Board drilling machine head

A drilling machine and plate technology, which is applied in the direction of drilling machines, stone processing tools, wood processing equipment, etc., can solve the problems of poor drilling hole shape, etc., and achieve the effects of drilling stability, quality improvement, and reinforcement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

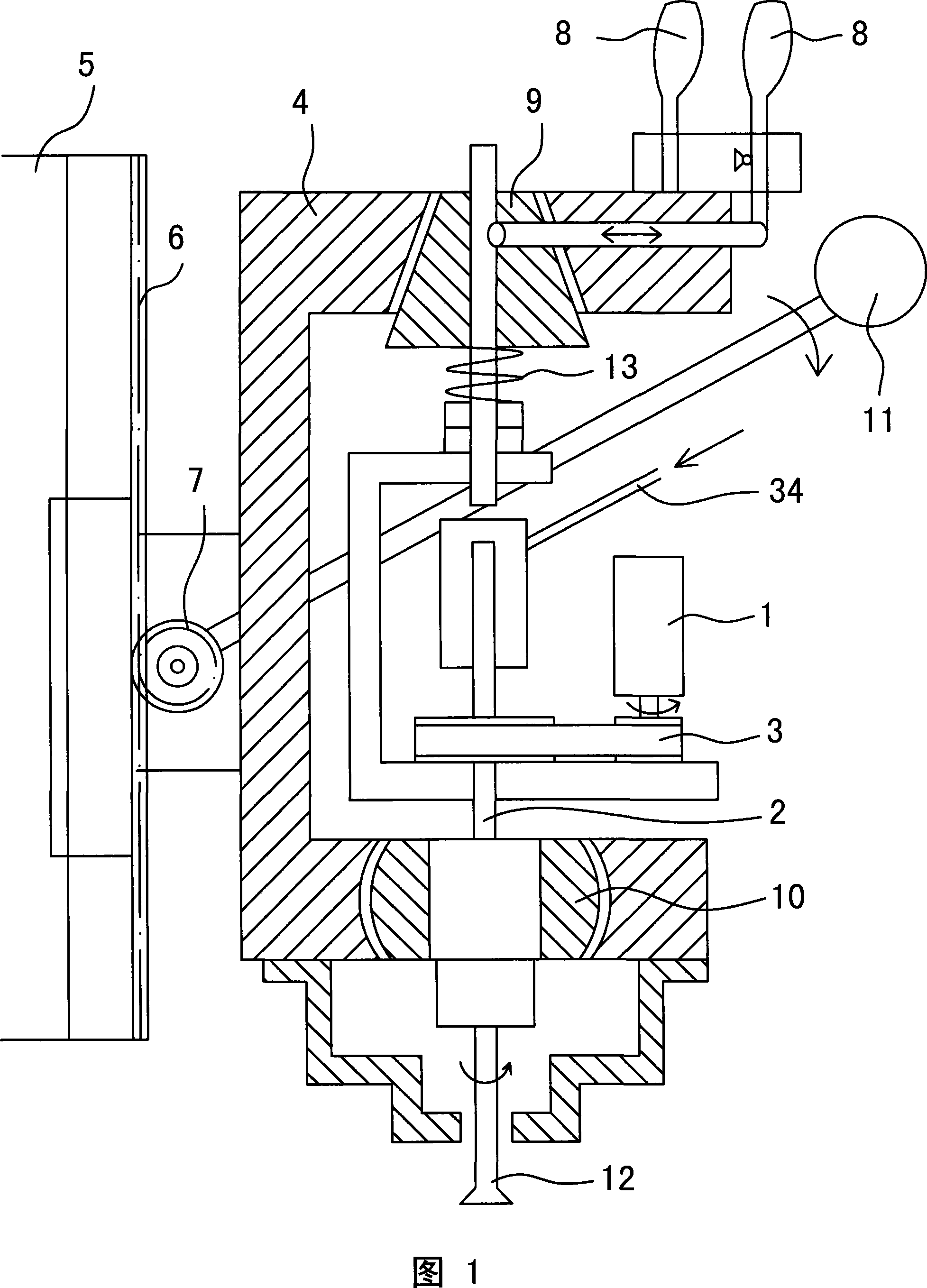

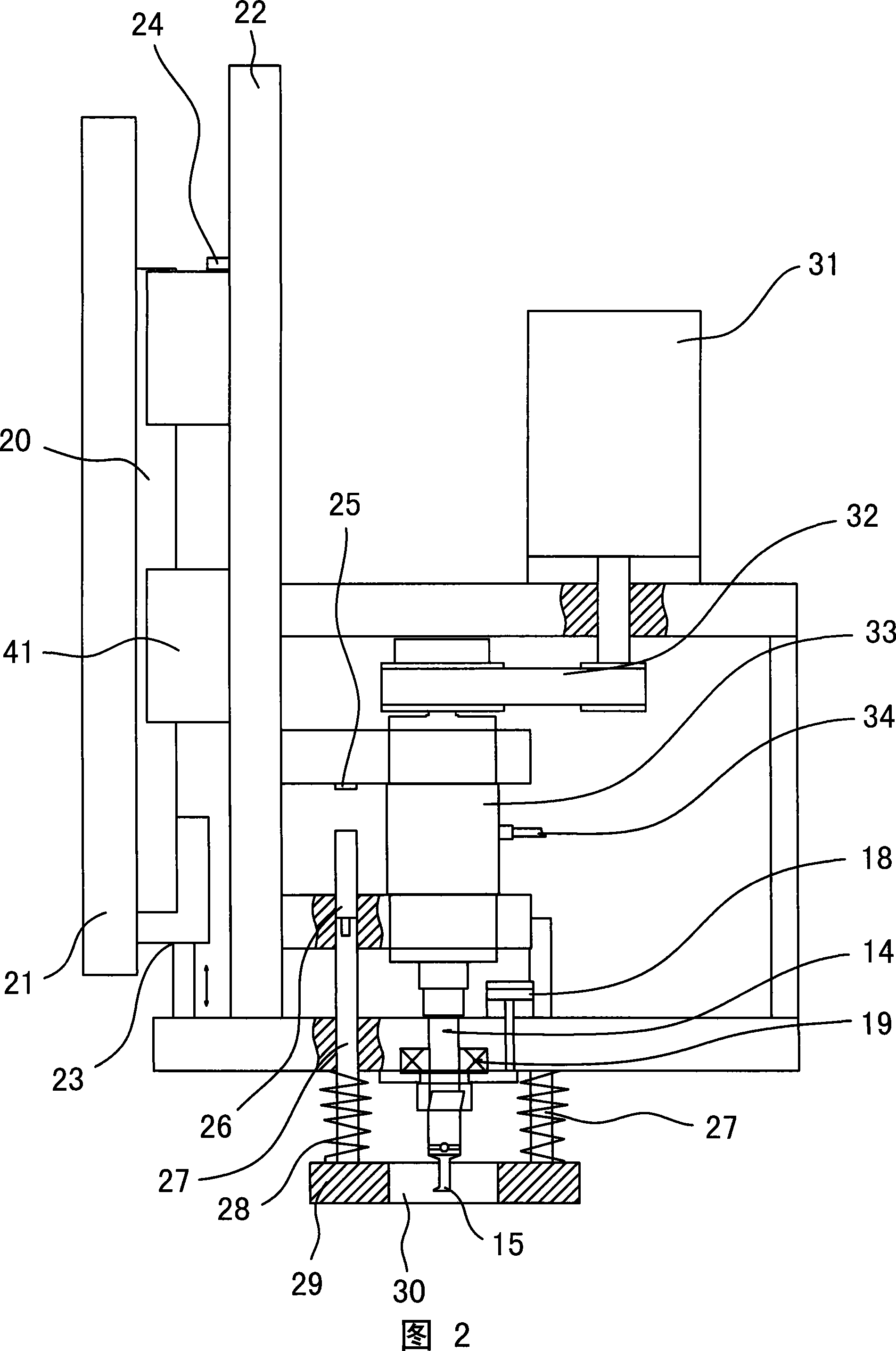

[0030] Embodiment: As shown in Fig. 2 and Fig. 3, a machine head of a plate drilling machine includes a main shaft rotation mechanism, a Z-axis feed mechanism, a cooling water supply structure and an eccentric drilling mechanism.

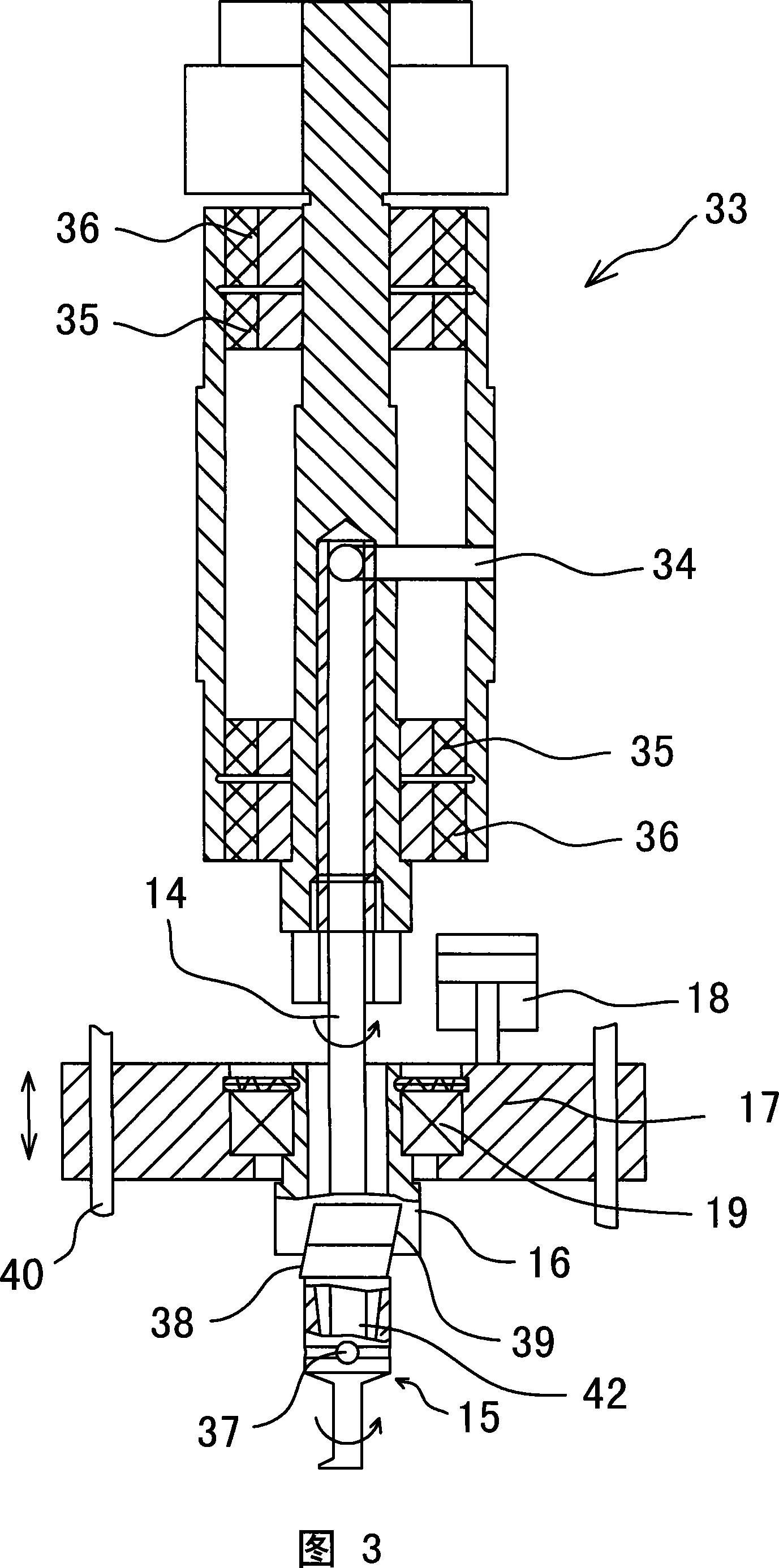

[0031] The eccentric drilling mechanism is mainly composed of a drill bit 15, a main shaft 14, an eccentric action block 16, a moving block 17 and a drilling cylinder 18. The shank end of the drill bit 15 is provided with a tapered counterbore 42, and the counterbore 42 is larger than the diameter of the lower end of the main shaft. The main shaft 14 The lower end of the drill bit stretches into the counterbore 42, and is hinged with the drill bit 15 through the pin 37 in the middle section (seeing figure 3), so that the drill bit 15 can swing and deflect relative to the main shaft 14, that is, the drill bit 15 can still swing with the hinged point as the base point. The tail of the drill bit 15 is provided with a pair of first inclined surfaces 38 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com