Tunnel boring machine cutterhead for assisting rock breaking through high-pressure water jet

A technology of high-pressure water jetting and tunneling, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve problems affecting the speed of tunneling and construction, damage and failure of key components, and high cost ratio of tools, so as to ensure the destructive power and damage The effect of reducing the scope, shortening the construction period, and ensuring the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

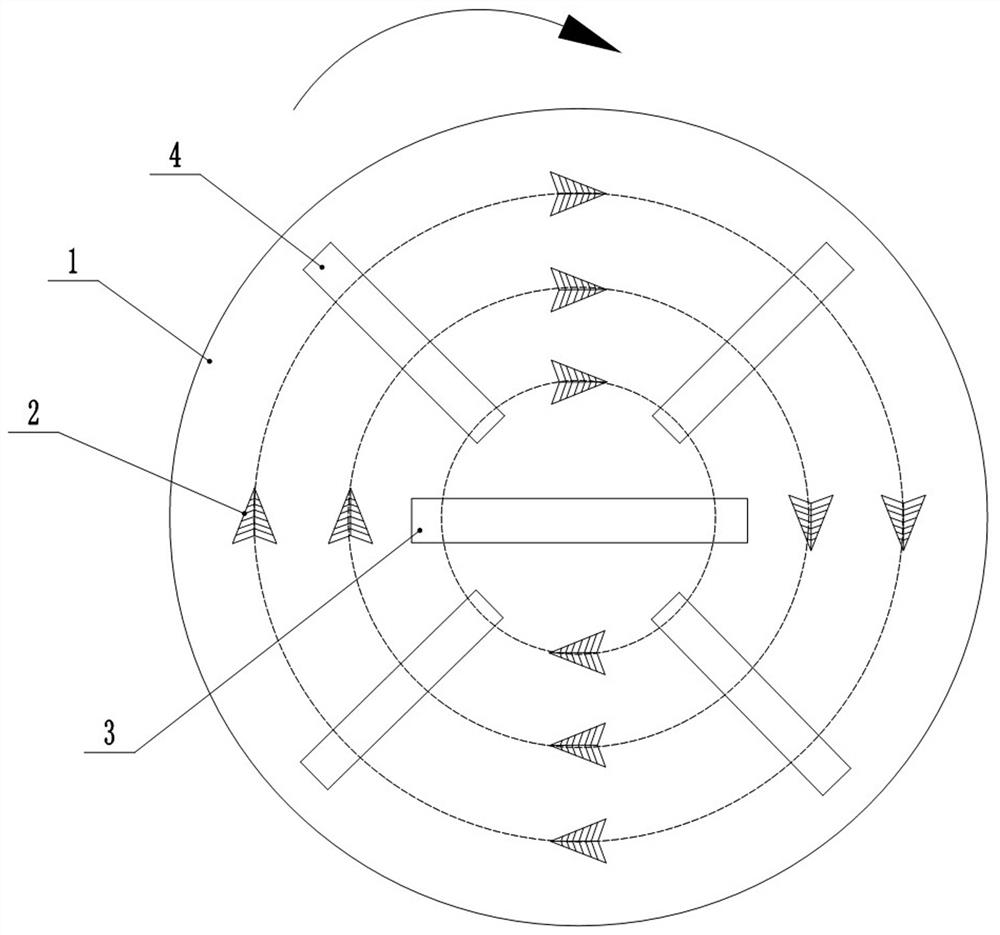

[0020] Such as Figure 1-Figure 4 As shown, the present invention provides a tunnel boring machine cutter head with high-pressure water jet assisting rock breaking, including a cutter head 1 body, a first hob assembly 3 arranged on the cutter head 1 body, a plurality of first hob The knife assembly 4 and a plurality of scrapers 2 ; the first hob assembly 3 and the first hob assembly 4 both include a rotating shaft 8 and a plurality of hobs 9 arranged on the rotating shaft 8 .

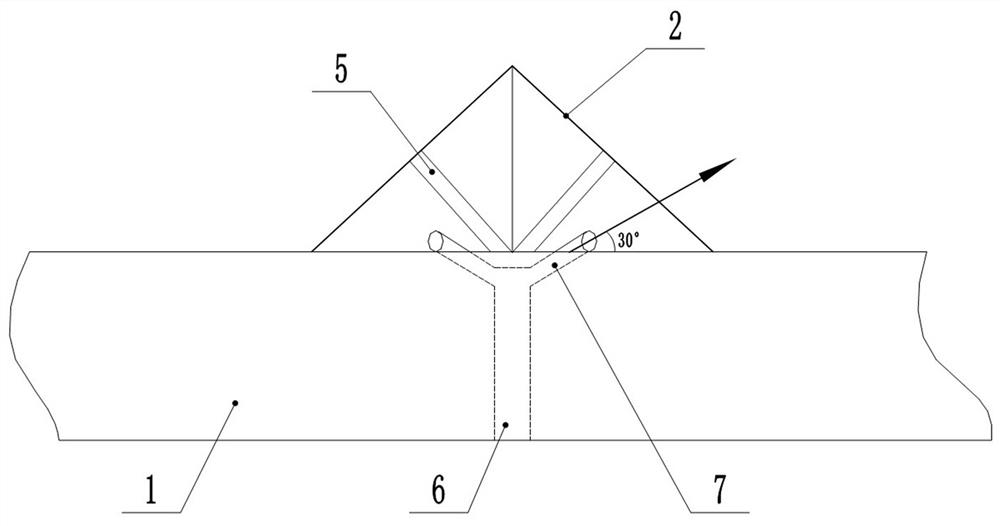

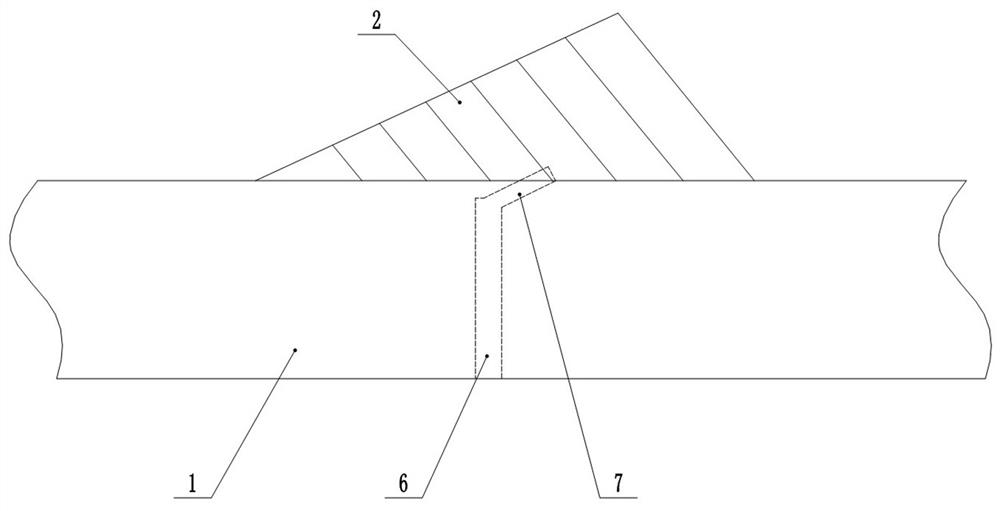

[0021] The scraper 2 is in the shape of a plowshare, and the cutterhead 1 body is provided with a nozzle 6 for introducing high-pressure water. The end of the nozzle 6 is provided with a pair of nozzles 7 positioned below the scraper 2. 7 The penetrating power of the sprayed water to the face of the face, the angle between the spray direction of the spray head 7 and the surface of the cutterhead 1 body is 30°.

[0022] This structural design can effectively prevent the dregs from clogging the nozzle 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com