Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Guaranteed drilling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

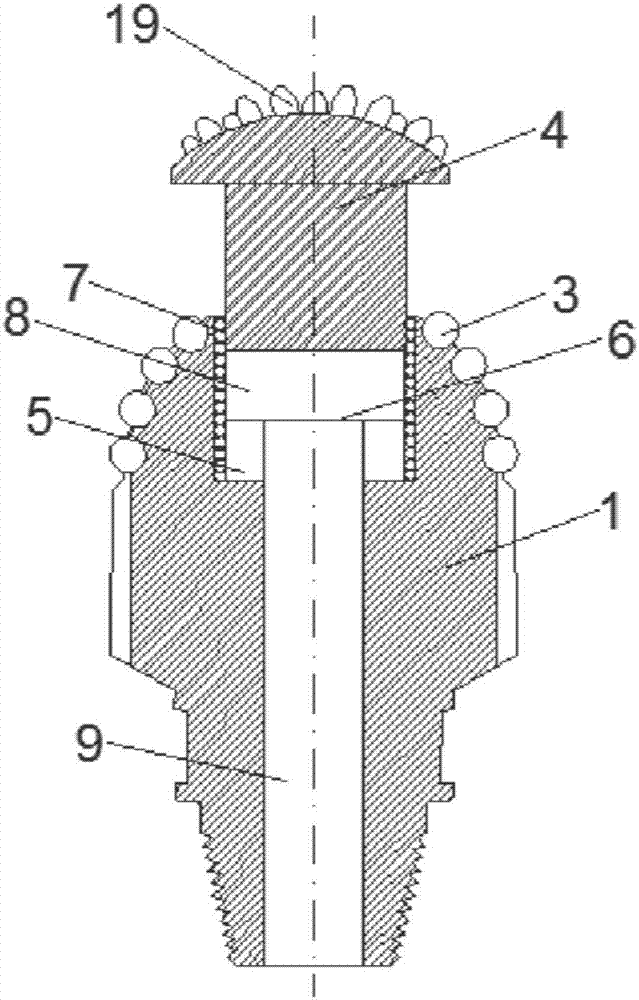

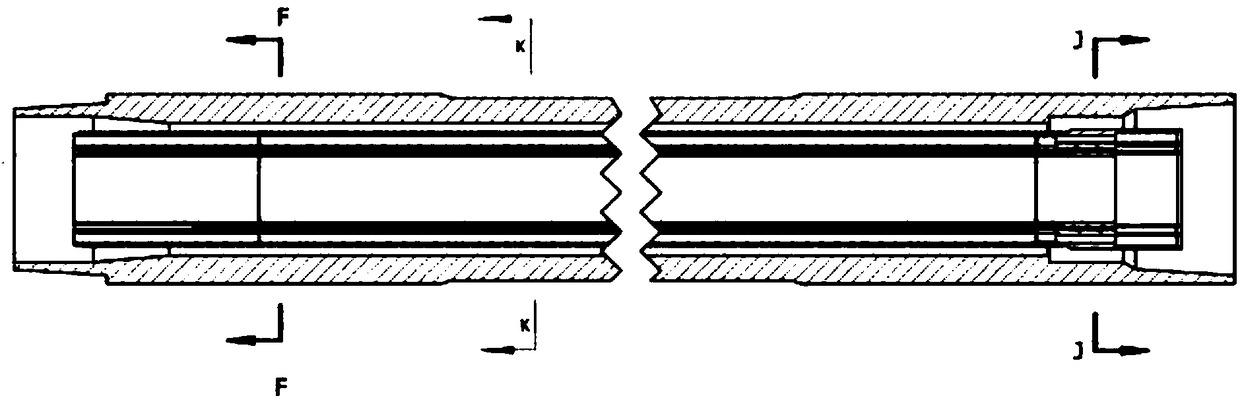

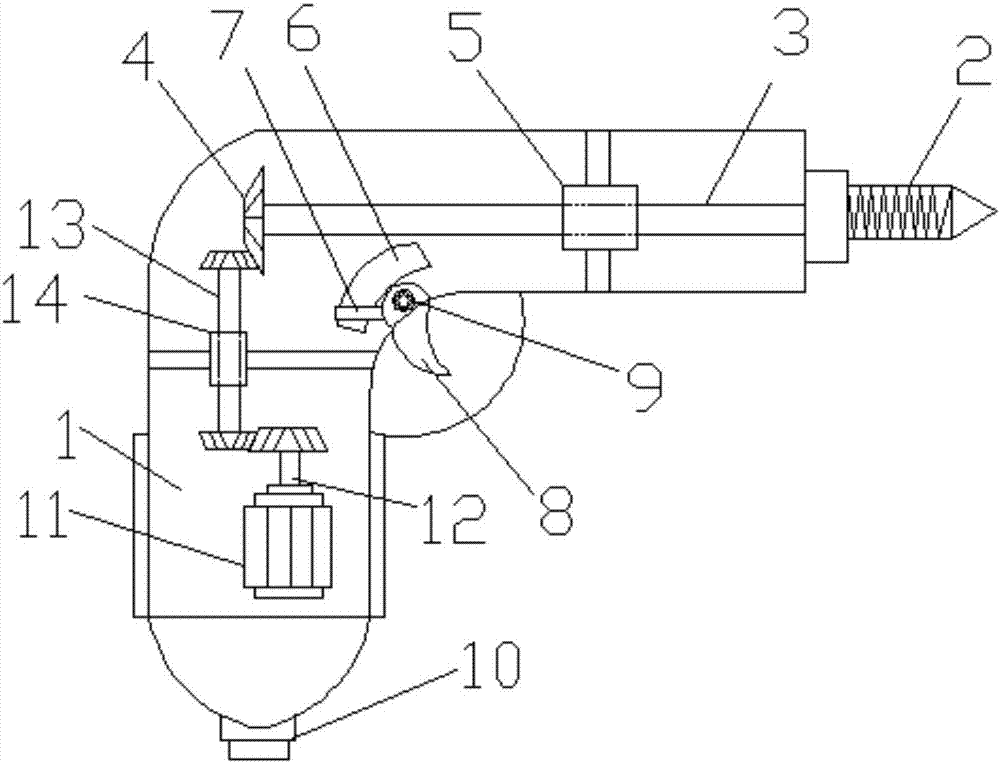

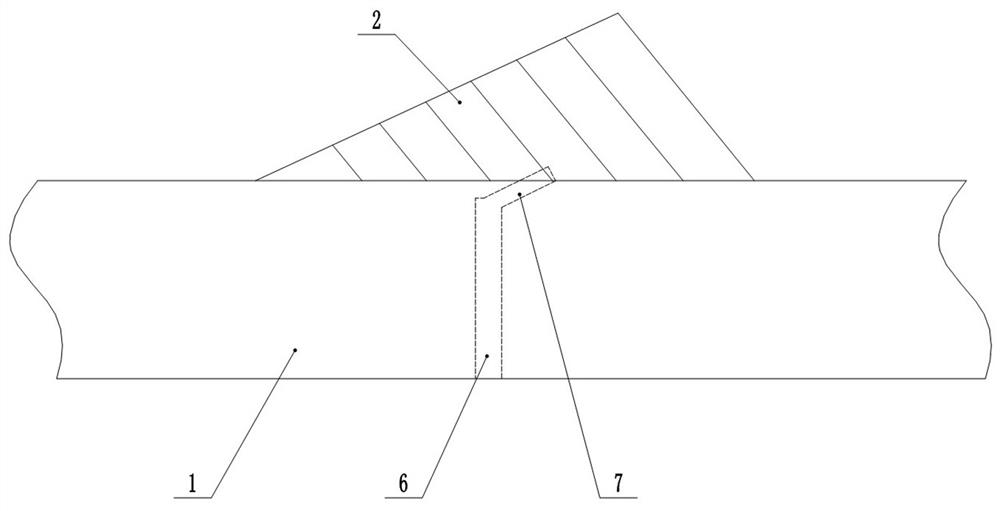

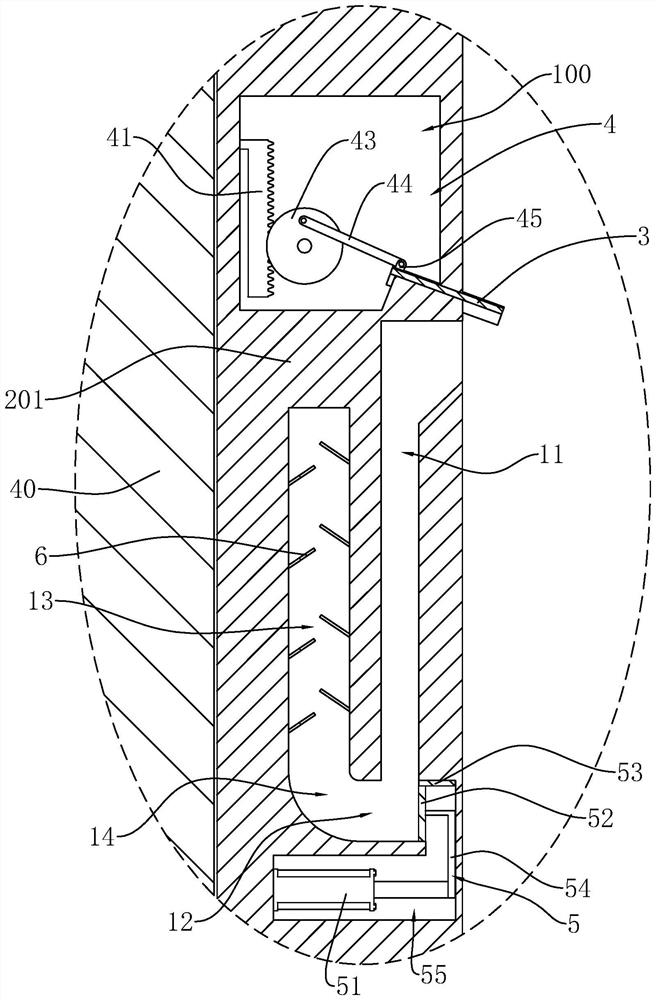

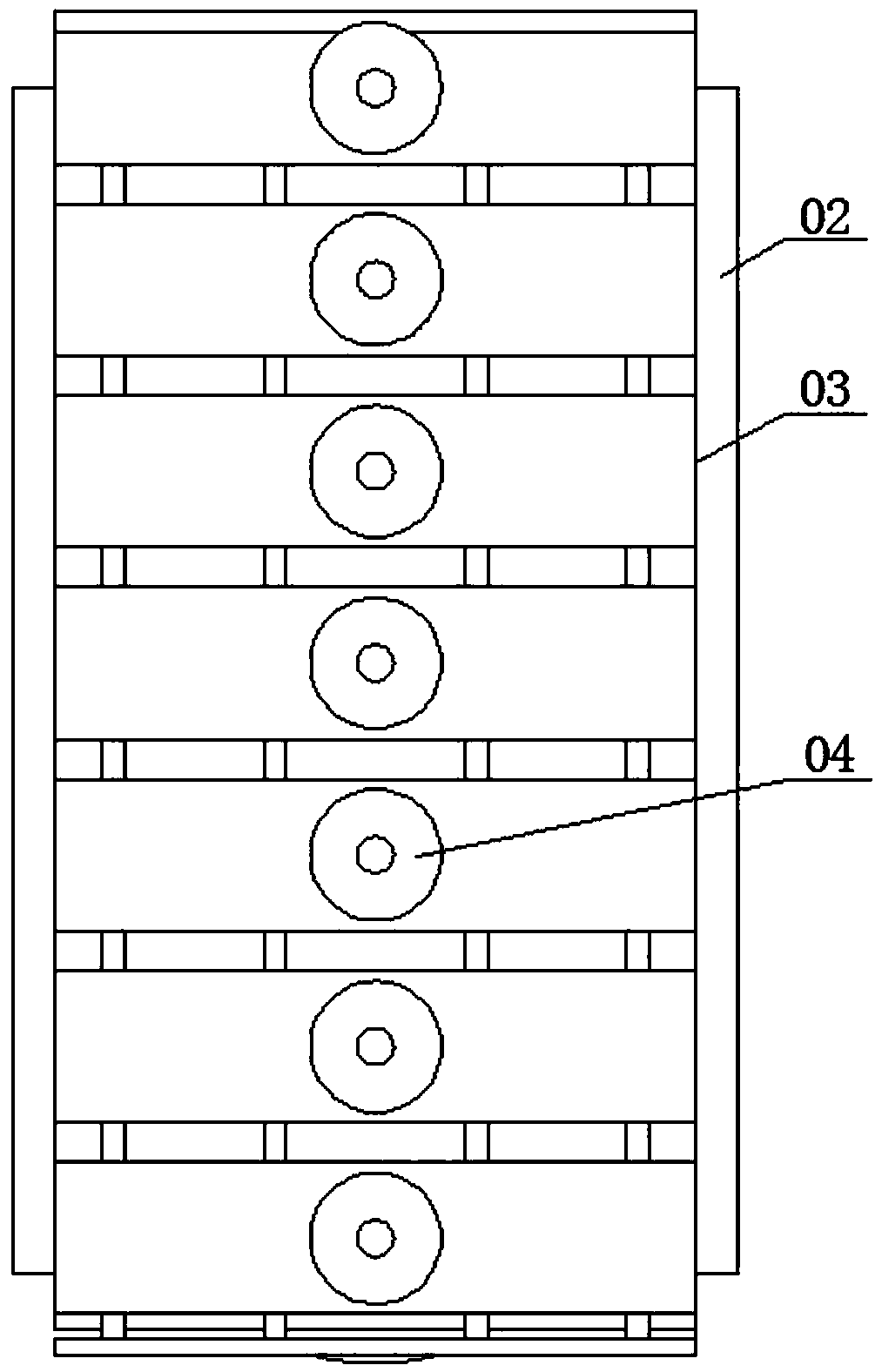

Device for online detection for stress of hobbing cutter of tunnel boring machine

ActiveCN103698075AGrasp the working status in timeExtended service lifeMeasurement of force componentsElastomerAudio power amplifier

The invention discloses a device for online detection for stress of a hobbing cutter of a tunnel boring machine. The device comprises a shaft end supporting structure of a cutter central shaft, a sensor for detecting the stress of the hobbing cutter, a signal amplifier, a transmitting antenna, a signal receiving device and a monitoring computer, wherein the shaft end supporting structure of the cutter central shaft comprises a shaft end structure of the cutter central shaft, a supporting wedge and a locking wedge, and the sensor is formed on the supporting wedge. The supporting wedge is used as an elastomer, the sensor for detecting the stress of the hobbing cutter is formed through pasting a resistance strain piece on the elastomer, and when the heading machine works, the sensor can be used for online detecting stress in three directions borne by a cutting edge of the hobbing cutter, so that the tunneling operation scheme can be adjusted according to the condition, the service life of the cutter is prolonged, and further good tunneling efficiency can be obtained. The device can also be used for identifying whether string wear occurs or not and timely grasping the working state of the hobbing cutter, and the tunneling efficiency can be ensured due to the fact that when the cutting edge is subjected to string wear, the cutter can be timely replaced.

Owner:TIANJIN UNIV

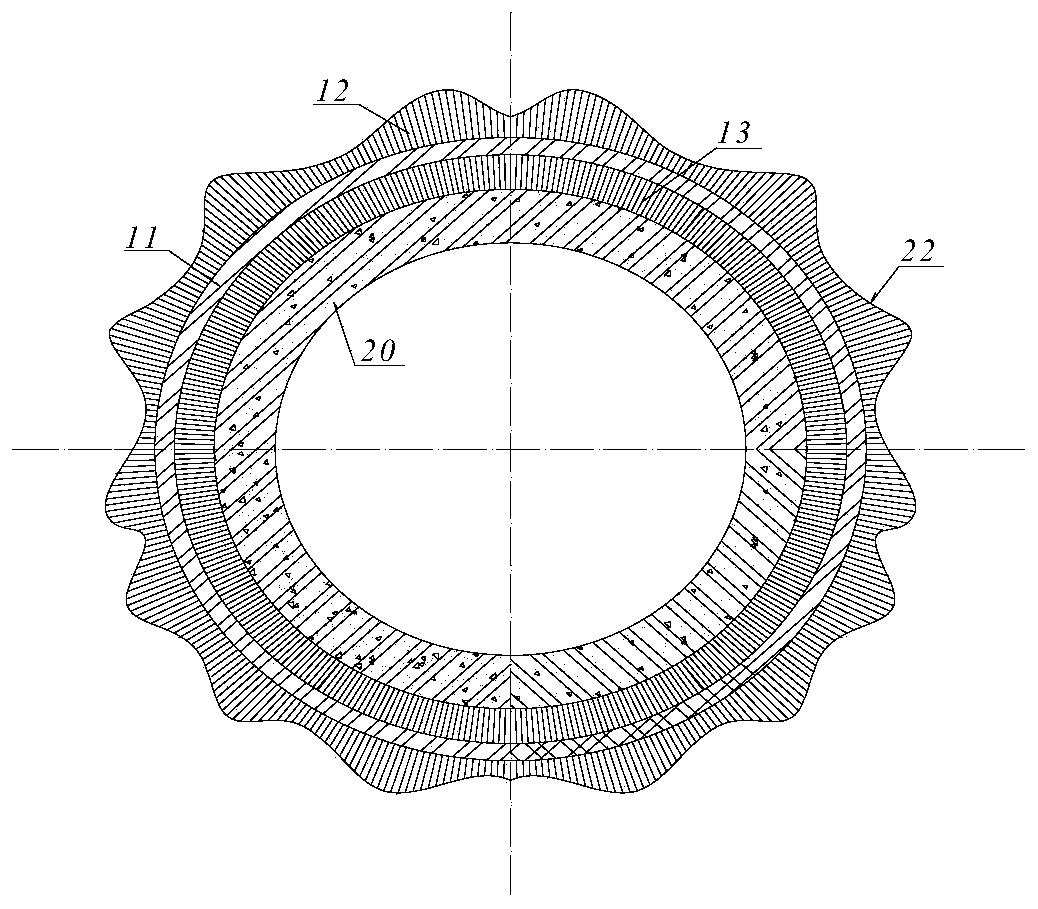

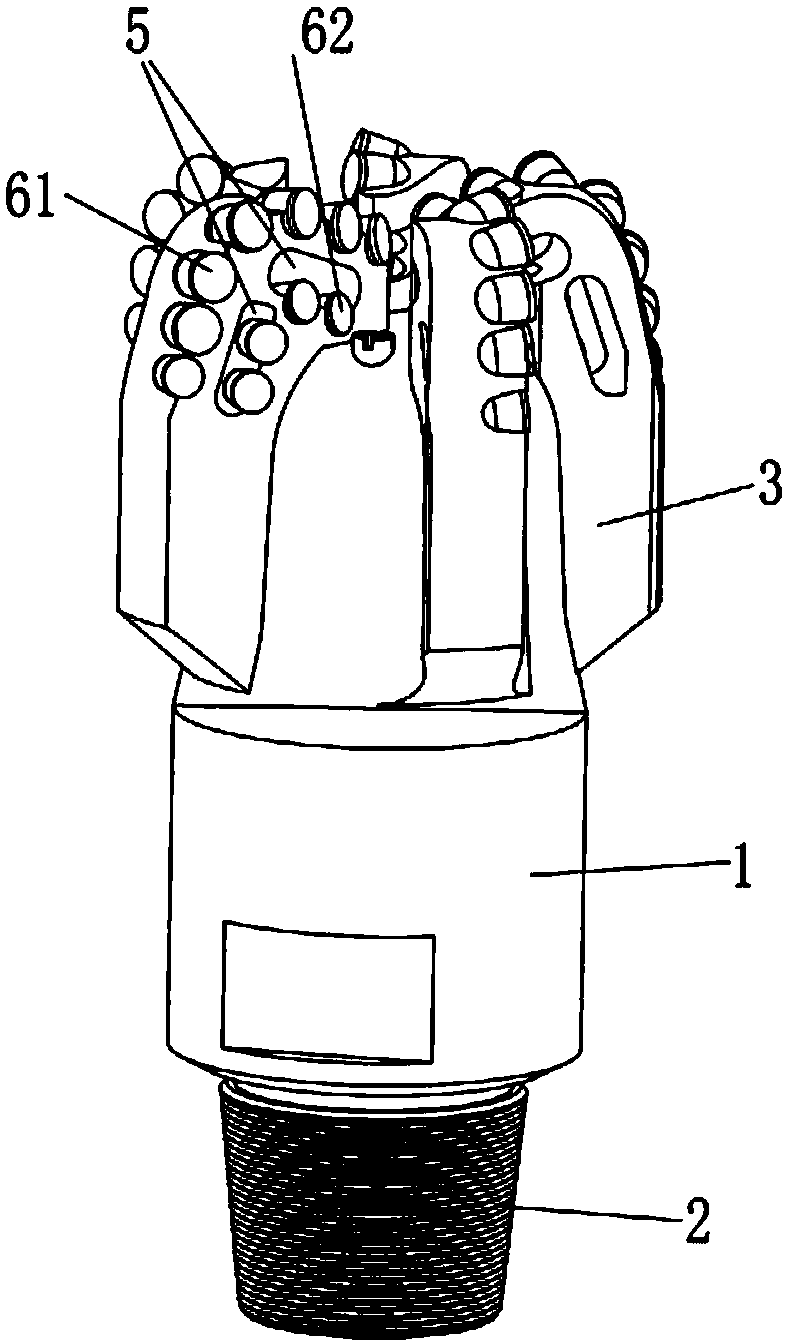

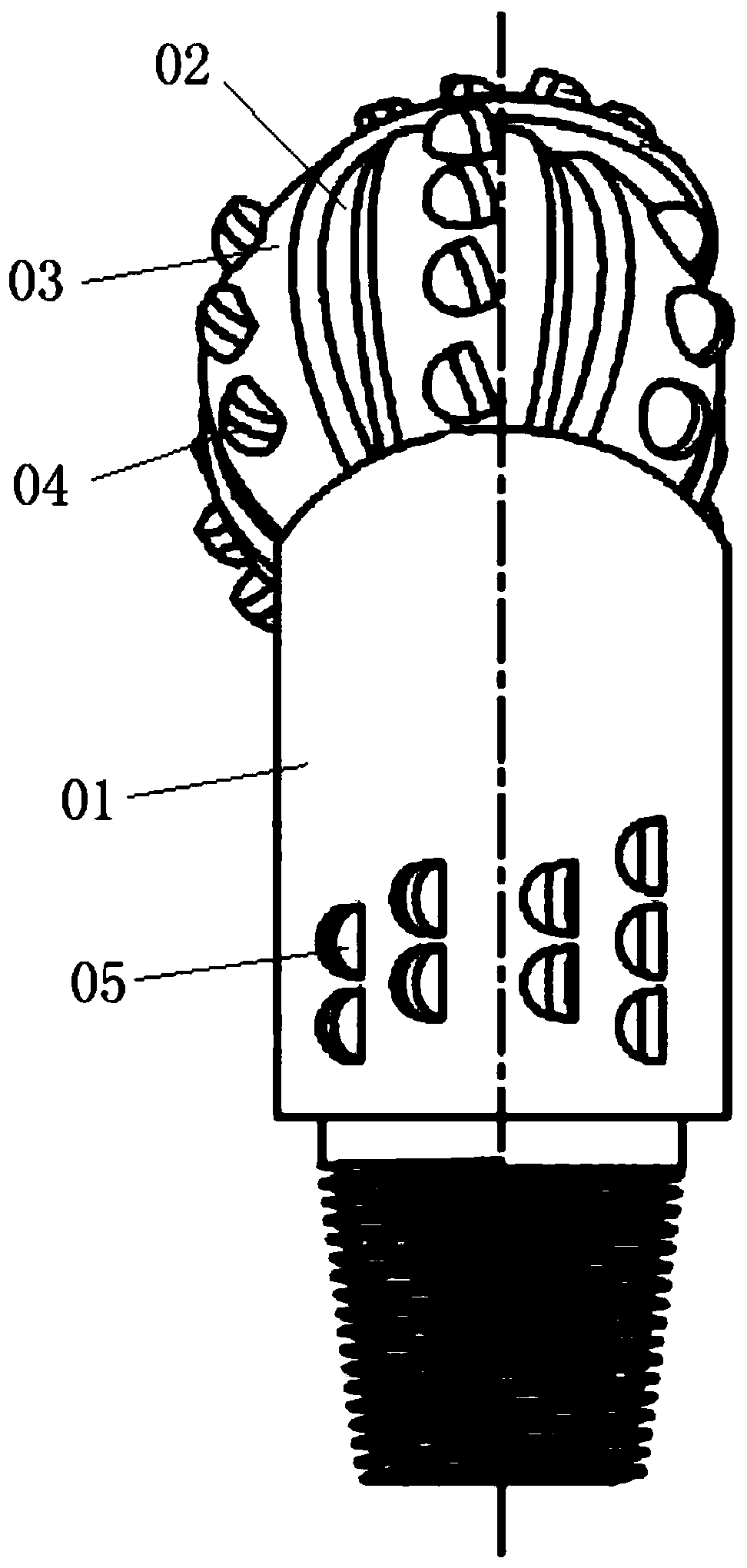

Long-service-life drill bit with self-repairing capacity

ActiveCN105781426AReduced consolidation strengthImprove the efficiency of "self-healing"Drill bitsConstructionsPetroleumSelf repair

The invention discloses a long-service-life drill bit with self-repairing capacity, and belongs to the technical field of drilling equipment for petroleum and natural gas, mine engineering, building foundation engineering construction, geology, hydrology and the like. The long-service-life drill bit with the self-repairing capacity comprises a drill bit body and at least one blade; a plurality of first groups of cutting teeth are formed in the blade; slots are formed in the tooth distribution surface of the blade and / or the gauge protection surface of the blade and are used for fixing the first groups of the cutting teeth; at least one empty groove and at least one second group of cutting teeth are formed in at least one blade; slots are formed in the empty groove and are used for fixing the second group of the cutting teeth; at least part cutting edges of the second group of the cutting teeth are exposed from the inner surface of the empty groove. According to the long-service-life drill bit with the self-repairing capacity, after the cutting teeth in a certain area of the drill bit is worn completely, new cutting teeth can be exposed naturally to realize self-repairing of the drill bit, so that the self-repaired drill bit can drill continuously and effectively.

Owner:SOUTHWEST PETROLEUM UNIV +1

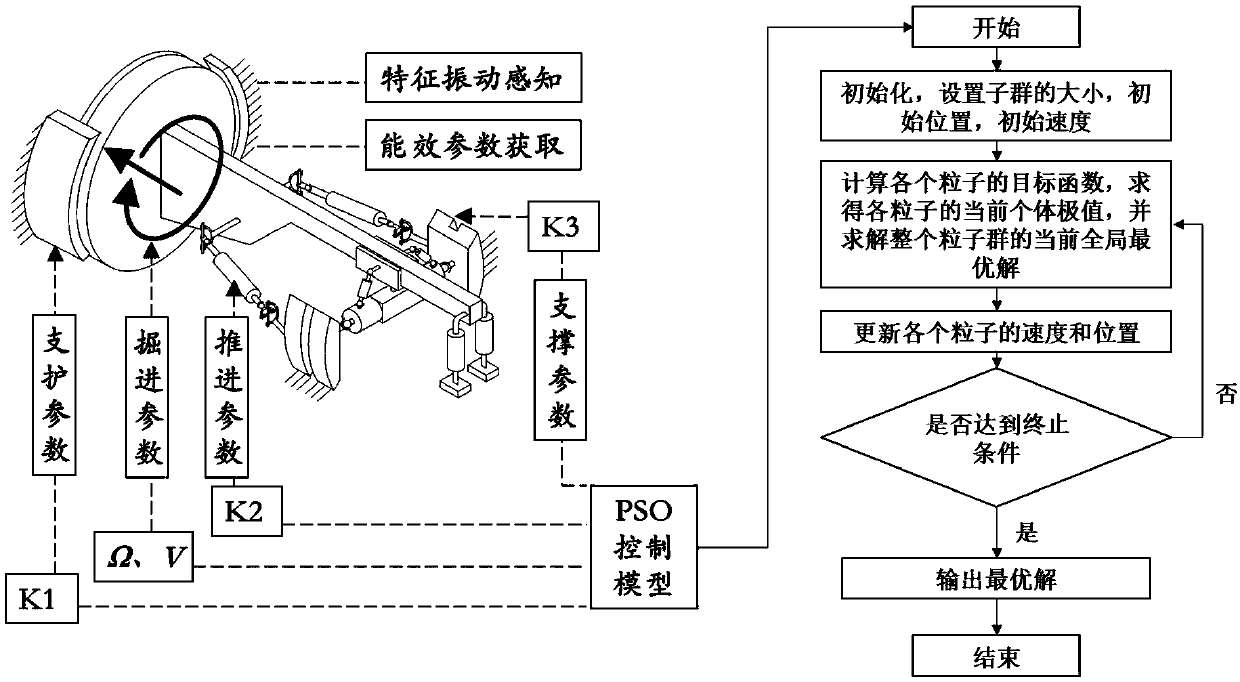

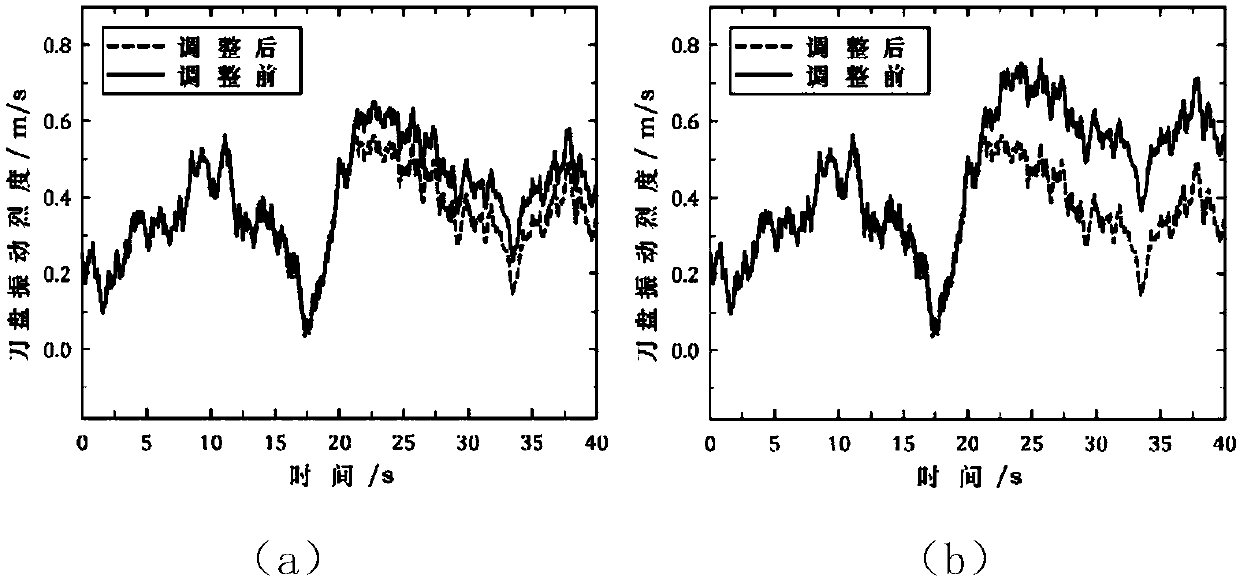

TBM vibration damping control method based on particle swarm optimization algorithm PSO

A TBM vibration damping control method based on a particle swarm optimization algorithm PSO comprises the following steps: 1, building a TBM concentration parameter dynamics model; 2, modeling each rigidity node in the TBM concentration parameter dynamics model; 3, taking the minimum TBM vibration intensity and the minimum TBM driving specific energy as targets, and building a multi-target optimization vibration damping control model; 4, using the PSO algorithm to solve the multi-target optimization vibration damping control model, comparing the real time measured vibration parameter with a theory vibration parameter calculated by the concentration parameter dynamics model, further adjusting a control parameter, related to the vibration parameter, in the multi-target optimization vibrationdamping control model; using the optimization iteration algorithm to obtain the optimal rigidity parameter and driving parameter, further adjusting the control parameter in the TBM actual operation process according to the optimal rigidity parameter and driving parameter, thus realizing optimization control of TBM vibration, and realizing the high efficiency driving target of the TBM under the low vibration level conditions.

Owner:SHANGHAI JIAO TONG UNIV

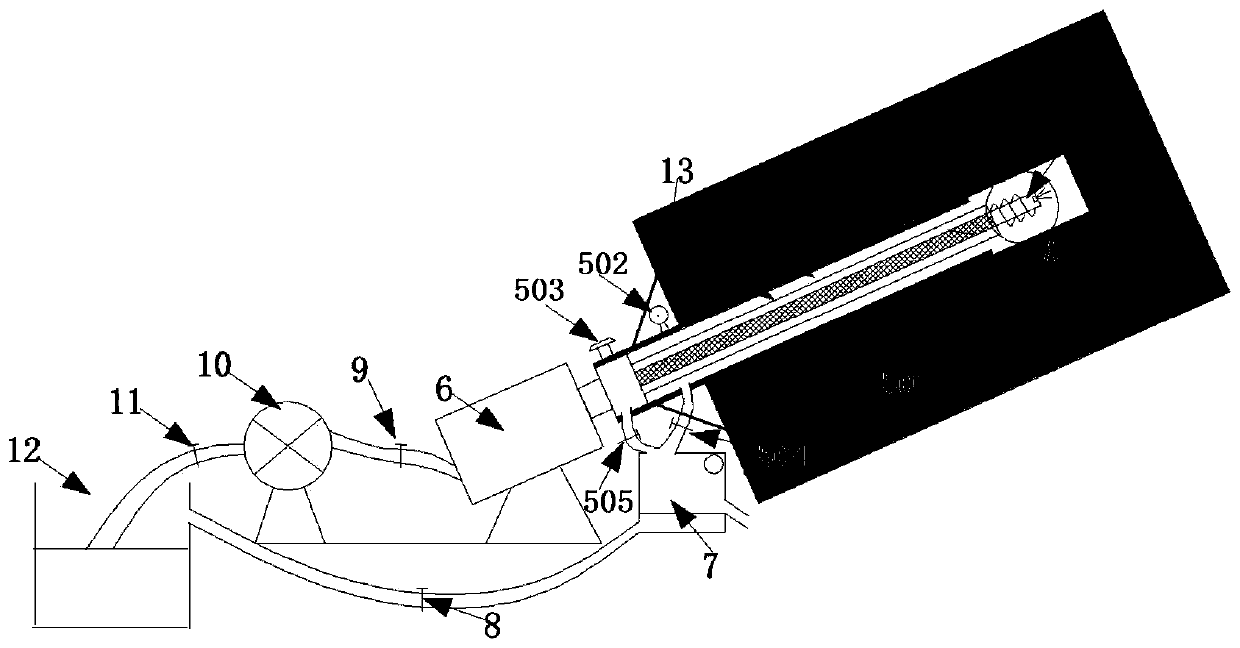

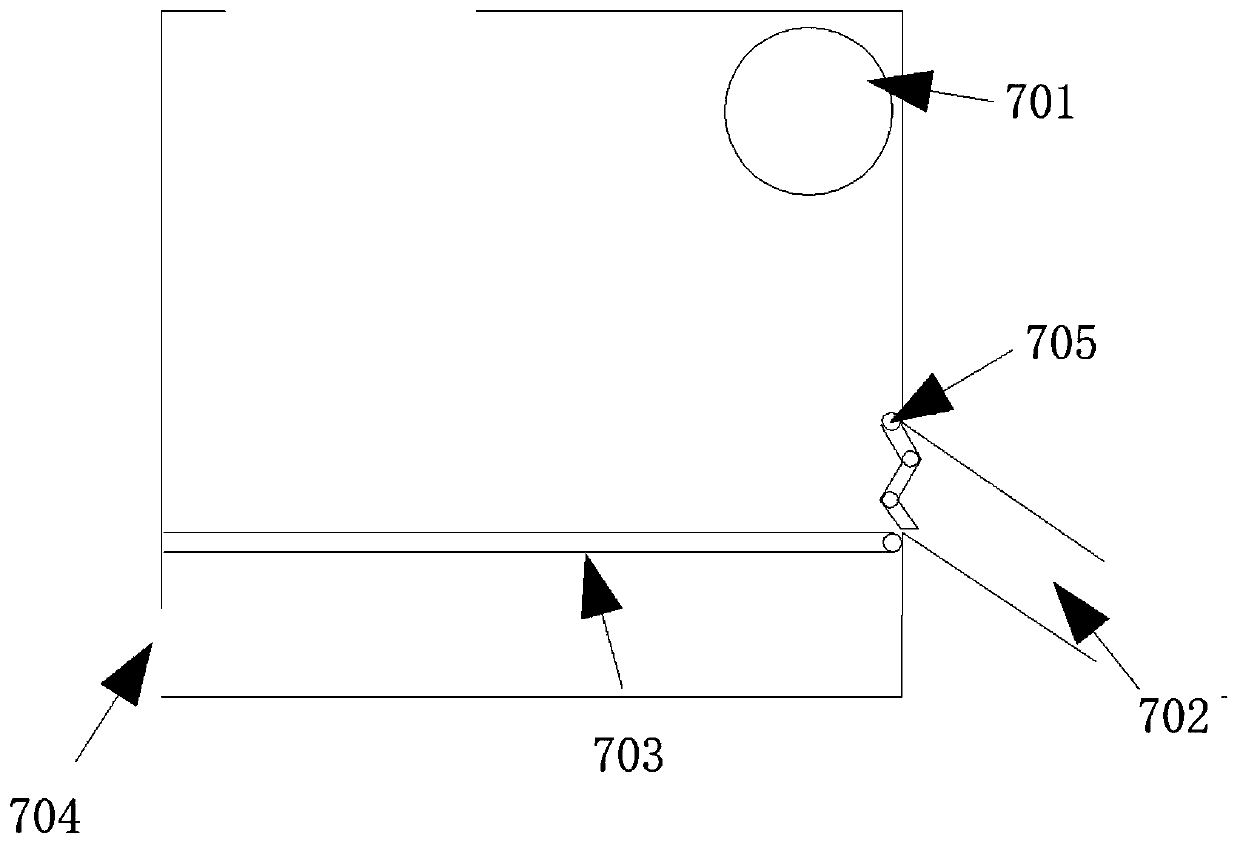

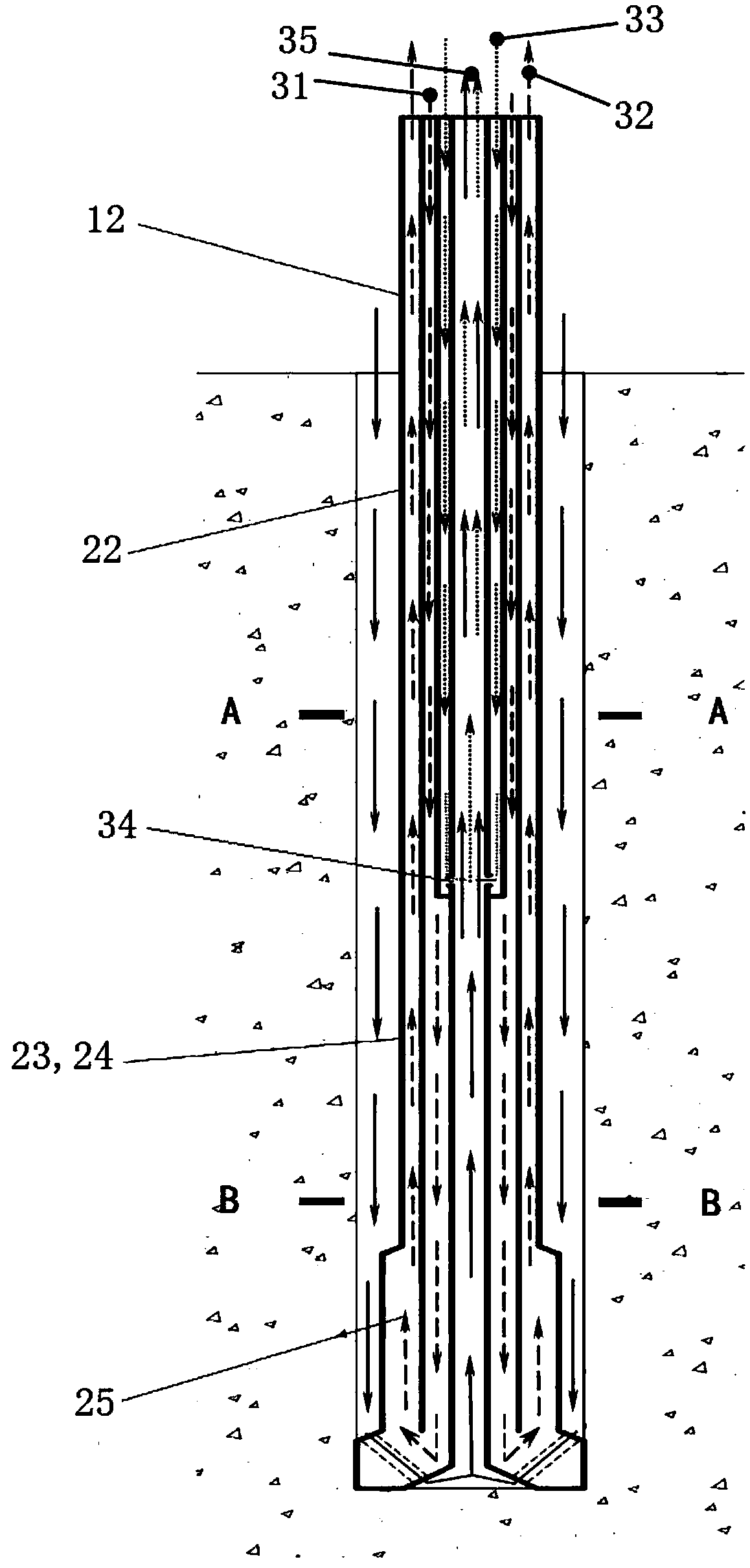

Soft outburst coal seam long drill hole forming system and method

PendingCN111425138AStable pressureEfficient and smooth drilling operationDrill bitsDrilling rodsPressure stabilizationSlag

The invention provides a soft outburst coal seam long drill hole forming system and method. The system comprises a water jet generation system, a drill tool system, a supporting sleeve pipe, a pressure-retaining system and a gas-slag separator, wherein the drill tool system comprises a spiral drill bit, a drill rod and a drilling machine; the drilling machine clamps the tail end of the drill rod;the supporting sleeve pipe is arranged in the drill rod; the pressure-retaining system comprises a pressure-retaining pipe, a pressure display and a pressure-retaining sealing device; the front end ofthe pressure-retaining pipe stretches into the drill hole and the back end of the pressure-retaining pipe is placed outside the drill hole; and the drilling machine drives the drill rod to rotate anddrills into a coal rock seam. The hole forming method comprises the steps of placing the pressure-retaining pipe, drilling and crushing, pushing the supporting sleeve pipe out of the drill bit and the like. The system guarantees stable pressure in the drill hole and solves the problems of hole collapse, drill burying and the like occurring in long-distance drilling, thereby realizing efficient and smooth drilling operation, utilizing waste water maximally to perform circulating operation and significantly improving construction efficiency and economic benefit.

Owner:CHONGQING UNIV

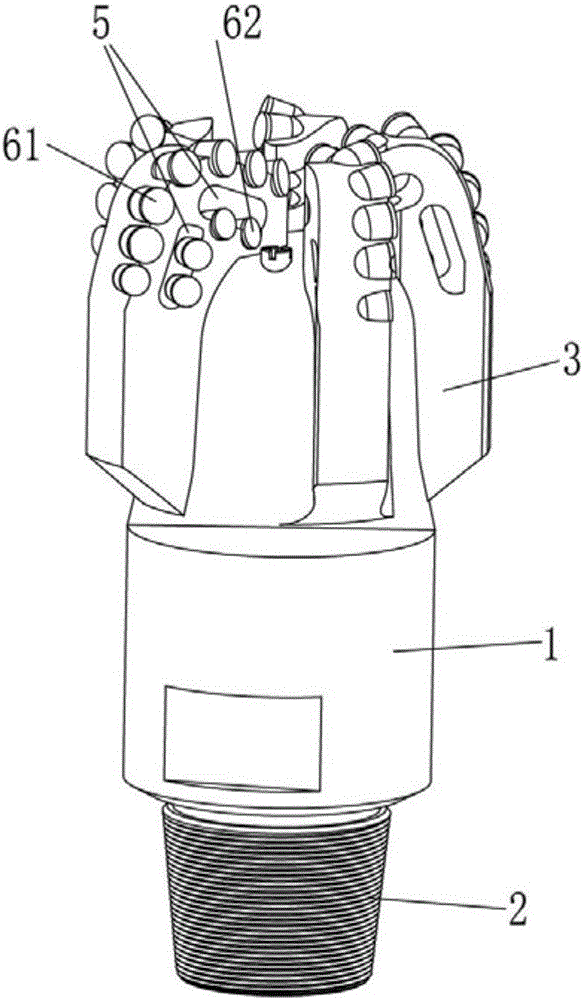

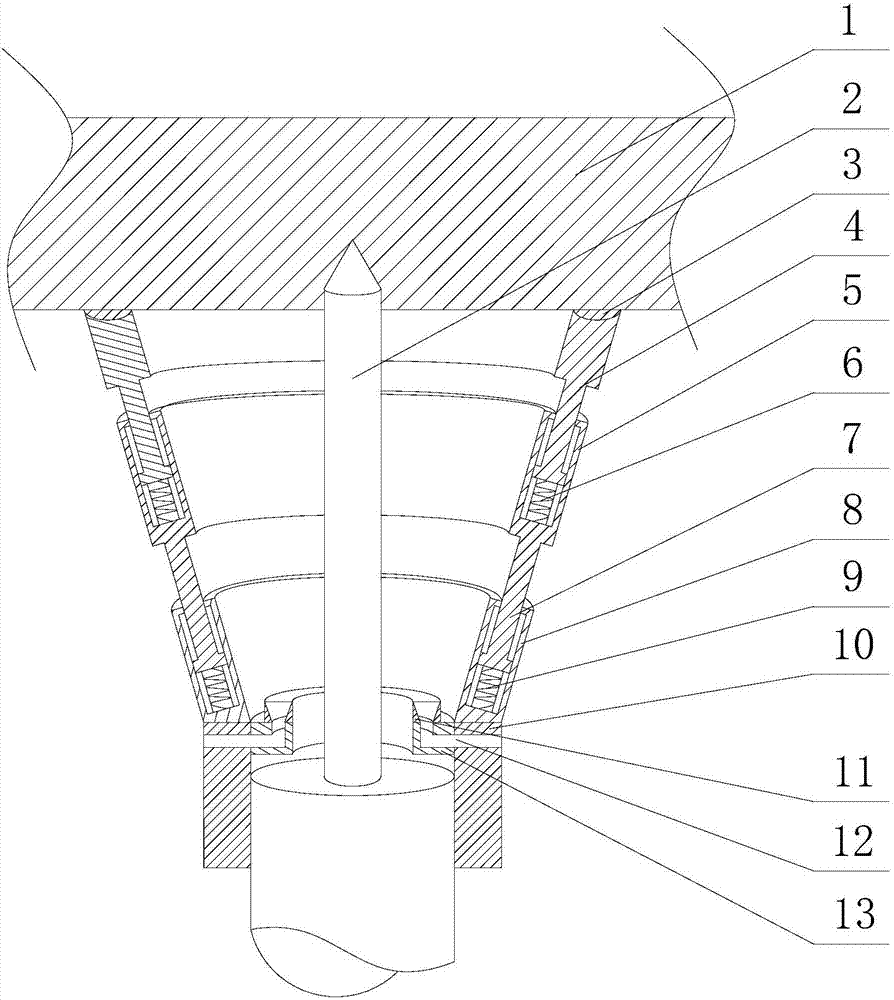

Stretchable breaking type PDC compound drill bit

InactiveCN107503690AImprove rock breaking efficiencyExtended service lifeDrill bitsConstructionsPetroleumRock breaking

The invention provides a retractable and broken PDC composite drill bit, which relates to the technical field of oil drilling tools, and includes a drill body and a blade fixed on the drill body. The blade is provided with several cutting teeth. The drill bit The center of the body is provided with a breaker bit detachably connected to the drill body, an embedding groove for inserting the breaker bit, and an ejection mechanism, and the ejection mechanism is arranged in the drill body and is fixedly connected with the breaker bit; the drill body A floating support block is arranged between the broken drill bit. Through the implementation of this technical solution, the rock-breaking efficiency of the core of the drill bit can be effectively improved, and the technical problem that the PDC bit is difficult to drill in the hard formation is overcome; and the drill bit body around the broken bit body will not be caused faster Wear and tear is conducive to improving the service life of the drill bit and saving drilling costs.

Owner:弘毅天承知识产权股份有限公司

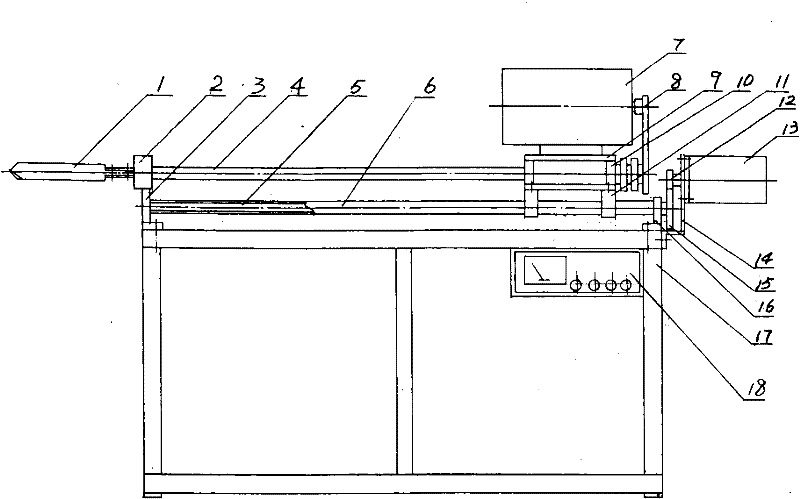

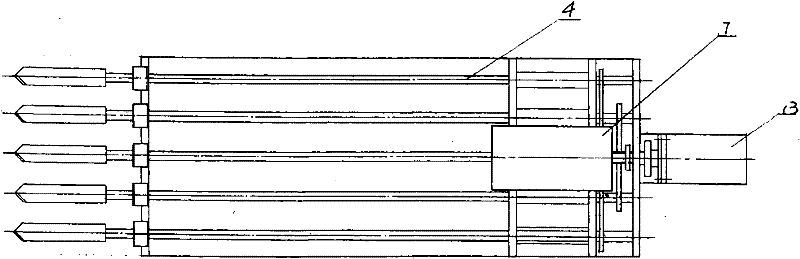

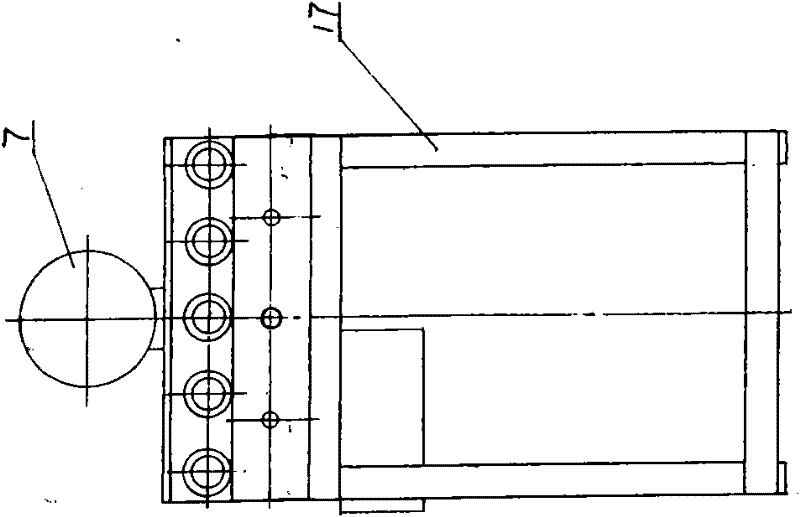

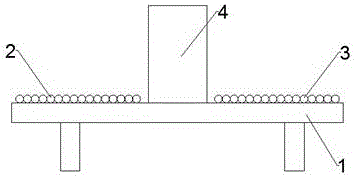

Aerated Concrete Block Horizontal Deep Hole Group Drilling Machine

InactiveCN102259392AMeet the requirements of drilling 1 meter deep holeEasy to assemble and disassembleStone-like material working toolsElectrical controlEngineering

The invention discloses a horizontal deep hole group drilling machine for aerated concrete blocks capable of drilling multiple deep holes on aerated concrete blocks. , Drilling motor, transmission system, motor base, movable drill frame, linear slider, pinion gear, automatic advance and retreat knife motor, motor bracket, large gear, screw bracket, rack, electrical control box, the twist drill is drilled together The rods are connected together, the composite bearing is connected with the guide rod bracket, installed on the left side of the frame, the rear of the drill pipe is connected to the movable drill frame, the drilling motor is connected to the motor base on the movable drill frame, and the knife advances and retreats automatically The motor is fixed on the motor bracket and connected to the upper right side of the frame. The large gear is connected to the automatic advance and retreat knife motor and the screw control. The movable drill frame connected to the linear slider moves forward and backward on the guide rod. The guide rod and the screw rod are installed on the screw rod. On the bracket, the electrical control box is installed on the upper right side of the rack.

Owner:郝钰 +1

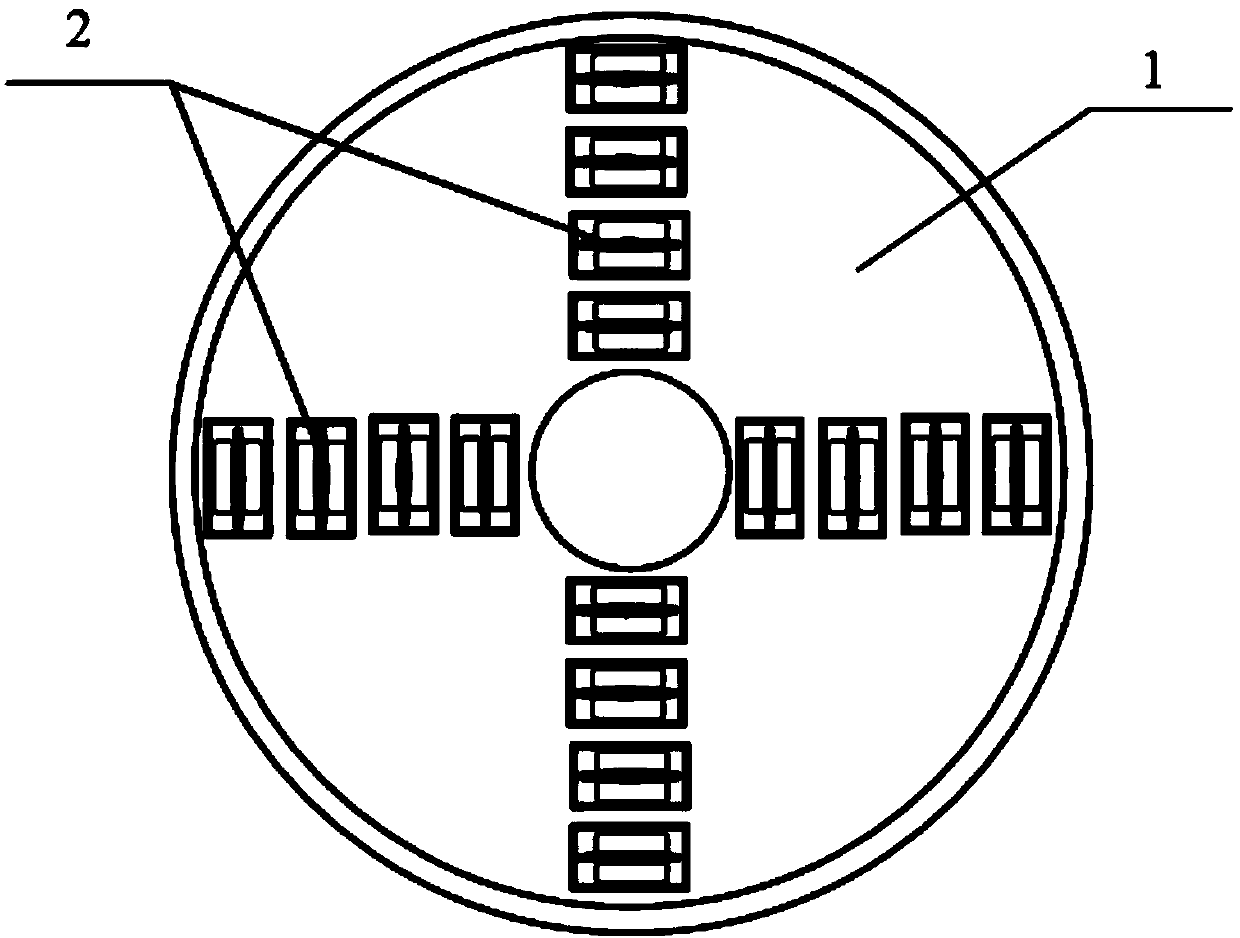

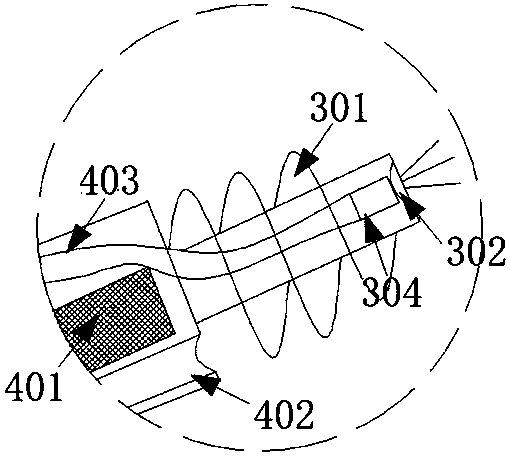

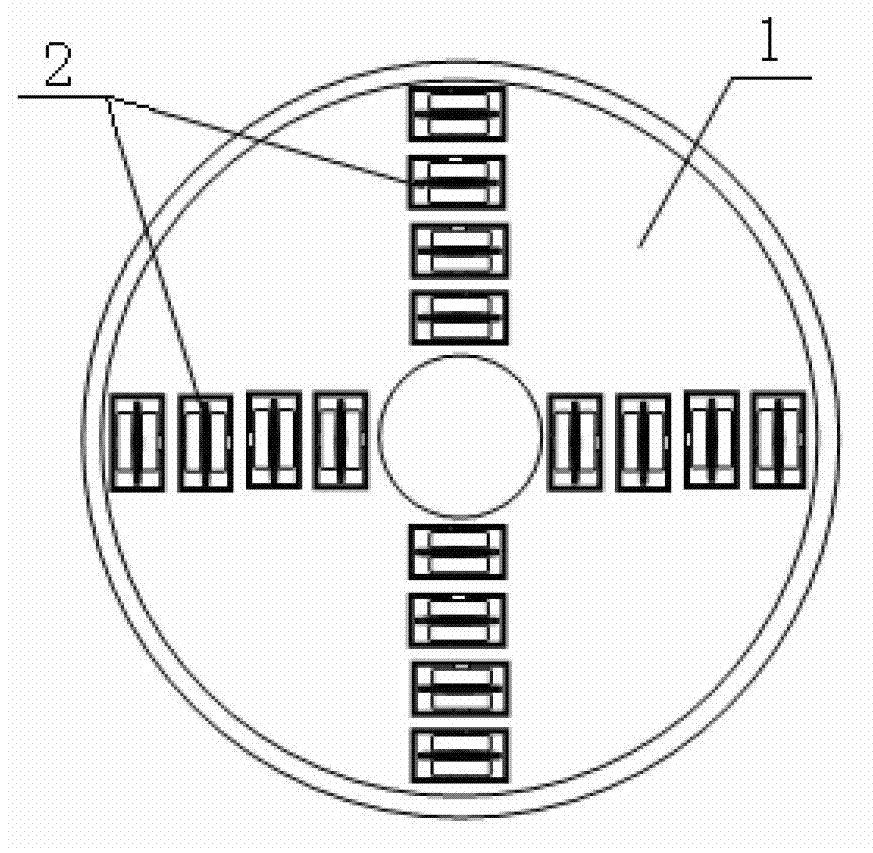

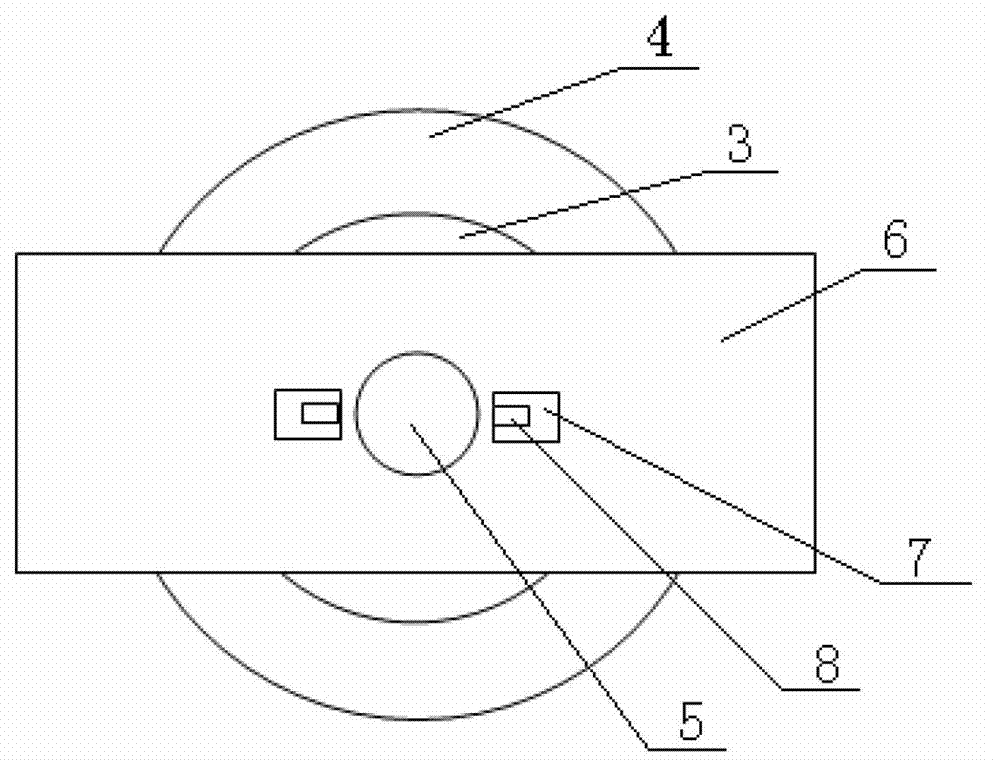

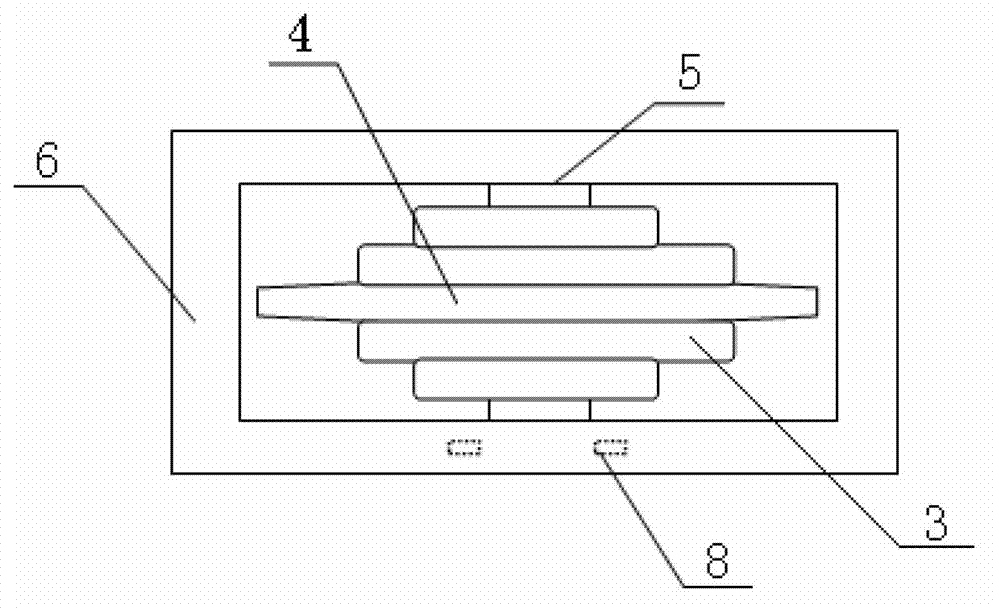

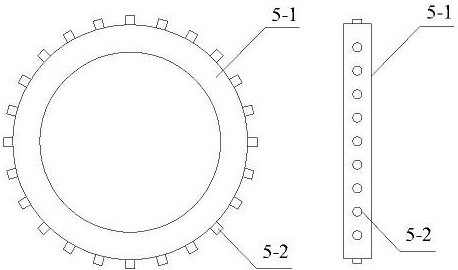

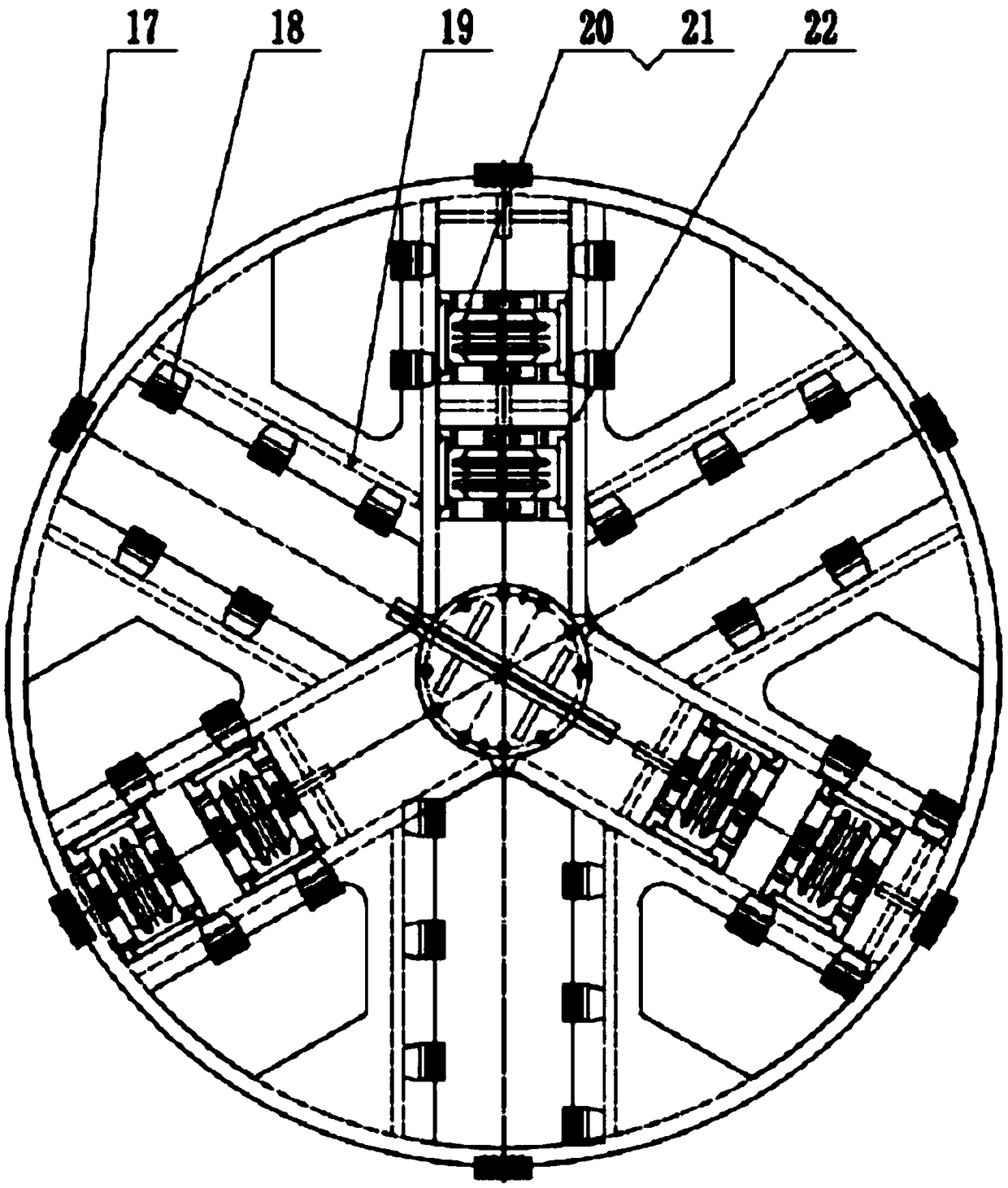

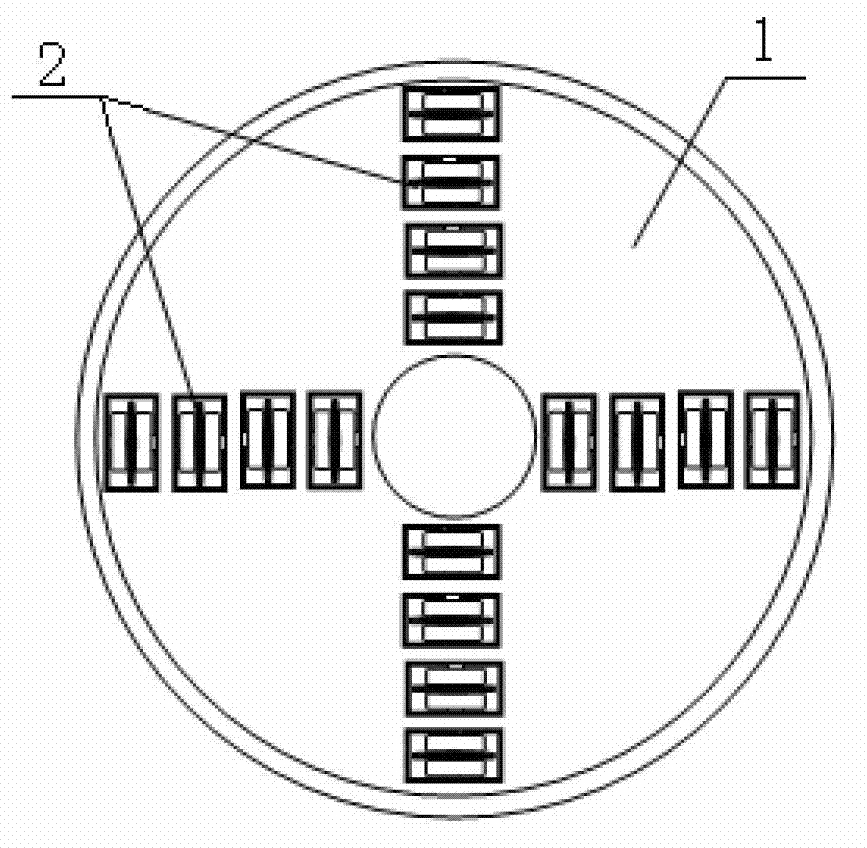

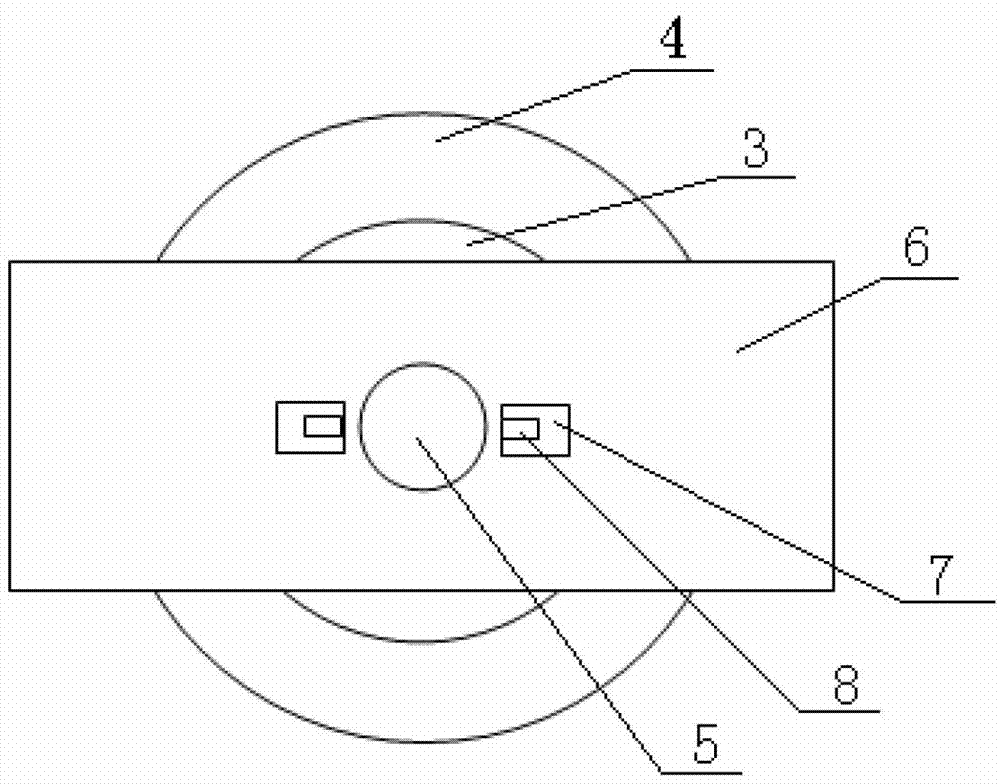

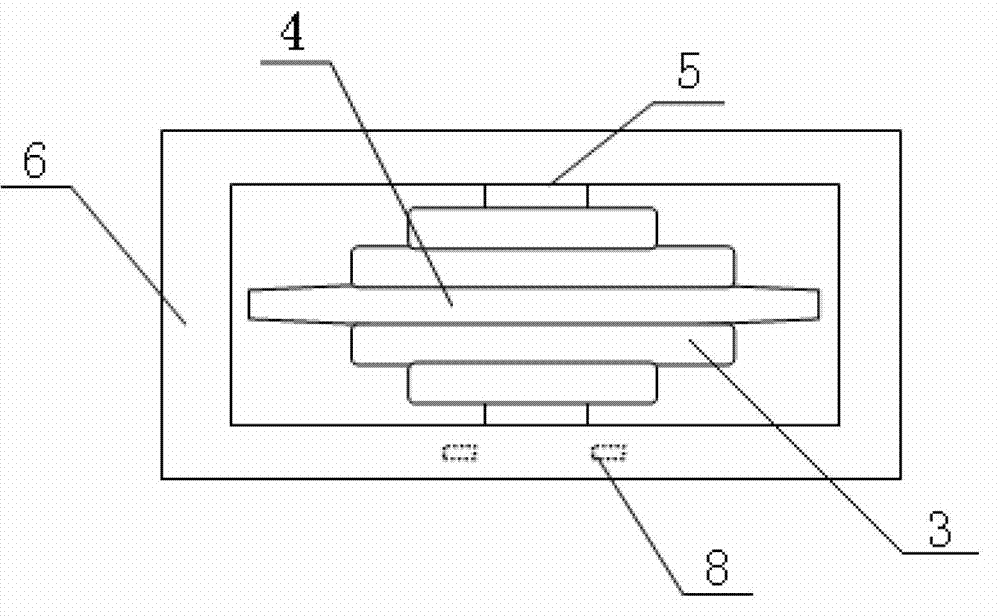

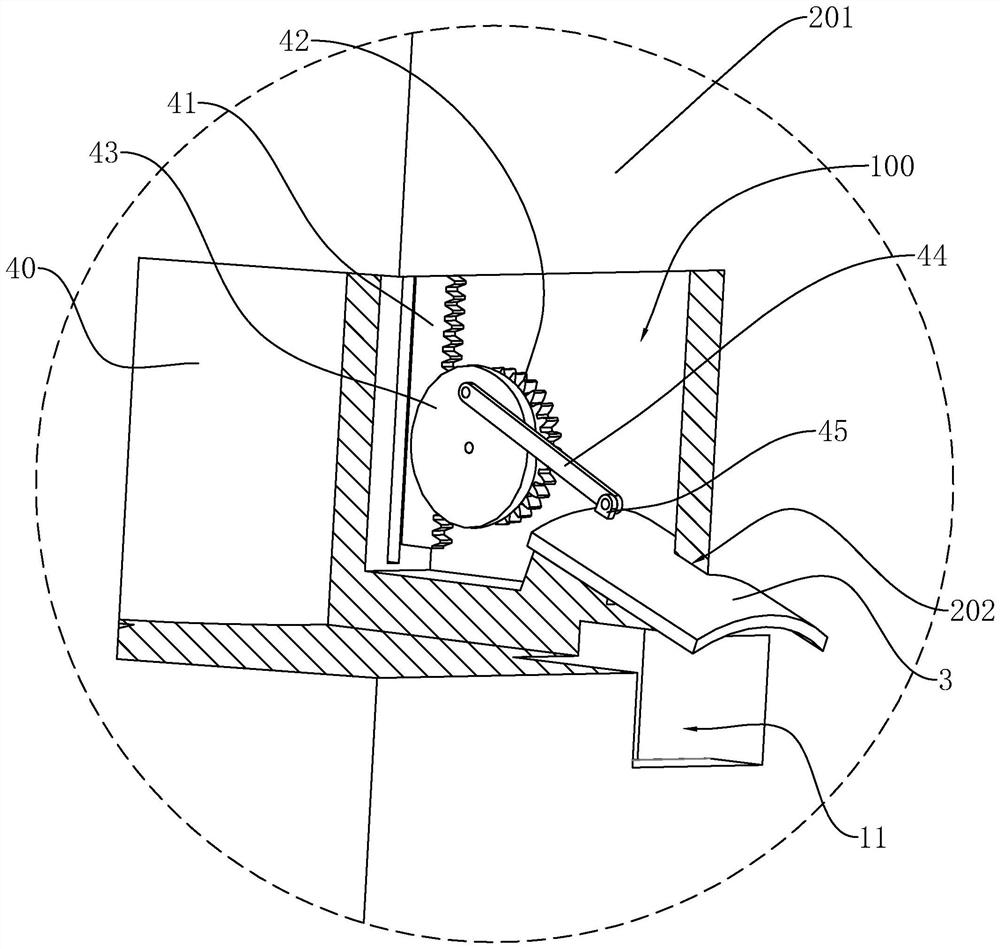

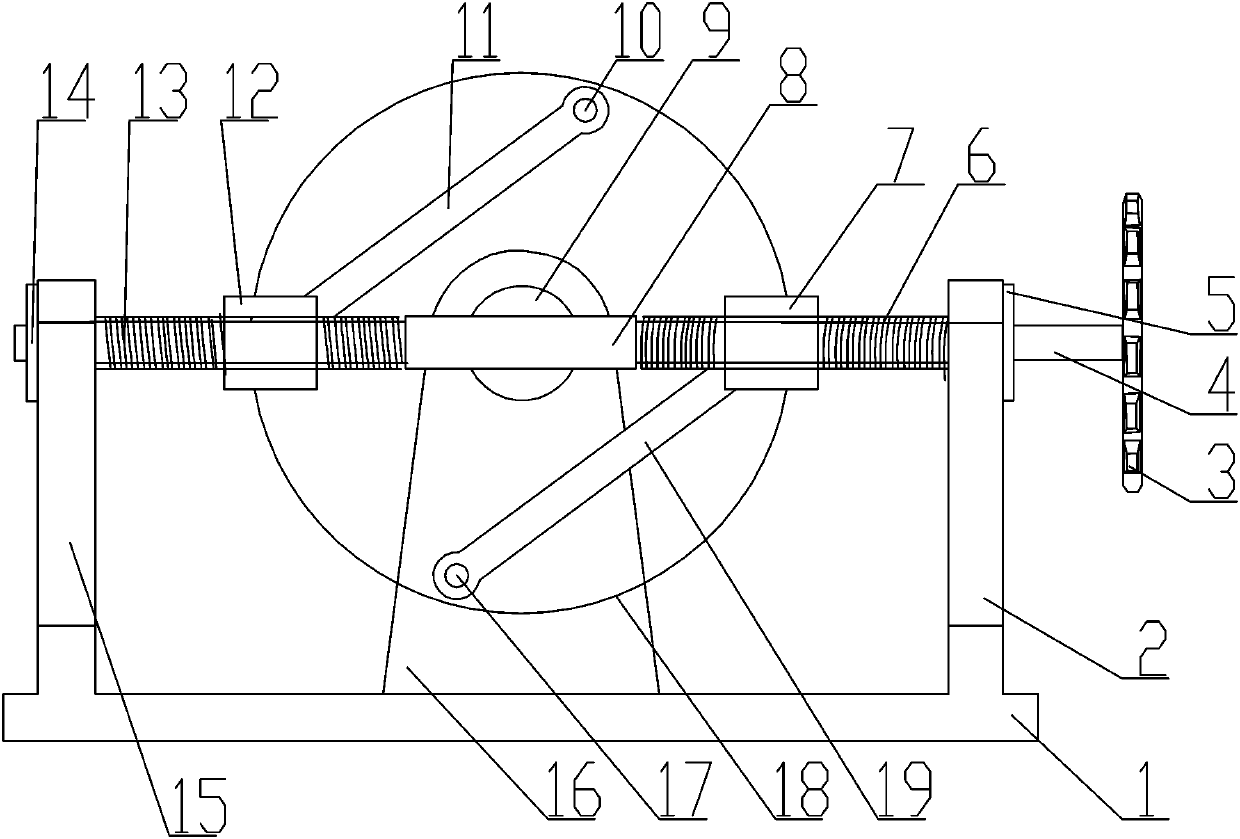

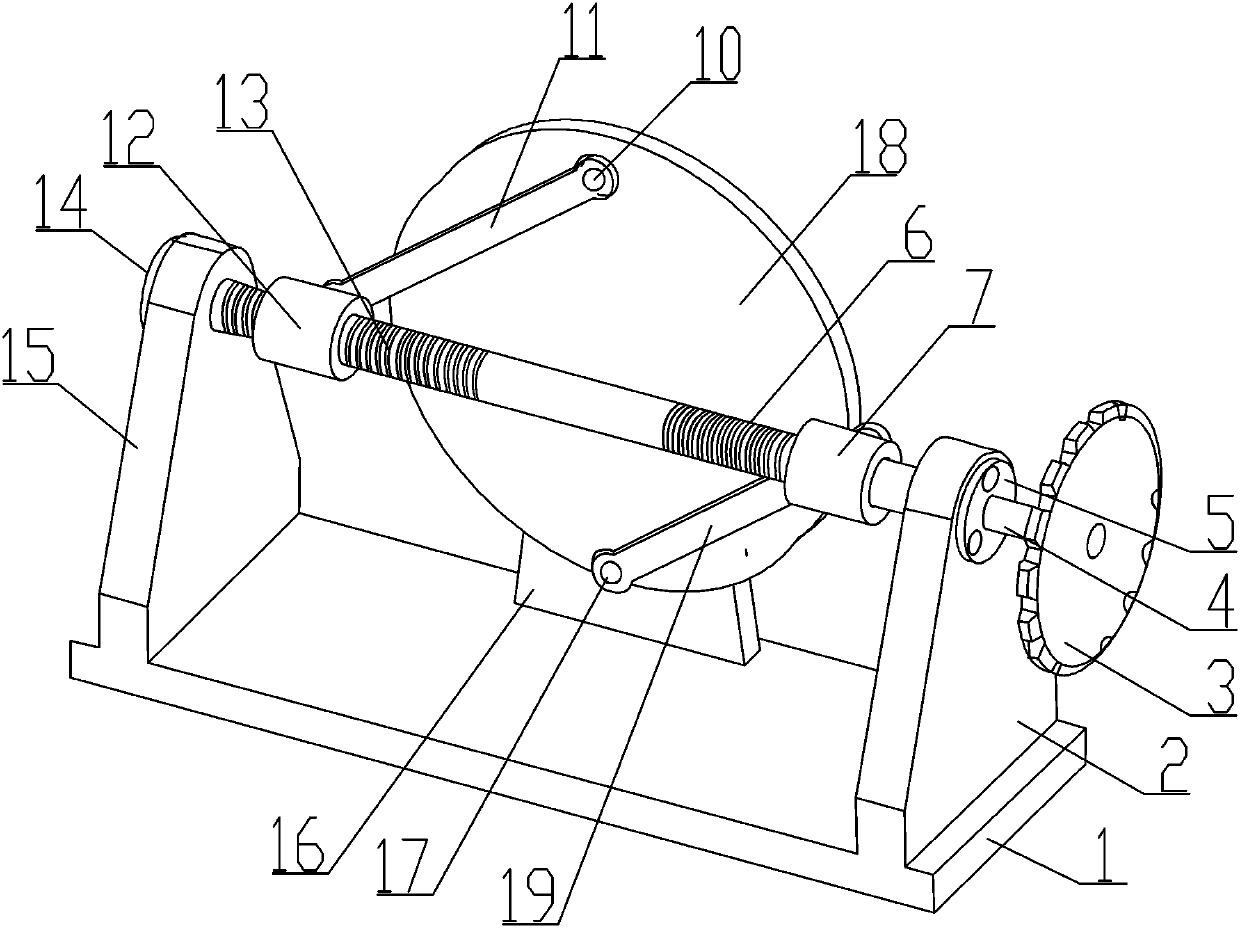

Online testing device for hob blade string abrasion of heading machine

ActiveCN103195437AGrasp the working status in timeGuaranteed drilling efficiencyAcceleration measurementTunnelsVibration amplitudeMachine

The invention discloses an online testing device for hob blade string abrasion of a heading machine. The online testing device is characterized in that a hob is sleeved on a hob center shaft through a bearing, and the center shaft is mounted on a frame hob holder which is assembled in a base of a hob plate. Acceleration sensors can sense the moving state of the hob to emit signals, so that rectangular holes are arranged on two sides of the center shaft outside the hob holder and on a horizontal axis of the hob center shaft. The acceleration sensors are disposed in the rectangular holes, the hole walls of the rectangular holes close to the direction of the hob center shaft is planes, and the planes serve as measuring surfaces of the acceleration sensors. If the hob blade string abrasion occurs, the vibration state of the hob can be changed, that is, the hob vibration amplitude and frequency can be changed obviously. The acceleration sensors can determine whether the hob blade enters a string abrasion state according to the detected vibration amplitude and frequency, the hob working state can be mastered timely, and the hob can be replaced timely in case of abrasion, accordingly, the heading efficiency can be guaranteed.

Owner:TIANJIN UNIV

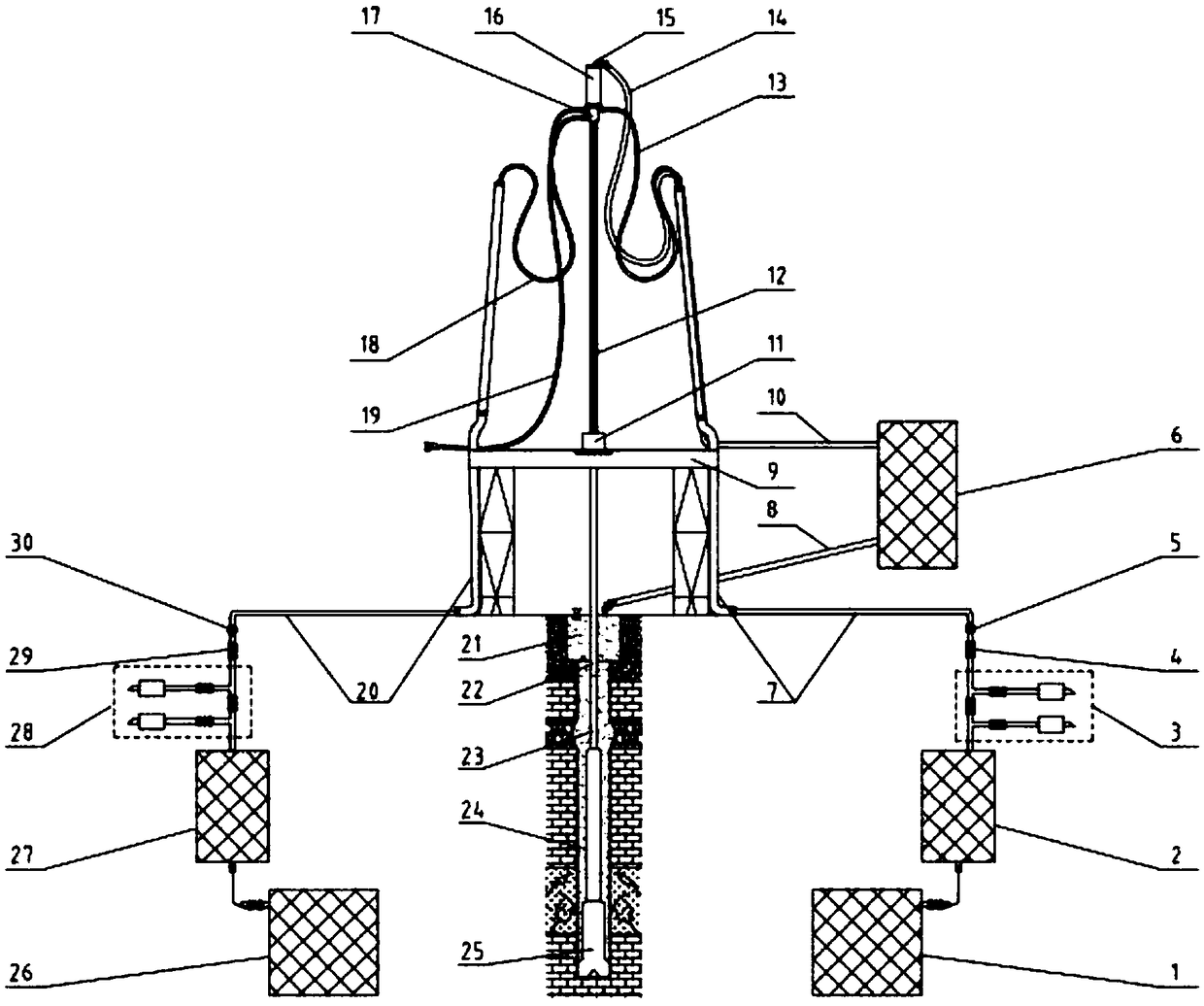

Drilling system with multiple circular flow channels for large-scale borehole hard rock drilling and drilling process

The invention discloses a drilling system with multiple circular flow channels for large-scale borehole hard rock drilling and a drilling process. The drilling system includes underground air hammer ground manifold equipment, gas lift manifold equipment, a drilling drive device, drilling tools for the circular flow channels and slurry circulating equipment; the underground air hammer ground manifold equipment and the gas lift manifold equipment are both correspondingly communicated with the drilling tools for the circular flow channels through the drilling drive device, and the slurry circulating equipment is connected with the drilling drive device through anti-erosion goosenecks and a sand discharging pipeline. The system integrates the advantages of reversely circular sand discharging through gas lift and closed-type reversely-circular air hammers, ensures the drilling efficiency and significantly decreases the gas feeding amount at the same time; decrease of investment on equipmentis facilitated, the occupied area of space is reduced, the demands for power and drilling fluids are decreased, and the fuel consumption is reduced.

Owner:BEIJING CAPITAL HEAT CO LTD

Drilling assistant tool applied to hanging bar installation procedure

ActiveCN106938403AEasy to observe in real timeInterfere with line of sightMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a drilling assistant tool applied to a hanging bar installation procedure. The drilling assistant tool comprises a conical barrel I, a conical barrel II, a conical barrel III and a sleeve, wherein the small-diameter section of the conical barrel III is connected with the upper end face of the sleeve; a first annular cavity is arranged on a main body of the conical barrel III; a plurality of springs II are arranged on the bottom part of the first annular cavity; an extending section is arranged on the end face of the conical barrel II along a circumferential direction of the small-diameter section of the conical barrel II; a through hole is formed in the first annular cavity; the lower section of the extending section movably penetrates through the through hole so as to be connected with the plurality of springs II; a second annular cavity is arranged on a main body of the conical barrel II; a plurality of springs I are arranged on the bottom part of the second annular cavity; an annular hole is formed in the second annular cavity; the small-diameter section of the conical barrel I movably penetrates through the annular hole so as to be connected with the plurality of springs I. According to the drilling assistant tool applied to the hanging bar installation procedure provided by the invention, operating personnel can conveniently observe an installation hole drilling progress in real time, concrete dust produced due to drilling is prevented from interfering sights of the operating personnel, and the occurrence of accidents caused by dust splash is prevented.

Owner:CHINA MCC5 GROUP CORP

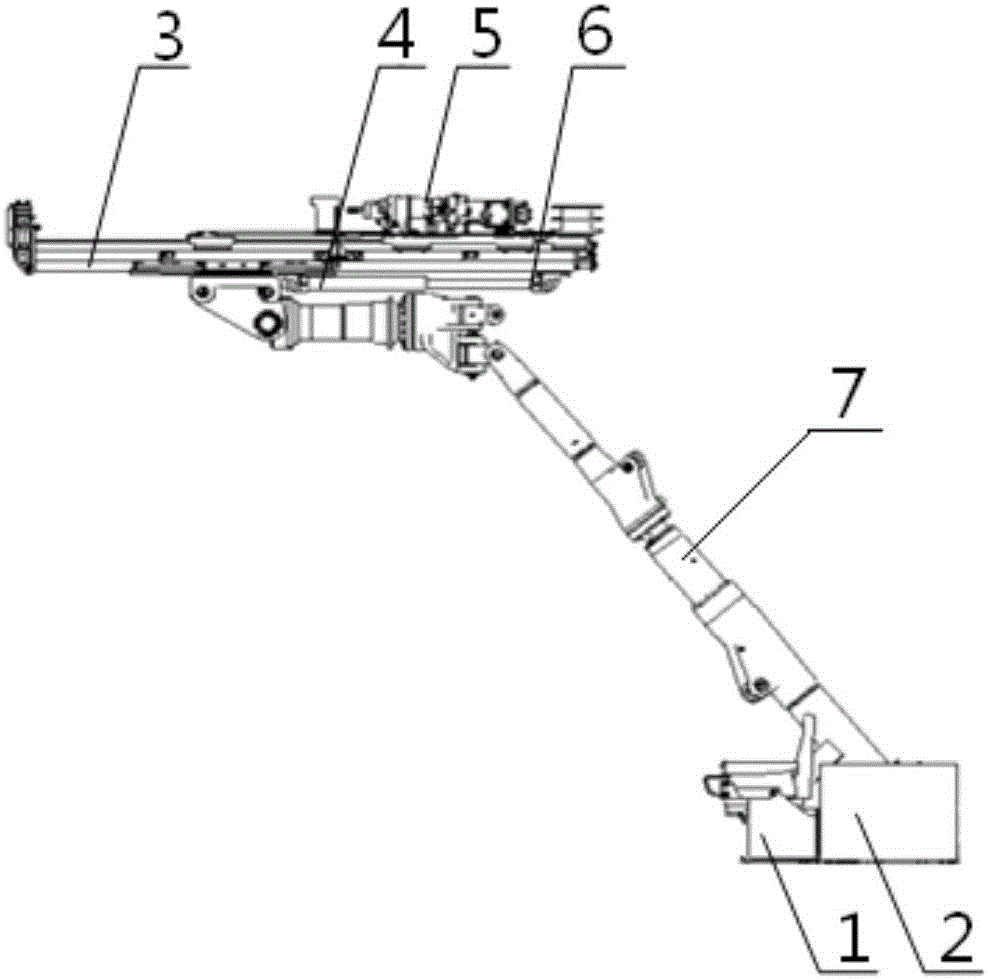

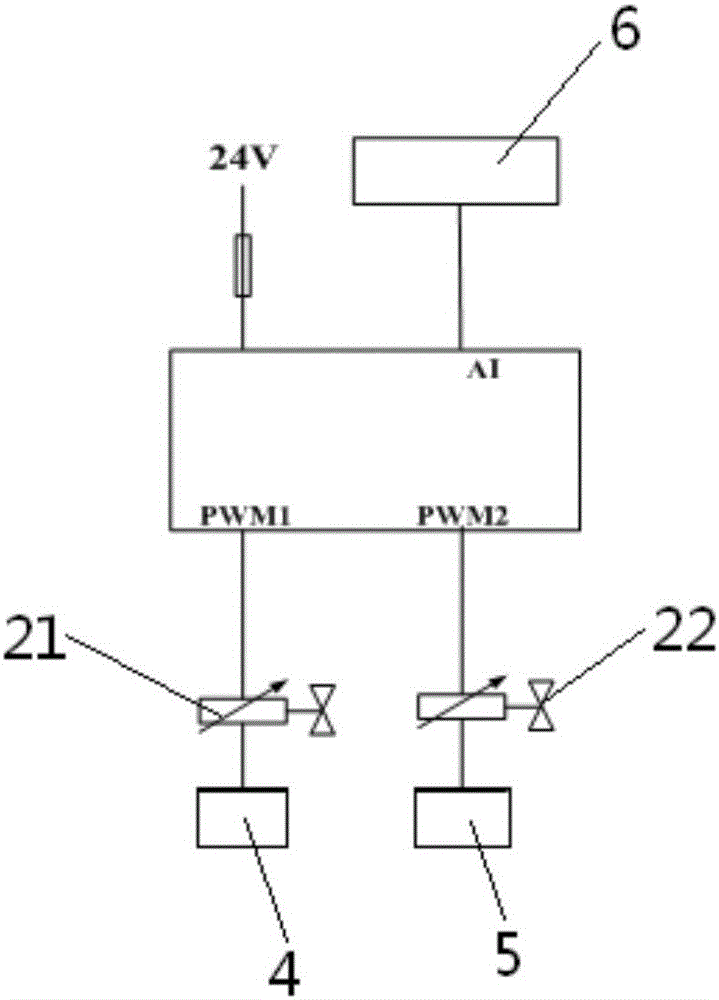

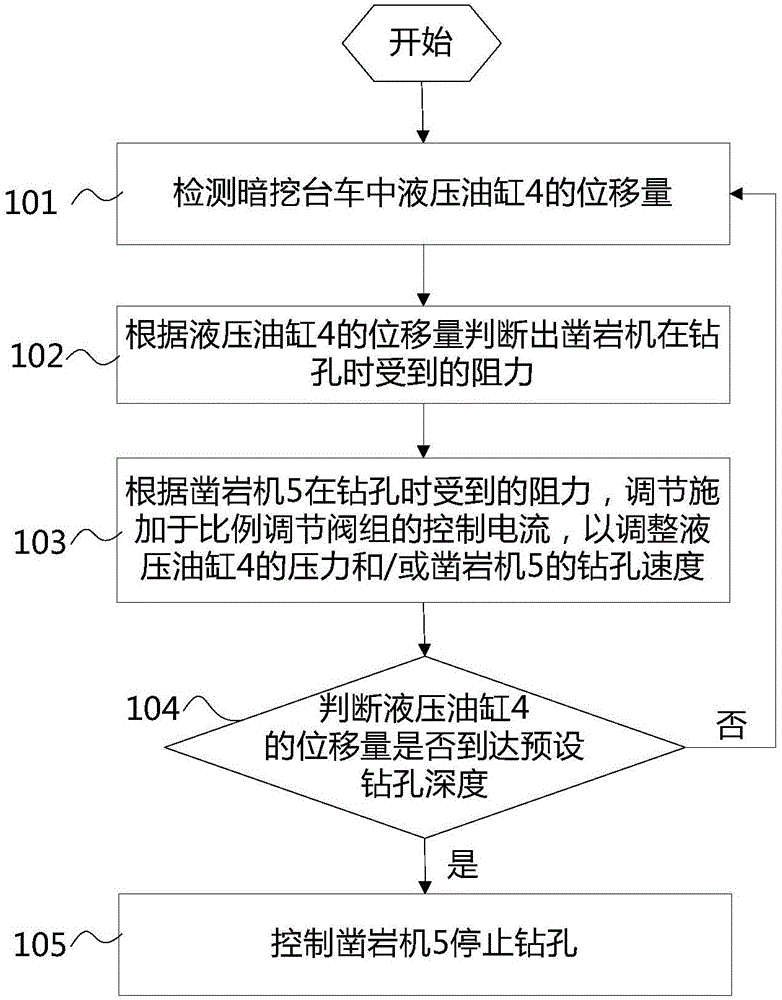

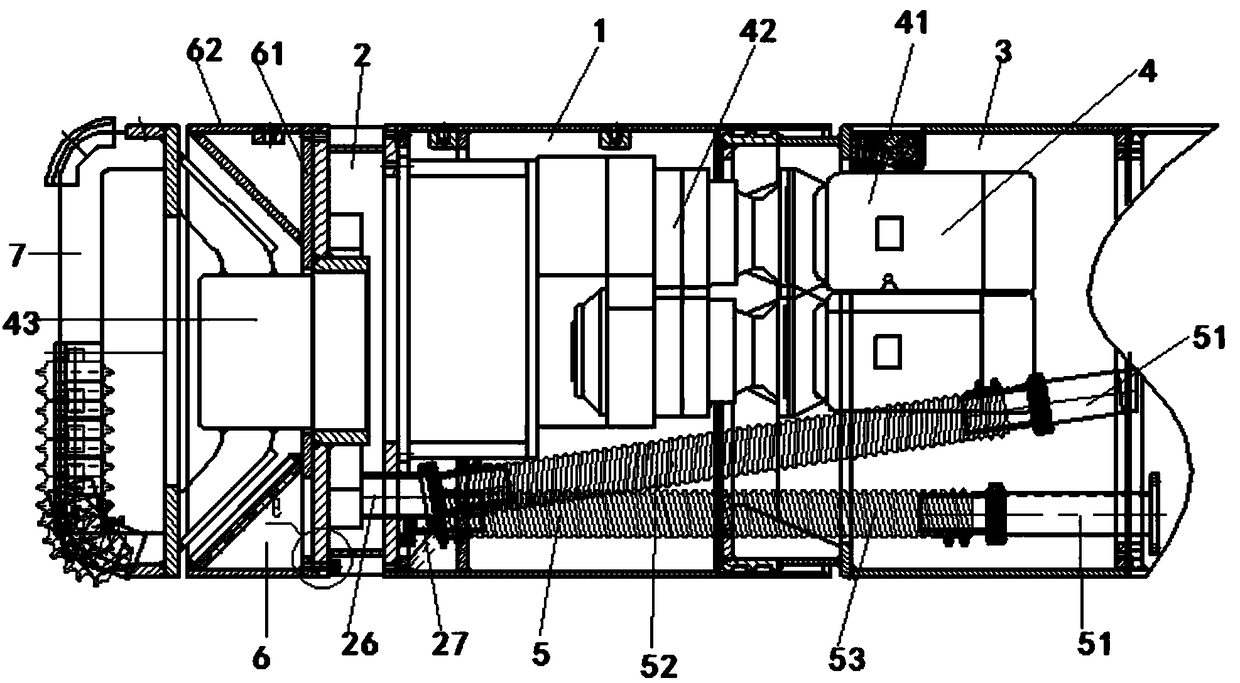

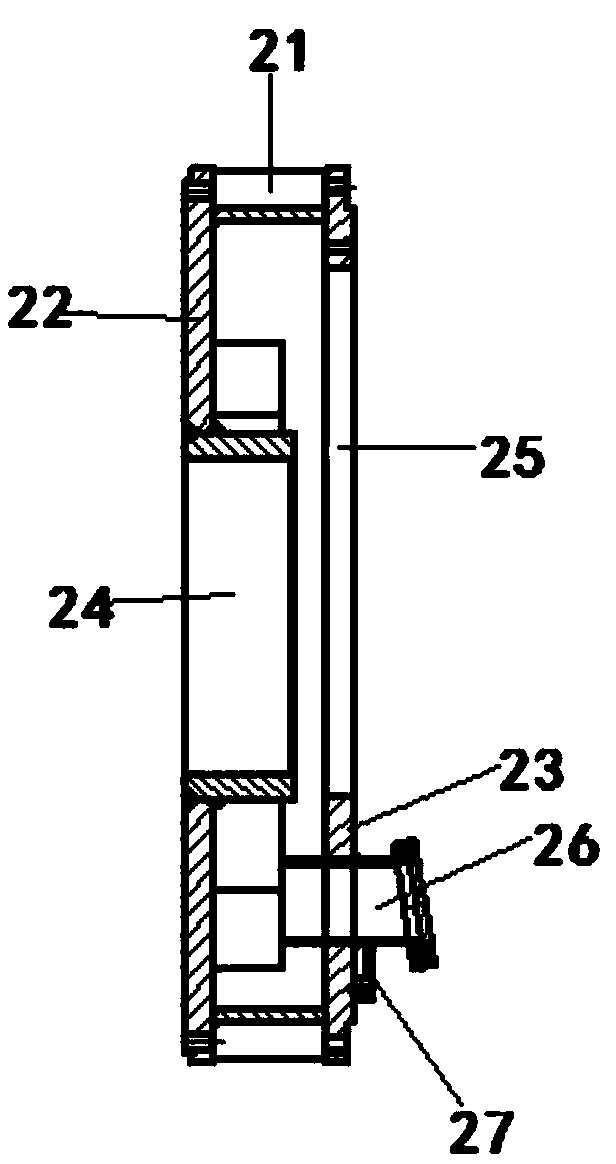

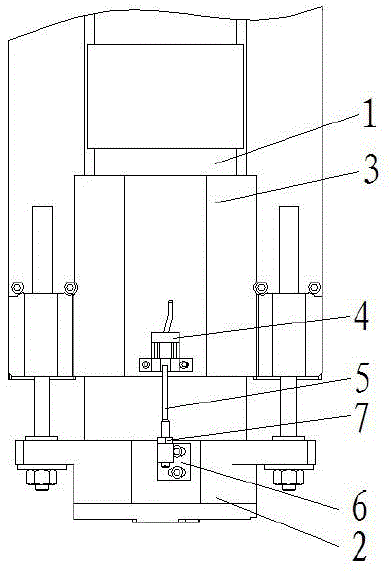

Underground excavation trolley drilling depth control method and system and underground excavation trolley drilling device

ActiveCN106223973AAvoid failureReduce the phenomenon of stuck drillTunnelsAutomatic control for drillingHydraulic cylinderAutomatic control

The invention relates to underground excavation trolley drilling depth control method and system and an underground excavation trolley drilling device. The control method comprises the following steps: detecting displacement of a hydraulic cylinder (4) in an underground excavation trolley; judging resistance received by a rock drill (5) during drilling according to the displacement of the hydraulic cylinder (4); regulating control current applied to a proportioning valve block (2) according to the resistance received by the rock drill (5) during drilling, so as to adjust pressure of the hydraulic cylinder (4) and / or drilling speed of the rock drill (5). The control method provided by the invention has the advantages that power of the whole drilling device can be automatically controlled in a drilling process, so as to be matched with resistance variation in the drilling process, drilling speed is more uniform, the phenomenon that a drilling tool is jammed due to a drill bit is avoided, service lives of the drill bit and a drill rod are prolonged while drilling efficiency is guaranteed, and the drilling device is avoided from breaking down in a working process.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

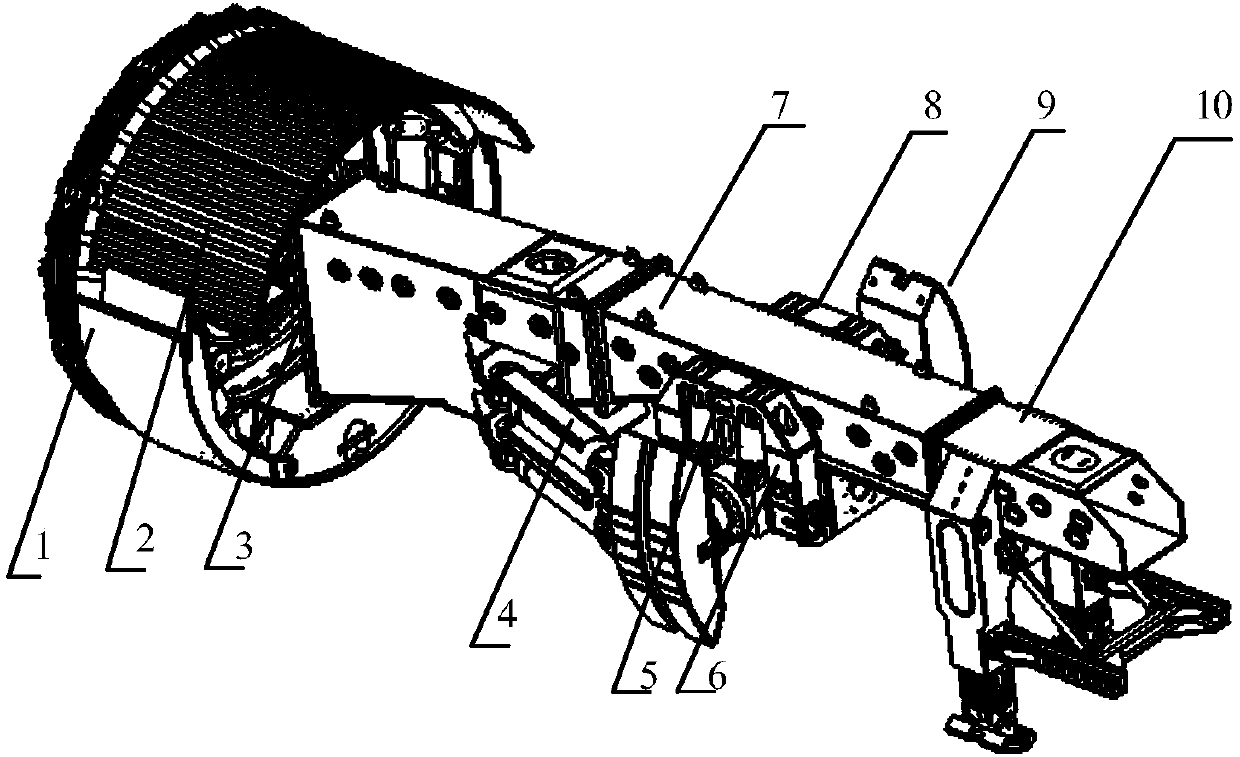

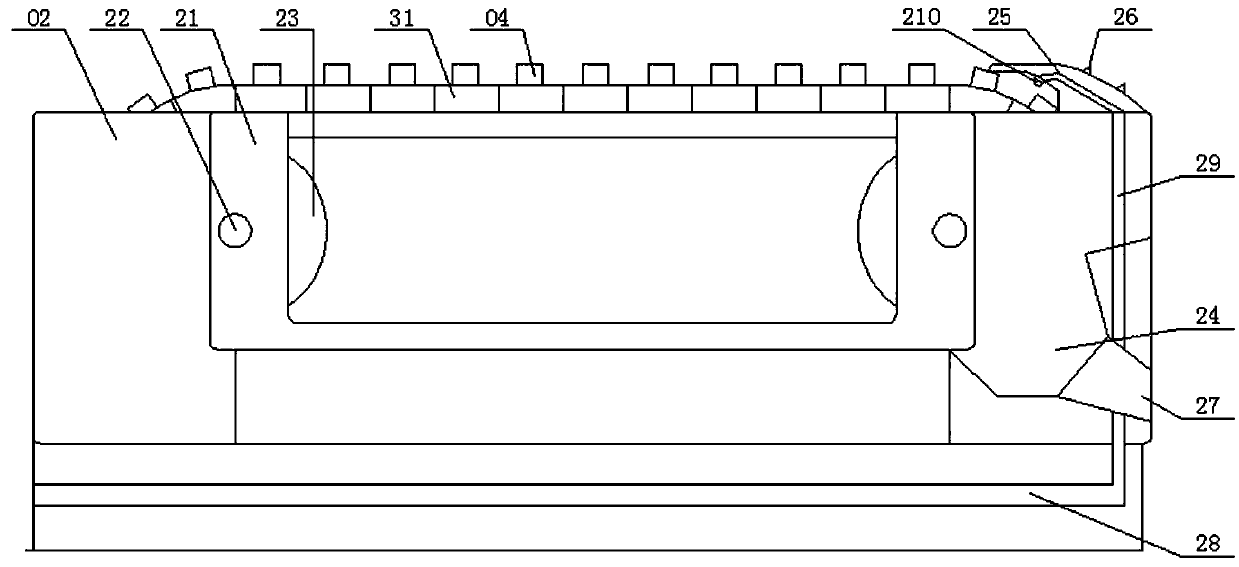

Miniature rock pipe jacking machine with replaceable cutter head and mud bin

PendingCN108412513AGuaranteed drilling efficiencyEasy to install and removeTunnelsEngineeringPower output

The invention discloses a miniature rock pipe jacking machine with a replaceable cutter head and a mud bin. The pipe jacking machine comprises a front cylinder, the front end of the front cylinder isfixedly sleeved with a connecting cylinder, the rear end of the front cylinder is fixedly sleeved with a rear cylinder, and a cone crushing mud bin is fixedly connected to the front end of the connecting cylinder through bolts; a power system is fixedly installed in the front cylinder, the power system includes a motor and a speed reducer connected to the motor, one end of the speed reducer is provided with a power output shaft, a hob cutter head is fixedly installed on one end of the power output shaft, and the hob cutter head is located in the cone crushing mud bin. The pipe jacking machinecan adapt to rock stratums as well as silt soft soil stratums, and the tunneling efficiency is ensured. The installation and removal are simple and convenient, the safety is ensured, and the cost is saved.

Owner:安徽唐兴装备科技股份有限公司

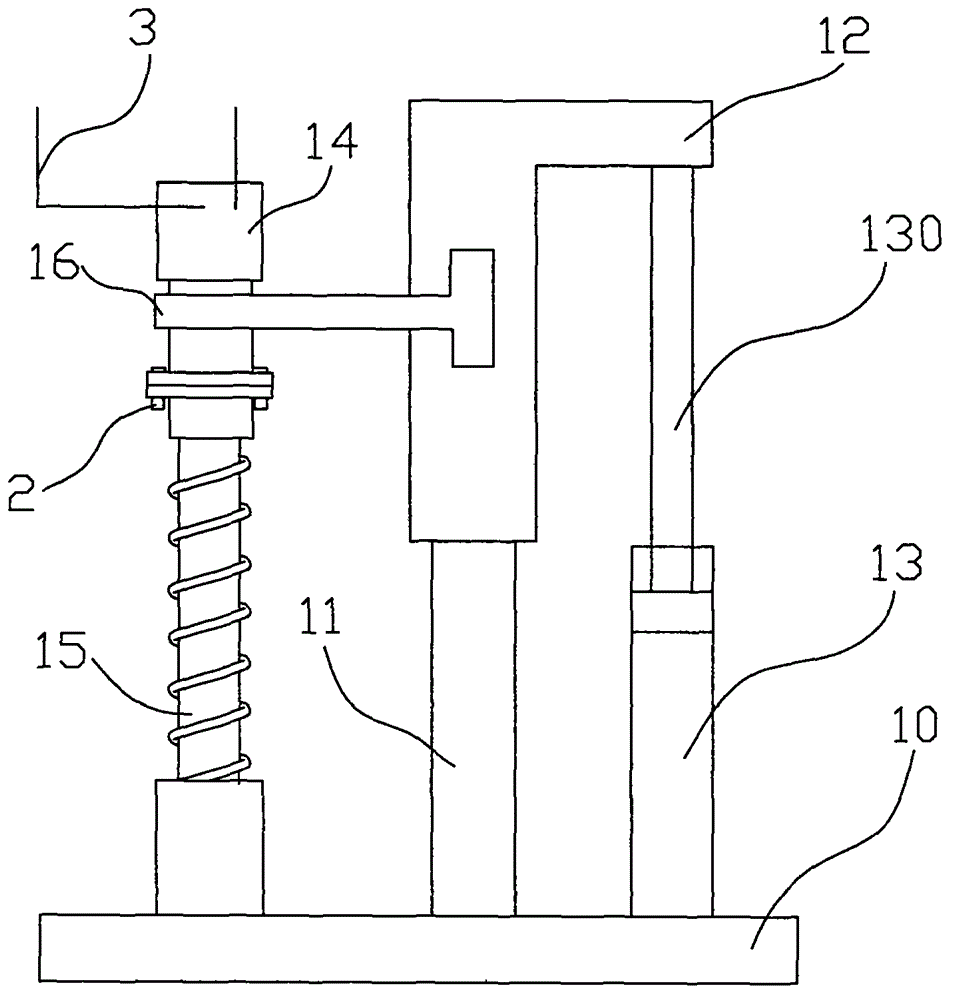

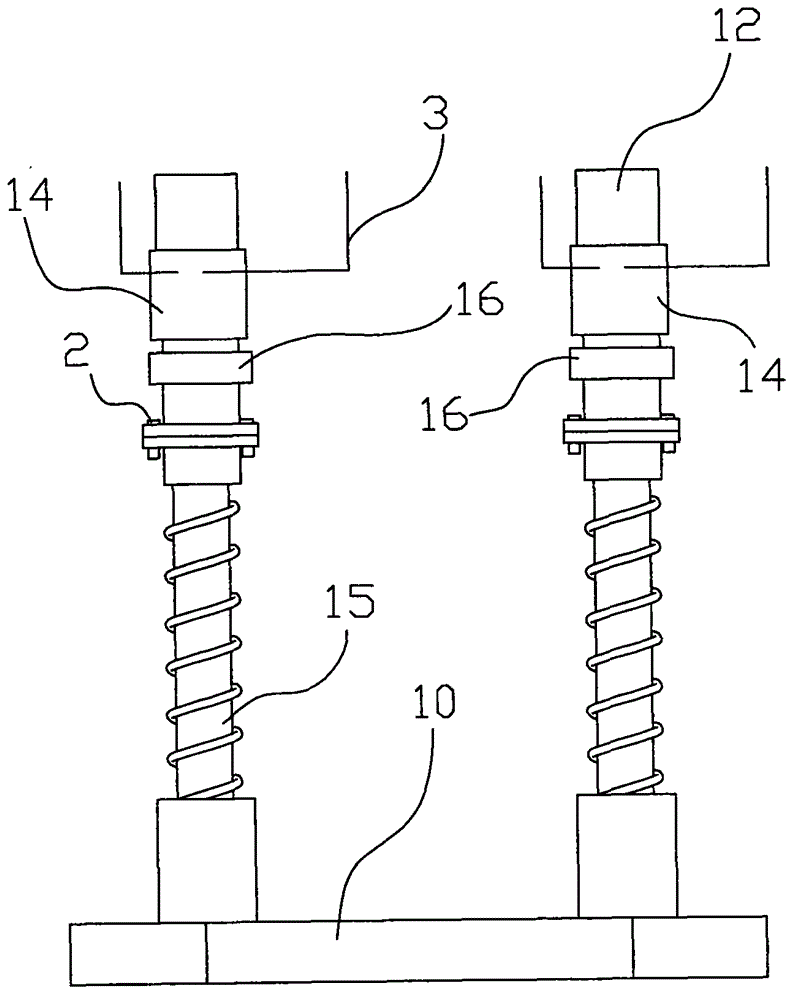

Support with fixable front end for horizontal directional drilling machine

InactiveCN102943622AImprove stabilityGuaranteed drilling accuracyDerricks/mastsDirectional drillingHydraulic motorEngineering

The invention discloses a support with a fixable front end for a horizontal directional drilling machine. The support comprises a base, a sliding sleeve rod, a hydraulic oil cylinder, a sliding sleeve, a hydraulic motor, a drilling rod and a reversing valve, wherein the base is fixedly arranged at the front end of the horizontal directional drilling machine through a clamping rack; the sliding sleeve rod and the hydraulic oil cylinder are fixedly mounted on the base, and are connected with the sliding sleeve; the hydraulic motor is connected with the drilling rod and the sliding sleeve respectively; and the reversing valve is connected with the hydraulic motor through a hydraulic oil tube. When the front end of the drilling machine is fixed, the hydraulic motor positively rotates so as to drive the drilling rod to rotate. Meanwhile, the hydraulic oil cylinder does withdraw motion; the sliding sleeve drives the hydraulic motor to move in a base direction through a connection piece; furthermore, the drilling rod gradually and rotatably drills into soil, so that the front end of the drilling machine can be fixedly arranged; and otherwise, the hydraulic motor reversely rotates, the hydraulic oil cylinder extends out, and the drilling rod gradually retreats from the soil. The support provided by the invention has the advantages that the drilling machine can be prevented from being up-warped at the front end in a working process, and the offset phenomenon can be prevented from occurring in a drilling process, so that the drilling precision and the drilling efficiency can be ensured.

Owner:CHTC JOVE HEAVY IND

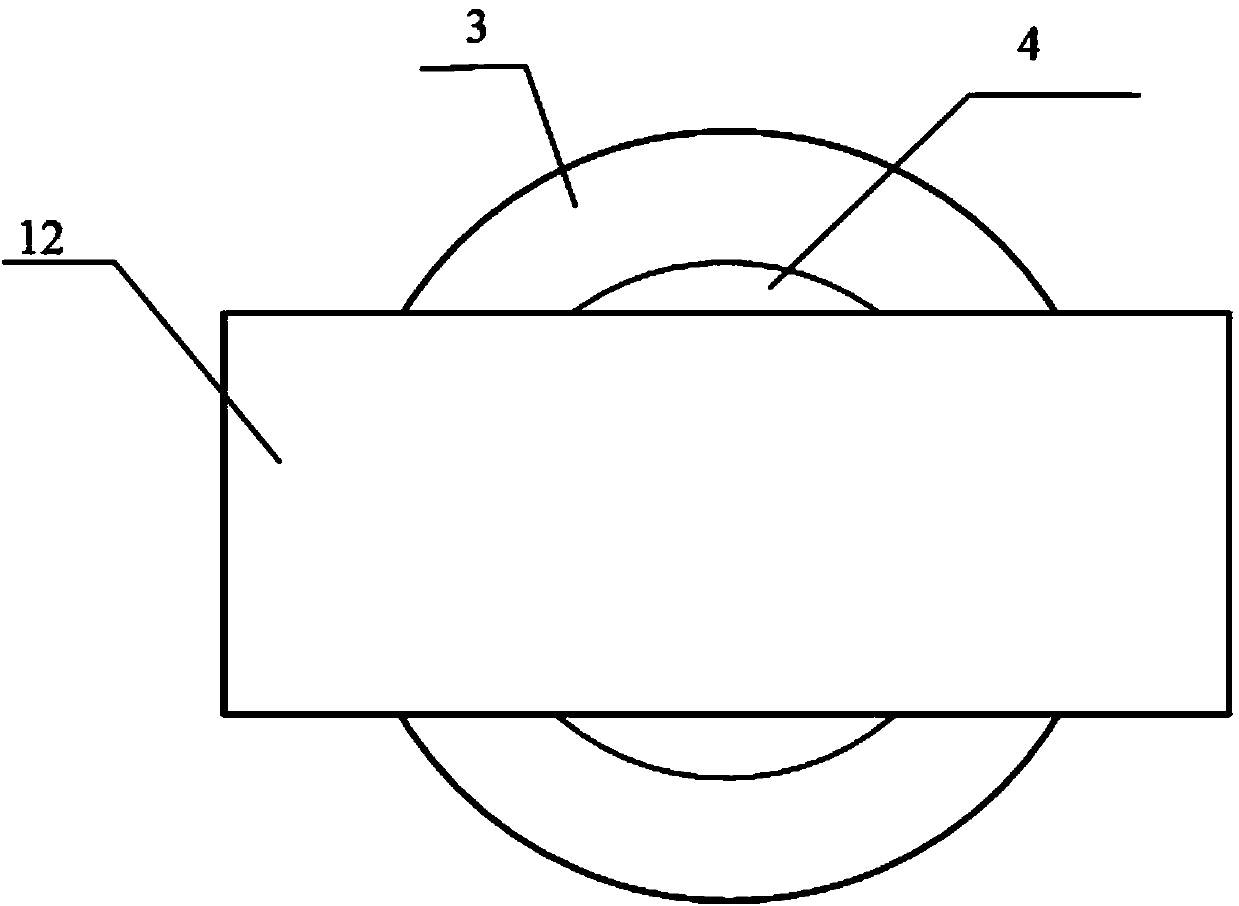

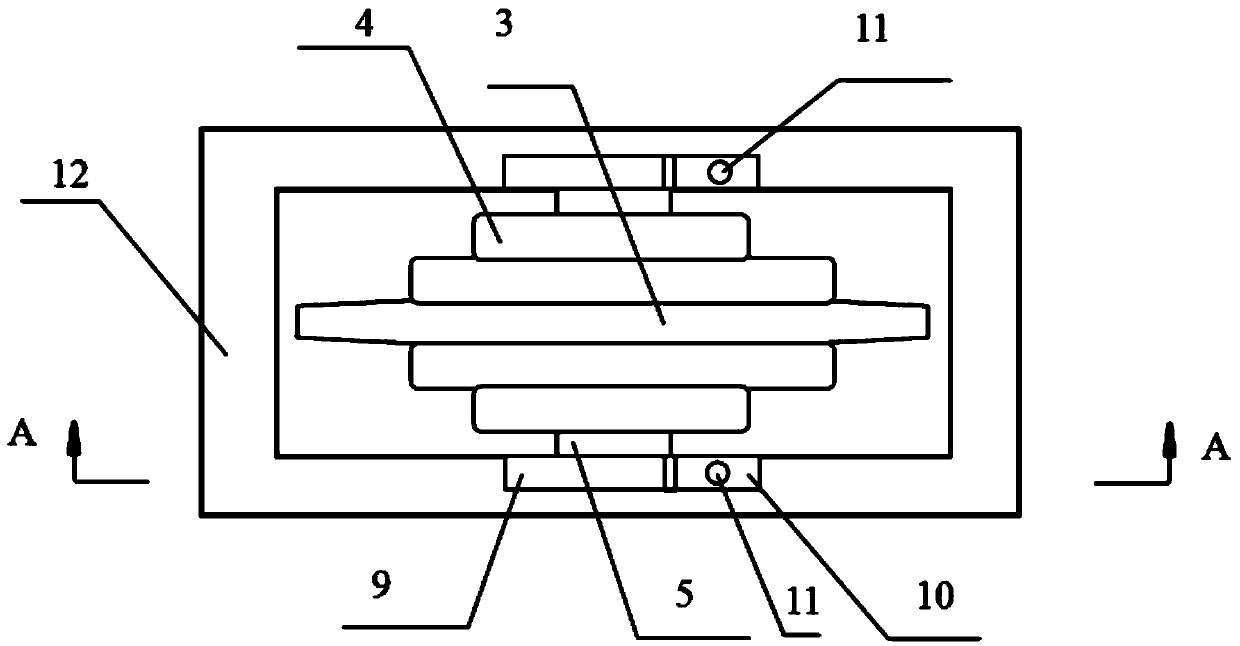

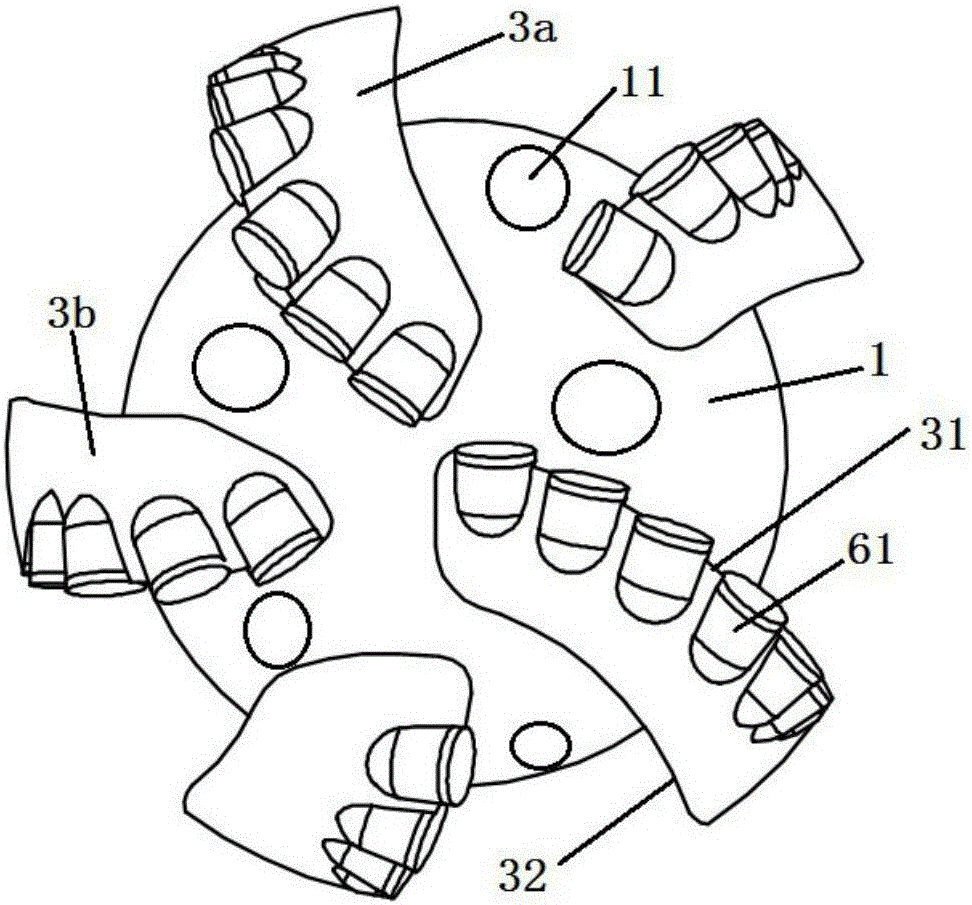

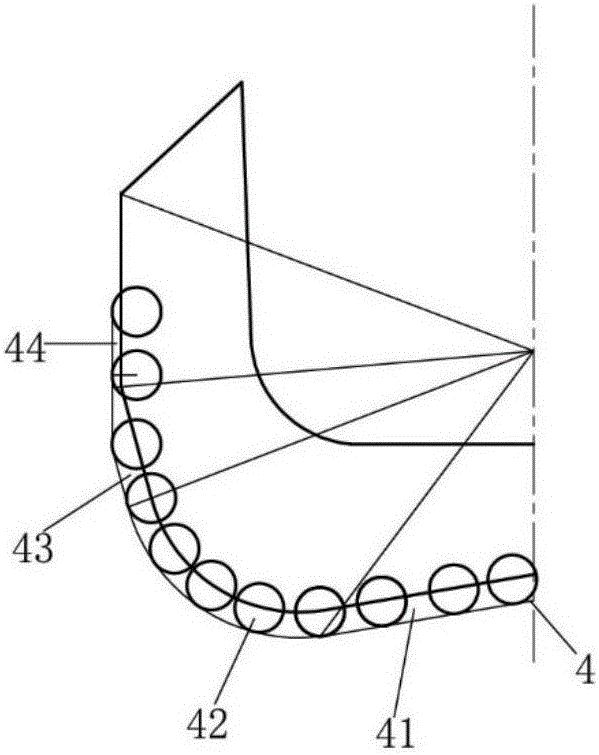

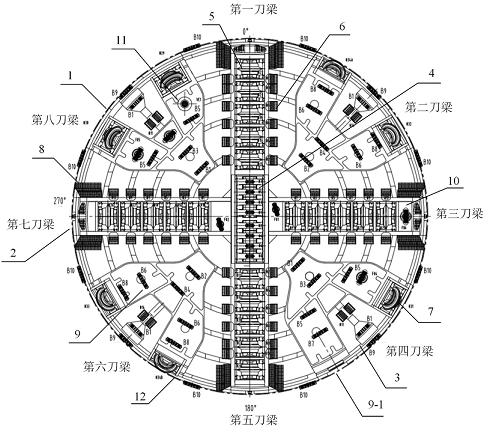

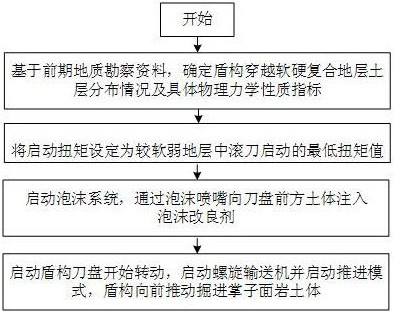

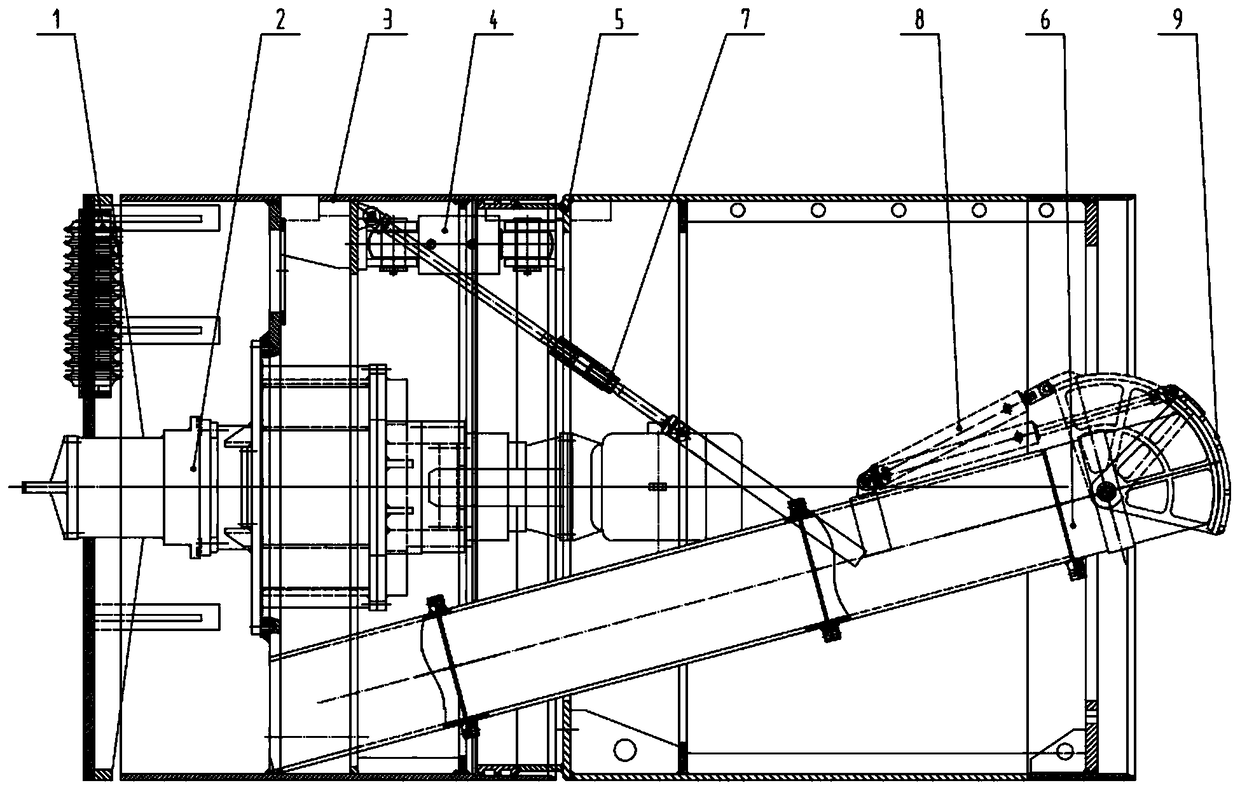

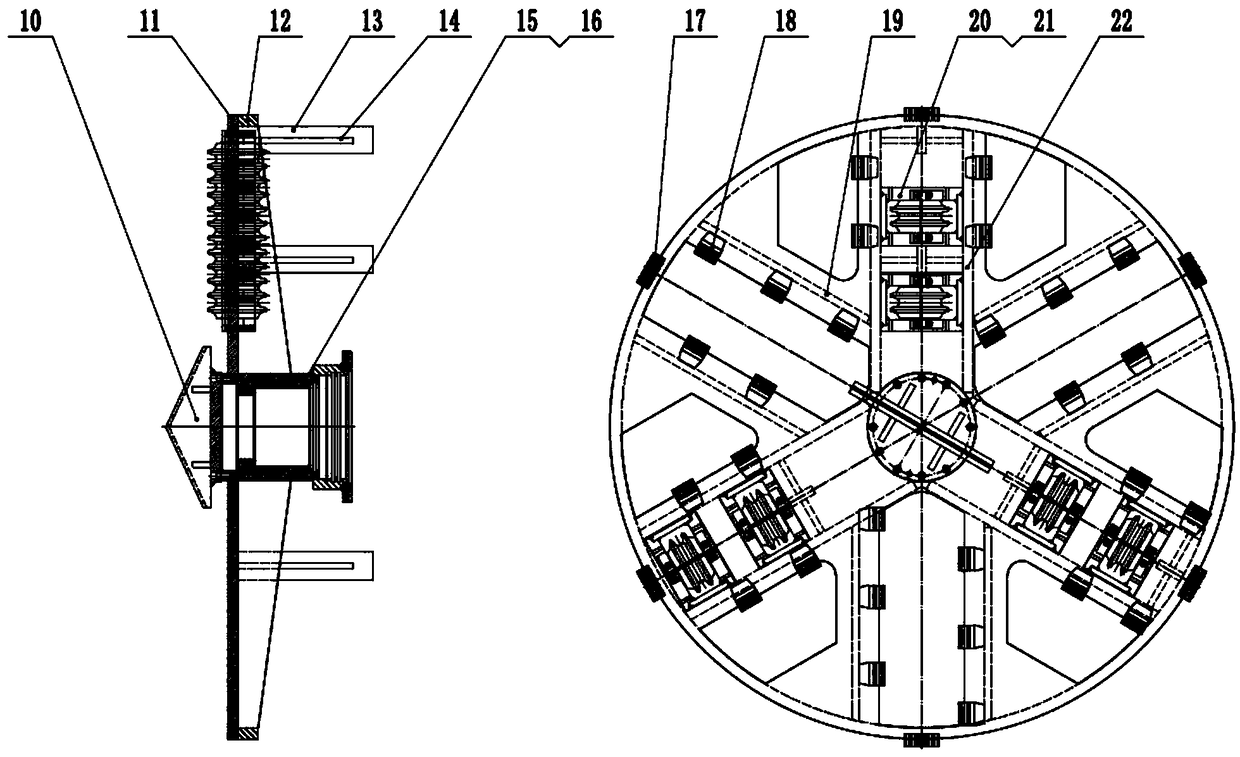

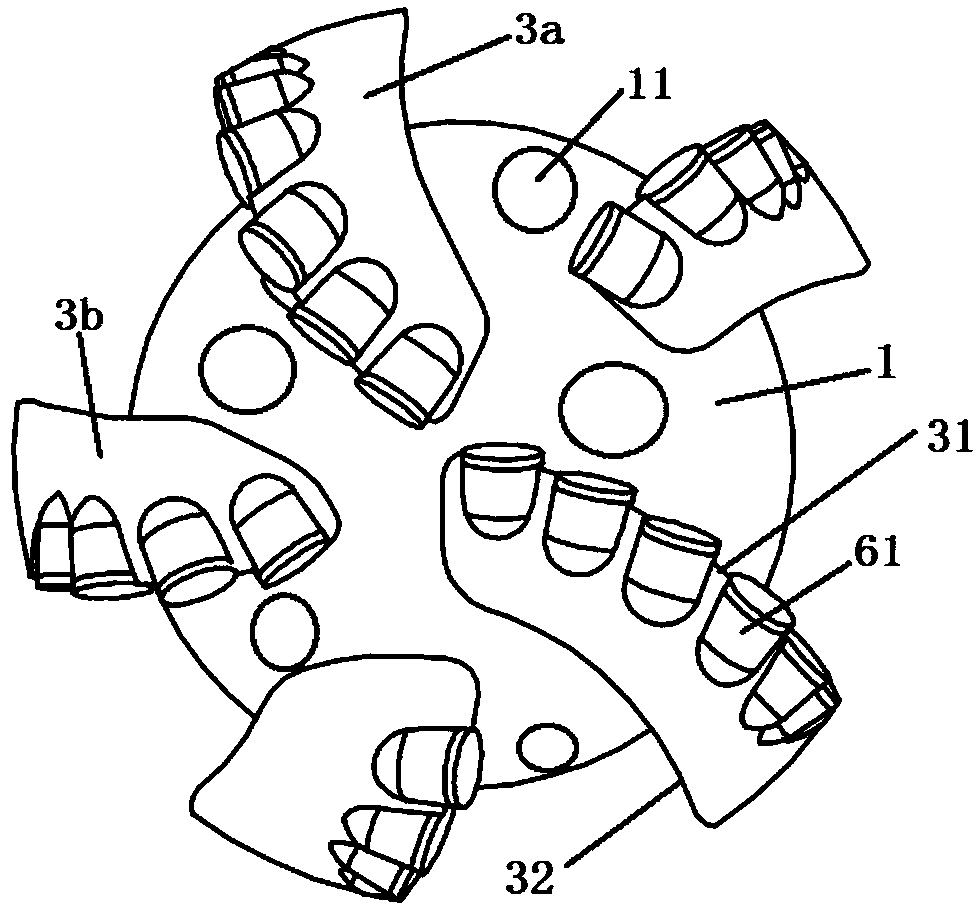

Shield cutter head suitable for soft and hard composite stratum and tunneling method

PendingCN112431601AEffective rotationGuaranteed stabilityTunnelsClassical mechanicsStructural engineering

The invention provides a shield cutter head suitable for a soft and hard composite stratum and a tunneling method. The cutter head comprises a shield cutter head body (1), a cross-shaped main cutter beam (2), an auxiliary cutter beam (3), a center serrated cutter (4), a front hob (5), a cutter (6), an edge hob (7), an edge scraper (8), a fixed serrated cutter (9), a foam nozzle (10), a wear detection cutter (11), a wear-resistant steel plate (12) and other components. The cross-shaped main cutter beam is composed of a first cutter beam, a third cutter beam, a fifth cutter beam and a seventh cutter beam, and the auxiliary cutter beam is composed of a second cutter beam, a fourth cutter beam, a sixth cutter beam and an eighth cutter beam. The method comprises the steps of determining the starting torque of the hobs, selecting and setting the starting torque of the hobs as the starting torque of the hobs of the soft soil stratum, starting a foam system to spray a foam modifier, and pushing a tunneling face rock-soil body forwards by a shield. The opening rate of the cutter head reaches 43%, the cutter head is particularly suitable for tunneling of a typical gravel-argillaceous siltstone composite stratum, and the risk of mud pasting of the cutter head is reduced.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP +1

Thick mud type rock pipe-jacking machine with replaceable cutter head for cobble stratum

PendingCN108716408AGuaranteed drilling efficiencyEasy to install and removeTunnelsSocial benefitsReducer

The invention discloses a thick mud type rock pipe-jacking machine with a replaceable cutter head for cobble stratum. The thick mud type rock pipe-jacking machine comprises a hob cutter head, a powersystem, a front cylinder and a mud removing system, wherein a connecting cylinder is fixed at the front end of the front cylinder in a sleeving manner; a rear cylinder is fixed at the rear end of thefront cylinder; the front cylinder is connected with the rear cylinder by virtue of a corrective cylinder; the power system is fixedly mounted in the front cylinder; working power is provided for eachcomponent of the pipe-jacking machine by the power system; and the power system comprises a motor and a reducer connected with the motor. The thick mud type rock pipe-jacking machine disclosed by theinvention has the beneficial effects that the pipe-jacking machine disclosed by the invention is capable of adapting to the cobble stratum and also adapting to slush soft soil stratum, and the tunneling efficiency is ensured. The installation and detachment can be simple and convenient, the safety is ensured, and the cost is saved. According to the pipe-jacking machine disclosed by the invention,the tunneling efficiency of the cobble stratum is ensured, the tunneling of various stratum is realized by replacing the cutter head, and the benefits are maximized. The untwisting structure has excellent social benefits and is suitable for popularization and application.

Owner:安徽唐兴装备科技股份有限公司

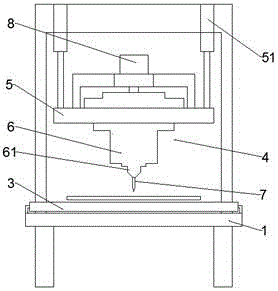

Punching device for machining and producing motor end cover

InactiveCN112756649AGuaranteed drilling efficiencyAvoid inefficient drillingFeeding apparatusDriving apparatusElectric machineryDrill hole

The invention discloses a punching device for machining and producing a motor end cover, and relates to the technical field of motor end cover punching. The punching device comprises a bottom frame, a material rotating mechanism is mounted on the upper surface of the bottom frame, a height adjusting mechanism is fixedly mounted on the left side of the bottom frame, a top plate is placed above the bottom frame, and a punching driving mechanism is mounted on the top plate. According to the punching device for machining and producing the motor end cover, a second servo motor operates to drive a driving gear to rotate, the driving gear drives two transmission gears to synchronously rotate in opposite directions, the two transmission gears rotate to drive two driven gears to synchronously rotate, and the rotating direction of the driven gears is the same as that of the second servo motor. Second fixing columns are driven to rotate, drill bits at the bottoms are driven to rotate, the telescopic end of a first electric push rod retracts, the height of the drill bits is reduced, punching treatment is conducted after the drill bits make contact with an end cover body, the two drill bits are driven by a single motor to conduct synchronous rotating punching, and the drilling efficiency can be better guaranteed.

Owner:BEIHUA UNIV

Rotating speed adjustable handheld perforating device

InactiveCN107538045AReduce volumeEasy to carry and transportPortable drilling machinesPunchingHand held

The invention discloses a hand-held drilling device with adjustable rotating speed, which comprises a device main body, a drilling drill bit, a drill bit connecting rod, a bevel gear, a drill bit connecting rod fixing piece, a resistance piece, a connecting paddle, a trigger, a spring, and a wire protection layer , a rotating motor, a rotating shaft, a transmission rod and a transmission rod fixing piece, the right side of the device main body is provided with a drilling drill, the left side of the drilling drill is provided with a drill connecting rod, and the left side of the drilling connecting rod is connected with the bevel gear Connection, the lower side of the drill bit connecting rod is provided with a resistance sheet, and the left side of the resistance sheet is provided with a connecting paddle. The hand-held punching device with adjustable speed has the characteristics of small size, easy to carry and transport, and is equipped with a wire protection layer, which can ensure that the wire will not be damaged due to strong vibration or bumps during use and carrying, which greatly guarantees The service life of the device is extended, the work efficiency of the staff is greatly improved, the difficulty of work is reduced, and time and effort are saved.

Owner:张泓泽

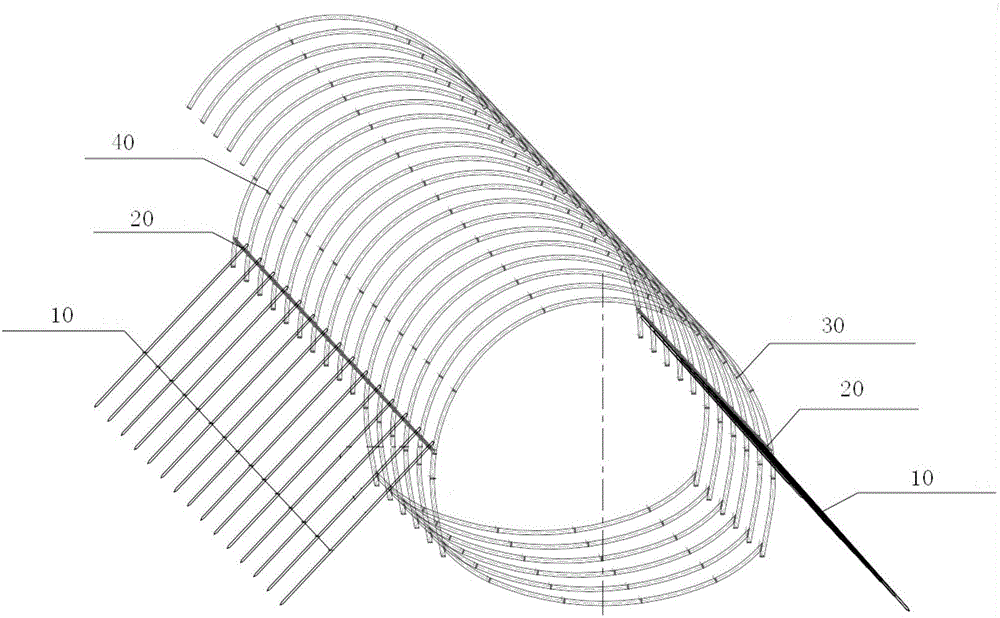

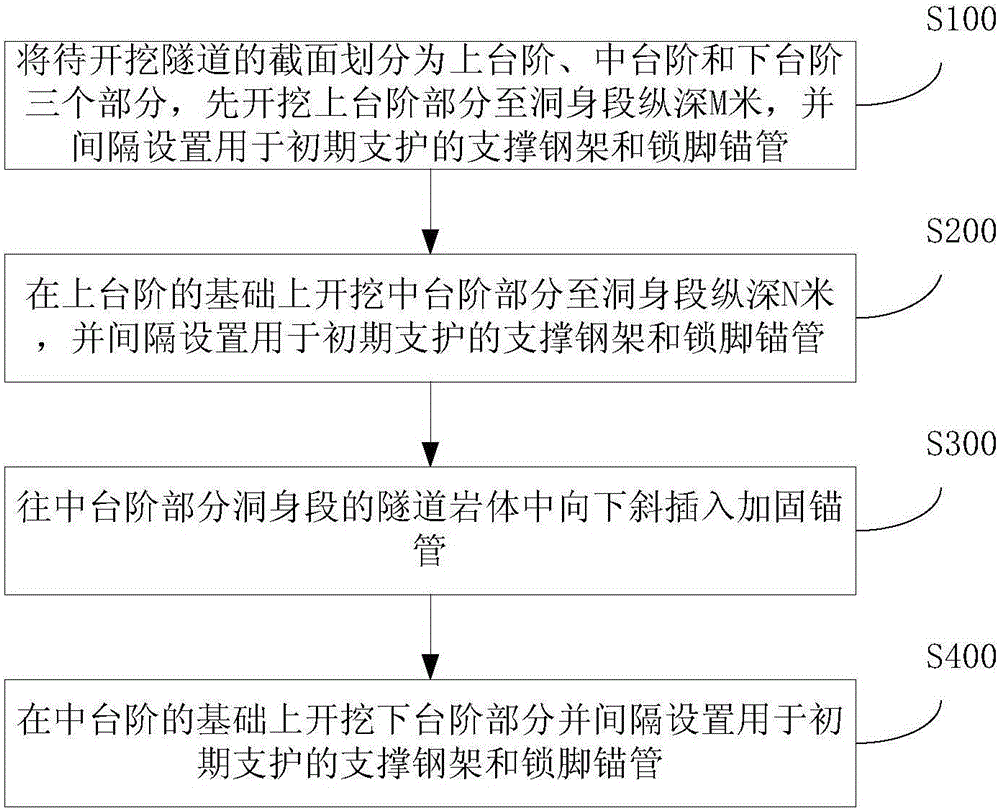

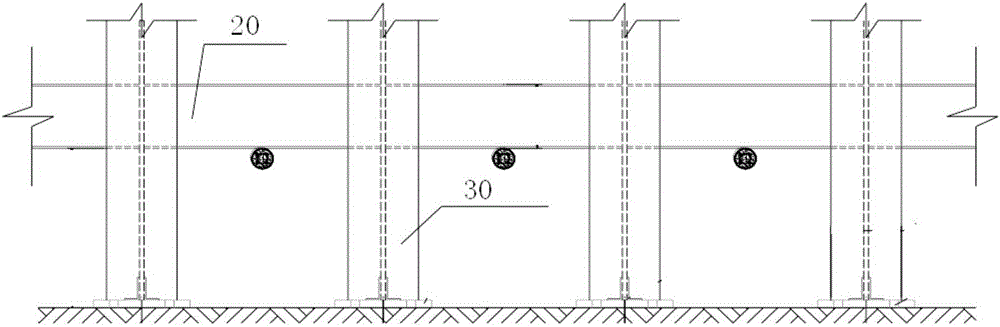

Construction method for controlling deformation of anchor piles at barrel segment of tunnel

ActiveCN105840209AEnhanced longitudinal stiffness and load carrying capacityEnsuring safety and driving efficiencyUnderground chambersTunnel liningSteel frameBearing capacity

The invention provides a construction method for controlling deformation of anchor piles at a barrel segment of a tunnel. The construction method comprises the following steps of: dividing a section of a tunnel to be excavated into three parts, i.e. an upper step, a middle step and a lower step, firstly, excavating the part of the upper step to an in-depth M-meter position of the barrel segment, and arranging supporting steel frames and locking anchor pipes, which are used fora primary support, at intervals; based on the upper step, excavating the part of the middle step to an in-depth N-meter position of the barrel segment, and arranging the supporting steel frames and the locking anchor pipes, which are used for the primary support, at intervals; obliquely inserting reinforcing anchor pipes downwards into tunnel rock mass of the barrel segment at the part of the middle step; based on the middle step, excavating the part of the lower step and arranging the supporting steel frames and the locking anchor pipes, which are used for the primary support, at intervals. Compared with the prior art, in the construction method for controlling deformation of the anchor piles at the barrel segment of the tunnel, which is provided by the invention, the longitudinal rigidity and bearing capacity of the primary support are reinforced, integral sinking, deformation and fracture of a cavern primary support system are controlled, and construction safety and tunneling efficiency of the tunnel are ensured.

Owner:THE 1ST ENG CO LTD OF CHINA RAILWAY 25TH BUREAU GRP +1

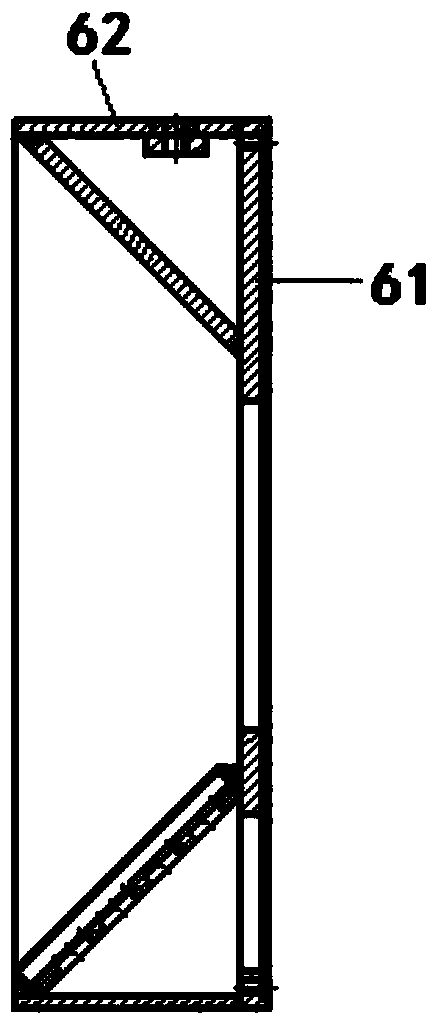

External sealing structure for tunnel heading machine

PendingCN110056364AEffective barrierGuaranteed drilling efficiencyUnderground chambersTunnel liningTunnel boring machineTunnel wall

The invention provides an external sealing structure for a tunnel heading machine. Filled grout channeling to a cutterhead of the heading machine is effectively avoided, and the tunneling efficiency of the tunnel heading machine is ensured. The external sealing structure is arranged at the tail part of a steel shell of the tunnel heading machine, a tunnel lining structure extends a certain distance into the tail part of the steel shell, an annular gap between the peripheral wall of the tunnel lining structure and the newly-excavated tunnel wall after excavation of a tunnel is filled with the grout, and the external sealing structure has the characteristics that outer annular spring steel plates are fixedly arranged on the positions, on the peripheral wall, of the tail end of the steel shell, one or more outer-layer annular wire brushes with the tail ends being in contact with the newly-excavated tunnel wall after excavation of the tunnel are fixedly arranged on the positions, on the peripheral wall of the steel shell, behind the outer annular spring steel plates, sealing grease is injected into an outer annular cavity between the outer annular spring steel plates and the outer-layer annular wire brushes as well as between every adjacent outer-layer annular wire brushes to form sealing, and the grout is prevented from channeling into the gap between the peripheral wall of the steel shell and the newly-excavated tunnel wall after excavation of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

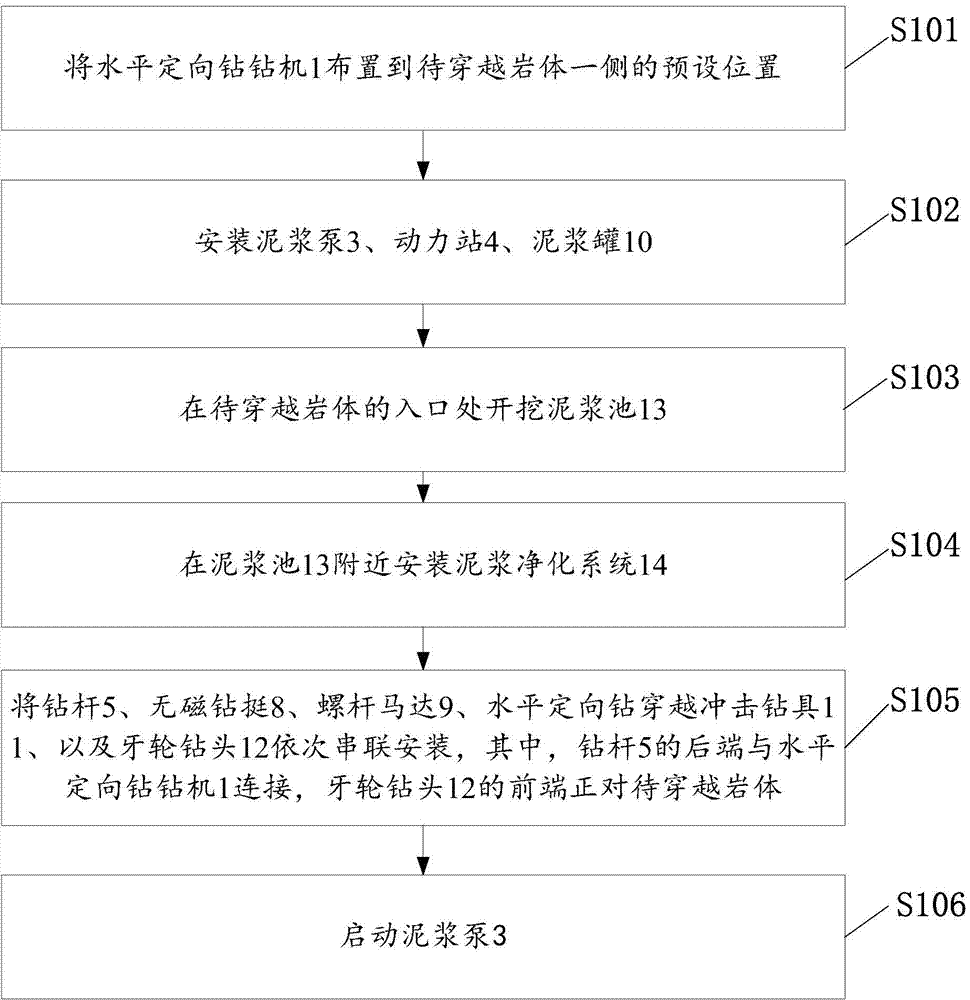

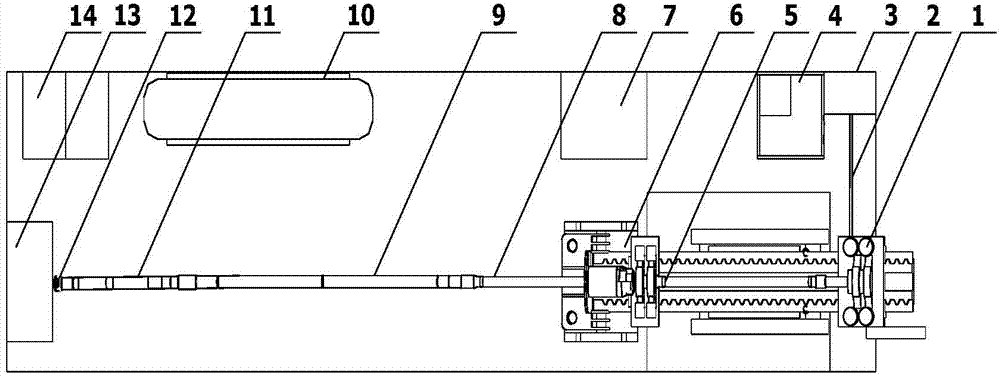

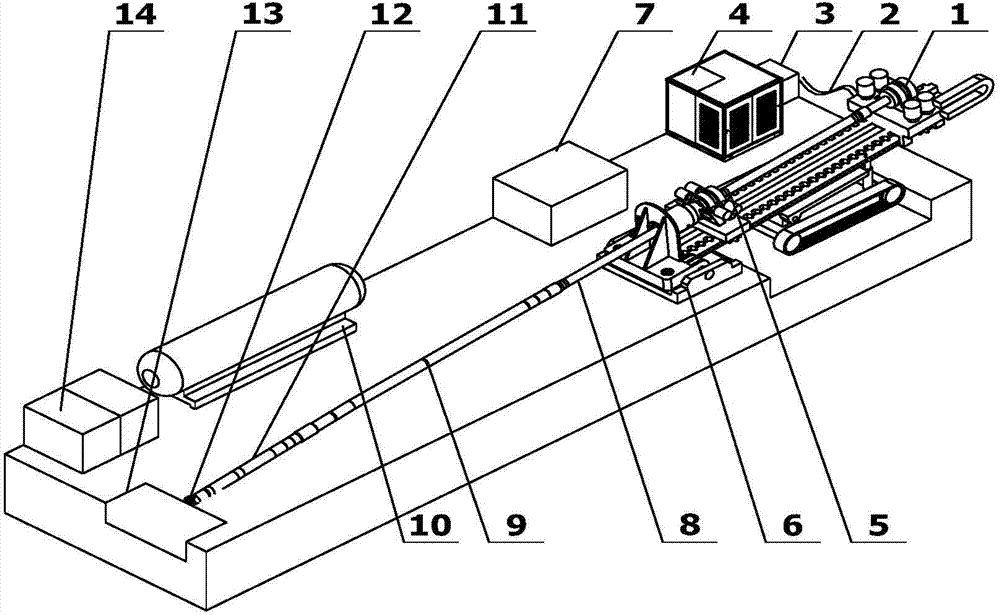

Percussive-rotary drilling method and system for horizontal directional drilling crossing

InactiveCN104763332AIncrease Front Positive PressureIncrease cutting forceDirectional drillingBorehole drivesPositive pressureDirectional drilling

The invention discloses a percussive-rotary drilling method and system for horizontal directional drilling crossing. The percussive-rotary drilling method and system for the horizontal directional drilling crossing combine a percussive rock breaking mode with a rotary cutting mode, the rock crack extends through the high-frequency percussion of a horizontal directional drilling crossing percussion drilling tool for the rock, and the rotary cutting efficiency is improved; by means of the high-frequency percussion of the horizontal directional drilling crossing percussion drilling tool for the rock, the positive pressure at the front end of a drill can be improved, the problem of low drilling pressure at the drill end due to long-distance drilling is avoided, enough drilling pressure is provided, the front end of the drill can cut in the rock layer, the secondary abrasion of the drill is avoided, and the service life of the drill is prolonged; impulsion provided by the horizontal directional drilling crossing percussion drilling tool directly acts on the drill to impact the rock, the rotary drilling cutting ability can be greatly improved, the rock layer drilling efficiency is guaranteed, the construction period is shortened, and the drilling cost is lowered.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Online testing device for hob blade string abrasion of heading machine

ActiveCN103195437BGrasp the working status in timeGuaranteed drilling efficiencyAcceleration measurementTunnelsVibration amplitudeHorizontal axis

The invention discloses an online testing device for hob blade string abrasion of a heading machine. The online testing device is characterized in that a hob is sleeved on a hob center shaft through a bearing, and the center shaft is mounted on a frame hob holder which is assembled in a base of a hob plate. Acceleration sensors can sense the moving state of the hob to emit signals, so that rectangular holes are arranged on two sides of the center shaft outside the hob holder and on a horizontal axis of the hob center shaft. The acceleration sensors are disposed in the rectangular holes, the hole walls of the rectangular holes close to the direction of the hob center shaft is planes, and the planes serve as measuring surfaces of the acceleration sensors. If the hob blade string abrasion occurs, the vibration state of the hob can be changed, that is, the hob vibration amplitude and frequency can be changed obviously. The acceleration sensors can determine whether the hob blade enters a string abrasion state according to the detected vibration amplitude and frequency, the hob working state can be mastered timely, and the hob can be replaced timely in case of abrasion, accordingly, the heading efficiency can be guaranteed.

Owner:TIANJIN UNIV

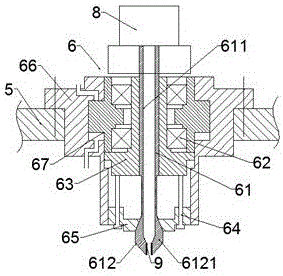

Novel circuit board punching equipment

InactiveCN106455334ASimple structureImprove replacement efficiencyPrinted circuit manufacturePunchingEngineering

The invention provides novel circuit board punching equipment. The novel circuit board punching equipment includes a workbench, wherein the workbench is provided with a feeding machine, a discharging machine and a puncher; the puncher includes a lifting plate, a clamping device and a punching needle; two ends of the lifting plate are each provided with a first cylinder; the clamping device includes a clamping head, bearings, a push sleeve, guide bars, a locking plate, a second cylinder and a piston which is arranged in the second cylinder; the clamping head includes a guide pipe and a clamping part; the upper end of the guide pipe is enclosed; the clamping part is formed by at least three clamping lobes; the top end of the clamping head is connected with an electric rotating machine; a through hole being adapted to the guide pipe is formed in the push sleeve; an inner cone hole is formed in the locking plate; the guide pipe of the clamping head penetrates through the through hole of the push sleeve; the clamping part is arranged in the inner cone hole of the locking plate; and one end of the guide bar is connected with the locking plate, and the other end of the guide bar is connected with the push sleeve. The novel circuit board punching equipment has the advantages that the clamping device is simple in structure and can firmly clamp punching needles with different size; and as exchanging of the punching needles is simple and quick, the exchanging efficiency of the punching needles can be improved, and the punching efficiency and the punching quality can be guaranteed.

Owner:南京万云信息技术有限公司

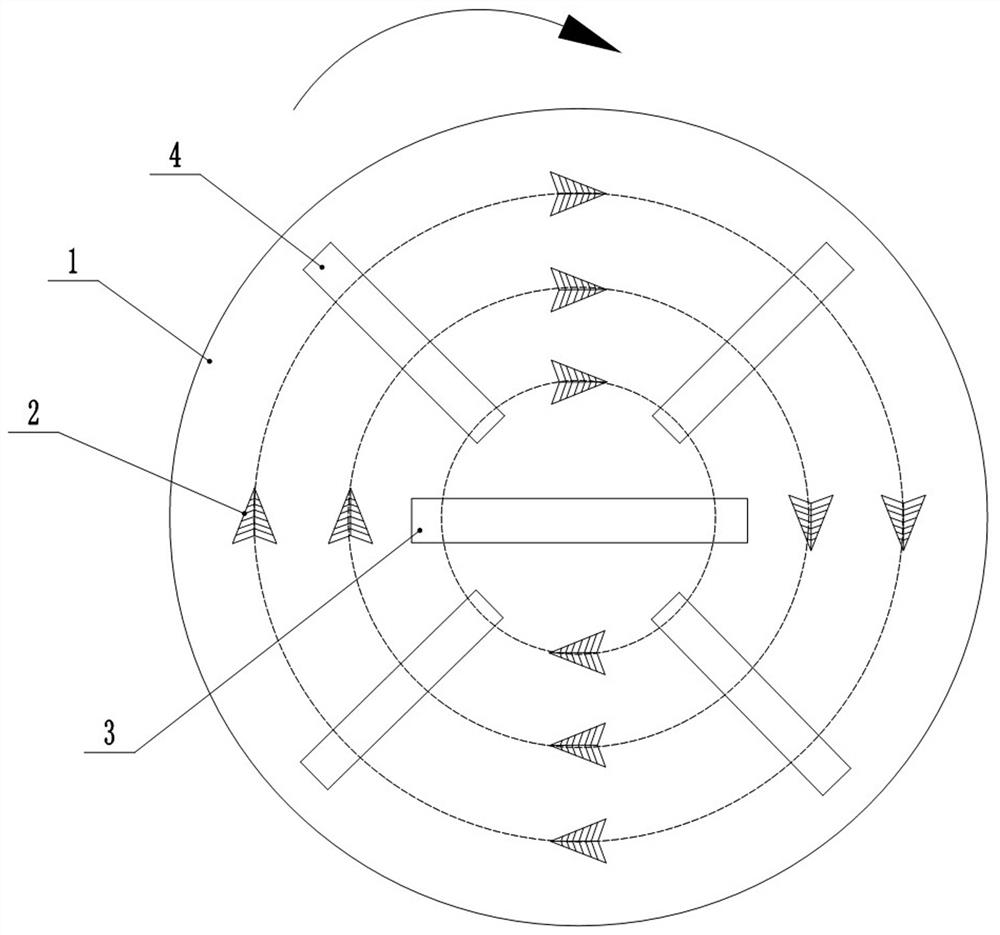

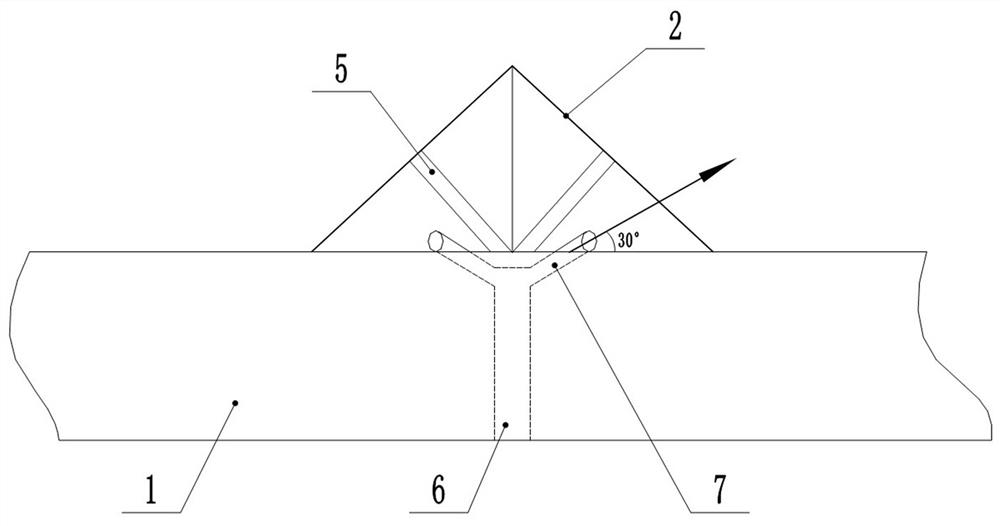

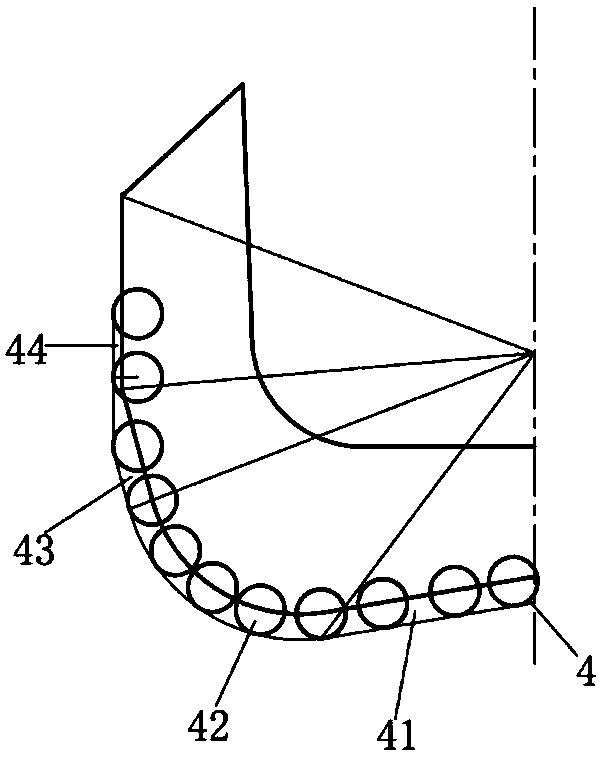

Tunnel boring machine cutterhead for assisting rock breaking through high-pressure water jet

ActiveCN112160763AHighlight substantiveSignificant progressTunnelsTunnel boring machineHigh pressure water

The invention provides a tunnel boring machine cutterhead for assisting rock breaking through a high-pressure water jet. The cutterhead comprises a cutterhead body, a first hob assembly, a second hobassembly and a scraper, wherein the first hob assembly, the second hob assembly and the scraper are arranged on the cutterhead body. Each of the first hob assembly and the second hob assembly comprises a rotating shaft and a plurality of hobs arranged on the rotating shaft. The scraper is plowshare-shaped, a spray pipe used for introducing high-pressure water is arranged on the cutter head body and located below the scraper, a pair of spray heads is arranged at the end of the spray pipe, and the included angle between the spray direction of the spray heads and the surface of the cutter head body is 30 degrees. The rotating areas of the first hob assembly and the second hob assembly are intersected. The first hob assembly is provided with hobs which move along the spraying track of each spray head on the tunnel face. According to the cutterhead, the scraper, the hob and the high-pressure water jet are mutually combined to efficiently crush the tunnel face in the tunneling process, so that the service life of the scraper and the hob can be prolonged, and the tunneling efficiency of the tunnel is greatly improved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +1

PCB plate drilling machine vibration-proof position inductor

InactiveCN105729567AReduce vibrationAvoid mechanical shockMetal working apparatusMachining vibrationsEngineering

The invention discloses a PCB plate drilling machine vibration-proof position inductor comprising a drilling machine main shaft and a main shaft support seat, a drilling machine chip suction shield, an induction unit arranged between the main shaft support seat and the drilling machine chip suction shield; the induction unit comprises a sensor fixed on the main shaft support seat, an induction seat fixed on the drilling machine chip suction shield, and an induction part with one end connected with the induction seat; a damper is arranged between the induction part and the induction seat, thus preventing machinery shock generated in high speed running process of the equipment, reducing induction part vibration, and ensuring boring efficiency of the equipment.

Owner:王忠义

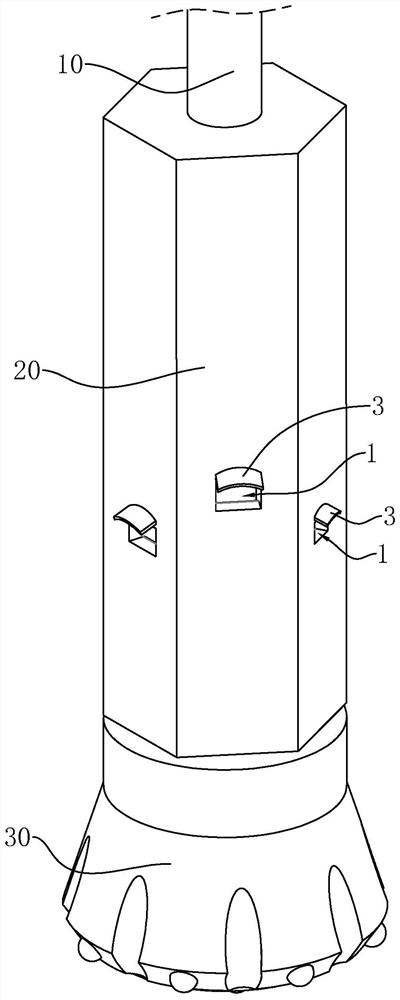

Pneumatic down-the-hole hammer drilling device

PendingCN114541961AReduce accumulationGuaranteed drilling efficiencyBorehole drivesFlushingSlagEngineering

The pneumatic down-the-hole hammer drilling device comprises a drill rod, an impacter and a drill bit, a rear connector of the impacter is fixedly connected with the drill rod, a drill rod clamping sleeve of the impacter is connected with the drill bit, a shell of the impacter is provided with a slag collecting cavity, an opening of the slag collecting cavity is located in the peripheral face of the shell, and the opening of the slag collecting cavity is communicated with the drill rod. The shell is further provided with a guide plate and a first driving mechanism, the guide plate is located over an opening of the slag collecting cavity, and the end, away from the axis of the shell, of the guide plate is obliquely arranged downwards; the first driving mechanism is used for driving the guide plate to extend out of the outer side of the shell in a sliding mode or retract into the shell in a sliding mode. By arranging the extendable guide plate, when the disintegrating slag is blown by compressed air to move upwards, the movable disintegrating slag is guided into the slag collecting cavity by the guide plate, so that the disintegrating slag accumulation between the outer surface of the shell and the wall of the drill hole is reduced, and the drilling efficiency is ensured.

Owner:中冶华南建设工程有限公司

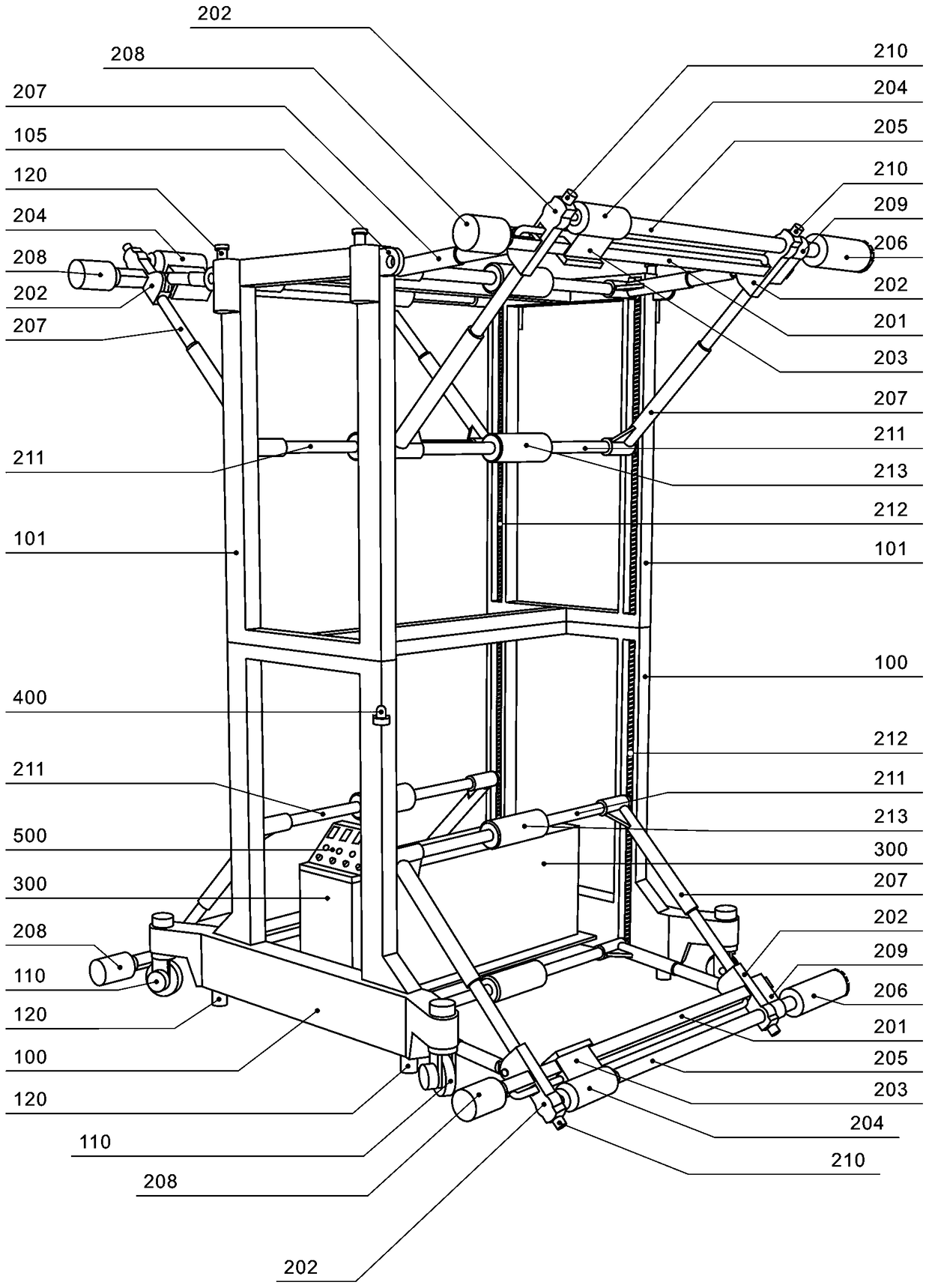

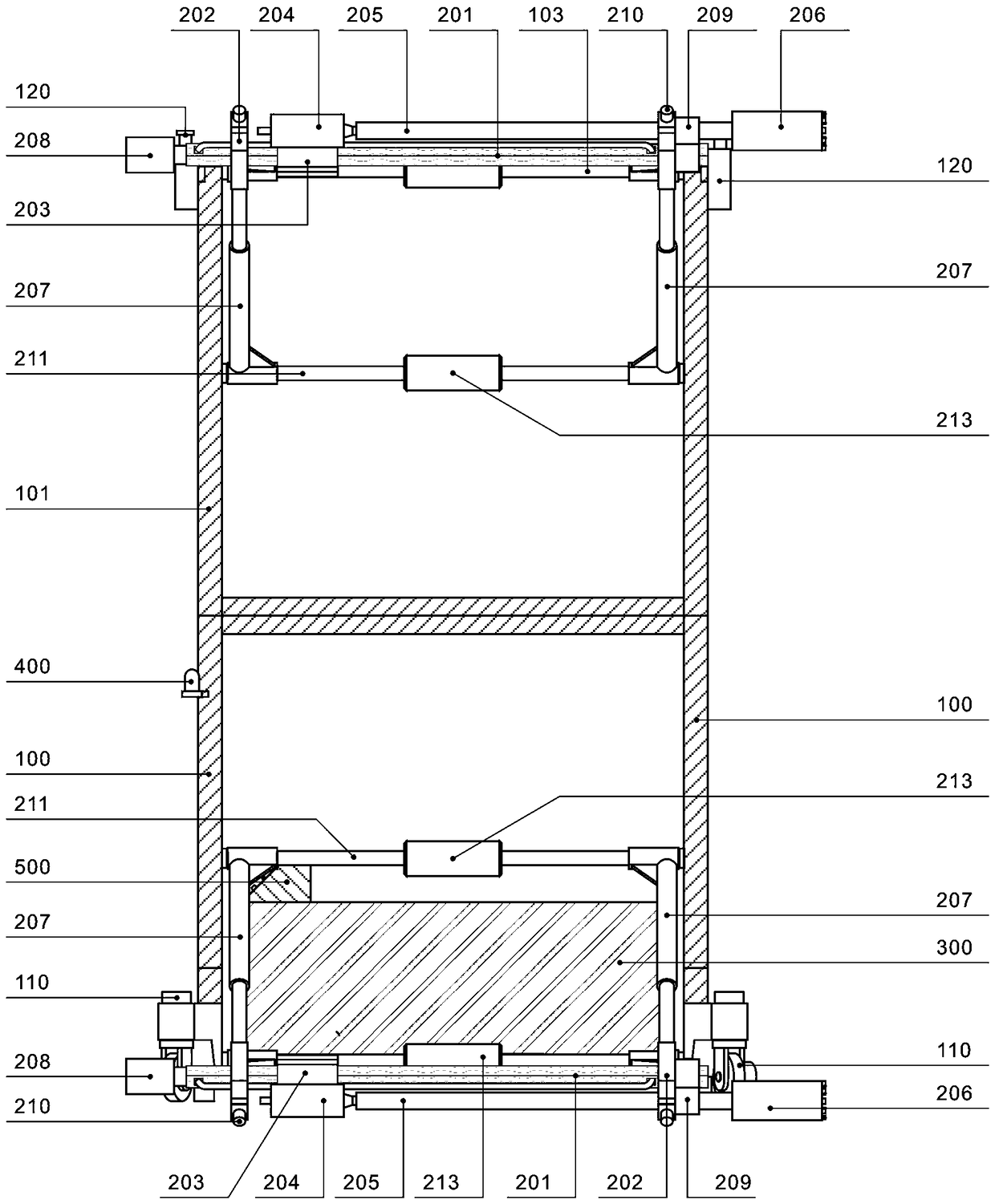

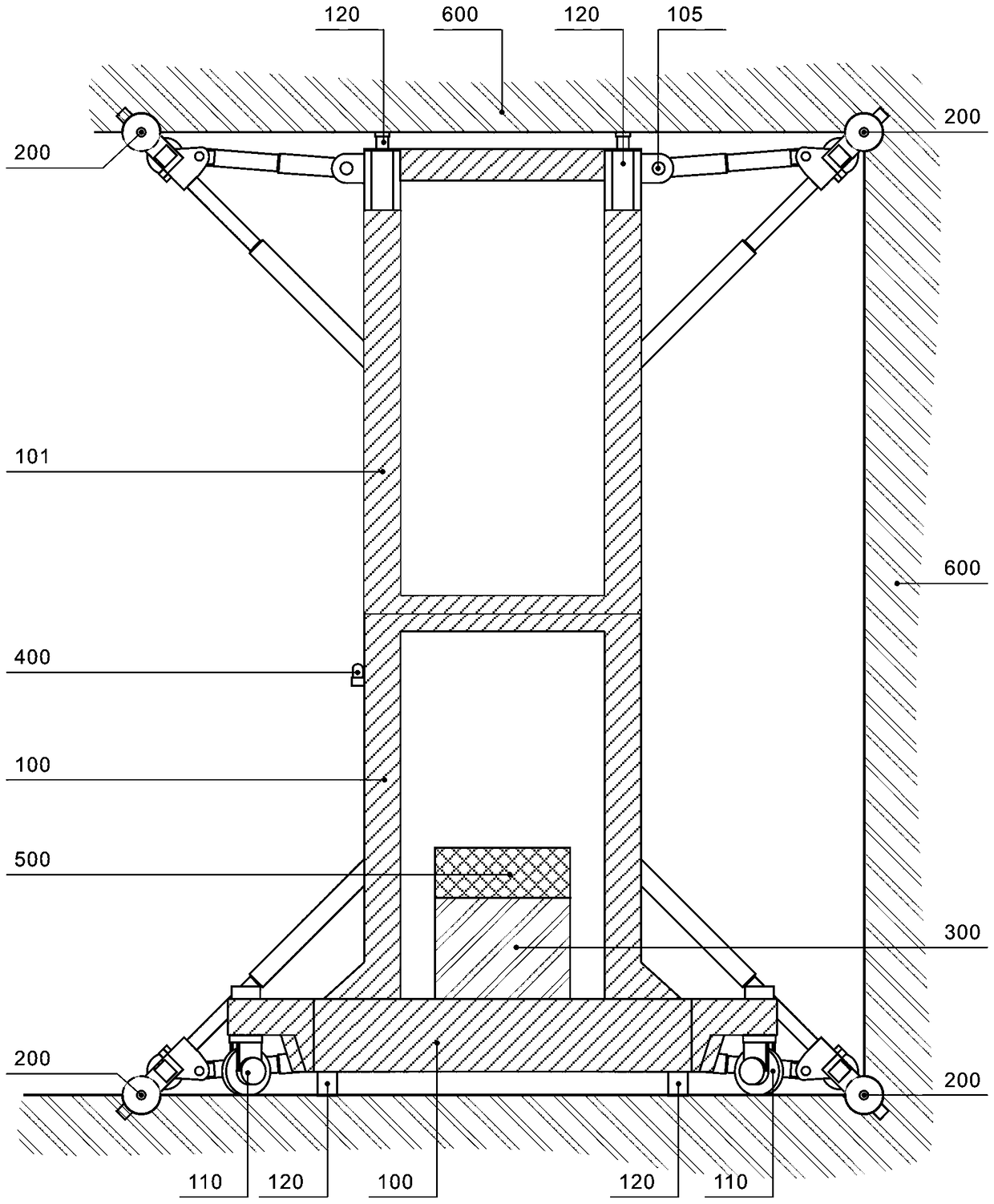

Hole drilling machine for rock hole mining

The invention discloses a hole drilling machine for rock hole mining. The hole drilling machine comprises a main rack, an expansion rack, drilling machine systems, a main crate, a measuring system, acirculating system and a control system. According to the hole drilling machine for rock hole mining, a rack travelling mechanism and a telescopic supporting mechanism are arranged on the main rack, and thus the hole drilling machine can be well suitable for the work environment in a tunnel. Through supporting rod lifting devices and telescopic connecting rods on the drilling machine systems, thehole drilling positions of the drilling machine systems can be conveniently adjusted. The multiple drilling machine systems integrated on the main rack cooperate with the measuring system, the circulating system and the control system, and thus the hole drilling efficiency is improved.

Owner:赵兵

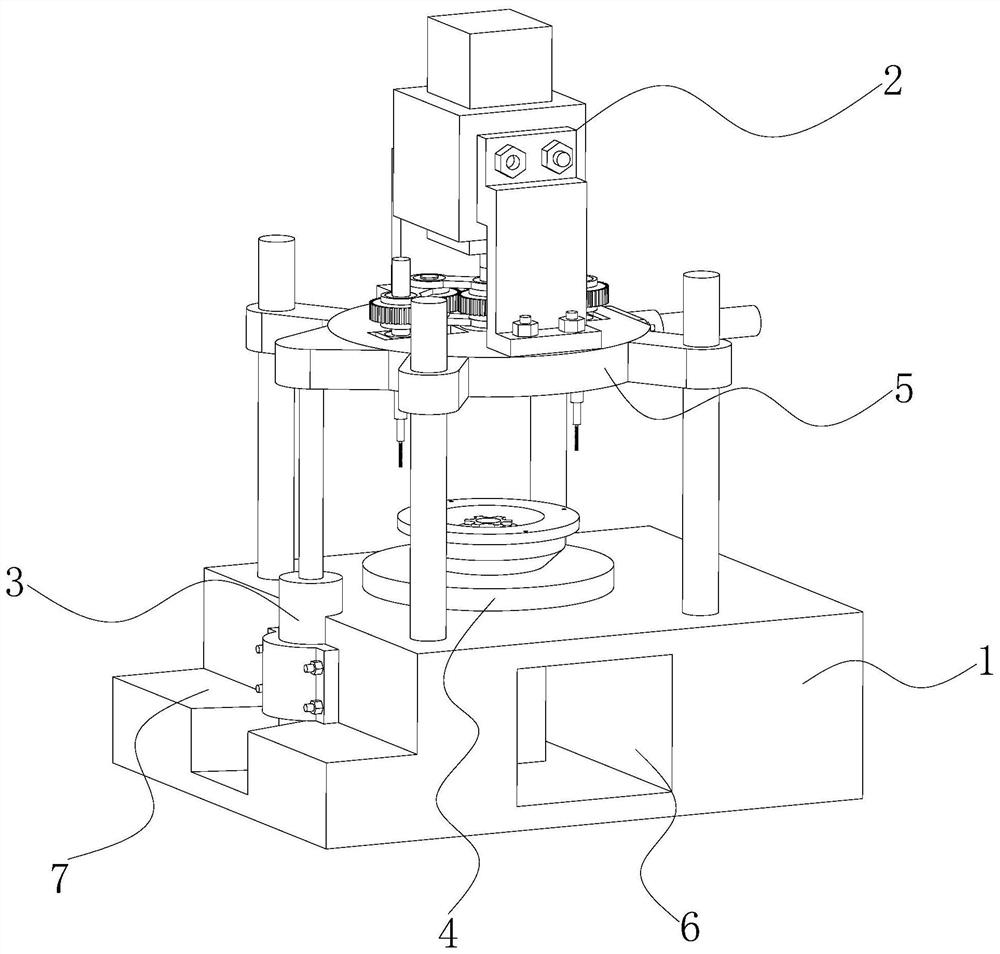

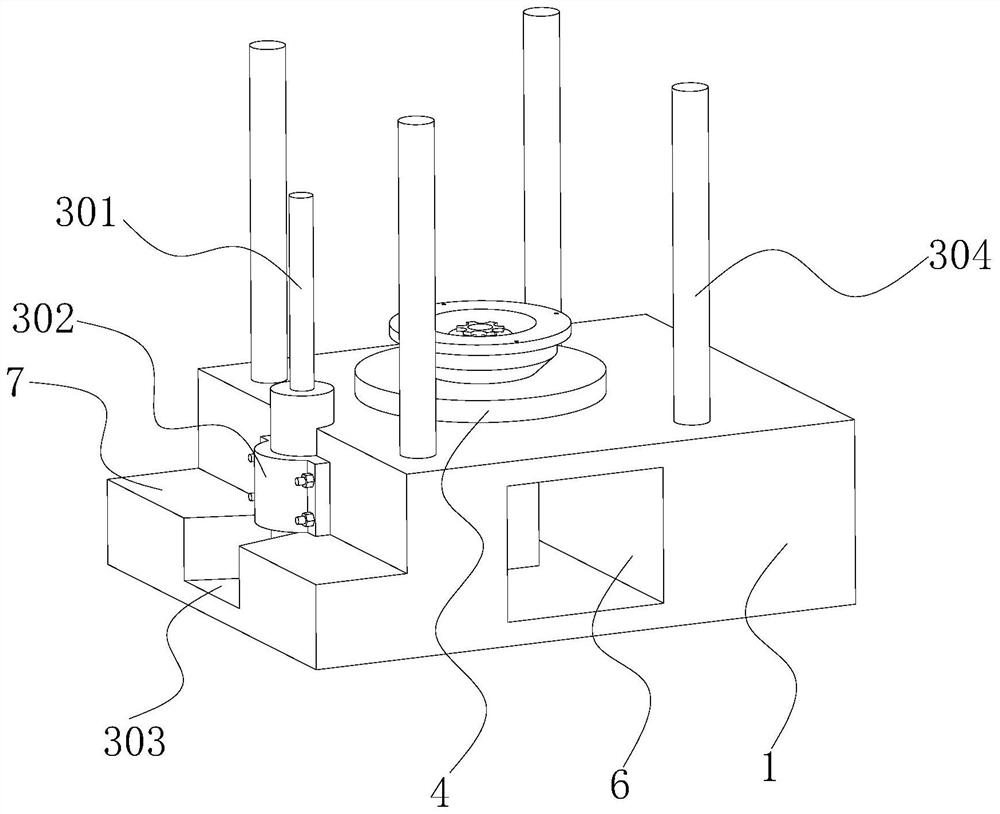

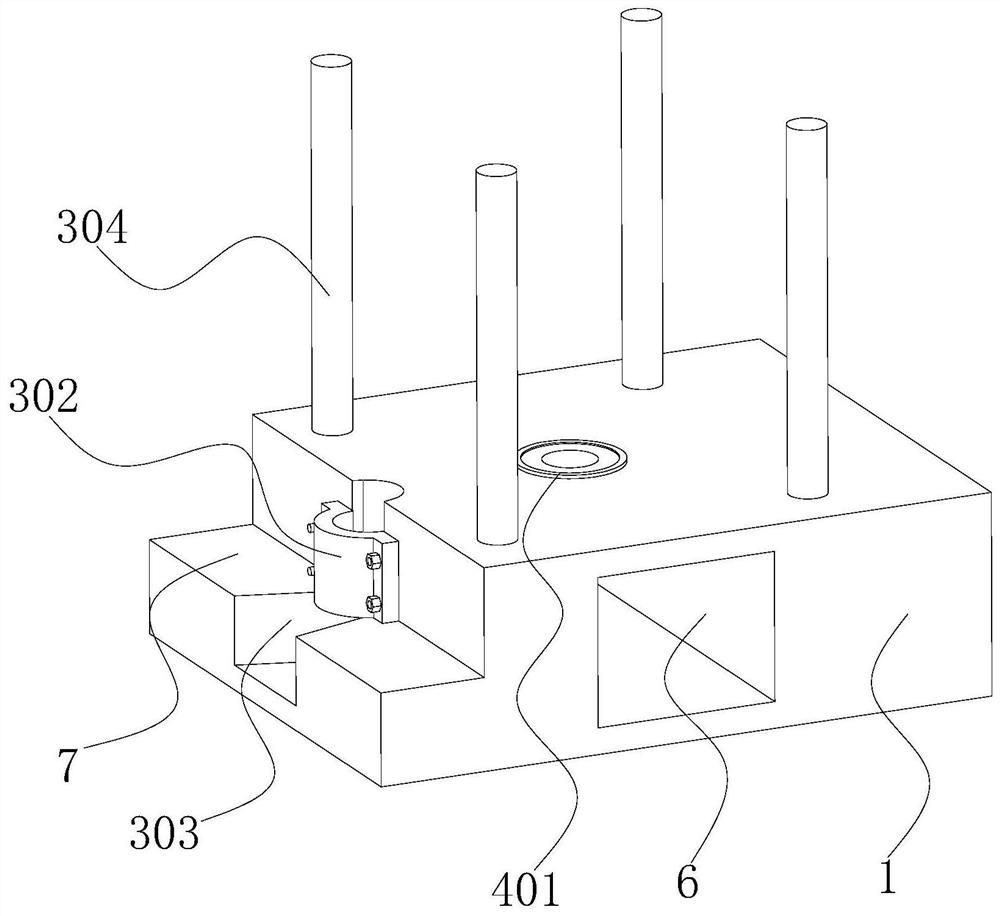

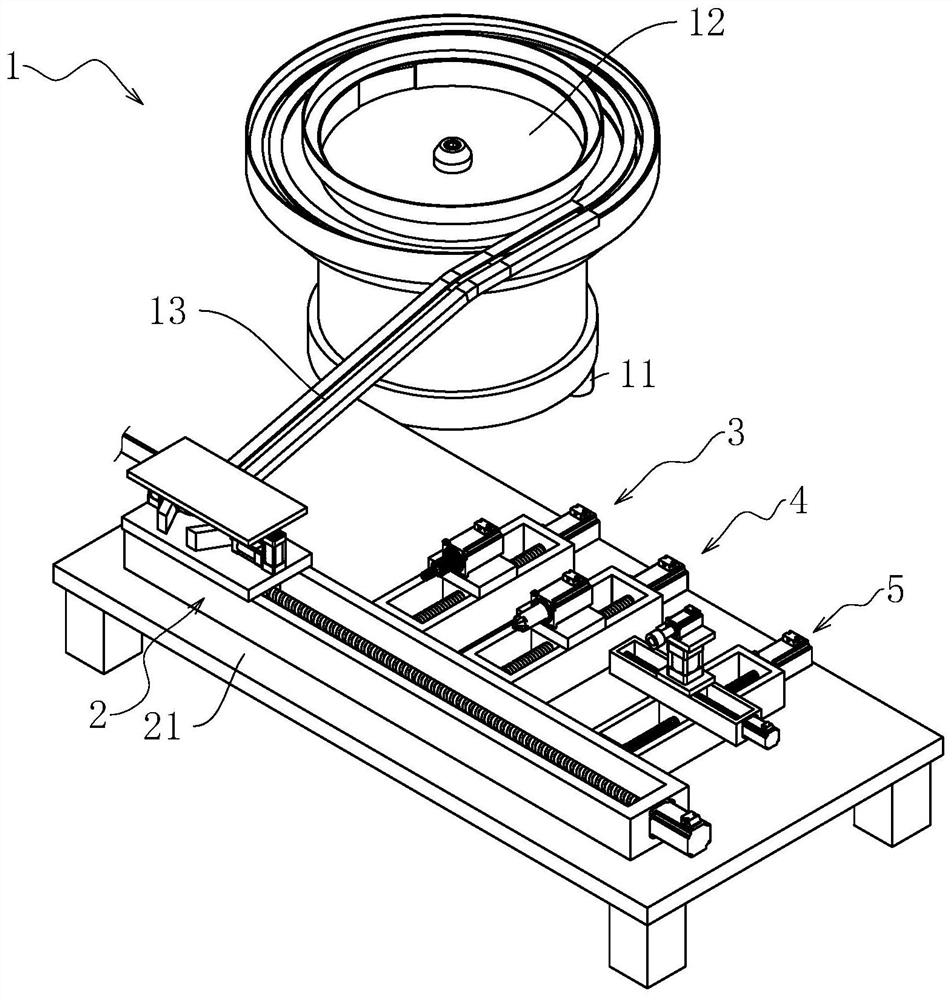

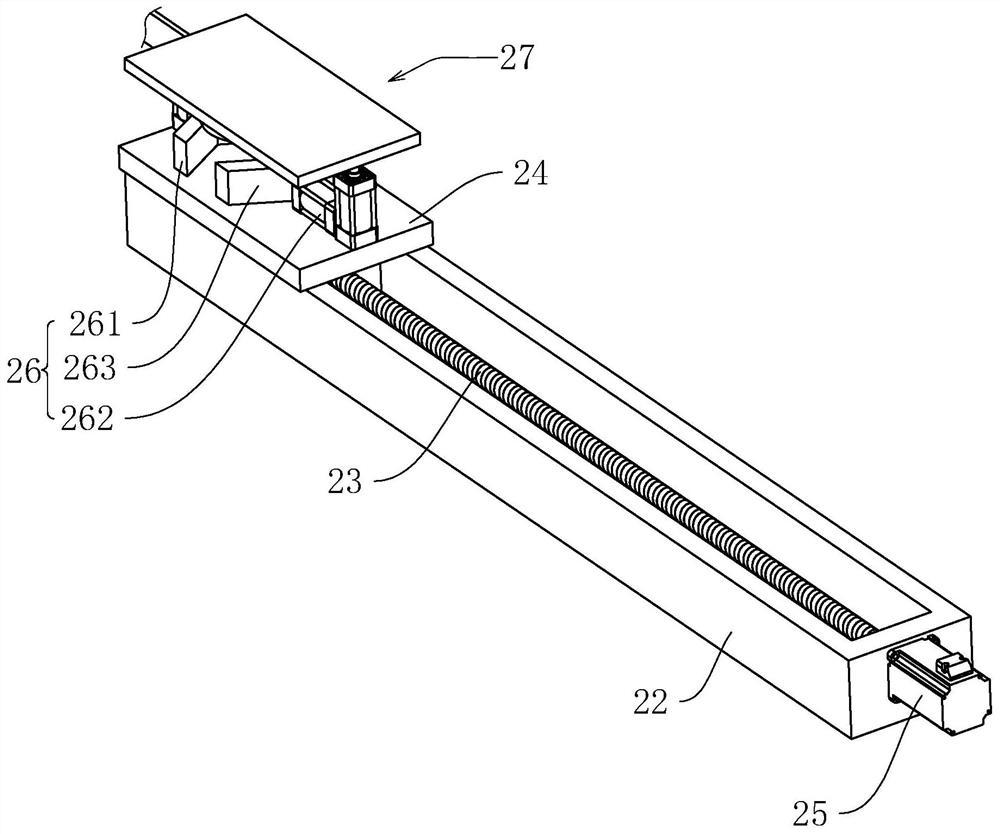

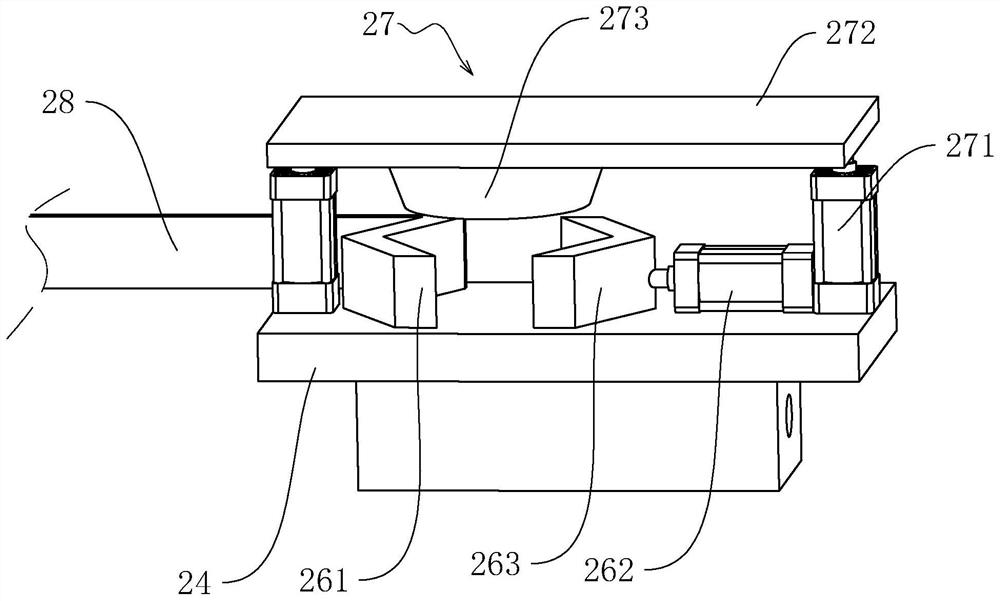

High-precision indexing turntable for outer circle equal-indexing drilling of tubular parts and operation method

ActiveCN110405535AReliable clamping and fixingSimple clamping processPrecision positioning equipmentBoring/drilling componentsEngineeringScrew thread

Owner:CHINA THREE GORGES UNIV

A long-life drill bit with self-healing ability

ActiveCN105781426BIncrease the tooth densityExtend your lifeDrill bitsConstructionsPetroleumSelf repair

Owner:SOUTHWEST PETROLEUM UNIV +1

Valve body transverse drilling equipment and drilling method thereof

PendingCN113333808AGuaranteed processing efficiencyEnsure drilling qualityOther manufacturing equipments/toolsMetal working apparatusHole drilling methodMachining

The invention relates to the field of valve body drilling, in particular to valve body transverse drilling equipment. The equipment comprises a conveying mechanism, and a coarse drilling mechanism and a fine drilling mechanism are sequentially arranged on the two sides of the conveying mechanism in the conveying direction; and the conveying mechanism comprises a workbench, a conveying rail is arranged on the workbench, a bearing plate is arranged on the conveying rail, a conveying driving part for driving the bearing plate to move along the conveying rail is arranged on the workbench, and a limiting assembly for fixing the valve body is arranged on the bearing plate. The valve body transverse drilling equipment has the effect of improving the valve body drilling machining efficiency.

Owner:SUZHOU ENVIL MACHINERY

A roller cone bit

The invention belongs to the technical field of drill bits and discloses a roller bit to solve the problem of short service life and poor cutting performance of the existing single-cone roller bits. The roller bit comprises a base; a roller cone is connected to the base; a mounting groove is installed on an external circumference of the roller cone; the mounting groove sleeves a mounting plate; the mounting plate is provided with multiple cutting teeth; a rotating direction of the mounting plate is vertical to the rotating direction of the roller cone; a roller cone end part away from the baseis provided with a protecting cover; a vertical gap is formed between the inner wall of the protecting cover and an external rim of the cutting teeth which is rotating to the place;; the roller coneis provided with a cooling liquid channel; the protecting cover is provided with a liquid outlet channel which is connected with the cooling channel therein; the liquid outlet channel is provided witha nozzle facing the cutting teeth; the cutting teeth on each mounting plate are spiral type; the spiral direction of the formation of each cutting tooth is from the root of the roller cone to the tipof the roller cone.

Owner:成都锐钻钻头制造有限公司

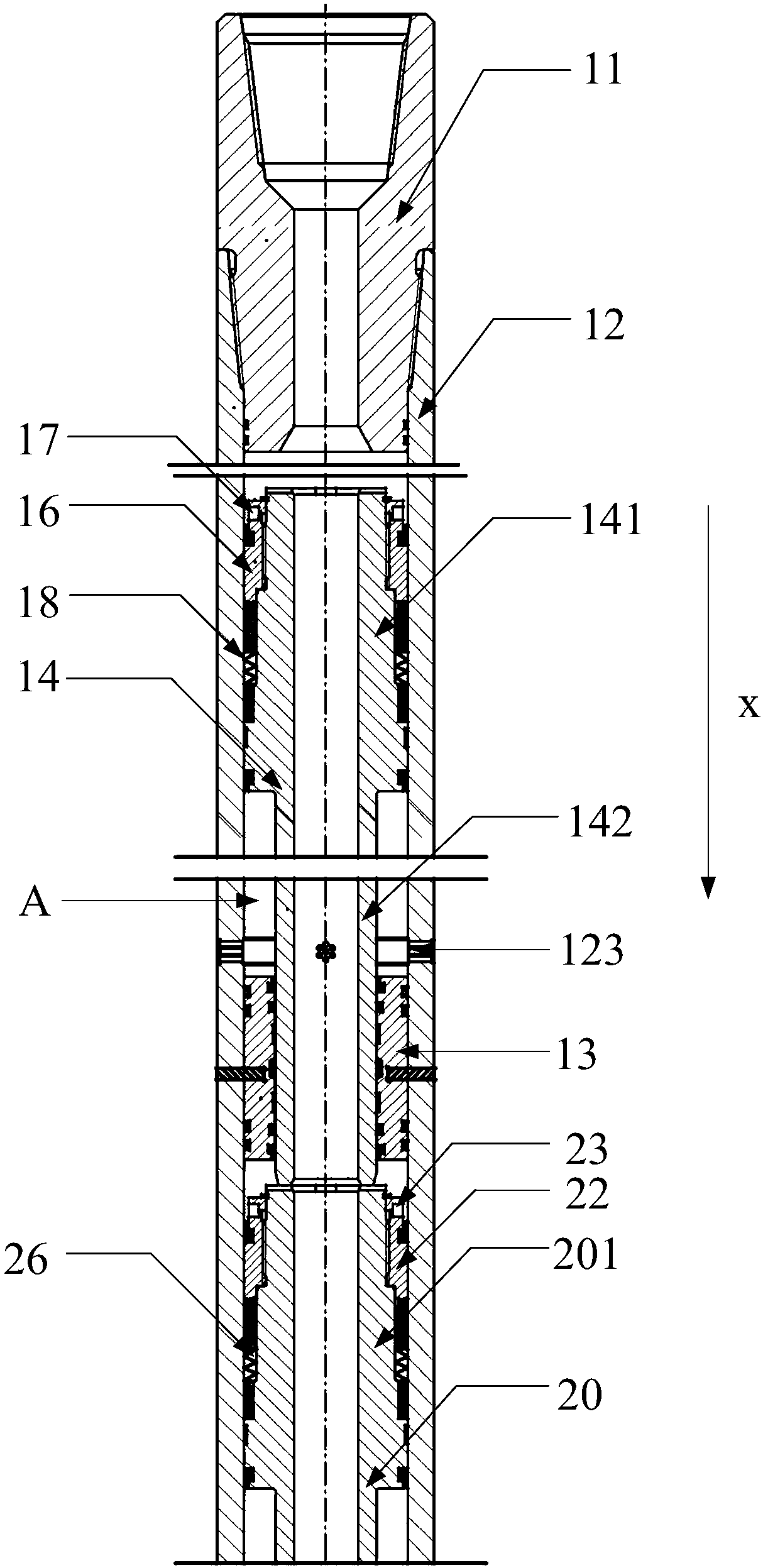

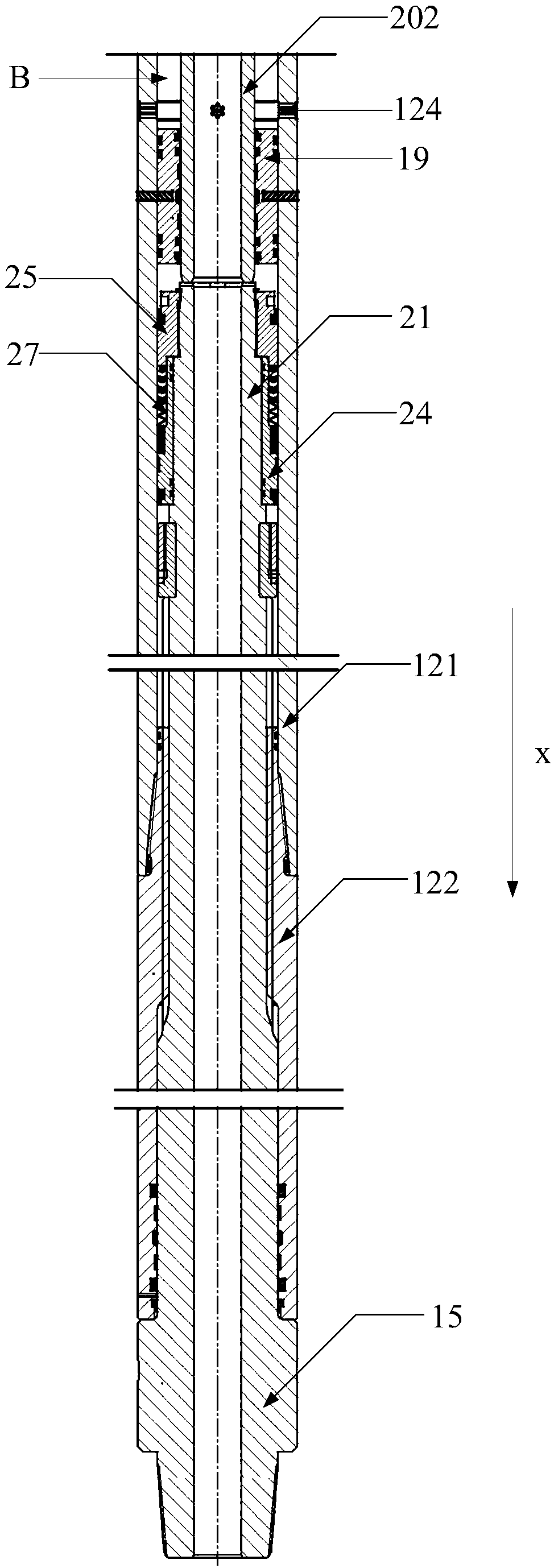

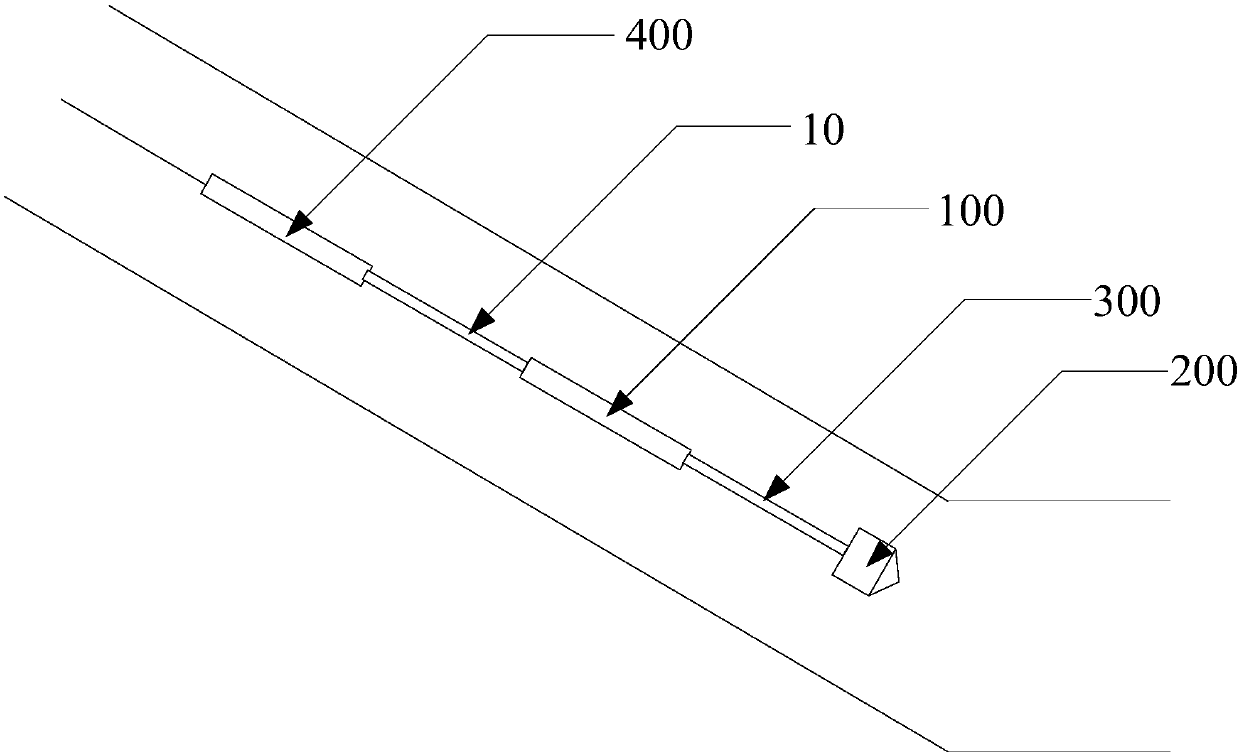

Drilling tool

ActiveCN107780842AGuaranteed thrustGuaranteed drilling speedEarth drilling toolsBorehole drivesBiochemical engineeringPiston rod

The invention discloses a drilling tool, and belongs to the field of drilling and production. The drilling tool comprises an upper connector, a shell, a first piston, a first piston rod and an outputshaft, wherein the upper connector is connected with the shell, the first piston is fixed in the shell, a first through hole is formed in the first piston, a first step is arranged between the head segment and the tail segment of the first piston rod, the tail segment of the first piston rod penetrates through the first through hole and is connected with one end of the output shaft, and the otherend of the output shaft is connected with a drill bit; the first piston rod is capable of driving the output shaft to move when the end face of the head segment bears pressure of mud flowing from theupper connector until the first step of the first piston rod makes contact with the first piston. Thrust exerted on the drill bit is ensured by the drilling tool comprising the first piston rod, the first piston and the output shaft, and therefore drilling speed and drilling operation efficiency are ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com