Preparing method for repetitive-gradient porous titanium alloy for promoting sacralization

A gradient porous, titanium alloy technology, applied in the medical field, can solve problems such as large elastic modulus and poor tissue compatibility, increase fusion strength and pull-out force, increase growth rate and ingrowth ability, and overcome tissue compatibility poor sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

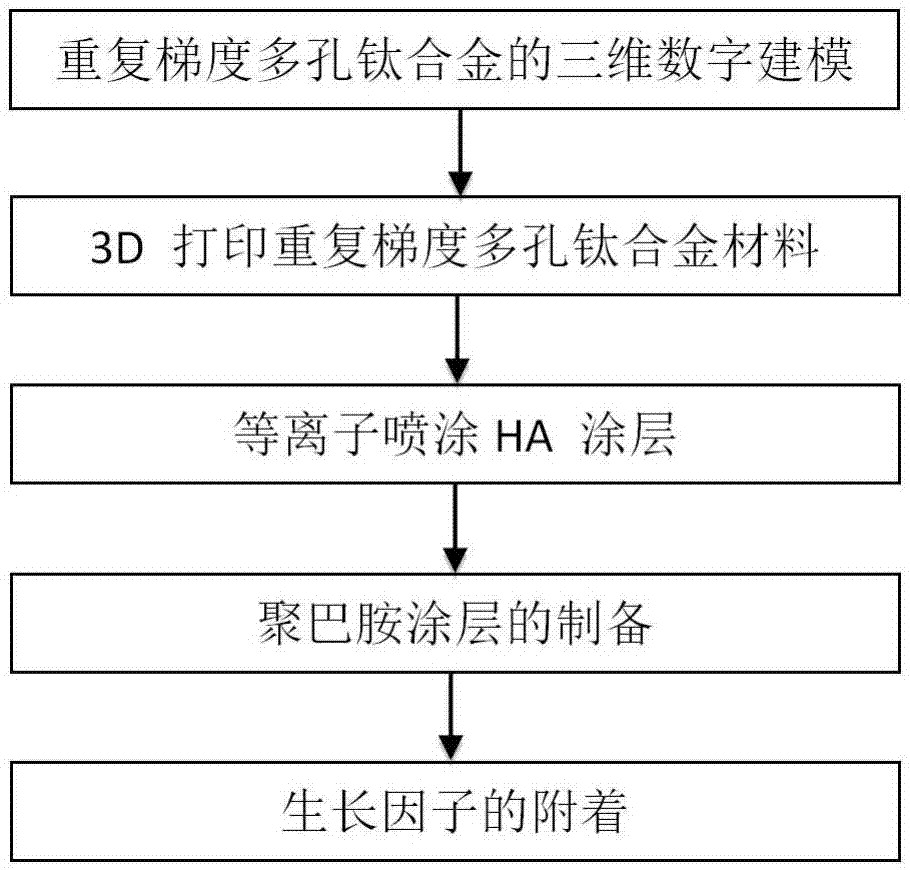

[0015] like figure 1 As shown, this specific embodiment provides a method for preparing a repeatedly gradient porous titanium alloy that promotes bone fusion, and the method includes the following steps:

[0016] Step 1. Establishing a 3D digital model of a repetitive gradient porous titanium alloy

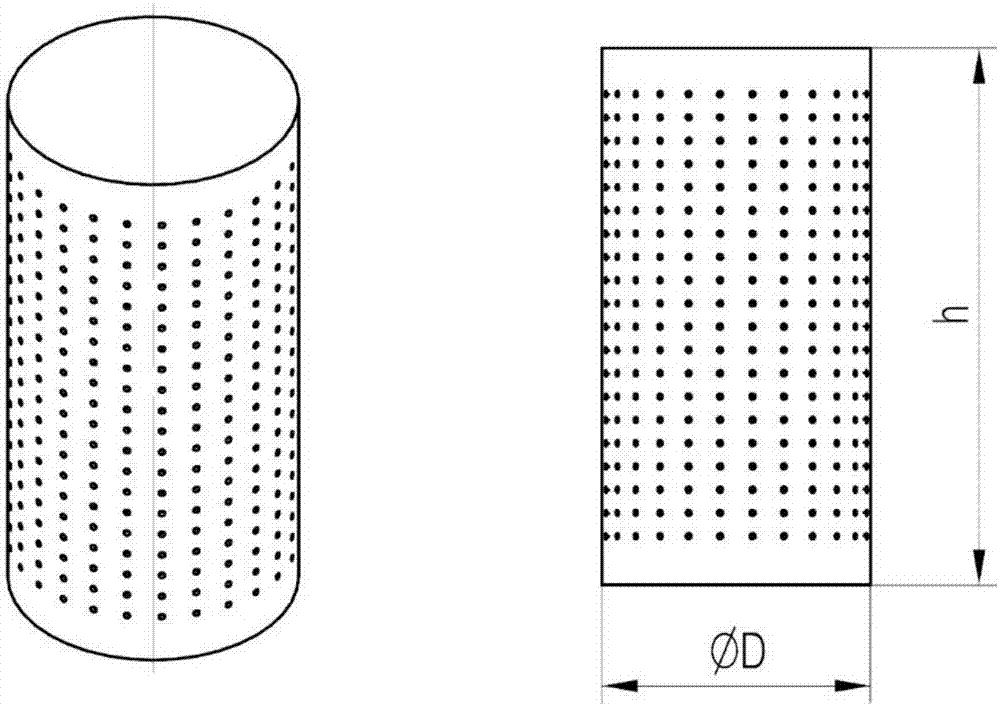

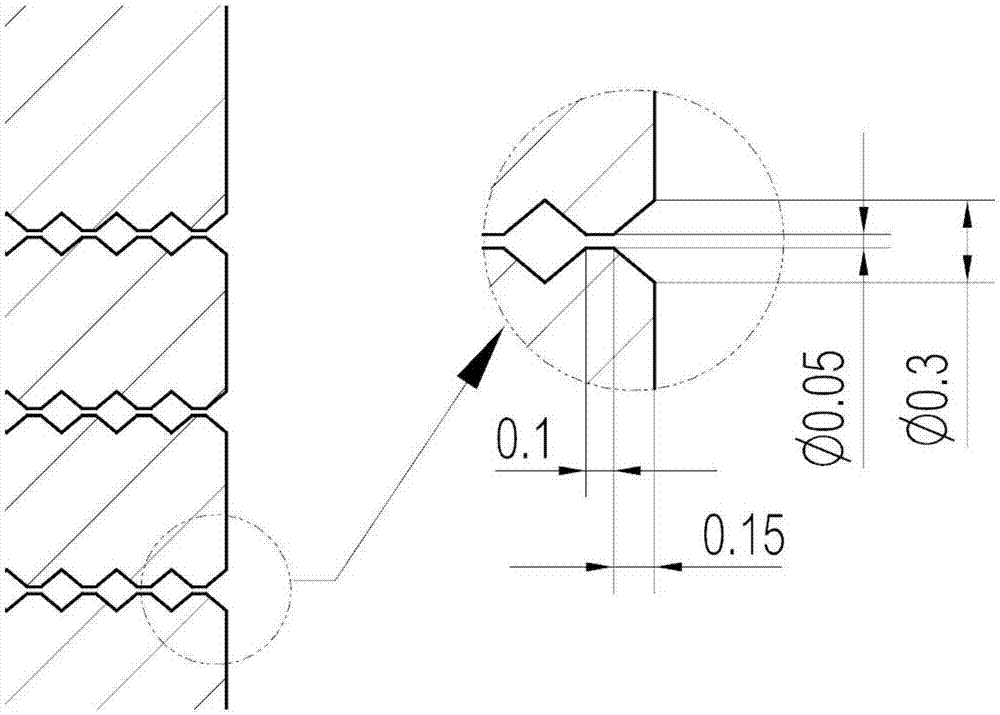

[0017] In this step, a three-dimensional model of the porous titanium alloy rod is established using three-dimensional digital modeling software. Designing the three-dimensional model of the titanium alloy bar includes designing the structure and size of the bar. The porous titanium alloy rod is used to be implanted into tissue to realize the repair of bone tissue damage. A typical bar structure design such as figure 2 shown. The rod is in the shape of a rod, and a plurality of holes are formed therein, and the holes extend from the outer surface of the rod to the inside of the rod. in such as figure 2 In the shown structure, the plurality of holes on the surface of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com