Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

584results about How to "Benefit maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

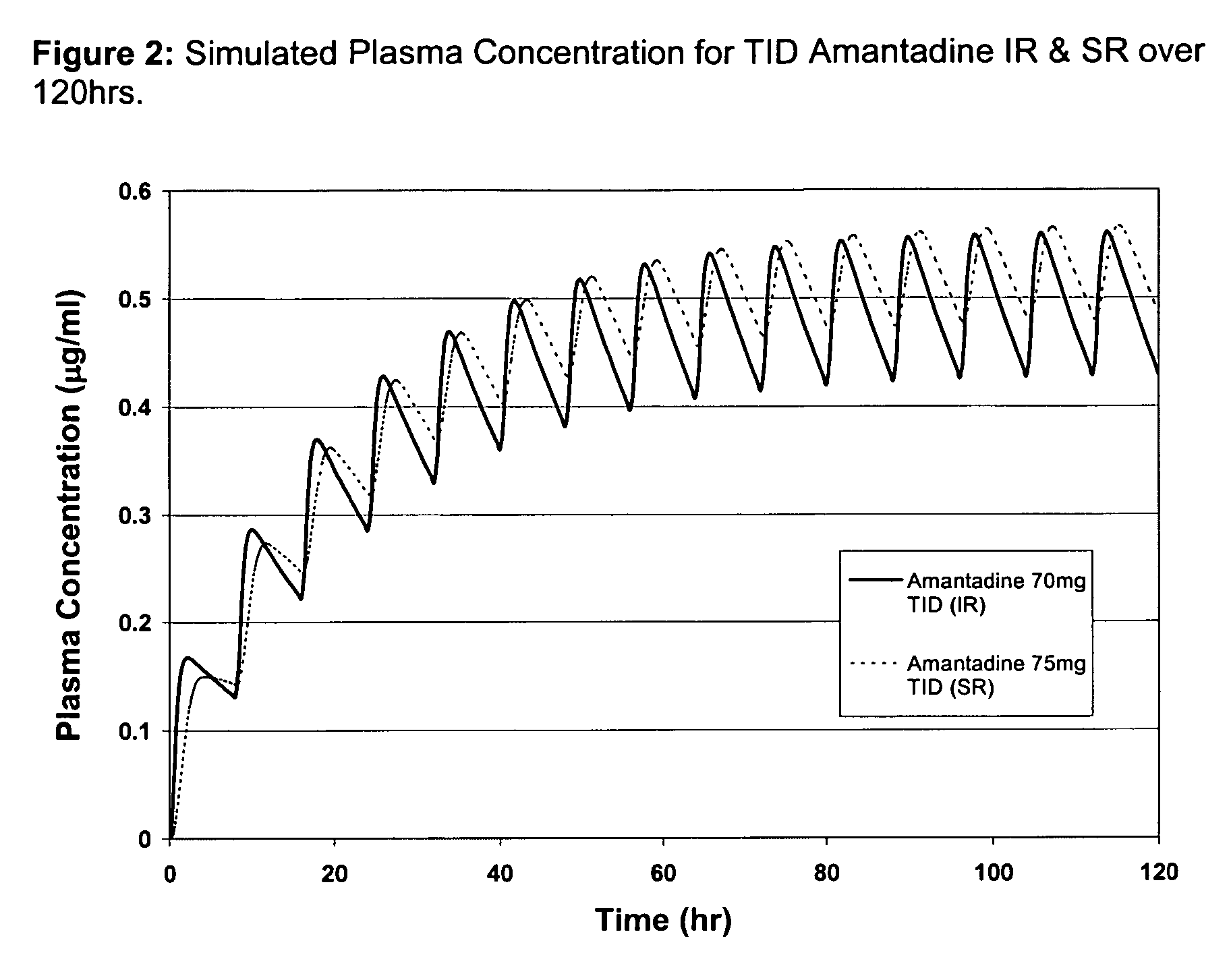

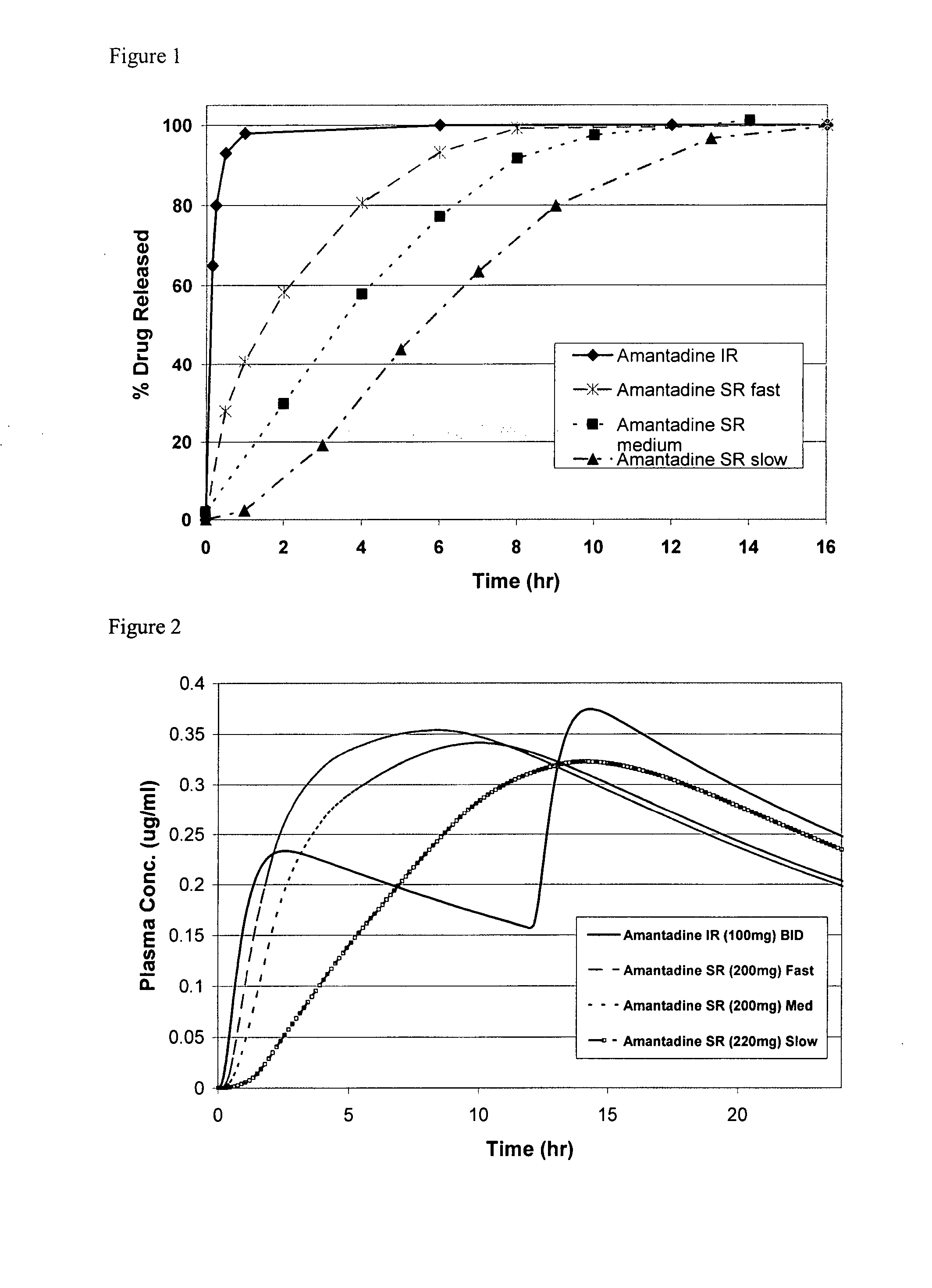

Methods and compositions for the treatment of psychiatric conditions

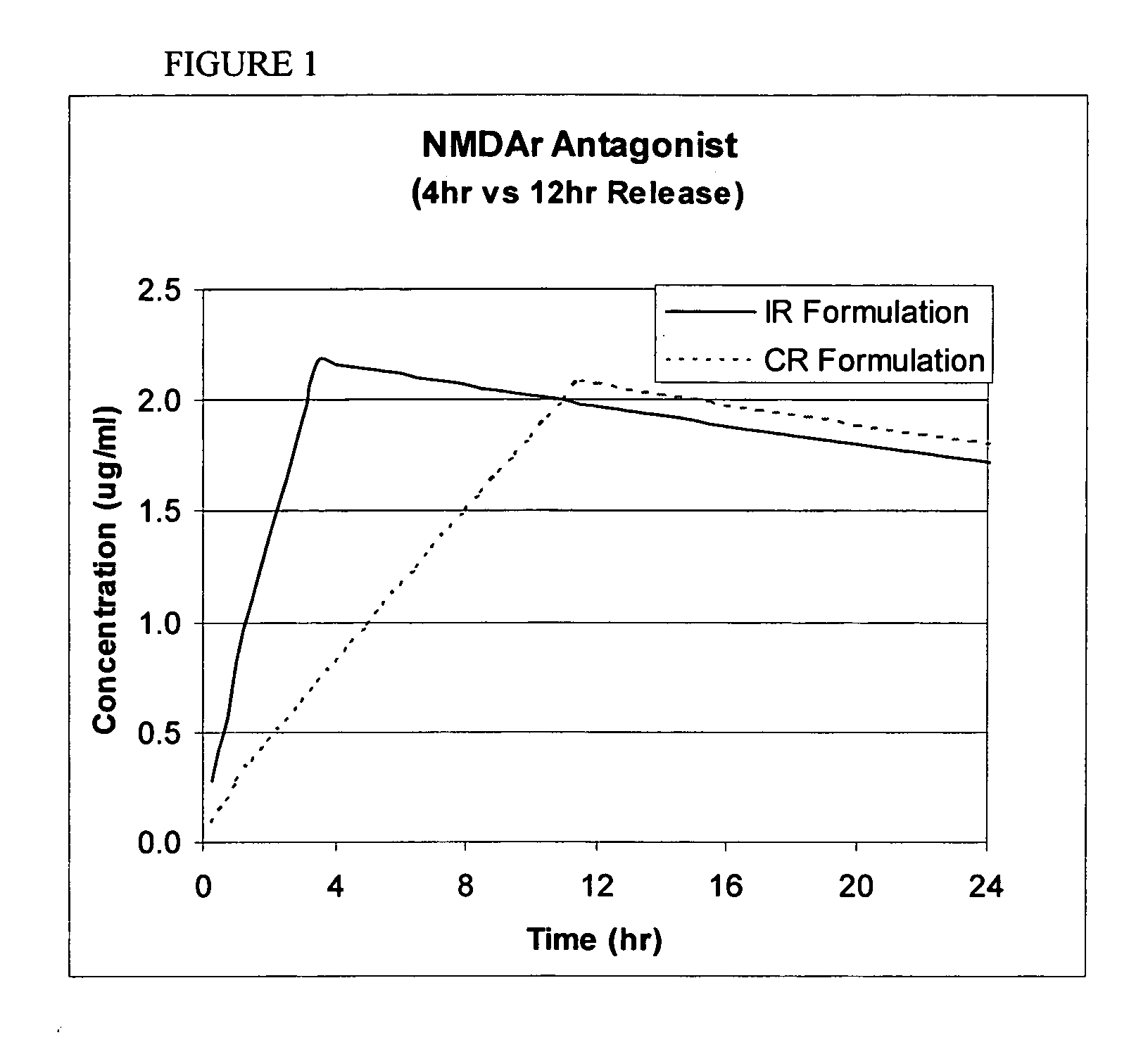

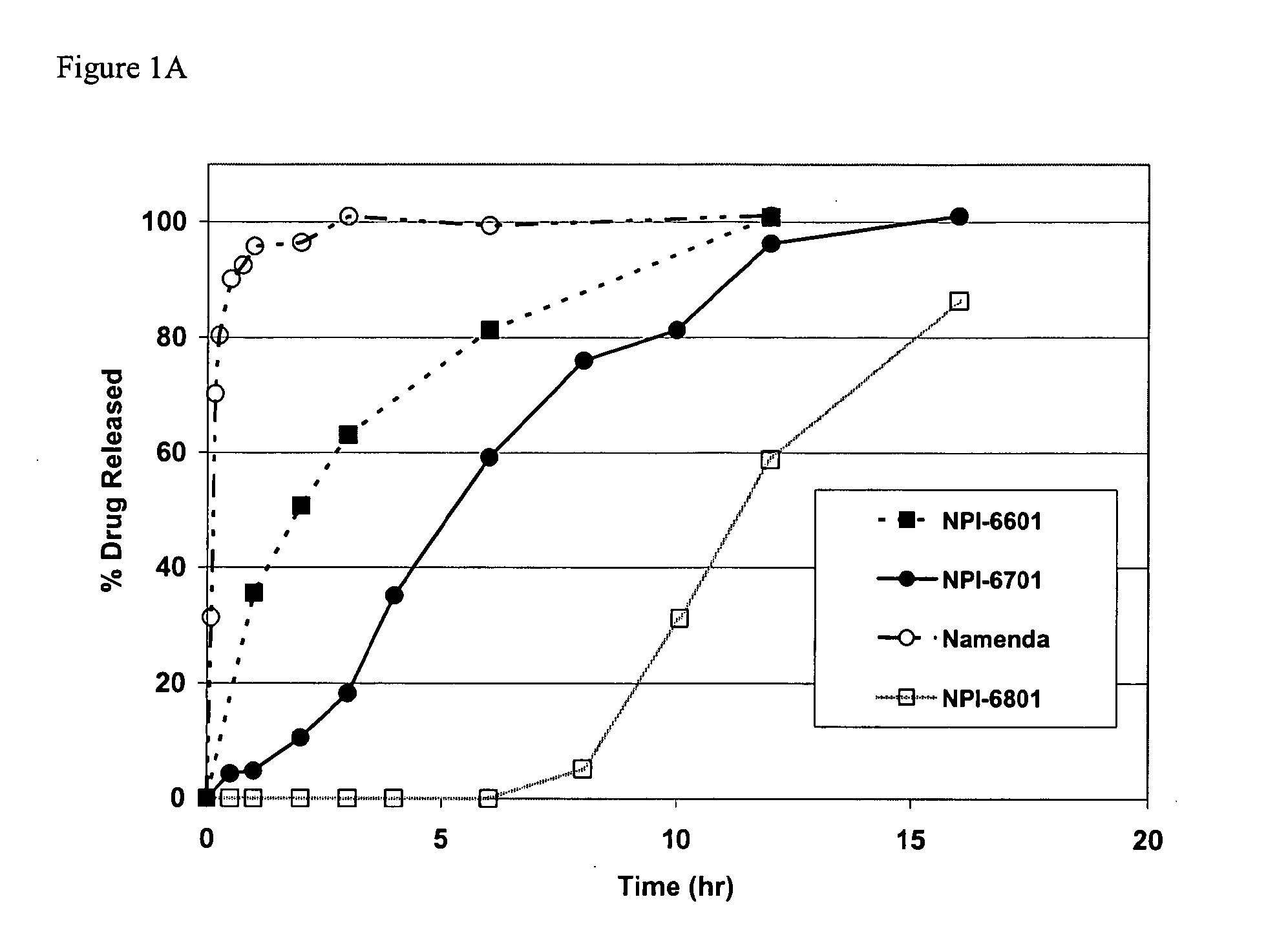

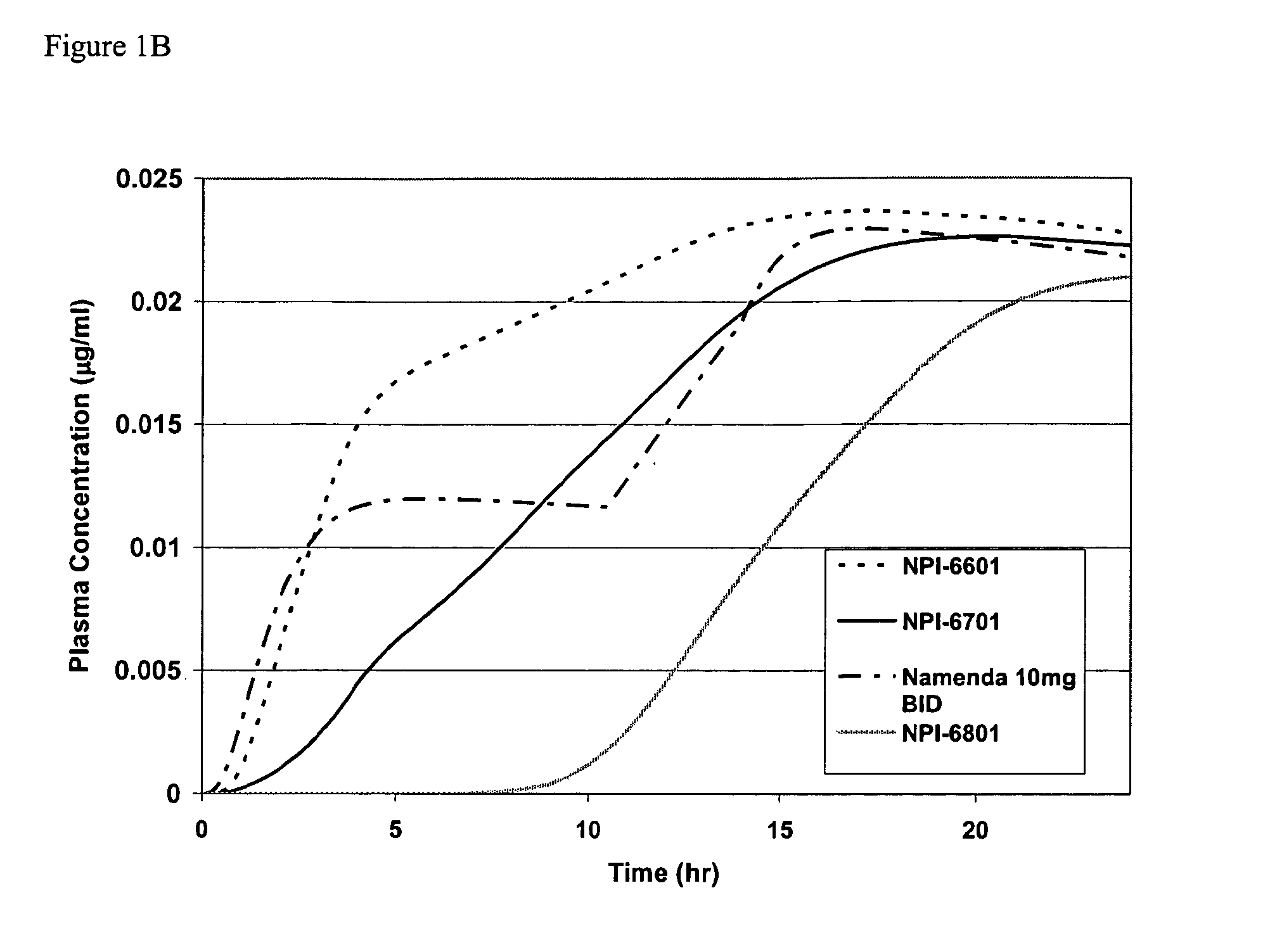

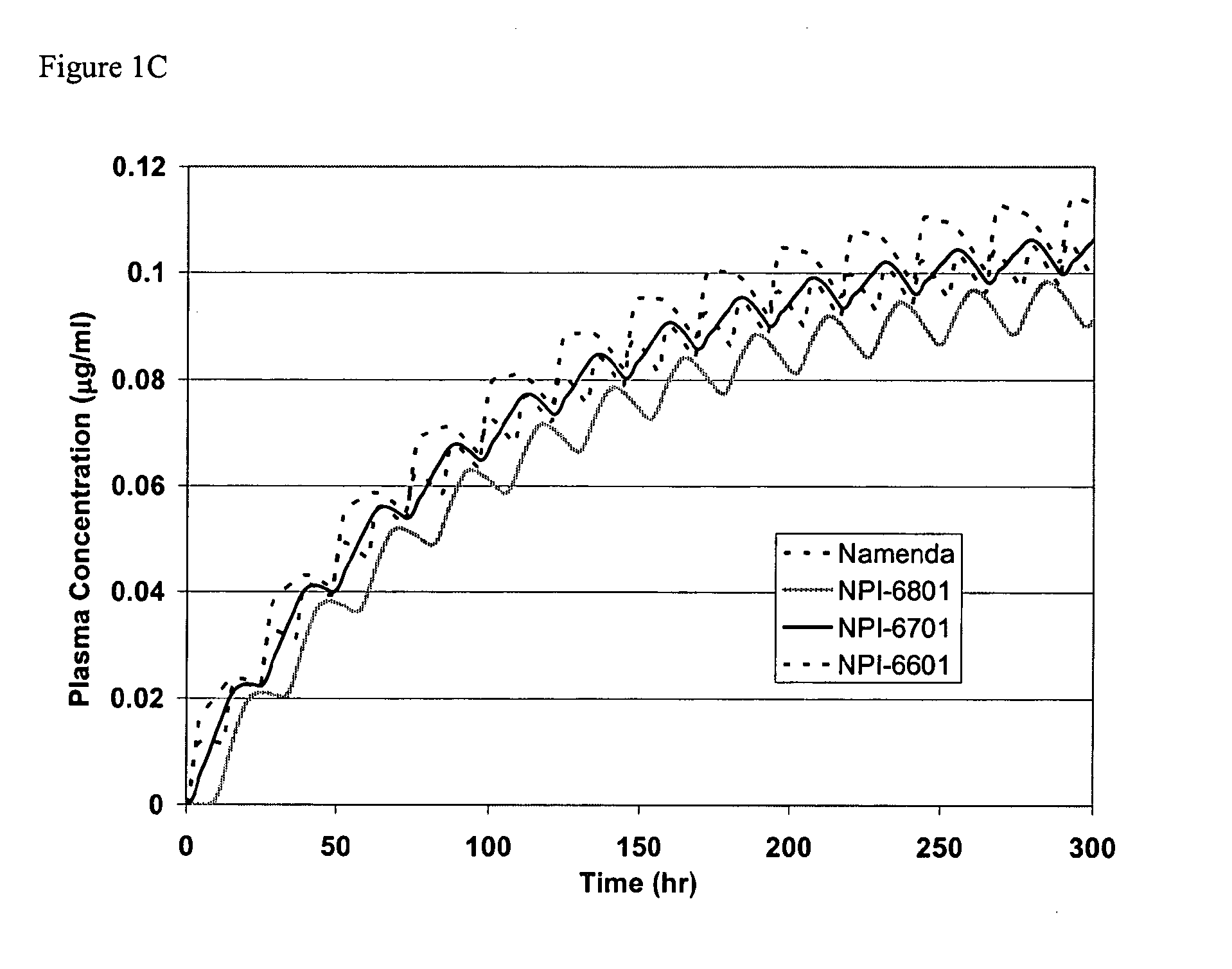

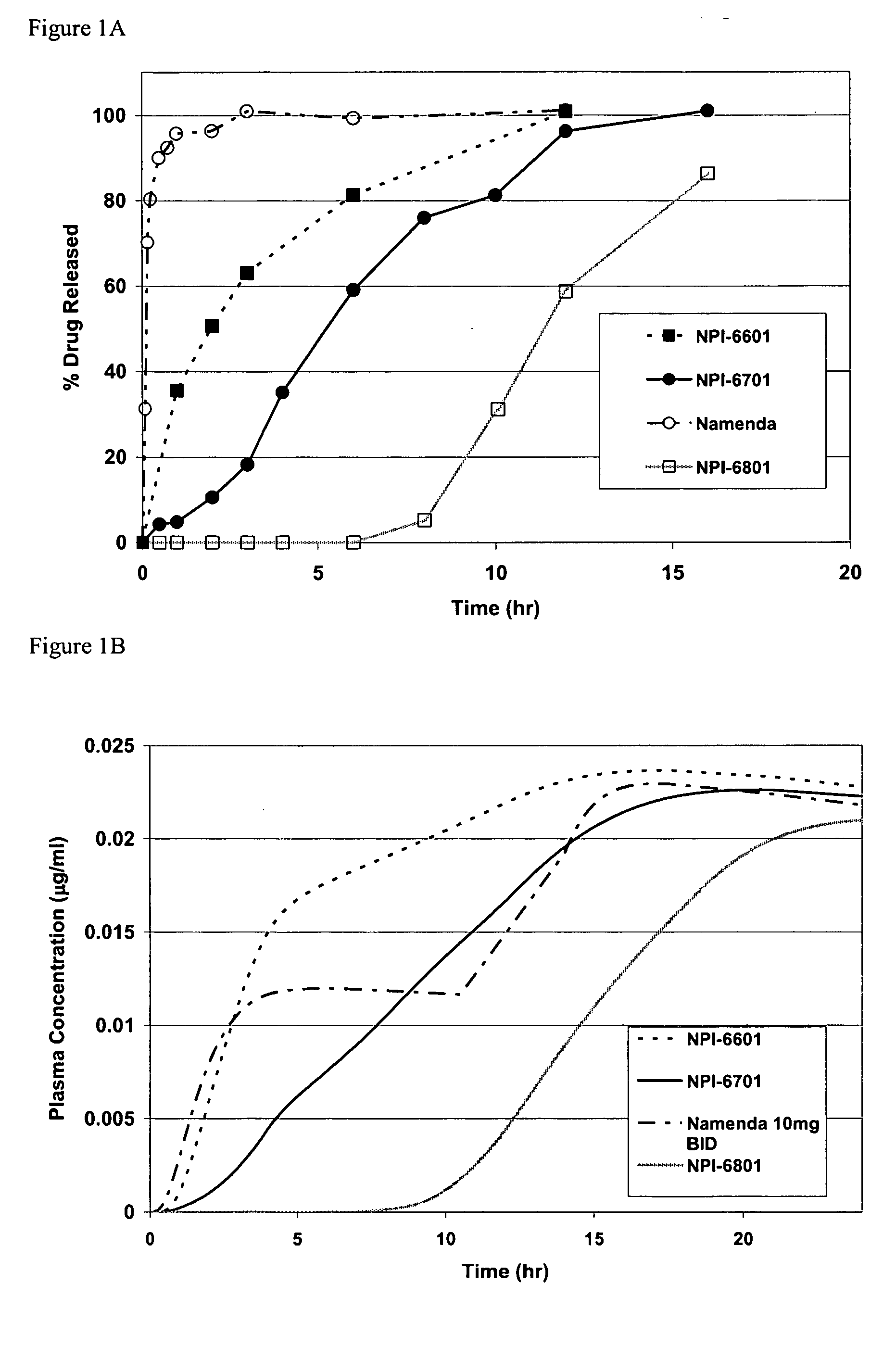

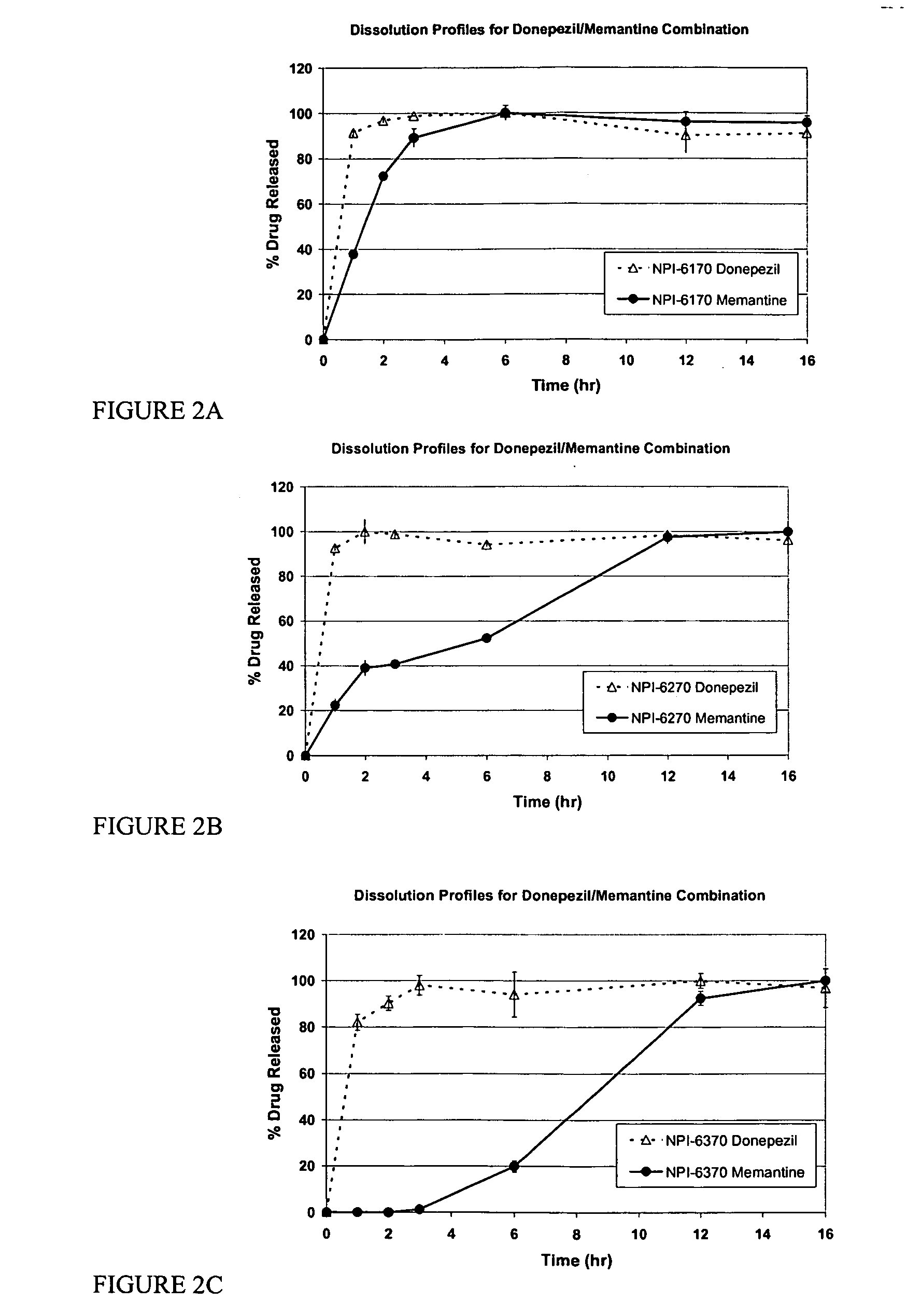

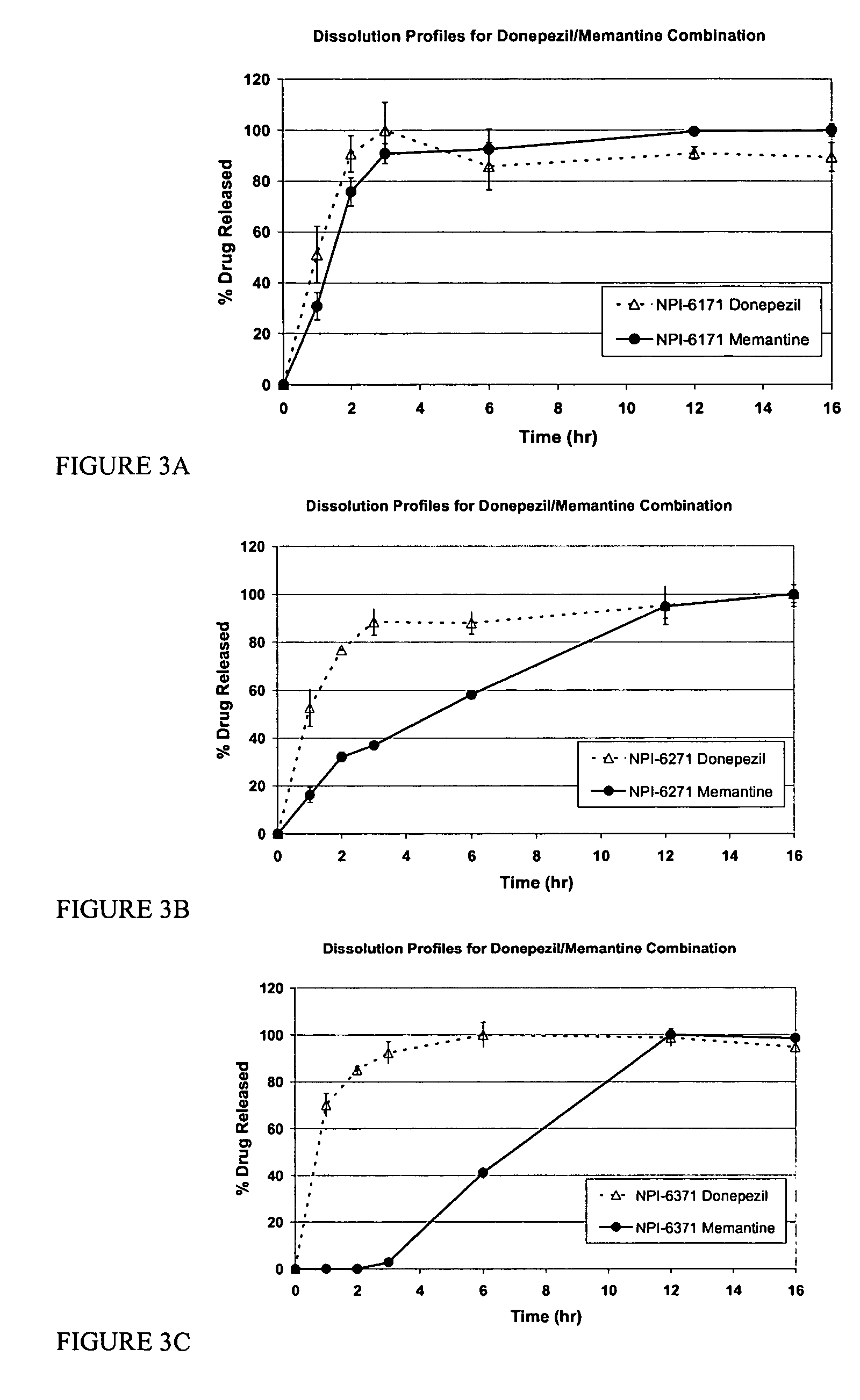

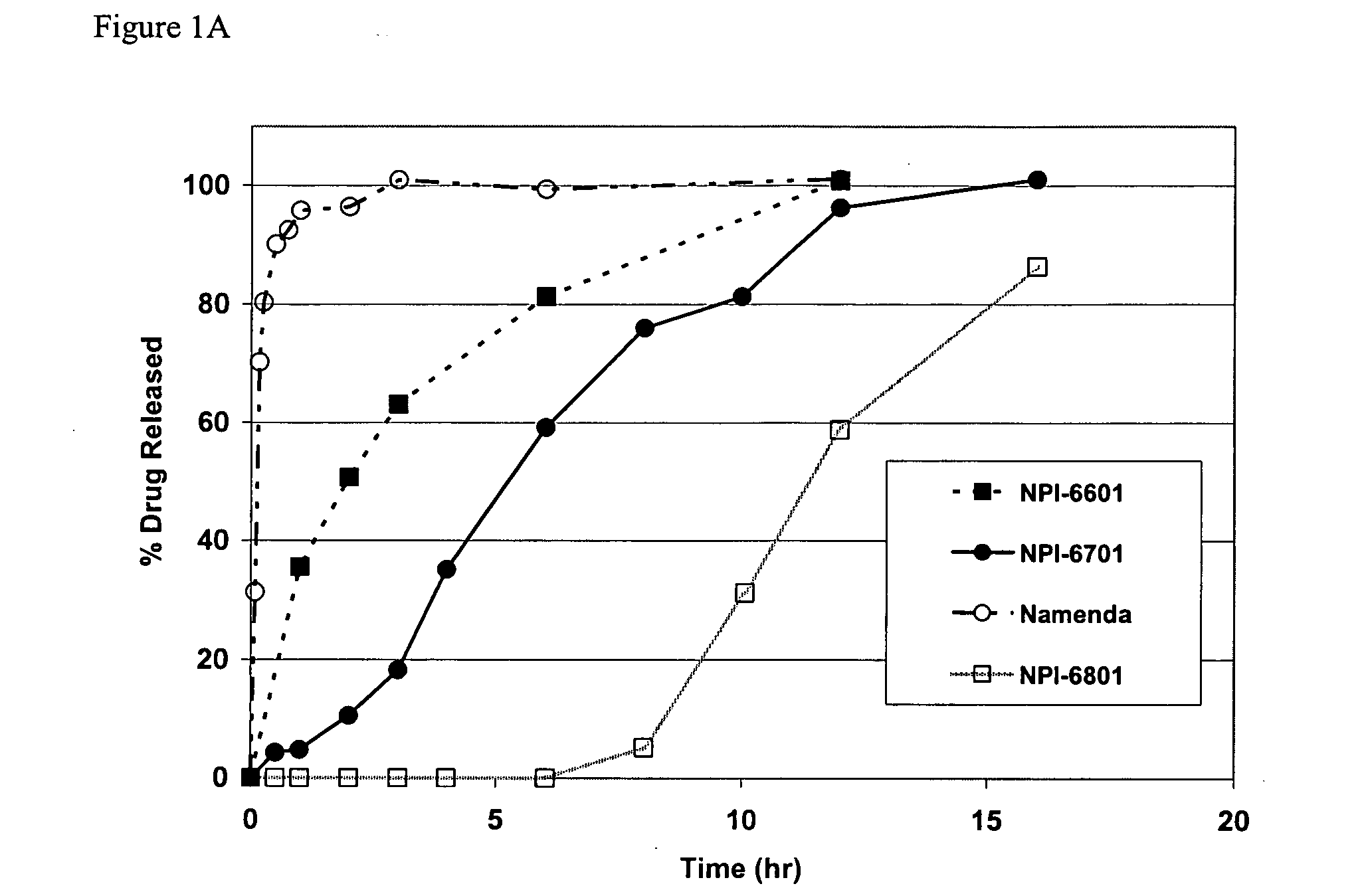

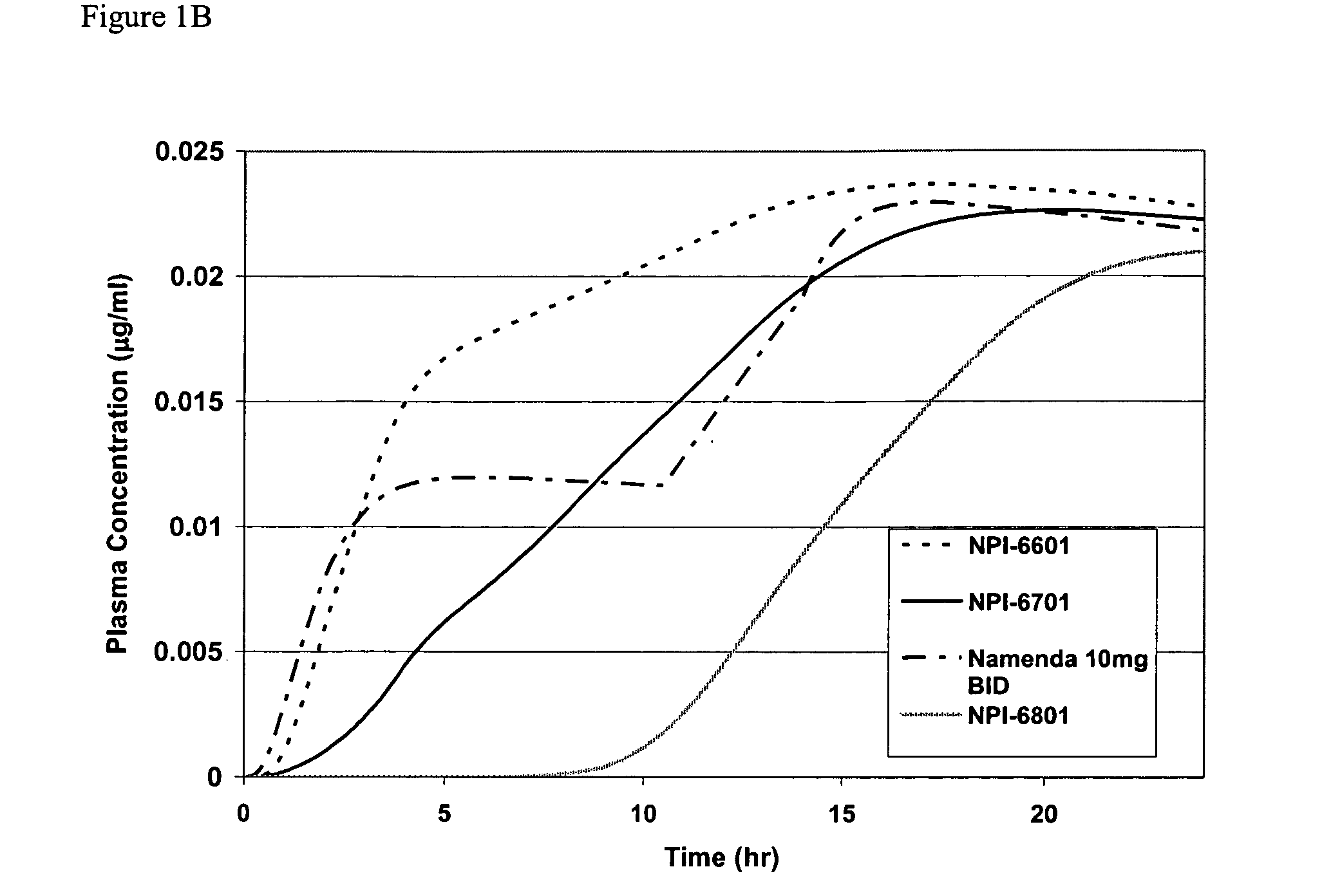

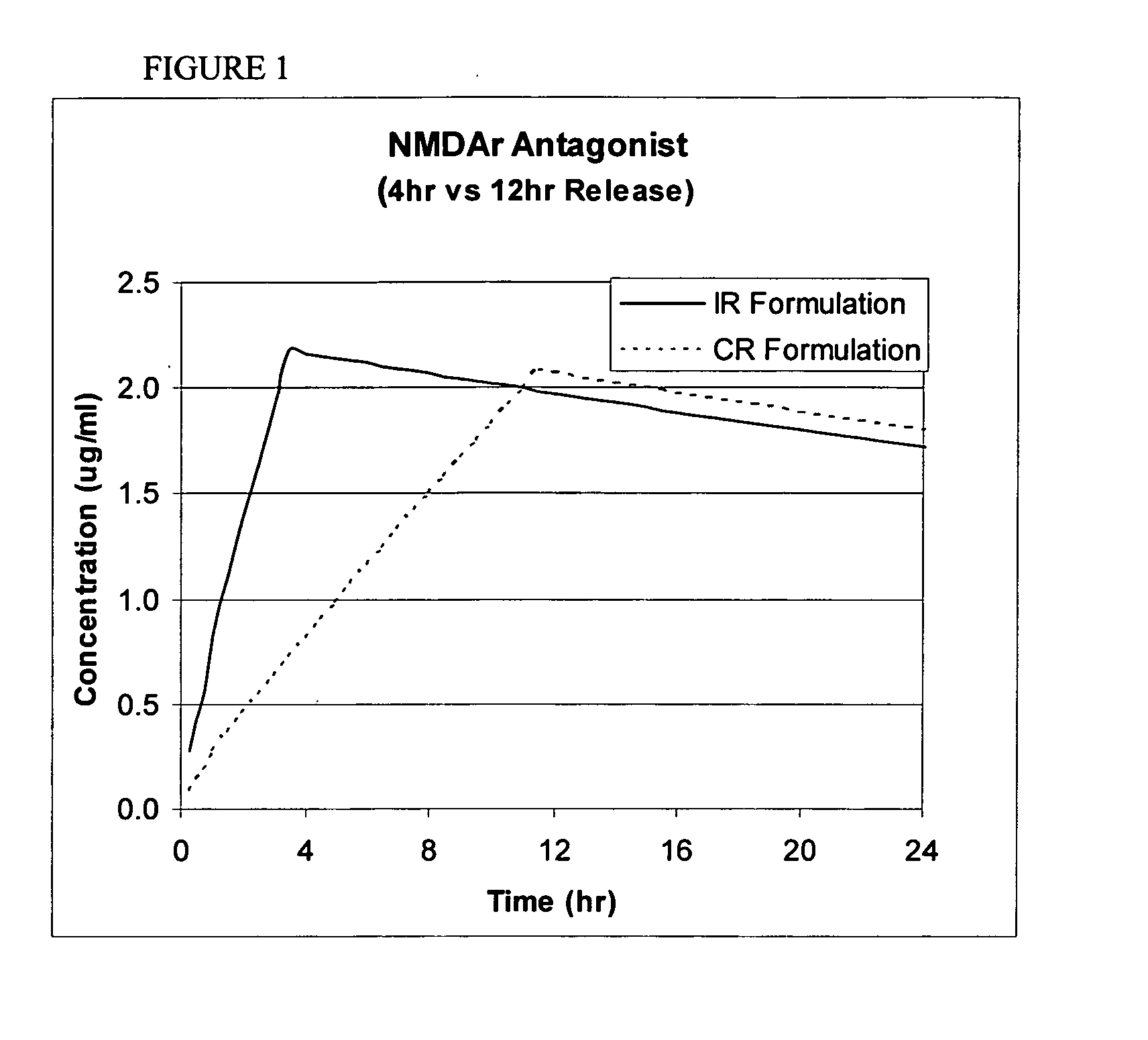

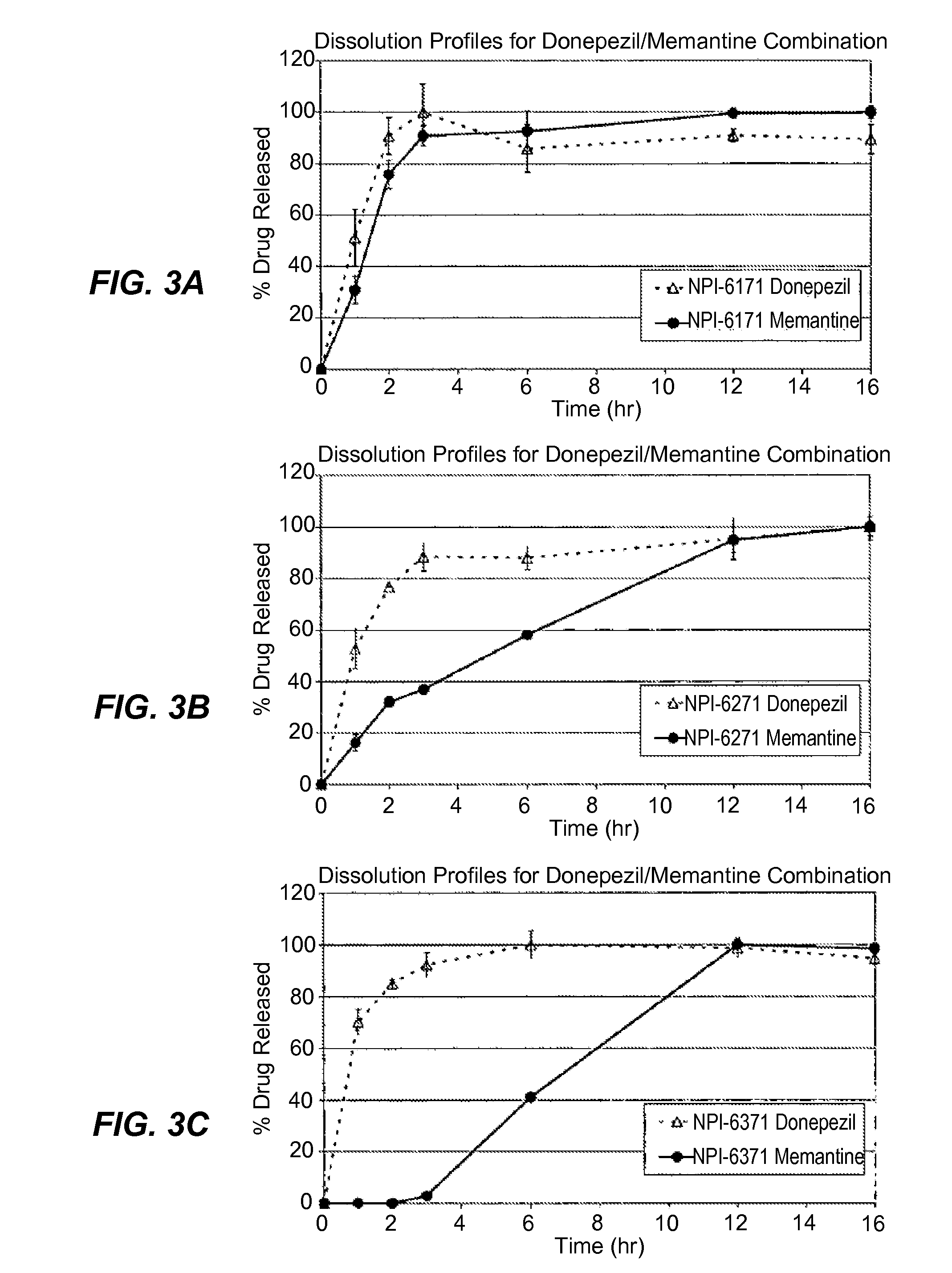

InactiveUS20050209218A1Low variabilityMaximizes therapeutic benefitBiocideNervous disorderDiseasePsychogenic disease

Owner:ADAMAS PHARMA INC

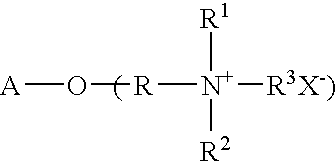

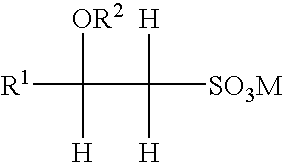

Personal care compositions containing cationically modified starch and an anionic surfactant system

ActiveUS20060002880A1Increase depositionReduce cleaningCosmetic preparationsHair cosmeticsPersonal careWater soluble

Personal care compositions comprise (a) from about 0.01 wt. % to about 10 wt. % of a water-soluble cationically modified starch polymer, wherein said water-soluble cationically modified starch polymer has a molecular weight from about 1,000 to about 200,000 and a charge density from about 0.7 meq / g to about 7 meq / g; (b) from about 5 wt. % to about 50 wt. % of an anionic surfactant system, said anionic surfactant system comprising at least one anionic surfactant and having an ethoxylate level and an anion level, (i) wherein said ethoxylate level is from about 1 to about 6, and (ii) wherein said anion level is from about 1 to about 6; and (c) a cosmetically acceptable medium. Personal care compositions as described above further comprise from about 0.01 wt. % to about 10 wt. % of one or more oily conditioning agents. Methods of treating hair or skin comprise applying the personal care compositions as described above to the hair or skin and rinsing the hair or skin.

Owner:THE PROCTER & GAMBLE COMPANY

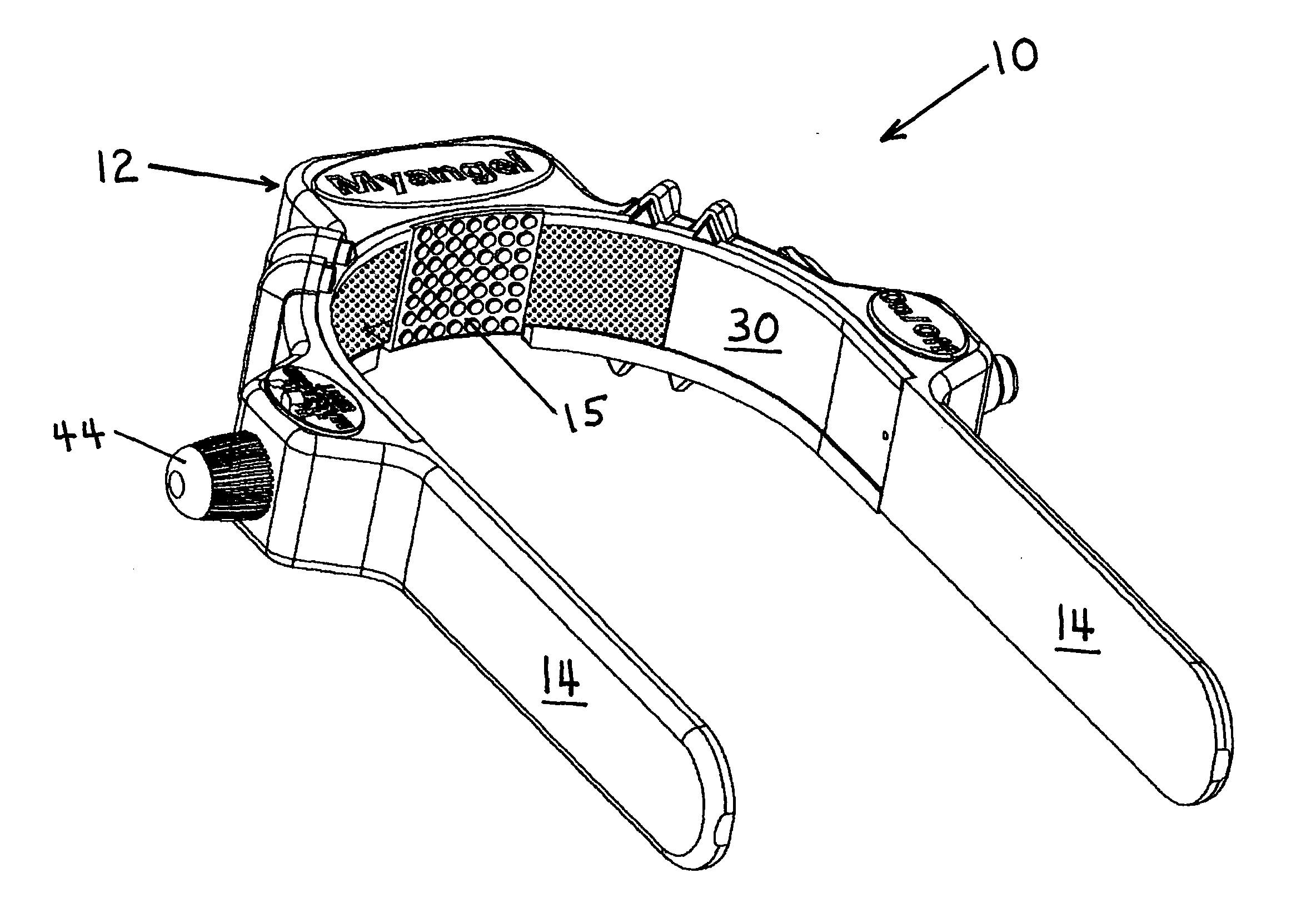

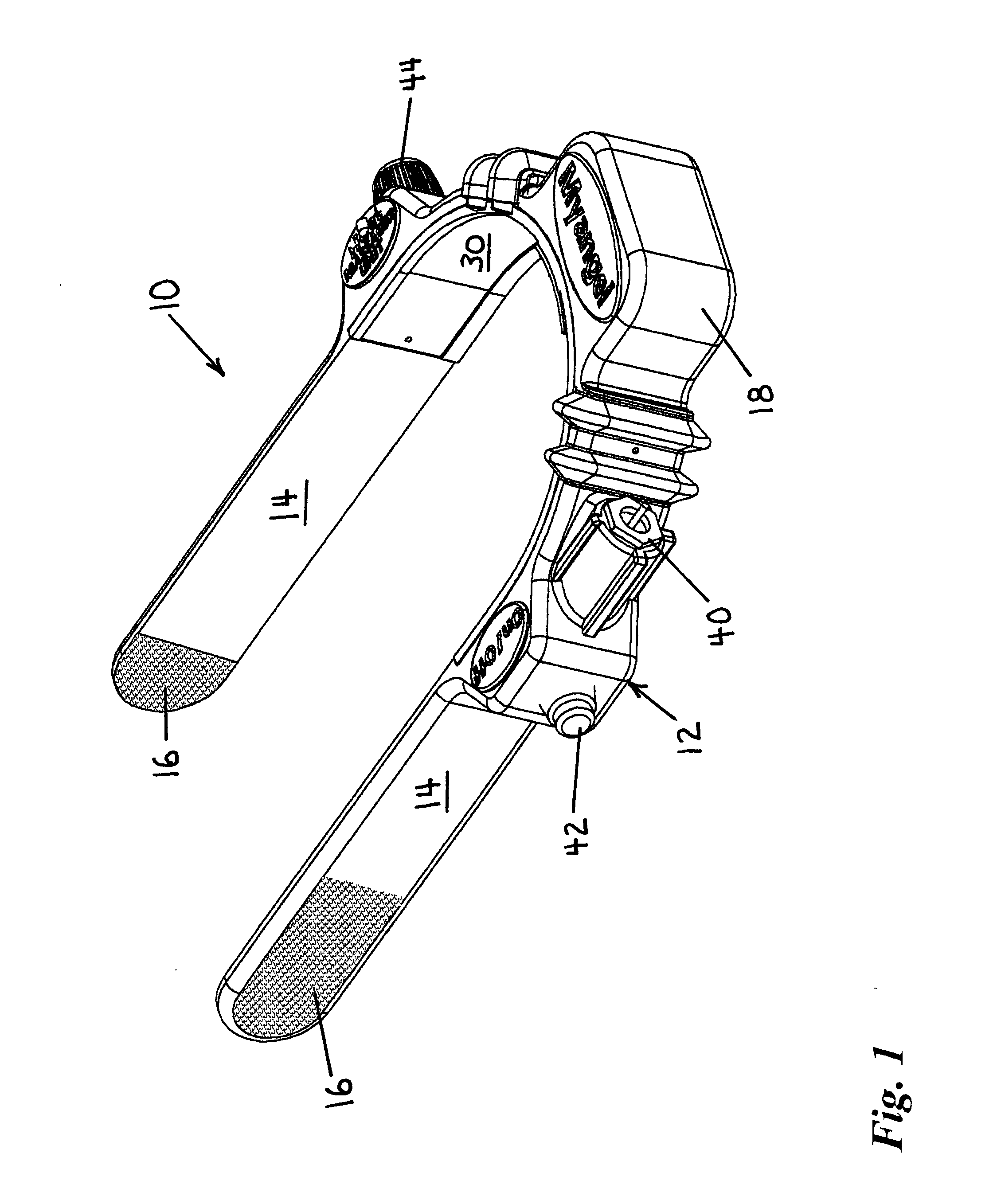

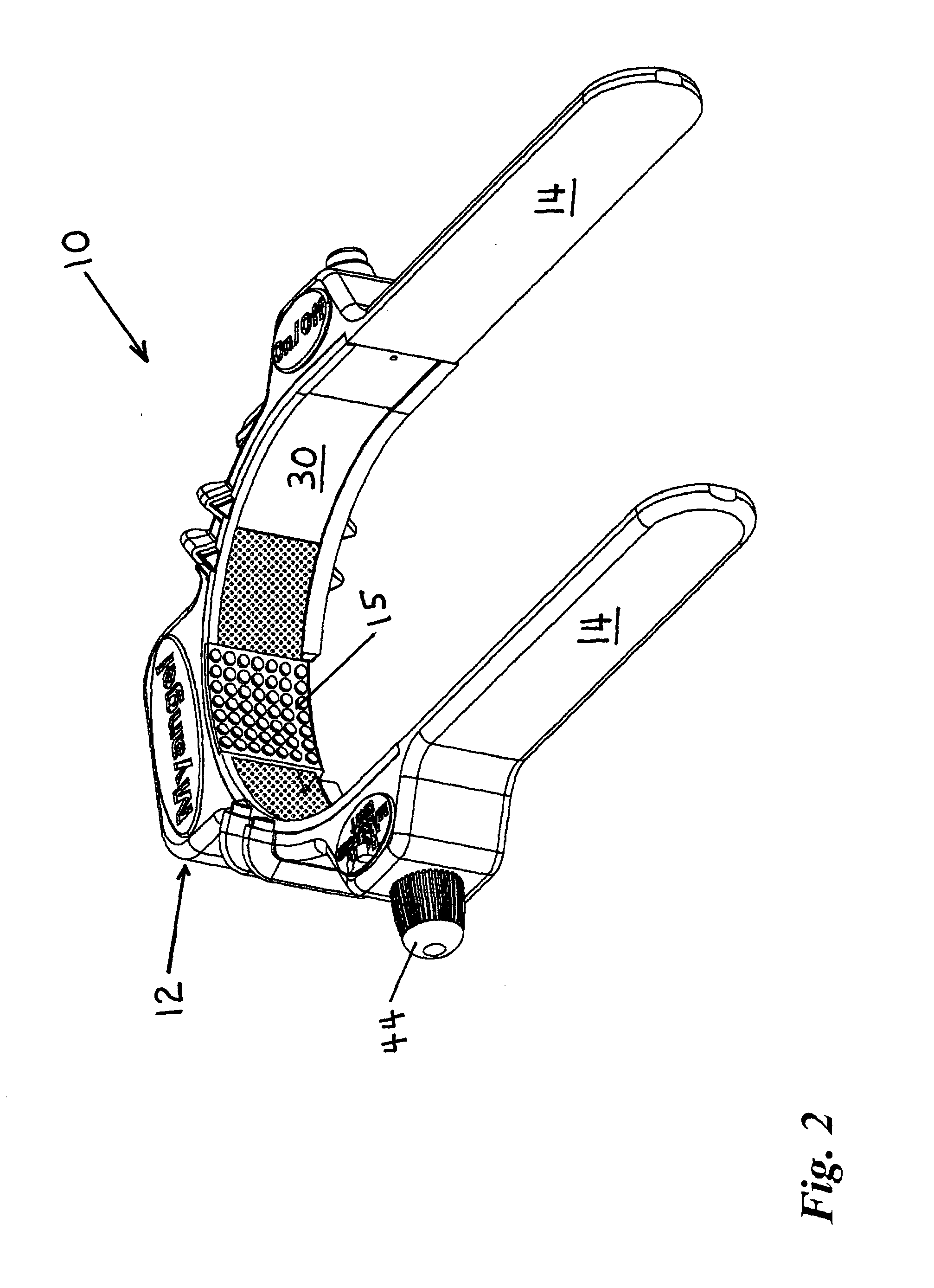

Cervical heat and vibration massage apparatus

A compact, neck massager configured as a collar-type device adapted to be worn about a persons neck and adapted for providing the most effective natural relaxation therapies, namely gentle vibration and soothing heat to the neck and spine is disclosed. The device generally comprises a collar sculpted to fit comfortably around the neck and secured by flexible straps with connectable ends to facilitate removable attachment of the device around the user's neck. The collar includes a housing containing an electric motor powered alternatively by a battery or AC power source. The electric motor is adapted with an output shaft having an eccentric mass for converting rotational movement of a motor into a vibration movement for transmission to the cervical area through the housing. The device further includes a heating band disposed on the inner surface thereof for selectively transmitting heat to the cervical area. A control circuit is provided to enable the user to selectively vary the power supplied between the electric motor and heating element thereby varying the transmission of therapeutic vibration and heat to the neck. The electrical components are configured to function as an RLC circuit such that system oscillates between heat and vibration thereby maximizing therapeutic benefits.

Owner:BURS DOROTHY M

Methods and Compositions for Treating Migraine Pain

InactiveUS20100029665A1Benefit maximizationEliminate side effectsBiocideNervous disorderHeadache severeVascular headache

The present invention provides novel methods and compositions for the treatment and prevention of headaches, vascular headaches, migraine headaches, cluster headaches, and migraine. One of the headaches, vascular headaches, migraine headaches, cluster headaches, and migraine treated by the methods and compositions of the invention is migraine.

Owner:MEYERSON LAURENCE R +3

Methods and compositions for the treatment of CNS-related conditions

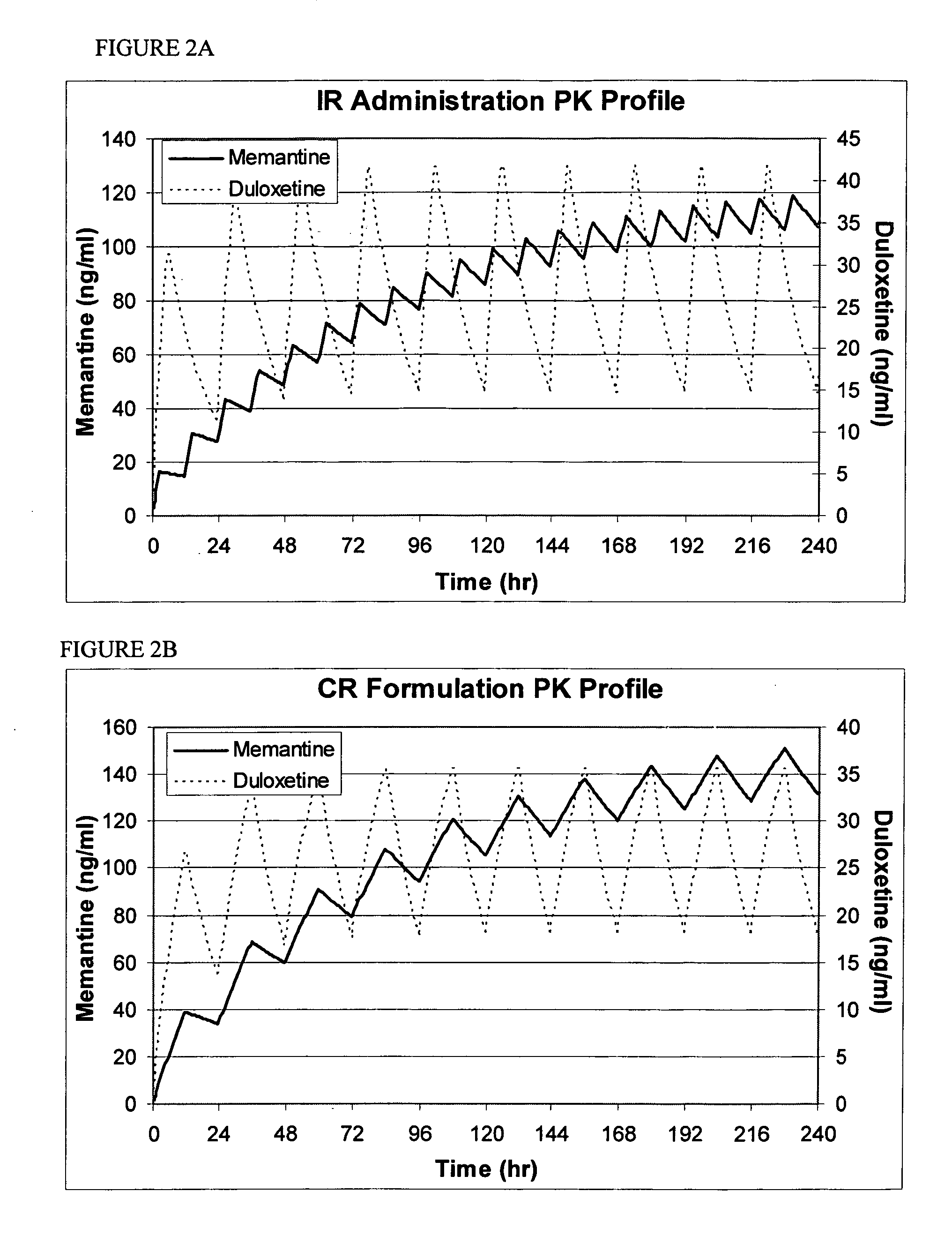

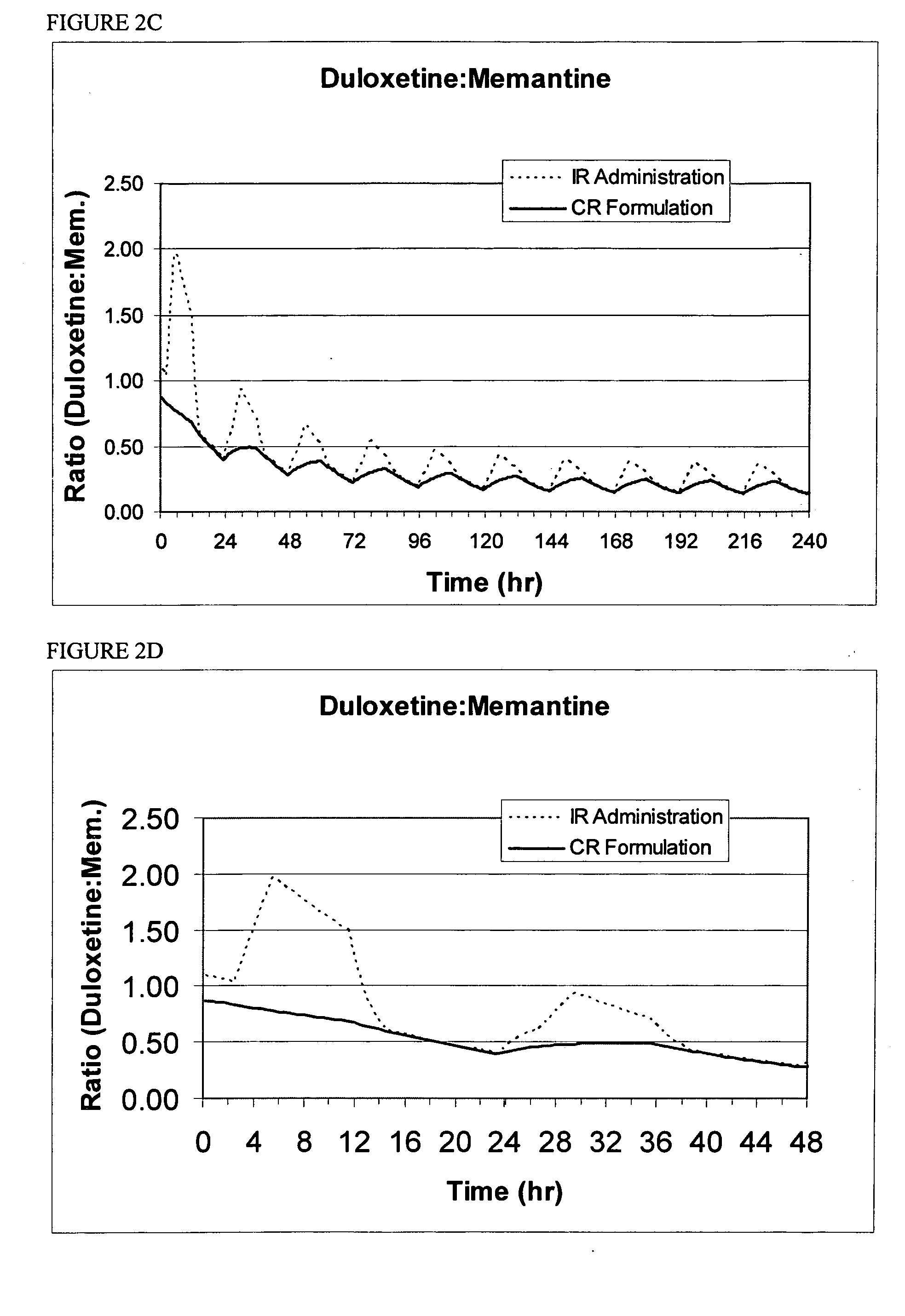

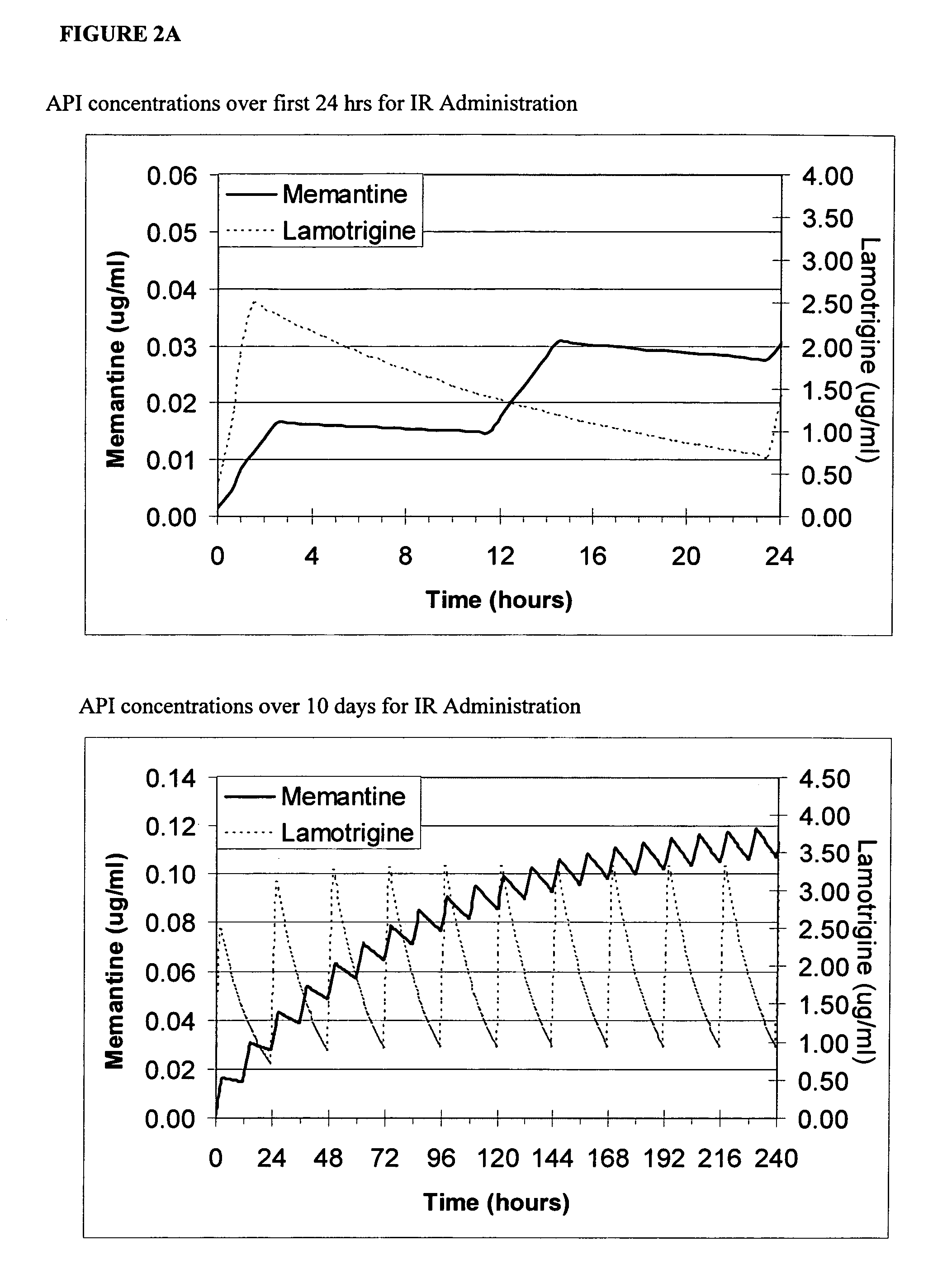

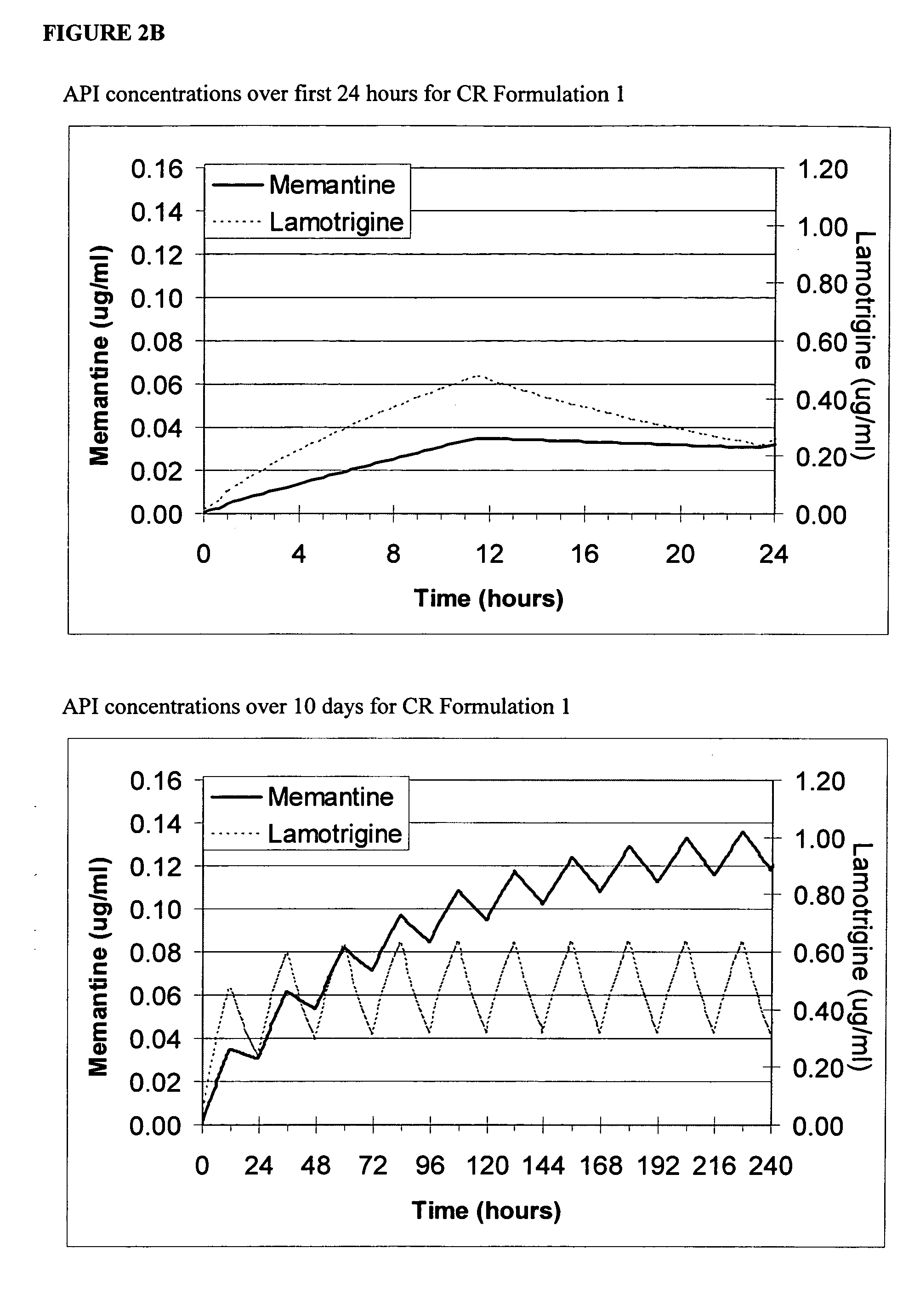

ActiveUS20060252788A1Reduce and even minimize variationMinimizing CratioBiocideNervous disorderDiseasePsychiatry

The present invention provides novel methods and compositions for the treatment and prevention of CNS-related conditions. One of the CNS-related conditions treated by the methods and compositions of the invention is Alzheimer's disease.

Owner:ADAMAS PHARMA LLC

Methods and compositions for treating migraine pain

InactiveUS20060240043A1Low variabilityMaximizes therapeutic benefitBiocideBacterial antigen ingredientsHeadache severeHeadaches

The present invention provides novel methods and compositions for the treatment and prevention of headaches, vascular headaches, migraine headaches, cluster headaches, and migraine. One of the headaches, vascular headaches, migraine headaches, cluster headaches, and migraine treated by the methods and compositions of the invention is migraine.

Owner:NEUROMOLECULAR INC +1

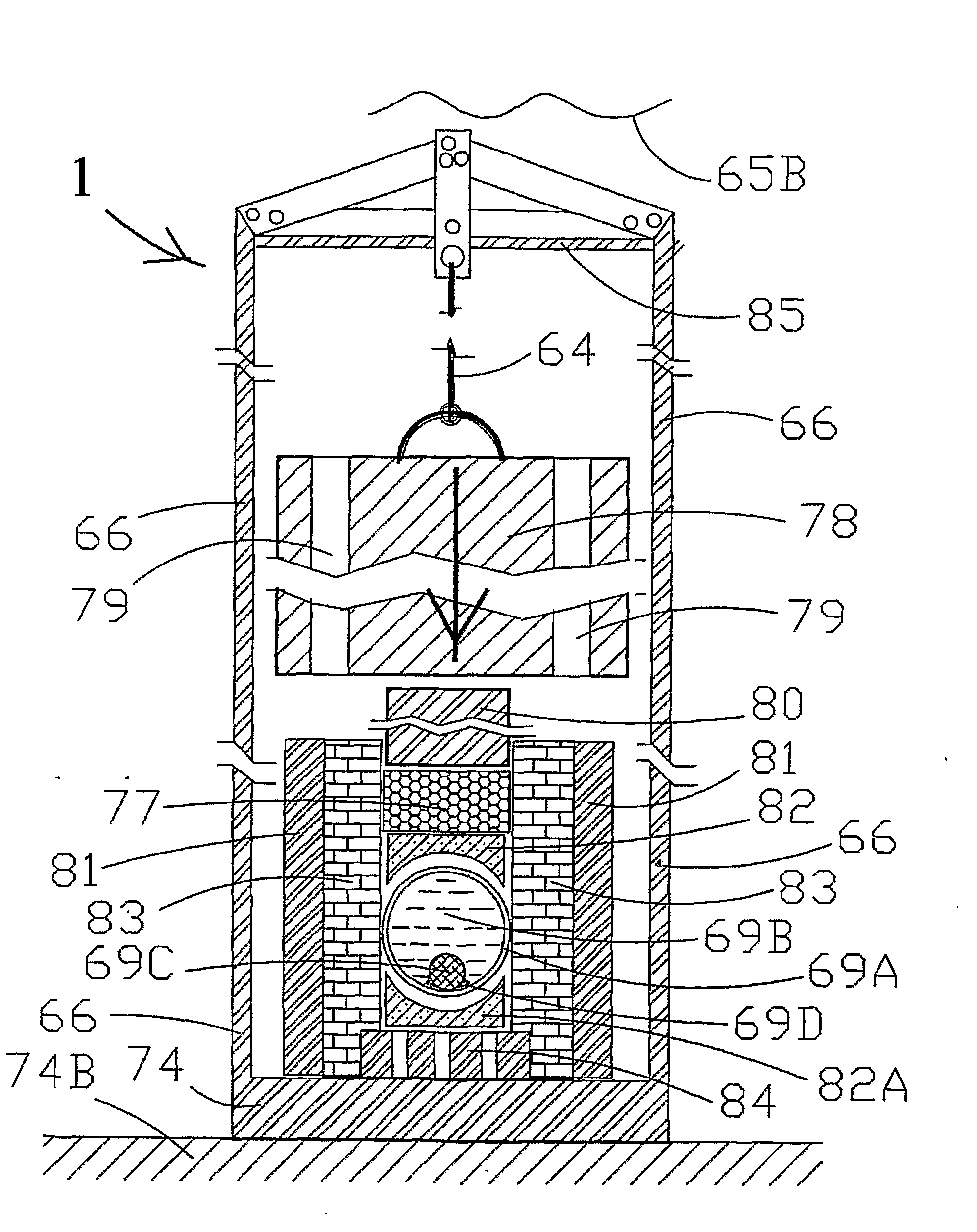

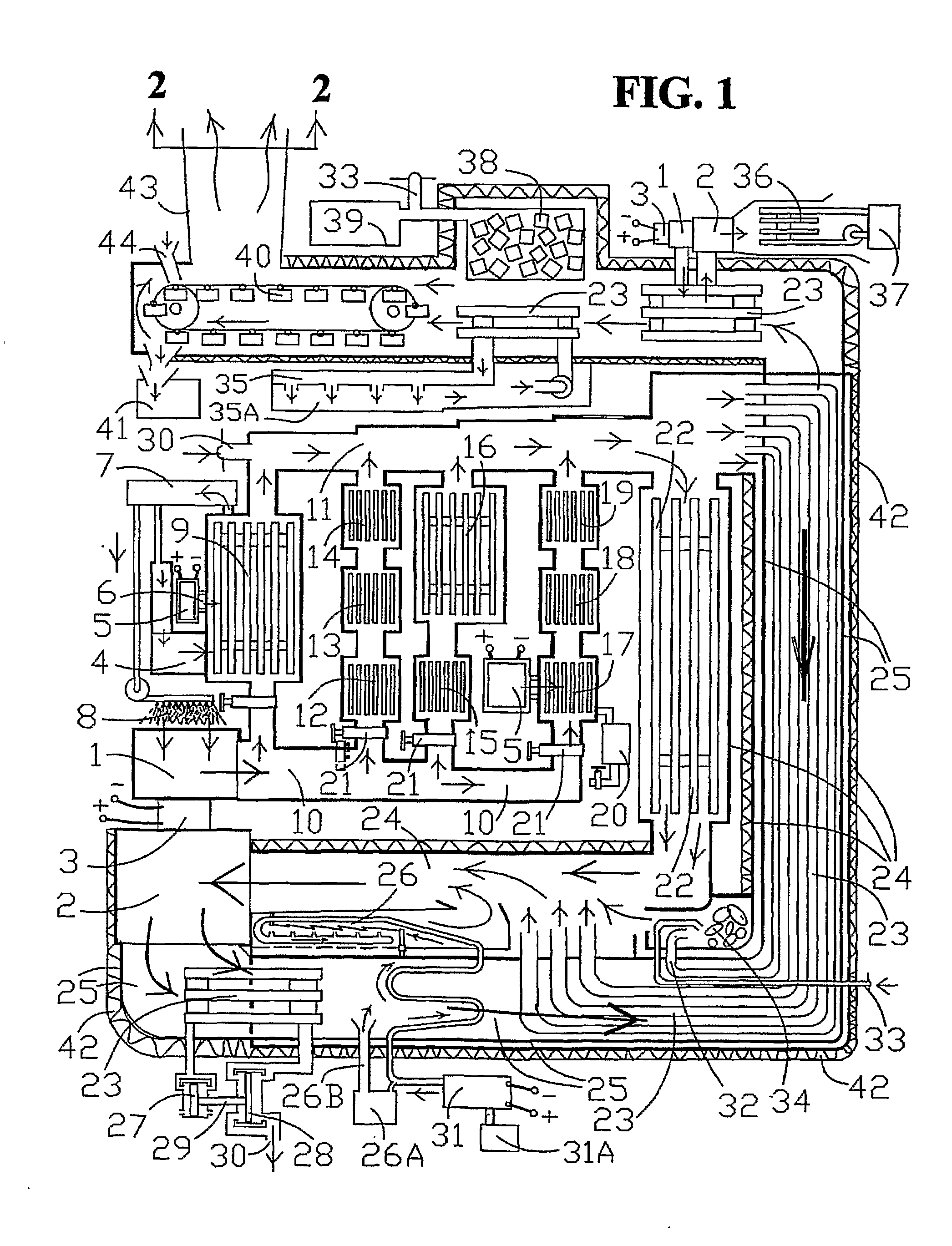

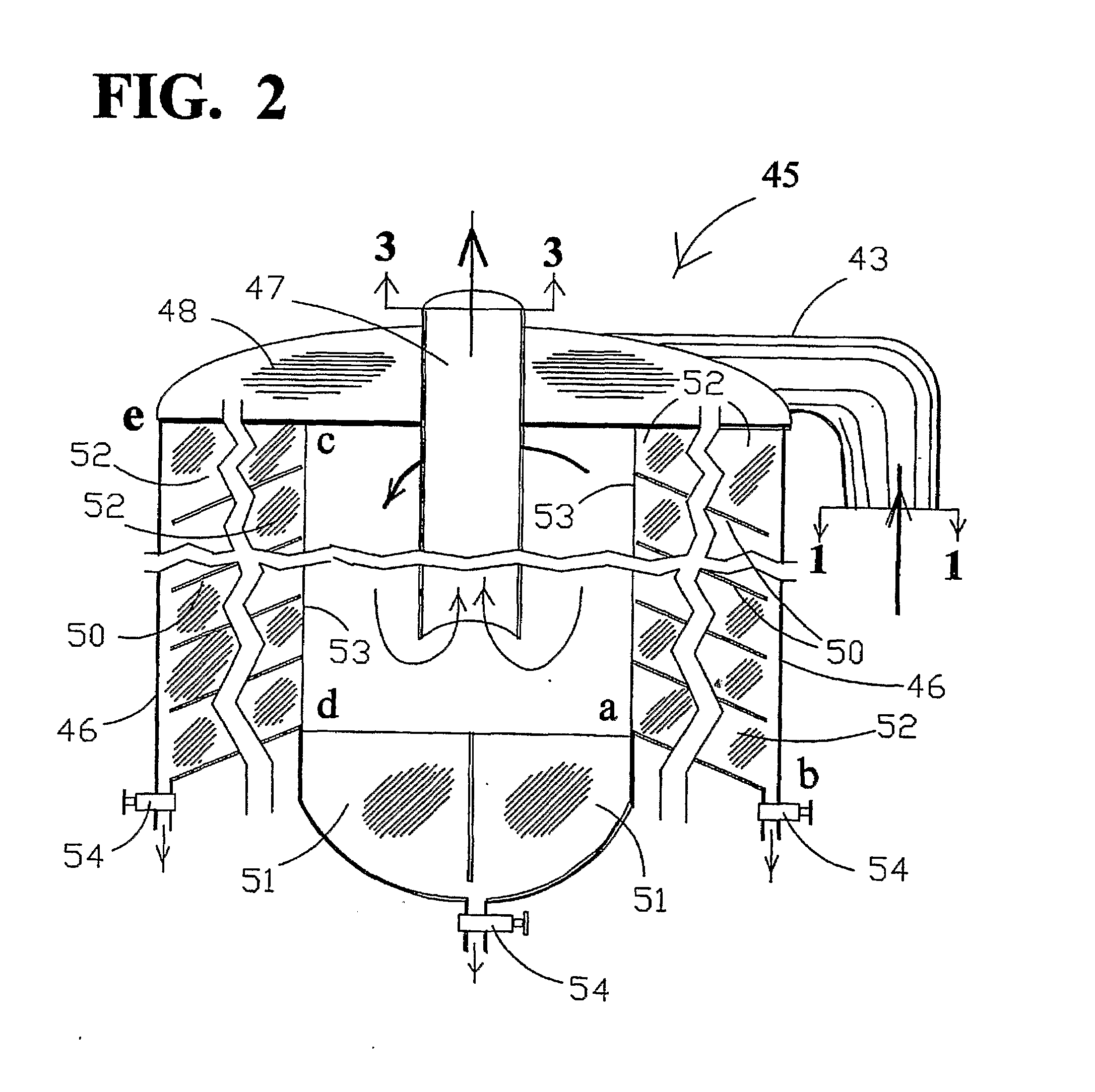

Heat Energy Recapture And Recycle And Its New Applications

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

Composition and method for treating neurological disease

ActiveUS8389578B2Maintain and enhance efficacyEffective compositionBiocideNervous disorderDiseaseNervous system

Owner:ADAMAS PHARMA LLC

Composition and method for treating neurological disease

ActiveUS20060189694A1Maintain and enhance efficacyEffective compositionBiocideNervous disorderNeurological disorderPharmacology

Owner:ADAMAS PHARMA LLC

Methods and compositions for the treatment of epilepsy, seizure disorders, and other CNS disorders

InactiveUS20050245460A1Benefit maximizationReducing unwanted side effectBiocideNervous disorderDiseaseEpileptic disorder

Owner:NEUROMOLECULAR INC

Microwave packaging with indentation patterns

InactiveUS20060011620A1Improve cooking resultsGood cooking effectMilk preparationReady-for-oven doughsCooking & bakingEngineering

Indentation patterns in microwave packaging materials can enhance the baking and browning effects of the microwave packaging materials on food. The indentation patterns can provide venting to either channel moisture from one area of the food product to another, trap moisture in a certain area to prevent it from escaping, or channel the moisture completely away from the food product. The indentation patterns can cause the microwave packaging material underneath a food product to be slightly elevated above the cooking platform in the base of a microwave. The indentation patterns can lessen the heat sinking effect of the cooking platform by providing an air gap for insulation. Elevating the base of the microwave packaging material further allows more incident microwave radiation to propagate underneath the microwave packaging material to be absorbed by the food product or by microwave interactive materials in the microwave packaging material that augment the heating process.

Owner:GRAPHIC PACKAGING INT

Methods and compositions for treating nociceptive pain

InactiveUS20060052370A1Low variabilityMaximizes therapeutic benefitBiocideNervous disorderPreventing painPain duration

Owner:NEUROMOLECULAR PHARMA +1

Methods and Compositions for the Treatment of CNS-Related Conditions

ActiveUS20100311697A1Benefit maximizationEliminate side effectsBiocideNervous disorderDiseaseMedicine

Owner:ADAMAS PHARMA LLC

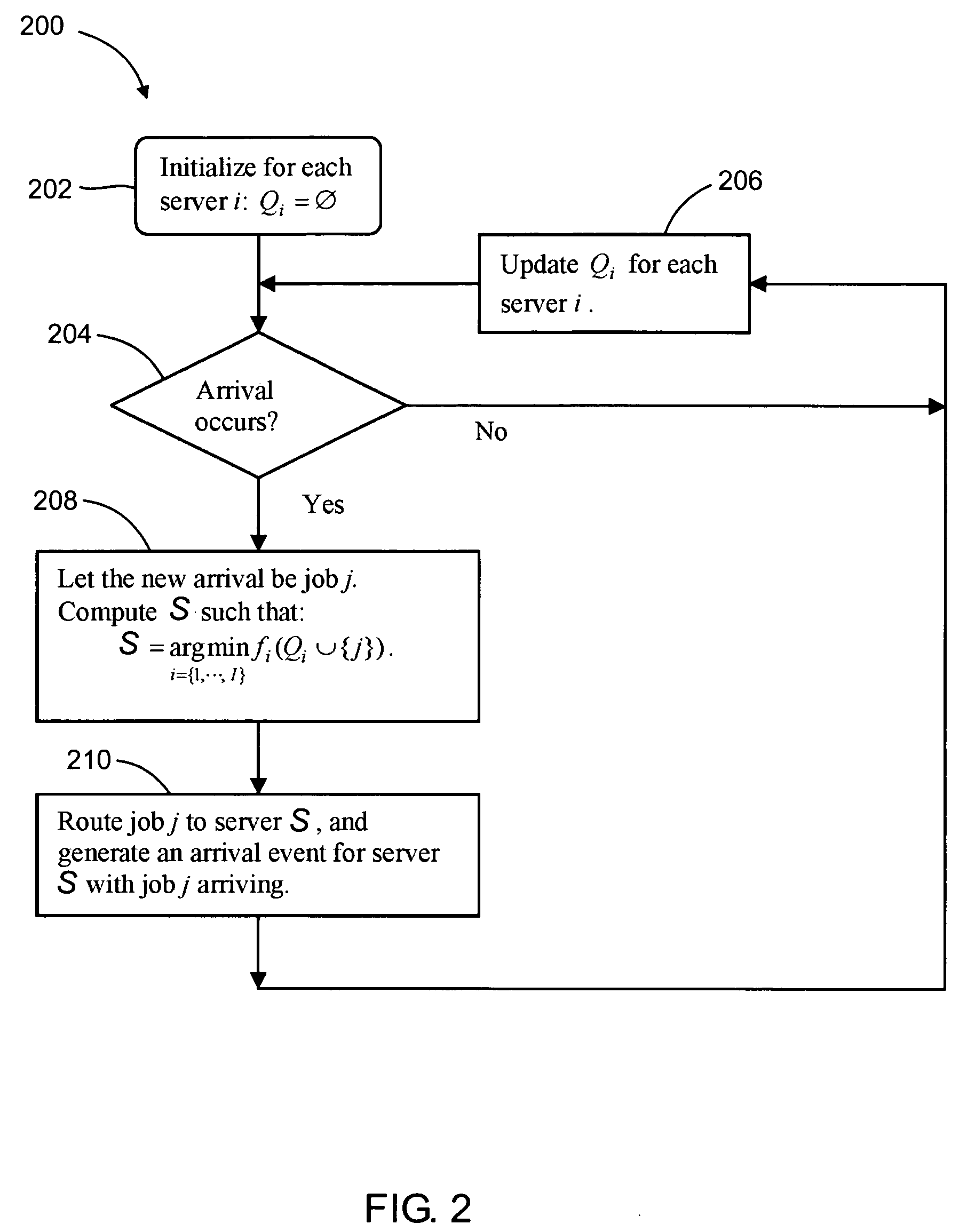

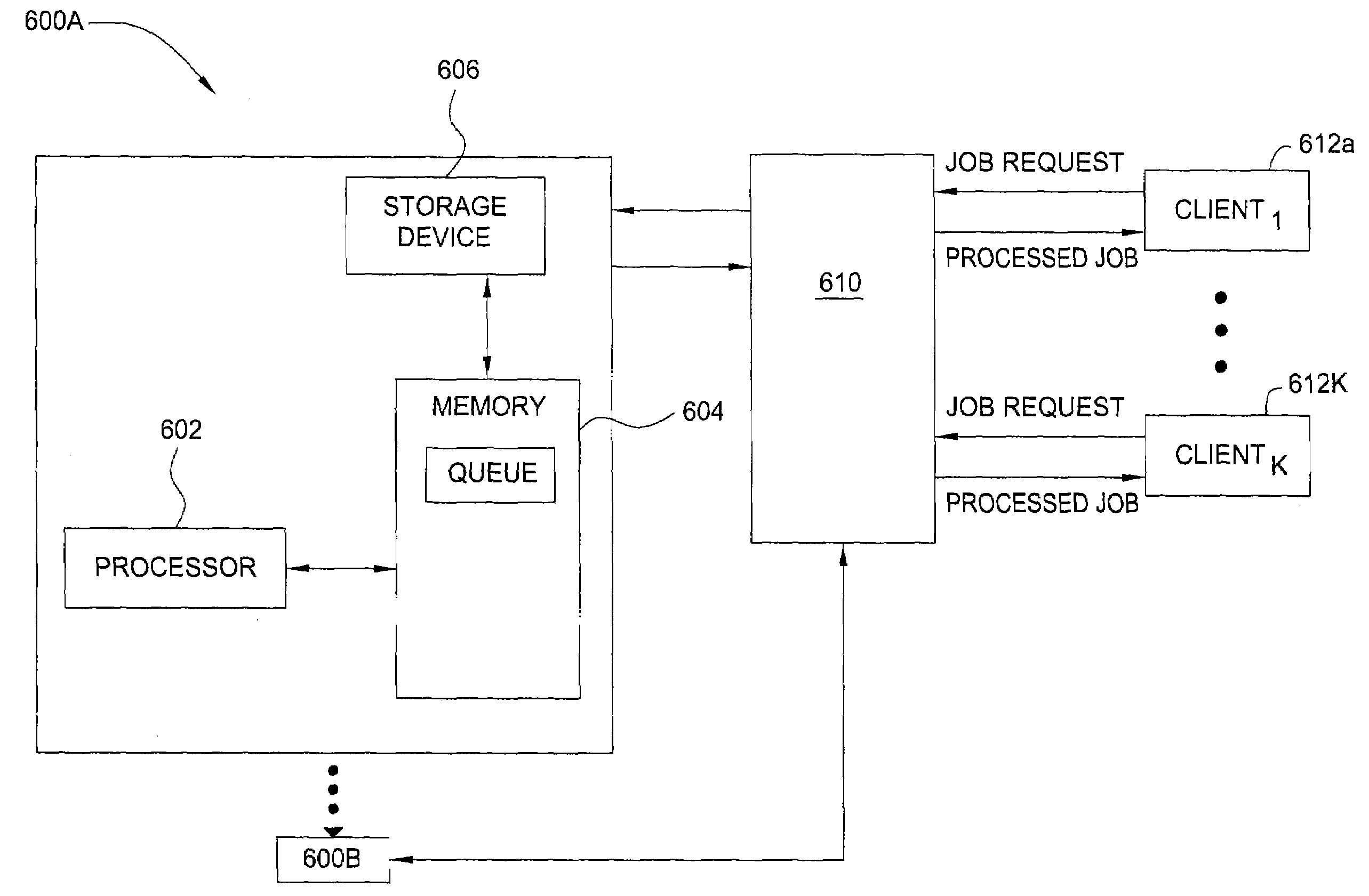

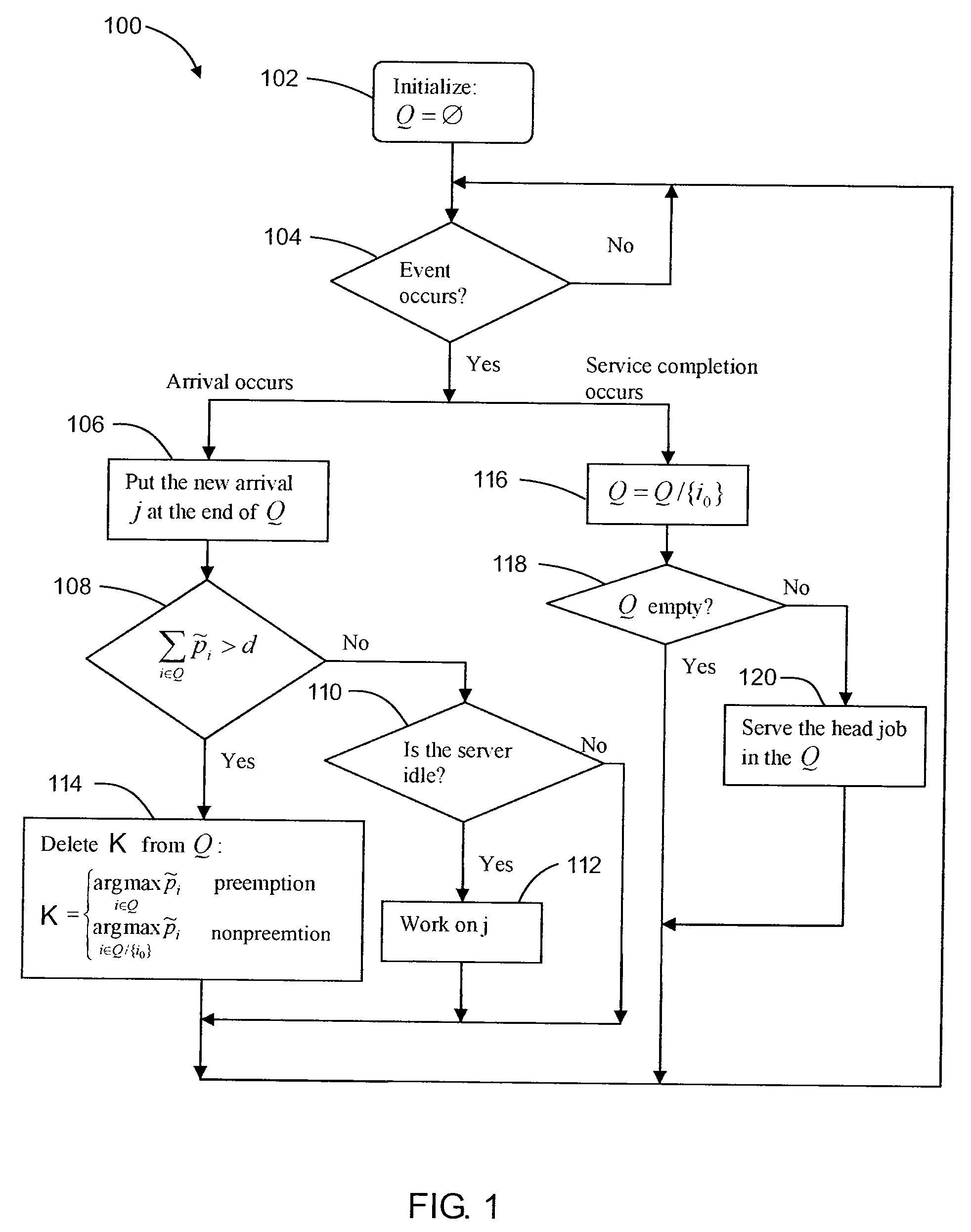

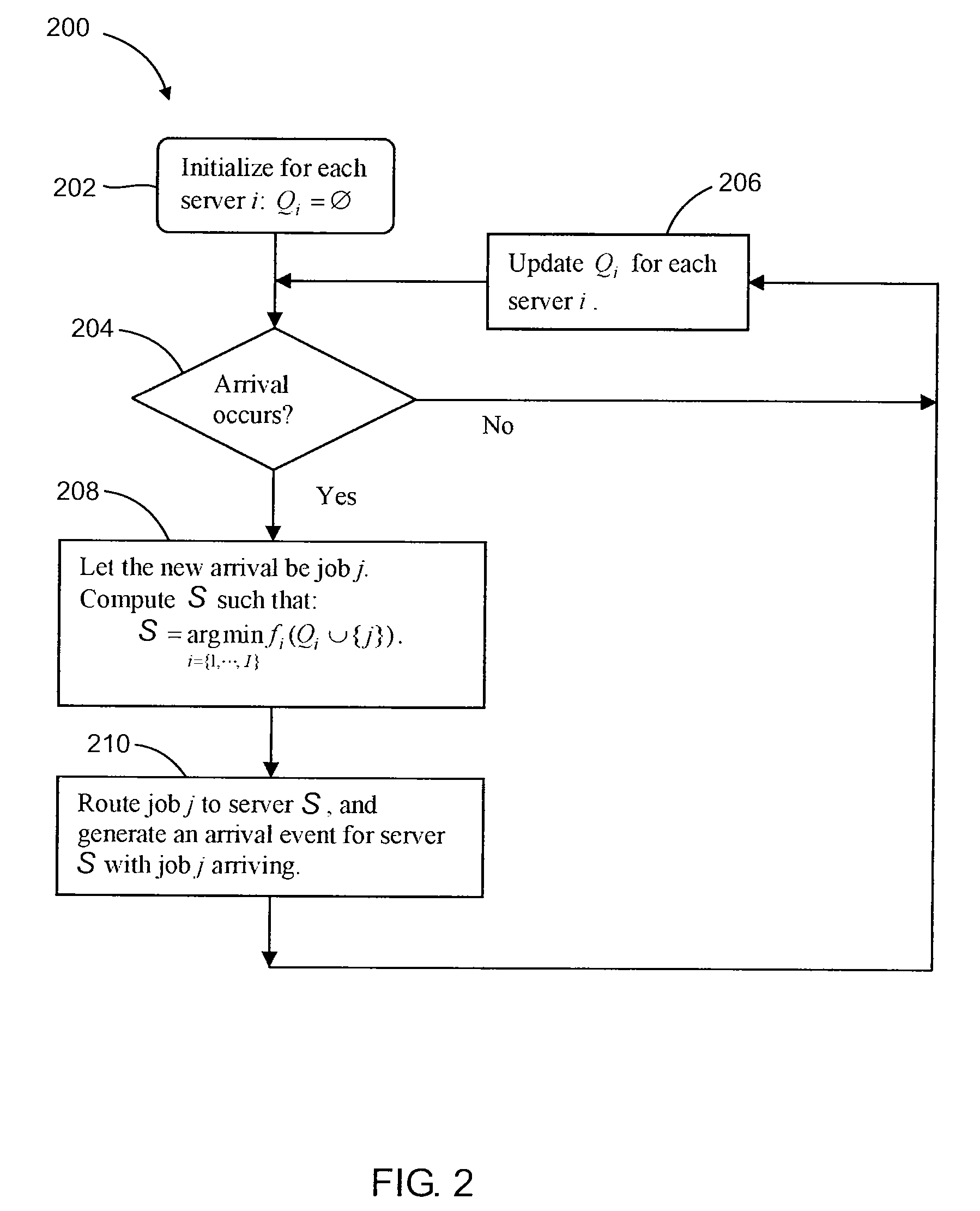

Method and apparatus for on-demand resource allocation and job management

InactiveUS20050114860A1Optimizes system outputOptimizes service provider profitProgram initiation/switchingResource allocationService-level agreementOn demand

The invention is a method and apparatus for on-demand resource planning for unified messaging services. In one embodiment, multiple clients are served by a single system, and existing system resources are allocated among all clients in a manner that optimizes system output and service provider profit without the need to increase system resources. In one embodiment, resource allocation and job scheduling are guided by individual service level agreements between the service provider and the clients that dictate minimum service levels that must be achieved by the system. Jobs are processed in a manner that at least meets the specified service levels, and the benefit or profit derived by the service provider is maximized by prioritizing incoming job requests within the parameters of the specified service levels while meeting the specified service levels. Thus, operation and hardware costs remain substantially unchanged, while system output and profit are maximized.

Owner:MAPLEBEAR INC

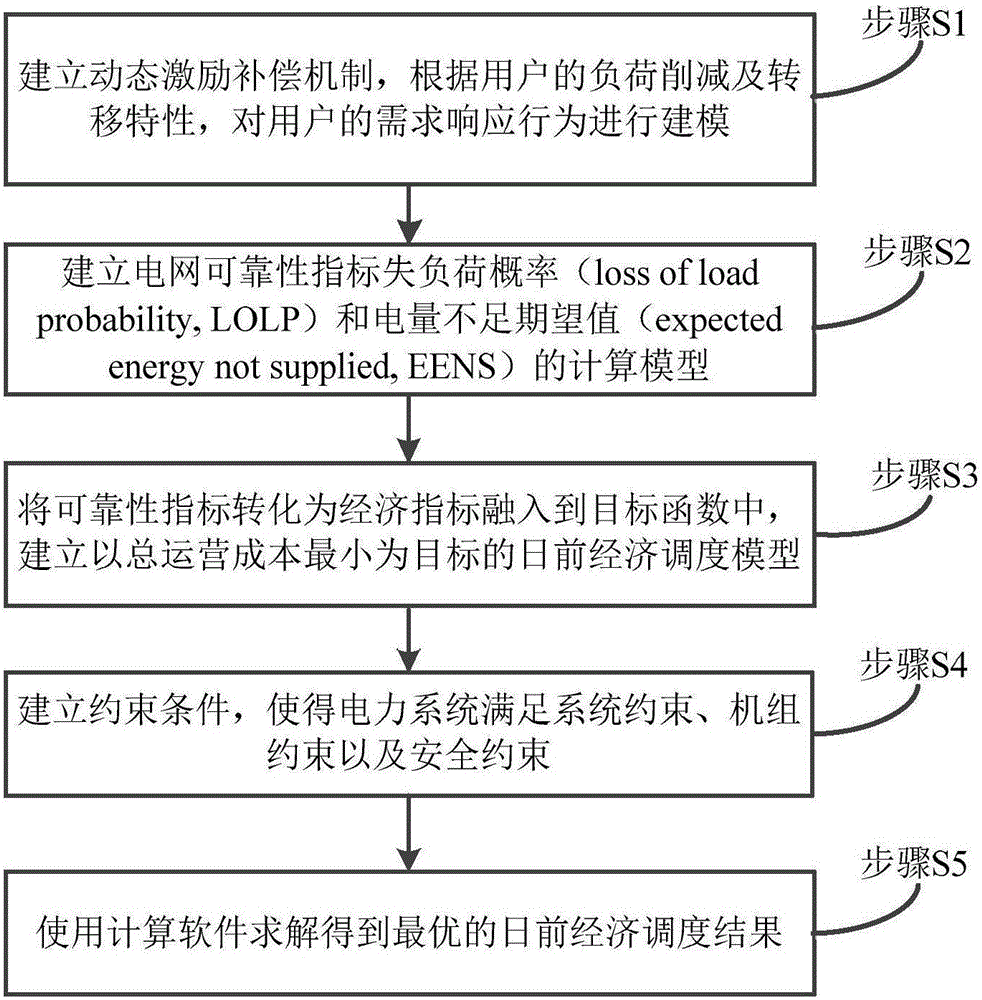

Power grid safety optimization dispatching method considering demand response

ActiveCN106712005AReduce operating costsOptimizing Load ProfilesData processing applicationsSystems intergating technologiesOperational costsComputational model

The invention discloses a power grid safety optimization dispatching method considering demand response. The method comprises the following steps: establishing a dynamic excitation compensation mechanism, and carrying out modeling on demand response behaviors of a user according to load shedding and transfer features; establishing a calculation model of power grid reliability index loss-of-load probability and expected energy not supplied; converting a reliability index into an economic index and integrating the index into an objective function, and establishing a day-ahead economic dispatch model with the total operation cost minimum being as an objective; establishing constraint conditions to enable an electric power system to meet system constraints, unit constraints and security constraints; and carrying out solving through calculation software to obtain an optimal day-ahead economic dispatch result. The demand response and reliability index are integrated into day-ahead dispatching of the electric power system, and the optimal dispatching model considering dynamic excitation compensation and expected power failure loss is established, thereby coordinately solving the problem of unit commitment of a generation power side and the problem of supply-demand interaction of a demand side and realizing economy and security of operation of a power grid.

Owner:SOUTHEAST UNIV

Personal care compositions containing cationically modified starch and an anionic surfactant system

InactiveUS20070160555A1Increase depositionReduce cleaningCosmetic preparationsHair cosmeticsPersonal careWater soluble

Personal care compositions comprise (a) from about 0.01 wt. % to about 10 wt. % of a water-soluble cationically modified starch polymer, wherein said water-soluble cationically modified starch polymer has a molecular weight from about 250,000 to about 15,000,000 and a charge density from about 0.2 meq / g to about 5 meq / g; (b) from about 5 wt. % to about 50 wt. % of an anionic surfactant system, said anionic surfactant system comprising at least one anionic surfactant and having an ethoxylate level and an anion level, (i) wherein said ethoxylate level is from about 1 to about 6, and (ii) wherein said anion level is from about 1 to about 6; and (c) a cosmetically acceptable medium. Personal care compositions as described above further comprise from about 0.01 wt. % to about 10 wt. % of one or more oily conditioning agents. Methods of treating hair or skin comprise applying the personal care compositions as described above to the hair or skin and rinsing the hair or skin.

Owner:THE PROCTER & GAMBLE COMPANY

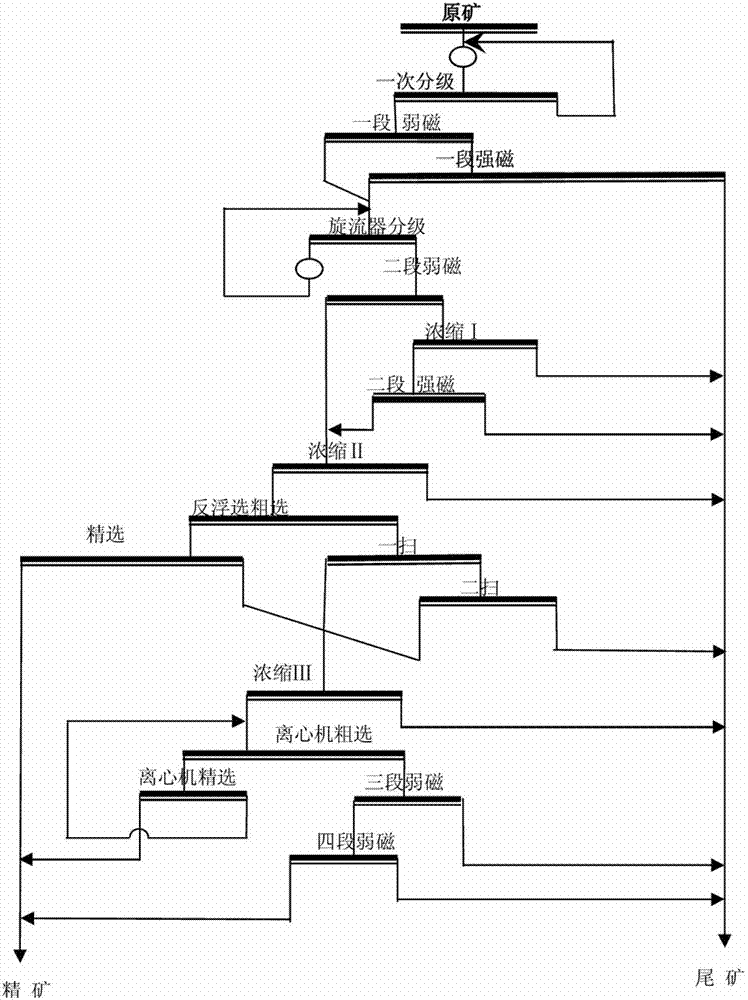

New technology for sorting lean hematite and magnetite orecontaining iron carbonate

The invention relates to a new technology for sorting a lean red magnetite ore containing iron carbonate, which is characterized by comprising the following steps of: enriching and discarding tailings by adopting a 'technology for stage grinding and strong magnetic discarding tailings', thereby obtaining a mixed magnetic concentrate; sorting the mixed magnetic concentrate by adopting an 'open-circuit reverse flotation technology with one-stage roughing, one-stage fining and two-stage scavenging', thereby obtaining a high-grade hematite and magnetite concentrate; adopting a 'close-circuit centrifuge technology with one-stage roughing and one-stage fining' for sorting a high iron carbonate ore enriched in mine obtained by adopting the 'open-circuit reverse flotation technology', thereby obtaining a siderite concentrate; feeding the centrifuge tailings into a weak magnetic machine and sorting; and recycling fine fraction magnetic concentrates. The new technology provided by the inventionhas the advantages that the lean hematite and magnetite ore containing iron carbonate is sorted by adopting a 'combined sorting process flow with stage grinding, strong magnetic discarding tailings, reverse flotation-centrifuge', so that the sorting indexes of the whole iron grade of the obtained comprehensive concentrate being more than 65% and the metal recovery rate being more than 65% are achieved and the maximization of utilization benefit of iron ore resources is realized.

Owner:鞍钢集团矿业设计研究院有限公司

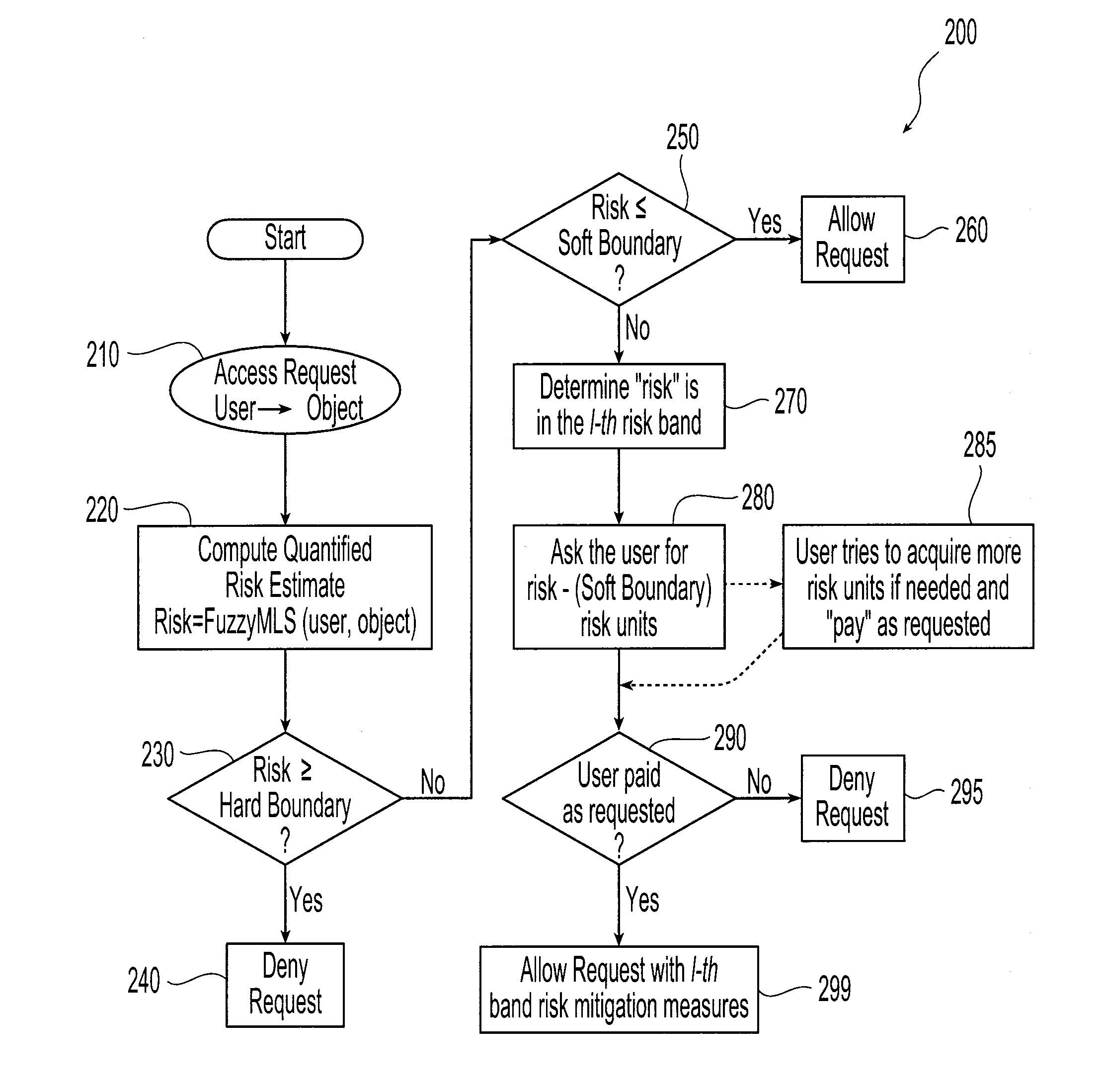

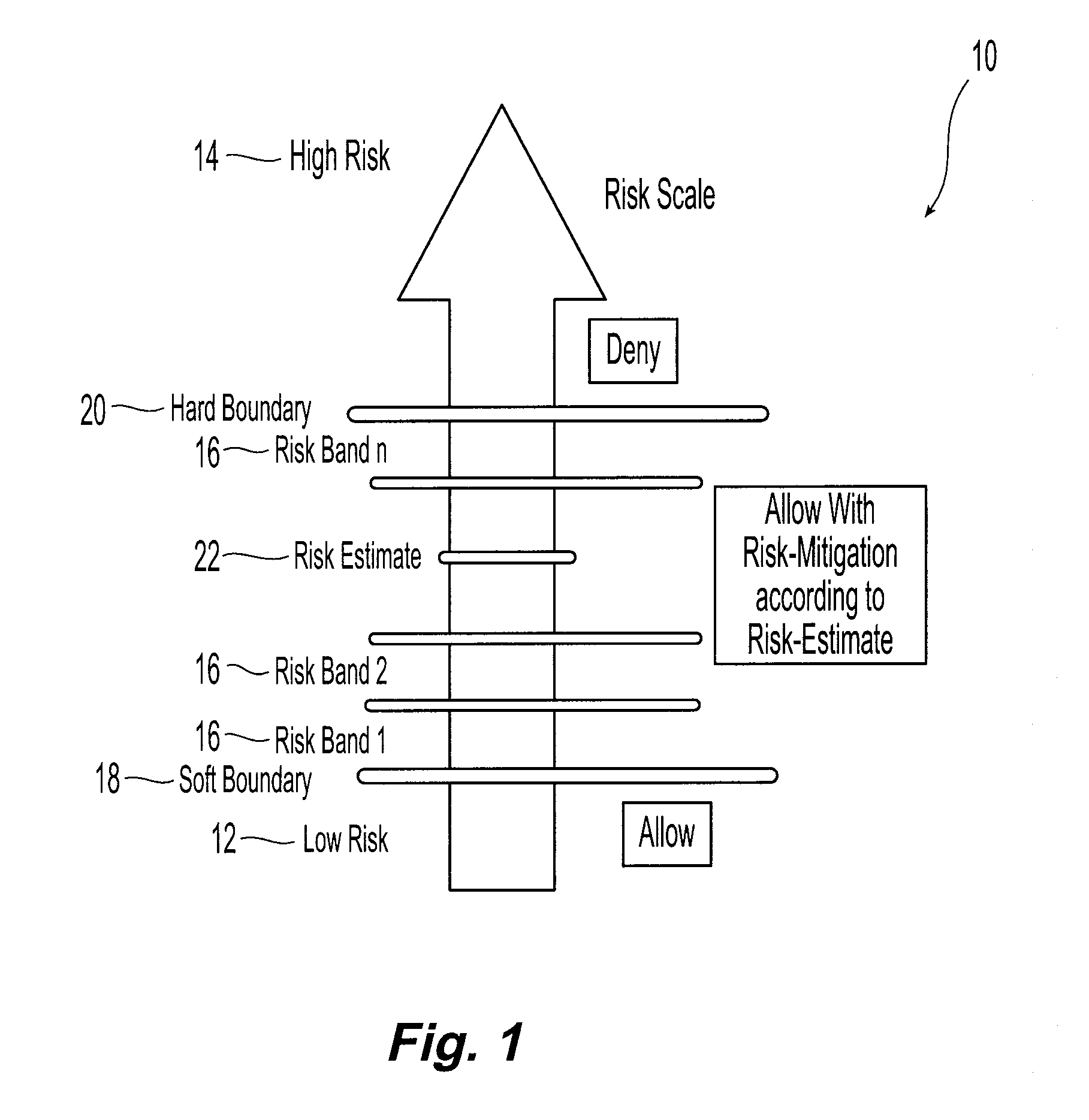

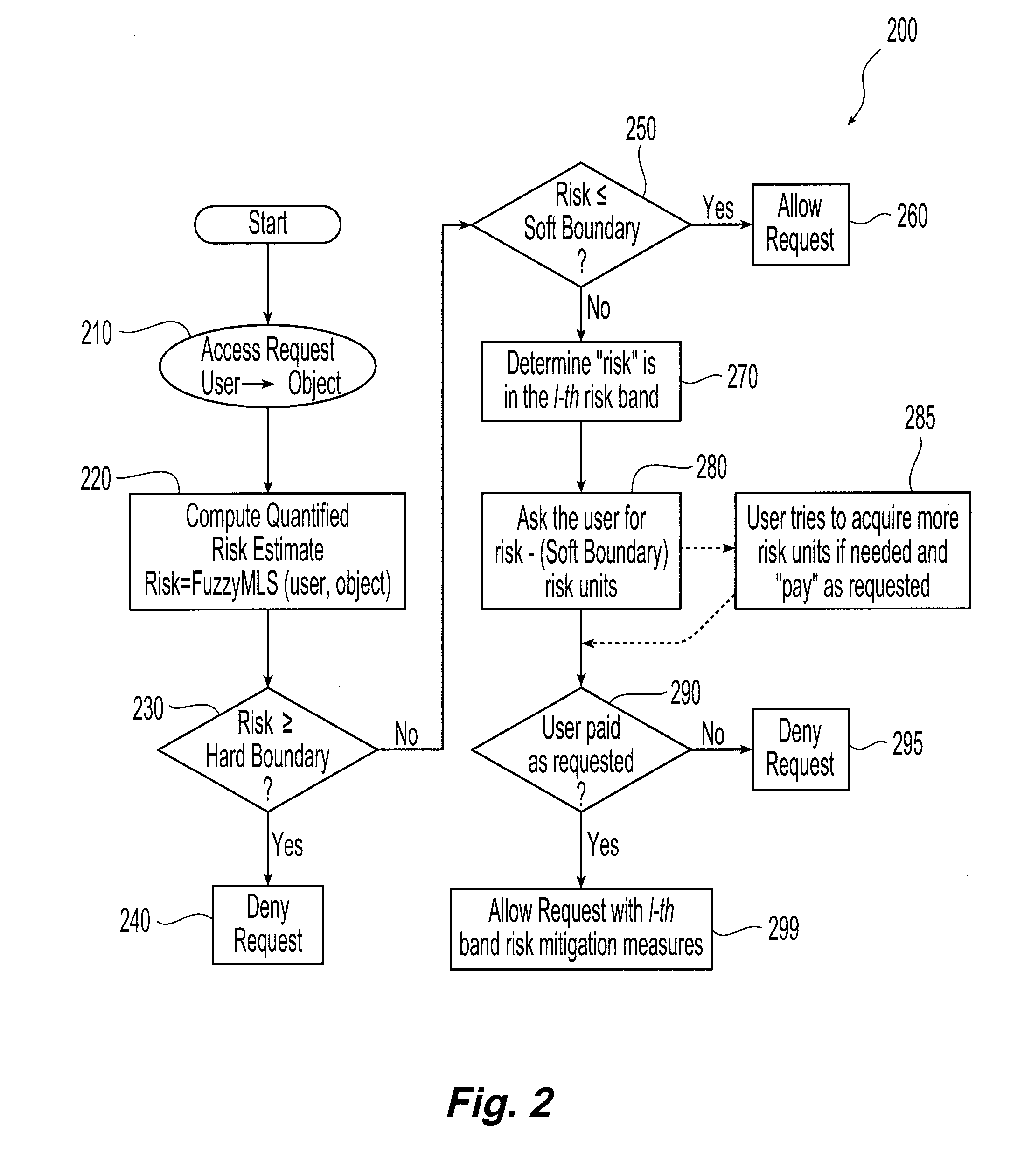

Risk Adaptive Information Flow Based Access Control

InactiveUS20110173084A1Benefit maximizationSuffer damageDigital data processing detailsAnalogue secracy/subscription systemsRisk quantificationKnowledge management

Systems and methods are provided to manage risk associated with access to information within a given organization. The overall risk tolerance for the organization is determined and allocated among a plurality of subjects within the organization. Allocation is accomplished using either a centralized, request / response or free market mechanism. As requested from subjects within the organization for access to objects, i.e. information and data, are received, the amount of risk or risk level associated with each requested is quantified. Risk quantification can be accomplished using, for example, fuzzy multi-level security. The quantified risk associated with the access request in combination with the identity of the object and the identity of the subject are used to determine whether or not the request should be granted, denied or granted with appropriated mitigation measures.

Owner:IBM CORP

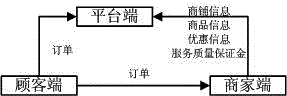

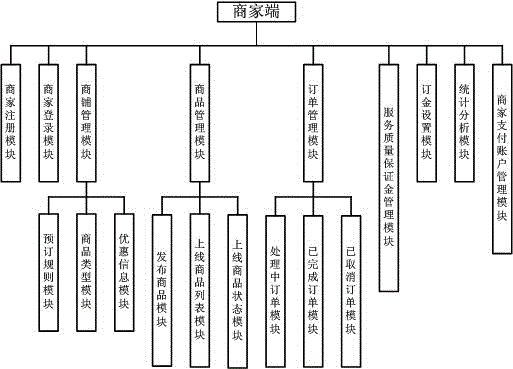

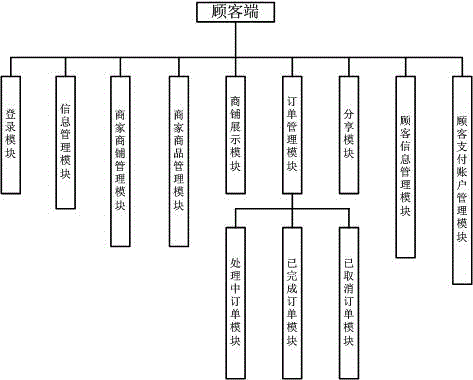

Commodity and service online ordering and management Internet platform

InactiveCN106022490AProfit maximizationImprove efficiencyReservationsMarketingOrder processingLicense

The invention aims at providing a commodity and service online ordering and management Internet platform, and the platform comprises a merchant terminal which is used by a merchant for publishing store information, commodity specific information and special offer information, displaying and processing an order; a customer terminal which is used by a customer for meeting a commodity ordering request, and generating an order; and a platform terminal which is used by the merchant for storing, displaying and storing of store information, commodity information and special offer information, displaying the order, storing and tracking the order processing operation of the merchant, supervising and guaranteeing the execution process of the order. The advantages of the platform are that the customer can directly order the commodity and service, published by the merchant of a real store, on the platform, such as a room number and a license plate number, and can order the needed commodity and service at any time; The merchant can directly display and process the order of the customer through the platform. The platform achieves the direct communication between the customer and the merchant, reduces the agent link, reduces the operation cost for the merchant, and brings more benefits to the customer.

Owner:刘翔英 +1

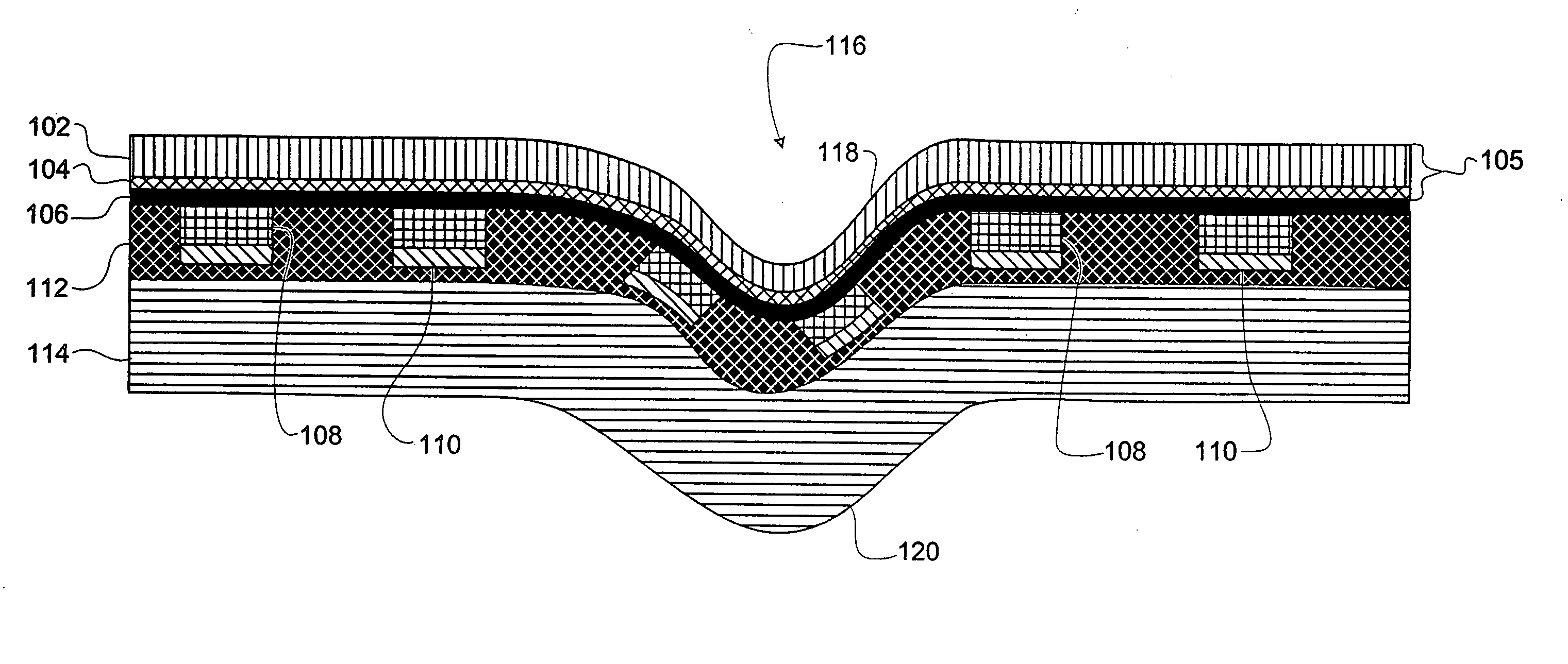

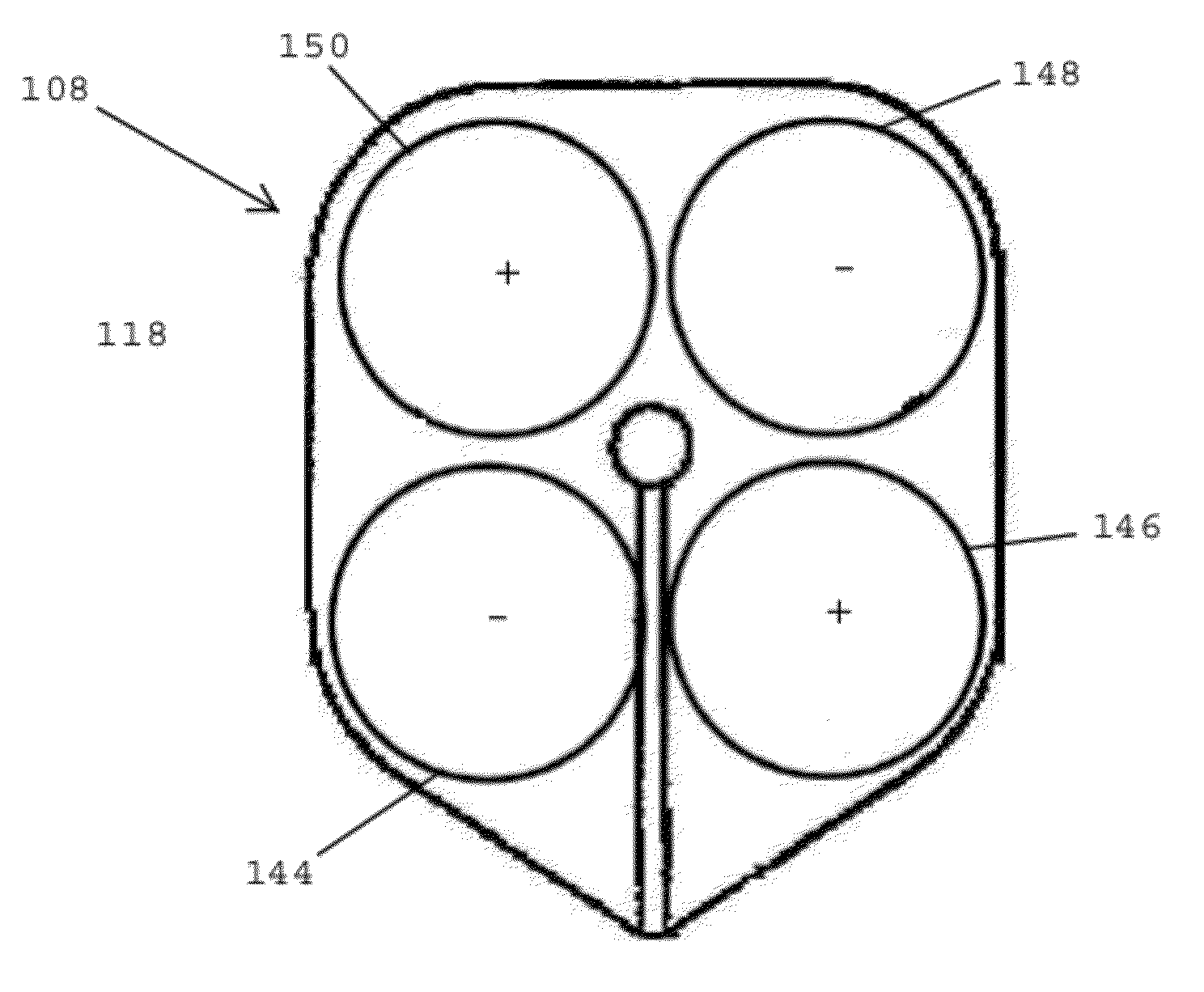

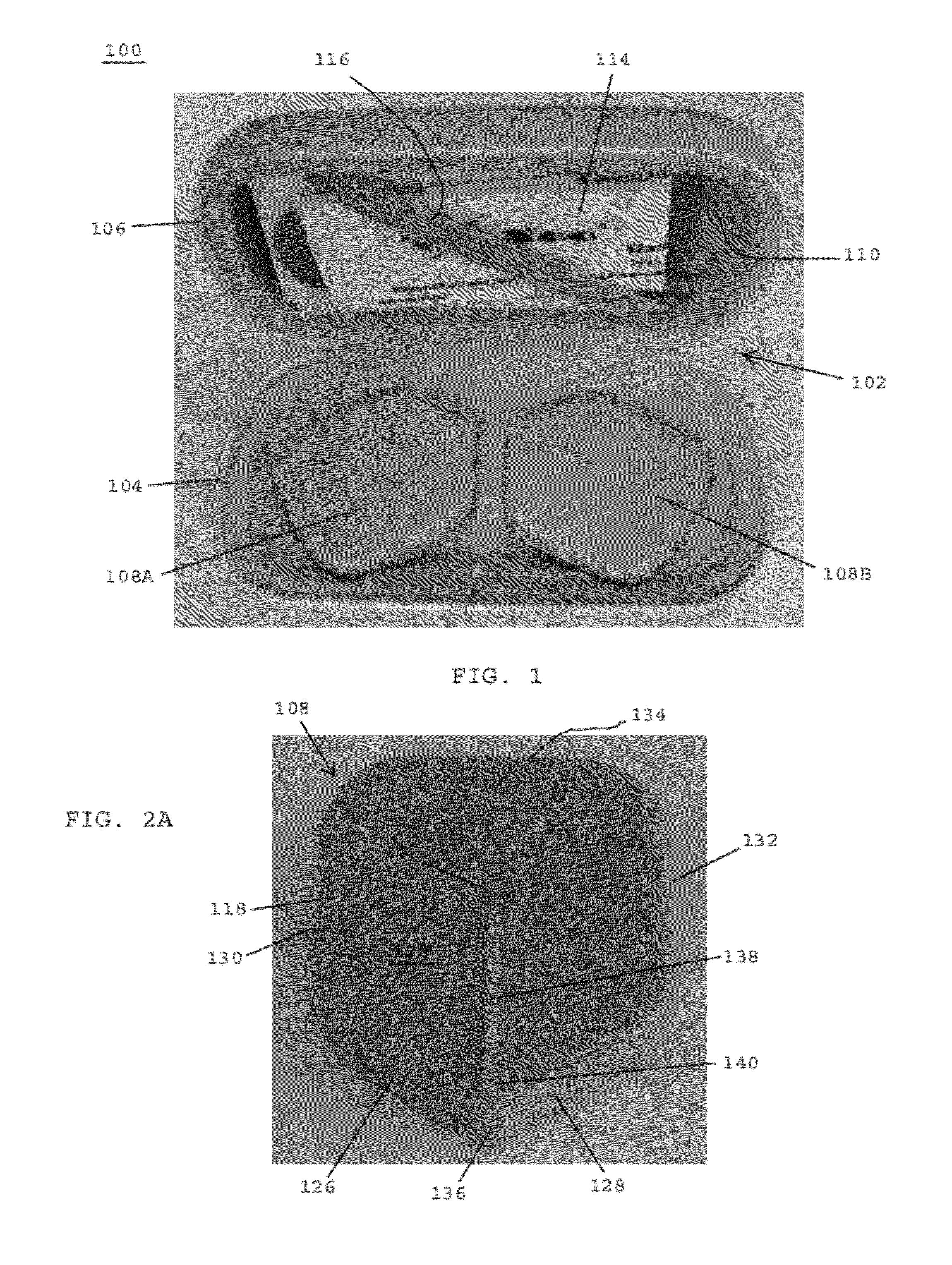

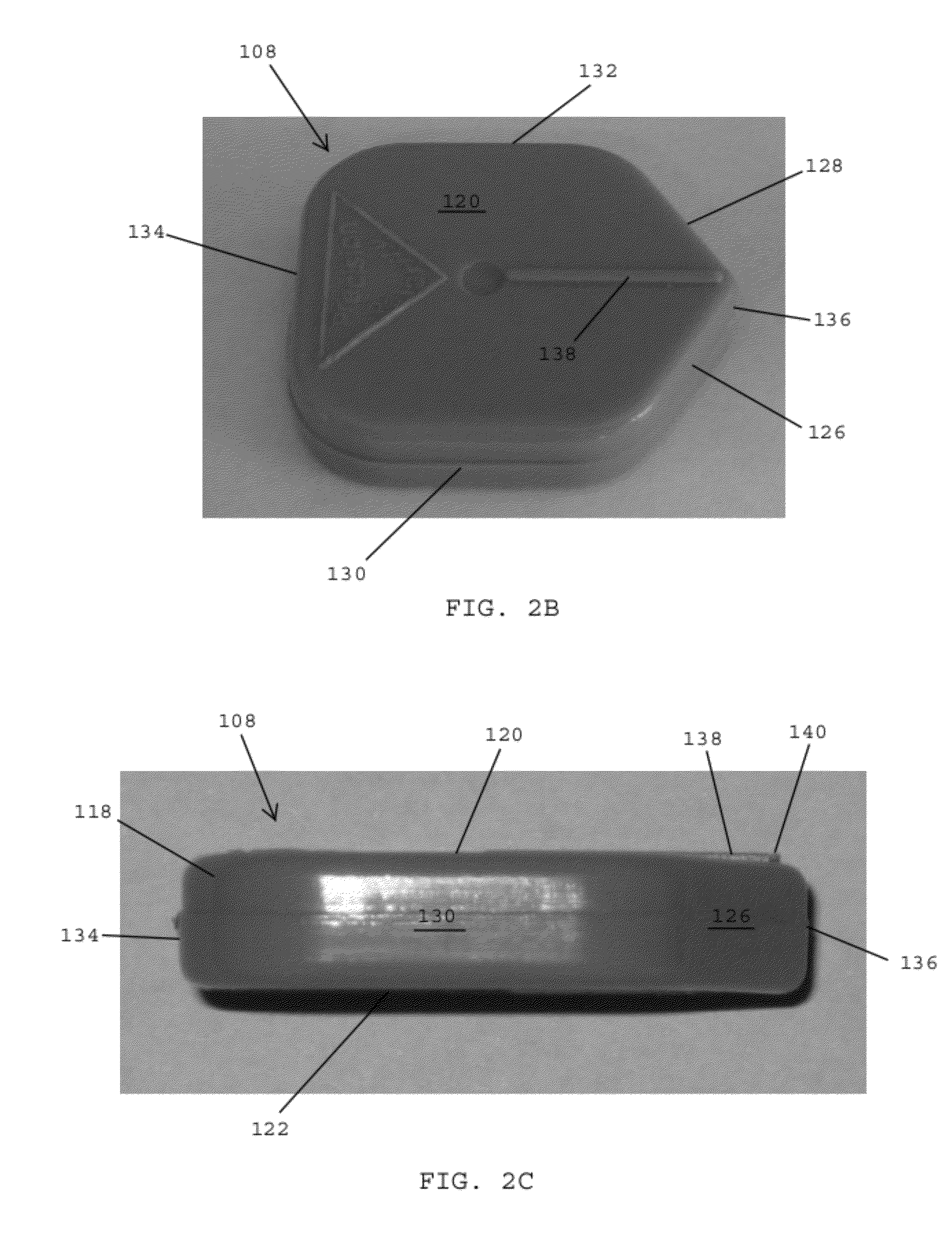

Multi-polar magnetic devices for treating patients and methods therefor

A system for treating patients includes a first magnetic device including a set of four magnetic discs arranged in a square array, the four magnetic discs including two having negative magnetic poles lying in a first plane and two having positive magnetic poles lying in the first plane, wherein the two magnetic discs having negative magnetic poles extend along a first diagonal line and the two magnetic discs having positive magnetic poles extend along a second diagonal line that crosses the first diagonal line, and a housing containing the four magnetic discs for maintaining the magnetic discs in the square array arrangement, the housing including an alignment marker for aligning the first magnetic device on a patient.

Owner:BLMJ HLDG

Personal Care Compositions Containing Cationically Modified Starch and an Anionic Surfactant System

InactiveUS20090176675A1Increase depositionReduce cleaningCosmetic preparationsHair cosmeticsPersonal careSodium Pyrithione

Personal care compositions comprise (a) from about 0.01 wt. % to about 10 wt. % of a water-soluble cationically modified starch polymer, wherein said water-soluble cationically modified starch polymer has a molecular weight from about 850,000 to about 15,000,000 and a charge density from about 0.2 meq / g to about 5 meq / g; (b) from about 5 wt. % to about 50 wt. % of an anionic surfactant system, said anionic surfactant system comprising at least one anionic surfactant and having an ethoxylate level and an anion level, (i) wherein said ethoxylate level is from about 1 to about 6, and (ii) wherein said anion level is from about 1 to about 6; c) an effective amount of a pyrithione or a polyvalent metal salt of a pyrithione; d) an effective amount of a zinc-containing layered material; and (e) a cosmetically acceptable medium. Personal care compositions as described above further comprise from about 0.01 wt. % to about 10 wt. % of one or more oily conditioning agents. Methods of treating hair or skin comprise applying the personal care compositions as described above to the hair or skin and rinsing the hair or skin.

Owner:THE PROCTER & GAMBLE COMPANY

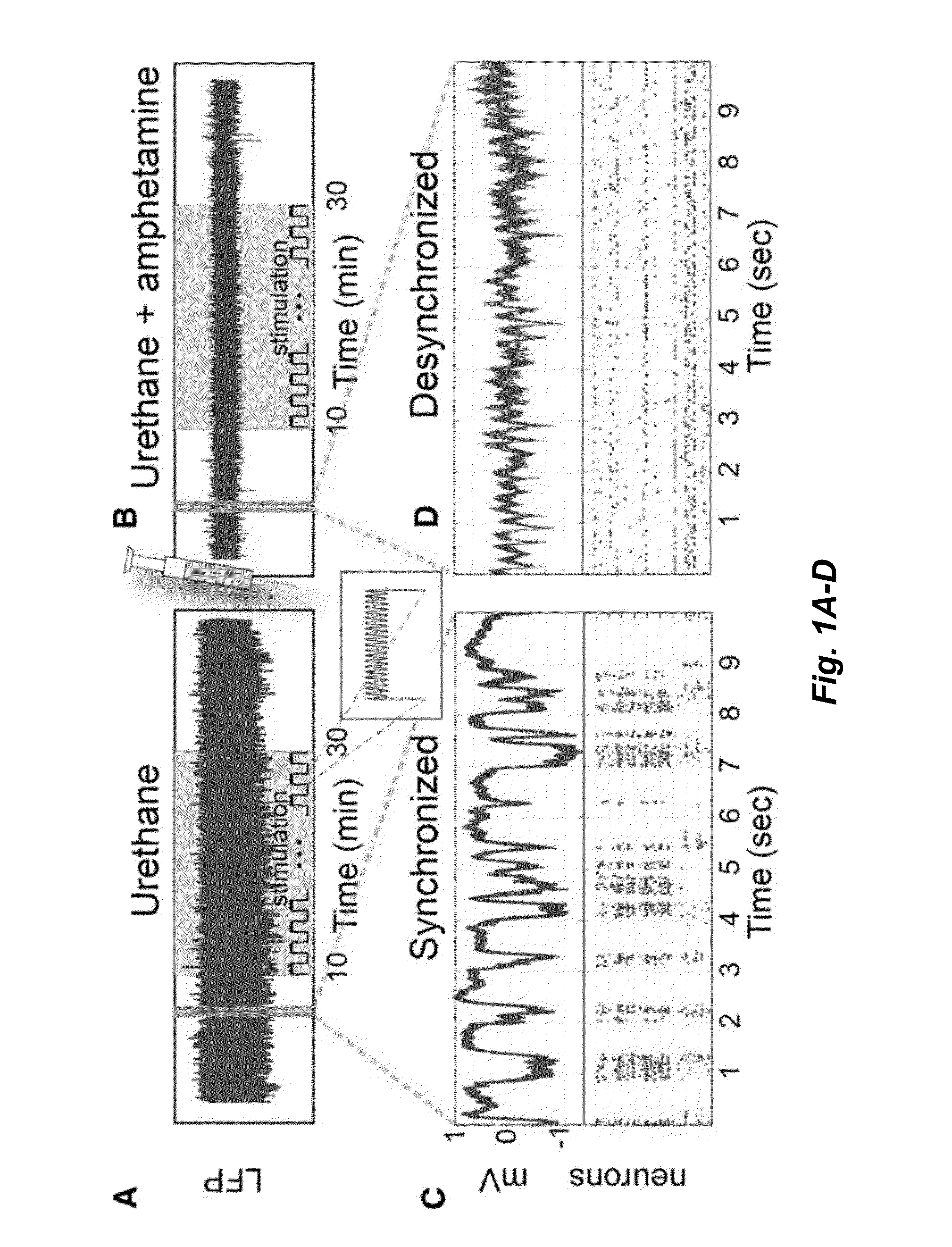

Brain state dependent therapy for improved neural training and rehabilitation

InactiveUS20160022168A1Good curative effectRapid assessmentElectroencephalographyHead electrodesDiseaseReal time analysis

The disclosure provides an apparatus and method for assessing brain plasticity by measuring electrical brain biomarkers, for example, with a near real-time analysis of electrical brain biomarkers, where an increase or decrease in at least one biomarker is indicative of a state of brain plasticity in response to a stimulus or treatment. Brain plasticity can be measured with or without an added stimuli, for example, to determine the best time for learning. Also provided is a method for treating a neurological disease or trauma by applying an electrical or drug stimulus to a patient, where the stimulus is increased or decreased depending on the changes of electrical brain biomarker of the patient. This treatment can occur in near real-time, so a course of treatment can be tailored immediately to a patient's needs.

Owner:THE UNIV OF LETHBRIDGE

Combinations Therapy for Treatment of Demyelinating Conditions

InactiveUS20080279819A1Low variabilityMaximizes therapeutic benefitBiocideNervous disorderCombination therapyMultiple sclerosis

The present invention provides novel methods and compositions for the treatment and prevention of demyelinating conditions. One demyelinating condition treated by the methods and compositions of the invention is multiple sclerosis. Also treated are symptoms associated with multiple sclerosis.

Owner:ADAMAS PHARMA INC

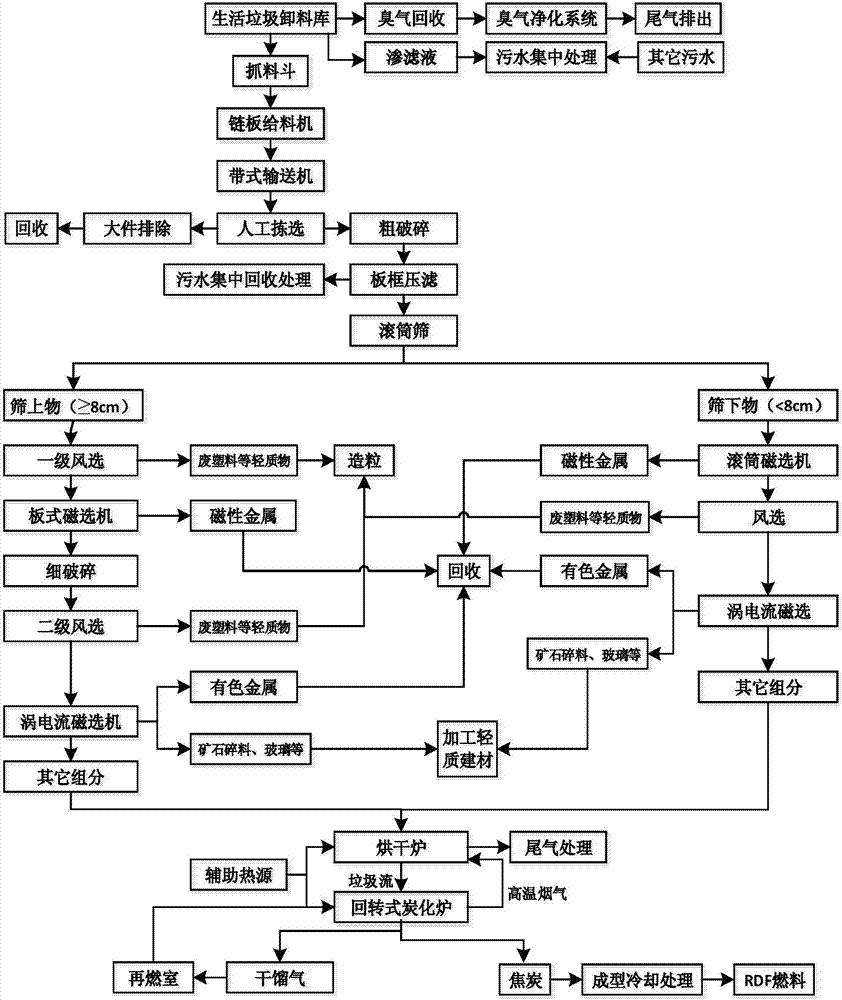

Urban household garbage sorting and charring comprehensive treatment resource recovery method

InactiveCN107497831AHigh degree of automationImprove sorting efficiencyTransportation and packagingSolid waste disposalSolid carbonResource recovery

A urban household garbage sorting and charring comprehensive treatment resource recovery method comprises the first step of garbage sorting treatment, wherein original household garbage is subjected to uniform feeding, manual large garbage sorting, coarse crushing, plate-frame pressure filtering, rolling cylinder screening, full-closed mechanical selecting by winnowing, plate-type magnetic separator treating, eddy current magnetic separator treating and fine crushing process treatment; the second step of garbage drying treatment; the third step of garbage charring treatment, wherein a rotary charring furnace is adopted, and garbage charring is carried out in a normal-pressure low-temperature and low-oxygen atmosphere so that solid carbon can be prepared; the fourth step of coke forming and cooling treatment; the fifth step of bad smell purifying treatment, wherein bad smell generated in a household garbage discharging warehouse and bad smell generated in all treatment process links are collected to a bad smell purifying system through a negative pressure induced draught system; and the sixth step of waste water purifying treatment. The urban household garbage sorting and charring comprehensive treatment resource recovery method is relatively high in automation degree, sorting efficiency and recovery utilization rate and has more sorting functions.

Owner:李新方

Method and apparatus for on-demand resource allocation and job management

ActiveUS20080263558A1Increase resourcesHigh outputProgram initiation/switchingResource allocationService-level agreementResource allocation

The invention is a method and apparatus for on-demand resource planning for unified messaging services. In one embodiment, multiple clients are served by a single system, and existing system resources are allocated among all clients in a manner that optimizes system output and service provider profit without the need to increase system resources. In one embodiment, resource allocation and job scheduling are guided by individual service level agreements between the service provider and the clients that dictate minimum service levels that must be achieved by the system. Jobs are processed in a manner that at least meets the specified service levels, and the benefit or profit derived by the service provider is maximized by prioritizing incoming job requests within the parameters of the specified service levels while meeting the specified service levels. Thus, operation and hardware costs remain substantially unchanged, while system output and profit are maximized.

Owner:MAPLEBEAR INC

Methods and compositions for the treatment of viral infections

Compositions for treating flu comprise an M2 inhibitor, and optionally a neuraminidase inhibitor, wherein at least one of said M2 inhibitor or said neuraminidase inhibitor is provided in an extended release dosage form.

Owner:NEUROMOLECULAR PHARMA

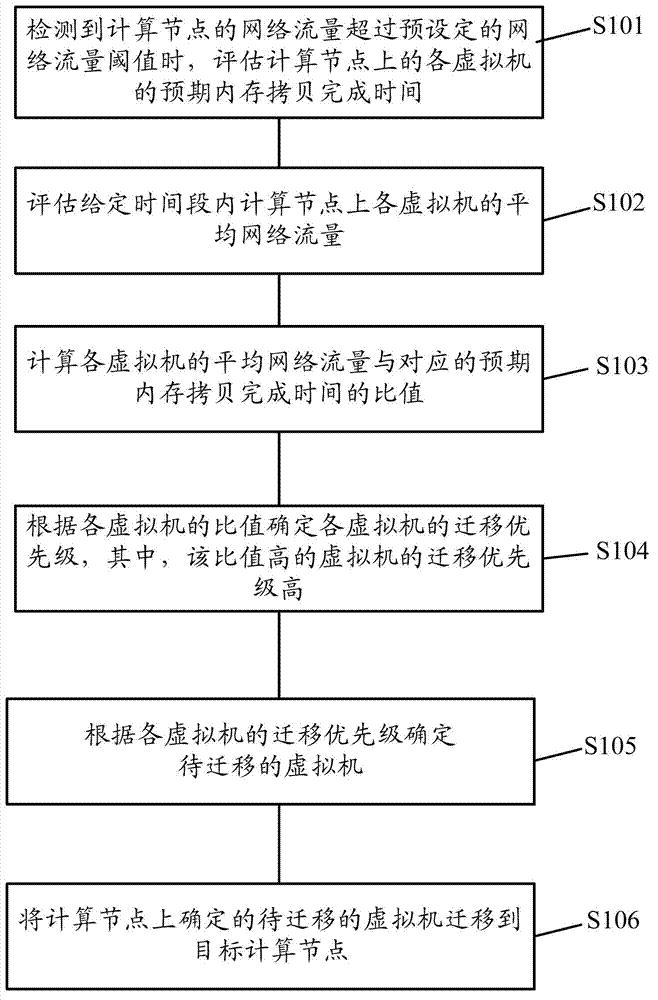

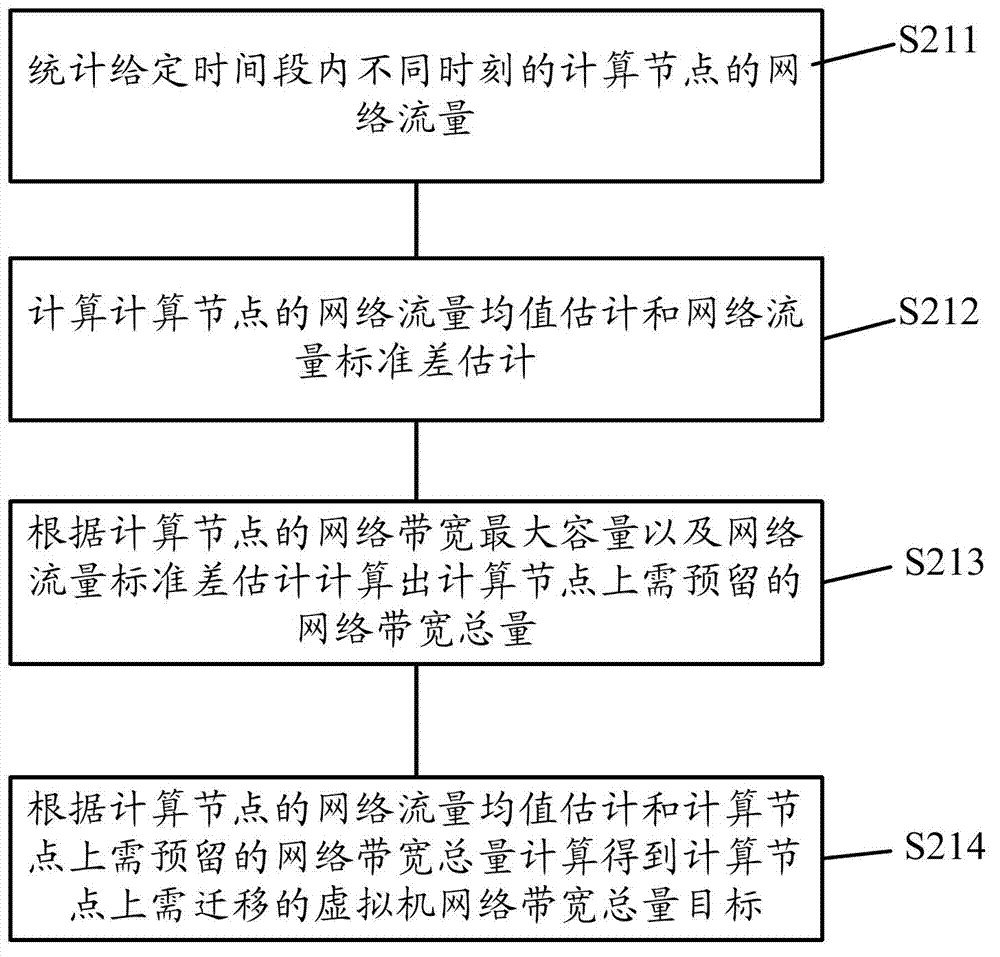

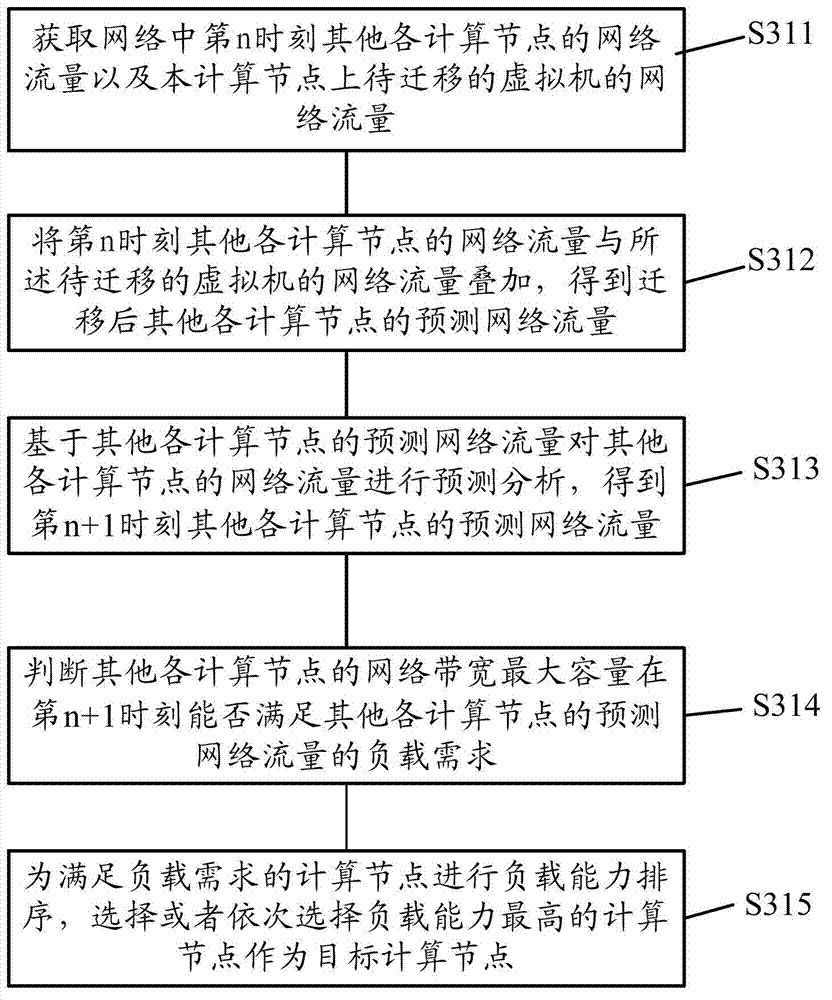

Method and system for scheduling network resources based on virtual machine migration

ActiveCN102929715AReduce loadBenefit maximizationProgram initiation/switchingTransmissionTraffic capacityResource based

The invention discloses a method for scheduling network resources based on virtual machine migration. The method comprises the following steps of: when the network flow of a computation node is detected to be more than a preset network flow threshold value, evaluating the expected copy finish time of the memory of each virtual machine on the computation node, and evaluating the average network flow of each virtual machine on the computation node in a given period of time; calculating the ratio of the average network flow of each virtual machine to the corresponding expected copy finish time of the memory; determining the migration priority of each virtual machine according to the ratio, wherein the virtual machine with a higher ratio has a higher migration priority, and the virtual machine to be migrated is determined according to the migration priority of each virtual machine; and migrating the virtual machine to be migrated, which is determined on the computation node, to a target computation node. By the method, the network load on the computation node can be reduced, and the actual benefit of migration operation is maximized. The invention also discloses a system for scheduling the network resources based on the virtual machine migration.

Owner:DAWNING CLOUD COMPUTING TECH CO LTD

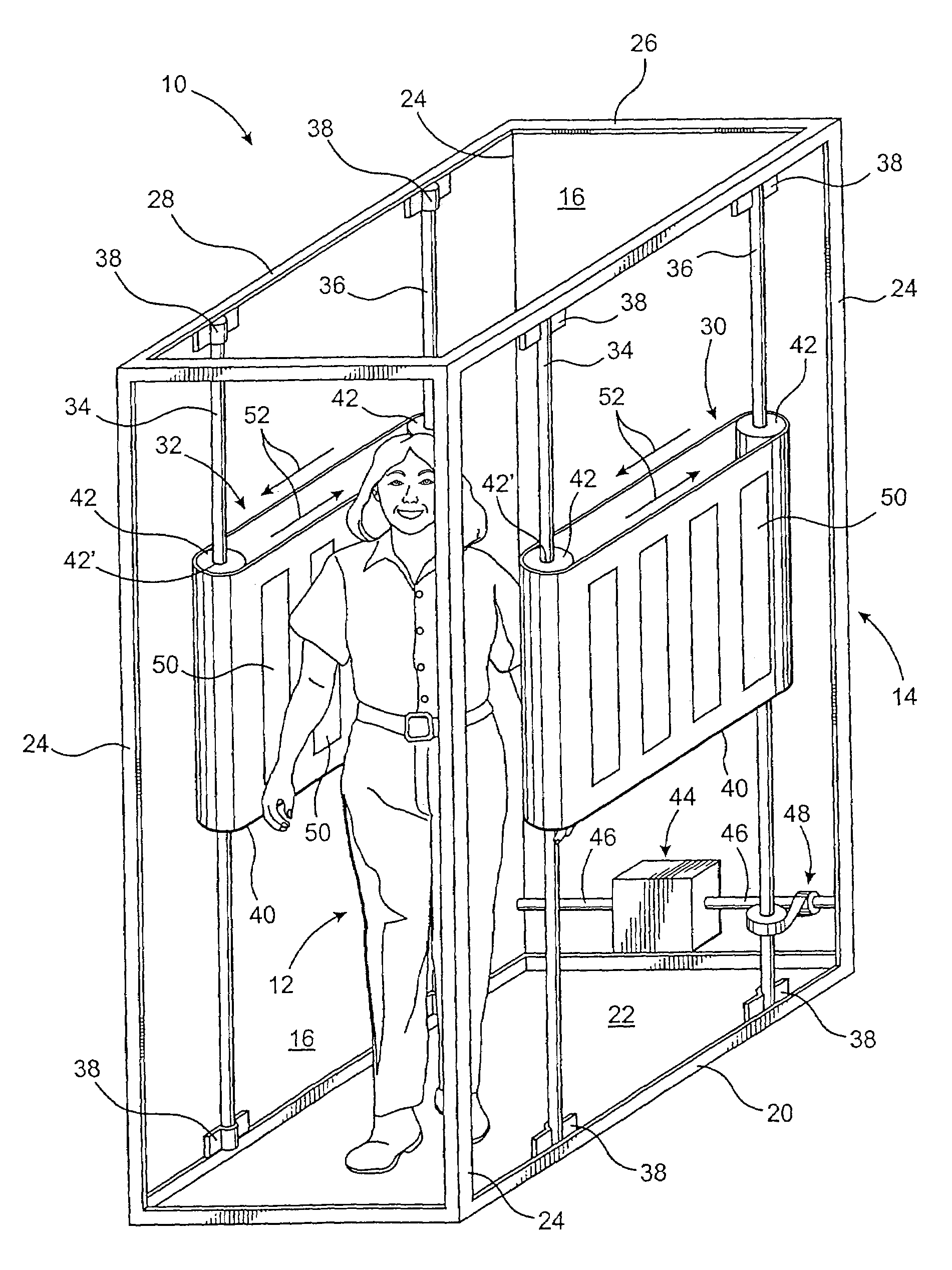

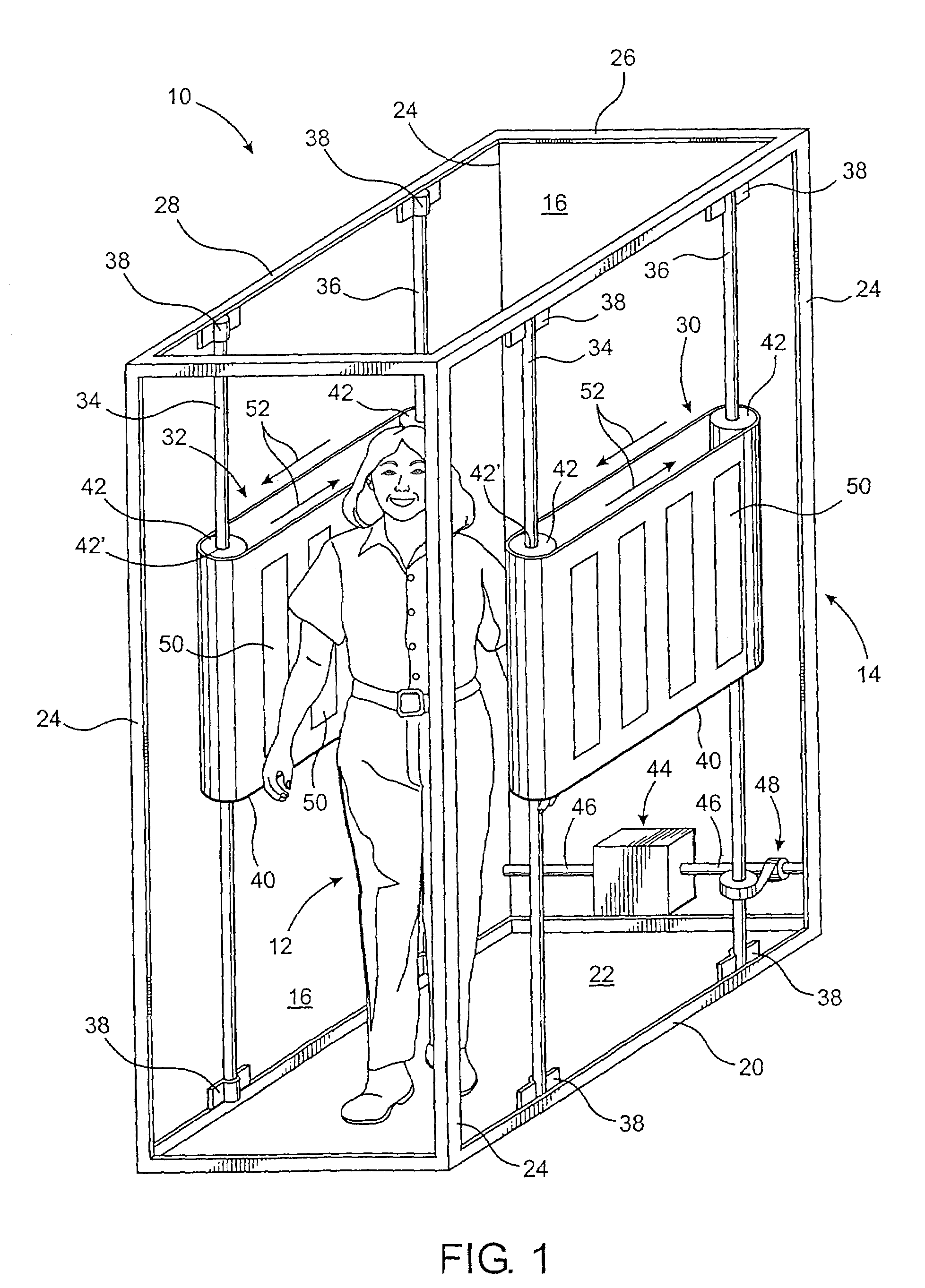

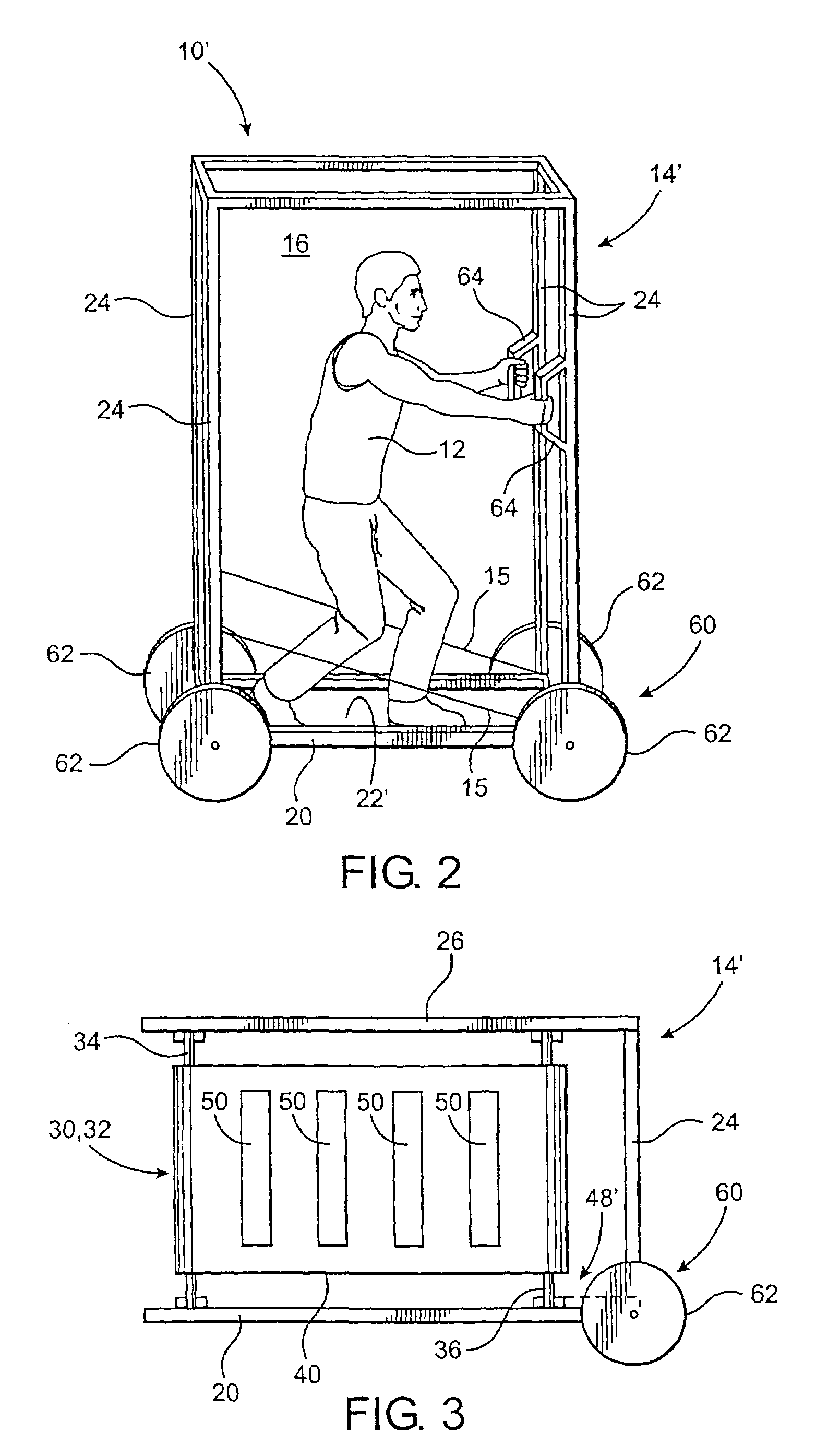

Therapeutically beneficial movable magnetic fields

The present invention relates to a therapeutically beneficial assembly utilizing one or more moveable magnetic fields passing through a treatment area, which is dimensioned and configured to accommodate a user in a standing, walking and / or running orientation therein. A generating assembly comprises at least one but preferably at least two magnetic arrays each mounted in moveable relation to the treatment area and comprising a conveyor-like base having a plurality of magnets connected thereto and moveable therewith. The plurality of magnets of each of said magnetic array are disposed to generate a different magnetic field moveable through said treatment area such that the user therein is exposed to the one or more moveable magnetic fields.

Owner:CANCIO HUMBERTO

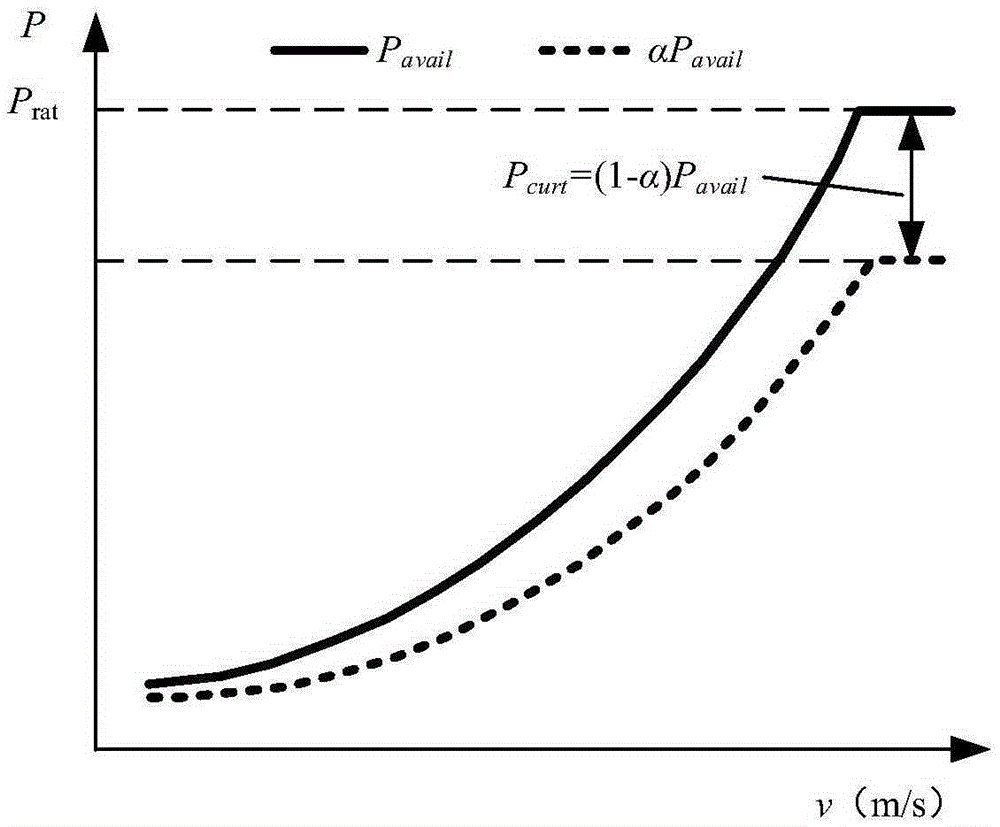

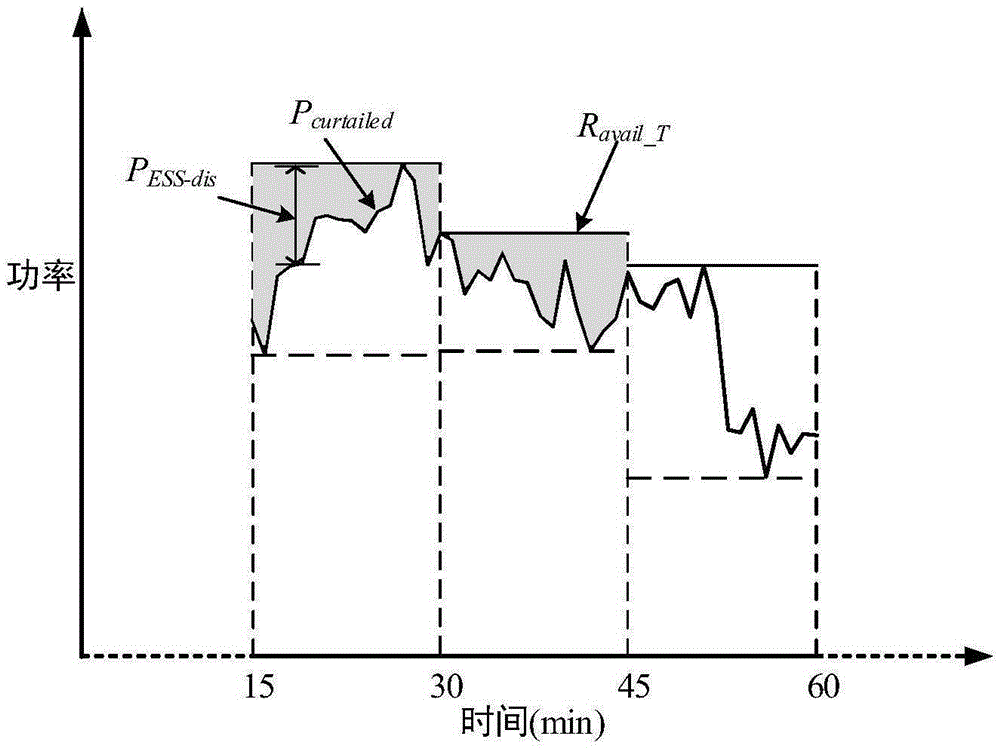

Energy storage configuration method for coordinating wind electric field to participate one time frequency modulation of electric power system

ActiveCN105337294AReduce economic lossEasy to configureEnergy storageAc network load balancingElectric power systemElectric power

The invention discloses an energy storage configuration method for coordinating a wind electric field to participate one time frequency modulation of an electric power system, which is characterized by comprising backup proportional wind abandoning method that the wind electric field provides to the electric power system for the backup of one time frequency modulation, determination of effective backup capacity of the wind electric field, an evaluation index of wind abandoning utilization rate when the wind electric field provides one time frequency modulation backup to the electric power system, a control strategy A for coordinating the wind electric field to participate the electric power system one modulation energy storage modulation system, control strategy B for coordinating the wind electric field to participate the one time frequency modulation energy storage system of the electric power system, the energy storage system rated power capacity of the energy storage system and the determination content of the capacity of the rated energy. The invention can reduce the economic loss of the wind electric power field caused by the wind abandoning electric quantity on the premise that the same one time frequency modulation backup is provided, realizes the optimal configuration of the rated power of the energy storage system and the energy capacity, and can maximize the benefit. The invention is scientific, reasonable, good in effect and strong in adaptability.

Owner:STATE GRID LIAONING ELECTRIC POWER CO LTD SHENYANG POWER +2

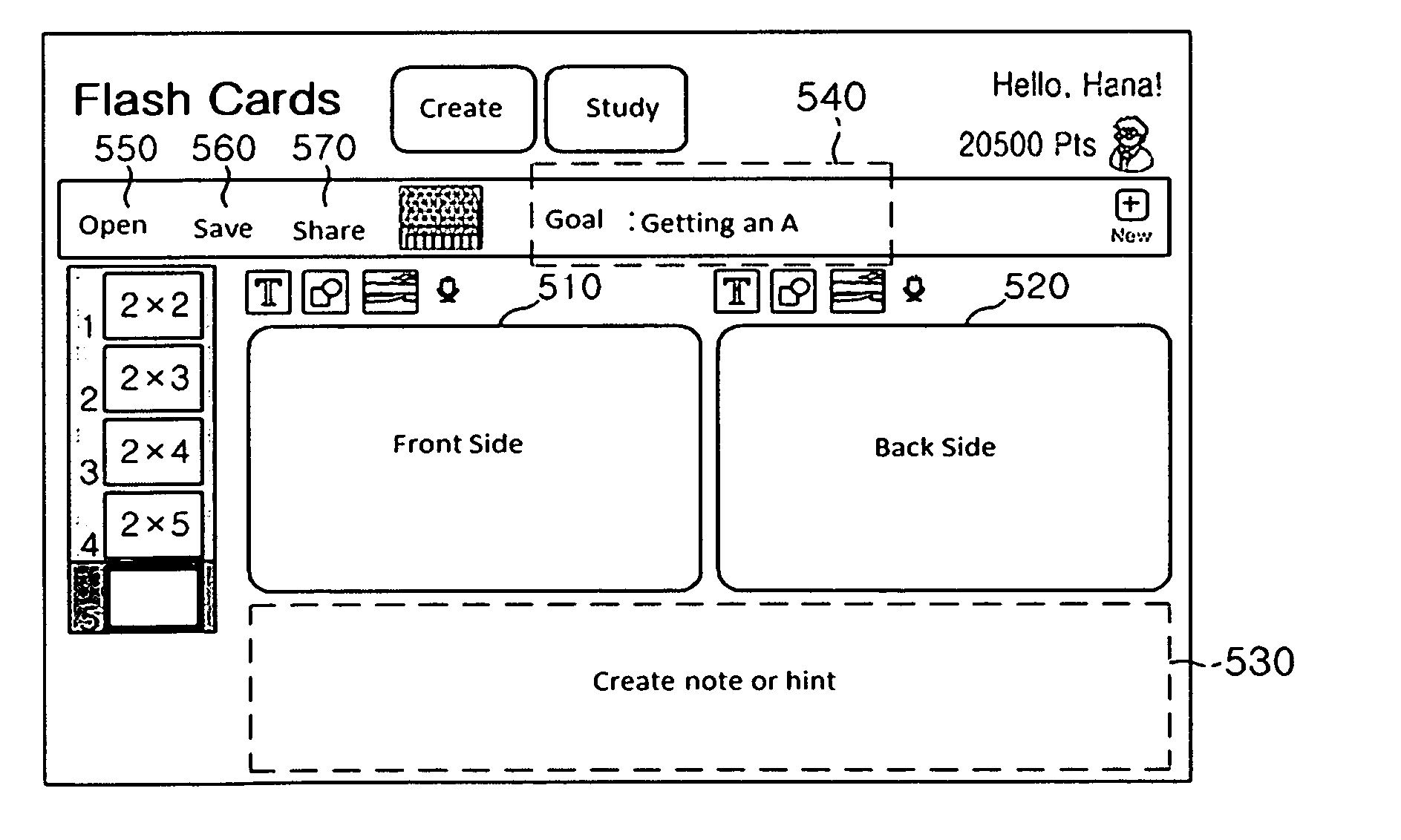

Studying system and method with virtual cards

InactiveUS20110318723A1Aiding efficiencyMaximize the benefitsElectrical appliancesMechanical appliancesSession managementStudy methods

The studying system and studying method using virtual card are described. The present invention comprises: (1) a course scheduling feature that divides study courses into a plurality of study sessions considering the learning situations of the user, selects and assigns virtual flash cards to such study sessions, and determines the sequence of such virtual flash cards contained in such study sessions; (2) a session management feature that carries out such study sessions by displaying the front side of the virtual flash cards contained in such study sessions and by allowing the users to enter answers to such virtual flash cards; and (3) an entry management feature that provides an interface for users to enter such answers. The present invention provides a distinct studying method by dividing a study course into a plurality of study sessions, assigning virtual flash card decks to appropriate such study sessions and determining the order of such virtual flash cards, displaying the front side of such virtual flash cards to the user, and allowing the user to enter the answer for each virtual flash card. The invention maximizes learning the benefits of users by providing and displaying virtual flash cards in the order that best suits the users' situations.

Owner:JEONG YOUNG JOO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com