Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Grasp the working status in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

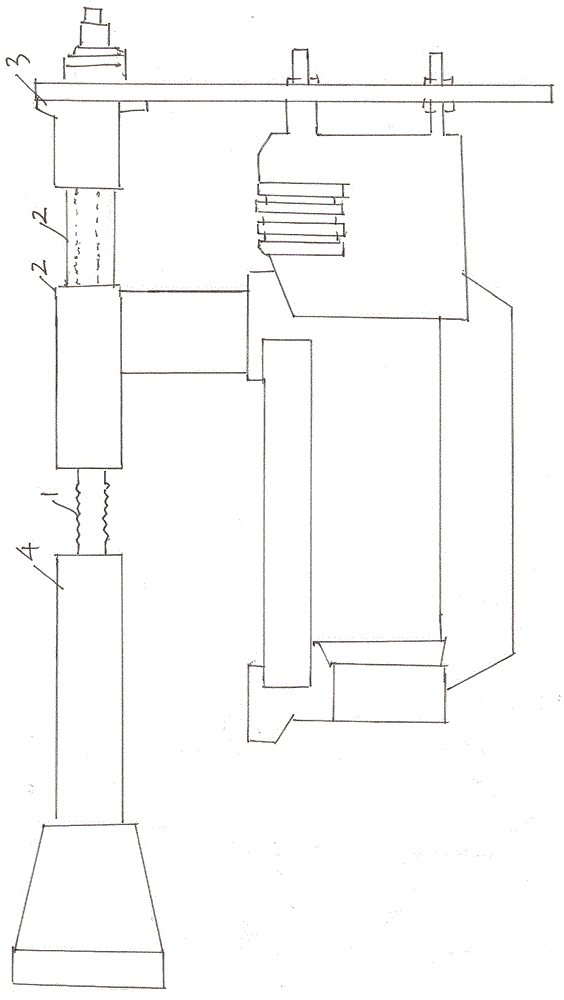

Device for online detection for stress of hobbing cutter of tunnel boring machine

ActiveCN103698075AGrasp the working status in timeExtended service lifeMeasurement of force componentsElastomerAudio power amplifier

The invention discloses a device for online detection for stress of a hobbing cutter of a tunnel boring machine. The device comprises a shaft end supporting structure of a cutter central shaft, a sensor for detecting the stress of the hobbing cutter, a signal amplifier, a transmitting antenna, a signal receiving device and a monitoring computer, wherein the shaft end supporting structure of the cutter central shaft comprises a shaft end structure of the cutter central shaft, a supporting wedge and a locking wedge, and the sensor is formed on the supporting wedge. The supporting wedge is used as an elastomer, the sensor for detecting the stress of the hobbing cutter is formed through pasting a resistance strain piece on the elastomer, and when the heading machine works, the sensor can be used for online detecting stress in three directions borne by a cutting edge of the hobbing cutter, so that the tunneling operation scheme can be adjusted according to the condition, the service life of the cutter is prolonged, and further good tunneling efficiency can be obtained. The device can also be used for identifying whether string wear occurs or not and timely grasping the working state of the hobbing cutter, and the tunneling efficiency can be ensured due to the fact that when the cutting edge is subjected to string wear, the cutter can be timely replaced.

Owner:TIANJIN UNIV

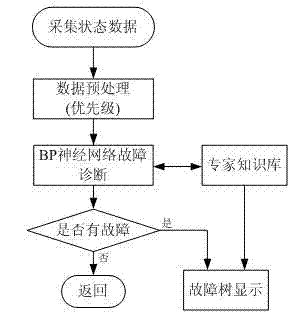

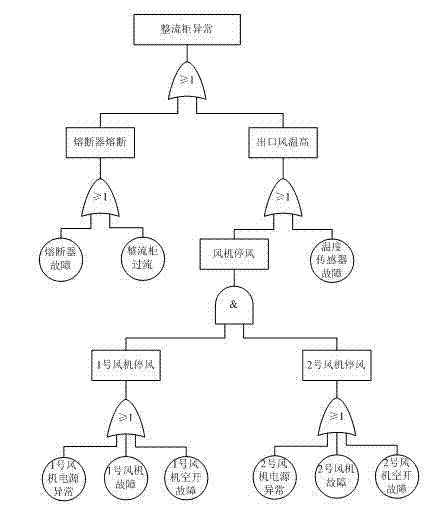

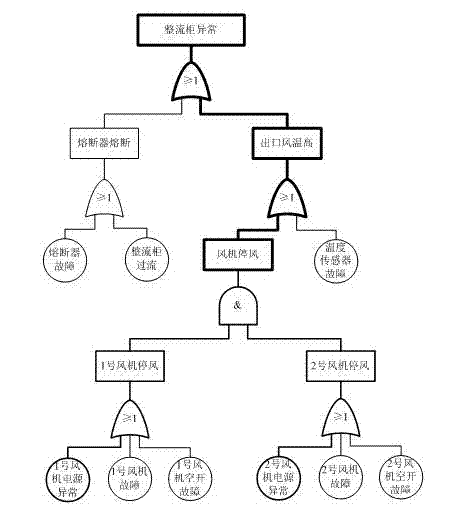

Failure analysis and exhibition method of power generator excitation system

InactiveCN102968113AGrasp the working status in timeHandling in timeElectric testing/monitoringSignal classificationHigh level analysis

The invention discloses a failure analysis and exhibition method of a power generator excitation system. The failure analysis and exhibition method comprises the following steps of: 1, on the basis of failure analysis and induction, establishing a power generator excitation system failure tree; 2, classifying failure signals of the failure tree obtained in the step 1 according to the severity orders of the failures; 3, determining the priority of signal processing according to the severity orders of the failures in accordance with the failure signal classifying in the step 2, and locating a failure source; 4, exhibiting a diagnosis result in the step 3 on the failure tree by using different modes according to different types of the failures in accordance with the correspondence of the diagnosis result in the step 3 to the failure tree of the power generation excitation system, wherein the failure tree is established in the step 1; and 5, establishing an expert knowledge base. According to the invention, the timeliness of the failure diagnosis of the power generation excitation system can be increased, abnormal information is subjected to high-level analysis, the failure source is finally located, a simple and visual failure display interface is provided for a worker, and the maintenance time can be greatly reduced.

Owner:NARI TECH CO LTD

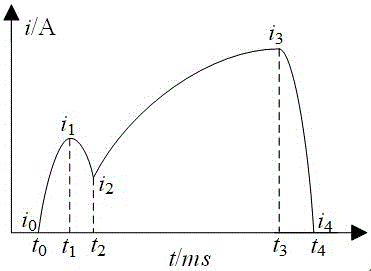

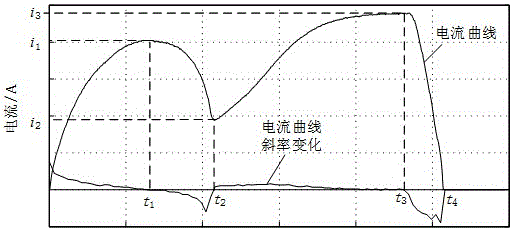

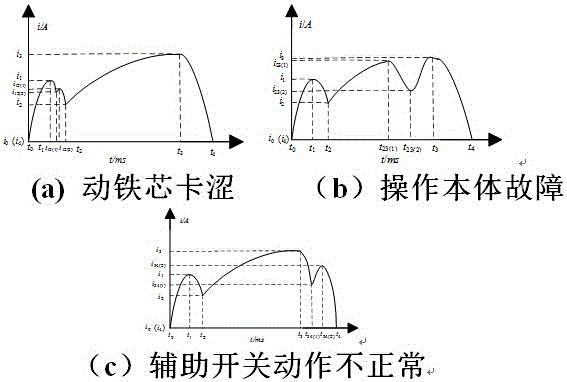

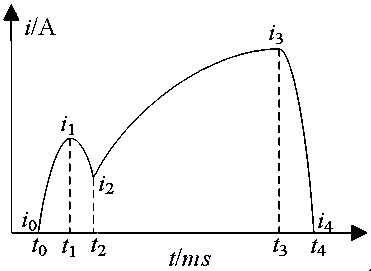

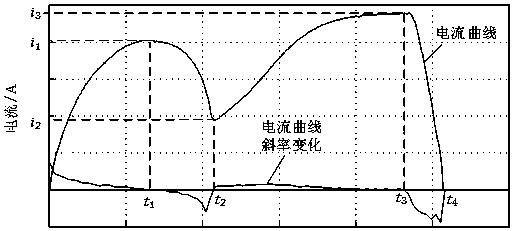

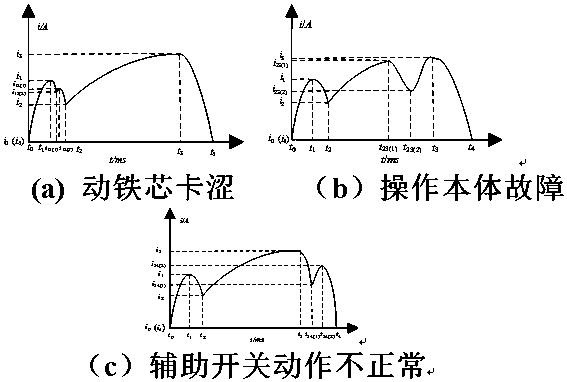

State comprehensive evaluation method for high-voltage circuit breaker operating mechanism based on switching-on and switching-off coil currents

ActiveCN106019131AJudging the running statusGrasp the working status in timeCircuit interrupters testingEvaluation systemElectrical current

The invention relates to a state comprehensive evaluation method for a high-voltage circuit breaker operating mechanism based on switching-on and switching-off coil currents. The method comprises the steps: firstly removing an interference signal in a coil current signal through employing a five-point cubic smoothening filtering; secondly extracting a coil current characteristic value, and building an evaluation system model. The method can achieve the accurate evaluation of the state of the high-voltage circuit breaker operating mechanism, and is of great significance to a maintainer for making a maintenance plan.

Owner:SICHUAN UNIV

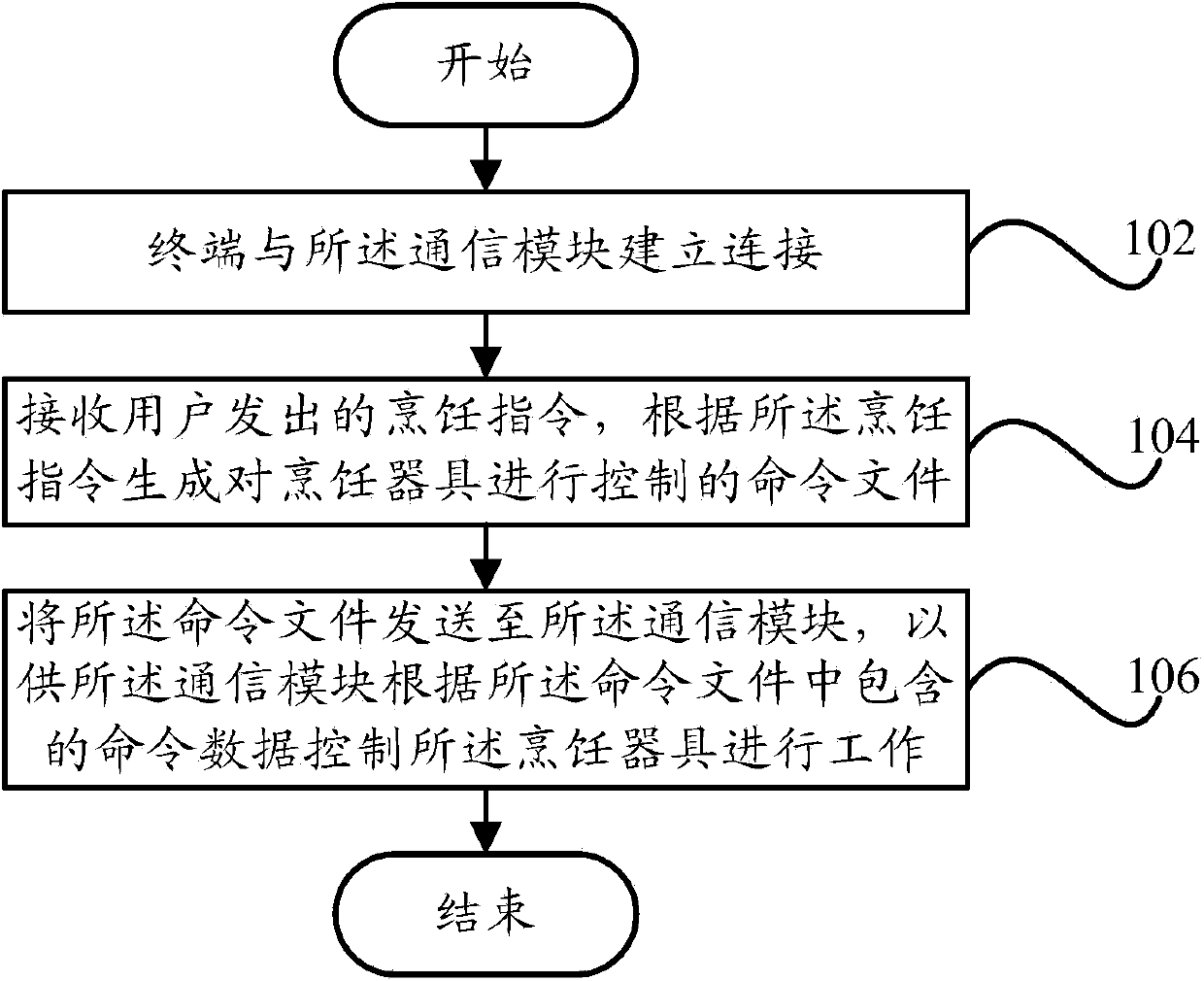

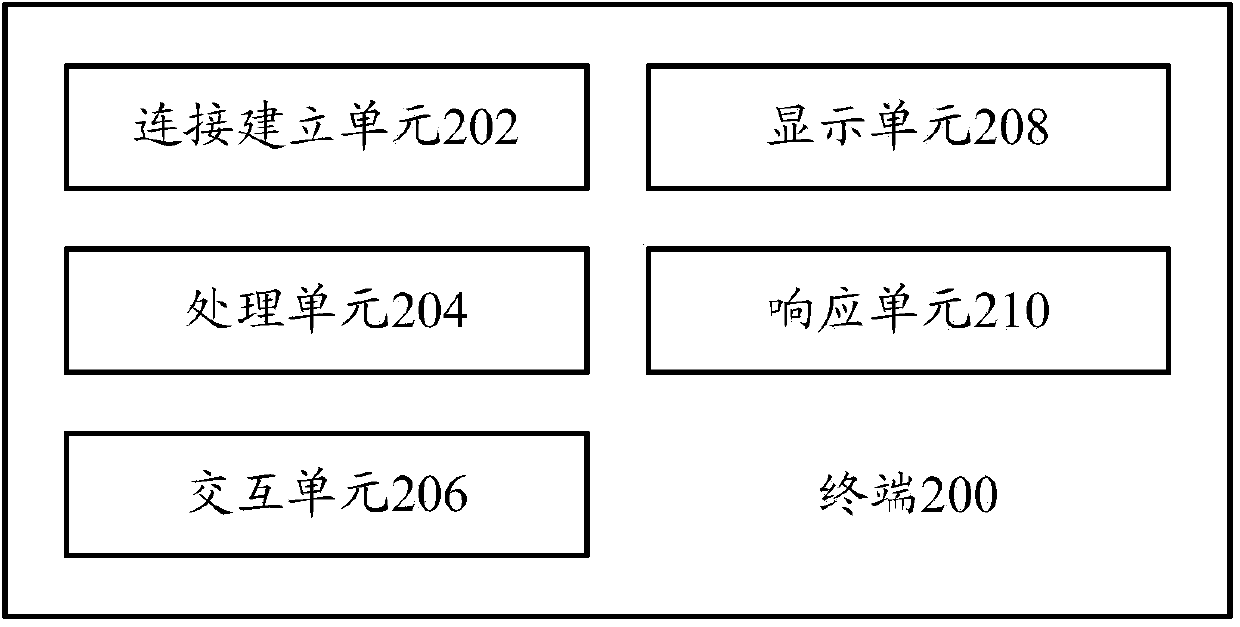

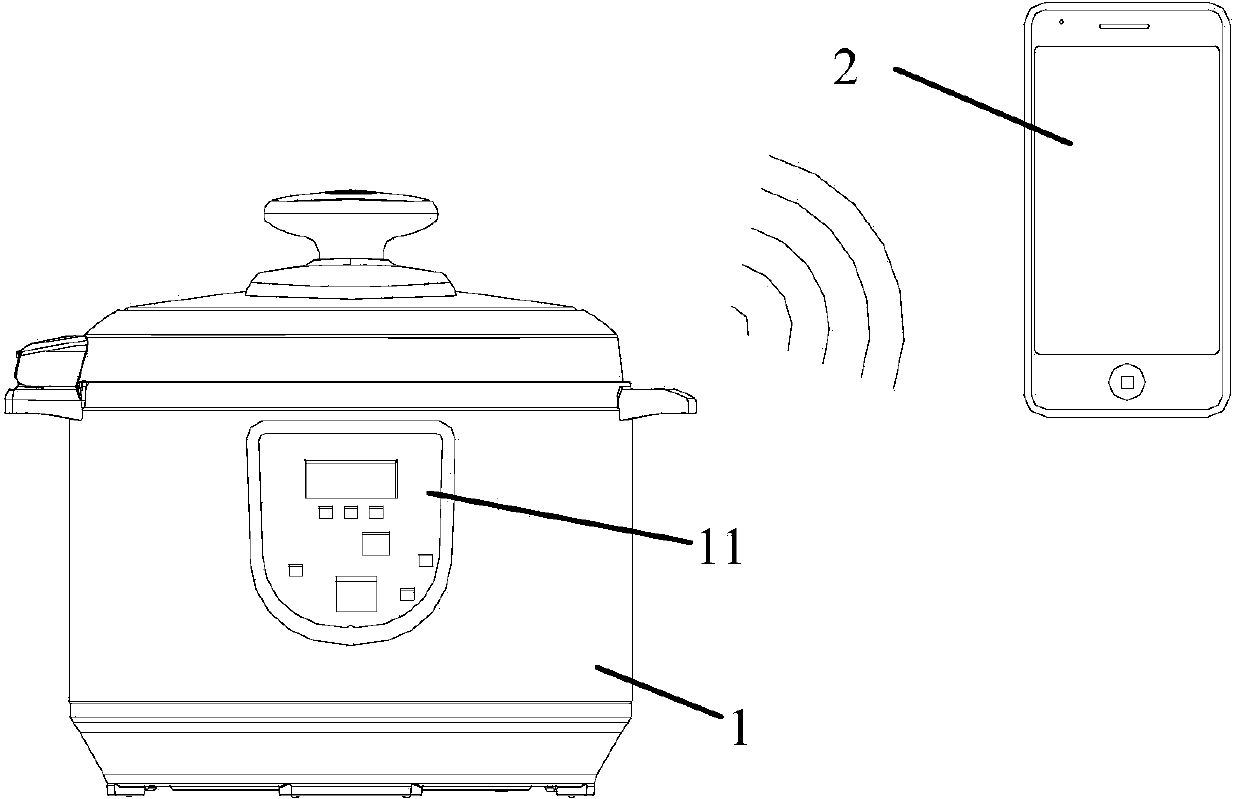

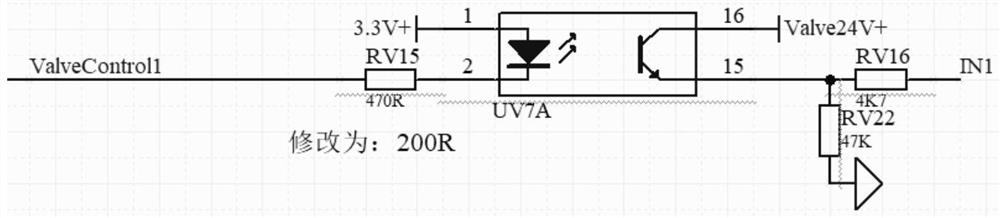

Method and terminal for controlling cooking tool through terminal

InactiveCN104199319AGrasp the working status in timeSolve functionProgramme control in sequence/logic controllersManufacturing engineeringCrowds

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

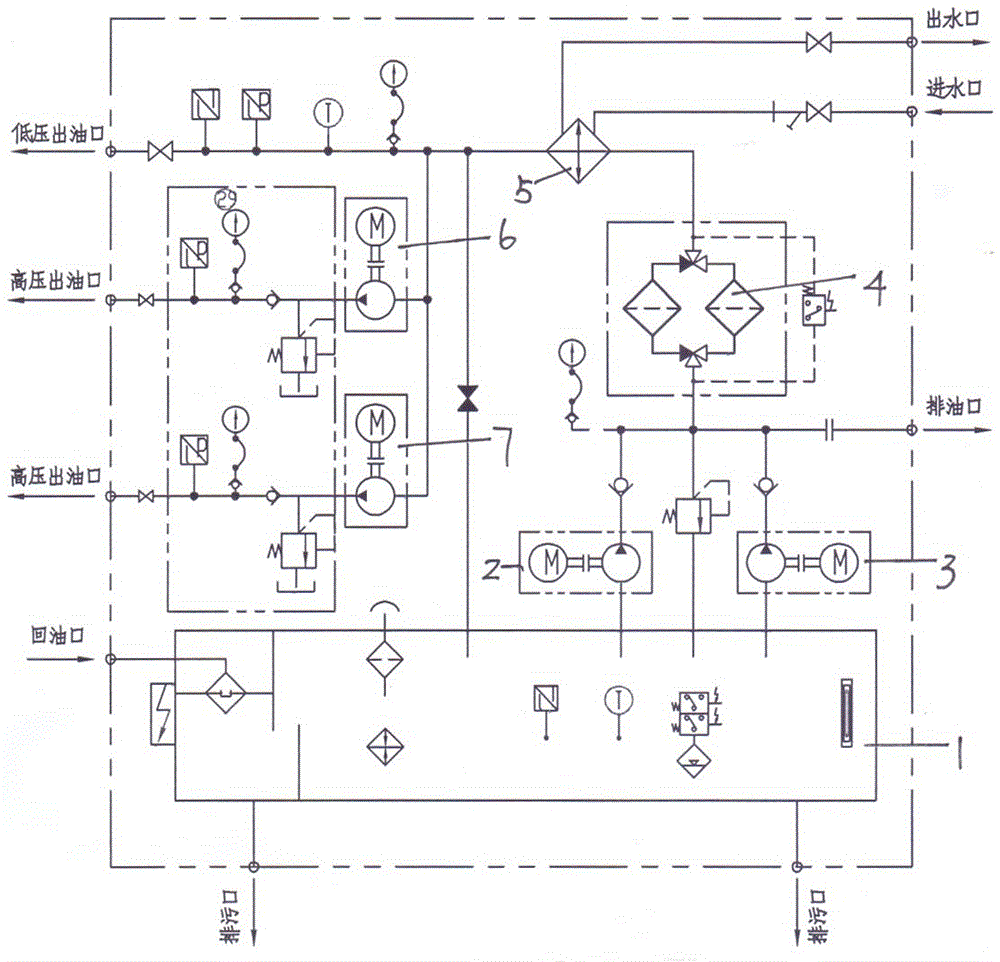

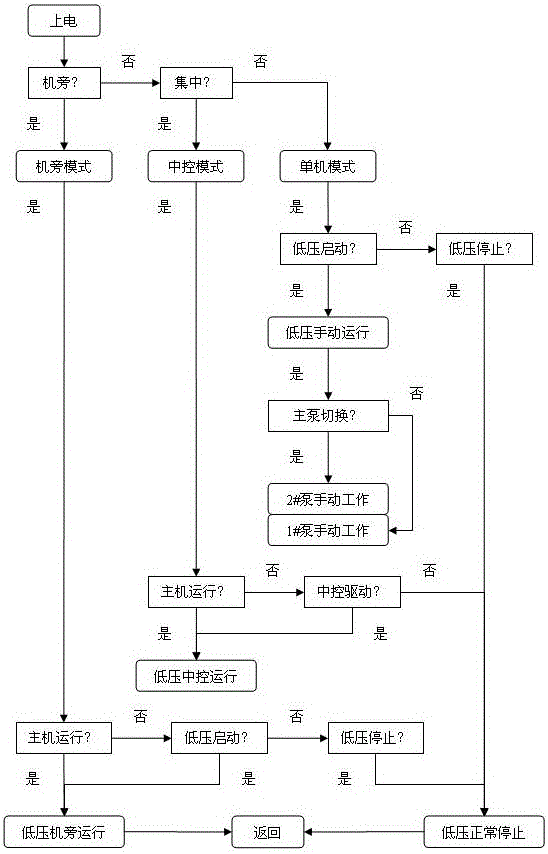

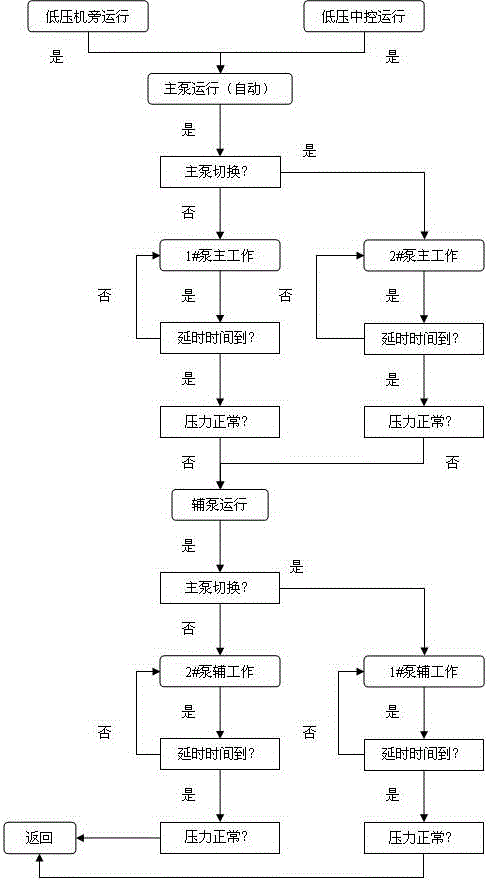

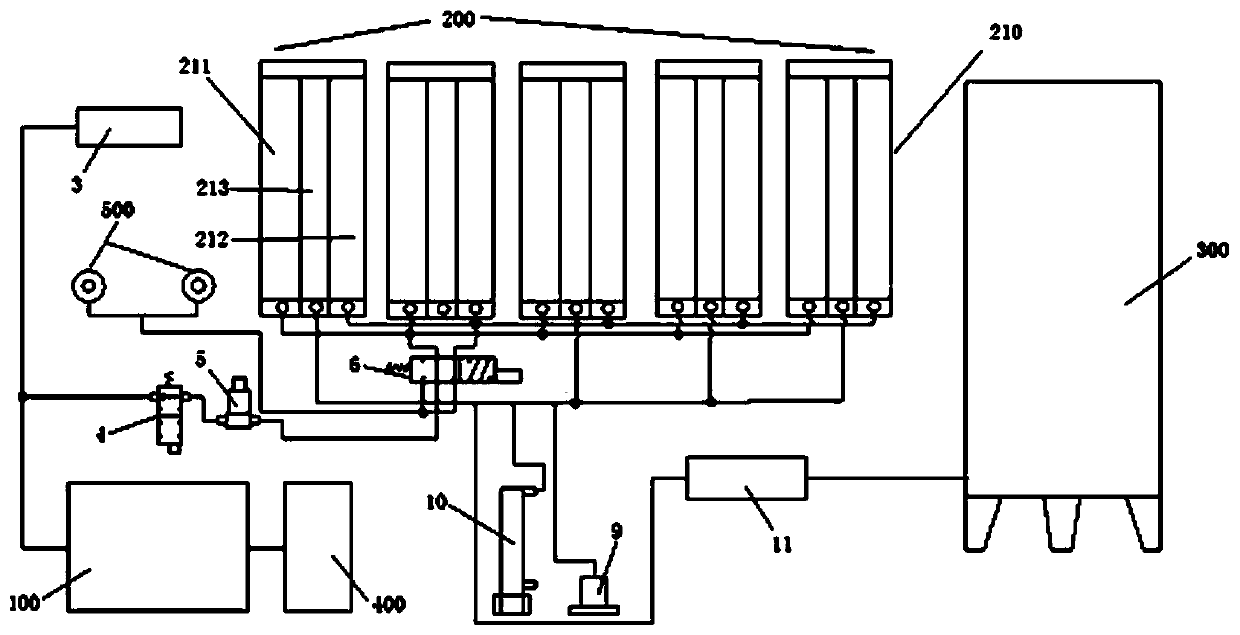

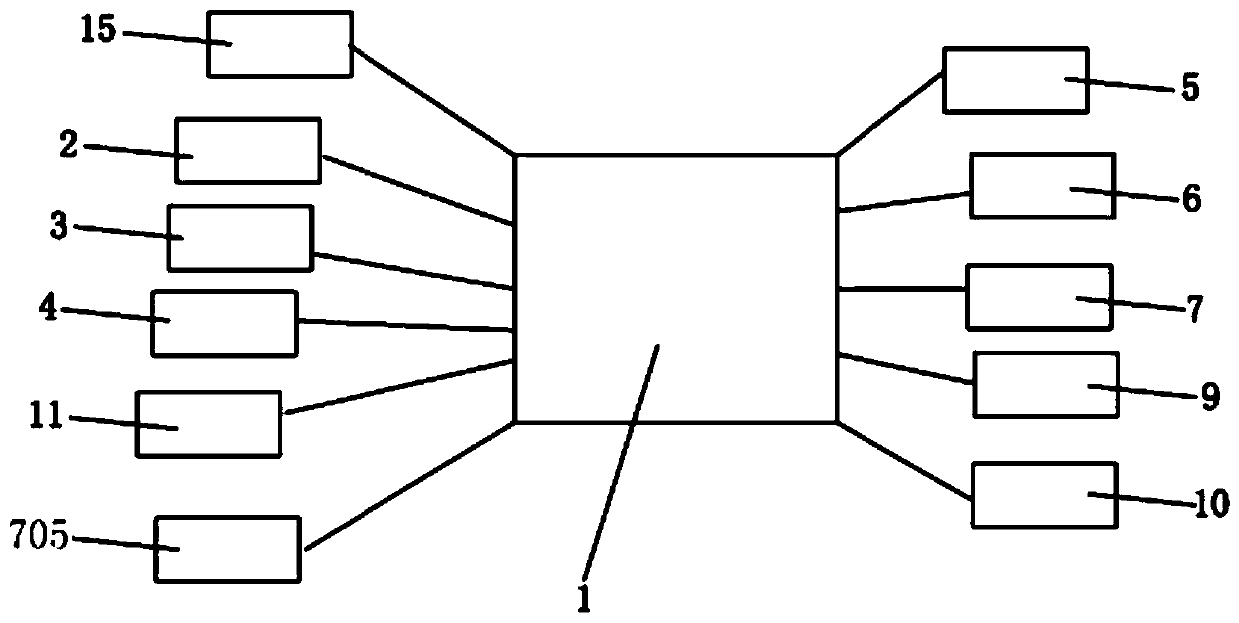

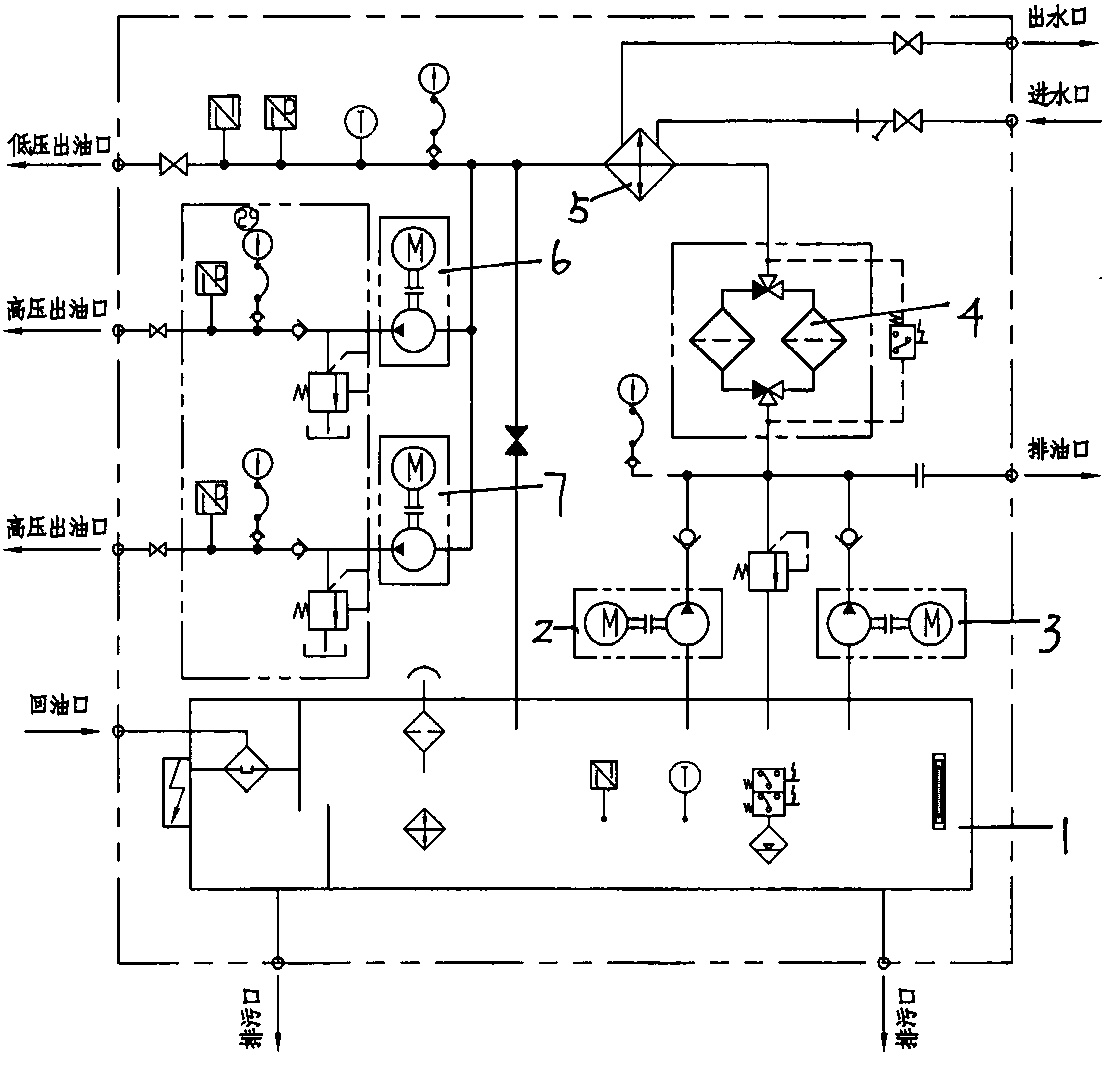

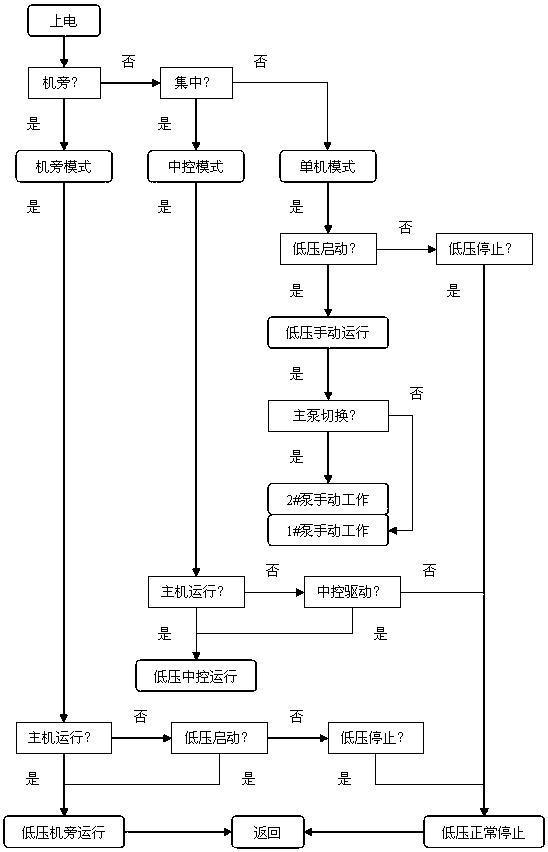

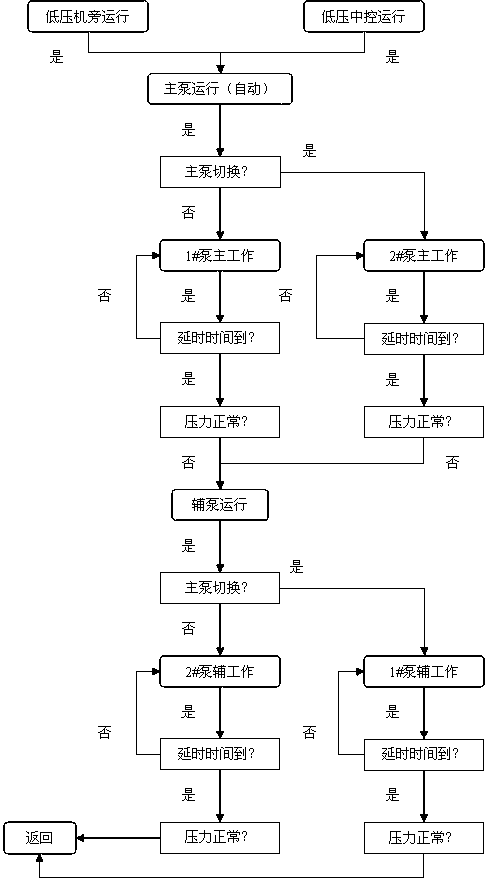

Intelligentized high-low-pressure lubrication device

ActiveCN106287187AReasonable structureCompact structureLubrication elementsLubricationProgressive cavity pump

The invention discloses an intelligentized high-low-pressure lubrication device, which is characterized by comprising an oil tank, wherein the oil tank is connected with an oil outlet pipeline and an oil return pipeline; a control cabinet of a control system for controlling the working of an electric component on the oil outlet pipeline is fixedly arranged on the oil tank, and a touch type display screen is arranged on the control cabinet of the control system; the oil outlet pipeline comprises a NO.1 low-pressure pump and a NO.2 low-pressure pump which are connected in parallel, a filter is arranged behind the pumps which are connected in parallel, an oil cooler is arranged between the filter and an oil outlet, a NO.3 high-pressure pump and a NO.4 high-pressure pump which are connected in parallel are connected behind the cooler, and the oil tank is connected with an oil return port connected with an oil return pipeline; a safety valve channel is connected in parallel with two screw pumps which are connected in parallel; a heater is arranged in the oil tank; an electromagnetic water valve is arranged on a cooling water channel of the oil cooler. The intelligentized high-low-pressure lubrication device has a reasonable structure, a lubrication tank body structure and an electric control tank body structure are integrated as a whole, the structure is more compact and the use is convenient; by adopting the electric control device with the touch type display screen, the working state of the controlled component can be mastered in time; and the working performance of the control system is excellent.

Owner:江苏指南润滑液压科技有限公司

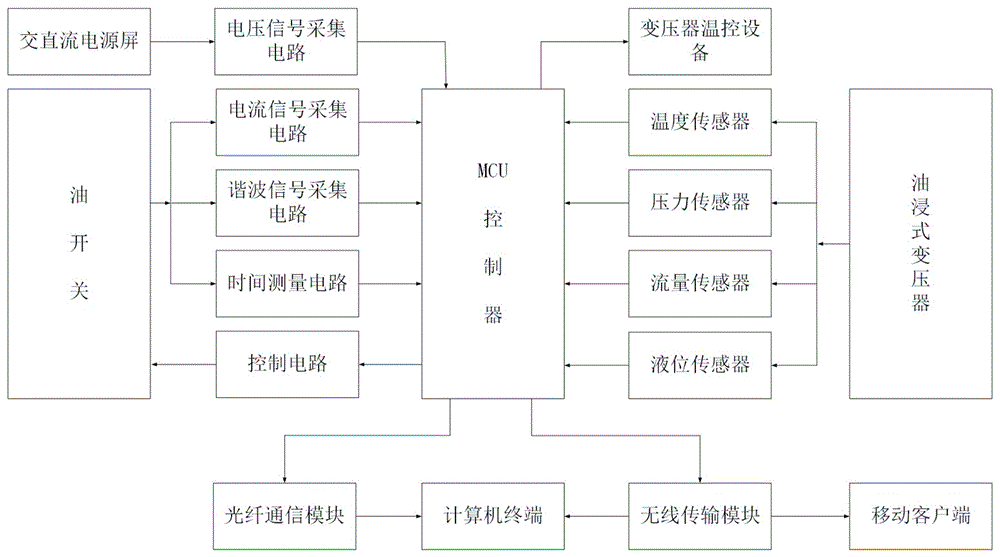

Online monitoring and early warning system of transformer substation oil-immersed transformer

InactiveCN106207969AGrasp the working status in timeReal-time online monitoringEmergency protective arrangements for automatic disconnectionEarly warning systemTransformer

The invention provides an online monitoring and early warning system of a transformer substation oil-immersed transformer. Parameter information of an oil-immersed transformer, an AC / DC power supply screen and an oil switch is monitored through a transformer monitoring device, a voltage signal collecting circuit and an oil switch monitoring device respectively, and communication control connection with a computer is carried out through an MCU controller, so that the integral running state of the oil-immersed transformer system is conveniently controlled in time. The online monitoring and early warning system of the transformer substation oil-immersed transformer has the advantages of being scientific in design, safe, efficient, simple, convenient, economical and practical.

Owner:HENAN KAIQI POWER IND

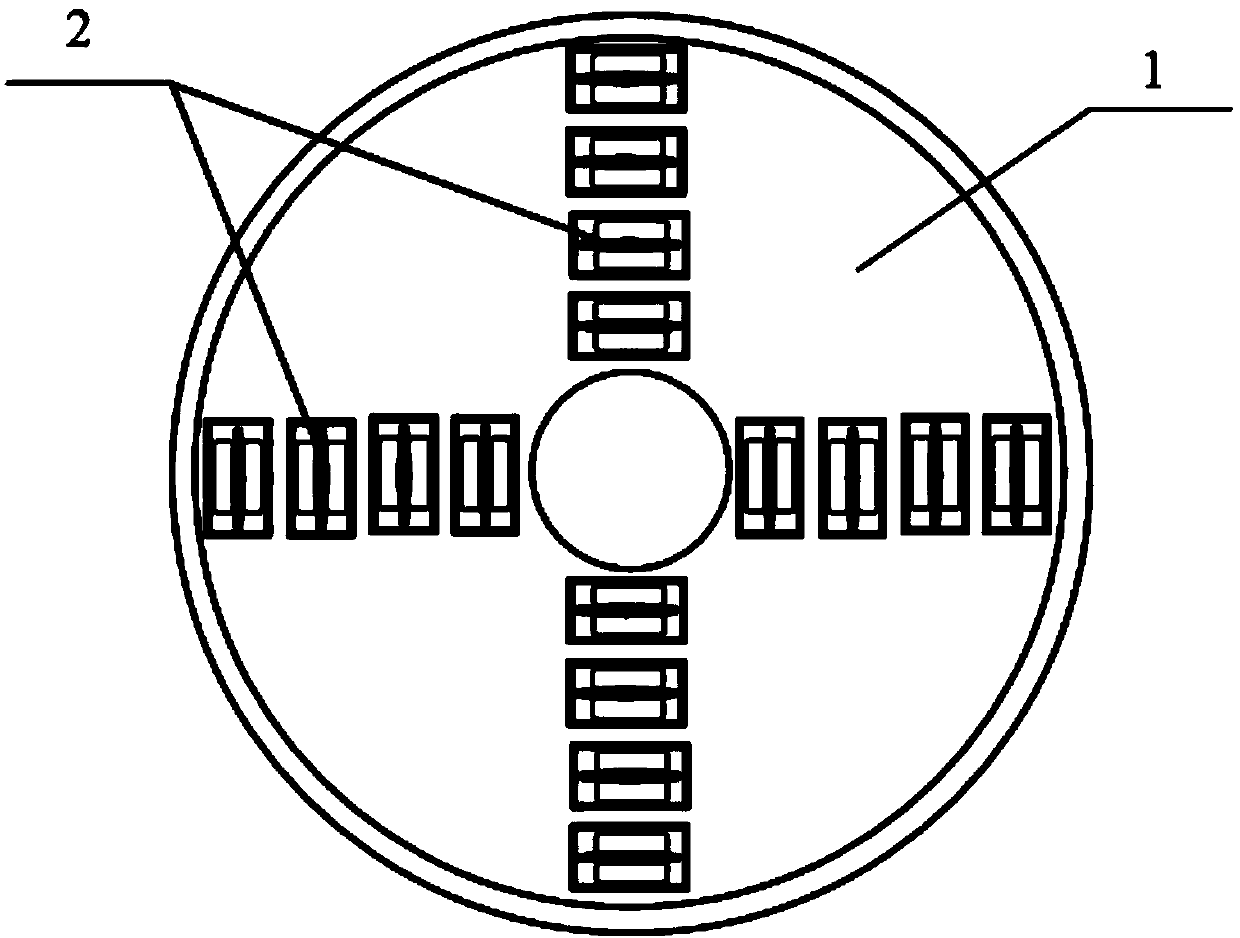

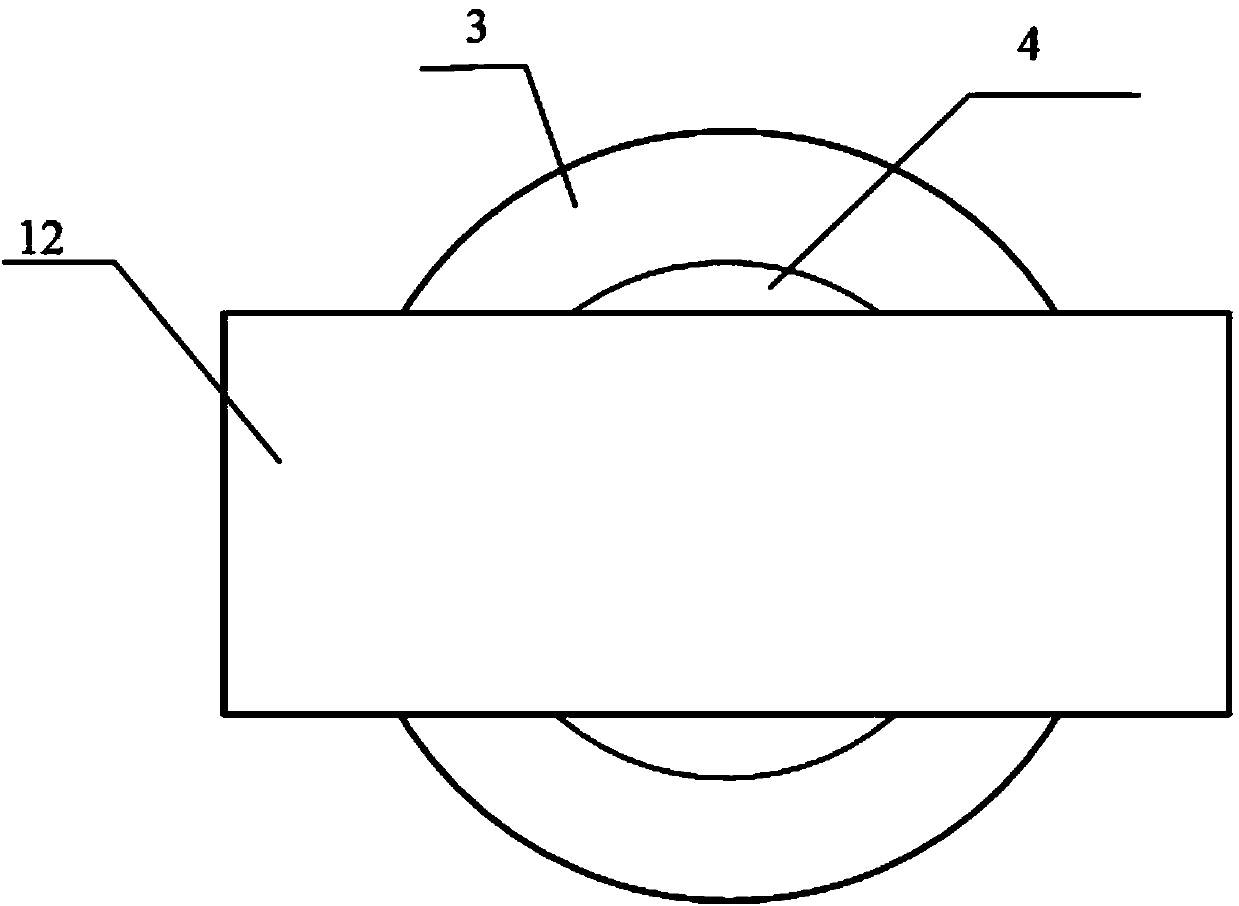

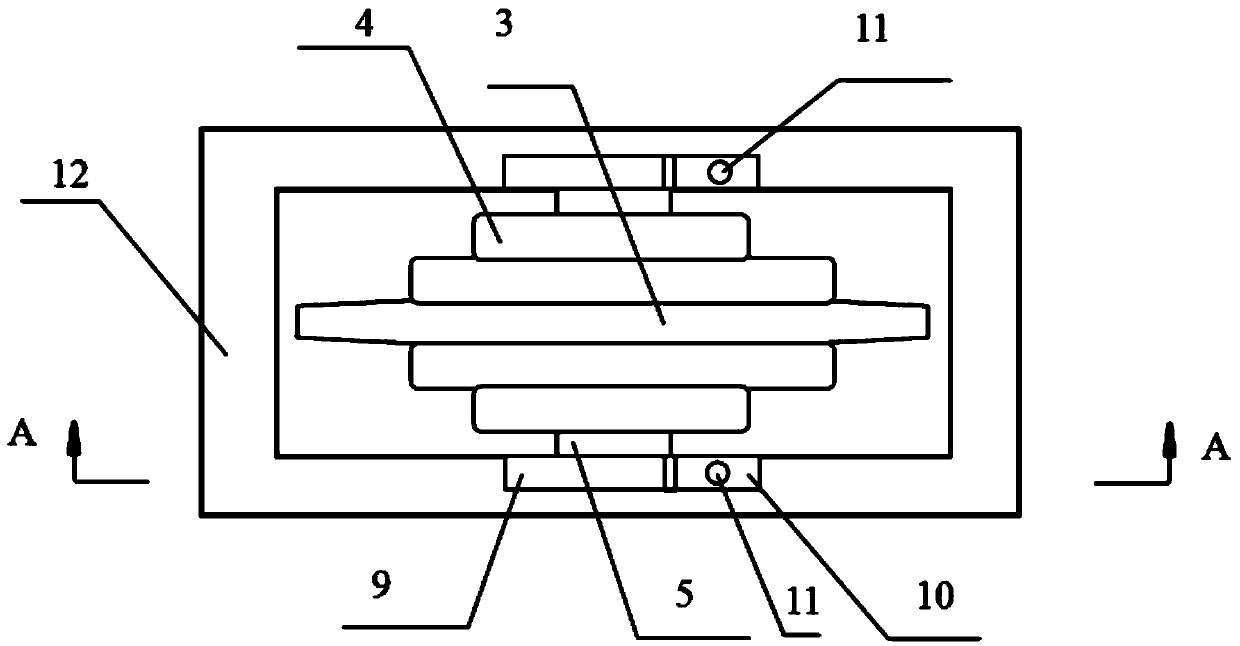

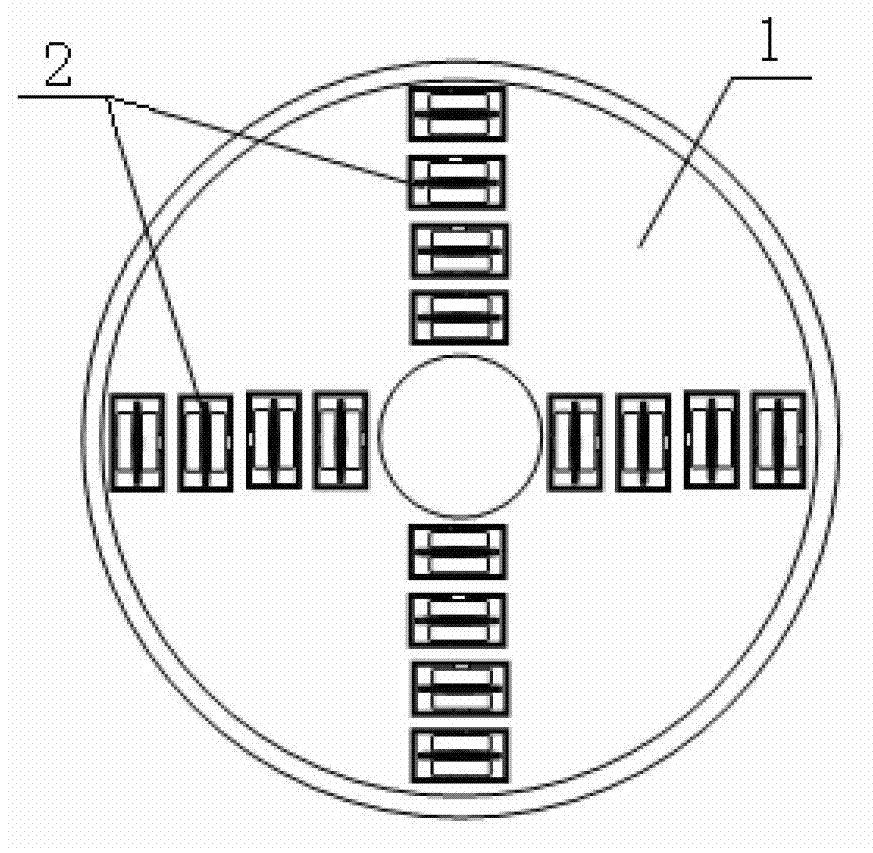

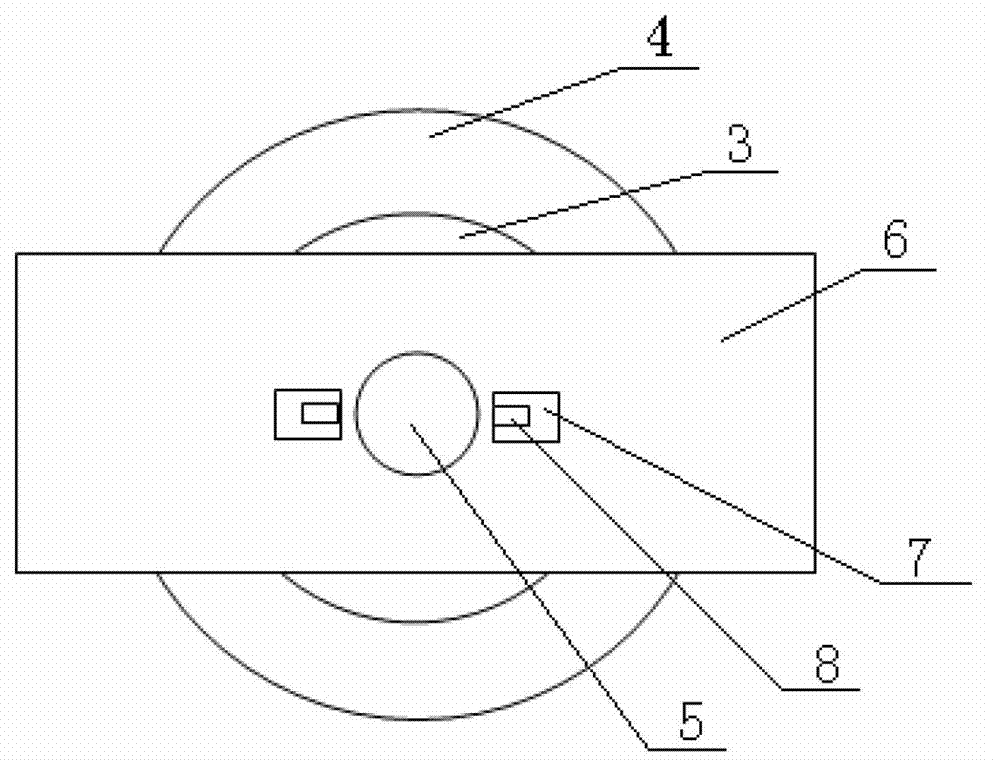

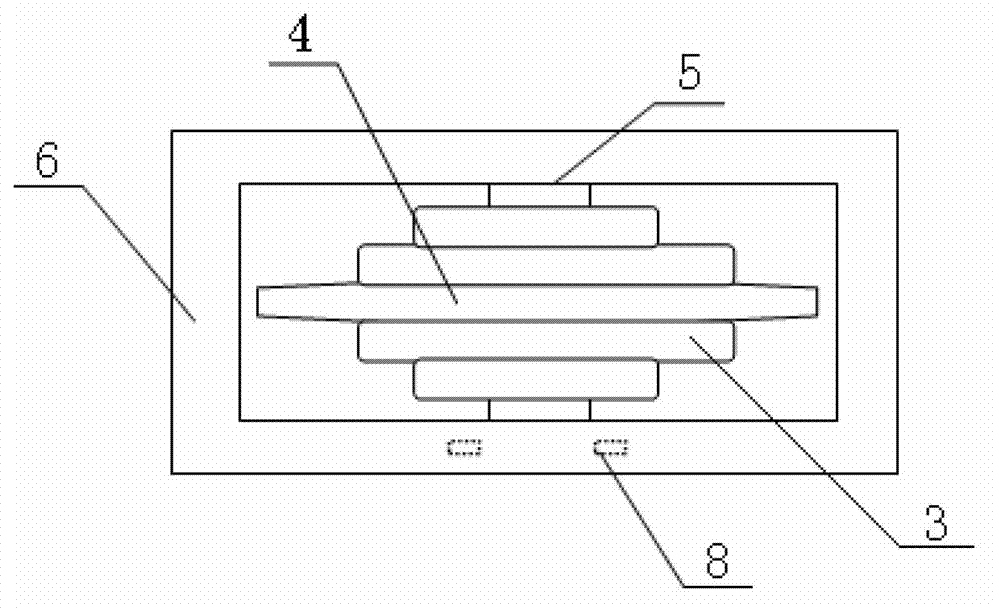

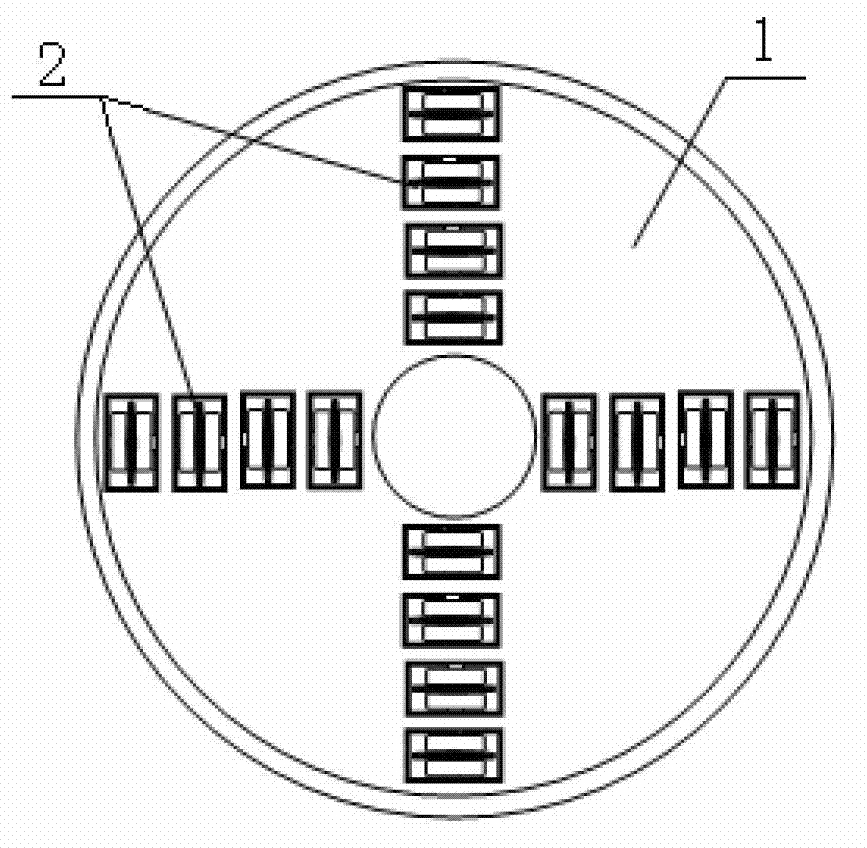

Online testing device for hob blade string abrasion of heading machine

ActiveCN103195437AGrasp the working status in timeGuaranteed drilling efficiencyAcceleration measurementTunnelsVibration amplitudeMachine

The invention discloses an online testing device for hob blade string abrasion of a heading machine. The online testing device is characterized in that a hob is sleeved on a hob center shaft through a bearing, and the center shaft is mounted on a frame hob holder which is assembled in a base of a hob plate. Acceleration sensors can sense the moving state of the hob to emit signals, so that rectangular holes are arranged on two sides of the center shaft outside the hob holder and on a horizontal axis of the hob center shaft. The acceleration sensors are disposed in the rectangular holes, the hole walls of the rectangular holes close to the direction of the hob center shaft is planes, and the planes serve as measuring surfaces of the acceleration sensors. If the hob blade string abrasion occurs, the vibration state of the hob can be changed, that is, the hob vibration amplitude and frequency can be changed obviously. The acceleration sensors can determine whether the hob blade enters a string abrasion state according to the detected vibration amplitude and frequency, the hob working state can be mastered timely, and the hob can be replaced timely in case of abrasion, accordingly, the heading efficiency can be guaranteed.

Owner:TIANJIN UNIV

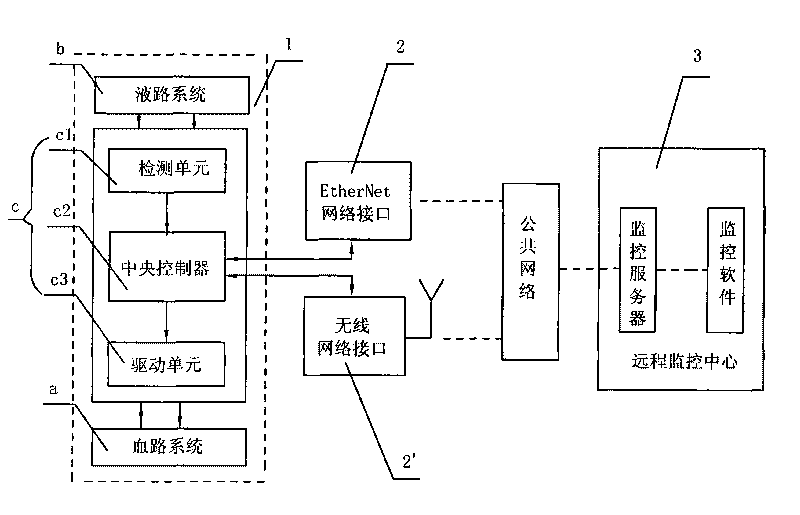

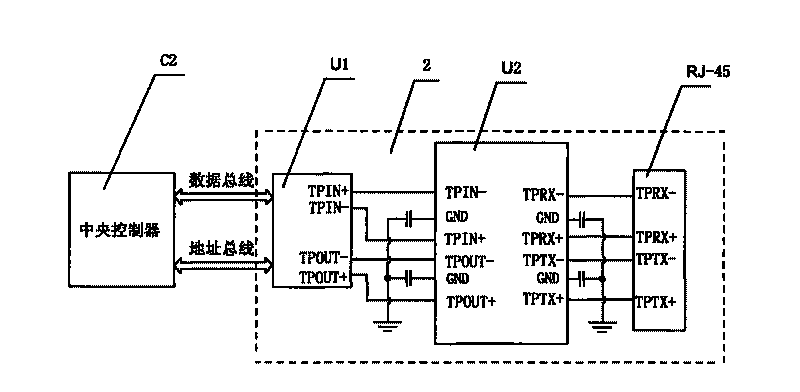

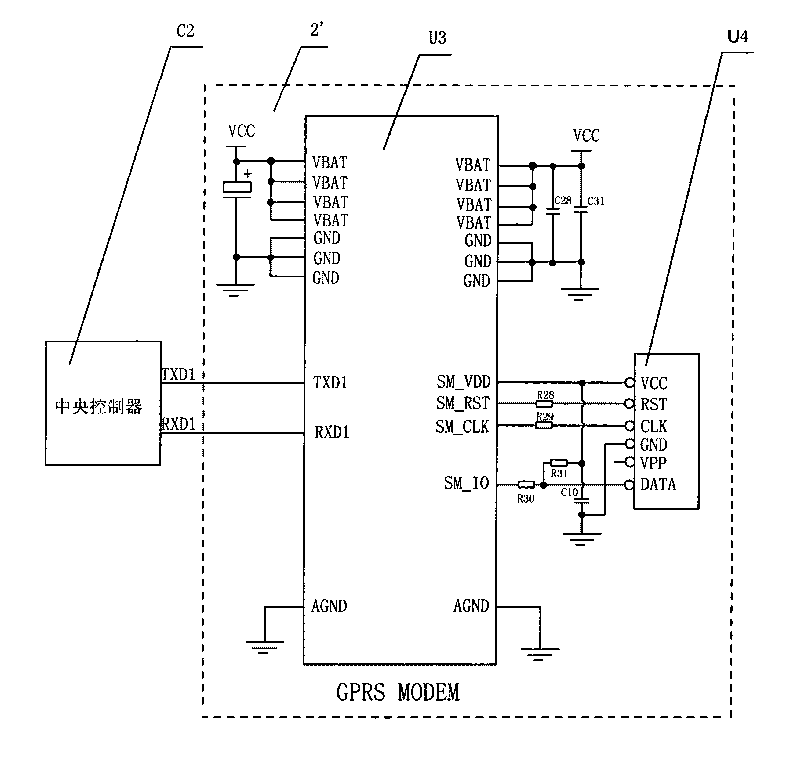

Blood purification system capable of being remotely monitored

InactiveCN101708348AConvenient remote online consultationReliable Maintenance and Repair GuaranteeDialysis systemsEngineeringNetwork interface

The invention discloses a blood purification system capable of being remotely monitored, comprising blood purification equipment which consists of a blood path system, a liquid path system and a monitoring system, wherein the monitoring system is provided with a detection unit, a central controller and a drive unit. The blood purification system is characterized in that the central controller is accessed to a common network by an Ethernet network interface and then connected with a remote monitoring center. The invention has remarkable advantages of not only retaining all function of the complete appliance of the traditional blood purification equipment, but also accessing the blood purification equipment in the common network; and a remote monitoring center is used for monitoring the blood purification system on line in real time, which not only can grasp the working state of the blood purification equipment in time and enable monitors of the equipment to provide reliable maintenance guarantee in time, but also can record the change conditions of various physiological parameters of patients in the treatment process so as to be convenient for medical technologists to carry out remote on-line consultation.

Owner:SWS HEMODIALYSIS CARE CO LTD

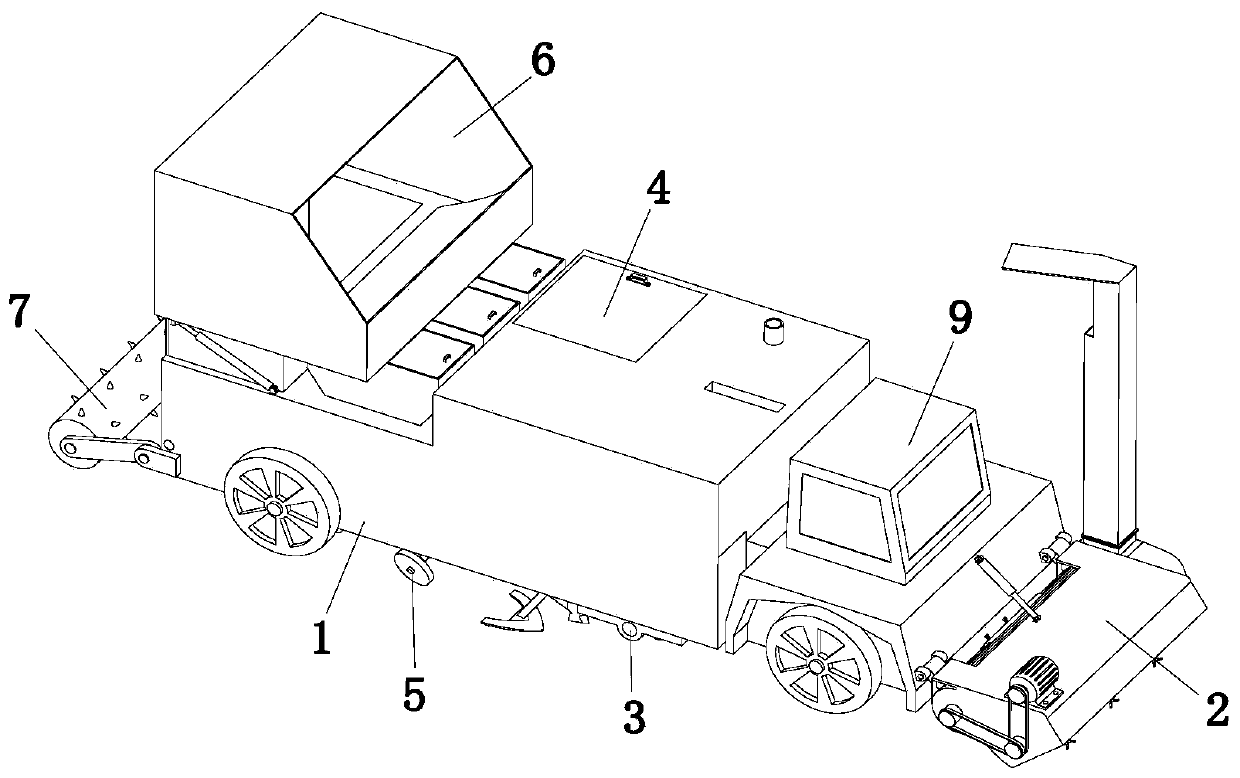

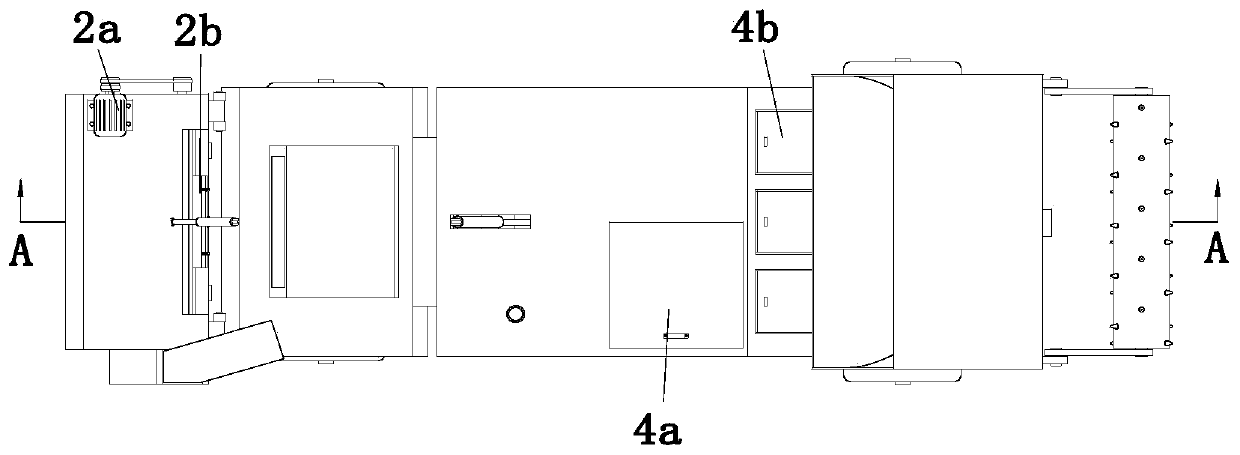

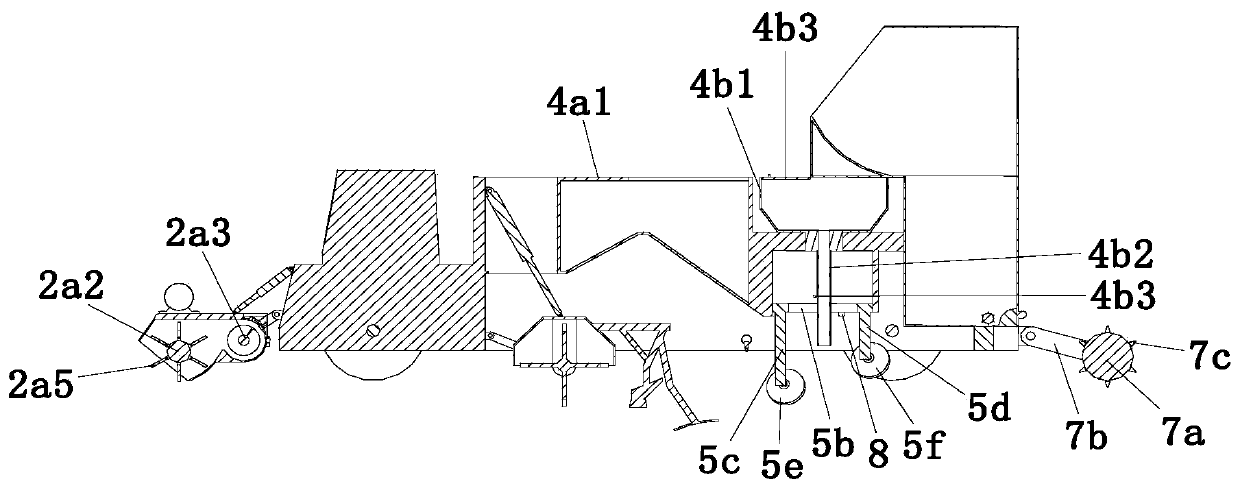

Intelligent local loosing and rotating and even straw covering corn planter

The invention discloses an intelligent local loosing and rotating and even straw covering corn planter, and belongs to the technical field of agricultural mechanical devices. The corn planter comprises a vehicle body, a straw collecting mechanism, a local loosening and rotating mechanism, a sowing and fertilizer applying mechanism, a soil covering mechanism, a straw scattering mechanism and a compacting mechanism. The straw collecting mechanism comprises a collecting and smashing assembly and a pressure detecting assembly. The pressure detecting assembly is installed on the collecting and smashing assembly. The sowing and fertilizer applying mechanism comprises a fertilizer applying assembly, a sowing assembly and a plurality of grating sensors. A plurality of cameras are arranged at the lower end of the soil covering mechanism. A hydraulic system is arranged on the vehicle body. A cab is arranged at the front end of the vehicle body. A controller and a displayer are arranged in the cab. The vehicle body can also be an existing tractor. The intelligence of the corn planter is improved, the straw collecting mechanism and the sowing and fertilizer applying mechanism can be automatically monitored, the working state of the corn planter can be monitored in time, the corn planter is prevented from being damaged, the straw return-to-field effect is better, and the growth of corn is facilitated.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

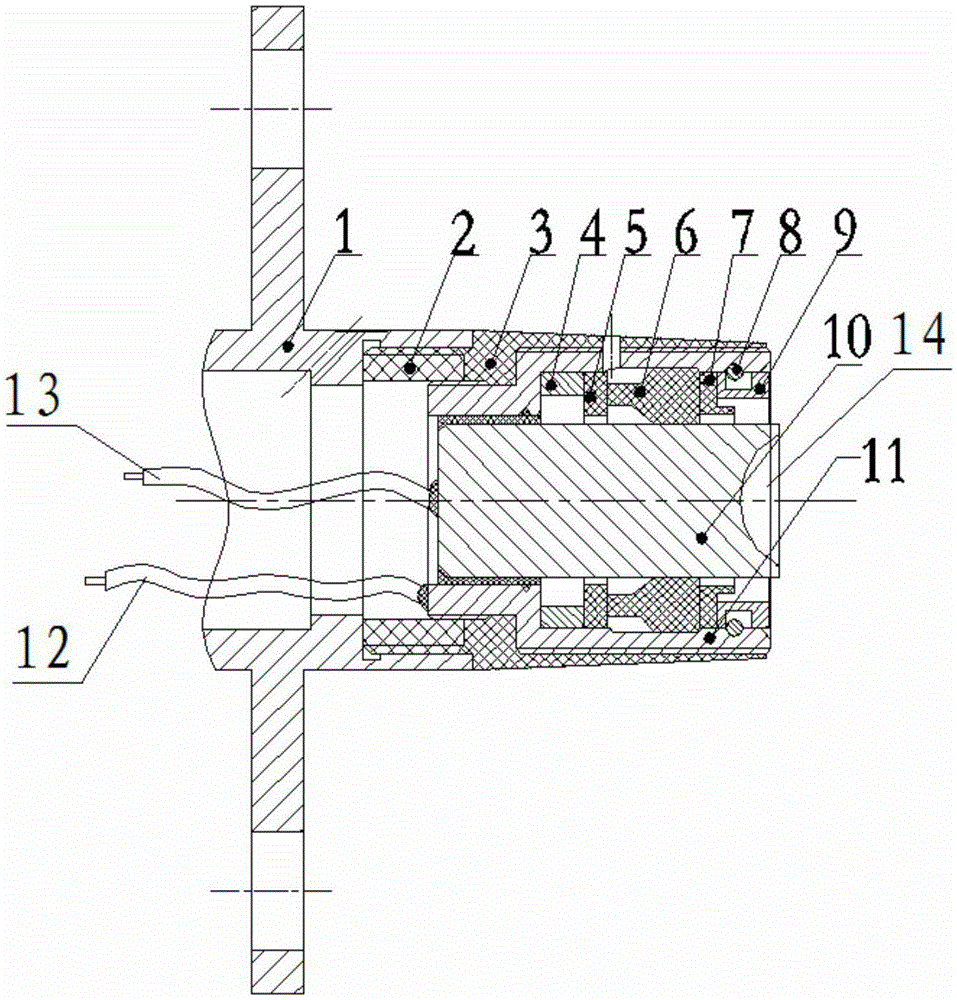

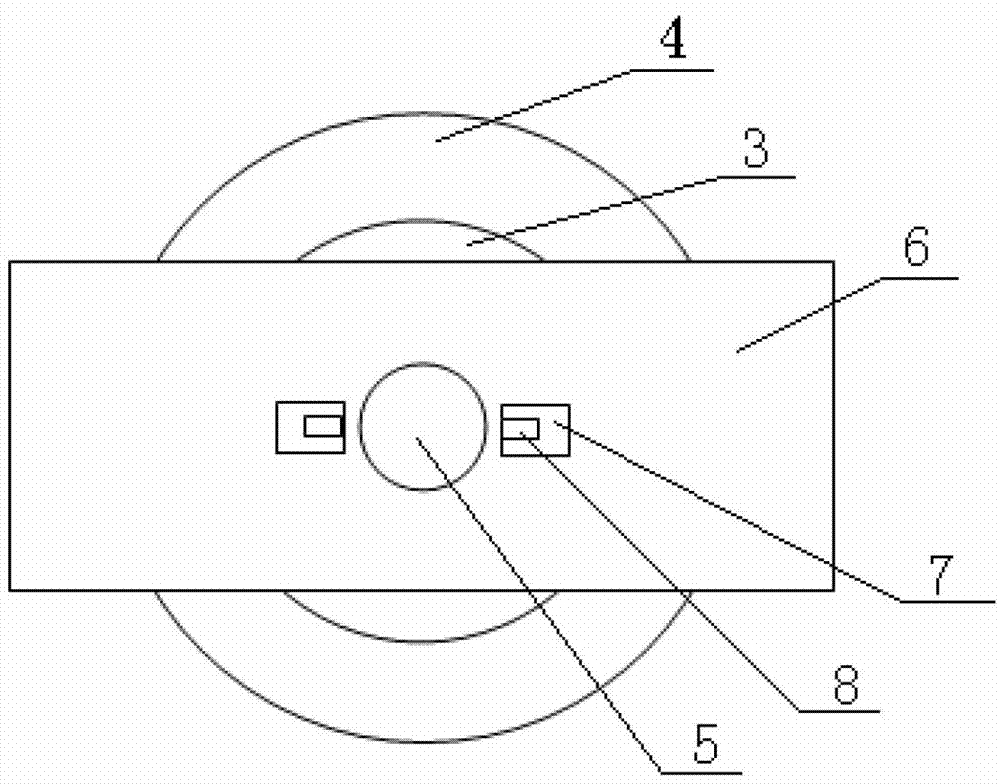

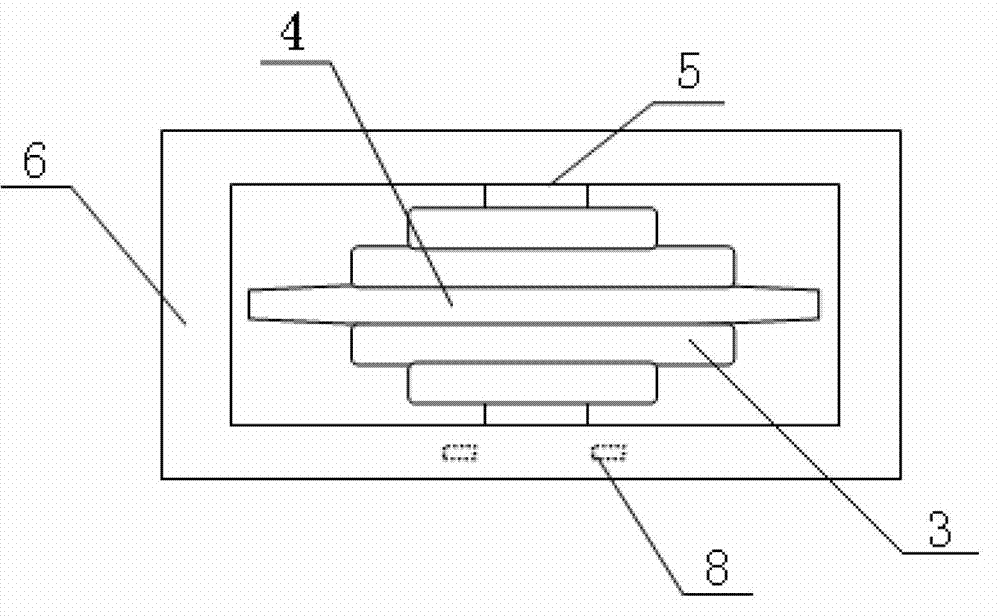

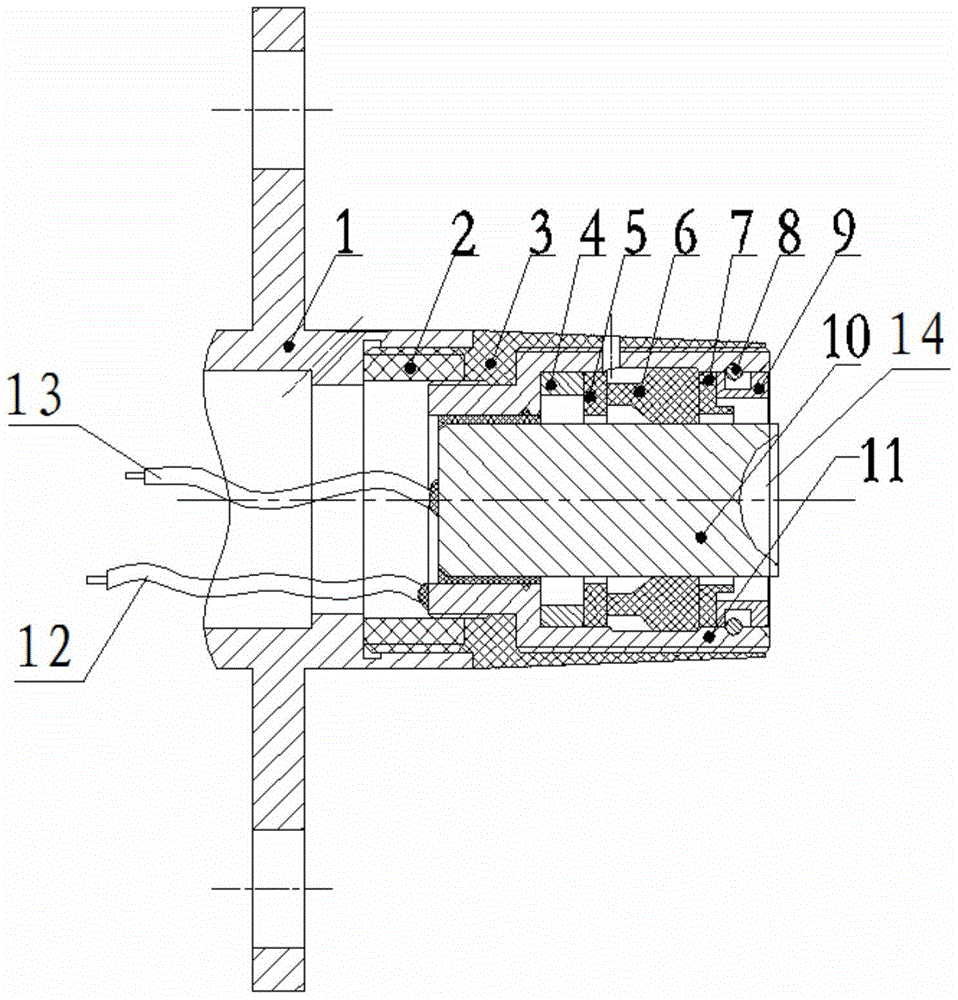

Monitoring structure and method for aircraft engine oil

ActiveCN105298647AGrasp the working status in timeIncrease thrust-to-weight ratioAircraft componentsTurbinesLap jointEngineering

The invention relates to the field of aircraft engines, in particular to a monitoring structure and method for aircraft engine oil. The monitoring structure comprises shells, insulating casing pipes, fusible pieces, gaskets, sealing rings, insulating linings, check rings, electrodes, a magnet and outer linings. A third pin of a cable plug is connected to the magnet, and a second pin of the cable plug is connected to the corresponding outer lining. The magnet is fixed in the outer linings. The outer linings and the insulating casing pipes which are connected with the outer linings are connected with the shells. The fusible pieces, the gaskets, the sealing rings, the insulating linings and the electrodes are installed in the outer linings and outside the magnet in sequence from inside to outside. The fusible pieces, the gaskets, the sealing rings, the insulating linings and the electrodes are fixed through the check rings in electrode clamping ring grooves. According to the monitoring structure and method for the aircraft engine oil, due to the fact that magnetic poles and the fusible pieces are arranged, the temperature of magnetic metal chips in oil liquid and the temperature of the oil liquid are monitored at the same time, and the monitoring structure can be in lap joint with an online detection system to be applied to monitoring of oil of key parts of engines of various types .

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

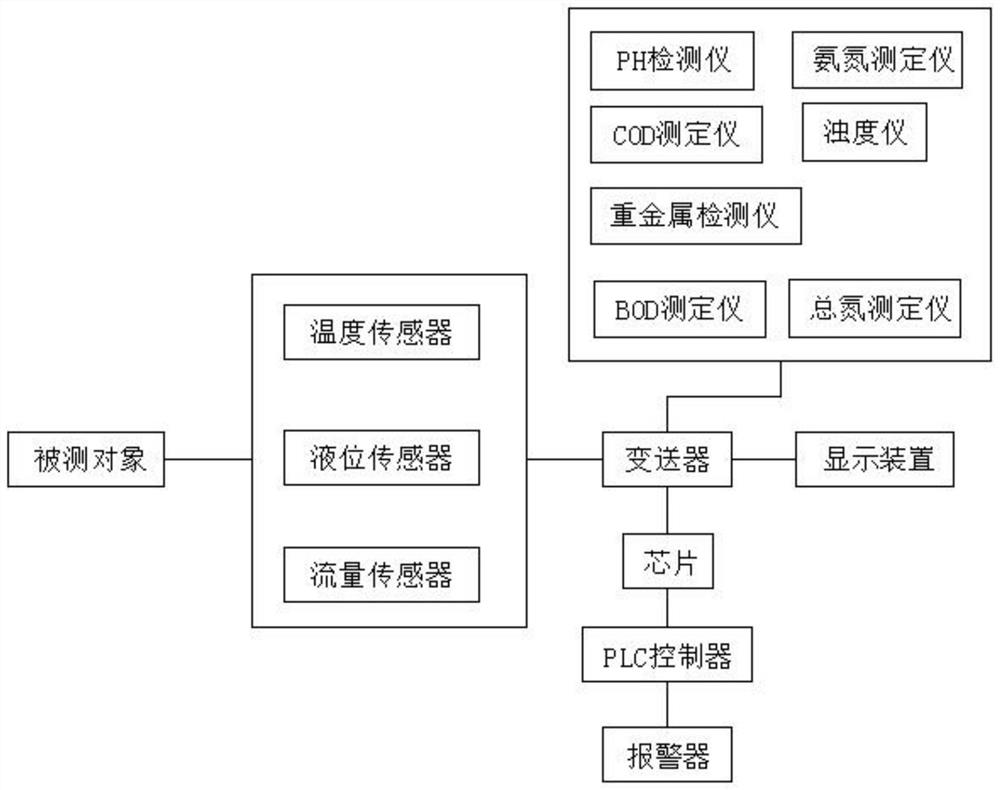

Monitoring system of coal bed gas screw pump well

InactiveCN102169337BGrasp the working status in timeAppropriate measuresTotal factory controlProgramme total factory controlWireless controlPower factor

The invention discloses a monitoring system of a coal bed gas screw pump well, comprising a solar control device, a sensor, a multi-parameter recorder, a current transformer, an electric parameter collector, a wireless controller, a liquid level automatic monitor, a central control computer, a portable data acquisition unit and monitoring diagnosis software, wherein the multi-parameter recorder can be used for measuring the voltage and current parameters of the screw pump well through the current transformer and the electric parameter collector and computing the other electric parameters suchas the active power, the power factor and the like; and the data monitoring diagnosis software is arranged in the central control computer and used for receiving test data are received, forming a database, carrying out comprehensive analysis and diagnosis on the test parameters in the database and automatically describing the change conditions of the parameters of the coal bed gas well according to the historic data parameters. The historic recording curves of all the parameter data are expressed in a form of K line graph so that the parameter change of each well in each day and any period oftime can be checked conveniently.

Owner:SHENYANG SENSOR TECH

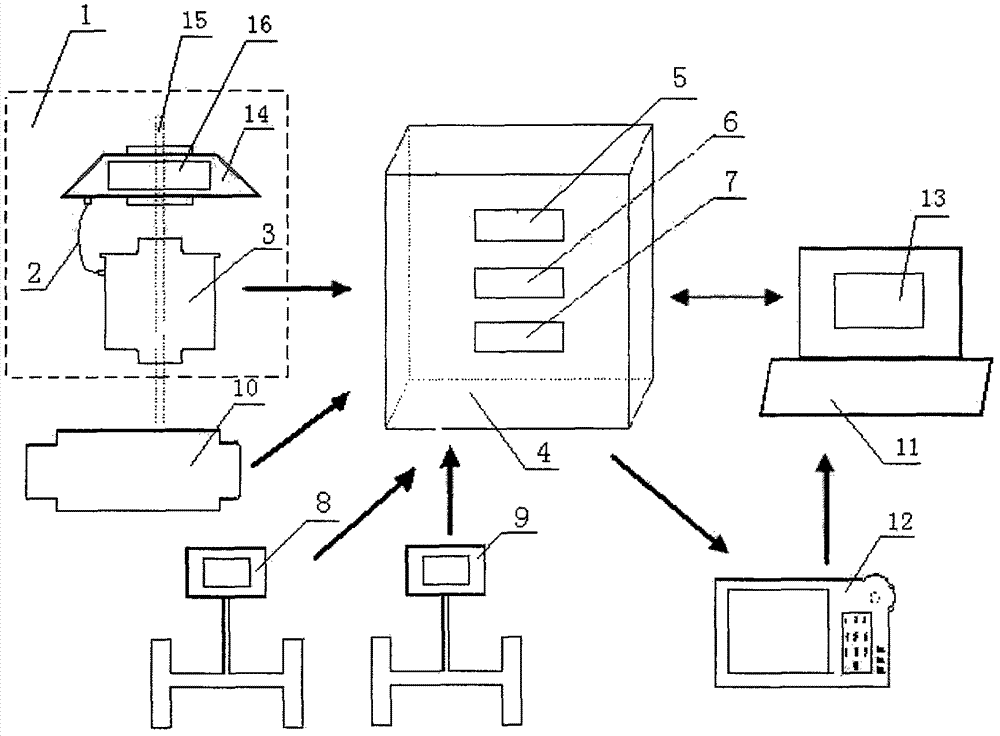

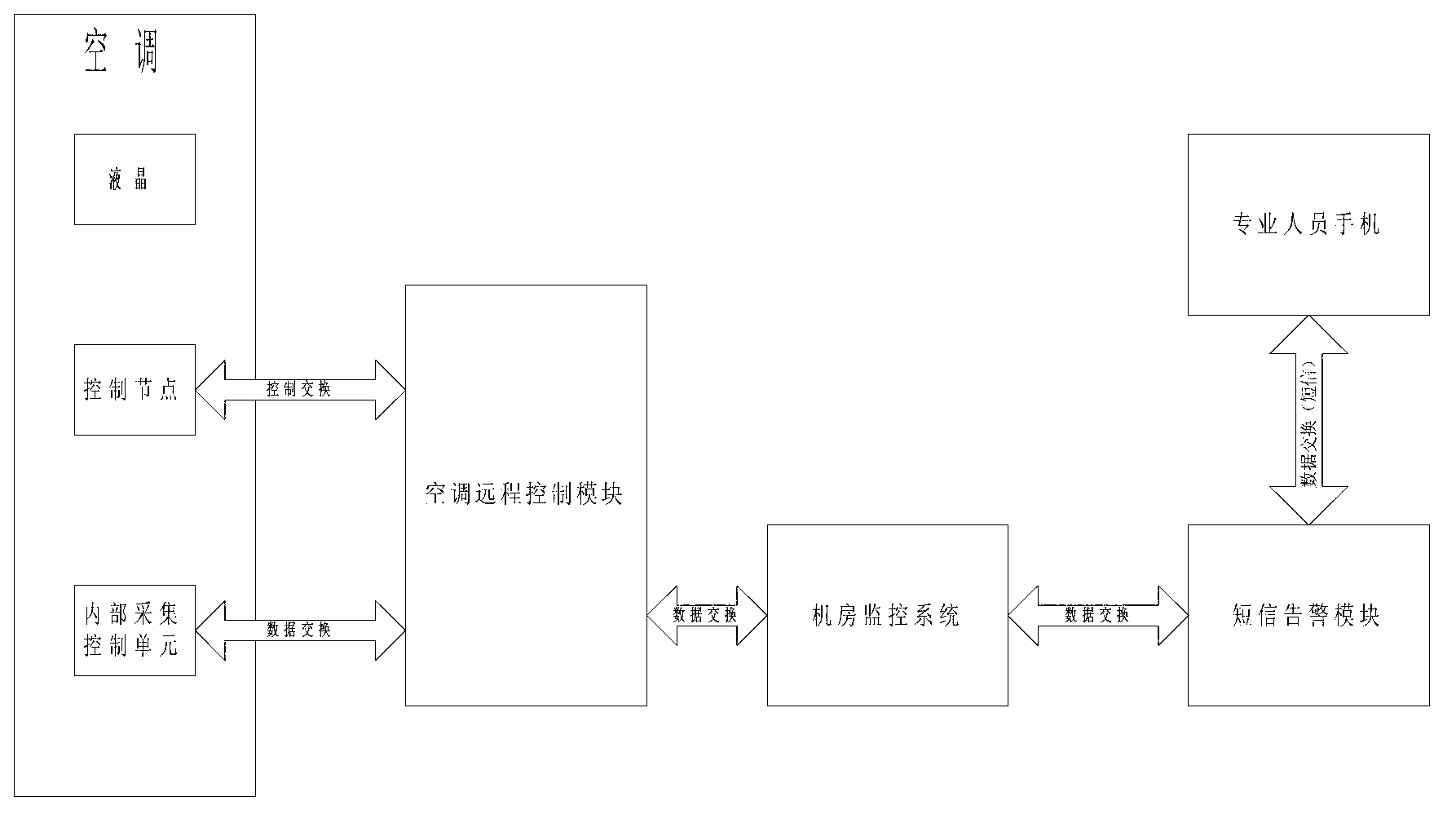

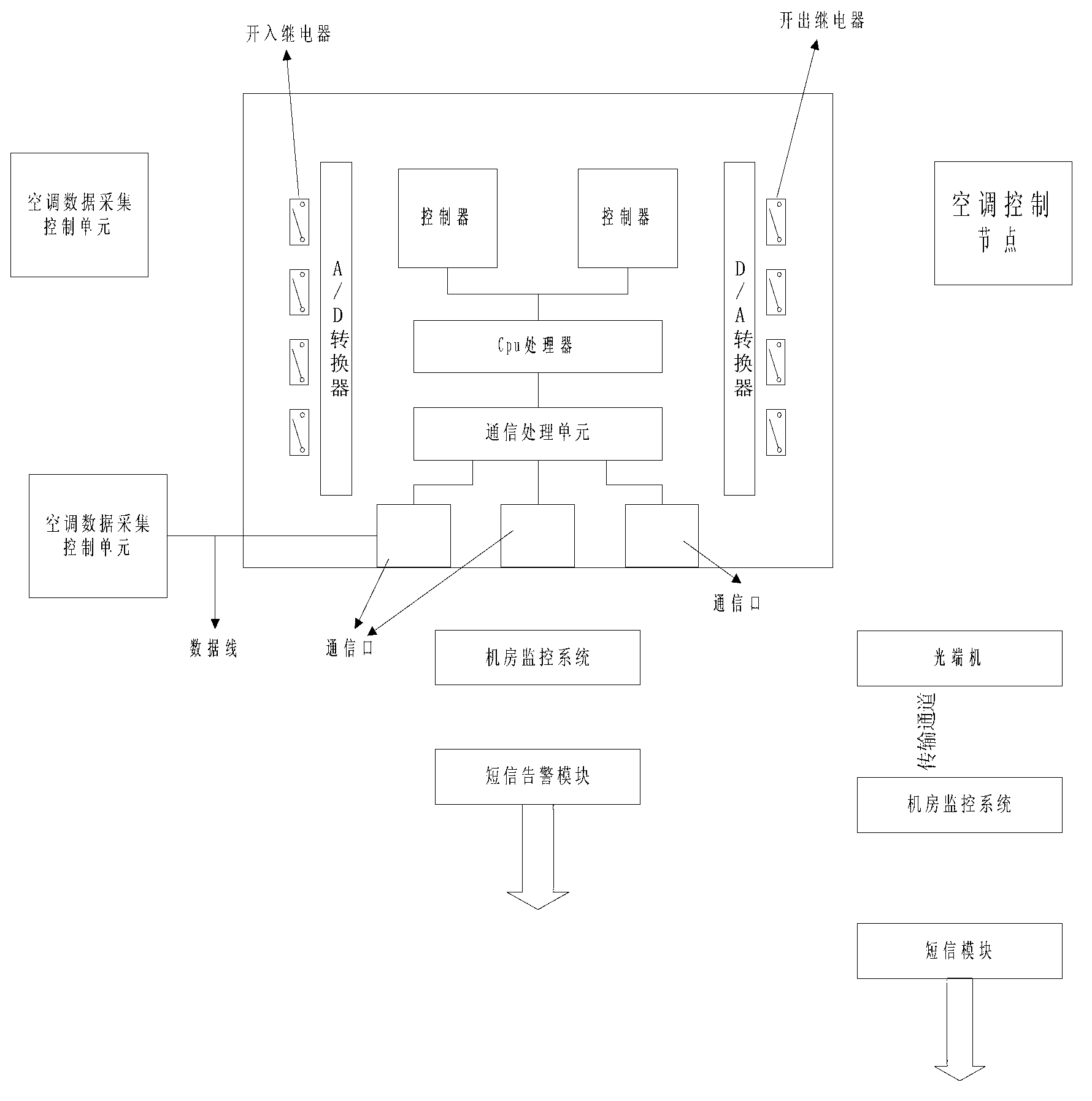

Precise air-conditioner remote control system based on Ethernet

ActiveCN103256690AReduce troubleshooting timeImprove work efficiencySpace heating and ventilation safety systemsLighting and heating apparatusLiquid-crystal displayControl system

The invention relates to a precise air-conditioner remote control system based on the Ethernet. The remote control system comprises an air-conditioner, an air-conditioner remote control module, a machine room monitoring system, a short message alarming module and a mobile phone. Control nodes and an internal collection control unit are installed in the air-conditioner, liquid crystal display is achieved, the control nodes and the internal collection control unit in the air-conditioner are connected with the air-conditioner remote control module connected with the a machine room system, and the machine room monitoring system is connected with the short message alarming module which is connected with the mobile phone of a professional in a short message communication mode. According to the system, work states of remote equipment can be mastered in time, measurement and control can be carried out on the remote equipment at any time, operation is easy and convenient, what is needed is to connect relative signal wires, the system is convenient to set and can be set through the mobile phone or computer software, and the system has functions of prewarning, remote control, remote measurement and the like and can effectively guarantee normal operation of the equipment.

Owner:STATE GRID CORP OF CHINA +1

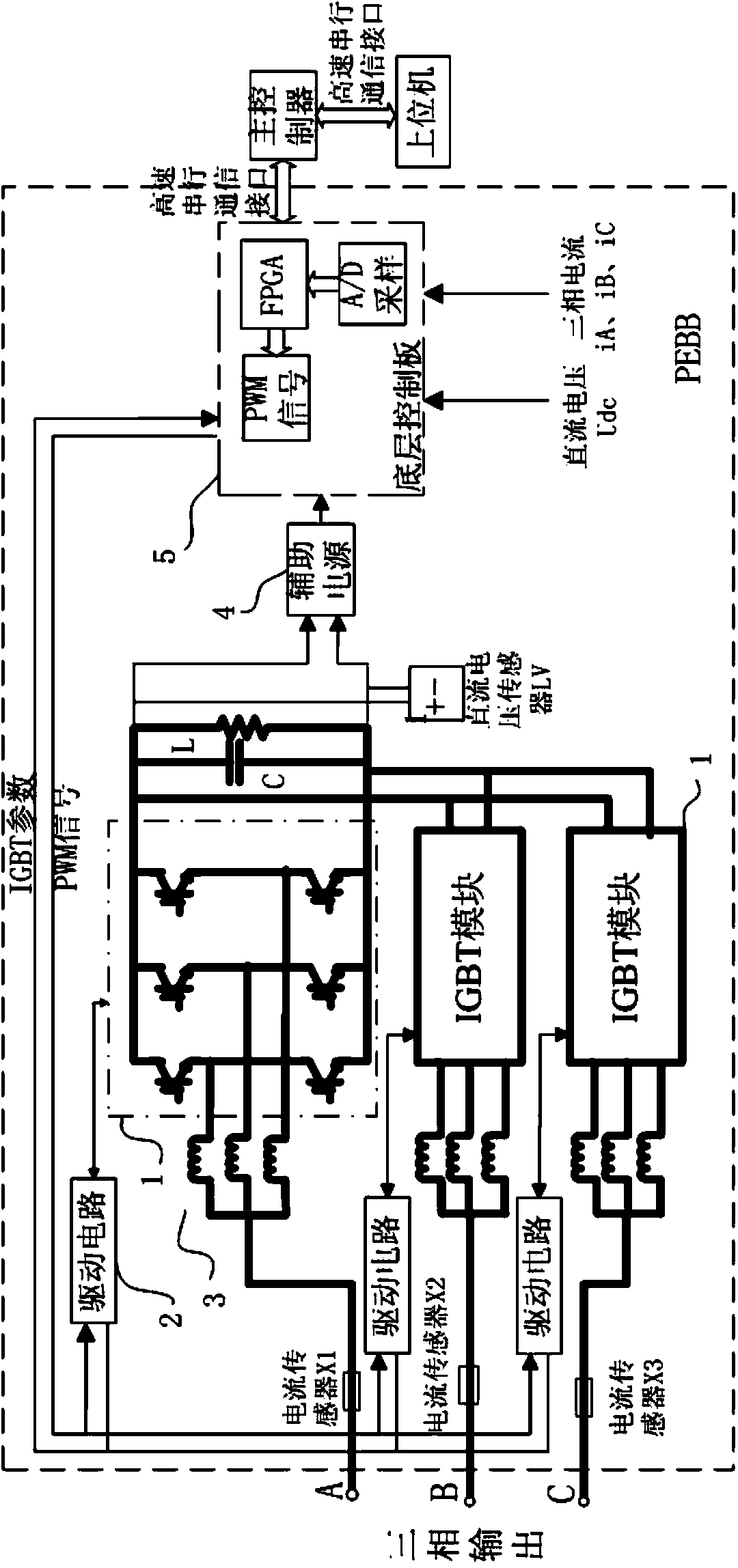

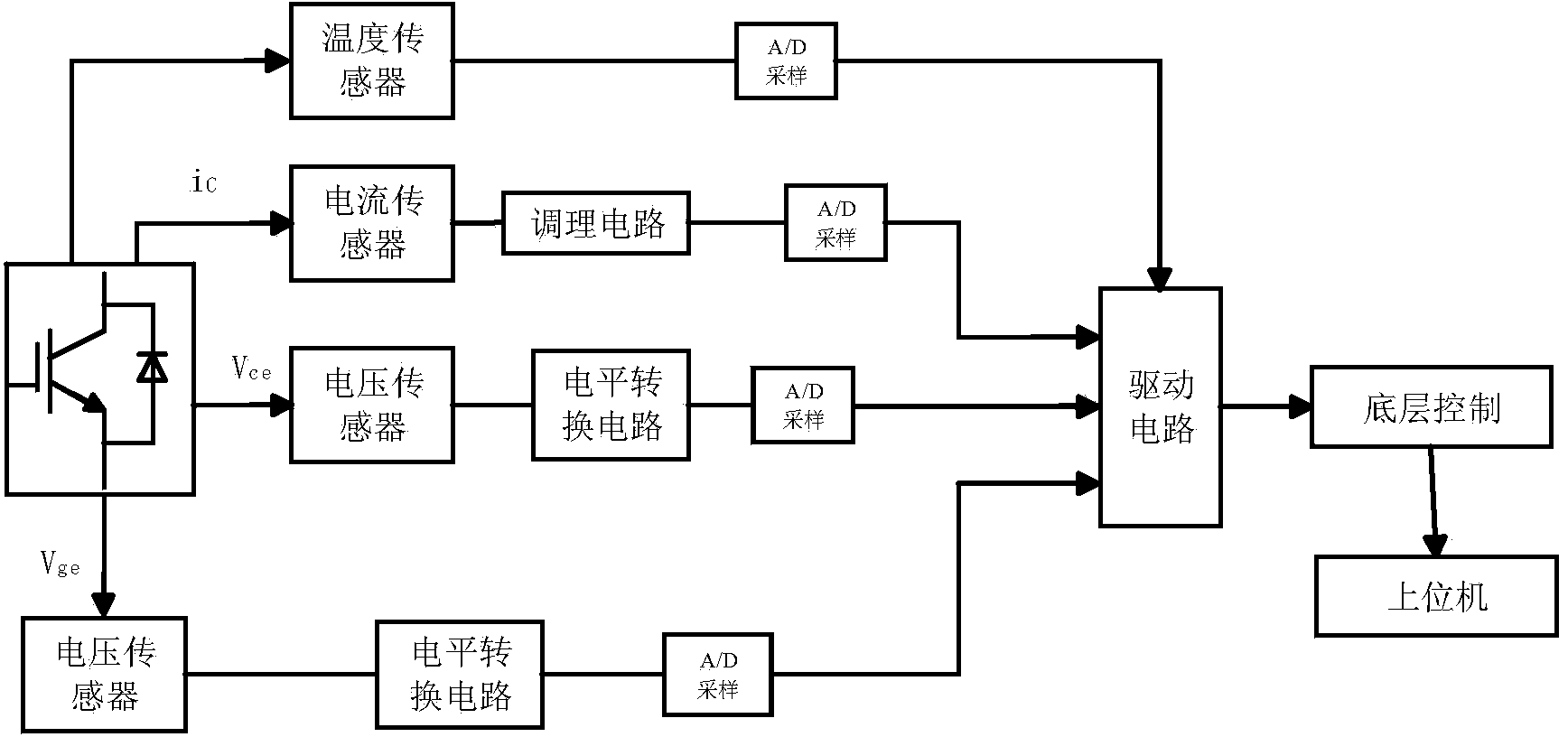

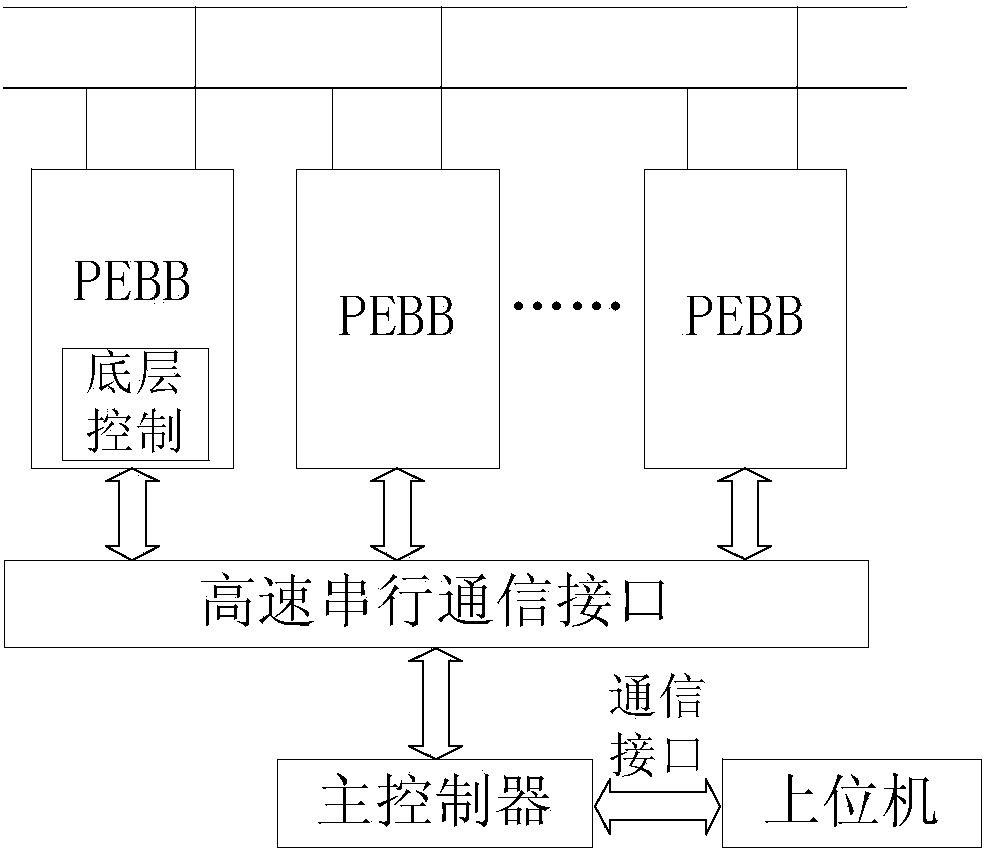

PEBB modular structure for wind power converter, parallel connection structure of PEBB modular structures and appearance structure of PEBB modular structure

InactiveCN103929047AIncrease power levelReduce volumeWind energy generationCooling/ventilation/heating modificationsEngineeringCurrent sharing

The invention discloses an intelligent PEBB modular structure for a wind power converter. The intelligent PEBB modular structure for the wind power converter comprises three IGBT modules, three drive circuits, three current-sharing inductor groups, three current sensors, a direct-current voltage sensor, a direct-current supporting capacitor, a direct-current side capacitor, an auxiliary power supply and a bottom layer control panel, wherein each current-sharing inductor group comprises three current-sharing inductors. According to the intelligent PEBB modular structure for the wind power converter, on the basis of modularization, the bottom layer intelligent control function is achieved, the power level of the converter is improved, the maintenance process is simplified, the on-line intelligent diagnosis function is also achieved by the wind power converter, and therefore workers can grasp the working condition of modules which are connected in parallel in time. The invention further discloses a mutual parallel connection structure of a plurality of intelligent PEBB modular structures, wherein the mutual parallel connection structure is suitable for double-fed converters with different power demands and full-power converters with different power demands. In addition, the invention discloses an appearance structure of the intelligent PEBB modular structure; in this way, the modular size is reduced, cost is reduced, and practicability is improved.

Owner:SHANGHAI ELECTRICGROUP CORP

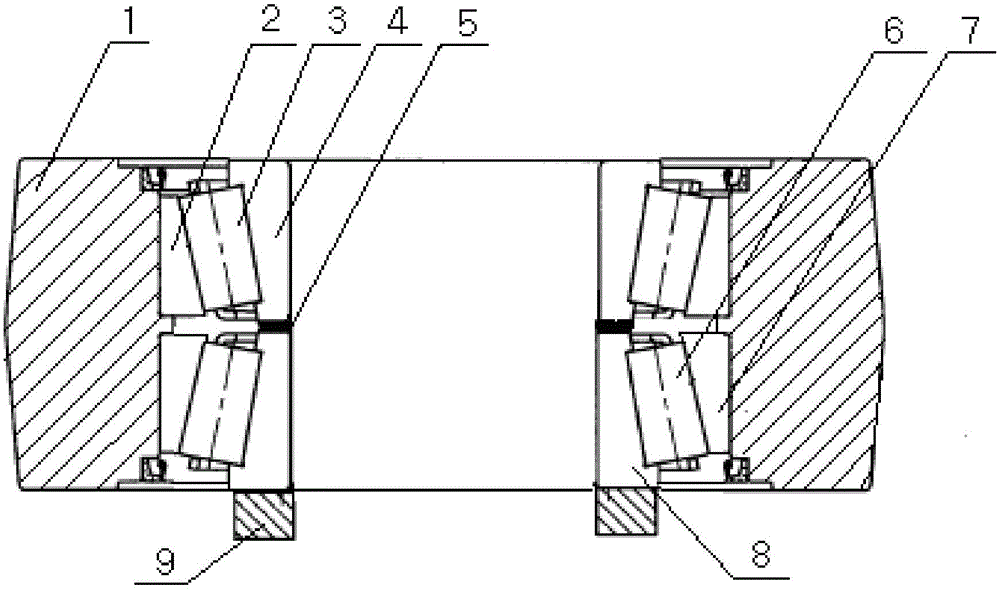

Universal mill double-row tapered roller bearing play adjusting method

ActiveCN104889168AImprove work rateGrasp the working status in timeRolling equipment maintainenceMetal rolling arrangementsAgricultural engineeringFeeler gauge

The invention provides a universal mill double-row tapered roller bearing play adjusting method. A heated vertical roller is lifted onto an outer ring of a lower-row bearing; then, an outer ring of an upper-row bearing is mounted on the vertical roller; after the temperature of the vertical roller is lowered, an oil seal is mounted in the vertical roller, an inner ring of the lower-row bearing and an inner ring of the upper-row bearing are mounted on the vertical roller in sequence, and the vertical roller uniformly rotates; an original radial gap value x of the bearings and an original gap value y between the inner ring of the lower-row bearing and the inner ring of the upper-row bearing are respectively measured by a feeler gauge, a thickness h of adjusting washers of the outer ring of the lower-row bearing and the outer ring of the upper-row bearing is calculated according to a formula, the inner ring of the lower-row bearing and the inner ring of the upper-row bearing are lifted out from the vertical roller, and after the machined washers are mounted, the inner ring of the upper-row bearing is mounted in the vertical roller again. The method can effectively prolong the service life of the bearings, reduces the machine stop accidents, decreases the spare part consumption and the production cost, relieves the labor intensity of workers, and greatly improves the mill operability while improving the labor productivity.

Owner:ANGANG STEEL CO LTD

Online testing device for hob blade string abrasion of heading machine

ActiveCN103195437BGrasp the working status in timeGuaranteed drilling efficiencyAcceleration measurementTunnelsVibration amplitudeHorizontal axis

The invention discloses an online testing device for hob blade string abrasion of a heading machine. The online testing device is characterized in that a hob is sleeved on a hob center shaft through a bearing, and the center shaft is mounted on a frame hob holder which is assembled in a base of a hob plate. Acceleration sensors can sense the moving state of the hob to emit signals, so that rectangular holes are arranged on two sides of the center shaft outside the hob holder and on a horizontal axis of the hob center shaft. The acceleration sensors are disposed in the rectangular holes, the hole walls of the rectangular holes close to the direction of the hob center shaft is planes, and the planes serve as measuring surfaces of the acceleration sensors. If the hob blade string abrasion occurs, the vibration state of the hob can be changed, that is, the hob vibration amplitude and frequency can be changed obviously. The acceleration sensors can determine whether the hob blade enters a string abrasion state according to the detected vibration amplitude and frequency, the hob working state can be mastered timely, and the hob can be replaced timely in case of abrasion, accordingly, the heading efficiency can be guaranteed.

Owner:TIANJIN UNIV

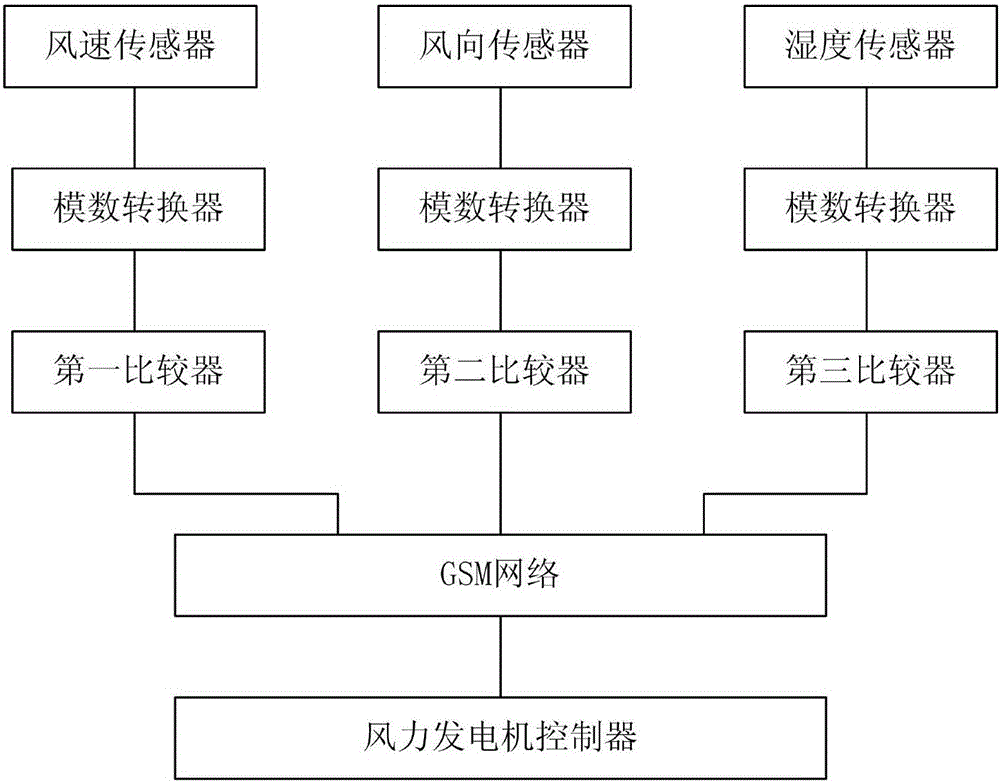

Monitoring device for wind driven generator

PendingCN106523276AGrasp the working status in timeIntelligent control of working statusWind motor controlMachines/enginesElectricityWind driven

The invention discloses a monitoring device for a wind driven generator. The monitoring device comprises a wind driven generator controller, a wind speed sensor, a wind direction sensor, a humidity sensor, and a GSM network, wherein the wind speed sensor is electrically connected with one input terminal of a first comparator through an analog-digital converter; the other input terminal of the first comparator is a wind speed threshold input terminal; the wind direction sensor is electrically connected with one one input terminal of a second comparator through an analog-digital converter; the other input terminal of the second comparator is a wind direction threshold input terminal; the humidity sensor is electrically connected with one input terminal of a third comparator through an analog-digital converter; the other input terminal of the third comparator is a humidity threshold input terminal; an output terminal of the first comparator, an output terminal of the second comparator and an output terminal of the third comparator are all electrically connected with a signal input terminal of the GSM network; and a signal communication terminal of the GSM network is electrically connected with a signal input terminal of the wind driven generator controller.

Owner:TIANJIN JIEJIN METAL PROD

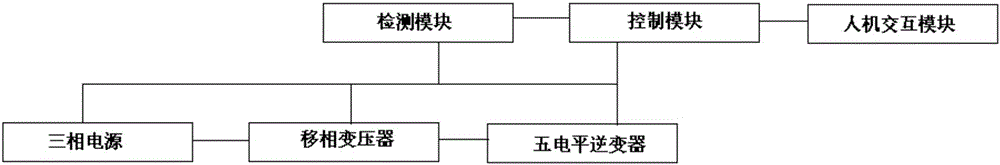

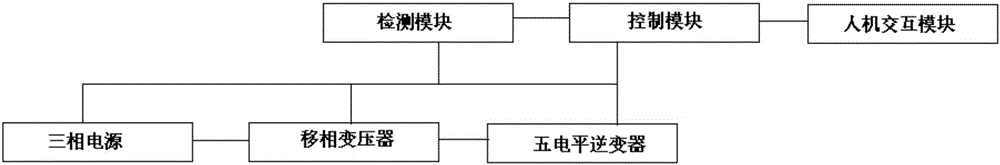

Rectifier three-phase power supply-based variable-frequency governor

InactiveCN105743413AGrasp the working status in timeGuaranteed uptimeAC motor controlFrequency changerPhase shifted

The invention discloses a rectifier three-phase power supply-based variable-frequency governor, which comprises a detection module, a control module, a human-computer interaction module, a three-phase power supply, a phase-shifting transformer and a five-level inverter, wherein the three-phase power supply, the phase-shifting transformer and the five-level inverter are sequentially connected with one another; output ends of the three-phase power supply, the phase-shifting transformer and the five-level inverter are connected with an input end of the detection module; the output end of the detection module is connected with the input end of the control module; the output end of the control module is connected with the input ends of the human-computer interaction module and the five-level inverter; the rectifier three-phase power supply-based variable-frequency governor can carry out real-time monitoring on parameters of a voltage, a frequency, a fault and the like of a motor in a frequency converter, timely grasp the working state of the frequency converter and can timely take corresponding measures to ensure normal operation of the frequency converter according to the parameter change condition.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

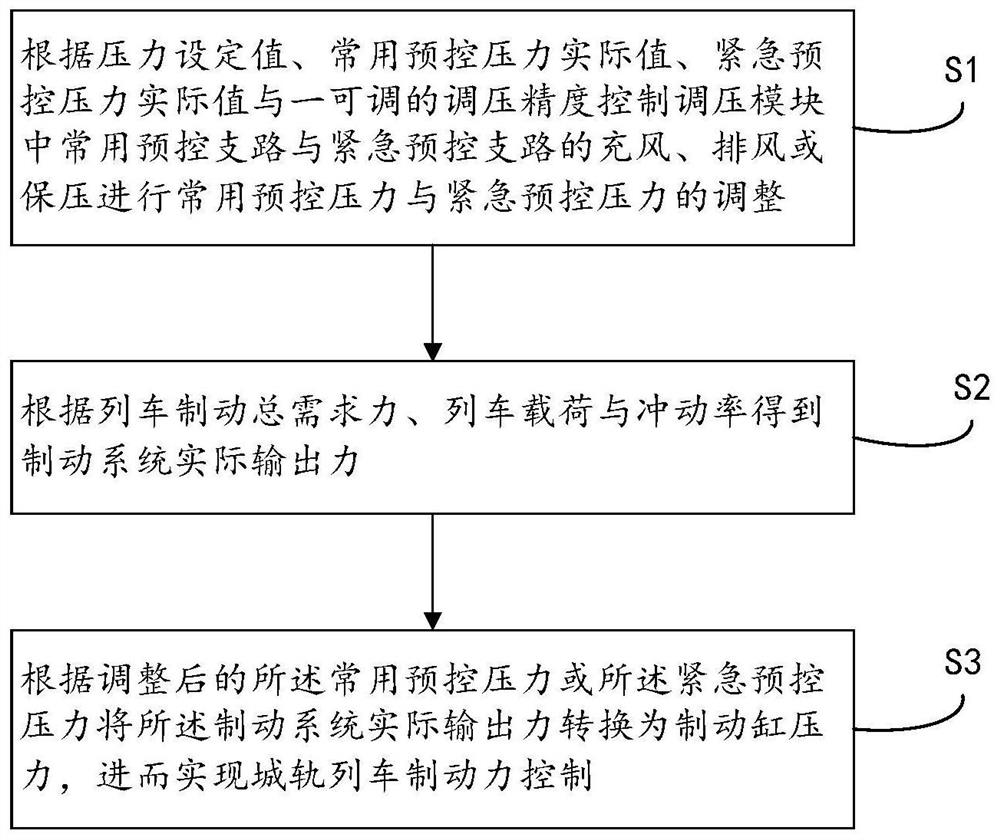

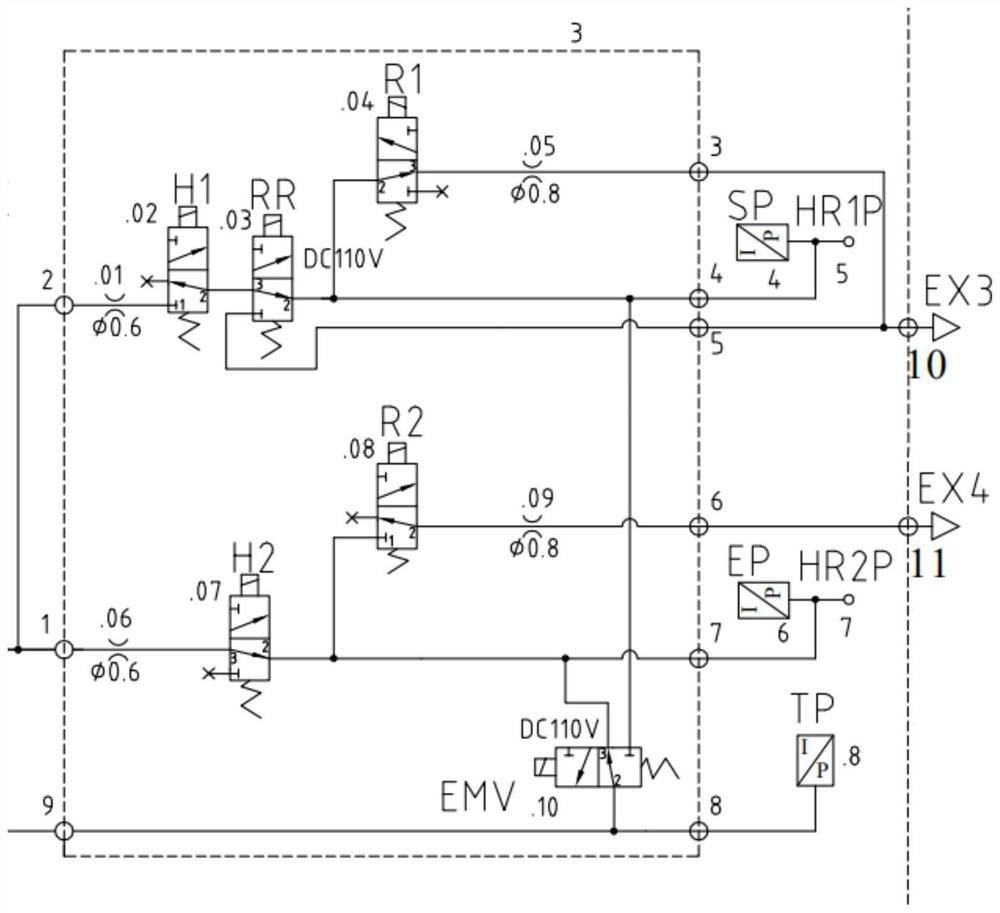

Braking force control method and device

ActiveCN113335243AGrasp the working status in timeReal-time fault diagnosisBrake safety systemsControl theoryMechanical engineering

The invention discloses a braking force control method and device. The method comprises the following steps: adjusting common pre-control pressure and emergency pre-control pressure according to a pressure set value, a common pre-control pressure actual value, an emergency pre-control pressure actual value and air charging, air exhausting or pressure maintaining of a common pre-control branch and an emergency pre-control branch in an adjustable pressure adjusting precision control pressure adjusting module; obtaining the actual output force of the braking system according to the train braking total demand force, the train load and the impulse rate; and converting the actual output force of the braking system into brake cylinder pressure according to the adjusted common pre-control pressure or emergency pre-control pressure, and then realizing urban rail train braking force control. According to the method, the impulse applied by the braking force can be adjusted through cooperation of the software program and the pressure adjusting module, and the comfort of passengers taking the urban rail train is guaranteed.

Owner:QINGDAO SRI TECH CO LTD

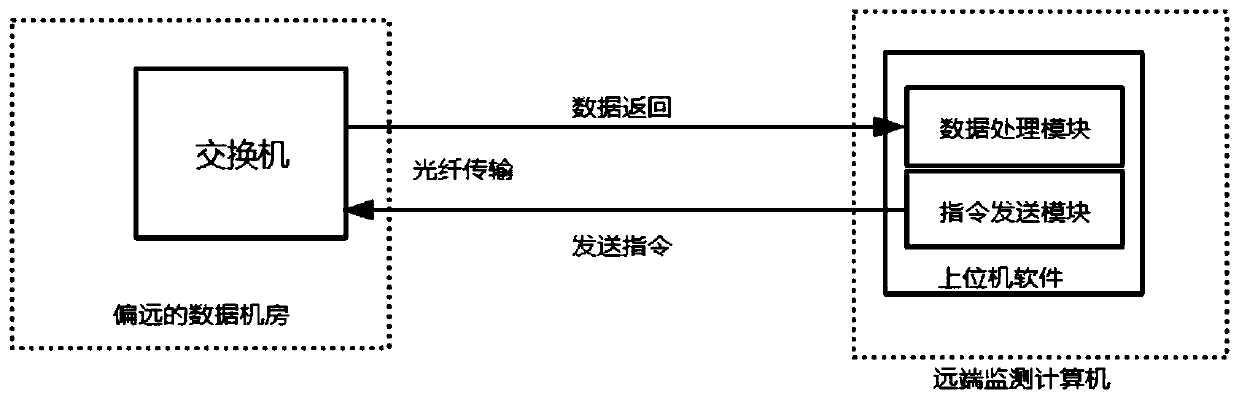

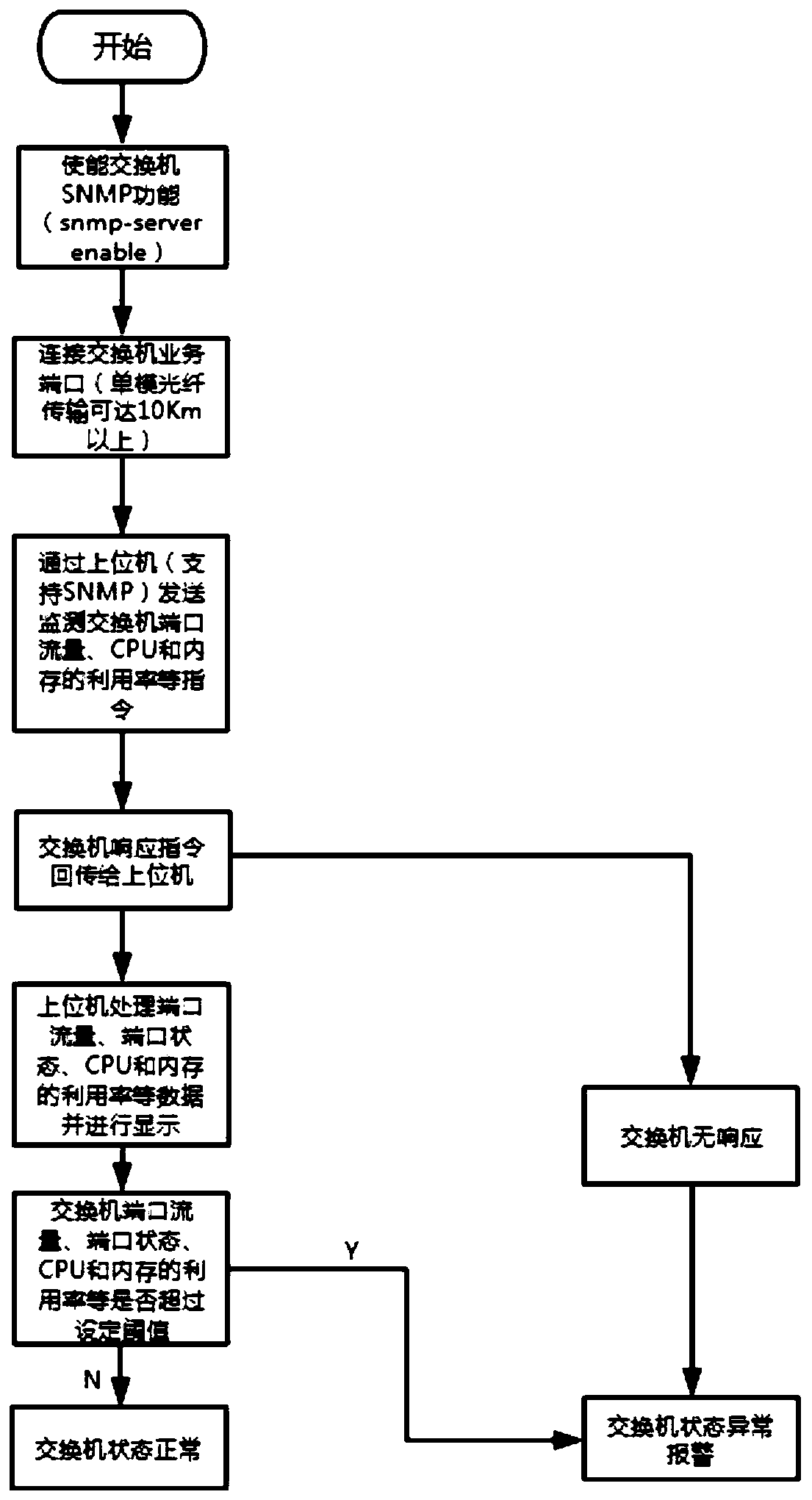

System for remotely monitoring switch state information in real time and implementation method

PendingCN111327470AReduce labor costsReduce riskData switching networksEmbedded systemNetwork management

The invention discloses a system for remotely monitoring state information of a switch in real time and an implementation method. Belonging to the technical field of network switching, the technical problem to be solved by the invention is how to realize remote real-time monitoring of information such as the port state and the port flow of a switch in a machine room. Timely discovery of switch state anomalies, the real-time performance and convenience of switch management are improved; reducing manpower cost, the adopted technical scheme is as follows: the method comprises the following steps:preparing raw materials; the system comprises a far-end data machine room and a far-end monitoring computer, a switch is arranged in the far-end data machine room, the switch is connected with the far-end monitoring computer, an upper computer software unit is arranged in the far-end monitoring computer, and the upper computer software unit is in data communication with the switch through an SNMPnetwork management protocol; and the upper computer software unit polls and sends an instruction to the switch and processes, analyzes and graphs the response data of the switch so as to obtain the state information of the switch in real time.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

A structure and method for monitoring lubricating oil of an aero-engine

ActiveCN105298647BGrasp the working status in timeIncrease thrust-to-weight ratioAircraft componentsTurbinesAviationLap joint

The invention relates to the field of aero-engines, in particular to an aero-engine lubricating oil monitoring structure and method. The structure includes a housing, an insulating sleeve, a fusible sheet, a gasket, a sealing ring, an insulating bush, a stop ring, an electrode, a magnet, and an outer bushing. Pin 3 of the cable plug is connected to the magnet, and the cable plug The No. 2 pin in the outer bushing is connected to the outer bushing, the magnet is fixed in the outer bushing, the outer bushing and insulating sleeve connected to each other are connected to the shell, and the fusible sheet is installed inside the outer bushing and outside the magnet in sequence from inside to outside , Gasket, sealing ring, insulating bushing and electrode, fusible sheet, gasket, sealing ring, insulating bushing and electrode are fixed by the stop ring in the electrode collar groove. The invention realizes the simultaneous monitoring of the magnetic metal shavings in the oil and the temperature of the oil by setting the magnetic poles and the fusible sheet, and can be overlapped with an online detection system, and can be applied to the monitoring of lubricating oil at key parts of various types of engines.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

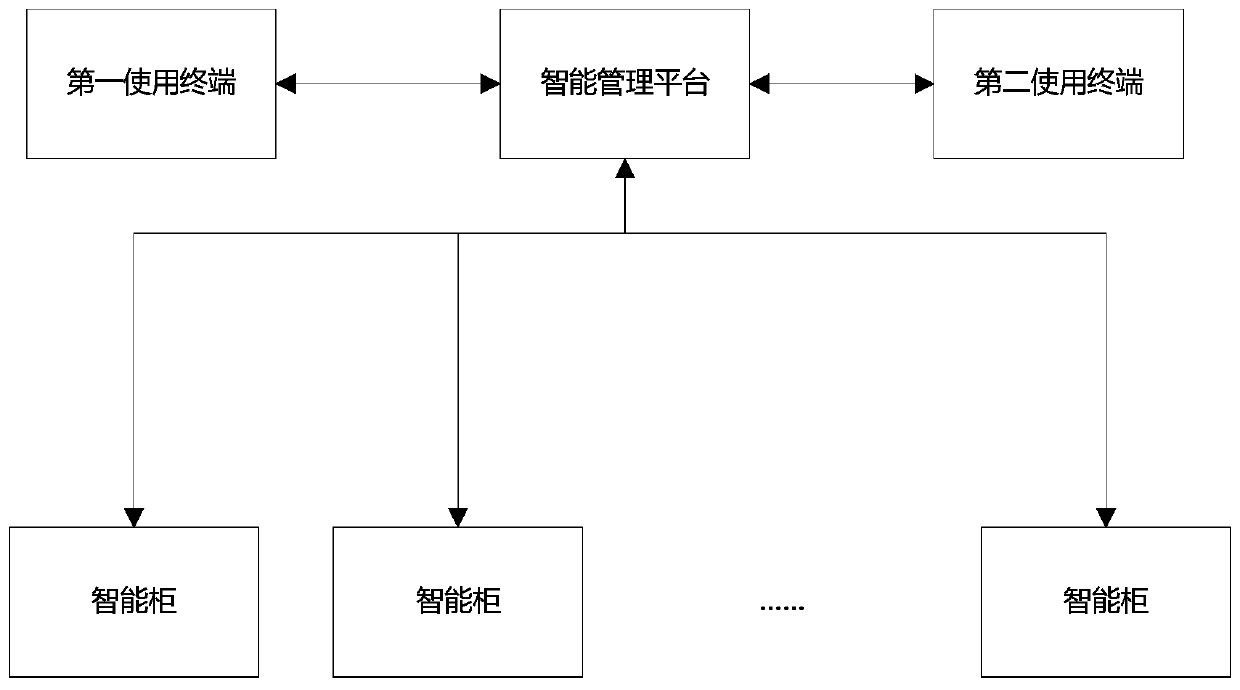

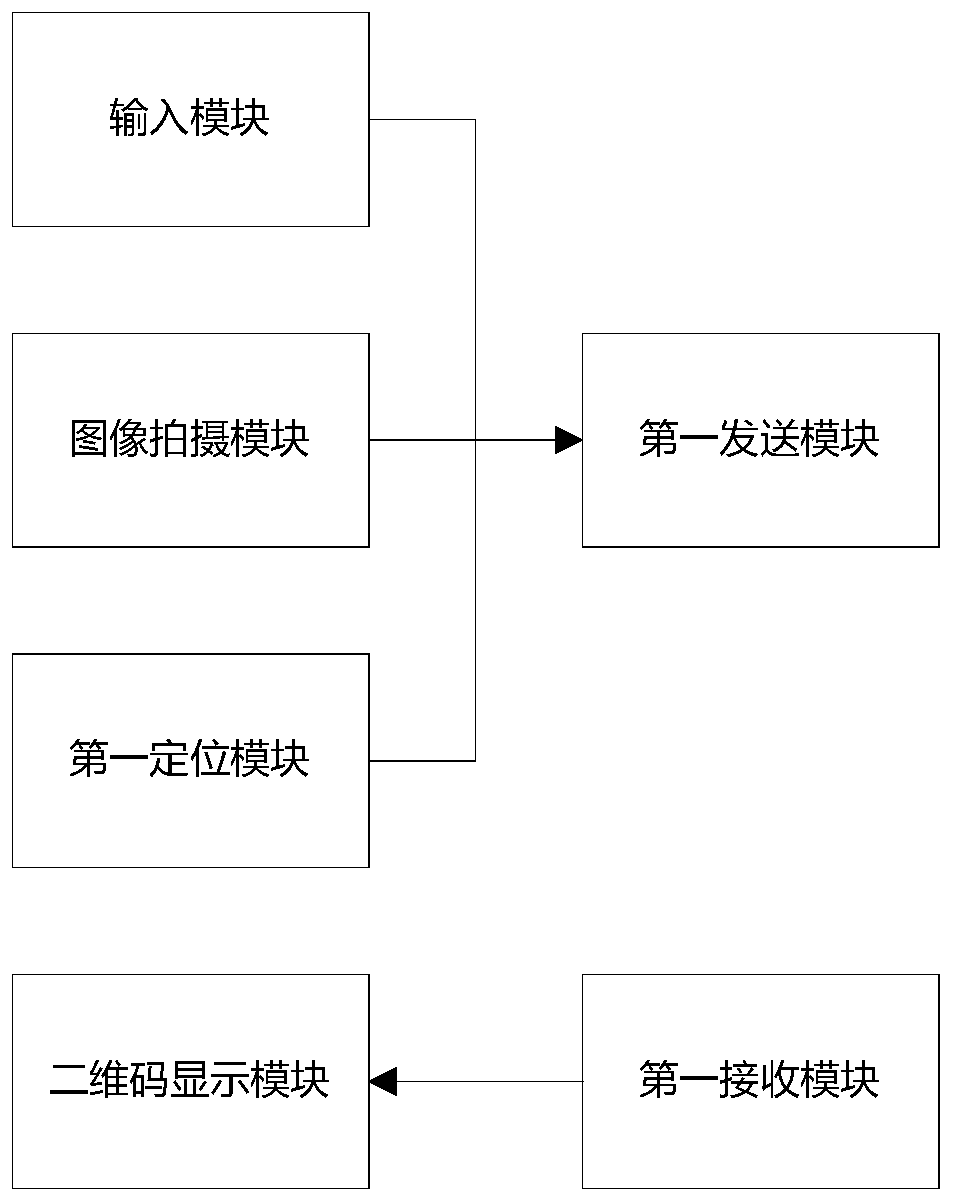

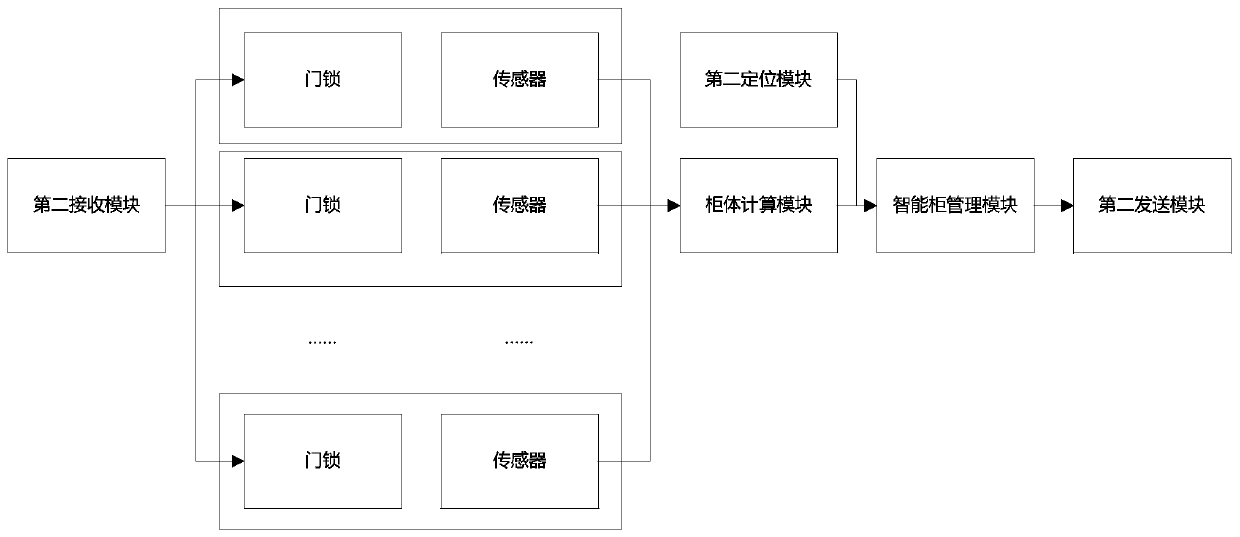

Intelligent office supply access system and storage and taking method

InactiveCN111192412ARealize intelligent storageSmart Storage MeetsApparatus for meter-controlled dispensingIndividual entry/exit registersIntelligent managementSmart system

The invention relates to an intelligent office supply access system and a storage and taking method. The intelligent office supply access system comprises an intelligent management platform, and a first use terminal and a second use terminal which are in communication connection with the intelligent management platform, the system also comprises multiple groups of intelligent cabinets installed atdifferent places. Each group of intelligent cabinets comprise a plurality of cabinet bodies with different sizes; and each group of intelligent cabinets are in communication connection with the intelligent management platform. The storage and taking method is set based on an the office supply intelligent system. According to the invention, intelligent storage of the intelligent cabinets is achieved, the space utilization rate of the intelligent cabinets and the convenience of office supply storage are greatly improved, the intelligent cabinets can be reasonably arranged and distributed according to needs so as to meet the requirement for storage of various office supplies with different sizes and different consuming frequencies, and intelligent consuming of all categories of office supplies is achieved.

Owner:JIANGSU ANFANG ELECTRIC POWER TECH +1

Oxygenerator monitoring system and oxygenerator

PendingCN109896502AGrasp the working status in timeReal-time monitoring of running dynamicsOxygen preparationElectricityMonitoring system

An oxygenerator monitoring system comprises a control device, a data collection and feedback device and an output device which are electrically connected with an oxygenerator. The oxygenerator monitoring system is characterized in that the data collection and feedback device and the output device are electrically connected with the control device, and the data collection and feedback device is connected with the oxygenerator to detect needed parameters. By the oxygenerator monitoring system, working condition of each key node of the oxygenerator can be known timely, and working abnormality ofa certain part of the oxygenerator can be timely detected, so that targeted maintenance can be performed at the part. After adopting the oxygenerator monitoring system, running state of the oxygenerator can be monitored remotely in real time, and a powerful technical guarantee can be provided for stable running of the oxygenerator.

Owner:北京唯氧绿色科技有限公司

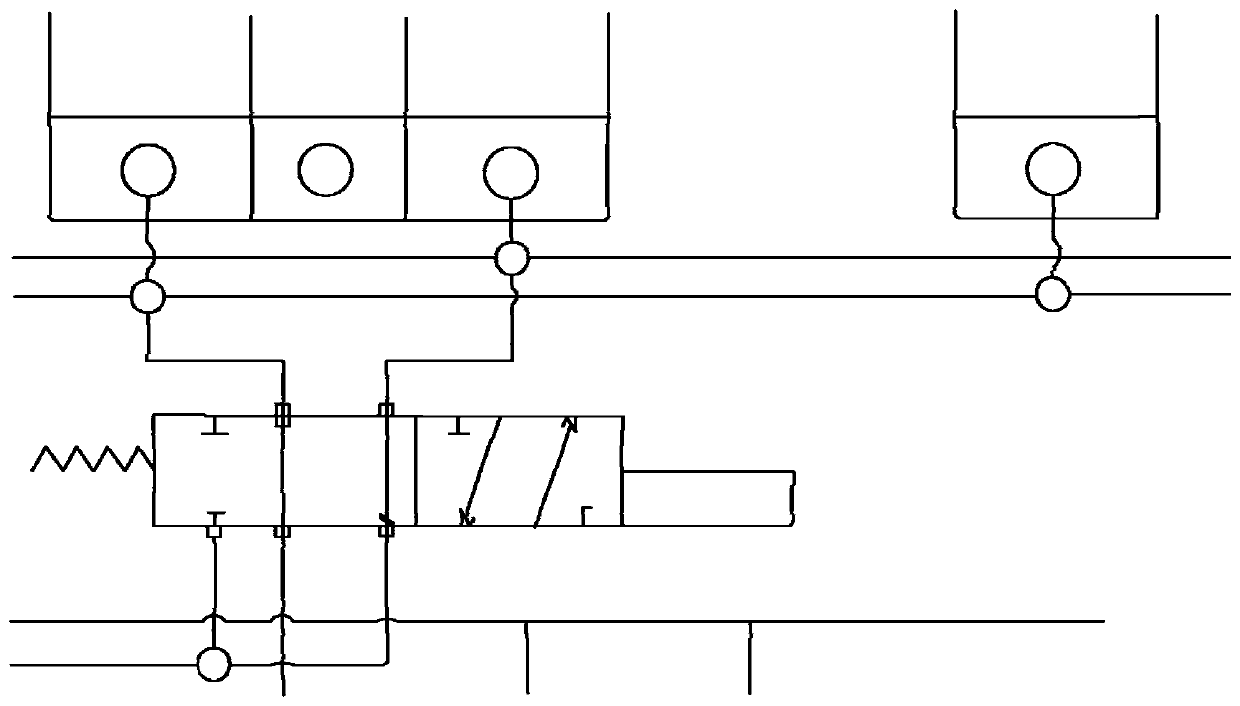

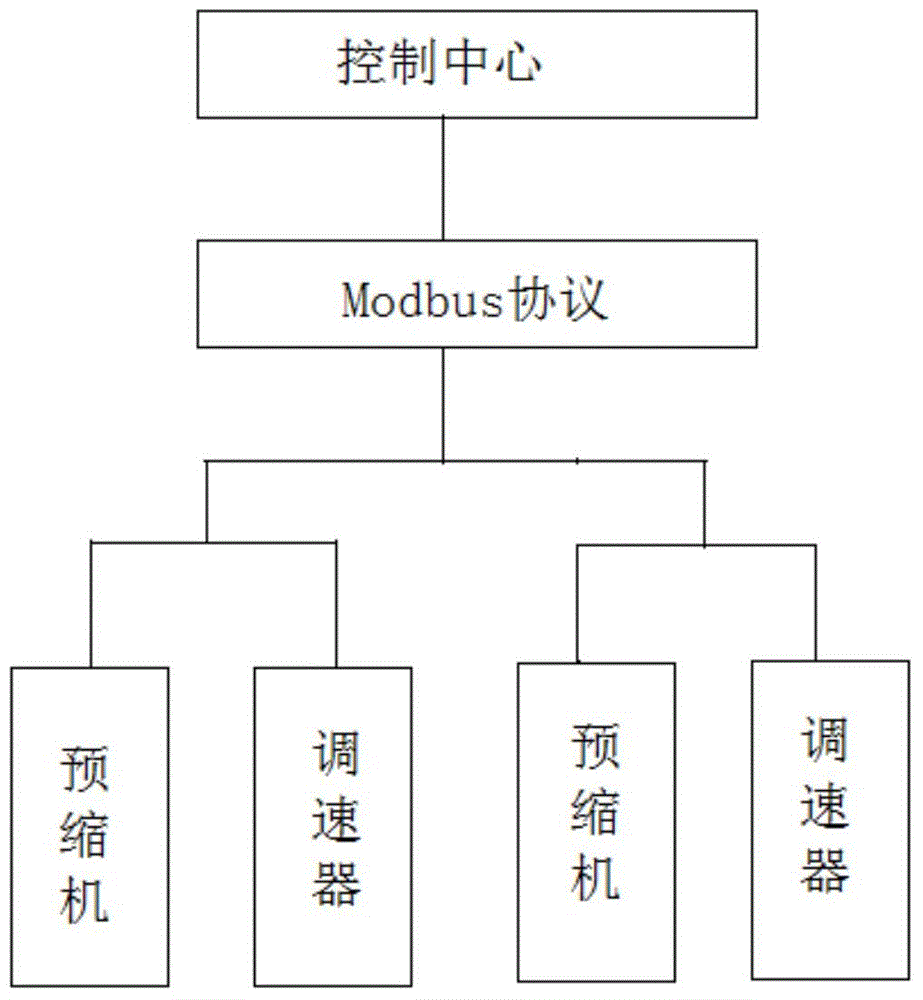

Preshrinking machine with Modbus frequency conversion speed regulation system

InactiveCN104868822AHigh degree of automationLess investmentAC motor controlPhase shiftedFrequency changer

The invention discloses a preshrinking machine with a Modbus frequency conversion speed regulation system. Multiple preshrinking machines are connected with a control center via the Modbus protocol; each preshrinking machine is provided with a frequency conversion speed regulator; the frequency conversion speed regulator comprises a detection module, a control module, a man-machine interaction module, a three-phase power supply, a phase-shift transformer and a five-level inverter; the three-phase power supply, the phase-shift transformer, the five-level inverter and the preshrinking machine are successively connected; all the three-phase power supply, the phase-shift transformer, the five-level inverter and the preshrinking machine are connected with the detection module; the detection module, the control module and the man-machine interaction module are connected successively; and the control module is connected with the detection module, the man-machine interaction module and the five-level inverter. Parameters including the voltage, frequency and fault of a motor in a frequency converter can be monitored in real time, the working state of the frequency converter is mastered timely, and measures can be adopted timely according to change of the parameters to ensure normal operation of the frequency converter.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

Intelligent high and low pressure lubrication device

ActiveCN106287187BGrasp the working status in timeImprove workabilityLubrication elementsIntelligent lightingWork performance

The invention discloses an intelligentized high-low-pressure lubrication device, which is characterized by comprising an oil tank, wherein the oil tank is connected with an oil outlet pipeline and an oil return pipeline; a control cabinet of a control system for controlling the working of an electric component on the oil outlet pipeline is fixedly arranged on the oil tank, and a touch type display screen is arranged on the control cabinet of the control system; the oil outlet pipeline comprises a NO.1 low-pressure pump and a NO.2 low-pressure pump which are connected in parallel, a filter is arranged behind the pumps which are connected in parallel, an oil cooler is arranged between the filter and an oil outlet, a NO.3 high-pressure pump and a NO.4 high-pressure pump which are connected in parallel are connected behind the cooler, and the oil tank is connected with an oil return port connected with an oil return pipeline; a safety valve channel is connected in parallel with two screw pumps which are connected in parallel; a heater is arranged in the oil tank; an electromagnetic water valve is arranged on a cooling water channel of the oil cooler. The intelligentized high-low-pressure lubrication device has a reasonable structure, a lubrication tank body structure and an electric control tank body structure are integrated as a whole, the structure is more compact and the use is convenient; by adopting the electric control device with the touch type display screen, the working state of the controlled component can be mastered in time; and the working performance of the control system is excellent.

Owner:江苏指南润滑液压科技有限公司

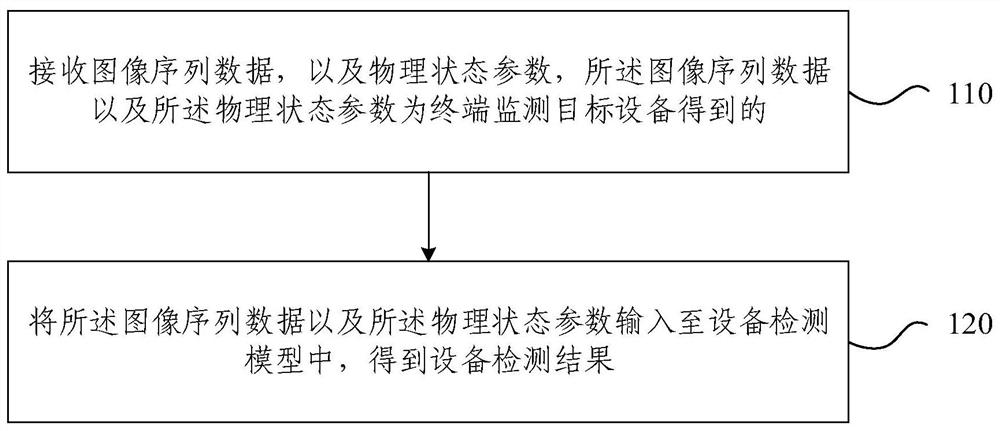

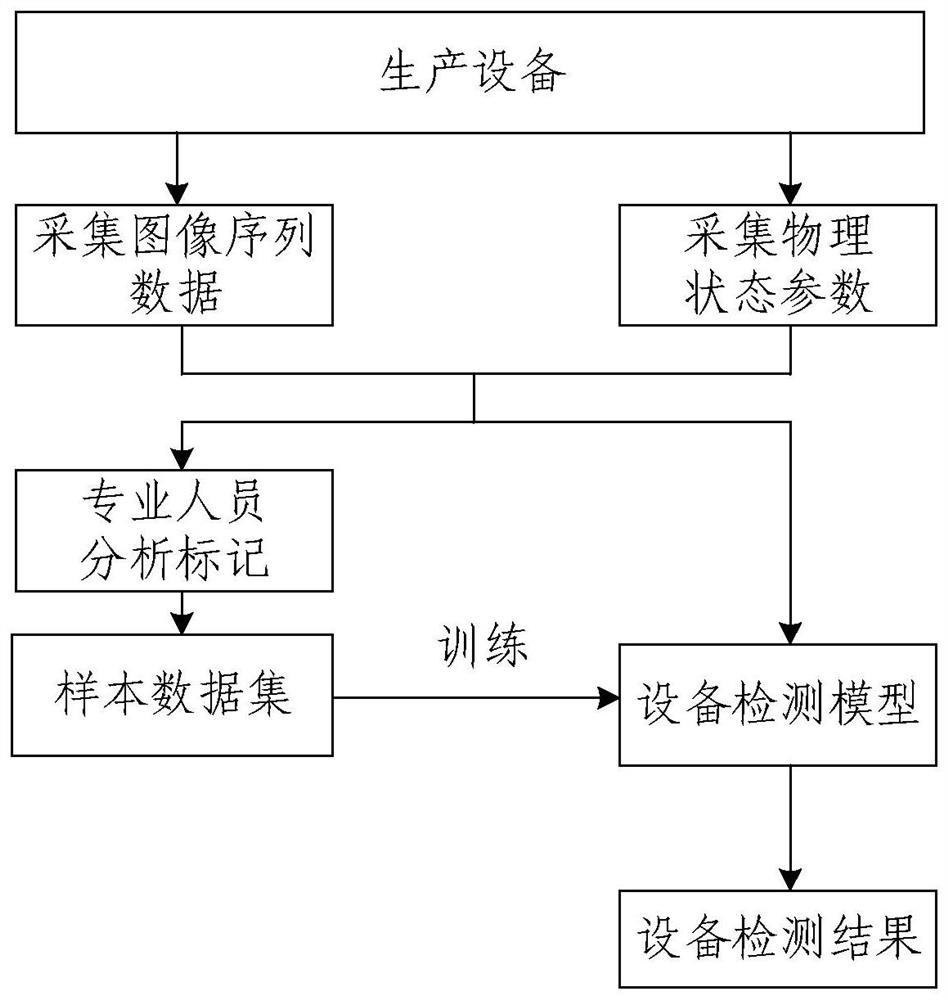

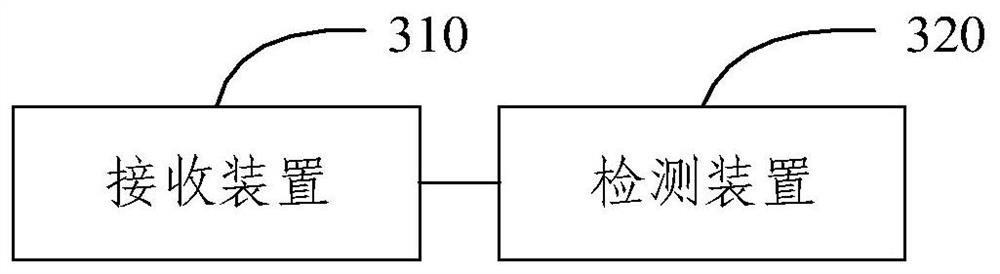

Equipment detection method and device

PendingCN113589789AGrasp the working status in timeReduce labor costsProgramme controlElectric testing/monitoringEngineeringNetwork model

The invention provides an equipment detection method and device, and the method comprises the steps: receiving image sequence data and physical state parameters, wherein the image sequence data and the physical state parameters are obtained by monitoring target equipment by a terminal; inputting the image sequence data and the physical state parameters into an equipment detection model to obtain an equipment detection result, wherein the equipment detection model is obtained by training by taking the image sequence sample data and the physical state sample parameters as samples and taking the equipment detection result sample data corresponding to the image sequence sample data and the physical state sample parameters as labels. According to the equipment detection method and device provided by the invention, the image sequence data and the physical state parameters sent by the terminal are received and input into the equipment detection model, and the equipment detection result is obtained by using a neural network model, so that a server side can master the working state of production equipment in time, the labor cost is reduced, and the detection efficiency is improved.

Owner:盛景智能科技嘉兴有限公司

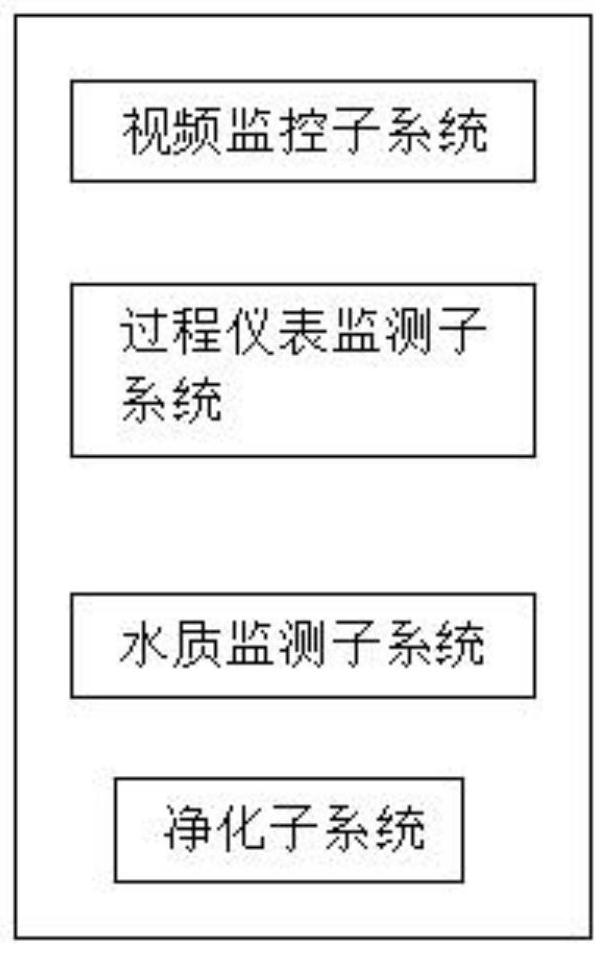

Sewage plant supervision control system

InactiveCN112607930AAvoid the phenomenon of improper disposal into the riverGrasp the working status in timeWater/sewage treatment by irradiationSpecific water treatment objectivesVideo monitoringEnvironmental resource management

The invention relates to the technical field of supervision and control systems, and discloses a sewage plant supervision and control system, which comprises a video monitoring subsystem, a process instrument monitoring subsystem, a water quality monitoring subsystem and a purification subsystem, and is characterized in that the video monitoring subsystem monitors the working conditions of sewage plant workers in real time; a camera in the video monitoring subsystem is connected with a video server, the video server is connected with a local area network switch, the local area network switch exchanges data, the local area network switch is connected with the video monitoring server through an optical fiber or a wireless channel, and the video monitoring server is connected with the video monitoring client; according to the invention, the improved supervision control system effectively improves the supervision means and measures for sewage treatment, can avoid the phenomenon that sewage is discharged into a river due to improper treatment, and enables a leader to master the operation of sewage plant equipment and the working conditions of workers in time, thereby improving the supervision level.

Owner:安徽海航环保科技有限公司

Variable-frequency speed regulator based on three-phase power supply

InactiveCN105763132AGrasp the working status in timeGuaranteed uptimeAC motor controlFrequency changerTransformer

The invention discloses a variable-frequency speed regulator based on a three-phase power supply. The variable-frequency speed regulator comprises a detection module, a control module, a human-machine interaction module, the three-phase power supply, a phase-shifting transformer, a five-level inverter. The three-phase power supply, the phase-shifting transformer, and the five-level inverter are connected successively. The output end of the three-phase power supply, the output end of the phase-shifting transformer, the output end of the five-level inverter are connected with the input ends of the detection module. The output end of the detection module is connected with the input end of the control module. The output end of the control module is connected with the input end of the human-machine interaction module and the input end of the five-level inverter. The variable-frequency speed regulator may monitor parameters, such as voltage, frequency, faults and the like, of a motor inside a frequency converter in real time, timely knows the operating state of the frequency converter, and may timely take corresponding measures according to a parameter change to guarantee the normal operation of the frequency converter.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

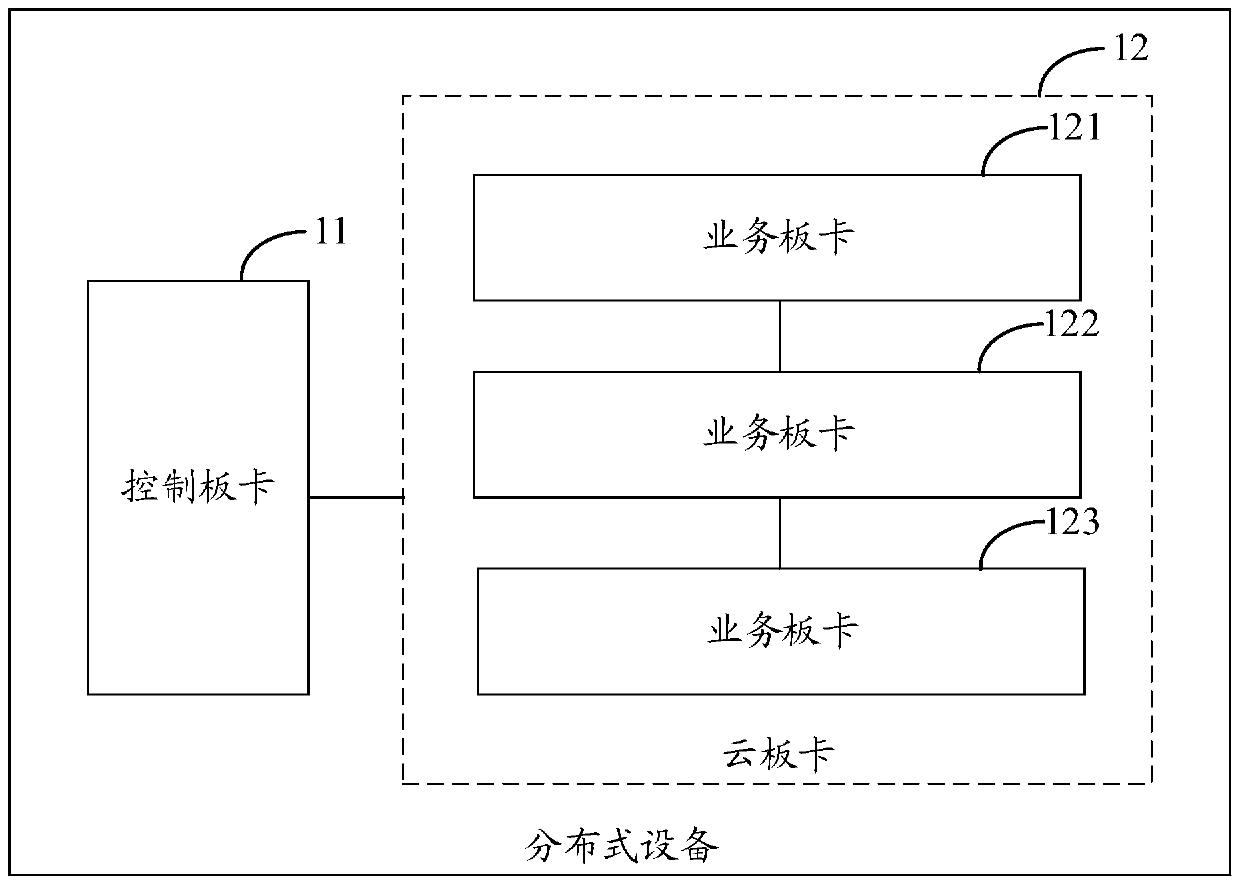

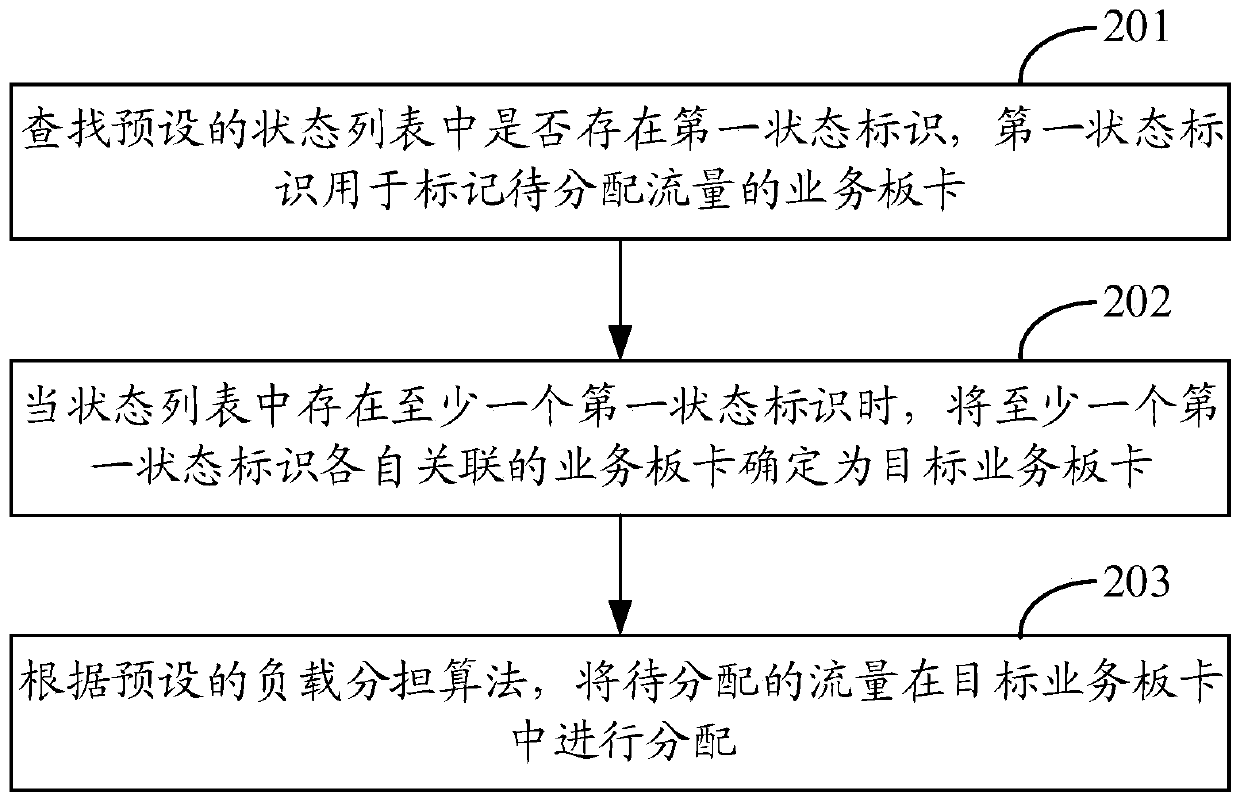

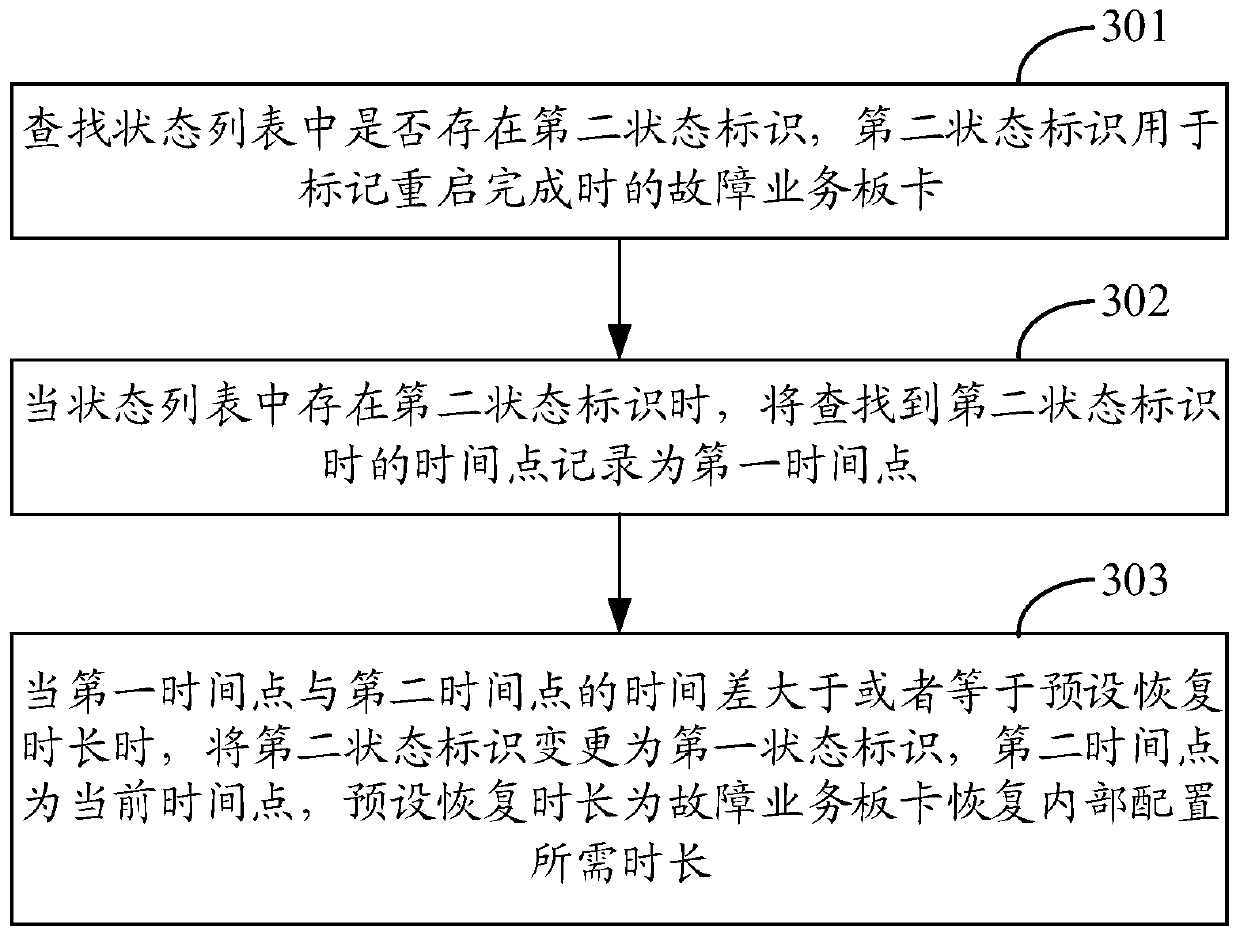

A flow distribution method and device

ActiveCN106789711BGrasp the working status in timeData switching networksPacket lossDistribution method

The invention provides a method and a device for distributing traffic. The method comprises the following steps: searching to judge whether a first state identification exists in a preset state list or not, wherein the first state identification is used for marking a service board card to be subjected to traffic distribution; when at least one first state identification exists in the state list, determining service board cards associated with the at least one first state identification to be target service board cards; distributing to-be-distributed traffic in the target service board cards according to a preset load sharing algorithm. By application of the embodiment of the invention, the condition that the traffic is distributed to a fault service board card when the fault service board card appears in a cloud board card is avoided, and the problem that packet loss is generated when the traffic is distributed to the fault service board card is solved.

Owner:HANGZHOU DPTECH TECH

Programmable three-position switch

ActiveCN103311008BGrasp the working status in timeReasonable structureSwitch power arrangementsContact positionControl theory

The invention discloses a programmable three-position switch. A screw is driven by a motor. A rotary encoding sensor for sensing rotation conditions of the screw is disposed on the screw and is connected with an encoder controller. The encoder controller is connected with a programmable controller which controls the motor to rotate. The rotary encoding controller outputs moving contact position signals to the programmable controller. The programmable controller further controls the motor to positively or reversely rotate and stop according to the moving contact position signals, so that the rotation states of the screw are controlled. The programmable three-position switch is reasonable in structure, convenient to operate, precise in operating position, and fine in operating performance.

Owner:JIANGSU DONGYUAN ELECTRIC APPLIANCEGROUP

A comprehensive evaluation method for the state of high-voltage circuit breaker operating mechanism based on opening and closing coil current

ActiveCN106019131BJudging the running statusGrasp the working status in timeCircuit interrupters testingEngineeringEvaluation system

The invention relates to a state comprehensive evaluation method for a high-voltage circuit breaker operating mechanism based on switching-on and switching-off coil currents. The method comprises the steps: firstly removing an interference signal in a coil current signal through employing a five-point cubic smoothening filtering; secondly extracting a coil current characteristic value, and building an evaluation system model. The method can achieve the accurate evaluation of the state of the high-voltage circuit breaker operating mechanism, and is of great significance to a maintainer for making a maintenance plan.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com