Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

512 results about "Hardened steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

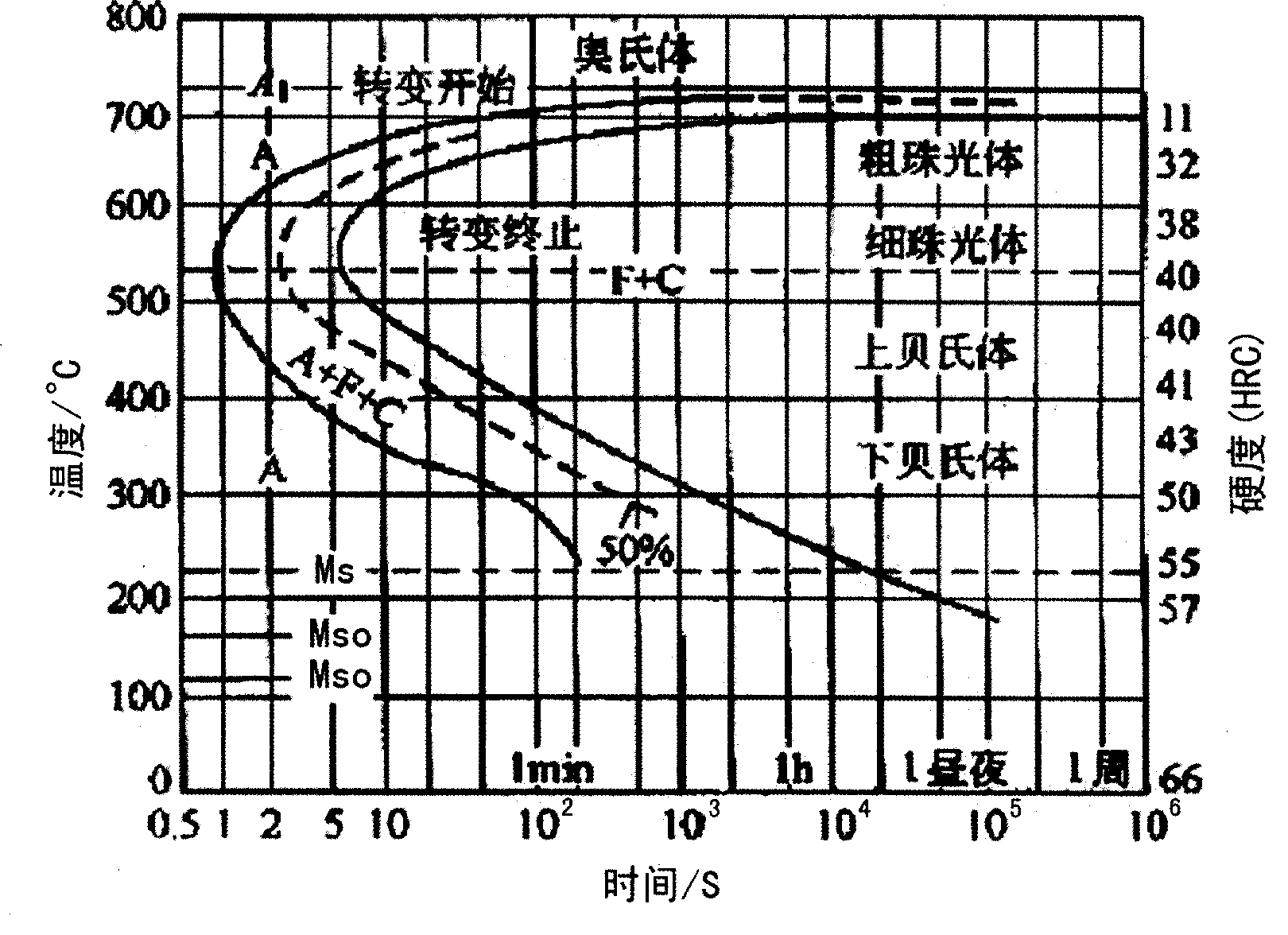

The term hardened steel is often used for a medium or high carbon steel that has been given heat treatment and then quenching followed by tempering. The quenching results in the formation of metastable martensite, the fraction of which is reduced to the desired amount during tempering. This is the most common state for finished articles such as tools and machine parts. In contrast, the same steel composition in annealed state is softer, as required for forming and machining.

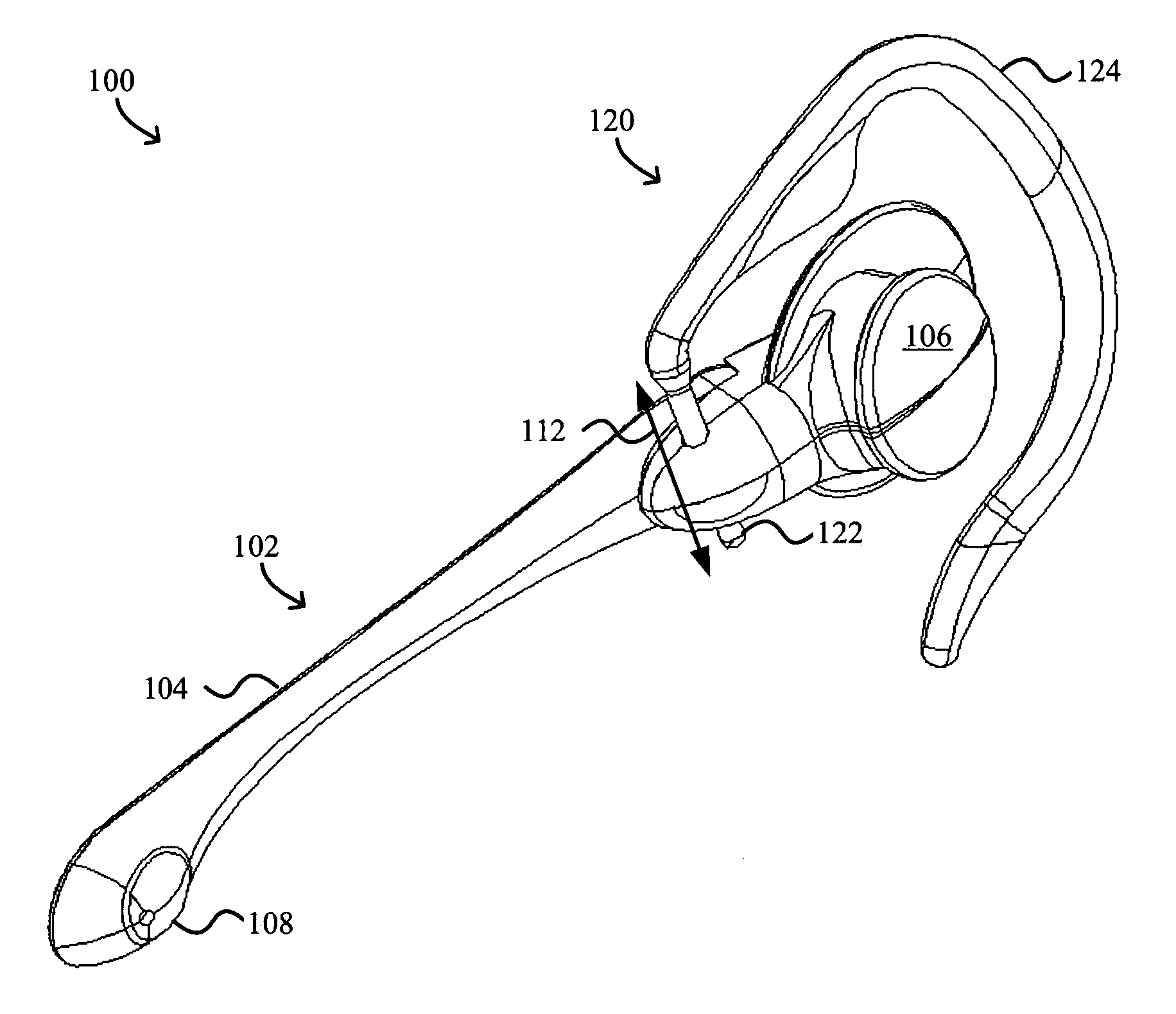

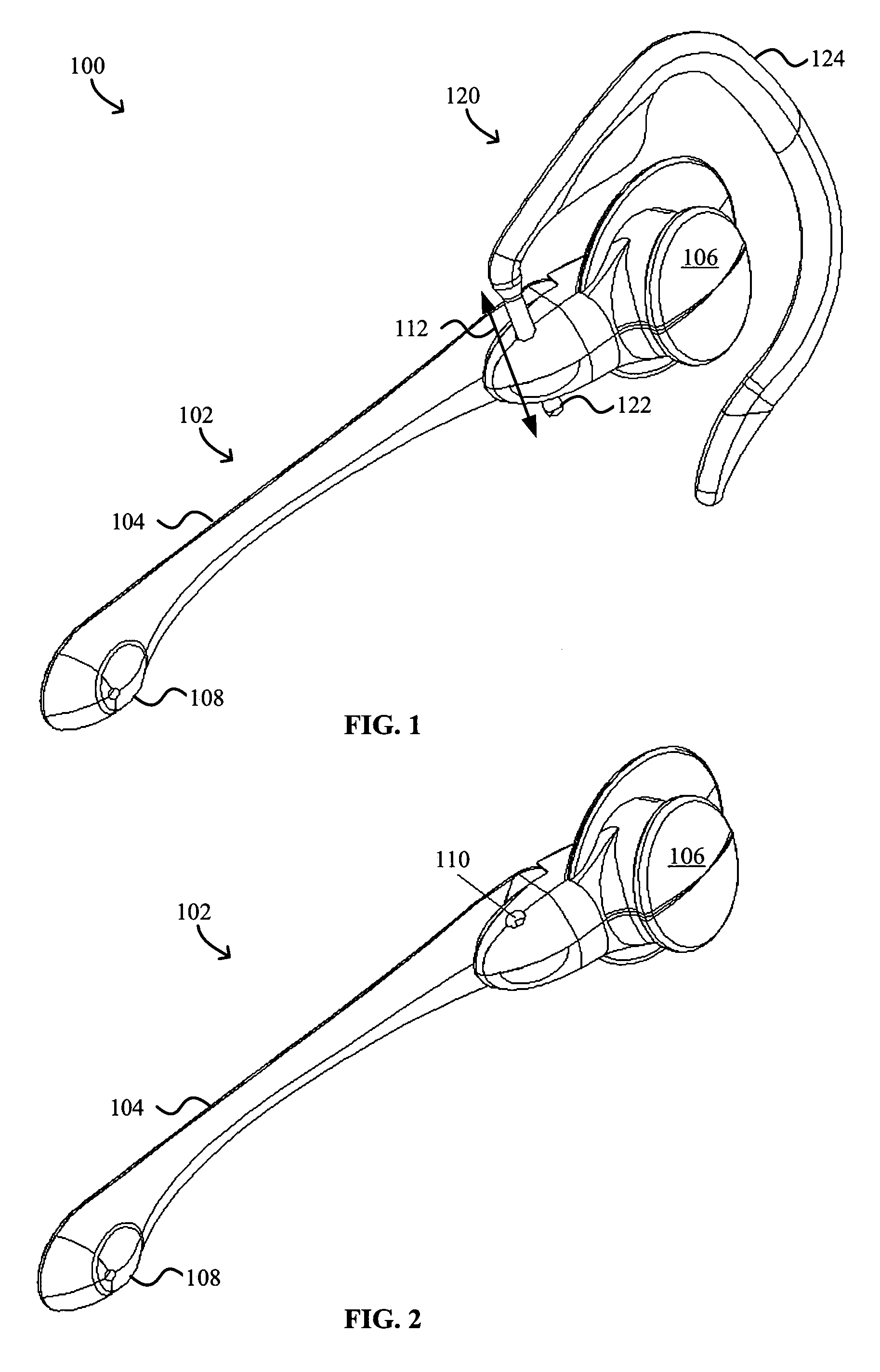

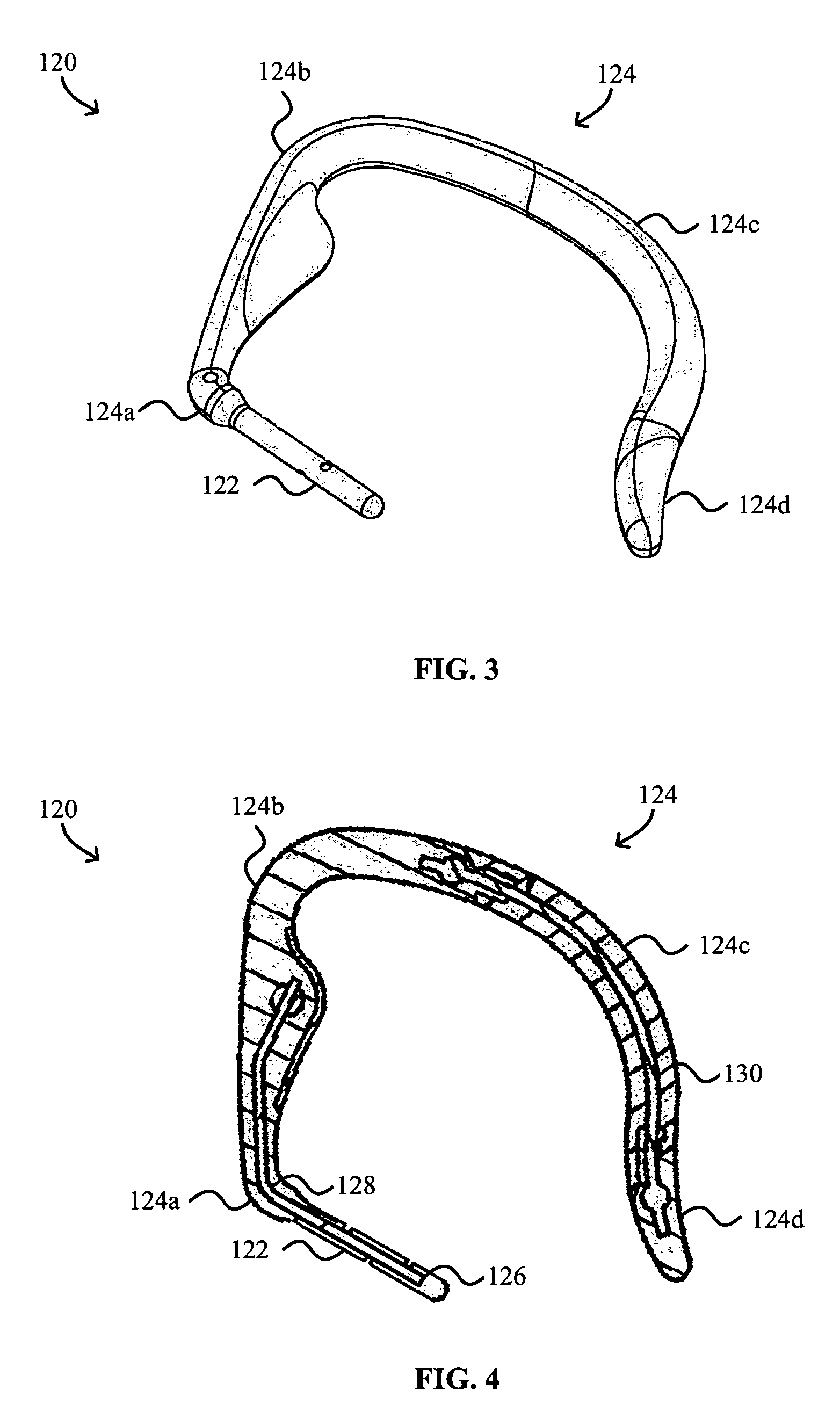

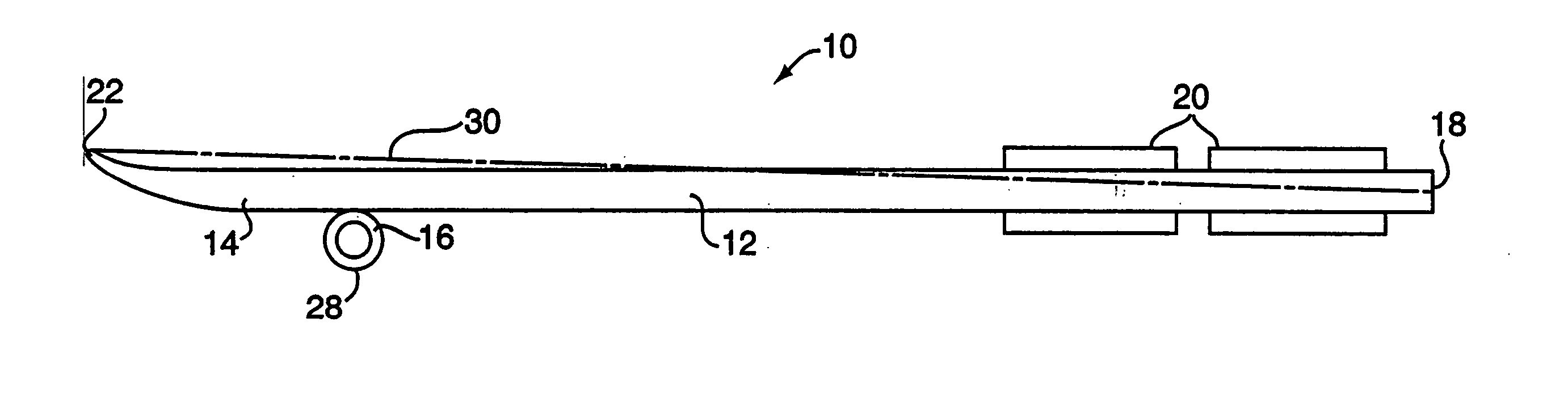

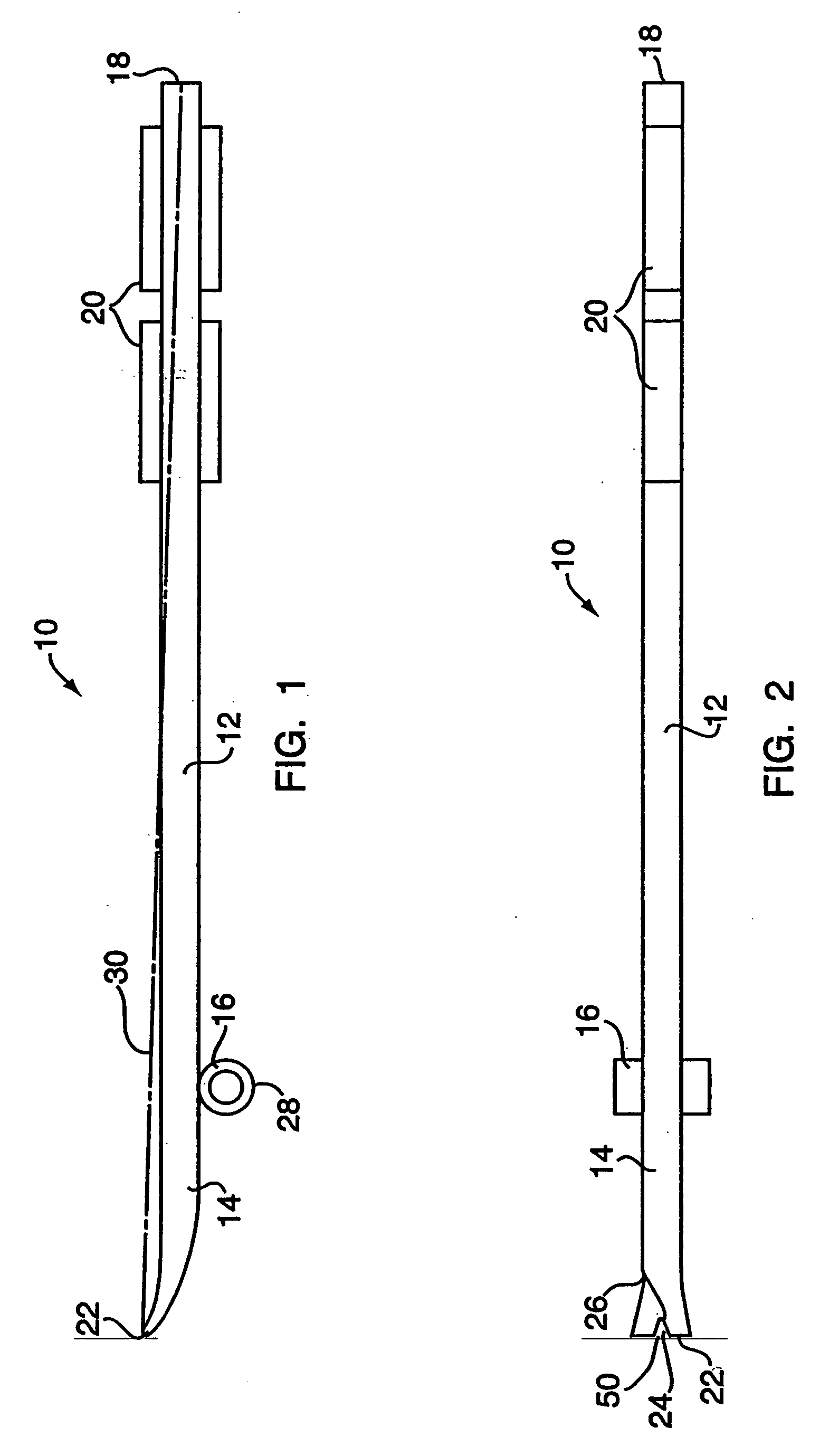

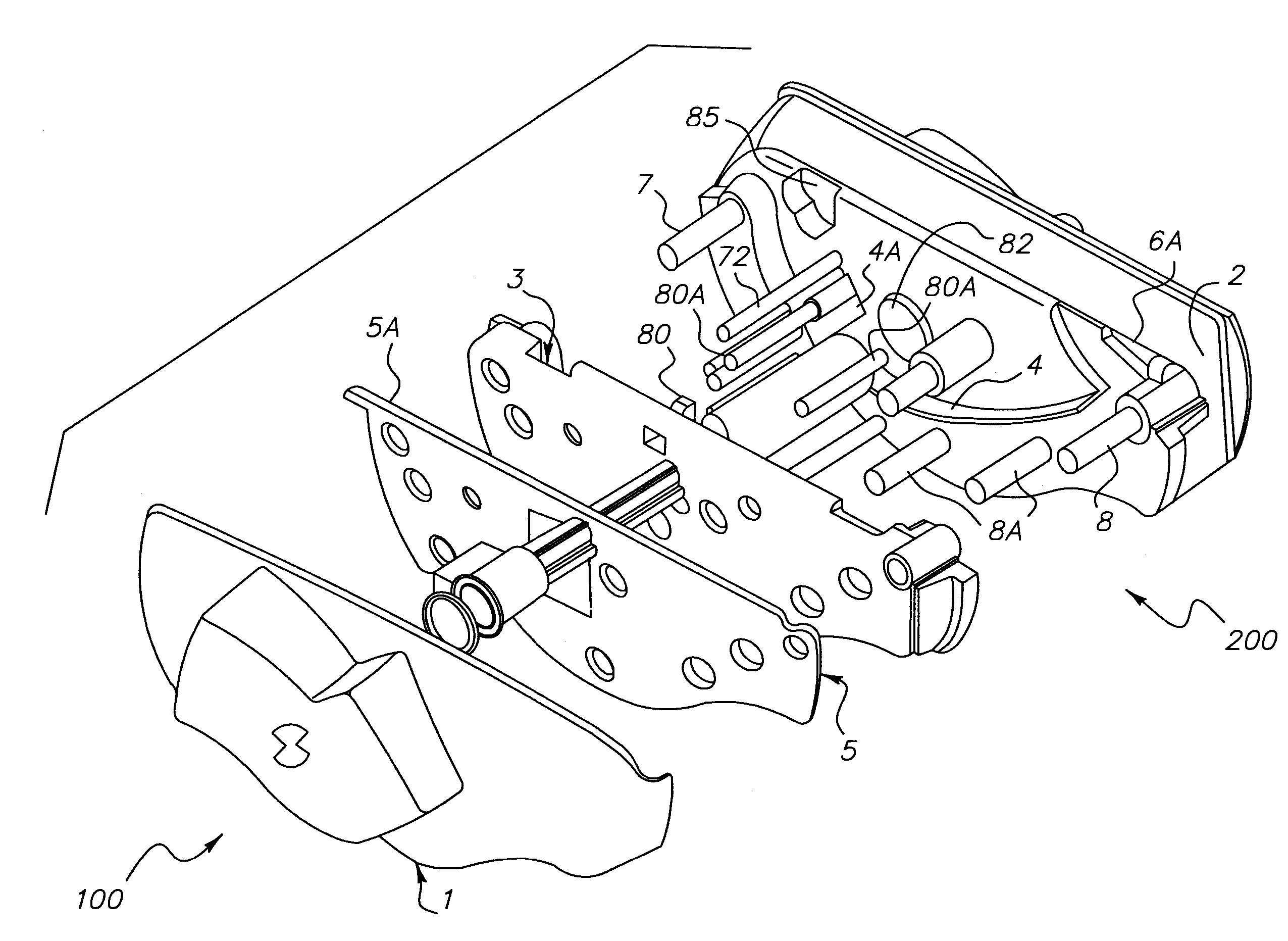

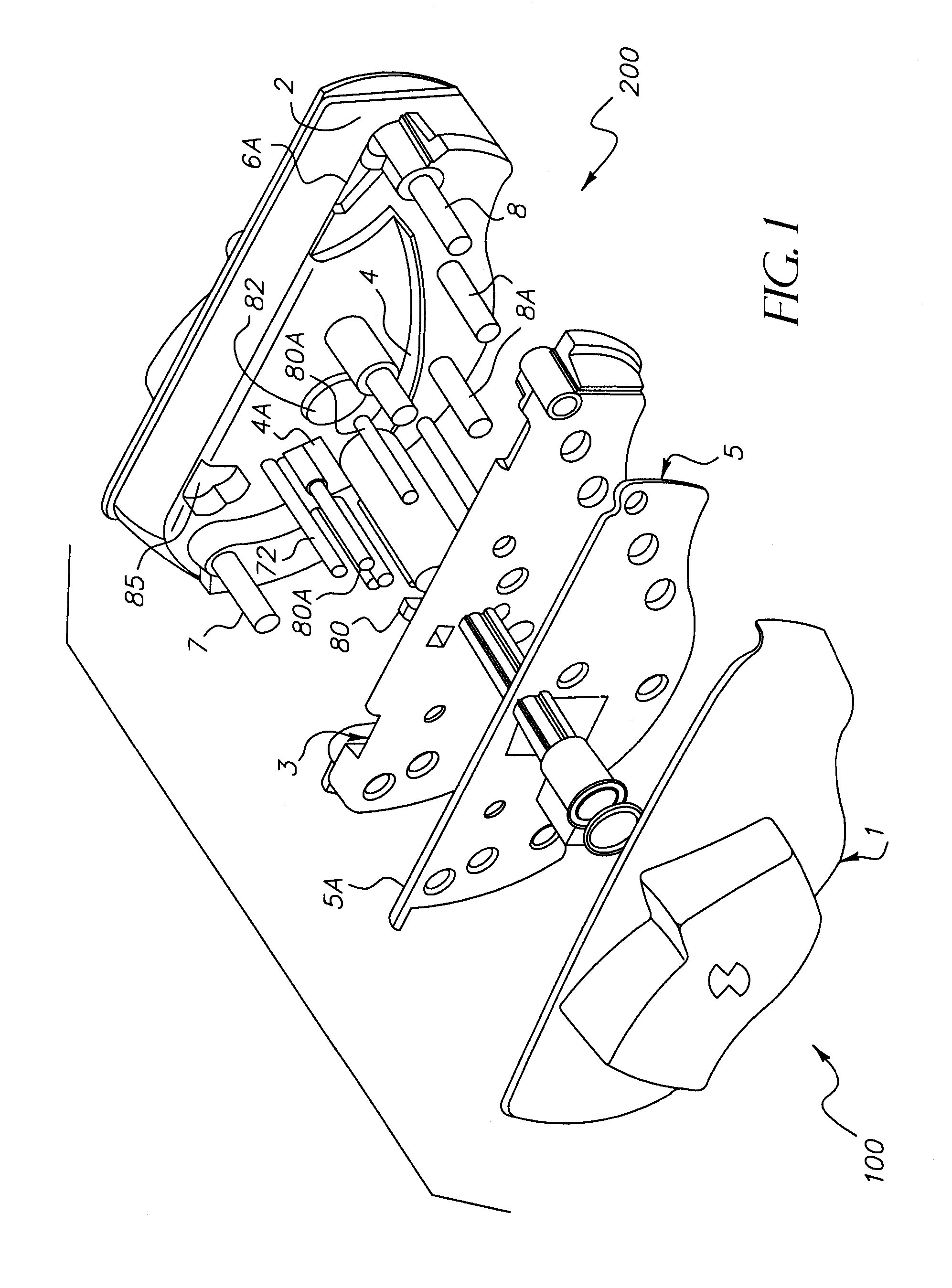

Earloop for telecommunications headset

ActiveUS7106877B1Improve reliabilityQuality improvementDeaf-aid setsEarpiece/earphone manufacture/assemblyHeadphonesUltimate tensile strength

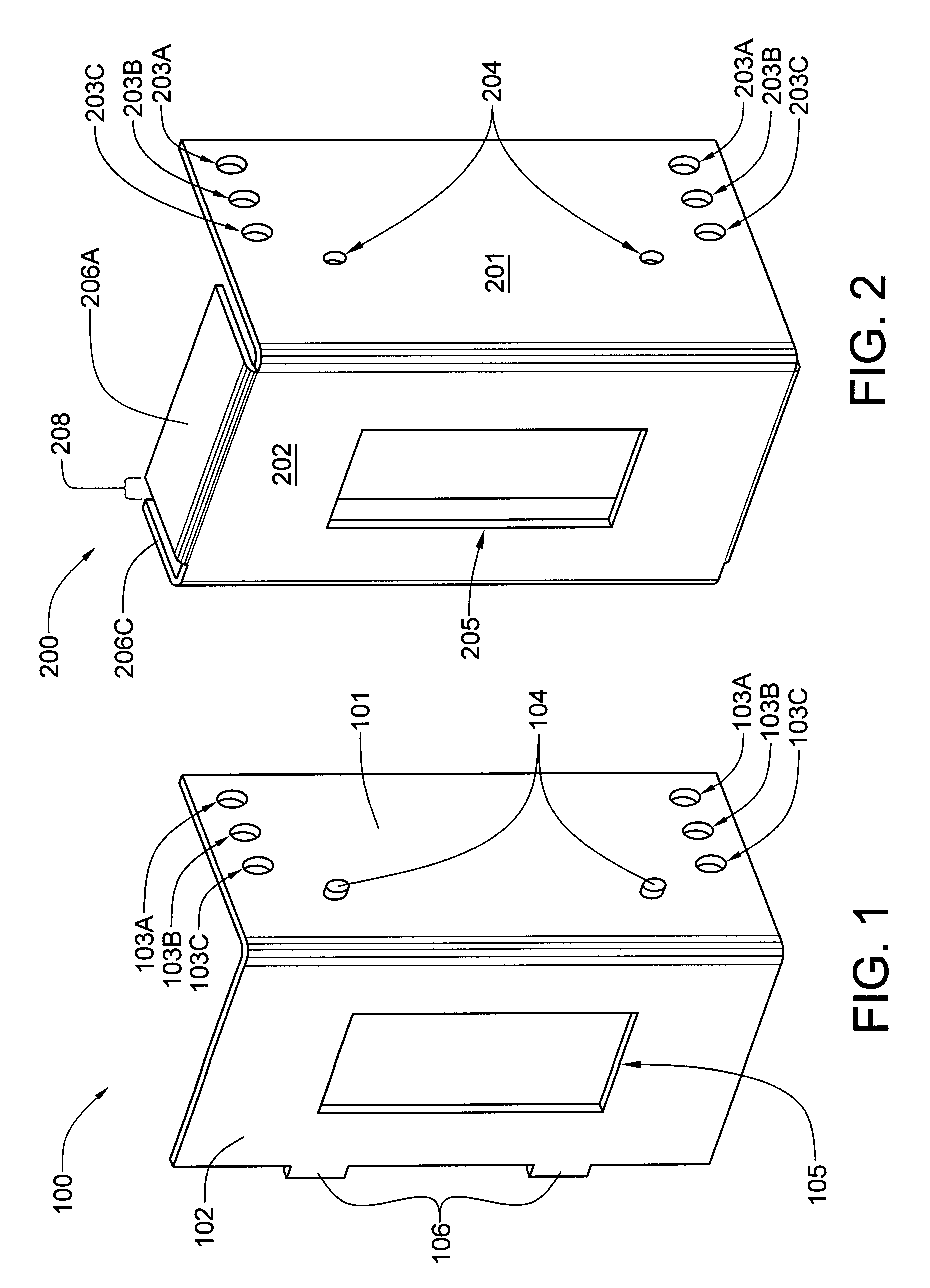

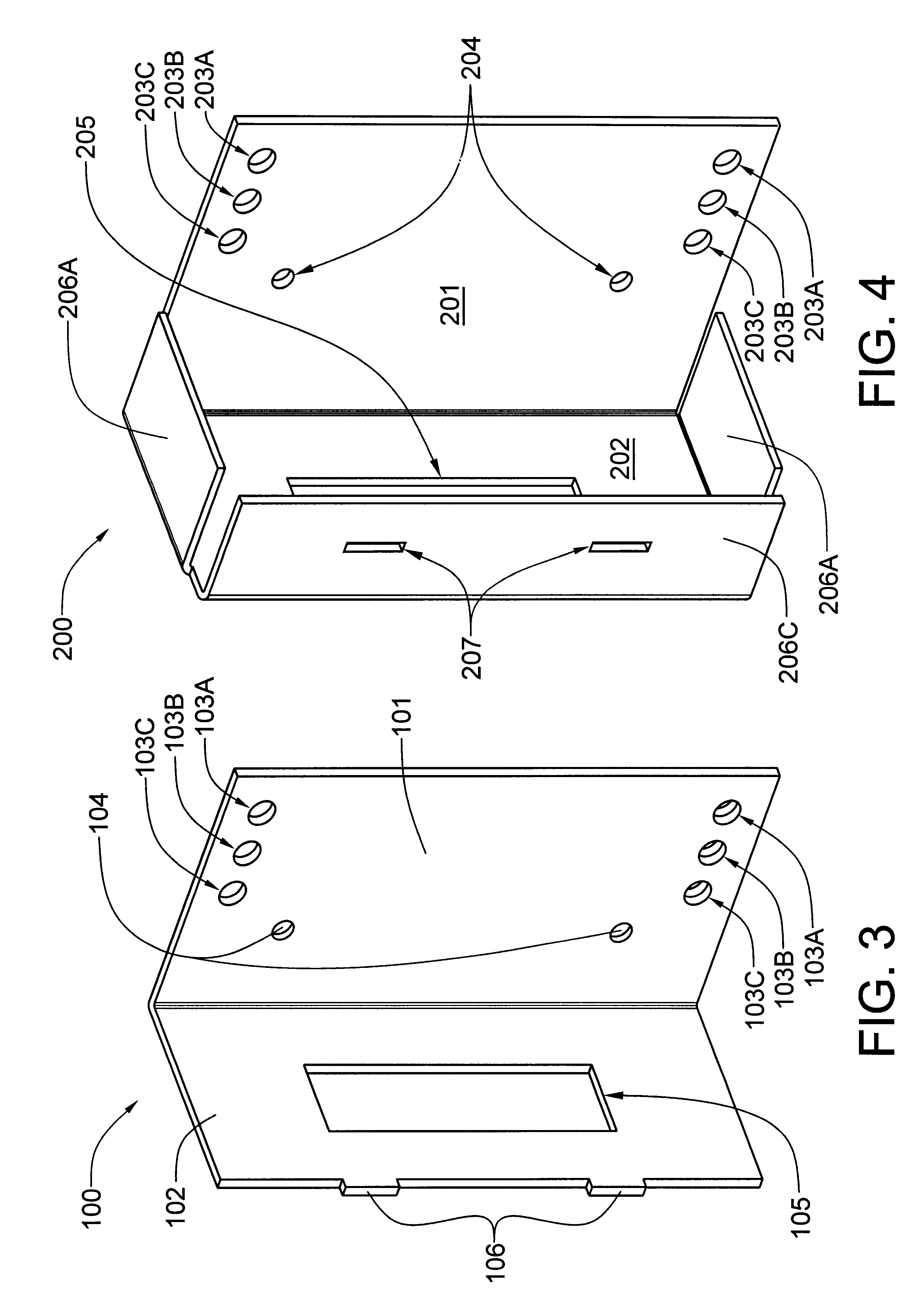

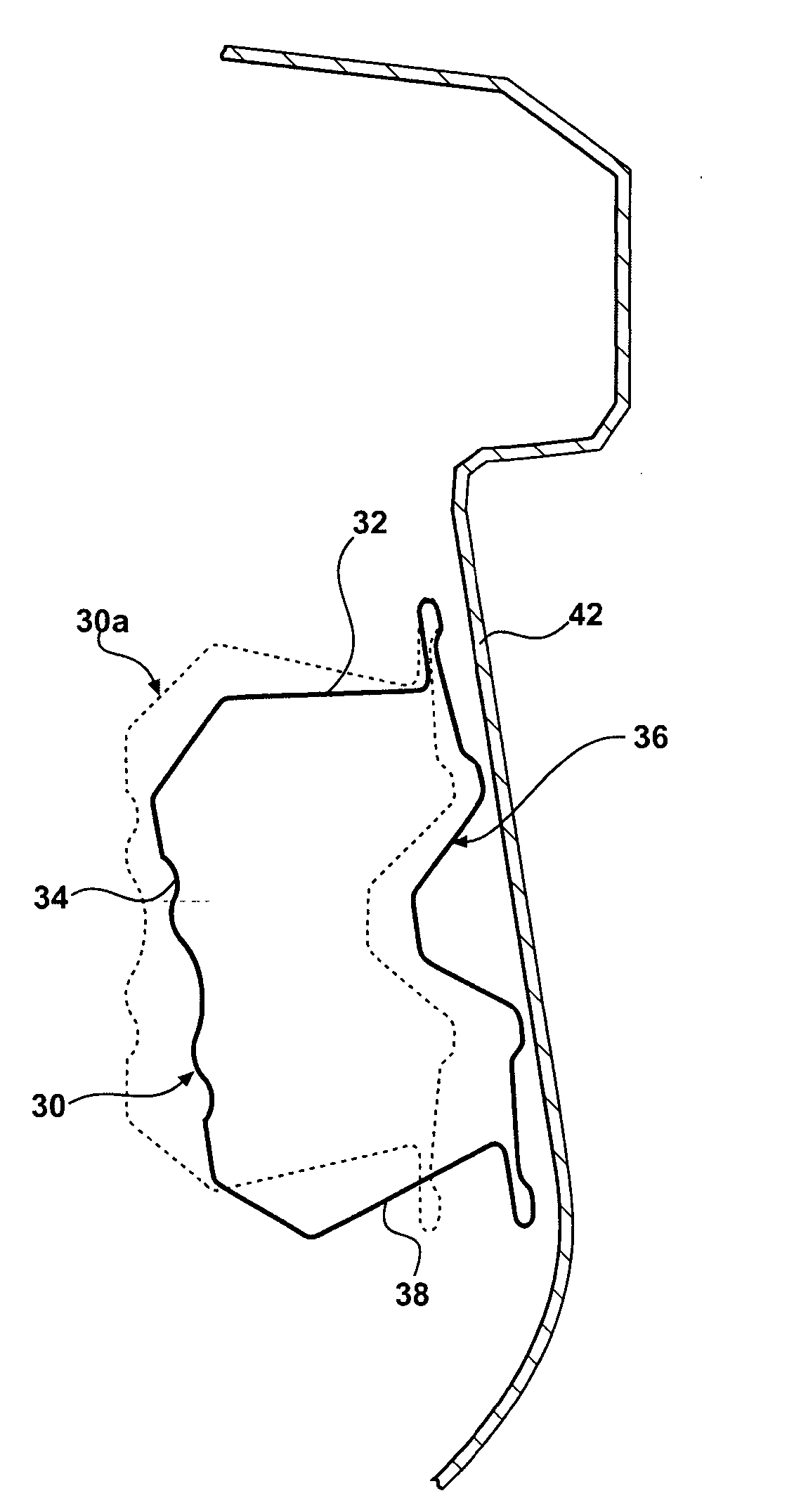

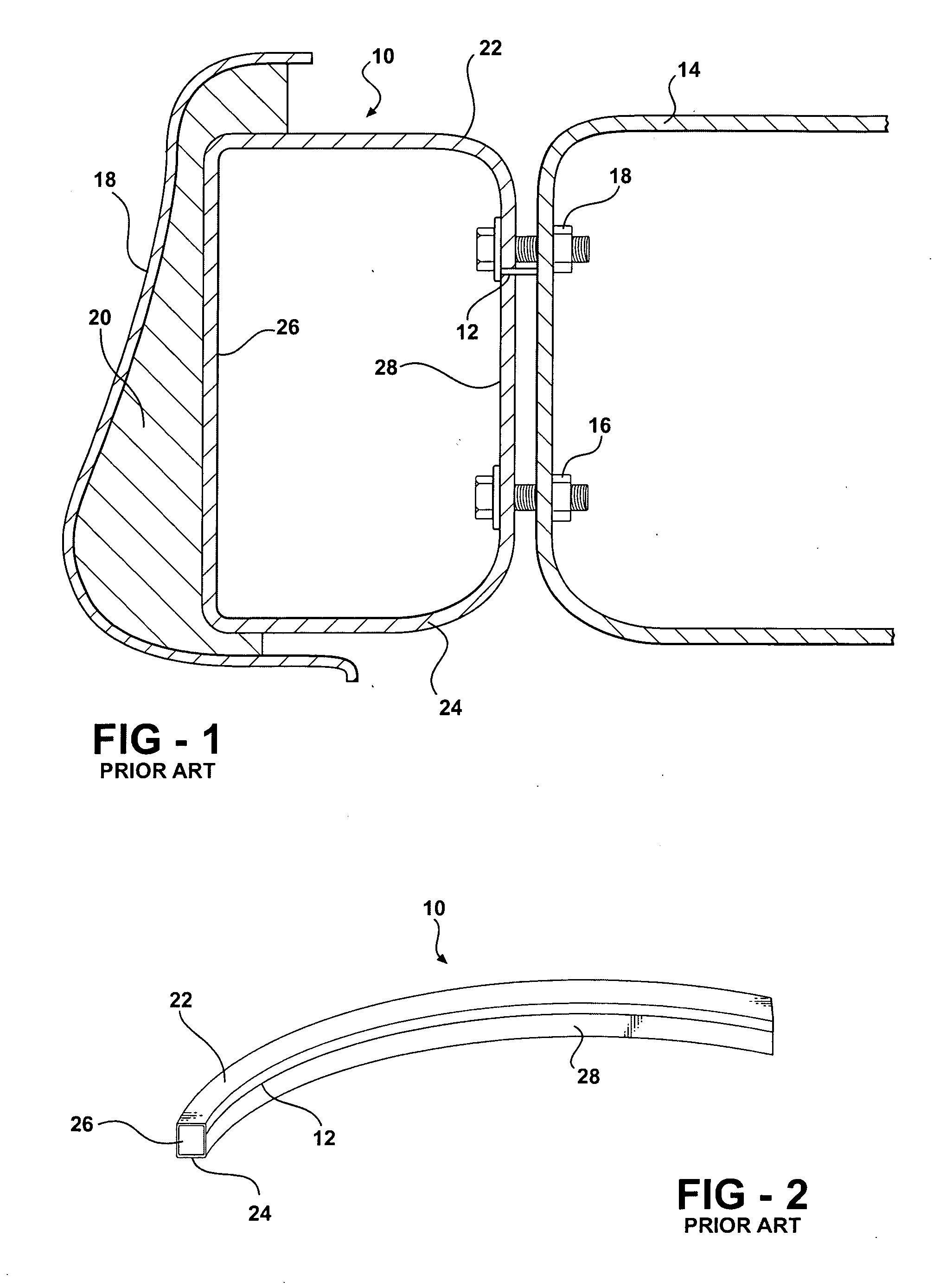

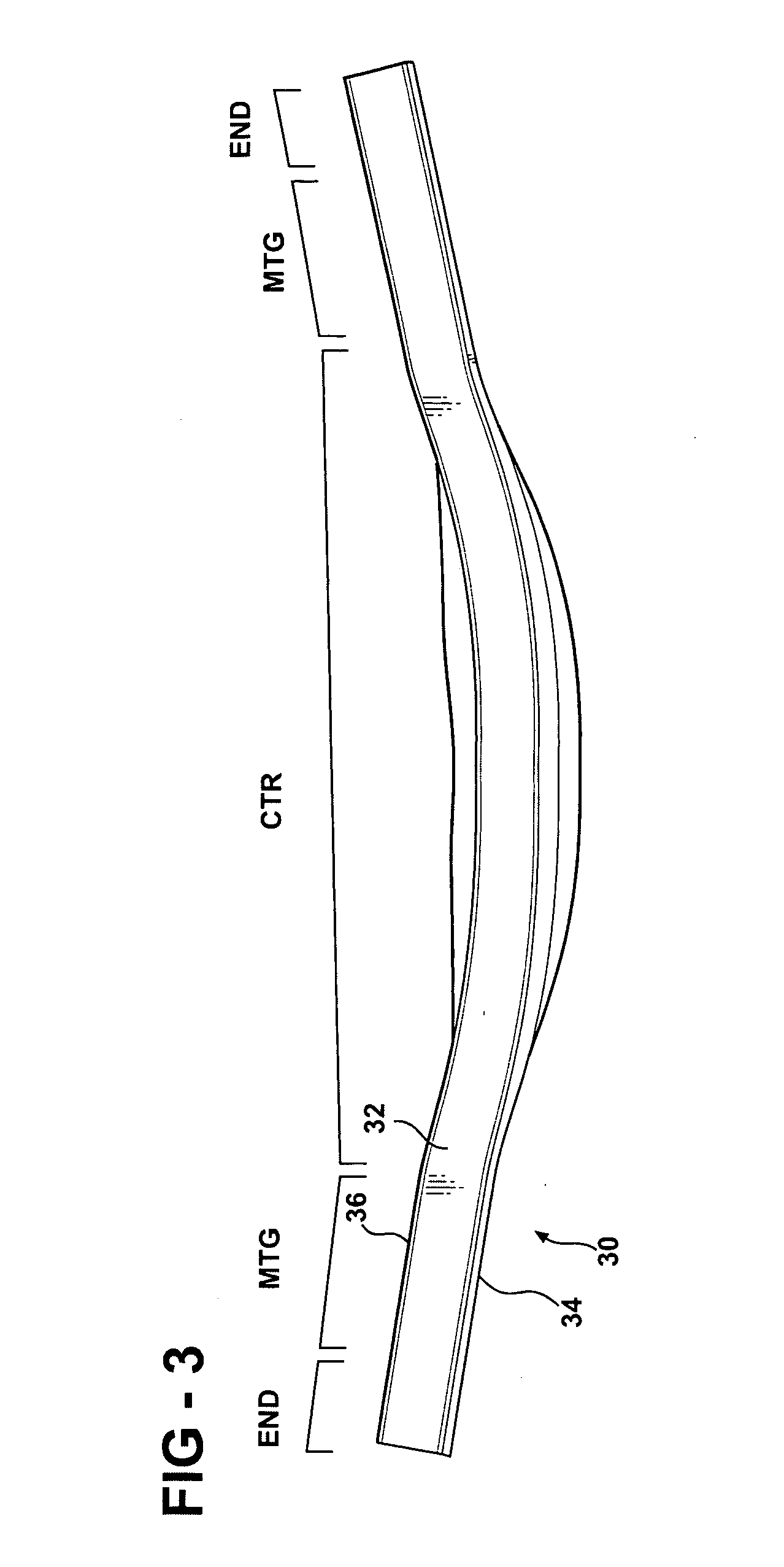

Earloops with improved post design for increased reliability and quality for over-the-ear style headsets are disclosed. The earloop includes an earloop main body having connecting and stabilizer portions and a post extending from the connection portion for insertion into a corresponding opening in an audio receiver / transmitter assembly. An embedded hardened steel member extends from the post into the connection portion. The stabilizer portion is configured to be positioned over, around and behind a user's ear. The earloop may be incorporated in a headset that includes the audio receiver / transmitter assembly that defines an opening to receive the post therethrough. The audio assembly may be positionable along a length of the post and rotatable about the post. The hardened steel member increases the stiffness and strength and minimizes breakage of the post and thus increases the reliability, quality, and useful life of the earloop and / or headset.

Owner:PLANTRONICS

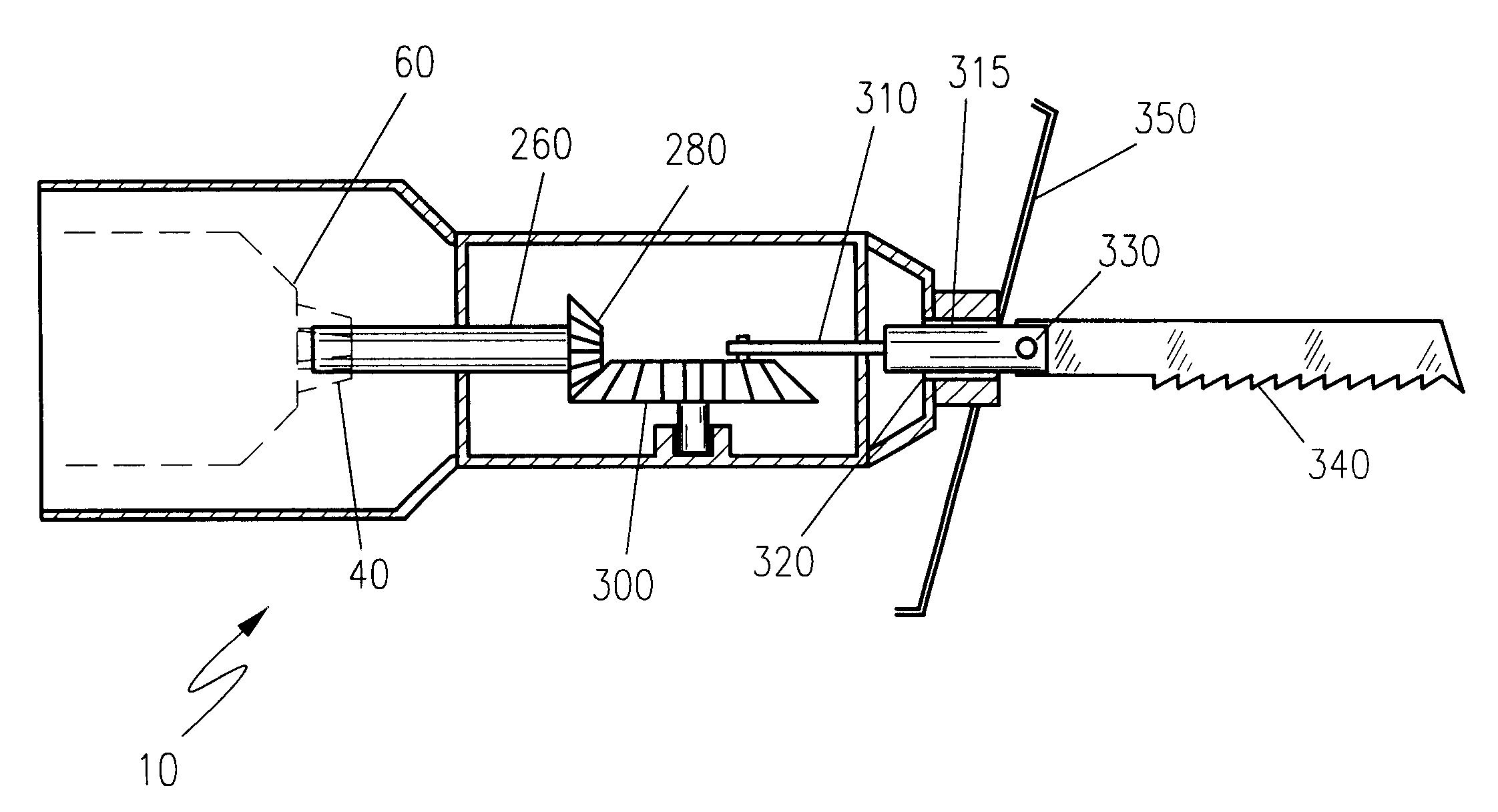

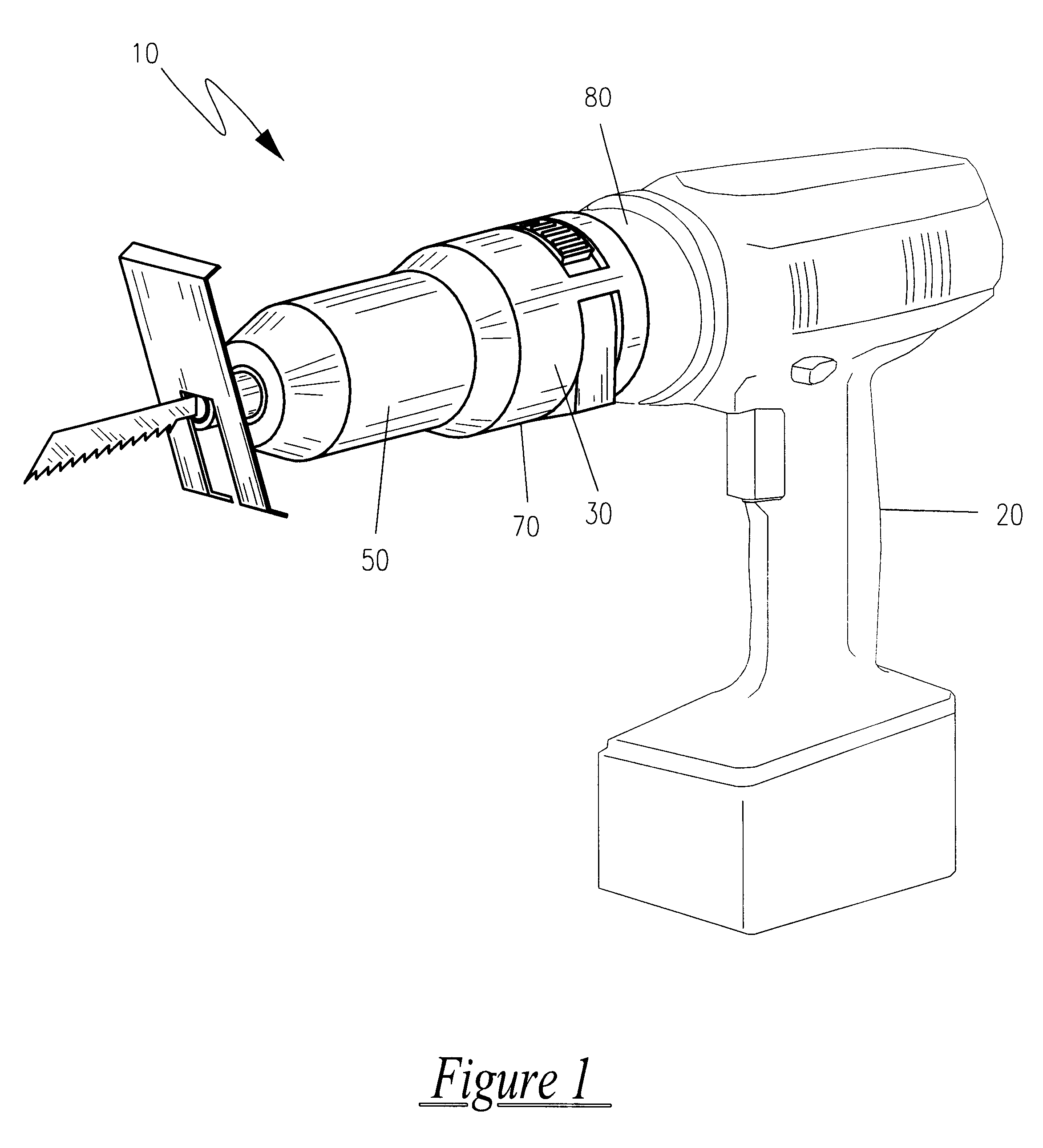

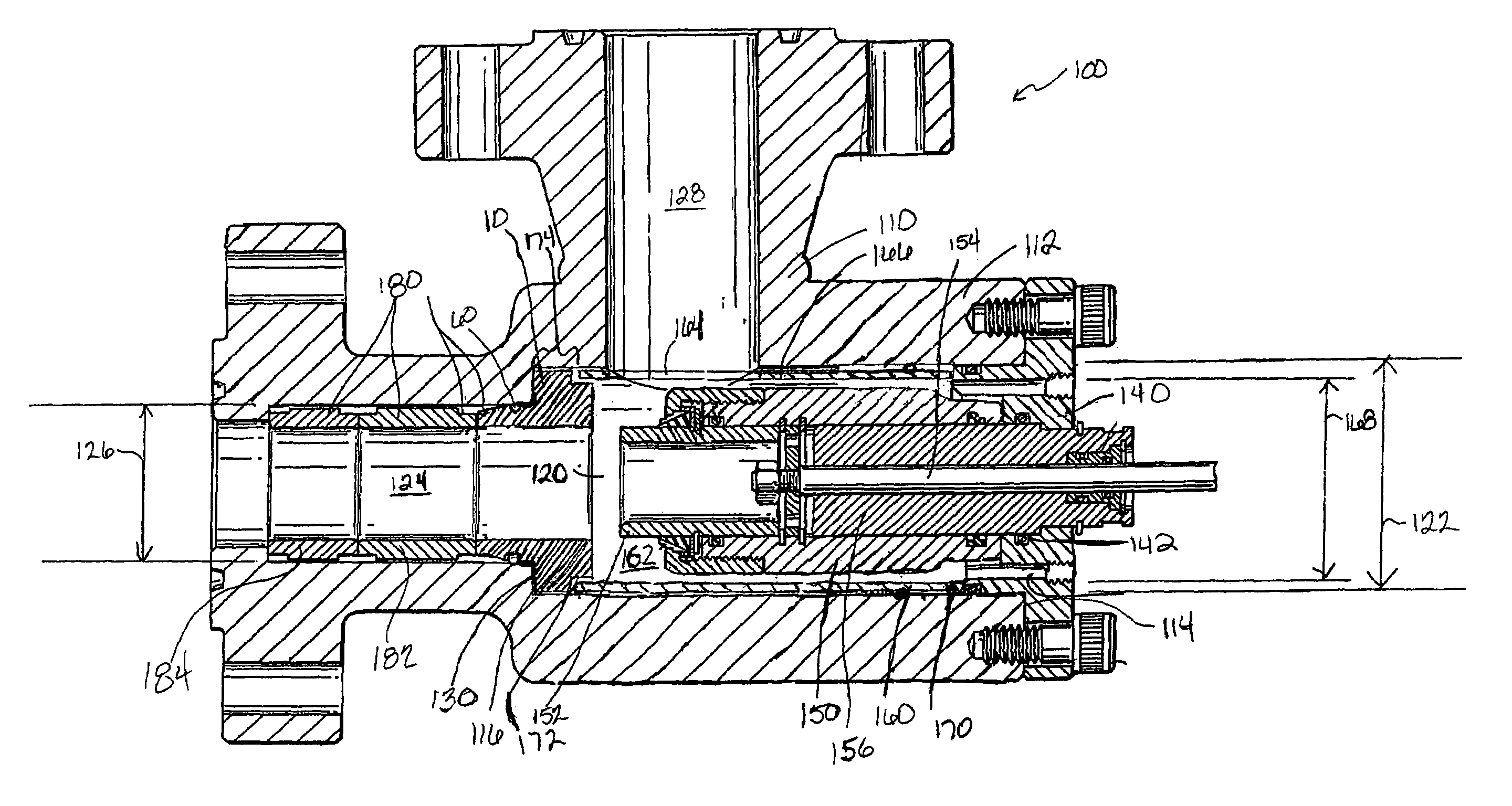

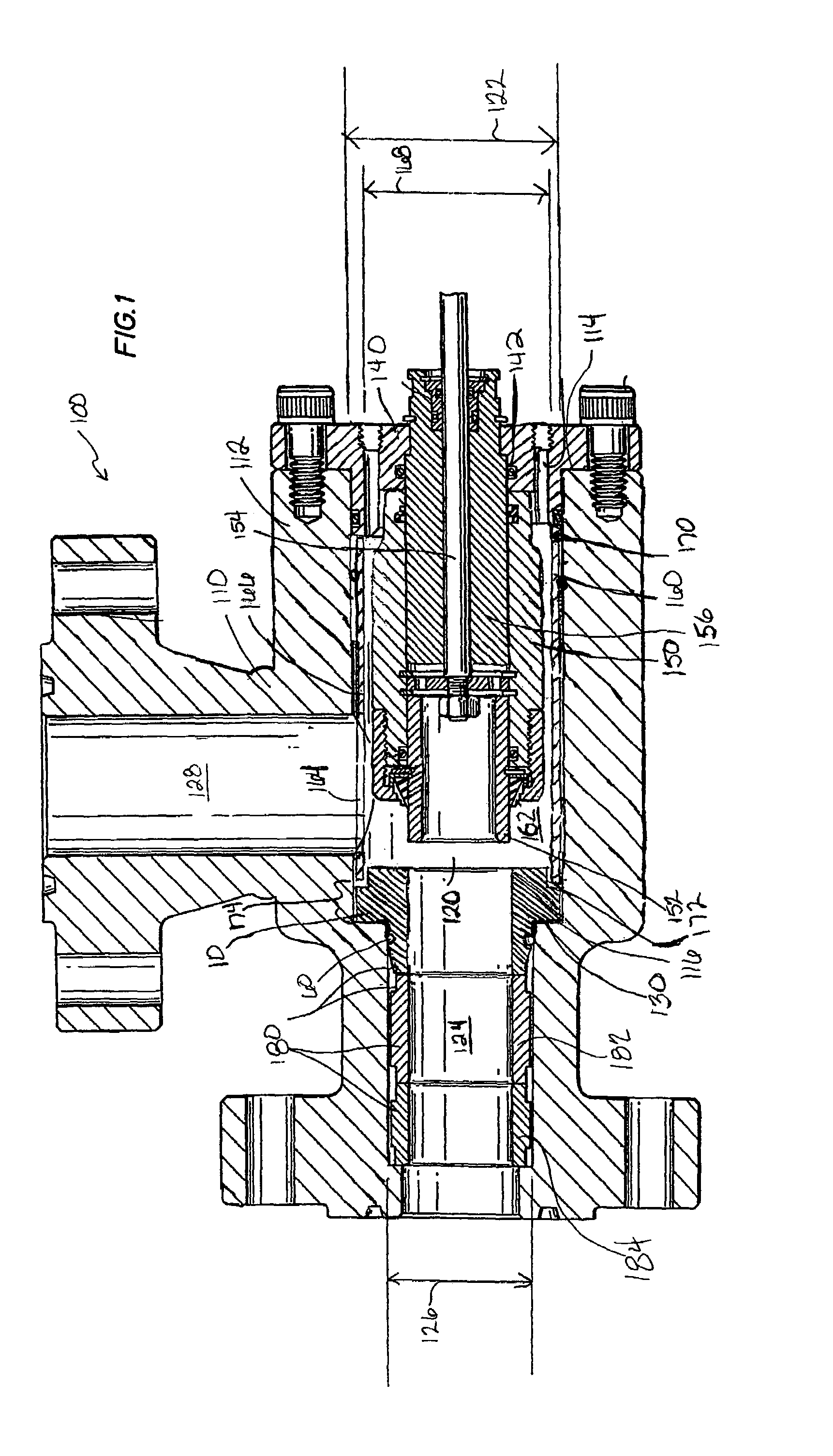

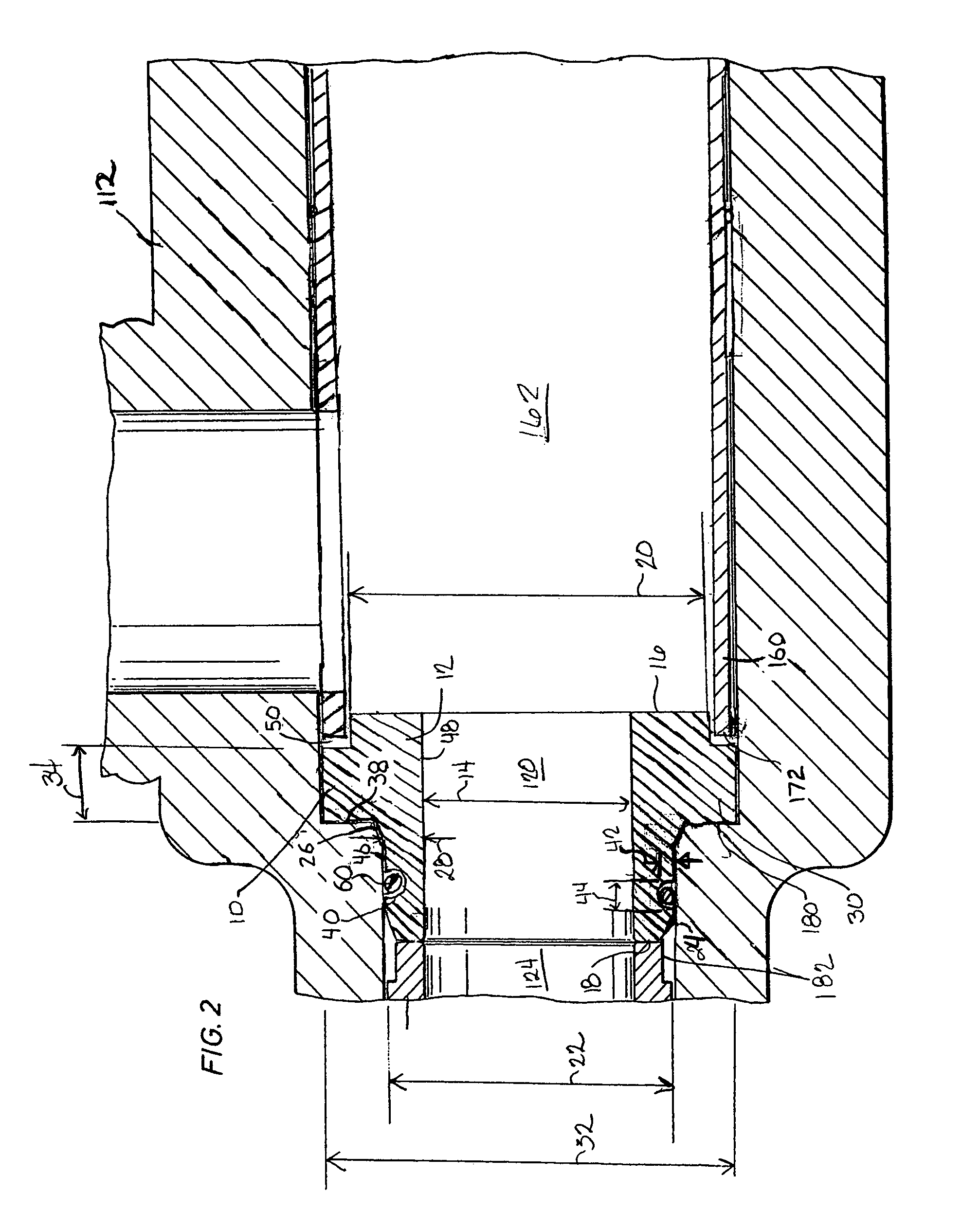

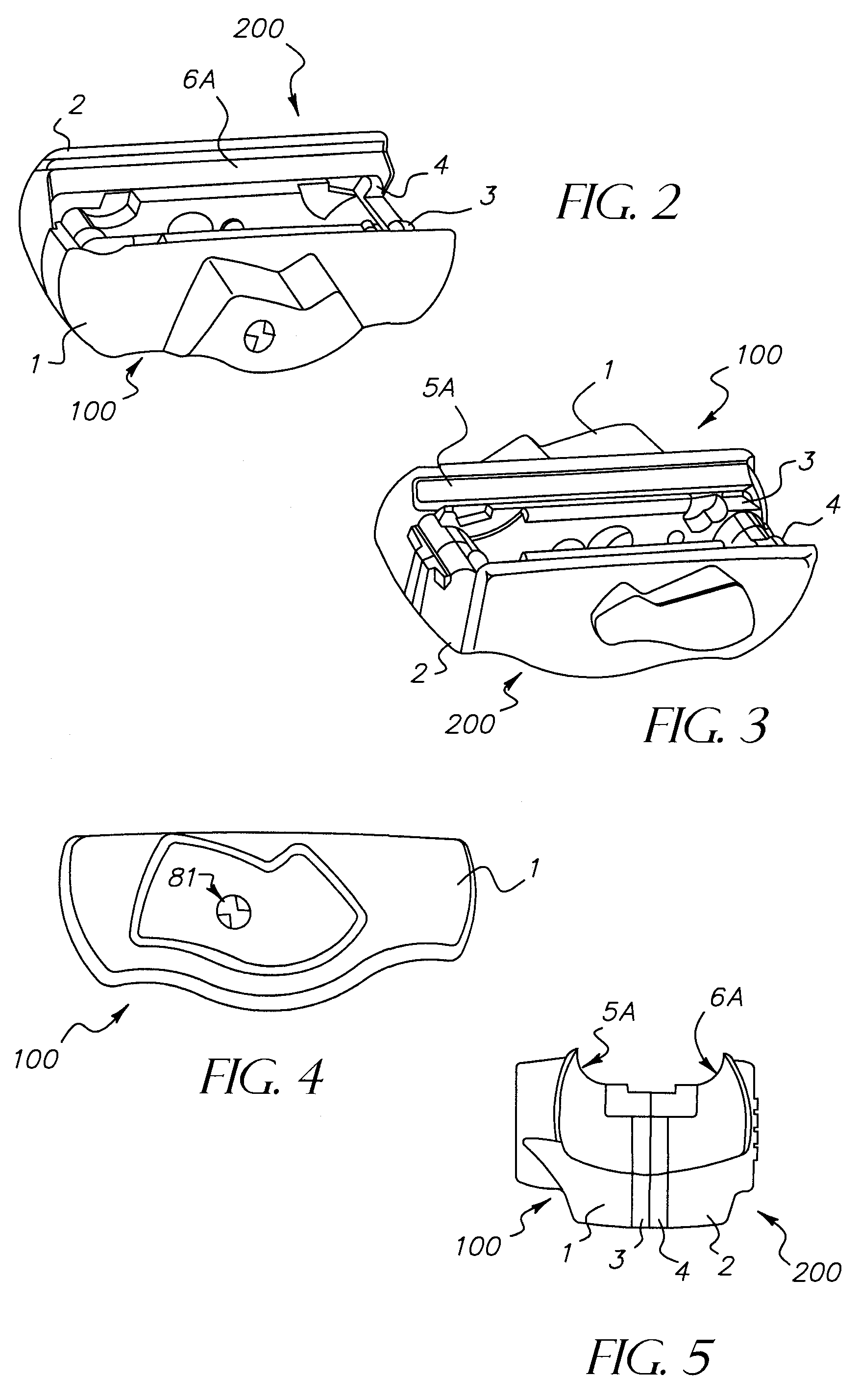

Reciprocating saw attachment for electric drill

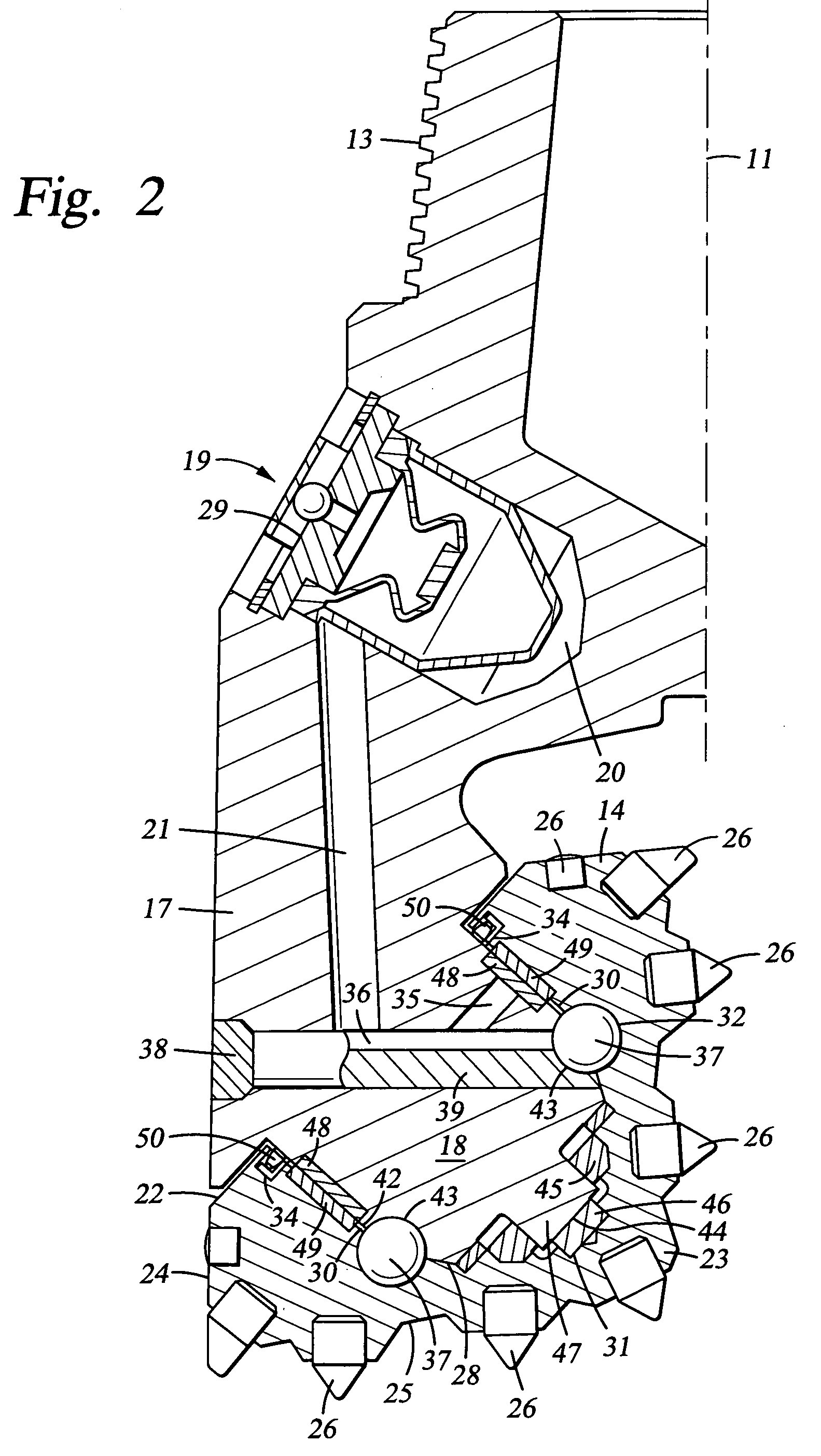

InactiveUS6264211B1Save spaceShorten the timeDrilling machinesTransportation and packagingGear wheelCoupling

A universal, quick connect, reciprocating saw attachment for electric drills is disclosed, designed as an adapter that converts a power rotary drill into a reciprocating saw. The present invention converts the rotary action of a drill into the necessary reciprocating action to power a saw blade. The present invention adapts to the housing of various cordless drills and provides for a connection of a steel shank to the drill chuck. A gear box with a reciprocating mechanism inside the housing then provides a coupling to a saw blade to provided the necessary cutting action of a conventional reciprocating saw. Additionally, there are buttons that are designed to expand in and out to tighten the chuck which holds the adapter. The housing is made of a heavy duty impact resistant plastic with the associated gears and reciprocating mechanism made from hardened steel. Coupled with a cordless drill, and a saw blade, the present invention provides for the functions of two, usually separate, power tools in the convenience of one.

Owner:GRANADO RENE

Trim insert for choke assembly

A trim insert for a choke assembly is disclosed, wherein the trim insert is a tubular member with a substantially constant inner diameter. A first end of the device is positioned within an adjacent upstream sleeve and a second end is sealingly retained within the discharge channel of the choke assembly. A flange coaxially retains the tubular member between the sleeve and a shoulder of the choke body. The trim insert is made of an erosion resistant material, such as tungsten carbide, hardened steel, or a ceramic. Additionally, the inner surface of the tubular member may be coated with a hardening compound to provide additional erosion resistance.

Owner:MI

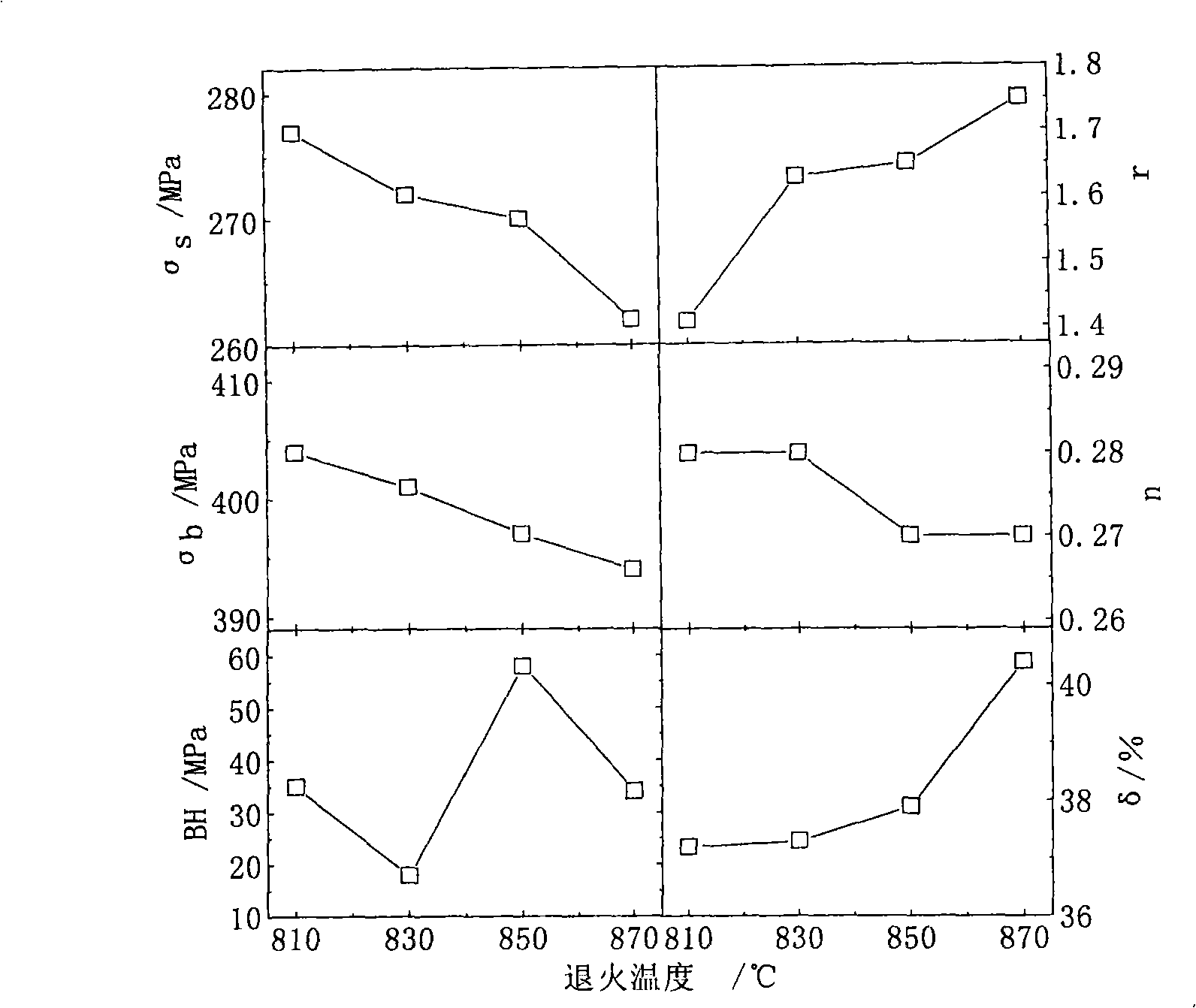

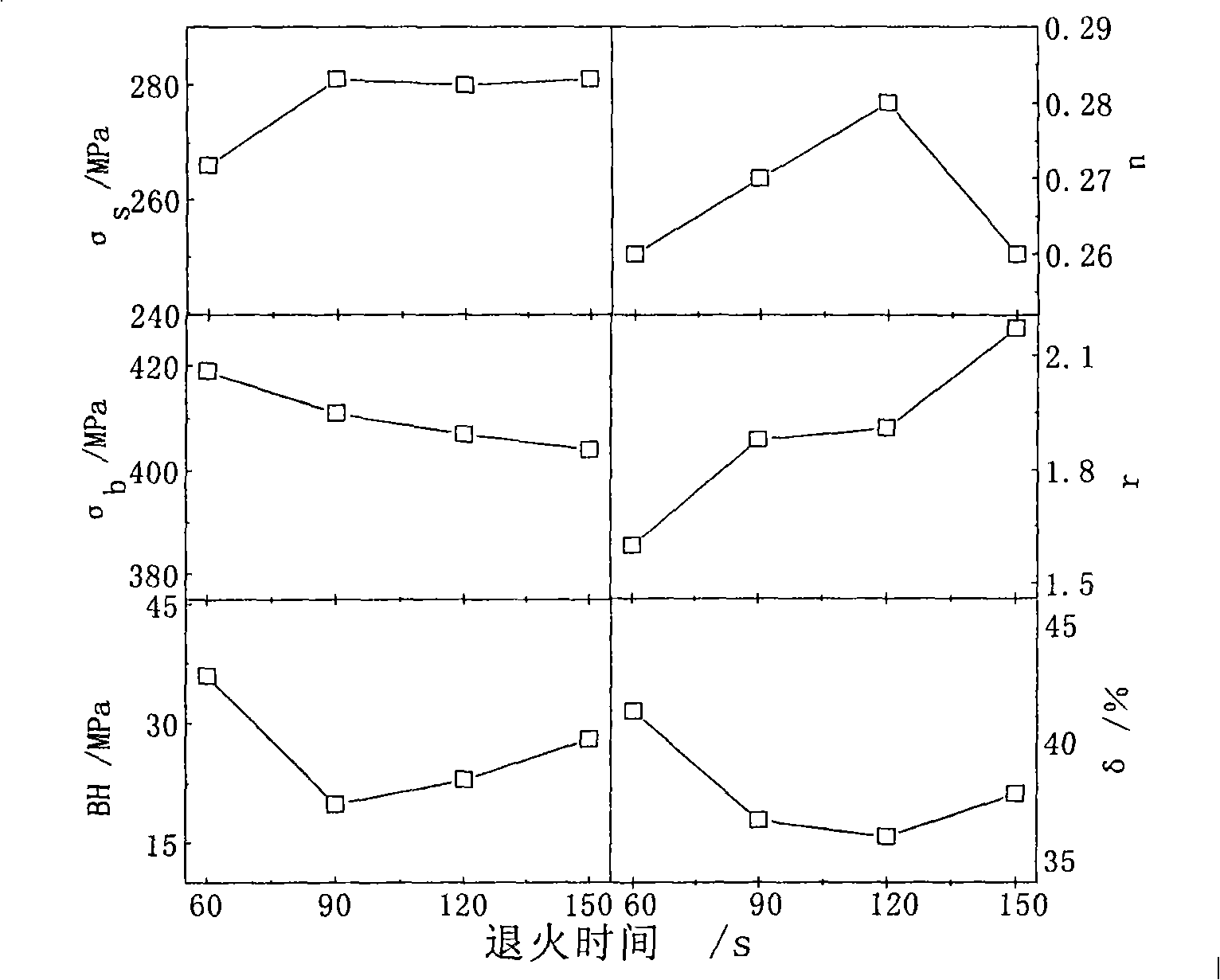

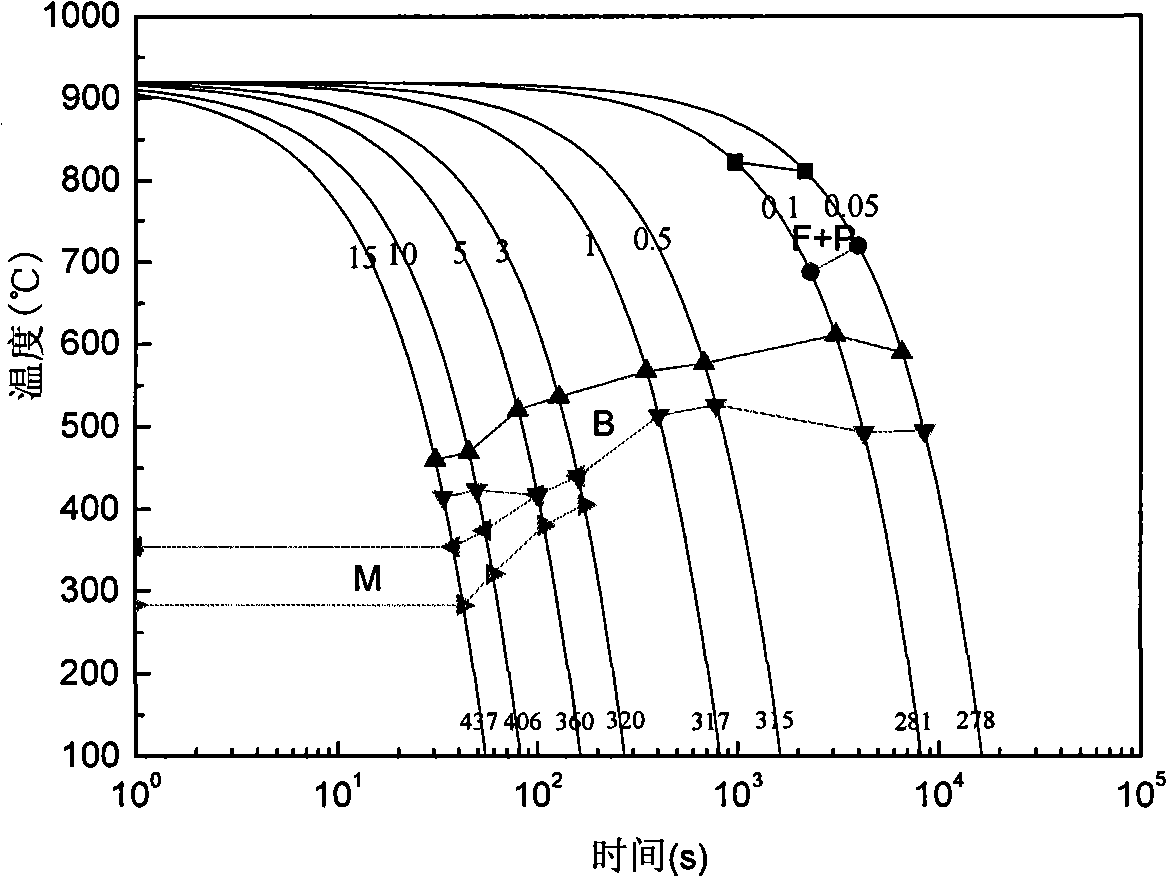

Alloyed hot galvanizing bake hardening steel and method for manufacturing same

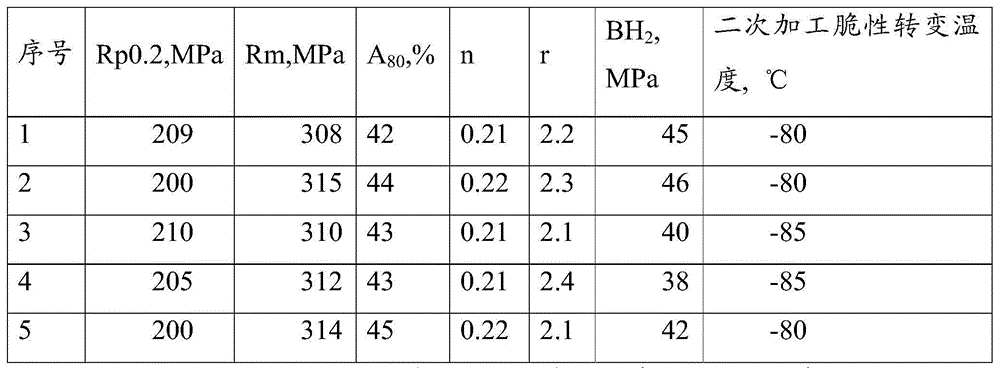

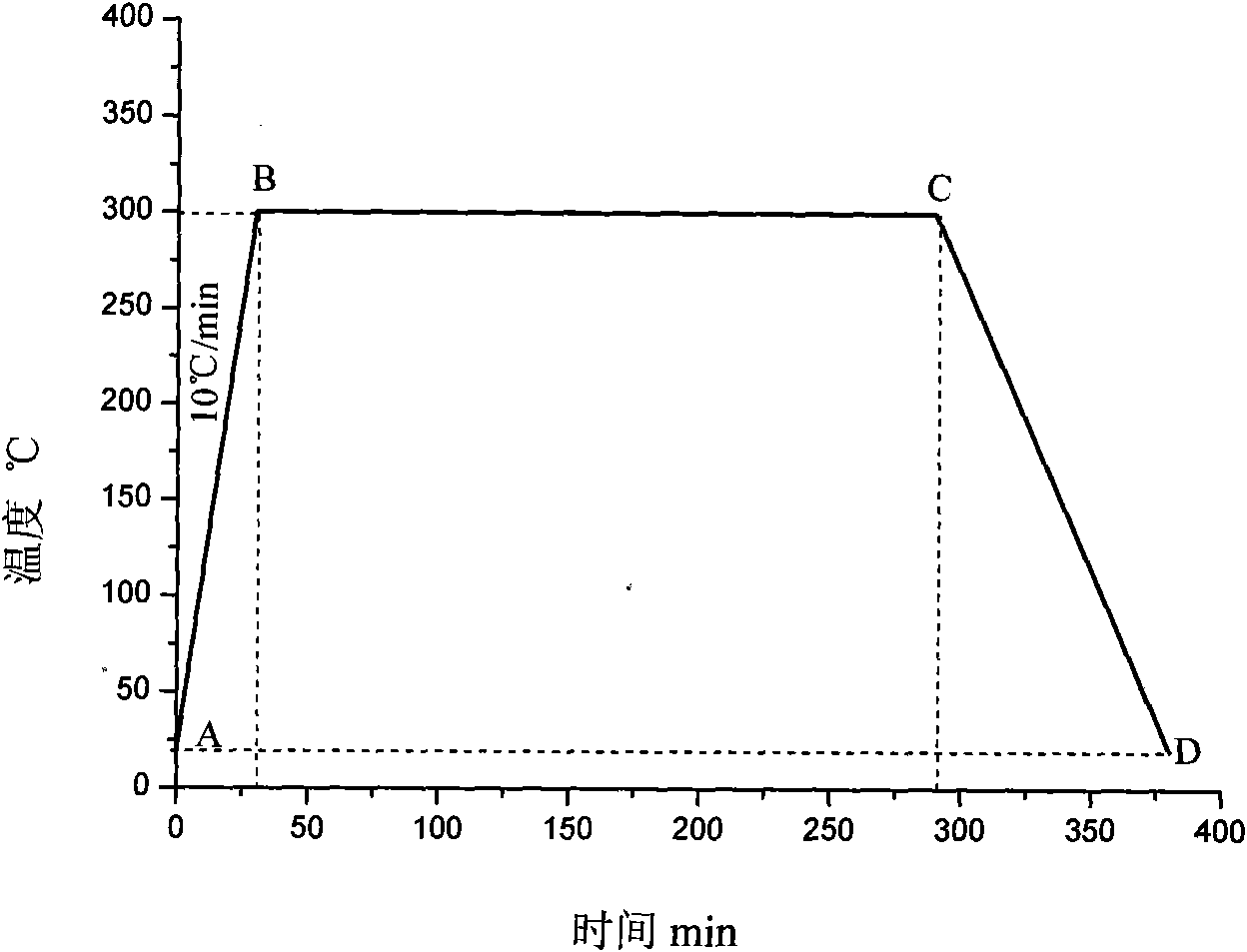

ActiveCN101230437ANot easy to produceImprove PlatabilityHot-dipping/immersion processesTemperature control deviceCooking & bakingSheet steel

The invention relates to an alloyed hot-galvanized baking-hardened steel plate and the manufacturing method thereof, which solves the problems of the anti-pulverization of the galvanized layer, the surface quality and the baking-hardened value. The mass percentage for the chemical components of a baseplate is as follows: C 0.0015 to 0.0025 percent, Si less than or equal to 0.030 percent, Mn 0.50 to 0.60 percent, P 0.050 to 0.060 percent, S less than or equal to 0.015 percent, N less than or equal to 0.003 percent, sol.Al 0.030 to 0.055 percent, Nb 0.004 to 0.015 percent, O less than or equal to 0.0050 percent and the rest are Fe and unavoidable impurities. The weight of the galvanized layer (for a single side) is 30-60g / m2 and the mass percentage for the Fe component of the galvanized layer is 8 to 12 percent. The steel plate of the invention has excellent anti-pulverization performance of the galvanized layer, excellent surface quality and appropriate baking-hardened value.

Owner:BAOSHAN IRON & STEEL CO LTD

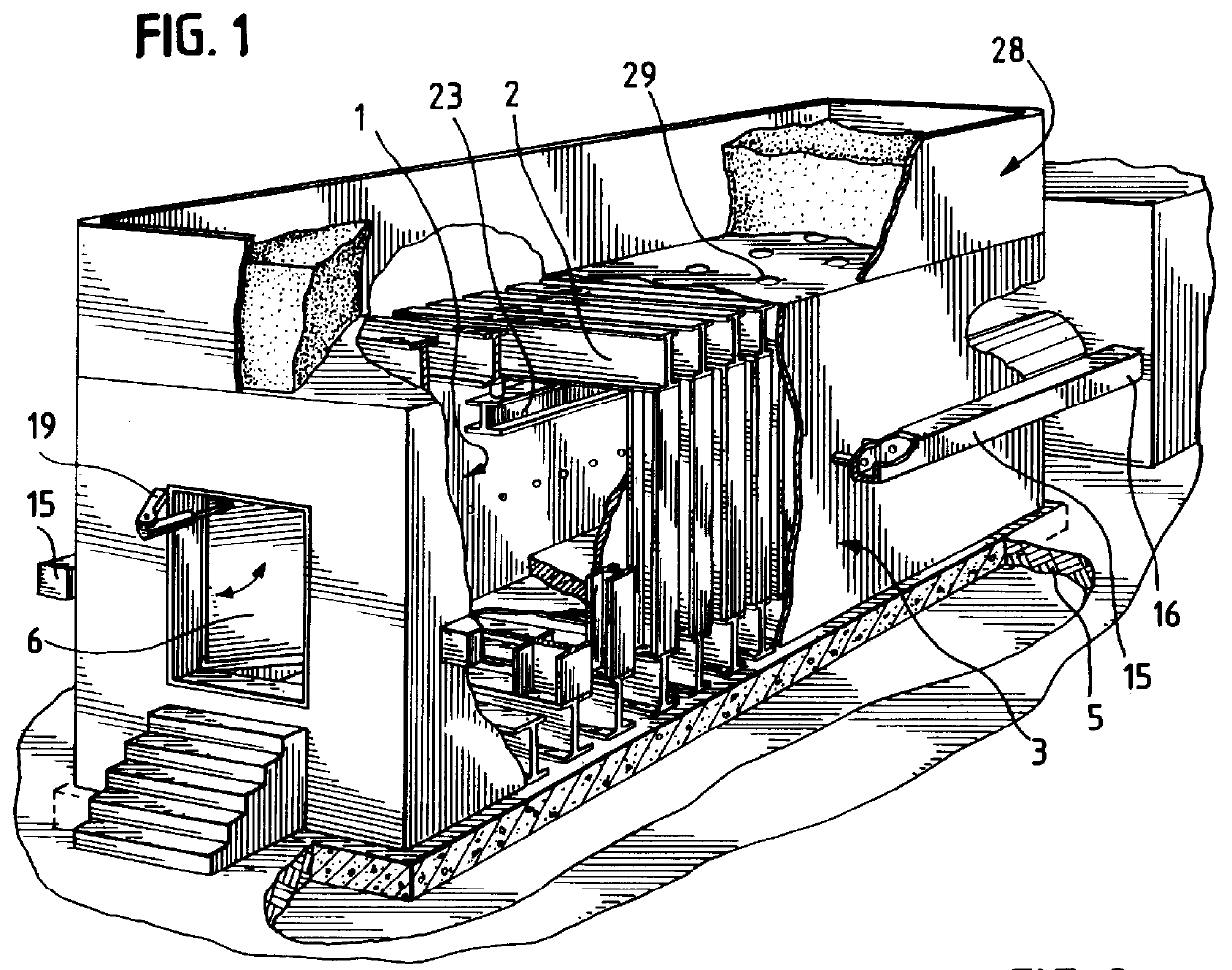

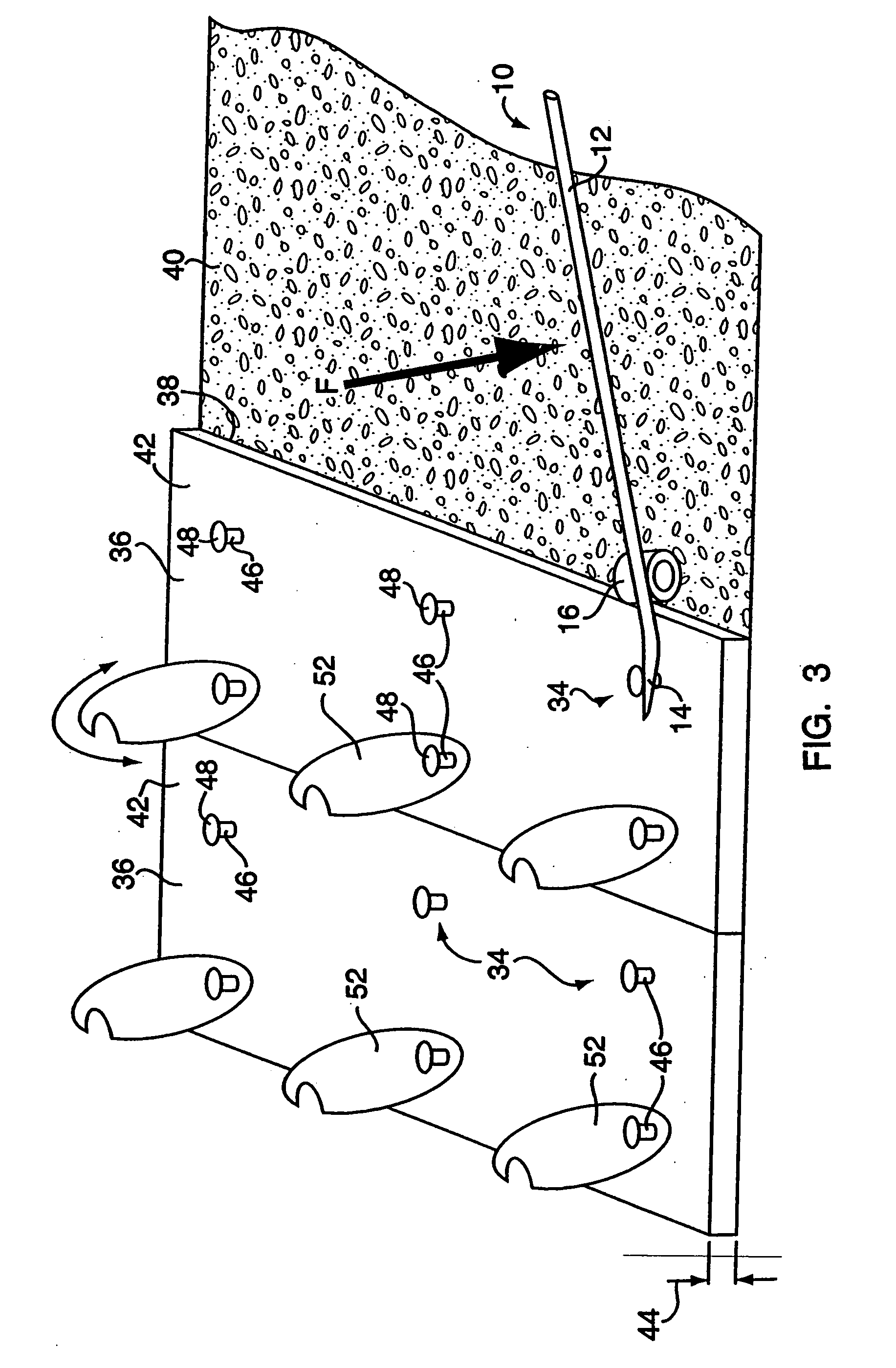

Method and an apparatus for producing packaging containers for liquid foods, as well as packaging containers

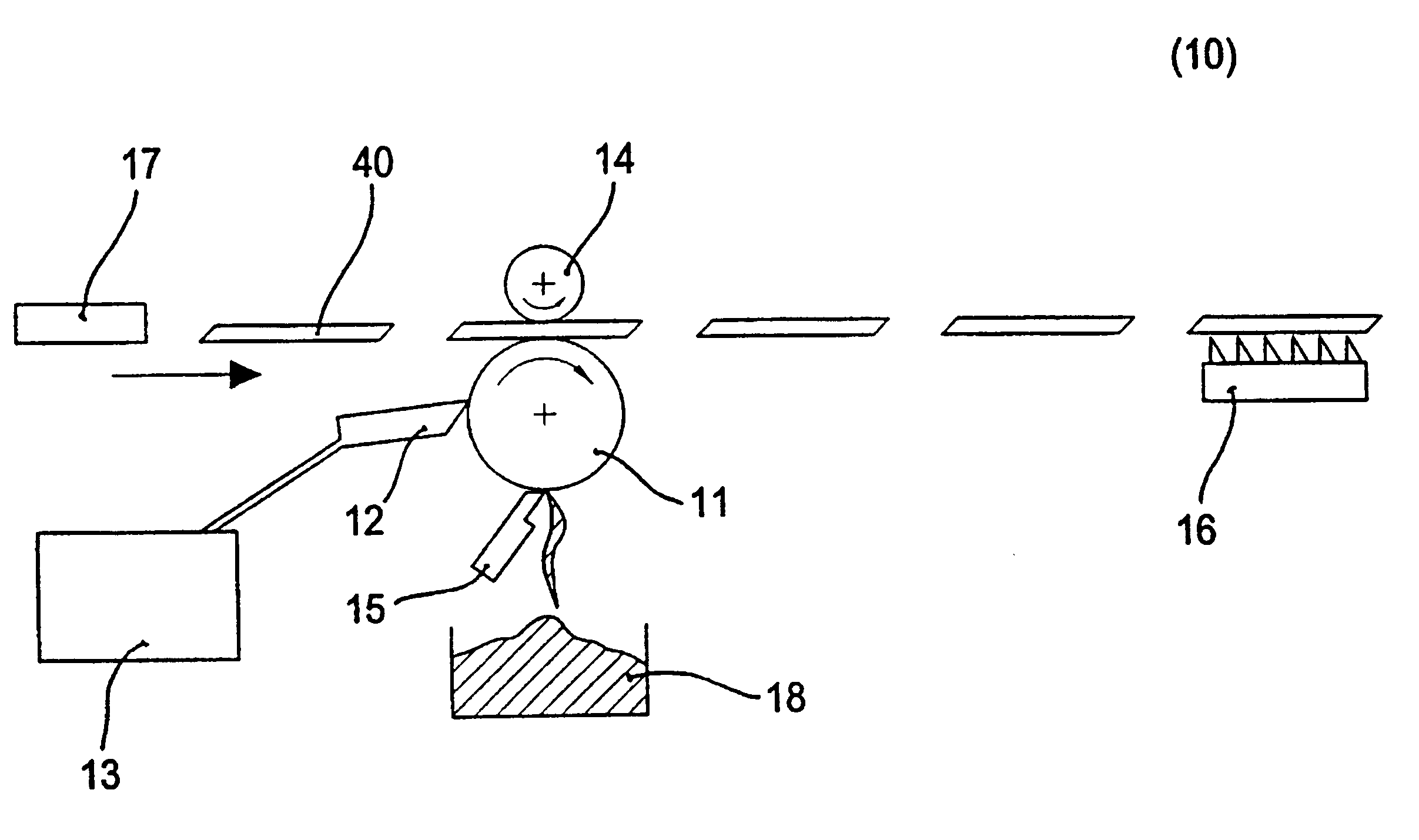

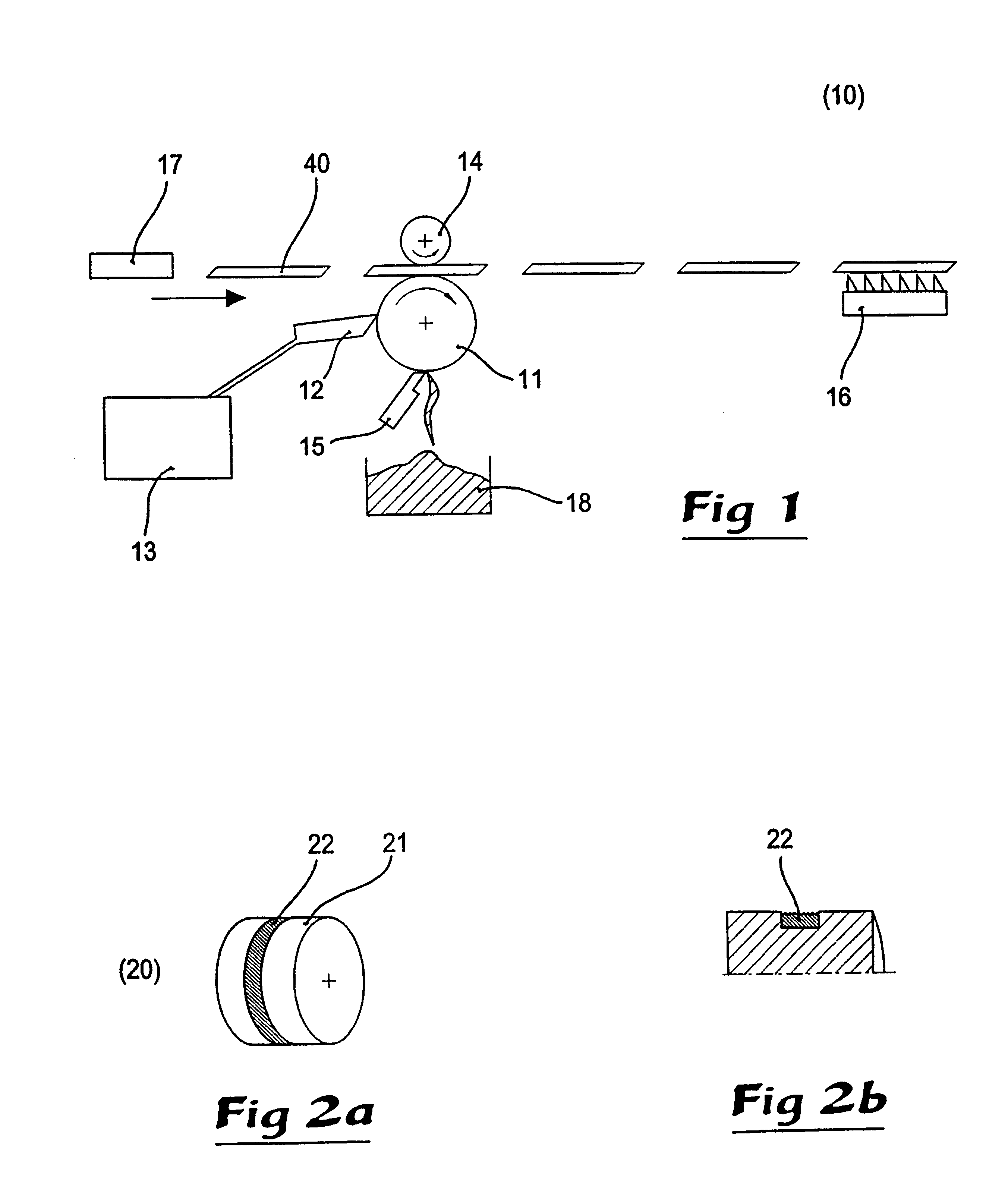

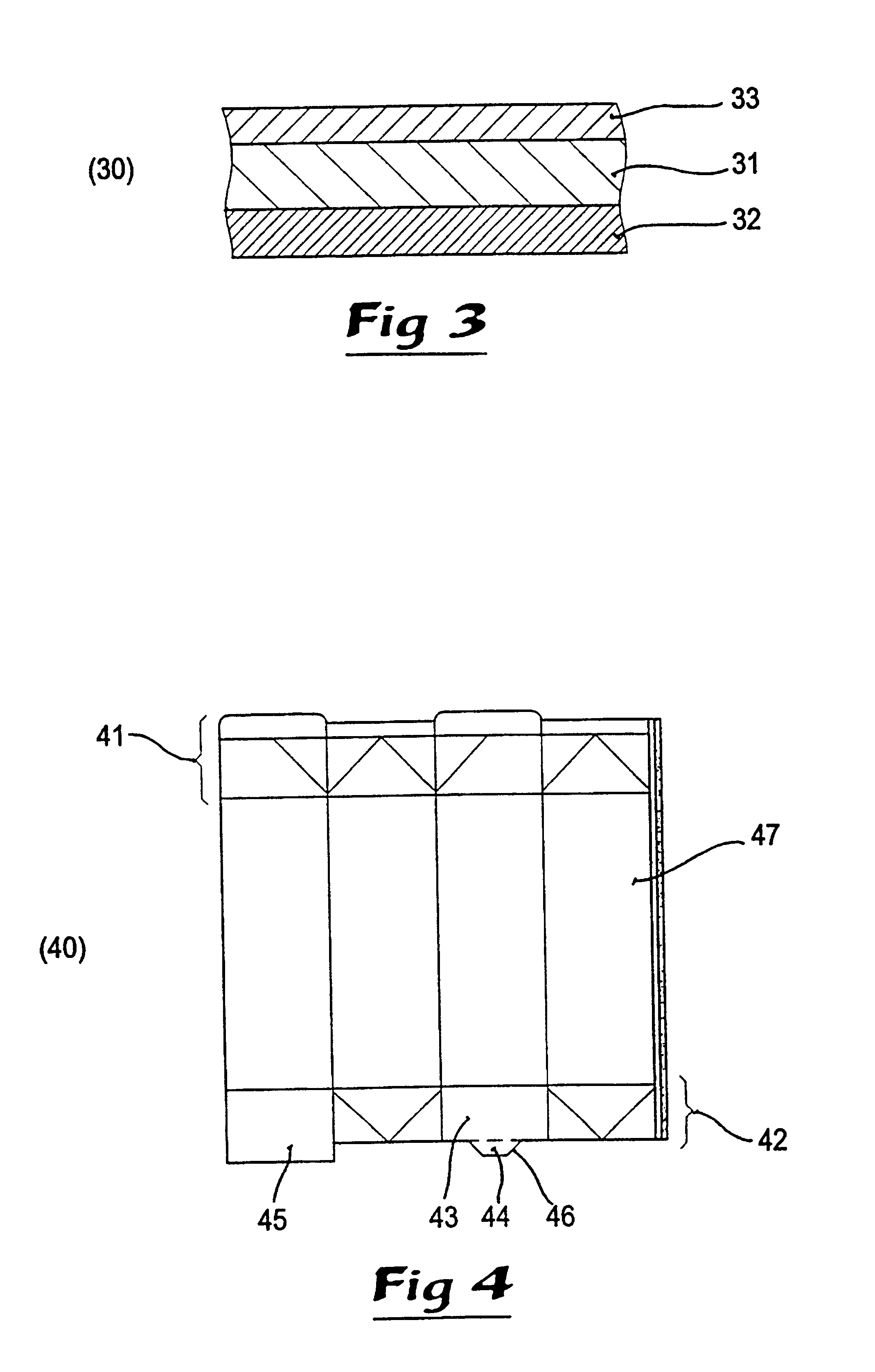

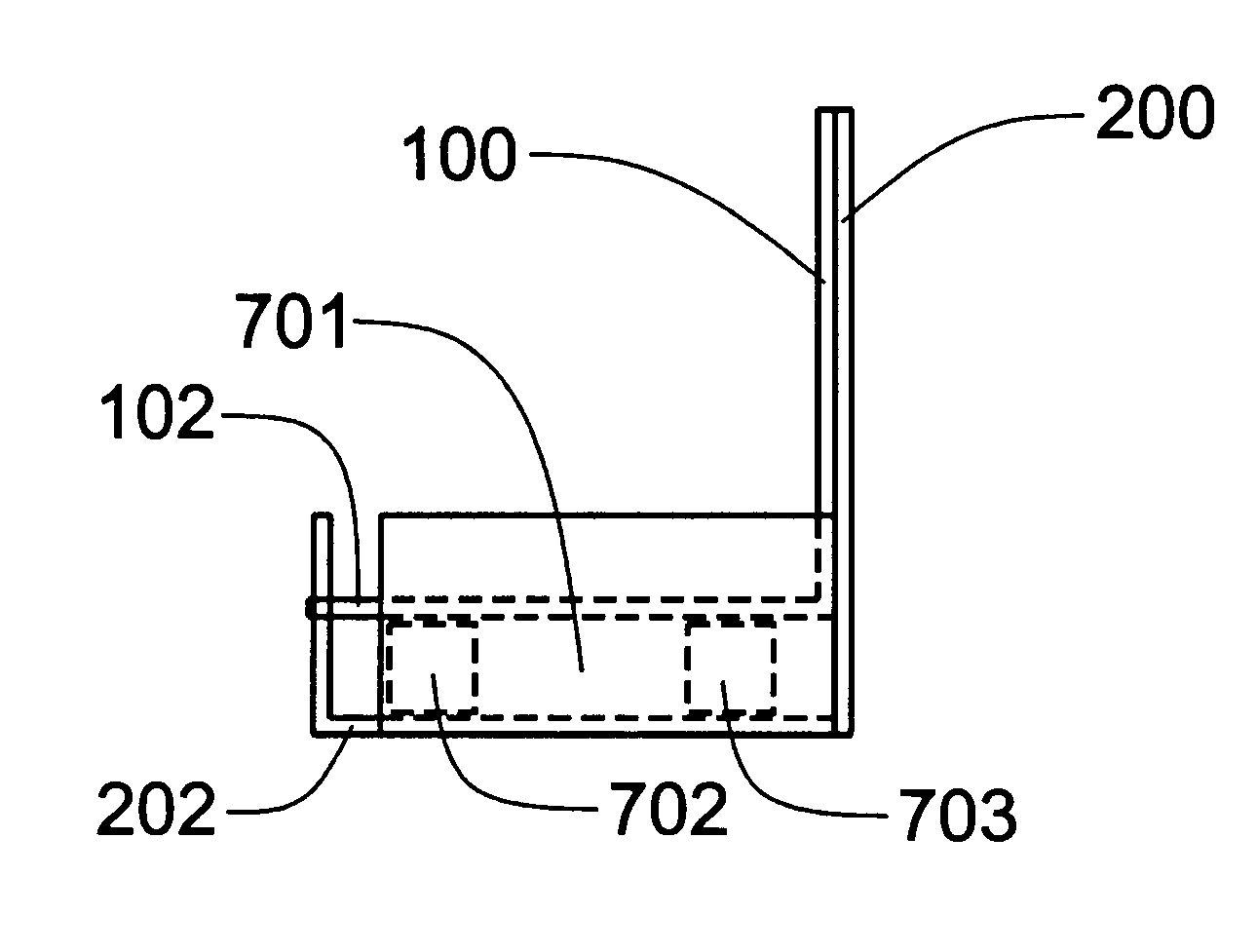

The disclosure relates to a method and an apparatus (10) for producing a packaging container for liquid foods from a packaging container blank (40) by permanently uniting and sealing at least two of its edges (61, 65) with the aid of a hot melt glue, the hot melt glue being applied along one of the two edges with the aid of a heated applicator roller (11). The circumferential surface (21) of the hot roller is preferably made of hardened steel with a coating (22) countersunk in a groove int he surface along the circumference of the circumferential surface, the coating possessing good slippage properties in relation to the hot melt glue and the coating being of a width which corresponds to the region intended for application. A counter roller (14) acts on the opposite side of the packaging laminate blank against the applicator roller for controlling the outflow of the applied hot melt glue strand. How melt glue is applied to the applicator roller by means of a heated nozzle (12) and the surplus which is not transferred to the packaging laminate blank is scrapped off from the applicator roller by means of a doctor blade (15). The hot melt glue is preferably an ethylene vinyl acetate based composition with a high melting point and high viscosity which is applied at least approx. 180° C.

Owner:TETRA LAVAL HLDG & FINANCE SA

Bracket assembly for mounting a reed switch and associated magnet

A bracket assembly for mounting a reed switch and associated magnet on an overhead opening door includes first and second interlocking pieces, both of which are stamped from sheet metal that is, preferably, non-ferromagnetic. Each of the pieces incorporates an opening sized to slidably receive a locking door bolt fabricated from a ferromagnetic material such as mild or hardened steel. For a currently preferred embodiment of the invention, both pieces of the bracket assembly are stamped from sheet aluminum. Both the reed switch and its associated magnet mount may mount on either piece, so long as they are on opposite sides of the opening. The assembly incorporates an opening that is sized to receive a slidable, locking bolt fabricated from a ferromagnetic material such as mild or hardened steel. When the bolt is withdrawn from the opening, the reed switch is activated, thereby generating a signal which can be input to a security system. For a preferred embodiment of the invention, both the reed switch and the magnet are adhesively bonded to the bracket assembly on opposite sides of the opening. The first and second pieces reversably snap together to form a box in which the reed switch and the magnet are enclosed. In order to install the bracket assembly on the rail of an overhead door track, screws or rivets are placed through both the first and second pieces and secured to the door track rail.

Owner:QUICK SWITCH ENTERPRISES

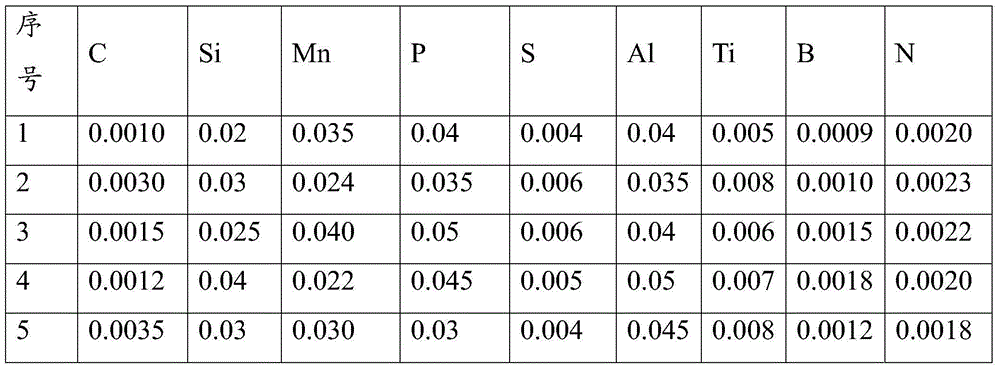

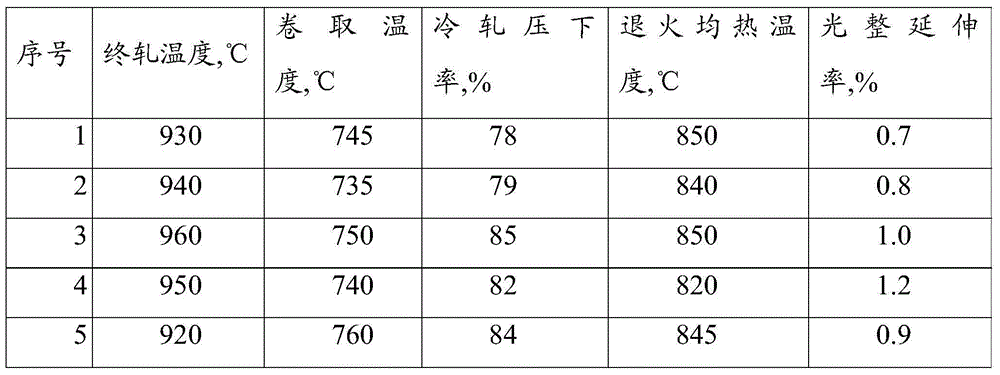

Niobium and titanium composite added ultra-low carbon baking hardening steel plate and manufacturing method thereof

The invention relates to an ultra-low-carbon roasting hardened steel sheet with composite addition of niobium and titanium and a manufacturing method thereof, which belong to the material processing technical field. The compositions in weight percent of the ultra-low-carbon roasting hardened steel sheet are 0.002 to 0.005 percent of carbon, less than or equal to 0.5 percent of silicon, 0.9 to 1.2 percent of manganese, 0.08 to 0.1 phosphor, less than or equal to 0.06 percent of sulfur, 0.02 to 0.05 percent of aluminum, less than or equal to 0.06 percent of nitrogen, 0.01 to 0.02 percent of titanium, 0.01 to 0.02 percent of niobium, and the balance being iron. The microalloy titanium in the steel is used for fixing the carbon, the nitrogen, the sulfur and the niobium in the steel and controlling the carbon, and simultaneously has the function of thinning crystal grains. The the ultra-low-carbon roasting hardened steel sheet has the advantages that the ultra-low-carbon roasting hardened steel sheet can simultaneously have high strength, r value, extensibility and BH value and good room temperature resistant timeliness after the required steel undergoes hot rolling, cold rolling and continuous annealing.

Owner:UNIV OF SCI & TECH BEIJING +1

Machining process of engine connecting rod

The invention discloses a machining technology of an engine connecting rod. The machining process comprises the following steps: forging, blank making and cutting, and taking high carbon non-hardened steel as a raw material; main procedures of the forging and blank making: blanking, heating, blank making, blocker forging, finish forging, trimming, punching, normalizing after shaping, and forced cooling in a forced cooling mode so as to reduce the temperature of a forging parts below 600 DEG C in 10min; cutting after defect detection and powerful shot blasting; the main procedures of the cutting: coarsely grinding or milling two end faces, roughly boring a big head pore and a small head pore, drilling and tapping a bolt hole, and cutting and machining a cracking tank on the big head pore of the connecting rod by cracking tank machining equipment; putting the connecting rod into the cracking equipment for breaking due to expansion, and assembling bolts; and finely grinding the sides of the connecting rod, finely boring the big pore and the small head pore, washing and checking. The technical proposal can help save time, reduce manufacturing procedures and improve assembly accuracy of the connecting rod.

Owner:ZHEJIANG YUEJIN MACHINERY

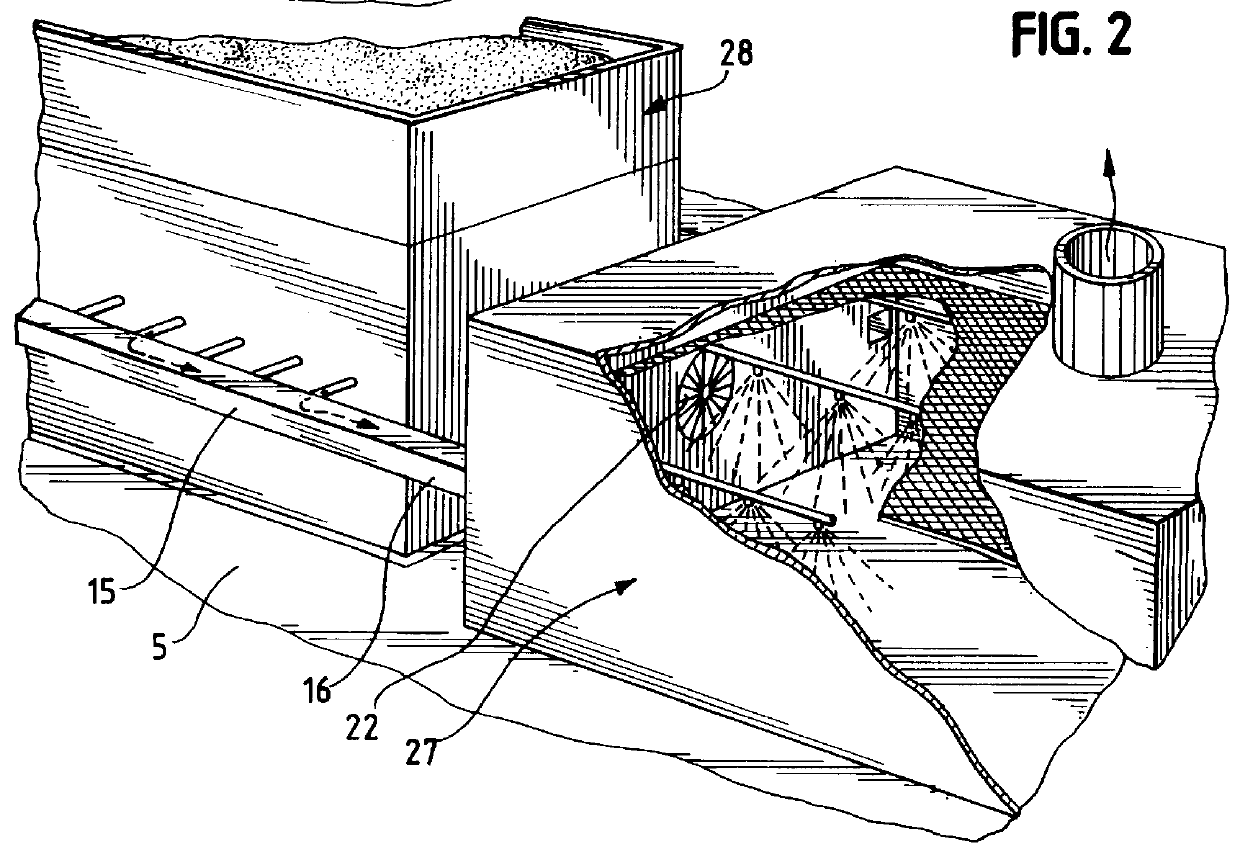

Method and apparatus for containing and suppressing explosive detonations

[A method and apparatus for enclosing, controlling and suppressing the detonation of explosives in an explosion chamber is disclosed. The device comprises an elongate double-walled steel explosion chamber anchored to a concrete foundation, and having a double-walled access door for charging new workpieces, and a double-walled vent door for discharging the products of the explosion. The double walls of the chamber, access door and vent door are filled with granular shock damping material such as silica sand, and the floor of the chamber is covered with granular shock-damping bed such as pea gravel. Along the outside of the chamber are steel manifolds from which a linear array of vent pipes penetrates the double walls of the chamber, with each pipe terminating in a hardened steel orifice through which the explosion combustion products pass. Within the chamber, plastic polymer film bags containing water are suspended from steel wires over the explosive material, and at each end of the chamber.] A method and apparatus for containing and suppressing the detonation of explosives utilizing a sealable double-walled chamber having a floor, an access door and a vent door. The chamber walls are filled, and the floor is covered, with granular shock-damping material. Orificed vent pipes penetrate the chamber walls to vent explosion products into one or more exhaust manifolds. Water-filled bags are positioned around the explosive to absorb energy from the detonation.

Owner:ABC NACO +2

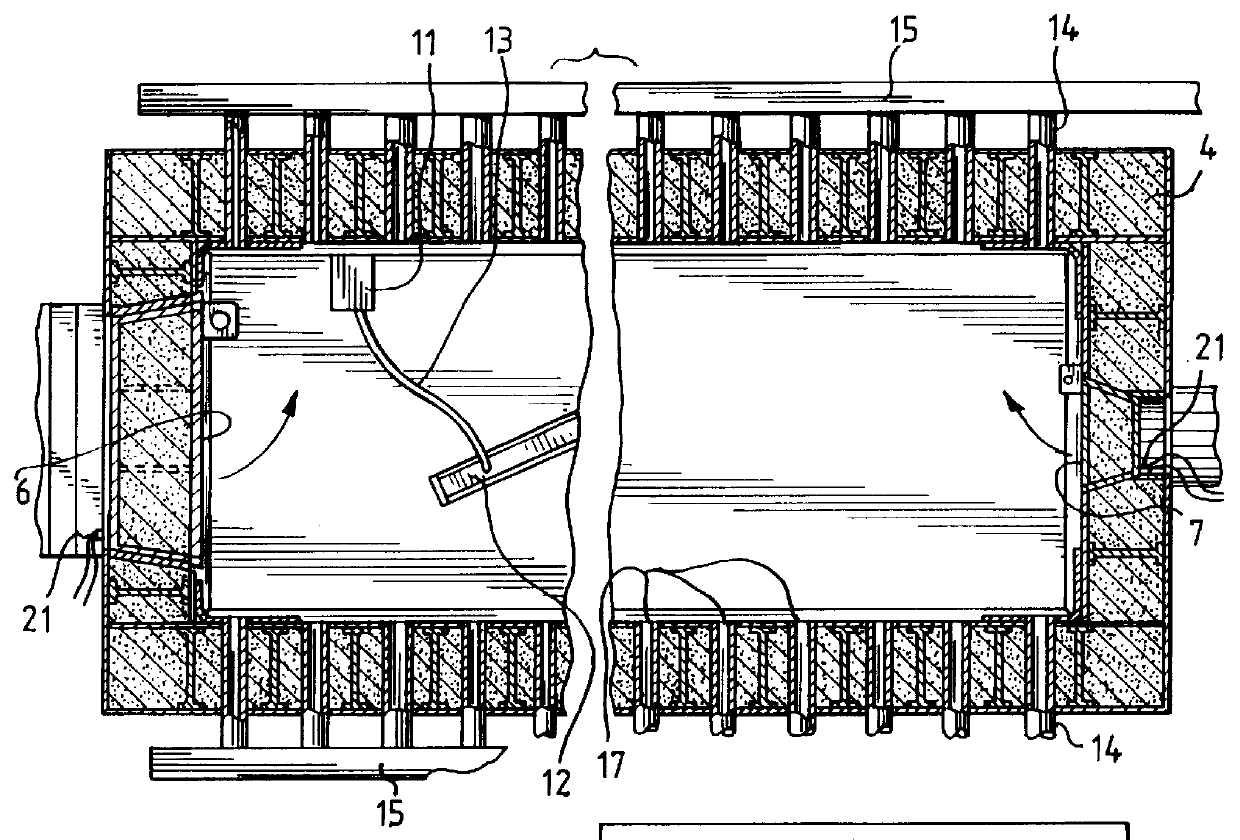

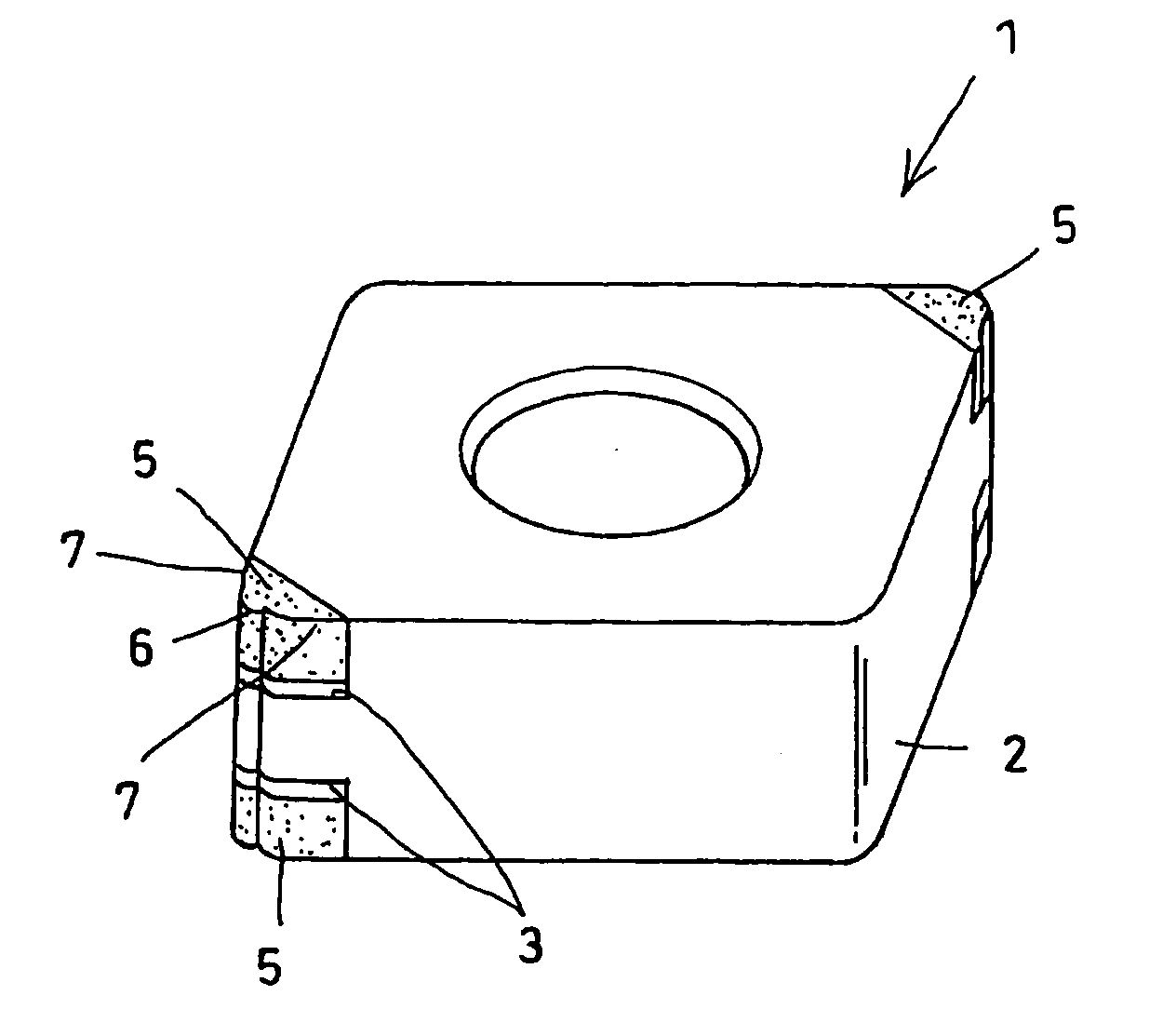

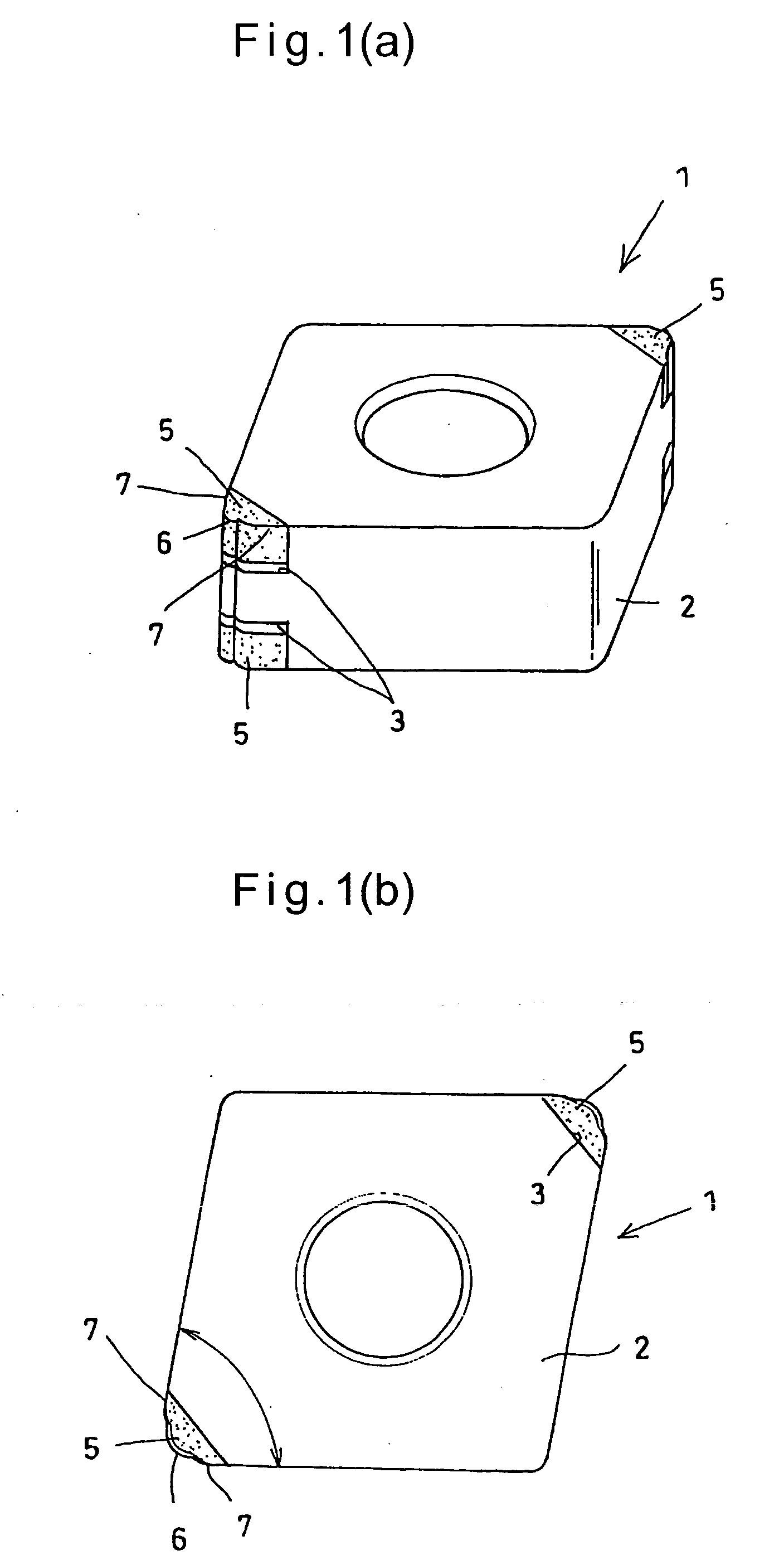

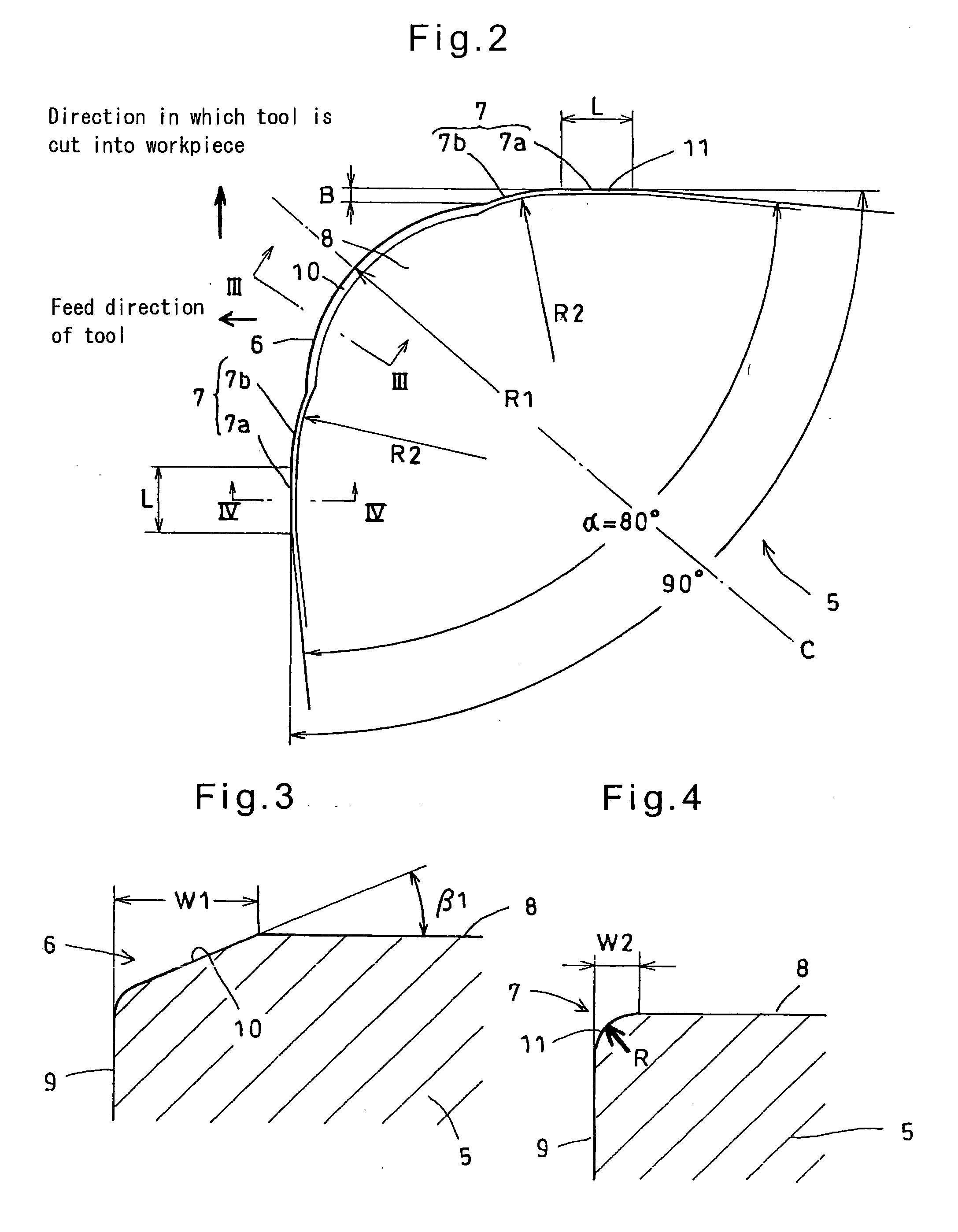

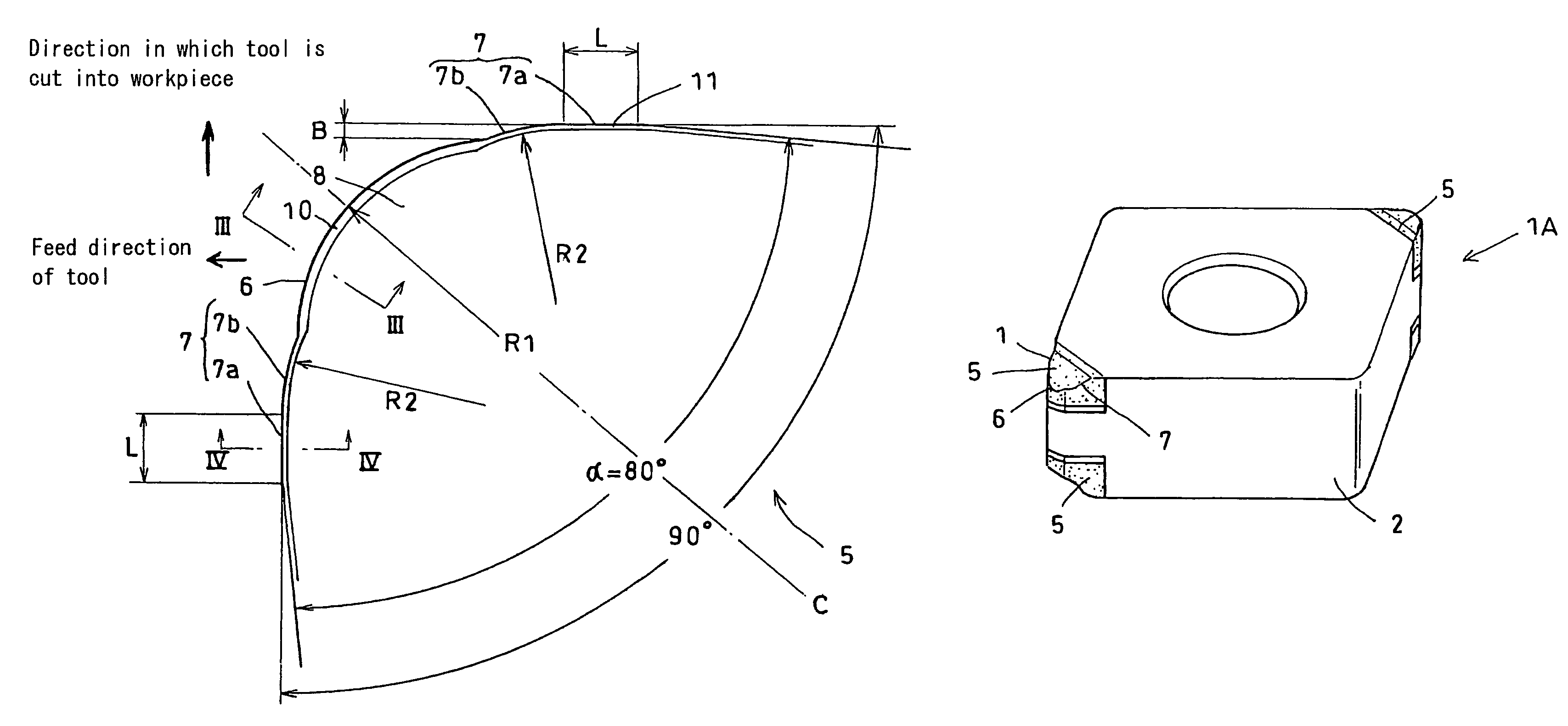

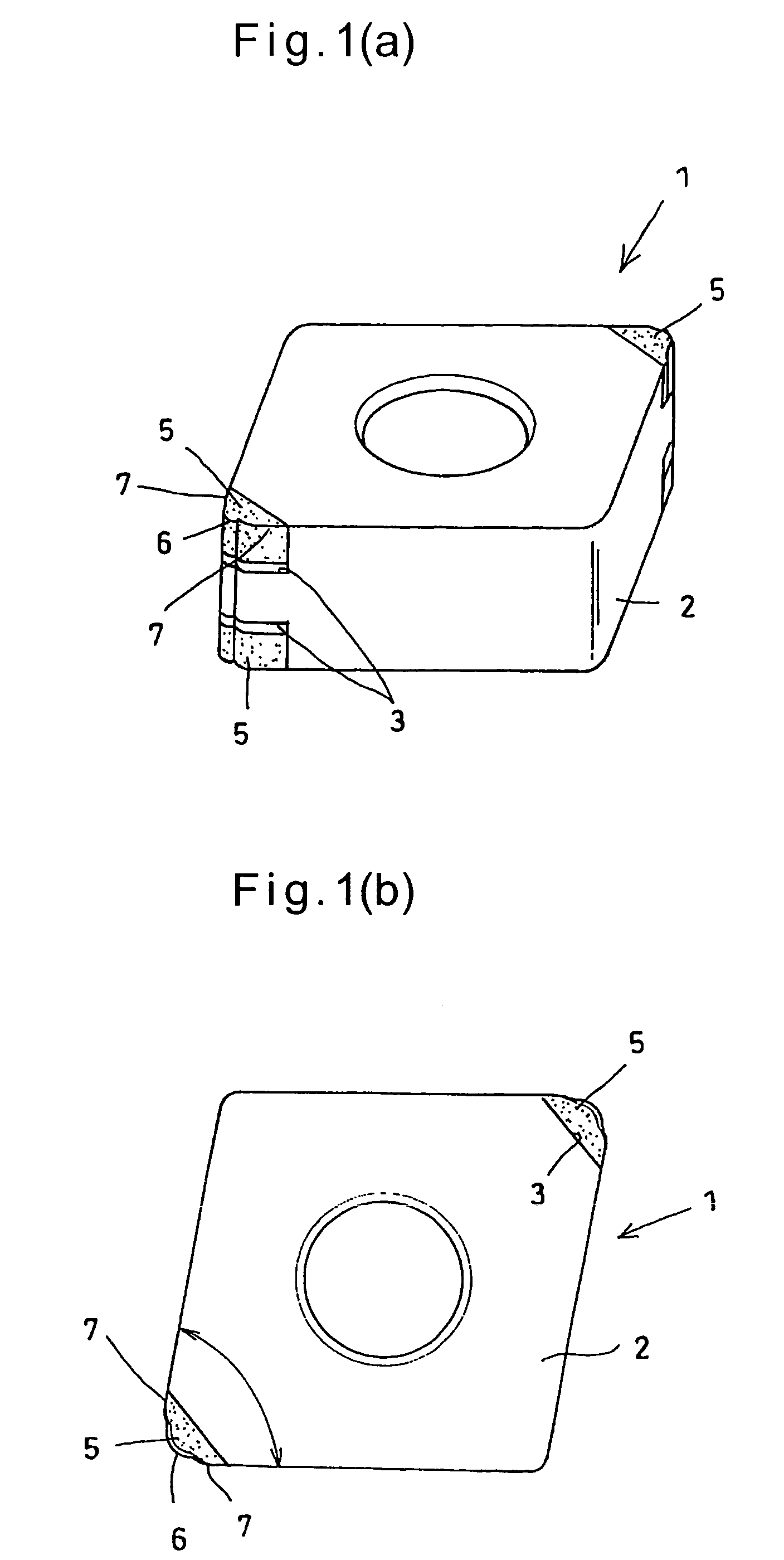

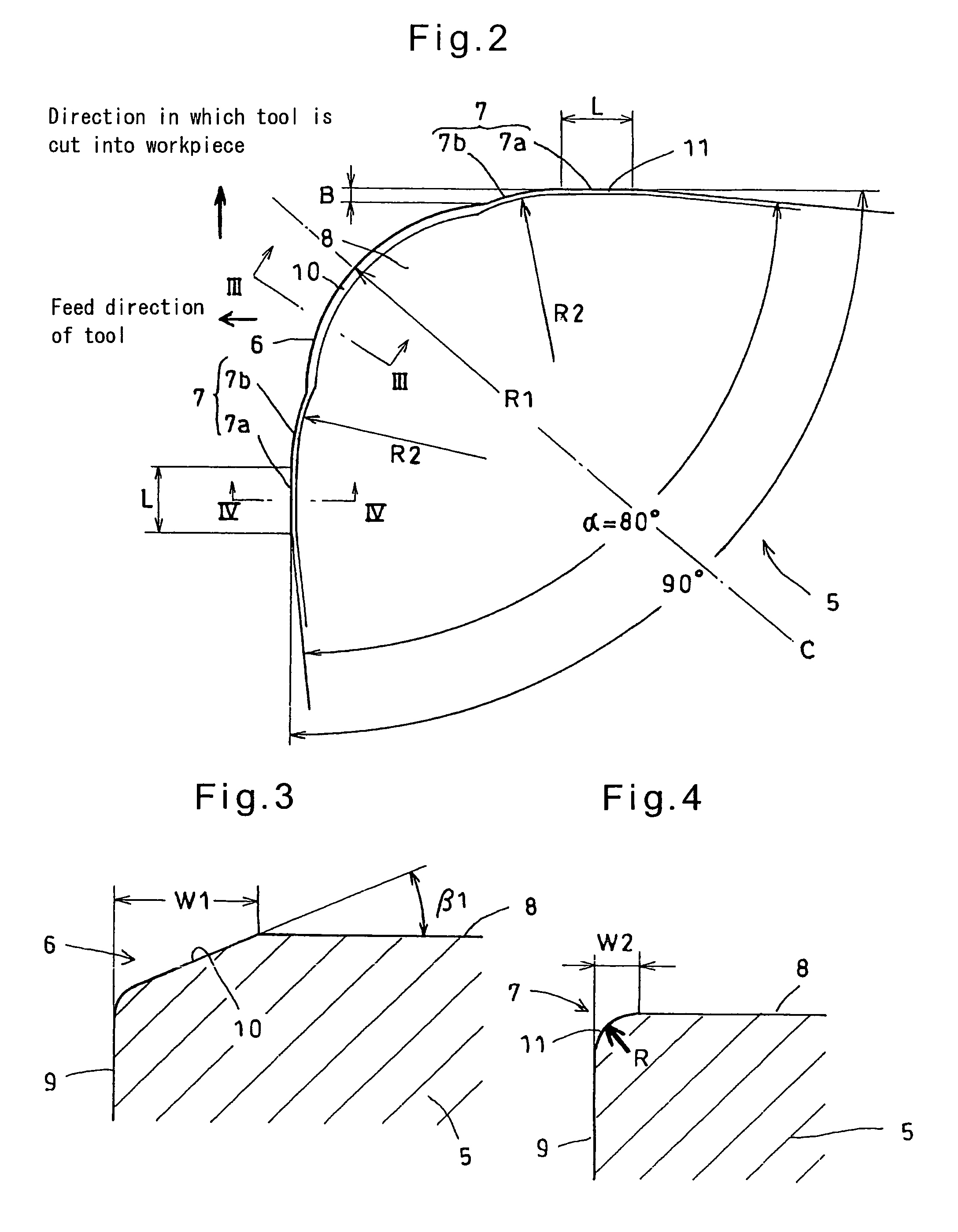

Cutting Tool for High-Quality High-Efficiency Machining and Cutting Method Using the Same

ActiveUS20080292415A1Improve machine efficiencyLarge widthTool workpiece connectionCutting insertsHardened steelEngineering

It is an object to provide a cutting tool which can perform high-quality, high-efficiency machining of a workpiece such as hardened steel.The cutting tool includes a finishing cutting edge 6 which initially cuts into the workpiece, and superfinishing cutting edges 7 for finishing the workpiece cut by the finishing cutting edge. The superfinishing cutting edges 7 project from the finishing cutting edge by a predetermined amount B in such a direction that the depth of cut of the superfinishing cutting edges increases. Each superfinishing cutting edge includes a burnishing portion 7a having a predetermined width L in the feed direction of the tool, and a wiper portion 7b. The superfinishing cutting edges 7 burnish the finished surface formed by the finishing cutting edge, while removing a affected layer formed by the finishing cutting edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

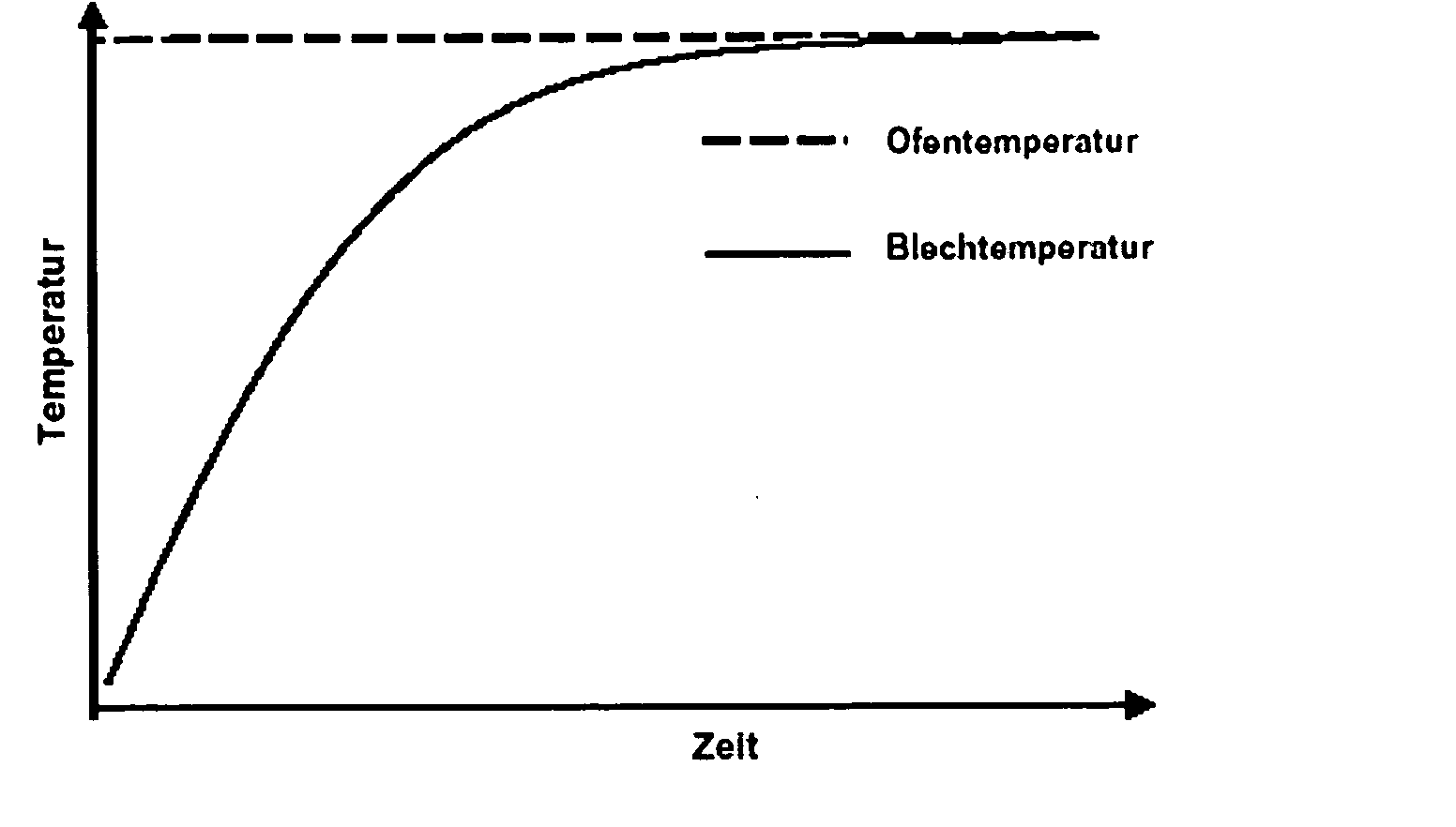

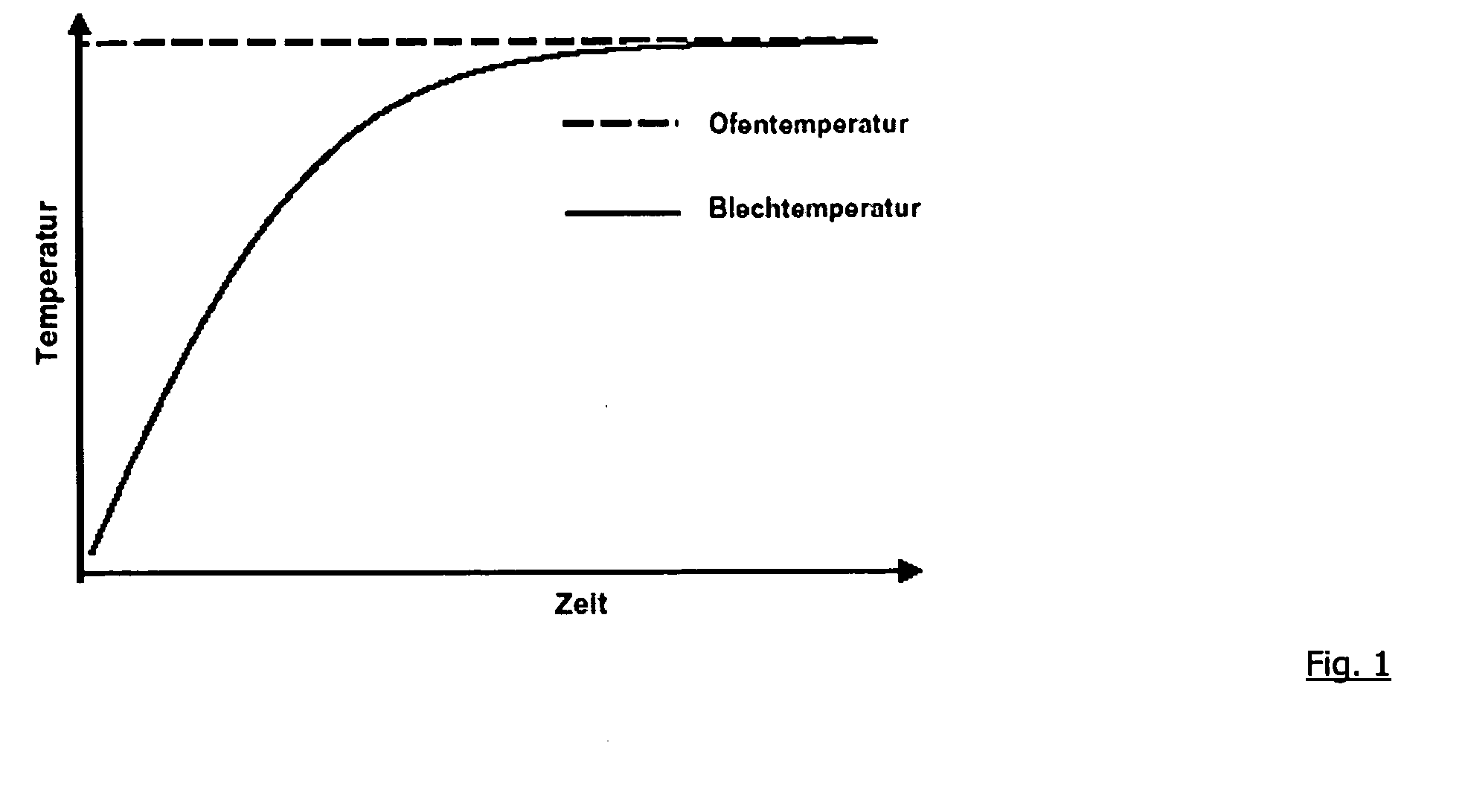

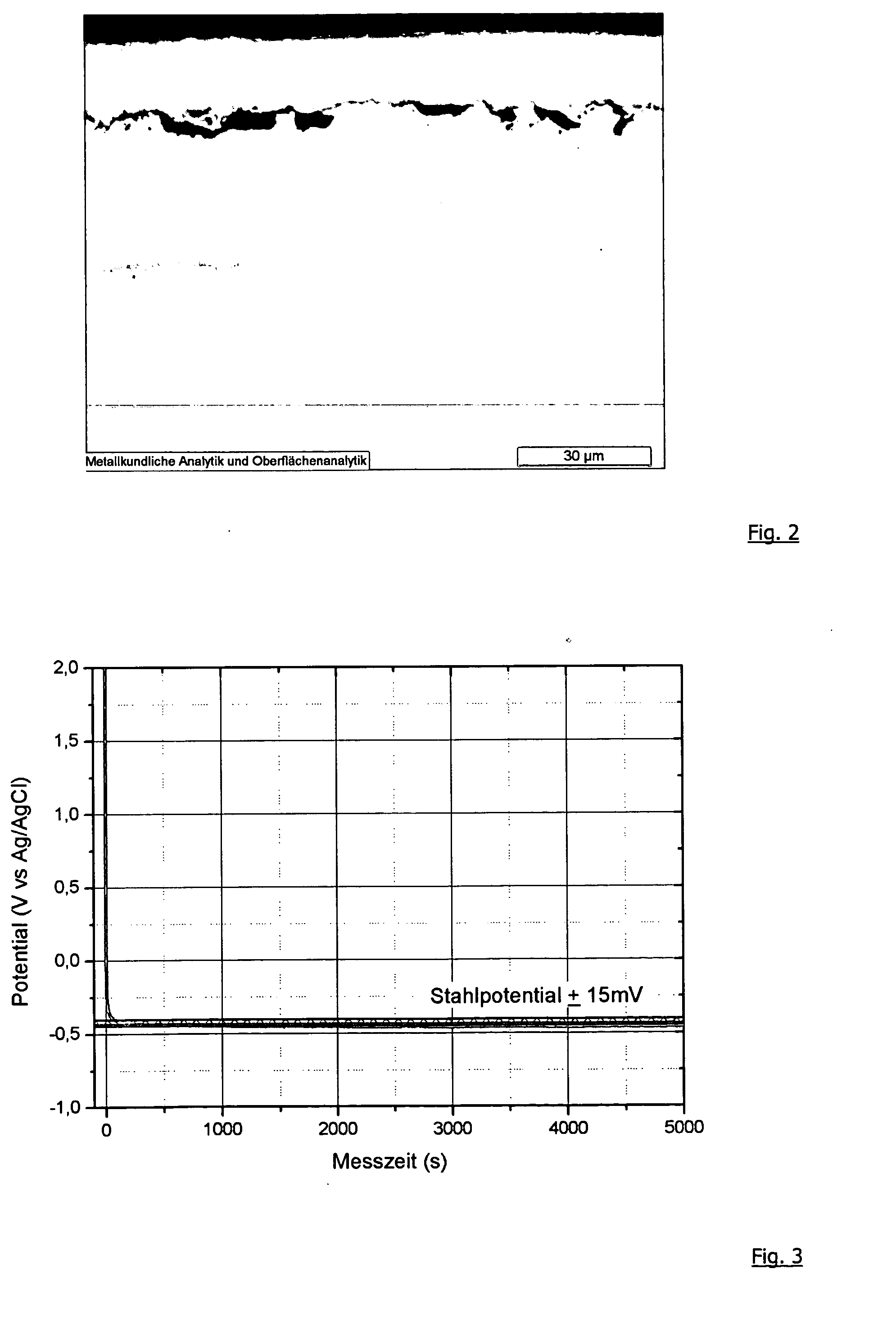

Method for Producing a Hardened Steel Part

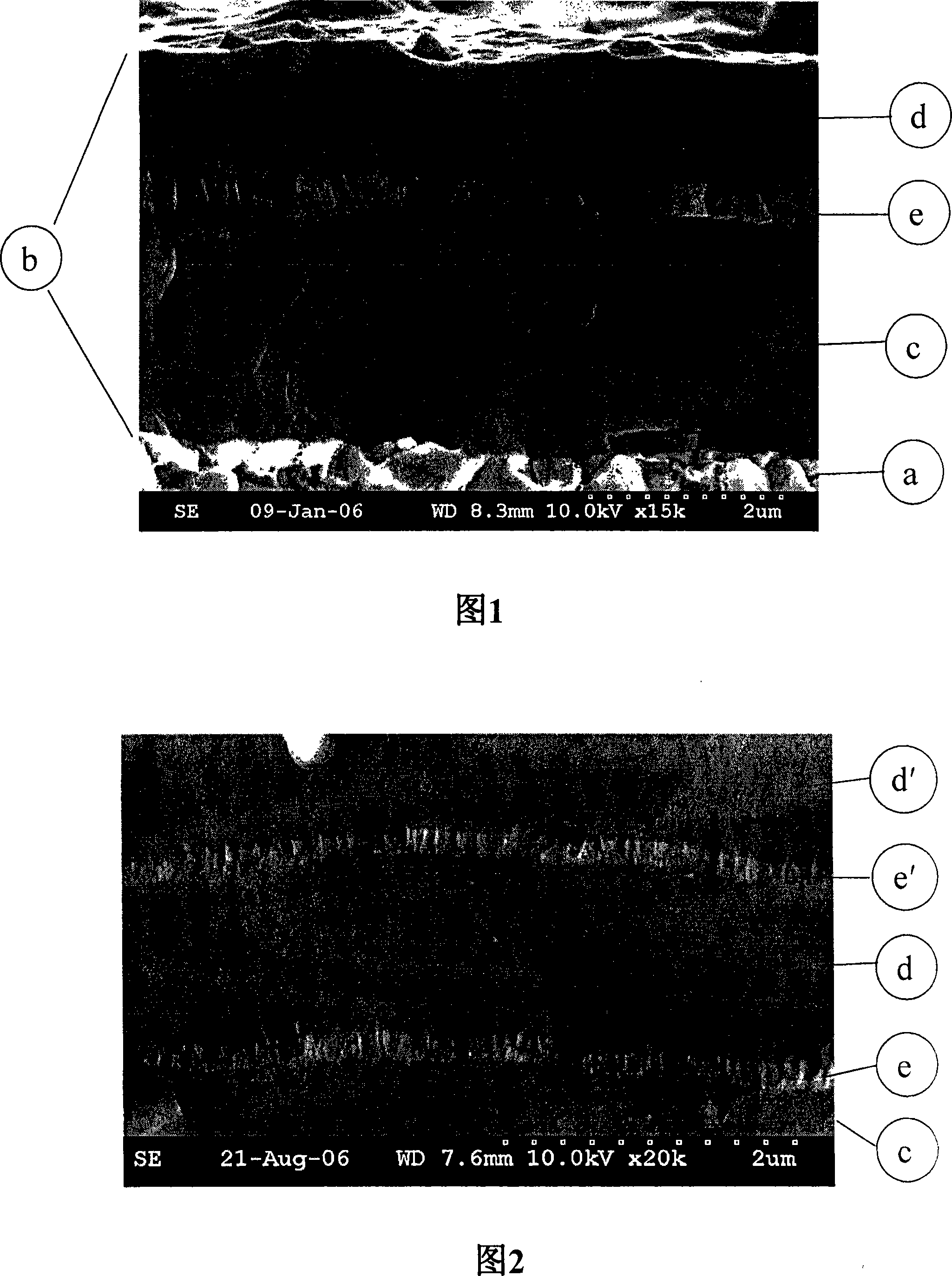

ActiveUS20070256808A1Surprising effectEfficient productionHot-dipping/immersion processesFoundry mouldsAlloyProtection layer

The invention relates to a method for producing a hardened steel part having a cathodic corrosion protection, whereby a) a coating is applied to a sheet made of a hardenable steel alloy in a continuous coating process; b) the coating is essentially comprised of zinc; c) the coating additionally contains one or more oxygen-affine elements in a total amount of 0.1% by weight to 15% by weight with regard to the entire coating; d) the coated steel sheet is then, at least in partial areas and with the admission of atmospheric oxygen, brought to a temperature necessary for hardening and is heated until it undergoes a microstructural change necessary for hardening, whereby; e) a superficial skin is formed on the coating from an oxide of the oxygen-affine element(s), and; f) the sheet is shaped before or after heating, and; g) the sheet is cooled after sufficient heating, whereby the cooling rate is calculated in order to achieve a hardening of the sheet alloy. The invention also relates to a corrosion protection layer for the hardened steel part and to the steel part itself.

Owner:VOESTALPINE STAHL GMBH

Cutting tool for high-quality high-efficiency machining and cutting method using the same

It is an object to provide a cutting tool which can perform high-quality, high-efficiency machining of a workpiece such as hardened steel.The cutting tool includes a finishing cutting edge 6 which initially cuts into the workpiece, and superfinishing cutting edges 7 for finishing the workpiece cut by the finishing cutting edge. The superfinishing cutting edges 7 project from the finishing cutting edge by a predetermined amount B in such a direction that the depth of cut of the superfinishing cutting edges increases. Each superfinishing cutting edge includes a burnishing portion 7a having a predetermined width L in the feed direction of the tool, and a wiper portion 7b. The superfinishing cutting edges 7 burnish the finished surface formed by the finishing cutting edge, while removing a affected layer formed by the finishing cutting edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

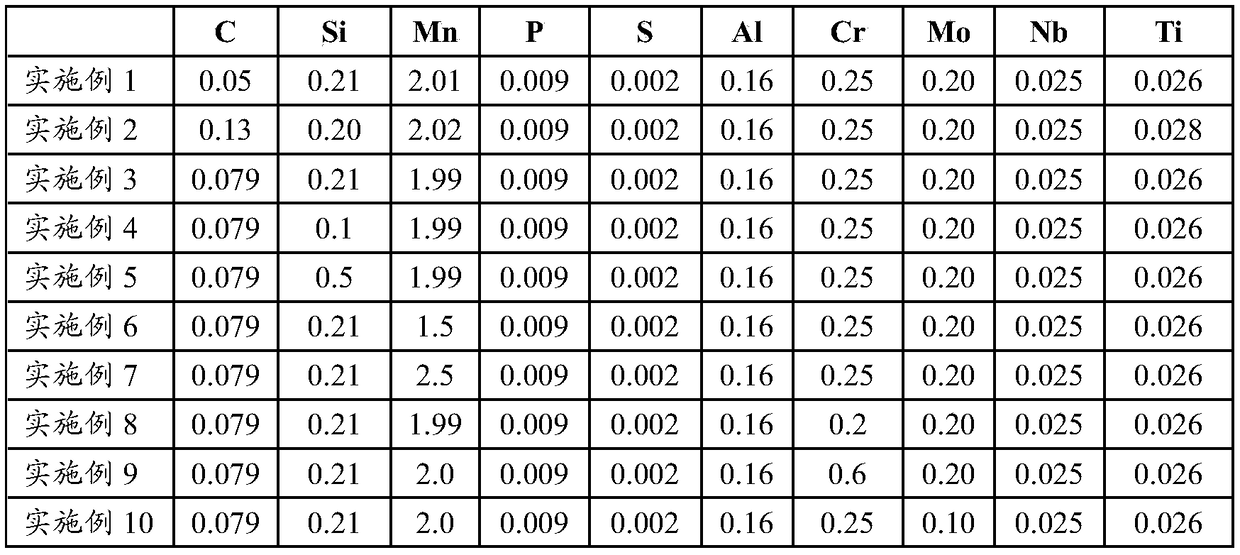

Cold-rolled hot-galvanized complex phase steel and preparation method thereof

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Owner:SHOUGANG CORPORATION

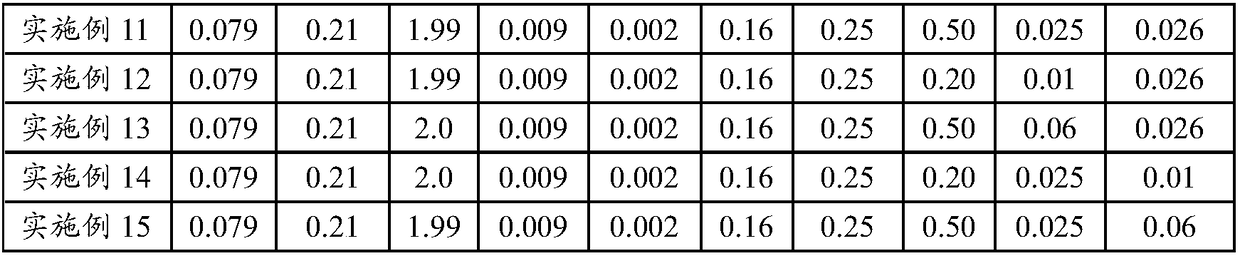

Dynamic seal with soft interface

Owner:SMITH INT INC

High strength weldable ageing hardening steel and its production method

A weldable high-strength steel hardened by ageing contains proportionally C, Si, Mn, P, S, Nb, Mo, Ni, Ti, Cu, Cr and Fe. Its preparing process includes smelting, desulfurizing, top blowing, converting, vacuum treating, casting and rolling. Its advantages are excellent mechanical performance and low-temp toughness, and high resistance to atmosphere and seawater corrosion and fatigue.

Owner:武钢集团有限公司

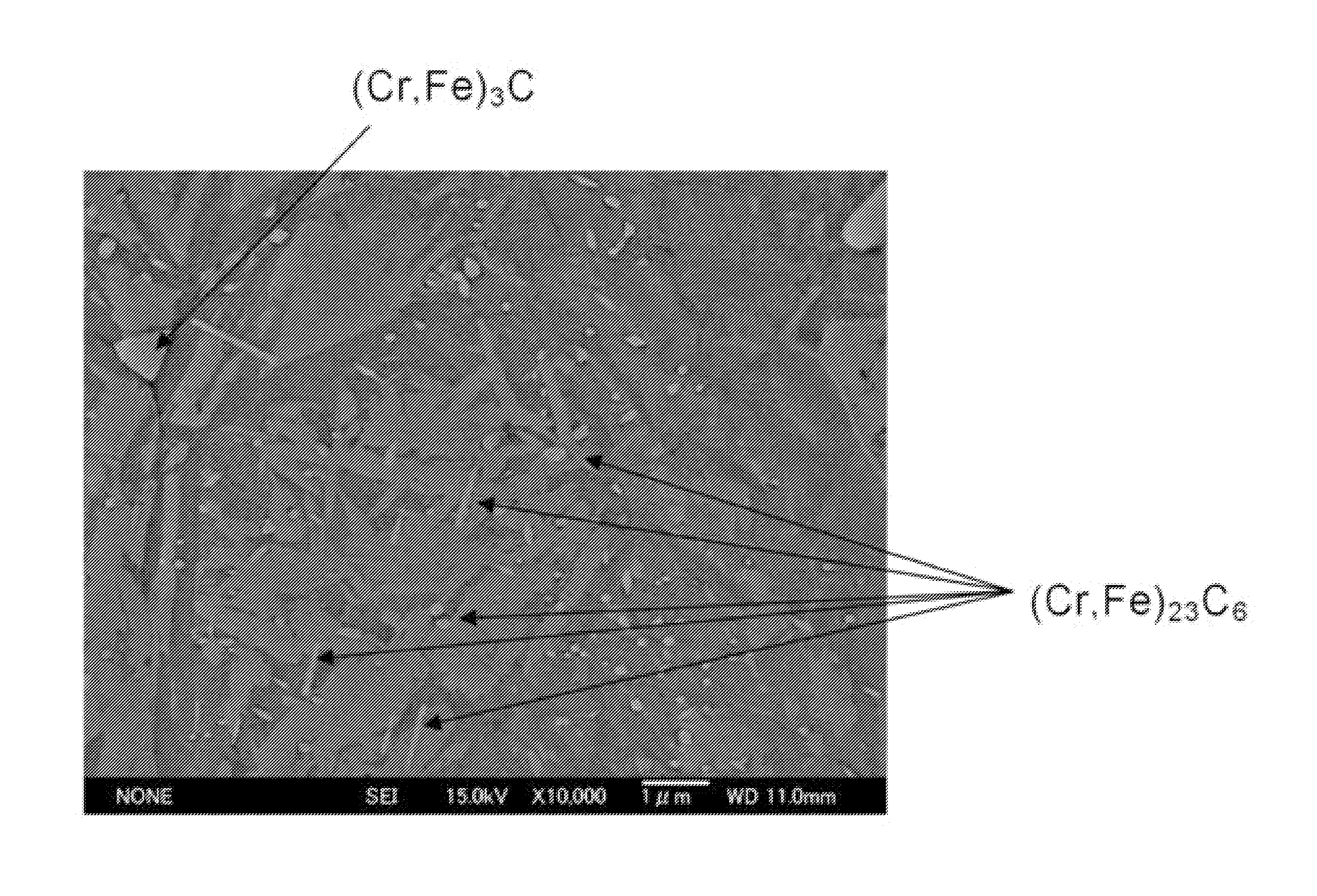

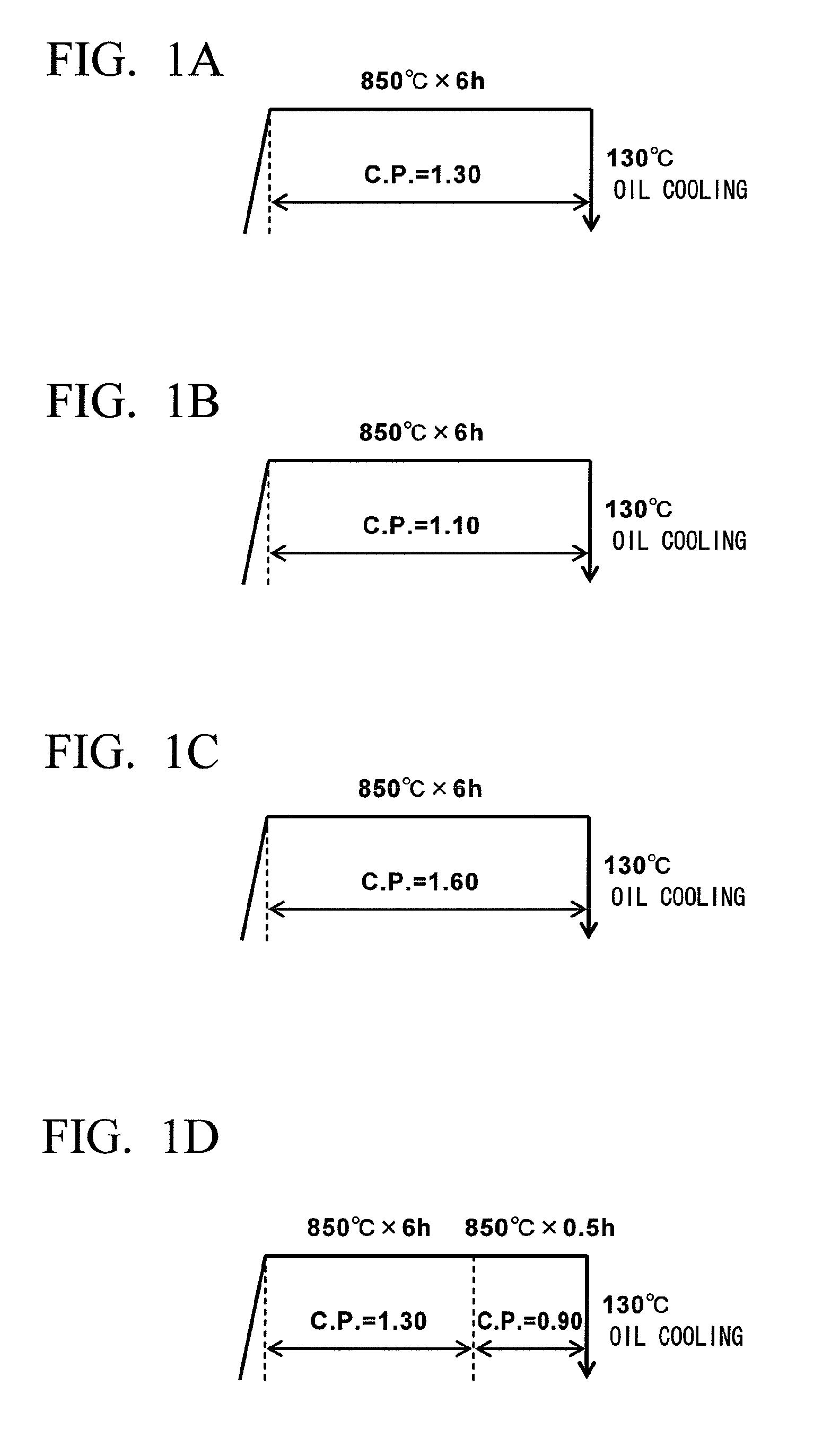

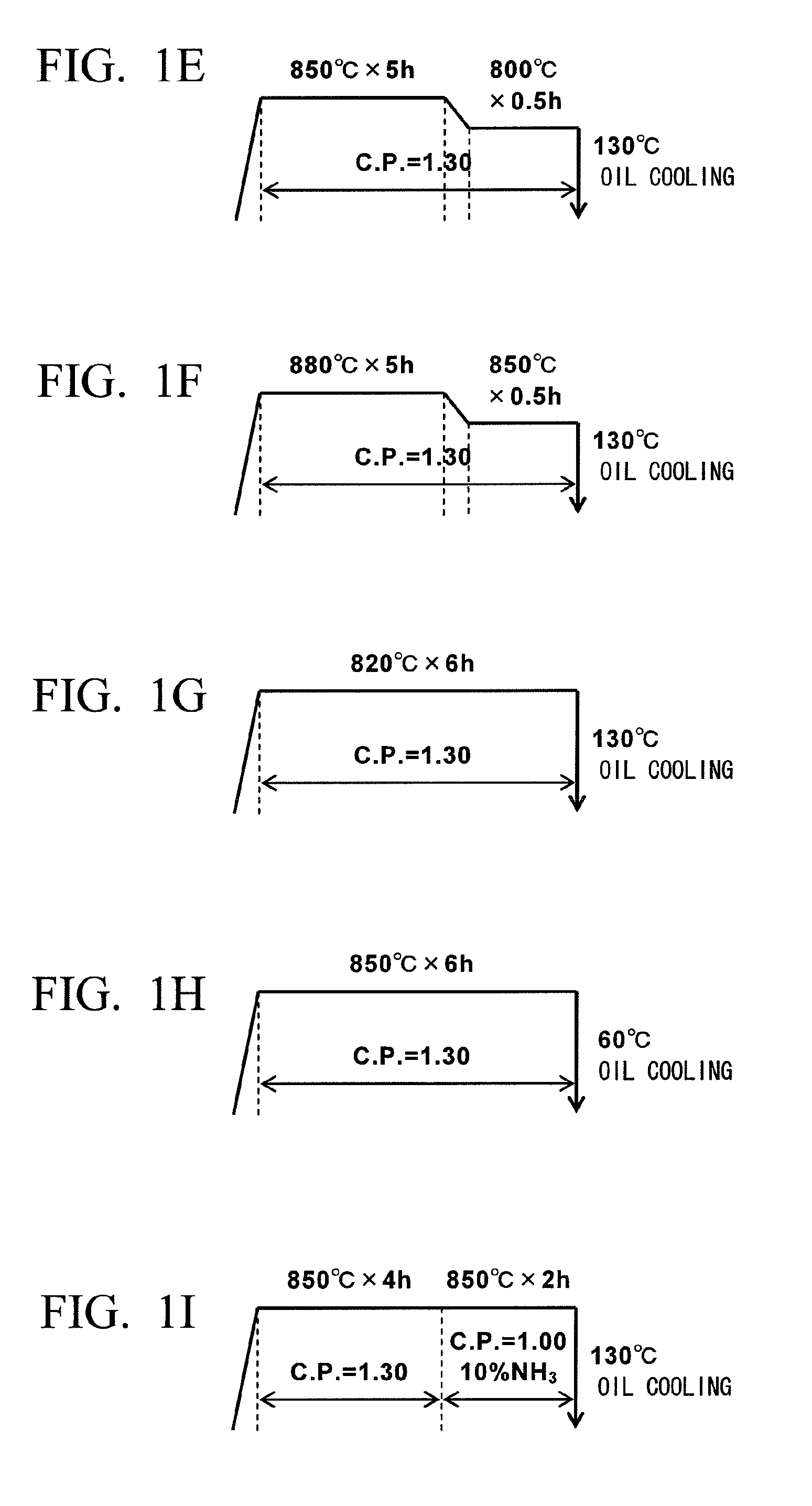

Steel for surface layer hardening treatment, surface layer-hardened steel part, and method of manufacturing the same

InactiveUS20120018050A1High tooth surface fatigue strengthEasy to shapeV-beltsSolid state diffusion coatingSurface layerChemical composition

In the steel for a surface layer hardening which is treated with carburizing in a temperature range of 800° C. to 900° C., chemical composition thereof contains, by mass %, C: 0.10% to 0.60%, Si: 0.01% to 2.50%, Mn: 0.20% to 2.00%, S: 0.0001% to 0.10%, Cr: 2.00% to 5.00%, Al: 0.001% to 0.50%, N: 0.0020% to 0.020%, P: 0.001% to 0.050%, and O: 0.0001% to 0.0030%; the remaining portion thereof includes Fe and unavoidable impurities; and the total amount of Cr, Si, and Mn satisfies, by mass %, 2.0≦Cr+Si+Mn≦8.0.

Owner:NIPPON STEEL CORP

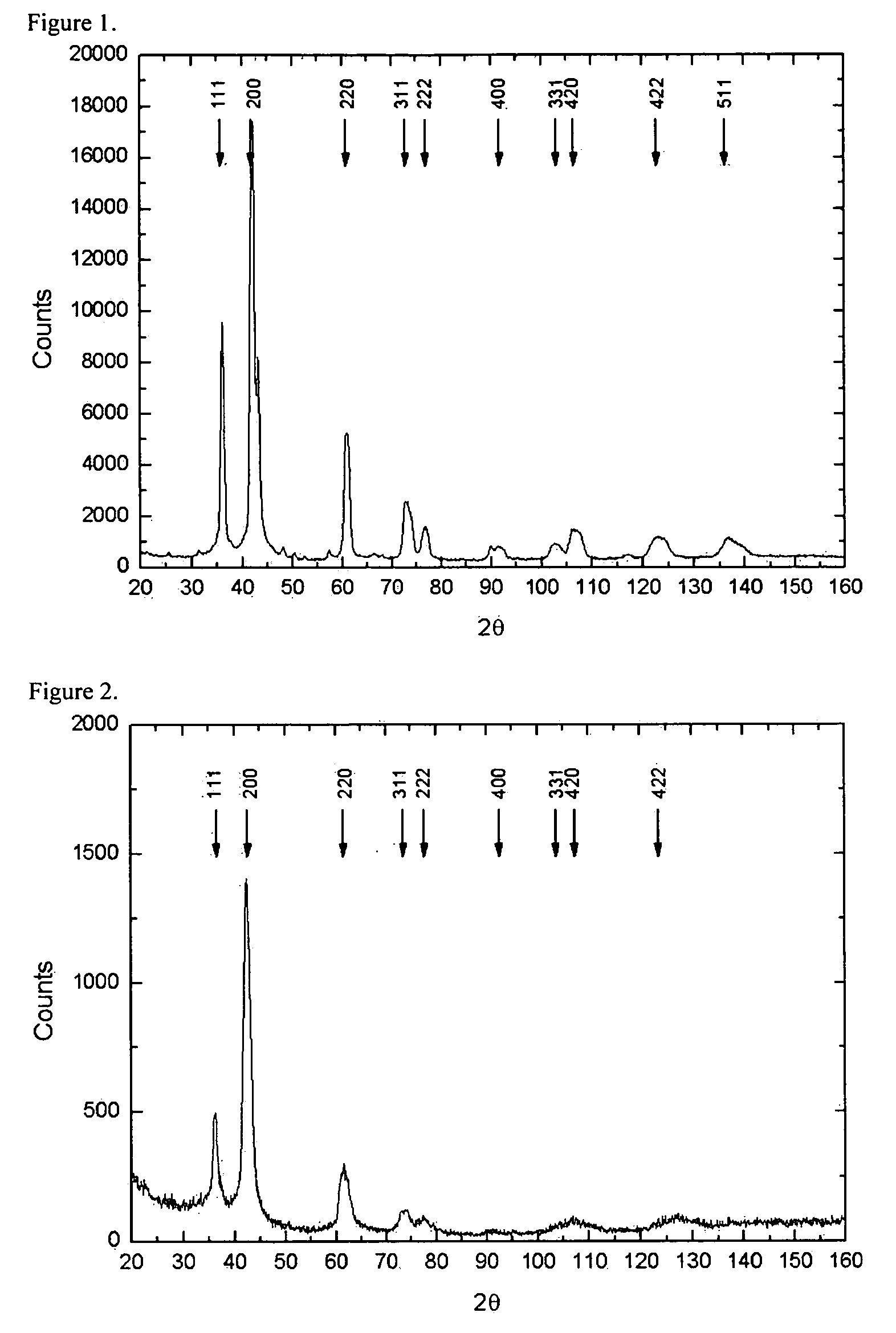

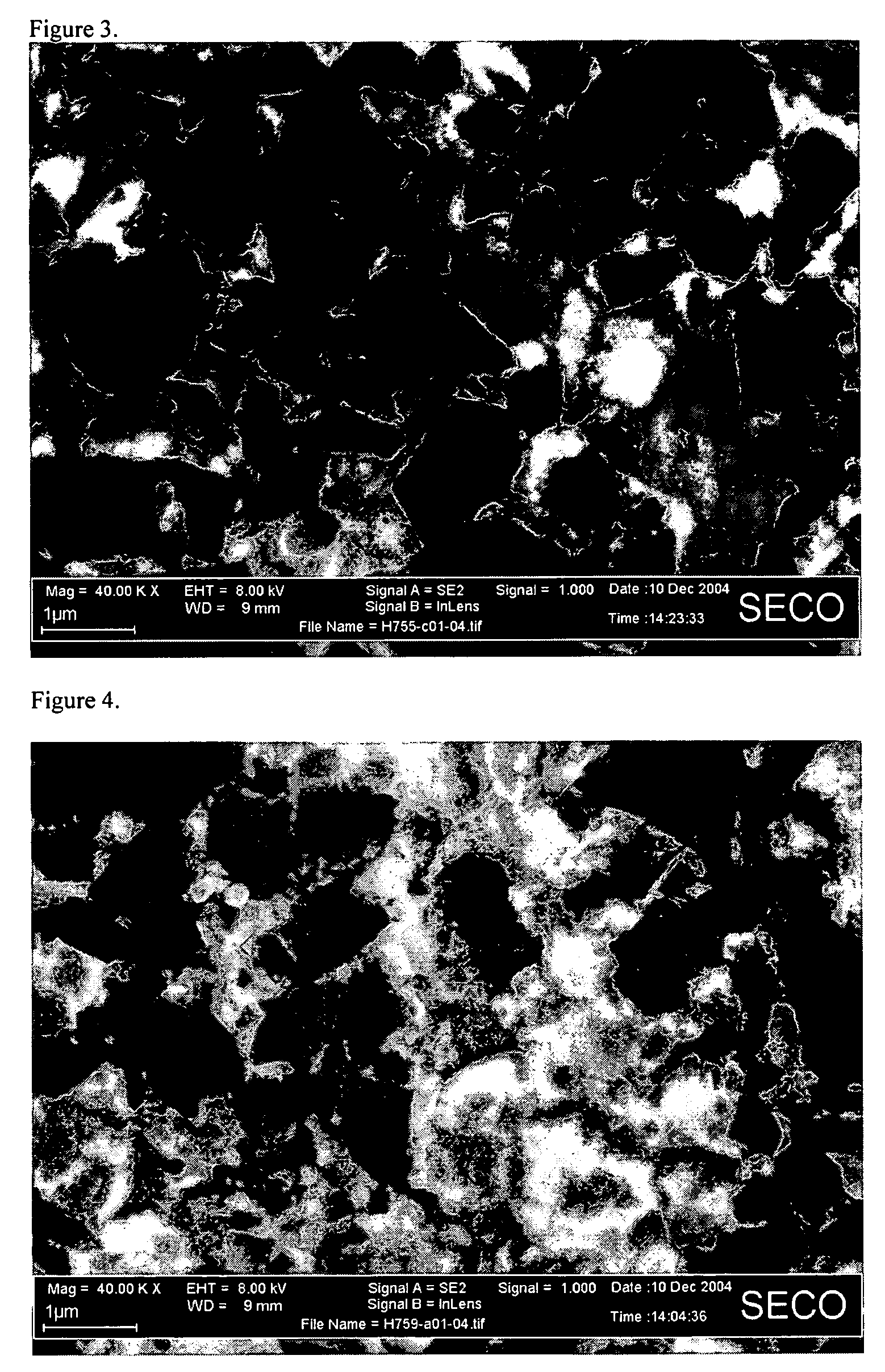

PVD-coated cutting tool insert

InactiveUS6884497B2Improve performanceImproved propertyPigmenting treatmentMilling cuttersAlloyCemented carbide

A coated cemented carbide insert (cutting tool), particularly useful for milling at high cutting speeds in alloyed steels, tool steels and milling in hardened steels includes a WC-Co cemented carbide containing NbC and TaC and a W-alloyed binder phase, and a coating including an inner layer of TixAlyN, 0.8<x+y<1.2, with 0.25<x / y<1.45, with columnar grains.

Owner:SECO TOOLS AB

Hot-dip galvanized ultra-low carbon bake-hardening steel and production method thereof

The invention discloses hot-dip galvanized ultra-low carbon bake-hardening steel. The hot-dip galvanized ultra-low carbon bake-hardening steel comprises the following chemical components in percentage by mass: 0.001-0.005% of C, 0-0.12% of Si, 0-1.0% of Mn, 0-0.50% of P, 0.01-0.30% of Al, 0.004-0.01% of Ti, 0.0003-0.0040% of B, less than or equal to 0.010% of S and less than or equal to 0.01% of S as limiting elements and the balance of Fe and unavoidable impurities. The invention also discloses a production method of the hot-dip galvanized ultra-low carbon bake-hardening steel. According to the hot-dip galvanized ultra-low carbon bake-hardening steel and the production method thereof which are disclosed by the invention, by adding the B element and reasonably controlling key alloying elements such as C, Mn, P and Ti and hot-rolling, cold-rolling and hot-dip galvanizing processes, the hot-dip galvanized ultra-low carbon bake-hardening steel which has the advantages of secondary processing embrittlement resistance and excellent comprehensive mechanical properties is produced, the requirements of high-end car users are met and considerable economic benefits are brought.

Owner:SHOUGANG CORPORATION

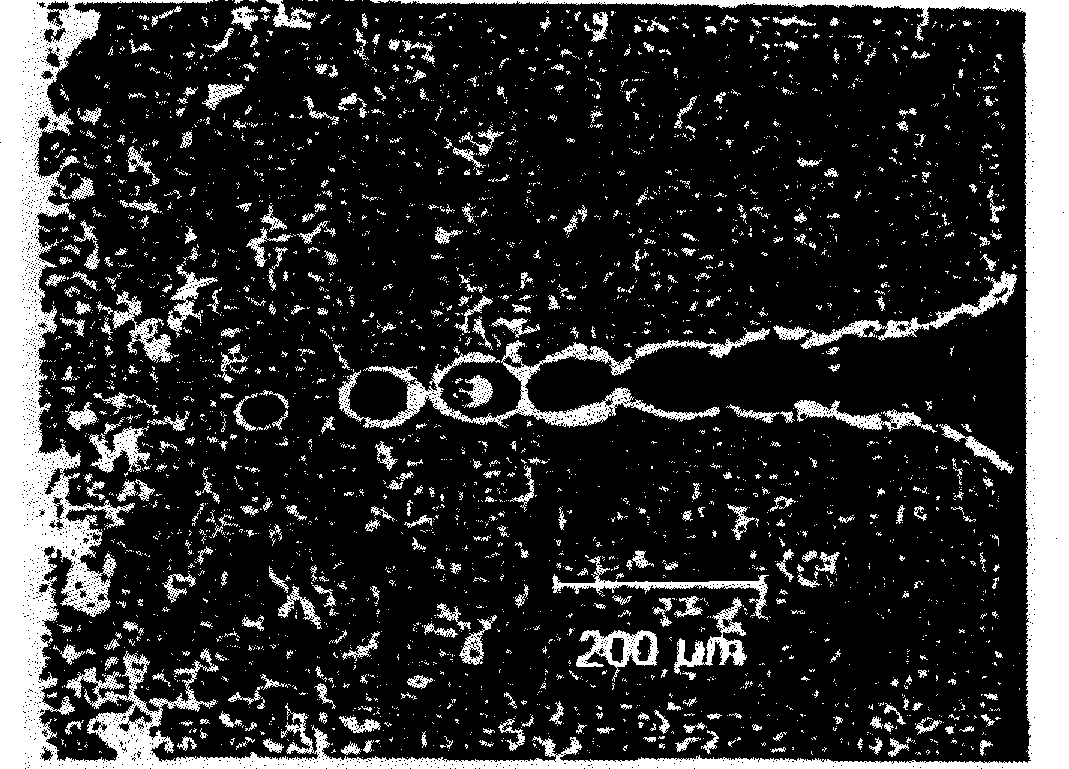

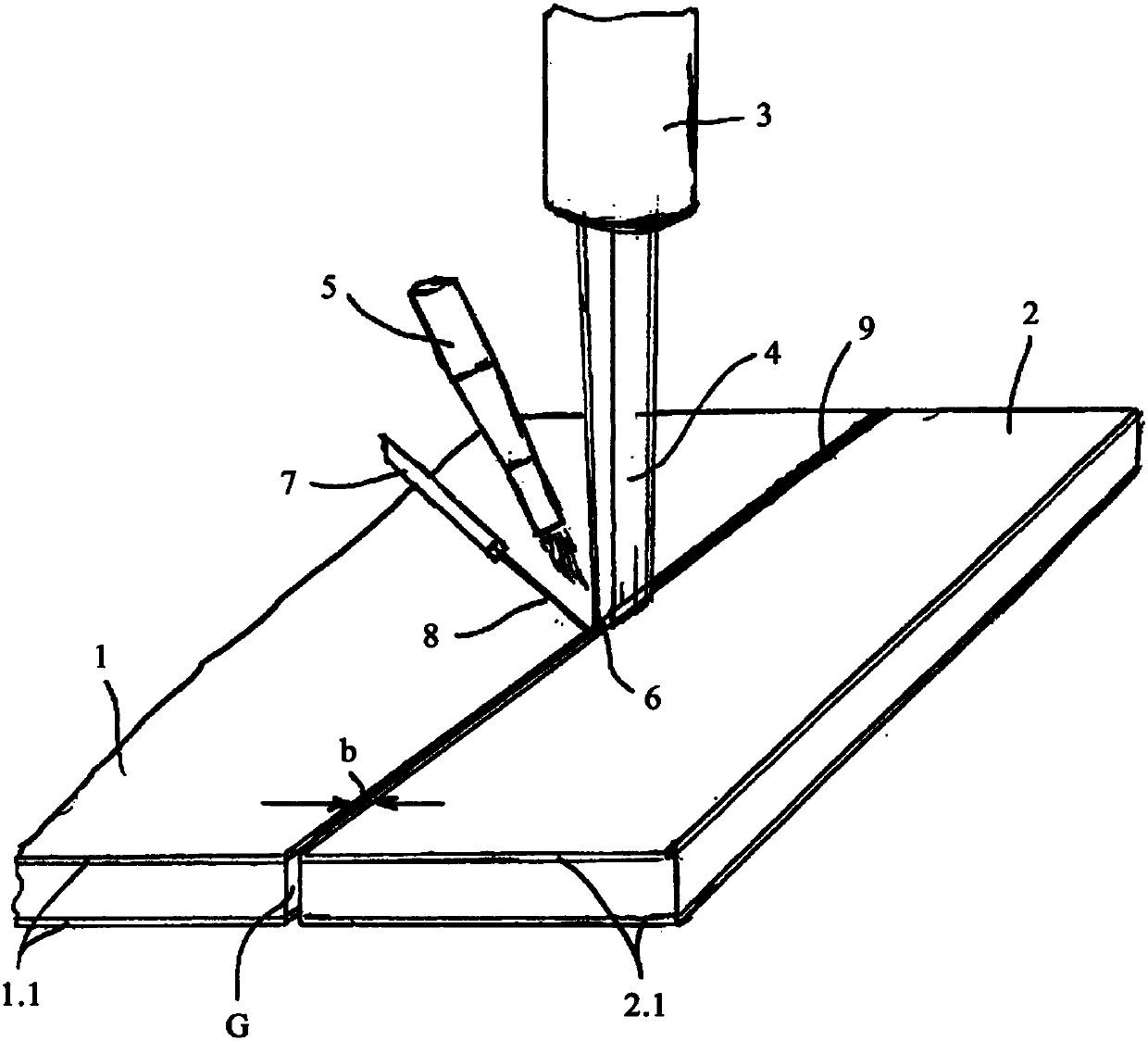

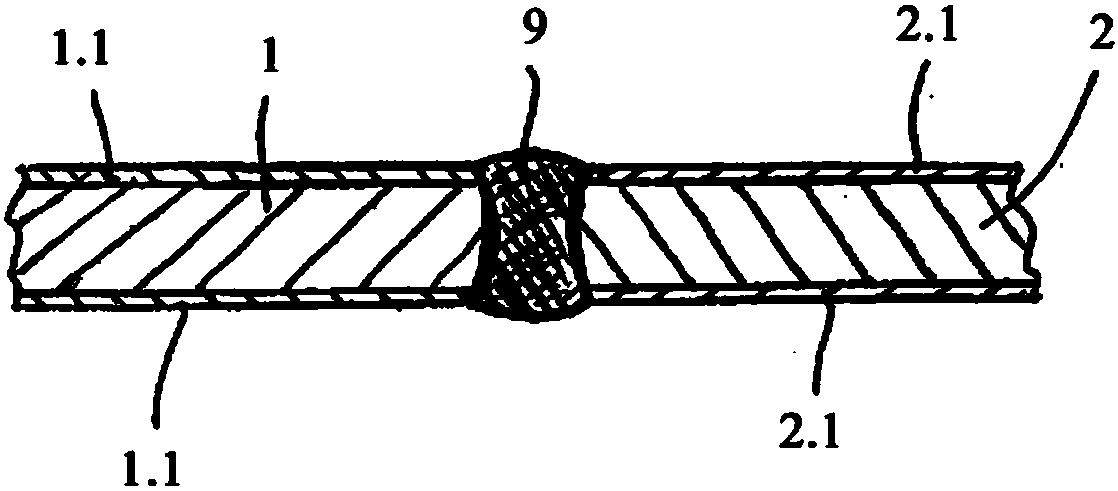

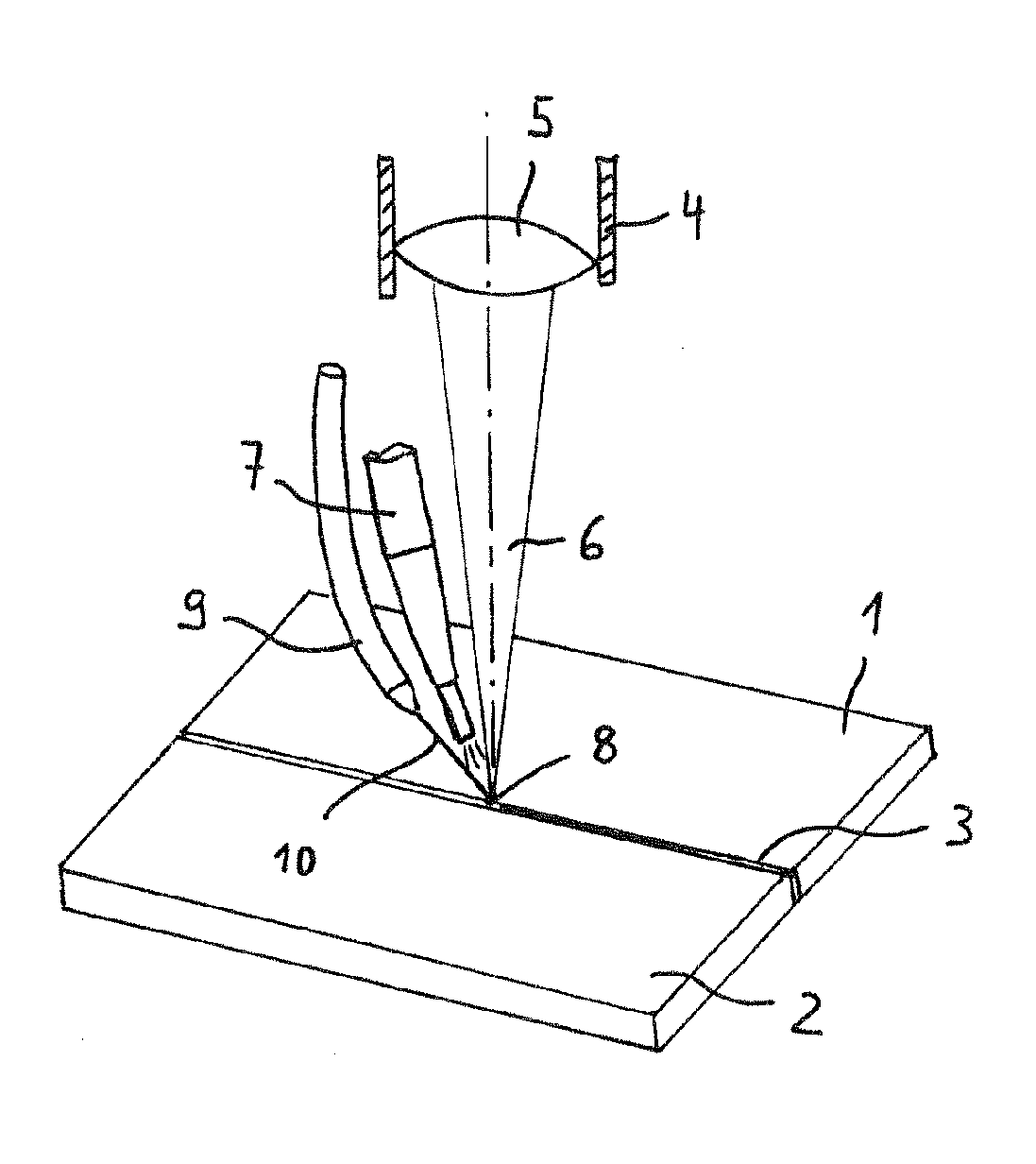

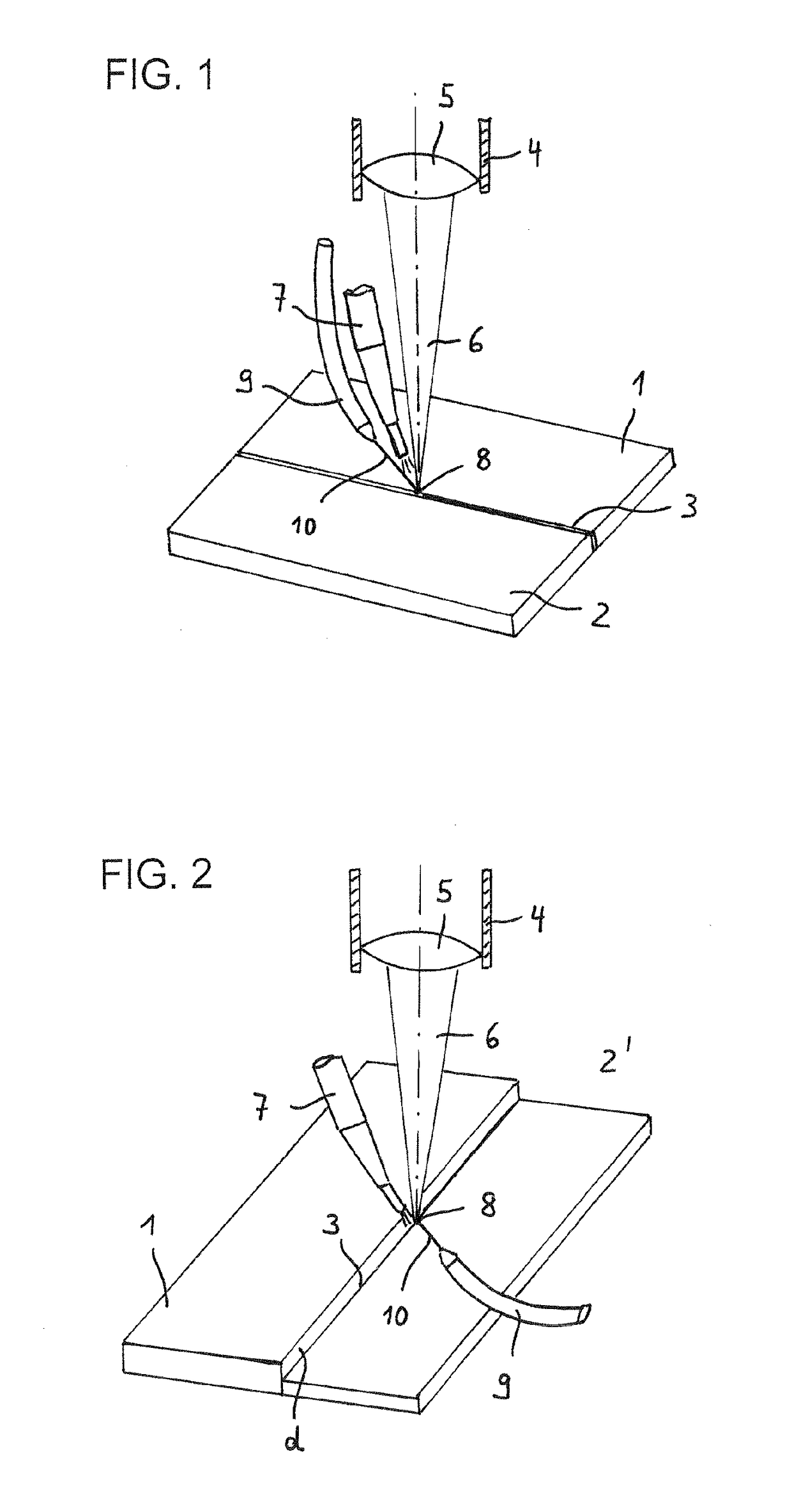

Laser welding method for producing a semi-finished sheet metal product from hardenable steel, comprising an aluminum- or aluminum-silicon-based coating

ActiveCN108025400AWelding/cutting media/materialsWelding/soldering/cutting articlesMetal coatingButt joint

The invention relates to a method for producing a tailored hot-formable semifinished sheet metal product. At least two steel sheets (1, 2') with different degrees of material quality and / or thicknessare joined together by a butt joint by means of laser welding. At least one of the sheets is made of a press-hardened steel and has an aluminum- or aluminum-silicon-based metal coating (1.1, 2.1). According to the invention, the steel sheets (1, 2') are welded to each other with a gap (G) which is delimited by the sheet borders to be welded together and which has an average width (b) of at least 0.15 mm. Filler wire (8) material is introduced into the gap (G) to such a degree that the proportion of the filler wire volume introduced into the gap (G) to the volume of the steel sheet material melted by the laser beam is at least 20%. The method according to the invention does not require the coating to be removed from the edges of the sheet borders to be welded together in advance and thus offers substantial cost advantages.

Owner:WISCO TAILORED BLANKS

Method and apparatus for removing modular forms

A method and apparatus for removing modular forms includes a lever arm having a first longitudinal end and a second longitudinal end. A projection such as a hardened steel pin extends beyond the first longitudinal end for engaging a hole defined in a form. The projection extends in a direction generally parallel to a longitudinal axis of the lever arm. A fulcrum is coupled to the lever arm. The fulcrum is disposed closer to the first longitudinal end relative to the second longitudinal end. A knuckle guard is coupled to and is disposed on a same side of the lever arm relative to the fulcrum. The knuckle guard is disposed closer to the second longitudinal end relative to the first longitudinal end.

Owner:FORM PULLER TOOL CO

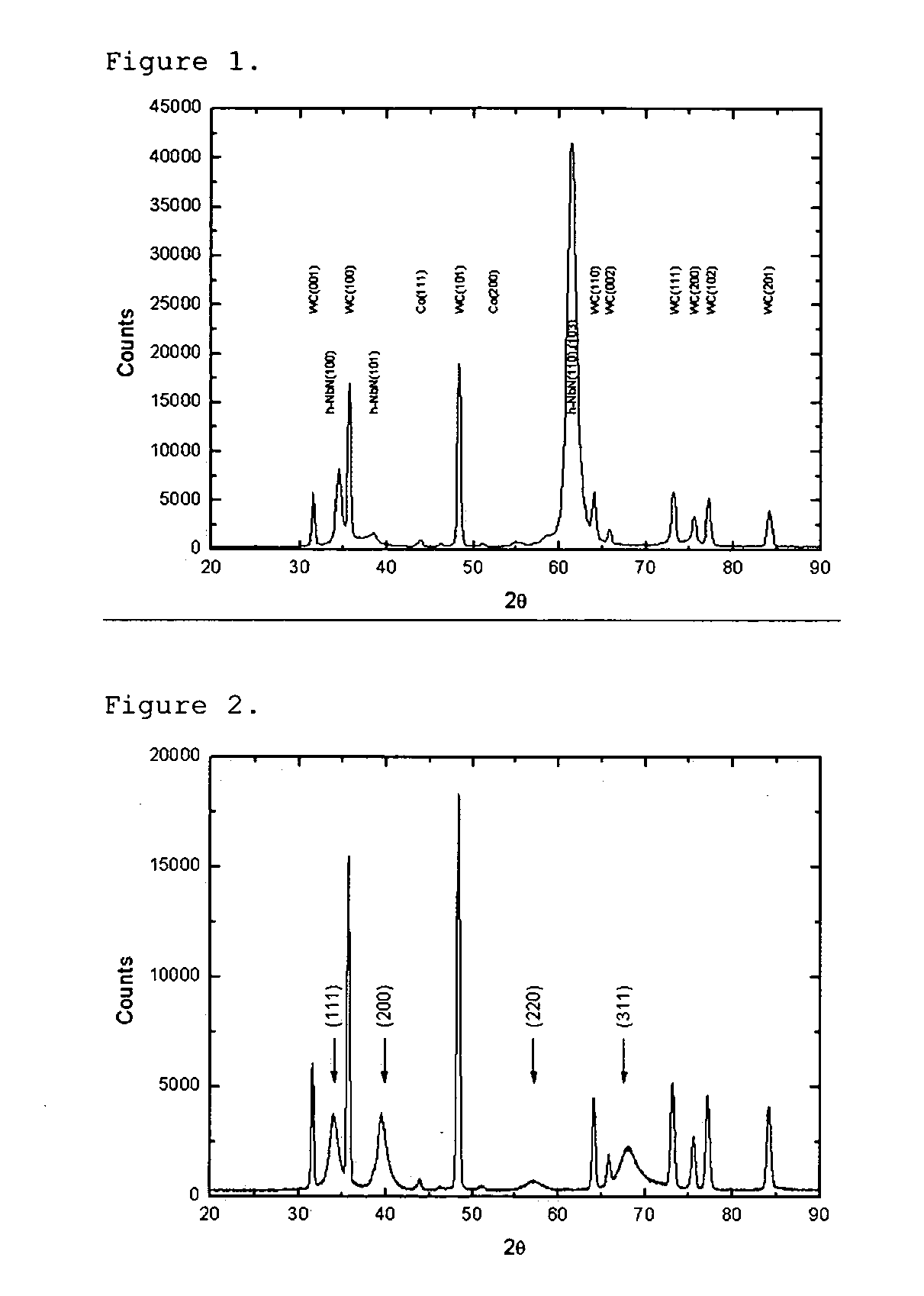

Thin wear resistent coating

InactiveUS20070178330A1Improve performanceImprove layer performancePigmenting treatmentOther chemical processesMilling cutterEnd mill

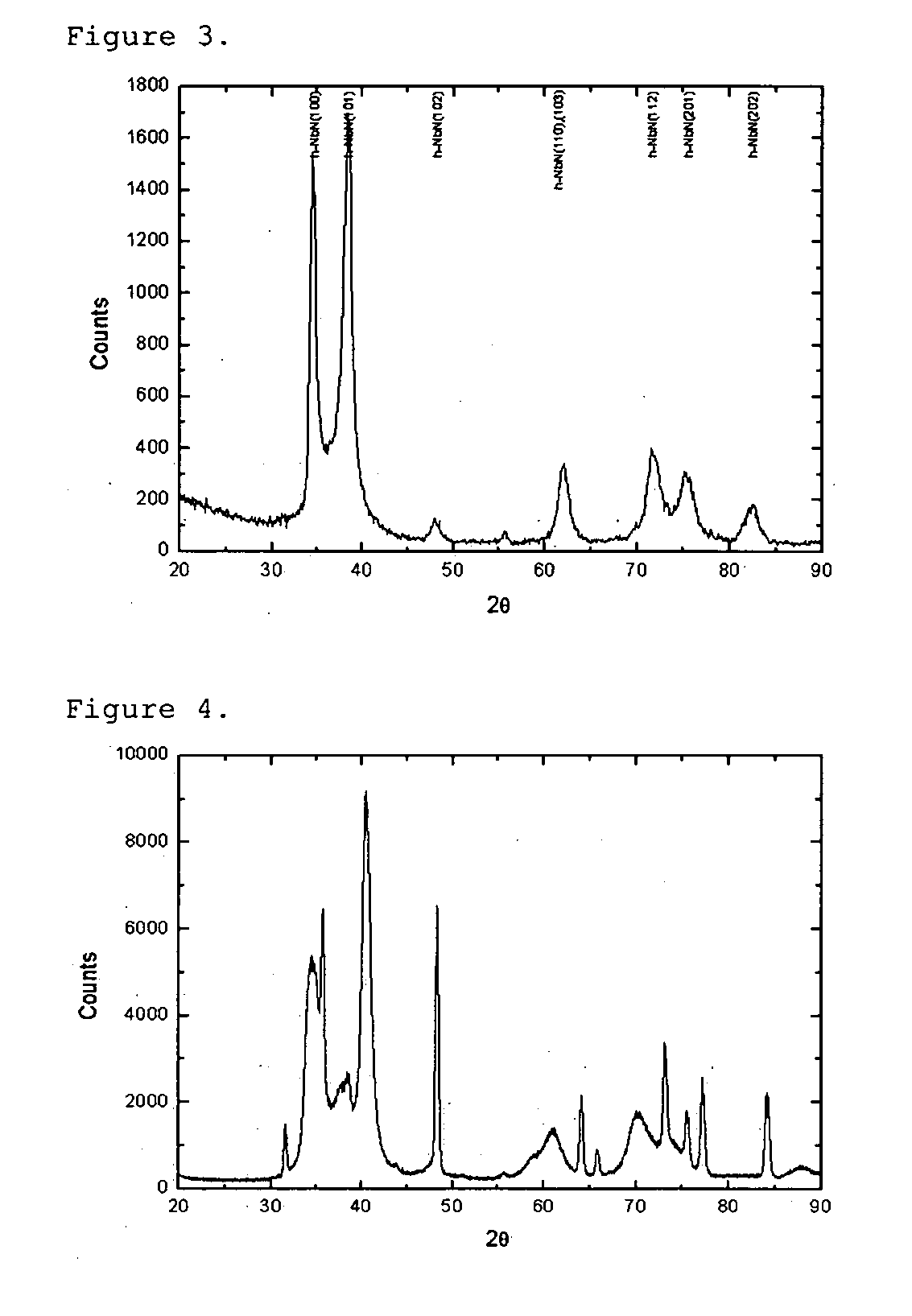

The present invention relates to a cutting tool insert, solid end mill, or drill, comprising a substrate and a coating. The coating is composed of one or more layers of refractory compounds of which at least one layer comprises a h-Me1Me2X phase, where Me1 is one or several of the elements V, Cr, Nb, and Ta and Me2 is one or several of the elements Ti, Zr, Hf, Al, and Si and X is one or several of the elements N, C, O or B. The ratio R=(at-% X) / (at-% Me1+at-% Me2) of the h-MelMe2X phase is between 0.5 and 1.0, preferably between 0.8 and 1.0 and X contains less than 30 at-% of O+B. This invention is particularly useful in metal cutting applications where the chip thickness is small and the work material is hard e.g. copy milling using solid end mills, insert milling cutters or drilling of hardened steels.

Owner:SECO TOOLS AB

Composite coating for finishing of hardened steels

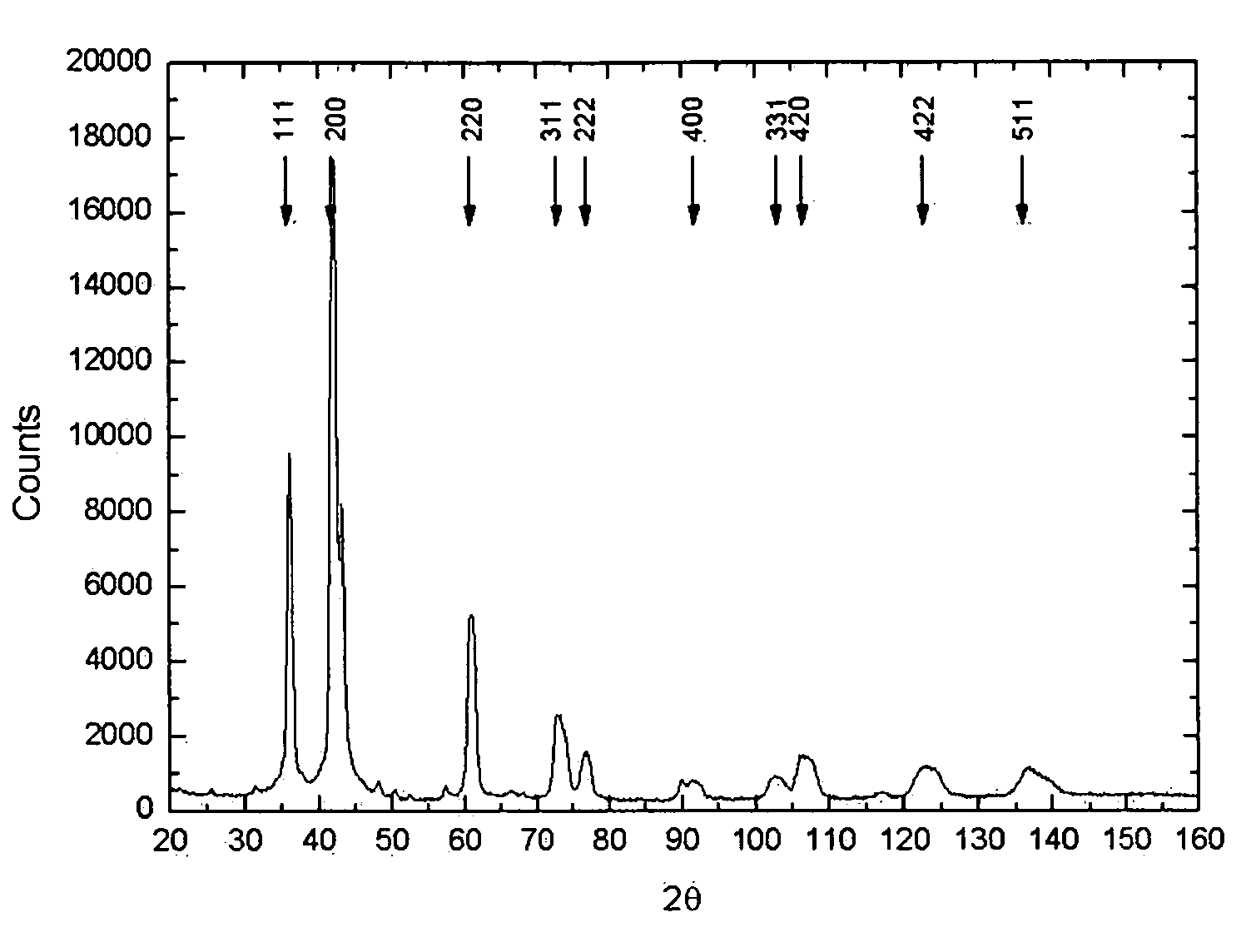

InactiveUS20060292399A1Improve adhesion strengthImprove performanceMilling cuttersVacuum evaporation coatingMilling cutterMetal machining

The present invention relates to a cutting tool insert, solid end mill, or drill, comprising a substrate and a coating. The coating is composed of one or more layers of refractory compounds of which at least one layer comprises a cubic (Me,Si)X phase, where Me is one or more of the elements Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and Al, and X is one or more of the elements N, C, O or B. The ratio R=(at-% X) / (at-% Me) of the c-MeSiX phase is between 0.5 and 1.0 and X contains less than 30 at-% of O+B. This invention is particularly useful in metal machining applications where the chip thickness is small and the work material is hard e.g. copy milling using solid end mills, insert milling cutters or drilling of hardened steels.

Owner:SECO TOOLS AB

Universal fixed pin trigger block

A firearm trigger locking device with two sides and fixed hardened steel pins. The device is designed to be universal for a particular family of guns—e.g., all rifles, all shotguns, or all handguns (or all revolvers or automatic pistols)—of a given firearm manufacturer. The device further features a pin behind the trigger to prevent firing, hardened steel plates in each side sufficient in size to cover the trigger guard and prevent transverse application of a saw to the trigger guard, and a ring of hardened steel pins around the periphery of the trigger guard to prevent application of a saw between the plates. The method for producing this trigger locking device uses lateral and axial profiles of the family of firearms to develop features and feature locations that will allow it to be used with any member of the family of firearms.

Owner:REGAL PROD LLC

Method for producing boron-containing non-quenching and tempering plastic mold steel

ActiveCN101352724AReduce uniformityReduce sensitivityTemperature control deviceMetal rolling arrangementsStress reliefQuenching

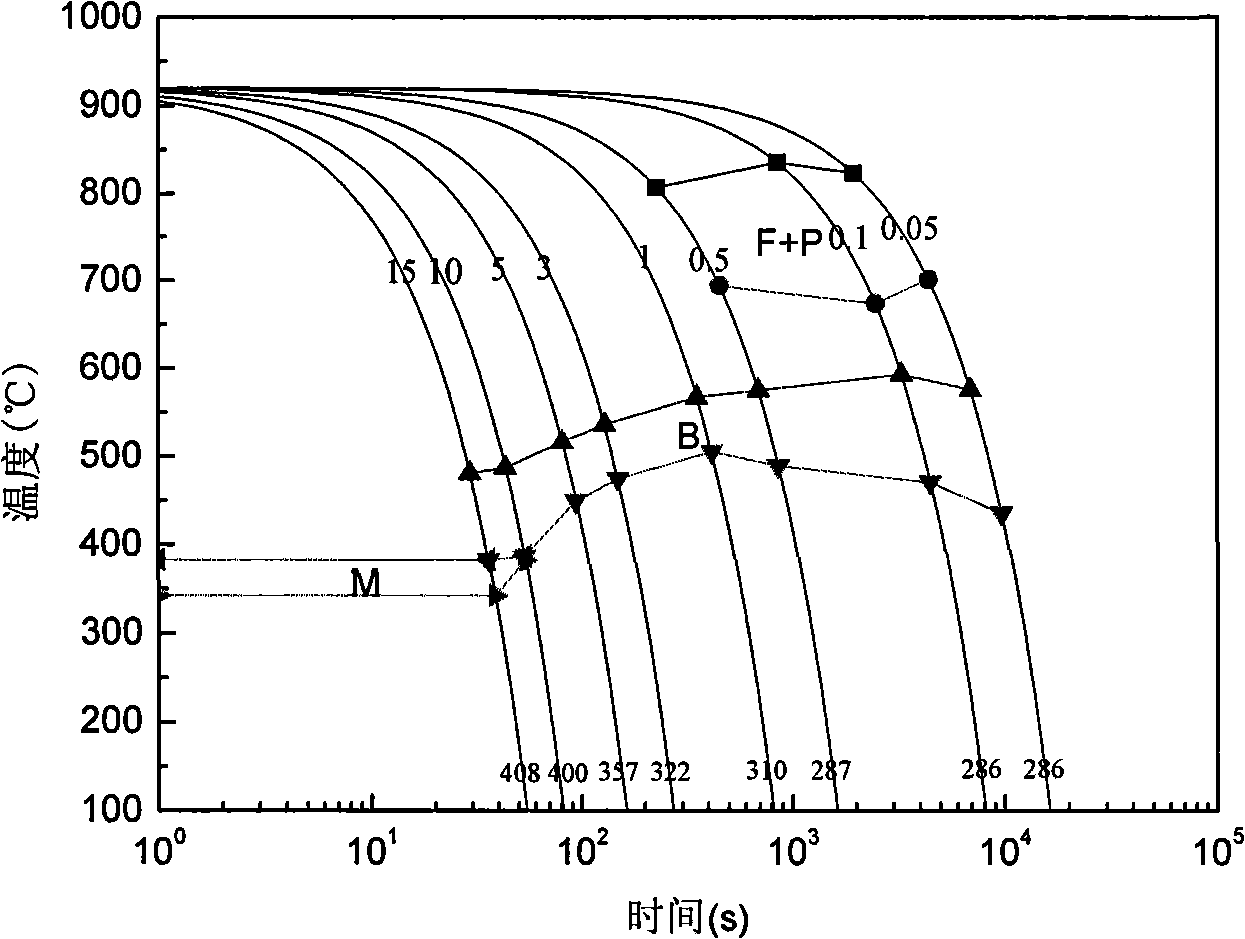

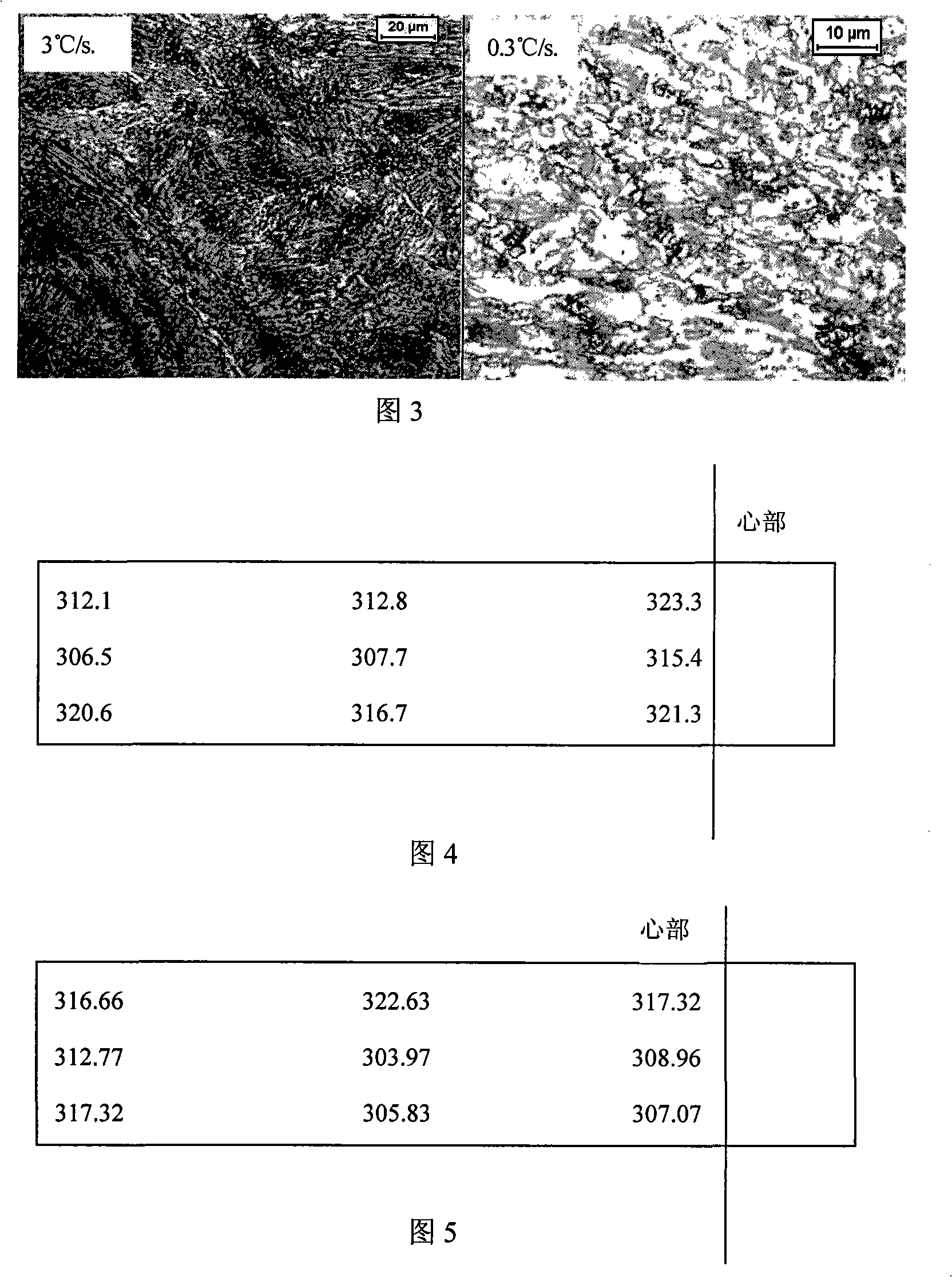

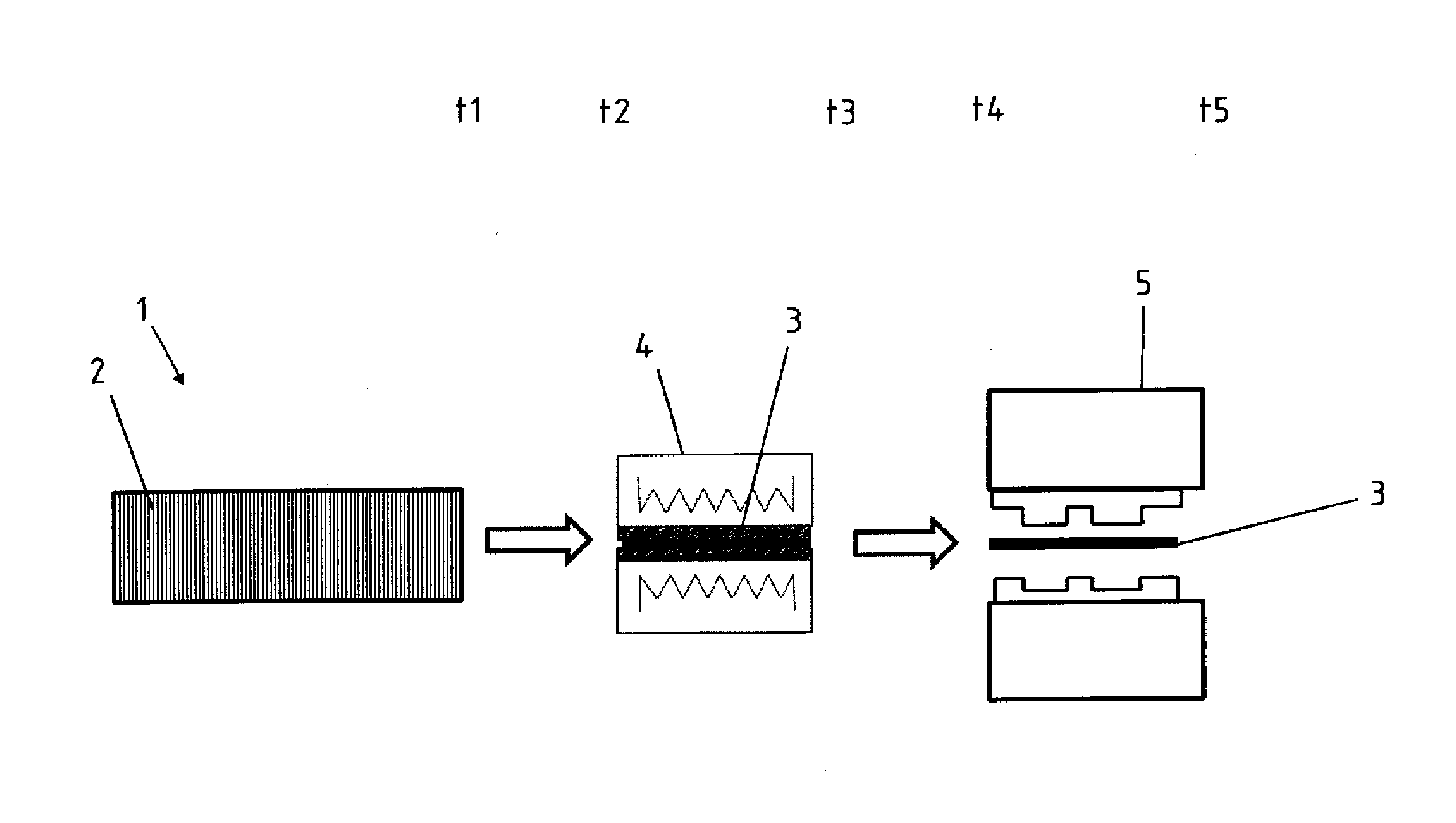

A production method of a boracic non-hardened and tempered plastic die steel belongs to the technical field of medium steel plate production. The process is that a continuous casting billet is soaked at the temperature of 1150-1250 DEG C; the hot rolling temperature is controlled, the start rolling temperature of the finish rolling is 900-950 DEG C, and the finishing rolling temperature is 840-880 DEG C; the steel plate is in controlled cooling after the hot rolling, and the cooling speed is controlled at 1-5 DEG C per second; and tempering treatment is required after rolling. The methods of controlled rolling and controlled cooling are adopted to obtain the 20-80mm bainite structure steel plate, stress relief tempering is carried out after rolling, and the combination property of the steel plate meets the process requirements of P20 pre-hardened steel. The yield strength of the steel plate is not less than 650MPa, the tensile strength is not less than 900MPa, the hardness of the cross section is 280-330HV, and the polishing property meets the requirements of P20 pre-hardened steel plates.

Owner:SHOUGANG CORPORATION

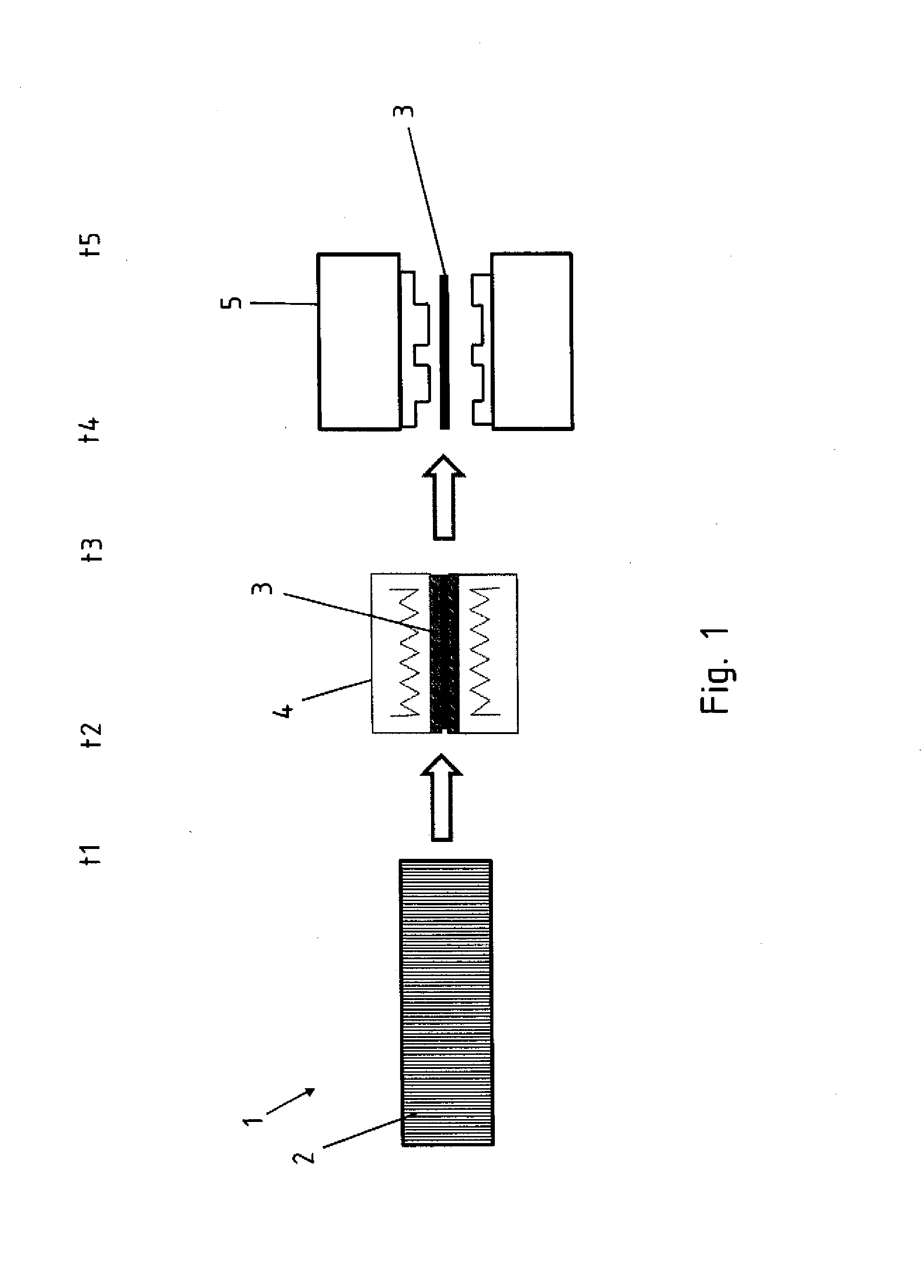

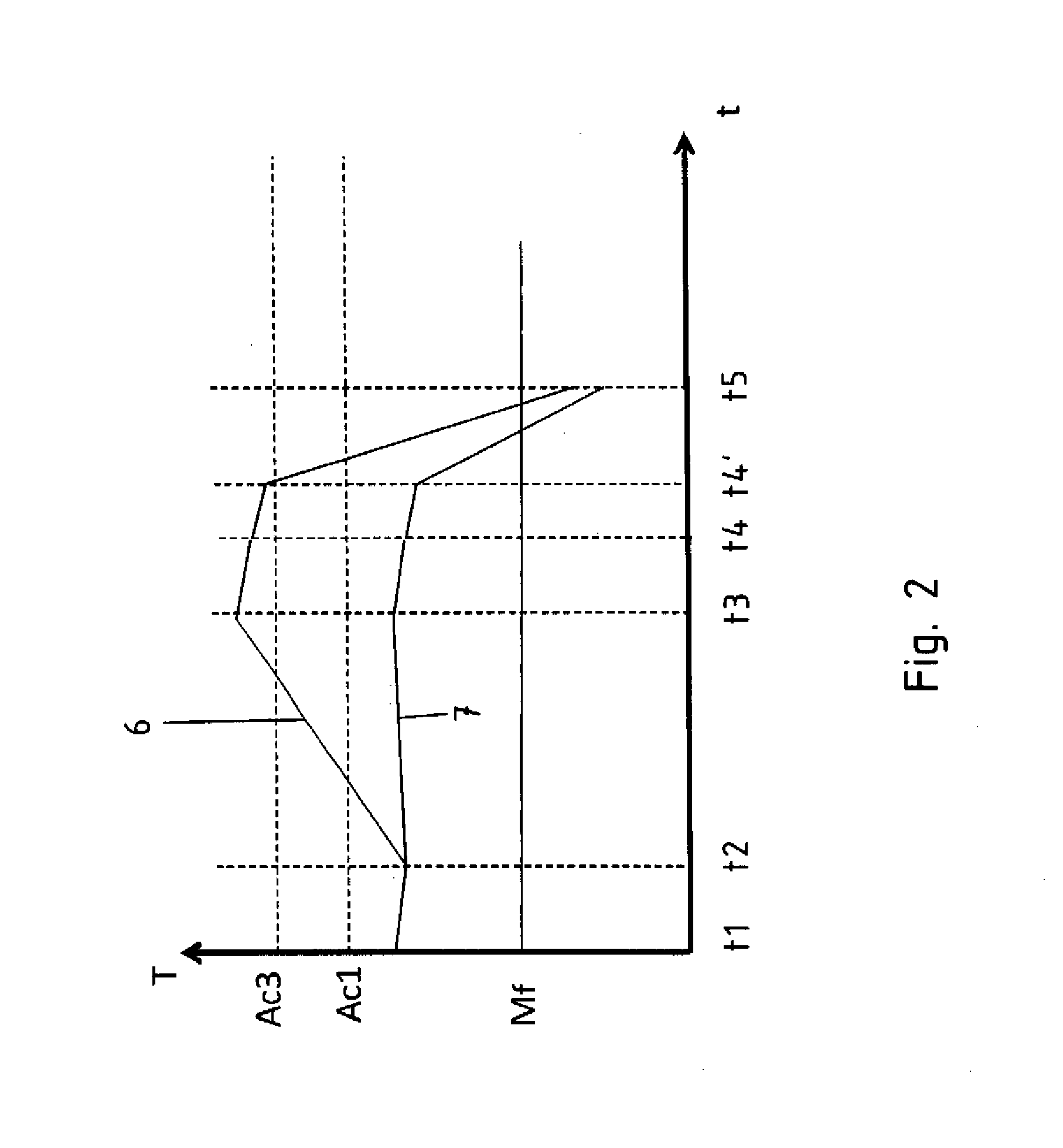

Hot forming line and method for producing a hot formed and press hardened motor vehicle part

ActiveUS20140124104A1Increased acquisition costFlexible useShaping toolsIncreasing energy efficiencyMotor vehicle partHardened steel

A hot forming line for producing hot formed and press hardened steel sheet products, includes: a forming device; a heating device having a temperature treatment station, wherein the temperature treatment station includes an upper tool and a lower tool, and at least one temperature treatment source; and exchangeable temperature treatment plates for conductive temperature treatment of a blank or part inserted into the temperature treatment station, wherein the exchangeable temperature treatment plates are constructed for arrangement on the upper tool and / or the lower tool, and the temperature treatment source is constructed for heating or cooling the temperature treatment plates. The temperature treatment station is constructed for treating different regions of the blank or part with different temperatures by conductive contact of the temperature treatment plates with the blank of part.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Coated cemented carbide endmill

InactiveCN101204864AIncreasing the thicknessThickness does not decreaseLayered productsVacuum evaporation coatingWear resistantMetal machining

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting tip of metal ceramic based on titanium carbonitride toughened by crystal whisker, and preparation method

This invention relates to a method for preparing SiC whiskers toughened Ti(CN)-based metal ceramic tool blade. The tool blade is composed of Ti (CN) as the major phase, SiC whiskers as the toughening agent, and metal binding phase and carbide hard phase as the additives. The method comprises: mixing the above components, molding, and sintering in vacuum to obtain a high compactness. Compared with traditional TN metal ceramic tool blade, the SiC whiskers toughened Ti(CN)-based metal ceramic tool blade has such advantages as high strength, high toughness, high wear resistance, high heat resistance, and high cuttability, and can be used for high speed milling, finish turning or semi-finish turning of carbon steel, stainless steel, hardened steel, wear-resistant cast iron and high-strength steel.

Owner:SECTION OF SCI & TECH DEV

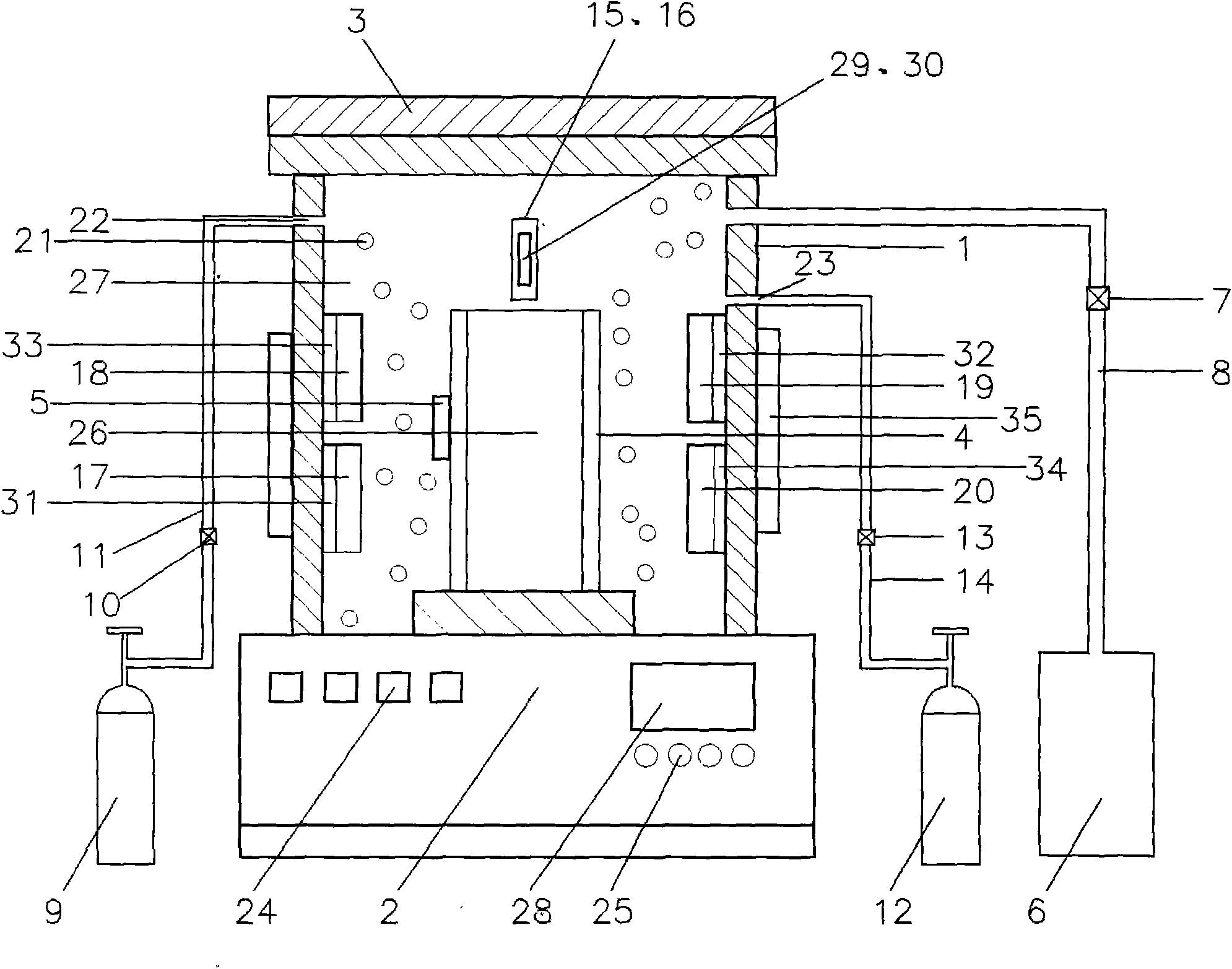

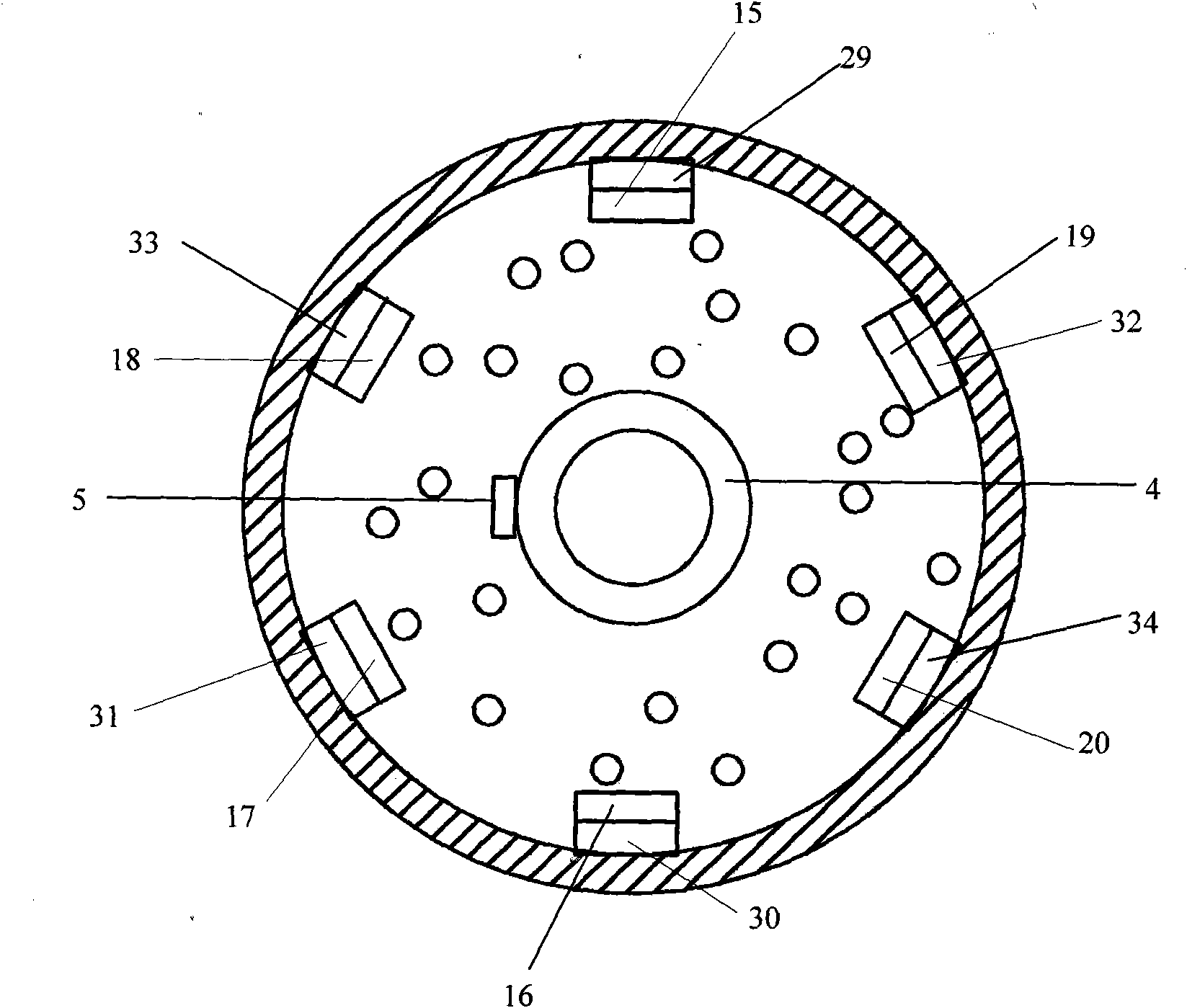

Preparation method of chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering

InactiveCN101575696AImprove mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingAluminum IonShielding gas

The invention relates to a preparation method of a chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering, which comprises the following steps: a chromium-tungsten-manganese steel plate is taken as a basal body, chromium and aluminum as a target source of metal ion, nitrogen gas as reactant gas, and argon gas as ion bombardment gas and protection gas; in a vacuum sputtering furnace, in a closed magnetic field state, in the argon gas and at the temperature of 300 DEG C, the surface of the chromium-tungsten-manganese steel plate is sputtered with chromium ion, aluminum ion and nitrogen ion and the chromium-aluminum-nitrogen hard film is formed on the surface of the steel plate, and then the low temperature tempering and alloying solid solution are conducted, thus greatly improving mechanical property, hardness, intensity, abrasive resistance and erosion resistance of the surface of the chromium-tungsten-manganese steel plate. The mechanical property of the chromium-tungsten-manganese steel plate can be improved by 466% compared with that of hardened steel plates. The preparation method has short process flow, precise technique, accurate and detailed measurement values, the film with thickness of 4,600nm, and the alloy layer with good solid solution effect and being not easy to peel off, thus being the ideal treatment method for strengthening and hardening the surface of alloy tool steel.

Owner:TAIYUAN UNIV OF TECH

Elongated bumper bar with sections twisted rotationally about the axis of elongation and method of making the same

A bumper system for an automotive vehicle includes a rolled steel tube having a box or C-shaped cross section fixed to the forward ends of the side rails of the vehicle so as to extend transversely to the vehicle's longitudinal axis. The forward surface of the vehicle is formed by a plastic fascia which may have sloped surfaces for styling or aerodynamic reasons. The space between the forward end of the bumper bar and the fascia is filled with foam intended to absorb energy in an impact. To better match the sloped sections of the fascia, certain sections of the bumper bar are twisted about the longitudinal axis of the bar to create surfaces inclined relative to the vertical. The bars are formed by roll forming a steel web into an elongated member having generally vertical opposed faces. A section of the rolled member is heated above a metallurgical transition temperature. Then sections to be inclined are twisted about the longitudinal axis of the bumper bar in a die forming station and are then quenched to form a hardened steel member.

Owner:NOBLE ADVANCED TECH

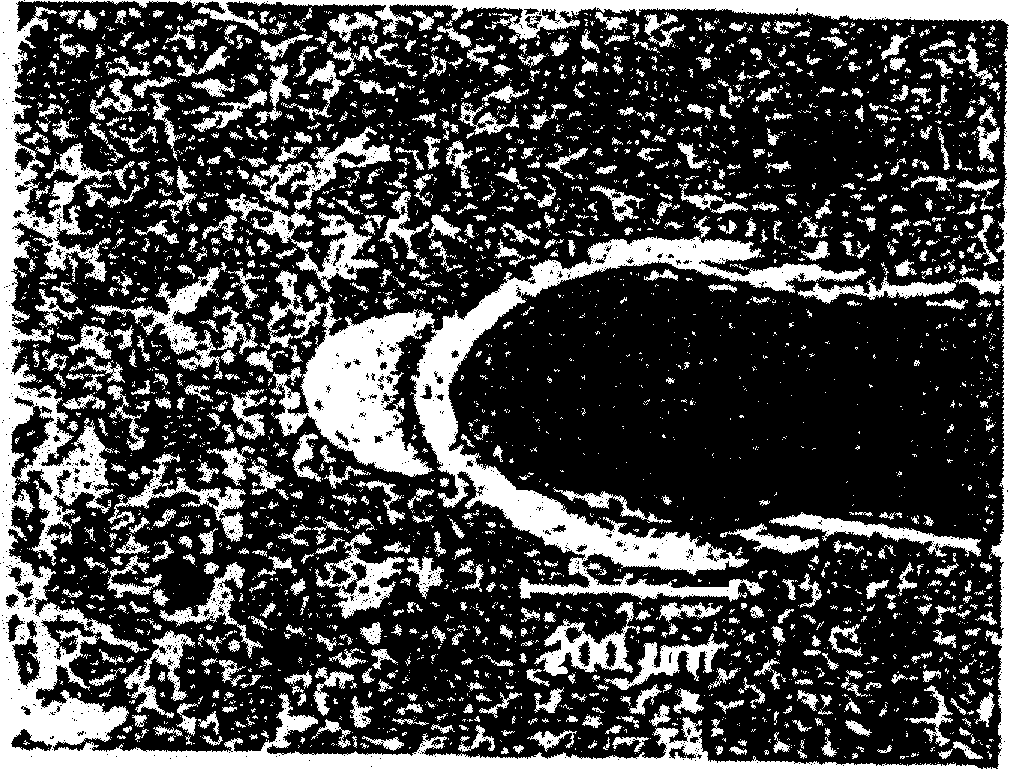

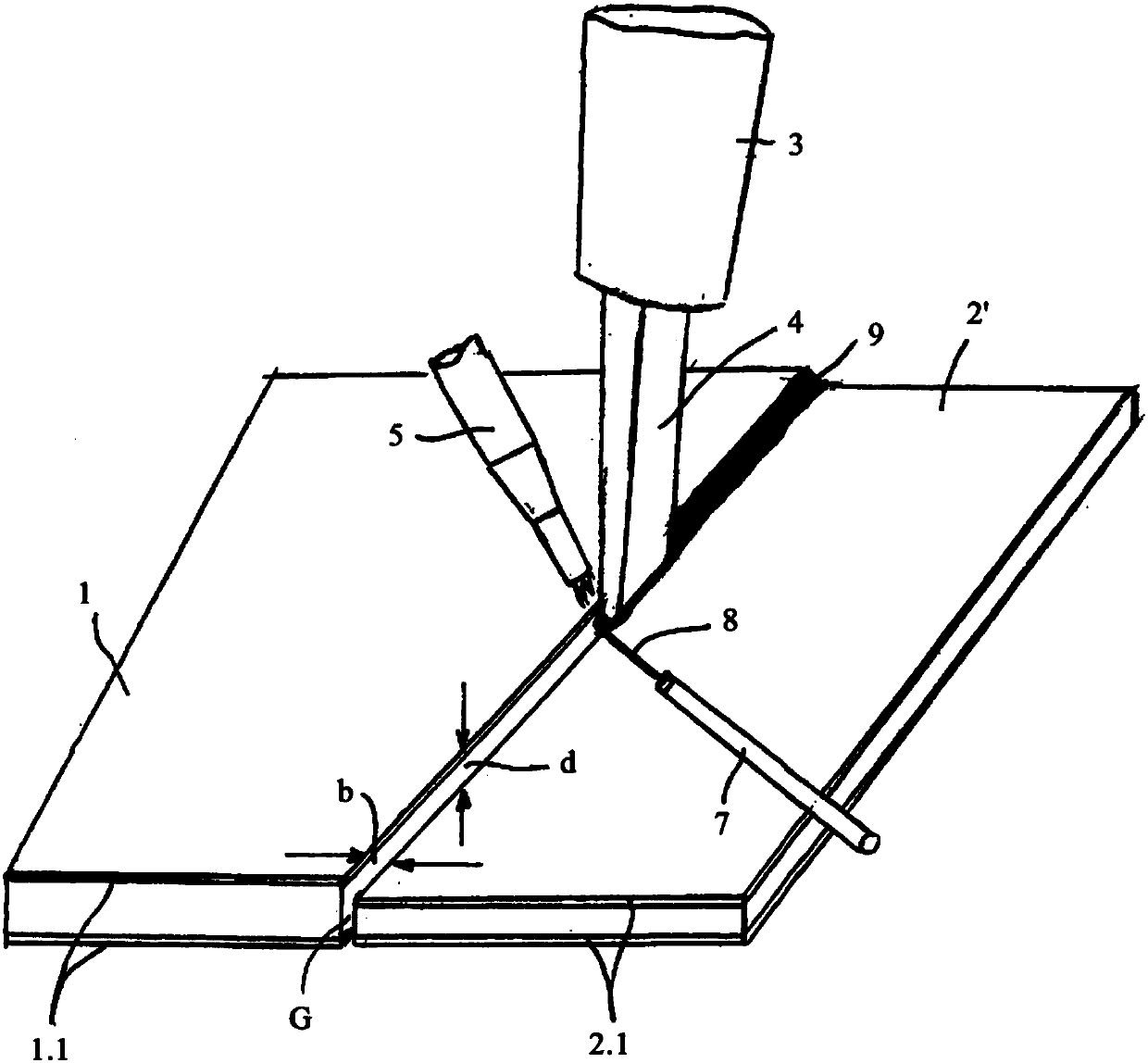

Method for laser welding one or more workpieces of hardenable steel in a butt joint

ActiveUS9623515B2Reliable preventionInhibition formationWelding/cutting media/materialsWelding/soldering/cutting articlesButt jointMolten bath

A method for laser welding of one or more workpieces made from press hardenable steel, in a butt joint, in which the workpiece or the workpieces have a thickness of at least 1.8 mm and / or a jump in thickness of at least 0.4 mm arises at the butt joint including supplying filler wire into a molten bath generated by a laser beam. In order to ensure that the weld seam can reliably harden into a martensitic structure during the hot forming (press hardening), the filler wire contains at least one alloy element from the group of manganese, chromium, molybdenum, silicon and nickel, wherein the at least one alloy element is present in the filler wire with a mass proportion that is larger by 0.1% by weight than the mass proportion of the element in the press hardenable steel of the workpiece or the workpieces.

Owner:WISCO TAILORED BLANKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com