Support with fixable front end for horizontal directional drilling machine

A technology of horizontal directional drilling rig and fixed support, which is applied in directional drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of drilling rig deviation, insufficient propulsion, and affecting drilling quality, so as to improve stability and ensure drilling quality. Hole accuracy, the effect of ensuring the efficiency of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The fixed support at the front end of the horizontal directional drilling machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

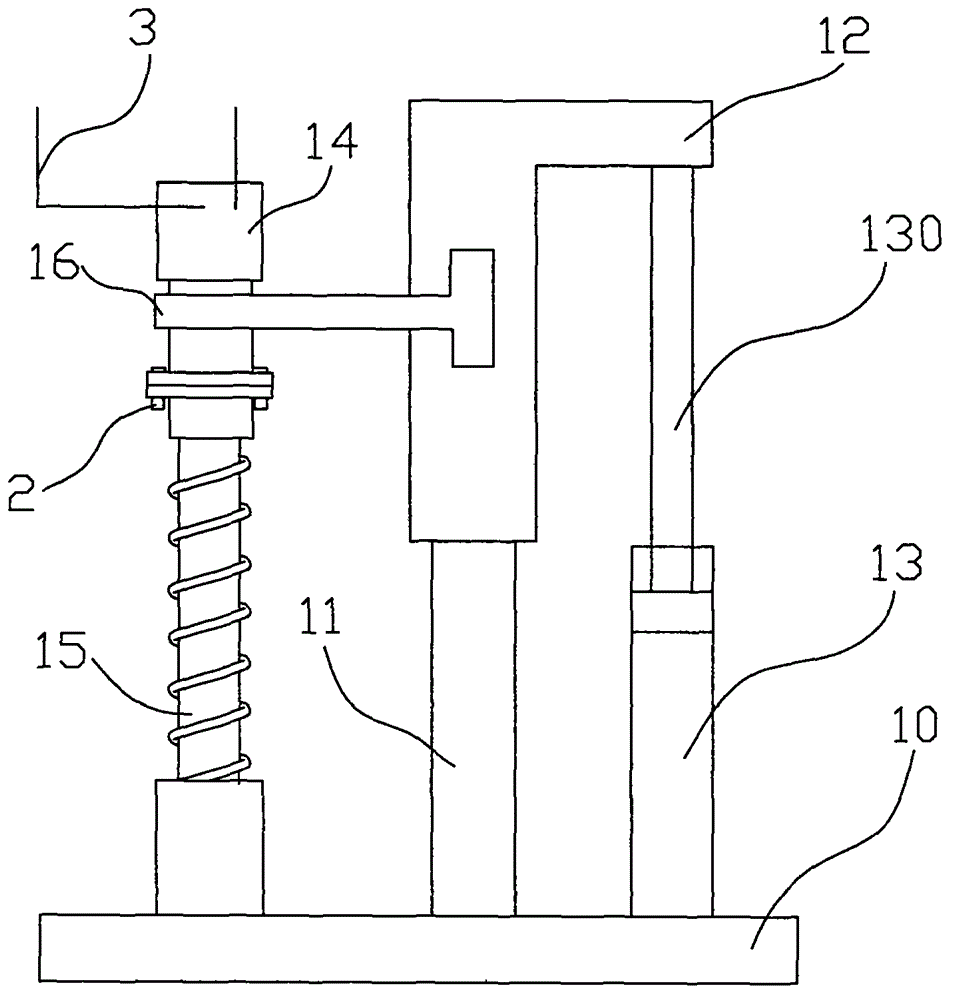

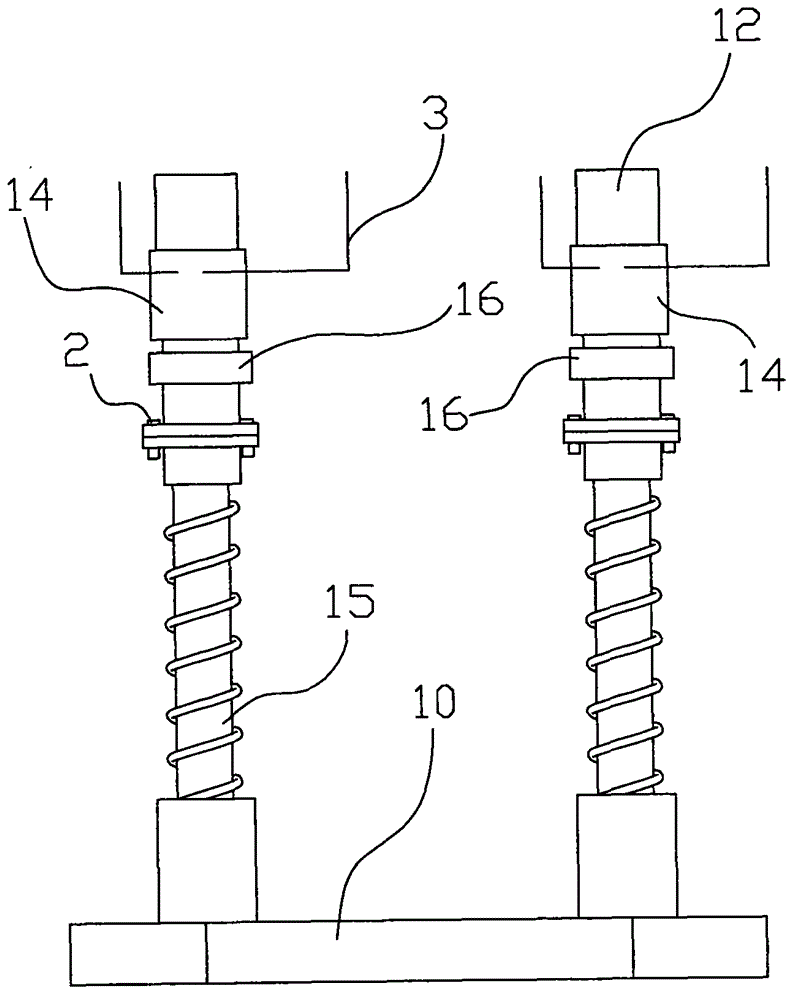

[0016] The fixed support at the front end of the horizontal directional drilling rig according to the present invention is mainly used for fixing the front end of the horizontal directional drilling rig, which is connected with the hydraulic system of the horizontal directional drilling rig, see figure 1 and figure 2 As shown, it includes a base 10, a sliding sleeve rod 11, a sliding sleeve 12, a hydraulic cylinder 13, a hydraulic motor 14, a drill pipe 15, a connecting piece 16 and a reversing valve (not shown).

[0017] Wherein, the base 10 is fixed on the front end of the horizontal directional drilling machine through a clamping frame (not shown in the figure); , the sliding sleeve 12 can slide up and down on the sliding sleeve rod 11; the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com