Valve body transverse drilling equipment and drilling method thereof

A technology of horizontal drilling and valve body, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problem of reduced processing efficiency of the valve body, reduce the thrust of the drilling position, and ensure Drilling efficiency, the effect of ensuring the drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-6 The application is described in further detail.

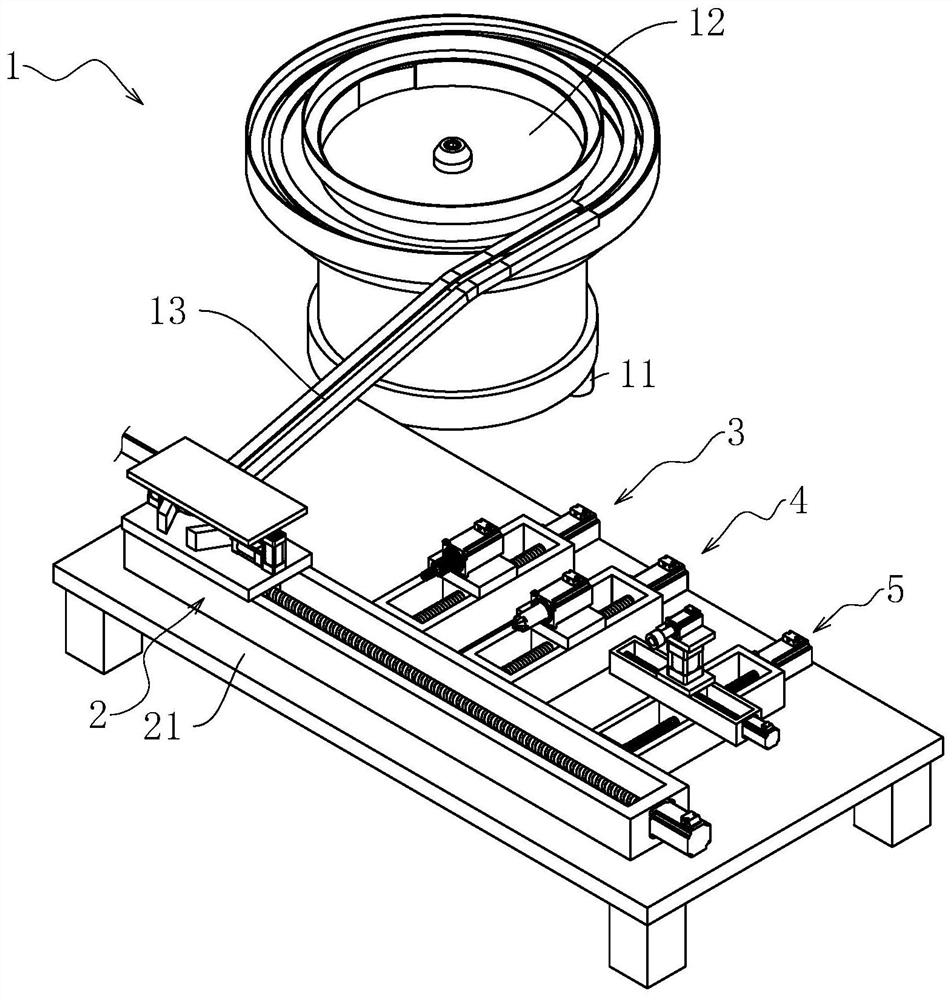

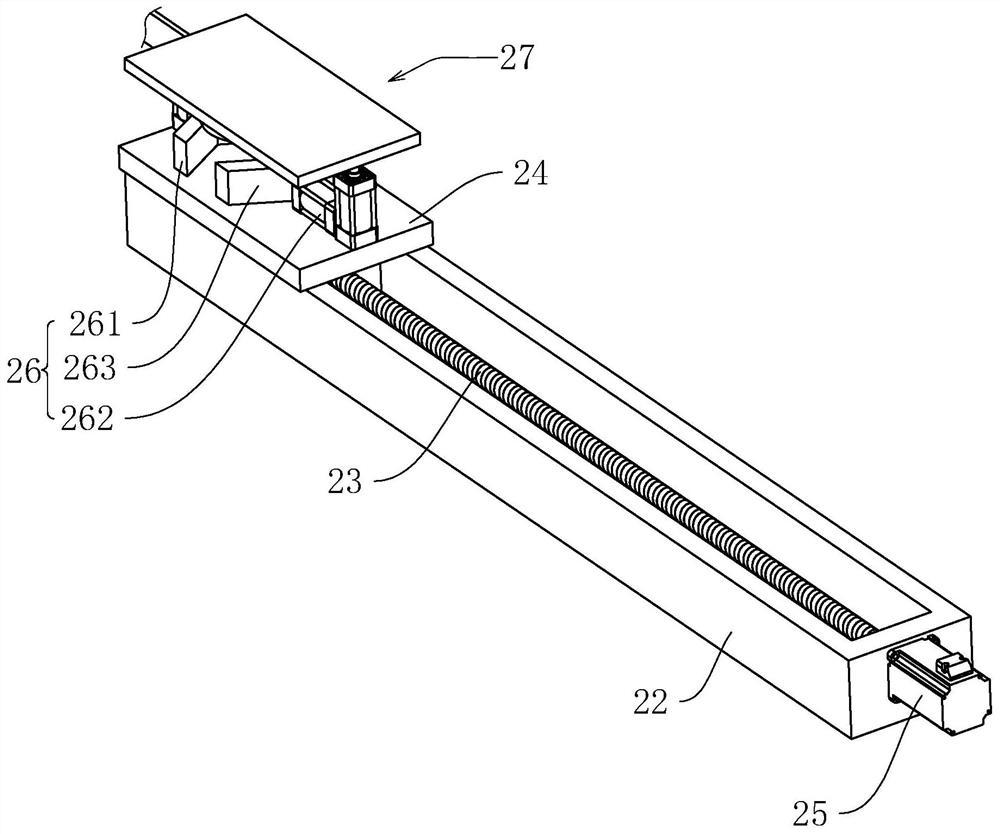

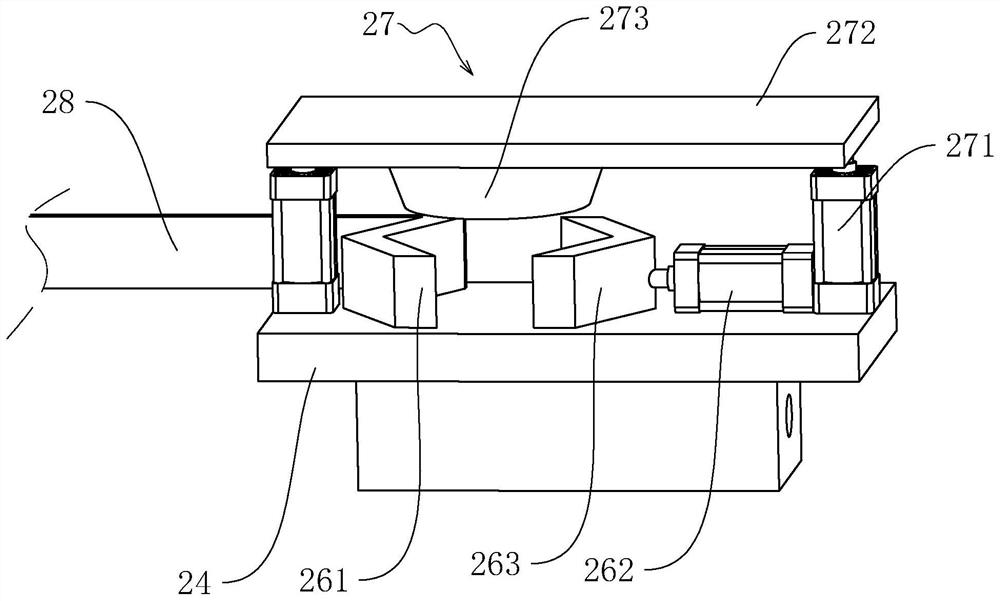

[0042] The embodiment of the present application discloses a valve body transverse drilling device. refer to figure 1 , The valve body transverse drilling equipment includes an automatic feeding mechanism 1, and the end of the automatic feeding mechanism 1 is provided with a transport mechanism 2. The side of the transport mechanism 2 is provided with a rough drilling mechanism 3 , a fine drilling mechanism 4 and a grinding mechanism 5 in sequence along the valve body transport direction.

[0043] refer to figure 1 and figure 2 , the automatic feeding mechanism 1 includes a feeding rack 11, a vibrating discharge tray 12 is fixed on the feeding rack 11, and an inclined downward guide rail 13 is installed on the discharge port of the vibrating discharge tray 12, and the guide rail 13 The end is connected with the transport mechanism 2 . If the small valve body is processed, seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com