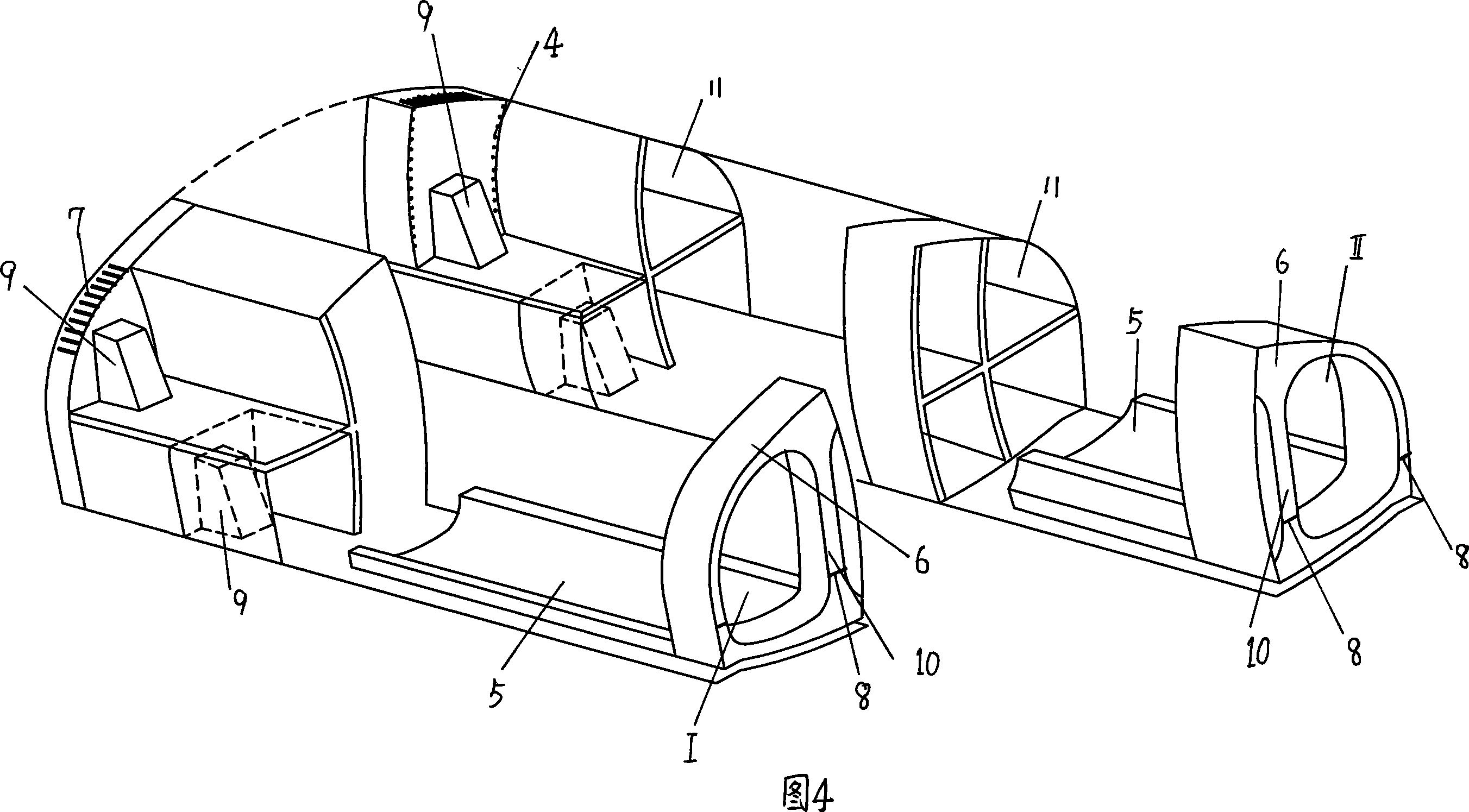

[0020] A construction method for double-side tunnels of a triple-arch tunnel in weak geological conditions. First, the tunnel section is divided into three parts according to the clearance size and use requirements, namely two side tunnels I, II and middle tunnel III. The specific construction steps are as follows: (1) side tunnels Hole excavation: The present invention divides the excavation section of each side hole into four (or six or eight) pilot tunnels 11, and then adopts the principle of CRD method to excavate, each pilot tunnel is staggered by 5-7m, leaving about 2m staggered excavation, the footage per cycle is determined according to the steel grid spacing of the initial support 4, and the concrete is sprayed in time to stabilize the excavation surface after excavation; (2) Side tunnel lining: firstly, according to the geological conditions, section size and after Stress analysis, one-time full-section demolition of temporary support, the specific method is to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com