Percussive-rotary drilling method and system for horizontal directional drilling crossing

A technology of horizontal directional drilling and drilling rigs, applied in directional drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of low drilling pressure, reduce secondary wear, shorten construction period, and improve drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

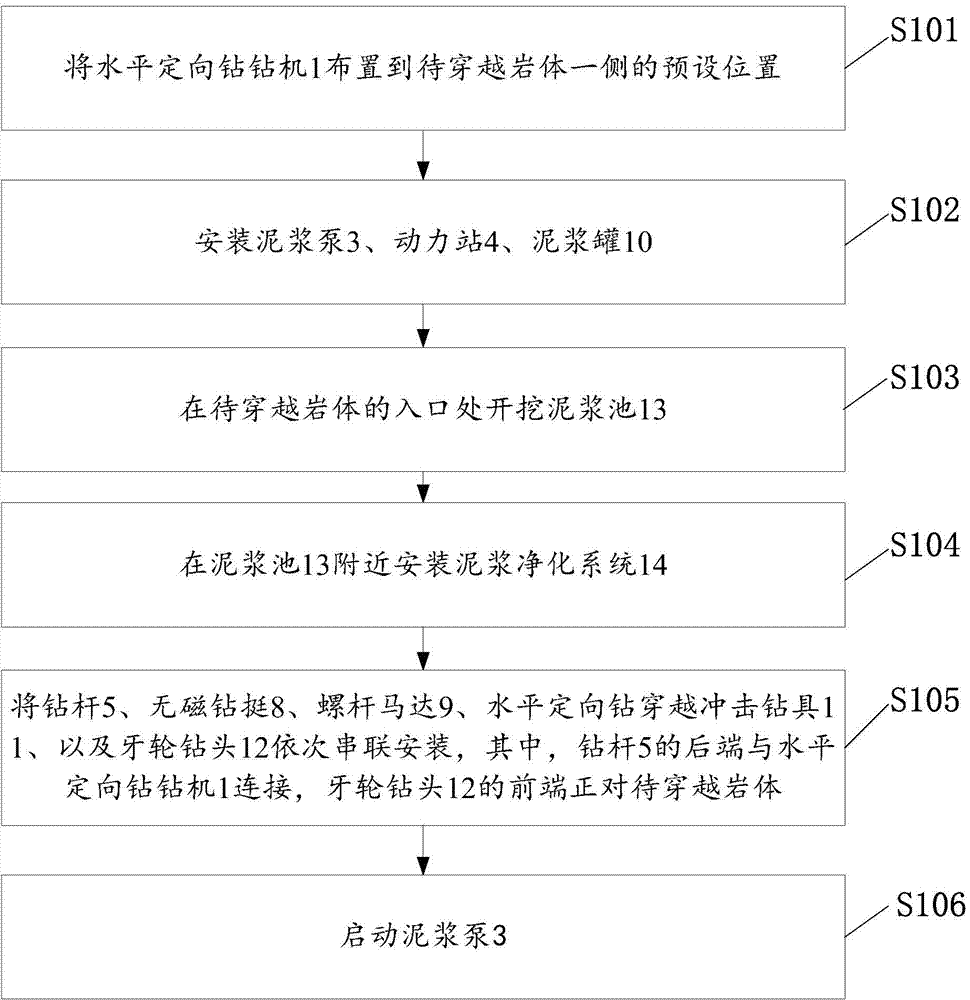

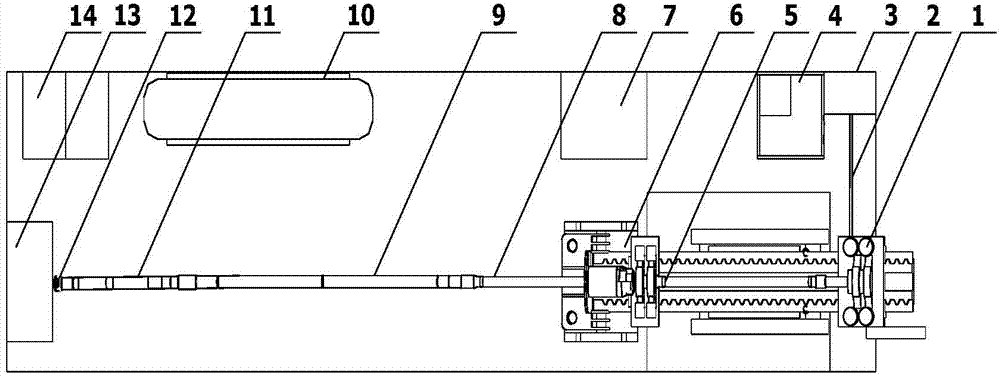

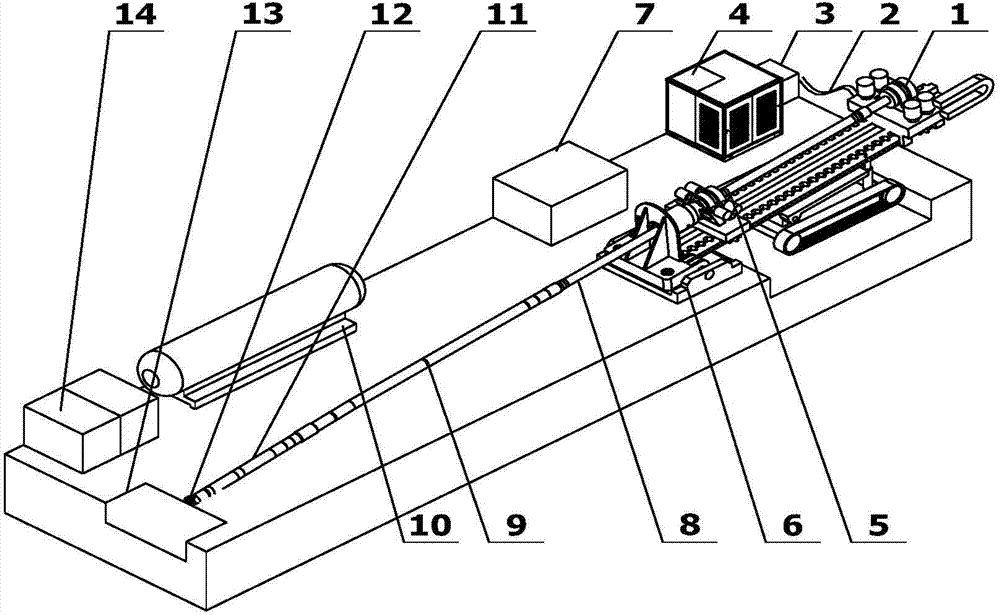

[0044] This embodiment provides a horizontal directional drilling percussion rotary drilling method, which is suitable for horizontal directional drilling pilot hole crossing projects in hard rock formations, such as Figure 1~3 As shown, the method includes:

[0045] Step S101: Arranging the horizontal directional drilling machine 1 to a preset position on one side of the rock mass to be traversed.

[0046] In the specific implementation process, after entering the construction site, according to the design crossing curve depth and the parameter information of the specific conditions on both sides of the rock mass to be crossed, determine the distance from the horizontal directional drilling rig 1 to the rock mass to be crossed, based on the horizontal directional drilling rig 1 to the distance from the rock mass to be crossed, adjust the position of the horizontal directional drilling rig 1 to the preset position, and keep the position of the horizontal directional drilling ...

Embodiment 2

[0061] Based on the same inventive concept, this embodiment provides a horizontal directional drilling through impact rotary drilling system, such as Figure 2~3 shown, including:

[0062] Horizontal directional drilling rig 1 is arranged on one side of the rock mass to be traversed;

[0063] Drill pipe 5, non-magnetic drill jack 8, screw motor 9, horizontal directional drilling hydraulic impact drill 11, roller cone bit 12; among them, drill pipe 5, non-magnetic drill jack 8, screw motor 9, horizontal directional drilling hydraulic The impact drilling tool 11 and the roller cone bit 12 are connected in series in sequence, the rear end of the drill rod 5 is connected to the horizontal directional drilling machine 1, the front end of the roller cone bit 12 is facing the rock mass to be crossed, and the horizontal directional drilling machine 1 is used to drill the drill rod 5 Provides thrust, torque and speed;

[0064] Mud tank 10, used for storing mud;

[0065] The mud pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com