Method and apparatus for containing and suppressing explosive detonations

a technology of explosive detonation and method, applied in the direction of lighting and heating apparatus, combustion types, manufacturing tools, etc., can solve the problems of large space occupation, substantial danger to equipment and personnel, and uncontrolled use of explosives, so as to dampen and suppress the shock and noise of each detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

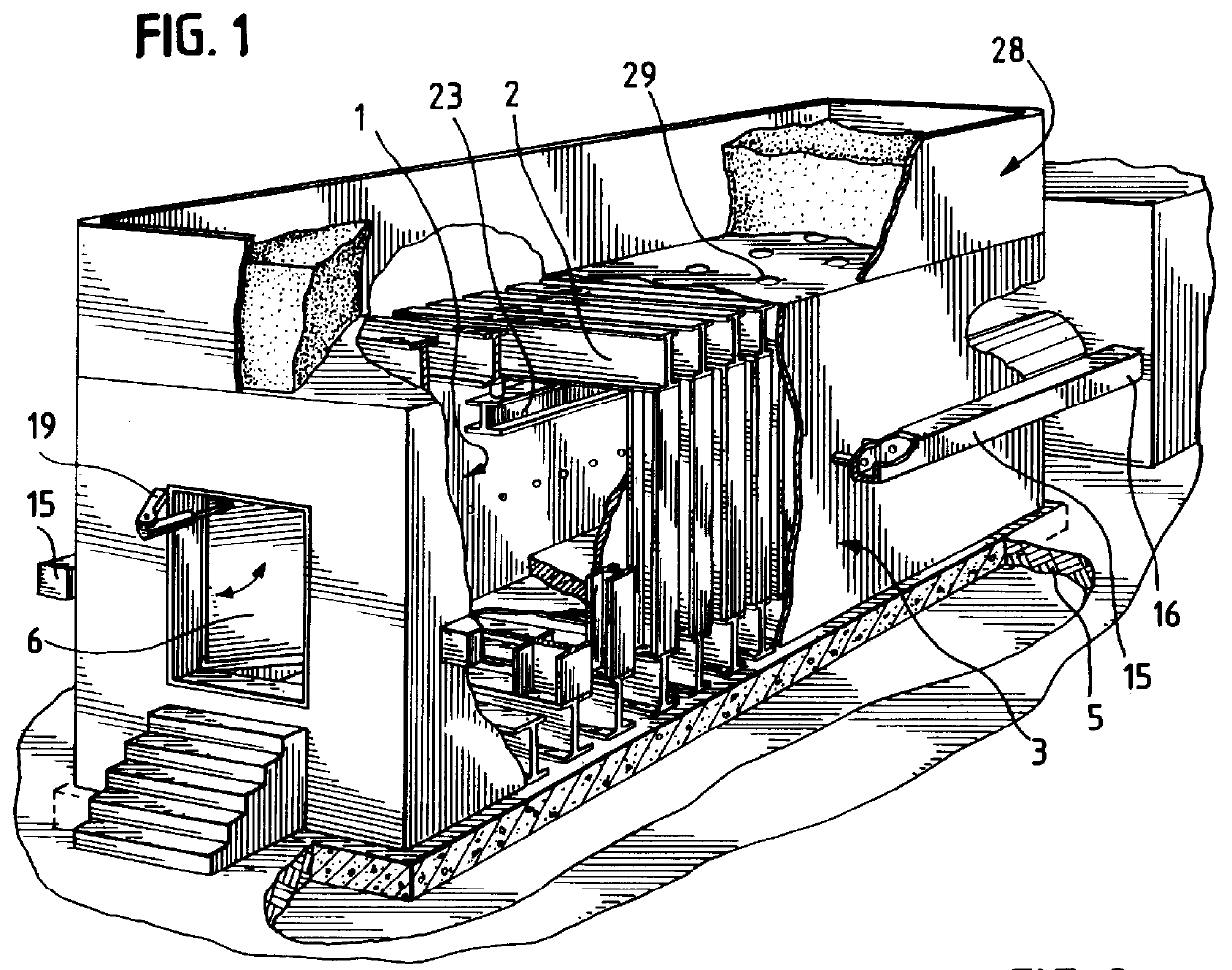

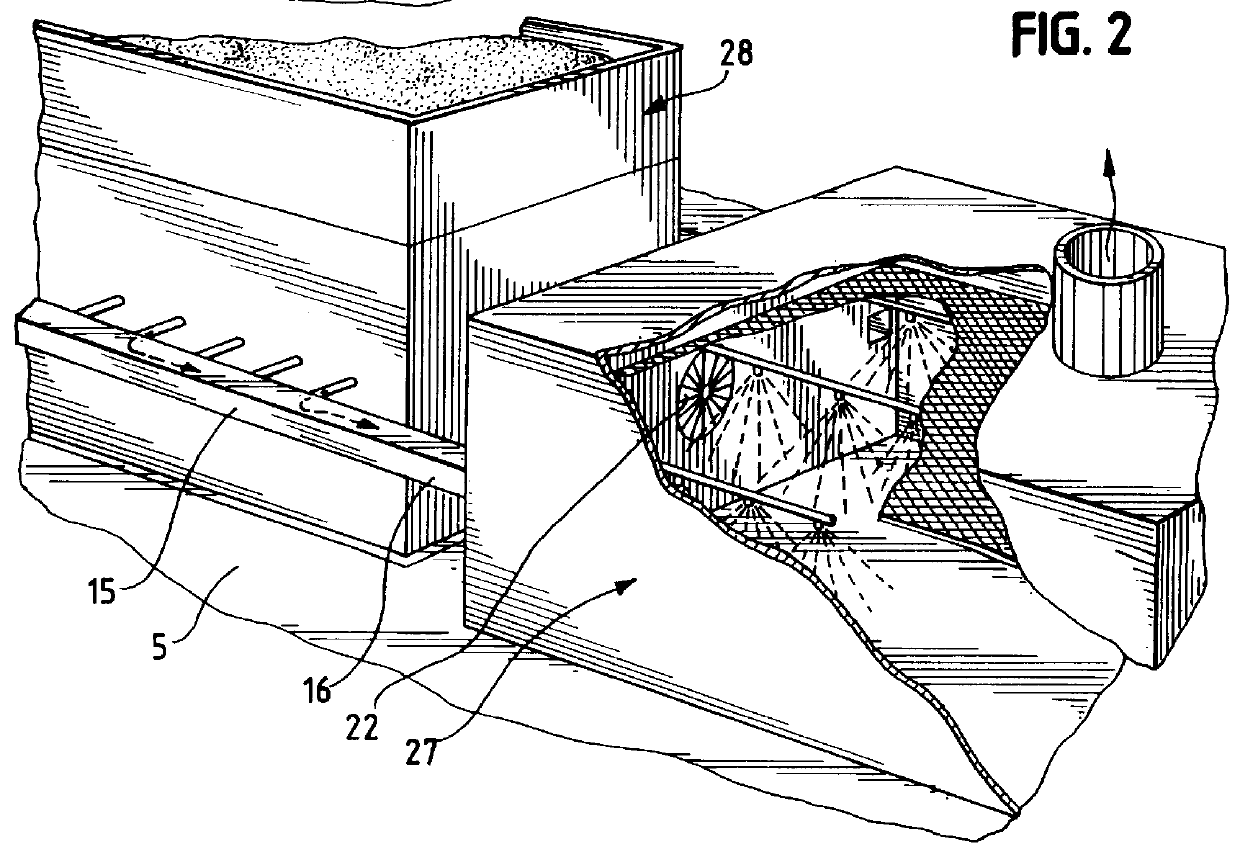

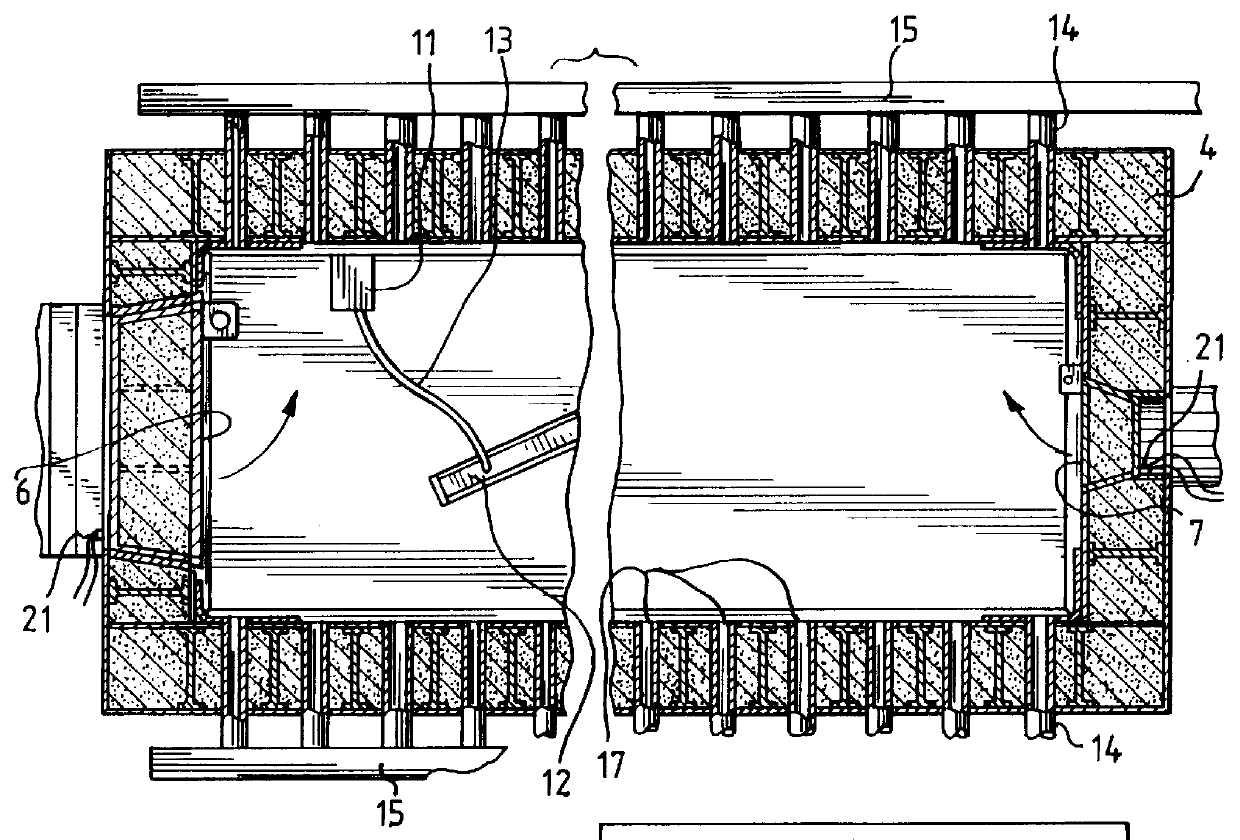

Turning to the drawings, FIG. 1 is a sectional perspective of the improved explosion chamber of the present invention. The chamber comprises an inner casing 1 having a ceiling, floor, side walls and ends, being fabricated of sheet steel using conventional welding techniques. Surrounding the inner casing 1 are a plurality of spaced circumstantial flanges or ribs 2 over which a welded sheet steel outer casing 3 is constructed so that the ribs 2 cause the outer casing 3 to be spaced from the inner casing 1 and leaving a gap which is then filled with a granular shock-damping material .Iadd.4.Iaddend.. In the preferred embodiment, the inner and outer metal casings are constructed of three-quarter inch thick sheet steel separated by circumferential steel I-beam ribs 2 spaced every two feet. All seams are continuous-welded. According to the invention, the space between the inner and outer casing 3 is filled with a firm, granular shock-absorbing material, preferably silica sand.

The explosio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com