Braking force control method and device

A control method and braking force technology, applied in the direction of brakes, brake components, brake safety systems, etc., can solve problems such as poor pressure regulation accuracy, slow response to emergency braking, and difficult troubleshooting of solenoid valves, and achieve voltage regulation accuracy High, fast response time, precise effect of train braking control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

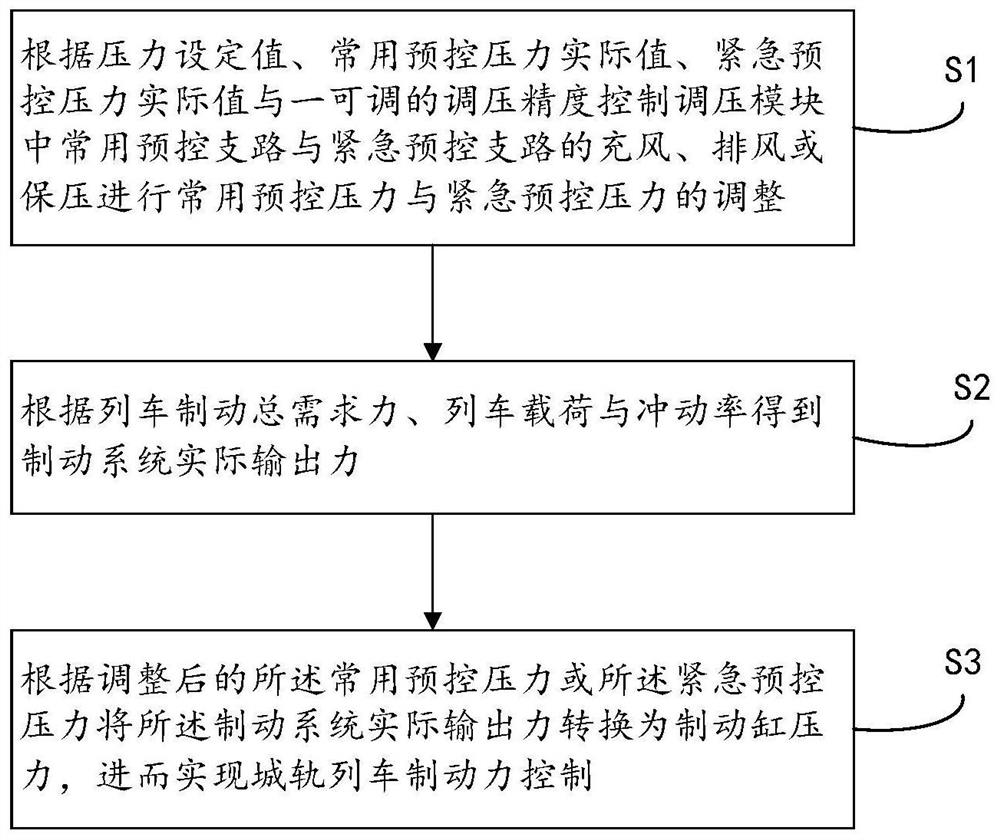

[0058] figure 1 It is a schematic diagram of the steps of a braking force control method provided by the present invention. like figure 1 As shown, this embodiment discloses a specific implementation of a braking force control method (hereinafter referred to as "method").

[0059] Specifically, the method disclosed in this embodiment mainly includes the following steps:

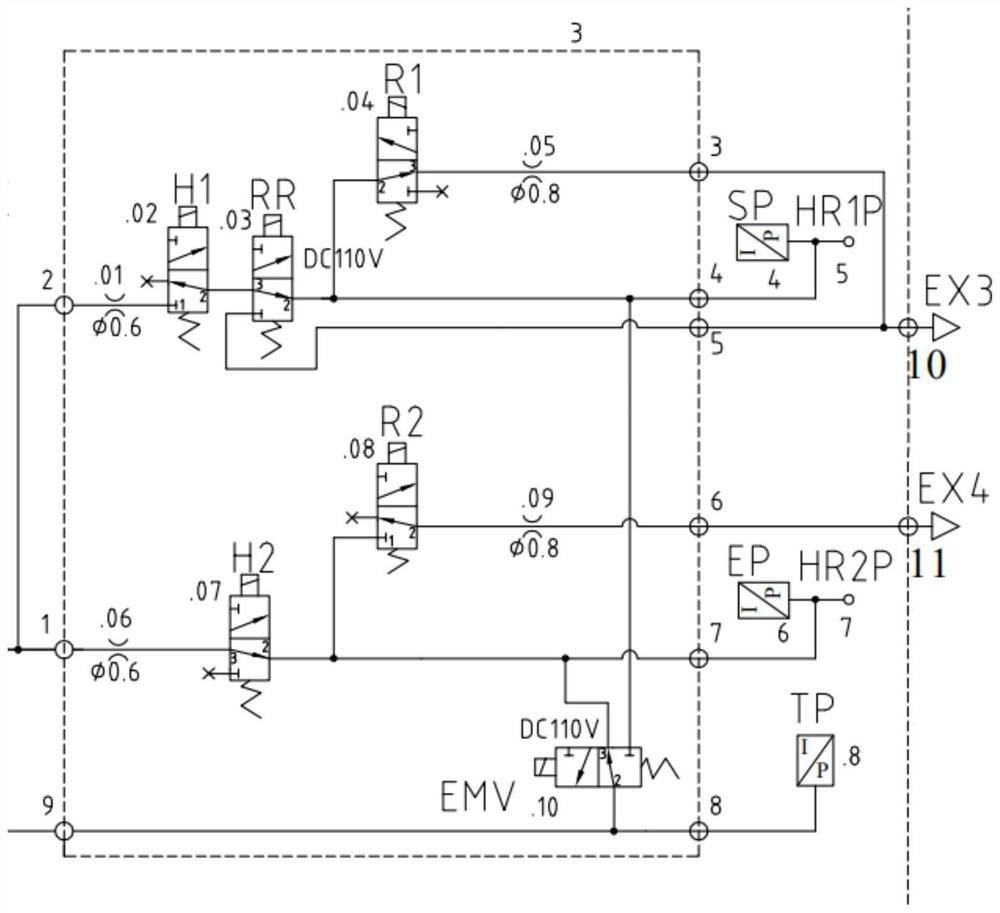

[0060] Step S1: According to the pressure setting value, the actual value of the common pre-control pressure, the actual value of the emergency pre-control pressure and the pressure regulation accuracy, control the air filling, exhaust or maintenance of the common pre-control branch and the emergency pre-control branch in the pressure regulation module. adjust the common pre-control pressure and emergency pre-control pressure;

[0061] Wherein, step S1 specifically includes the following contents:

[0062] When the emergency valve is energized, according to the pressure set value, the actual value of the ...

Embodiment 2

[0074] In combination with the braking force control method disclosed in the first embodiment, this embodiment discloses a specific implementation example of a braking force control device (hereinafter referred to as "device").

[0075] The devices include:

[0076] Pre-control pressure adjustment unit: according to the pressure setting value, the actual value of the common pre-control pressure, the actual value of the emergency pre-control pressure and the pressure regulation accuracy, the air charging and exhaust of the common pre-control branch and the emergency pre-control branch in the pressure regulation module are controlled. Adjust the common pre-control pressure and emergency pre-control pressure by wind or pressure holding;

[0077] Impulse limiting unit: obtain the actual output force of the braking system according to the total demand force of train braking, train load and impulse rate;

[0078] Brake cylinder pressure conversion unit: convert the actual output fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com