Hole drilling machine for rock hole mining

A drilling machine and hole mining technology, which is applied to drilling equipment, earthwork drilling, support devices, etc., can solve the problems of low drilling efficiency and large volume, and achieve the effect of ensuring drilling efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

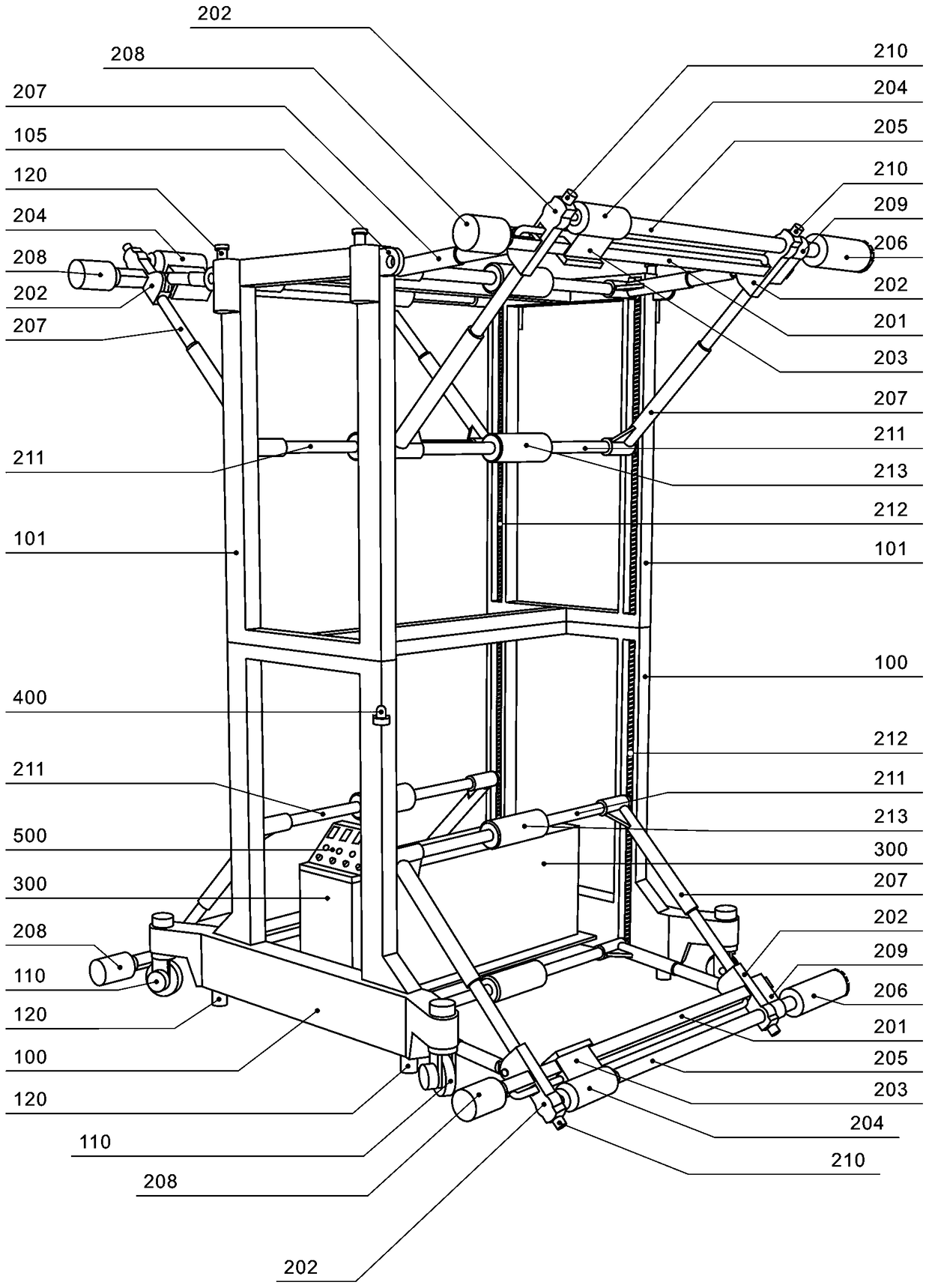

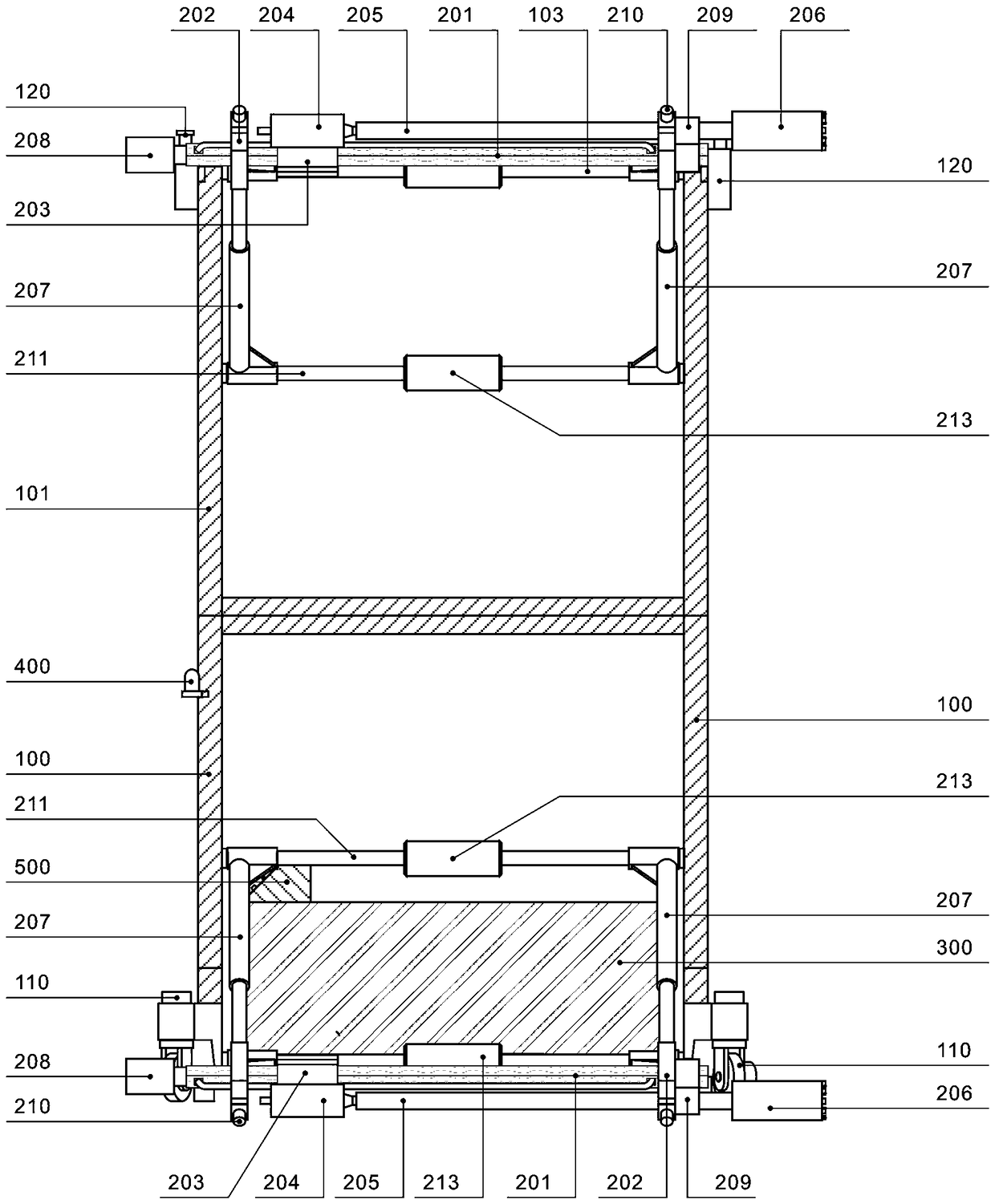

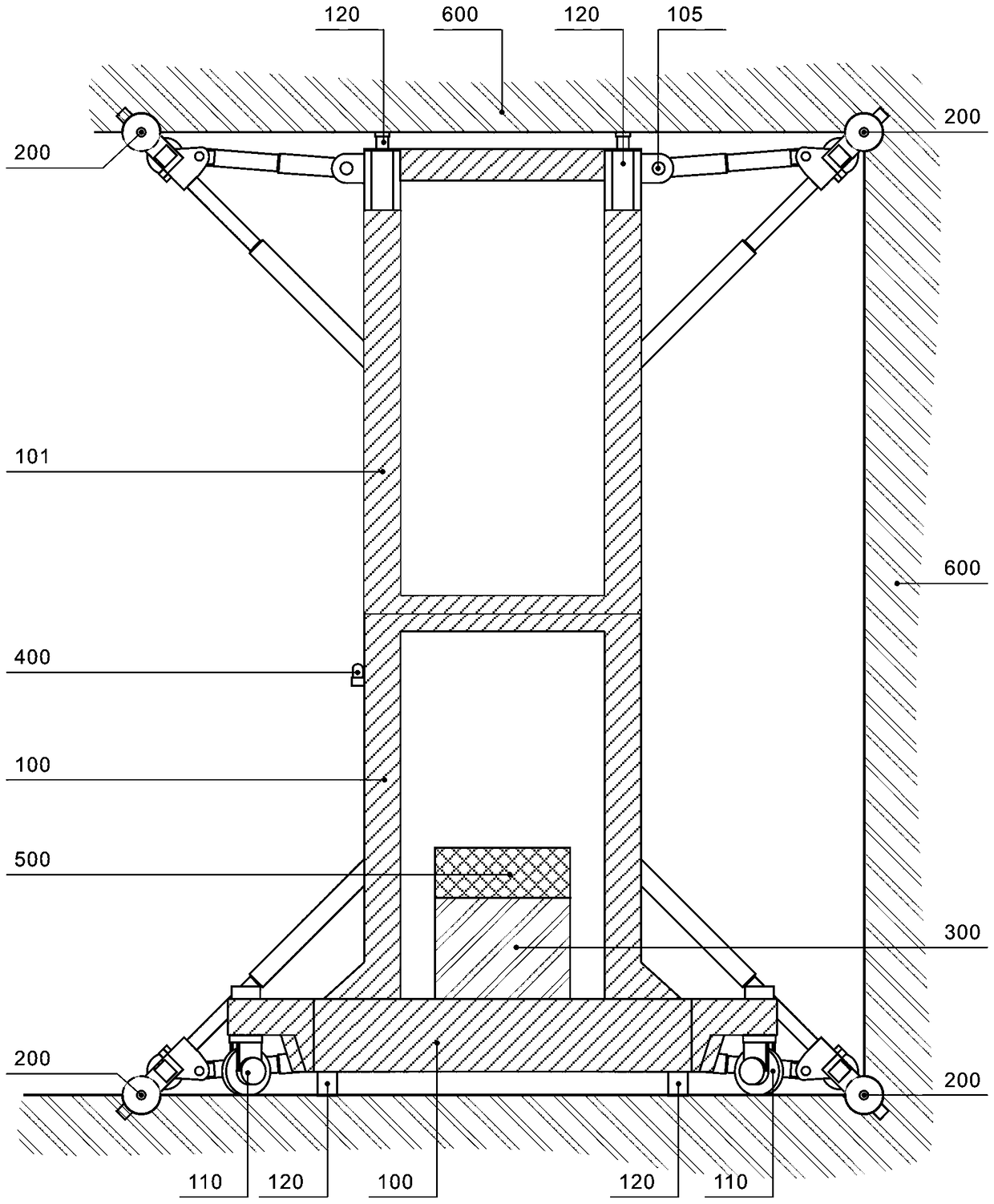

[0008] The present invention will be further described in detail below with reference to the accompanying drawings. according to figure 1 , figure 2 , image 3 As shown, the present invention consists of the following parts: a main frame (100), an extension frame (101), a drilling rig system (200), a main frame (300), a measurement system, a circulation system, and a control system (500). The main frame (100) is a frame structure, and N (where N≧1) drilling rig systems (200) are arranged on each side of the main frame (100). A frame traveling mechanism (110) is arranged on the main frame (100). A retractable support mechanism (120) is provided on the main frame (100). A suspension ring (105) is arranged on the main frame (100). The frame traveling mechanism (110) is composed of a universal wheel, a universal wheel drive device and an automatic steering mechanism of the universal wheel. The frame traveling mechanism (110) may also be a crawler structure. The automatic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com