Soft outburst coal seam long drill hole forming system and method

A technology for protruding coal seams and long drilling holes, applied in the direction of drill pipes, drill pipes, drill bits, etc., can solve the problems of inability to guarantee construction safety, affect the efficiency of drilling construction, and buried drills, so as to improve construction efficiency and economic benefits, Efficient and smooth drilling operations to ensure the effect of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

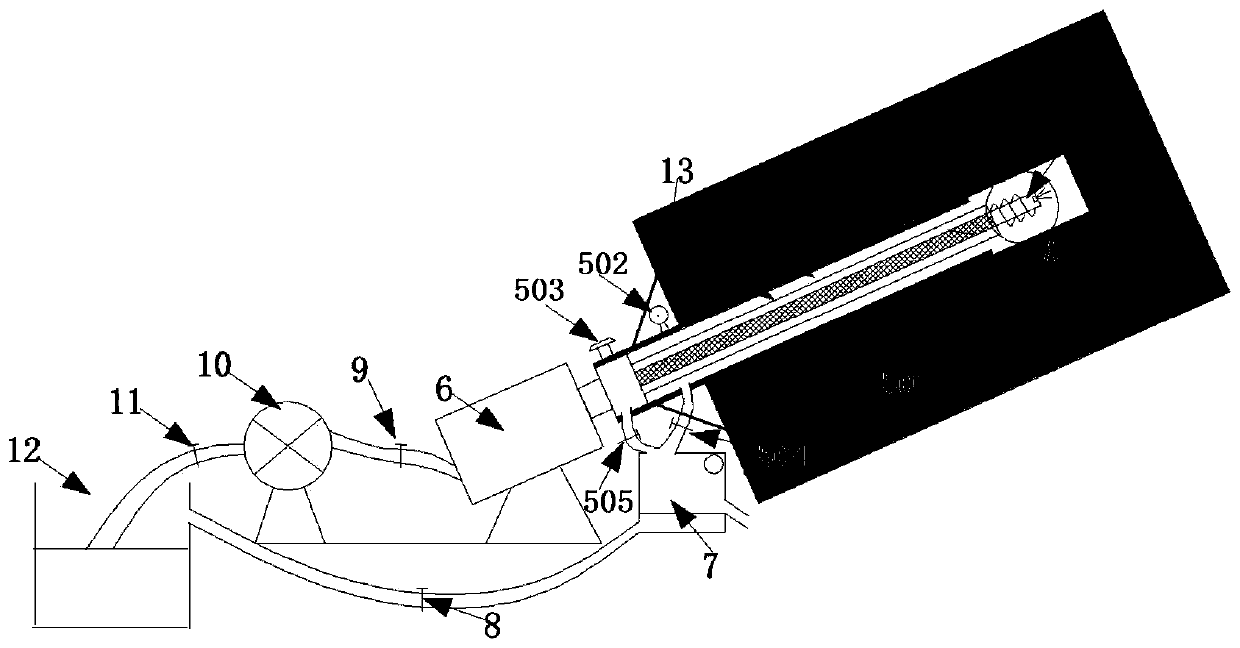

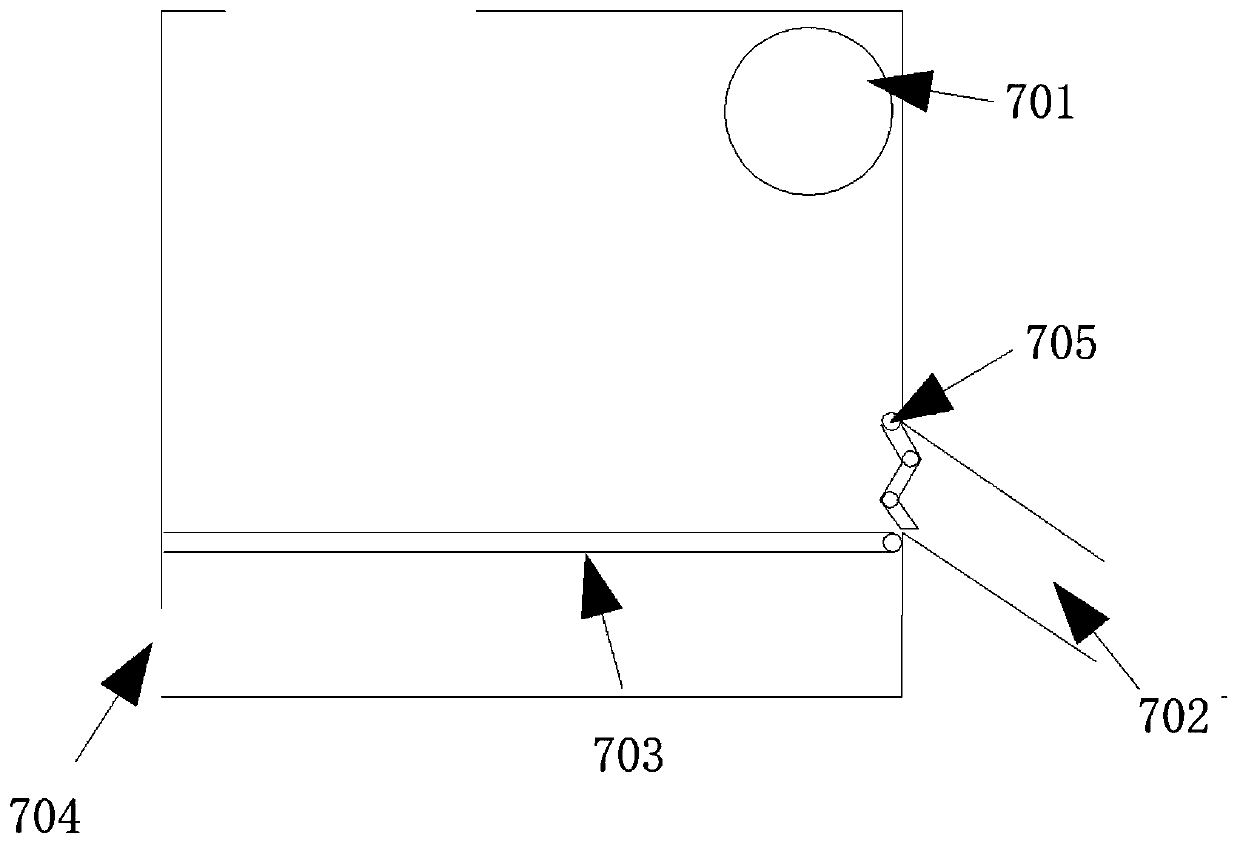

[0036] see figure 1 with figure 2 , This embodiment discloses a long drilling system for soft and outburst coal seams, including a water jet generation system, a drilling rig drilling tool system, a pressure maintaining system 5 and an air slag separator 7 .

[0037] The water jet generation system includes a booster pump 10 and a nanofluid storage tank 12 . A nanofluid pipeline valve 11 is arranged on the pipeline between the booster pump 10 and the nanofluid storage tank 12 .

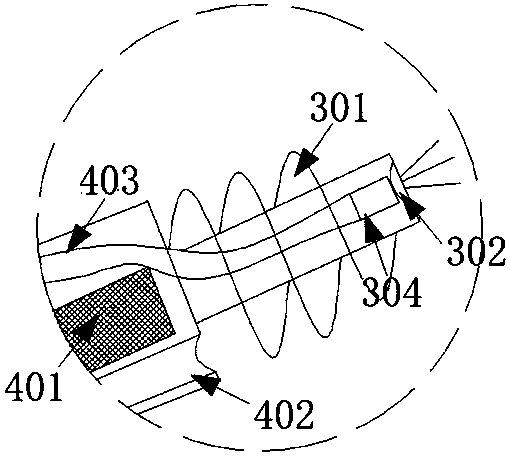

[0038]The drilling tool system of the drilling rig includes an auger bit 3 , a drilling rod 4 and a drilling machine 6 . The auger bit 3 is installed on the head end of the drill rod 4 . A helical blade 301 is arranged on the outer wall of the auger bit 3 . The auger bit 3 has an axial channel 304 inside. The top of the auger bit 3 is provided with a high-pressure nozzle 302 for high-pressure water injection. The auger bit 3 communicates with the axial channel 304 . The drilling machine 6 clam...

Embodiment 2

[0044] This embodiment discloses a basic long drilling system for soft outburst coal seams, including a water jet generation system, a drilling rig drilling tool system, a support casing 401 , a pressure maintaining system 5 and an air slag separator 7 .

[0045] The water jet generation system includes a booster pump 10 and a nanofluid storage tank 12 . A nanofluid pipeline valve 11 is arranged on the pipeline between the booster pump 10 and the nanofluid storage tank 12 .

[0046] The drilling tool system of the drilling rig includes an auger bit 3 , a drilling rod 4 and a drilling machine 6 . The auger bit 3 is installed on the head end of the drill rod 4 . A helical blade 301 is arranged on the outer wall of the auger bit 3 . The auger bit 3 has an axial channel 304 inside. The top of the auger bit 3 is provided with a high-pressure nozzle 302 for high-pressure water injection. The auger bit 3 communicates with the axial channel 304 . The drilling machine 6 clamps the...

Embodiment 3

[0050] The main structure of this embodiment is the same as that of Embodiment 2, wherein a one-way valve is provided in the axial channel 304 to ensure that no waste water flows back from the nozzle of the high-pressure nozzle 302 during the drilling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com