Miniature rock pipe jacking machine with replaceable cutter head and mud bin

A technology of pipe jacking machine and cutter head, which is applied in mining equipment, earth-moving, tunneling, etc., can solve the problems of increasing construction cost, slow excavation efficiency, and easy formation of mud cakes on rock cutter head, so as to save costs, install and dismantle Simple and convenient, the effect of maximizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

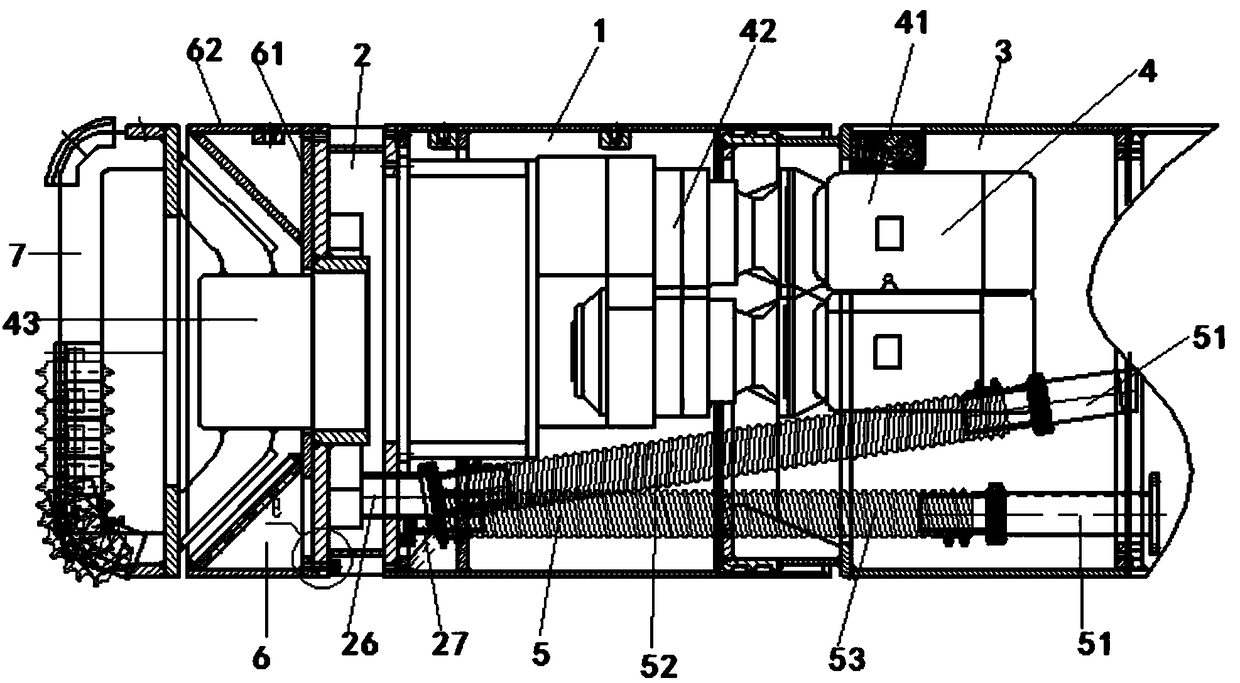

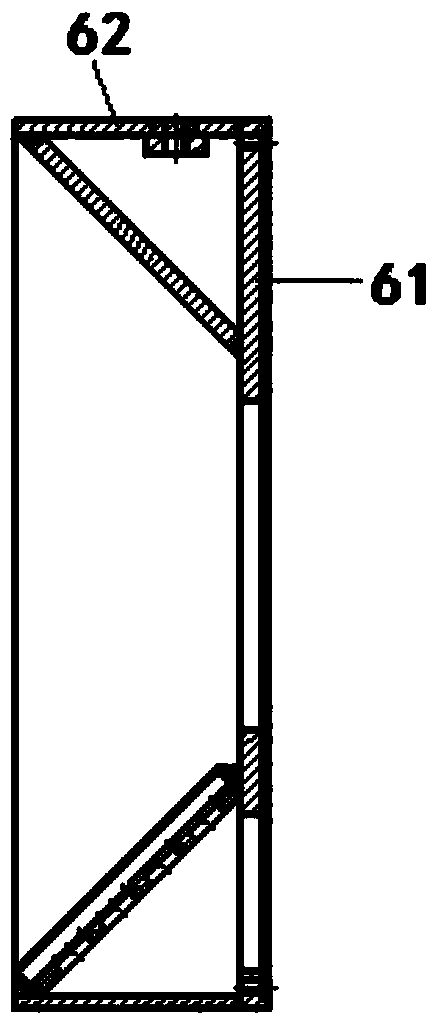

[0018] A miniature rock pipe jacking machine with replaceable cutter head and mud bin, such as figure 1 As shown, it includes a front cylinder 1, the front end of the front cylinder 1 is sleeved and fixed with a connecting cylinder 2, the rear end is sleeved and fixed with a rear cylinder 3, and the front end of the connecting cylinder 2 is fixed with a cone crushing mud bin 6 through bolt connection;

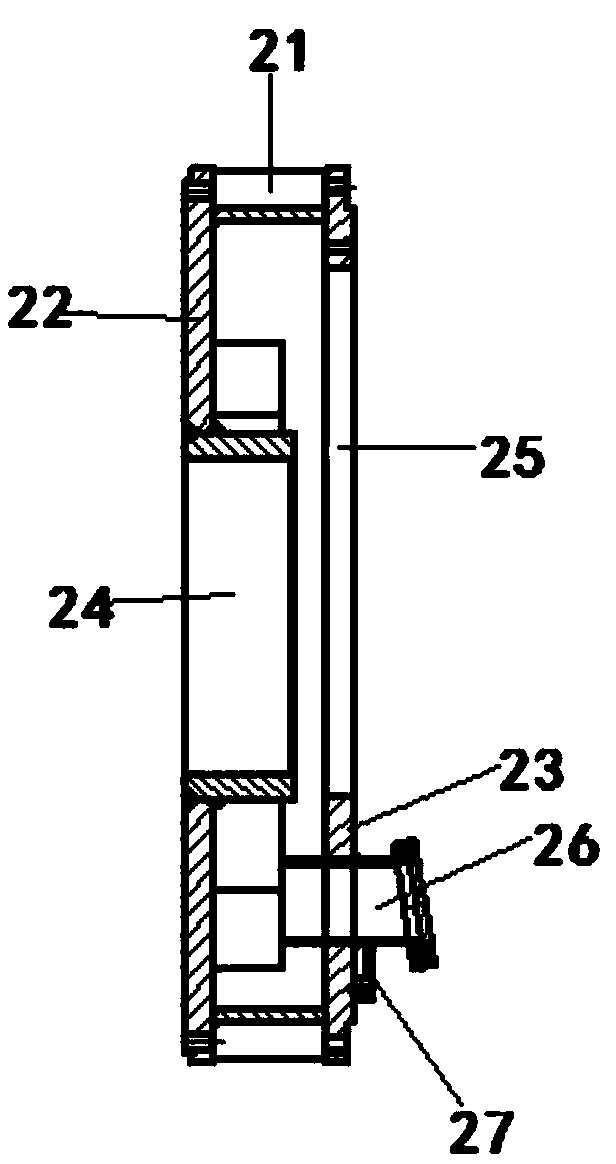

[0019] Such as figure 2 As shown, a power system 4 is installed and fixed in the front tube 1, the power system 4 includes a motor 41 and a reducer 41 connected to the motor 41, one end of the reducer 42 is provided with a power output shaft 43, and one end of the power output shaft 43 is installed The hob cutter head 7 is fixed, and the hob cutter head 7 is located in the cone crushing mud bin 6; the motor 41 is located in the rear cylinder 3; the connecting cylinder 2 includes a cylinder wall 21, and two ends of the cylinder wall 21 are connected and fixed respectively. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com