Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

587results about "Drilling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

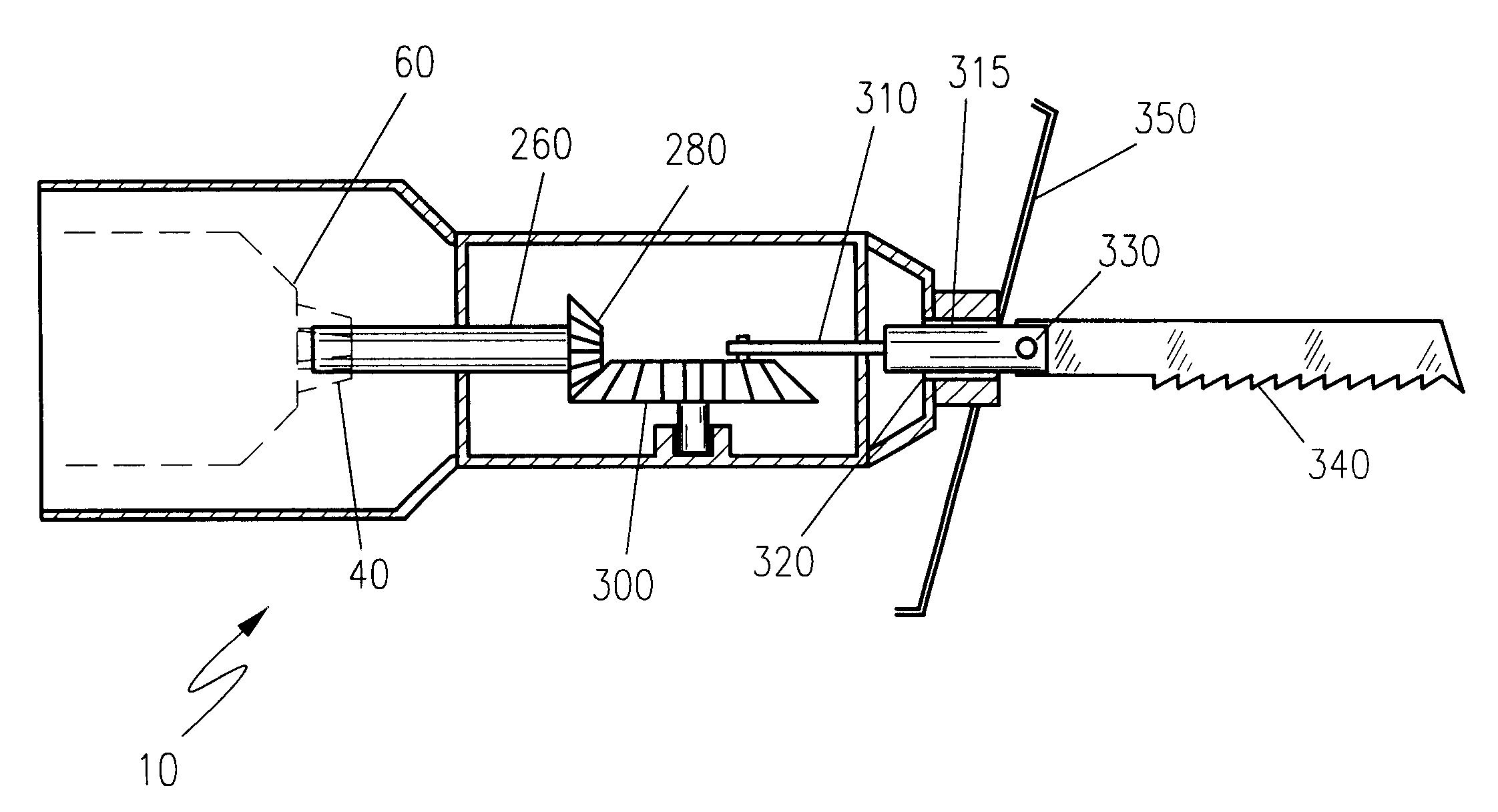

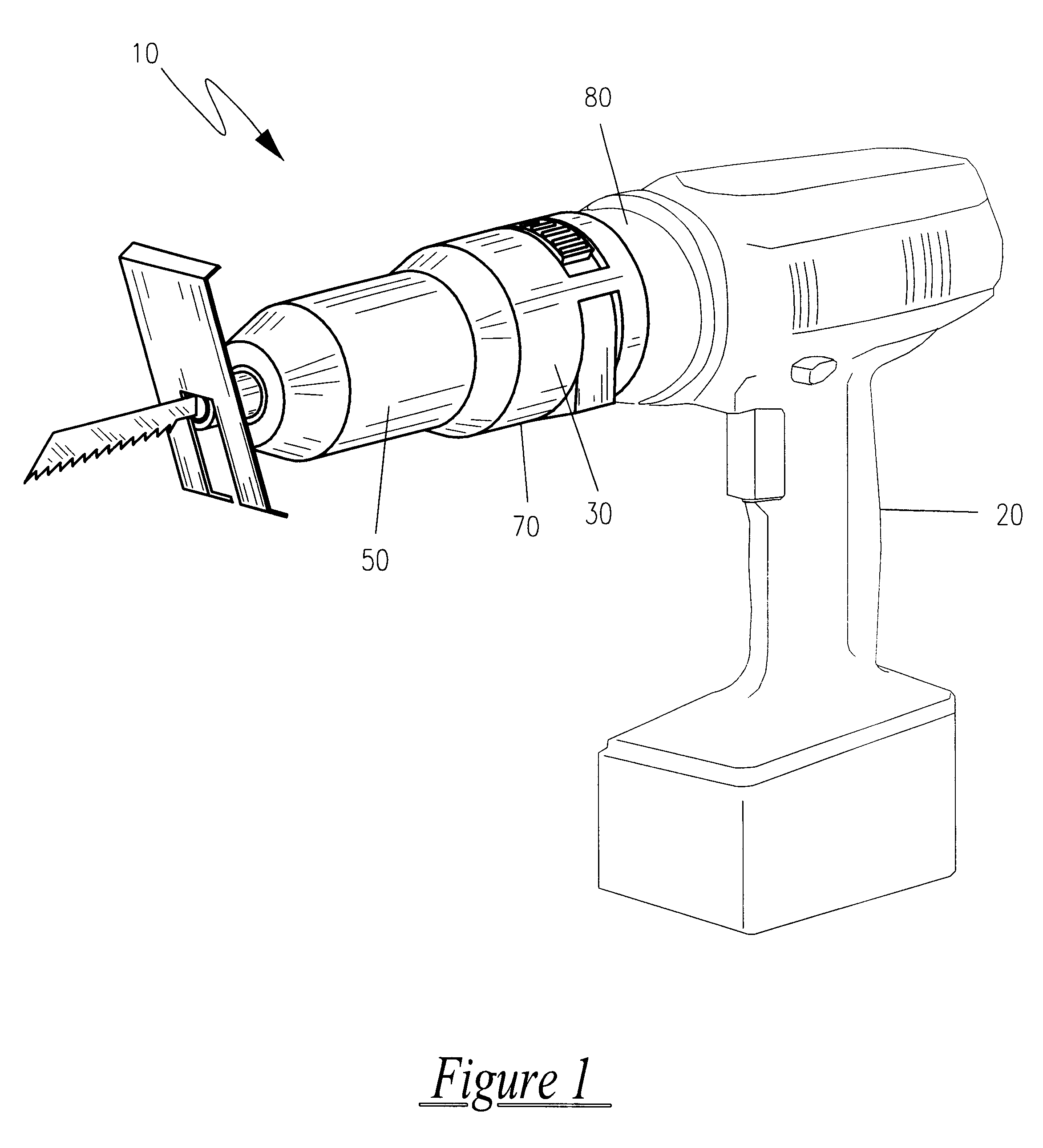

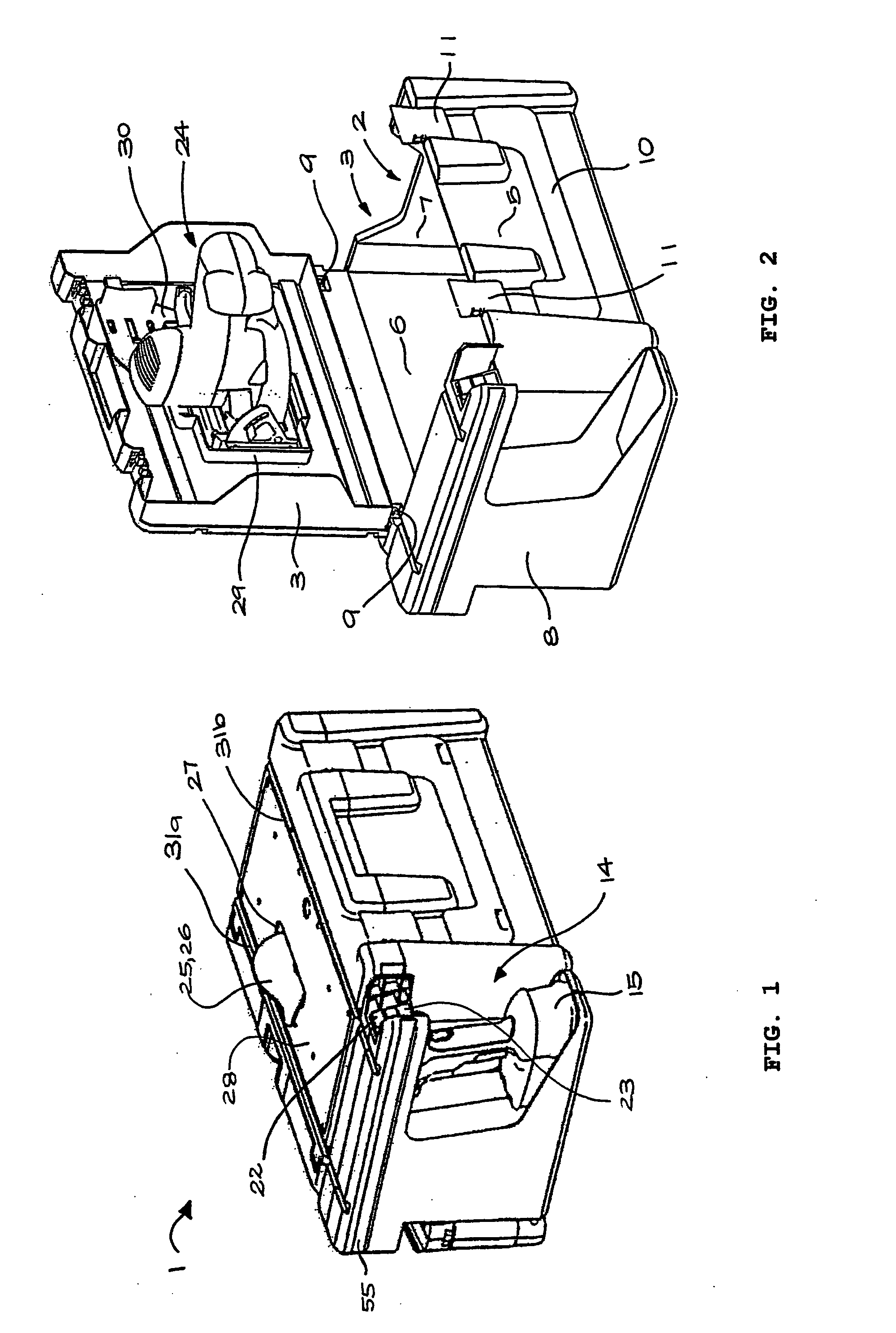

Reciprocating saw attachment for electric drill

InactiveUS6264211B1Save spaceShorten the timeDrilling machinesTransportation and packagingGear wheelCoupling

A universal, quick connect, reciprocating saw attachment for electric drills is disclosed, designed as an adapter that converts a power rotary drill into a reciprocating saw. The present invention converts the rotary action of a drill into the necessary reciprocating action to power a saw blade. The present invention adapts to the housing of various cordless drills and provides for a connection of a steel shank to the drill chuck. A gear box with a reciprocating mechanism inside the housing then provides a coupling to a saw blade to provided the necessary cutting action of a conventional reciprocating saw. Additionally, there are buttons that are designed to expand in and out to tighten the chuck which holds the adapter. The housing is made of a heavy duty impact resistant plastic with the associated gears and reciprocating mechanism made from hardened steel. Coupled with a cordless drill, and a saw blade, the present invention provides for the functions of two, usually separate, power tools in the convenience of one.

Owner:GRANADO RENE

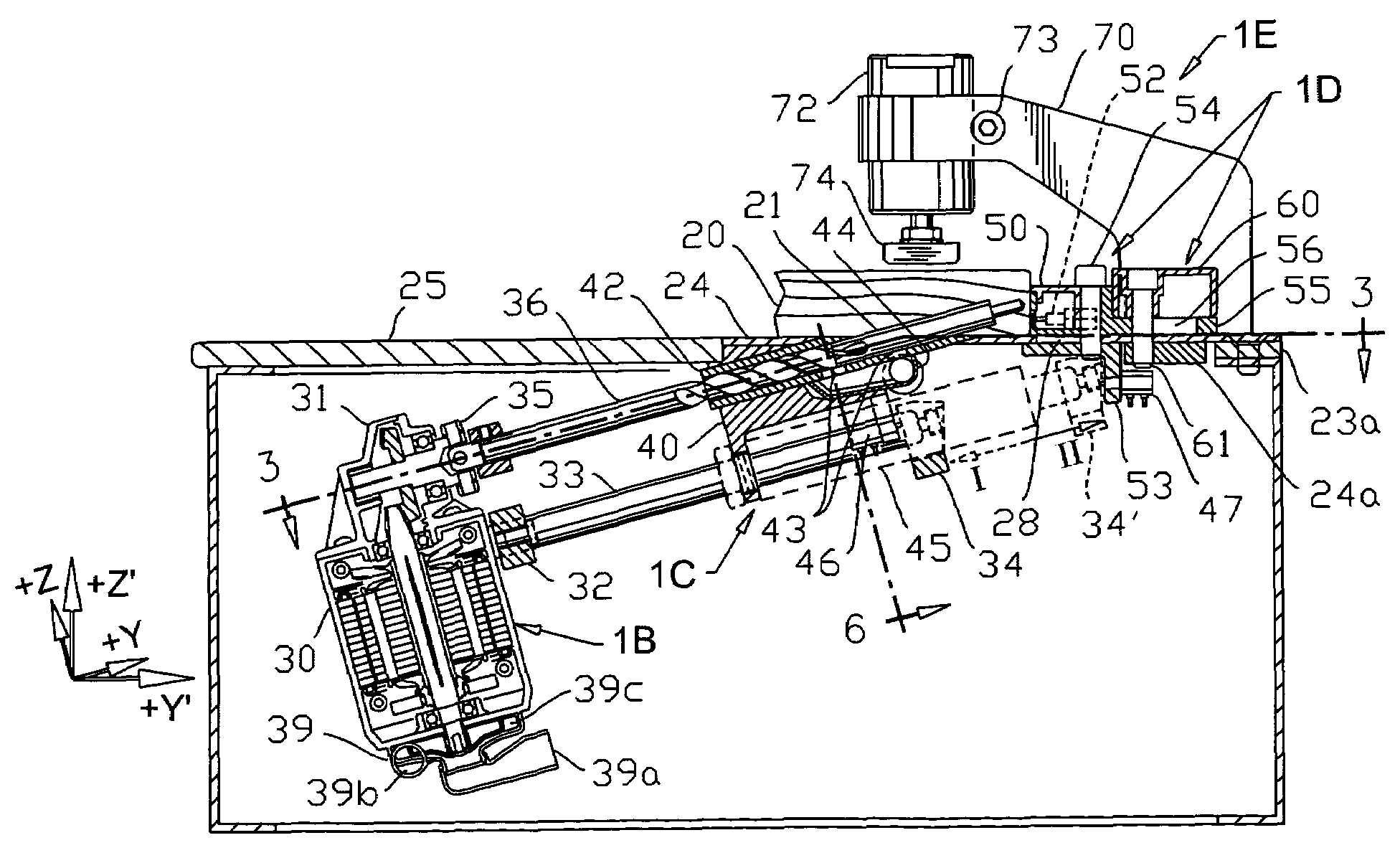

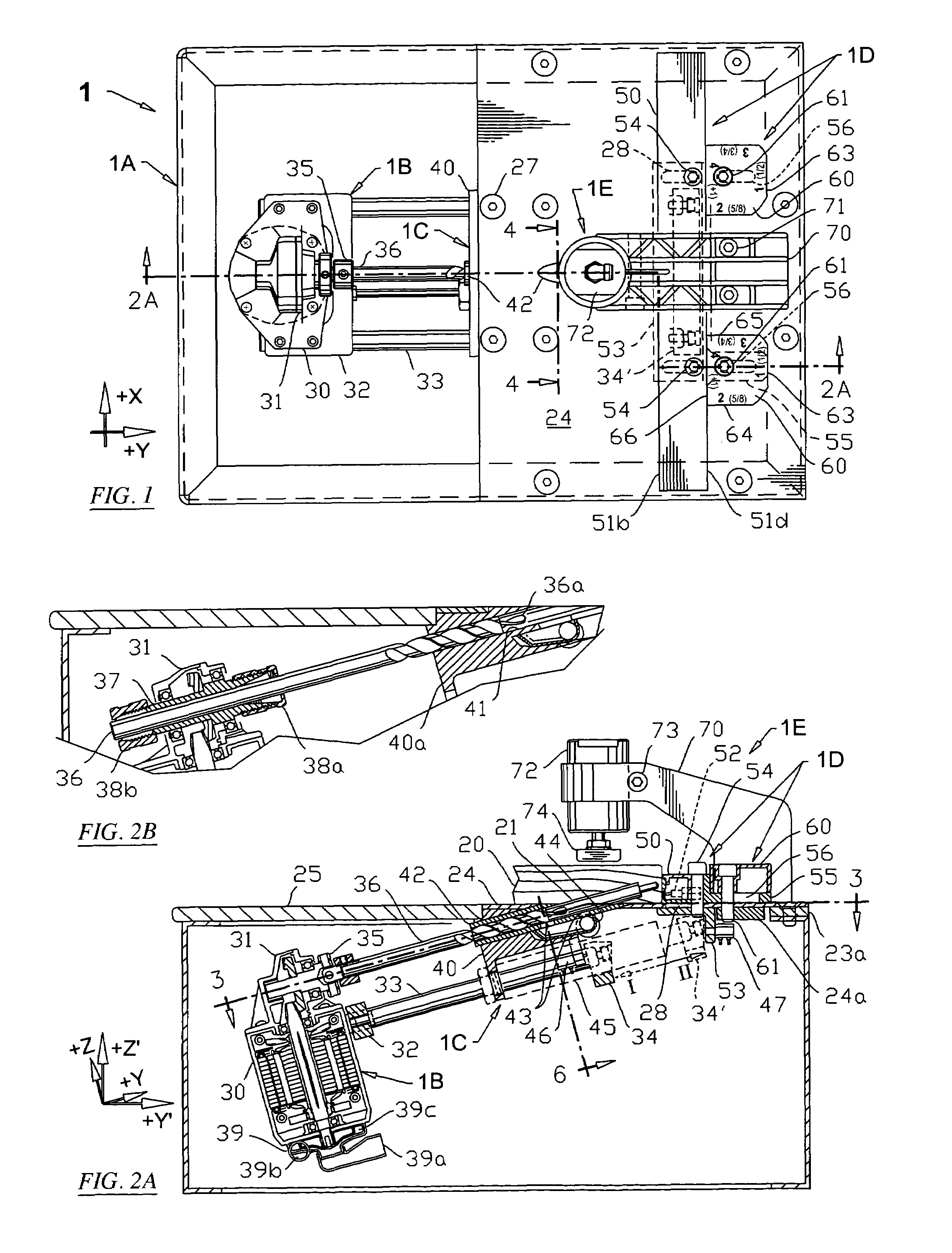

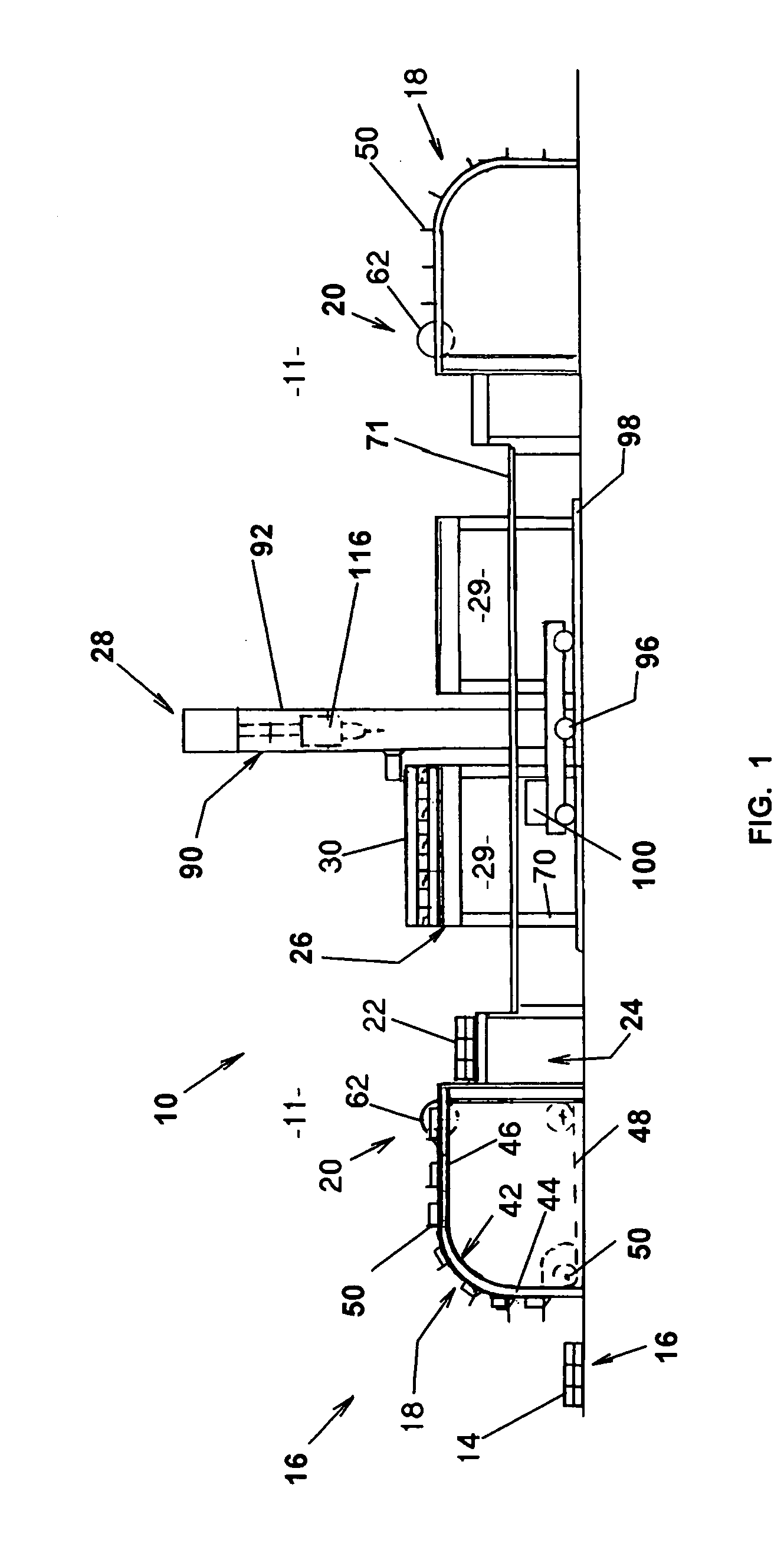

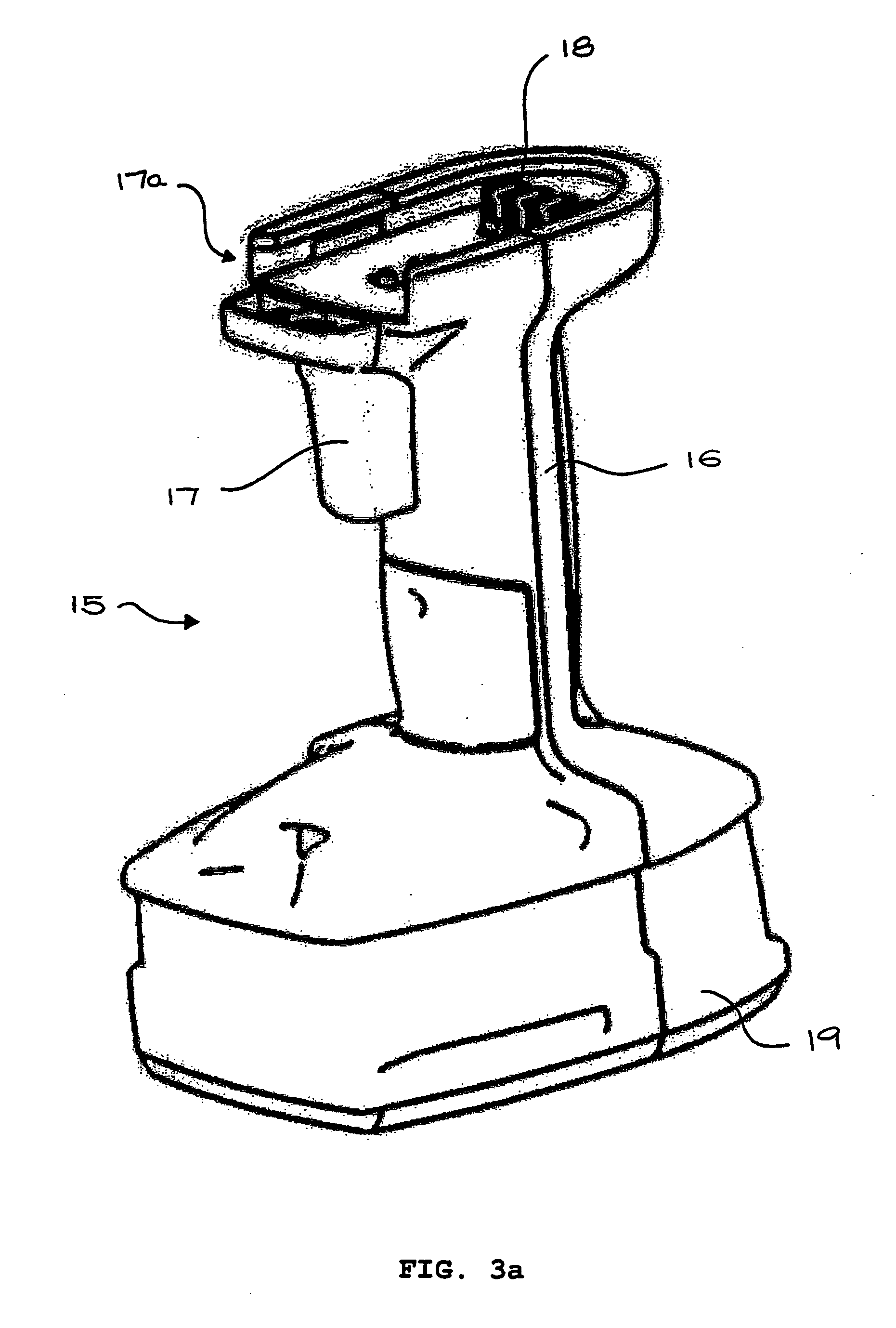

Pocket hole drilling machine

ActiveUS7374373B1Wear minimizationDrilling/boring measurement devicesThread cutting machinesEngineeringActuator

A pocket-hole drilling apparatus for drilling pocket-holes in a workpiece is disclosed. In one embodiment, an initiation switch actuates clamping the workpiece and the movement of a drilling module to cut a pocket-hole. The drilling module has a motor and a step-drill mounted thereon, which is slidably mounted on a guide module. The axis of the drilling module movement intersects work surface. In another embodiment, a movable fence provides the adjustability of pocket-hole depth. In yet another embodiment, two actuator tips are disposed in a fence to prevent the drilling of a pocket-hole through the sidewall of a workpiece. In still another embodiment, a short stroke clamping actuator is used to prevent human finger injury. In still another embodiment, a blower or an ejector pump is used to remove wood chips, wherein the blower is either attached to a drilling motor or to a separate blower motor; the ejector pump is mounted near the drill guide. In still another embodiment, two pocket-drills are slidably mounted on a block so as to drill two pocket-holes and to adjust pocket-hole spacing. In still another embodiment, a mounting structure is disposed either underneath or above the work surface to mount drilling module(s) so as to drill multiple pocket-holes into a wide workpiece at one setup. In still another embodiment, a drill guide forms a clearance for the cutting edges of the step-drill to minimize wear on the edges. In a further embodiment, an actuator provides both clamping and drilling movements, wherein the actuator is an electric motor or a hand lever.

Owner:KREG ENTERPRISES

Jig for fitting locks to doors

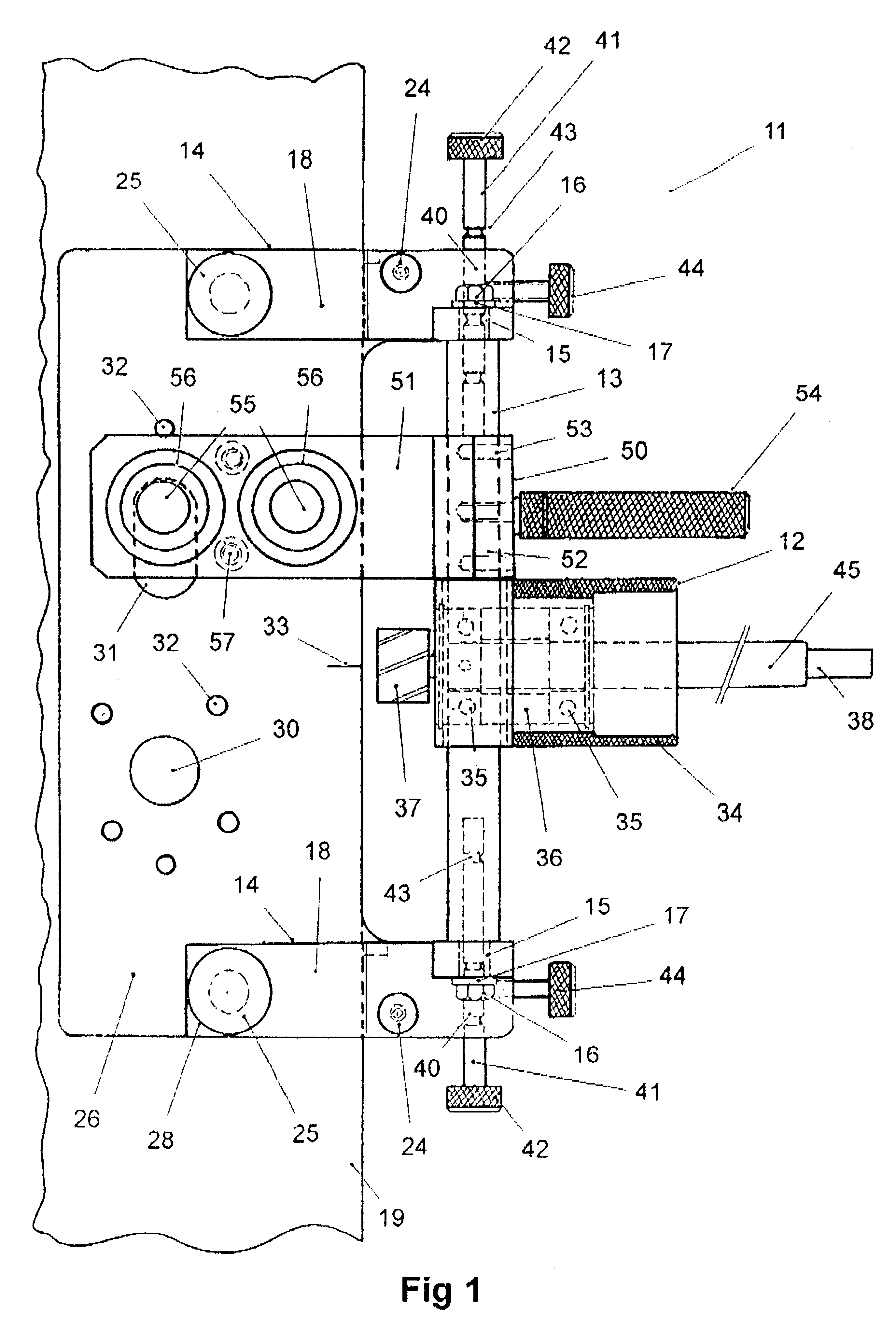

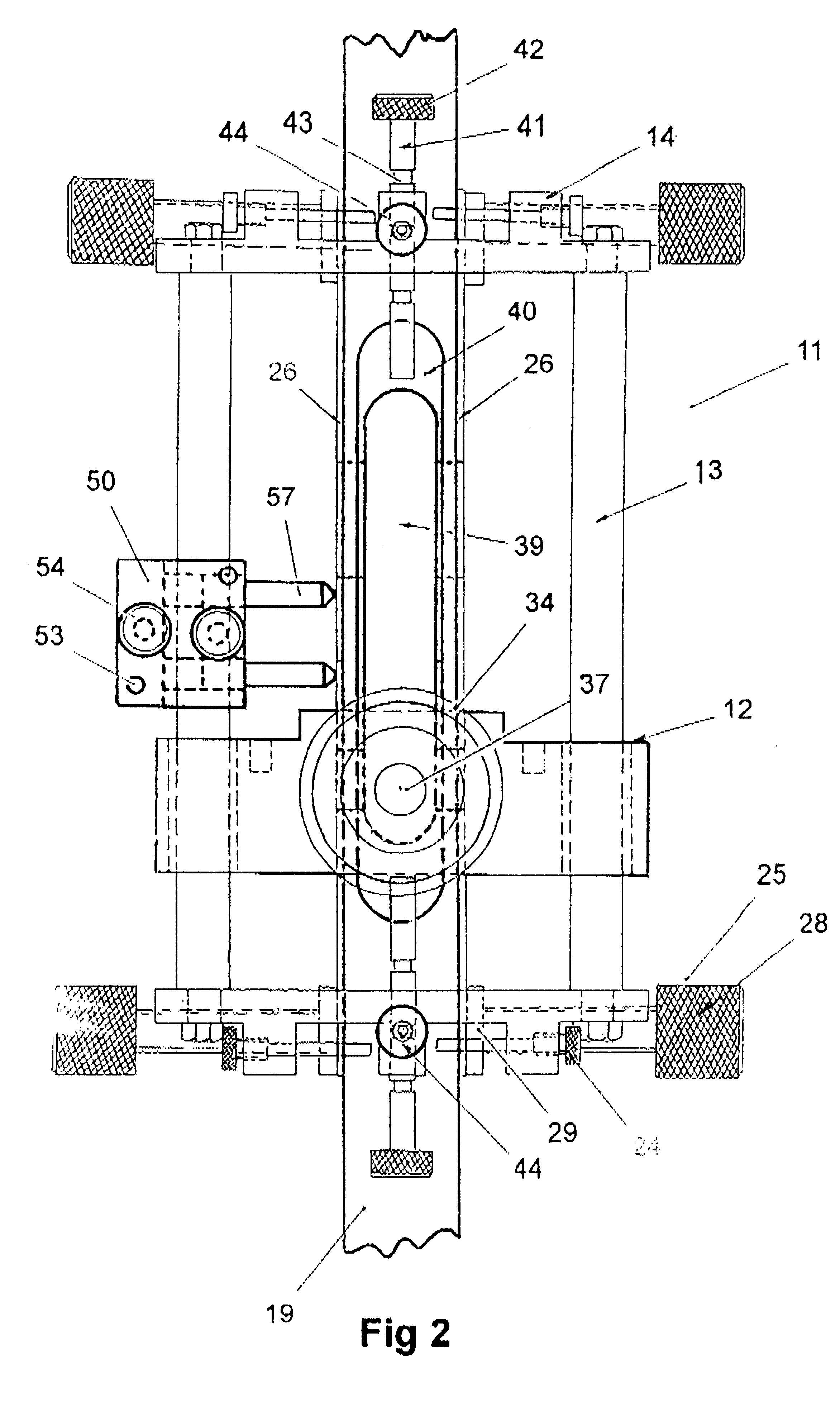

InactiveUS6343632B1Eliminate damageEasy alignmentDrilling/boring measurement devicesThread cutting machinesLocking mechanismEngineering

A jig (11) for removable fitment along the edge of a door (19) which provides a suitable combination of guides and stops to allow the location and operation of suitable cutting tools such as drills or routers. The jig comprises a pair of parallel guide plates (26) the distance between which is adjustable for removable fitment to opposing surfaces of the door. Guide holes (30, 31, 32) are located in the guide plates through which a drill or other suitable tool may be inserted. The jig has guide means (12) associated therewith for allowing location of a suitable tool at the edge of the door for making a cylindrical hole or for machining a mortise therein for receiving the body of a mortise lock or a rebate for receiving the face plate of the lock mechanism. A guide block (50) to facilitate accurate drilling is also disclosed.

Owner:ZIVOJINOVIC ZARKO

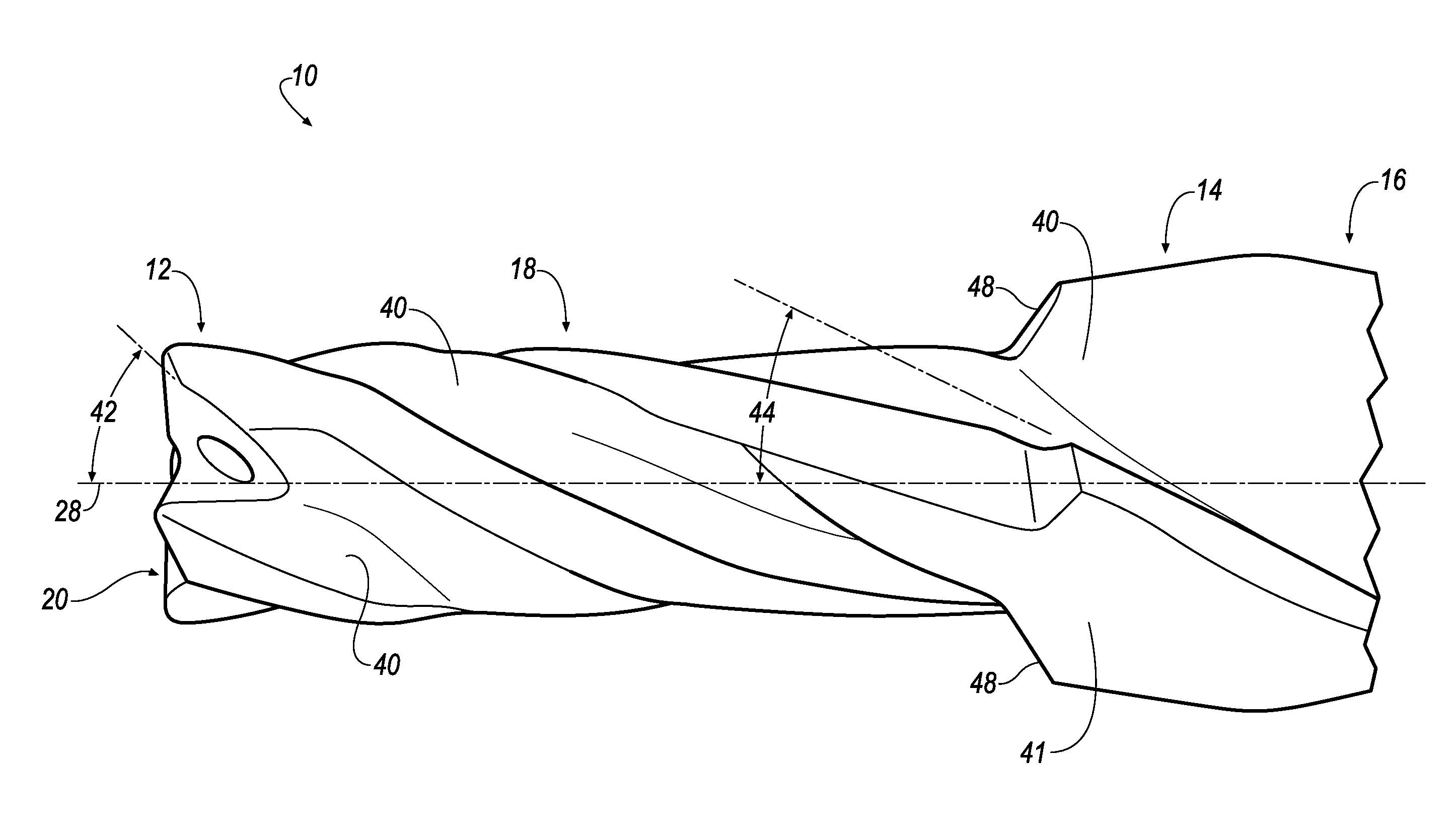

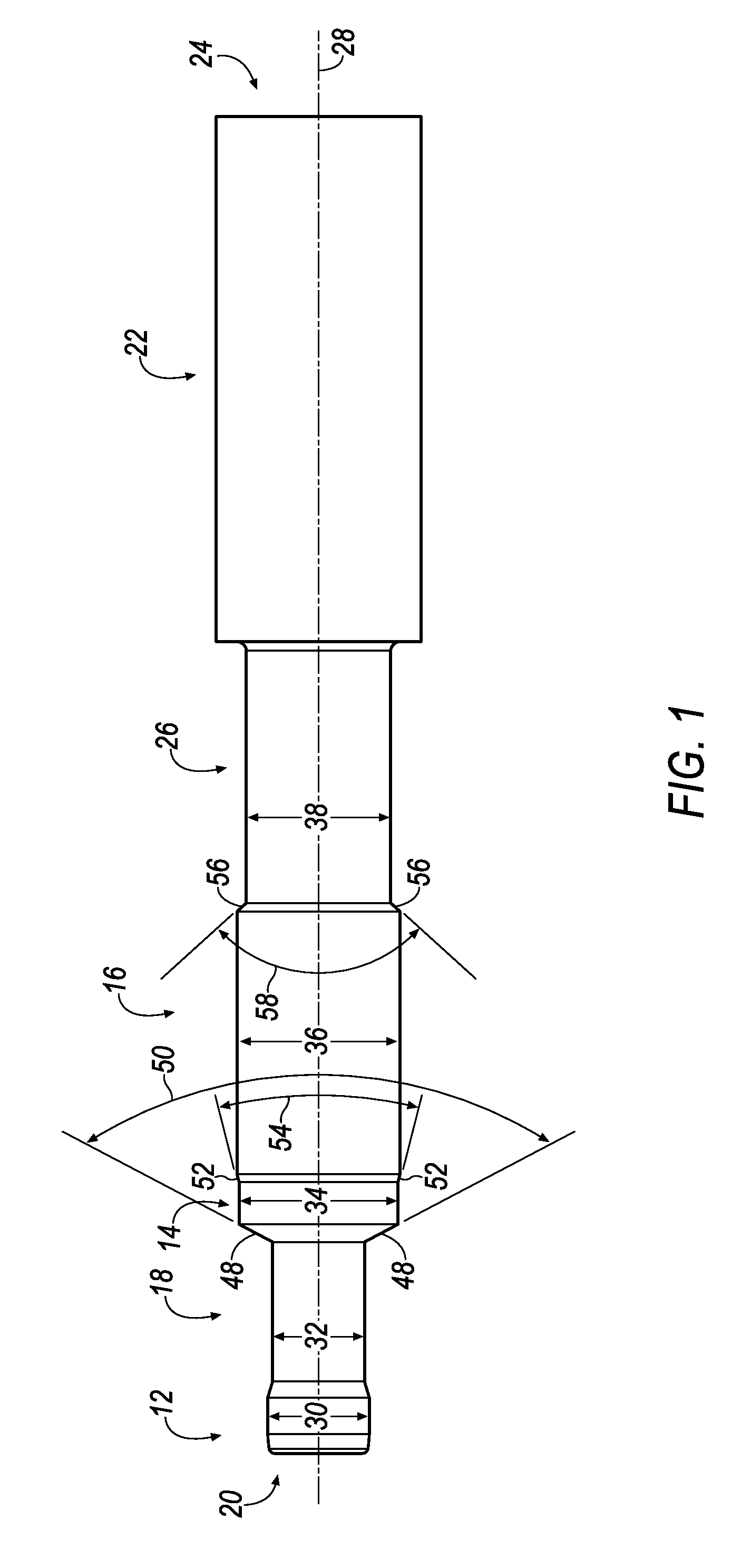

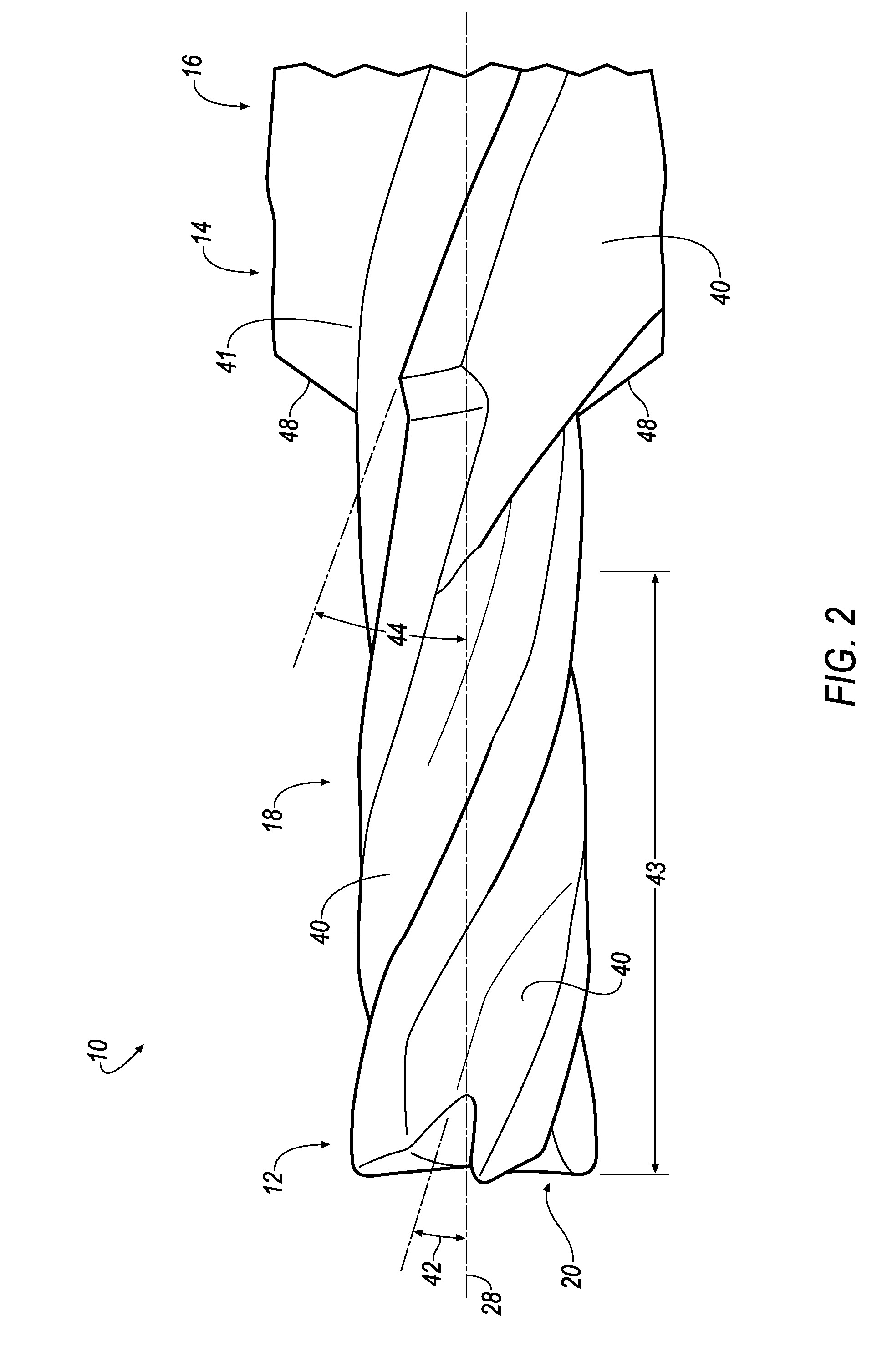

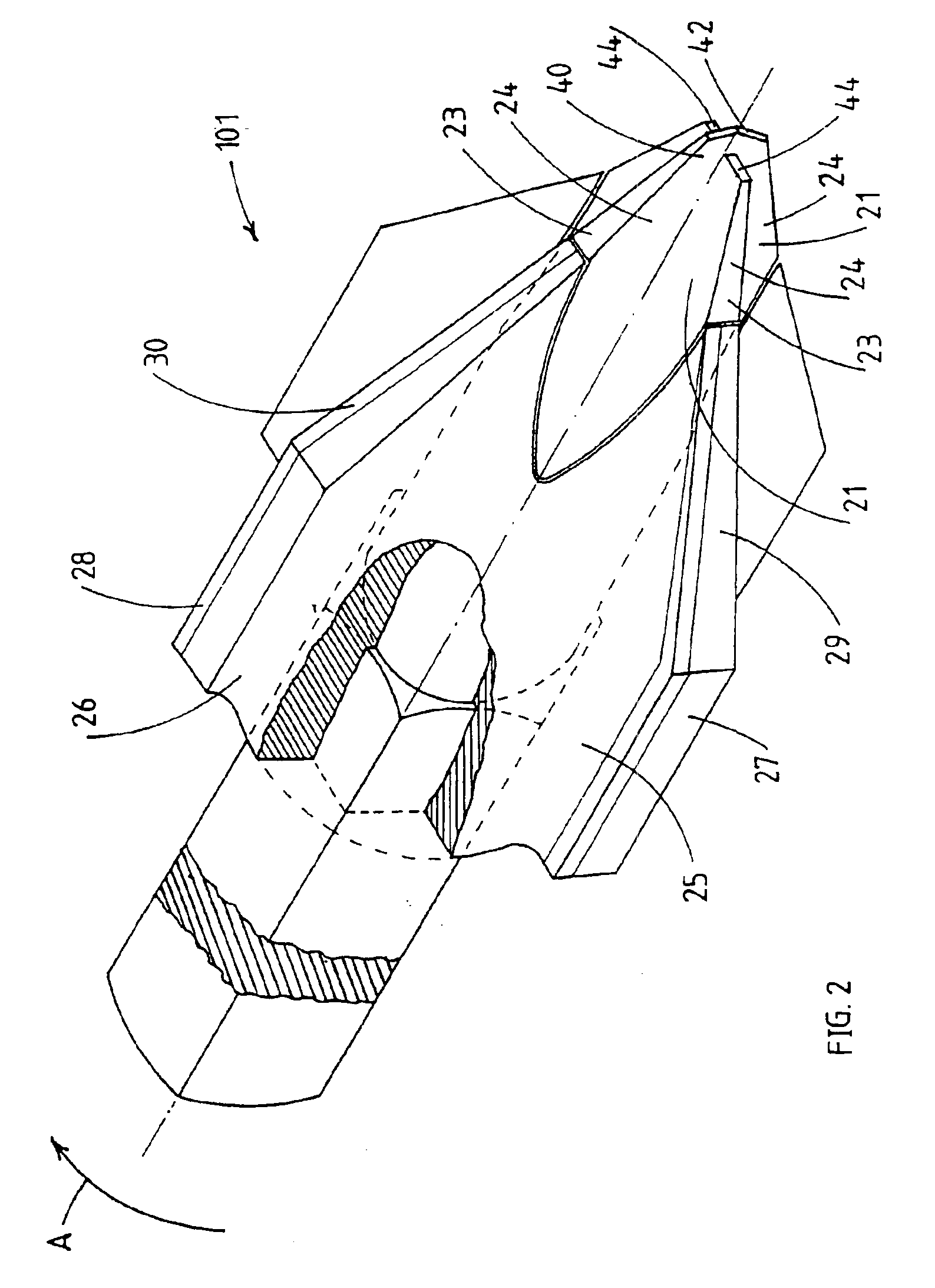

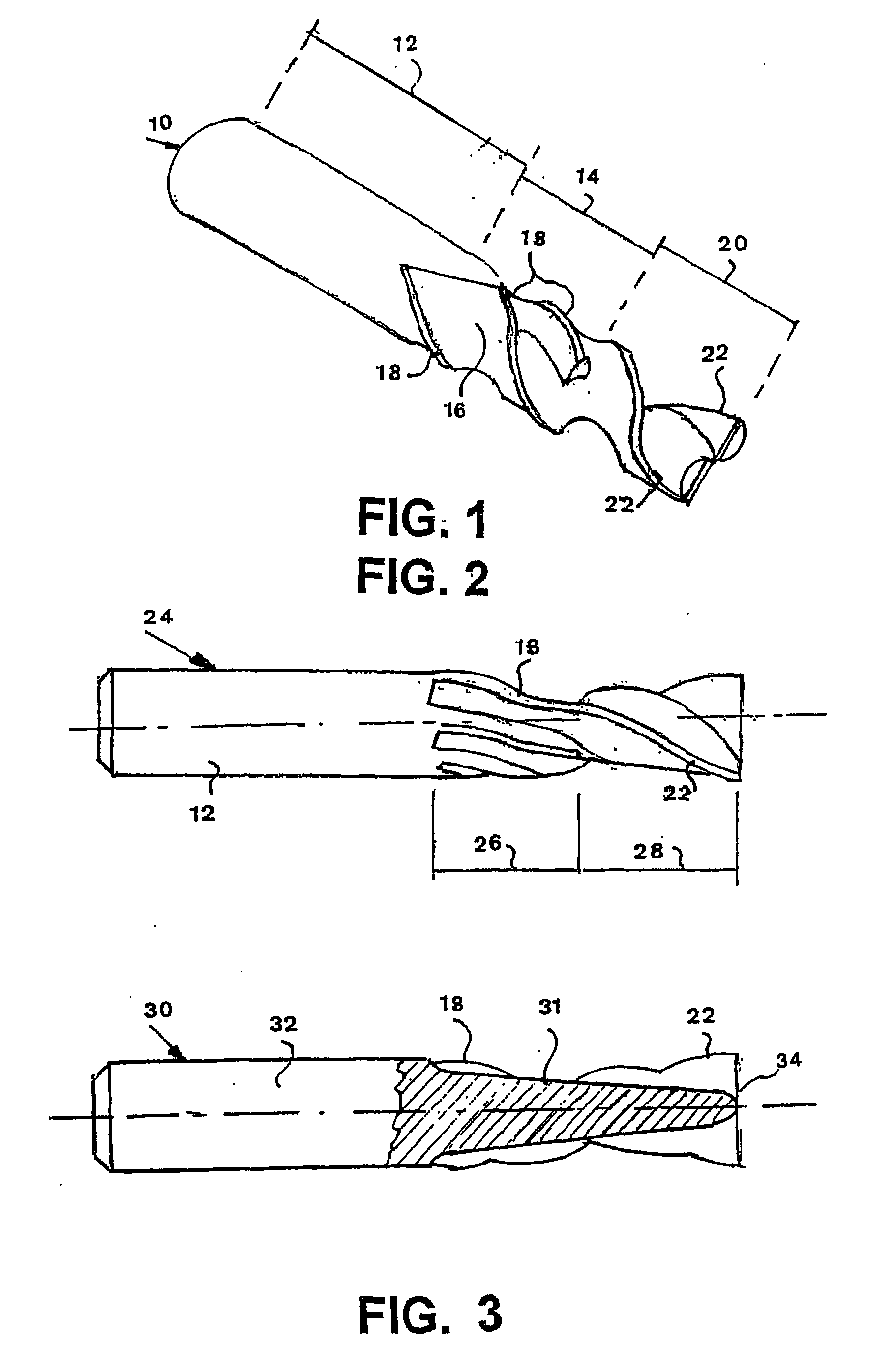

Combination end milling/drilling/reaming cutting tool

ActiveUS20120051863A1Improve fatigue lifeFaster cycle timeDrilling machinesMilling cuttersEngineeringMechanical engineering

A combination end milling / drilling / reaming cutting tool includes an end milling portion, a drilling portion, and a reaming portion. The cutting tool also includes a neck portion between the end milling portion and the drilling portion, and a clearance neck portion between a shank and the reaming portion. A method of machining a workpiece using the combination end milling / drilling / reaming cutting tool is also disclosed.

Owner:KENNAMETAL INC

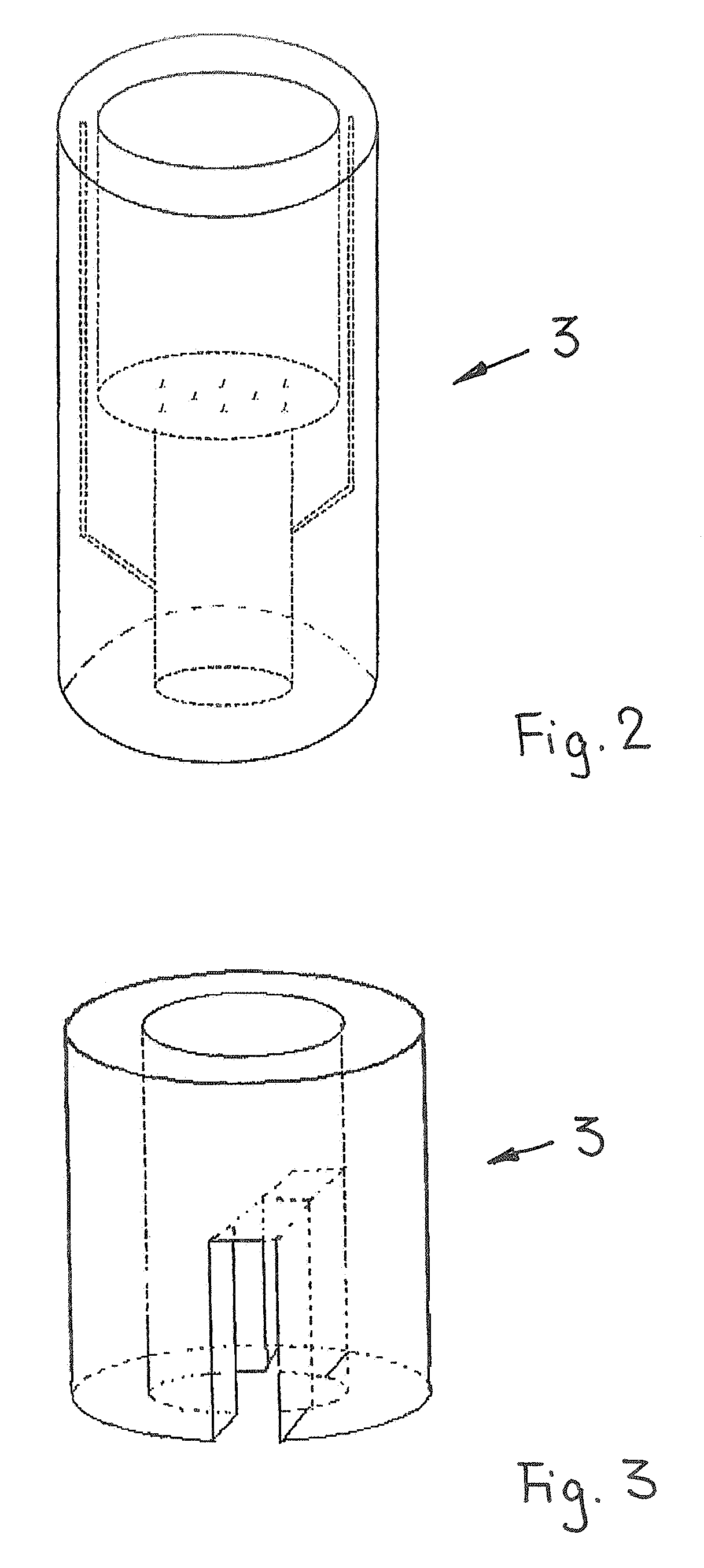

Multi-Blade Curette Tool

A multi-blade curette tool for use in spinal surgery. The curette tool includes an elongated member having a first end and a second end. A handle is disposed at the first end. A curette head is disposed at the second end. The curette head is generally tapered toward the first end and the second end. The curette head includes a convexly-shaped and generally tapered nose portion, a base portion, and a plurality of blades. Each blade extends between the base portion and the nose portion, and each of the plurality of blades is provided with at least one cutting element. A drive stem connects the handle and the curette head. At least one cutting element of each blade is adapted to remove spinal disk material upon rotation of the curette tool in at least one direction.

Owner:SPINAL ELEMENTS INC

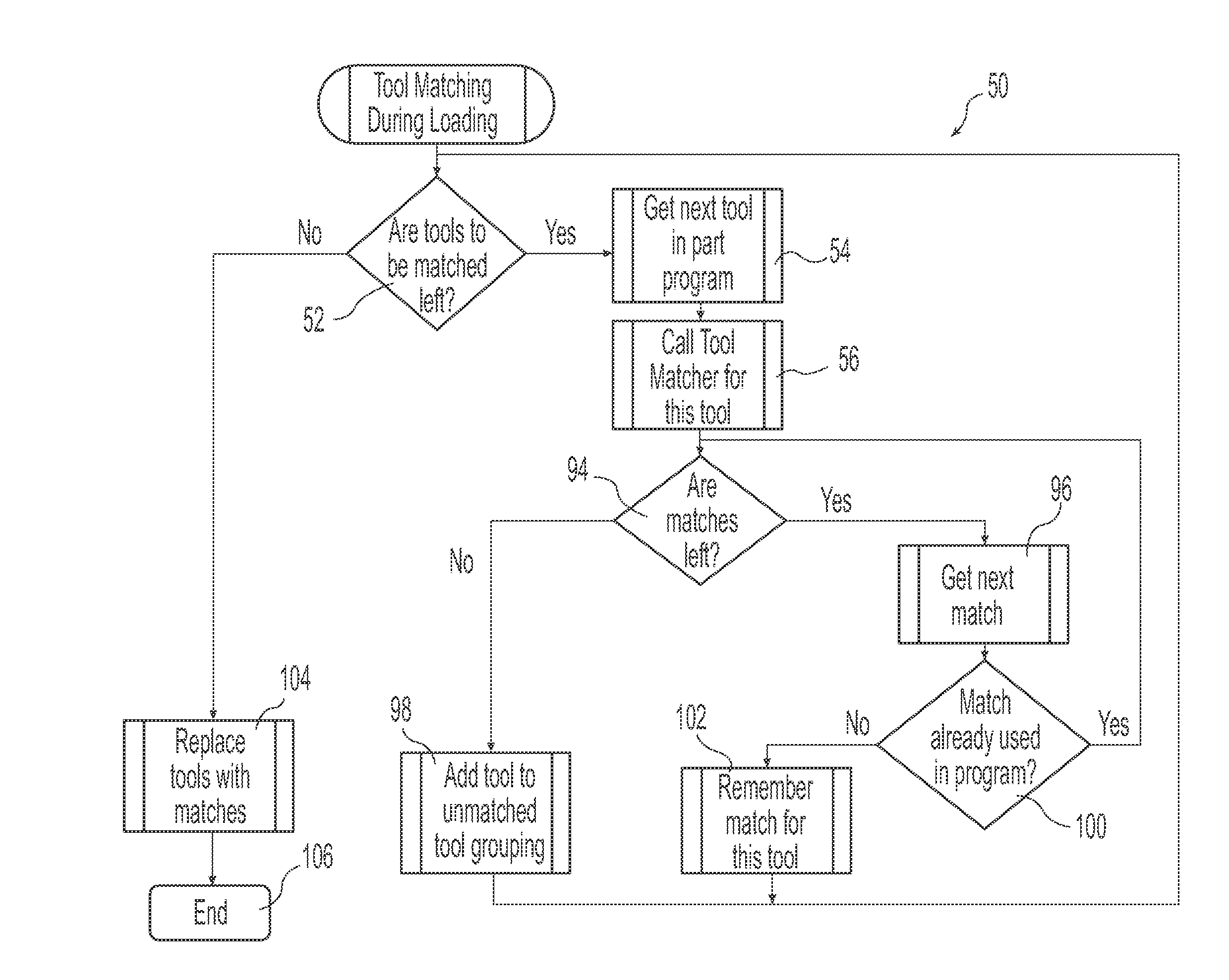

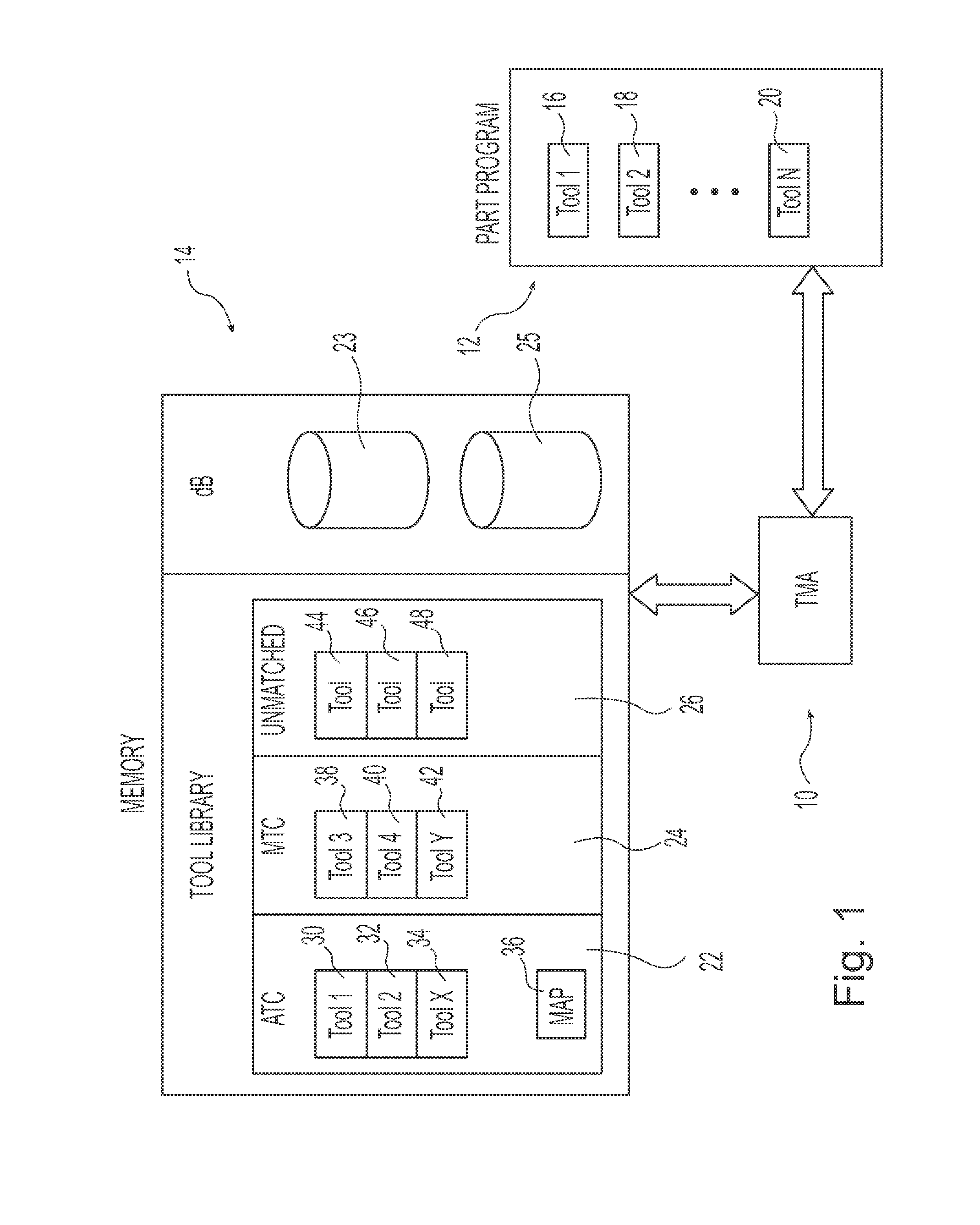

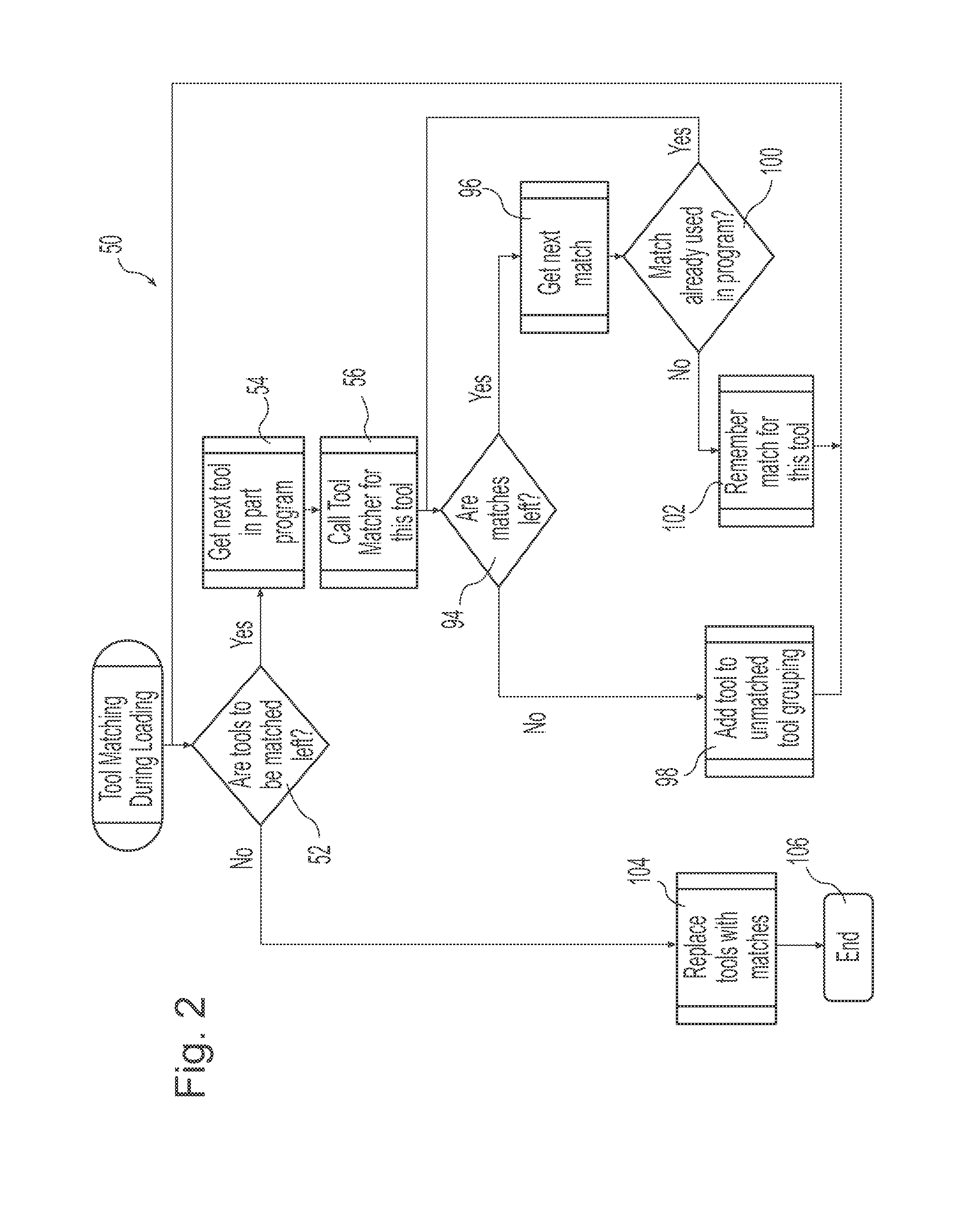

System and method for tool use management

The present invention provides a system and method for tool use management wherein a CNC machine retains information identifying the tools associated with the machine as well as their current locations (if any), and executes an algorithm for determining the source tools needed by a part program and matching the source tools with the available tools.

Owner:HURCO

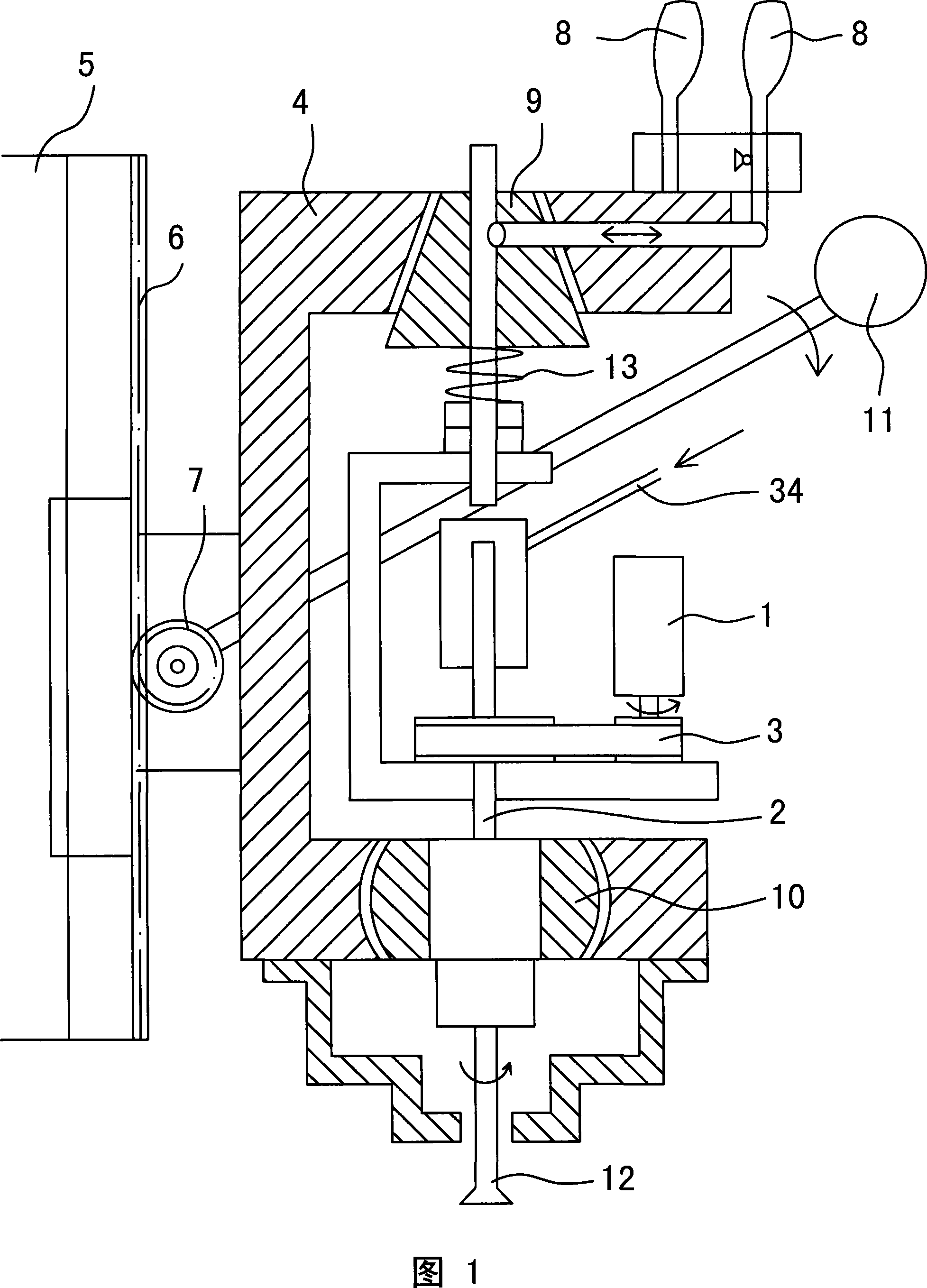

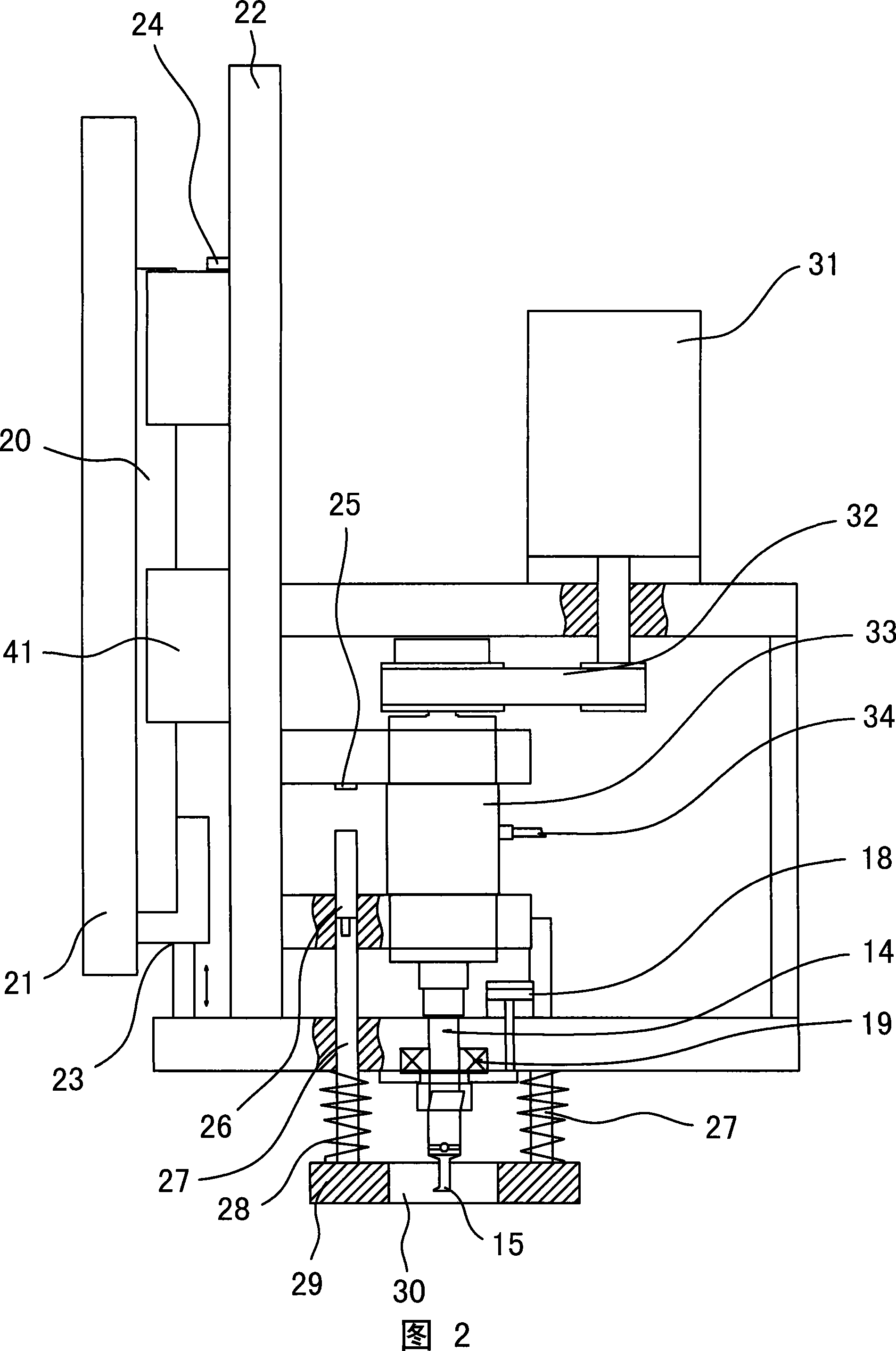

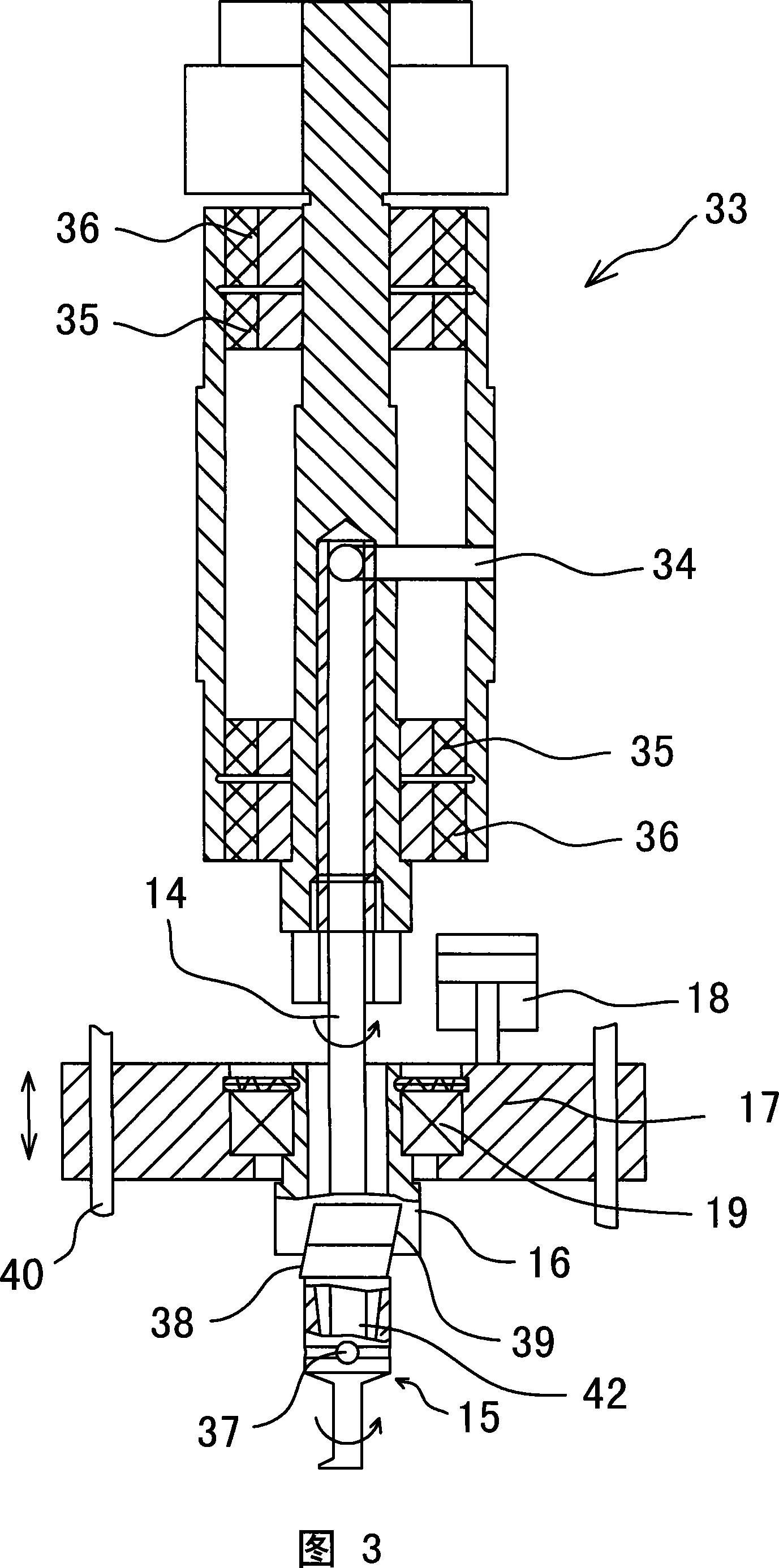

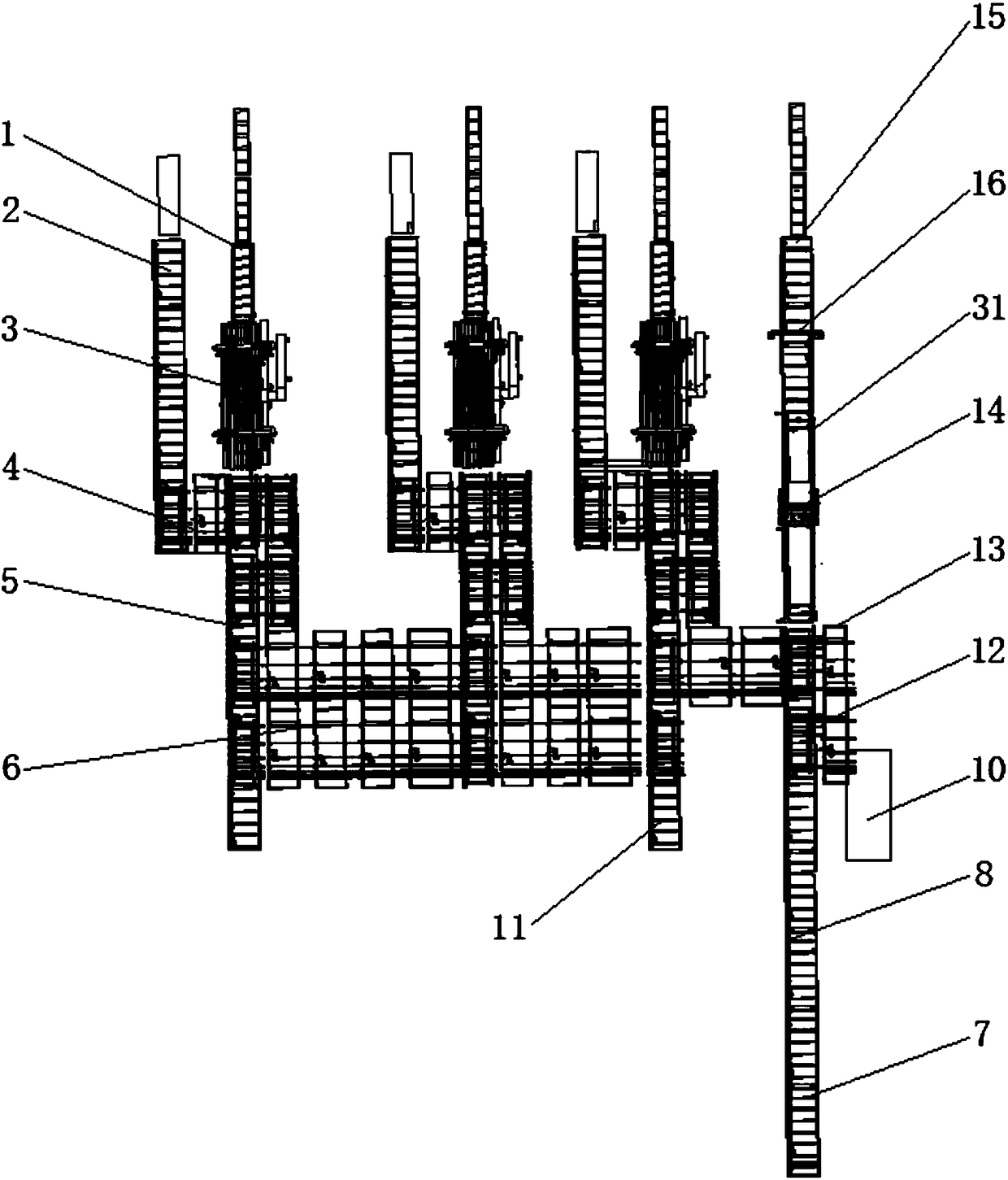

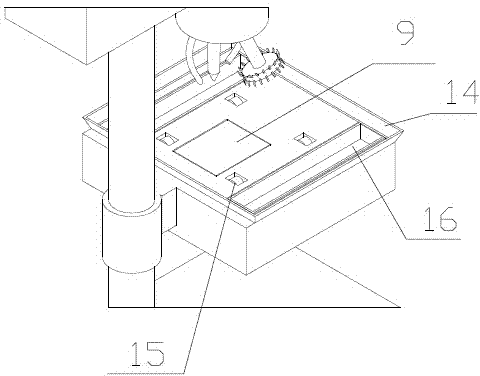

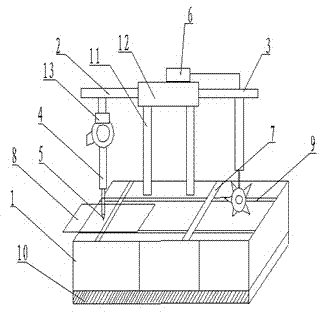

Board drilling machine head

InactiveCN101100092AImprove pullout forceGood cavityDrilling machinesStone-like material working toolsEngineeringMechanical engineering

The plate drilling machine head includes one main shaft rotating mechanism, one Z-axis feeding mechanism, one cooling water providing mechanism, and one eccentric reaming mechanism. The eccentric reaming mechanism comprises one bit with one pair of first bevels in the tail for controlling its swing, one main shaft with lower end hinged to the middle section of the bit for swinging the bit, one eccentric block with one pair of second bevels to slide fit the first bevels, one shifting block capable of shifting in Z direction, and one reaming stroke acting unit acting on the shifting block in Z direction. The present invention has high quality of drilled hole.

Owner:苏州工业园区科特建筑装饰有限公司

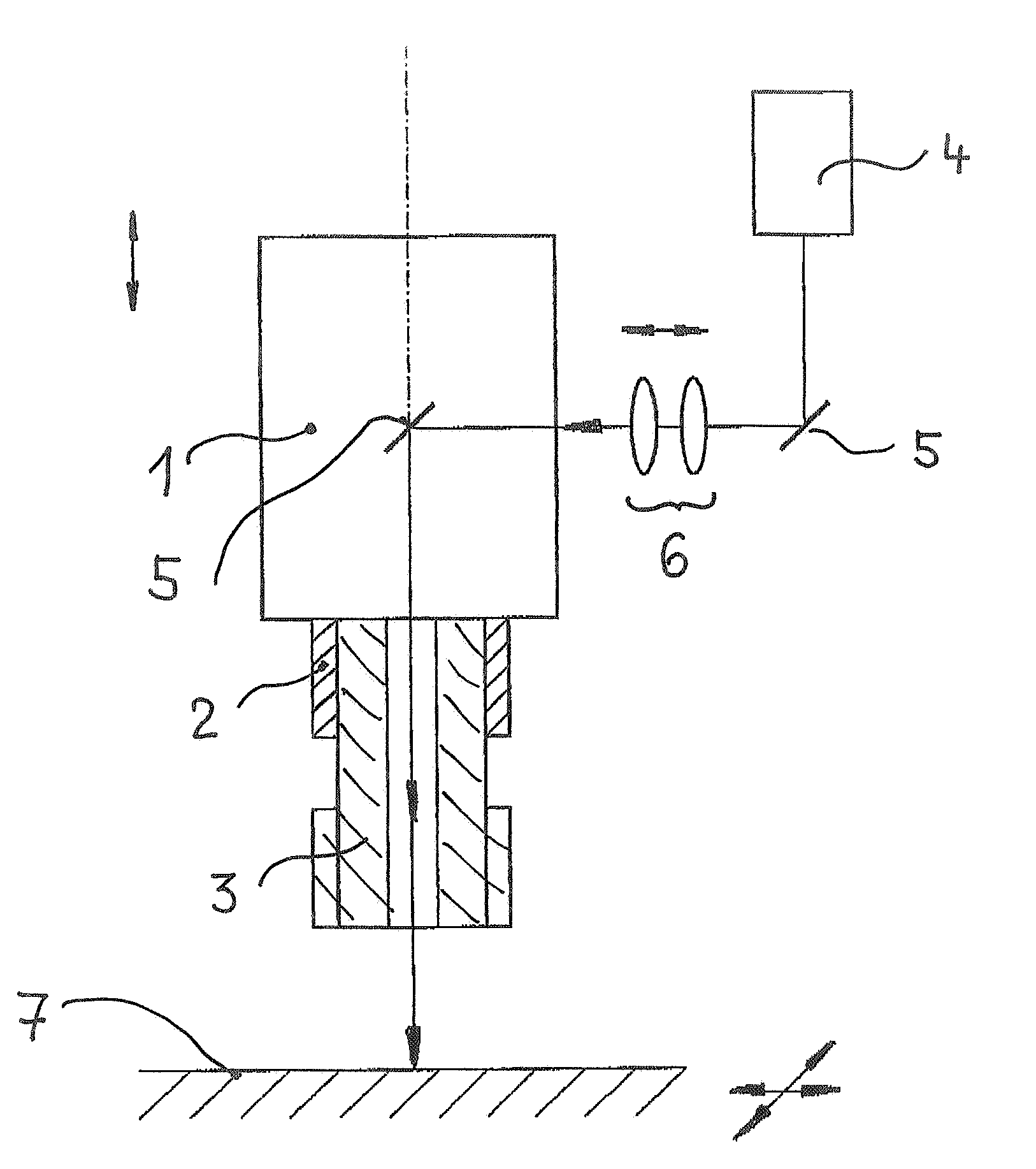

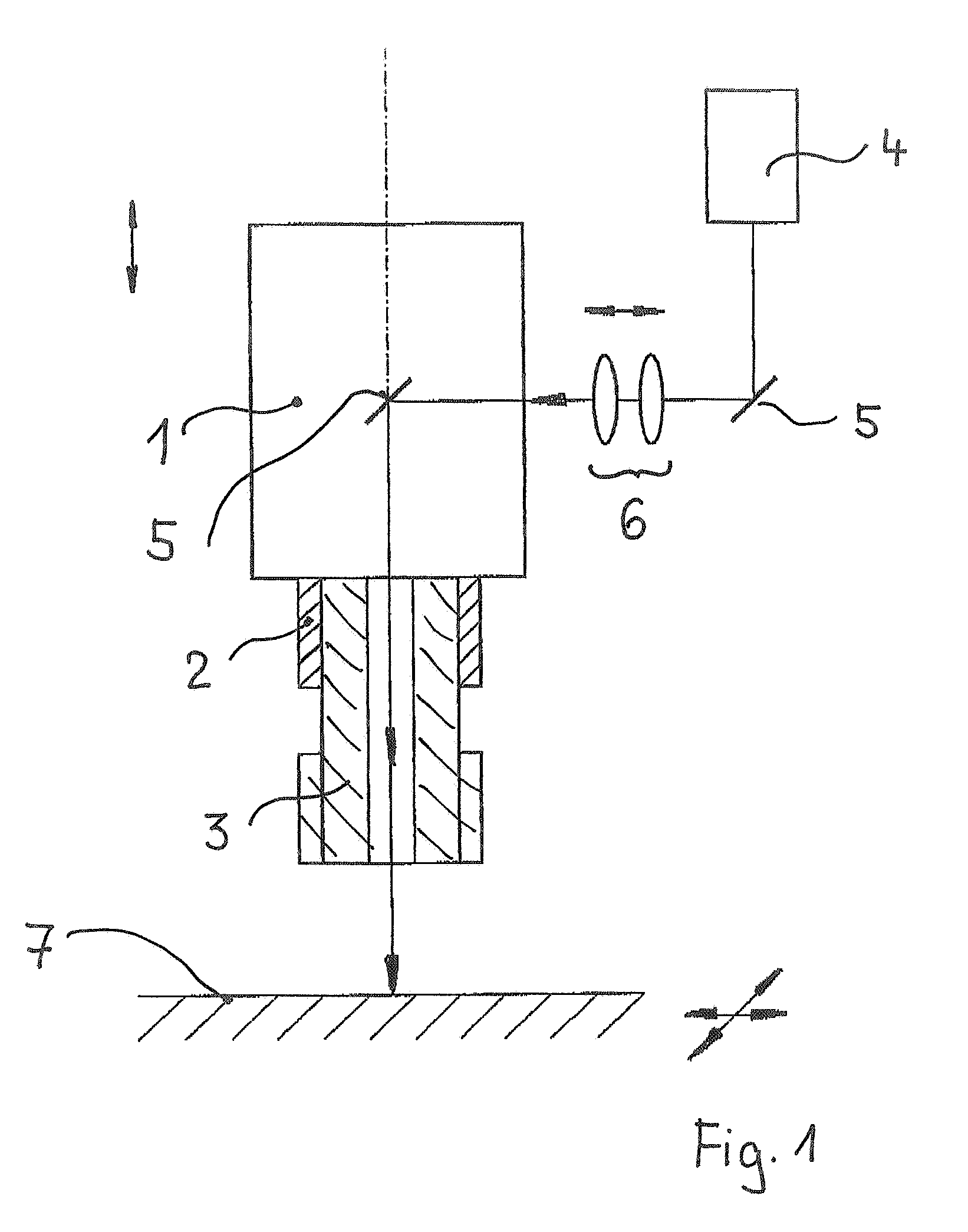

Combination apparatus for machining material with a milling cutter and a laser

The invention is directed to an apparatus for cutting material by means of a milling cutter and laser radiation. The apparatus comprises a milling unit, a work spindle, a milling cutter, a laser, deflecting elements, focusing optics, and a work table. According to the invention, a workpiece can be milled and lasered simultaneously or successively at the same cutting location in that the laser beam is coupled into a channel coaxial to the mill axis.

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

Tool and method for forming a lug hole

A single tool that provides multiple machining operations for forming a lug hole through a vehicle wheel hub includes an end portion having a first diameter and a mid-portion having a second diameter that is greater than the first diameter. A spade drill bit is mounted upon the end portion and a bore cutting tool is mounted upon the mid-portion.

Owner:HAYES LEMMERZ INT

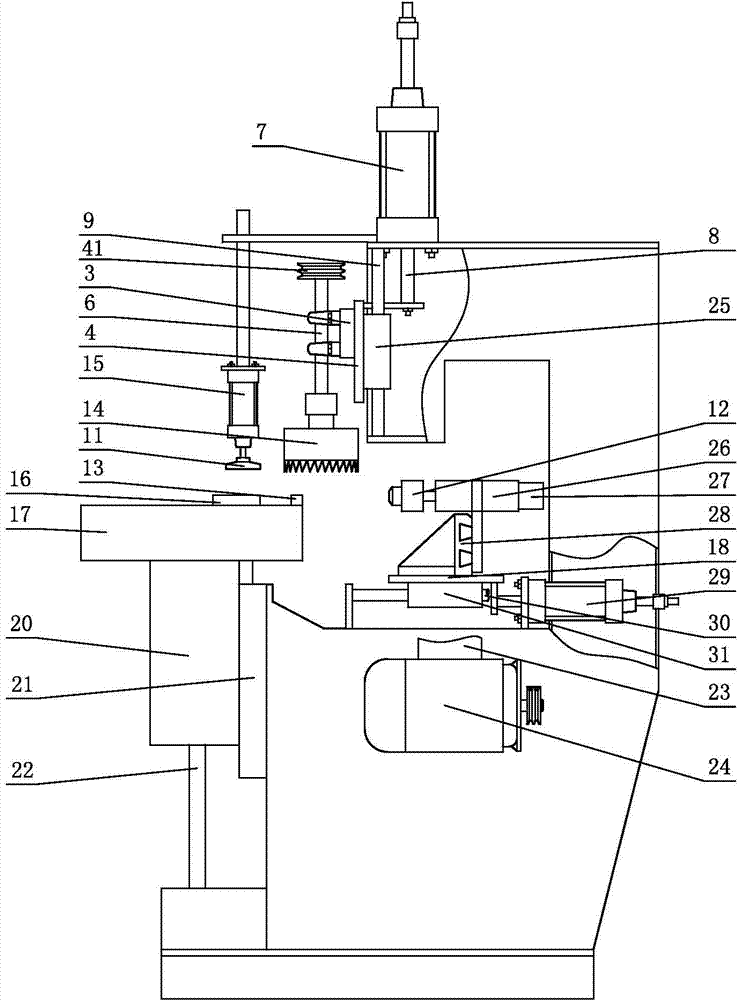

Full-automatic wood door lock, hinge groove and hole processor

InactiveCN101279454ASolve processing problemsImprove processing efficiencyDrilling machinesWood mortising machinesMilling cutterEngineering

The invention relates to a wood processing device, in particular to a full-automatic lock for wooden door, the groove of a hinge and a hole processing machine, which comprises a frame. The invention is characterized in that: a working table which is controlled by a motor to move horizontally and used for placing a wooden door forms a sliding fitting with the frame, and a clamping device for wooden door is arranged at the side edge of the frame; an electric milling cutter device for hinge which can horizontally move along the X direction relative to the frame is arranged at the front side of the frame, an electric drilling and milling device for fade lockhole which can move in the Y direction is arranged at the rear side of the frame and an electric drilling and milling device for door side lock groove which can move along the Y direction is arranged below the electric drilling and milling device for fade lockhole. Various motors and cylinders of the wood processing device are controlled by a computer chip controller, thus ensuring that the drills, and milling knives lift and prone automatically according to the program or simultaneously sequentially complete a plurality of cutting and manufacturing of holes and grooves required for arrangement of locks or hinges on the fade or at the side of a door. The problem of processing the inclined plane groove is solved, and the processing efficiency, the slotting quality and the processing precision are significantly enhanced. Furthermore, the wood processing device can process an inclined plane groove, thus solving the problems of processing of inclined plane grooves and significantly enhancing the processing efficiency, the grooving quality and the processing precision.

Owner:TAIZHOU EVOK MASCH CO LTD

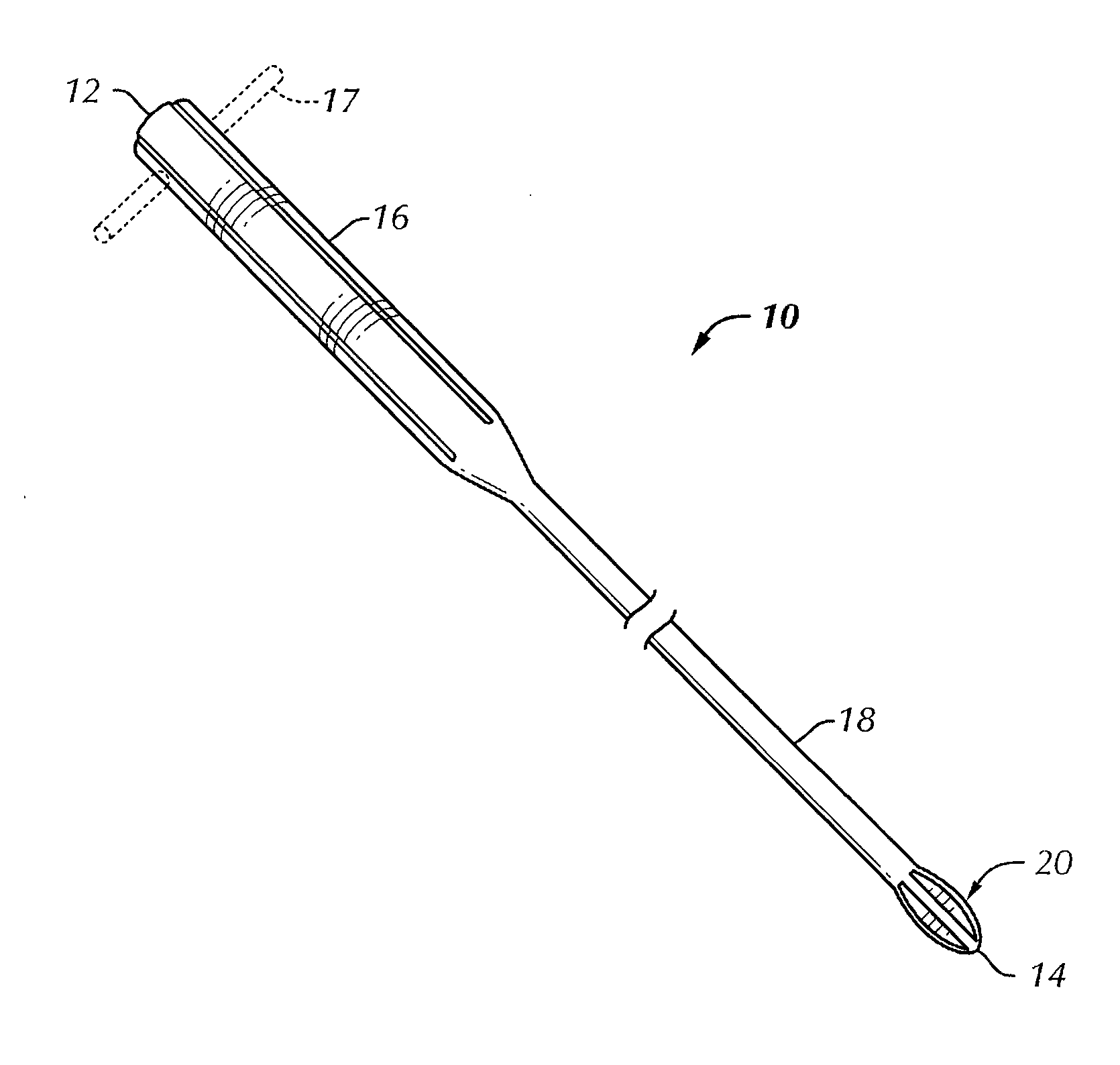

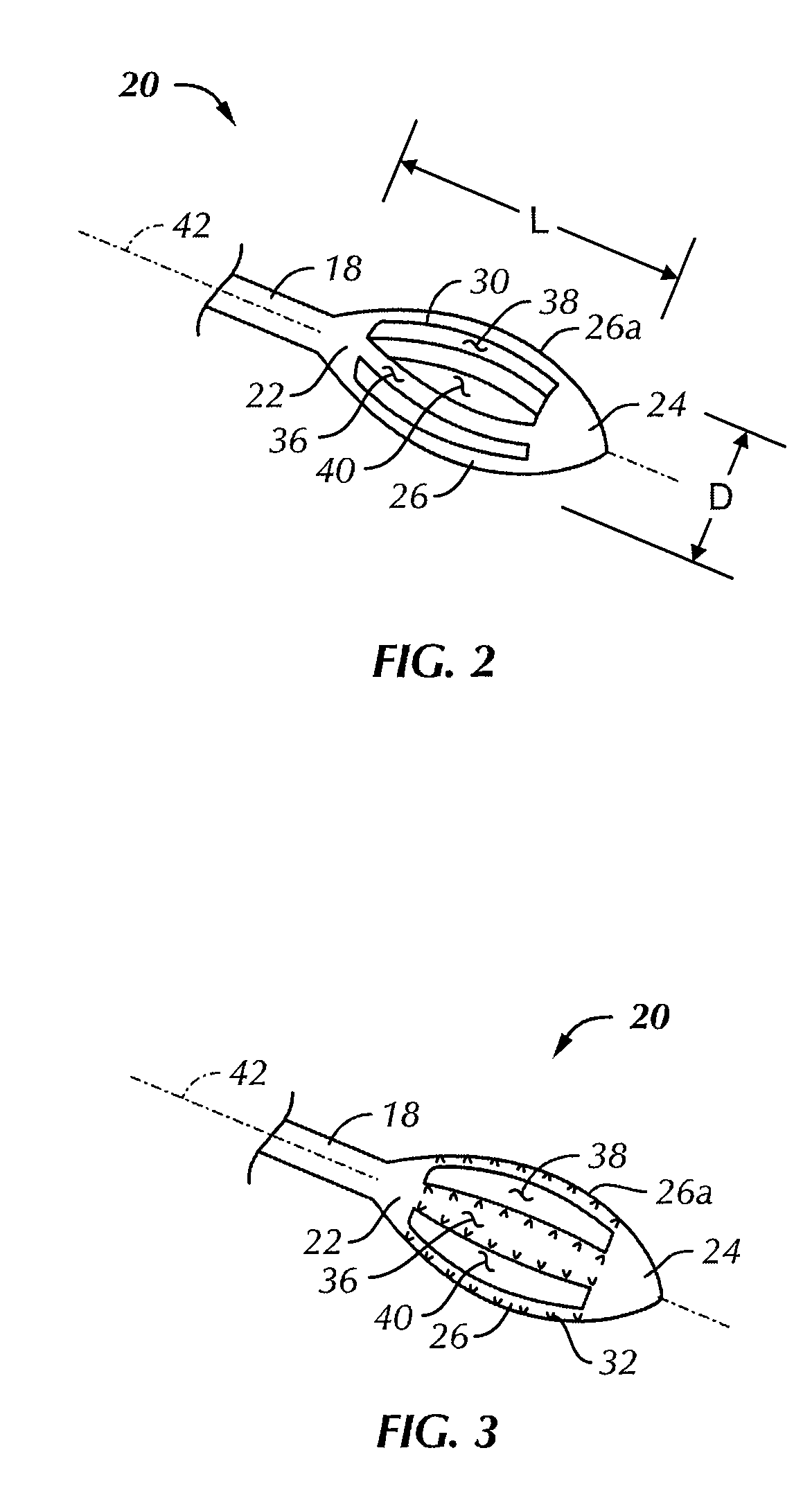

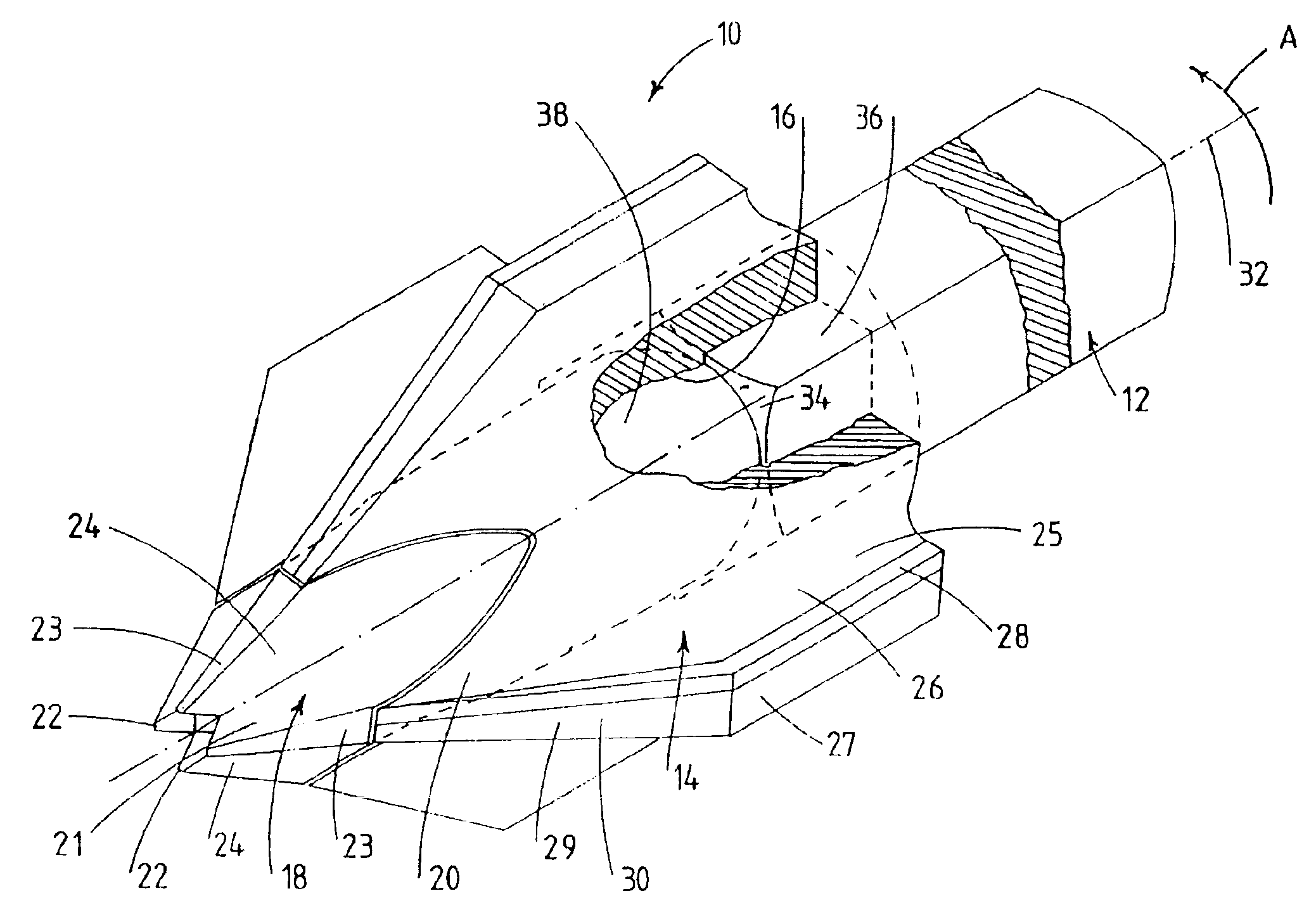

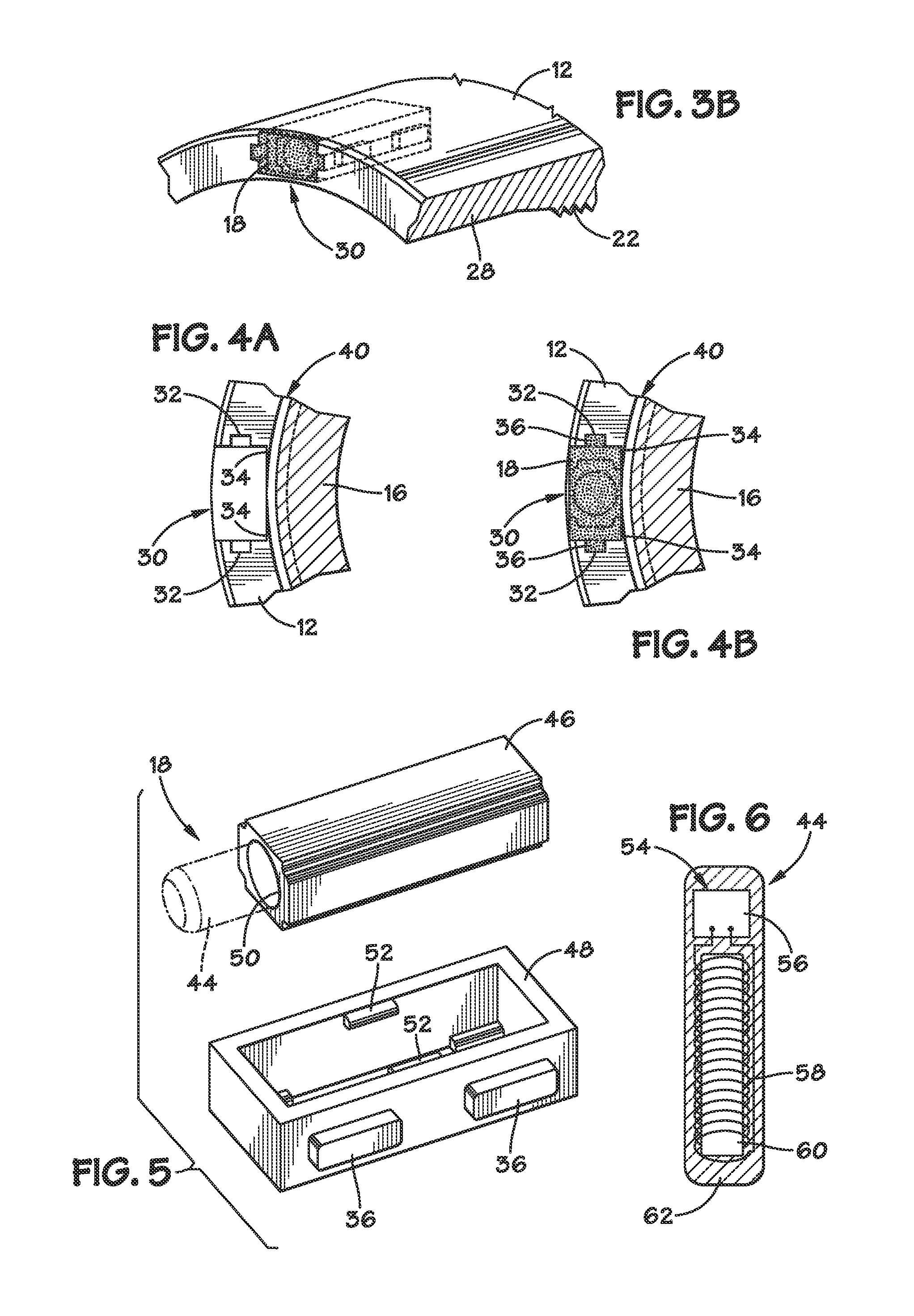

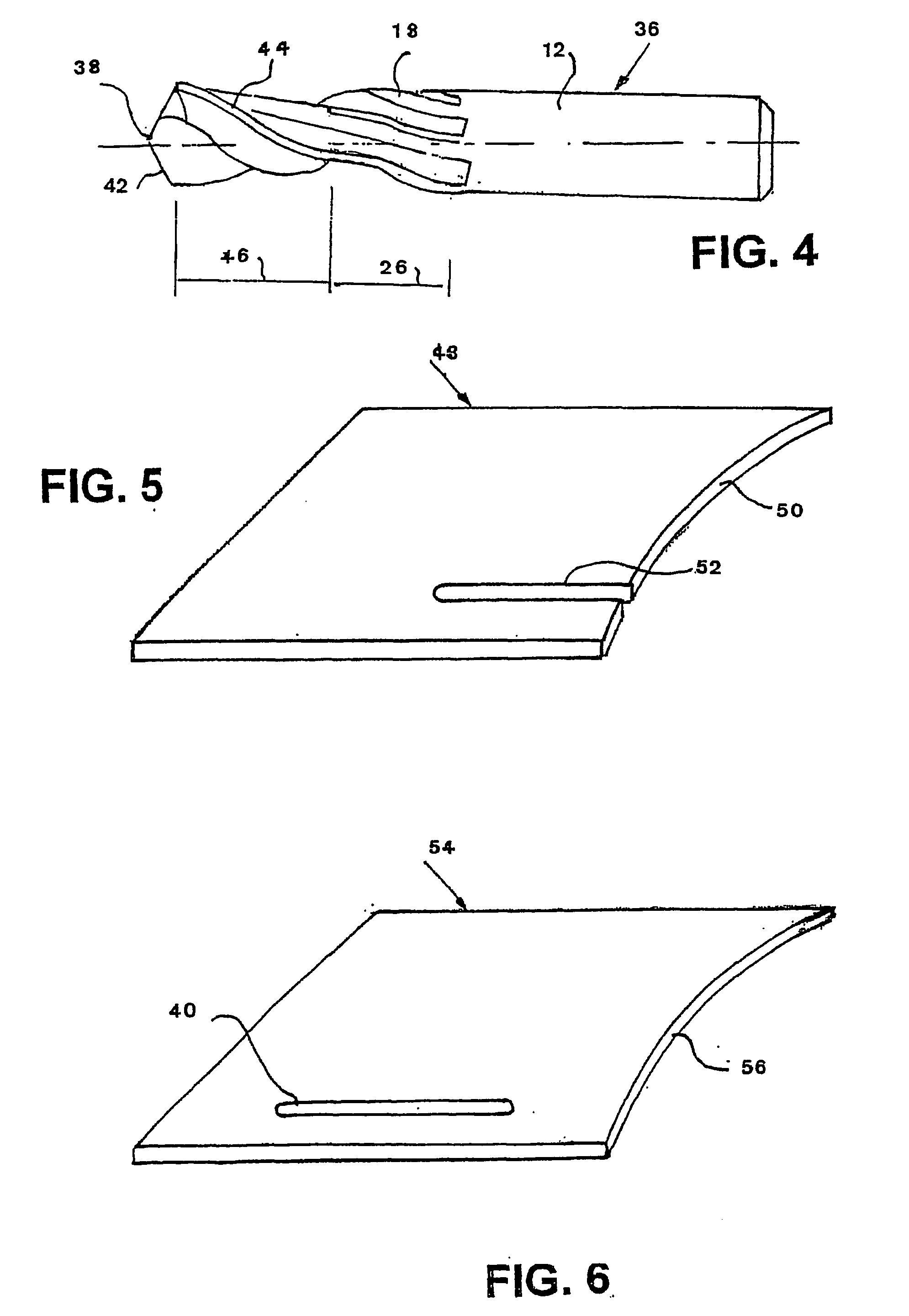

Screwdriving and countersinking bit

The invention provides a bit (10) for use with a rotatable tool, said bit including: a shaft (12) having a rearward end adapted to be held by a chuck of the rotatable tool, and a forward end (18) having cutting tips formed thereon; a reaming head (14) including a body having a bore (16) adapted to receive the shaft therethrough in a sliding fit, the body having a plurality of cutting blades (26) formed on at least one peripheral surface thereof; the bore and / or the shaft having formations thereon such that when the rearing head has the shaft operatively located in the bore the reaming head is rotationally locked into the shaft; the reaming head and the shaft being separable from each other to allow either component to be replaced independently of the other. The invention also provides a bit having a tip end and shank end for use with a rotatable tool, said bit having at least 4 blades (24) to engage ard drive a screw when said rotatable tool is rotated, each blade including at said tip end a bevel so as to form a cutter (22) at the extremity of said blade, each bevel and / or cutter being able to cut in the same rotational direction. The invention further provides a method of making a bit for use as a screwdriver and countersinker, said method including the steps of: 1) forming at least a four blade screw driving end onto one end of blank, 2) forming a bevel at the extremity of each blade, said bevel producing an inclined plane cutter.

Owner:SAVETIME PROD

Identification tags and installation techniques

Various identification tags are disclosed. In one embodiment, a system includes a coupling with an extended skirt having an opening to receive an identification tag. The identification tag may be configured to be snapped into the opening, slid into the opening, or threaded into the opening, for example. The identification tag, such as an RFID tag, may include an electronics module to enable wireless communication with a reader. The electronics module may be received within a body to facilitate installation and retention of the tag and increase durability. The disclosed tags may also be installed in other components. Various other tags, systems, devices, and methods pertaining to identification tags are also disclosed.

Owner:VALLOUREC OIL & GAS FRANCE SAS

Three ply bolted temporary road mats and apparatus for manufacturing same

InactiveUS20050022363A1Increased bilateral stabilityRelieve pressurePortable bridgeThread cutting machinesDrillMultiple layer

An apparatus for making temporary road mats characterized by multiple layers of mutually perpendicular elongated timbers having an array of vertical intersections aligned in lateral rows. The apparatus includes a gang drill that moves relative to a roughly assembled mat for sequentially drilling the lateral rows of intersections.

Owner:CAROLINA MAT

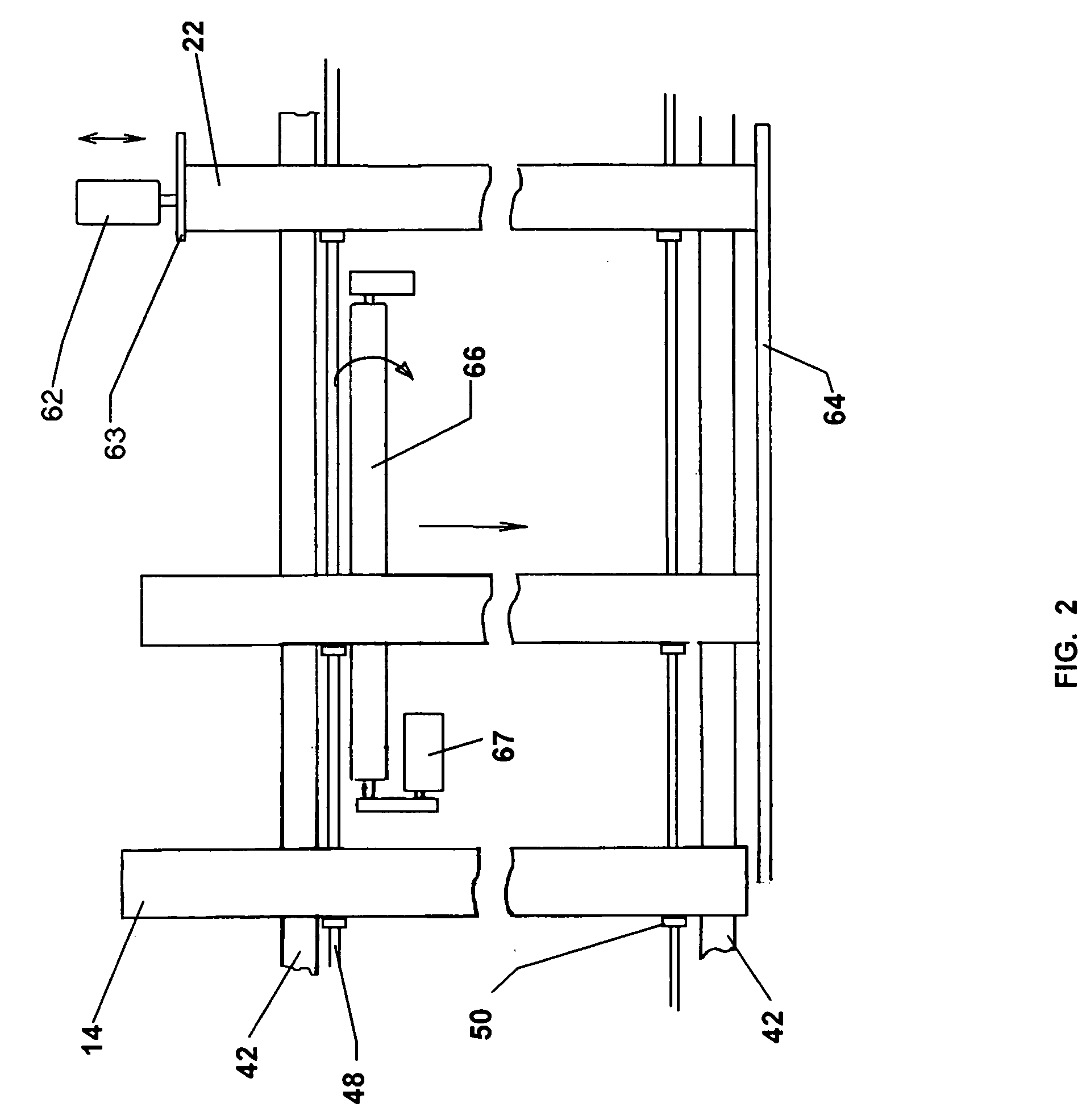

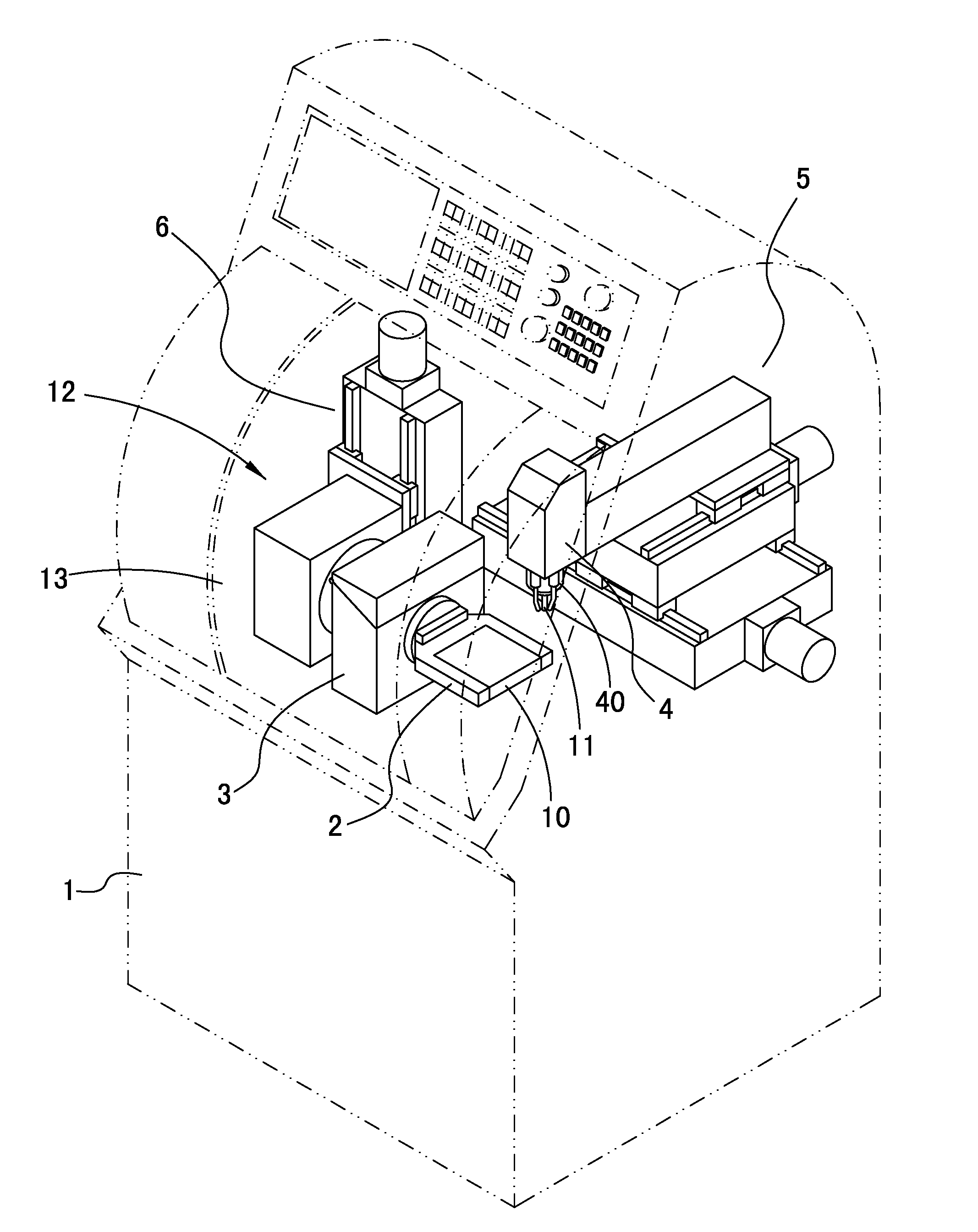

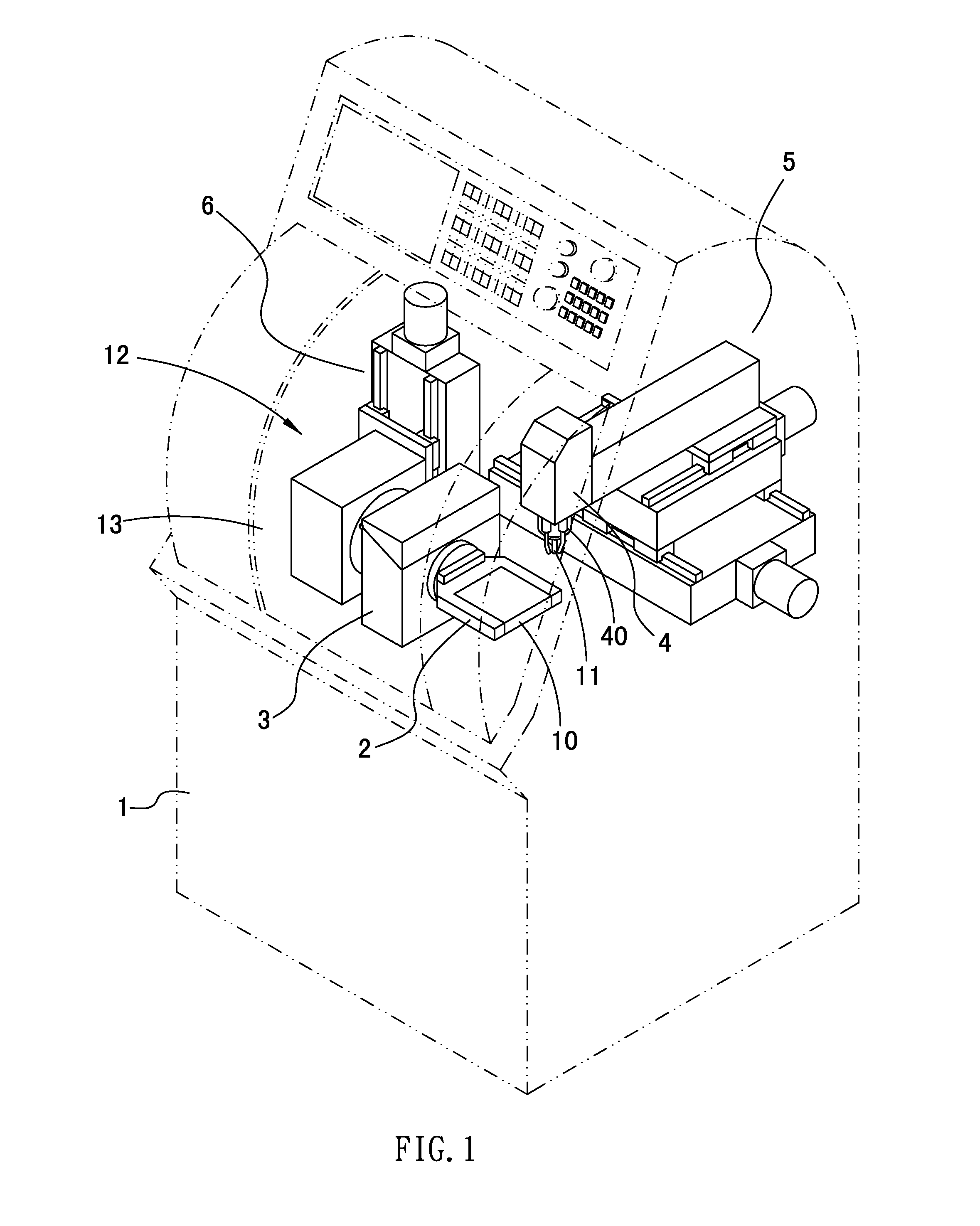

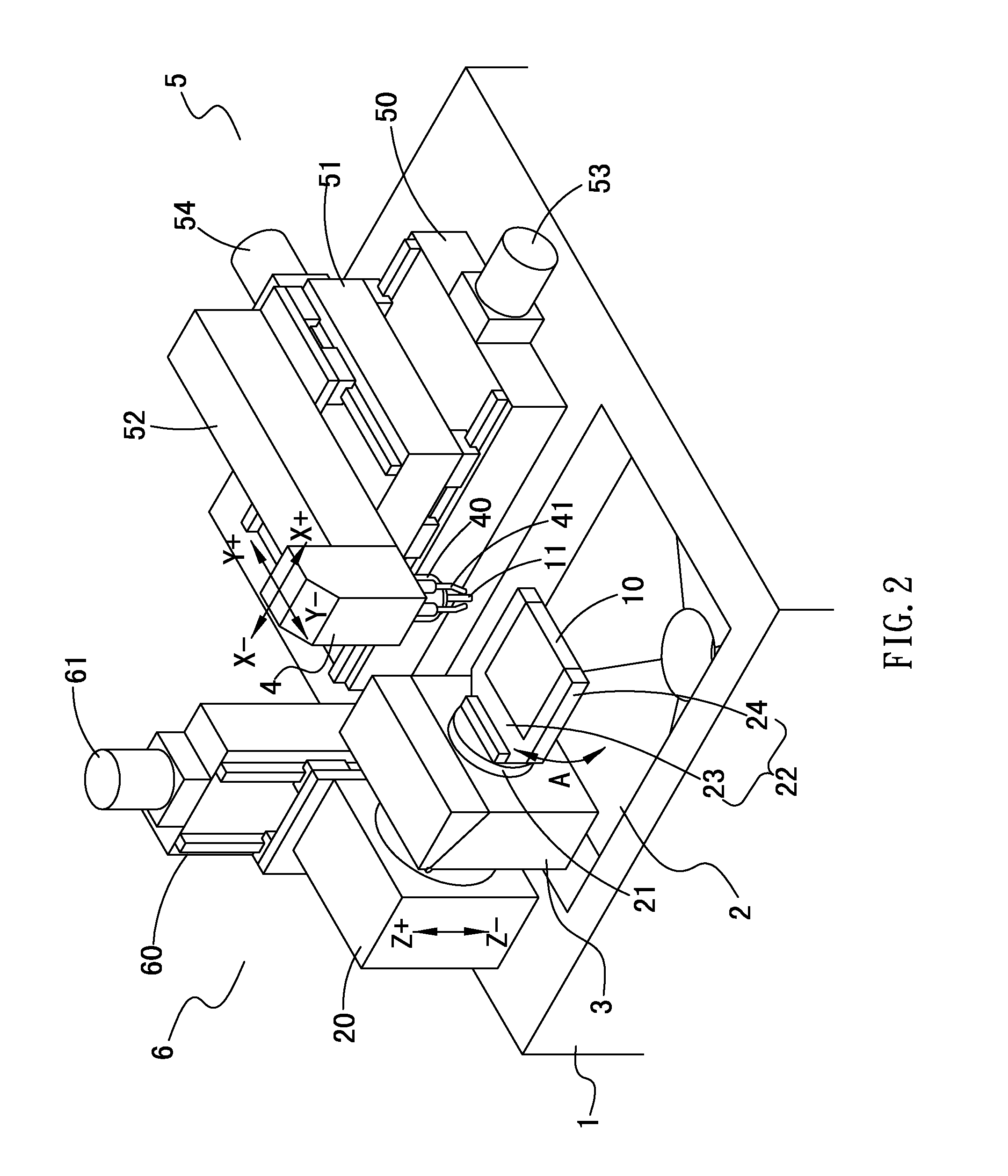

Multi-spindle machining machine with tool changing mechanism

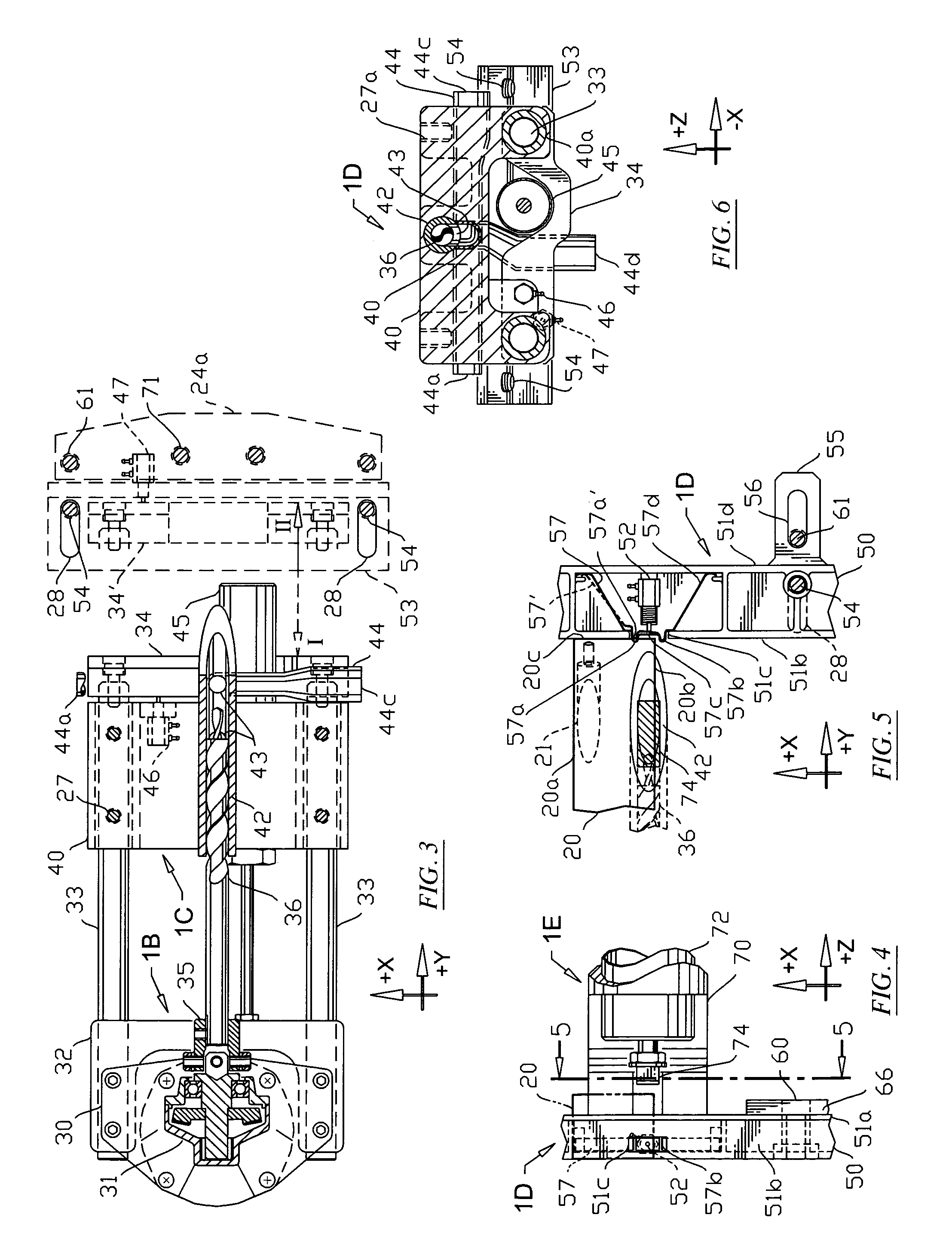

InactiveUS20110083307A1Low production costReduce sizing costsDrilling machinesTransportation and packagingRotational axisEngineering

A multi-spindle machining machine with a tool changing mechanism comprising a base; a carrier including a seat to move in Z axis, a rotary shaft fixed on the seat laterally to drive the seat to rotate in A axis, and a fixing holder coupled to an end portion of the rotary shaft to fix a workpiece; a tool changing mechanism including a mount mounted to the rotary shaft to rotate with the rotary shaft and a monitor fixed on the seat to measure a length of the tool clamped on the driving spindle, and including a plurality of slots to receive the tools respectively; a working head moving above the carrier and the tool changing mechanism in X and Y axes and including a driving spindle mounted on a lower end thereof to rotate axially, and the lower end of the driving spindle allowing to engage and disengage the tool.

Owner:SHENQ FANG YUAN TECH

Equipment for grooving and drilling on side of cutting board

ActiveCN103692499AReduce labor intensityRealize mechanical automationDrilling machinesMulti-purpose machinesEngineeringMachining

The invention belongs to the technical field of machining of cutting boards, and discloses equipment for grooving and drilling on the side of a cutting board. The equipment comprises a cutting board clamping table, a drilling device, a grooving device and a controller, wherein the drilling device is arranged behind the cutting board clamping table and comprises a drill bit and a drilling motor which drives the drill bit to rotate, and the forward projection point of the drill bit is located in a pre-drilling position of the cutting board which is positioned and clamped on the cutting board clamping table. The grooving device is arranged above the drilling device and comprises a cylindrical saw web and a grooving motor which drives the saw web to rotate around a cylinder axis. The downward projection of the cutting line of the cylindrical saw web is overlapped with an arc-shaped contour of a pre-cutting arch-shaped groove of the cutting board which is positioned and clamped on the cutting board clamping table. According to the equipment disclosed by the invention, the special cutting board clamping mechanism is designed, and an air cylinder device is selected to simulate actions in a manual operation process, so that mechanization and automation of the arch-shaped grooving and drilling are realized. Compared with manual operation, the mechanical and automatic operation has the advantages that the machining efficiency is high, the labor intensity of workers is reduced, and the labor cost is reduced.

Owner:ZHEJIANG SHUANGQIANG BAMBOO & WOOD CO LTD

Door body clamping device

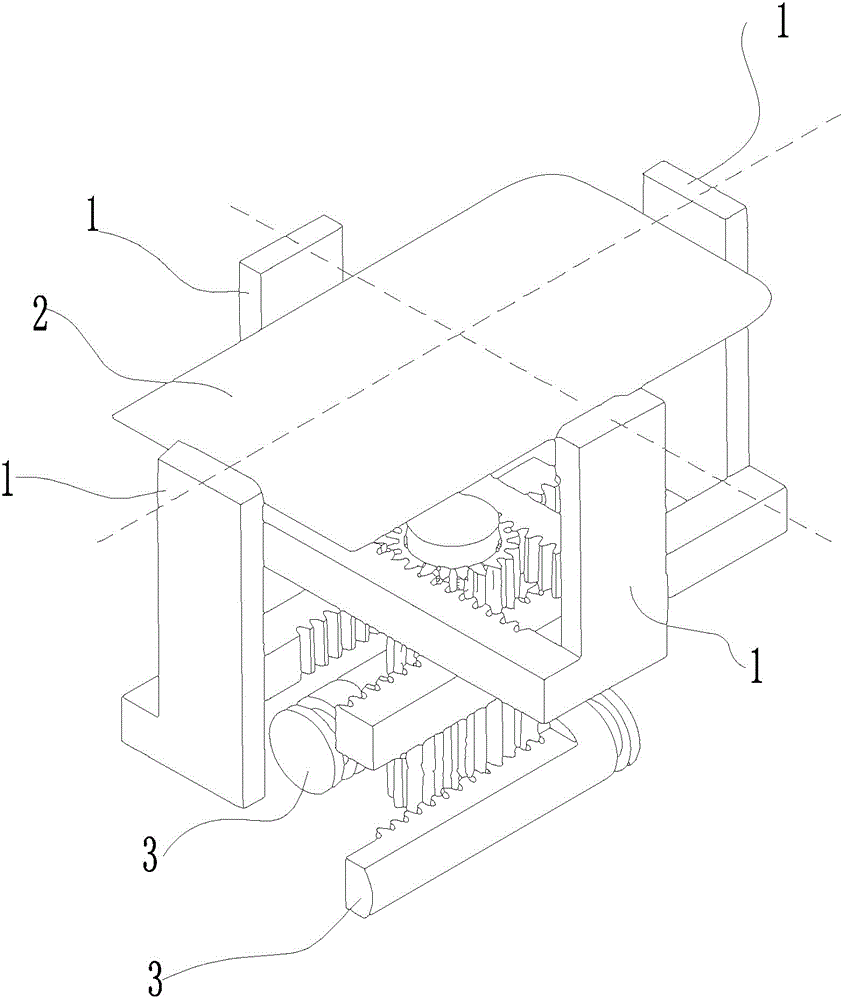

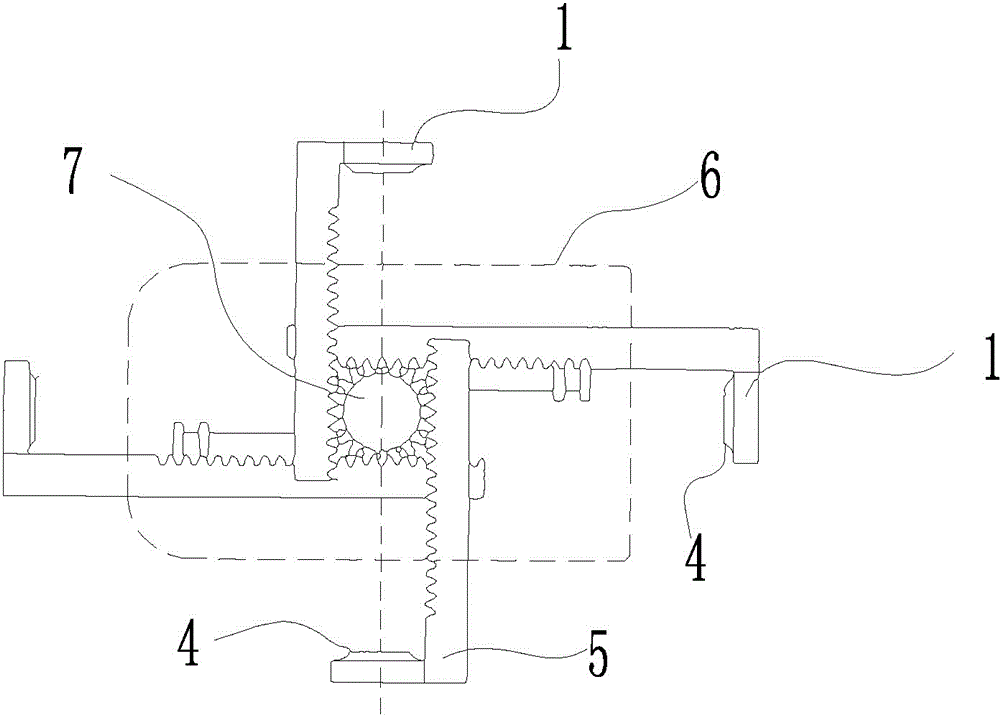

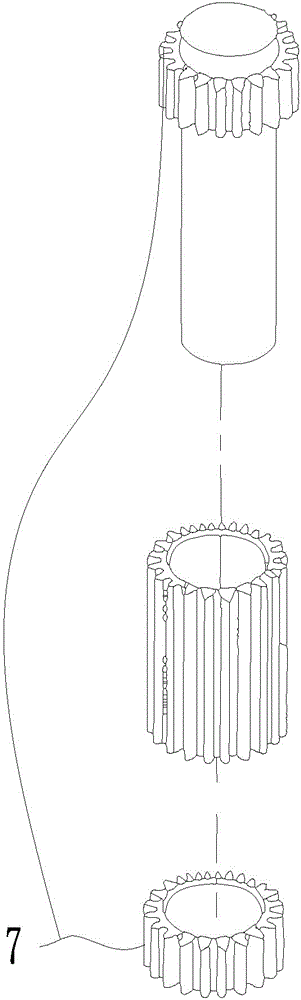

PendingCN104441077AAchieve clampingEasy to operateDrilling machinesProfiling/shaping machinesGear wheelElectric machinery

The invention relates to a door plate processing instrument, and particularly relates to a door body clamping device. The door body clamping device comprises a motor, four pressing plates in all, and a gear shaft, wherein the four resisting plates are used for pressing against a door body; one side of each pressing plate toward the adjacent side edge is a resisting surface; a rack of which the length direction is perpendicular to the resisting surface of each pressing plate is fixedly arranged below the pressing plate; the gear shaft is arranged below the door body; the racks which are respectively connected with the pressing plates with opposite positions are respectively arranged at two opposite sides of the gear shaft; the resisting plates and the racks form clamping function members; the clamping function members take the gear shaft as the center point and are in point symmetry distribution; the racks are meshed with the gear shaft; and the motor is fixedly connected with the lower end of the gear shaft or the motor is connected with the gear shaft through a transmission mechanism. The defect that the clamping device in the prior art cannot clamp from four surfaces is overcome; and the door body clamping device capable of automatically resetting is provided.

Owner:CHONGQING OFAN DOOR IND

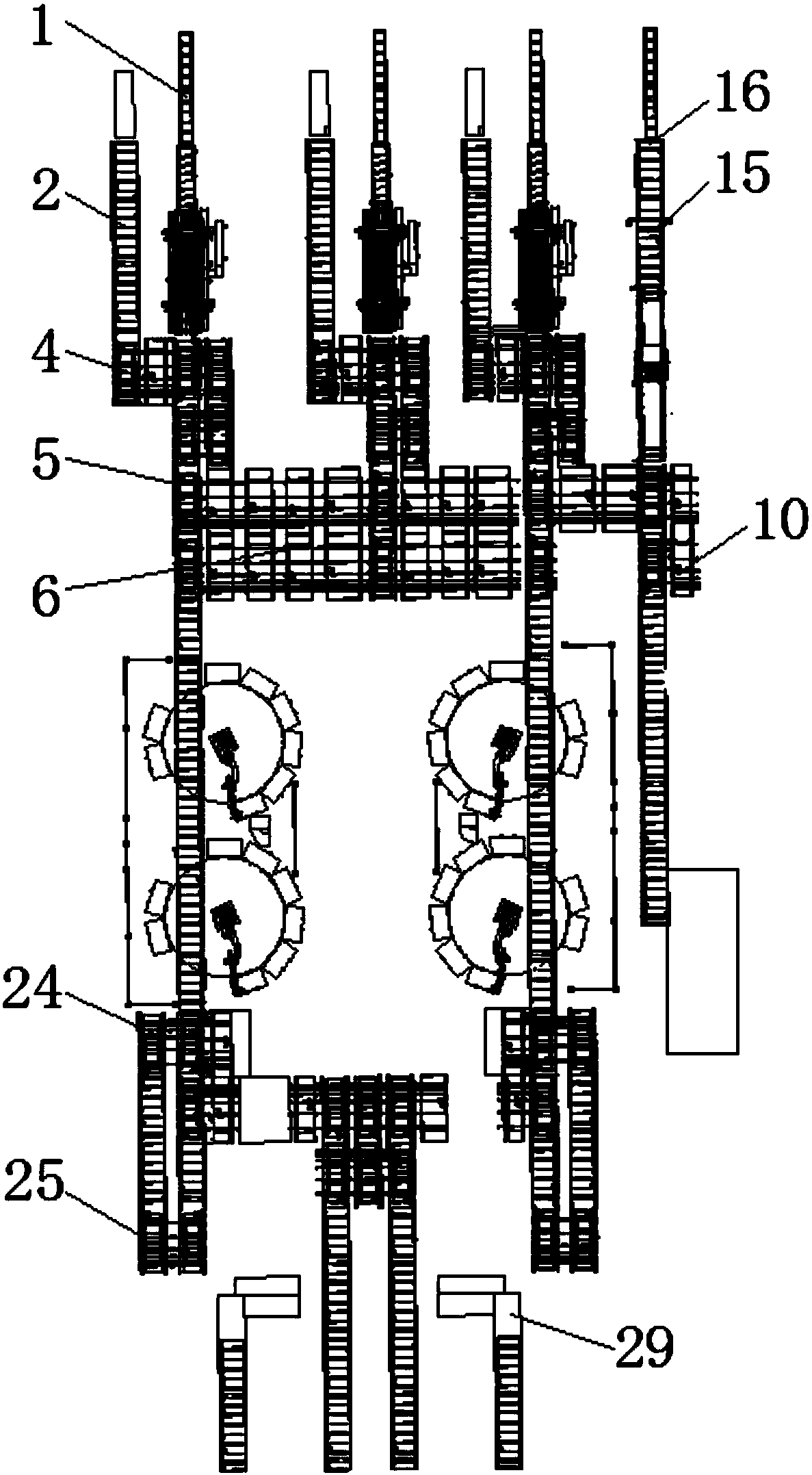

Intelligent board sorting system

ActiveCN108080288ASorting in real timeAccurate sortingDrilling machinesCleaning using toolsMaterial resourcesEngineering

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

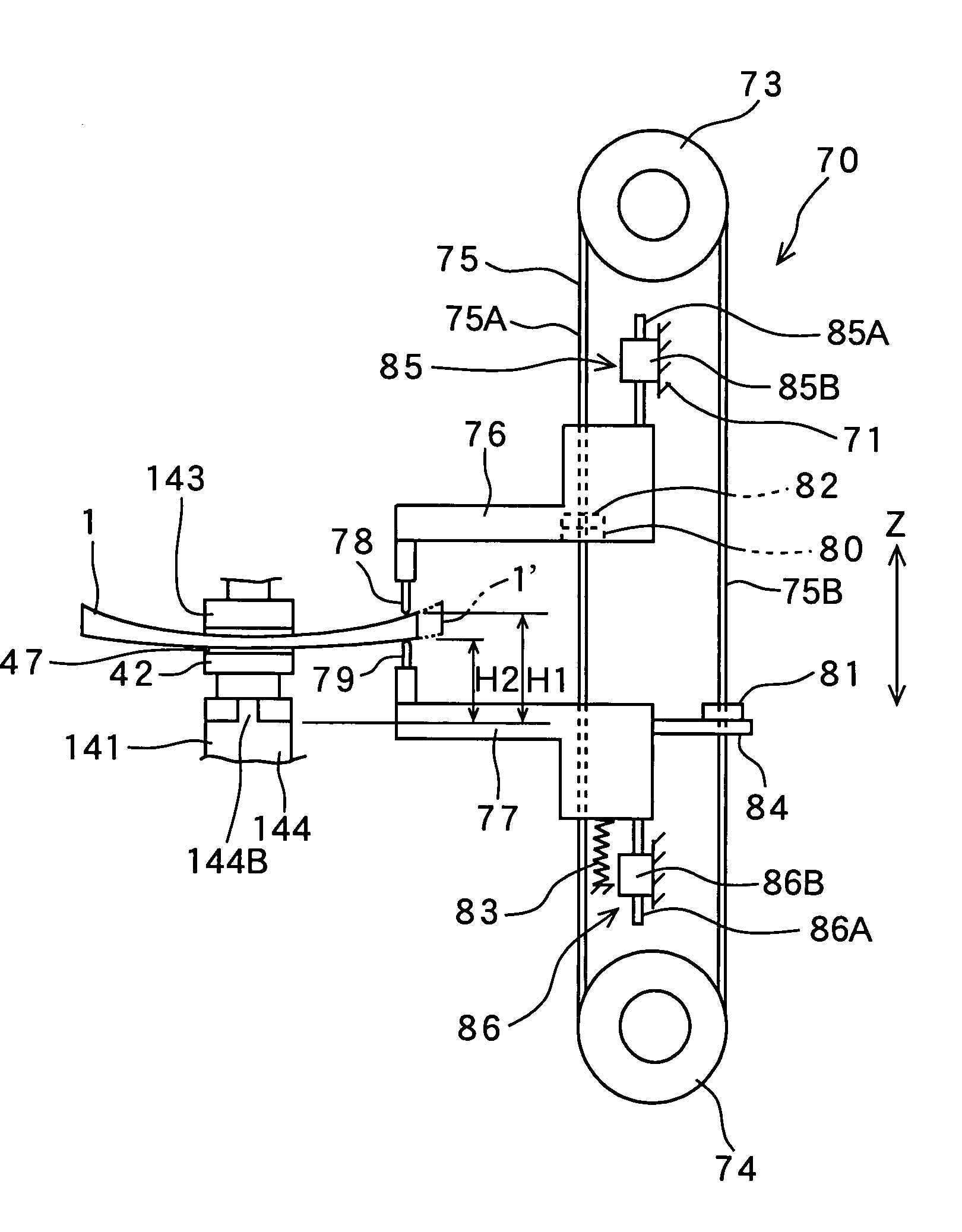

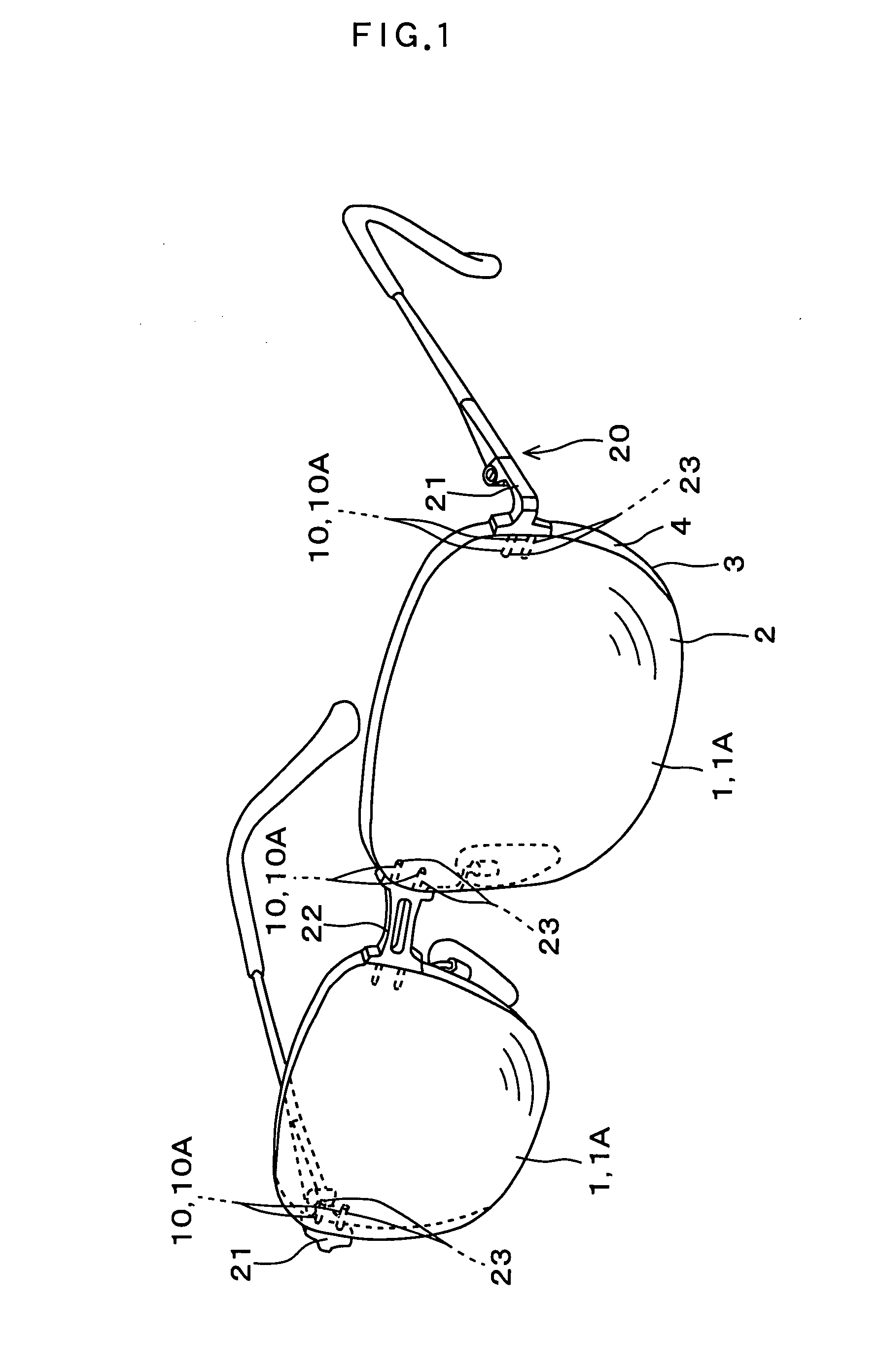

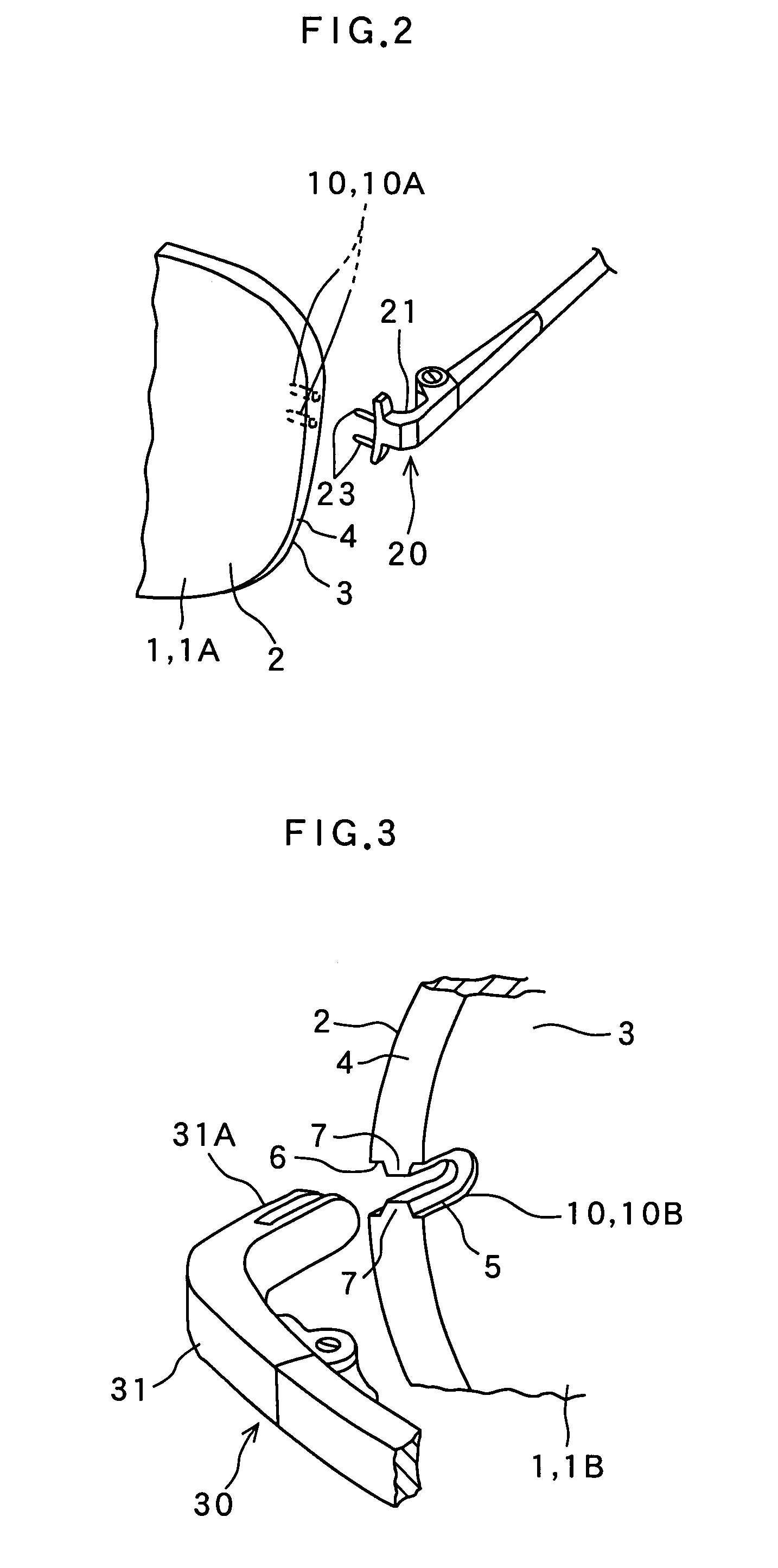

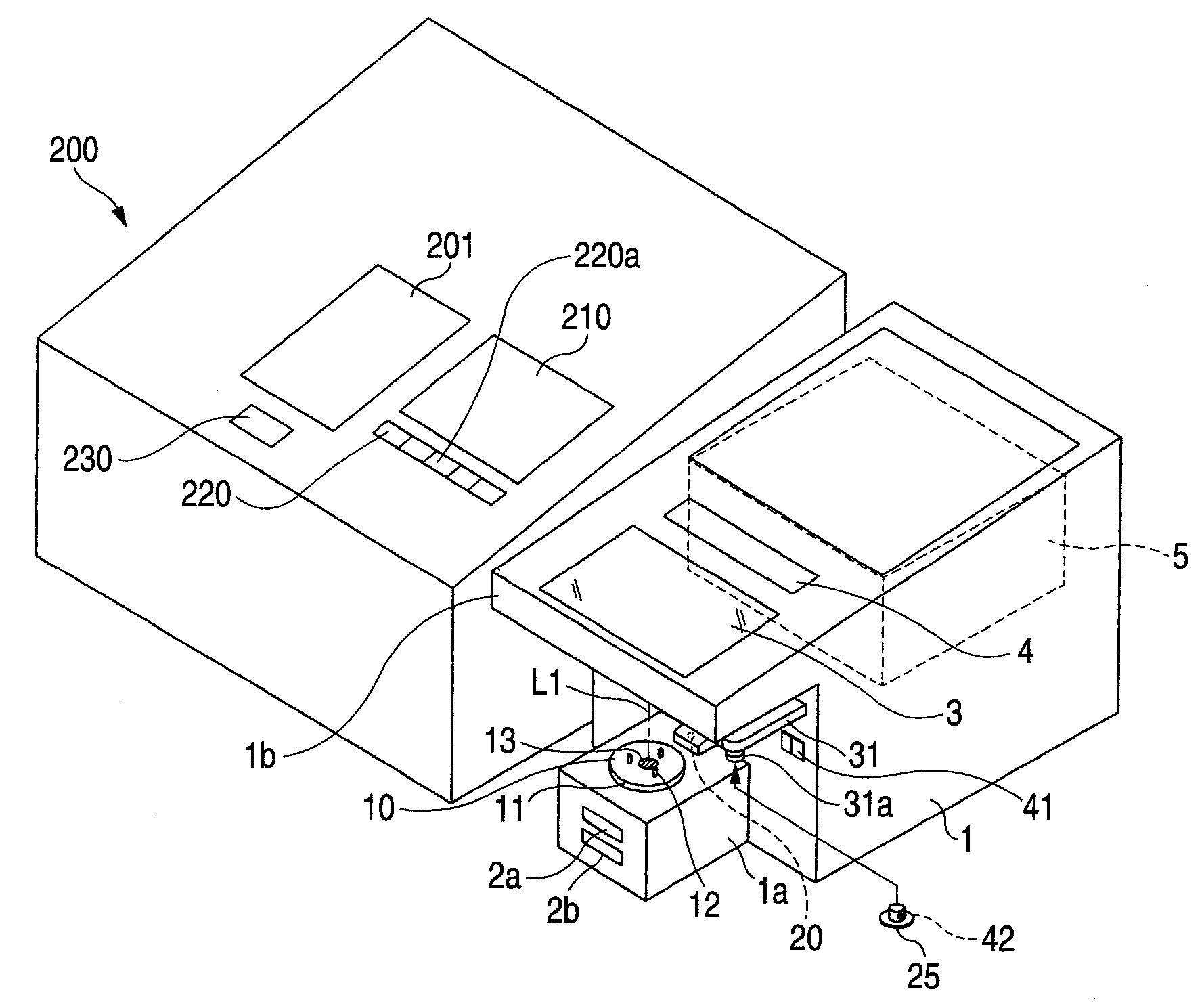

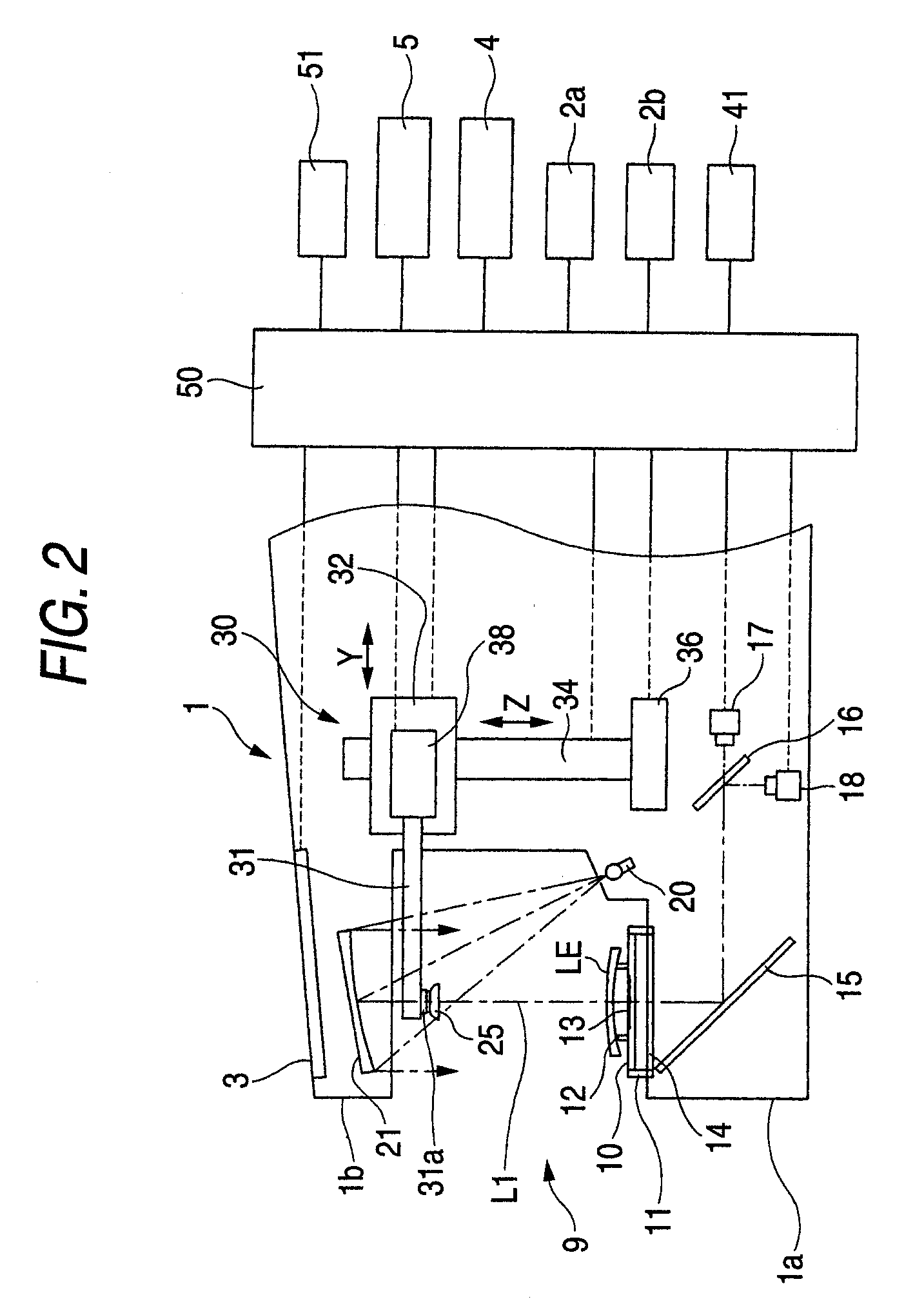

Device and method for measuring and machining spectacle lens, spectacle lens manufacturing method, and spectacles manufacturing method

A mounting part for mounting spectacle frame components such as lugs can be machined after confirming that a lens thickness at a mounting part-machined portion where the mounting part is machined is equal to or larger than the specified value, and can be installed the spectacle lens components on the spectacle lens with a requested strength. The device, the method for the above, a spectacle lens manufacturing method, and a spectacles manufacturing method are given. The spectacle lens (1) is fed to a lens thickness measuring device (70) by a lens feeder. The fed amount of the spectacle lens in this feeding is based on the measured results of a distance between a frame center forming a block center by a lens holder in an edging for manufacturing the spectacle lens (1) from a raw material lens and the edge face of the spectacle lens (1) where the mounting part is to be machined. The thickness of the lens at the mounting part-machined portion can be accurately measured by the measuring device (70) even if an error produced in the edging is included in the distance.

Owner:HOYA CORP

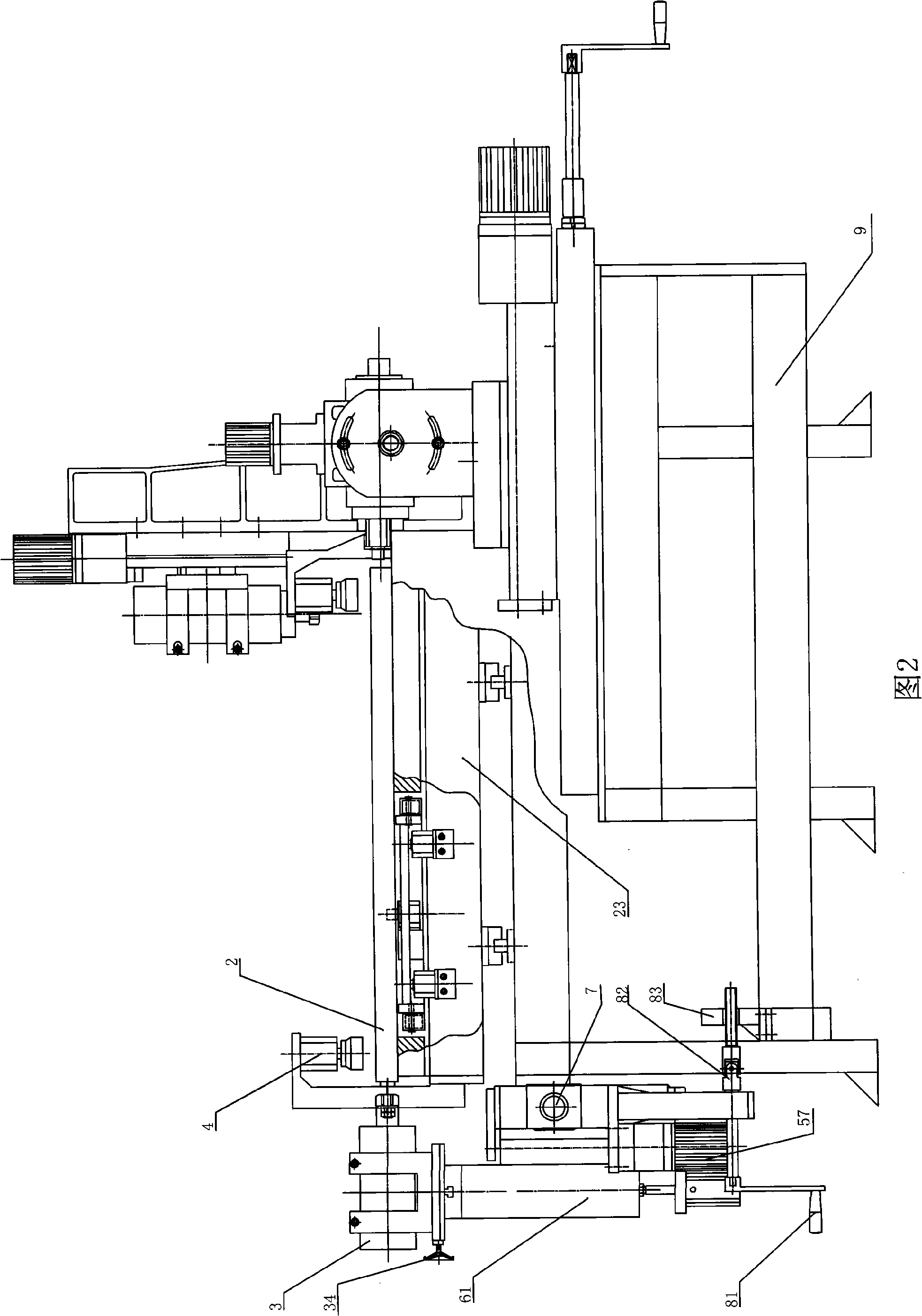

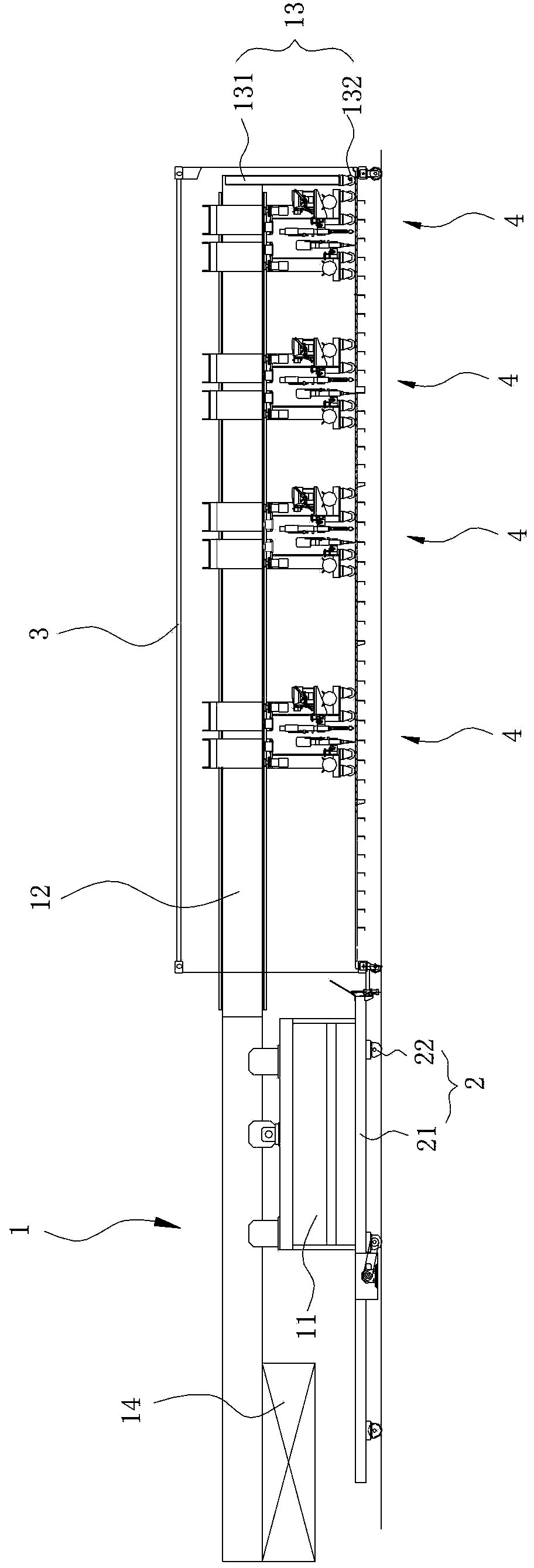

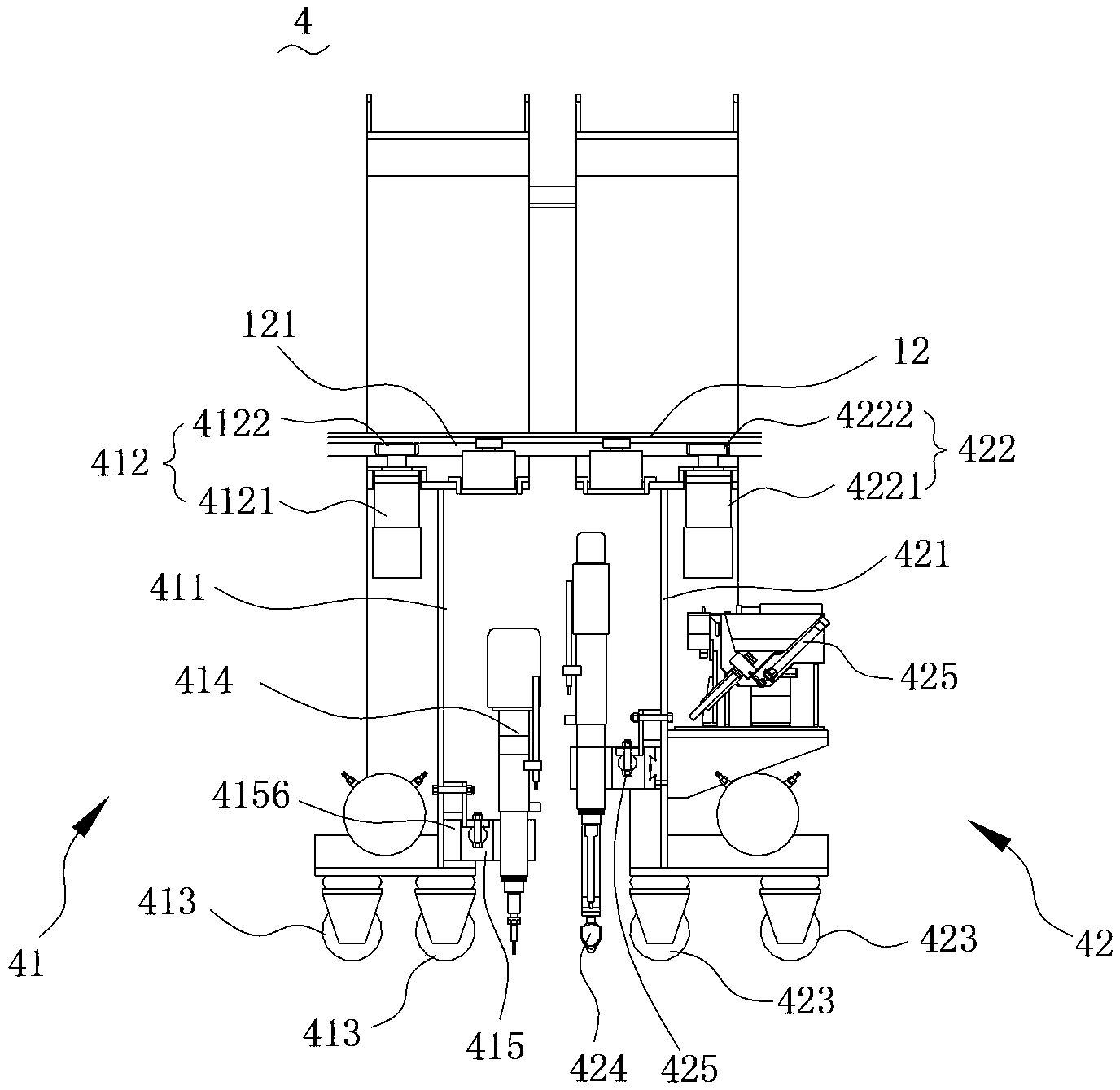

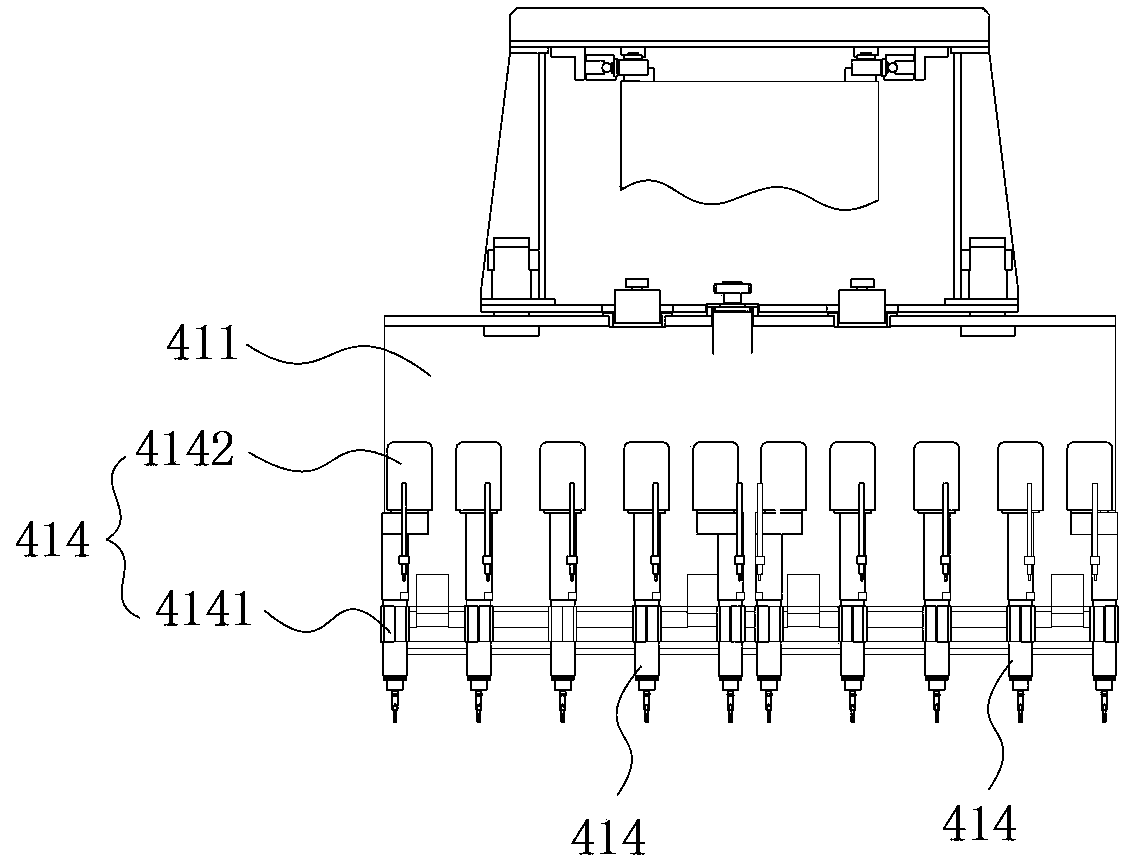

Automatic hole-drilling nail-locking machine for wood floor of container

ActiveCN103786194AIncrease productivityReduce in quantityStapling toolsDrilling machinesLocking mechanismEngineering

An automatic hole-drilling nail-locking machine for wood floor of a container is disclosed and comprises a pedestal, a crossbeam and at least a group of hole-drilling nail-locking mechanisms. The crossbeam extends longitudinally and an end of the crossbeam is installed on the pedestal. Each group of the hole-drilling nail-locking mechanisms comprises a hole-drilling assembly and a nail-locking assembly. The hole-drilling assembly comprises a plurality of drilling heads arranged transversely at intervals, and can be controlled to transversely move along the crossbeam. Each drilling head can be controlled to drill holes towards a set direction. The nail-locking assembly comprises a plurality of nail-locking heads arranged transversely at intervals and nail-delivery machines used for delivering nails for each nail-locking head, and can be controlled to transversely move along the crossbeam. Each drilling head can be controlled to drill holes towards a set direction. The automatic hole-drilling nail-locking machine is capable of achieving automatic location, drilling, nail delivery and nail locking, reducing the number of workers largely, increasing the production efficiency of the container and reducing the production cost.

Owner:东莞南方中集物流装备制造有限公司 +2

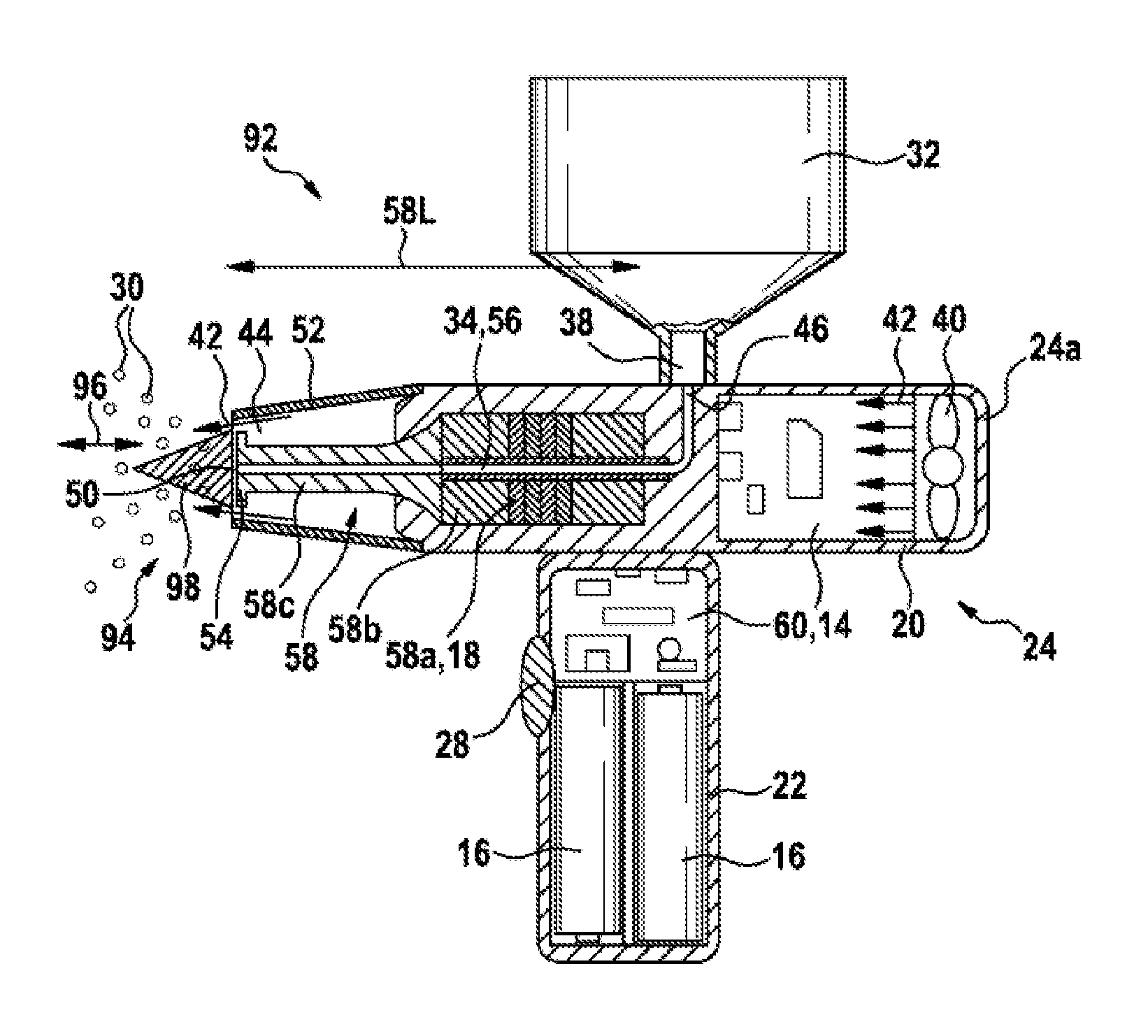

Minimal Quantity Lubricating System

InactiveUS20130206441A1Increase amplitudeEfficient droplet generationDrilling machinesPortable percussive toolsMachining processElectric power

A minimal quantity lubricating system for a handheld electric power tool is configured to output a lubricating fluid for cooling and / or lubricating a material machining process. The system comprises at least one oscillating unit, an electronic unit for applying at least control and / or feedback signals to the at least one oscillating unit, an operating power unit for providing electric power to the electronic unit, a storage tank for the lubricating fluid, and at least one nozzle associated with the at least one oscillating unit for feeding and atomizing the lubricating fluid in a tool working area. A fluid feed line connects the storage tank to a capillary feed of the lubricating fluid to the oscillating unit, and at least one fluid channel at least partially runs through the oscillating unit to connect the oscillating unit to the nozzle for pulsing the lubricating fluid.

Owner:ROBERT BOSCH GMBH

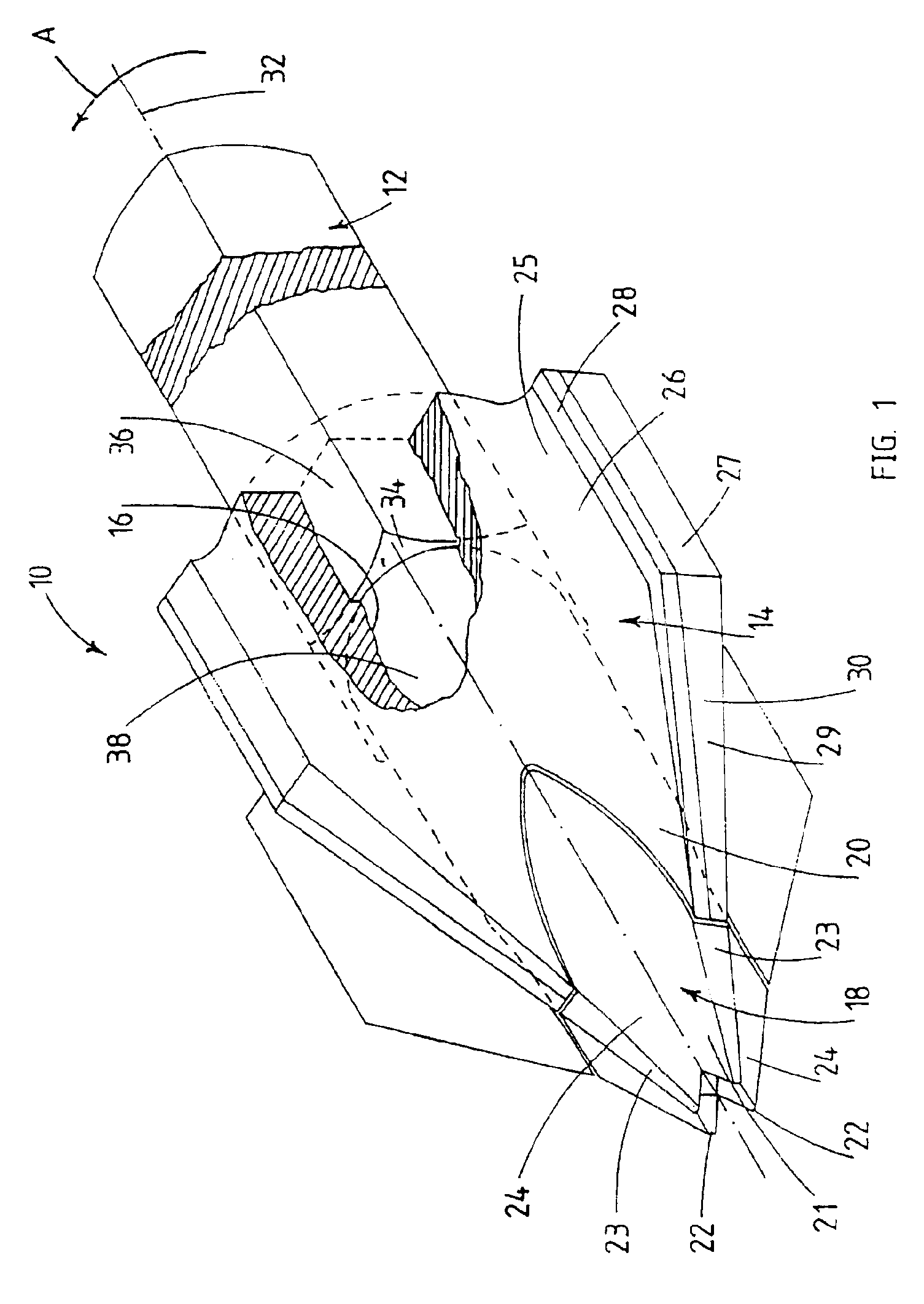

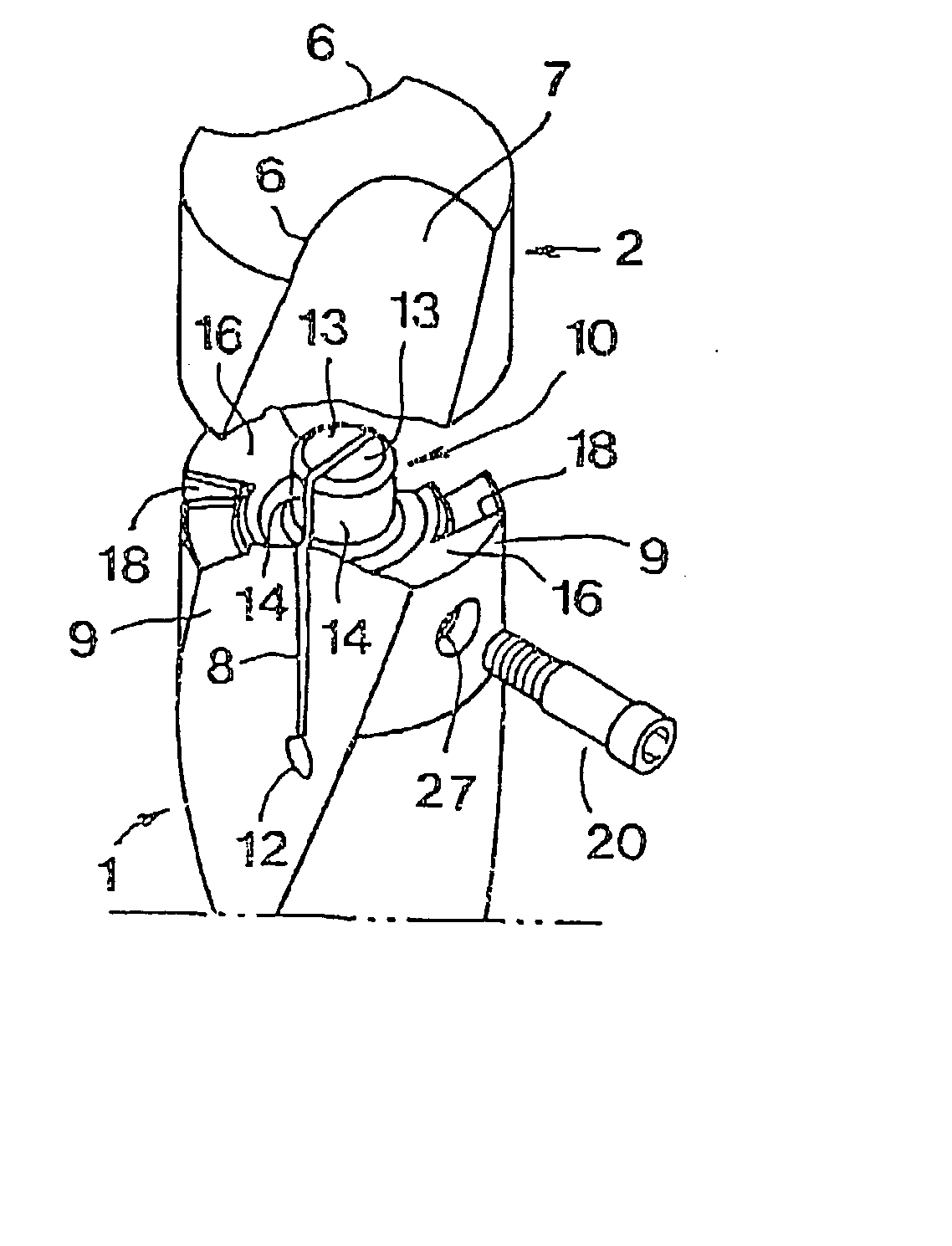

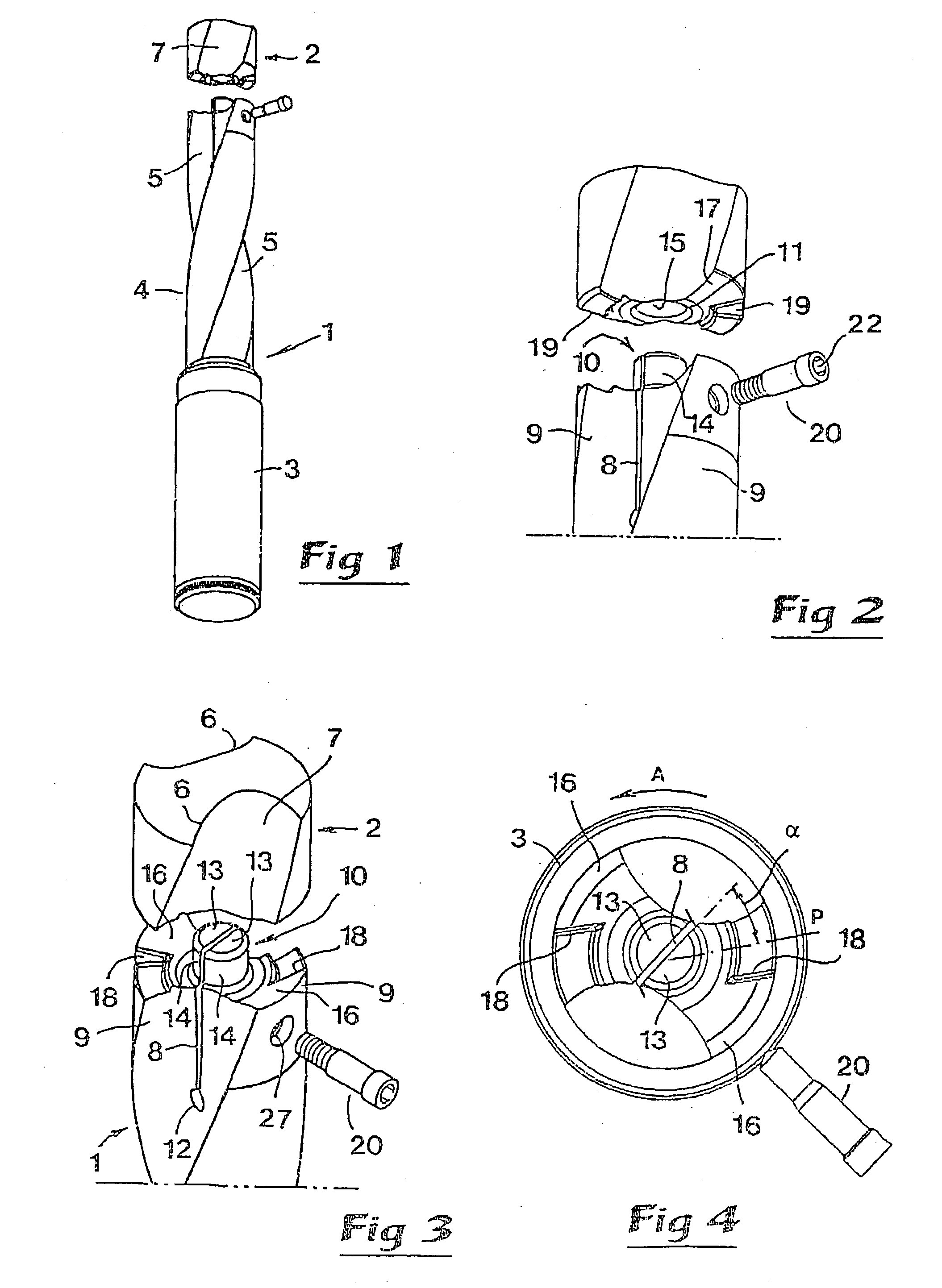

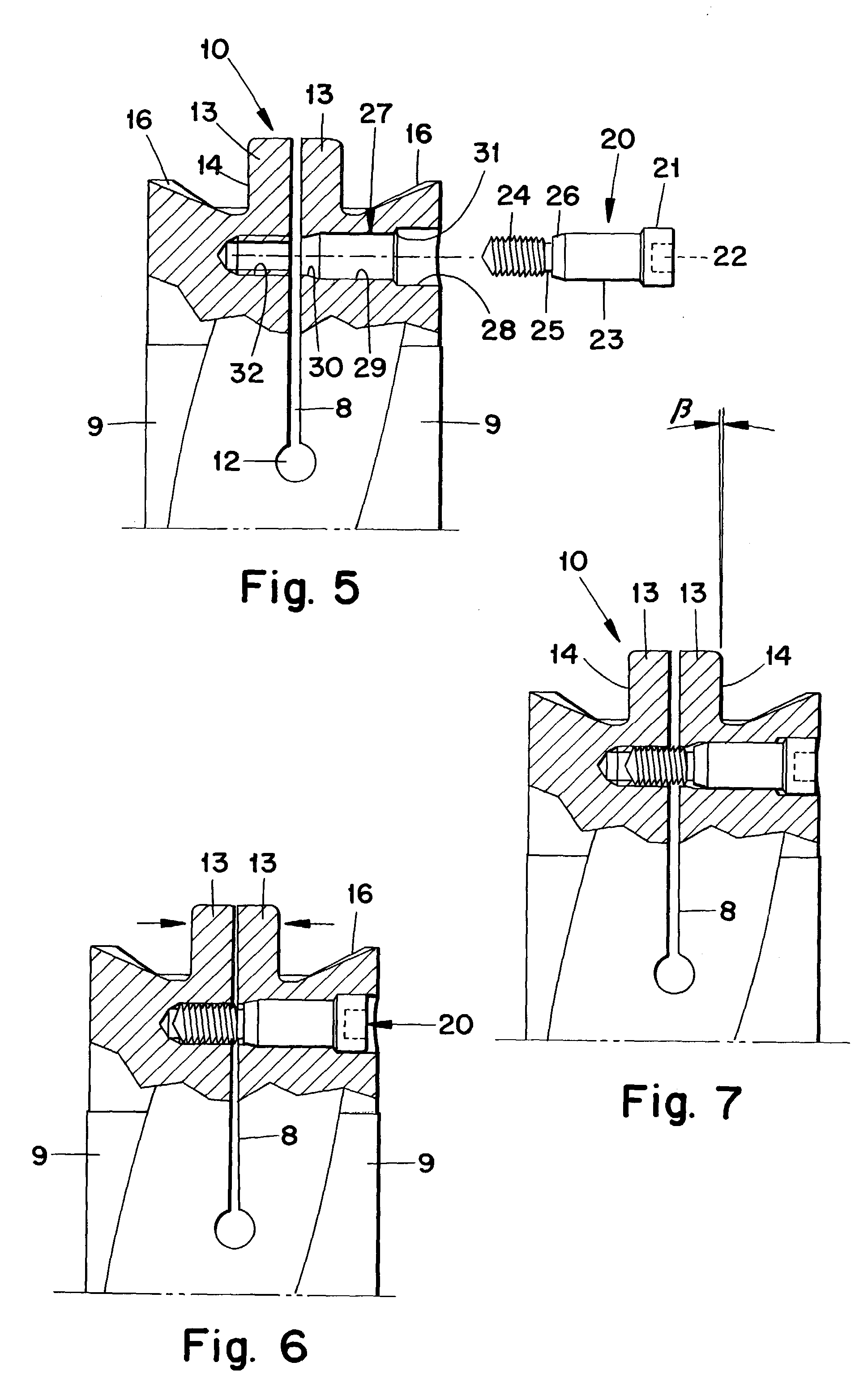

Rotatable tool with removable cutting part

InactiveUS20030091402A1Simple mounting and dismountingImprove convenienceWood turning toolsDrilling machinesCouplingAxial thrust

A rotatable tool for chip removing machining having a rotatable holder part and a cutting part that is detachably connected to a front end of the holder part. In a front end portion of the holder part, a forwardly open slot is formed, which separates two elastically flexible branches of the holder part. For clamping of the cutting part on the holder part, a male / female coupling is arranged, which comprises a centrical, male-like pin on one of the parts and a corresponding seat in the other part. Disposed on the holder part radially outside of the male / female coupling are thrust load carrying support surfaces, which surfaces are at least partially conical and are engaged by corresponding support surfaces of the cutting part. During a cutting operation, axial thrust loads transmitted to the axial thrust support surfaces cause the branches to be pressed in a direction intensifying the radial contact between the pin and the seat.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

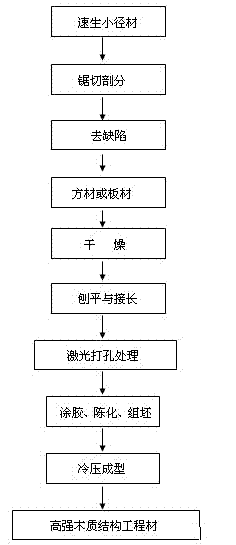

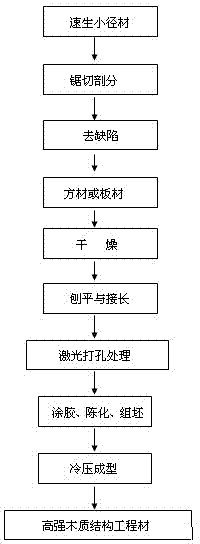

Method for producing high-strength wood structure engineering material

InactiveCN102241043AHigh strengthDrilling machinesDomestic articlesPunchingUltimate tensile strength

The invention discloses a method for producing a high-strength wood structure engineering material. The method is characterized by comprising the following steps of: before gluing split boards or squared timbers, carrying out laser punching treatment on the gluing surface of the boards or squared timbers; punching micro holes in a certain depth and a certain diameter on the gluing surface of the boards or squared timbers; and then gluing, assembling blanks and cold press forming. After forming, effective glue nails are formed on the gluing interfaces of the boards or squared timbers, so that the aim of enhancing the strength of the wood structure engineering material is achieved. According to the method disclosed by the invention, the effective glue nails are formed on the gluing interface, so that the strength of the wood structure engineering material can be remarkably improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

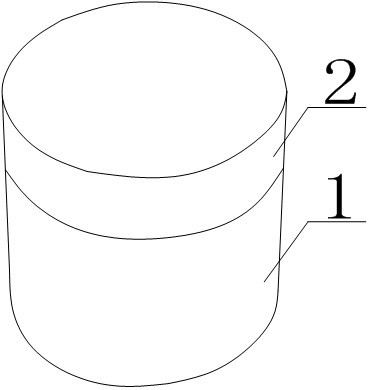

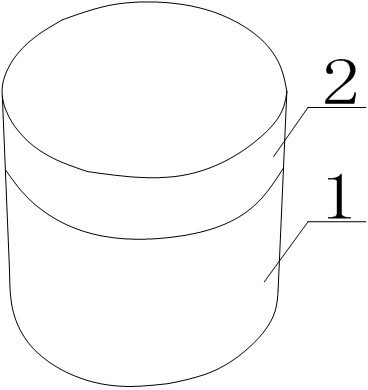

Diamond compact and manufacturing process for same

InactiveCN102606082AImprove ductilityEasy to shapeDrill bitsDrilling machinesAlloy substrateCemented carbide

The invention discloses a diamond compact, which comprises a hard alloy substrate and a diamond polycrystalline layer connected onto the upper end face of the hard alloy substrate, wherein the hard alloy substrate is integrated with the diamond polycrystalline layer to integrally form a cylinder shape, and the hard alloy substrate is made of hard alloy containing 2%-13% of cobalt. The invention further discloses a manufacturing process for the diamond compact. Abrasion resistance of the diamond compact is improved by reducing the cobalt content in the hard alloy of the hard alloy substrate, so that the service life of the diamond compact is prolonged.

Owner:成都比拓超硬材料有限公司

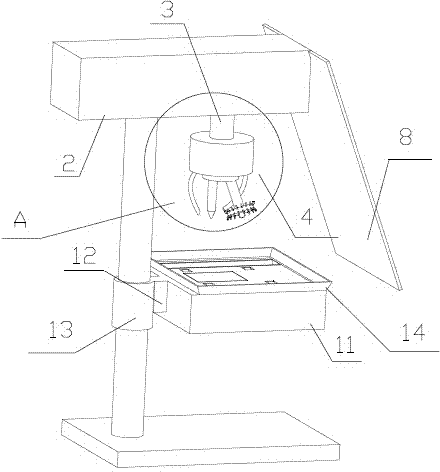

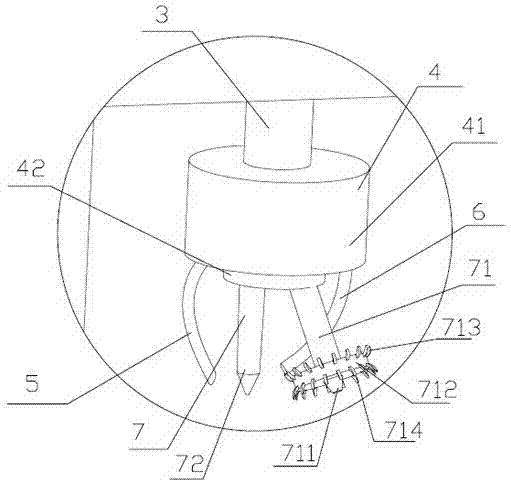

High-efficiency punching device suitable for furniture board

ActiveCN104325519AImprove work efficiencyAvoid wear and tearDrilling machinesDrilling toolsPunchingInjection device

The invention relates to the field of furniture processing equipment, and in particular relates to a high-efficiency punching device suitable for a furniture board. The device is realized by the following technical scheme: the high-efficiency punching device suitable for the furniture board comprises a stand, a drilling device, an operating board, a lifting device, an oil injection device and a cleaning device, wherein the drilling device is used for punching the furniture board; the operating board is connected with the stand, can move along the vertical direction of the stand and is used for containing the furniture board; one end of the lifting device is connected with the stand, the other end of the lifting device is connected with the drilling device, and the lifting device is capable of adjusting the vertical distance of the drilling device relative to the stand; the oil injection device is used for injecting engine oil at the drilled position; the cleaning device is used for cleaning the drilled position by spraying water. The invention aims at providing the high-efficiency punching device suitable for the furniture board, a drill bit does not need to be manually replaced, and the high-efficiency punching device has the functions of lubricating by injecting oil and cleaning by spraying water.

Owner:ZHEJIANG BOTAI FURNITURE

Rotatable tool with removable cutting part

InactiveUS20030091403A1Simple mounting and dismountingImprove convenienceWood turning toolsDrilling machinesCouplingEngineering

Rotatable tool for chip removing machining includes a rotatable holder part and a cutting part that is detachably connected to a front end of the holder part. In the front end of the holder part, a forwardly open slot is formed, which separates two elastically flexible branches of the holder part. For clamping of the cutting part on the holder part, a male / female coupling is provided, which comprises a pin on either the holder part or the cutting part and a corresponding pin-receiving seat in the other part. If the pin is on the holder part, then a manually induced elastic deformation of the branches towards one another reduces the diameter of the pin to enable the pin to enter the female part. Subsequent return of the branches toward a rest state thereof causes the diameter of the pin to expand and tightly hold the cutting part. Alternatively, if the seat is disposed on the holder part, then a manually induced elastic deformation of the branches away from one another increases the diameter of the seat to enable the pin to enter the female part. Subsequent return of the branches toward the rest state causes the diameter of the seat to contract and tightly hold the cutting part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Mult- purpose end-mill

InactiveUS20050117982A1Eliminate disadvantagesShorten the timeDrilling machinesTransportation and packagingMilling cutterEngineering

A multi-purpose end-mill to be used for different machining purposes, in particularly useful for closed or open contours machining. The end-mill comprises a cylindrical shank portion connected to a first cutting portion provided with a plurality of spaced-apart cutting teeth and a second portion provided with a plurality of different spaced-apart cutting teeth.

Owner:HANITA METAL WORKS

Toolbox apparatus to which power tools may be mounted to provide a workstation

ActiveUS20080083106A1Effective and efficient in operational useSimple designMetal sawing devicesDrilling machinesRechargeable cellHand tool

A portable toolbox has a compartment closed by a lid, the lid being configured to mount a powered saw module to an inner face thereof such that the saw blade extends from an outer side of the lid which provides a flat sawbench. The toolbox is used with powered hand tools of the type having a power handle module incorporating rechargeable batteries and control switch for engaging a variety of multi-purpose tools having respective electric motors. A battery station receives the power handle module and an associated circuit controls and supplies power to the saw. An adaptor fixture may be employed in one configuration to provide a drill press and in another to provide a saw fence. The adaptor fixture includes a sliding carriage for mounting a powered hand drill and jaws for clamping engagement with the toolbox when used as a fence.

Owner:C ENTERPRISE HK

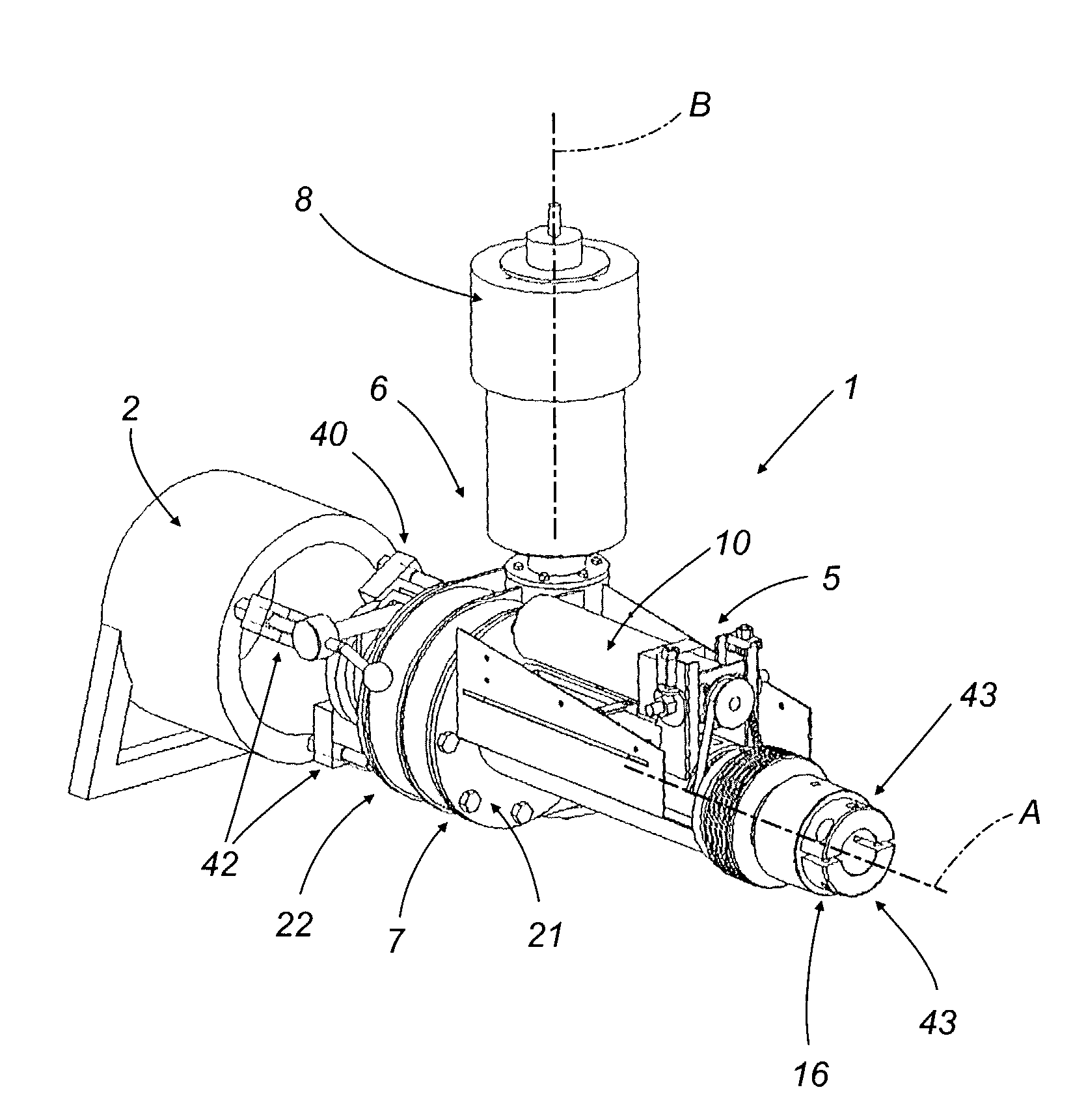

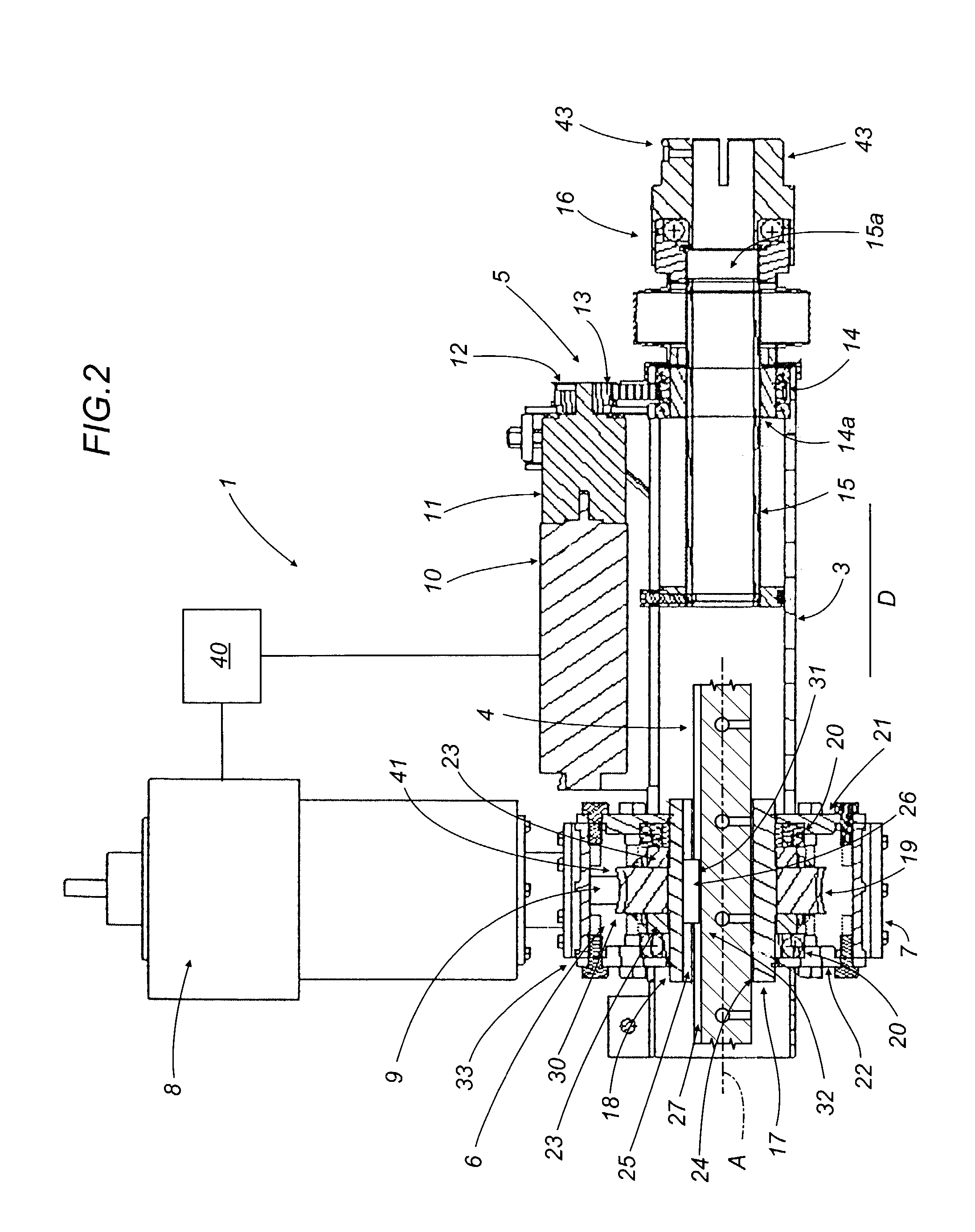

Portable boring and welding machine

InactiveUS7020942B2Functional and practical and simple in constructionThread cutting machinesDrilling machinesDrive shaftGear wheel

A portable boring and welding machine includes a tool shaft adapted to mount tools for boring and welding workpieces. The shaft extends along an axis and is driven by an electric motor. The motor and the shaft are connected by a helical gearwheel and worm pair, the helical gearwheel being connectable to the tool shaft, and the worm being connected to a drive shaft of the motor itself.

Owner:SIR MECCANICA

Furniture punching and cutting integrative machine

InactiveCN104493946AWill not deformImprove work efficiencyDrilling machinesMulti-purpose machinesPunchingEngineering

The invention discloses a furniture punching and cutting integrative machine. The integrative machine comprises a base; a buffer layer is arranged under the base; two supporting frames are arranged in the middle of the base; the two supporting frames are the same in height; a supporting frame platform is arranged on the supporting frames; the two ends of the supporting frame platform are connected with a punching supporting arm and a cutting supporting arm respectively; a motor is arranged on the supporting frame platform; a cutting head is arranged at the lower end of the cutting supporting arm; a cutting knife is arranged on the cutting head; the punching supporting arm is connected with a punching device; a drilling head is arranged under the punching device; a pneumatic press machine is arranged on the punching machine. The integrative machine has the beneficial effects that the integrative machine is high in working efficiency, and neat in cutting; the punched holes are free from deforming.

Owner:圣鹿(苏州)环保新材料科技有限公司

Eyeglass lens processing system

InactiveUS20080132147A1Reduce errorsEdge grinding machinesOptical surface grinding machinesEyeglass lensesEyewear

An eyeglass lens processing system for processing an eyeglass lens includes: a data inputting device that inputs a left and right target lens shape data and a layout data; a cup attaching device that attaches a lens fixing cup used for processing the eyeglass lens, the cup including an IC tag capable of rewriting data, the cup attaching device including a left / right information inputting unit that inputs which of left and right eyeglass lenses the attached eyeglass lens is, and a writing device that writes processing information including the left / right identifying information to the IC tag; and an eyeglass lens processing device that holds the eyeglass lens and processes the lens, the eyeglass lens processing device including a reading device that reads the information stored to the IC tag and a setting unit that sets the processing information based on the read left / right identifying information.

Owner:NIDEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com