Method for producing boron-containing non-quenching and tempering plastic mold steel

A technology of plastic mold steel and manufacturing method, applied in the direction of temperature control, metal rolling, etc., can solve the problems of high cost, long production cycle, and many production links, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

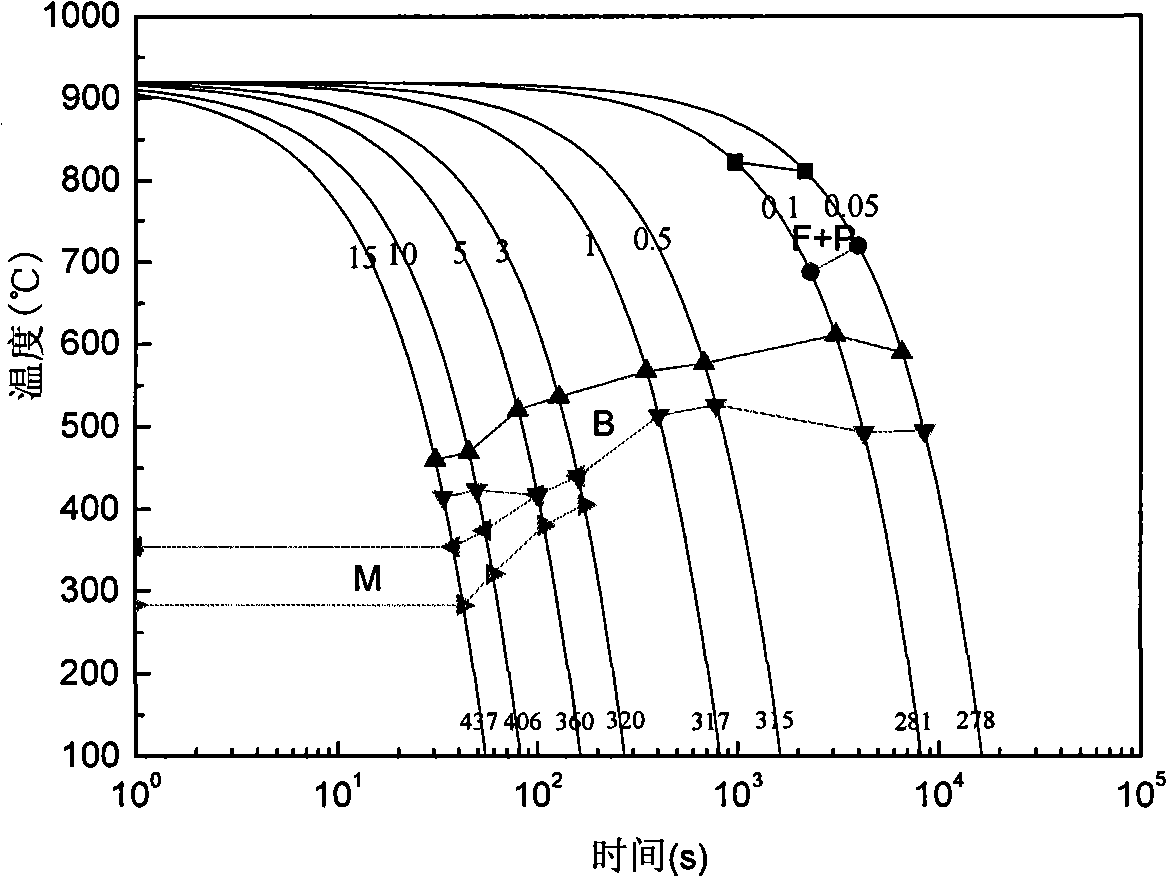

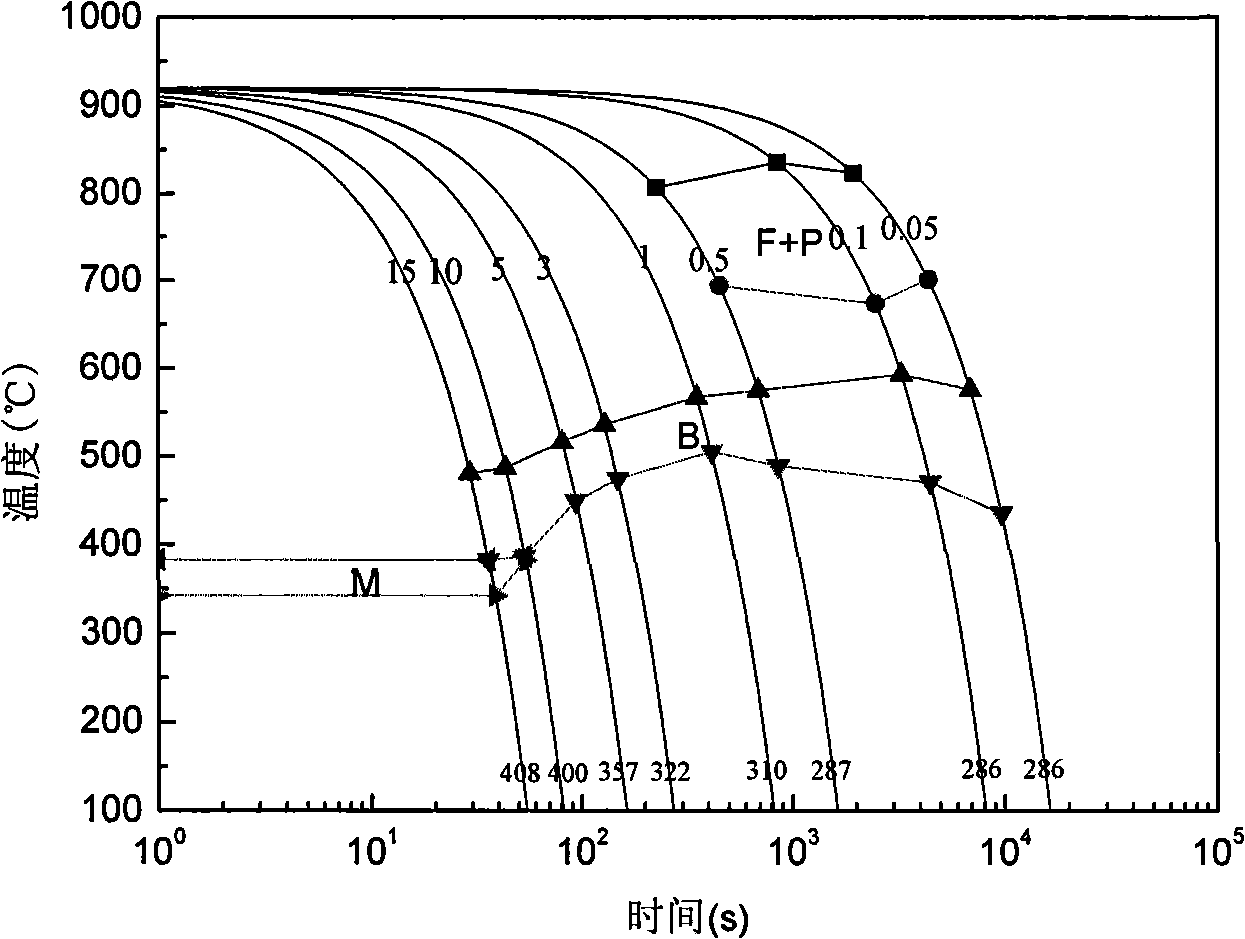

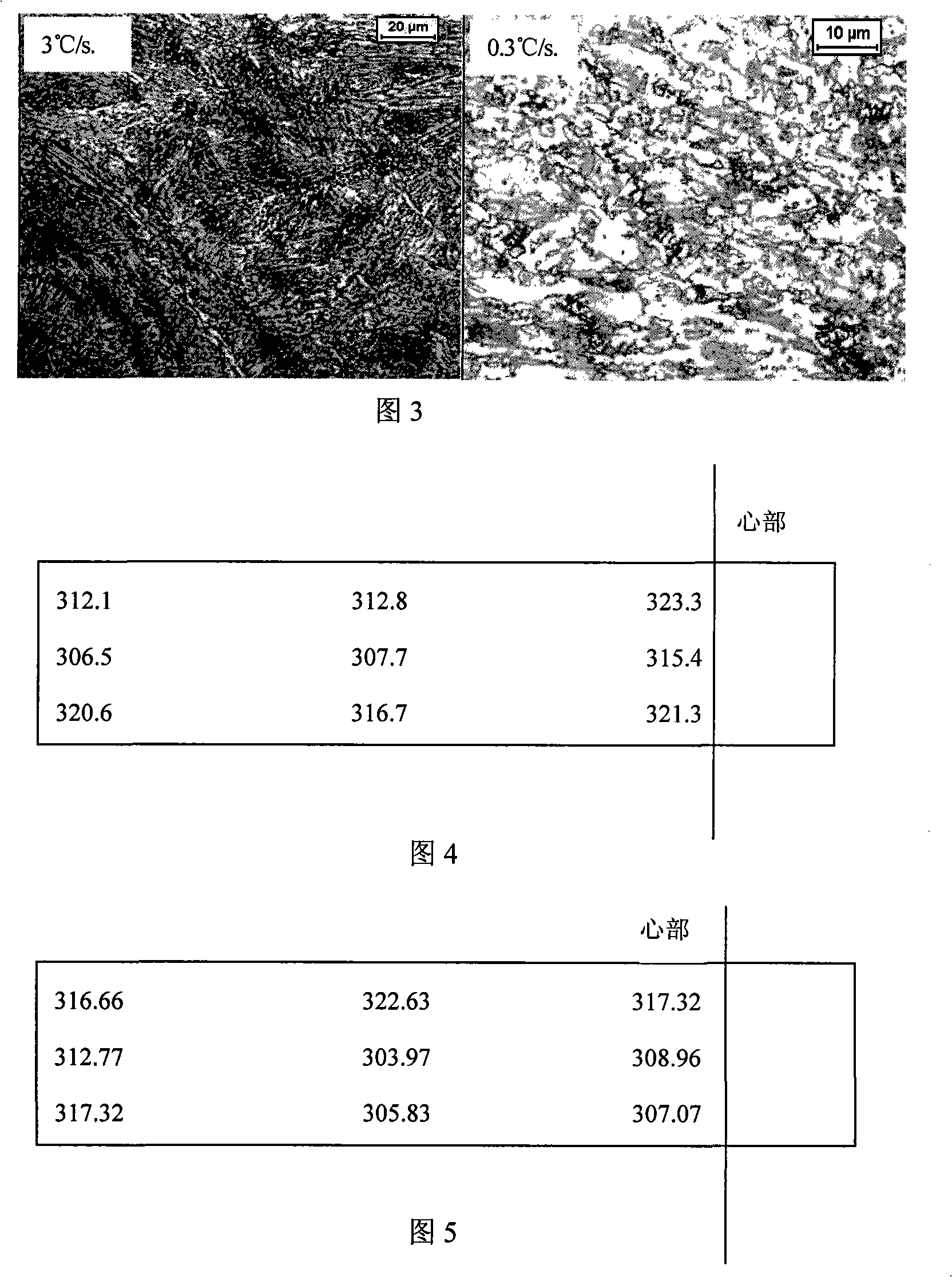

[0020] The chemical composition of the steel plate is shown in Example 1 in Table 1. The size of the cast slab is 220 mm × 1700 mm, and the size of the finished plate is 20 × 2000 × L. Rolling is carried out according to the production process shown in Example 1 in Table 2. 3 shows the mechanical properties. The hardness distribution of the cross-section of the steel plate is shown in Figure 4, the hardness difference is ≤20HV, and the polishability of the steel plate is shown in Table 4. The properties of the steel plates are in line with the requirements of P20 pre-hardened steel plates.

Embodiment 2

[0022] The chemical composition of the steel plate is as shown in Example 2 in Table 1. The size of the cast slab is 250 mm × 1700 mm, and the size of the finished plate is 50 × 2000 × L. Rolling is carried out according to the production process shown in Example 2 in Table 2. 3 shows the mechanical properties. The hardness distribution of the cross-section of the steel plate is shown in Figure 4, and the difference in hardness is ≤20HV. The polishability of the steel plate is shown in Table 4. The properties of the steel plates are in line with the requirements of P20 pre-hardened steel plates.

[0023] Table 1 embodiment measured chemical composition (mass fraction %, balance is Fe)

[0024]

[0025] Table 2 embodiment technological parameter

[0026]

[0027] Table 3 embodiment mechanical property

[0028]

[0029] Table 4 embodiment steel plate surface roughness

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com