Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce the flow cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

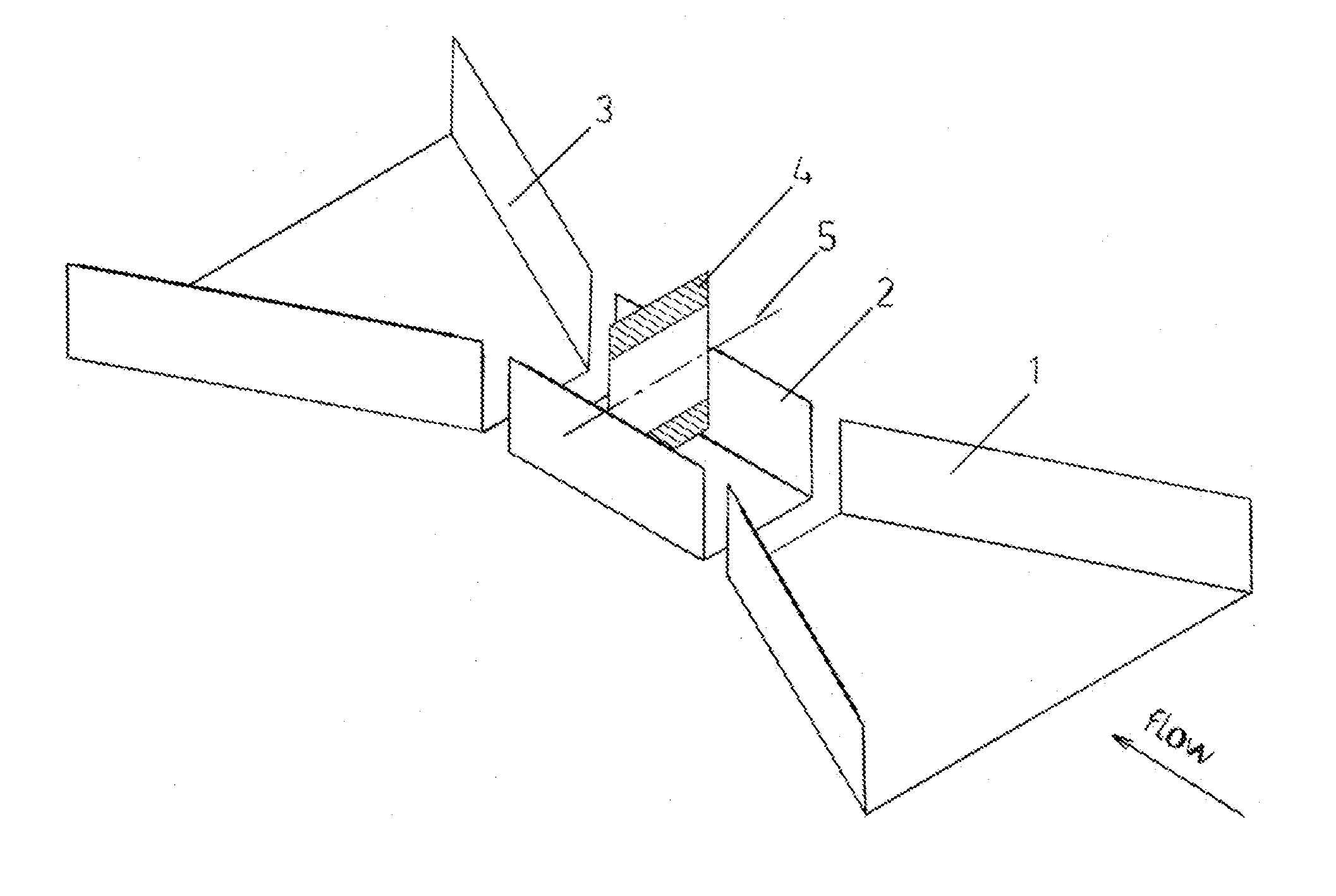

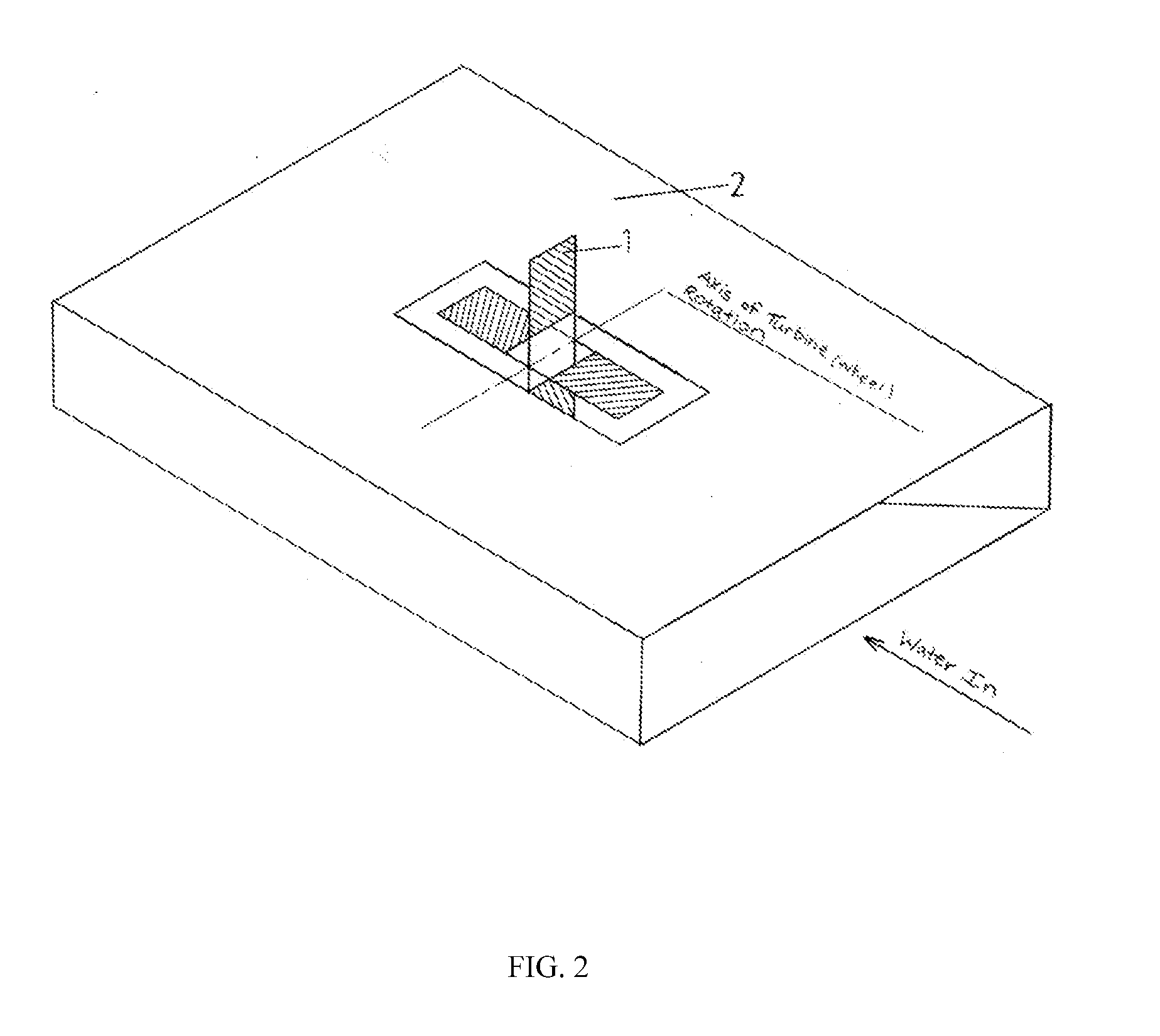

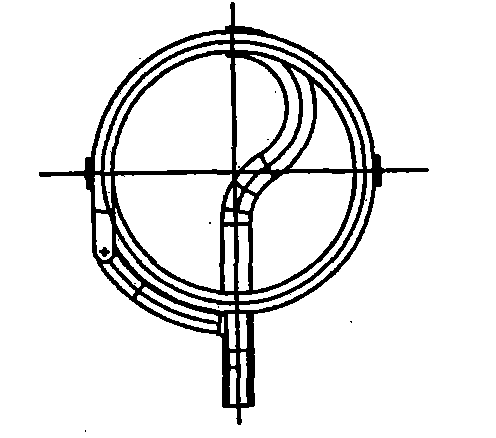

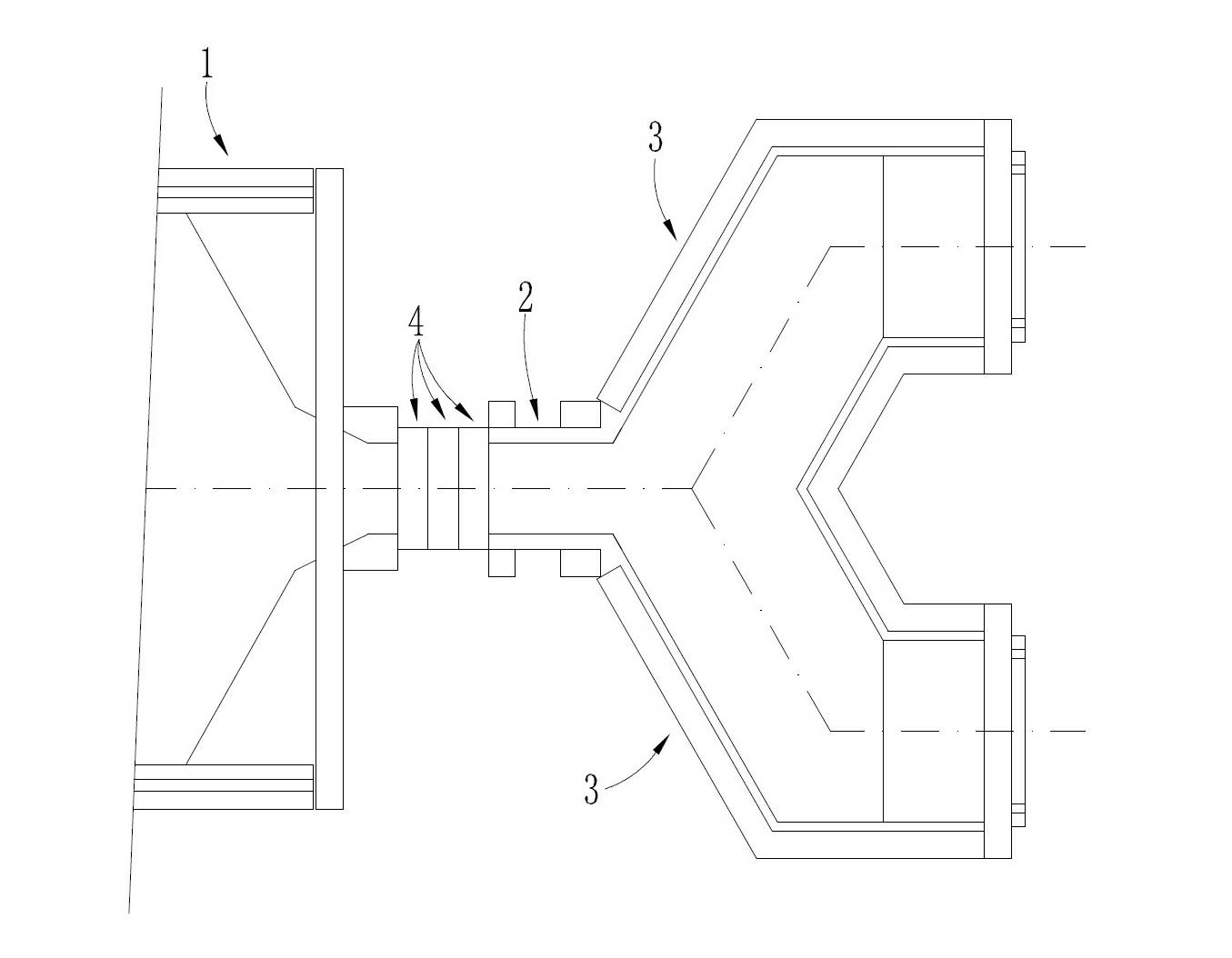

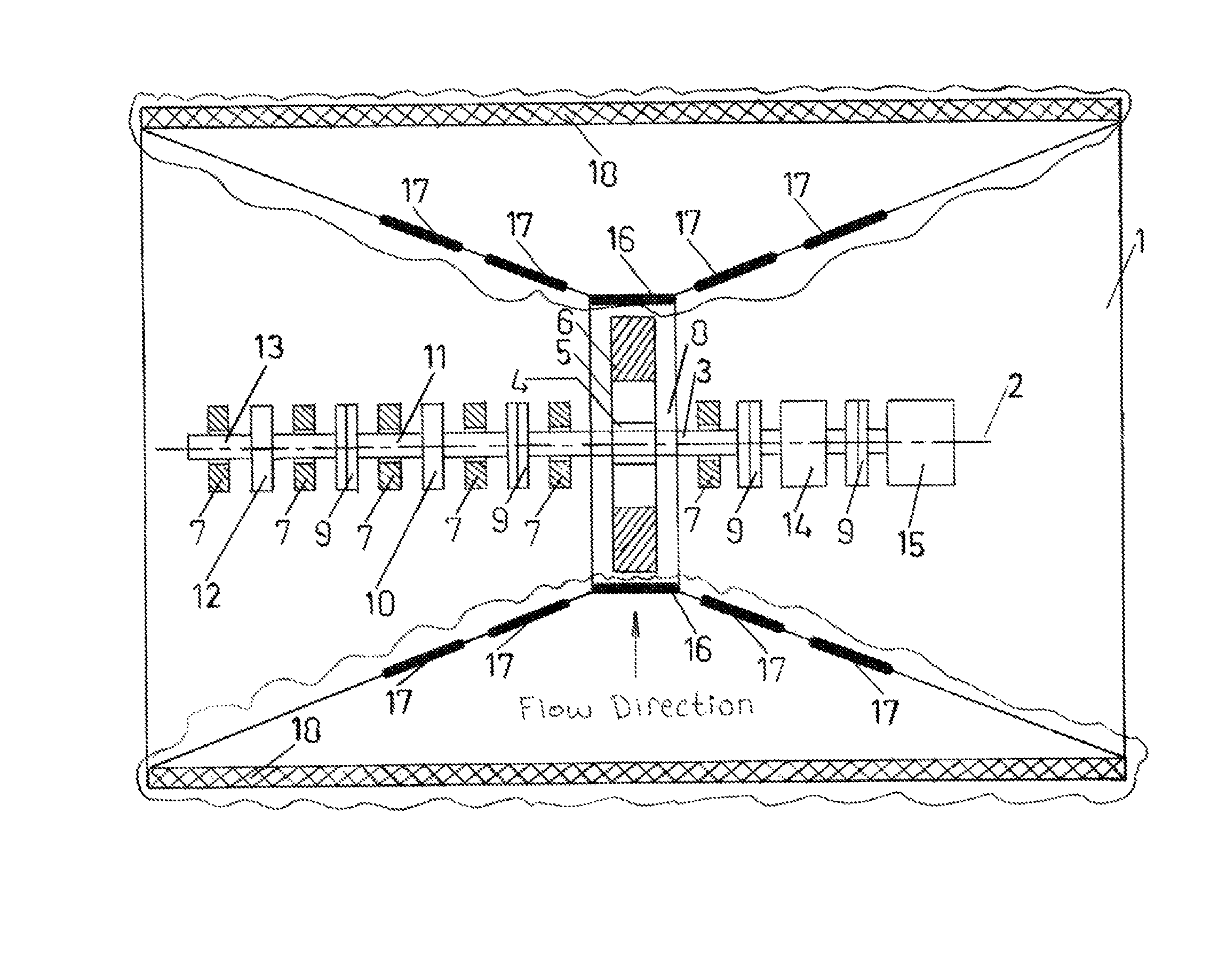

Renewable Energy Extraction Device

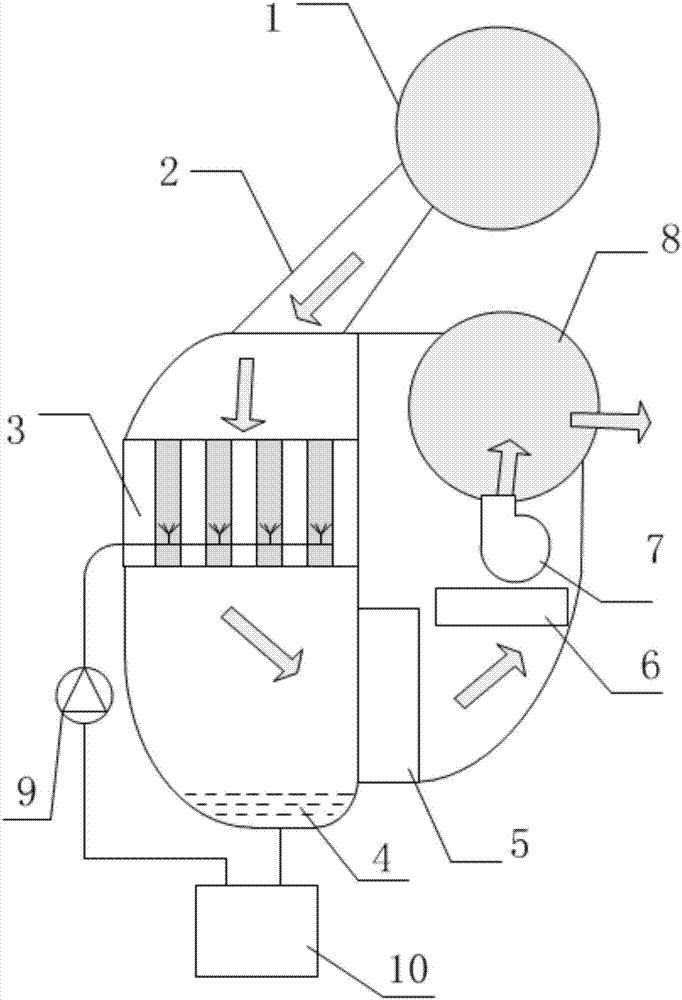

ActiveUS20130069369A1Simple and practical designWind energy efficientlyPropellersPump componentsAtmospheric airMechanical energy

Disclosed is a renewable energy extraction device and methods for producing renewable energy from flowing air or water. The renewable energy extraction device captures a relatively large amount of flowing water or atmospheric air and increases speed of the captured water or air by decreasing flow cross sectional area in the flow direction. An energy extraction component is used to extract energy of the high-speed water or air and convert it to rotational mechanical energy on a power shaft. A rotation direction control mechanism is used to make the power shaft always rotate in one direction, without coming to a stop, for ocean applications. The mechanical energy of the power shaft is transmitted to an electric generator, pump, compressor, or any other rotary equipment. After extraction of its energy, the captured air or water is released to its original source at a downstream location.

Owner:SALEHPOOR KARIM

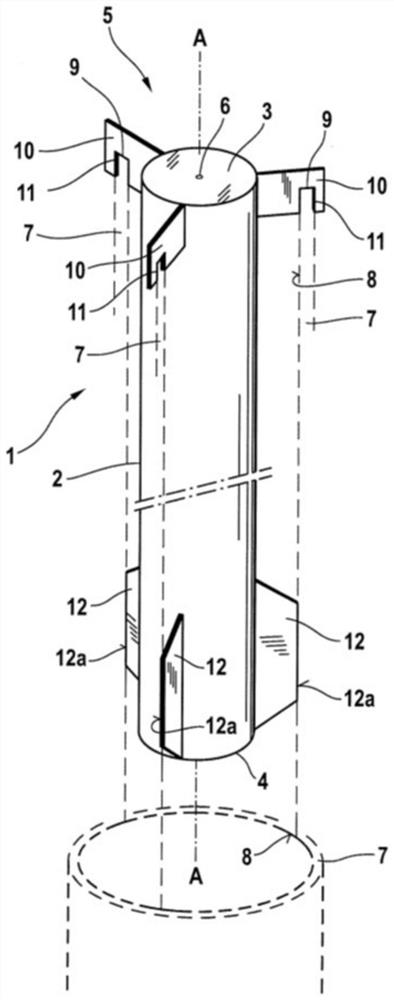

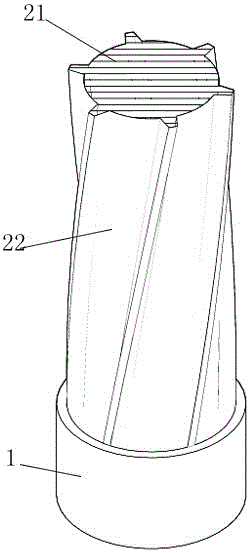

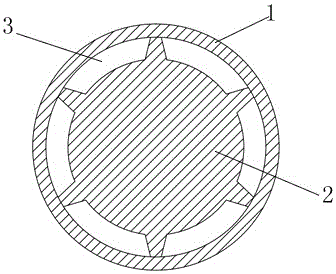

Complex turbine device with variable section

InactiveCN101985897AGuaranteed inflowAvoid enteringInternal combustion piston enginesBlade accessoriesImpellerLow speed

The invention discloses a complex turbine device with a variable section, comprising a double flow channel turbine volute, wherein the double flow channel turbine volute is provided with two air flow passageways; the double flow channel turbine volute is provided with a volute air outlet and a volute air inlet which are communicated with the air flow passageways; a complex turbine impeller is arranged in the double flow channel turbine volute; and the complex turbine impeller is formed by compounding two turbine impellers which correspond to the two air flow passageways one by one. In the invention, the variable section function can be achieved by design and development of the turbine of a turbocharger and by using the complex turbine device, thereby effectively solving the defects of poor reliability and high cost of a vane type turbocharger with the variable section, effectively improving the efficiency of the turbine of an engine in low speed and increasing the torque output of the turbine.

Owner:KANGYUE TECH

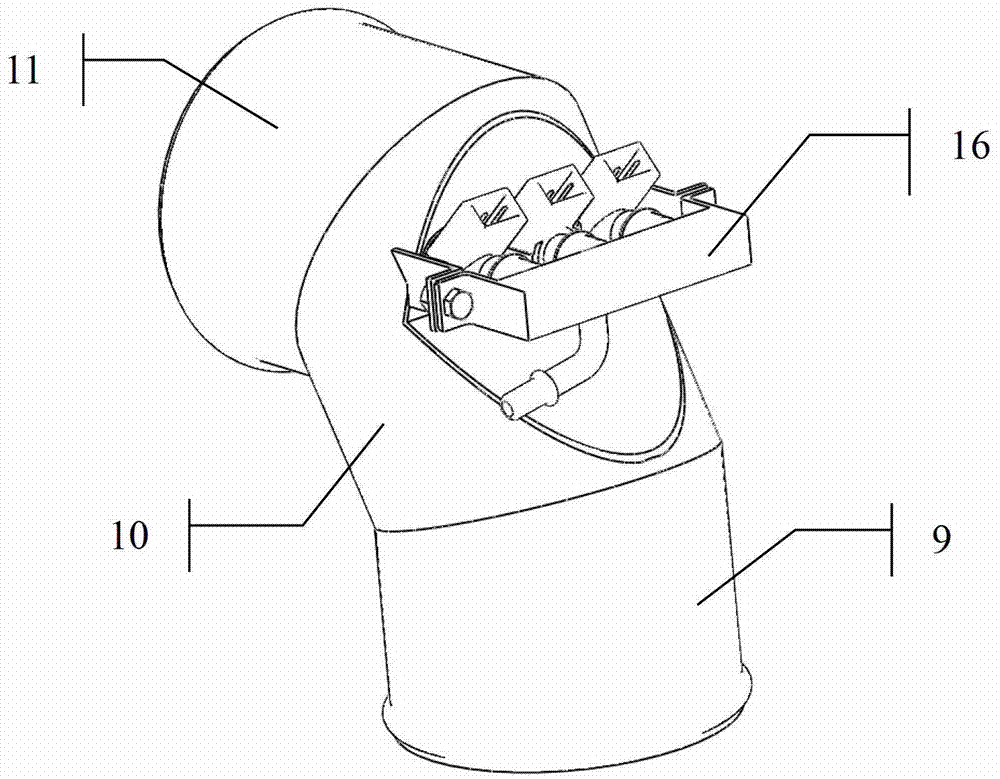

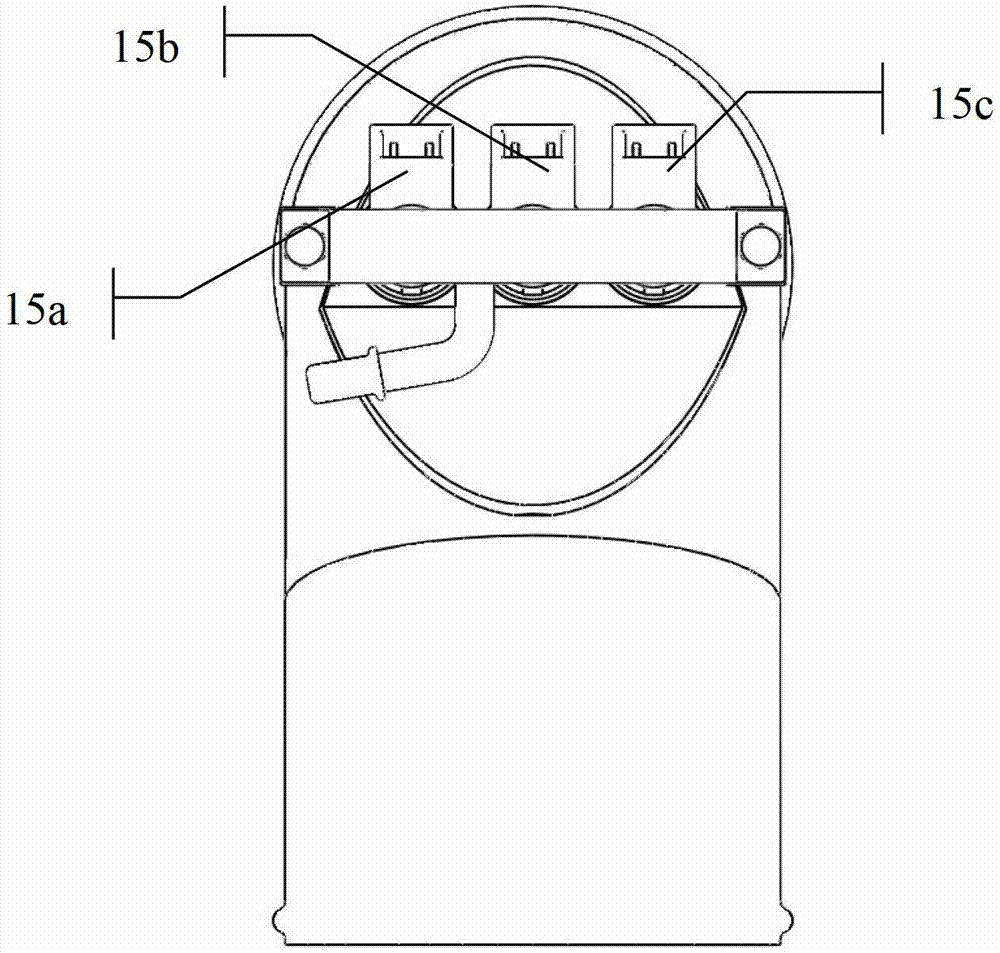

Air inlet regulating device of flow-passage-changeable turbine

ActiveCN102182544ARealize intake and exhaust pressure requirementsGuaranteed to workInternal combustion piston enginesTurbineInlet flow

The invention discloses an air inlet regulating device of a flow-passage-changeable turbine. The air inlet regulating device comprises a turbine shell, an executing device and an air inlet flow regulating device, wherein the executing device is in transmission connection with the air inlet flow regulating device; an exhaust gas bypass device is arranged on the turbine shell; and the executing device is in transmission connection with the exhaust gas bypass device. The executing device can control the air inlet flow regulating device and the exhaust gas bypass device at the same time, so as to select the air inlet flow passage of the flow-passage-changeable turbine and control the air inlet flow and the exhaust gas bypass flow; and on the premise of ensuring the high-efficiency work of the turbine, the section-changeable function of a supercharger is realized, and the requirement for the whole-working-condition pressurization of an engine can be met.

Owner:康跃科技(山东)有限公司

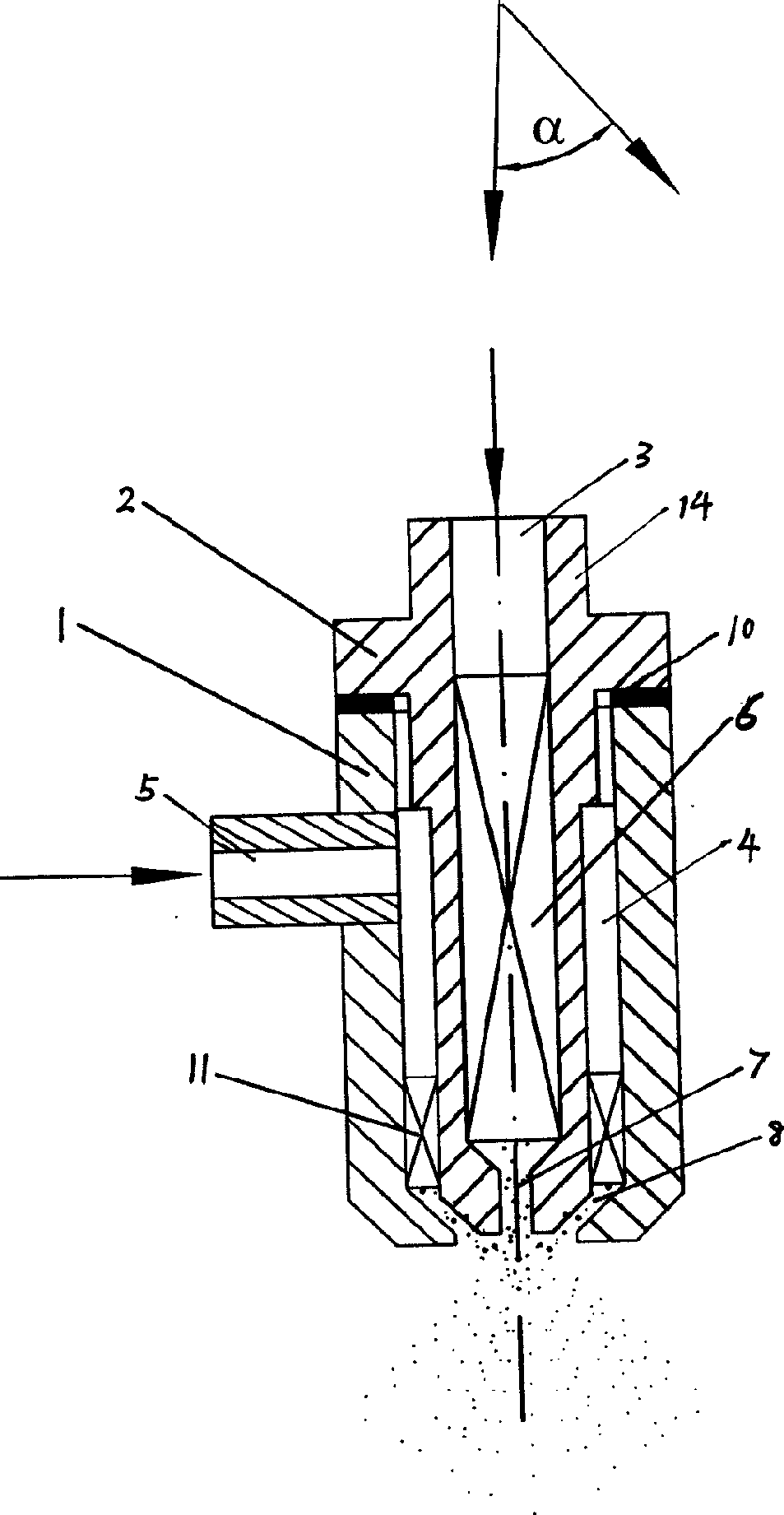

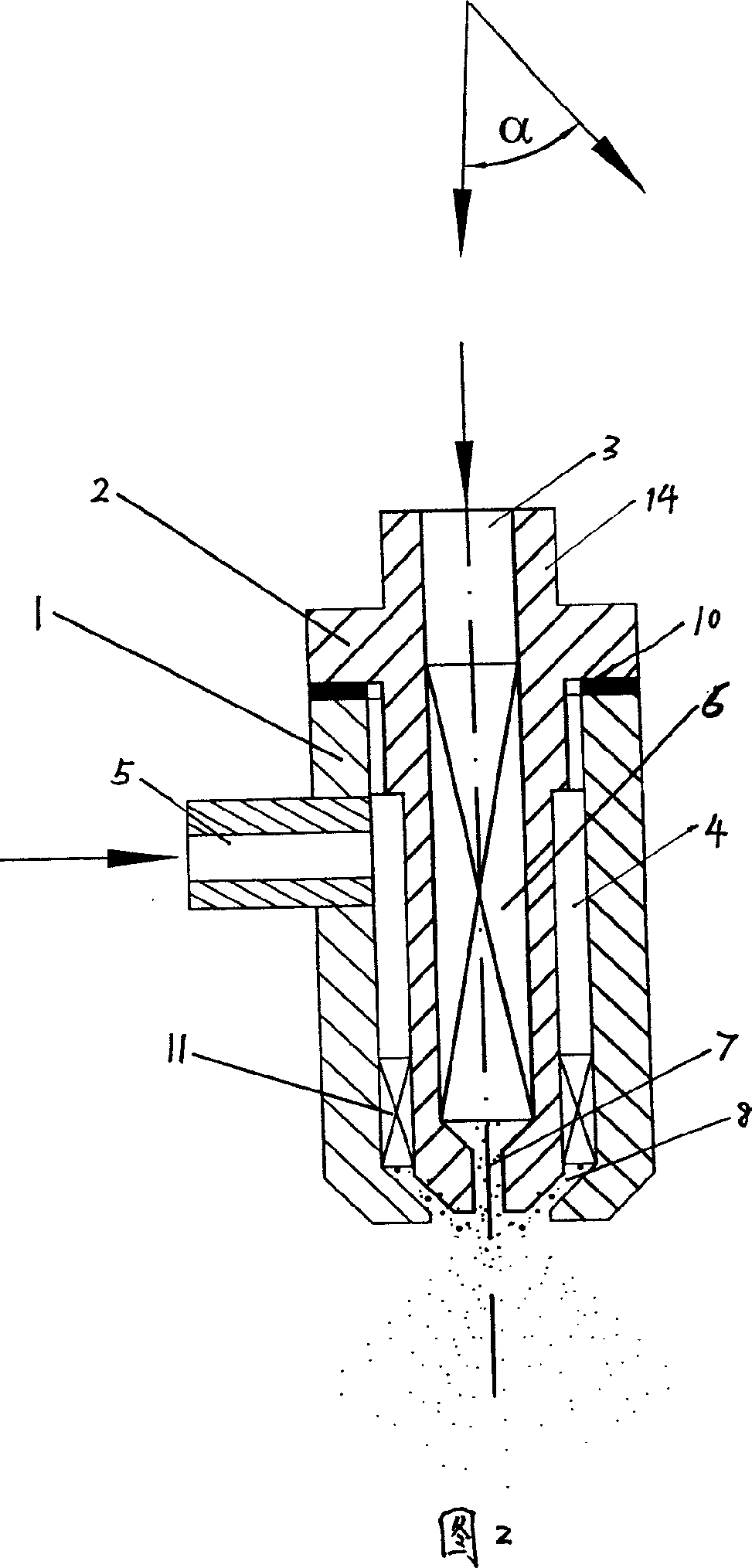

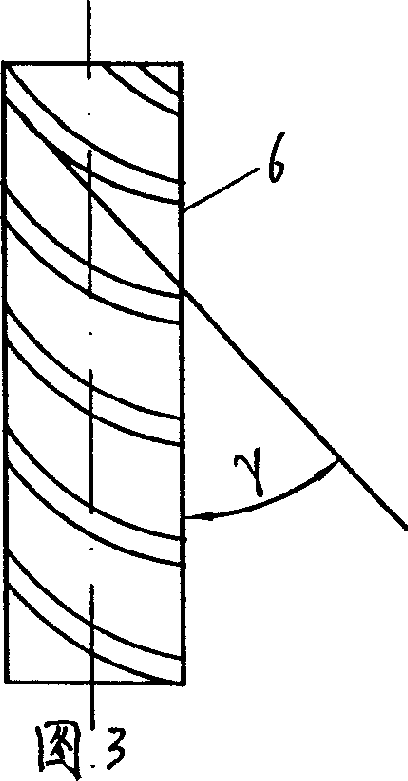

Film pre-forming two flowing type nozzle, stillpot with the nozzle and technique for producing ultra-fine dust utilizing the stillpot

InactiveCN1689682AIncrease mass transfer rateReduce the flow cross-sectional areaSolution crystallizationChemical/physical/physico-chemical nozzle-type rreactorsUltra fineSupercritical fluid

The present invention discloses one kind of pre-filming flow nozzle, stillpot with the nozzle and the production process of superfine particle in the stillpot with the nozzle. The nozzle includes casing, pre-filming unit, flow channel, ring gap flow channel, etc. and has the structure with greatly lowered flow resistance on solution and less jamming caused by the solute particle. The stillpot has simple structure, convenient operation, light labor strength and excellent sealing effect owing to the C-shaped metal sealing part with upper and lower sealing planes in linear contact state. By means of the supercritical fluid forced dispersing solution process in the stillpot with the nozzle, superfine solute particle may be prepared.

Owner:贺文智 +2

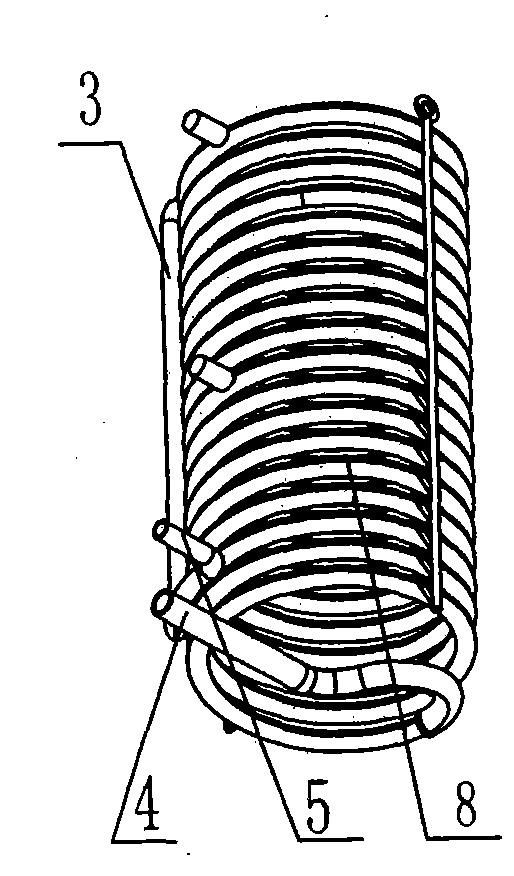

Heat pump water heater

ActiveCN101839547AReduce heat transfer areaReduce weightHeat pumpsHeat storage plantsEngineeringProcessing cost

The invention relates to a heat pump water heater and belongs to the technical field of water heaters. The water heater comprises a heat pump system which consists of a compressor, a condenser, a throttling element, and an evaporator. The condenser is arranged on a water tank of the water heater to form a heat exchange structure; and the condenser consists of at least two sections of heat exchange tubes which are connected in series along the flow direction of a refrigerant, and the flow area of the front section of the heat exchange tube is more than that of the rear section of the heat exchange tube. Because the heat exchange capacity of the condenser is effectively improved, the heat pump performance can be effectively improved when the heat exchange area is the same; the heat exchange area and weight needed by the condenser are greatly reduced on the premise of guaranteeing good operating effect of the heat pump; the materials and processing cost thereof are effectively saved; and the structural dimension is reduced. Therefore, the reliability is improved; and due to the simpleness and practicality of the structure and technology, the cost is reduced, and the market competitiveness of the products is improved.

Owner:A O SMITH CHINA WATER HEATER CO LTD

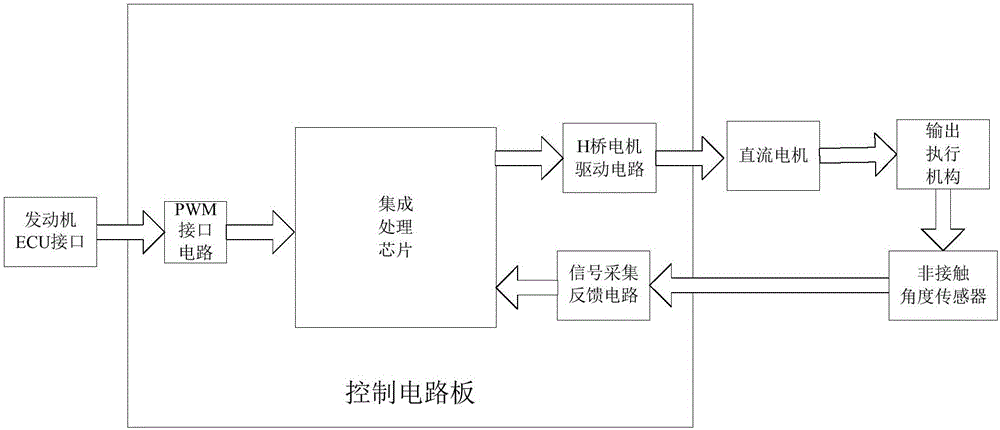

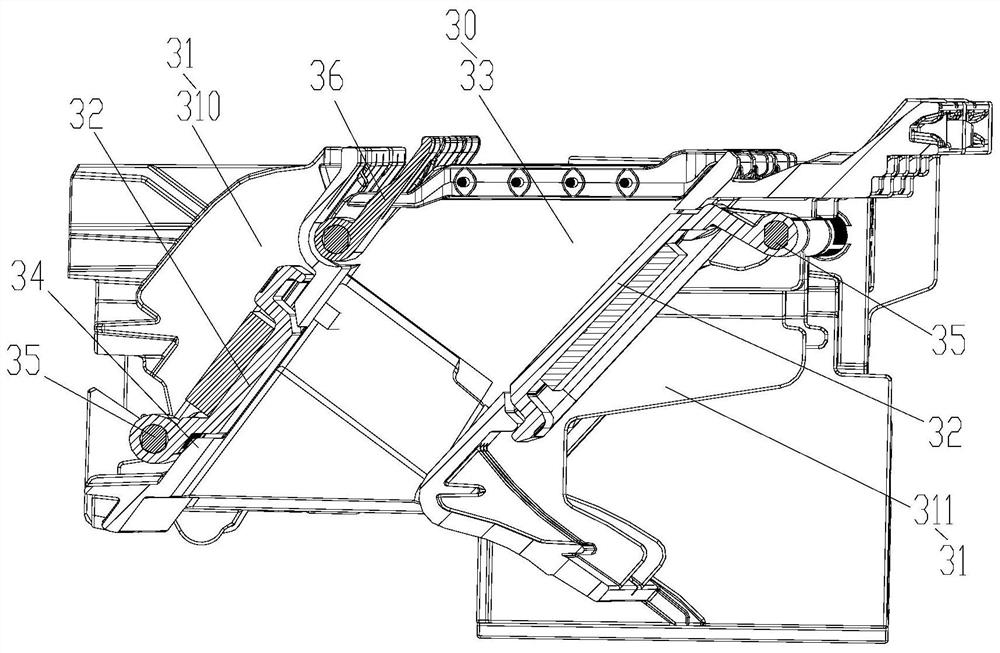

Electric control actuator for variable-geometry turbocharging

InactiveCN106640351AImprove economyReduce the flow cross-sectional areaInternal combustion piston enginesEngine componentsElectric controlActuator

The invention discloses an electric control actuator for variable-geometry turbocharging. The electric control actuator for variable-geometry turbocharging comprises a bottom casing, a plastic cover plate, a DC motor, a worm gear and worm unit, an output shaft, a non-contact high-precision position sensor and an integrated processing circuit PCB, wherein the DC motor is fixed in the bottom casing through a spring press piece, and a pinion is mounted at the shaft tail end of the DC motor and meshed and connected with the worm gear and worm unit; a rotor of the non-contact inductive sensor is prepared from a stamping part conducting material made of a closed wire in specific geometry and is fixed at the top end of the output shaft through a positioning hole, and a helical gear is mounted in the middle of the output shaft and meshed with the worm gear and worm unit for actuation output; and the integrated processing circuit PCB is inlaid in the plastic cover plate. Motor control is driven by angle signals acquired by an engine ECU to change the flow sectional area (nozzle opening) of a turbine nozzle, a supercharger and an engine are matched optimally, and the electric control actuator has the advantages of high real-timeness, high control precision, large torque and the like.

Owner:上海电控研究所有限公司

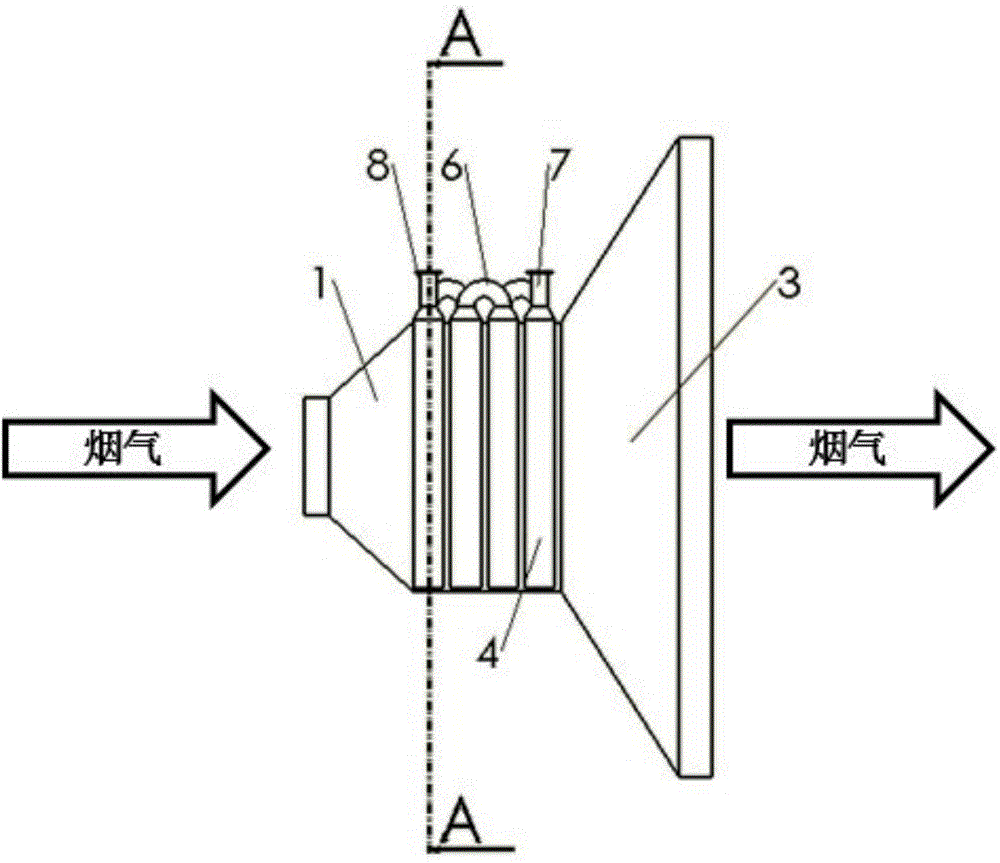

Novel tube panel type water tube heat exchanger integrated with electrostatic precipitator

ActiveCN103604113AMake full use of the flue spaceSmall footprintCombustion technology mitigationFeed-water heatersElectrical resistance and conductancePlate heat exchanger

A novel tube panel type water tube heat exchanger integrated with an electrostatic precipitator consists of a plurality of rows of tube panels, wherein each row of tube panels consists of heat exchanger headers at two ends and a plurality of heat exchanging tube bundles which are connected with the heat exchanger headers at the two ends; tube ends of the heat exchanger heads at the two ends of each of the adjacent tube panels are connected to one another through large-diameter elbows, so that working media of the adjacent tube panels are connected to one another; and heat exchanging tube bundles of each tube panel are arranged in a flue structure in a middle section of an extension section of an inlet of the precipitator. The heat exchanger does not occupy the other effective space in front of the inlet of the electrostatic precipitator; the waste heat of the smoke can be reasonably used; and the specific resistance of the soot is reduced, so that the efficiency of the electrostatic precipitator is improved. The novel tube panel type water tube heat exchanger integrated with the electrostatic precipitator has the advantages that the structure is simple and compact, modular production and modular assembly can be realized, and field installation is quite convenient.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP +1

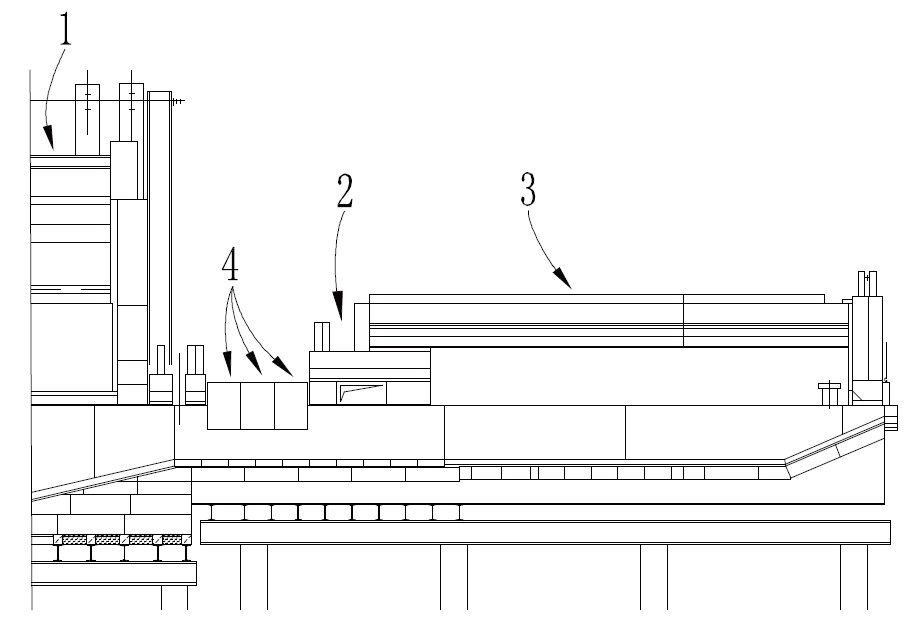

Energy saving ultra clear glass kiln

InactiveCN102417289AImprove energy savingReduce widthGlass furnace apparatusDirect communicationKiln

An energy saving ultra clear glass kiln comprises a plurality of cooling forehearth limbs and a melting zone, a clarification zone and a neck that are successively connected. At least one neck is included, and each neck is connected to at least one cooling forehearth limb and provided with a molten glass deep separation apparatus. One the one hand, each neck communicates with at least one cooling forehearth limb, namely a cooling transverse pathway is canceled, and a structure form of direct communication to the forehearth limb is employed; the cooling forehearth limb becomes an independent cooling portion, is in a small cooling portion arrangement and has little heat radiation; therefore, an area of the cooling portion is reduced, and molten glass flow in the cooling portion is smooth, and each ton of molten glass (discharge) accounts for 0.1-0.15m<2> of the cooling portion. on the other hand, the arrangement of molten glass deep separation apparatus compresses width of the neck, increases length of the neck, reduces a circulation section area of the molten glass at the neck, separates the molten glass in the neck and plays a role of reducing backflow of the molten glass. Thereby, the amount of the molten glass with obviously reduced temperature in the cooling portion flowing back to the clarification zone and the melting zone through the neck is effectively reduced, and liquid flow of the molten glass is much reasonable. The kiln has good energy saving effect.

Owner:陈永林

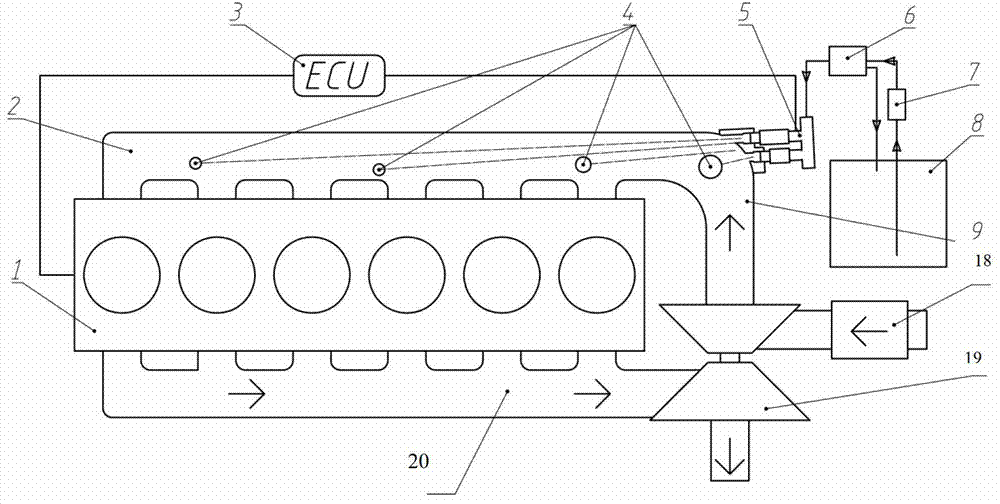

Penetration distance-composited alcohol spraying method and device

InactiveCN102953887AAlleviate heat load imbalanceReduce heat loadInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustionAlcohol

The invention relates to methyl alcohol spraying method and a device in mixed combustion of diesel oil and alcohol, and in particular relates to a penetration distance-composited alcohol spraying method and device, which speed up the evaporation and gasification of methyl alcohol drops and improves the uniformity of the mixtures of methyl alcohol and air which enter cylinders. The invention adopts the following technical scheme that an elbow is arranged at the joint of an intake manifold and an intake pipe of an engine; two or more spray nozzles with different penetration distances for spraying alcohol are installed at the elbow; center lines of the spray orifices of the spray nozzles are parallel to the axis of the intake manifold or incline downward with respect to the axis of the intake manifold. The alcohol spraying method and the device realize at least two alcohol spraying penetration distances and enable the alcohol to land at different parts of the intake manifold of the engine after being sprayed out from the spray nozzles. The multi-penetration-distance alcohol spraying device enables the alcohol liquid to reach different parts of the intake manifold of the engine, reduces the thermal load of the engine, and reduces the waste heat brought away by the cooling water of the engine.

Owner:TIANJIN UNIV

Exhaust gas recirculating device for marine diesel engine

PendingCN108005759AHigh speed coolingImprove cooling effectExhaust apparatusExhaust gas recirculationParticulatesCombustion chamber

An exhaust gas recirculating device for a marine diesel engine comprises a dynamic wave washer. By means of the characteristics of efficient washing and high heat exchanging coefficients of the dynamic wave washer, particular matter and sulfur dioxide in exhaust gas are removed, the exhaust gas is cooled to a certain degree, and the washed exhaust gas is subjected to further cooling of an air cooler, dewatering of a drip separator and pressurizing of an air blower, enters a scavenging header and a combustor to take part in combustion. By means of the exhaust gas recirculating device for the marine diesel engine, efficient washing of the circular exhaust gas can be achieved; compared with existing EGR washing equipment, the structure is greatly simplified, and the initial investment and therunning cost of EGR are reduced; and great potential is provided for following upgrading and improving of the EGR device.

Owner:CSSC POWER INST CO LTD

Undisturbed switching control method of pneumatic regulation valve

InactiveCN109058473AIncrease elastic potential energyReduce elastic potential energyOperating means/releasing devices for valvesEqualizing valvesHandoff controlEngineering

The invention discloses an undisturbed switching control method of a pneumatic regulation valve. The undisturbed switching control method of the pneumatic regulation valve relates to a device body anda first cavity formed in the device body. A first rotary shaft which extends upwards and downwards is rotatably arranged in the first cavity. The tail end of the top of the first rotary shaft is in power connection with a motor fixedly arranged in the top end wall of the first cavity. According to the undisturbed switching control method of the pneumatic regulation valve, the structure of a device is simple, the performance is reliable, and mounting, maintenance and repair are convenient; the device can automatically detect the rate of flow passing through the device and compares the flow rate with an initial setting, automatic dynamic regulation is conducted according to the flow rate, and thus, it is ensured that the rate of flow passing through the valve is constant; meanwhile, the device can be switched into a manual mode according to requirements, the flow data and the operating state of the device are not changed in the switching process, and thus, undisturbed switching betweenthe automatic mode and the manual mode is achieved; and in addition, the device can generate compressed gas through a micro gas pump, and an external gas source is not needed, so that the mounting procedure is greatly simplified, and the maintenance cost of the device is reduced.

Owner:俞李娜

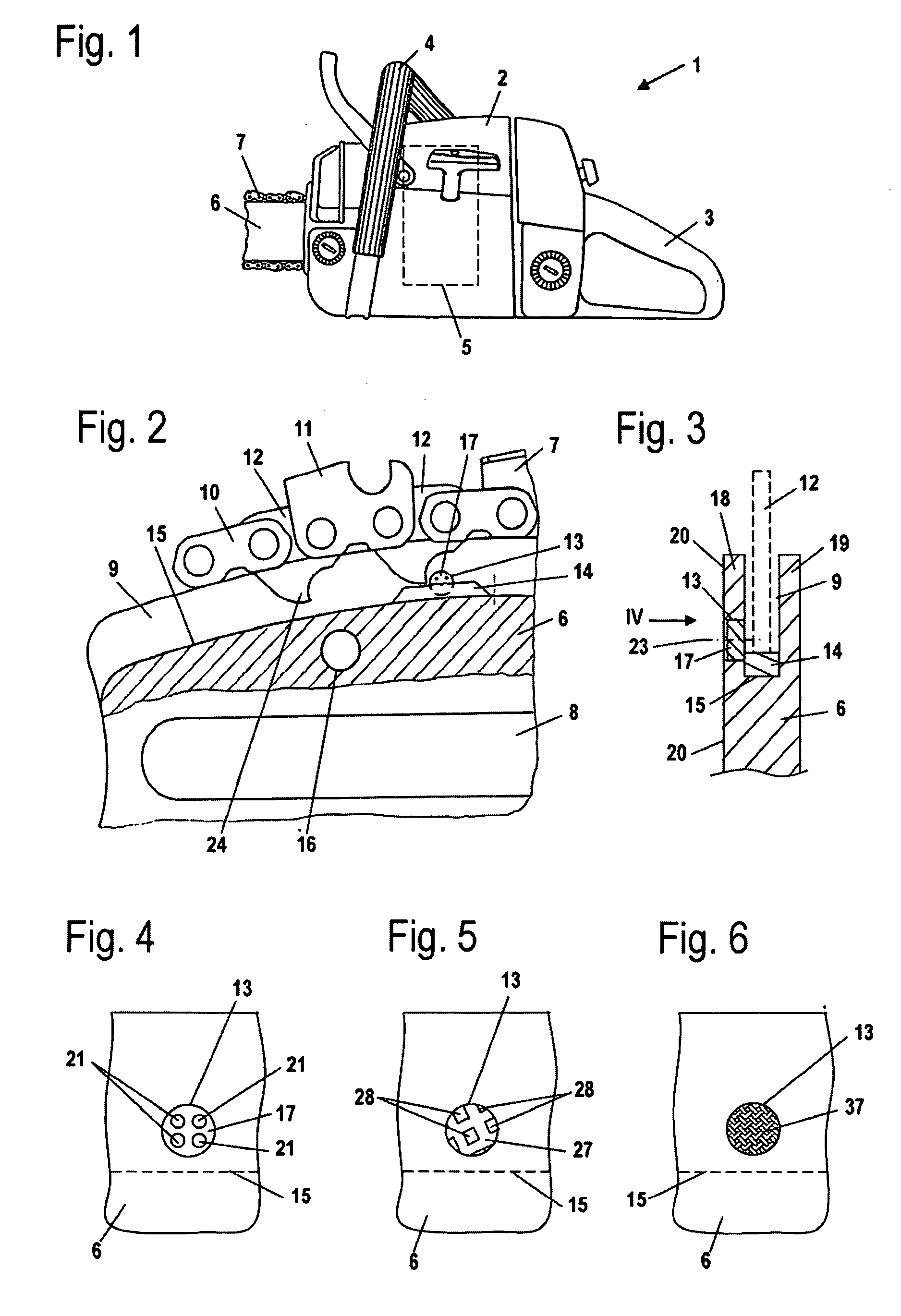

Guide Bar Arrangement

InactiveUS20090151173A1Easy to manufactureReduce pollutionMetal sawing devicesMetal sawing accessoriesMechanical engineeringFree flow

A guide bar arrangement has a guide bar having a guide groove that extends about an outer circumference of the guide bar. A saw chain is driven in circulation in the guide groove about the guide bar. The guide groove is delimited by a groove base, a first sidewall and a second sidewall positioned opposite the first sidewall. The guide bar has an opening for supply of oil into the guide groove, wherein the opening extends from an exterior side of the guide bar, wherein the exterior side extends in a longitudinal direction of the guide bar, into the guide groove and opens in the first sidewall into the guide groove. An insert is secured in the opening and reduces a free flow cross-sectional area of the opening.

Owner:ANDREAS STIHL AG & CO KG

Renewable energy extraction device

ActiveUS9086047B2Increase speedReduce the flow cross-sectional areaPropellersPump componentsAtmospheric airMechanical energy

Disclosed is a renewable energy extraction device and methods for producing renewable energy from flowing air or water. The renewable energy extraction device captures a relatively large amount of flowing water or atmospheric air and increases speed of the captured water or air by decreasing flow cross sectional area in the flow direction. An energy extraction component is used to extract energy of the high-speed water or air and convert it to rotational mechanical energy on a power shaft. A rotation direction control mechanism is used to make the power shaft always rotate in one direction, without coming to a stop, for ocean applications. The mechanical energy of the power shaft is transmitted to an electric generator, pump, compressor, or any other rotary equipment. After extraction of its energy, the captured air or water is released to its original source at a downstream location.

Owner:SALEHPOOR KARIM

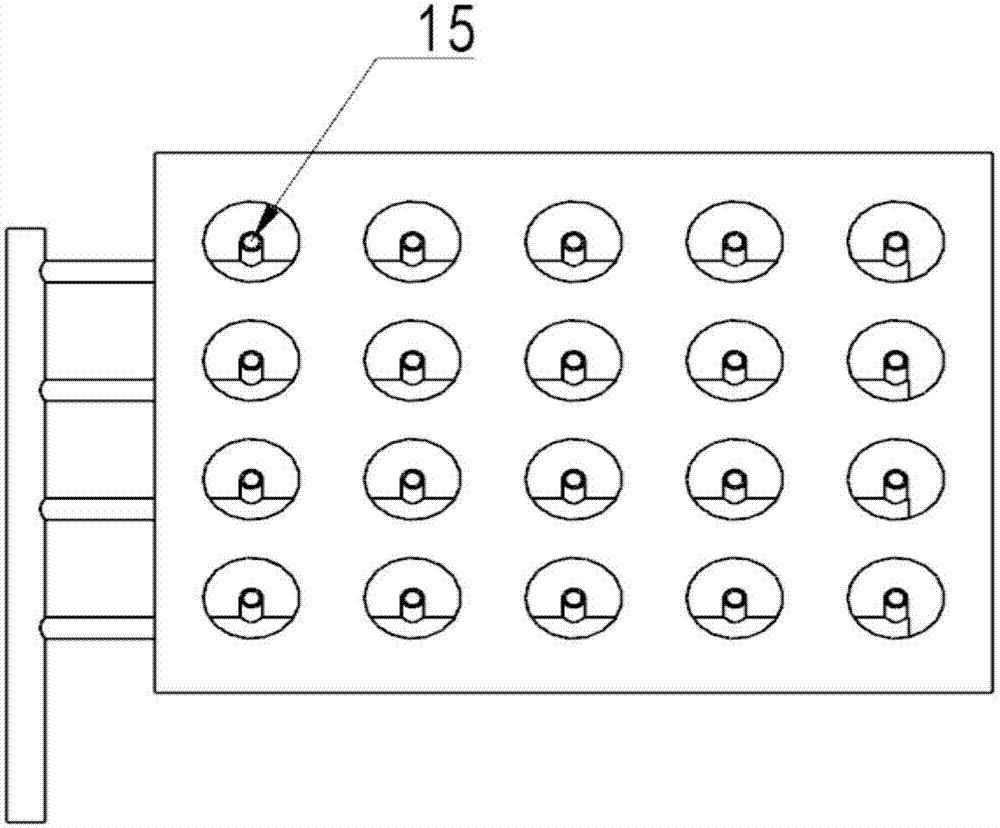

Impurity filter for water quality pretreatment

InactiveCN106966520AControl flow rateIncrease surface areaTreatment involving filtrationMultistage water/sewage treatmentFiltrationWater filter

The invention discloses an impurity filter for water quality pretreatment, which comprises a support frame and a filter box, the filter box is arranged on the support frame, a liquid inlet hopper is arranged on the top of the filter box, and a diverter plate is arranged on the bottom of the liquid inlet hopper , there is a diversion hole on the diverter plate, a spray head is provided at the bottom of the diverter plate, the spray head is connected with the diversion hole, a water filter frame is arranged in the filter box, the water filter frame is located under the sprinkler head, and the water filter frame There is a grille at the bottom of the filter box, and filter plates are installed obliquely in the water filter frame, and the adjacent filter plates are equidistantly distributed. There are liquid outlet pipes on both sides of the bottom of the filter box, and H-shaped support plates are installed on the support frame. The support plate is movably connected with a rotating plate, and both ends of the rotating plate are provided with accommodating grooves, and liquid collecting cups are arranged on the accommodating grooves. The invention has a simple structure, efficiently removes the impurities mixed in the water body through physical filtration and adsorption, reduces the turbidity of the water, achieves the purpose of clarifying the water quality, and facilitates later detection work.

Owner:嵊州市卓普净水设备有限公司

Anti-fouling device for heat exchanger and use thereof

PendingCN114424011AReduce foulingReduce the flow cross-sectional areaPigmenting treatmentSpacing meansCombustionProcess engineering

The present disclosure relates to a device for reducing fouling in heat exchanger tubes and a heat exchanger comprising such an anti-fouling device. The anti-fouling device includes an elongate displacer insertable into a heat exchanger tube to reduce the flow cross-sectional area in a portion of the tube. It also includes a mount connected to the elongated displacer for attaching the device to the end of the heat exchanger tube. The mount is configured to hold the replacement body in a spaced apart relationship from the inner surface of the tube when the replacement body is inserted into the tube. The disclosed anti-fouling device effectively reduces fouling in a heat exchanger in a reliable manner over an extended period of time, without maintenance or without external control, can be provided at a relatively low cost, is easy to install, and can also be retrofit to existing heat exchangers. It is particularly suitable for mitigating problems associated with fouling in heat exchangers encountered by thermal combustion or process gases, such as in the production of carbon black, fumed silica or other particulate matter, without contaminating or adversely affecting the properties of products recoverable from the process gases.

Owner:欧励隆工程炭知识产权有限两合公司

High-efficiency low-resistance lubricating oil cooler

PendingCN110567296ALow flow resistanceIncrease the effective heat transfer temperature differenceHeat exchanger casingsStationary tubular conduit assembliesJet aeroplaneEngineering

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Part for increasing convective heat transfer coefficient of condensate, refrigerating system and cooling and heating air conditioner

InactiveCN105135930AImprove convective heat transfer coefficientIncrease flow rateEvaporators/condensersSpace heating and ventilation detailsConvective heat transferEngineering

The invention provides a part for increasing the convective heat transfer coefficient of condensate, a refrigerating system comprising the part and a cooling and heating air conditioner. The part is embedded into a tail end pipe of a condenser and comprises a main rod. A plurality of outer grooves are formed in the outer surface of the main rod. A plurality of channels for the condensate to flow are formed between the outer grooves of the main rod and the inner surface of the pipe. By means of the part, the new heat bridge channels are provided for heat delivering from the condensate in direct contact with the part to the inner surface of the pipe, the flowing sectional area of the condensate in an existing pipe is greatly reduced, the flowing speed of the condensate is greatly increased, and therefore the Reynolds number of the condensate on the inner side of the tail end pipe of the condenser and the convective heat transfer coefficient of the condensate to the inner wall of the pipe are greatly increased.

Owner:SHANGHAI BOHAN THERMAL ENERGY TECH

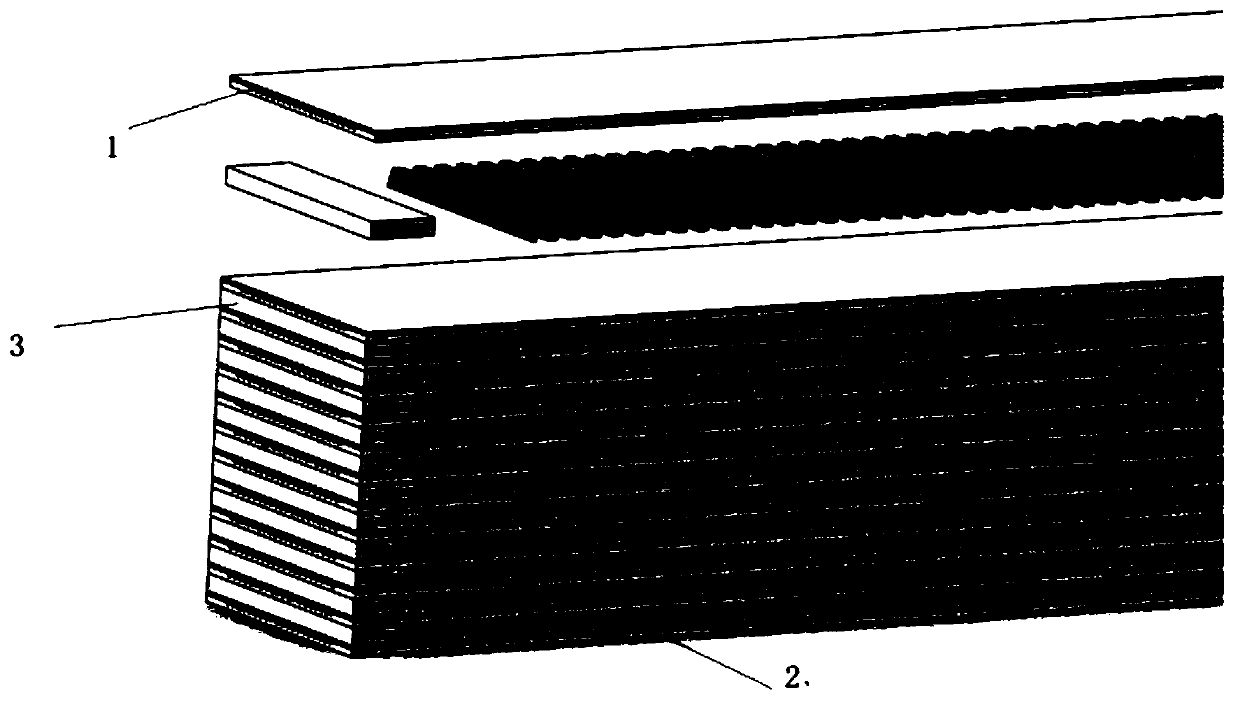

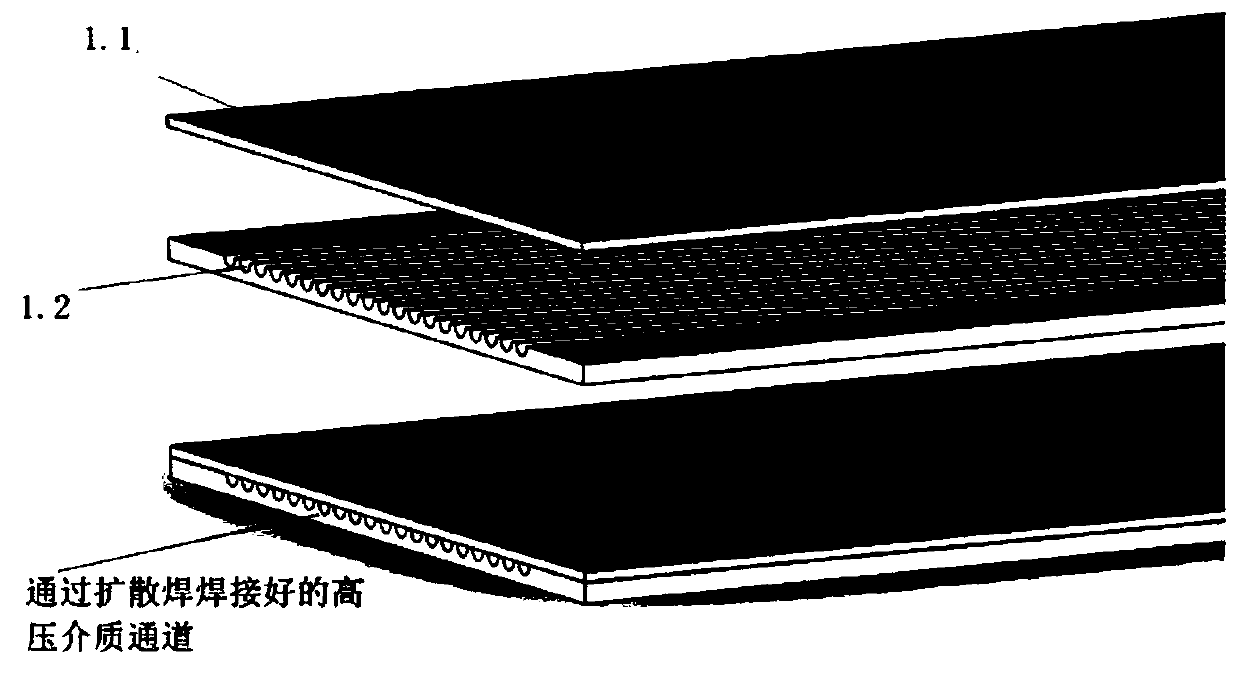

Printed circuit board air-cooled heat exchanger core

PendingCN110701929AReduce volumeGuaranteed resistanceLaminated elementsStationary plate conduit assembliesCold airThermal coefficient

The invention discloses a printed circuit board air-cooled heat exchanger core. The core comprises multiple high-pressure medium channels, multiple air channels and high-pressure channel head cushionstrips. The high-pressure medium channels and the multiple air channels arranged in a spaced manner, the high-pressure medium channels are arranged on the topmost end and the bottommost end, and the high-pressure channel head cushion strips are arranged on the two sides of the air channels. When an air-cooled heat exchanger works, high-pressure media flow to the other end from one ends of the high-pressure medium channels, cold air flows to the other side from one sides of the air channels, the outer surface of metal plates of the high-pressure medium channels are transversely flushed, and thecooling effect is achieved. The heat exchanger core has the advantages of being resistant to high pressure, high in heat exchange coefficient, small in size and capable of saving cost and machining time.

Owner:XIAN THERMAL POWER RES INST CO LTD

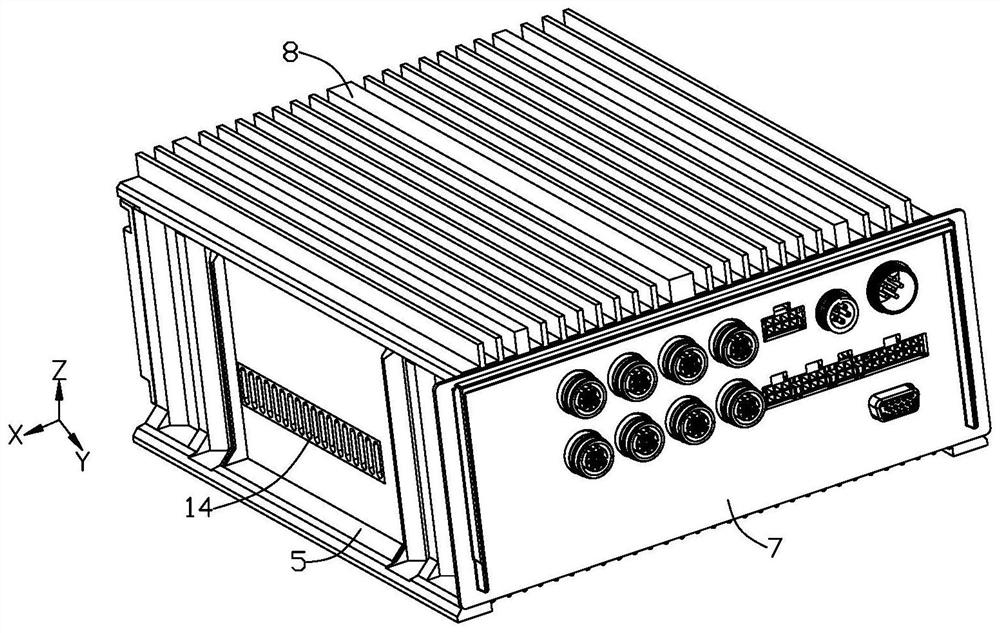

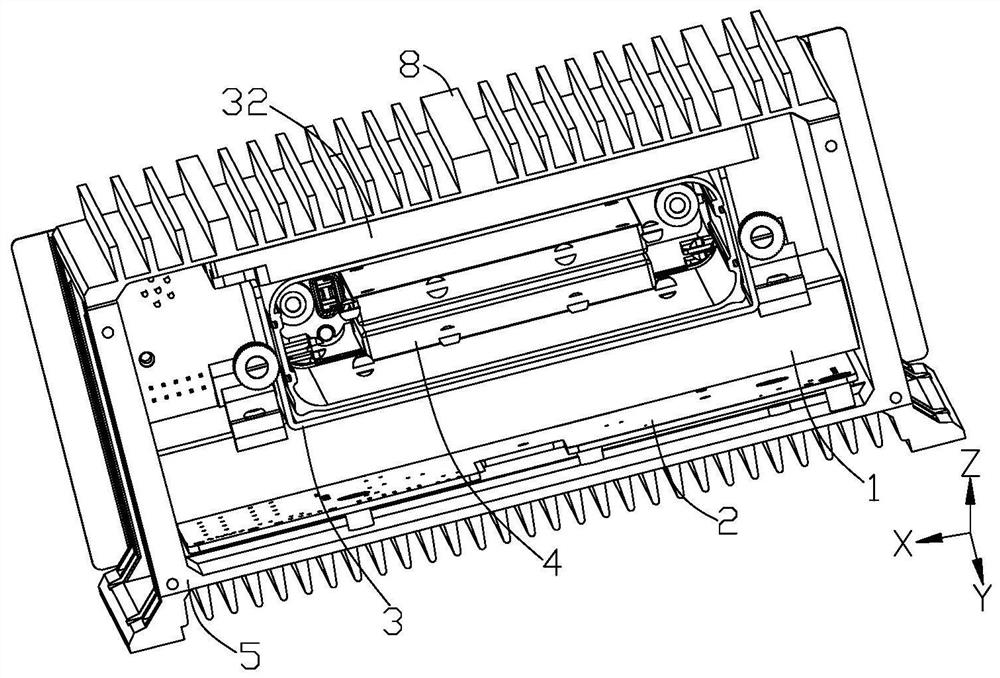

Electronic equipment

ActiveCN113365466AImprove cooling efficiencyReduce the flow cross-sectional areaTelevision system detailsColor television detailsHigh electronElectronic component

The invention relates to electronic equipment. The electronic equipment comprises a shell assembly and a heat dissipation assembly, wherein the shell assembly forms a first cavity, and the first cavity is used for accommodating at least part of electronic elements; at least part of the heat dissipation assembly is located in the first cavity, the heat dissipation assembly is provided with a second cavity, and the first cavity is not communicated with the second cavity; and the second cavity is provided with a gas inlet and a gas outlet, and external gas can enter the second cavity through the gas inlet and can be discharged through the gas outlet, so that external dust, liquid and other substances can be prevented from entering the first cavity to influence the electronic elements, the functional stability and reliability of the electronic elements are improved, and the service life of the electronic elements and the service life of the electronic equipment are prolonged. In addition, when the first cavity is not communicated with the second cavity, external gas only circulates in the second cavity of the heat dissipation assembly, so that the circulation sectional area of the gas is reduced, the flowing speed of the gas is increased, and the heat dissipation efficiency of the heat dissipation assembly is improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Pipe network pressure-superposed water supply equipment

InactiveCN111894083AFirmly connectedEasy inspection and maintenanceService pipe systemsWater mainsTemperature controlWater storage

The invention provides pipe network pressure-superposed water supply equipment. The equipment comprises a water taking chamber, wherein a temperature control chamber and a water supply chamber are sequentially arranged at the top of the water taking chamber from left to right, a water storage device is arranged inside the temperature control chamber, and a water feeding pipe is arranged on the lower side face of the water storage device; a first communicating pipe is arranged on the right side face of the water storage device, the right end of the first communicating pipe communicates with theleft end of a second communicating pipe through a one-way valve, and the right end of the second communicating pipe extends into the water supply chamber; a first electric cylinder bottom plate is fixed to the right side face of the interior of the temperature control chamber through a first series of bolt sets, and the left end of the first electric cylinder bottom plate is fixedly connected with the right end of a first electric cylinder; and a first action rod is arranged at the power output end at the left side of the first electric cylinder, and a heater is arranged at the left end of the first action rod. By means of the technical scheme, the technical problems that in the prior art, the automatic heating capacity for cold water is not achieved, automatic flow stabilizing control cannot be achieved, and intermittent water taking and filtering cannot be achieved are effectively solved, and application and popularization are facilitated.

Owner:贺俊威

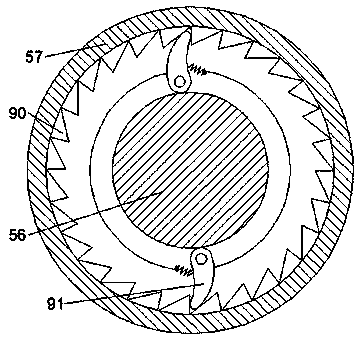

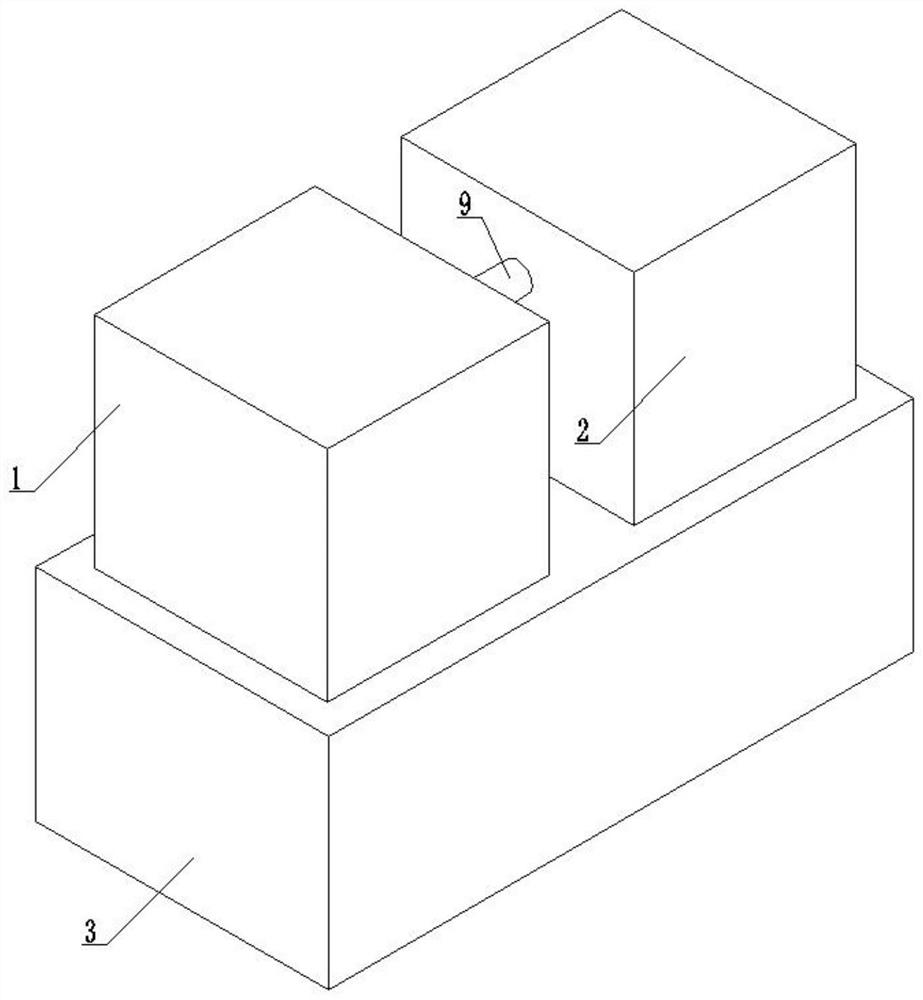

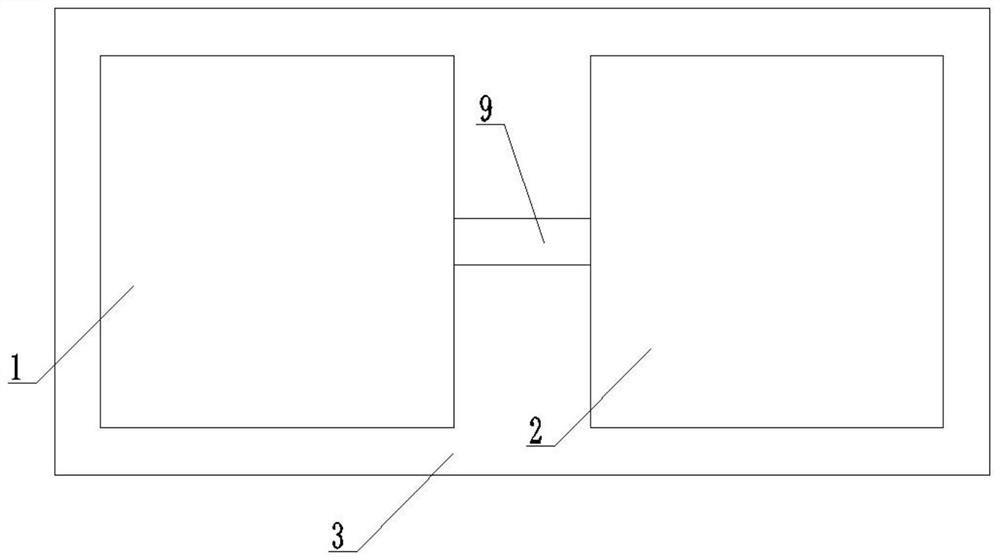

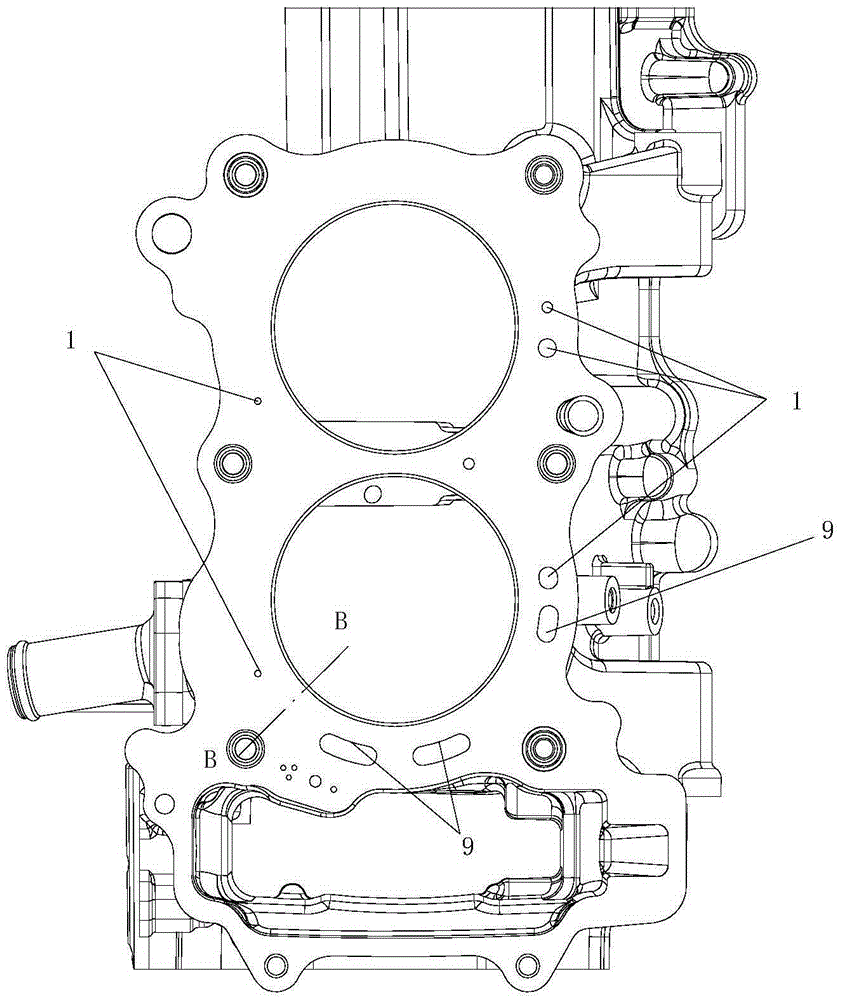

Cylinder body water jacket with orifice plug and engine cylinder body

ActiveCN105386888AImprove cooling effectReduce the flow cross-sectional areaCylinder headsCylindersCooling effectEngineering

The invention discloses a cylinder body water jacket with an orifice plug. The cylinder body water jacket comprises an annular runner, a water inlet and a water outlet, wherein the annular runner is arranged around all steam cylinder holes; the water inlet and the water outlet are formed in a cylinder body and communicated with the annular runner; the orifice plug allowing cooling liquid to flow in single direction along the annular runner is disposed in the annular runner. By means of the cylinder body water jacket with the orifice plug, the flow of the cooling liquid passing through the side walls of all the cylinder holes in the cylinder body can be kept uniform, and the flow speed and pressure of the cooling liquid can be effectively increased so as to improve the cooling effect of an engine.

Owner:CHONGQING LONCIN ENGINE

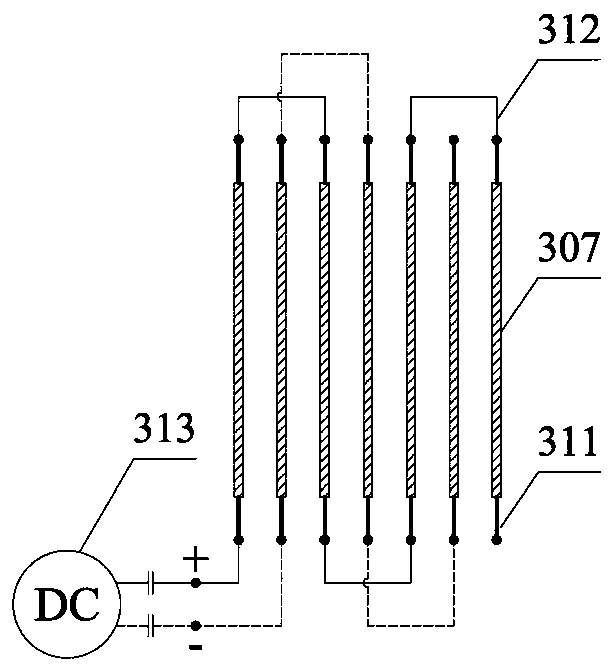

Electrochemical treatment system for printing ink wastewater

PendingCN109809651AMild reaction conditionsDosage is lessWater contaminantsMultistage water/sewage treatmentElectrochemistryHydroxyl radical

The invention discloses an electrochemical treatment system for printing ink wastewater. Firstly, a metastable phase in acidified printing ink wastewater is removed through an electronic flocculationtechnology; then a non-active metal oxide composite electrode with a catalytic capability is used as an electrode and the wastewater is catalyzed under the action of an electric field to form intermediate products including hydroxyl free radicals with strong oxidization performance and the like; organic matters in the wastewater are oxidized and processes including chain breaking, breaking and thelike are finished; the COD (Chemical Oxygen Demand) in the wastewater is reduced and the biodegradability of the wastewater is improved. The electrochemical treatment system disclosed by the invention has the characteristics that an oxidant does not need to be added, reaction conditions are moderate, the sludge amount is less, the biochemical performance of output water is good, the operation cost is low, the system is simple, stable and reliable, the automation degree is high and the like.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

Apparatus for mixing a substance into a medium

InactiveUS8721840B2Improve mixing efficiencyImprove the mixing effectFlow mixersTransportation and packagingFiberEngineering

The invention relates to an apparatus for mixing a gaseous or liquid substance into fiber suspension. The apparatus includes a tubular body, which defines a space that forms a flow channel for the suspension, in which body an inlet and an outlet for the suspension are arranged so that the suspension flows through the flow channel mainly in the axial direction. Further the apparatus comprises a feed member that extends into the flow channel transversely against the flow direction of the suspension and has a cylindrical wall provided with openings for leading the substance from the feed member into the flow channel. At least one protrusion is arranged on the inner surface of the tubular body in the region the feed member. A throttling member is arranged in the flow channel downstream of the feed member in the flow direction of the suspension, and a mixing chamber is formed in the flow channel between the feed member and the throttling member.

Owner:ANDRIZ OY

Flow guide device, air conditioner indoor unit and air conditioner

PendingCN113719992AReduce the flow cross-sectional areaDucting arrangementsMechanical apparatusAir volumeEngineering

The invention provides a flow guide device, an air conditioner indoor unit and an air conditioner. The flow guide device is mounted at a port of an air duct, and the flow guide device comprises a flow guide channel communicated with the air duct and used for guiding airflow; the flow guide channel comprises multiple circulation branches; a adjusting component is arranged in each circulation branch in a position-adjustable mode so as to avoid at least part of the airflow in each circulation branch when the airflow flows into the air duct, or block at least part of the airflow in each circulation branch when the airflow flows out of the air duct; and multiple adjusting parts are arranged, and the multiple adjusting parts and the multiple circulation branches are arranged in a one-to-one correspondence manner, wherein all the adjusting parts operate independently. The problem that in the prior art, the efficiency of adjusting the air volume of the air conditioner through a fan is low is solved.

Owner:GREE ELECTRIC APPLIANCES INC

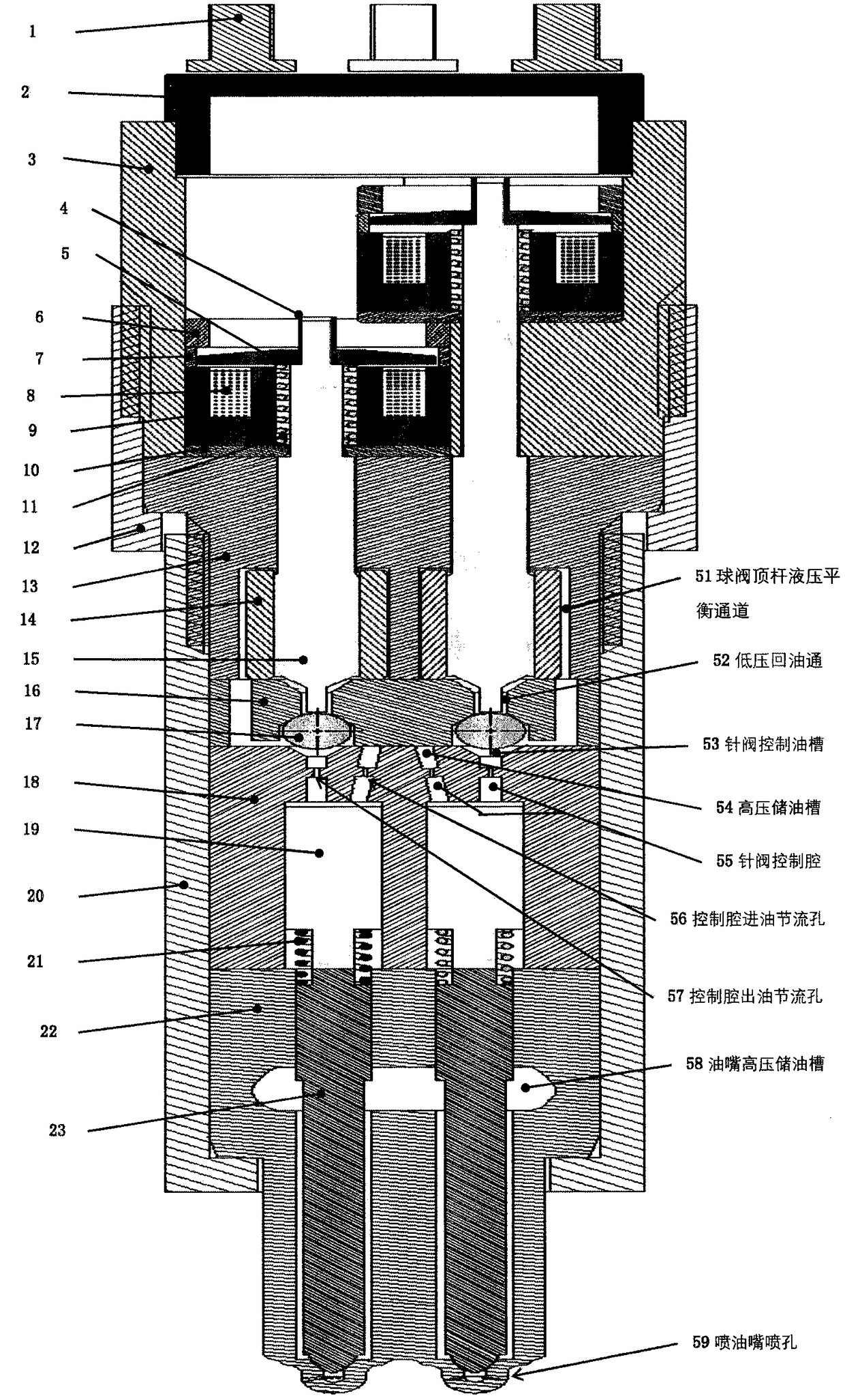

Single double-needle valve double-nozzle high-pressure common rail oil injector for medium-heavy diesel engine

PendingCN108443040ASmall preloadReduce suctionFuel injection apparatusMachines/enginesSolenoid valveCommon rail

The invention provides a single double-needle valve double-nozzle high-pressure common rail oil injector for a medium-heavy diesel engine. The single double-needle valve double-nozzle high-pressure common rail oil injector comprises a magnetic core valve seat, a ball valve ejector rod base mounting screw cap, a ball valve ejector rod base, a valve needle control rod base, an oil nozzle mounting screw cap and an oil nozzle valve body; two electromagnetic valves are arranged in the magnetic core valve seat, two valve needle control rods are arranged in the valve needle control rod base, two valve needle cavities are formed in the oil nozzle valve body, two oil nozzles are arranged at the lower ends of the valve needle cavities, and two oil nozzle valve needles which are connected with the two valve needle control rods and are used for controlling the two oil nozzles are arranged in the valve needle cavities. In addition, a ball valve ejector rod and a high-pressure sealing ball valve arearranged in a split mode, and the ball valve ejector rod is designed into a large-diameter section and a small-diameter section, so that the needed electromagnetic force is further reduced. The function of the high-pressure common rail oil injector is more suitable for a diesel engine to inject diesel oil compared with a traditional oil injector, under the condition that the pressure of a fuel system is not increased, the atomization effect of high-pressure diesel injection can be further improved, and the emission level of an engine original machine can be improved; and meanwhile, the oil spraying rate rule is optimized, and the power level of the diesel engine is further explored.

Owner:李玉龙

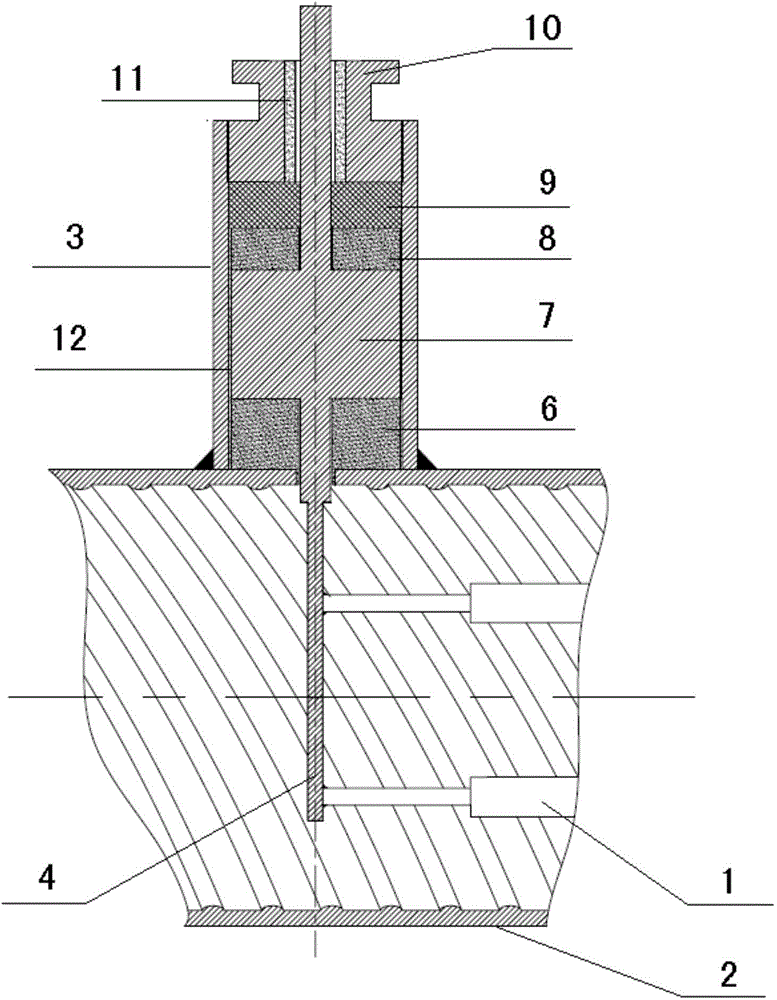

Compact type organic working medium high-temperature and high-voltage electric heater

InactiveCN104619056AIncreased turbulenceReduce the flow cross-sectional areaOhmic-resistance heating detailsHeating element shapesEngineeringHigh pressure

The invention discloses a compact type organic working medium high-temperature and high-voltage electric heater. The compact type organic working medium high-temperature and high-voltage electric heater comprises a heating pipe which is arranged in an outer pipe at a heating section; flange connectors are symmetrically arranged at two ends of the outer pipe at the heating section; bases are correspondingly arranged at the left side and the right side of the outer pipe at the heating section; a binding post which is inserted into the outer pipe at the heating section and is connected with the heating pipe is arranged in the base; the upper end of the binding post is connected with an external power supply; a mica post, a cylindrical section, another micro post, a sealing ring and a hollow nut are sequentially arranged in the base from bottom to top; insulating sleeves are arranged at the outer side of the cylindrical section and the inner side of the hollow nut. The compact type organic working medium high-temperature and high-voltage electric heater has the advantages of being practical, efficient, simple to operate, cost saving, safe, reliable, and resistant to high temperature and high voltage.

Owner:TIANJIN UNIV

Internally cooled airfoil for a rotary machine

InactiveUS9890646B2Improve cooling effectRelieve stressEngine fuctionsBlade accessoriesTrailing edgeCooling channel

An internally cooled airfoil for a rotary machine, for example, a gas turbine engine includes a suction and pressure side wall each extending in an axial direction, i.e. from a leading to a trailing edge of the airfoil. A suction wall sided cooling channel and a pressure wall sided cooling channel extend in the axial direction. A feed chamber is defined between a first and second inner wall for feeding the suction wall and pressure wall sided cooling channel each by at least one through hole inside of the first and second inner wall. The suction wall sided cooling channel and the pressure wall sided cooling channel extend into the trailing edge region separately. The suction wall sided cooling channel and the pressure wall sided cooling channel join before discharging at the trailing edge.

Owner:ANSALDO ENERGIA IP UK LTD

Film pre-forming two flowing type nozzle, stillpot with the nozzle and technique for producing ultra-fine dust utilizing the stillpot

InactiveCN1313184CAvoid easy cloggingIncrease flow resistanceSolution crystallizationChemical/physical/physico-chemical nozzle-type rreactorsEngineeringUltra fine

The present invention discloses one kind of pre-filming flow nozzle, stillpot with the nozzle and the production process of superfine particle in the stillpot with the nozzle. The nozzle includes casing, pre-filming unit, flow channel, ring gap flow channel, etc. and has the structure with greatly lowered flow resistance on solution and less jamming caused by the solute particle. The stillpot has simple structure, convenient operation, light labor strength and excellent sealing effect owing to the C-shaped metal sealing part with upper and lower sealing planes in linear contact state. By means of the supercritical fluid forced dispersing solution process in the stillpot with the nozzle, superfine solute particle may be prepared.

Owner:贺文智 +2

Heat management device of cold-heat-electricity supply system based on gas IC engine

InactiveCN1321311CGuaranteed stabilityReduce surface tensionLiquid coolingInternal combustion piston enginesEngineeringInternal combustion engine

A heat supervisor of cooling , heating and electricity linkage system for gas combustion engine features arranging smoke heat transfer tube and water heat transfer tube of engine cylinder packing in working media liquid below supervisor ; using heat transfer tubes of heat use section and radiation section , gas flow leading plate , gas flow tilt leading plates and casing to form condensing channel for leading steam of working media downwards and channel for leading said steam upwards ; using baffle , casing and gas flow leading plate to enclose a gas storage chamber with condensing tube in it and elongating their liquid seals into working media liquid .

Owner:SHANGHAI JIAO TONG UNIV

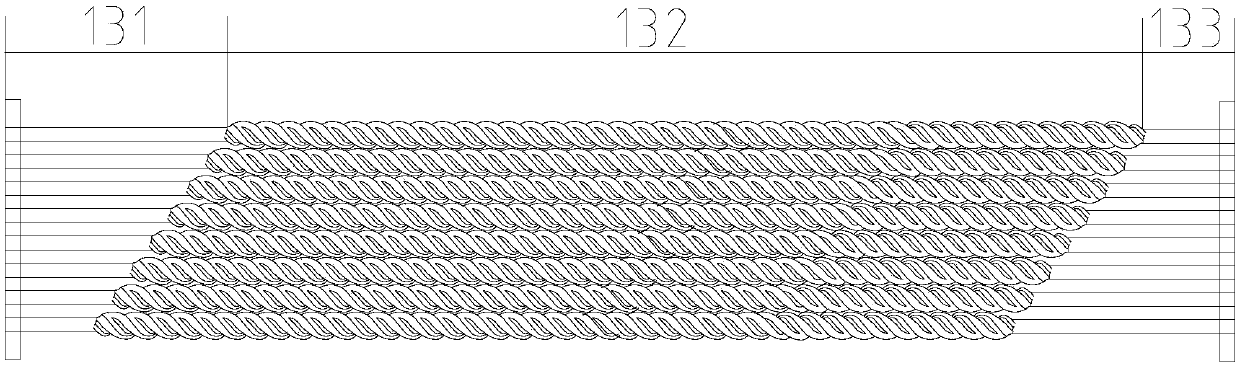

Sintering device for large-size optical fiber loosing powder rod and method

ActiveCN107512848AReduce the flow cross-sectional areaIncrease gas flow rateGlass making apparatusGlass productionResource consumptionMetallurgy

The invention discloses a sintering device for a large-size optical fiber loosing powder rod and a method. The sintering device comprises a sintering furnace core pipe and a rod conveying device, wherein the rod conveying device is used for realizing the up-and-down and rotating motion of a loosing powder rod in the sintering furnace core pipe; an air inlet is formed at the bottom of the sintering furnace core pipe; an air outlet is formed on the upper part of the sintering furnace core pipe; a flow guide cover is arranged under the loosing powder rod on the inner wall of the sintering furnace core pipe; an air guide cover is arranged as a conical air guide cover with small upper part and big lower part; and the air guide cover is located above the air inlet. According to the invention, the flow guide cover is arranged for guaranteeing the concentrated distribution of the reaction gas on the middle part of the sintering furnace core pipe and more effective contact with the loosing powder rod; the flowing section area is reduced, the air flow speed is increased and the air turbulence degree is increased, so that the thickness of surface air film of the loosing powder rod is reduced; the dispersing of the reaction gas into the loosing powder rod is benefited, so that an optical fiber prefabricated rod with low and uniform OH ion content can be acquired and the resource consumption can be reduced.

Owner:长飞光纤潜江有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com