Shield cutter head suitable for soft and hard composite stratum and tunneling method

A shield cutter head, soft and hard composite technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems that the dregs cannot be guaranteed to enter the soil bin smoothly, the hob is not considered, and the impact force is large, so as to avoid Severe wear, improve rock breaking efficiency, and prevent string grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

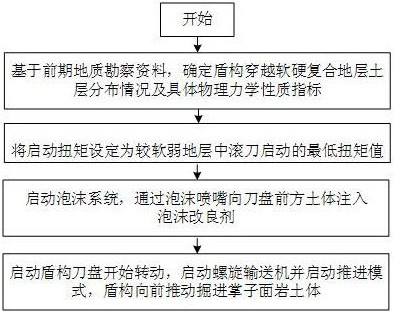

Method used

Image

Examples

Embodiment Construction

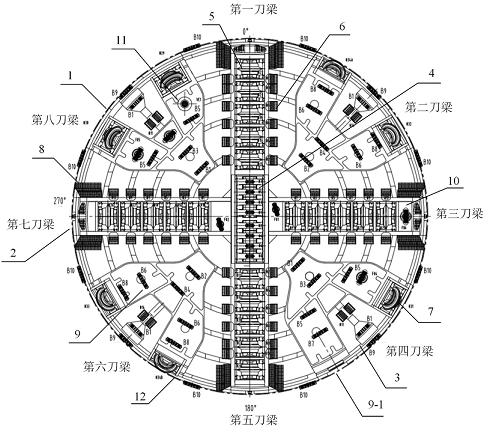

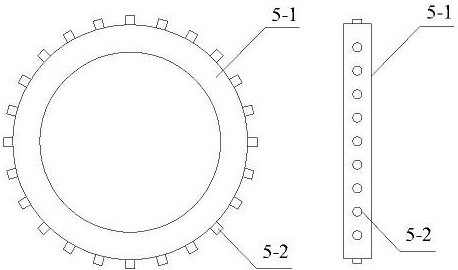

[0032] Such as figure 1 and figure 2As shown, this embodiment is a shield cutter head suitable for soft-hard composite formations, mainly including a shield cutter head 1, a cross-shaped main knife beam 2, an auxiliary knife beam 3, a center tooth knife 4, a front hob 5, an inlay Tooth hob blade 5-1, alloy column teeth 5-2, cutter 6, edge hob 7, edge scraper 8, fixed tooth cutter 9, super digging tooth cutter 9-1, foam nozzle 10, wear detection knife 11, Wear-resistant steel plate 12 and other necessary components not listed.

[0033] The main working principle of a shield cutter head suitable for soft-hard composite formations in this embodiment is as follows:

[0034] The main load-bearing structure of the shield cutter head 1 is formed by the cross-shaped main knife beam 2 and the auxiliary knife beam 3 .

[0035] Eight central toothed cutters 4 with a cutter height of 175mm are installed at the center of the cross-shaped main cutter beam 1, and the cutter spacing is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com