Rotary tool, in particular drill

A technology of rotating cutters and drills, which is applied to milling cutters, reamers, twist drills, etc. It can solve problems such as high thermal load, high mechanical load, and increased burrs, and achieve simple geometry, avoid burrs, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Parts having the same effect in the figures are provided with the same reference symbols.

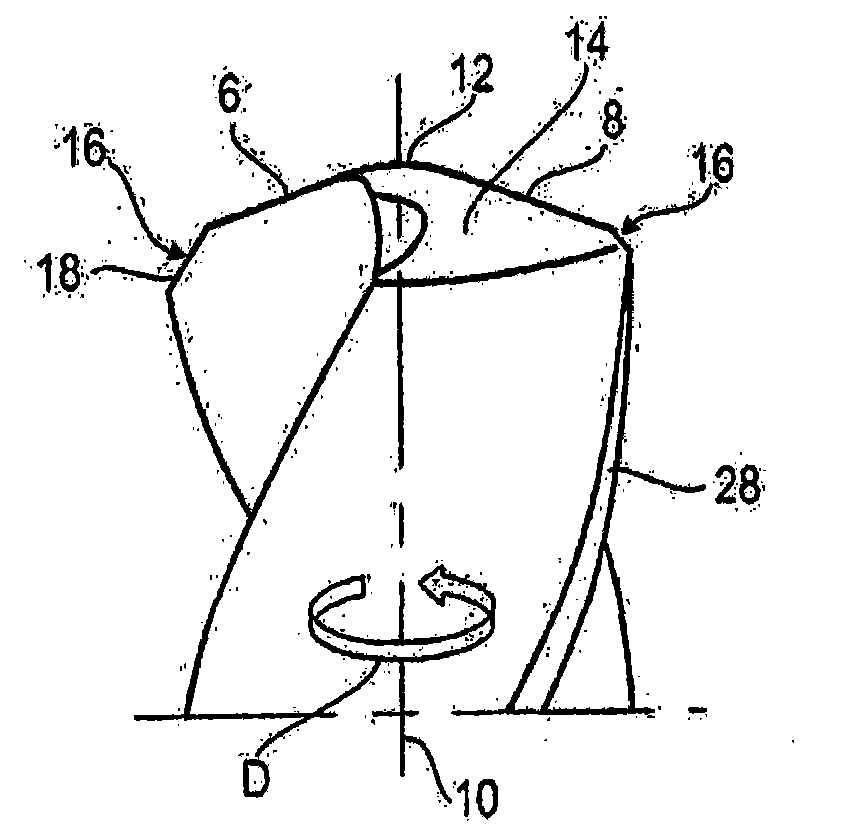

[0027]These individual details and features are illustrated below with reference to a rotary tool designed as a twist drill 2 . The only partially shown twist drill 2 has a drill point 4 as a cutting head, on which a plurality of main cutting edges 6, 8 (two in the exemplary embodiment) are formed at the end face . In the following, one main cutting edge is called leading cutting edge 6 and the other main cutting edge is called free cutting edge 8 . The two main cutting edges 6 , 8 are connected to one another by a chisel edge 12 in the region of a central axis of the drill 2 which simultaneously forms an axis of rotation 10 . During use, the drill bit 2 is rotated in a direction of rotation D about a drill central axis 10 . The drill point 4 is substantially designed in the shape of a conical side surface, so that the main cutting edges 6 , 8 extend obliquely outward from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com