Stretchable breaking type PDC compound drill bit

A composite drill bit and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of thermal wear, increased PDC tooth wear speed, and high penetration difficulty, so as to ensure mechanical rigidity, avoid rapid wear, and increase connection area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0028] The present invention will be described in further detail below by means of specific embodiments:

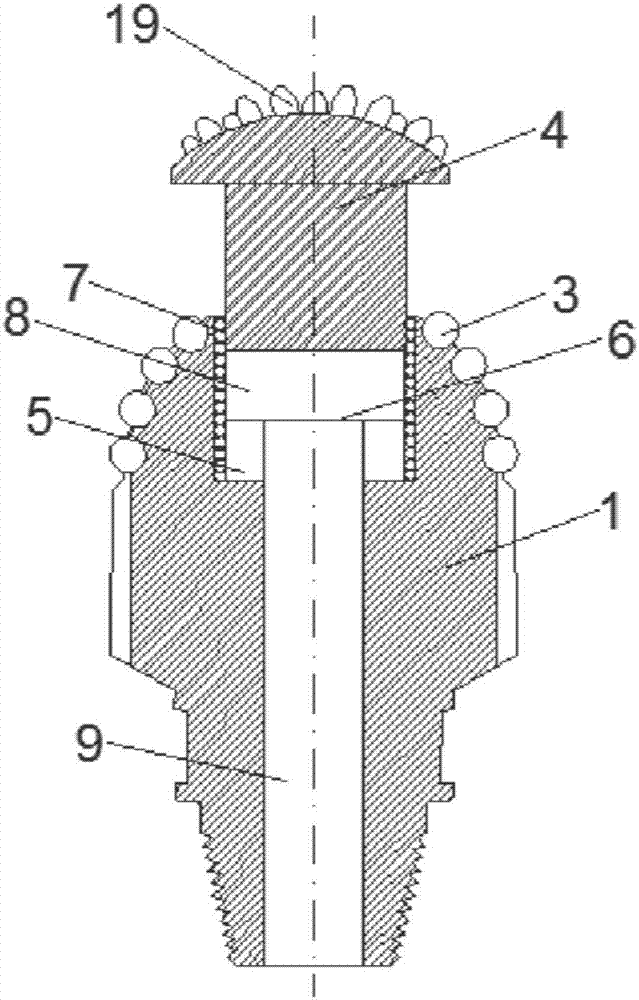

[0029] Such as figure 1 As shown, the present embodiment provides a retractable broken PDC composite drill bit, including a drill body 1 and a blade 2 integrally formed with the drill body 1, the blade 2 includes a main blade 16 and an auxiliary blade 17, the main blade 16 and The secondary blades 17 are fixed on the bit body 1 in the form of an Archimedes spiral, the main blade 16 and the secondary blade 17 are provided with several drill bit cutting teeth 3, and the main blade 16 and the secondary blade 17 are provided with The drill bit cutting teeth 3 on the main cutter wing 16 and the auxiliary cutter win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com